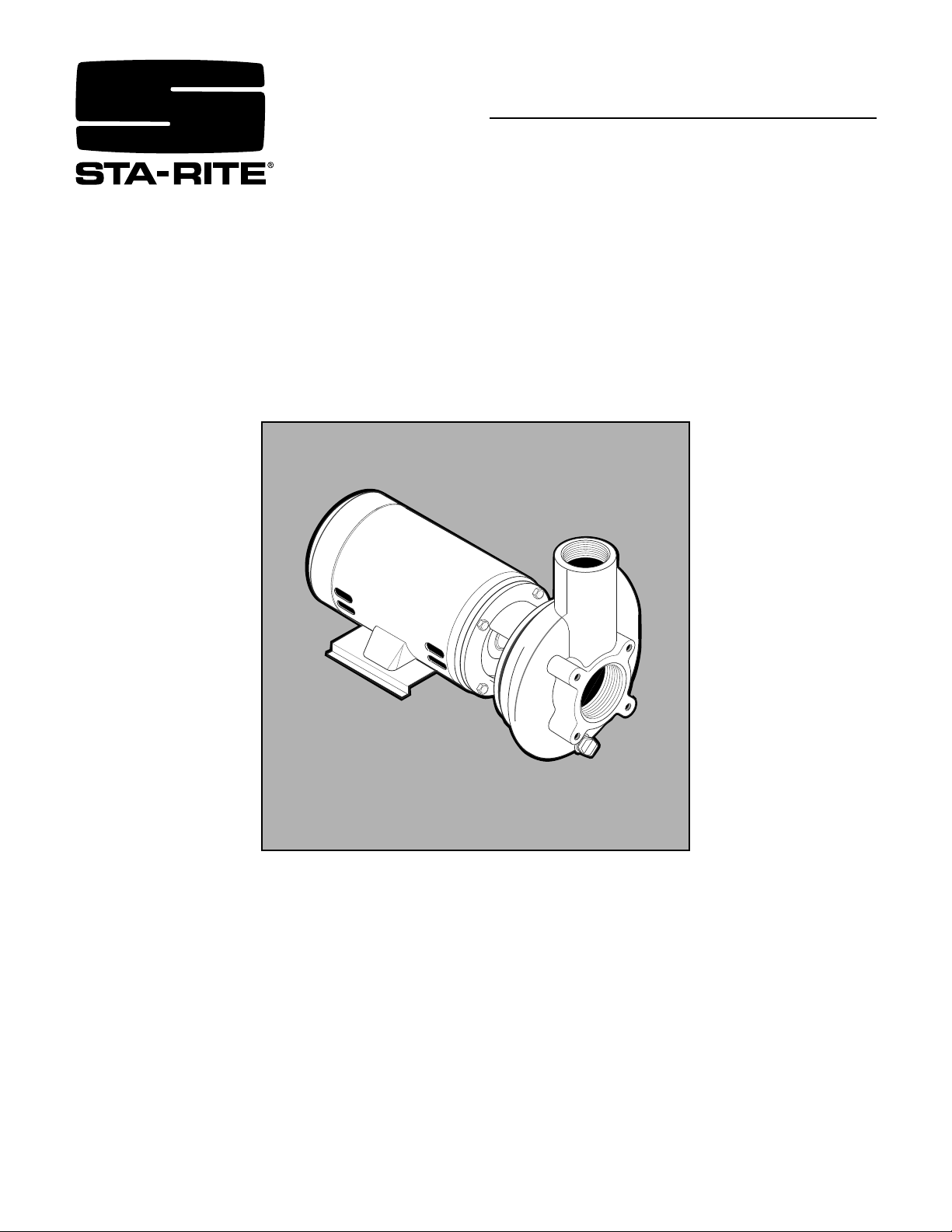

Sta-Rite CCH2H-137S Installation Manual

OWNER’S MANUAL

Centrifugal Pumps

© 2004, Sta-Rite Industries PRINTED IN U.S.A. S150 (Rev. 2/23/04)

293 Wright Street, Delavan, WI 53115

“C” and “CC” Series

Installation/Operation/Parts

For further operating, installation,

or maintenance assistance:

Call 1-262-728-9181

Safety 2

READ AND FOLLOW

SAFETY INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol on your

pump or in this manual, look for one of the following signal words and be

alert to the potential for

personal injury:

warns about hazards that will cause serious personal injury,

death or major property damage if ignored.

warns about hazards that can cause serious personal injury,

death or major property damage if ignored.

warns about hazards that will or can cause minor personal

injury or property damage if ignored.

The label NOTICE indicates special instructions which are important but

not related to hazards.

Carefully read and follow all safety instructions in this manual and

on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Motor normally operates at high temperature and will be too

hot to touch. It is protected from heat damage during operation by an

automatic internal cutoff switch. Before handling pump or motor, stop

motor, and allow it to cool for 20 minutes.

Ta b le of Contents 3

Page

General Safety ....................................................................................................2

Warranty..............................................................................................................3

Installation........................................................................................................4-5

Maintenance ....................................................................................................5-7

Troubleshooting .................................................................................................8

Repair Parts ..................................................................................................9-11

LIMITED WARRANTY

Sta-Rite Industries warrants to the original consumer of the products listed below, that they will be free from

defects in material and workmanship for the Warranty Period from the date of original installation or manufacture

as noted.

Product Warranty Period

Water Systems Products – jet pumps, whichever occurs first:

small centrifugal pumps, submersible pumps 1 year from date of original installation, or

and related accessories 2 years from date of manufacture

Hydro-Flow Filters 1 year from date of purchase

Signature 2000 Fibrewound Tanks 5 years from date of original installation

Pro-Source Steel Pressure Tanks 5 years from date of original installation

Pro-Source Epoxy-Line Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products 1 year from date of original installation, or

2 years from date of manufacture

Our warranty will not apply to any product that has been subject to negligence, misapplication, improper installation or maintenance. In the event a three phase submersible motor is operated with single phase power

through a phase converter, or if three-leg ambient compensated, extra-quick trip overload relays of recommended size are not used, our warranty is void.

Buyer’s only remedy and Sta-Rite Industries’ only duty is to repair or replace defective products (at Sta-Rite

Industries’ choice). Buyer agrees to pay all labor and shipping charges associated with this warranty and to

request warranty service through the installing dealer as soon as a problem is discovered. If warranty service is

requested more than 30 days after the Warranty Period has ended, it will not be honored.

STA-RITE INDUSTRIES SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE WARRANTY PERIOD PROVIDED HEREIN.

Certain states do not permit the exclusion or limitation of incidental or consequential damages or the placing of

limitations on the duration of an implied warranty, therefore, the limitations or exclusions herein may not apply.

This warranty sets forth specific legal rights and obligations, however, additional rights may exist, which may

vary from state to state.

Supersedes all previous publications.

Sta-Rite Industries, 293 Wright St., Delavan, WI 53115

Installation 4

SERIES C/CC CENTRIFUGAL PUMPS

The “C” and “CC” Series pumps are close coupled pumps with optional

traps. “CC” Series have cast iron volutes and adapters. “C” Series have

bronze volutes and adapters. Impellers on both series are bronze.

INSTALLATION

Location of Unit

Install pump as close to liquid source as possible, using short, simple

suction piping.

Piping should be as direct as possible; elbows and other fittings greatly

increase friction losses.

Allow service and maintenance access.

Mount on solid, rigid, vibration-free foundation.

Protect pump against flooding and excess moisture.

Piping

Pump is not self-priming. Unless liquid source level is above pump suction at all times, install a foot valve on suction pipe.

Support both suction and discharge piping independently near the pump

to avoid placing strains on pump. Start all piping at pump to avoid strains

left by a gap at last connection.

If possible, increase size of both suction and discharge piping if more

than short runs are required.

NOTICE: Never use a suction pipe smaller than the suction connection of

the pump.

NOTICE: If a reducer is necessary in the suction piping, always use an

eccentric reducer with the straight side on top.

NOTICE: BE SURE suction does not leak. Suction pipe must slope gradually upward to the pump. Avoid any fittings which might cause an air

trap.

Install gate valve and union in suction and discharge lines. If complete

pump removal is required for service, close gate valves and disconnect at

unions.

Grounding the Motor

Can shock, burn or cause death.

Ground motor before working

on pump or motor.

Install, ground, wire and maintain this pump in accordance with the

National Electrical Code, Article 250, or applicable local Codes and

Ordinances.

Ground the pump permanently using a wire of size and type specified

by National or Local Electrical Code.

Connect ground wire first. Connect to ground first, then to motor terminal provide. Do not connect motor to electrical power supply until unit is

permanently grounded. Any other sequence may cause serious shock

hazard. Do not ground to a gas supply line.

The motor grounding wire need not be larger than the wires supplying the

motor, provided the supply wires conform to the wiring date included in

this manual (see Table I, Page 5).

Hazardous

voltage

Loading...

Loading...