Sta-Rite BMMG-59S Installation Manual

OWNER’S MANUAL

INSTALLATION AND OPERATING INSTRUCTIONS

REPAIR PARTS LIST

60 CYCLE “J” and “JB” SERIES

CENTRIFUGAL PUMP

©2005 S873 (Rev. 4/28/09)

MODELS

HP MEDIUM HEAD MODELS HIGH HEAD MODELS

1/3 JBMB-56S – JMB-56L – JBHB-61S – JHB-61HL –

1/2 JBMC-56S JBMC3-56S JMC-56L JMC3-56 JBHC-61S JBHC3-61S JHC-61HL JHC3-61H

3/4 JBMD-57S JBMD3-57S JMD-57L JMD3-57 JBHD-62S JBHD3-62S JHD-62HL JHD3-62H

1 JBME-58S JBME3-58S JME-58L JME3-58 JBHE-63S JBHE3-63S JHE-63HL JHE3-63H

1-1/2 JBMF-40S JBMF3-40S JMF-40L JMF3-40 JBHF-51S JBHF3-51S JHF-51HL JHF3-51H

2 JBMG-41S JBMG3-41S JMG-41L JMG3-41 JBHG-52S JBHG3-52S JHG-52HL JHG3-52H

2-1/2 JBMMG-59S JBMMG3-59S – – JBHHG-53S JBHHG3-53S JHHG-53HL JHHG3-53H

293 WRIGHT STREET, DELAVAN, WISCONSIN 53115

S

T

A

-

I

E

S

T

A

-

R

I

T

E

671 0294

S

T

A

R

I

T

E

S

T

A

-

S

T

A

-

R

I

T

E

S

T

A

-

R

R

o

t

a

t

i

o

n

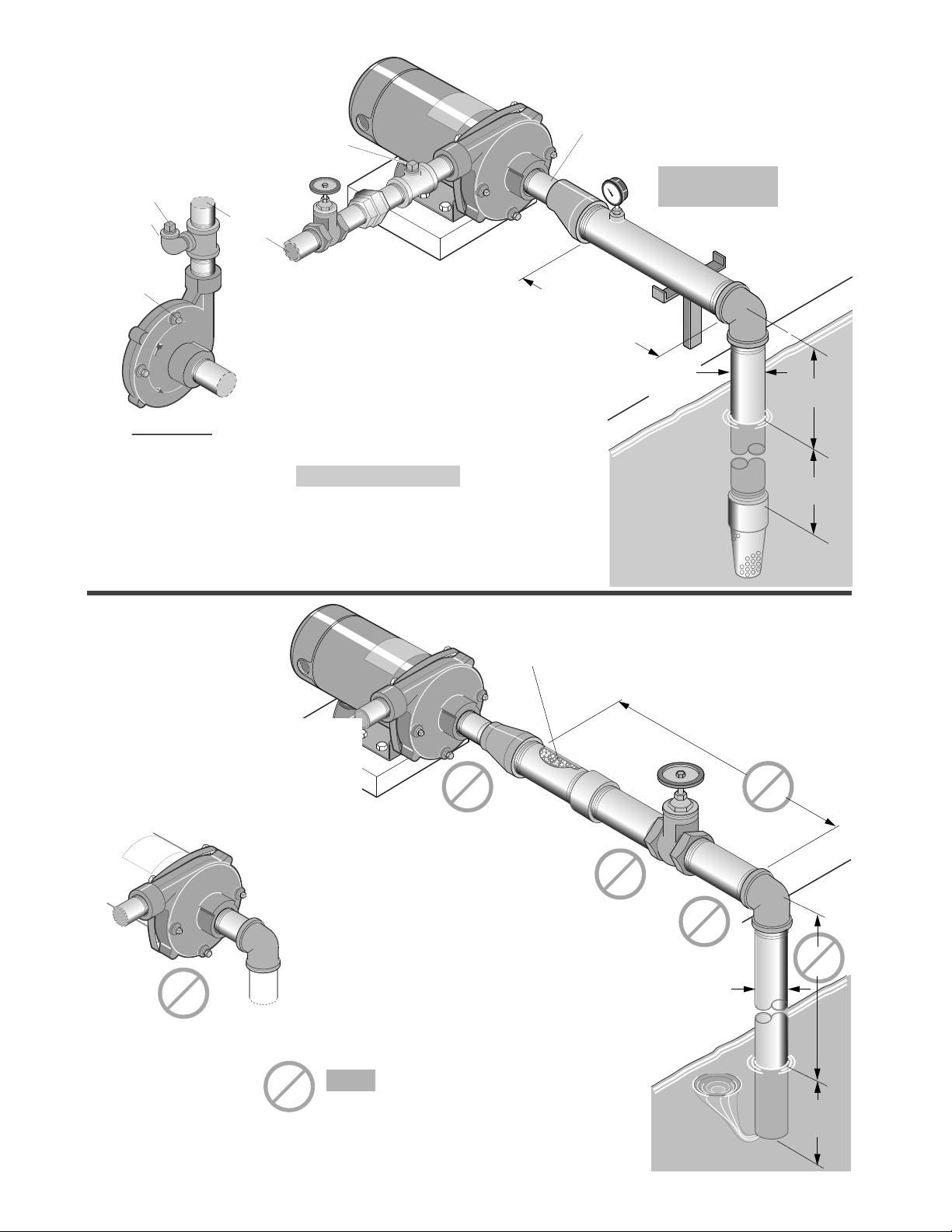

Support suction pipe

as required

Support discharge

pipe as required

As close

as possible

4 x "D"

minimum

Foot

Valve

Pipe diameter

"D"

Straight run, short as

possible but at least 6

times pipe diameter ("D")

sloping away from pump

Short length of

straight pipe

after reducer

Important:

All connections must

be air tight

Eccentric

Reducer

Solid, level

base

Tee and

Priming Plug

Rotated Volute

Gate

Valve

Union

Discharge

to service

Recommended pump suction

and discharge connections

Vent

Plug

Priming

Plug

Street Elbow

T

A

R

I

E

S

T

A

-

R

I

T

E

A

-

R

T

S

T

A

-

R

I

T

E

Not recommended pump suction

and discharge connections

Elbow immediately

in front of pump

suction.

On the discharge avoid:

Quick closing valves.

Small I.D. pipe.

Numerous fittings.

Misalignment.

Sharp turns in piping run.

High

lift

Pipe diameter "D"

insufficient size

Pipe submerged

less than 4 x "D"

will cause vortexing

Long suction

run

Concentric

Reducer

Use of excess fittings

means potential air leaks

Valve

Unsupported

Pipe

Concentric Reducer causes high

spots along the suction line resulting

in air pockets.

684 0294

Figure 1

Figure 2

2

3

PIPING - GENERAL

Support both suction and discharge piping independently at a

point near the pump to avoid putting a strain on the pump

housing. Start all piping AT THE PUMP.

Increase pipe diameter at both the suction and discharge by

one (1) standard pipe size (minimum) to obtain desired performance and flow rate. Refer to Table I when sizing pipe for

your pumping system.

NOTE: Do not use pipe with smaller diameter on the suction

side of pump.

TABLE I

Pipe Tapping Recommended

Size On Pump Pipe Size

Suction Discharge Suction Discharge

1-1/4 1 1-1/2 1-1/4

1-1/2 1-1/4 2 1-1/2

2 1-1/2 3 2

SUCTION PIPE

Increase pipe size from pump tapping as shown in Table I.

Figure 1 (Page 2) depicts a recommended run of pipe and fit-

tings for the suction side of a centrifugal pump. Please refer

to this illustration when choosing pipe and fittings for your

suction connection.

IMPORTANT: All connections must be air tight!

Figure 2 (Page 2) depicts conditions that are NOT DESIR-

ABLE on the suction side of a centrifugal pump and may

cause problems in flow rate and priming. Please look this

illustration over carefully before choosing pipe and fittings for

your suction connection.

DISCHARGE PIPING

Increase pipe size from pump tapping as show in Table I.

Figure 1 (Page 2) depicts a recommended run of pipe and fittings for the discharge. Install tee with priming plug as close

to pump as possible. Figure 2 (Page 2) notes conditions that

should be avoided. Please read over carefully before making

discharge connection.

PRIMING THE PUMP

A pump is primed when all air in the suction line and pump

volute has been evacuated and replaced with water.

To Prime:

1. Close valve in discharge line.

2. Remove priming plug from tee and fill pump and suction

line with water until water is flowing back out of tee.

3. Replace priming plug.

4. Start pump and slowly open valve until desired water flow

is achieved.

NOTE: If water is not being pumped, turn off pump, close

valve, and repeat steps 1 thru 4.

If pump volute is rotated as shown in Figure 1 (Page 2),

loosen vent plug when priming to evacuate air trapped inside

volute and tighten when volute is completely filled with water.

Risk of explosion and scalding. Never run

pump against closed discharge. To do so can boil water

inside pump, causing hazardous pressure buildup and possible explosion.

Risk of flooding. Do not run the pump dry.

This will damage mechanical seal and void warranty. It may

cause burns to person handling pump.

Motor normally operates at high tempera-

ture and will be too hot to touch. It is protected from heat

damage during operation by an automatic internal cutoff

switch. Before handling pump or motor, stop motor and allow

it to cool for 20 minutes.

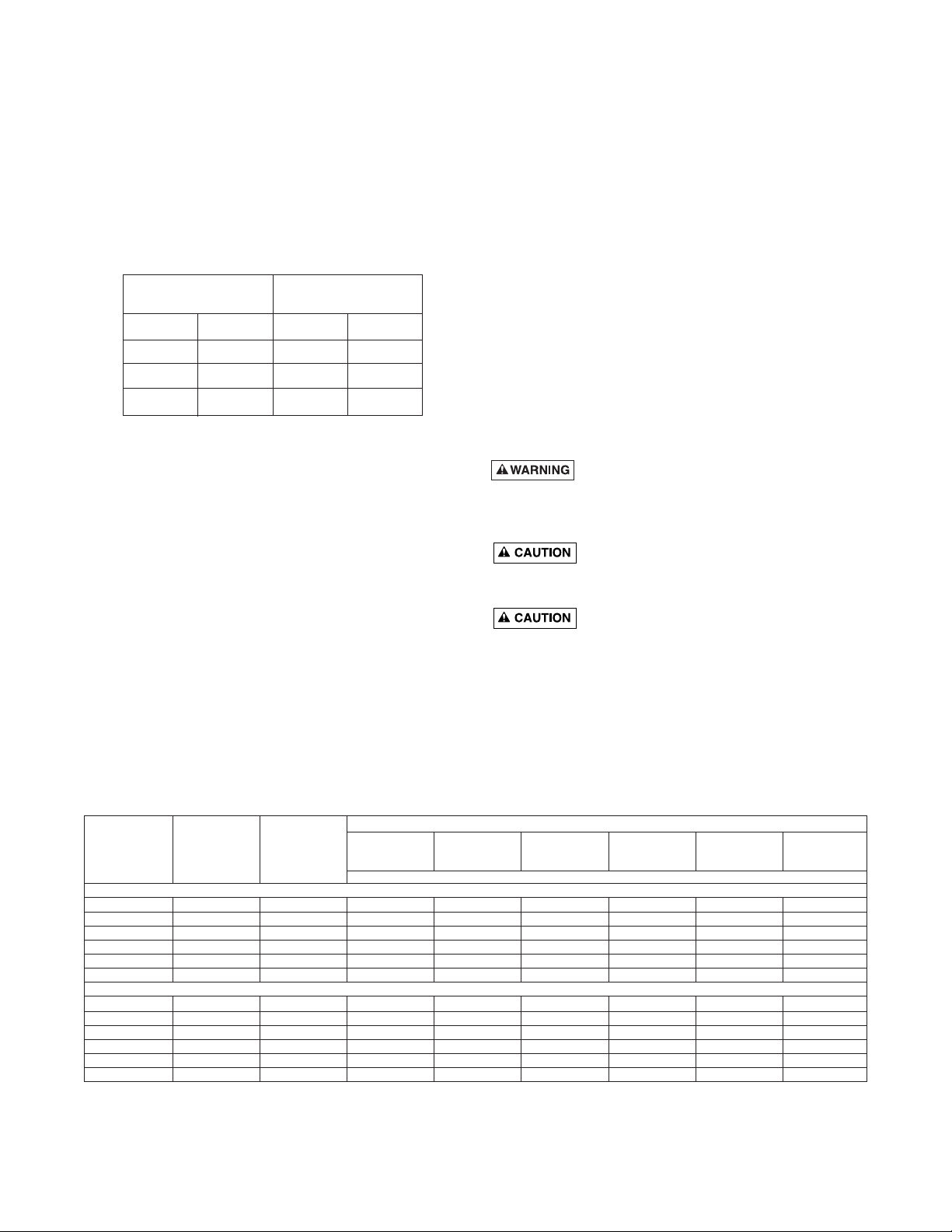

TABLE II - RECOMMENDED FUSING AND WIRING DATA - 60 CYCLE MOTORS

DIAMETER IN FEET FROM MOTOR TO METER

BRANCH 0’ 51’ 101’ 201’ 301’ 401’

MOTOR MAX. LOAD FUSE* TO TO TO TO TO TO

HP AMPERES RATING 50’ 100’ 200’ 300’ 400’ 500’

AMPS WIRE SIZE

SINGLE PHASE - 115/230 VOLT

1/3 9.4/4.7 15/15 14/14 14/14 10/14 10/14 6/14 6/12

1/2 9.4/4.7 15/15 14/14 14/14 10/14 10/14 6/14 6/12

3/4 12.2/6.1 20/15 12/14 12/14 10/14 8/14 6/12 6/12

1 14.8/7.4 20/15 12/14 12/14 8/14 6/14 6/12 4/10

1-1/2 19.2/9.6 25/15 10/14 10/14 8/14 6/12 4/10 4/10

2 24.0/12.0 30/15 12/14 10/14 6/14 6/12 4/10 4/10

THREE PHASE - 230/460 VOLT

1/2 2.3/1.15 15/15 14/14 14/14 14/14 14/14 14/14 14/14

3/4 3.1/1.55 15/15 14/14 14/14 14/14 14/14 14/14 14/14

1 3.6/1.8 15/15 14/14 14/14 14/14 14/14 14/14 14/14

1-1/2 4.7/2.35 15/15 14/14 14/14 14/14 14/14 14/14 14/14

2 6.8/3.4 15/15 14/14 14/14 14/14 14/14 12/14 12/14

2-1/2 8.5/4.25 15/15 14/14 14/14 14/14 14/14 12/14 10/14

*A Fusetron is recommended instead of a fuse in any motor circuit.

4

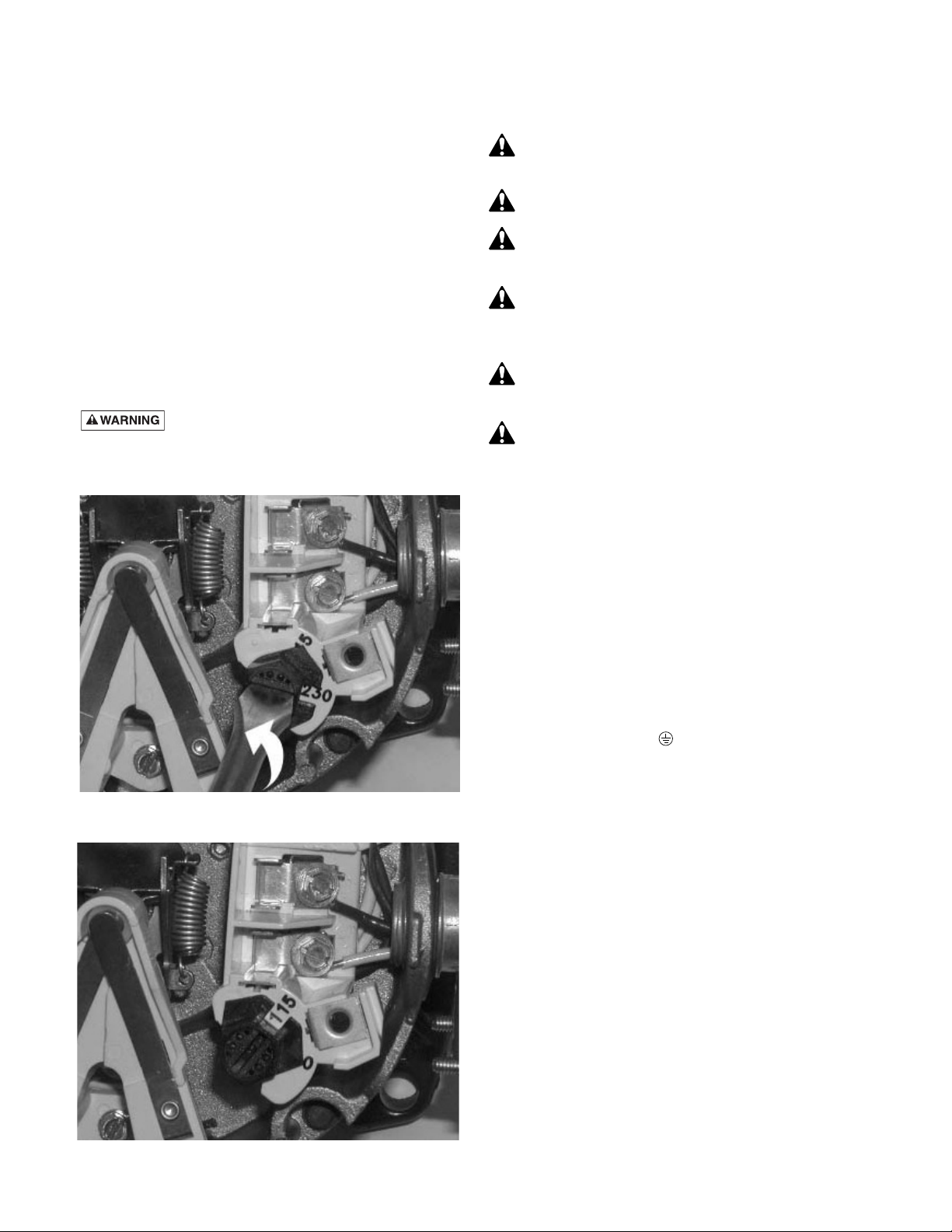

Connection diagram for dual voltage, single-phase motors.

Your dual-voltage motor’s terminal board (under the motor

end cover) will match one of the diagrams below. Follow that

diagram if necessary to convert motor to 115 Volt power.

Connect power supply wires to L1 and L2. For 3-phase

motors, or if motor does not match these pictures, follow the

connection diagram on the motor nameplate.

THE MOTOR IS SET FOR 230 VOLTS

WHEN SHIPPED.

To change the motor to use 115 volts:

1. Turn off power

2. Remove the back motor cover.

3. Use a screwdriver or 1/2” wrench and turn the voltage

selector dial counterclockwise until 115 shows in the dial

opening.

4. Reinstall the motor cover.

Hazardous voltage. Can shock, burn, or

cause death. Disconnect power to motor before working on

pump or motor. Ground motor before connecting to power

supply.

WIRING

Ground motor before connecting to electrical power

supply. Failure to ground motor can cause severe

or fatal electrical shock hazard.

Do not ground to a gas supply line.

To avoid dangerous or fatal electrical shock, turn

OFF power to motor before working on electrical

connections.

Supply voltage must be within ±10% of nameplate

voltage. Incorrect voltage can cause fire or damage

motor and voids warranty. If in doubt consult a licensed

electrician.

Use wire size specified in Wiring Chart (Page 3). If

possible, connect pump to a separate branch circuit

with no other appliances on it.

Wire motor according to diagram on motor name-

plate. If nameplate diagram differs from diagrams

above, follow nameplate diagram.

1. Install, ground, wire and maintain your pump in compliance

with the National Electrical Code (NEC) in the U.S., or the

Canadian Electrical Code (CEC), as applicable, and with all

local codes and ordinances that apply. Consult your local

building inspector for code information.

2. Provide a correctly fused disconnect switch for protection

while working on motor. For switch requirements, consult

your local building inspector for information about codes.

3. Disconnect power before servicing motor or pump. If the

disconnect switch is out of sight of pump, lock it open and

tag it to prevent unexpected power application.

4. Ground the pump permanently using a wire of the same

size as that specified in wiring chart (Page 3). Make ground

connection to green grounding terminal under motor

canopy marked GRD. or .

5. Connect ground wire to a grounded lead in the service

panel or to a metal underground water pipe or well casing

at least 10 feet long. Do not connect to plastic pipe or insulated fittings.

6. Protect current carrying and grounding conductors from

cuts, grease, heat, oil, and chemicals.

7. Connect current carrying conductors to terminals L1 and L2

under motor canopy. When replacing motor, check wiring

diagram on motor nameplate against Figure ##. If the motor

wiring diagram does not match either diagram in Figure 3,

follow the diagram on the motor.

IMPORTANT: 115/230 Volt single phase models are shipped

from factory with motor wired for 230 volts. If power supply is

115 volts, remove motor canopy and reconnect motor as

shown in Figure 3. Do not try to run motor as received on 115

volt current.

8. Motor has automatic internal thermal overload protection. If

motor has stopped for unknown reasons, thermal overload

may restart it unexpectedly, which could cause injury or

property damage. Disconnect power before servicing

motor.

9. If this procedure or the wiring diagrams are confusing, con-

sult a licensed electrician.

ELECTRICAL

Figure 3: Changing the Voltage Setting

Figure 4: Motor Set for 115 Volt Operation

5

PUMP SERVICE

This centrifugal pump requires little or no service other than

reasonable care and periodic cleaning. Occasionally, however, a shaft seal may become damaged and must be replaced.

The procedure as outlined below will enable you to replace

the seal.

NOTICE: Pumps use mechanical seals with a rubber seat

ring or a sealing O-Ring. THESE SEALS ARE COMPLETELY INTERCHANGEABLE.

NOTICE: The highly polished and lapped faces of this seal

are easily damaged. Read instructions and handle the seal

with care.

Some models are equipped with an impeller screw, which has

a left hand thread. Before unscrewing the impeller, remove

the impeller screw.

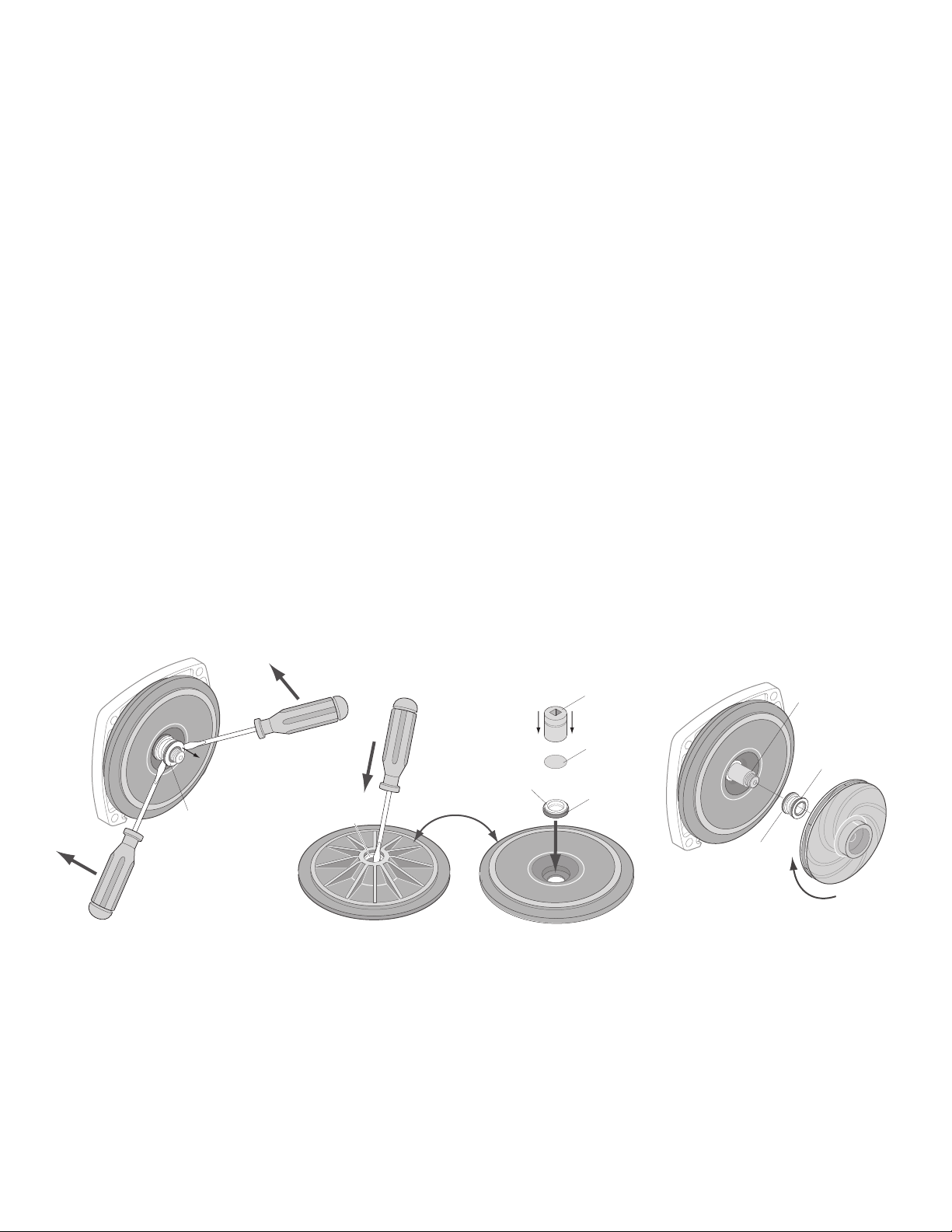

REMOVAL OF OLD SEAL

1. After unscrewing impeller, carefully remove rotating part of

seal by prying up on sealing washer, using two screwdrivers (see Figure 5A). Use care not to scratch motor

shaft.

2. Remove seal plate from motor and place on flat surface,

face down. Use a screwdriver to push ceramic seat out

from seal cavity (see Figure 5B).

INSTALLATION OF FLOATING SEAT (Figure 5C)

1. Clean polished surface of floating seat with clean cloth.

2. Turn seal plate over so seal cavity is up, clean cavity thoroughly.

3. Lubricate outside rubber surface of ceramic seat with

soapy water and press firmly into seal cavity with finger

pressure. If seat will not locate properly in this manner,

place cardboard washer over polished face of seat and

press into seal cavity using a 3/4” socket or 3/4” piece of

standard pipe.

4. DISPOSE OF CARDBOARD WASHER. Be sure polished

surface of seat is free of dirt and has not been damaged

by insertion. Remove excess soapy water.

INSTALLATION OF ROTATING

PART OF SEAL UNIT (Figure 5D)

1. Reinstall seal plate using extreme caution not to hit ceramic portion of seal on motor shaft.

2. Inspect shaft to make sure that it is clean.

3. Clean face of sealing washer with clean cloth.

4. Lubricate inside diameter and outer face of rubber drive

ring with soapy water and slide assembly on motor shaft

(sealing face first) until rubber drive ring hits shaft shoulder.

5. Screw impeller on shaft until impeller hub hits shaft shoulder. This will automatically locate seal in place and move

the sealing washer face up against seat facing. Reinstall

impeller screw (if used).

Seal Plate

Mechanical seal

rotating half

Mechanical seal

stationary half

A-Seal removal-rotating half B-Seal removal-stationary half C-Stationary half installation D-Rotating half installation

T

u

r

n

o

v

e

r

Polished

surface

Rubber

surface

Cardboard

washer

(supplied w/seal)

3/4" socket

or pipe

Sealing

face

Rubber drive

ring

Impeller

Shaft

shoulder

5939 0109

FIGURE 5

SERVICE

Loading...

Loading...