Owner’s/Operator’s Manual

Model 6TS, L6TS,

and PEA-6SS

Submersible

Turbines

INSTALLATION / OPERATION

MAINTENANCE

Table of Contents:

Safety ................................................................1

General .............................................................1

Specifications....................................................2

Pre-Installation Procedures and Checks .......2-3

Installation......................................................3-5

Submergence....................................................3

Three-Phase Current Unbalance......................5

Service ...........................................................6-7

Pump Disassembly/Assembly .....................7-10

Preventative Maintenance ..............................10

Troubleshooting ..............................................11

Repair Parts...............................................12-15

Warranty..........................................................16

PN524 (2/23/07)

READ AND FOLLOW SAFETY

INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, be alert to the

potential for personal injury.

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

The label NOTICE indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in this

manual and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

GENERAL CONSIDERATIONS

Before installing your submersible turbine pump, review

the following checklist.

Be sure the well is clear of sand and abrasive material

before installing pump. Abrasive materials in the water

cause component wear and reduce pump capacity and

discharge pressure. Never use the pump to develop or

clean the well. Permanent pump damage can result within

the first few hours of operation.

If the well casing is suspected of being crooked, check it

with a gauge of identical length and diameter as the pump

and motor with two lengths of pipe attached. Serious damage can result if the pump becomes lodged in a crooked

casing.

Be sure the well can supply a high-capacity turbine pump.

The well should be deep enough to cover the pump unit

with water, even at extreme pumping rates. Typically, the

pump should be submerged 10 to 20 feet below the lowest

water level and at least 5 feet above the bottom of the well.

Air entrained in the water reduces performance and will

damage the pump.

Your pump is designed to provide maximum efficiency

under specific capacity and head conditions. Do not operate it beyond specified limits.

System controls and pump must match. Do not interchange controls with other models. Serious damage can

result to the unit if pump and controls do not match.

Average number of starts per day will influence motor and

control component life (starters, relays, capacitors, etc).

Select pump size, tank size and control components for

lowest practical number of starts per day. Excessive

cycling accelerates bearing, spline, and pump wear and

control contact erosion.

This pump should be serviced

by authorized personnel only.

For more information,

please call 1-888-237-5353 or

contact your local Distributor.

PREINSTALLATION PROCEDURES

AND CHECKS

Electrical Splices and Connections

Splices must be waterproof. Make a strong mechanical

bond between the motor leads and the cable to avoid high

resistance at the connection. A poor mechanical connection, or a poorly wrapped splice, can cause motor

problems and motor failure.

Before connecting the motor to the cable, perform a

ground check to assure that the motor has not been

damaged. Attach one end of an ohmmeter lead to any of

the three motor leads and the other ohmmeter lead to the

pump intake bracket. A new motor must have a resistance

of 2 megohms or greater. If not, contact your dealer.

Repeat for all three leads.

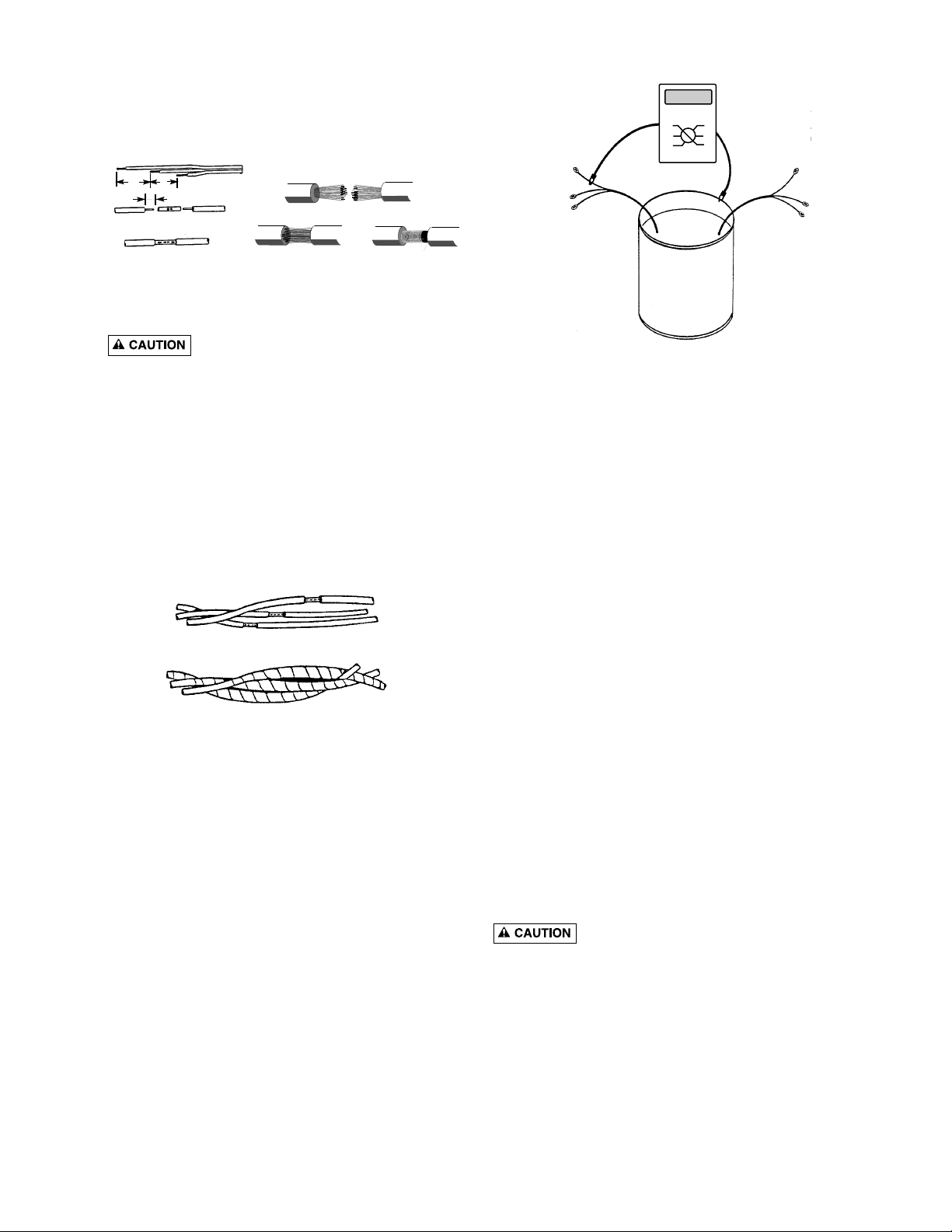

Prepare the cable and make the mechanical connections

(Figure 1A) and splices as follows:

1. Cut motor leads and corresponding cable ends at 3-inch

spacings to stagger connections for a smooth splice.

2. Cut connecting cable to match the motor leads.

NOTICE: Match color coded wires, red to red, black to

black, and white to white.

3. When using a butt connector, expose bare wire for

about 1/2". When using stranded wire, expose about

1" of wire.

NOTICE: Butt connectors may be used with solid wires

through 8 AWG, or stranded wires through 10 AWG.

4. Clean exposed ends of wire thoroughly with emery

cloth or sandpaper to assure good electrical

connections.

5A. BUTT CONNECTORS (Figure 1A): Insert wires into con-

nector until insulation butts up against connector. Crimp

connector to wires with a pair of crimping pliers. Pull on

cable to make sure the connection is solid and tight.

5B. SOLDERED CONNECTIONS (Figure 1A):

NOTICE: Do not use acid core solder or corrosive

solder paste.

I. Straighten individual cable strands and spread

apart slightly.

II. Clean each strand and push strands of cable into

matching (color-coded) open strands of the motor

leads.

III. Wrap entire length of joint with fine copper wire

until strands are compressed.

2

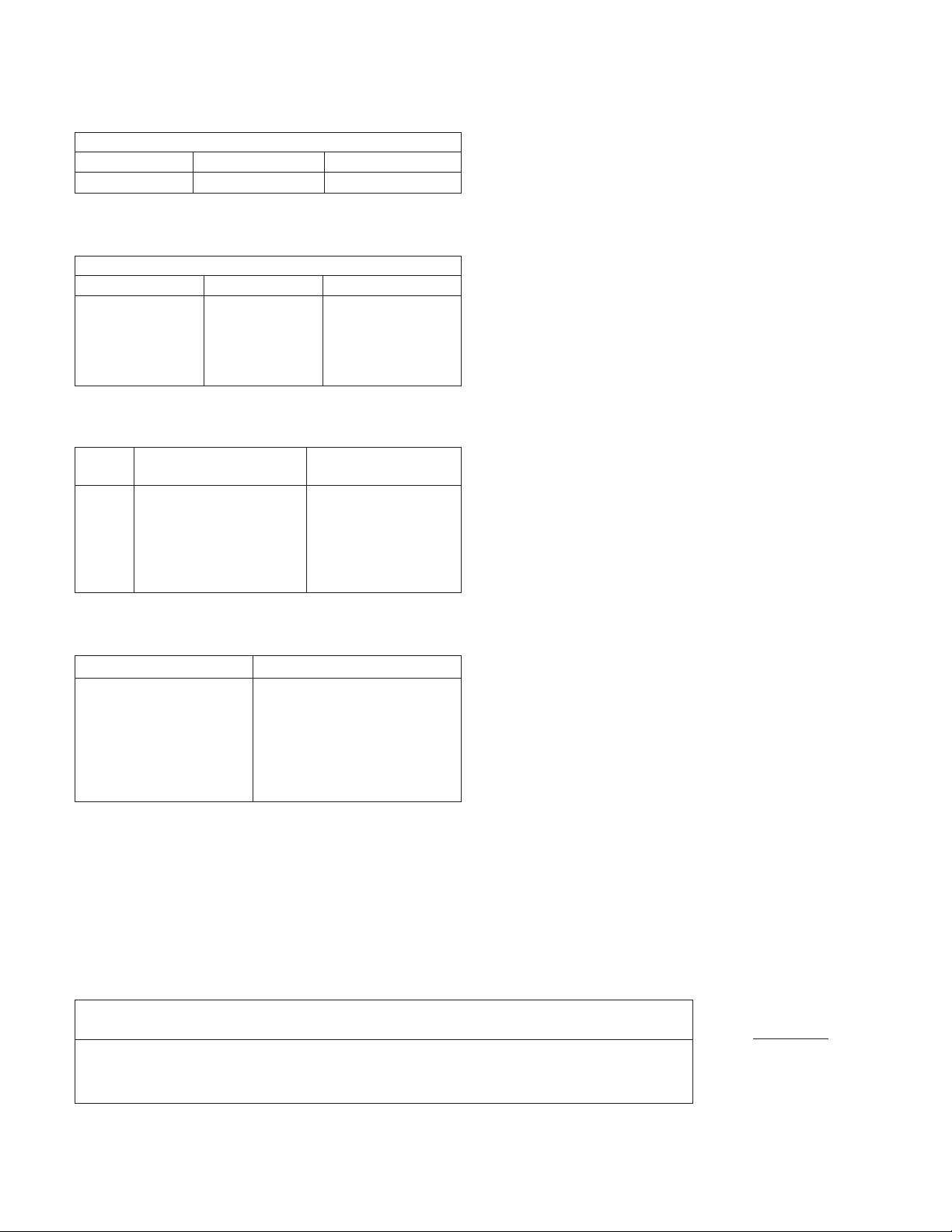

SPECIFICATIONS

Average Number of Starts per Hour

HP Rating Single Phase Three Phase

1 to 50 15 15

Weight per Foot (Lbs)

Pipe Size (In) Full Empty

2-1/2 7.9 5.8

3 10.8 7.6

4 16.3 10.8

5 23.3 14.62

6 31.5 18.97

Table I: Frequency of Starts

Table II: Weight of Pipe (Column)

Table III: Weight of Cable per 1000 Ft. (lbs.)

AWG 3-Phase 1-phase

Size Nom. Dia. Weight Nom. Dia. Weight

12-3 .500 140 .487 130

10-3 .545 186 .517 161

8-3 .771 328 .750 293

6-3 .965 525 .826 400

4-3 1.071 717

2-3 1.243 1066

AWG Wire Size Resist (Ohms/Ft)

14 .0050

12 .0032

10 .0020

8 .0013

6 .0008

4 .0005

2 .0003

Table IV: Cable Wire Resistance

Casing GPM

Size 20 40 60 80 100 120 140 160 180 200 220 240

6" ID 1.2 2.3 3.5 4.6 5.8 7.0 8.1 9.3 10.4 11.6 12.7 13.9

8" ID – 0.5 0.7 0.9 1.2 1.4 1.6 1.9 2.1 2.3 2.6 2.8

}

FPS

10" ID – – 0.3 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.3 1.4

NOTICE: If flow rate past motor is expected to be less than

rate shown in table, install a shroud around motor to force

cooling flow past shell. To minimize erosion to shell if flow

rate is expected to be more than 10 FPS (especially if sand

is present), reduce flow through pump to reduce flow past

shell.

Table V: Cooling Flow Rates Past Submersible Motors In Feet Per Second (FPS)

6" Nominal Motor (5.38" OD)

Formula to find flow rate:

FPS =

GPM x .409

D12– D2

2

D1 = Casing inside diameter

D2 = Motor outside diameter

IV. Apply heat and solder. Solder will follow the heat;

make sure solder flows throughout the joint. Pull

firmly on cable to test joint.

6. Repeat Step 5 for each lead.

7. Taping splice (Figure 1B):

Because friction tape is not water

resistant, never use friction tape on a water-tight

splice. Use Scotch Number 33, or equivalent.

7A. Clean joints and adjoining cable/wire insulation of all

grease and dirt, and build up joint area with tape until

it matches diameter of cable.

7B. Starting 1-1/2" back from the joint, firmly apply one

layer of tape, overlapping about half the previous lap

and continuing approximately 1-1/2" beyond joint. Cut

tape evenly and press both ends firmly against cable.

7C. Apply two additional layers of tape, as described in

Step 7B, beginning and ending 1-1/2" beyond the

previous starting/ending points.

Splice and Cable Continuity Test

Before installing pump check cable and splices as follows

(see Figure 1C):

1. Submerge cable and splice in steel barrel filled with

water. Make sure both ends of cable are out of water.

2. Clip one ohmmeter lead to barrel. Test each lead in

cable successively by connecting the other ohmmeter

lead to the three cable leads, one after the other.

3. If resistance reading goes to zero on any cable lead, a

leak to ground is present. Pull splice out of water. If

meter reading changes to "infinity" (no reading) the

leak is in the splice.

4. If leak is not in splice, slowly pull cable out of water

until reading changes to "infinity". Reading will change

to "infinity" when leak comes out of water.

5. Repair cable by splicing as explained under "Electrical

Splices and Connections".

Rotation Check (3-Phase Only)

After satisfactorily completing continuity test, connect

cable to pump controller. Check 3-phase motors for correct

rotation. If necessary, reverse any two cable leads at the

controller and recheck rotation. Permanently mark and

match to control box terminals for future reference.

Connect cable to motor controller and then wire controller

to disconnect switch. Connect temporary jumper wire

between proper terminals in controller to temporarily

energize magnetic coil.

Momentarily engage disconnect switch and note direction

of rotation. The shaft should rotate counterclockwise when

viewed from the top or shaft end of the motor. If rotation is

incorrect, reverse any two wires; mark wires to correspond

with the controller terminal numbers.

NOTICE: Pump is water lubricated. Do not operate the

pump for more than 5 seconds while it is out of water.

INSTALLATION

General

After completing all connections and tests so far, connect

a 5-foot length of pipe to pump.

Lower pump into well with pipe clamps attached to the 5foot pipe. Attach a standard length of pipe to 5-foot length

and lower pump CAREFULLY into well.

NOTICE: Do not use a pipe longer than 5 feet for the first

connection. Hoisting pump upright with a long length of pipe

can cause pump misalignment from excessive leverage.

Use extreme care when lowering pump

and cable to avoid damage to cable insulation.

Anchor power cable to pipe every 20 feet with adjustable

steel band clamps. Protect insulation from clamps with

pieces of split rubber hose inserted between clamps and

cable. Attach cable to pipe halfway between clamps with

waterproof tape (Scotch No. 33 or equivalent).

Submergence

Be sure the pump is always submerged, even at extreme

pumping rates. Install pump at least 10 to 20 feet below

the lowest "drawdown" water level and at least 5 feet

above bottom of well.

3

Figure 1A: Cable Splicing: Solid Wire, Stranded Wire

Figure 1B: Stagger splices and tape

Figure 1C: Splice and Cable continuity

a.

3"

3"

1

"

b.

c.

2

Ohmmeter set at

Rx100K or

Voltmeter set at

H1 Ohms

Attach lead to

metal tank or

immerse in water

d.

e.

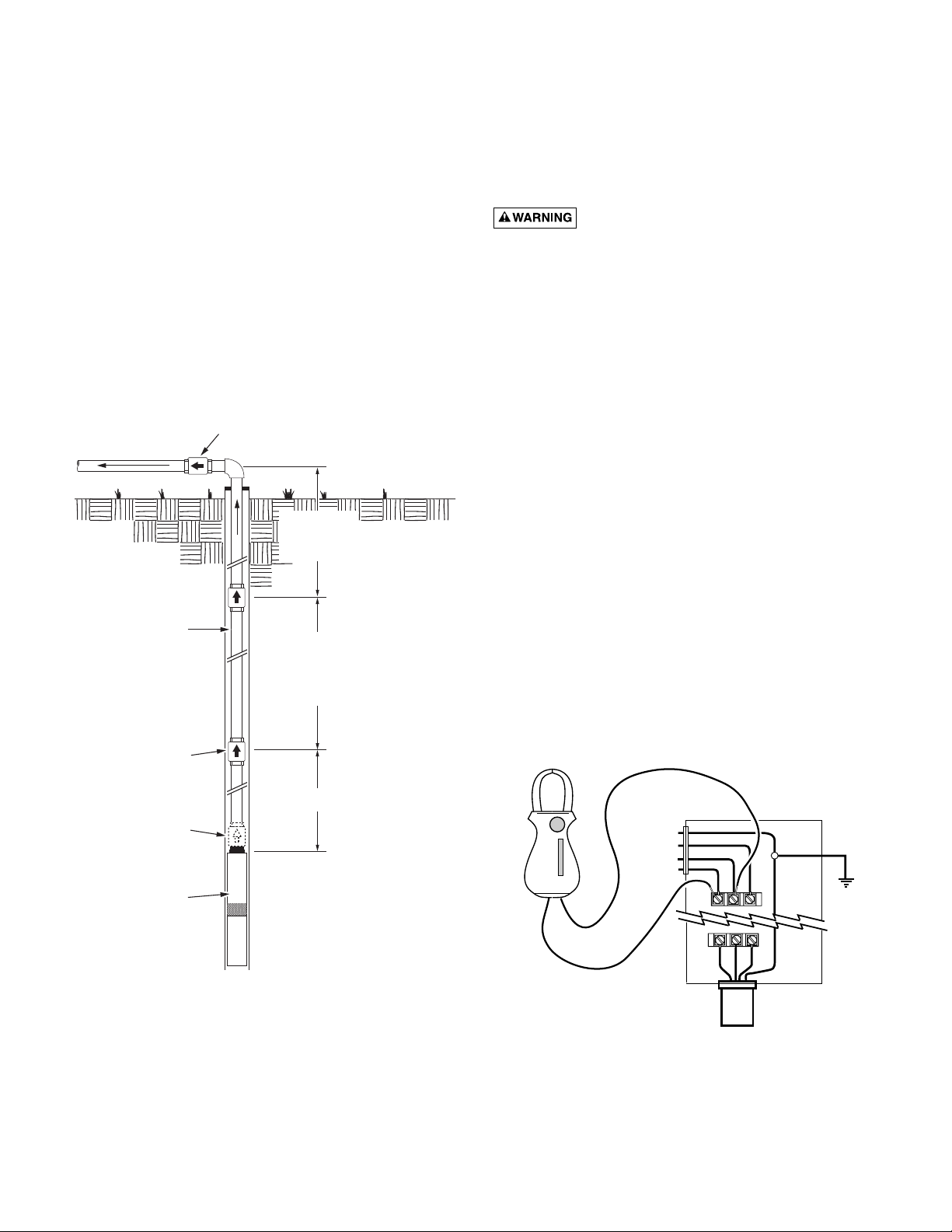

Check Valves

Pump back spin and hydraulic shock can cause severe

damage to the pump and motor. Install at least one check

valve in the discharge pipe (riser pipe) to help prevent this.

Install the first check valve in the pump discharge or in the

discharge pipe it self, not more than 25’ above the pump.

Install another check valve not more than 200 feet above

the first one. Repeat, all the way up the riser pipe. The last

check valve on the riser pipe should be not more than 200’

below the surface. Finally, install a check valve near the well

head in the horizontal pipe at the surface (see Figure 2).

NOTICE: To avoid water hammer and pipe breakage, do

not put a check valve exactly half-way up the riser pipe (that

is, with equal distance down to the pump and up to the

surface), especially if it is the only check valve in the riser

pipe after the pump discharge check. The ‘equal distance’ in

both legs of the pipe can allow resonations from water

hammer which can blow the pump off the riser pipe.

Well and Pump Test

Check and record static water level of well before starting

tests. Before making final piping connections, test flow

rate, capacity, and condition of well.

NOTICE: Do not operate pump with discharge valve

closed. Operate pump only within pressure and flow limits

of operating range established by performance curve.

NOTICE: If sand is present in discharge, allow pump to

run with discharge completely open until water is clear. If

loud rattling noises develop, pump is probably cavitating.

Gradually close discharge valve until rattling stops.

INSTALLATION -

ELECTRICAL TESTS

Risk of high voltage electrical shock

when testing. Can stun, burn, or kill.

Only qualified electricians should perform these tests.

When testing, use all normal precautions for the

voltages involved.

Electrical test of motor, cable, connections

The cable and splices can be damaged as the pump is

lowered into the well. To electrically test them, attach one lead

of ohmmeter to pipe. Attach other lead to each cable lead in

turn. See motor owner's manual for required resistance in a

good motor. A low reading indicates that cable or splice has

developed a leak to ground. Remove pump from well and

correct problem before proceeding with installation.

Measure electrical resistance between motor leads and

well casing when motor is cold.

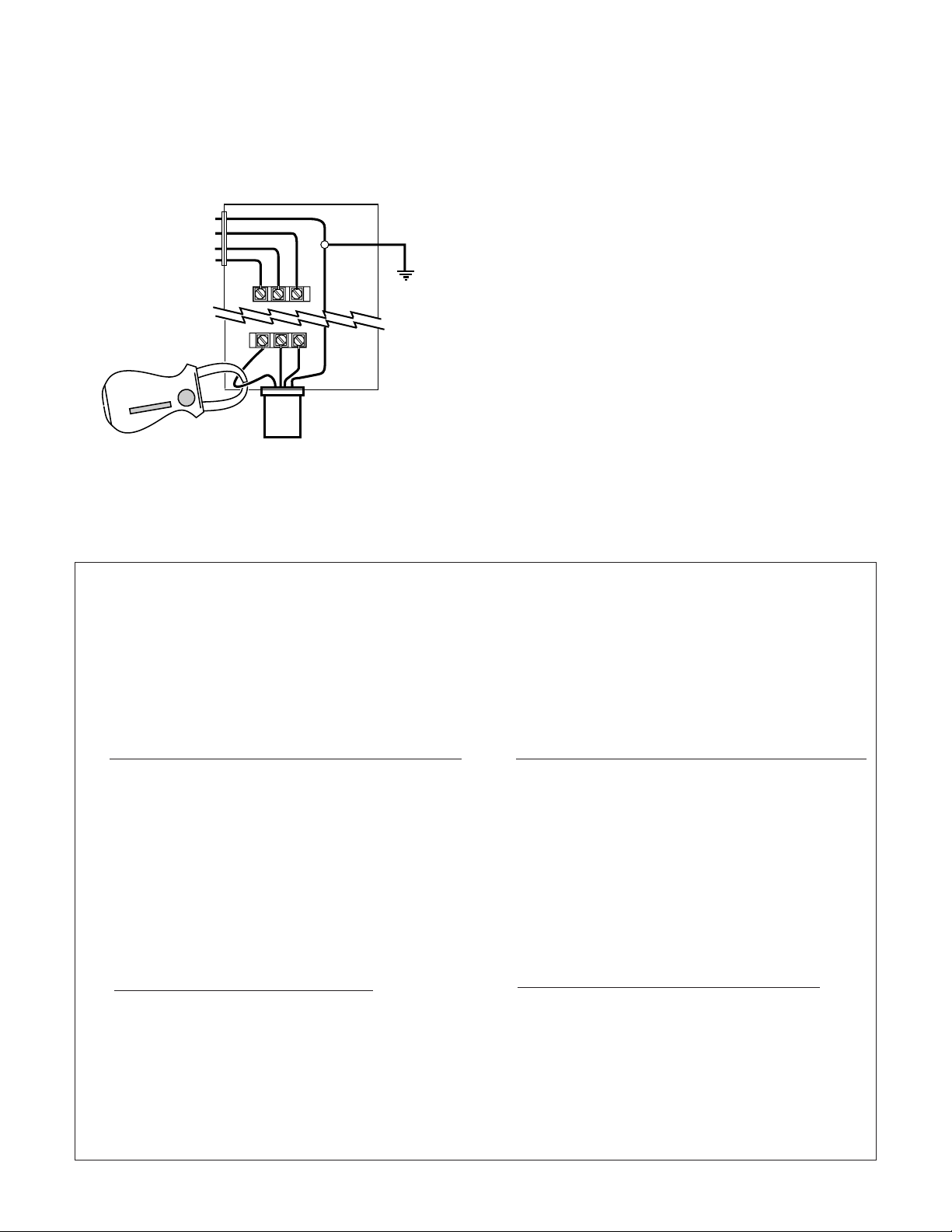

Voltage test (Figure 3)

Low or high voltages can cause motor failure. While pump

is operating, check voltage across each pair of leads at

motor controller. Readings more than 10% above or below

rated nameplate voltage can damage pump; correct before

placing pump in service. Test as follows:

1. Disconnect main power supply and open controller.

2. Connect power and start pump. For 3-phase motors,

read voltage across three pairs of leads (L1 – L3, L3 –

L2, L2 – L1) while pump is operating. For single phase

motors, read voltage across L1 and L2 while pump is

operating. Voltage should be within ±10% of motor

nameplate rated voltage. If not, consult power company.

Load current test (Figure 4)

Load current should be obtained on each motor lead at the

controller. Partially close pump discharge valve (keep

pressure and flow within specified operating range) until

4

Figure 3: Voltage Test

Figure 2: Check Valve Location

Check Valve at surface

To Service

Riser Pipe

1st. Check Valve

not more than

25 Ft. above pump

OR

1st. Check Valve

mounted directly

on pump

Submersible

Pump

200' Max

Top Check

To Surface

Not

to

Scale

Install Check

Valves Every 200'

For Full Length

of Riser Pipe

25' Max

To avoid water hammer and

pipe or pump damage,

DO NOT install a check valve

half-way between the pump

and ground level.

Controller

G

L3

Incoming

L2

Power

L1

Ground

To Pump

maximum amp reading has been obtained. Compare

reading with motor nameplate rating. If reading is 15% or

more over rated load, check for incorrect voltage in

supply line or overload due to abrasives in pump. Find

and correct problem before putting pump in service.

Current unbalance test (3 Phase only)

Determine current unbalance by measuring current in

each power lead. Measure current for all three possible

hookups. Use example and worksheet (Page 5) to

calculate current unbalance on a three phase supply

system and retain for future reference.

NOTICE: Current unbalance should not exceed 5%. If

unbalance cannot be corrected by rolling leads, locate

and correct source of unbalance.

If, on all three possible hookups, the reading furthest from

average stays on the same power lead, most of the

unbalance is coming from the power source.

However, if the reading furthest from average changes

leads as the hookup changes (that is, stays with a

particular motor lead), most of the unbalance is on the

"motor side" of the starter. In this case, consider a

damaged cable, leaking splice, poor connection, or faulty

motor winding.

5

Figure 4: Load Current Test

3-Phase Current Unbalance - Example

Here is an example of current readings at maximum

pump loads on each leg of a three wire hookup. Make

calculations for all three possible hookups.

A. For each hookup, add the readings for the three legs:

Ex.: Hookup #1 Hookup #2: Hookup #3

L1 = 51Amps L1 = 50 Amps L1 = 50 Amps

L2 = 46 Amps L2 = 48 Amps L2 = 49 Amps

L3 = 53 Amps L3 = 52 Amps L3 = 51 Amps

Total 150 Amps Total 150 Amps Total 150 Amps

B. Divide each total by three to get average amps:

Example: 150/3 = 50

Example: 150/3 = 50

Example: 150/3 = 50

C. For each hookup, find current value farthest from

average (Calculate the greatest current difference

from the average).

Ex. #1 Ex. #2 Ex. #3

50 Amps 50 Amps 50 Amps

–46 Amps –48 Amps –49 Amps

= 4 Amps = 2 Amps = 1 Amps

D. Divide this difference by the average and multiply by

100 to obtain the percentage of unbalance. Example:

Ex. 1: 4/50 = .08 x 100 = 8%

Ex. 2: 2/50 = .04 x 100 = 4%

Ex. 3: 1/50 = .02 x 100 = 2%

Use smallest percentage unbalance, in this case Ex. 3.

3-Phase Current Unbalance - Worksheet

Use this worksheet to calculate curent unbalance for your

installation.

A. Add the readings for the three legs:

Ex.: Hookup #1 Hookup #2: Hookup #3

L1 = Amps L1 = Amps L1 = Amps

L2 = Amps L2 = Amps L2 = Amps

L3 = Amps L3 = Amps L3 = Amps

Total Amps Total Amps Total Amps

B. Divide each total by three to get average amps:

Hookup #1: /3 =

Hookup #2: /3 =

Hookup #3: /3 =

C. For each hookup, find current value farthest from

average (Calculate the greatest current difference

from the average).

Hookup #1 Hookup #2 Hookup #3

Amps Amps Amps

Amps Amps Amps

Amps Amps Amps

D. Divide this difference by the average to obtain the

percentage of unbalance:

Hookup #1: / = x100 = %

Hookup #2: / = x100 = %

Hookup #3: / = x100 = %

Use hookup with smallest percentage unbalance.

Current Unbalance Example and Worksheet

Controller

G

L3

Incoming

L2

Power

L1

Ground

To Pump

Loading...

Loading...