Page 1

SEPARATION TANKS

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

MODEL

60SEP

Furnish this manual to the end user of

this tank; its use will reduce service

calls and chance of injury and will

lengthen tank life.

Pentair Water Pool and Spa, Inc.

1620 Hawkins Ave., Sanford, NC 27330 • (800) 831-7133 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (800) 831-7133 • (805) 553-5000

Visit us on the Internet @ www.pentairpool.com or www.staritepool.com

© 2009 Pentair Water Pool and Spa, Inc. Printed in U.S.A. S303 (Rev. A 4/16/09)

Page 2

SEPARATION TANKS

o avoid unneeded service calls, prevent possible injuries, and get the most

T

out of your filter, READ THIS MANUAL CAREFULLY!

The Sta-Rite Separation Tank:

• Is designed to separate spent diatomaceous earth and other solids form

swimming pool water when backwashing your DE filter.

• Is an excellent performer; durable, reliable.

Table of Contents

Safety Instructions ...................................................................................2-3

General Information/Dimensions.................................................................4

Installation..................................................................................................5

Operation ...................................................................................................6

Opening/Closing Tank ................................................................................6

Maintenance/Inspection ...........................................................................7-8

Winterizing.................................................................................................8

Repair Parts List...........................................................................................9

READ AND FOLLOW SAFETY

INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol on your system or in

this manual, look for one of the following signal words and be alert to the

potential for personal injury.

DANGER warns about hazards that will cause serious personal injury, death or

major property damage if ignored.

WARNING warns about hazards that can cause serious personal injury, death

or major property damage if ignored.

CAUTION warns about hazards that will or can cause minor personal injury or

property damage if ignored.

The label NOTICE indicates special instructions which are important but not

related to hazards.

Carefully read and follow all safety instructions in this manual and on filter.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

2

Page 3

ncorrectly installed equipment may fail, causing severe injury

I

or property damage. Read and follow operational parameters given below

when installing equipment described in this owner’s manual.

. Follow instructions and procedures in owner’s manual for installation,

1

operation, and maintenance of equipment.

2. Do not connect any part of pool or spa system to city water system, well

water system, or to any other type of high pressure water system or supply.

3. Do not attempt to use pool or spa equipment in any type of installation

other than a pool or spa.

4. Trapped air under pressure in system can cause explosion and serious in-

jury. Follow instructions in owner’s manual or on equipment to make sure

that no air is trapped in the system before testing or operating equipment.

Equipment that is incorrectly pressure tested may explode,

causing severe injury or property damage. Pressure testing should only be

done by trained pool professionals, following test parameters given below

when testing the equipment described in this owner's manual.

1. Make physical check for correct tightness of all clamps, bolts, lids, and

system accessories prior to test. See owner’s manuals covering equipment

being tested for this information.

2. Make sure there is no air entrapped in system. Release all air in system

before testing.

3. When using a Sta-Rite pump and trap, tighten trap lid to 30 ft. lbs.

(4.1 kg-m.) torque before testing.

4. Water pressure for testing must be 25 PSI (172kPa) or less.

5. Water temperature for testing must be 100°F (38°C) or less.

6. Test length must be 24 hours or less.

7. After test, make visual check of system to make sure that it is ready for

operation. Remove Sta-Rite trap lid and retighten hand-tight only.

8. Exceeding any one of limits 2 through 6 or omitting physical checks

specified in Steps 1 and 7 can result in equipment and property damage

or physical injury.

NOTICE: These parameters apply to Sta-Rite pool and spa equipment only.

For non-Sta-Rite equipment, consult manufacturer.

BEFORE WORKING

ON FILTER:

If filter clamps are

adjusted or removed

under pressure,

tank may explode,

causing severe injury or

major property damage.

1. Stop pump.

2. Open air release

valve.

3. Release all pressure

from system.

BEFORE WORKING

ON PUMP OR MOTOR

Filter pumps require

hazardous voltage

which can shock,

burn, or cause death

Disconnect power to

motor.

3

Page 4

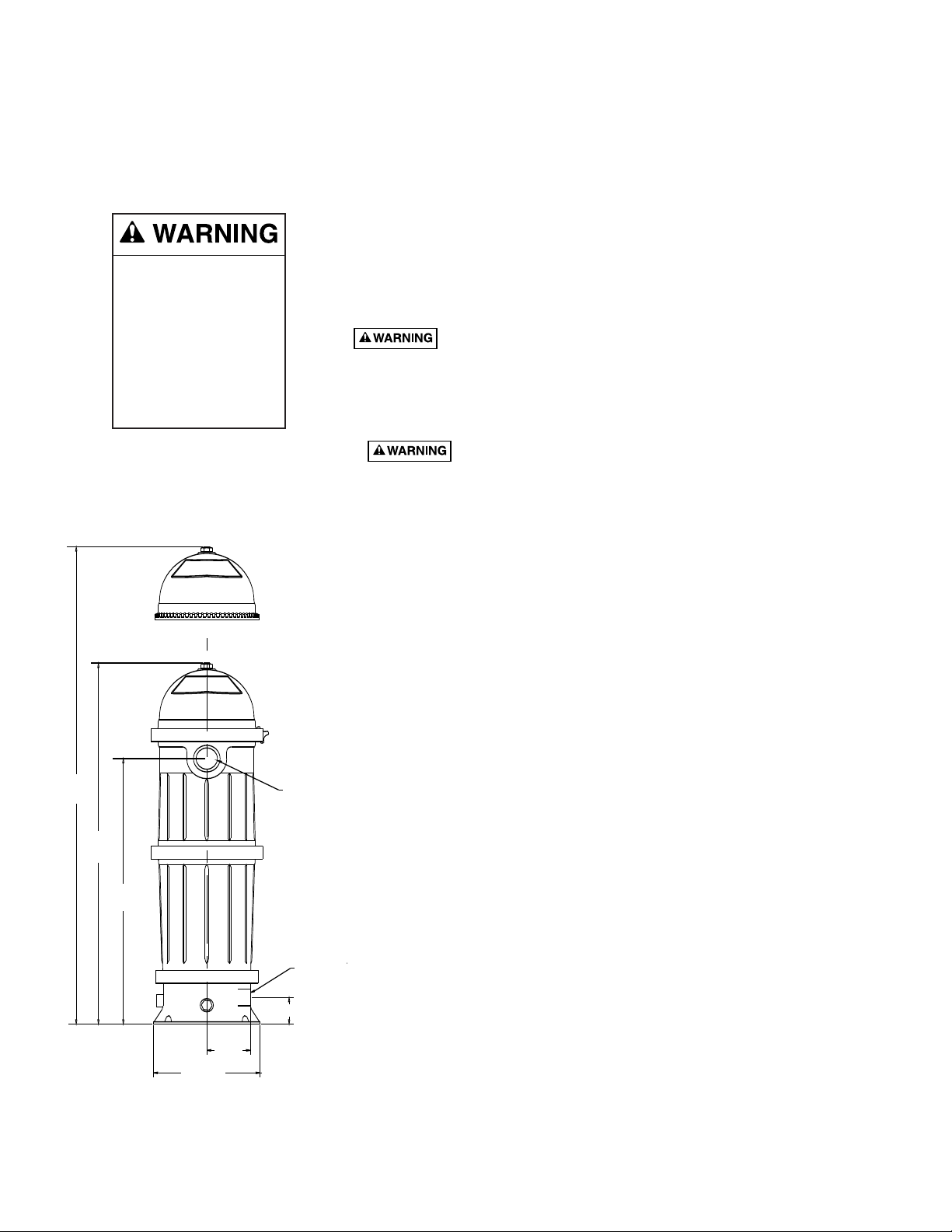

Hazardous pressure.

12" DIA.

(305)

4 7/8"

(124)

29 7/8"

(759)

40 5/8"

(1032)

2" NPT

1 1/2" NPT

3"(76.2)

70"

(1778)

Can cause severe

injury or major

property damage

from tank blow up.

Release all pressure

and read instructions

before working on

separation tank.

GENERAL INFORMATION

lean a new pool as well as possible before filling pool and operating filter.

C

Excess dirt and large particles of foreign matter in the system can cause serious damage to the filter and pump.

eep pool water pH at recommended level (7.2 to 7.6).

K

Be sure both clamps are in place and knobs are securely tightened before

starting filter. If filter is improperly disassembled or assembled, it will explode

under pressure! To avoid danger of severe injury or major property damage,

always follow service instructions in this manual when working on filter!

NEVER operate this filter system at more than 50 pounds per

square inch (50 PSI/345kPa) pressure!

On a new pool installation, we recommend:

1. Disassemble the filter after the initial cleanup.

To prevent severe injury or major property damage, follow

instructions in your filter owner’s manual.

2. Remove and hose down the element assembly to remove contaminants.

Figure 1 - Dimensions in inches (mm)

4

Page 5

INSTALLATION - GENERAL

WASTE LINE

FROM FILTER

(

BACKWASH)

(4) BYPASS

V

ALVE

(3) DRAIN

VALVE

RETURN

LINE

T

O POOL

(NORMAL

OPERATION)

S

IGHT

GLASS

AIR RELEASE

VALVE (1)

SEPARATION

T

ANK

LID

C

LAMP

KNOB (2)

nstallation of separation tank should only be done by qualified, licensed

I

personnel.

Separation tank mount must

rovide space and lighting for easy access for routine maintenance.

P

Provide adequate ventilation and drainage for pump.

Be protected from weather and reasonably level.

Be less than three feet above pool water level.

Be as close to pool as possible to reduce line loss from pipe friction.

Piping

All piping must conform to local and state plumbing and sanitary codes.

Figure 2 - Piping

Never use pipe joint sealing compound on pipe and fittings that are plastic or

may come into contact with plastic. Use only Teflon®tape, Plasto-Joint Stik

®

or Silastic 732®RTV on PVC pipe and fittings; pipe joint compound may

cause stress cracking of plastic components. Use pipe joint compounds only

on metal-to-metal joints.

Support pipe independently to prevent strains on filter or pump.

Use 1-1/2" (38mm) or larger pipe to reduce pressure losses.

NOTICE: Filter locations remote from pool are possible but may require larger

pipe to produce adequate flow through filter.

Check local codes if considering a remote installation.

Fittings restrict flow; for best efficiency use fewest possible fittings.

Keep piping tight and free of leaks: pump suction line leaks may cause

trapped air in filter tank or loss of prime at pump; pump discharge line leaks

may show up as dampness or jets of water.

Valves

A Multi-port Valve to allow backwash cleaning is recommended.

A recirculation line with shutoff valve installed between pool return line and

pump suction will allow recirculation of water during precoat if you have a

precoat pot.

Electrical

BE SURE filter grounding and bonding meets local and National Electrical

Code standards. All wiring, grounding and bonding of associated equipment

must meet local and National Electrical Code standards.

New Installations:

NOTICE: A new pool should be cleaned as well as possible before filling pool

and operating filter system. See your Filter Owner’s Manual for initial startup

and cleaning procedures.

5

Page 6

OPERATION

WASTE LINE

FROM FILTER

(BACKWASH)

(4) BYPASS

VALVE

(3) DRAIN

VALVE

RETURN

LINE

T

O POOL

(NORMAL

OPERATION)

SIGHT

GLASS

AIR RELEASE

VALVE (1)

SEPARATION

TANK

LID

CLAMP

KNOB (2)

CLAMP

FILTER

DO NOT PULL

CLAMP OUTWARD

FROM FILTER

hen the filter is backwashed, use separation tank as follows to clean the

W

diatomaceous earth filter media of pool residue, hair, etc. During normal

filter operation the separation tank is not in use.

Backwashing through Separation Tank:

1. Turn filter pump OFF.

2. Put filter valve in BACKWASH position.

3. Open Air Release Valve (Key No. 1, Figure 3).

4. Open return line By-Pass Valve (Key No. 4, Figure 3).

5. Start filter pump. when a steady stream of water comes out of Air Release

Valve, close Air Release Valve and continue to backwash until water is

clear in sight glass.

6. STOP filter pump. Return filter handle to FILTER position; close return line

Bypass Valve.

7. Open small drain valve (Key No. 3) below By-Pass Valve and open Air

Release Valve on Separation Tank lid. Allow Separation Tank to drain.

To avoid tank blow-up and severe personal injury or major

Hazardous

pressure.

property damage, BE SURE filter pump is off and all pressure is

released from system before proceeding to next step (opening

tank).

Figure 3

Figure 4

OPENING/CLOSING TANK

Opening Tank:

1. STOP FILTER PUMP and disconnect electrical power to pump before

working on separation tank..

2. CLOSE suction and return line valves (if used).

3. OPEN air release valve on top of separation tank.

4. WAIT until all pressure is released from separation tank and system before

loosening any clamps.

Releasing any clamp with pressure on system will cause tank

Hazardous

pressure.

1. Open air release valve (Key No. 1, Figure 3) on to of separation tank to

release all presure from inside of tank.

2. Open drain valve (Key No. 3, Figure 3) and drain all water from tank.

3. Remove clamp knob from top clamp.

4. Loosen top clamp; remove top clamp by lifting it straight up over tank or

dropping it onto filter base.

NOTICE: Do not pull clamp sideways to remove; to do so will bend and

damage clamp.

5. Remove tank lid from upper tank body. Be careful not to damage “O” Ring.

Place tank head in clean area.

or tank head to blow off of base, causing severe injury or

major property damage! NEVER adjust, tighten or loosen any

“V” band clamp when tank is under pressure!

6

Page 7

Figure 5: Lift basket to

remove.

Clamp Inspection

1. Check for broken or cracked welds.

2. Check threads for galling, dirt, excessive wear.

3. Check knob/nut for cracks, breakage, thread wear, thread galling, etc.

4. Check tank sealing surfaces and

clamp inner surface for dirt or corrosion. Clean where necessary.

5. Replace any parts showing damage

or visible wear and tear.

Clamp Tightening

1. Normal tightening will cause

threads to squeak; do not use the

squeak as an indication of tightness.

2. Tap clamp with a mallet while tightening to aid clamp seating.

3. Tighten until clamp ends are between 1/4" and 3/8" apart.

4. If tank leaks after tightening clamp,

proceed as follows:

A. Stop pump; release all pressure.

B. Remove clamp; clean clamp,

O-Ring, and tank flanges.

C. Follow instructions under

"Reassembly/Closing Tank"(at

right) to reassemble tank.

D. If leak persists, consult your

pool professional.

5. In normal use, middle and bottom

clamps should not need removal.

MAINTENANCE:

. Thoroughly clean separation tank bag as follows:

1

. Remove bag (see Figure 5) and dump spent DE into waste container.

A

NOTICE: Do not expose bag to direct sun for long periods. Direct sun will

cause the cloth to deteriorate.

B. Hose down bag and replace in separation tank.

C. Replace with a new bag if necessary.

2. Inspect "V" Band clamps.

f faulty “V” band clamp is used, clamp may fail, causing tank

I

to blow up. This can cause severe injury or major property

damage.

3. Clean air release valve of accumulated dirt, hair, etc.

Reassembly/Closing Tank:

1. Clean “O” Ring and sealing area of tank body. Check "O" Ring for damage.

If it is damaged, replace it. If it is OK, lubricate with approved lubricant

(see chart) and place in seat.

NOTICE: Top and middle clamps and “O” Rings are not interchangeable

with bottom clamp and “O” Ring; DO NOT mix them up.

2. Do not remove or damage safety and instruction labels during cleaning.

Replace any decals which may have been damaged.

3. Install clamp and knob assembly; tighten knob securely hand tight. To assist

sealing, tap clamp around tank with mallet while tightening knob. Gap

between ends of clamp should be 1/4" to 3/8" when clamp is tight and

properly seated (see side-bar at left). If not, consult your pool professional.

4. Replace plugs or close valves in Tank Drain and Auxiliary Drain ports.

NOTICE: Leave Air Release Valve OPEN and return line By-Pass Valve

CLOSED. Separation Tank should not be under pressure during normal

filter operation.

6. Consult Filter Owner’s Manual for filter startup procedure.

STA-RITE APPROVED O-RING LUBRICANTS

Petroleum Jelly (Vaseline®) Semi-Permanent Lubrication

Parker Super-O-Lube™ Semi-Permanent Lubrication

Aqua-Lube®by Allube

5% or less Mild Soap Solution Assembly Lubrication

See side-bar (at left) for clamp inspection instructions.

Semi-Permanent Lubrication

7

Page 8

SEPARATION TANK

INSPECTION

Weekly Inspection: S

bypass valve, make sure separation tank is not under pressure.

kimmer basket - remove debris. For systems with

Bi-Yearly Inspection: Check separation tank/return line bypass valve for

proper sealing as follows: With filter valve in `FILTER’ position and separation

tank cover off, start pump. No water should enter separation tank from lower

port. If water does enter, stop pump and inspect bypass valve for leaks and

debris. Clean or replace as necessary.

WINTERIZING

1. Open air release valve; open all system valves. Position multiport valve

between port positions to allow air passage to all ports.

2. Remove all drain plugs from trap, pump, valve, filter, and separation tank.

3. Drain all piping and cover system with plastic or tarpaulin to keep it dry.

8

Page 9

1

2

2

0

4

1

9

5

, 6, 7

8

9

18

5, 7

15

8

4

17

16

15

11,7

12

13

10

14

3

REPAIR PARTS

Key Part No. Part

No. Description Used No.

1 Air release valve Assembly 1 25010-0200

2 O-Ring 1 *

Lid Assembly

3

(Incl. #1, #20, & Decals) 1 25005-9001

4 O-Ring 2 31935-0001

Decal “Top Clamp” 2 WC27-46

5

6 Decal “Pressure Warning” 1 WC27-23

7 Decal “Clamp Warning” 3 WC27-19

8 “V” Clamp 2 25010-9101

9 Separation bag 1 25005-0015

10 Separation tank liner 1 25005-0016

11 “V” Clamp 1 25010-9100

12 1-1/2" PVC plug 1 36205-4008T

13 Base assembly 1 WC104-78PB

14 Decal “Thread Seal Warning” 1 WC27-27

15 Clamp nut 2 WC36-1

16 O-Ring 1 WC9-3

17 Lower body 1 25010-0001

18 Upper body 1 25005-0001

19 Clamp knob 1 WC36-22

20 1/4" NPT Plug 1 WC78-40T

• Model Decal 1 32155-4050

• Warning Decal 1 32155-4049

• Operating Instruction Decal 1 32155-4051

•Not Illustrated.

*Standard hardware item; purchase locally.

9

Page 10

This page is blank.

10

Page 11

This page is blank.

Page 12

© 2009 Pentair Water Pool and Spa, Inc. All rights reserved.

This document is subject to change without notice.

1620 Hawkins Ave., Sanford, NC 27330 • (800) 831-7133 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (800) 831-7133 • (805) 553-5000

Trademarks and Disclaimers: Sta-Rite®is a trademars and/or registered trademars of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United

States and/or other counties. Plasto-Joint Stik®is a registered trademark of La-Co Industries, Inc., Teflon®is a registered trademark of E.I. Du Pont De Nemours and

Company Corporation, Silastic 732®is a registered trademark of Dow Corning Corporation, Vaseline®is a registered trademark of Unilever Supply Chain, Inc.,

Parker Super O-Lube™ is a trademark of Parker Hannifin Corp., Aqua-Lube®is a registered trademark of Tifco Industries, Inc. Unless noted, names and brands of others

that may be used in this document are not used to indicate an affiliation or endorsement between the proprietors of these names and brands and Pentair Water Pool and

Spa, Inc. Those names and brands may be the trademarks or registered trademarks of those parties or others.

S303 (Rev. A 4/16/09)

Loading...

Loading...