Page 1

CSPH, CCSPH, 5CSPH AND 5CCSPH SERIES

CENTRIFUGAL PUMPS WITH TRAP

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

Pentair Water Commercial Pool and Aquatics

™

© 2008 Pentair Water Pool and Spa, Inc. All rights reserved.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000

Sta-Rite® and Pentair Water Commercial Pool and Aquatics™ are trademarks and/or registered trademarks of Pentair Water Pool and Spa, Inc.

and/or its affiliated companies in the United States and/or other countries. Unless noted, names and brands of others that may be used in this document are not used to indicate an affiliation or endorsement between the proprietors of these names and brands and Pentair Water Pool and Spa, Inc.

Those names and brands may be the trademarks or registered trademarks of those parties or others.

Printed in U.S.A. S248 (Rev B 09/08/08)

This manual should be given to the end user of this pump; its use will reduce

service calls and chance of injury and will lengthen pump life.

H.P. Phase 230/460V/60 Hz. 200V/60 Hz. 190/380V/50 Hz.

CSPH Series CSPH2 Series 5CSPH Series

5 3 – – 5CSPHJ3-142

7.5 1 CSPHK-142 – –

7.5 3 CSPHK3-142 CSPH2K3-142 5CSPHK3-143

7.5 3 CSPHK3-142S – –

10 1 CSPHL-143 – –

10 3 CSPHL3-143 CSPH2L3-143 5CSPHL3-144

10 3 CSPHL3-143S – –

15 3 CSPHM3-144 CSPH2M3-144 5CSPHM3-145

15 3 CSPHM3-144S – –

20 3 CSPHN3-145 CSPH2N3-145 –

20 3 CSPHN3-145S – –

CCSPH Series CCSPH2 Series 5CCSPH Series

5 3 – – 5CCSPHJ3-142

7.5 1 CCSPHK-142 – –

7.5 3 CCSPHK3-142 CCSPH2K3-142 5CCSPHK3-143

7.5 3 CCSPHK3-142S – –

10 1 CCSPHL-143 – –

10 3 CCSPHL3-143 CCSPH2L3-143 5CCSPHL3-144

10 3 CCSPHL3-143S – –

15 3 CCSPHM3-144 CCSPH2M3-144 5CCSPHM3-145

15 3 CCSPHM3-144S – –

20 3 CCSPHN3-145 CCSPH2N3-145 –

20 3 CCSPHN3-145S – –

2868 0997ASB

Page 2

‘

CSPH’ SERIES SELF-PRIMING

CENTRIFUGAL PUMP and TRAP

To avoid unneeded service calls, prevent possible injuries, and get the most out

of your pump, READ THIS MANUAL CAREFULLY!

The Sta-Rite ‘CSPH’ Series Self-priming Centrifugal pump:

Is designed for use with commercial swimming pools or as a centrifugal pump.

Is an excellent performer; durable, reliable.

Table of Contents

Safety Instructions .....................................................................................3

Dimensions and Specifications ...............................................................4-5

Uncrating and Inspection............................................................................6

Installation...............................................................................................6-9

Electrical .............................................................................................10-11

Operation ............................................................................................11-12

Maintenance.............................................................................................13

Troubleshooting Guide..............................................................................14

Disassembly/Assembly.............................................................................15

Repair Parts List..................................................................................16-19

Warranty ...................................................................................................20

2

For technical information about this

product, contact the installer or

call Customer Support at:

Sanford, North Carolina (8 A.M. to 5 P.M.)

Phone: (800) 831-7133

Moorpark, California (8 A.M. to 5 P.M.)

Phone: (800) 831-7133

Fax: (800) 284-4151

Visit www.pentairwater.com and pentaircommercial.com

Page 3

3

READ AND FOLLOW SAFETY

INSTRUCTIONS!

This is the safety alert symbol. When you see this symbol on your system or in this manual, look for one of the following signal words and be

alert to the potential for personal injury.

warns about hazards that will cause death, serious personal

injury, or major property damage if ignored.

warns about hazards that can cause death, serious personal

injury, or major property damage if ignored.

warns about hazards that will or can cause minor personal in-

jury or property damage if ignored.

NOTICE indicates special instructions not related to hazards.

Carefully read and follow all safety instructions in this manual and on equipment. Keep safety labels in good condition; replace if missing or damaged.

Incorrectly installed or tested equipment may fail, causing

severe injury or property damage.

Read and follow instructions in owner's manual when installing and operating

equipment.

1. Have a trained pool professional perform all pressure tests.

2. Do not connect system to a high pressure or city water system.

3. Use equipment only in a pool or spa installation.

4. Install pump with at least 2 hydraulically balanced main drains equipped

with correctly installed, screw-fastened, anti-entrapment certified covers.

See Page 6.

4. Trapped air in system can cause explosion. BE SURE all air is out of sys-

tem before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, and system accessories before testing.

• Release all air in system before testing.

• Tighten Sta-Rite trap lid to 25 ft. lbs. (3.5 kg-m) torque for testing.

• When pressure testing pumps and traps listed in this manual, water pres-

sure for test must be less than 40 PSI (2.8 kg/cm

2

).

• Water Temperature for test must be less than 100oF (38oC).

• Limit test to 24 hours. After test, visually check system to be sure it is

ready for operation. Remove trap lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment only.

For non-Sta-Rite equipment, consult manufacturer.

IMPORTANT

SAFETY

INSTRUCTIONS

Always follow basic safety precautions with this equipment,

including the following.

To reduce the risk

of injury, do not permit children to

use this product unless they are

closely supervised at all times.

This pump is for

use with permanently installed

pools and may also be used with

hot tubs and spas if so marked.

Do not use with storable pools. A

permanently installed pool is

constructed in or on the ground

or in a building such that it cannot be readily disassembled for

storage. A storable pool is constructed so that it may be readily

disassembled for storage and reassembled to its original integrity.

SAVE THESE

INSTRUCTIONS

Page 4

4

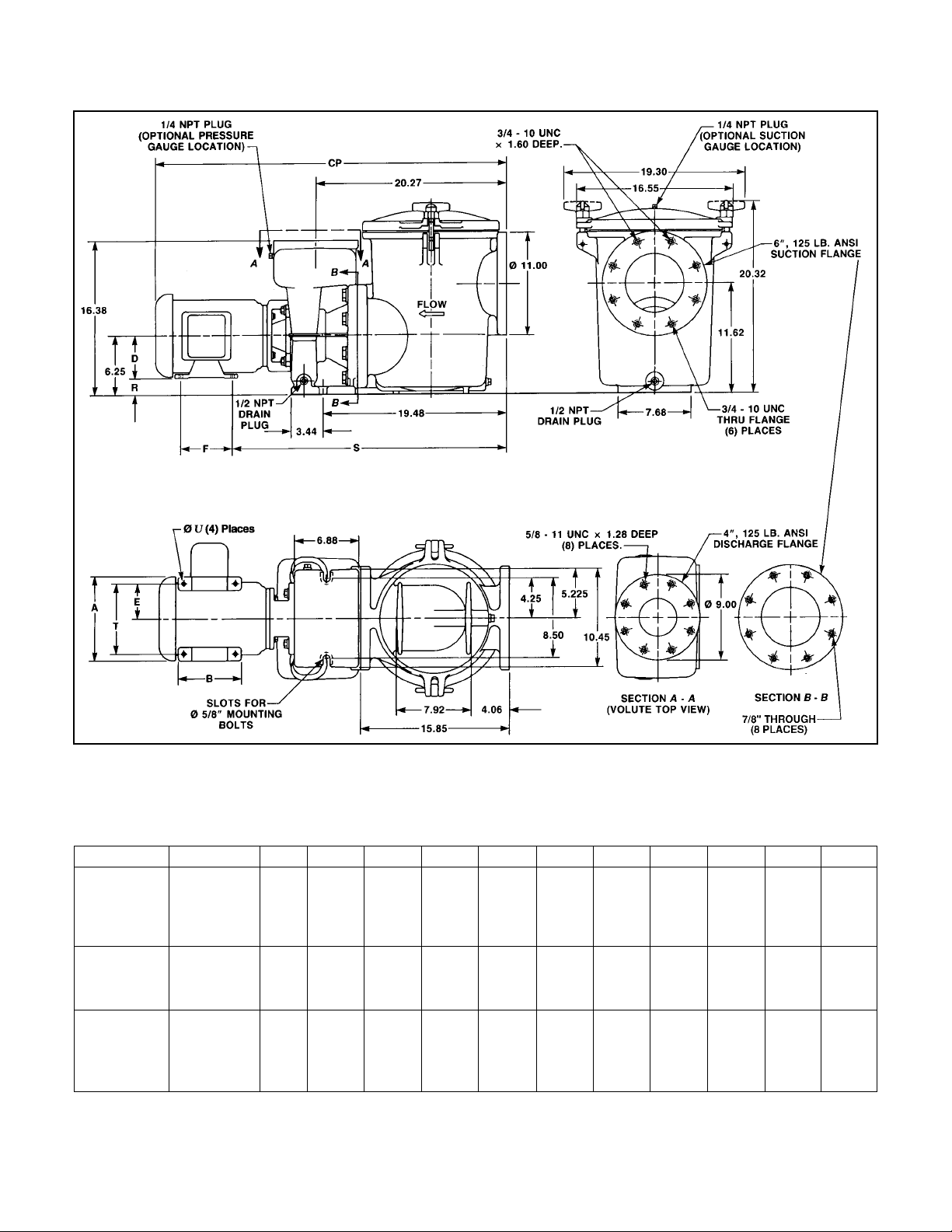

Table I – OUTLINE DIMENSIONS – In Inches*

(Includes Package 184)

* CCSPH models are dimensionally equivalent to CSPH models.

Model No. Volt/Hz/Ph HP A B CP D E F R S T U

CSPHK-142 230/60/1 7.5 10.62 7.00 39.44 5.25 4.25 5.50 1.00 30.00 8.50 .44

CSPHK3-142 230-460/60/3 7.5 9.00 6.75 40.31 4.50 3.75 5.50 1.75 29.13 7.50 .44

CSPHL-143 230/60/1 10 10.35 8.26 42.69 5.25 4.25 7.00 1.00 30.00 8.50 .44

CSPHL3-143 230-460/60/3 10 10.62 7.00 41.00 5.25 4.25 5.50 1.00 30.00 8.50 .44

CSPHM3-144 230/460/60/3 15 10.62 8.50 42.50 5.25 4.25 7.00 1.00 30.00 8.50 .44

CSPHN3-145 230/460/60/3 20 12.50 10.80 46.75 6.25 5.00 8.20 0.00 31.62 10.00 .54

CSPH2K3-142 200/60/3 7.5 9.00 6.75 40.31 4.50 3.75 5.50 1.75 29.13 7.50 .44

CSPH2L3-143 200/60/3 10 10.62 8.50 42.50 5.25 4.25 7.00 1.00 30.00 8.50 .44

CSPH2M3-144 200/60/3 15 10.62 8.50 42.50 5.25 4.25 7.00 1.00 30.00 8.50 .44

CSPH2N3-145 200/60/3 20 13.38 12.44 48.50 6.25 5.00 10.00 0.00 31.65 10.00 .54

5CSPHJ3-142 190/380/50/3 5 9.00 6.75 38.93 5.25 3.75 5.50 1.75 28.90 7.50 .44

5CSPHK3-143 190/380/50/3 7.5 10.62 7.00 40.93 5.25 4.25 5.50 1.00 28.87 8.50 .44

5CSPHL3-144 190/380/50/3 10 10.62 8.50 42.35 5.25 4.25 7.00 1.00 28.87 8.50 .44

5CSPHM3-145 190/380/50/3 15 12.50 10.80 46.68 6.25 5.00 8.25 0.00 31.25 10.00 .44

Page 5

5

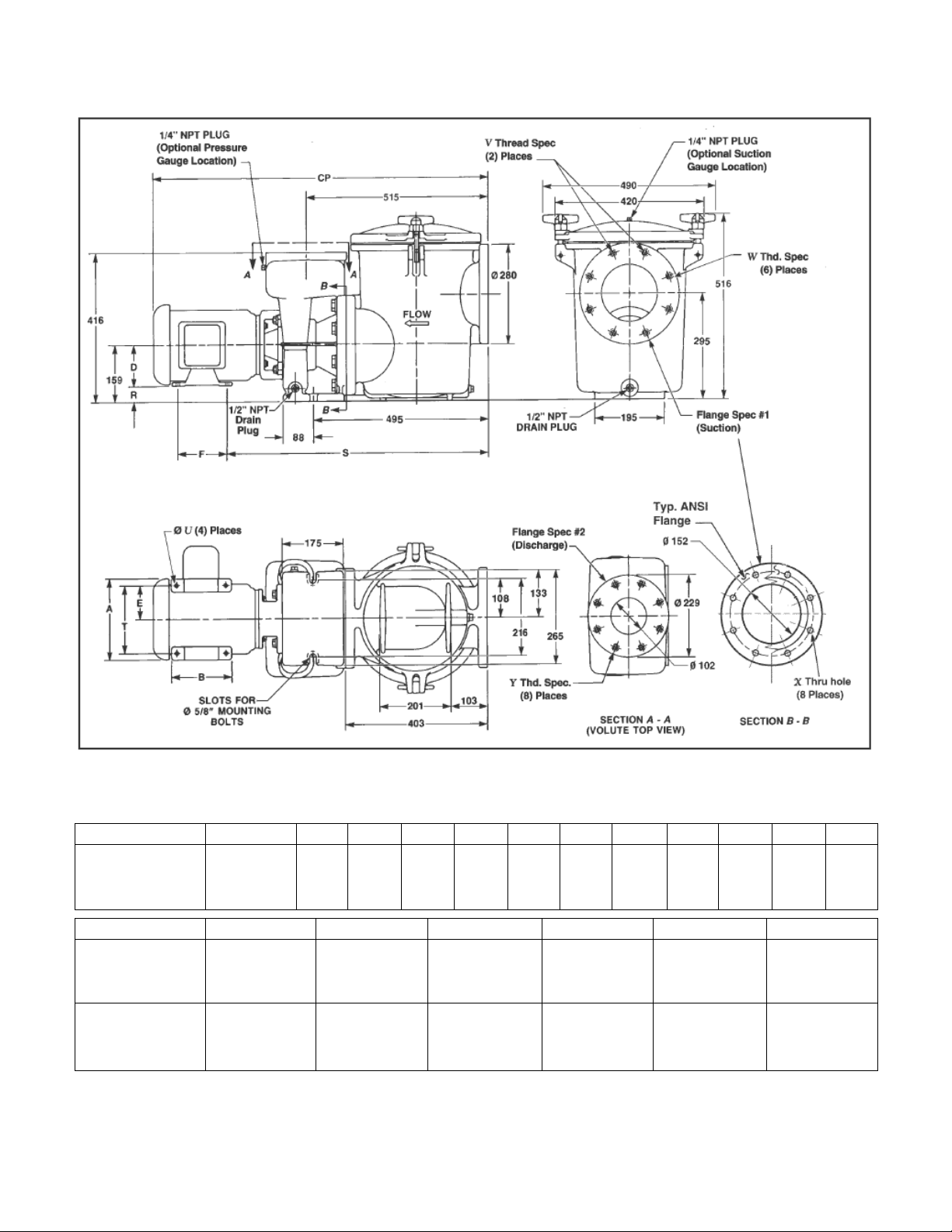

Table II – OUTLINE DIMENSIONS and Flange Specs – In Millimeters*

(Includes Package 184 and 184C)

* 5CCSPH (epoxy coated) models are dimensionally equivalent to 5CSPH models and use the same flange

specifications as equivalent 5CSPH models.

Model No. Volt/Hz/Ph HP A B CP D E F R S T U

5CSPHJ3-142, -142E 190/380/50/3 5 229 171 989 114 95 140 44 734 191 11

5CSPHK3-143, -143E 190/380/50/3 7.5 270 179 1,040 133 108 140 25 733 216 11.5

5CSPHL3-144, -144E 190/380/50/3 10 270 216 1,076 133 108 178 25 733 216 11.5

5CSPHM3-145, -145E 190/380/50/3 15 318 274 1,186 159 127 210 0 794 254 13.5

Model No. Flange Spec #1 Flange Spec #2 V Thd. Spec W Thd. Spec X Thru Hole Y Thd. Spec

5CSPHJ3-142

5CSPHK3-143 6” 4” 3/4”-10 UNC 3/4”-10 UNC Ø22.35 mm 5/8”-11 UNC

5CSPHL3-144 125 Lb. 125 Lb. x 31.75 mm Thru Thru x 32.5 mm

5CSPHM3-145 ANSI ANSI Deep Deep

5CSPHJ3-142E

5CSPHK3-143E M20 x 2.5 M20 x 2.5 Ø22mm M16 x 2

5CSPHL3-144E N/A N/A 29 mm Thru Thru 29.5 mm

5CSPHM3-145E Deep Deep

Page 6

6

UNCRATING AND INSPECTION

Handle with care.

Pump and strainer are heavy. Remove outer carton before trying to move.

Check items received against packing list to be sure that all equipment has been re-

ceived.

Inspect for shipping damage. If found, file claim with carrier immediately.

Cleanup

Clean up all trash and other materials which will interfere with installation from foundation

and surrounding area.

For easy assembly, make sure all threaded joints and mating surfaces are clean. If necessary, clean with wire brush and solvent.

Fire and explosion hazard. To reduce danger of explosion and fire, do not

use gasoline as a cleaning solvent.

Remove all foreign material (packing, etc.) from pump and strainer.

Fire and burn hazard. Modern motors run at high temperatures. To reduce the

risk of fire, do not allow leaves, debris, or foreign matter to collect around the pump motor.

To avoid burns when handling the motor, let it cool for 20 minutes before trying to work on it.

INSTALLATION

Only qualified, licensed personnel should install pump and wiring.

Location

Ambient air temperature should be kept at 104° F (40° C) or less.

Store pool chemicals away from pump.

Foundation

Foundation must:

Be located away from corrosive or flammable liquids.

Have enough ventilation to maintain air temperature at less than the maximum ambient

temperature rating (Max. Amb.) listed on the motor model plate. If this pump is installed in

an enclosure/pump house, the enclosure must have adequate ventilation and air circulation to keep the temperature in the enclosure at or below the motor’s rated ambient temperature whenever the pump is running.

Be Solid - Level - Rigid - Vibration free.

NOTICE:

These pumps must be

installed with strainer

PKG 184/184C in order

to have NSF Certification

at the installation; see

NSF Standard 50.

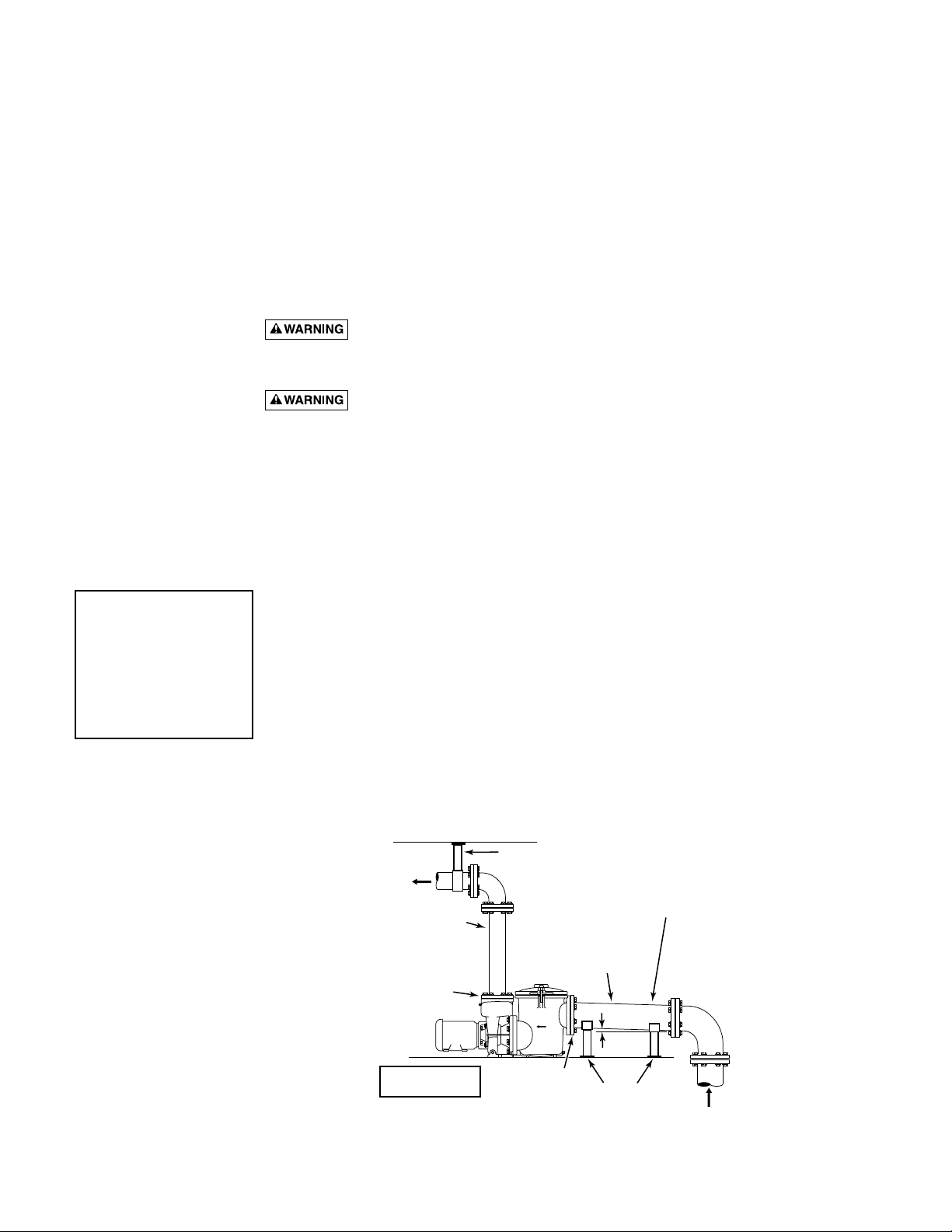

CSP/CCSP Pump Piping

Installation Diagram. Suction Lift Installation

Support pipe

To

Filter

Discharge pipe diameter

4" or larger. The distance

to the first elbow must be

at least 5 times the pipe

diameter.

4", 125 Lb. ANSI

Flange Connection

Not to Scale

6", 125 Lb. ANSI

Flange Connection

Straight run, as short as possible but at least

6 times pipe diameter (to stabilize flow) from

nearest fitting to strainer. Slope pipe

upward toward pump.

Minimum suction

pipe diameter 6".

FLOW

Support pipe

Long-Radius

elbows

preferred.

From pool suction

plumbing. Maximum

suction lift 10'.

Page 7

7

Be provided with necessary hold-down bolts, washers, and shims.

Allow pump inlet to be as close to water level as possible.

Use short, direct suction pipe (to reduce friction losses).

Maximum suction lift is 10’ (3 m).

Allow for gate valves in suction and discharge piping.

If vertical suction lift is higher than 5 feet, installation of a foot valve at lowest portion of

the vertical suction pipe may be needed.

Have adequate floor drainage to prevent flooding.

Be protected from excess moisture.

Allow adequate access for servicing pump and piping.

POOL PUMP SUCTION

REQUIREMENTS

Pump suction is hazardous and can trap and drown or disembowel bathers.

Do not use or allow anyone else to use a pool, spa, or hot tub unless it has at least two

suction outlets to each pump suction line (see “Outlets Per Pump,” below). Do not use or

operate swimming pools, spas, or hot tubs if a suction outlet cover is missing, broken, or

loose. Follow the guidelines below for a pump installation which minimizes risk to users of

pools, spas, and hot tubs.

Entrapment Protection

The pump suction system must provide protection against the hazard of suction entrapment or hair entrapment/entanglement.

Suction Outlet Covers

All suction outlet covers must be maintained. They must be replaced if cracked, broken,

or missing.

See Page 8 for outlet cover certification requirements.

All suction outlets must have correctly installed, screw-fastened covers in place.

Outlets Per Pump

Provide at least two hydraulically balanced main drains, with covers (see Figure 1, Page

8), for each swimming pool pump suction line. The centers of the main drains (suction fittings) must be at least three feet apart.

CSP/CCSP Pump Piping

Installation Diagram. Flooded Suction Installation

Support pipe

To

Filter

Discharge pipe diameter

4" or larger. The distance

to the first elbow must be

at least 5 times the pipe

diameter.

4", 125 Lb. ANSI

Flange Connection

Not to Scale

Isolation valves full

open when pumping.

Straight run, as short as possible

but at least 6 times pipe diameter

(to stabilize flow) from nearest

fitting to strainer.

FLOW

6", 125 Lb. ANSI

Flange Connection

Support pipe

From pool suction

plumbing.

Minimum suction

pipe diameter 6".

Long-Radius

elbows

preferred.

Page 8

The system must be built so that it cannot operate with the pump drawing water from only

one main drain (that is, there must be at least two main drains connected to the pump

whenever it is running, see Figure 1). However, if two main drains run into a single suction line, the single suction line may be equipped with a valve which will shutoff both main

drains from the pump (see Figure 1).

More than one pump can be connected to a single suction line as long as the requirements above are met.

Water Velocity and Flow Rates

The maximum water velocity must be six feet per second or less unless the outlet complies with the latest ASME/ANSI Specification for Suction Fittings For Use in Swimming

Pools, Spas, Hot Tubs, and Whirlpool Bathtub Applications.

If 100% of the pump’s flow comes from the main drain system, the maximum water velocity in the pump suction hydraulic system must be six feet per second or less even if one

main drain (suction fitting) is completely blocked. The flow through the remaining main

drain(s) must comply with the latest ASME/ANSI Specification for Suction Fittings For

Use in Swimming Pools, Spas, Hot Tubs, and Whirlpool Bathtub Applications.

Piping – General

System piping must be at least equal to size of pump connections.

To prevent strain on the pump casing and foundation, pipe and fittings must be aligned to

pump without forcing.

To avoid strains on the pump, support both suction and discharge pipes independently.

Place these supports near the pump.

To avoid a strain left by a gap at the last connection, start all piping at the pump and run

pipe away from the pump.

Piping – Suction

Hazardous suction. Risk of severe injury or drowning from hair or body entrapment. To reduce risk of entrapment against pump suction opening, connect pump to

multiple drains and skimmers of non-entrapment design. See “Pool Pump Suction

Requirements,” Page 7.

NOTICE: If pump suction becomes clogged, pump will cavitate, damaging pump internal

parts. Keep suction pipe clear of debris, dirt, etc.

NOTICE: To prevent flooding when removing pump for service, all flooded suction systems must have valves in suction and discharge pipes. Use at least 6” (152 mm) pipe.

Never use a suction pipe smaller than the pump suction connection.

8

Figure 1 – Recommended pump suction layout. See Pages 6 and 7 for Pump Installation drawings.

Hazardous suction.

Can trap hair or

body parts, causing

severe injury

or death.

Do not block

suction.

IAPMO Certified

Anti-entrapment

Cover or Suction Fitting,

screw-fastened to

Main Drain Sump

Suction Outlet

(Main Drain)

Valves OK between

pump and Tee

At Least

3 Feet

IAPMO Certified

Anti-entrapment

Cover or Suction Fitting,

No valves between

Tee and Main Drains

screw-fastened to

Main Drain Sump

Suction Outlet

(Main Drain)

Pump

2762 0197

Page 9

9

Use larger pipe as required to keep water velocity below six feet per second in suction

lines and ten feet per second in discharge lines. If code requires a lower water velocity,

comply with the code.

Suction pipe must rise continuously from source to pump. To avoid airlocking, do not

allow high spots in pipe.

When using reducer to connect to pump flange, use an eccentric reducer with the straight

side on top.

Piping – Discharge

To minimize friction losses, make piping one size larger than pump openings.

Fittings restrict flow; for best performance use fewest possible fittings.

Avoid fittings which could cause an air trap.

Pool fittings must conform to International Association of Plumbing and Mechanical

Officials (IAPMO) standards.

Strainer

Hazardous pressure. Maximum hydrostatic test pressure is 40 PSI (275

kPa) water pressure. To avoid explosion hazard, DO NOT test strainer with air pressure.

Air pressure in strainer can blow cover off of strainer body, which can cause severe or

fatal injury. Remove vent plug (Key No. 9, Page 19) and release ALL air (wait for a steady

stream of water from vent) before hydrostatically testing strainer.

To avoid breaking pump or putting unnecessary strains on pump or strainer body, support

pipe independently of pump/strainer.

Center the strainer cover when installing it (especially when pressure testing).

When installing cover, clean O-Ring groove in strainer body, and lubricate with petroleum

jelly as follows:

A. O-Ring;

B. Sealing surfaces of strainer cover and body;

C. Threads and faces of wing nuts.

This will prevent corrosion, improve seal, and ease maintenance.

If strainer is installed backwards, debris will collect in suction pipe instead of in strainer

basket. Install strainer with cast-on flow arrows pointing in direction of water flow.

Basket will only go into strainer one way; don’t force it.

ELECTRICAL

Pressure Drop Curve for Strainer Packages:

184 and 184C

Maximum Flow Rate 850 GPM

2.0

(13.8)

1.5

(10.3)

1.0

(6.9)

.5

(3.5)

PRESSURE DROP in P.S.I. (kPa)

0

100

(378.5)

200

(757)

300

(1138.5)

400

(1514)

Flow in GPM (LPM)

500

(1892.5)

600

(2271)

700

(2649.5)

800

(3028)

900

(3406.5)

Page 10

10

Disconnect power at service panel before connecting motor.

Ground motor before connecting to electrical power supply.

Failure to ground motor can cause severe or fatal electrical

shock hazard.

Do not ground to a gas supply line.

To avoid dangerous or fatal electrical shock, turn OFF power to motor before working on electrical connections.

Match supply voltage to nameplate voltage. Incorrect voltage and/or wiring can

cause fire or seriously damage motor and voids warranty.

All electrical wiring, grounding, and bonding must be done by a licensed electrical

contractor who is familiar with commercial swimming pool installations and

electrical codes and requirements.

NOTICE: Due to wide variation in electrical equipment, power supply, and installation

requirements, this manual does not make specific recommendations concerning auxiliary

equipment or fusing/wiring.

Wire sizing, wire type, branch circuit fuse protection, motor starter, control equipment,

and related items must meet National Electrical Code and local code requirements.

Motors are supplied by several manufacturers and nameplate data (service factor, maximum amperage, etc.) will vary. Consult control manufacturer and motor nameplate on

your pump to correctly choose and size motor starter and control equipment for your particular installation. Specific electrical questions or problems should be addressed to the

manufacturer of the electrical component in question.

Voltage/Phase

Voltage at motor must be not more than 10% above or below motor nameplate rated

voltage or motor may overheat, causing overload tripping and reduced component life. If

voltage is less than 90% or more than 110% of rated voltage when motor is running at full

load, consult power company.

Do not try to connect 3-phase motors to single phase power supply or single phase motors to 3-phase power supply.

Emergency Shutoff

Install an Emergency Shutoff Switch near pool. Clearly mark this switch and mount it in a

location that is accessible to bathers or pool operating personnel (e.g. lifeguards). Make

sure that all lifeguards and pool personnel understand the switch’s use in case of emergency (entrapment, electrical malfunction, etc).

Grounding/Bonding

Install, ground, bond and wire motor according to local and National Electrical Code

requirements.

Permanently ground motor. Use green grounding terminal provided under motor canopy

or access plate; use size and type wire required by code. Connect motor ground terminal

to electrical service ground.

Bond motor to pool structure according to local or National Electrical Code. Use a solid

copper conductor, size No. 8 (6.0 mm2) AWG or larger.

Wiring

Pump must be permanently connected to circuit; be sure no other appliances are on the

same circuit.

Make sure that motor nameplate connection diagram includes connection diagram for

available voltage. If not, consult power company or a licensed electrician.

Check rotation before attaching strainer and before making final connection to power

supply. Pump should rotate counterclockwise when viewed through pump suction port.

Hazardous voltage.

Can shock, burn,

or cause death.

Ground pump before

connecting to

power supply.

Page 11

11

To change rotation: Three phase motors: Reverse any two leads to motor.

Single phase motors: Follow motor manufacturer’s instructions to reverse.

OPERATION

Hazardous suction. Can trap hair or body parts, causing severe injury or

death by drowning. Do not block pump or strainer suction with body. Small children using

pool must ALWAYS have close adult supervision!

Explosion hazard. Do not run pump against closed discharge valve. To do

so can boil water in pump body, and can cause severe burns to people working on pump.

FFire and burn hazard. Modern motors run at high temperatures. To reduce

the risk of fire, do not allow leaves, debris, or foreign matter to collect around the pump

motor. To avoid burns when handling the motor, let it cool for 20 minutes before trying to

work on it. An automatic internal cutoff switch protects the motor from heat damage during operation.

NEVER run pump dry. Running pump dry may damage seals, causing

leakage and flooding. Fill pump with water before starting motor.

Before removing strainer cover:

1. STOP PUMP before proceeding.

2. CLOSE GATE VALVES in suction and discharge pipes.

3. RELEASE ALL PRESSURE from pump and piping system.

After pressure test, release all pressure before removing strainer cover!

NOTICE: Provide adequate ventilation. Ambient air temperature should be 104° F (40° C)

or less.

NOTICE: To prevent corrosion damage, store pool chemicals in another room away from

pump.

Priming Pump

Hazardous Pressure! Before removing strainer cover, remove vent plug in

cover and release all pressure from system.

In a flooded suction system open suction/discharge valves to prime. If pump is not in a

flooded suction system, remove strainer cover; fill strainer and pump with water.

If necessary, use a wrench on flats when removing wing nuts.

When installing cover, clean O-Ring sealing surface on strainer body, and

lubricate with petroleum jelly as follows:

A. O-Ring and Sealing surfaces of strainer cover and body;

B. Threads and faces of wing nuts.

This will prevent corrosion, improve seal, and ease maintenance.

Center strainer cover when installing it (especially when pressure testing).

Hand tighten wing nuts. When tightening, alternate back and forth between nuts to

compress O-Ring evenly.

Maximum wing nut torque is 25 ft.-lbs. (3.5 kg.-m).

Start pump; it should prime now. Priming time will depend on vertical length of suction lift

(10'/3m maximum) and horizontal length of suction pipe.

Pump is tested to prime to 10 feet (3m) in nine minutes, using 6” piping. Priming time will

vary with altitude above sea level.

If pump does not prime, make sure that all valves are open, suction pipe end is under

water and that there are no leaks in suction pipe. See Troubleshooting Guide, Page 14.

Page 12

12

NOTICE: To avoid corrosion damage to pump and strainer, do not add chemicals to system

anywhere on suction side of pump (including into skimmers). Do not pour chemicals into

strainer. Follow chemical manufacturer’s instructions when mixing or adding chemicals to system.

Storage/Winterizing

NOTICE: Allowing pump to freeze will damage pump and void warranty.

NOTICE: Do not use anti-freeze (except propylene glycol) in your pool system. Propylene

glycol (RV anti-freeze) is non-toxic and will not damage plastic system components.

Other anti-freezes are highly-toxic and may damage plastic system components.

Drain all water from pump and piping when expecting freezing temperatures or when

storing pump for a long time.

Keep motor dry and covered during storage.

To avoid condensation/corrosion problems, do not cover pump with plastic.

For outdoor/unprotected installation:

1. Enclose entire system in a weatherproof enclosure.

2. To avoid condensation/corrosion damage, allow ventilation; do not wrap system in plas-

tic.

3. Use a 40% propylene glycol/60% water solution to protect pump to -50° F (-46° C).

Draining Pump

Hazardous Voltage. Can shock, burn or cause death. Disconnect all power

before draining the pump.

Explosion Hazard. Purging the system with compressed air can cause

components to explode causing risk of severe injury or death to anyone nearby.

1. Pump down water level until it is below all inlets to pool.

2. Remove the strainer cover. When the interior is dry, replace the strainer cover.

3. To prevent pump from freezing, drain pump body and strainer through the two drain

plugs. Gravity drain the system as far as possible.

4. Clean the pump thoroughly and replace the priming plug.

5. Be sure the motor is kept dry and covered.

Startup for Winterized Equipment

1. Remove any temporary weather protection placed around the system for shutdown.

2. Follow the filter manufacturer’s instructions for reactivation of the filter.

3. Inspect all electrical wiring for damage or deterioration over the shutdown period. Have

a qualified serviceman repair wiring as needed.

4. Inspect and tighten all watertight connections.

5. Open all valves in suction and return piping.

6. Remove any winterizing plugs in the system.

7. Drain all antifreeze from the system.

8. Close all drain valves and replace all drain plugs in the piping system.

9. Prime pump according to instructions, Page 11.

Page 13

13

MAINTENANCE - Strainer

Hazardous pressure. Before removing strainer cover, loosen or remove

1/4” NPT vent plug in cover and release all pressure.

NOTICE: Do not allow strainer to freeze.

If system will be shut down for one day or more, drain strainer and system to prevent

corrosion.

Remove strainer cover to allow interior to dry out when storing for the season. When

interior is dry, replace cover.

Remove drain plug when storing for season. Leave plug out until system is restarted the

following season.

To remove strainer cover, unscrew two wing nuts. If necessary, use a wrench on flats

when removing wing nuts.

NOTICE: A clogged basket will cause cavitation, which will damage strainer basket,

impeller, and pump. Clean weekly or each time you vacuum pool, whichever comes first.

NOTICE: Basket is a close fit in body of strainer. When cleaning basket, do not deform.

Hose basket out well.

DO NOT hammer on basket or otherwise mistreat it.

When installing cover, clean O-Ring groove in strainer body.

Lubricate O-Ring, sealing surfaces of strainer cover and body, and threads and faces of

wing nuts with petroleum jelly to prevent corrosion, improve seal, and ease maintenance.

Center strainer cover when installing it (especially when pressure testing).

Hand tighten wing nuts. When tightening, alternate back and forth between nuts to

compress O-Ring evenly.

Maximum wing nut torque is 25 ft.-lbs. (3.5 kg-m).

If possible, protect from weather at all times.

For storage of outdoor installation:

1. Drain system.

2. Dry as much as possible.

3. Lubricate with petroleum jelly.

4. Reassemble.

5. Leave drain plug out during storage.

Page 14

14

CAUSE CORRECTIVE ACTION

___________________________________________________________________________________________________________________

I. ELECTRICAL

___________________________________________________________________________________________________________________

A. NO VOLTAGE IN POWER SYSTEM Check phase-to-phase on line side of starter contactor.

Check circuit breaker or fuses.

___________________________________________________________________________________________________________________

B. NO VOLTAGE ON ONE PHASE Check phase voltage on line side of starter contactor. Isolate open

(THREE PHASE UNITS) circuit (circuit breaker, fuse, broken connections, etc.)

___________________________________________________________________________________________________________________

C. LOW VOLTAGE AT MOTOR Running voltage across each leg of motor must be ± 10% of nominal

voltage shown on nameplate.

___________________________________________________________________________________________________________________

D. MOTOR LEADS IMPROPERLY GROUPED Refer to lead grouping diagram on motor nameplate.

FOR VOLTAGE

___________________________________________________________________________________________________________________

E. CONTROL FAILURE Check control device, starter contactor, H-O-A selector switch, etc.,

for malfunction.

___________________________________________________________________________________________________________________

F. THERMAL OVERLOAD SWITCH OPEN Check for drag or other overload.

___________________________________________________________________________________________________________________

G. INSULATION FAILURE Check motor or windings to ground with megohmmeter.

___________________________________________________________________________________________________________________

H. OPEN WINDINGS Check leg-to-leg with ohmmeter.

___________________________________________________________________________________________________________________

I. FREQUENCY VARIATION Check frequency of power system. Must be less than 5% variation from

motor nameplate rating.

___________________________________________________________________________________________________________________

J. WRONG DIRECTION OF ROTATION Reverse rotation of three phase motor by interchanging any two leads.

See Manufacturer's Instructions for reversing single phase motor.

___________________________________________________________________________________________________________________

2. MECHANICAL

___________________________________________________________________________________________________________________

A. FLOW THROUGH PUMP COMPLETELY OR Locate and remove obstruction. Refer to Repair Instructions

PARTIALLY OBSTRUCTED for disassembly.

___________________________________________________________________________________________________________________

B. PUMP NOT PRIMED Reprime. Inspect suction system for air leaks.

___________________________________________________________________________________________________________________

C. INTERNAL LEAKAGE Check impeller for wear of controlled clearances. (See Repair Instructions.)

___________________________________________________________________________________________________________________

D. LOOSE PARTS Inspect, repair.

___________________________________________________________________________________________________________________

3. SYSTEM

___________________________________________________________________________________________________________________

A. PRESSURE REQUIRED BY SYSTEM AT DESIGN Compare pump pressure and flow rate against pump characteristic curve.

FLOW RATE EXCEEDS PRESSURE RATING OF Check for closed or partially closed valve in discharge piping system.

PUMP Reduce system pressure requirement. Increase pressure capability of pump.

___________________________________________________________________________________________________________________

B. OBSTRUCTION IN SUCTION PIPING Locate and remove obstruction.

___________________________________________________________________________________________________________________

C. PRESSURE RATING OF PUMP EXCEEDS Compare pump pressure and flow rate against pump characteristic curve.

PRESSURE REQUIREMENT OF SYSTEM AT Inspect discharge piping system for breaks, leaks, open by-pass valves, etc.

DESIGN FLOW RATE If necessary, reduce flow rate by partially closing discharge valve.

___________________________________________________________________________________________________________________

D. SUCTION LIFT EXCEEDS 10' DESIGN Locate pump closer (vertically) to water source.

MAXIMUM.

PROBABLE CAUSE

GROUP 1 GROUP 2 GROUP 3

SYMPTOM ELECTRICAL MECHANICAL SYSTEM

ABCDEFGH I JABCDABCD

PUMP RUNS, BUT NO

WATER DELIVERED

•• •• •

NOT ENOUGH WATER DELIVERED

•• ••••••

NOT ENOUGH PRESSURE

•• ••••••

EXCESSIVE VIBRATION

•• • • • •

ABNORMAL NOISE

••• • ••

PUMP STOPS

••••••••

OVERHEATING

••• •• •• •

TROUBLESHOOTING

Page 15

15

‘

CSPH’

COMMERCIAL POOL PUMP

DISASSEMBLY/ASSEMBLY

Locate your Model Number on the correct Exploded View, Pages 16, 17 or 18, for Key

Numbers.

1. Disconnect all power to pump. Close valves to isolate pump from system.

2. Drain pump and trap; be sure to vent strainer (Key No. 9, Page 19).

3. Support motor so it does not drop when bracket (Key No. 4) is unbolted from the vo-

lute.

4. Unbolt the bracket (Key No. 4) from volute (Key 20); slide bracket, impeller and motor

out as a unit.

5. Remove impeller screw (Key No. 15), stat-o-washer (Key No. 14), impeller washer

(Key No. 13).

6. With a wheel puller, pull impeller (Key No. 11).

7. Remove shaft seal retaining ring (Key No. 7).

8. To remove or assemble the shaft sleeve (Key No. 8) call customer service. (ref. TSB #

C80-173SA).

9. Unbolt the bracket from motor and slide bracket off shaft, bringing the rotating portion

of the mechanical seal (a portion of Key No. 6) with it.

10. Turn bracket face down on bench; tap out stationary half of seal (the other portion of

Key No. 6).

11. Inspect the impeller skirt (outside impeller eye) and the wear ring (Key No. 22) for

damage, pitting or wear; replace it if necessary.

12. Remove old gaskets and clean all gasket surfaces.

Fire and explosion hazard. DO NOT use gasoline as a cleaning solvent.

13. Press in new stationary seal half (a portion of Key No. 6). If necessary, protect seal

surface with a cardboard washer and tap into place using a piece of plastic pipe for a

press. DO NOT scratch, nick or mar seal face.

14. Install the bracket (Key No. 4) on motor (Key No. 1); be careful not to nick seal on

shaft shoulder.

15. Slide rotating half of new seal (a portion of Key No. 6) onto shaft sleeve (Key No. 8),

polished face first; be

careful not to nick seal on shaft shoulder.

16. Install the shaft seal retaining ring (Key No. 7).

NOTICE: Do not lubricate shaft gaskets as this may interfere with sealing.

17. Install a new impeller gasket (Key No. 10) on the shaft.

18. Install the impeller (Key No. 11) on shaft. Pull impeller into place with impeller screw

(Key No. 15) and impeller washer (Key No. 13).

19. Remove impeller screw and washer, clean up screw with wire brush and prime with

Loctite Primer T.

20. Install impeller gasket (Key No. 12), impeller washer (Key No. 13), stat-o-washer (Key

No. 14), and impeller screw (Key No. 15) in that order. Use Loctite #271 to secure impeller screw. Tighten as shown: 3/8” impeller screw to 200 inch-lbs. (2.3 kg-m) torque;

1/2” impeller screw to 450 inch-lbs. (5.2 kg-m) torque.

21. Install new volute gasket (Key No. 9) and slide motor/impeller/bracket assembly into

place; bolt up to volute.

Tighten nuts and lockwashers (Key Nos. 2 and 3) to 450 inch-lbs. (5.2 kg-m) torque.

22. If pump is below water level: Close drains; open system valves to fill pump. If pump is

above water level: Fill strainer and prime pump. Open system valve if they were

closed at disassembly.

23. When pump is full, close pump and strainer vent plugs.

24. Reconnect power to pump and system is ready for operation.

Page 16

16

T

r

u

a

r

c

19

20

21

22

1

18

17

23a,23b

24

4

2

3

5

6

7

8

9

11

12

13

14

15

16

10

2868 0697

7.5 HP 10 HP 15 HP 20 HP

CSPHK-142(1Ph) CSPHL-143(1Ph)

CCSPHK-142(1Ph) CCSPHL-143(1Ph)

Key Part No. CSPHK3-142(3Ph) CSPHL3-143(3Ph) CSPHM3-144(3Ph) CSPHN3-145(3Ph)

No. Description Used CCSPHK3-142(3Ph) CCSPHL3-143(3Ph) CCSPHM3-144(3Ph) CCSPHN3-145(3Ph)

1 Motor, 230V, 1 Phase 1 S22351 62500-0101 – –

1 Motor, 230/460V, 3 Phase 1 S22353 S22356 S22357 S28574

2 Nut, 1/2” 4 S23488 S23488 S23488 S23488

3 Lockwasher, 1/2” 4 U43-13SS U43-13SS U43-13SS U43-13SS

4 Bracket (1 Phase - CSPH) 1 L05328 L05328 – –

4 Bracket (1 Phase - CCSPH) 1 16830-2203 16830-2203 – –

4 Bracket (3 Phase - CSPH) 1 L05329 L05328 L05328 L05779

4 Bracket (3 Phase - CCSPH) 1 16830-2201 16830-2203 16830-2203 16830-2202

5 Stud, 1/2-13x1-1/2” Long 4 30747-0152 30747-0152 30747-0152 30747-0152

6 Mechanical Shaft Seal 1 S32014 S32014 S32014 S32015

7 Retaining Ring 1 S11207 S11207 S11207 S16767

8 Shaft Sleeve 1 37447-0001L 37447-0001L 37447-0001L 37447-0002L

9 Gasket (Volute to Bracket) 1 S04757 S04757 S04757 S04757

10 Gasket (Impeller to Shaft Sleeve) 1 33455-8044 33455-8044 33455-8044 33455-8046

11 Impeller 1 16830-0209 16830-0210 16830-0211 16830-0212

12 Gasket (Impeller to Washer) 1 33455-8043 33455-8043 33455-8043 33455-8045

13 Impeller Washer 1 38917-0203 38917-0203 38917-0203 38917-0204

14 Stat-O-Seal Washer 1 C43-46SS C43-46SS C43-46SS C43-46SSA

15 Impeller Screw 3/8-16x1” Long 1 S23566 S23566 S23566 –

15 Impeller Screw 1/2-13x1” Long 1 – – – S23619

16 Vent Plug 1/4” NPT 1 U78-57DV U78-57DV U78-57DV U78-57DV

17 Hardware Kit: Includes 8 each

5/8” Capscrews and Lockwashers 1 16830-0400 16830-0400 16830-0400 16830-0400

18 Gasket (Volute Discharge) 1 33450-8042 33450-8042 33450-8042 33450-8042

19 Gasket (Volute Suction) 1 33450-8041 33450-8041 33450-8041 33450-8041

20 Volute (CSPH) 1 16830-0100 16830-0100 16830-0101 16830-0101

20 Volute (CCSPH) 1 16830-2102 16830-2102 16830-2103 16830-2103

21 Drain Plug 1/2” NPT, Brass 1 U78-59D U78-59D U78-59D U78-59D

22 Wear Ring 1 16830-0120 16830-0120 16830-0120 16830-0120

23A Capscrew 1/2-13x1” Long* 4 S23619 S23619 S23619 S23619

23B Capscrew 3/8-16x1” Long** 4 S23566 – – –

24 Lockwasher 1/2” 4 U43-13SS U43-13SS U43-13SS U43-13SS

24 Lockwasher 3/8”** 4 U43-12SS – – –

• Nameplate 1 32157-0072 32157-0072 32157-0072 32157-0072

• Decal 1 U27-404 U27-404 U27-404 U27-404

• Warning Tag 1 U63-123 U63-123 U63-123 U63-123

• Tag, Instructions, Rotating Seal 1 U63-13 U63-13 U63-13 U63-13

• Tag, No Motor Overload** 1 U63-75 U63-75 U63-75 U63-75

• Decal, Thermal Protection 1 32165-4020 32165-4020 32165-4020 32165-4020

• Tag, Hazardous Suction 1 61002-0012 61002-0012 61002-0012 61002-0012

• Not illustrated. * 7-1/2HP: 1 Phase only. ** 3 Phase only.

Repair Parts List

CSPH and

CCSPH (Epoxy Lined)

Energy Efficient Pool Pumps

60 Hz.

Page 17

17

T

r

u

a

r

c

19

20

21

22

1

18

17

23a,23b

24

4

2

3

5

6

7

8

9

11

12

13

14

15

16

10

2868 0697

7.5 HP 10 HP 15 HP 20 HP

CSPH2K3-142(3Ph) CSPH2L3-143(3Ph) CSPH2M3-144(3Ph) CSPH2N3-145(3Ph)

CCSPH2K3-142(3Ph) CCSPH2L3-143(3Ph) CCSPH2M3-144(3Ph) CCSPH2N3-145(3Ph

Key Part No. CSPHK3-142S(3Ph) CSPHL3-143S(3Ph) CSPHM3-144S(3Ph) CSPHN3-145S(3Ph)

No. Description Used CCSPHK3-142S(3Ph)CCSPHL3-143S(3Ph) CCSPHM3-144S(3Ph) CCSPH

145S(3Ph)

1 Motor, (CSPH2 and CCSPH2) 200V 1 16830-0320 16830-0320 16830-0320 16830-0320

1 Motor, (CSPH and CCSPH) 208-230/460V 1 62500-0754 62500-0105 62500-0154 62500-0204

2 Nut, 1/2” 4 S23488 S23488 S23488 S23488

3 Lockwasher, 1/2” 4 U43-13SS U43-13SS U43-13SS U43-13SS

4 Bracket (CSPH2) 1 L05329 L05328 L05328 L05779

4 Bracket (CCSPH2) 1 16830-2201 16830-2203 16830-2203 16830-2202

5 Stud, 1/2-13x1-1/2” Long 4 30747-0152 30747-0152 30747-0152 30747-0152

6 Mechanical Shaft Seal 1 S32014 S32014 S32014 S32015

7 Retaining Ring 1 S11207 S11207 S11207 S16767

8 Shaft Sleeve 1 37447-0001L 37447-0001L 37447-0001L 37447-0002L

9 Gasket (Volute to Bracket) 1 S04757 S04757 S04757 S04757

10 Gasket (Impeller to Shaft Sleeve) 1 33455-8044 33455-8044 33455-8044 33455-8046

11 Impeller 1 16830-0209 16830-0210 16830-0211 16830-0212

12 Gasket (Impeller to Washer) 1 33455-8043 33455-8043 33455-8043 33455-8045

13 Impeller Washer 1 38917-0203 38917-0203 38917-0203 38917-0204

14 Stat-O-Seal Washer 1 C43-46SS C43-46SS C43-46SS C43-46SSA

15 Impeller Screw 3/8-16x1” Long 1 S23566 S23566 S23566 –

15 Impeller Screw 1/2-13x1” Long 1 – – – S23619

16 Vent Plug 1/4” NPT 1 U78-57DV U78-57DV U78-57DV U78-57DV

17 Hardware Kit: Includes 8 each

5/8” Capscrews and Lockwashers 1 16830-0400 16830-0400 16830-0400 16830-0400

18 Gasket (Volute Discharge) 1 33450-8042 33450-8042 33450-8042 33450-8042

19 Gasket (Volute Suction) 1 33450-8041 33450-8041 33450-8041 33450-8041

20 Volute (CSPH2) 1 16830-0100 16830-0100 16830-0101 16830-0101

20 Volute (CCSPH2) 1 16830-2102 16830-2102 16830-2103 16830-2103

21 Drain Plug 1/2” NPT, Brass 1 U78-59D U78-59D U78-59D U78-59D

22 Wear Ring 1 16830-0120 16830-0120 16830-0120 16830-0120

23 Capscrew 1/2-13x1” Long 4 S23566* S23619 S23619 S23619

24 Lockwasher 1/2” 4 – U43-13SS U43-13SS U43-13SS

24 Lockwasher 3/8” 4 U43-12SS – – –

• Nameplate 1 32157-0072 32157-0072 32157-0072 32157-0072

• Decal 1 U27-404 U27-404 U27-404 U27-404

• Warning Tag 1 U63-123 U63-123 U63-123 U63-123

• Tag, Instructions, Rotating Seal 1 U63-13 U63-13 U63-13 U63-13

• Tag, No Motor Overload 1 U63-75 U63-75 U63-75 U63-75

• Decal, Thermal Protection 1 32165-4020 32165-4020 32165-4020 32165-4020

• Tag, Hazardous Suction 1 61002-0012 61002-0012 61002-0012 61002-0012

• Not illustrated. * Part Number S23566, Capscrew, 3/8-16x1” Long (7.5 HP only).

Repair Parts List

CCSPH2 (Epoxy lined) and CSPH2

Energy Efficient 200 Volt, 60 Hz.

CCSPH (Epoxy lined) and CSPH

Super Efficient 208-230/460 Volt, 60 Hz.

Page 18

18

T

r

u

a

r

c

19

20

21

22

1

18

17

23a,23b

24

4

2

3

5

6

7

8

9

11

12

13

14

15

16

10

2868 0697

5 HP 7.5 HP 10 HP 15 HP

5CSPHJ3-142 5CSPHK3-143 5CSPHL3-144 5CSPHM3-145

5CCSPHJ3-142 5CCSPHK3-143 5CCSPHL3-144 5CCSPHM3-145

Key Part No.

No. Description Used

1 Motor, 190/380/50/3 1 16830-0280 16830-0340 16831-0340 16832-0340

2 Nut, 1/2” 4 S23488 S23488 S23488 S23488

3 Lockwasher, 1/2” 4 U43-13SS U43-13SS U43-13SS U43-13SS

4 Bracket (5CSPH) 1 L05329 L05328 L05328 L05779

4 Bracket (5CCSPH) 1 16830-2201 16830-2203 16830-2203 16830-2202

5 Stud, 1/2-13x1-1/2” Long 4 30747-0152 30747-0152 30747-0152 30747-0152

6 Mechanical Shaft Seal 1 S32014 S32014 S32014 S32015

7 Retaining Ring 1 S11207 S11207 S11207 S16767

8 Shaft Sleeve 1 37447-0001L 37447-0001L 37447-0001L 37447-0002L

9 Gasket (Volute to Bracket) 1 S04757 S04757 S04757 S04757

10 Gasket (Impeller to Shaft Sleeve) 1 33455-8044 33455-8044 33455-8044 33455-8046

11 Impeller 1 16830-0209 16830-0210 16830-0211 16830-0212

12 Gasket (Impeller to Washer) 1 33455-8043 33455-8043 33455-8043 33455-8045

13 Impeller Washer 1 38917-0203 38917-0203 38917-0203 38917-0204

14 Stat-O-Seal Washer 1 C43-46SS C43-46SS C43-46SS C43-46SSA

15 Impeller Screw 3/8-16x1” Long 1 S23566 S23566 S23566 –

15 Impeller Screw 1/2-13x1” Long 1 – – – S23619

16 Vent Plug 1/4” NPT 1 U78-57DV U78-57DV U78-57DV U78-57DV

17 Hardware Kit: Includes 8 each

5/8” Capscrews and Lockwashers 1 16830-0400 16830-0400 16830-0400 16830-0400

18 Gasket (Volute Discharge) 1 33450-8042 33450-8042 33450-8042 33450-8042

18 Gasket (Volute Discharge, E-Suffix models) 1 33459-1049 33459-1049 33459-1049 33459-1049

19 Gasket (Volute Suction) 1 33450-8041 33450-8041 33450-8041 33450-8041

19 Gasket (Volute Suction, E-Suffix models) 1 33459-1048 33459-1048 33459-1048 33459-1048

20 Volute (5CSPH) 1 16830-0100 16830-0100 16830-0101 16830-0101

20 Volute (5CCSPH) 1 16830-2102 16830-2102 16830-2103 16830-2103

20 Volute (5CSPH, E-Suffix models) 1 16830-0110 16830-0110 16830-0111 16830-0111

20 Volute (5CCSPH, E-Suffix models) 1 16830-2112 16830-2112 16830-2113 16830-2113

21 Drain Plug 1/2” NPT, Brass 1 U78-59D U78-59D U78-59D U78-59D

22 Wear Ring 1 16830-0120 16830-0120 16830-0120 16830-0120

23A Capscrew 1/2-13x1” Long 4 S23566 S23619 S23619 S23619

23B Capscrew 3/8-16x1” Long 4 S23566 – – –

24 Lockwasher 1/2” 4 U43-13SS U43-13SS U43-13SS U43-13SS

24 Lockwasher 3/8” 4 U43-12SS – – –

• Nameplate 1 32157-0072 32157-0072 32157-0072 32157-0072

• Decal 1 U27-404 U27-404 U27-404 U27-404

• Warning Tag 1 U63-123 U63-123 U63-123 U63-123

• Tag, Instructions, Rotating Seal 1 U63-13 U63-13 U63-13 U63-13

• Tag, No Motor Overload 1 U63-75 U63-75 U63-75 U63-75

• Not illustrated.

Model numbers with suffix ending in “E” do not include Hardware Kit. Order 8 each of Part Numbers 37007-0650 and 38917-0207.

Repair Parts List

5CSPH and

5CCSPH (Epoxy Lined),

ANSI and DIN (with E Suffix)

Pool Pumps

50 Hz.

Page 19

19

Part Number

Key Part Standard Flange

No. Description Qty. PKG 184, 184C

1 Strainer Body (PKG 184) 1 16401-0010

1 Strainer Body (PKG 184C) 1 16401-2015

2 Spring Pin 2 35857-0031

3 Toggle Bolt 2 30767-0011

4 Wing Nut 2 35404-0319

5 Strainer Basket 1 16401-0102

6 O-Ring 1 35505-0421

7 Strainer Cover (PKG 184) 1 16401-0210

7 Strainer Cover (PKG 184C) 1 16401-2215

8 Pipe Plug, 1/2” Square Head Brass 1 U78-59D

9 Vent Plug, 1/4” Square Head 1 U78-57DV

• Gasket, Suction Flange 2 33450-8041

• Capscrew, M20x2.5, 50 mm Lg., SS 16 ––

• Lockwasher, M20 SS 16 ––

• Tag, Hazardous Suction 1 61002-0012

• Hardware Kit: Includes 16 each

3/4-10x2” Capscrews and

3/4” Lockwashers (PKG 184, 184C) 1 16830-0401

PKG 184 Strainer Repair Parts List

PKG 184C Epoxy Lined Strainer Repair Parts List

• Not illustrated.

6

5

1905 0795

9

7

4

3

2

1

8

Page 20

Complete bottom portion completely and mail within 10 days of installation to:

Pentair Water Commercial Pool and Aquatics, 293 Wright St., Delavan , WI 53115

Warranty Registration Card

Name

Address

City State Zip

Installation (or Purchase) Date

Product Purchased

Model Number

■■ New installation ■■ Replacement

Years pool has been in service ■■ less than 1 ■■ 1-3 ■■ 3-5 ■■ 5-10

This product was purchased from:

Company name

Address

City State Zip

PENTAIR WATER POOL AND SPA

®

LIMITED WARRANTY

This product is manufactured by Pentair Water Pool and Spa, Inc. and is warranted to be free of defects in material and/or workmanship for one

(1) year from the original date of installation.

The foregoing warranties relate to the original consumer purchaser (“Purchaser”) only. Pentair Water Pool and Spa, Inc. shall have the option to

repair or replace the defective product, at its sole discretion. Purchasers must pay all labor and shipping charges necessary to replace the product

covered by this warranty. Requests for warranty service must be made through the installing dealer. This warranty shall not apply to any product

that has been subject to negligence, misapplication, improper installation or maintenance, or other circumstances which are not in Pentair Water

Pool and Spa’s direct control. Failure to have product installed by a professional in compliance with local codes will void any and all manufacturers

warranty.

This warranty sets forth Pentair Water Pool and Spa’s obligation and Purchaser’s exclusive remedy for defective products.

PENTAIR WATER POOL AND SPA SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL OR CONTINGENT DAMAGES

WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

SHALL NOT EXTEND BEYOND THE DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty lasts,

so the above limitations or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

Supersedes all previous publications.

S248 (Rev B. 09/08/08)

Technical Support

Sanford, North Carolina (8 A.M. to 5 P.M.) - Phone: (800) 831-7133

Moorpark, Califonia (8 A.M. to 5 P.M.) - Phone: (800) 831-7133 - Fax: (800) 284-4151

Loading...

Loading...