Page 1

®

ELECTRIC

CONVEYOR OVEN

230V MODELS

8B-UM1833

8B-UM1850

Installation and

Operation

Instructions

2M-Z6701 Rev D 3/23/06

8B-UM1850

Page 2

SAFETY SYMBOL

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specifi cations and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specifi cations contained in this sheet are subject to change

without notice. While Star Manufacturing exercises good faith efforts to provide

information that is accurate, we are not responsible for errors or omissions

in information provided or conclusions reached as a result of using the

specifi cations. By using the information provided, the user assumes all risks in

connection with such use.

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

MAINTENANCE AND REPAIRS

Contact your local dealer for service or required maintenance. Please record the model number, serial

number, voltage and purchase date in the area below and have it ready when you call to ensure a faster

service.

Model No.

Serial No.

Voltage

Purchase Date

2

Page 3

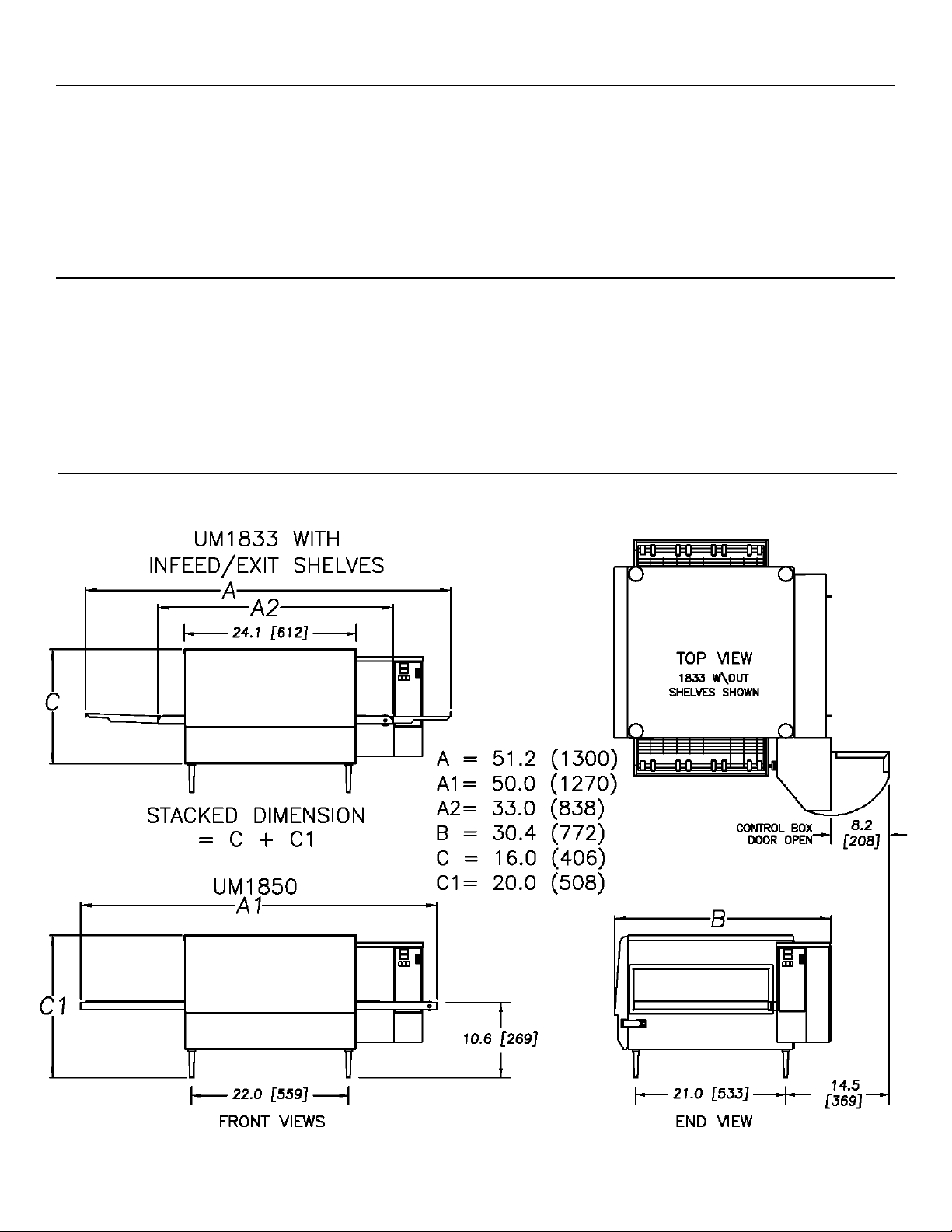

SPECIFICATIONS

8B-UM1833-230V

Rating/Connection: 6,600 Watts (3 x 2,000W element assembly)

Terminal block supplied (L1, L2, L3, N, Ground)

Electrical Supply: Separate service per oven - 15 Amp, 400/230 VAC, 3 phase, 50 Hz

Approximate Weight (1833 Oven with Legs): Installed - 180 Lbs (81.8 kg), Shipping - 210 Lbs (95.5 kg)

Dimensions: Width: 51.2" (130.0 cm) - Oven with Shelves

Depth: 30.4" (77.2 cm)

Height: 20.0" (50.8 cm) - Single Oven with Legs

36.0" (91.4 cm) - Double Oven with Legs

8B-UM1850-230V

Rating/Connection: 6,600 Watts (3 x 2,000W element assembly)

Terminal block supplied (L1, L2, L3, N, Ground)

Electrical Supply: Separate service per oven - 15 Amp, 400/230 VAC, 3 phase, 50 Hz

Approximate Weight (1850 Oven with Legs): Installed - 210 Lbs (95.5 kg), Shipping - 240 Lbs (109.1 kg)

Dimensions: Width: 50.0" (127.0 cm)

Depth: 30.4" (77.2 cm)

Height: 20.0" (50.8 cm) - Single Oven with Legs

36.0" (91.4 cm) - Double Oven with Legs

2

Page 4

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor for

use directly by the general public in food service locations.

First and foremost, each crate should be examined before signing the Bill of Lading to report

any visible damage by the trucker in transit and to account for the proper number of crates.

If there is apparent damage, arrangements should be made to fi le a claim against the carrier.

Interstate Commerce Regulations require that the claim must be initiated by the consignee.

Proper and secure storage facilities should be arranged for the oven(s) if necessary to protect

it from outdoor or damp conditions at all times before installation.

-IMPORTANT-

When you have all the crates unloaded, open the crates and remove all plastic covers.

Inspect at once for concealed damage. If anything appears to be damaged, contact the

appropriate persons immediately to fi le a damage claim. After completing this inspection,

fi nish unpacking the oven. Be sure to remove all paper protection and packing material

from the unit prior to heating.

CAUTION

FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

-IMPORTANTTHIS APPLIANCE MUST BE INSTALLED BY QUALIFIED PERSONS AND INSTALLED

IN ACCORDANCE WITH THE RULES IN FORCE WITHIN THE COUNTRY OF

DESTINATION.INSTALLATION

The ovens are equipped for the voltage indicated on the nameplate mounted on the rear of

the control box. They will operate on alternating current (AC) only. A cord bushing is supplied

in the bottom of the control box. This allows the installer-supplied cord to be connected to the

terminal block connections located behind the rear access door. The oven must be connected

to power per all applicable codes. A means of disconnecting the oven from power should be

supplied for safety and ease of maintenance.

The appliance must be positioned so the plug is accessible. A hormonized, 300/500V,

oil-resistant, fl exible cord with 65°C minimum ratings must be used. Choose appropriate

conductors in relation to the length of the cord (1.0 square mm minimum) and operating

conditions (i.e. temperature).

-IMPORTANT-

WARNING

DO NOT CONNECT TO DIRECT CURRENT (DC).

Installation of the electric oven should conform to the:

NATIONAL ELECTRIC CODE AND ALL LOCAL ELECTRIC CODES AND

ORDINANCES AND THE LOCAL ELECTRIC COMPANY RULES AND

REGULATIONS.

Page 5

PURCHASER'S RESPONSIBILITY

It is the responsibility of the purchaser:

1. To see that the electric services for the oven are installed on site in accordance with the

manufacturer's specifi cations.

2. To unload, uncrate, and install the oven in its proper location and in accordance with this

installation operation manual.

3. To see that electric services are connected properly by a qualifi ed installer of your choice.

All such connections must be in accordance with applicable code requirements.

4. To arrange for inspection and operation check-out by an authorized service technician.

The warranty becomes effective upon verifi cation of proper installation.

IMPORTANT SAFETY INFORMATION

Do not attempt to operate the oven until connection of utility service has been fully inspected

by an authorized service technician or a Star Service Representative. This service is required

by Star in order to assist the purchaser in proper start-up of the oven on site. Please note the

specifi c details on the Warranty and make certain that service connections are made to proper

utility services.

The warranty shall not apply if the oven is started up and operated prior to the utilities and oven

being inspected and check-out made by an authorized service technician or a Star Service

Representative.

CAUTION

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ

ALL INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

CAUTION

Minimum clearances must be maintained from all walls and combustible materials. Minimum

clearances for this unit should be 0 inches from the rear (rear bumpers provided must be in place)

and 6 inches from both sides. Keep the oven free and clear of all combustible material.

CAUTION

Do not obstruct the ventilation holes in the control panels as these provide cooling air for the

controls.

WARNING

The oven is to be operated only on the type of electricity shown on the specifi cation plate.

INSTALLATION INFORMATION

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF

QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR

SERVICE BY OTHER THAN QUALIFIED PERSONNEL MAY RESULT IN DAMAGE

TO THE OVEN AND/OR INJURY TO THE OPERATOR.

Qualifi ed installation personnel are individuals, a fi rm, a corporation, or a company which either

in person or through a representative are engaged in and responsible for:

1. The installation of electrical wiring from the electric meter, main control box, or service outlet

to the electric appliance.

Qualifi ed installation personnel must be experienced in such work, familiar with all precautions

required, and have complied with all requirements of state or local authorities having

jurisdiction.

Page 6

LOCATION

The well-planned and proper placement of your oven will result in long-term operator convenience

and satisfactory performance. It is essential that an adequate air supply to the oven be

maintained to provide a suffi cient fl ow of ventilation air. Follow these guidelines:

1. Place the oven in an area that is free of drafts.

2. Keep the oven area free and clear of all combustibles such as paper, cardboard, fl ammable

liquids, and solvents.

3. Do not place the oven on a curb base or seal to a wall. This will restrict the fl ow of air and

prevent proper ventilation to the blower motors. This condition must be corrected to prevent

permanent damage to the oven.

4. On all models, tripping of the blower motor's thermal overload device indicates an excessive

ambient temperature at the back of the oven. This condition must be corrected to avoid

permanent damage to the oven.

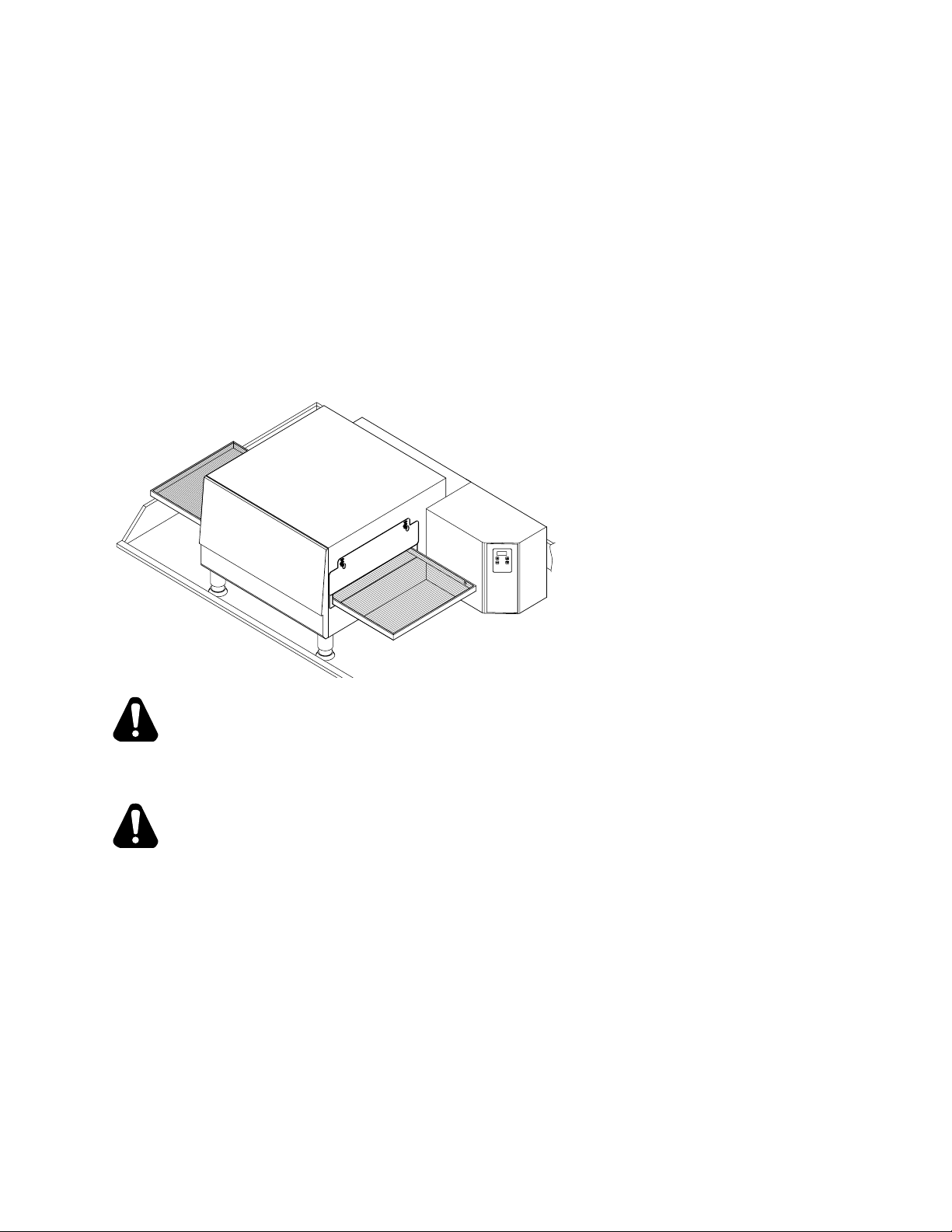

This appliance must be installed on a

sturdy counter or stand using the feet

provided for cleaning clearance. As

a minimum, 24" of clearance on the

discharge end of the oven should be

allowed for removal of the conveyor

assembly if the oven is not on a mobile

cart. Also allow room for a service

technician to access the control box

door and the fan motor cover over

the rear of the oven if the oven is not

movable.

CAUTION

Any surface the oven is mounted on should have a raised area around the perimeter to prevent

the oven from accidentally sliding off the edge. Serious injury or death could occur if the oven

falls on a person.

CAUTION

Any cart that the oven is mounted on must be deep and wide enough to provide a stable

platform. A cart with a narrow stance could allow the oven to tip over, causing property damage

or serious harm to people.

Page 7

VENTILATION

Local codes prevail. These are the "authority having jurisdiction" as stated by the National

Fire Protection Association, Inc. in NFPA 96-Latest Edition. For further ventilation information

see below.

A ventilation hood may be required to remove heat and cooking odors. The hood and HVAC

installation must meet local codes to gain approval by the authority having jurisdiction.

Requirements may vary throughout the country depending on the location by city, county, and

state. Obtain information from the authority having jurisdiction to determine the requirements

for your installation. Obtain information and review copies of codes or documents that will

be used to inspect and approve your installation. Your ventilation hood supplier and HVAC

contractor should be contacted to provide guidance.

CAUTION

Prevent airfl ow through the cooking tunnel. Air must NOT be directed onto the oven's

front or rear or to the sides of the cooking area. This can cause incomplete or uneven

baking and increased energy consumption.

ELECTRICAL CONNECTION

Before making any electrical connections to this unit, check that the power supply is adequate

for the voltage, amperage, and phase requirements stated on the rating plate. A wiring diagram

is included herewith.

When installed, this appliance must be electrically grounded and its installation must comply with

the National Electric Code, ANSI-NFPA 70, latest version, manufacturer's installation instructions,

and applicable local municipal building codes. In Canada, all electrical connections are to be

in accordance with CSA C22.1 - Canadian Electrical Code Part 1 and/or local codes.

This appliance is equipped with a fi ve-pole terminal and cord bushing to which the

customer/installer can attach. Each line (L1, L2, L3) should have 230V potential referenced

to the neutral (N) connection. An earth (ground) connection is also provided for a fi ve-

wire system.

Page 8

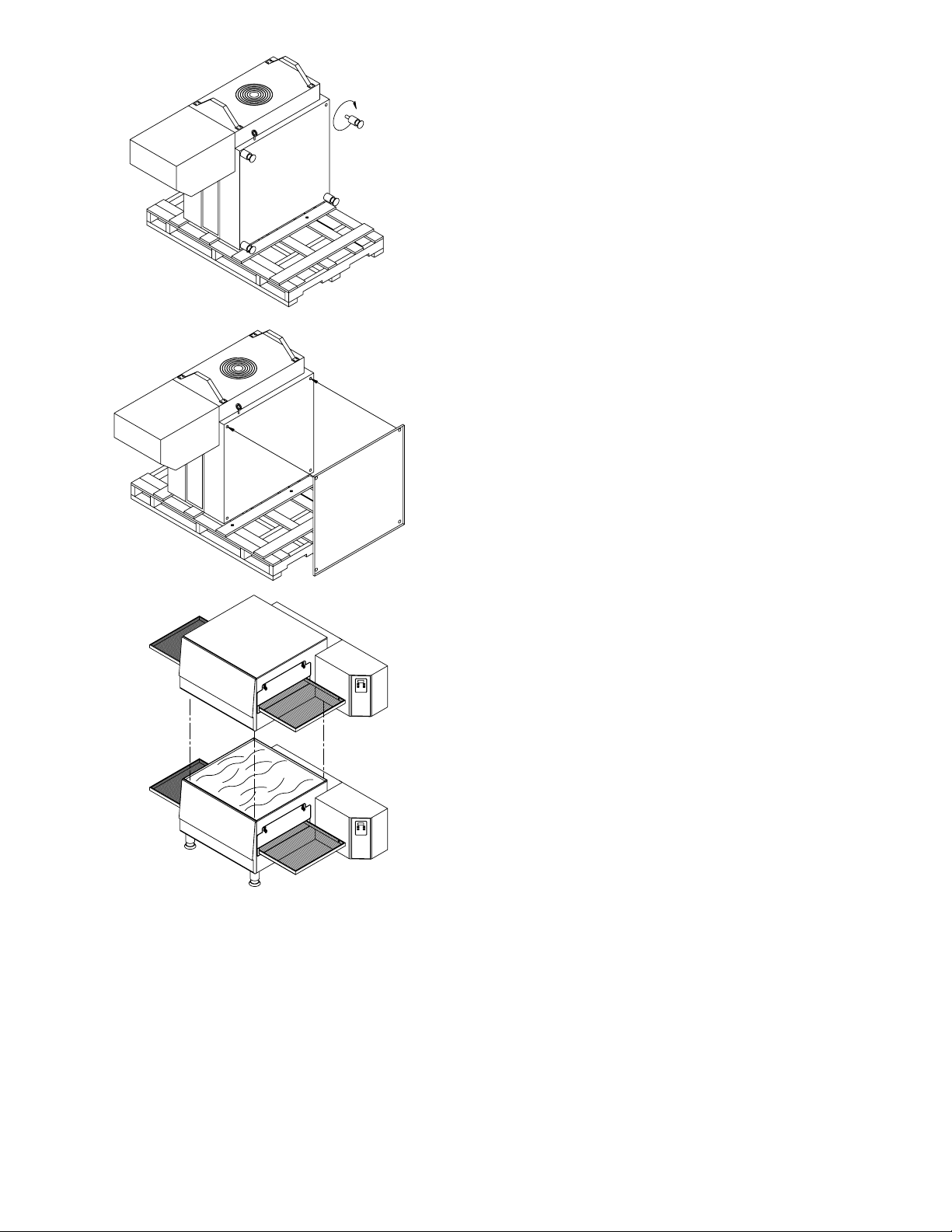

STACKING INSTRUCTIONS

The following instructions should be followed when stacking

more than one unit.

Single Oven (or Bottom) Cart Install:

1. Remove door, conveyor, and fi nger assemblies.

2. Unbolt unit from shipping crate (4 bolts).

3. Turn unit on front as shown.

4. Thread the four legs into the bottom of the oven.

5. CAREFULLY lift oven upright.

Stacked Oven Install Preparation:

1. Remove door, conveyor, and fi nger assemblies.

2. Unbolt unit from shipping crate (4 bolts).

3. Turn unit on front as shown.

4. Remove top of lower oven (4 screws total, 2 each front and

rear) and bolt to stacked oven base using 3/8 - 16 bolts.

5. Place top oven on lower unit and re-attach with screws for

top of lower oven.

OPERATING INSTRUCTIONS

DO NOT ATTEMPT TO OPERATE THE OVEN until connection

of utility service and installation has been fully inspected (start-up

check-out) by an authorized service technician or a Star Service

Technician in order to assure the oven is properly installed and

in working order. The warranty becomes effective upon

verifi cation of proper installation.

CAUTION

DO NOT WORK AROUND THE CONVEYOR BELT

WITH LONG HAIR, LOOSE CLOTHING, OR DANGLING

JEWELRY. GETTING CAUGHT IN THE BELT COULD

RESULT IN DISMEMBERMENT OR FATAL INJURY.

Unless specifi ed otherwise, conveyor travel is factory set for

left to right operation when facing the front of the oven. If a

direction change is required, refer to "DISPLAY INFORMATION,"

section 3 for instructions on how to program the controller for

a direction change. In addition, the conveyor belt must be

changed to travel in the new direction.

SAFETY OPERATING INSTRUCTIONS

The information contained in this section is provided for the use of qualifi ed operating personnel.

Qualifi ed operating personnel are those who have carefully read the information contained in

this manual, are familiar with the functions of the oven and/or have had previous experience

with the operation of the equipment described. Adherence to the procedures recommended

herein will assure the achievement of optimum performance and long, trouble-free service.

Page 9

Please take time to read the following safety operating instructions. They are the key to the

successful operation of your Ultra-Max Conveyor Oven.

SAFETY TIPS

For your safety, read before operating.

If you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switches.

3. Use an exterior phone to call your gas

supplier immediately.

4. If you cannot reach your gas supplier, call

the fi re department.

In the event of a power failure:

1. Turn all switches off.

2. DO NOT attempt to operate the oven until

the power is restored.

“TIME” LIGHT

To Start:

Push power switch "ON."

If burner does not light in one minute

push the power switch to the "OFF"

position and wait five minutes.

After five minutes, retry.

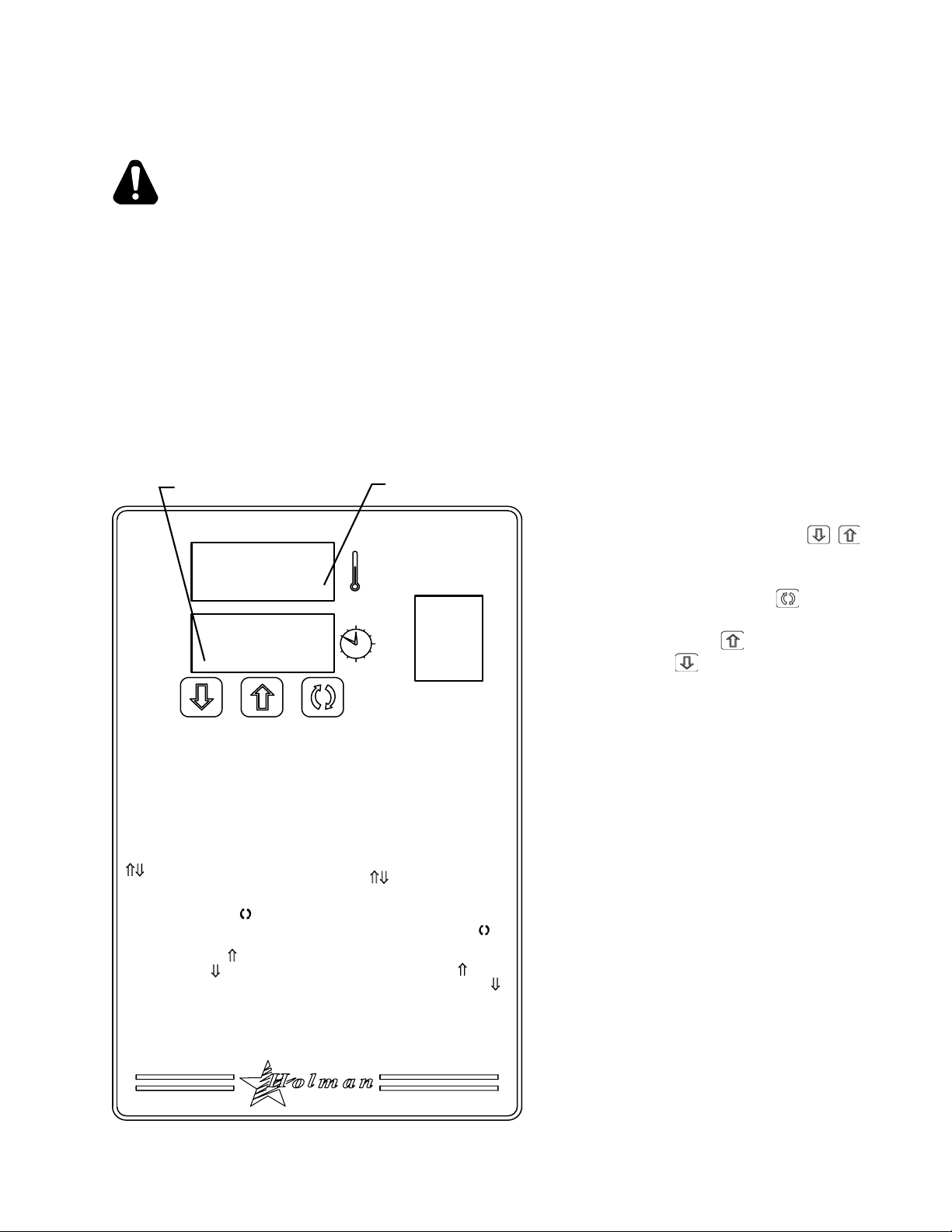

Adjusting TIME and TEMPERATURE:

1) Press the up and down buttons

( ) at the same time, hold for four

seconds until TIME display is blank.

2) Press the enter button ( ) to

switch between TIME and

TEMPERATURE.

3) Press the up button ( ) to increase

or the down button ( ) to decrease

TIME or TEMPERATURE. Hold

button down for faster display

changes.

4) After five seconds, the new numbers

will be saved and the oven will display

new settings.

“HEAT” LIGHT

ON / MARCHE

OFF / ARRÊTE

Pour Commencer:

Poussez le commutateur de puissance à

"MARCHE."

Si le brûleur n'allume pas en une minute,

poussée le commutateur de puissance dans

la position de "ARRÊTE" et attend 5 minutes.

Après cinq minutes, nouvelle tentative.

Ajustement du TEMPS et de la

TEMPÉRATURE:

1) Tenez "vers le haut" et "vers le bas"

boutonne ( ) en même temps. Tenez

les boutons pendant quatre secondes

jusqu'à ce que l'affichage de la

TEMPS soit blanc.

2) Appuyez sur le bouton de "entrée" ( )

pour commuter entre le TEMPS et la

TEMPÉRATURE.

3) Tenez "vers le haut" bouton ( ) pour

augmenter ou "vers le bas" boutonnez ( )

pour diminution de le TEMPS ou

TEMPÉRATURE. Maintenez le bouton pour

des changements plus rapides.

4) Après cinq secondes, les nouveaux

nombres seront sauvés et le four montrera

de nouveaux arrangements.

General Safety Tips:

1. If the oven needs to be moved for any

reason, the power must be disconnected

from the unit before doing so.

2. DO NOT remove the control box cover

unless the oven is unplugged.

OPERATION

To turn the oven on:

1. Push the power switch to "ON."

2. After the fan begins to build pressure,

the pressure switch will provide power to

the control board to engage the heating

element contactor. You should hear an

initial "click" from the contactor as it begins

to heat.

To adjust the time and temperature:

1. Press the DOWN and UP arrows ( ) at

the same time. Hold for four seconds until

the TEMPERATURE display goes blank.

2. Press the ENTER button (

) to switch

between TIME and TEMPERATURE.

3. Press the UP arrow (

DOWN arrow (

) to increase or the

) to decrease the TIME or

TEMPERATURE. Hold either button down

for faster display changes.

4. After fi ve seconds, the new numbers will

be saved and the oven will display the new

settings.

To turn the oven off:

1. Push the power switch to "OFF." The

oven is equipped with a cool-down feature

for motor shaft and bearing protection.

This enables the blower motor(s) to run

regardless of the controller status. The

blower(s) continue to run until the oven

cools to a safe temperature.

A Star Manufacturing Company

Page 10

DISPLAY INFORMATION

When operating the oven, there are three levels of

access:

1. Store Level - General employees would know

these functions and how to change them. While

the oven is running, enter this mode by holding the

DOWN and UP arrows (

four seconds. The TIME display goes blank and

the TEMP setpoint is displayed. Adjust with the

DOWN or UP arrows. The ENTER button (

toggles between TIME and TEMP. The parameter

that can be adjusted is displayed, the other is

blank. When TIME and TEMP are adjusted as

needed, wait fi ve seconds and SAVE is displayed.

The values are accepted and the controller begins

controlling to these new values. The conveyor

continues to operate at the same speed until a

new value is accepted. The temperature control

output should be OFF during changes.

2. Manager Level - This is a lock so that TIME and

TEMP cannot be changed even at the Store Level.

While the oven is running, enter this mode by

holding the DOWN and UP arrows simultaneously

for 4 seconds. The TIME display goes blank and

the TEMP setpoint is displayed. Release the

UP arrow and continue to hold the DOWN arrow

for an additional 4 seconds. The TEMP display

shows LOC as the TIME display shows nO, which

indicates that the TIME/TEMP parameters can be

changed

) simultaneously for

)

after reaching the STORE level. yES indicates

that the parameters cannot be changed even after

entering the STORE level. The LOC setting can

be toggled using the ENTER button (

).

ADDITIONAL FUNCTIONS

The conveyor belt direction and the temperature

display can be changed on the conveyor oven

by a qualifi ed technician. To change the belt

direction, the technician must reverse the motor

direction and rotate the conveyor belt for proper

oven function. A technician can also change the

temperature display from Fahrenheit to Celsius.

These changes can be made by the technician

during the start-up/check-out or at a later date.

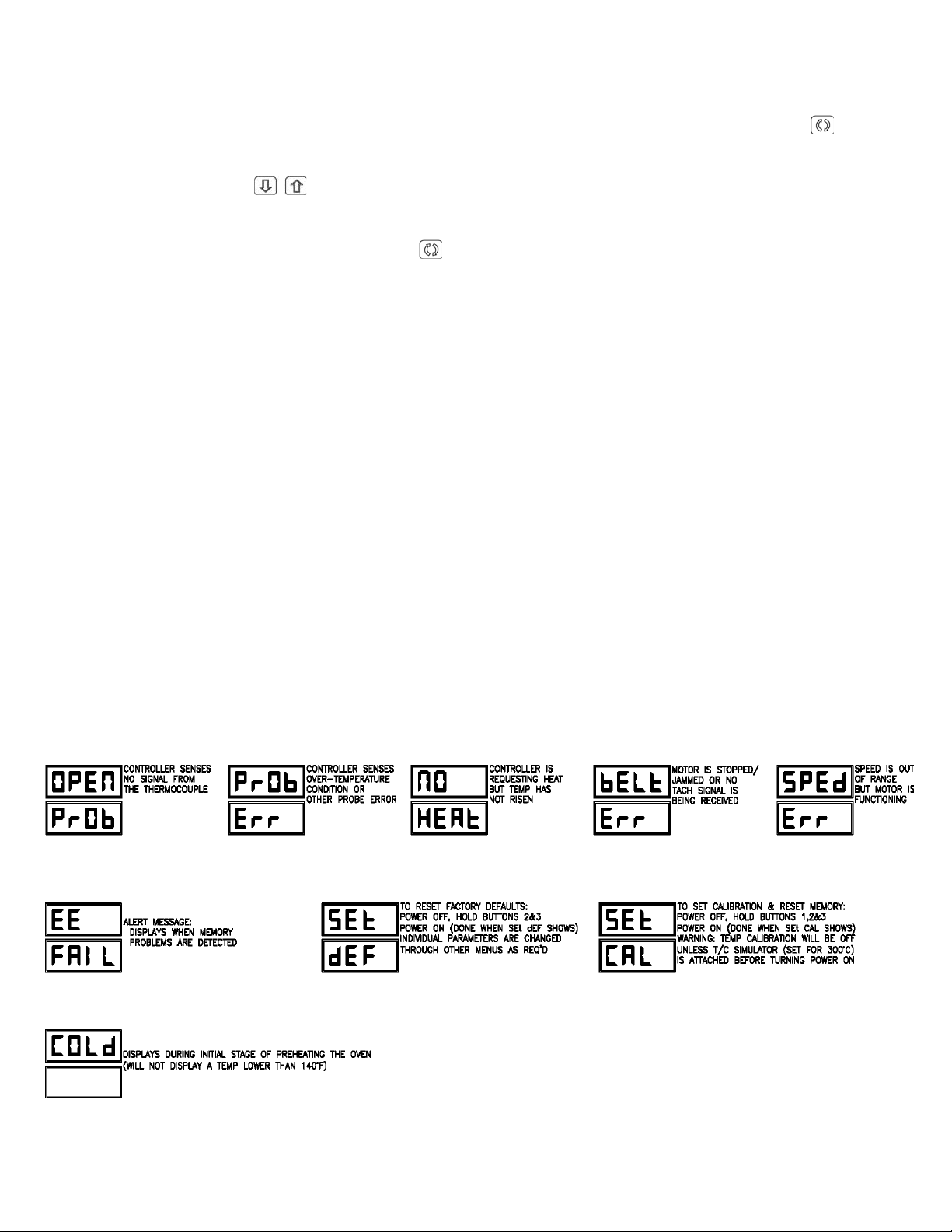

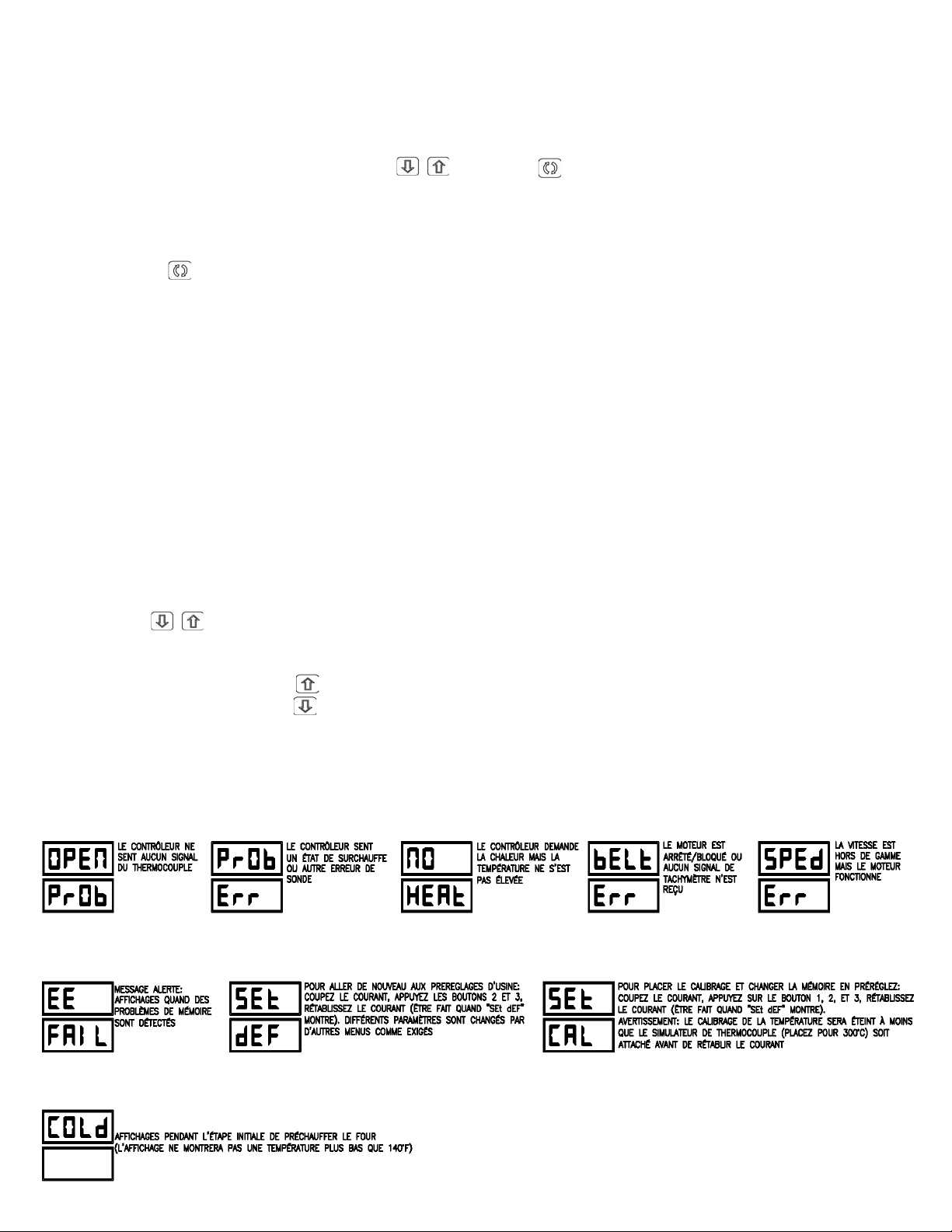

ERROR CODES

Error codes will display as fl ashing text messages for

diagnostic purposes. Any temperature or thermocouple

error should turn the temperature output OFF and leave

the conveyor running at the same speed. The belt

error should turn the temperature output OFF. The

speed error should display when the motor is unable

to settle at the chosen speed. This might occur if a

fast speed is chosen that the motor is unable to spin

fast enough to achieve. The speed signal output will

remain the same but the display will fl ash the error

message.

Page 11

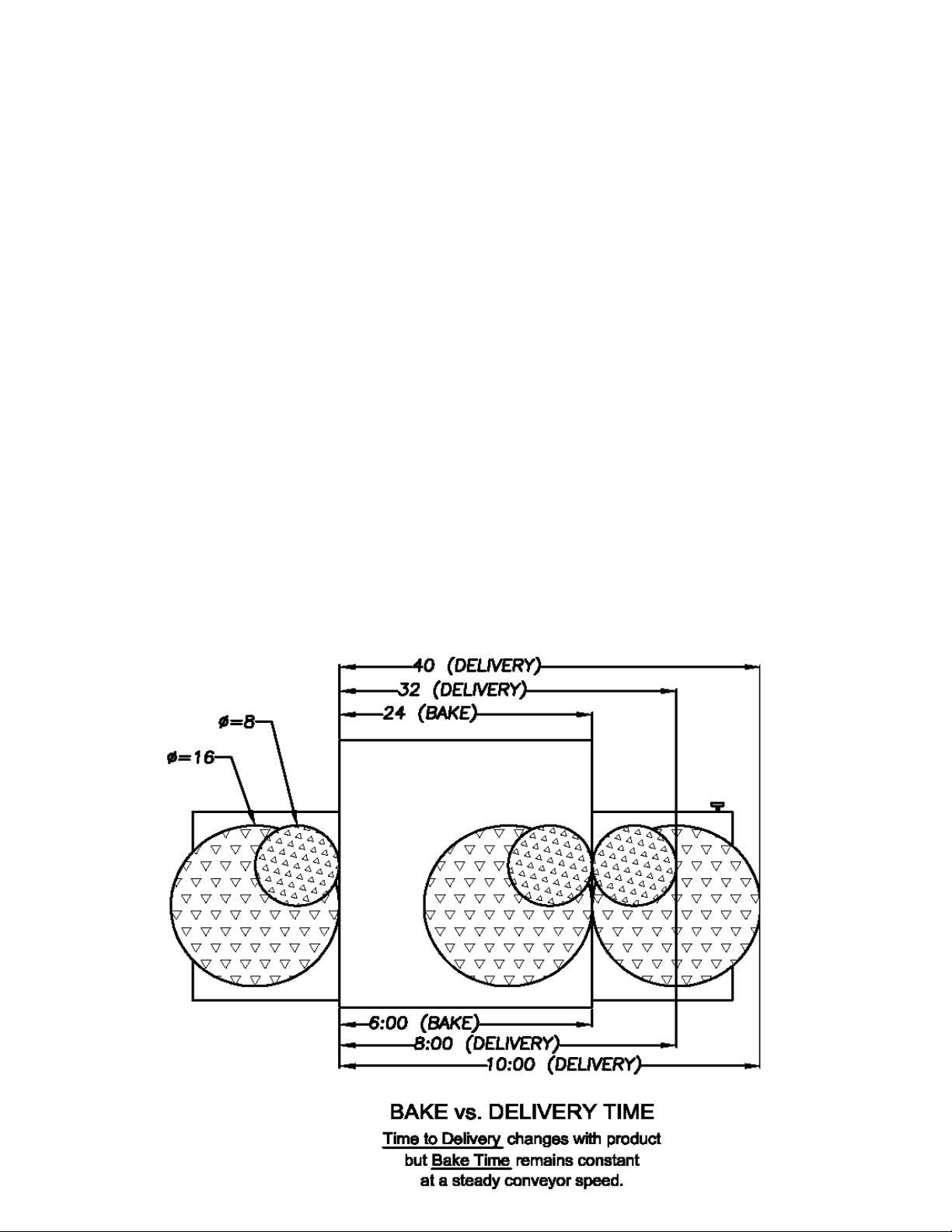

BAKE TIME VERSUS TEMPERATURE

1. Bake time is actually conveyor speed and is defi ned

as the time the product is actually in the oven.

This is measured by noting the time when the

leading edge of the product enters the oven and

the time the leading edge of the product leaves

the oven. This is adjusted by using the conveyor

speed controller.

2. Bake temperature is adjusted by changing the

setpoint of the temperature controller to the desired

bake temperature. When the oven reaches the

desired temperature, the red dot in the lower right

corner of the temperature display will turn off and

on as the controller maintains the temperature.

CONVEYOR SPEED

Bake Time (Conveyor Speed) - As stated previously, bake

time (conveyor speed) is defi ned as the amount of time

elapsed between the time the leading edge of the product

enters the oven and the leading edge of the product exits

the oven. Bake time is controlled by adjusting the digital

speed controller. The setting on the control panel indicates

the actual bake time.

Bake time will be the same for any size product.

TIME OF DELIVERY

The time of delivery is the amount of elapsed time between

the period when the leading edge of the product enters the

oven and the trailing edge of the product is fully discharged

and is ready to be delivered to the customer.

3. When establishing a bake time and temperature

for a given product, the general rule shall be as

the bake time increases the bake temperature

decreases and the reverse is also true; increase

temperature, decrease time. However, there

are limits to the above rule. Going to extremes

will result in a burnt exterior and raw interior or

it will result in a very light color but over-baked

product.

4. Once a good bake has been established, the fi ne

adjustments should be made by holding either

the bake time or bake temperature constant, then

varying the other.

Time of delivery changes if the product size

changes.

Tip: Train yourself not to pull the product out of the oven

when the leading edge comes out. Always wait until the

entire product has passed under the air nozzle holes - the

product needs this time to fully bake.

Page 12

MAINTENANCE INSTRUCTIONS

CAUTION

DISCONNECT THE POWER SUPPLY BEFORE SERVICING OR CLEANING THIS OVEN.

SAFEGUARD THE POWER SO IT CANNOT BE ACCIDENTALLY RESTORED. FAILURE

TO DO SO COULD RESULT IN DISMEMBERMENT, ELECTROCUTION, OR FATAL INJURY.

THERE IS MORE THAN ONE POWER SUPPLY CONNECTION POINT WHEN OVENS ARE

STACKED, SO MAKE SURE THAT ALL SWITCHES ARE IN THE OFF POSITION BEFORE

CLEANING OR MAINTENANCE.

No electrical components should be subjected to moisture. It is therefore important that the

oven is wiped down carefully. NEVER throw buckets of water over the oven or subject it to

pressure washing from a hose or a pressure spray. If water or other liquid is spilled on the

oven, make sure that none of it has entered the control box area before switching the oven

ON. If in doubt, call your service company.

CAUTION

Adhere to the following warnings when cleaning or maintaining your conveyor oven:

1. The oven must be cool. Do not use power cleaning equipment, steel wool, or wire brushes

on stainless steel surfaces.

2. Do not use a caustic or an alkaline base cleaner on the interior of the oven. This will ruin

the aluminized fi nish of the oven interior.

3. When using cleaning solutions, be sure they meet local and national health standards.

Follow this recommended cleaning schedule for proper oven performance:

DAILY

1. Clean the conveyor belt using a nylon brush. Allow any foreign material to drop into the

crumb pans.

2. Empty and clean the crumb pans. Use a hot water and detergent mix. Rinse with clean

water.

EVERY MONTH

1. Brush and clean the guard on the motor cooling fan.

EVERY THREE MONTHS

1. Unplug the oven.

2. Remove the crumb pans.

3. Remove the conveyor assembly.

4. Unlatch and remove the front door. Remove all internal airfl ow components.

5. Clean the oven interior with an appropriate oven cleaner.

6. Clean the conveyor assembly, crumb pans, and other removable components. Wash in

a hot water, detergent mix and rinse with clean water. For diffi cult cleaning areas, use a

heavy-duty de-greaser or oven cleaner.

7. Move the oven and clean under it. Be careful not to damage the oven's electrical cord or

plug when moving.

8. Reassemble the oven.

EVERY TWELVE MONTHS

A factory authorized service person should:

1. Open and clean the inside of the control box.

2. Check and tighten all electrical components.

If maintenance is required, contact your local service company, a factory representative,

or Star Manufacturing.

Page 13

DIRECTIONS FOR DISASSEMBLY

1. Remove crumb trays and/or

shelves from both ends.

4. Finish removing the conveyor

assembly from the right end

of the oven.

2. Push the spring-loaded

coupling in to disengage the

pin in the shaft. Rotate the

shaft so the pin will not go

back in the coupling slots.

5. Upper fi nger assembly can

be removed complete or

the small handle (left) can

be used to slide nozzle and

columnating plate out before

removing the main body.

3. Lift up the left end of the

conveyor frame so the crumb

tray supports (UM1850 only)

clear the tunnel opening.

Push the conveyor frame

through the opening.

6. Upper nozzle (with slot) and

columnating plates (with tab).

Extruded holes all point in the

same direction (down toward

the conveyor).

7. The lower fi nger assembly can

be removed complete or the

nozzle can be slid off to reveal

the recessed columnating

plate.

8. The columnating plate also

has a slot that must align with

a tab on the fi nger to ensure

proper orientation. Extruded

holes point up toward the

bottom of the conveyor.

9. The oven body is now ready to

be wiped clean. Reassemble

the fi nger and conveyor parts

in the reverse order after

cleaning.

Page 14

CONVEYOR BELT TENSION

The conveyor belt of the Ultra-Max Conveyor Oven

does not have a tension adjustment. If the belt

becomes too loose, a link will have to be removed

to tighten. A belt that is too tight will also cause

operational problems due to excessive drag. We

suggest that you have a qualifi ed service technician

perform this adjustment.

CAUTION

Careful consideration should be exercised prior

to removing a belt link because a belt that is too

tight will impede the smooth operation of the

conveyor.

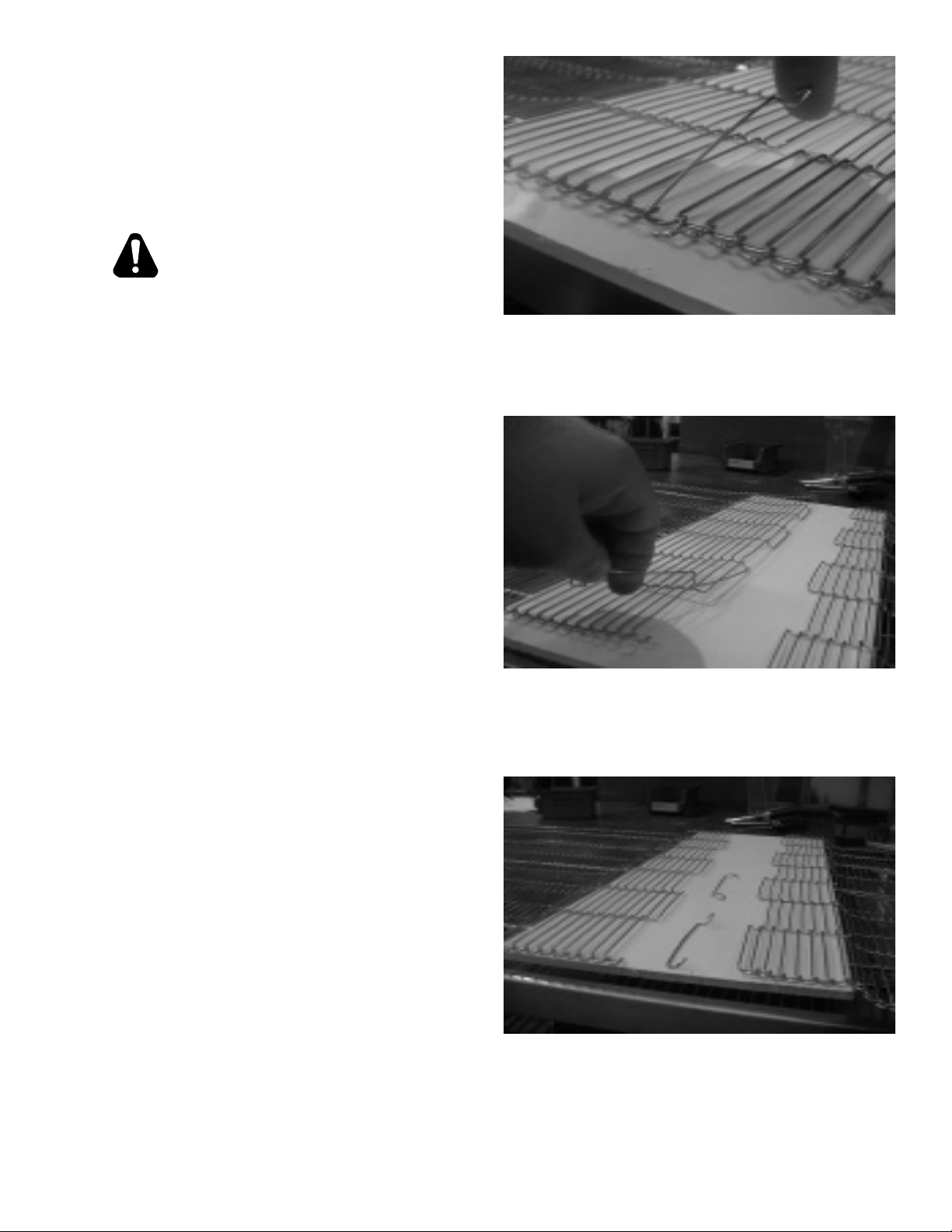

CONVEYOR BELT LINK REMOVAL

An entire link can be removed with the conveyor

assembly either in or out of the oven. This may be

necessary as the belt stretches after continuous

use. Following are the necessary steps for removing

links:

Remove the outside master links on the right

and left sides of the conveyor belt. Remove the

center splice clips next.

1. Move the splice clips to either end of the oven for

easy access.

2. Unhook the splice clips using long nose pliers.

3. Unhook the full link to be removed and slide it out.

Do not discard the link removed as it may be used

for making spare splice clips.

4. Reconnect the inside splice clips.

5. Reconnect the outside splice clips.

6. Replace all parts removed from the oven.

7. Straighten any bent wires to ensure smooth

sprocket engagement.

Unhook the end loop and pull up on the link

section. Save this link as it may be used for

making splice clips.

Check the orientation of the splice clips (the hooks

should be up). The belt shown is the top section,

ready for left-to-right travel.

Page 15

INTERNATIONAL ONE (1) YEAR EQUIPMENT WARRANTY

All workmanship and materials in “STAR” products are warranted for a period of one year from the date shipped from the factory or

one year from the date shown on the proof of purchase of the end-user when purchased through an authorized “STAR” dealer/dis-

tributor in a commercial foodservice location.

“STAR’s” obligation under this warranty is limited to the replacement of the defective part(s) only without charge. This warranty is

void if damage occurs from improper installation, misuse or abuse, disassembly or tampering of unit for any purpose other than repair

by a qualifi ed service agent, wrong voltage, incorrect or fl uctuating voltage conditions, wrong gas, improper gas or gas conditions,

operated contrary to the installation and operating instructions, operated in an application for which the unit is not suited, or if the unit

is not maintained and/or cleaned in a suitable manner.

Any expense in connection with installation, or any cost of making adjustments on a unit to conform to electric or gas service at the

point of installation, are not covered by this warranty.

* The warranty period for the JetStar series six (6) ounce popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is fi ve (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Tefl on/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not

apply if damage occurs to Tefl on/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive

cleaners. This warranty does not apply to the “non-stick” properties of such materials.

* This warranty is not valid on Conveyor Ovens unless a “start-up/check-out has been performed by a Factory Authorized Technician.

In order to make a claim under this warranty; a warranty report must be fi led with Star Manufacturing International Inc. in St. Louis,

Missouri, U.S.A. by the dealer/distibutor through which product was purchased. All details, including serial number and model number of the defective unit, must be included. Failure to fi le a claim within a 120 Day time period may result in the claim being refused.

“STAR” may forego the necessity of returning the part for inspection dependent upon the expense involved. However, “STAR”

requires defective parts to be held in the claimant’s possession for a period of ninety (90) days for possible inspection by a “STAR”

representative or designated inspector .

The foregoing warranty is lieu of any and all other warranties, expressed or implied, and constitutes the entire warranty.

PARTS WARRANTY

Parts that are sold for out-of-warranty repair are warranted for a period of ninety days. The part only is warranted; no labor.

SERVICES NOT COVERED BY WARRANTY

1. Labor

2. Mileage and/or travel time

3. Installation and/or adjustment of equipment

4. Operation contrary to the installation and operating instructions

5. Cleaning of equipment

6. Seasoning of griddle plates

7. Voltage conversions/adjustments

8. Gas conversions

9. Pilot light conversion/adjustments

10. Thermostat calibration/adjustments

11. Resetting of circuit breakers or safety controls

12. Replacement of bulbs/lamps

13. Replacement of fuses

14. Damages due to improper installation

15. Damages from abuse or misuse

16. Damage created by acts of God, Acts of War, or Civil Disturbance

08-05 rms

Page 16

8

5

40

C

A

2

2

1

C

T

O

O

2

N

3938

3x2000W COILS

40

39

38

J1

J1

37

19

L2 L1

XF1

24V

208V

7

230V

3325

CONTACTOR

L3

L2

L1

34 23

45

14

43

44

5

421

L3NL2L1

45

3

1

1

35

6

18

FUSE BLOCK

(2) @ 5A

16

14

TL2

2

3

TS1

4

TL1

6

DS

7

1

83015

14

S1

25

2

PLUG ON BACK OF MOTOR

IS SHOWN ROTATED 180°

7

1

20

27

28

X

X

X

46

37

16

44

43

3246

1 24VDC RETURN (COMMON)

7 +24VDC

2 DIRECTION

3 ENABLE (ACTIVE LOW)

4 FAULT (ACTIVE LOW)

5 COMMON

6 COMMON

8 TACH (12 PPR)

9 VOLTAGE INPUT (SPEED)

10 +5V (USE FOR SPEED POT ONLY)

11 BRAKE (ACTIVE LOW)

12 COMMON

8

2

3

9

10

4

5

11

6

12

GM/C

13

42

29

X

X

12

X

29

42

28

12

27

OCB

SECOND GENER

CN5 TO

SMALL MOTOR

7 = SPEED (GRD)

6 = SPEED SIGNAL

5 = SPEED (5V REF)

4 = (NOT USED)

3 = TACH (GND)

2 = TACH (+5V)

1 = TACH SIGNAL

1

CN3

CN3

TO MOTOR

6 = COM

5 = ENABLE

4 = DIR

3 = SPEED

2 = COM

1 = TACH

1

C

CN2 (

IN

OUTPUT

SOLEN

3 = C

2 =

1 =

Page 17

M1

M

C

E

D

S

C

BLU

BRN

BLK

BLK BRN

C1

17

- GEARMOTOR & CONTROLLER

GM/C

- CAPACITOR, CIRC FAN MOTOR

C1

- DIRECT SPARK IGNITION CONTROLLER

DSIC

PS

- POWER SUPPLY, 24VDC 150W PS

M1

- MOTOR, CIRC FAN

OCB

- OVEN CONTROL BOARD

TS1

- COOL DOWN T-STAT

TL2

- CONTROL BOX TEMP LIMIT (MAN RESET)

TL1

- COOK CHAMBER TEMP LIMIT (BULB & CAP)

CB

- CIRCUIT BREAKER

SE

- SPARK ELECTRODE

FS

- FLAME SENSOR

DS

- DIFFERENTIAL PRESSURE SWITCH

S1

- SWITCH, MAIN

XF1

- TRANSFORMER, 230V-24V

CON

- CONTACTOR

TB

- TERMINAL BLOCKS (2)

CB

- CONNECTION BLOCK

FRACTIONS ±1/64 DECIMALS ±.005 ANGLES ±1°

DR.

TOLERANCES UNLESS OTHERWISE NOTED

RDL 04/30/03

CK.

R

STAR MFG. INTERNATIONAL, INC.

#10 SUNNEN DRIVE, ST. LOUIS, MO. 63143, USA

BL

DATE

9

89

5

4

_

15

21

19

_

_

_

_

B

COND GENERATION

TO

LL MOTOR

PEED (GRD)

PEED SIGNAL

PEED (5V REF)

NOT USED)

ACH (GND)

ACH (+5V)

ACH SIGNAL

CN1 T/C TYPR K

YEL(+) RED(-)

SH (SHIELD)

CN2 (24V)

OTOR

OM

NABLE

IR

PEED

OM

ACH

INPUT

OUTPUT TO

SOLENOID

3 = COM

2 = 24V

1 = N/C

2 = N

1 = H

CN4

TB

10

36

21

41

BLU

18

30

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L INC.

10

PR

17

TL2

TL1

DS

NC

NO

C

"L" "H"

T/C

TS1

4

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

FINISH

---

TITLE

REVISIONS

MATERIAL

---

MODEL NO.

UM-1833

WIRING DIAGRAM, 400/230

361320

32

41

CN1

3

5

6

4

7

1,2: AC IN

3: FG

4,5: -V OUT

CN2

1

33

CN4

25

_

1

34

23

6,7: +V OUT

PS

NOTES:

12

SET VOLTAGE TO 230V

BEFORE INSTALLING

C 9/23/04

UPDATED OVEN CONTROL BOARD

LTR DAT E

A 09/15/03

B 03/26/04

PART NO.

SHOW BEND IN T/C FOR NEW MOUNT

ADD 2ND GENERATION CONTROLLER

DESCRIPTION OF CHANGE

SK-1987

FOR FIELD WIRING BY INSTALLER WITH CORD OR FLEXIBLE

C

CONDUIT. (2) EXTRA J1 JUMPERS FOR SINGLE PHASE USE

(TIE L1,L2,L3 TOGETHER) WRAP THESE WITH OTHER LOOSE

SHIP PARTS

CG

RDL

DR

RDL

Page 18

Page 19

PARTS LIST March 23, 2006, Rev D

Ultra-Max Electric Conveyor Oven

8B-UM1833/1850-230V - Main Assembly

MODEL

Number

Key

Number

1 G9-Z5716 2 TUNNEL SHROUD

2 G9-Z5745 1 INFEED SHELF

3 G9-Z5362 1 EXIT SHELF

4 2A-Z0314 4 ADJUSTABLE LEG

5 2C-Z5182 4 THUMB SCREW

6 2M-Z5747 1 CONTROL GRAPHIC

7 2M-Z5665 1 FRONT GRAPHIC

8 2P-Z4996 4 VENT PLUG

9 2R-Z5174 2 LATCH

10 2R-Z5188 2 LATCH KEEPER

11 2V-Z6696 1 PRESSURE TUBE

12 G9-Z5574 1 HOSE SECTION

13 2V-Z5789 1 PROBE TUBE

14 G9-EC0025 1 CONVEYOR FRAME UM1833

G9-EC0043 1 CONVEYOR FRAME UM1850

15 2A-Z6538 1 DRIVESHAFT ASSEMBLY

17 2A-Z5586 1/2 IDLER SHAFT ASSEMBLY UM1833 / UM1850

18 2B-Z5709 1 BELT - 6' UM1833

2B-Z5169 1 BELT - 10' UM1850

19 2B-Z5170 4 BELT SPLICE CLIP

20 2P-Z5168 4 BEARING

21 2P-Z6368 2 BEARING - DRIVE UM1850

22 G9-Z5281 1 PAN STOP

23 G9-Z6193 2 CRUMB TRAY

24 G9-Z5682 1 FAN INLET GUARD

25 G9-EC0030 1 FAN BAFFLE

26 2N-Z6603 1 HEATING ELEMENT - THREE PHASE (220V)

2N-Z7477 1 HEATING ELEMENT - THREE PHASE (240V)

27 2U-Z5710 1 HOT AIR BLOWER

28 G9-EC0063 1 REAR COVER

29 2E-Z6630 1 POWER RESISTOR, 50ohm 208/230V

2E-Z5663 2 POWER RESISTOR BRACKETS

30 2B-Z5607 1 REAR FAN GUARD

31 2K-Z2895 1 SPLIT BUSHING

32 G9-Z5772 1 ACCESS DOOR

33 2E-Z5711 1 MOTOR CAPACITOR

34 2E-Z6650 1 CONTACTOR

35 2C-Z5195 1 CONDUIT HANGER

Part

Number

Per

Unit

Description and Model Designation

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 20

Page 21

PARTS LIST March 23, 2006, Rev D

Ultra-Max Electric Conveyor Oven

8B-UM1833/1850-230V - Control Box

MODEL

Number

Key

Number

1 2E-Z6651 1 TERMINAL BLOCK, INPUT

2 G9-EC0014 1 CONTROL BOX DOOR ASSEMBLY

3 G9-Z7283 1 CONTROLLER, TIME/TEMPERATURE

4 2E-Z5683 1 VACUUM LIMIT SWITCH

5 2T-Z5175 1 THERMOSTAT, 120F

6 2T-Z5176 1 THERMOSTAT, 140F

7 2T-Z5177 1 HIGH TEMPERATURE LIMIT THERMOSTAT

8 2E-Z1858 1 SWITCH - LIGHTED

9 2J-Z5189 1 THERMOCOUPLE ASSEMBLY

10 G9-Z6610 1 POWER SUPPLY, 24VDC-150W (230V INPUT)

11 G9-Z5738 1 LID, CONTROL BOX

12 2U-Z5171 1 GEARMOTOR

13 G9-Z5740 1 GEARMOTOR BRACKET

14 2A-Z6534 1 SPRING-LOADED COUPLING ASSEMBLY

15 2B-Z5775 2 FAN WIRE GUARD

16 2E-Z4597 2 TERMINAL BLOCK

17 2C-Z0216 2 SCREW M4 (METRIC)

18 2E-Z5741 1 TRANSFORMER

19 2K-Z1971 4 SPACER

21 2C-Z5797 2 SCREW M3 (METRIC)

22 2K-3485 1 BUSHING - HEYCO

23 2E-Z5680 2 FUSE

24 2E-Z5681 1 FUSEHOLDER

25 2C-Z3350 1 HALF CLAMP

Part

Number

Per

Unit

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 22

Page 23

PARTS LIST March 23, 2006, Rev D

Ultra-Max Electric Conveyor Oven

8B-UM1833/1850-230V - Finger Assembly

Key

Number

1 G9-GC0037 1 LOWER FINGER BAFFLE

2 G9-EC0048 1 LOWER FINGER WELDMENT

3 G9-Z6407 1 LOWER COLUMNATING PLATE

4 G9-Z6406 1 LOWER NOZZLE

5 G9-Z6409 1 UPPER NOZZLE

6 G9-Z6411 1 UPPER COLUMNATING PLATE

7 G9-EC0055 1 UPPER FINGER WELDMENT

Number

Part

MODEL

Number

Per

Unit

Description

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 24

TENSION DE COURROIE DE CONVOYEUR

La bande de conveyeur du Ultra-Max Convoyeur

Four n'a pas un ajustement de tension. Si la ceinture

devient trop lâche, un lien devra être enlevé pour serrer.

Une ceinture qui est volonté trop serrée également

posent des problèmes opérationnels dus à la drague

excessive. Nous proposons que vous fassiez effectuer

à un technicien qualifi é de service cet ajustement.

La considération soigneuse devrait être exercée

avant d'enlever un lien de ceinture parce qu'une

ceinture qui est volonté trop serrée empêchent

l'opération du convoyeur.

DÉPLACEMENT D'UN BANDE DE CONVEYEUR

Un lien entier peut être enlevé avec le convoyeur dans

ou hors du four. Ceci peut être nécessaire pendant que

la ceinture s’étend après utilisation continue. Suivre les

étapes nécessaires pour des liens d’enlèvement:

1. Déplacez les épissure attaches à n'importe quelle

extrémité du four pour l'accès facile.

2. Décrochez les épissure attaches en utilisant de

longues nez pinces.

3. Décrochez le plein lien à enlever et glissez-le

dehors. Ne jetez pas le lien enlevé en tant que

lui peut être employé pour faire des rechange

épissure attaches.

4. Rebranchez les épissure attaches d'intérieur.

5. Rebranchez les épissure attaches d’extérieur.

6. Remplacez toutes les pièces enlevées du four.

7. Pour assurer l'enclenchement doux de pignon,

rendez tous les fi ls égaux.

ATTENTION

Enlevez les maillons de jonction extérieurs des côtés

gauches et droits de la conveyeur bande. Enlevez les

centrales épissure attaches après.

Décrochez la boucle extrémité et tirez vers le haut sur

la section de lien. Économiser ce lien comme il peut

être employé pour faire des épissure attaches.

Vérifi ez l'orientation des épissure attaches (les

crochets devraient être vers le haut). La ceinture

montrée est la section supérieure, préparent pour le

voyage de gauche à droite.

Page 25

DIRECTIONS POUR LE DÉMONTAGE

1. Enlevez les plateaux et les

étagères de miette des deux

extrémités.

4. Finissez d'enlever le

convoyeur de la droite

extrémité du four.

2. Poussez l'accouplement

à ressort dedans pour

désengager la goupille

dans l'axe. Tournez l'axe

ainsi la goupille n'ira pas

de nouveau dans les fentes

d'accouplement..

5. Le doigt supérieur peut être

complet enlevé ou la petite

poignée (gauche) peut être

utilisée pour glisser le bec et

le plat columnating dehors

avant d’enlever le corps

principal.

3. Soulevez vers le haut

l’extrémité gauche de

l’armature de convoyeur

ainsi des appuis de plateau

de miette (UM1850 seulement)

clairement l’ouverture de

four. Poussez l’armature de

convoyeur par l’ouverture de

four.

6. Bec supérieur (avec la fente)

et plats columnating (avec

plat d’alignement). Évier

trous tout point dans la même

direction (vers le bas vers le

convoyeur).

7. Le doigt inférieur peut être

enlevé complet ou le bec peut

être enlevé pour indiquer le

columnating enfoncé plat.

8. Le plat columnating a

également une fente qui doit

aligner avec une étiquette

sur le doigt pour assurer

l’orientation appropriée. Les

trous expulsés se dirigent

vers le haut vers le fond du

convoyeur.

12

9. Le corps de four est

maintenant prêt à être essuyé.

Rassemblez les pièces de

doigt et de convoyeur dans

l’ordre d’inversion après

nettoyage.

Page 26

INSTRUCTIONS D’ENTRETIEN

ATTENTION

DÉBRANCHEZ LA PUISSANCE AVANT D'ENTRETENIR OU NETTOYER LA FOUR.

SAUVEGARDEZ LA PUISSANCE AINSI ELLE NE PEUT PAS ÊTRE ACCIDENTELLEMENT

RECONSTITUÉE. LE DÉMEMBREMENT, L’ELECTROCUTION, OU LA MORT PEUVENT

SE PRODUIRE SI VOUS NE COUPEZ PAS LE COURANT. QUAND DES FOURS SONT

EMPILÉS IL Y A LES RACCORDEMENTS DE PUISSANCE MULTIPLES, AINSI ARRÊTEZ

TOUS LES FOURS AVANT LE NETTOYAGE OU L’ENTRETIEN.

Aucun composant électrique ne devrait être soumis à l’humidité. Il est donc important que le

four soit essuyé vers le bas soigneusement. Ne jetez jamais les seaux eau au-dessus du four

ou soumettez-les à la pression délogeant un d’une d’une tuyau ou un pulvérisateur de pression.

Si on renverse l’eau ou tout autre liquide sur le four, assurez-vous qu’aucune de lui n’est entrée

dans le secteur de boîte de commande avant de brancher le four. En cas de doute, appelez

votre compagnie de services.

Adhérez aux avertissements suivants en nettoyant ou en maintenant votre four de convoyeur

de gaz:

1. Le four ne doit pas être chaud. N’employez pas l’équipement de nettoyage de puissance,

les laines en acier, ou les brosses métalliques sur des surfaces d’acier inoxydable.

2. N’employez pas un décapant bas caustique ou alkalin sur l’intérieur du four. Ceci ruinera la

fi nition aluminisée de l’intérieur de four.

3. En utilisant des solutions de nettoyage, soyez sûr qu’elles répondent à des normes locales

et nationales de santé.

Suivez ces recommandations pour nettoyer et maintenir de four:

CHAQUE JOUR

1. Nettoyez la bande de conveyeur en utilisant une brosse en nylon. Permettez à n’importe

quel matériel étranger de se laisser tomber dans les casseroles de miette.

2. Nettoyez les casseroles de miette. Employez une eau chaude et un mélange détersif.

Rinçage avec de l'eau propre.

CHAQUE MOIS

1. Balayez et nettoyez la garde sur le ventilateur de moteur.

TOUS LES TROIS MOIS

1. Débranchez le four.

2. Enlevez les casseroles de miette.

3. Enlevez le convoyeur.

4. Délacez et enlevez la porte avant. Enlevez tous les composants internes de fl ux d'air.

5. Nettoyez l’intérieur de four avec un détergent approprié de four.

6. Nettoyez le convoyeur, les casseroles de miette, et d’autres composants démontables. Lavez

dans un mélange de détersif et l'eau chaude, rincent alors par de nettoyez l’eau. Pour des

secteurs diffi ciles de nettoyage, employez un "solvant de graisse "ou le détergent de four.

7. Déplacez le four et nettoyez sous lui. Prêtez attention pour ne pas endommager les cordes

ou les connecteurs électriques en se déplaçant.

8. Rassemblez le four.

ATTENTION

TOUS LES DOUZE MOIS

Une personne de service autorisée par usine devrait faire ce qui suit:

1. Ouvert et nettoyez l'intérieur de la boîte de commande.

2. Vérifi ez et serrez tous les composants électriques.

Si l'entretien est exigé, entrez en contact avec votre compagnie de services locale, un représentant

d'usine, ou Star Manufacturing.

11

Page 27

TEMPS DE CUISINIER CONTRE LA

TEMPÉRATURE DE CUISINIER

1. Le temps de cuisinier est réellement vitesse de

convoyeur et est défi ni car le temps le produit

est réellement dans le four. Ceci est mesuré en

notant le moment où le principal bord du produit

entre dans le four et le temps le principal bord du

produit part du four. Ceci est ajusté en employant

le contrôleur de vitesse de convoyeur.

2. La température est ajustée en changeant le

setpoint du contrôleur de température en désiré

font la température au four cuire. Quand le four

atteint la température désirée, le point rouge dans

le bon coin inférieur de l'affi chage de la température

s'allumera au loin et comme le contrôleur maintient

la température.

3. En établissant un temps de cuisinier et une

température pour un produit, la règle générale

est que quand le temps de cuisinier augmente la

température diminue. L'inverse est également vrai:

Augmentez la température, diminuez le temps.

Cependant, il y a des limites à la règle ci-dessus.

La trop de chaleur ou temps peut avoir comme

conséquence un produit brûlé.

4. Une fois un bon cuisinier a été établi, les

ajustements fi ns devrait être fait en jugeant le temps

de cuisinier ou la constante de la température de

cuisinier, changeant alors l’autre.

VITESSE DE CONVOYEUR

Temps de Cuisinier (Vitesse De Convoyeur) - Comme

indiqué précédemment, le cuisinier que le temps

(vitesse de convoyeur) est défi ni comme la quantité de

temps s’est écoulée entre le moment le principal bord

du produit écrit le four et le principal bord du produit

sort le four. Le temps de cuisinier est commandé

en ajustant le contrôleur numérique de vitesse.

L’arrangement sur le panneau de commande indique

le temps réel de cuisinier.

Le temps de cuisinier sera le même pour n’importe

quel produit de taille.

TEMPS DE LA LIVRAISON

La temps de la livraison est la quantité de temps

écoulé entre la période où le principal bord du produit

entre dans le four et le rebord arrière du produit

est entièrement déchargé et est prêt à être livré au

client.

La temps de la livraison change si la taille de

produit change.

Note: Rappelez-vous de ne pas tirer le produit hors

du four quand le principal bord sort. Attendez toujours

jusqu'à ce que le produit entier ait passé sous les

trous d'air - les besoins de produit cette fois de faire

cuire entièrement.

10

Page 28

L’INFORMATION D’AFFICHAGE

En actionnant le four, il y a trois niveaux d’accès:

1. Stockez De Niveau - Les employés généraux

sauraient ces fonctions et comment les changer.

Tandis que le four fonctionne, entrez ce mode

en tenant la DUNE et LEVEZ les fl èches (

) simultanément pendant quatre secondes.

L’affi chage de TEMPS va blanc et le setpoint de

la TEMPÉRATURE est montré. Ajustez avec

la DUNE ou LEVEZ les fl èches. Le bouton de

ENTREZ (

TEMPÉRATURE. Le paramètre qui peut être

ajusté est montré, l’autre est blanc. Quand

le TEMPS et la TEMPÉRATURE sont ajustés

comme nécessaires, attendez cinq secondes

et ÉCONOMISER est montré. Les valeurs

sont acceptées et le contrôleur commence à

commander à ces nouvelles valeurs. Le convoyeur

continue à fonctionner à la même vitesse jusqu’à

ce qu’une nouvelle valeur soit acceptée. Le

rendement de commande de température devrait

être arrêté pendant les changements.

2. Niveau De Directeur - C'est une serrure de

sorte que le TEMPS et la TEMPÉRATURE ne

puissent pas être changés même au "Stockez

de Niveau." Tandis que le four fonctionne,

entrez ce mode en tenant la DUNE et LEVEZ les

fl èches (

secondes. L’affi chage de TEMPS va blanc et

le setpoint de la TEMPÉRATURE est montré.

Libérez la fl èche LEVEZ (

maintenir la fl èche DUNE (

4 secondes. L'affi chage de la TEMPÉRATURE

montre "LOC" pendant que l'affichage de

TEMPS montre "nO," ce qui indique que les

paramètres de TEMPS/TEMPERATURE peuvent

) bascule entre le TEMPS et la

) simultanément pendant quatre

) et continuez à

) pendant encore

être changés aprèsatteinte du "Stockez de

Niveau." "yES" indique que les paramètres ne

peuvent pas être changés même après entrez

le "Stockez de Niveau." L'arrangement de "LOC"

peut être basculé utilisant le bouton de ENTREZ

(

).

FONCTIONS ADDITIONNELLES

La direction de bande de conveyeur et l’affi chage

de la température peuvent être changés sur le

four de convoyeur par un technicien qualifi é. Pour

changer la direction de ceinture, le technicien

doit renverser la direction de moteur et tourner la

bande de conveyeur pour la fonction appropriée

de four. Un technicien peut également changer

l’affi chage de la température de Fahrenheit en

Celsius. Ces changements peuvent être faits par

le technicien pendant le start-up/check-out ou à

une date ultérieure.

CODES D’ERREUR

Les codes d’erreur montreront en tant que messages

de clignotant des textes pour des buts diagnostiques.

La n’importe quelle température ou erreur de

thermocouple devrait tourner la température produite

au loin et laisser le convoyeur fonctionnant à la

même vitesse. L’erreur de ceinture devrait tourner la

température produite au loin. L’erreur de vitesse devrait

montrer quand le moteur ne peut pas arranger à la

vitesse choisie. Ceci pourrait se produire si on choisit

une vitesse rapide que le moteur ne peut pas tourner

assez rapidement pour réaliser. Le rendement de

signal de vitesse demeurera le même mais l’affi chage

clignotera le message d’erreur.

9

Page 29

Veuillez prendre du temps de lire les consignes

d’utilisation de sûreté suivante. Elles sont la clef

à l’opération réussie de votre four de convoyeur

de Ultra-Max.

Pour votre sûreté, lisez avant l’opération.

Si vous sentez le gaz:

1. N’essayez pas de n’allumer aucun appareil.

2. Ne touchez aucun commutateur électrique.

3. Utilisez un téléphone extérieur pour appeler votre

fournisseur de gaz immédiatement.

4. Si vous ne pouvez pas atteindre votre fournisseur

de gaz, appelez le département de feu.

TIP DE SÛRETÉ

Pour ajuster le temps et la température:

1. Serrez la DUNE et LEVEZ les fl èches (

en même temps. Tenez pendant quatre secondes

jusqu’à ce que l’affi chage de la TEMPÉRATURE

aille blanc.

2. Appuyez sur le bouton de ENTREZ (

) pour commuter entre le TEMPS et la

TEMPÉRATURE.

3. Serrez LEVEZ la fl èche (

DUNE la fl èche (

TEMPÉRATURE. Maintenez l’un ou l’autre bouton

pour des changements plus rapides d’affi chage.

4. Après cinq en second lieu, les nouveaux nombres

seront sauvés et le four montrera les nouveaux

arrangements.

) pour diminuer le TEMPS ou la

) pour augmenter ou

)

En cas d’une panne de courant:

1. Arrêtez tous les commutateurs.

2. N’essayez pas d’actionner le four jusqu’à ce que

la puissance soit reconstituée.

Bouts Généraux De Sûreté:

1. Si le four doit être déplacé pour n’importe quelle

raison, le électricité doit être arrêté et démonté à

partir de l’unité.

2. N’enlevez pas la couverture de boîte de commande

à moins que le four soit débranché.

OPÉRATION

Pour allumer le four:

1. Poussez le commutateur de puissance à

"MARCHE."

2. Après que le ventilateur commence à établir la

pression, le mano-contact fournira la puissance au

tableau de commande d'engager le conjoncteur

élément de chauffe. Vous devriez entendre un

"click" en conjoncteur pendant qu'il commence à

chauffer.

Pour arrêter le four:

1. Poussez le commutateur de puissance au

"ARRÊTE." Le four est équipé d'un dispositif fraisvers le bas pour la protection d'axe et de roulement

de moteur. Ceci permet aux turbines de fonctionner

indépendamment du statut de contrôleur. Les

ventilateurs continuent à fonctionner jusqu'à ce que

le four se refroidisse à une température sûre.

8

Page 30

INSTRUCTIONS D’EMPILEMENT

Les instructions suivantes devraient être suivies en empilant plus

d’une unité.

Installation Simple de Chariot de Four (ou le Fond):

1. Enlevez la porte, le convoyeur, et les doigts.

2. Dévérouillez l’unité de la caisse d’expédition (4 boulons).

3. Tournez l’unité sur l’avant comme montré dans le schéma à la

page suivante.

4. Filetez les quatre jambes dans le fond du four.

5. Soulevez SOIGNEUSEMENT de four.

Le Four Empilé Installent La Préparation:

1. Enlevez la porte, le convoyeur, et les doigts.

2. Dévérouillez l’unité de la caisse d’expédition (4 boulons).

3. Tournez l’unité sur l’avant comme montré.

4. Enlevez le dessus du four inférieur (4 vis se montent, 2 avant

et arrière) et boulonnez à la base empilée de four avec 3/8 - 16

boulons.

5. Placez le four supérieur sur l’unité inférieure et le rattachez

avec des vis pour le dessus du four inférieur.

CONSIGNES D’UTILISATION

N’ESSAYEZ PAS D’ACTIONNER LE FOUR jusqu’à ce que le

raccordement du service et de l’installation de service ait été

entièrement inspecté (contrôle de mise en train) par un technicien

autorisé de service ou un technicien de service d’étoile afi n d’assurer

le four est correctement installé et dans l’ordre d’entretien. La

garantie devient effi cace lors de la vérifi cation de l’installation

appropriée.

NE TRAVAILLEZ PAS AUTOUR DE LA BANDE DE CONVEYEUR

AVEC DE LONGS CHEVEUX, HABILLEMENT LÂCHE,

OU BIJOUX BALANÇANTS. SE FAIRE ATTRAPER DANS

LA CEINTURE A PU AVOIR COMME CONSÉQUENCE LE

DÉMEMBREMENT OU LES DOMMAGES MORTELS.

Sauf indication contraire, le voyage de convoyeur est usine réglée

pour la gauche à la bonne opération en faisant face à l’avant du

four. Si un changement de direction est exigé, référez-vous à

l’”INFORMATION d’AFFICHAGE,” la section 3 pour des instructions

sur la façon dont programmer le contrôleur pour un changement

de direction. En outre, la bande de conveyeur doit être changée

en voyage dans la nouvelle direction.

CONSIGNES D’UTILISATION DE SÛRETÉ

L’information contenue dans cette section est donnée pour l’utilisation des personnels exploitants qualifi és. Les

personnels exploitants qualifi és sont ceux qui ont soigneusement lu l’information contenue en ce manuel, sont

au courant des fonctions du four et/ou ont eu une expérience précédente avec l’opération de l’équipement décrit.

L’adhérence aux procédures recommandées ci-dessus assurera l’accomplissement de l’exécution optima et du

long, sans panne service.

ATTENTION

7

Page 31

Cet appareil doit être installé sur un table ou fort position en utilisant les pieds donnés pour

le nettoyage. Minimum, on devrait permettre 24" de l'espace sur l'extrémité du four pour le

déplacement du convoyeur si le four n'est pas sur un chariot mobile. Permettez l'espace pour

qu'un technicien de service accède à de boîte de commande et à la couverture de moteur de

ventilateur au-dessus de l'arrière du four si le four n'est pas mobile.

ATTENTION

N’importe quelle surface que le four est monté

dessus devrait avoir un secteur augmenté

autour du périmètre pour empêcher le four

de tomber accidentellement le bord. Les

dommages ou la mort sérieux pourraient se

produire si le four tombe sur une personne.

N'importe quel chariot que le four est localisé

dessus doit être profond et long pour fournir

une plateforme stable. Un chariot étroit a pu

permettre au four de tomber d'et de dommages

la propriété ou de blesser sérieusement des

personnes.

ATTENTION

VENTILATION

Les codes locaux règnent. Ce sont l’”autorité ayant la juridiction” comme indiqué par le National

Fire Protection Association, Inc. dans le NFPA 96-Latest Edition. Pour davantage d’information

de ventilation voir ci-dessous.

Un capot de ventilation peut être exigé pour enlever la chaleur et des odeurs de cuisine. Le capot

et l’installation de la HVAC doivent rencontrer des codes locaux pour gagner l’approbation par

l’autorité ayant la juridiction. Les conditions peuvent changer dans tout le pays selon l’endroit par

la ville, le comté, et l’état. Obtenez l’information de l’autorité ayant la juridiction pour déterminer

les conditions pour votre installation. Obtenez les copies de l’information et de revue des codes

ou des documents qui seront employés pour inspecter et approuver votre installation. Votre

fournisseur de capot de ventilation et entrepreneur de la HVAC devraient être contactés pour

fournir des conseils.

Empêchez le fl ux d’air par le tunnel à cuire. De l’air ne doit pas être dirigé sur le four avant

ou arrière ou vers le côté du secteur à cuire. Ceci peut causer la cuisine inachevée et la

consommation d’énergie accrue.

ATTENTION

RACCORDEMENT ÉLECTRIQUE

Avant d’établir tous les rapports électriques à cette unité, vérifi ez que l’alimentation d’énergie

est proportionnée pour la tension, l’ampérage, et les conditions de phase indiquées de la plaque

de contrôle. Un diagramme de câblage est inclus sous ce pli.

Une fois installé, cet appareil doit être électriquement fondu et son installation doit être conforme

au Code de Electric de National, au ANSI-NFPA 70, à la dernière version, aux instructions

d’installation du fabricant, et aux codes municipaux locaux applicables de bâtiment. Au Canada,

tous les raccordements électriques sont d’être conformes CSA C22.1 - le Part 1 de Code de

Electrical de Canadian et/ou des codes locaux.

Cet appareil est équipé d’une douille de borne et de corde de cinq-poteau pour que le client/

installateur attache à. Chaque ligne (L1, L2, L3) devrait être 230V et offrir la référence au

raccordement neutre (N). Une sol raccordement est également donnée pour un cinq-fi lsystème.

6

Page 32

L’INFORMATION IMPORTANTE DE SÛRETÉ

N’essayez pas d’actionner le four jusqu’à ce que le raccordement du service de service ait

été entièrement inspecté par un technicien autorisé de service ou un technicien de Star. Ce

service est exigé par le Star afi n d’aider l’acheteur dans la mise en train appropriée du four sur

l’emplacement. Veuillez noter les détails spécifi ques sur la garantie et assurez-vous que des

rapports de service sont établis aux services de service appropriés.

La garantie ne s’appliquera pas si le four est commencé vers le haut et actionné avant les

utilités et le four étant inspectés et le contrôle fait par un technicien autorisé de service ou un

technicien de Star.

L’INSTALLATION INEXACTE, L’AJUSTE-MENT, LE CHANGEMENT, LE SERVICE, OU

L’ENTRETIEN PEUVENT CAUSER DES DÉGATS MATÉRIELS, DES DOMMAGES, OU LA

MORT. LISEZ TOUTES LES INSTRUCTIONS COMPLÈTEMENT AVANT D’INSTALLER OU

ENTRETENIR CET ÉQUIPEMENT.

Des dégagements minimum doivent être maintenus tous les murs et matériaux combustibles.

Les dégagements minimum pour cette unité devraient être à 0 pouces de l’arrière (les butoirs

arrière fournis doivent être en place) et à 6 pouces des deux côtés. Maintenez le four libre et

dégagé de tout le matériel combustible.

N’obstruez pas de ventilation trous dans les panneaux de commande en tant que ces derniers

fournissent air de refroidissement pour les commandes.

Le four doit être actionné seulement sur le type d’électricité montrés du plat de spécifi cations.

ATTENTION

ATTENTION

ATTENTION

ATTENTION

L’INFORMATION D’INSTALLATION

LES INSTRUCTIONS D’INSTALLATION CONTENUES CI-dessus SONT POUR L’USAGE DU

PERSONNEL QUALIFIÉ D’INSTALLATION ET DE SERVICE SEULEMENT. L’INSTALLATION

OU LE SERVICE PRÈS AUTRE QUE LE PERSONNEL QUALIFIÉ PEUT AVOIR COMME

CONSÉQUENCE LES DOMMAGES AU FOUR ET/OU AUX DOMMAGES À L’OPÉRATEUR.

Le personnel qualifi é d’installation est des individus, une société, une société, ou une compagnie

que chez la personne ou par un représentant sont engagé dedans, et responsable de:

1. L’installation du câblage électrique du mètre électrique, de la boîte de commande principale

ou de la sortie de service à l’appareil électrique.

Le personnel qualifi é d’installation doit être expérimenté dans un tel travail, au courant de toutes

les précautions priées, et s’est conformé à toutes les conditions de l’état ou des autorités locales

ayant la juridiction.

ENDROIT

Le placement bien projeté et approprié de votre four aura comme conséquence la convenance

d’opérateur à long terme et l’exécution satisfaisante.

Il est essentiel qu’à air proportionnée au four soit maintenue pour fournir un écoulement suffi sant

d’air de ventilation. Suivez ces directives:

1. Placez le four dans un secteur qui est exempt d’ébauches.

2. Maintenez le secteur de four libre et dégagé de tous les combustibles tels que le papier, le

carton, et les liquides infl ammables et les dissolvants.

3. Ne placez pas le four sur une base ou un joint de bord à un mur. Ceci limitera l’écoulement

d’air et empêchera la ventilation appropriée aux turbines. Cette condition doit être corrigée

pour empêcher des dommages permanents au four.

4. Sur tous les modèles, le déclenchement du dispositif thermique de la surcharge de la

turbine indique une température ambiante excessive au fond du four. Cette condition doit

être corrigée pour éviter d’endommager permanent le four.

5

Page 33

INFORMATIONS GÉNÉRALES

Cet équipement est conçu et vendu pour le usage commercial seulement par le personnel qualifi é et

expérimenté dans son opération et est pas vendu pour usage du consommateur dans et autour de la

maison ni pour usage directement par le grand public dans des endroits de service de traiteur.

En premier lieu, chaque caisse devrait être examinée avant de signer le connaissement pour

rapporter importe quels dommages évidents par le camionneur en transit, et pour expliquer le

nombre approprié de caisses. Se il y a des dommages apparents, des arrangements devraient

être pris pour classer une réclamation contre le porteur. Les règlements de commerce entre Etats

exigent que la réclamation doit être lancée par le destinataire. Des équipements appropriés et

bloqués de stockage devraient être arrangés pour oven(s) au besoin pour le protéger contre des

conditions extérieures ou humides à tout moment avant installation.

-IMPORTANT-

Quand vous faites décharger toutes les caisses, ouvrez les caisses et enlevez toutes les couvertures

en plastique. Inspectez immédiatement pour déceler les dommages cachés. Si quelque chose

semble être endommagé, contactez les personnes appropriées immédiatement pour classer une

réclamation de dommages. Après exécution de cette inspection, fi nissez de déballer le four. Soyez

sûr de enlever tout le matériel de papier de protection et emballage à partir de unité avant

chauffage.

POUR VOTRE SÛRETÉ NE STOCKEZ PAS OU EMPLOYEZ PAS ESSENCE OU AUTRES

VAPEURS ET LIQUIDES INFLAMMABLES À PROXIMITÉ DE CECI OU AUCUN AUTRE

APPAREIL.

ATTENTION

-IMPORTANT-

CET APPAREIL DOIT ÊTRE INSTALLÉ PAR LES PERSONNES QUALIFIÉES ET ÊTRE INSTALLÉ

SELON LES RÈGLES EN VIGUEUR DANS LE PAYS DE DESTINATION.INSTALLATION

Les fours sont équipés pour la tension de puissance indiquée sur la plaque signalétique montée

sur l'arrière de la boîte de commande. Ils fonctionneront sur le courant alternatif (C.A.) seulement.

Une douille de corde est fournie au fond de la boîte de commande. Ceci permet à la corde

installateur-fournie d’être reliée aux raccordements de TB situés derrière la porte d’accès arrière.

Le four doit être relié à la puissance par tous les codes applicables. Une manière de démonter le

four de la puissance devrait être fournie pour la sûreté et la facilité de l’entretien.

-IMPORTANT-

L'appareil doit être localisé où la prise est accessible. Harmonisée, 300/500V, corde huile-résistante

et fl exible avec des estimations minimum de 65 degrés C doit être employée. Choisissez les

conducteurs corrects par rapport à la longueur de la corde (1,0 millimètres carrés au minimum) et

des conditions de fonctionnement (la température, etc).

NE RELIEZ PAS AU COURANT CONTINU (C.C).

L'installation du four électrique se conformer au:

CODE ÉLECTRIQUE NATIONAL ET TOUTES LES CODES ET ORDONNANCES

ÉLECTRIQUES LOCALES ET LES RÈGLES ET LES RÈGLEMENTS DE LOCAL

ELECTRIC COMPANY.

ATTENTION

LA RESPONSABILITÉ DE L’ACHETEUR

Il est de la responsabilité de l’acheteur:

1. Pour voir que les services électriques pour le four sont installés sur l’emplacement selon les

caractéristiques du fabricant.

2. Pour décharger, désempaquetez, et installez le four dans son endroit approprié et selon ce

manuel d’opération d’installation.

3. Pour voir que services électriques sont reliés correctement par un installateur qualifi é de votre

choix. Tous tels raccordements doivent être conformes aux conditions applicables de code.

4. Pour assurer le contrôle d’inspection et d’opération par un technicien autorisé de service. La

garantie devient effi cace lors de la vérifi cation de l’installation appropriée.

4

Page 34

CARACTÉRISTIQUES

8B-UM1833-230V

Evaluer/Raccordement: 6,600W (3 x 2,000W élément assemblée)

Le TB a fourni (L1, L2, L3, N, Terre)

Alimentation Électrique: Indépendant service par Four - 15 Amp, 400/230 VAC, 3-phasé, 50 Hz

Poids Approximatif (1833 avec des jambes): Installé - 180 Lbs (81.8 kg), Transporté - 210 Lbs (95.5 kg)

Dimensions: Largeur: 51.2" (130.0 cm) - Four avec des étagères

Profondeur: 30.4" (77.2 cm)

Hauteur: 20.0" (50.8 cm) - Un four avec des jambes

36.0" (91.4 cm) - Deux fours avec des jambes

8B-UM1850-230V

Evaluer/Raccordement: 6,600W (3 x 2,000W élément assemblée)

Le TB a fourni (L1, L2, L3, N, Terre)

Alimentation Électrique: Indépendant service par Four - 15 Amp, 400/230 VAC, 3-phasé, 50 Hz

Poids Approximatif (1850 avec des jambes): Installé - 210 Lbs (95.5 kg), Transporté - 240 Lbs (109.1 kg)

Dimensions: Largeur: 50.0" (127.0 cm)

Profondeur: 30.4" (77.2 cm)

Hauteur: 20.0" (50.8 cm) - Un four avec des jambes

36.0" (91.4 cm) - Deux fours avec des jambes

3

Page 35

SYMBOLE DE SÛRETÉ

Ce symbole est prévu pour alerter l’utilisateur à la présence des

instructions importantes de fonctionnement et d’entretien du manuel

accompagnant l’appareil.

MAINTENEZ CE MANUEL POUR LA FUTURE RÉFÉRENCE

Employer n’importe quelle partie autre que les pièces fournies

par usine véritable de Star soulage le fabricant de toute la

responsabilité.

Star se réserve le droit de changer des caractéristiques et la

conception de produits sans communication préalable. De

telles révisions ne ont pas droit l’acheteur aux changements,

aux améliorations, aux additions ou aux remplacements

correspondants pour l’équipement précédemment acheté.

NOTIFICATION

NOTIFICATION

ENTRETIEN ET RÉPARATIONS

Entrez en contact avec votre agent autorisé local de service pour le service ou l'entretien requis.

Référez-vous à la liste autorisée de centre commercial équipée d'unité. Le service SVP de service de

Star (1-800-807-9054) disponible pendant des heures de travail normales pour répondre à toutes les

questions qui peuvent se poser. Veuillez avoir votre numéro et numéro de série de type pour un service

plus rapide.

2

Page 36

®

FOUR

de CONVOYEUR

ÉLECTRIQUE

230V MODÈLES

8B-UM1833

8B-UM1850

Instructions

d’installation

8B-UM1850

et d’opération

2M-Z6701 Rev D 3/23/06

Loading...

Loading...