Star TVD30, TVD Thermal Vection Series, TVD50 Installation And Operation Instructions Manual

Page 1

THERMAL VECTION

IL2263

Heat and Hold Drawer

MODEL

TVD30, TVD50

Installation and

Operation

Instructions

2M-Z14279 Rev. A 7/16/13

Page 2

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

Page 3

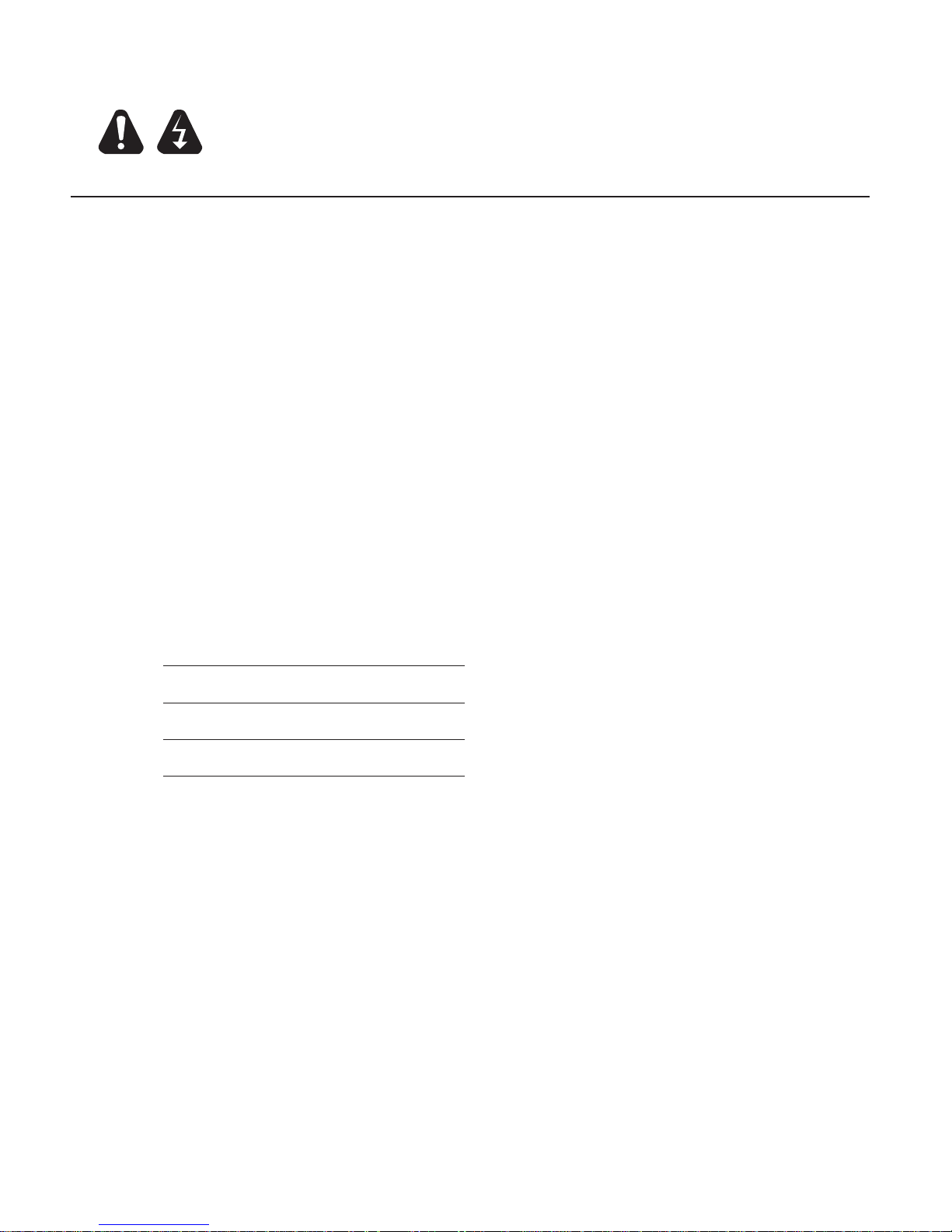

Width

Depth

Height

IL2186

SPECIFICATIONS

Electrical Specications

Model Voltage Watts Amps Cord

TD30

TD50 1370 11.4A

TD30 24"

TD50 36"

120V

Dimensions

Width Depth Height

700 5.8A

29.75" 6.25"

NEMA 5-15P

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

CAUTION

general public in food service locations.

VOLTAGE

The thermal vection is equipped for use on the voltage specied on the nameplate.

DO NOT CONNECT TO ANY OTHER TYPE OF CURRENT OR THE MACHINE

WILL BE SERIOUSLY DAMAGED.

WARNING

3

Page 4

OPERATION

START-UP

When the unit is rst turned on it will begin the PRE-HEAT mode. The current hold temperature will

be displayed for 3 seconds, then “PHT” (PREHEAT) will ash along with the “HEAT ON” lamp until

the unit has reached its preset hold temperature. When this has been reached, the audible alarm will

beep 3 times, the “HEAT ON” lamp will stop ashing and the display will read “RDY”.

COOKING

Load the unit with the product, (thawed not frozen) Press the “COOK” button to begin. The “COOK”

light will remain on and the Temp light will be on as the unit call for heat. “COOK” will display for 3

seconds, and then the internal cook timer will begin counting down.

Close the drawer.

When the timer reaches 00:00, the audible alarm will beep 3 times.

Then you have two options:

1.

Remove the product immediately from the Thermal Vection and place in on your preheated

roller grill for display, then press the “RESET” button. This will take the temperature back to the

PRE-HEAT mode temperature, until you are ready to cook again.

2.

Leave the product in the Thermal Vection until you are ready to serve, the unit will maintain the

HOLD temperature and an internal timer will begin to count down, after 3 hours an audible alarm

will sound for 3 seconds and the display will ash “DoNE” until the RESET button is pressed. At

this time the remaining product left in the unit has expired and needs to be discarded.

READING TEMPERATURE

At any point the operator can view the actual temperature by pressing the “TEMP” button. The

reading will be displayed in the temperature mode (°F or °C) which is programmed.

PROGRAMMING THE TEMPERATURE MODE

The temperature mode can be changed from °F to °C or °C to °F by pressing and holding the “TEMP”

button while turning on the main power switch. The set-point temperature that is displayed will be in

the changed temperature mode.

PROGRAMMING HOLD / PREHEAT TEMPERATURE MODE ( F / C)

The HOLD / PREHEAT temperature and hold time can be programmed using the following steps.

The default HOLD temp and TIME are 140°F (60°C) for 3 hours.

1. Simultaneously press and hold the “TEMP” and “HOLD” buttons for approx 3 seconds.

2. The display will show “----“

3. Release the buttons.

4. Enter the 4 digit security code. (4,3,2,1)

5. Once completed, the current hold / preheat temperature will be displayed.

6. To increase or decrease the temperature use the “UP” or “DOWN” arrows.

7. Press the “TEMP” button to save the change.

8. The current time duration for the HOLD mode is now displayed.

9. Use the “UP” or “DOWN” arrows to increase or decrease the HOLD time.

10. Press the “TEMP” button to save the new HOLD time.

11. Press the “TEMP” button again to exit the programming mode.

4

Page 5

PROGRAMMING THE COOK TEMPERATURE MODE

IL2139

TIME / TEMP

ON

HEAT

ON

TEMP

HOLD COOK

RESET

OFF

The cook temperature and time can be programmed with the following steps.

The unit comes from the factory set at 325°F (163°C) for 30 minutes.

1. Simultaneously press and hold the “TEMP” and “COOK” buttons for approx 3 seconds.

2. The display will show “----“

3. Release the buttons.

4. Enter the 4 digit security code. (4,3,2,1)

5. Once completed, the current COOK temperature will be displayed.

6. To increase or decrease the temperature use the “UP” or “DOWN” arrows.

7. Press the “TEMP” button to save the change.

8. The current time duration for the COOK mode is now displayed.

9. Use the “UP” or “DOWN” arrows to increase or decrease the COOK time.

10. Press the “TEMP” button to save the new COOK time.

11. Press the “TEMP” button again to exit the programming mode.

CLEANING

Clean the pans & covers with mild soap and water after each use. Wipe the exterior with damp cloth and

mild detergent daily.

For retaining the high luster on the stainless steel, use a non-abrasive standard stainless steel cleaner.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative, or a local service company for service or required

maintenance.

5

Page 6

2M-4497-2 10/2010

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

Visit our Website at: www.star-mfg.com Email: service@star-mfg.com

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in

which the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the

transportation company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of

the unit.

LIMITED EQUIPMENT WARRANTY

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is ve (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners, abrasive pads, product identiers and

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted. Labor to replace the part is chargeable to

the customer.

SERVICES NOT COVERED BY WARRANTY

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16. Replacement of bulbs

17. Replacement of fuses

18. Repair of damage created during transit, delivery, &

installation OR created by acts of God

* The Model 510FD Fryer.

* The Model 526TOA Toaster Oven.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model 518CMA & 526CMA Cheese Melter.

* The Model 12MC & 15MC & 18MCP Hot Food Merchandisers.

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* All QCS/RCS Series Toasters except Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

6

Page 7

STAR MANUFACTURING INTERNATIONAL INC.

SK2469 Rev A 1/13/2011

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL

TO STAR MFG. INT'L. INC. NO REPRODUCTION OR

DISCLOSURE OF ITS CONTENTS IS PERMITTED.

E11

E12E1E2

E3 E4

E7 E6 E5

1

5-15P-PLUG

BLACK

WHITE

GREEN

2

3

4

4

10

4

8

9

SENSOR

FAN

RELAY

TERMINAL

TRANSFORMER

SWITCH

CONTROL

BLOCK

BOARD

PROBE

5

6 7

11

11

12

12

HEATING

ELEMENT #1

HEATING

ELEMENT #2

FOR MODEL TVD-50

** FOR MODEL TVD-30, SAME AS MODEL TVD-50

EXCEPT REMOVE ELEMENT #2 & RELATED

WIRE #11 AND #12 FROM WIRE DIAGRAM.

FOR MODEL

TVD-30

WIRE DIAGRAM, 120V

7

Page 8

STAR MANUFACTURING INTERNATIONAL, INC.

Rev. - 5/25/11SK2514

MODEL: TVD THERMAL VECTOR

MAIN BREAKDOWN

See Detail B

See Detail A

1

2

3

7 864 5

9

10

5

11

12

13

14

18

18

17

16

15

16

15

8

Page 9

PARTS LIST July 16, 2013, Rev. A

Model: TVD THERMAL VECTION

Fig No. Part Number Quantity Description Application

1

2 2C-6349 23 SCREW #8X3/8 B THP STL NP ALL

3

4 2E-05-07-0351 1 TRANSFORMER 115/10V 6VA ALL

5 2C-Z2594 10 NUT 6-32 HEX W STL NP ALL

6 2E-05-07-0352 1 RELAY 30 AMP ALL

7 2E-Z2894 1 TERMINAL BLOCK (304) ALL

8 2K-76118 1 STRAIN RELIEF STR HEYCO 1 ALL

9 2A-Z11501 4 FOOT 1" SOLID RUBBER ALL

10 2E-Z1470 1 SENSOR-RTD 2000 OHM ALL

11 2K-08-07-0004 4 SPACER ROUND NYLON ALL

12 2J-Z13971 1 CONTROL BOARD-SINGLE-TVD ALL

13 2K-Z1971 4 SPACER .257X.75X.25 NYLON ALL

14 2E-Z1858 1 SWITCH-LIGHTED ALL

15 2R-Z14033 1 SLIDES-DWR-650MM-HI TEMP (SET) ALL

16 2C-Z14859 8 SCREW-8-32X1 PH #100FL SS ALL

17 2C-34285 10 SCREW 8-32X3/8 PH 100 FL ALL

18 2N-Z14538

NI A4-TVD022 1 INSULATION SET-TVD30 TVD30-120

NI A4-TVD018 1 INSULATION SET-TVD50 TVD50-120

NI A4-Z14679 1 CORD SET-120V-15A-RING TR ALL

A4-TVD016

A4-TVD015 TVD50-120

A4-Z14869

A4-Z14038 INSULATION, TOP-TVD50 TVD50-120

1 ASM-BODY COVER

1

1

2 TVD50-120

INSULATION, TOP-TVD30 TVD30-120

ELEMENT-675W-120V-10X18

TVD30-120

TVD30-120

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

9

Page 10

STAR MANUFACTURING INTERNATIONAL, INC.

Rev. - 5/25/11SK2515

MODEL: TVD THERMAL VECTOR

DETAIL BREAKDOWN

Detail A

Detail B

1

2

3

14

15

16

17 18

3

19

23

7

20

21

22

7

7

1213

9

11

10

8

4

5

6

10

Page 11

PARTS LIST July 16, 2013, Rev. A

Model: TVD DETAIL A & B PARTS LIST

Fig No Part No Qty Description Application

1 2C-Z14559

A4-Z14871 1 INSULATION-REAR-TVD30 RT

2

A4-Z14872 1 INSULATION-REAR-TVD30 LT

A4-Z14040 2 INSULATION-REAR-TVD50 TVD50-120

3 2C-Z3447 19 NUT 8-32 HEX W SS ALL

4 2U-Z14624 1 MOTOR,FAN-HI TEMP-120V ALL

5 2C-Z14859 3 SCREW-8-32X1 PH #100FL SS ALL

2H-Z14868

6

2H-Z14413 TVD50-120

7 2C-Z2893 30 NUT 10-24 HEX STL ZP ALL

A4-Z14867

8

A4-Z14412 TVD50-120

9 2R-Z14035 1 FAN BLADE, 3” CCW, 90 DEG ALL

10

11 2C-Z14640 1 NUT-M6X1-LH THREADS-SS ALL

12 A4-Z14423 1 COVER, FAN-TVD50 ALL

13 2C-Z10133 2 NUT, WING 10-24 ALL

14 A4-Z14425

15

16

17

18 2R-Z14033 1 SLIDES-DWR-650MM-HI TEMP (SET) ALL

19 2C-34285 10 SCREW 8-32X3/8 PH 100 FL ALL

20

21

22

23 2C-200067

2C-1811 2 WASHER 1/4 BURR STL NP

2C-08-07-0262 1 WASHER, SS 1/4 INT-LOCK

2B-Z14927

2B-Z16724 FALSE BTM-FULL PAN-WIRE TVD50-120

2D-Z14928

2D-Z14047 PAN,FULL X 1.5” DEEP TVD50-120

A4-Z14416

A4-Z14415 DRAWER FRAME-TVD50 TVD50-120

A4-TVD012

A4-TVD011 ASM-DRAWER LINER-TVD50 TVD50-120

A4-TVD014

A4-TVD013 TVD50-120

2M-Z14414

2M-Z13862 OVERLAY-DWR FRNT-TVD50 TVD50-120

8

10 TVD50-120

1 INSULATION, MOTOR-MICA

2 PLATE-MOTOR MOUNTING

1

2 TVD50-120

2

2

1

1

1 ASM-DRAWER FRONT

1

6

8 TVD50-120

WASHER-INSULATION 4MM HLE

LID-SERVING PAN-FULL SIZE

FALSE BTM-HALF PAN-WIRE TVD30-120

PAN, HALF X 1.5” DEEP TVD30-120

DRAWER FRAME-TVD30 TVD30-120

ASM-DRAWER LINER-TVD30 TVD30-120

OVERLAY-DWR FRNT-TVD30 TVD30-120

SCREW 6-32X1/4 THP SS

TVD30-120

TVD30-120

TVD30-120

TVD30-120

ALL

TVD30-120

TVD30-120

TVD30-120

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

11

Page 12

STAR INTERNATIONAL HOLDINGS INC. COMPANY

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303

www.star-mfg.com

Loading...

Loading...