Page 1

THERMAL PRINTER

TSP400

INSTALLATION MANUAL

GUIDE D’INSTALLATION

AUFSTELLANLEITUNG

MANUALE DI INSTALLAZIONE

Page 2

Page 3

TABLE OF CONTENTS

1. UNPACKING AND INSPECTION......................................................1

1-1. Unpacking ....................................................................................1

1-2. Handling Notes ............................................................................1

2. PARTS IDENTIFICATION AND NOMENCLATURE ......................2

3. FERRITE CORE INSTALLATION

*EUROPE ONLY ..................................3

Installation of the interface cable ferrite core......................................4

Installation of the peripheral unit cable ferrite core ............................4

4. CONNECTING THE INTERFACE CABLE ....................................... 5

4-1. RS-232C or RS-422A Serial interface .........................................5

4-2. Centronics-type Parallel interface............................................... 5

APPENDIX .............................................................................................24

Page 4

– 1 –

ENGLISH

1. UNPACKING AND INSPECTION

1-1. Unpacking

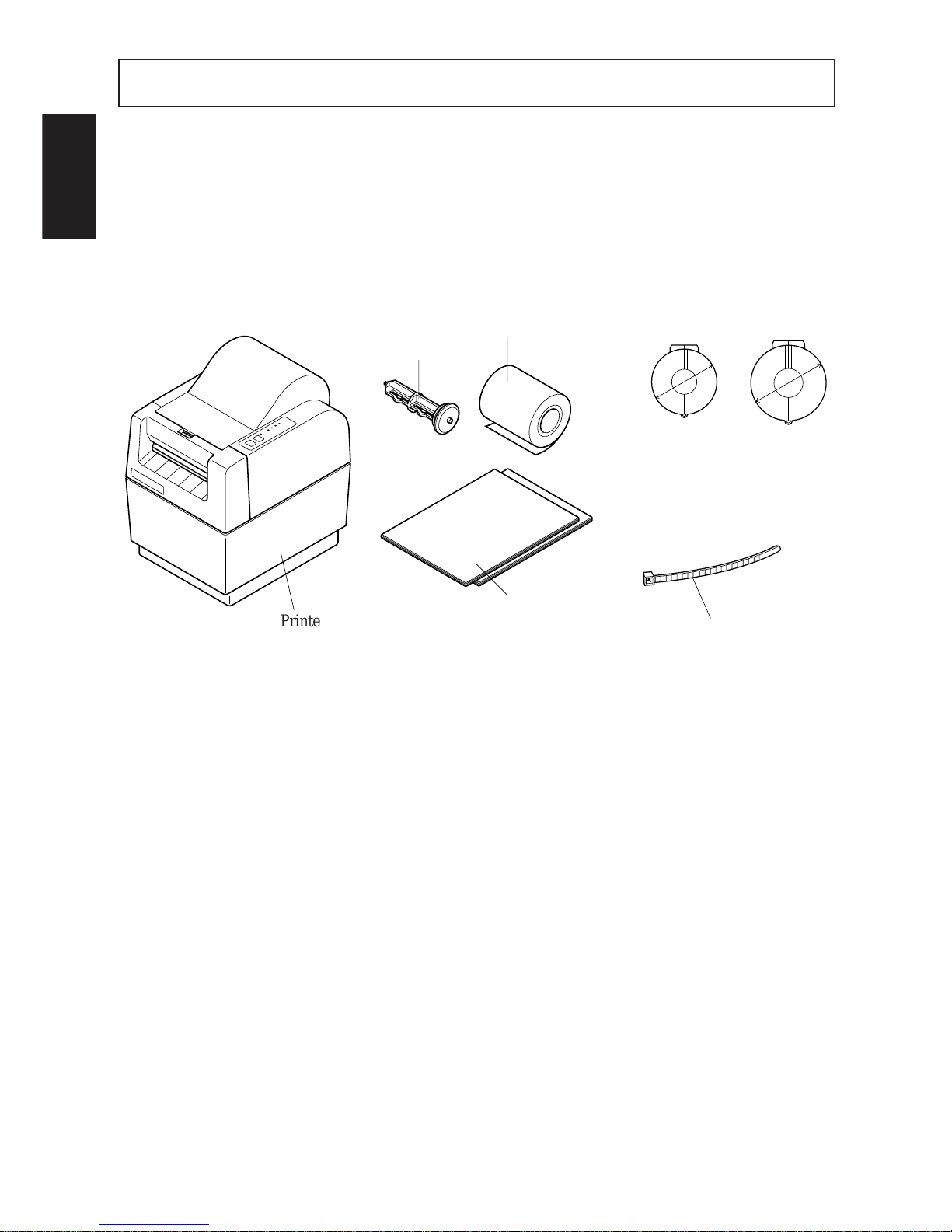

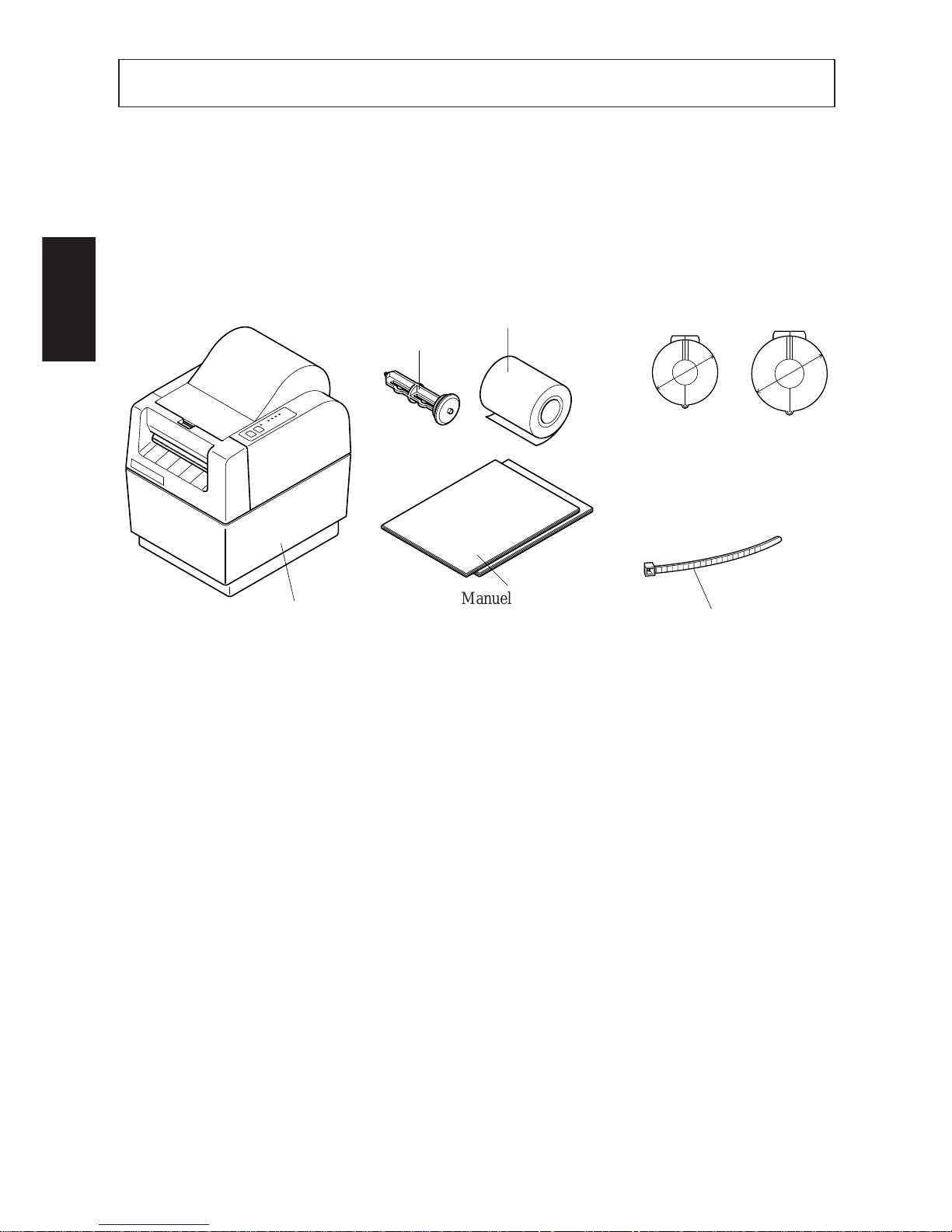

Check each item in the box against Figure 1-1 to make sure that you have

everything (there should be five items).

If any of these items are missing, contact your supplier.

Fig. 1-1

1-2. Handling Notes

Before you start setting up your printer, make sure that you have a suitable place

in which to locate it. By “a suitable place”, we mean:

• Close to an easily accessible socket-outlet.

• A firm, level surface which is fairly vibration-free

• Away from excessive heat (such as direct sunlight, heaters, etc)

• Away from excessive humidity

• Away from excessive dust

• With access to a steady power supply that is not subject to power surges. For

example, do not connect the printer to the same circuit as a large, noiseproducing appliance such as a refrigerator or an air conditioner.

NOTE: Make sure that the line voltage is the voltage specified on the printer’s

identification plate.

Ø24mm

Ø28mm

Printer

Paper-roll shaft

Sample paper roll

User’s manual

Installation Manual

fastener

(E.U. only)

Ferrite core for

interface cable

(E.U. only)

Ferrite core

for peripheral

unit cable

(E.U. only)

Page 5

– 2 –

ENGLISH

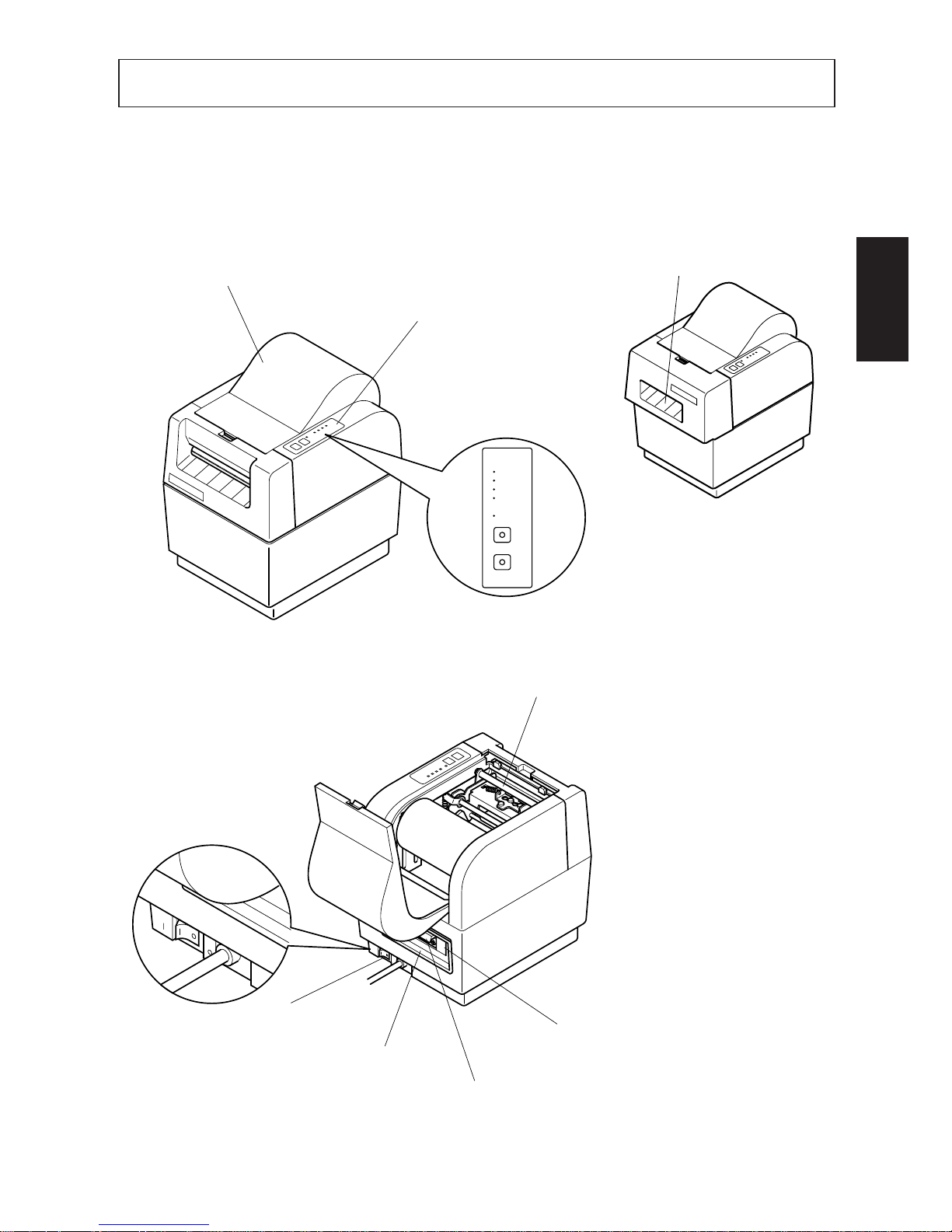

2. PARTS IDENTIFICATION AND NOMENCLATURE

To get acquainted with the printer’s components and capabilities, refer to

Figure 2-1.

Fig. 2-1

Printer cover

Protects the print head and

other internal components of

your printer.

Control panel

Indicates printer status

and makes control of

printer functions simple

and convenient.

Automatic paper cutter

(Controlled by command)

(TSP442)

POWER

HEAD UP

NO PAPER

ERROR

ON LINE

FEED

O

N

O

FF

ON

OFF

Power switch

Switches power on or off.

Connector cover

Interface connector

Connects the computer to the printer.

Peripheral drive connector

Only connects to peripheral units

such as each drawers, etc.

Release bar

Opens and closes the print head unit which holds

the paper against the platen.

(TSP412)

Page 6

– 3 –

ENGLISH

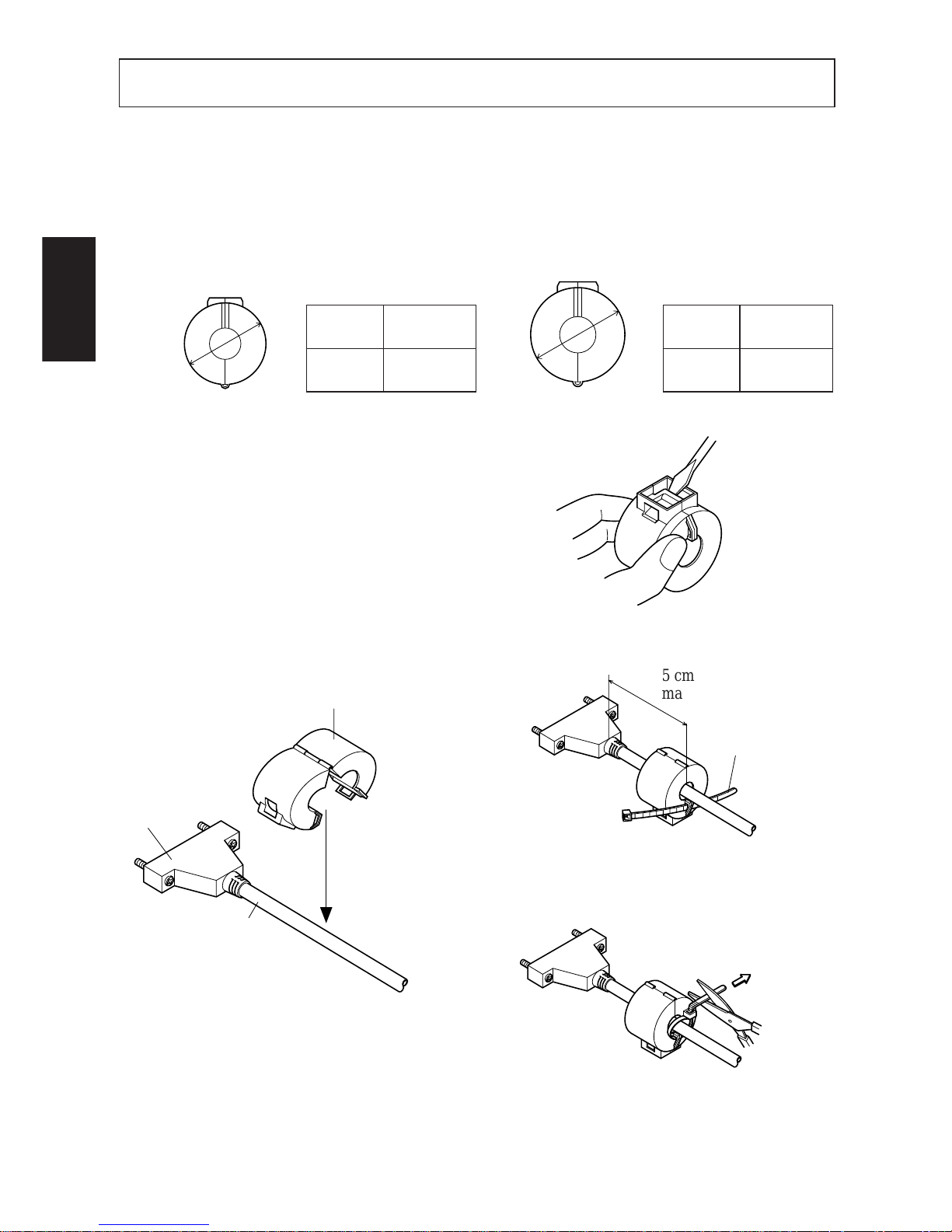

3. FERRITE CORE INSTALLATION *EUROPE ONLY

NOTE: Take special care when following the procedures listed below.

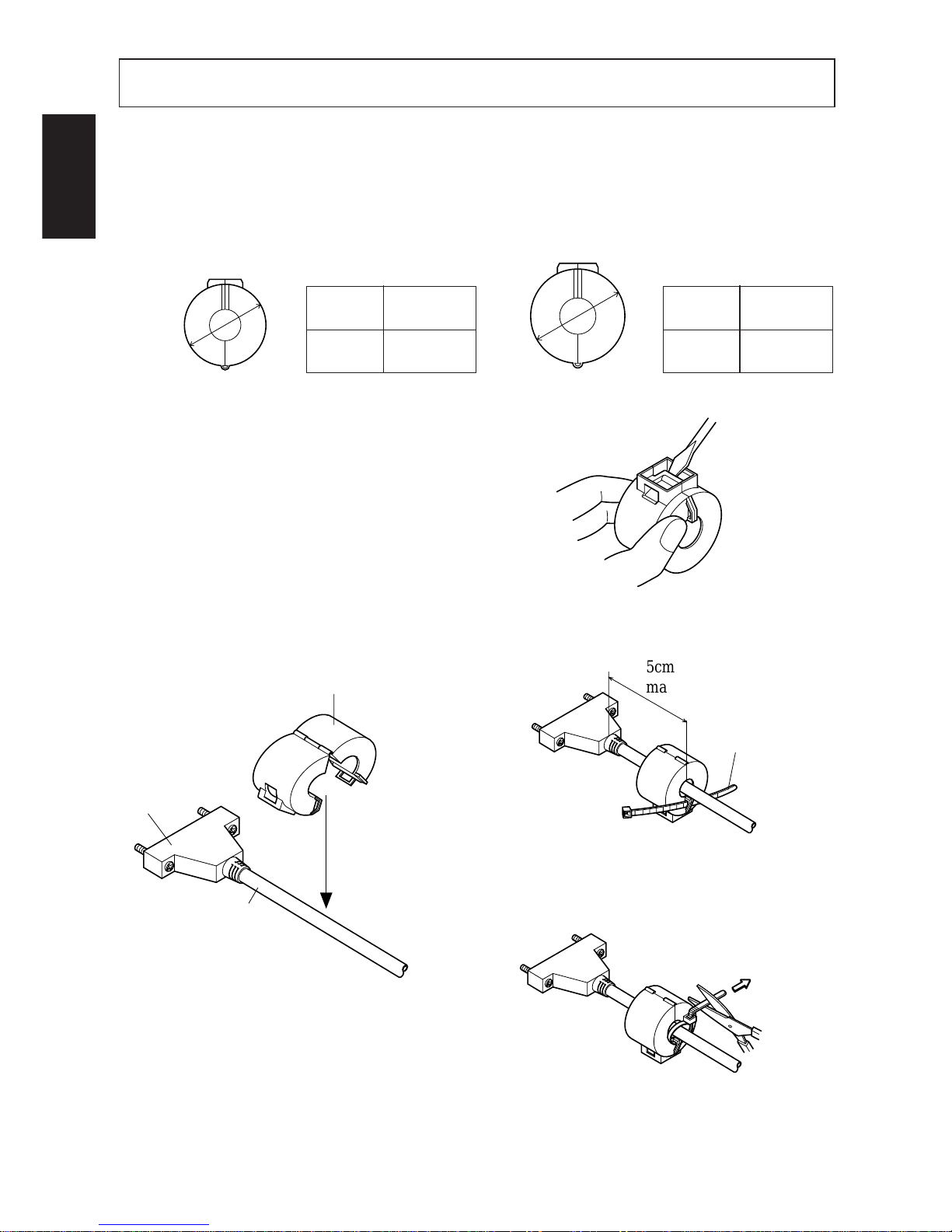

■ Two ferrite core noise filters, large and small, come packed with the printer.

The small noise filter is for the RS232C serial interface cable, while the larger

one is for the cable of peripheral units.

Fig. 3-4

Fig. 3-3

Fig. 3-1

Pass fastener through ferrite core.

Pass fastener around cable and lock it.

Cut off excess with scissors.

Product

Code

Model

Name

09990723

Ferrite Core

TFC-23-11-14

Product

Code

Model

Name

09990728

Ferrite Core

TFC-20-10-10

For Interface Cable For Peripheral Unit Cable

Ø28mm

Ø24mm

■ The ferrite cores are packed so they

are open, as shown in Fig. 3-2. If you

find that a ferrite core is not open, use

a pointed object to pry the plastic lock

of the ferrite core apart (Fig. 3-1).

When you do, take care not to damage

the ferrite core or the plastic lock.

5cm

maximum

Fastener

Pull and cut

Small ferrite Core(24mm diameter)

Interface

Cable

Fig. 3-2

Page 7

– 4 –

ENGLISH

Installation of the interface cable ferrite core

■ Clamp the small ferrite core onto the interface cable as shown in Fig. 3-2. Take

care to avoid damaging the interface cable when installing the ferrite core. The

ferrite core should be anchored firmly in place with the fastener that comes

with it, as shown in Fig.3-3 and 3-4.

Installation of the peripheral unit cable ferrite core

■ Clamp the large ferrite core onto the cable of the interface unit using the same

procedure as you do for the interface cable ferrite core. With the peripheral unit

cable ferrite core, however, you have to loop the cable as shown in Fig. 3-5.

Fig. 3-5

Ground wire

One loop

Large ferrite core

(28mm diameter)

5cm or less

Page 8

– 5 –

ENGLISH

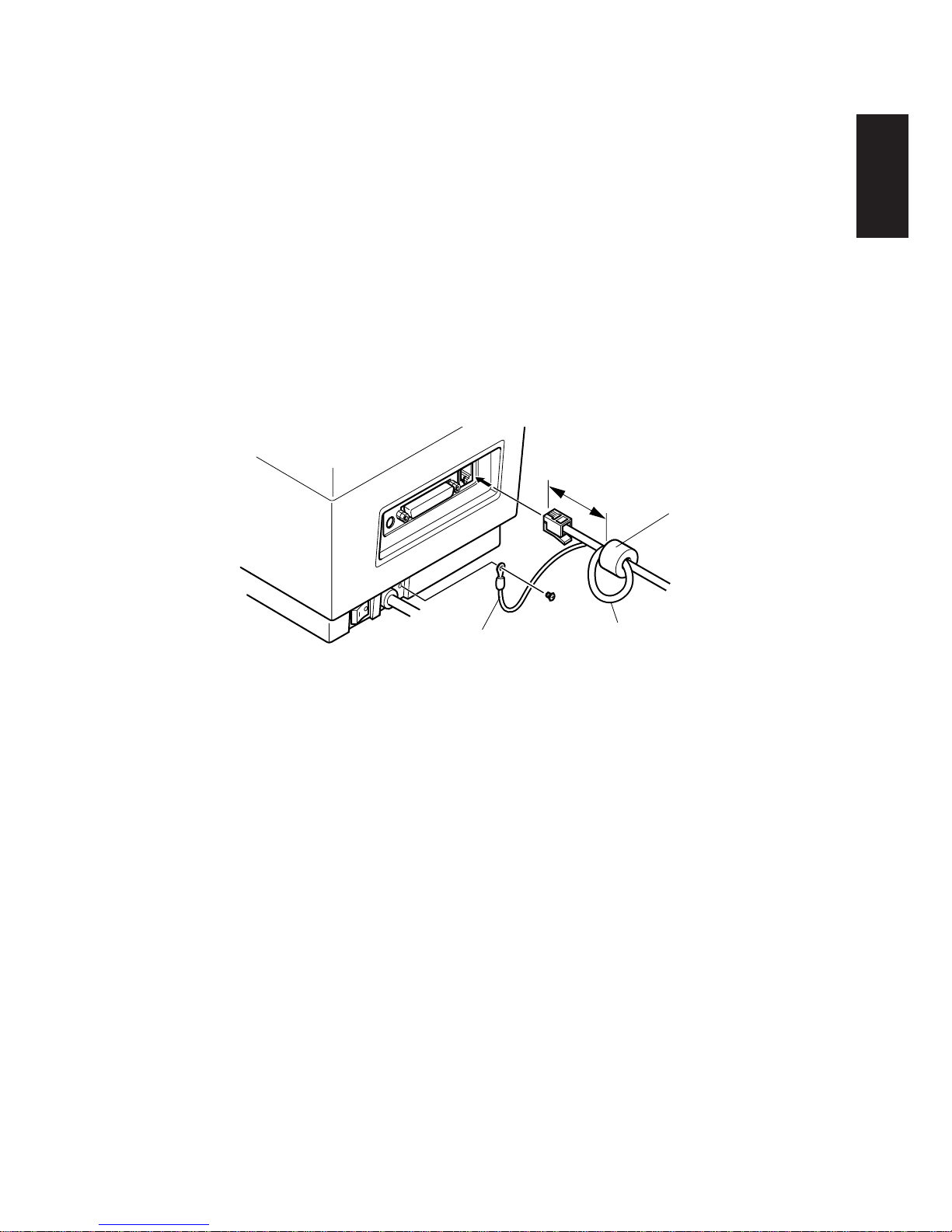

4. CONNECTING THE INTERFACE CABLE

4-1. RS-232C or RS-422A Serial interface

Follow the procedures below to connect the interface cable:

Fig. 4-1

1 Switch off the power to the printer

and computer.

2 Insert the interface cable into the

connector. (Be sure that the cable is

oriented correctly before inserting

it.)

3 Fasten the right and left screws to

fix them in place on the connector.

4 Connect the other end of the inter-

face cable to your computer.

Interface cable

Interface connector

NOTE: The data transfer conditions between the computer and the printer must

be made compatible with the DIP switch settings on the printer. (Refer

to “APPENDIX”.)

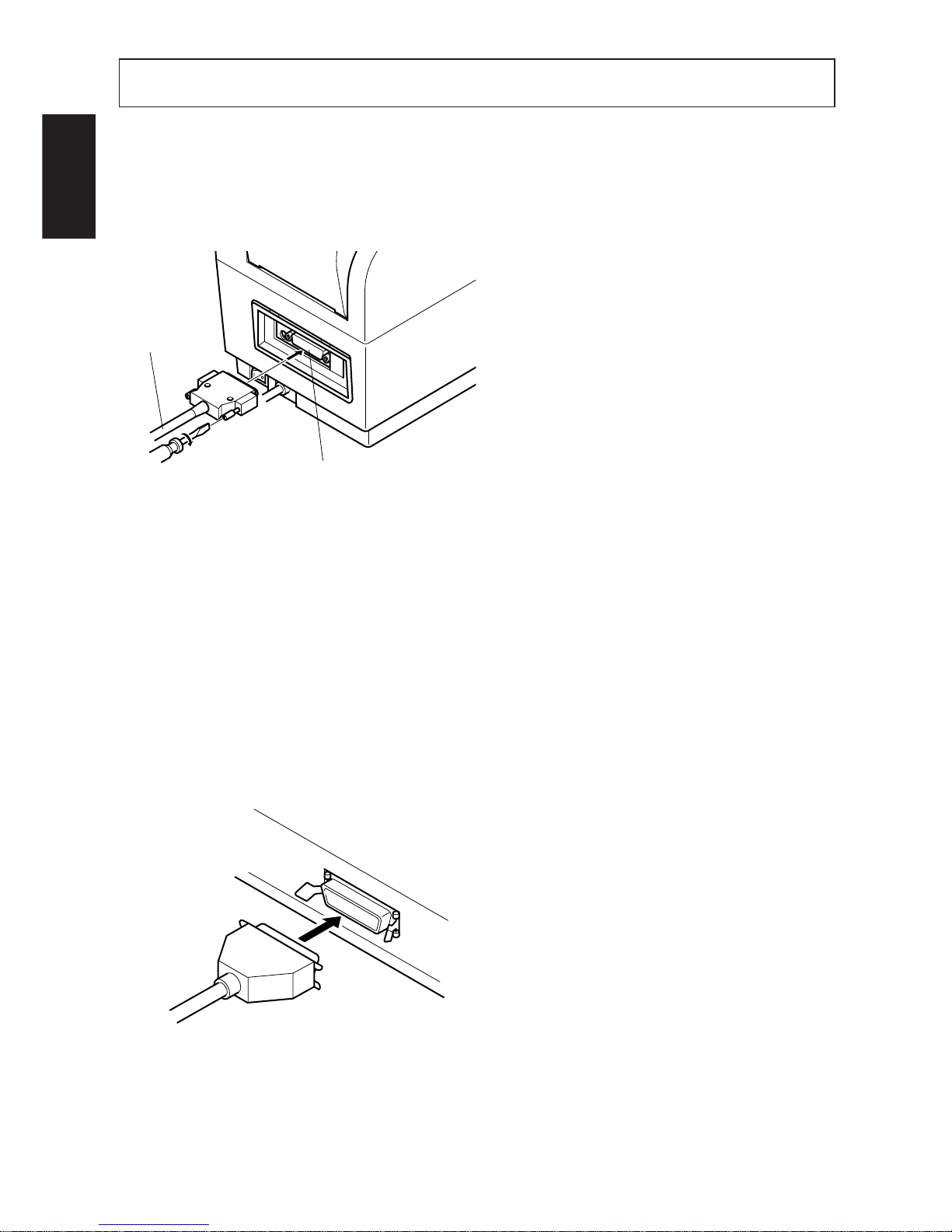

4-2. Centronics-type Parallel interface

1 Switch off the power to the printer

and computer.

2 Insert the interface cable into the

connector. (Be sure that the cable is

oriented correctly before inserting

it.)

3 Fasten the connector clasps.

4 Connect the other end of the inter-

face cable to your computer.

Fig. 4-2

Page 9

TABLE DES MATIERES

1. DEBALLAGE ET INSPECTION.......................................................7

1-1. Déballage .....................................................................................7

1-2. Remarques sur la manipulation....................................................7

2. IDENTIFICATION DES PIECES ET NOMENCLATURE ...............8

3. INSTALLATION DU TORE DE FERRITE

*EUROPE UNIQUEMENT ......9

Installation du tore de ferrite de câble d’interface.............................10

Installation du tore de ferrite de câble de périphérique .....................10

4. RACCORDEMENT DU CÂBLE D’INTERFACE ...........................11

4-1. Interface série RS-232C ou RS-422A........................................11

4-2. Interface parallèle type Centronics ............................................11

APPENDICE ...........................................................................................24

L’appendice n’est pas traduit.

Page 10

– 7 –

FRANÇAIS

1. DEBALLAGE ET INSPECTION

1-1. Déballage

Vérifier chaque pièce de la boîte en se référant à la Figure 1 afin de s’assurer qu’on

a bien tout reçu (il doit y avoir cinq pièces).

En cas d’absence d’une de ces pièces, contacter le fournisseur.

Fig. 1-1

1-2. Remarques sur la manipulation

Avant de commencer l’installation de l’imprimante, s’assurer qu’on dispose bien

d’un endroit approprié pour la mettre. Un “endroit approprié” doit satisfaire aux

conditions suivantes:

• A proximité d’une prise d’accès facile

• Surface ferme et à niveau pratiquement sans aucunes vibrations

• A distance de toute chaleur excessive (par exemple lumière du soleil directe,

radiateurs etc.)

• A distance de toute humidité excessive

• A distance de poussière excessive

• Accès à une source d’alimentation constante ne subissant pas de pointes

d’alimentation. Ainsi, par exemple, il ne faut pas relier l’imprimante au même

circuit qu’un appareil important bruyant du genre réfrigérateur ou climatiseur.

REMARQUE: S’assurer que la tension de ligne correspond à la tension indiquée

sur la plaque signalétique de l’imprimante.

Ø24mm

Ø28mm

Manuel d’utilisation

Manuel d’installation

Attache

(Europe uniquement)

Tore de ferrite de

câble d’interface

(Europe

uniquement)

Tore de ferrite

de câble de

périphérique

(Europe

uniquement)

Rouleau de papier échantillon

Arbre du rouleau

de papier

Imprimante

Page 11

– 8 –

FRANÇAIS

Automatic paper cutter

(Controlled by command)

(TSP442)

2. IDENTIFICATION DES PIECES ET NOMENCLATURE

Se référer à la Figure 2-1 pour se familiariser avec les composants et capacités de

l’imprimante.

Fig. 2-1

O

N

O

FF

ON

OFF

Couvercle du connecteur

Connecteur d’interface

Relie l’ordinateur à l’imprimante

Barre de déclenchement

Ouvre et ferme la tête d’impression qui retient le

papier contre le cylindre.

Couvercle d’imprimante

Protège la tête d’impression ainsi

que d’autres composants internes

de l’imprimante.

POWER

HEAD UP

NO PAPER

ERROR

ON LINE

FEED

(TSP412)

Couteau de papier

automatique

(pilotage par commande)

Tableau de commande

Indique l’état de l’imprimante et

simplifie les fonctions de

commande de l’imprimante tout en

facilitant leur exécution.

Interrupteur d’alimentation

Connecte ou coupe l’alimentation

Connecteur d’entraînement de

périphérique

Connexion uniquement à des

périphériques du genre caisses

enregistreuses etc.

Page 12

– 9 –

FRANÇAIS

3. INST ALLATION DU TORE DE FERRITE *EUROPE UNIQUEMENT

REMARQUE:Prendre des précautions spéciales en suivant les procédures

indiquées ci-dessous:

■ Deux filtres antibruit à tore de ferrite, un grand et un petit sont emballés avec

l’imprimante. Le petit filtre antibruit est prévu pour le câble d’interface série

RS232C et le grand doit être utilisé pour le câble de périphérique.

Fig. 3-4

Faire passer l’attache autour du câble et

la bloquer. Couper toute partie qui dépasse avec des ciseaux.

Pull and cut

Tirer et couper

■ Les tores de ferrite sont livrés ouverts

comme indiqué à la Fig. 3-2. Si un tore

de ferrite n’est pas ouvert, utiliser un

objet pointu pour forcer le verrouillage

en plastique du tore de ferrite (Fig.

3.1). Lorsque c’est le cas, prendre

soin de ne pas endommager le tore de

ferrite ni le verrouillage en plastique.

Fig. 3-1

Code du

produit

Nom du

modèle

09990723

Tore de ferrite

TFC-23-11-14

Code du

produit

Nom du

modèle

09990728

Tore de ferrite

TFC-20-10-10

Pour le câble d’interface Pour le câble de périphérique

Ø28mm

Ø24mm

Small ferrite Core(24mm diameter)

Interface

Cable

Fig. 3-2

Petit tore de ferrite (diamètre 24 mm)

Interface

Câble

Faire passer l’attache par le tore de ferrite

5cm

maximum

Fastener

5 cm

maximum

Attache

Fig. 3-3

Page 13

– 10 –

FRANÇAIS

Installation du tore de ferrite de câble d’interface

■ Serrer le petit tore de ferrite au câble d’interface de la manière indiquée à la Fig.

3-2. Prendre les précautions d’usage pour éviter d’endommager le câble

d’interface lors de l’installation du tore de ferrite. Il faut bien immobiliser le

tore de ferrite au moyen de l’attache fournie, comme indiqué à la Fig. 3-3 et à

la Fig. 3-4.

Installation du tore de ferrite de câble de périphérique

■ Serrer le grand tore de ferrite au câble d’interface en suivant la même procédure

que celle du tore de ferrite du câble d’interface. Dans le cas du tore de ferrite

du câble de périphérique, il faut toutefois faire une boucle avec le câble de la

manière indiquée à la Fig. 3-5.

Fig. 3-5

Ground wire

One loop

Large ferrite core

(28mm diameter)

5cm or less

5 cm ou moins

Grand tore de ferrite

(diamètre 28 mm)

Fil à la terre

Une seule boucle

Page 14

– 11 –

FRANÇAIS

4. Raccordement du câble d’interface

4-1. Interface série RS-232C ou RS-422A

Suivre les procédures indiquées ci-dessous pour relier le câble d’interface

Fig. 4-1

1 Couper l’alimentation à l’impri-

mante et à l’ordinateur.

2 Insérer le câble d’interface dans le

connecteur. (S’assurer que le câble

est orienté correctement avant de

l’insérer).

3 Serrer les vis droite et gauche pour

les immobiliser sur le connecteur.

4 Relier l’autre extrémité du câble

d’interface à l’ordinateur.

Interface cable

Interface connector

REMARQUE:Rendre compatibles les conditions de transfert de données entre

l’ordinateur et l’imprimante en réglant les microrupteurs de

l’imprimante en conséquence. (Se référer à “ANNEXE”).

4-2. Interface parallèle type Centronics

1 Couper l’alimentation à l’impri-

mante et à l’ordinateur.

2 Insérer le câble d’interface dans le

connecteur. (S’assurer que le câble

est orienté correctement avant de

l’insérer).

3 Fermer les attaches du connecteur.

4 Relier l’autre extrémité du câble

d’interface à l’ordinateur.

Câble d’interface

Connecteur d’interface

Fig. 4-2

Page 15

INHALTSVERZEICHNIS

1. AUSPACKEN UND KONTROLLE ................................................13

1-1. Auspacken..................................................................................13

1-2. Hinweise.....................................................................................13

2.

FUNKTION UND BEZEICHNUNG DER EINZELNEN BAUTEILE ..

14

3. INSTALLATION DER FERRITKERNE

*NUR EUROPA ..................... 15

Installation des Ferritkerns für das Schnittstellenkabel.....................16

Installation des Ferritkerns für das Peripheriegerätekabel ................16

4. ANSCHLUSS DES SCHNITTSTELLENKABELS ........................17

4-1. Serielle Schnittstellen RS-232C oder RS-422A.........................17

4-2. Parallele Centronics-Schnittstelle ..............................................17

ANHANG................................................................................................24

Der Anhang erscheint nur im englischen Teil dieser Bedienungsanleitung

Page 16

– 13 –

DEUTSCH

1. AUSPACKEN UND KONTROLLE

1-1. Auspacken

Überprüfen Sie an Hand von Abbildung 1 die Teile in der Verpackung, und stellen

Sie sicher, daß alle nötigen Positionen geliefert wurden; es sollten fünf sein.

Falls eines der Teile fehlen sollte, wenden Sie sich bitte an Ihren Händler.

Abb. 1-1

1-2. Hinweise

Wählen Sie für die Aufstellung Ihres Druckers zunächst einen geeigneten Platz

aus. Er sollte folgende Merkmale aufweisen:

• Er sollte nahe einer leicht zugänglichen Netzsteckdose sein.

• Er sollte eine stabile, ebene und erschütterungsfreie Oberfläche haben.

• Er sollte nicht übermäßiger Hitze ausgesetzt sein (wie direktem Sonnenlicht,

einer Heizung usw.).

• In der Druckerumgebung sollte keine übermäßige Luftfeuchtigkeit herrschen.

• Sie sollte nicht übermäßig staubig sein.

• Die Stromversorgung sollte stabil und nicht anfällig für Störungen sein. Sie

sollten den Drucker zum Beispiel nicht an einem Stromkreis zusammen mit

großen, eventuell Störungen verursachenden Geräten wie Kühlschrank oder

Klimaanlage betreiben.

HINWEIS: Stellen Sie sicher, daß die Spannung Ihres Stromnetzes der Betriebs-

spannung entspricht, die auf dem Typenschild des Druckers angegeben ist.

Bedienungsanleitung

Aufstellanleitung

Kabelbinder

(nur EU)

Ferritkern für das

Schnittstellenkabel

(nur EU)

Ferritkern für

Peripheriege–

rätekabel

(nur EU)

Papierrolle

Drucker

Achse für die

Papierrolle

Ø24mm

Ø28mm

Page 17

– 14 –

DEUTSCH

2. FUNKTION UND BEZEICHNUNG DER EINZELNEN BAUTEILE

Machen Sie sich in Abbildung 2-1 mit den Bestandteilen des Druckers und seinen

Funktionen vertraut.

Abb. 2-1

Entriegelungshebel

Mit ihm wird die Druckkopfeinheit entlastet und

angepreßt, mit der das Papier an die Walze gedrückt wird.

Druckerklappe

Sie schützt den Druckkopf und

andere Bauteile im Inneres Ihres

Druckers.

Automatic paper cutter

(Controlled by command)

(TSP442)

POWER

HEAD UP

NO PAPER

ERROR

ON LINE

FEED

(TSP412)

Automatischer

Papierschneider

(befehlsgesteuert)

Bedienfeld

Es zeigt den Druckerstatus an, und

mit ihm lassen sich die

Druckerfunktionen bequem und

einfach steuern.

O

N

O

FF

ON

OFF

Buchse für Peripheriegeräte

Sie dient zum Anschluß von

Peripheriegeräten wie etwa Geldladen,

etc.

Schnittstellenbuchse

An ihr wird der Computer an den Drucker

angeschlossen.

Abdeckung für die

Schnittstellenbuchse

Netzschalter

Mit ihm wird das Gerät an- und

ausgeschaltet.

Page 18

– 15 –

DEUTSCH

5cm

maximum

Fastener

3. INSTALLATION DER FERRITKERNE *NUR EUROPA

HINWEIS: Beachten Sie die folgenden Schritte besonders sorgfältig.

■ Zwei Ferritkerne zum Filtern von Störungen – ein großer und ein kleiner –

werden mit dem Drucker geliefert. Der kleine Entstörungsfilter findet am

Kabel für die serielle RS232C-Schnittstelle Verwendung, das große am Kabel

für Peripheriegeräte.

Abb. 3-4

■ Die Ferritkerne werden in der offenen

Stellung geliefert, siehe Abbildung 3-

2. Sollte ein Ferritkern nicht offen

sein, öffnen Sie den Plastikverschluß

des Ferritkerns mit einem spitzen Gegenstand (Abbildung 3-1). Achten Sie

dabei darauf, daß Sie weder Ferritkern

noch Plastikverschluß beschädigen.

Abb. 3-1

Produktnummer

09990723

Ferritkern

TFC-23-11-14

Produkt-

nummer

09990728

Ferritkern

TFC-20-10-10

für das Schnittstellenkabel für das Peripheriegerätekabel

Ø28mm

Ø24mm

Small ferrite Core(24mm diameter)

Interface

Cable

Abb. 3-2

kleiner Ferritkern (24 mm Durchmesser)

Stecker

Kabel

Abb. 3-3

Modell Modell

Führen Sie den Kabelbinder durch die

Öse am Ferritkern.

5 cm

Maximalabstand

Kabelbinder

Pull and cut

Straffziehen und

abschneiden

Führen Sie den Kabelbinder um das

Kabel, und ziehen Sie ihn fest. Schneiden Sie das überstehende Ende mit einer

Schere ab.

Page 19

– 16 –

DEUTSCH

Installation des Ferritkerns für das Schnittstellenkabel

■ Klemmen Sie den kleinen Ferritkern auf das Schnittstellenkabel, siehe Abbil-

dung 3-2. Achten Sie darauf, daß bei der Installation des Ferritkerns das Kabel

nicht beschädigt wird. Der Ferritkern sollte mit dem mitgelieferten Kabelbinder

sicher an seinem Platz befestigt werden. Siehe Abbildungen 3-3 und 3-4.

Installation des Ferritkerns für das Peripheriegerätekabel

■ Klemmen Sie den großen Ferritkern auf das Kabel für die Peripheriegeräte.

Gehen Sie dabei genauso vor wie oben beim Schnittstellenkabel beschrieben.

Bei diesem Ferritkern allerdings müssen Sie das Kabel in einer Schlaufe laufen

lassen, wie in Abbildung 3-5 gezeigt.

Abb. 3-5

Ground wire

One loop

Large ferrite core

(28mm diameter)

5cm or less

5 cm oder weniger

großer Ferritkern

(28 mm Durchmesser)

Massekabel

eine Schlaufe

Page 20

– 17 –

DEUTSCH

4. ANSCHLUSS DES SCHNITTSTELLENKABELS

4-1. Serielle Schnittstellen RS-232C oder RS-422A

Gehen Sie zum Anschluß des Schnittstellenkabels vor wie unten beschrieben.

Abb. 4-1

1 Schalten Sie Drucker und Compu-

ter aus.

2 Stecken Sie das Schnittstellenkabel

in die Buchse. (Vergewissern Sie

sich, daß das Kabel korrekt ausgerichtet ist, bevor Sie den Stecker

einstecken.)

3 Ziehen Sie die beiden Schrauben links

und rechts fest, so daß der Stecker

sicher an der Buchse befestigt ist.

4 Verbinden Sie das andere Ende des

Kabels mit Ihrem Computer.

Interface cable

Interface connector

Buchse

Schnittstellenkabel

HINWEIS: Die Datenübertragungsparameter von Computer und Drucker müs-

sen übereinstimmen. Sie werden mit den DIP-Schaltern des Drukkers eingestellt (siehe »Anhang«).

4-2. Parallele Centronics-Schnittstelle

1 Schalten Sie Drucker und Compu-

ter aus.

2 Stecken Sie das Schnittstellenkabel

in die Buchse. (Vergewissern Sie

sich, daß das Kabel korrekt ausgerichtet ist, bevor Sie den Stecker

einstecken.)

3 Klammern Sie den Stecker an der

Buchse fest.

4 Verbinden Sie das andere Ende des

Kabels mit Ihrem Computer.

Abb. 4-2

Page 21

INDICE

1. APERTURA E CONTROLLO DELLA CONFEZIONE .................19

1-1. Apertura della confezione ..........................................................19

1-2. Avvertenze .................................................................................19

2. IDENTIFICAZIONE E NOMENCLATURA DELLE PARTI ........20

3.

INSTALLAZIONE DEGLI ANELLI DI FERRITE

*SOLO EUROPA ..

21

Installazione dell’anello di ferrite del cavo d’interfaccia ..................22

Installazione dell’anello di ferrite del cavo dell’unità periferica ......22

4. COLLEGAMENTO DEL CAVO D’INTERFACCIA .....................23

4-1. Interfaccia seriale RS-232C o RS-422A ....................................23

4-2. Interfaccia parallela tipo Centronics ..........................................23

APPENDICE ...........................................................................................24

L’Appendice appare solo nella sezione in inglese di questo manuale.

Page 22

– 19 –

ITALIANO

1. APERTURA E CONTROLLO DELLA CONFEZIONE

1-1. Apertura della confezione

Confrontare il contenuto della confezione con i componenti mostrati nella Figura

1-1 per controllare di aver ricevuto tutto (nella scatola dovrebbero esserci cinque

componenti).

Nel caso mancasse qualcuna di queste parti, contattare il fornitore presso cui si

è effettuato l’acquisto.

Fig. 1-1

1-2. A vvertenze

Prima dell’installazione della stampante, assicurarsi di disporre di un luogo

adatto in cui collocarla. Per “luogo adatto”, intendiamo un luogo:

• vicino ad una presa elettrica facilmente accessibile

• su una superficie solida e piana che non subisca vibrazioni

• lontano da fonti di calore eccessivo (come luce diretta del sole, apparecchi di

riscaldamento, ecc.)

• lontano da umidità eccessiva

• lontano da polvere eccessiva

• con la possibilità di accedere ad una fonte di alimentazione elettrica stabile

non soggetta a sbalzi improvvisi di tensione. Ad esempio, non collegare la

stampante sullo stesso circuito elettrico di grossi apparecchi che producono

disturbi come frigoriferi o condizionatori d’aria.

NOTA: Assicurarsi che la tensione del proprio impianto elettrico corrisponda a

quella specificata sulla piastrina di identificazione della stampante.

Manuale di istruzioni

Manuale di installazione

Fascetta di fissaggio

(solo Europa)

Anello di ferrite

per cavo

d’interfaccia

(solo Europa)

Anello di ferrite

per cavo unità

periferica (solo

Europa)

Rotolo di carta campione

Stampante

Asta del

rotolo di carta

Ø24mm

Ø28mm

Page 23

– 20 –

ITALIANO

2. IDENTIFICAZIONE E NOMENCLATURA DELLE PARTI

Esaminare la Figura 2-1 per conoscere i componenti e le funzionalità della

stampante.

Fig. 2-1

Barra di apertura

Serve per aprire e chiudere l’unità della testina di stampa

che mantiene premuta la carta contro il rullo.

Coperchio della stampante

Protegge la testina di stampa e

gli altri componenti interni della

stampante.

Automatic paper cutter

(Controlled by command)

(TSP442)

POWER

HEAD UP

NO PAPER

ERROR

ON LINE

FEED

(TSP412)

Taglierina della carta

automatica

(Controllata tramite comando)

Pannello di controllo

Indica lo stato della stampante e

semplifica il controllo delle

funzioni della stampante.

O

N

O

FF

ON

OFF

Connettore d’interfaccia

Serve per collegare la stampante al computer.

Interruttore di alimentazione

Serve ad accendere e spegnere

la stampante.

Coperchio del

connettore

Connettore unità periferica

Serve per collegare la stampante ad

unità periferiche, come registratori di

cassa, ecc.

Page 24

– 21 –

ITALIANO

3. INSTALLAZIONE DEGLI ANELLI DI FERRITE

*SOLO EUROPA

NOTA: Prestare particolare attenzione durante l’esecuzione delle procedure

indicate di seguito.

■ Insieme alla stampante vengono forniti in dotazione due anelli di ferrite, uno

grande e uno piccolo, da utilizzare come filtri per la soppressione di eventuali

disturbi. Il filtro antidisturbi piccolo va fissato sul cavo d’interfaccia seriale

RS232C, mentre quello grande serve per il cavo di collegamento di unità

periferiche.

Fig. 3-4

5cm

maximum

Fastener

■ Gli anelli di ferrite sono confezionati

aperti, come mostrato in Fig. 3-2. Se si

trova uno degli anelli di ferrite chiuso,

aprirlo utilizzando un oggetto

appuntito per far leva sul dispositivo

di chiusura di plastica dell’anello di

ferrite (Fig. 3-1). Fare attenzione a

non danneggiare il nucleo di ferrite o

il dispositivo di chiusura di plastica.

Abb. 3-1

Fig. 3-3

Far passare la fascetta di fissaggio attraverso l’anello di ferrite.

Distanza

massima 5 cm

Pull and cut

Far passare la fascetta di fissaggio intorno al cavo e bloccarla. Tagliare la parte

in eccesso con delle forbici.

Fascetta di fissaggio

Tirare e tagliare

Small ferrite Core(24mm diameter)

Interface

Cable

Fig. 3-2

Anello di ferrite piccolo (diametro 24 mm)

Interfaccia

Cavo

Codice

prodotto

09990723

Anello di ferrite

TFC-23-11-14

Codice

prodotto

09990728

Anello di ferrite

TFC-20-10-10

Per il cavo d’interfaccia Per il cavo dell’unità periferica

Ø28mm

Ø24mm

Modello Modello

Page 25

– 22 –

ITALIANO

Installazione dell’anello di ferrite del cavo d’interfaccia

■ Fissare l’anello di ferrite piccolo sul cavo d’interfaccia come mostrato in Fig.

3-2, facendo attenzione a non danneggiare il cavo d’interfaccia. L’anello di

ferrite va saldamente bloccato in posizione con la fascetta di fissaggio fornita

in dotazione, come mostrato nelle Fig. 3-3 e 3-4.

Installazione dell’anello di ferrite del cavo dell’unità periferica

■ Fissare l’anello di ferrite grande sul cavo dell’unità periferica eseguendo la

stessa procedura vista per l’anello di ferrite del cavo d’interfaccia. Tuttavia,

quando si applica l’anello di ferrite sul cavo dell’unità periferica, è necessario

fare un cappio al cavo come mostrato in Fig. 3-5.

Fig. 3-5

Ground wire

One loop

Large ferrite core

(28mm diameter)

5cm or less

Distanza di 5 cm o inferiore

Filo di terra

Cappio

Anello di ferrite grande

(diametro 28 mm)

Page 26

– 23 –

ITALIANO

4. COLLEGAMENTO DEL CAVO D’INTERFACCIA

4-1. Interfaccia seriale RS-232C o RS-422A

Per collegare il cavo d’interfaccia, eseguire le procedure indicate di seguito:

1 Spegnere sia la stampante che il

computer.

2 Inserire il cavo d’interfaccia nel

connettore (assicurarsi che il cavo

sia orientato nel senso corretto prima di inserirlo).

3 Stringere le due viti di destra e sini-

stra per fissare il connettore.

4 Collegare l’altra estremità del cavo

d’interfaccia al computer.

Interface cable

Interface connector

Connettore d’interfaccia

Cavo d’interfaccia

Fig. 4-1

NOTA: Le caratteristiche di trasferimento dati tra il computer e la stampante

devono essere rese compatibili attraverso le impostazioni degli interruttori DIP della stampante (vedere l’“APPENDICE”).

4-2. Interfaccia parallela tipo Centronics

1 Spegnere sia la stampante che il

computer.

2 Inserire il cavo d’interfaccia nel

connettore (assicurarsi che il cavo

sia orientato nel senso corretto prima di inserirlo).

3 Bloccare i fermagli del connettore.

4 Collegare l’altra estremità del cavo

d’interfaccia al computer.

Fig. 4-2

Page 27

– 24 –

APPENDIX

APPENDIX

DIP SWITCHES

DIP switches are located on the interface board. The number of switches varies

according to the board, as follows.

Centronics No DIP switches

RS-232C One 8-bit DIP switch

RS-422A One 8-bit DIP switch and one 4-bit DIP switch

8

1

ON OFF

Page 28

– 25 –

APPENDIX

DIP-switch settings

a) DIP switch #1 (RS-232C, RS-422A)

Switch Setting ON OFF

1-1 Baud

1-2 Baud

1-3 Handshaking DTR X-ON/X-OFF

1-4 Data bits 8 bits 7 bits

1-5 Parity type Not used Used

1-6 Parity type Odd Even

1-7 DCI/DC3 Invalid

Valid (RS-232C only)

1-8 When turning power ON * Refer to the table below.

Baud 1-1 1-2

2400BPS OFF OFF

4800BPS OFF ON

9600BPS ON ON

19200BPS ON OFF

Factory settings : ALL ON

* When the printer’s power is ON.

ON OFF

DC1/DC3 valid mode Select Deselect

Adressable mode Deselect Select (RS-422A only)

DC1/DC3 invalid mode Select Select

b) DIP switch #2 (RS-422A only)

■ DIP SW 2 (RS-422A only)

Function

DC1/DC3

Addressable mode *2

DC1/DC3

Switch

invalid mode

#1 #2 #3 #4 #5 #6 #7 #8 #9 #10 #11 #12 #13 #14

valid mode

2-1

ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF

2-2

ON ON OFF OFF ON ON OFF OFF ON ON OFF OFF ON ON OFF OFF

2-3

ON ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF OFF OFF

2-4

ON ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF

Page 29

– 26 –

APPENDIX

Print Density Adjustment

Since the sensitivity of different types of heat-sensitive paper varies, you can

adjust the print density by varying the current supplied to the thermal head.

The print density can be adjusted using the variable resistor inside the hole beside

the interface connector on the back of the printer.

1. To adjust the density turn the resistor roughly two times using a small crosshead screwdriver.

2. Turn the resistor to the right (clockwise) for a darker print density or to the left

(counterclockwise) for a lighter density.

NOTE: If the density is increased to a higher level than necessary when printing

on highly sensitive heat-sensitive paper, the dots may be too large and the

print quality may decrease.

Excessively high energy adjustment may reduce head life.

Variable resistor

used to adjust the

print density

Page 30

– 27 –

APPENDIX

Sensor Adjustment

■ Sensor levels are adjusted at the factory. If necessary, you can readjust the

levels as described below.

1) Remove the ROM cover located beneath the paper-roll holding area.

2) Hold down the FEED and ON LINE switches while switching on the power, and

continue to hold them down until you hear a triple beep. (This will take about

five seconds.) When you hear the triple beep, release the buttons to enter

sensor-adjustment mode.

a) Reflective Sensor

• Insert a non-black area of paper into the mechanism’s sensor area.

• Rotate the main PCB’s sensor adjustment knob (VR4) to the point where the

HEAD UP indicator comes on.

b) Paper-Out Sensor

• Insert a non-black area of paper into the mechanism’s sensor area.

• Rotate the main PCB’s sensor adjustment knob (VR3) to the point where the

NO PAPER indicator comes on.

c) Transmissive Sensor

• Insert the backing portion of a label sheet into the mechanism’s transmissive

sensor area. (Insert the backing part only, not the label itself.)

• Adjust the main PCB’s coarse (VR1) and fine (VR2) adjustment knobs to the

point where the ERROR indicator comes on.

NOTE: When inserting paper, be sure to lower the head so that it is close to

its normal fixed position.

Page 31

– 28 –

APPENDIX

EPROM

VR4

Variable Resistances (Sensor Adjustment Knobs)

Main PCB

Interface PCB

VR2

VR3

VR1

Page 32

– 29 –

APPENDIX

Connectors and Signal Names (Serial Interface)

RS-232C Interface

Pin no Signal name

Direction

Function

1 F-GND – Frame ground

2 TXD OUT Outgoing data

3 RXD IN Incoming data

4 RTS OUT Request To Send: The printer sets this signal

to “SPACE” when it is ready to send.

5 CTS IN The host sets this signal to “SPACE” when it

is ready to send. NOTE: The printer does not

monitor this signal.

6 N/C Not used

7 S-GND – Signal ground

8 N/C Not used

9 ~ 10 N/C Not used

11 RCH OUT The printer sets this signal to “SPACE” when

it is ready to receive. This pin outputs the

same signal as pin 20, to which it is con-

nected.

12 N/C Not used

13 S-GND – Signal ground.

14 FAULT OUT The printer sets this signal to “MARK” to

indicate an error condition (machine error, no

paper, etc.).

15

Multi-Printer TXD

OUT Diode gate TXD

16

Multi-Printer DTR

OUT Diode gate DTR

17 ~ 19 N/C Not used

20 DTR OUT Data Terminal Ready: The printer sets this

signal to “SPACE” when it is ready to re-

ceive.

21 ~ 22 N/C Not used

23 ~ 25 N/C Not used

13 1

14

25

Page 33

– 30 –

APPENDIX

These pins carry data from the printer.

These pins carry data to the printer.

The host sets this signal to “SPACE” when it

is ready to send.

NOTE: The printer does not monitor this

signal.

The host sets this signal to “SPACE” when it

is ready to receive.

NOTE: The printer does not monitor this

signal.

The printer sets this signal to “SPACE” when

it is ready to receive.

The printer sets this signal to “SPACE” when

it is ready to receive.

RS-422A Interface

Pin no Signal name

Direction

Function

9 SD(+) OUT

10 SD(–) OUT

17 RD(+) IN

18 RD(–) IN

19 CS(+) IN

23 CS(–) IN

24 RS(+) OUT

25 RS(–) OUT

Interface Connections

Refer to the host computer’s interface specifications for details of how to connect

the interface. The following illustrations show typical connection configurations.

[RS-232C]

1

2

3

4

5

7

14

20

1

2

3

4

5

6

7

8

20

F-GND

TXD

RXD

RTS

CTS

DSR

S-GND

DCD

DTR

F-GND

TXD

RXD

RTS

CTS

S-GND

FAULT

DTR

Printer side IBM PC side

Page 34

– 31 –

APPENDIX

[RS-422A]

17

18

9

10

Twisted pair cable

Printer #n

RD

SD

SD

RD

17

18

9

10

Printer #n+1

RD

SD

Printer side Host side

Signal Name Sample Circuit

InputOutput

DATA 1

DATA 8

STROBE

BUSY

ACK

~

4.7k

Ω

74LS-equivalent

1kΩ

100Ω

1000pF

74LS-equivalent

1.8kΩ

74LS-equivalent

Page 35

– 32 –

APPENDIX

Connectors and Signal Names (Parallel Interface)

(18) (1)

(36) (19)

Conforms to Amphenol

connector 57-30360

(Printer Side)

Page 36

– 33 –

APPENDIX

PAIR RETURN

Pin no Signal name

Direction

Function

1 STROBE IN Strobe pulse for data read. Usually HIGH;

goes LOW to trigger data read.

2-9 DATA 1~8 IN Parallel data lines for eight-bit data. HIGH

is “1”; LOW is “0”.

10 ACK OUT Printer outputs this pulse for approxi-

mately 9µs to indicate that data read is

completed. Printer becomes ready to

receive new data at the moment the ACK

pulse ends.

11 BUSY OUT DC-level signal indicating printer’s current

status. LOW indicates that printer is ready to

receive the next data; HIGH indicates that

printer is unable to receive. The printer holds

this signal “HIGH” during any of the following conditions.

1 While data entry is in progress

2 While printer is offline 3 While error

condition exists

12 PAPER OUT OUT DC-level signal indicating whether printer

has paper. The signal stays LOW while paper

is present; it goes HIGH to indicate that paper

has run out.

13 SELECTED OUT DC-level signal; stays HIGH while printer is

online.

14-15 N/C Not used

16 SIGNAL GND Signal ground

17

CHASSIS GND

Printer-frame ground

18 +5V Outputs +5V (Max. 50mA)

19-30 TWISTED Return pins for various signals. Each pin is

connected to the corresponding signal line by

twisted pair line.

31 RESET IN LOW level causes printer to reset its control

circuitry and return to its initial state.

32 ERROR OUT Goes LOW to indicate that printer is unable to

print.

33 EXT GND Ground terminal for external connection

34-35 N/C Not used

36 – – Fixed “HIGH” at printer side

Page 37

– 34 –

APPENDIX

16

Modular plug MOLEX 90075-0007,

AMP641337 or JAPAN BURNDY B-66-4

Shield

Wire lead

Separated Ground wire

connected to shield (Europe only).

Ground wire

1 turn

Ferrite core

Distance within 5cm.

Peripheral Unit Drive Circuit

A drive circuit for driving peripheral units (such as cash drawers) is featured on

the main logic board of this printer. A modular connector for driving peripheral

units is featured on the output side on the drive circuit. When using this circuit,

connect the cable for the peripheral unit. (Cables must be prepared by the user.)

Note that Page Mode does not support external-device drive commands. Drive

commands are available only in Line Mode.

Use cables which meet the following specifications.

1. Use the modular plug as shown in Figure 17.

2. Separate ground wire is required for Europe only.

3. Use if the printer is to be used in Europe, the Ferrite core and the cable should

be separate, as shown in Figure 18.

CAUTION: DO NOT connect any other plug to the peripheral unit connector.

Cable specifications for peripheral unit.

Separate ground wire and noise filter are required for Europe.

Page 38

– 35 –

APPENDIX

[Drive output 24V, max. 1.0 A]

7824

F.G

TR1

M-GND

TR2

M-GND

TR3

+5V

+24V

R1

R2

6

5

4

3

2

1

L1

L2

R3

4.7kΩ

1/4W

Frame

ground

D1

D2

Peripheral

unit 1

With shield

Peripheral

unit 2

Compulsion

switch

■ Drive circuit

The recommended drive circuit is shown.

NOTES:

1. Peripheral units #1 and #2 cannot be driven simultaneously.

When driving a device continuously, do not use drive duty above 20%.

2. Compulsion switch status is available as status data.

3. Resistance for coils L1 and L2 is not less than 24 ohms.

4. Absolute maximum ratings for diodes D1 and D2 (at Ta=25˚C):

Average rectified current Io = 1A

Maximum forward surge current (60Hz,1-cycle sine wave) I

FSM=40A

5. Absolute maximum rating for transistors TR1 and TR2 (at Ta = 25˚C):

Collector current Ic = 2A

P 1996.1

Page 39

Printed in Japan, 80871025

HEAD OFFICE

STAR MICRONICS CO., LTD.

20-10 Nakayoshida, Shizuoka, 422 Japan

Tel: (054) 263-1115, Telefax: (054) 263-8714

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA, INC.

70-D Ethel Road West, Piscataway, NJ 08854 U.S.A

Tel: (908) 572-9512, Telefax: (908) 572-5095,

Telex: 299766 STAR UR

STAR MICRONICS DEUTSCHLAND GMBH

Westerbachstraße 59, D-60489 Frankfurt/Main 90, Germany

Tel: 0697-89990, Telefax: 0697-81006, Telex: 417 5825 STAR D

STAR MICRONICS U.K. LTD.

Star House, Peregrine Business Park, Gomm Road,

High Wycombe, Bucks, HP13 7DL, UK

Tel: 01494-471111, Telefax: 0494-473333

Loading...

Loading...