Page 1

THERMAL RE-WRITABLE

CARD READER / WRITER

TCP300 SERIES

•

User’s Manual

•

This ‘User’s Manual’ describes important information to enable you to use

the reader/writer safely.

Carefully read this manual before using the reader/writer and observe the

descriptions herein.

CARD SYSTEM SALES SECTION OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS CO., LTD. STAR MICRONICS AMERICA, INC.

536 Shimizuanatsushinnya, Shizuoka, 1150 King Georges Post Road, Edison,NJ 08837-3729 U.S.A.

424-0066 Japan Tel: 732-623-5555, Fax: 732-623-5590

Tel: 0543-47-0122, Fax: 0543-48-5013 http://www.starmicronics.com

STAR MICRONICS U.K. LTD.

Please access the following URL

Star House, Peregrine Business Park, Gomm Road,

http://www.star-micronics.co.jp/service/

High Wycombe, Bucks, HP13 7DL, U.K.

frame_sp_car_e.htm

Tel: 01494-471111, Fax: 01494-473333

for the lastest revision of the manual. http://www.starmicronics.co.uk

2003.09.01

Printed in Japan, 59082065

Page 2

TABLE OF CONTENTS

1. Precautions for Safe Use ........................................................ 1

2. General Description ................................................................ 4

3. Unpacking ............................................................................... 5

4. External Appearance and Part Names .................................... 6

5. Connect to and Setting External Devices ................................7

6. Interface Board Replacement (RS-232C to USB) ................. 10

7. Cleaning Cards...................................................................... 11

8. Troubleshooting.....................................................................12

9. General Specifications .......................................................... 14

Page 3

– 1 –

1. Precautions for Safe Use

Carefully read and obey the following items to prevent injury to yourself or to others

and to prevent damaging property.

Precautions for Reader/Writer Setup

1. Setup the reader/writer in a solid, and level location. Do not physically jar or shake

the reader/writer.

This can damage it or lead to injury.

2. Place the reader/writer in a location out of the reach of children.

Allowing children to touch the reader/writer can lead to injury.

3. Do not use or place the reader/writer in areas exposed to direct sunlight, or in high

temperatures areas such as next to fire or electric or kerosene heaters.

Exposing the reader/writer to excessive heat will cause it to become hot and breakdown, mis-operate or become burned.

4. Avoid using or storing the reader/writer in locations where liquids such as water or oils

can enter the internal reader/writer mechanisms, or in areas of high humidity.

Exposing the reader/writer to excessive moisture will cause it to become hot and can

cause electric shock, mis-operate or reader/writer failure.

5. Avoid using or storing the reader/writer in locations where dust or metallic powder can

enter the internal reader/writer mechanisms.

Exposing the reader/writer to excessive dust will cause it to become hot and can

cause electric shock, mis-operate or reader/writer failure.

6. Avoid using the reader/writer in locations where corrosive gases, ignition gases, chemicals or vapors are emitted.

Exposing the reader/writer to vapors will cause it to become hot, burn, cause electric

shock, or cause reader/writer failure.

7. Avoid using near objects that emit a magnetic field.

Magnetic fields can erase the information recorded on cards.

8. Use the appropriate power conditions for the TCP300 series.

The wrong type of power will cause the reader/writer to become hot and can cause

mis-operate or reader/writer failure.

9. Use an outlet that can easily be connected to and disconnected from.

10. Do not get power from a circuit to which electrical devices that generate electrical

noise are connected.

Using the same circuit can cause the reader/writer to mis-operate or can cause reader/

writer failure.

11. Allow plenty of space around the reader/writer for ventilation of heat and operation.

Not enough space will cause the reader/writer to become hot and can cause misoperate or reader/writer failure.

Always observe the following items.

Page 4

– 2 –

12. Do not store the accessory cleaning liquid in a location that is exposed to direct sunlight or near heat generating devices.

Storing near heat can cause fires.

13. Do not allow the accessory cleaning liquid to get in your eyes and do not drink it.

Drinking the liquid can cause health problems.

14. Do not store the accessory cleaning liquid in a location where children have access to it.

Drinking the liquid can cause health problems in children.

Precautions for Reader/Writer Use

1. Use only Star recommended cards.

The reader/writer and the card may not operate normally if other cards are used.

2. Do not use cards that are dirty or oily or wet in any other manner. Also, do not handle

cards with dirty or wet hands. Do not apply tape or glue to cards.

The reader/writer will not operate normally.

* If a card is dirty, clean the card and the reader/writer.

See section 7. Cleaning Cards for details on how to clean.

3. Do not store cards near devices that generate magnetic fields (such as cellular telephones, speakers, televisions, etc.) or approach magnets toward them.

Magnetic fields can erase the information recorded on cards.

4. Do not store cards in high temperature areas (such as dashboards in automobiles).

Storing in high temperature areas can cause cards to bend or it can erase the information recorded on cards.

5. Do not used bent cards.

Using bent cards can cause them to become jammed.

6. Insert cards in the indicated direction.

Inserting them incorrectly can cause mis-operation or it can erase the information

recorded on cards.

7. Absolutely never insert anything other than cards into the reader/writer.

Inserting other objects can cause the reader/writer failure or electrical shock.

8. Do not obstruct the inserting or discharging of cards.

Obstructing can cause the reader/writer failure, mis-operation or injury.

[TCP300]

(Figure for Reference)

Page 5

– 3 –

9. Do not cut the power while a card is being processed.

Cutting the power can erase the information recorded on cards.

10. In case of reader/writer error (abnormal sounds, abnormal odors, smoke, fire) turn off

the reader/writer immediately and unplug it from the power outlet.

Continuing use under such errors will cause the reader/writer failure or burns. Request repairs from the sales outlet.

11. Always hold the plug to unplug the power cord from its outlet. Pulling on the cord will

damage the cord. Do not pull on the cord. Do not place heavy objects on the power

cord. Do not use power cords that are damaged or deformed. Consult with your

sales outlet.

12. When discontinuing use for prolonged periods, always remove the power plug from

the outlet.

13. Avoid sudden changes in environment, such as changes in ambient temperature and

humidity.

Sudden changes can cause condensation and mis-operation. Allow the reader/writer

to sit in its new environment for at least one hour before use in the event there has

been a sudden change.

14. Do not use the reader/writer in an environment where condensation has formed.

Using the reader/writer in such an environment can cause the reader/writer to misoperate, electrical shocks or it can cause reader/writer failure.

15. To ensure reader/writer reliability, clean the reader/writer everyday, or when the cleaning

lamp has lit.

Continuing use without cleaning will cause the reader/writer errors. See section 7.

Cleaning Cards for details on how to clean.

16. Do not disassemble or modify the reader/writer.

Disassembling or modifying the reader/writer can cause the reader/writer to mis-operate, reader/writer failure or injury. If the reader/writer mis-operates, or appears to

need repair, contact your sales outlet.

17. Do not expose cards to direct sunlight or fluorescent lights for extended periods of

time.

Exposure to bright light will discolor cards.

18. When the print has faded:

Magnetically encoded information still remains on the card even when the print has

faded due to high temperatures. The card may be reprinted.

19. When cards are excessively dirty:

If cards are dirty or oily, problems can easily occur in reading and writing or cause

missing print and incomplete erasing of information.

* In such cases, clean the card and the reader/writer.

See section 7. Cleaning Cards for details on how to clean.

20. To use repeatedly:

To repeatedly print to the same card, allow for at least three minutes between prints.

When printing repeatedly to different cards, no wait is required.

Page 6

– 4 –

2. General Description

The TCP300 series reader/writers are equipped with a thermal type display mechanism

on a PET magnetic strip card reader/writer. They are connected to electrical devices

such as POS and are used to print/erase characters and images freely onto the surface of

cards.

• Main Features of the TPC300 Series Reader/writer

1. Reads/writes card magnetic stripe data

2. Prints/deletes the card display area

3. RS-232C and USB interface

4. Card can be reused between approximately 200 to 500 times under normal operating

conditions.

* Actual number of uses varies greatly according to type of card and environment.

Page 7

– 5 –

3. Unpacking

The following outlines the reader/writer and its accessories.

The reader/writer (TCP300 Series)

1. TCP300 reader/writer

2. Cleaning cards (2 cards)

3. Cleaning fluid

4. This manual

5. Ferrite core

2

4

3

5

1

Page 8

– 6 –

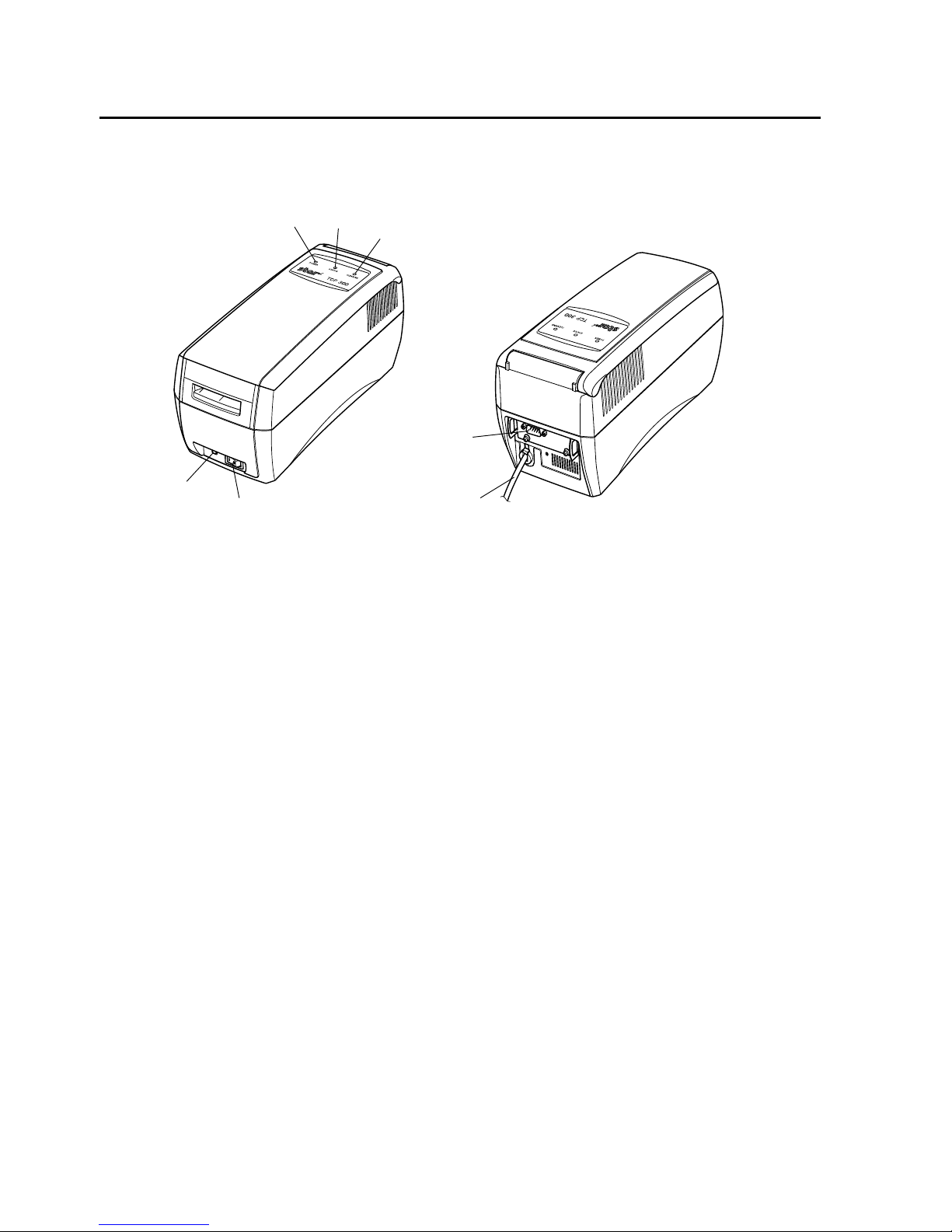

4. External Appearance and Part Names

The reader/writer (TCP300 Series)

1. Power Switch ............................ This turns the power to the reader/writer on and off.

2. Power Indicator Lamp .............. Indicates that reader/writer power is on.

3. Status Indicators ....................... Indicates printing ready, printing and errors.

4. Cleaning Lamp ......................... Indicates the reader/writer needs cleaning.

5. Interface Connector .................. Connects to host computer via a cable.

6. AC Cable .................................. Connects to power source.

7. Cleaning Switch ........................ Press the cleaning switch while turning the power on.

Insert a cleaning card dampened with alcohol to

6

1

5

4

3

7

2

Page 9

– 7 –

clean the reader/writer.

5. Connect to and Setting External Devices

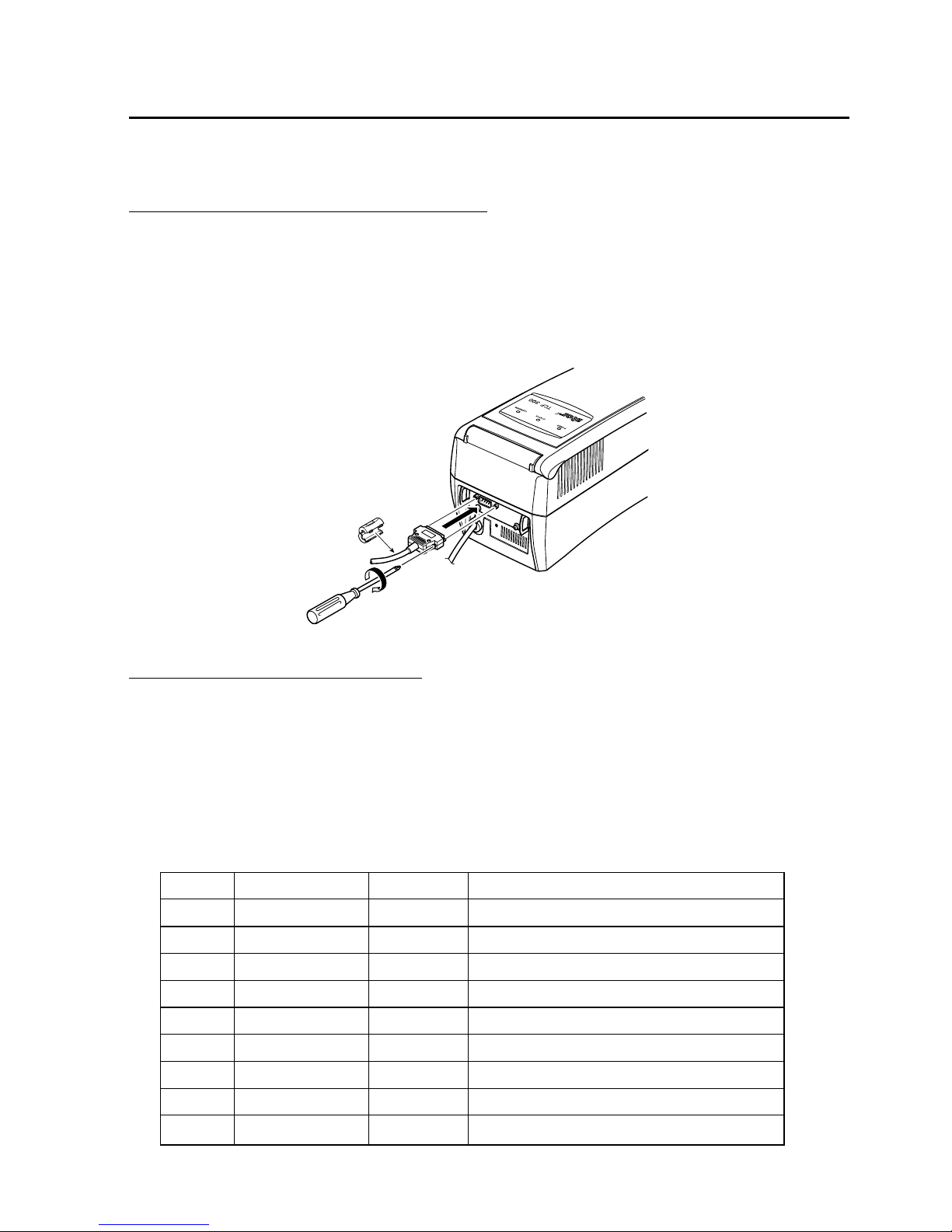

5-1 RS-232C Interface

<Mounting the RS-232C Interface Cable>

1. Cut the power to the host computer and reader/writer.

2. Connect one end of the interface cable to the reader/writer and the other end to the

host computer.

3. Mount the accessory ferrite core to the interface cable.

4. Tighten the left and right screws on the connector.

<RS-232C Serial Interface Cable>

1 Connectors D-Sub 9PIN (Male) * Reader/Writer Side

2 Compatible Connectors D-Sub 9PIN (Female) * Cable Side

3 Connector Pins See Table Below

4. I/O Circuit See Table Below

5. Level RS-232C

6. Cable Cross (Reverse) Cable

Pin No. Signal Name I/O Functions

1NC

-

Not Connected

2 RXD Input Reception Data

3 XD Output Transmission Data

4 DTR Output Data Terminal Ready

5 GND

-

Ground for Signal

6 DSR Input Data Set Ready (Not Detected)

7 RTS Output Transmission Request

8 CTS Input Transmission Ready (Not Detected)

9NC

-

Not Connected

Page 10

– 8 –

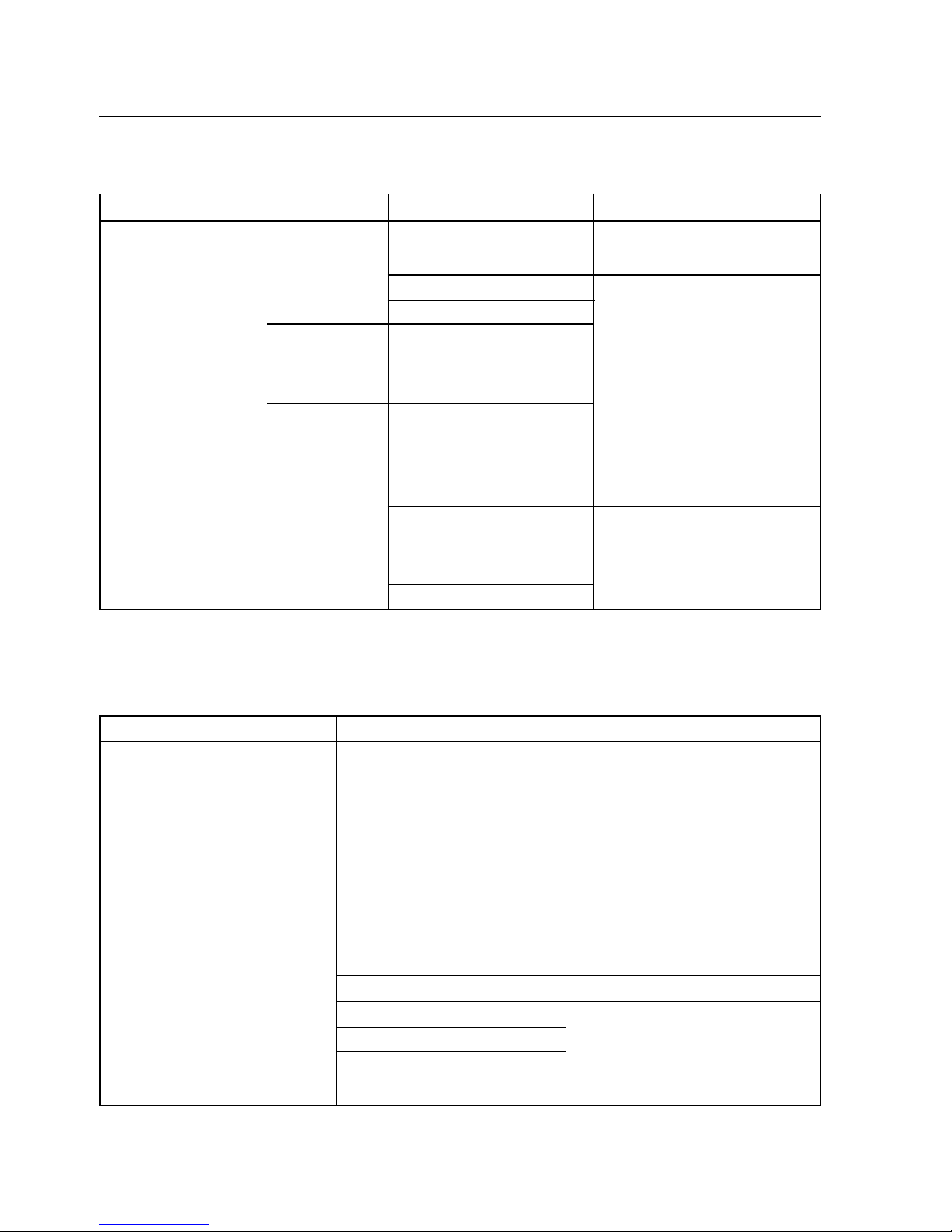

<Settings for Communication Speed>

To change the serial communication settings, change the following DIP switch settings.

(Ex-factory Default Settings: DSW 1 to 6 are ON, 7 and 8 are OFF.)

Switches ON OFF

DSW 1-1

Baud Rate Setting (See table below)

DSW 1-2

DSW 1-3 8 bit 7 bit

DSW 1-4 Parity Disabled Parity Enabled

DSW 1-5 Odd Parity Even Parity

DSW 1-6 Fixed at On

DSW 1-7 Fixed at Off

DSW 1-8 Fixed at Off

Baud Rates BPS 4800 BPS 9600 BPS 19200 BPS 38400 BPS

DSW 1-1 OFF ON ON OFF

DSW 1-2

ON ON OFF OFF

* Mistaken DIP switch settings will cause the reader/writer to mis-operate or reader/

writer failure. Be careful when making setting changes.

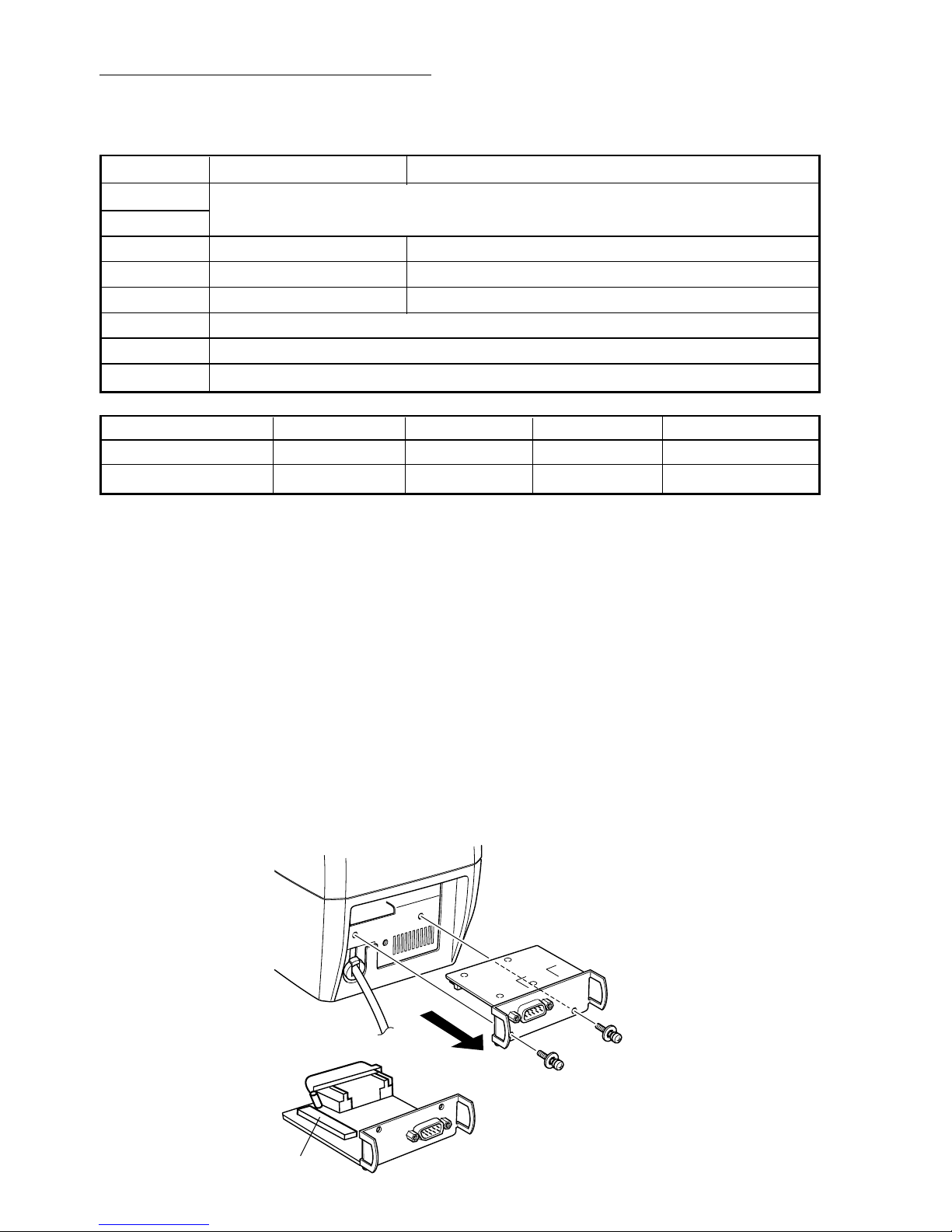

To change the DIP switch settings, do the following.

1. Check that the power is turned off for both the reader/writer and the host computer.

2. Remove the two screws.

3. Pull out the serial interface card to remove it.

4. Change the DIP switch settings on the serial interface card.

5. Push in the serial interface card to mount it.

6. Tighten the two screws.

7. Turn on the power for both the reader/writer and the host computer.

Note: The new settings will take effect when the reader/writer power is turned back on.

DIP Switches

Page 11

– 9 –

5-2. USB Interface

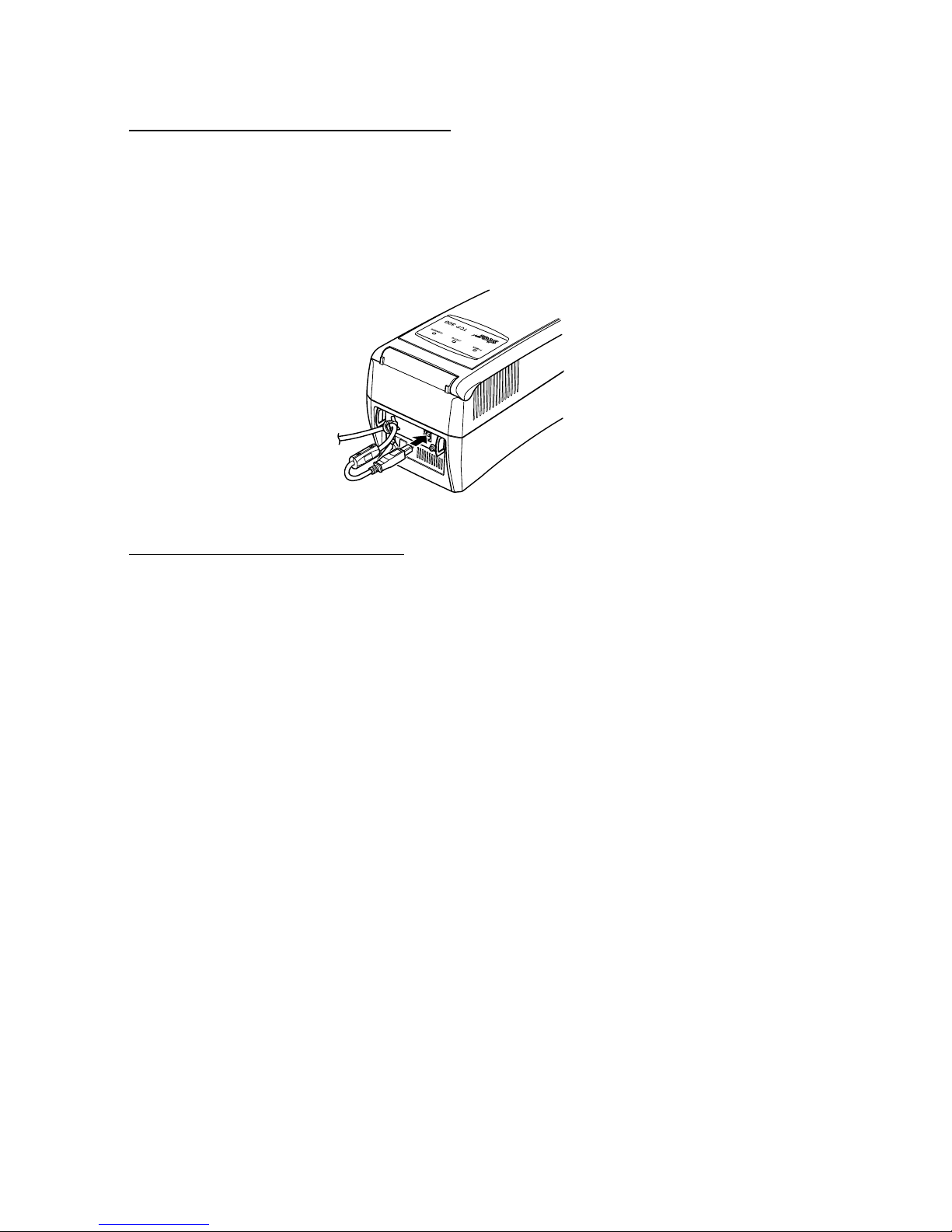

<Mounting the USB Interface Cable>

1. Connect one end of the interface cable to the reader/writer and the other end to the

host computer.

2. Mount the accessory ferrite core to the interface cable.

3. If a driver for the reader/writer is required, use the media that was distributed by your

agent to install the driver.

<USB Interface Specifications>

1 Communication Rating Conforms to USB 1.1 Specifications

2 Communication Speed USB Full Speed Mode (Max. 12 MBPS)

3 Communication Method USB Bulk Transmission Mode

4 Power Specifications USB Self-power Function

5 Connectors Type-B

Page 12

– 10 –

6. Interface Board Replacement (RS-232C to USB)

Replacement Procedures

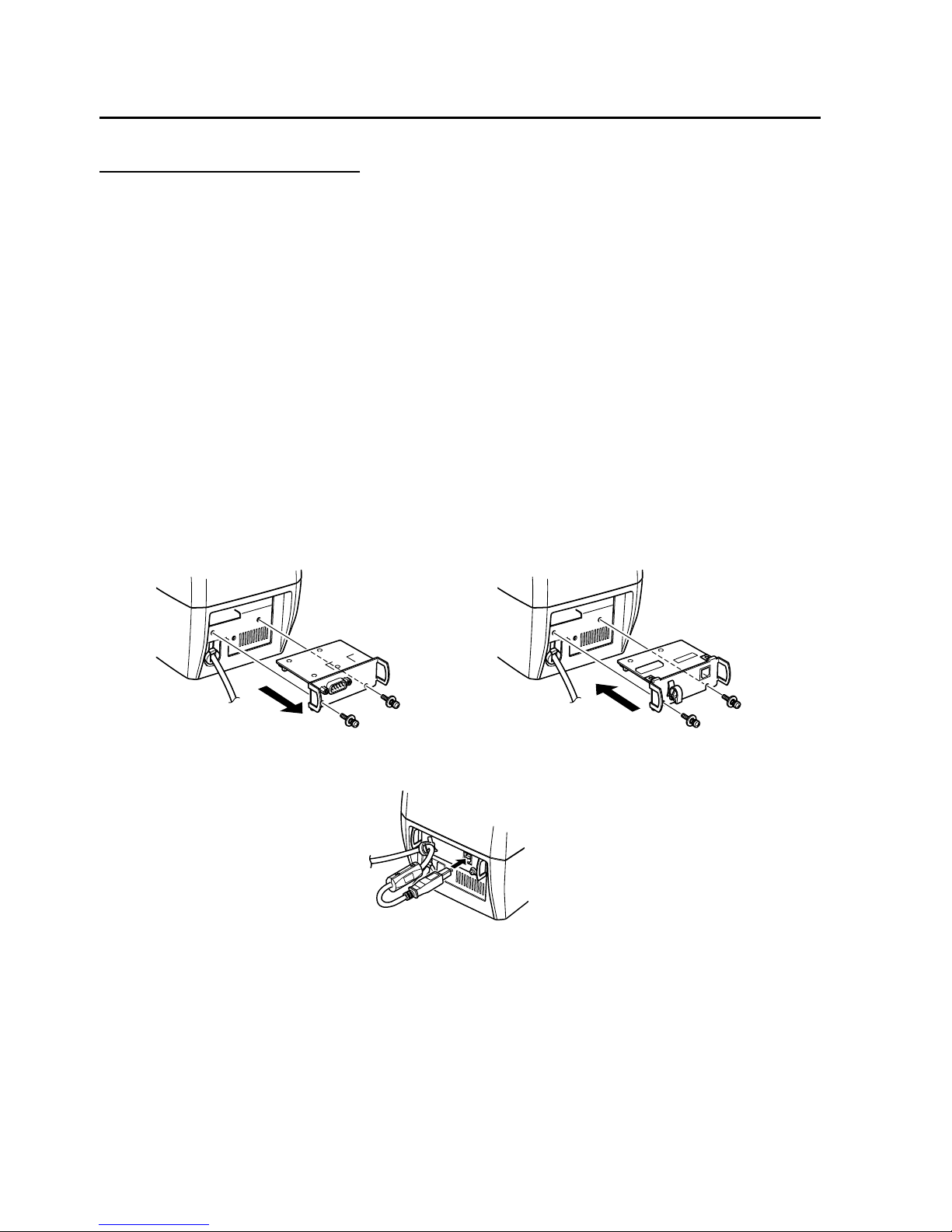

1. Turn off the power switch. Then, unplug the power cord from the outlet.

2. Remove the two screws as shown in the figure below.

3. Pull the RS-232C interface board in the direction of the arrow to remove it.

4. Insert the USB interface board to the reader/writer.

Note: Firmly insert so that the reader/writer connector and the interface board con-

nector are securely connected.

5. Tighten the two screws to fasten the USB interface board.

6. After mounting the interface board, connect the USB cable.

7. A USB cable is not an accessory part. Purchase one that meets specifications. Mount

the ferrite core to the cable and insert to the hook that fastens the cable.

Page 13

– 11 –

7. Cleaning Cards

There are two cleaning cards per reader/writer to clean the rollers. They are in a plastic

bag.

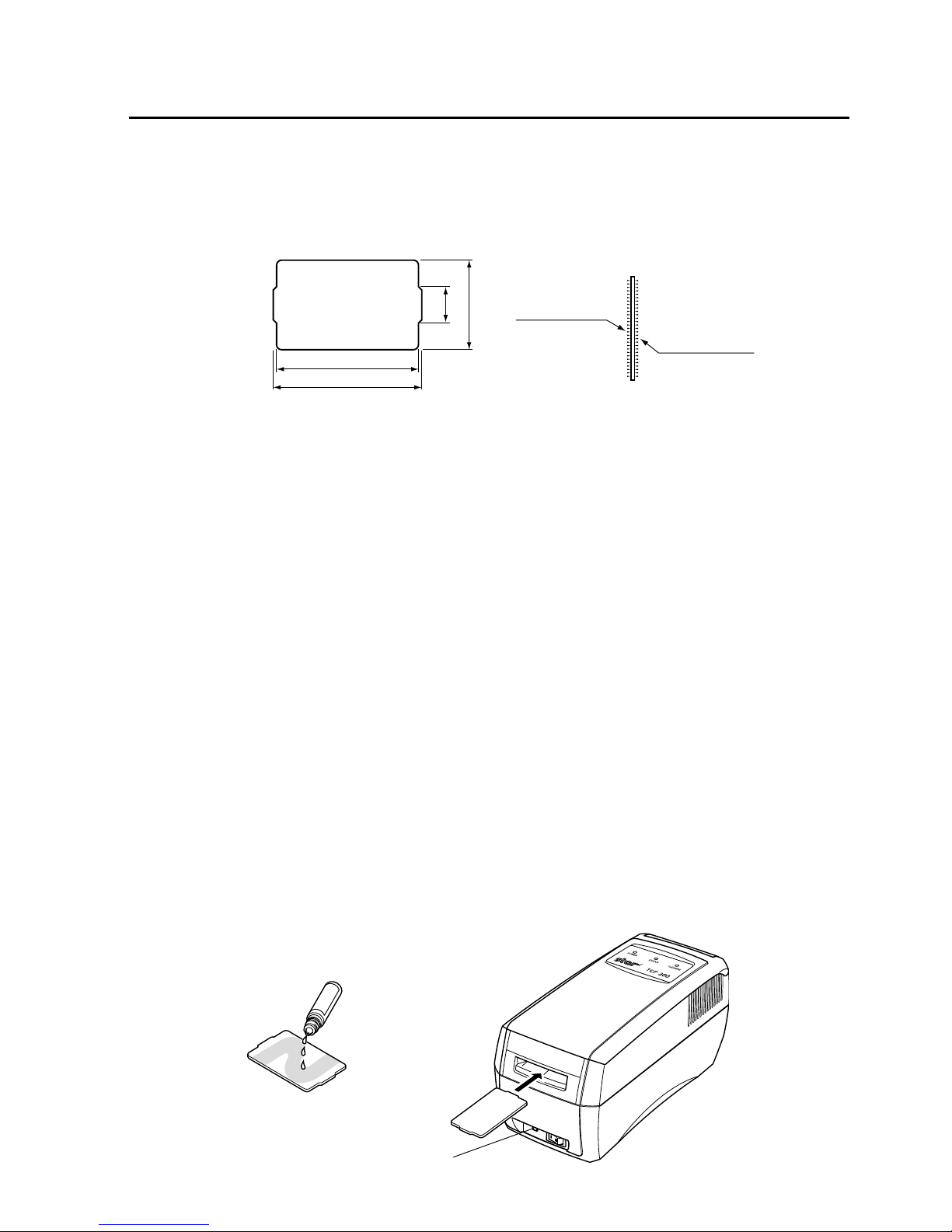

7-1 External Shape

7-2 Frequency of Use

1. Everyday, or once every 300 prints.

2. If errors occur repeatedly, or if there are printing problems, clean the reader/writer.

3. The cleaning LED will flash when there have been 300 printings. Clean the reader/

writer when this flashes.

7-3 How to Use

Use the following procedures to clean the reader/writer.

1. Press the cleaning switch.

2. Dampen the felt surfaces (both side) of a cleaning card with head cleaning liquid.

3. Insert the cleaning card from the normal card insertion inlet.

4. Allow the reader/writer to sit for approximately one minute before using again, to

allow it to dry.

Note: 1. Do not use bent cleaning cards. Using bent cards can cause them to become

jammed.

2. Use only the accessory head cleaning fluid or dedicated head cleaning fluids

for audio-video equipment. If cleaning cards are dirty, or if you run out of

cleaning fluid, purchase new materials from your sales outlet.

3. Cleaning cards can be used approximately 30 times. Contact your sales agent

if they are damaged or excessively dirty.

Felt Surface

Felt Surface

85.6

89.6

22.0

54.0

Cleaning Switch

Page 14

– 12 –

8. Troubleshooting

• Trouble when Turning on the Power

Symptom Possible Cause What to Do

The power indicator Won’t accept The power plug is not Correct connect the power

lamp does not light. cards. correctly connected. plug.

Broken wire in power cord.

Broken wire in fuse. Contact your dealer.

Accepts cards. Display LED burned out.

The power indicator Won’t accept Reader/writer error.

lamp lights. cards.

Accepts cards Bad Card Use a normal card.

but reader/ Card damaged, bent,

writer data erased on card,

operating or other user card.

incorrectly. Head is dirty. Clean using a cleaning card.

Composing system is

not operating normally. Contact your dealer.

Reader/writer error.

• Trouble when Operating

Symptom Possible Cause What to Do

Cards are not discharged. Card is jammed. Turn on power to reader/writer

again.

If cards are still not discharged,

turn off the power and open the

upper cover.

Then, pull the snap lever to

raise the upper portion of the

mechanism to remove the card.

Reading/Writing errors occur Inappropriate card. Use the recommended card.

Using other card type. Use the correct card.

Card data erased by magnet.

Card is bent. Issue a new card.

Card is damaged.

Head is dirty. Clean using a cleaning card.

Page 15

– 13 –

• Removing Jammed Cards

1. Turn off the power and unplug the reader/writer.

2. Press the cover opener.

3. Lift the upper cover while the cover is open.

4. While pulling the mechanism’s snap lever (green), lift the mechanism.

5. Remove the card while the cover is open.

Note: Do not touch the thermal head or erasing head. There is the danger of getting

burned.

6. Return the mechanism to its original position.

7. Close the upper cover.

Upper cover

Cover Opener

Snap lever

Thermal head

Erase head

Page 16

– 14 –

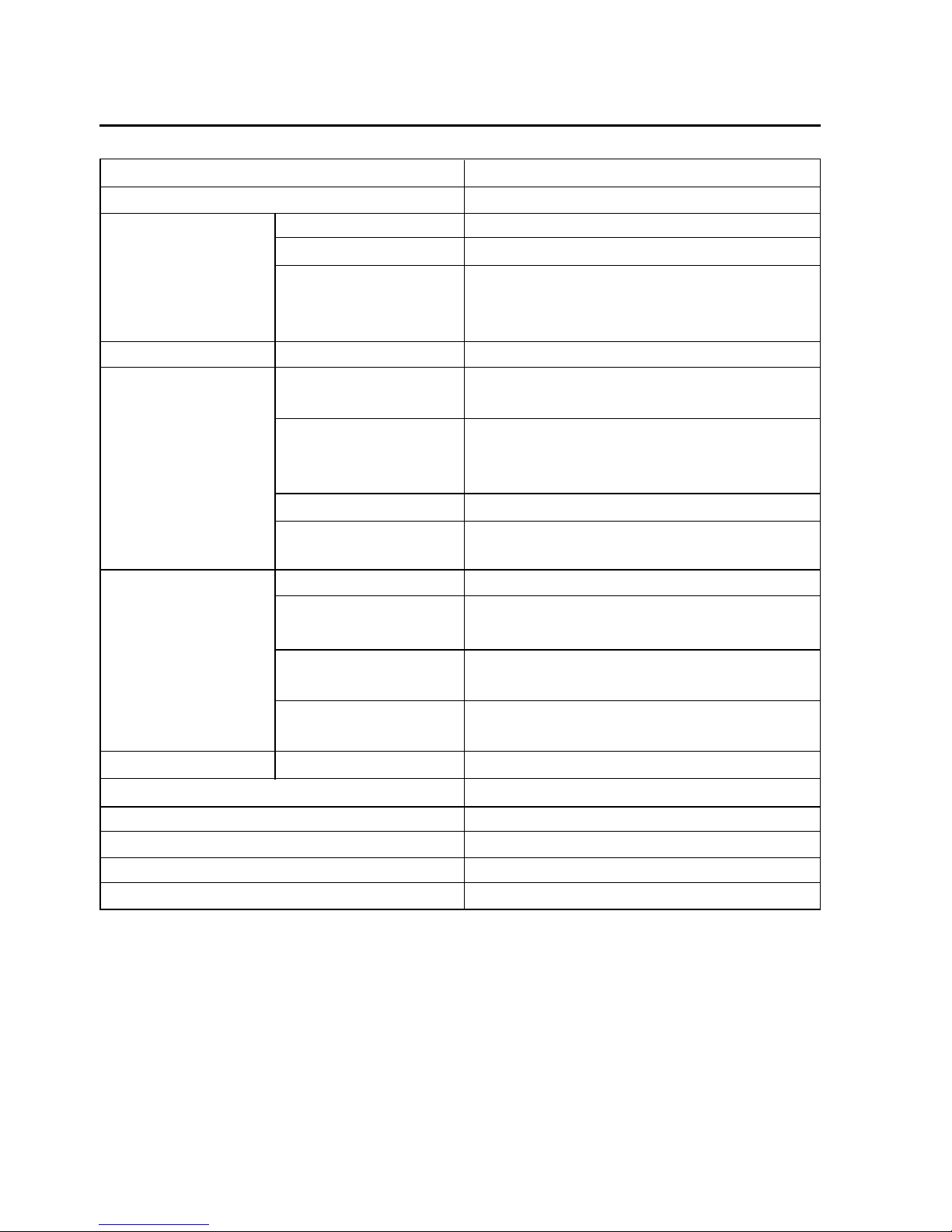

9. General Specifications

Specifications TCP300

Card Specification PET (Thin type card)

Card Transport Unit Transport Method Rollers

Card Insertion Direction One Direction

Card Travel Speed 400 mm/s (at high speed: When reading)

30 to 60 mm/s

(at slow speed: when erasing/printing)

Magnetic Stripe Functions * 1 Track or 3 Tracks Reading/Writing

Print Unit Number of Max. 20 characters x 13 lines (480 x 320 dots)

Print Characters

Printing Character Alphanumeric,

Types * Chinese Characters (BIG-5, GB Fonts),

External Characters, Graphics

Dot Configuration 24 x 12, 24 x 24, 48 x 24, 24 x 48, 48 x 48

Dot Pitch Vertical Direction: 0.125 mm

Horizontal Direction: 0.121 mm

Environment Location of Use Indoors

Conditions Ambient Temperature 5 to 35°C, 20 to 80% RH

and Humidity (There must be no condensation.)

Storage Temperature -30 to 65°C, 20 to 90% RH

and Humidity (There must be no condensation.)

Shock Durability 1.5 G 7 to 100 Hz XYZ Directions for

one hour (When packaged)

Reliability Reader/Writer Life 500,000 card passes under normal conditions.

Recommended cards STAR Recommended Thermal Re-writing Cards

Power Source * AC 90 to 132V/198 to 264 V

Interface * RS-232C D-sub 9 Pin/USB (optional)

Mass Approximately 2.5 kg

External Dimensions 119 (W) x 132.5 (H) x 270 (D) mm

* Differs according to specifications for destination.

Loading...

Loading...