Page 1

TC14A/TC18A

Domestic and Std. Export

English

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 (847)741-3300 FAX (847)741-4406

Conveyor Toaster

Models TC14A, TC18A

OWNER'S OPERATING AND INSTALLATION

MANUAL

P/N 39289

Rev. E V1 5/00

© 2000 Toastmaster, A Middleby Company.

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

I. DESCRIPTION AND SPECIFICATIONS

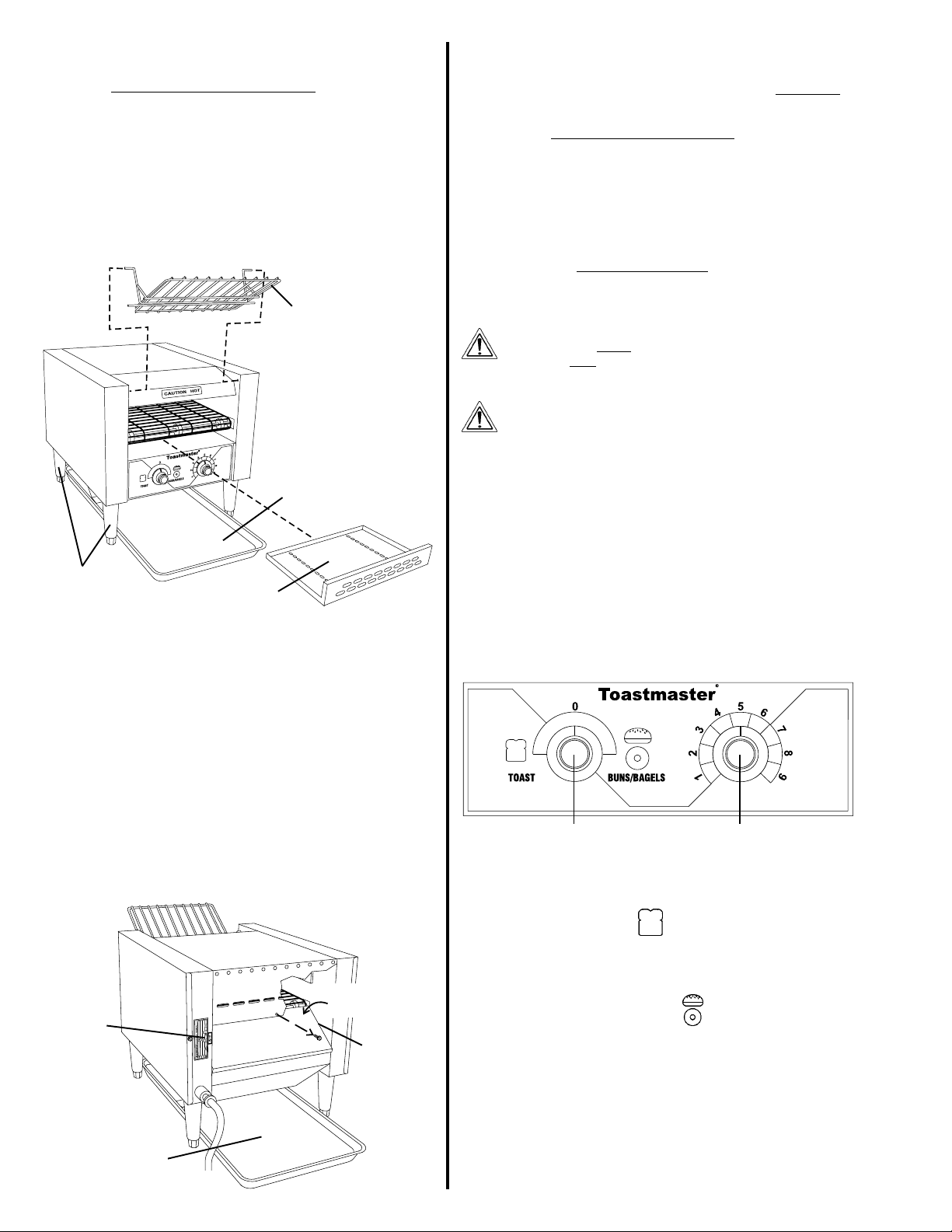

A. Component Location

The major components of the toaster are shown in Figure 1 below.

Figure 1

5. Conveyor

6. Return tray

B. Component Function (see Figure 1)

1-2. Toaster control knobs - see Section III, Operation.

3. Crumb tray - Collects crumbs from the toasted product. The tray

can be removed for cleaning.

4. Entry rack - Loaded with the bakery product to be toasted. The

product then slides onto the conveyor. The entry rack can be

removed for cleaning.

5. Conveyor - Transports the bakery product through the toaster,

between the top and bottom heating elements.

6. Return tray - Collects the toasted product. The tray can be removed

for cleaning.

C. Operating and Electrical Specifications

Pre-Heat Time: 20 minutes

Electrical Specifications/TC14A toaster models:

TC14A74. 120V, 50/60 Hz, 1 Ph, 1.7kW, 14.3A, NEMA 5-20P plug.

TC14A63. 208V, 50/60 Hz, 1 Ph, 1.8kW, 8.6A, NEMA 6-15P plug.

TC14A66. 240V, 50/60 Hz, 1 Ph, 1.8kW, 7.5A, NEMA 6-15P plug.

Electrical Specifications/TC18A toaster models:

TC18A63. 208V, 50/60 Hz, 1 Ph, 2.2kW, 10.5A, NEMA 6-20P plug.

TC18A66. 240V, 50/60 Hz, 1 Ph, 2.2kW, 9.1A, NEMA 6-20P plug.

NOTE

Electrical wiring diagrams are provided at the back of this Manual.

4. Entry rack

3. Crumb tray

2. Conveyor speed

control knob

1. Product

selection knob

WARNING: IN CASE OF FIRE

Disconnect the toaster from its power source IMMEDIATELY. This allows the unit to cool, making it easier to

put out the fire.

WARNING

FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ

THE INSTALLATION AND OPERATING INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

WARNING

DO NOT OPERATE THE CONVEYOR TOASTER ON

EITHER OF ITS SIDES, ON ITS REAR SURFACE, OR

WITHOUT LEGS. PREMATURE FAILURE OF THE

HEATING ELEMENTS WILL OCCUR.

WARNING

DISCONNECT THE TOASTER FROM ITS ELECTRICAL

POWER SUPPLY BEFORE CLEANING OR SERVICING.

CAUTION

Using any parts other than genuine Toastmaster factory parts relieves

the manufacturer of all liability.

IMPORTANT

Contact your authorized service agent to perform maintenance and

repairs. A service agency directory is supplied with your toaster.

IMPORTANT

Toastmaster (manufacturer) reserves the right to change specifications and product design without notice. Such revisions do not entitle

the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

This manual provides detailed information for the installation and

operation of your toaster. It also contains information to assist the

operator in diagnosing problems in the event of a malfunction. This

manual is an important tool for the operator and should be kept readily

available.

Page 2

II. INSTALLATION

IMPORTANT

IT IS THE CUSTOMERS RESPONSIBILITY TO REPORT ANY

CONCEALED OR NON-CONCEALED DAMAGE TO THE FREIGHT

COMPANY.

A. Assembly

1. Thread the 4 (102mm) legs into the four holes on the bottom of the

toaster. See Figure 2. Then, place the toaster in the desired location.

2. Install the entry rack and crumb tray into the front of the toaster, as

shown in Figure 2.

Figure 2 - Basic assembly and front-exit configuration

Entry rack

hanger rods fit

into holes on

toaster body

B. Electrical Utility Connection

IMPORTANT

THE ELECTRICAL CONNECTION TO THE TOASTER REQUIRES A

CIRCUIT BREAKER/FUSED DISCONNECT. ELECTRICAL SPECIFICATIONS ARE LISTED ON THE SERIAL PLATE (SHOWN IN FIGURE

3), AND IN THE ELECTRICAL SPECIFICATIONS ON PAGE 1 OF THIS

MANUAL.

CONSULT ALL APPLICABLE NATIONAL AND LOCAL CODES FOR

FURTHER ELECTRICAL CONNECTION REQUIREMENTS.

1. Before proceeding with the electrical connection, check the following:

a. Check that the electrical supply matches the toasters

requirements. Refer to the toasters serial plate (Figure 3)

and to the Electrical Specifications on Page 1.

b. Check that the appropriate receptacle is available for the power

cord plug.

WARNING

ENSURE THAT BOTH THE CIRCUIT BREAKER/FUSED DISCONNECT AND THE PRODUCT SELECTION KNOB ARE IN

THE OFF (0) POSITION BEFORE PROCEEDING.

WARNING

ENSURE THAT ANY PACKING MATERIAL RESIDUE HAS

BEEN REMOVED FROM INSIDE THE TOASTING CHAMBER.

Return tray

slides underneath

toaster

Legs (4)

thread into holes

in bottom of

toaster

Crumb tray

slides into opening

in front of toaster

3. TOASTERS INTENDED FOR FRONT-EXIT OPERATION ONLY:

Position the return tray underneath the toaster, as shown in Figure

2. Note that the return tray extends past the FRONT of the toaster

during front-exit operation.

4. TOASTERS INTENDED FOR STRAIGHT-THROUGH, REAREXIT OPERATION ONLY:

Remove the CENTER screw from the rear panel of the toaster,

as shown in Figure 3.

Push the rear panel forward into the toaster.

Position the return tray underneath the toaster as shown in

Figure 3. Note that the return tray extends past the REAR of

the toaster during rear-exit operation.

Figure 3 - Electrical connection and rear-exit configuration

3. Insert the power cord plug into its receptacle.

III. OPERATION

A. Location and Function of Controls

This section provides a basic description of the toaster controls, their

location, and the functions they perform. The operator MUST be familiar

with the controls. Refer to Figure 4.

Figure 4

1. Product

selection knob

1. Product Selection knob

2. Conveyor

speed control

knob

Serial plate

slides underneath

Return tray

toaster

2. Adjust

panel

1. Remove

screw

When set to TOAST ( ), switches on the conveyor, upper

heating element(s), and lower heating element(s).

When set to OFF (O), switches off the conveyor and all heating

elements.

When set to BUNS/BAGELS ( ), switches on the conveyor

and lower heating elements ONLY.

2. Conveyor Speed Control knob

Adjusts the speed of the conveyor. This controls the amount of

toasting that the bakery product receives.

1 is the minimum speed setting, which produces a darker

toasting of the bakery product.

9 is the maximum speed setting, which produces a lighter

toasting of the bakery product.

Page 3

B. Operation Procedure

1. Restore electrical power to the toaster at the circuit breaker/fused

disconnect.

2. Switch the Product Selection knob to either TOAST ( ) or BUNS/

BAGELS ( ), depending on the product to be toasted.

3. Allow the toaster to pre-heat for at least 20 minutes.

4. Adjust the toasting time (if necessary) by turning the conveyor speed

control knob.

5. Load the entry rack with the bakery product to be toasted. The

product will slide off the entry rack and onto the conveyor.

IMPORTANT

If the Product Selection knob is set to BUNS/BAGELS ( ), load

the bakery product CUT SIDE DOWN for proper toasting. Refer to

Figure 5.

6. After toasting, remove the product from the return tray.

7. During inactive periods, switch the Product Selection knob to the

BUNS/BAGELS ( ) position. This leaves only the lower heating

elements on, allowing a quicker recovery to normal toasting

temperatures.

Figure 5

C. Shutdown Procedure

1. Switch the Product Selection knob to the OFF (O) position.

2. Disconnect electrical power to the toaster at the circuit breaker/

fused disconnect.

3. Allow the toaster to cool.

D. Clearing Jams

WARNING

NEVER INSERT YOUR HANDS INTO THE TOASTING CHAMBER TO CLEAR A JAM. SERIOUS INJURY MAY RESULT.

CAUTION

NEVER use a plastic object to clear a jam. If the toaster is not completely cool, damage to the toaster may result.

CAUTION

When clearing a jam, use care to avoid damaging the heating elements.

1. Switch the Product Selection knob to the OFF (O) position.

2. Disconnect electrical power to the toaster at the circuit breaker/

fused disconnect.

3. Allow the toaster to cool.

CAUTION - HOT SURFACES

DO NOT ATTEMPT TO CLEAR THE JAM UNTIL THE TOASTER

HAS COOLED THOROUGHLY.

4. Carefully clear the jam using a long object as a probe. This object

should preferably be made of wood, which is less likely to damage

the heating elements.

Product selection

knob in BUNS/

BAGELS position

Load buns/bagels

CUT SIDE DOWN

for proper toasting

E. Daily Cleaning

WARNING

WHEN CLEANING THE TOASTER, NEVER APPLY ENOUGH

LIQUID TO STAND IN PLACE ON THE UNIT. DO NOT SPRAY,

RINSE, OR SUBMERGE THE TOASTER. EXCESSIVE MOISTURE IN THE UNIT WILL CAUSE A SEVERE ELECTRICAL

HAZARD AND MAY OTHERWISE DAMAGE THE TOASTER.

CAUTION

DO NOT clean your toaster using abrasive cleaners or pads. Both will

scratch and dull the finish.

1. With the conveyor running, use a brush to clean any crumbs off the

conveyor into the crumb tray.

2. Switch the Product Selection knob to the OFF (O) position.

3. Disconnect electrical power to the toaster at the circuit breaker/

fused disconnect.

4. Allow the toaster to cool.

CAUTION - HOT SURFACES

DO NOT TOUCH HOT SURFACES ON THE TOASTER, OR

REACH INTO THE TOASTING CHAMBER, UNTIL THE UNIT

HAS COOLED THOROUGHLY.

5. Wipe the exterior of the toaster with a sponge or cloth soaked in hot

or warm detergent water. Wipe with a clean, damp cloth to remove

the excess detergent, and then wipe again to dry the toaster.

6. Remove the crumb tray and the return tray from the toaster, and

empty them. Wash the trays in warm detergent water, and rinse

them.

CAUTION

Never remove the crumb tray while the conveyor is moving.

7. Remove the entry rack from the toaster. Wash the rack in warm

detergent water, and rinse it.

8. Towel the trays and entry rack dry. Reassemble all parts onto the

toaster.

Page 4

Wiring Diagram

Model TC14A74

120V Toasters

TOP ELEMENT

BTM ELEMENT 1

BTM ELEMENT 2

PRODUCT

SELECTION

SWITCH

GND

FAN

SPEED CONTROL

TERMINAL

BLOCK

MOTOR

CONVEYOR

Wiring Diagram

Model TC14A63, -66

208V and 240V

Toasters

Wiring Diagram

Model TC18A63, -66

208V and 240V

Toasters

TOP ELEMENT

BTM ELEMENT 1

BTM ELEMENT 2

TOP ELEMENT 1

TOP ELEMENT 2

BTM ELEMENT 1

BTM ELEMENT 2

PRODUCT

SELECTION

SWITCH

GND

PRODUCT

SELECTION

SWITCH

GND

TRANSFORMER

230V p

115V s

TERMINAL

BLOCK

TRANSFORMER

230V p

115V s

TERMINAL

BLOCK

FAN

SPEED CONTROL

FAN

SPEED CONTROL

MOTOR

CONVEYOR

MOTOR

CONVEYOR

Switch

Configuration

All Model TC14A

and TC18A Toasters

Toastmaster 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

Middleby Corp 24-Hour Service Hotline 1-800-238-8444

TOASTOFF

BUNS/

BAGELS

A Middleby Company

www.middleby.com

Loading...

Loading...