Page 1

1

Gasoline Tiller

Gasoline Tiller

SGT-25-450-H

GB

Original instructions

Page 2

2

2

Manufactured under license by:

MATRIX GmbH • Postauer Straße 26 • D-84109 Wörth/Isar • www.matrix-direct.net

Stanley is a registered trademark of The Stanley Works or its affiliates and is used under license.

GB

Page 3

3

3

GENERAL SAFETY RULES

ATTENTION: When using gasoline motors like this

one, basic safety rules must be observed in order

to reduce risk of accidents and/or damage to the

machine. Read all instructions again before using

the device in the future.

SAFETY PRECAUTIONS

• Read these instructions carefully.

• Never allow children or persons who are not

familiar with these instructions to operate the

machine. Local regulations may impose a limit on

the age of the operator.

• Never operate the machine around children or

pets.

• Keep in mind that the operator of the machine is

responsible for any accidents that may occur to

third parties and/or to their property.

• The machine must be operated solely by a

capable person who is qualified to operate it.

• Always wear appropriate footwear (safety shoes)

and long pants when operating this tool.

• Do not operate the machine when barefoot or

when wearing open sandals.

• Carefully inspect the area where the equipment

will be operated and remove any objects that could

be thrown by the machine.

CAUTION

-

Gasoline is extremely flammable:

- Store fuel only in containers designed for this

purpose.

- Refill the machine with fuel only when outdoors

and never smoke when re-filling the equipment

with fuel.

- Add fuel before starting up the motor. Never

remove the fuel tank plug or add gasoline while the

motor is running or when the engine is hot.

- If gasoline is spilled, do not attempt to start up the

motor; take the machine away from the area where

the gasoline was spilled and keep all sparks away

until the gasoline has evaporated.

• Replacing a defective muffler.

• Before each use, always check to be sure that

the tools are not worn out or damaged. When

changing a worn-out or damaged component or

bolt, change all similar components out in order to

preserve balance.

• Do not operate the machine in a confined space

where dangerous carbon monoxide vapors could

accumulate.

• Always be sure that the machine is balanced on

its stands.

• Walk, never run, with the machine.

• Work is a diagonal direction, never from up and

down.

• Pay very close attention when changing direction

on slopes.

• Never work on slopes that are too steep.

• Pay very close attention when reversing the

machine or pulling it towards you.

• Do not change direction adjustments and do not

exceed the speed limit of the motor.

• When starting the motor, following the

instructions carefully and keep your feet far away

from the blades.

• Do not put your hands or feet near or on rotating

parts.

• Never pick up or carry the machine while the

motor is running .

• Shut off the motor:

• Every time you leave the machine.

- Before refilling it with gasoline.

- When performing maintenance and cleaning

operations.

- While changing tools.

- When using any traction force other than the

engine to move the machine.

• Reduce the starter when shutting off the machine

and close the fuel hose when finished working.

• Use the tiller only with the blades provided.

• Always place your hands on the handlebar when

using the machine. Do not hold the machine by its

other parts while operating it.

• Keep all nuts, bolts and screws properly tightened

so that you are sure that equipment is in optimum

safety condition.

• Never store the equipment with gas in the tank,

inside a building where vapors could reach an

open flame or a spark.

G

B

Page 4

4

4

• Allow the motor to cool off before storing it in any

enclosed space.

• To reduce risk of fire, keep the storage area for

the machine, tail pipe and gasoline free of any

vegetation or excess lubricant.

• Replace any worn or damaged parts as a measure

of safety.

• If the fuel tank must be drained, it must be done

outdoors. Handle fuel in an environmentally safe

manner.

• The fuel tank must be drained every time the tiller

is moved.

• To reduce the effects of machine vibrations, wear

protective gloves when operating it.

• Be sure to take breaks after every 30-minute

period of work to avoid Hand Arm Vibration

Syndrome.

PRELIMINARY MEASURES:

When working, always wear stable shoes and long

pants.

Never operate the machine when barefoot or when

wearing light sandals.

Inspect the entire terrain on which you will be

operating the equipment and remove any objects

that could be thrown by the machine.

CAUTION!

– Gasoline is extremely flammable!

Store gasoline only in containers that are designed

for this purpose. Fill it up only in the open air and do

not smoke when filling it.

Fill the tank with gas before starting the motor. Do

not open the gas tank closure plug or fill it with

gasoline while the motor is operating, or when the

motor is hot.

If the gasoline overflows, do not attempt to start up

the motor for any reason.

Instead, remove the equipment from the area

where the gas has been spilled. Then, avoid all

attempts to start up the machine until all gasoline

vapors have evaporated

Replace any damaged tailpipes.

Before use, always visually inspect for worn or

damaged parts. If there are any worn or damaged

parts, or fastening bolts, the entire set must be

replaced.

HANDLING:

The engine must not be operated in enclosed

areas in which carbon monoxide, a dangerous

substance, could become concentrated.

Operate this machine only in daylight or with

proper lighting. Be sure that you keep the unit

balanced on its stands.

Do not operate the machine faster than you can

walk.

For wheeled machines: Work transversely relative

to the slope, never when climbing or descending.

Pay particular attention when you are changing

direction on a slope.

Be especially careful when you are making a

U-turn with the machine or when you are pulling it

towards you.

Never change the motor base adjustment or make

it run too quickly.

Use caution when starting up the motor, in

compliance with the manufacturer’s instructions

and be sure to keep a sufficient distance between

your feet and the tool or tools.

Never put your hands or feet on or under rotating

parts.

Never lift or carry a machine when its motor is

running.

Always shut off the motor before filling the fuel

tank with gasoline. When the motor is running

unloaded, be sure to close the flow restrictor.

If the machine has a gasoline shutoff valve, it must

be closed after any intervention

For safety reasons, the motor rotation speed must

not exceed the data indicated on the power plate.

Always use two persons to transport or store the

power tiller. Do not carry it all by yourself.

G

B

Page 5

5

5

SYMBOLS

Complies with appropriate safety

standards.

Keep bystanders away.

Only operate the

generator outside to ensure

adequate ventilation.

Do not smoke or have open flames

Stay away from rotating augers.

During operation, toxic gases are

produced e.g. carbon monoxide

(Which is a colorless and odorless

gas) this gas may lead to by

suffocation.

Wear eye protection.

Wear hearing protection.

Read these instructions for use

carefully.

wear gloves when operating

Wear safety footwear.

Never direct discharge towards

persons or property.

Do not touch a hot muffler, gear

housing or cylinder.

G

B

Important: Do not wear loose clothing,

neckties or jewelry (rings, wristwatches)

when operating this machine. They may be

caught by moving parts.

Page 6

6

6

G

B

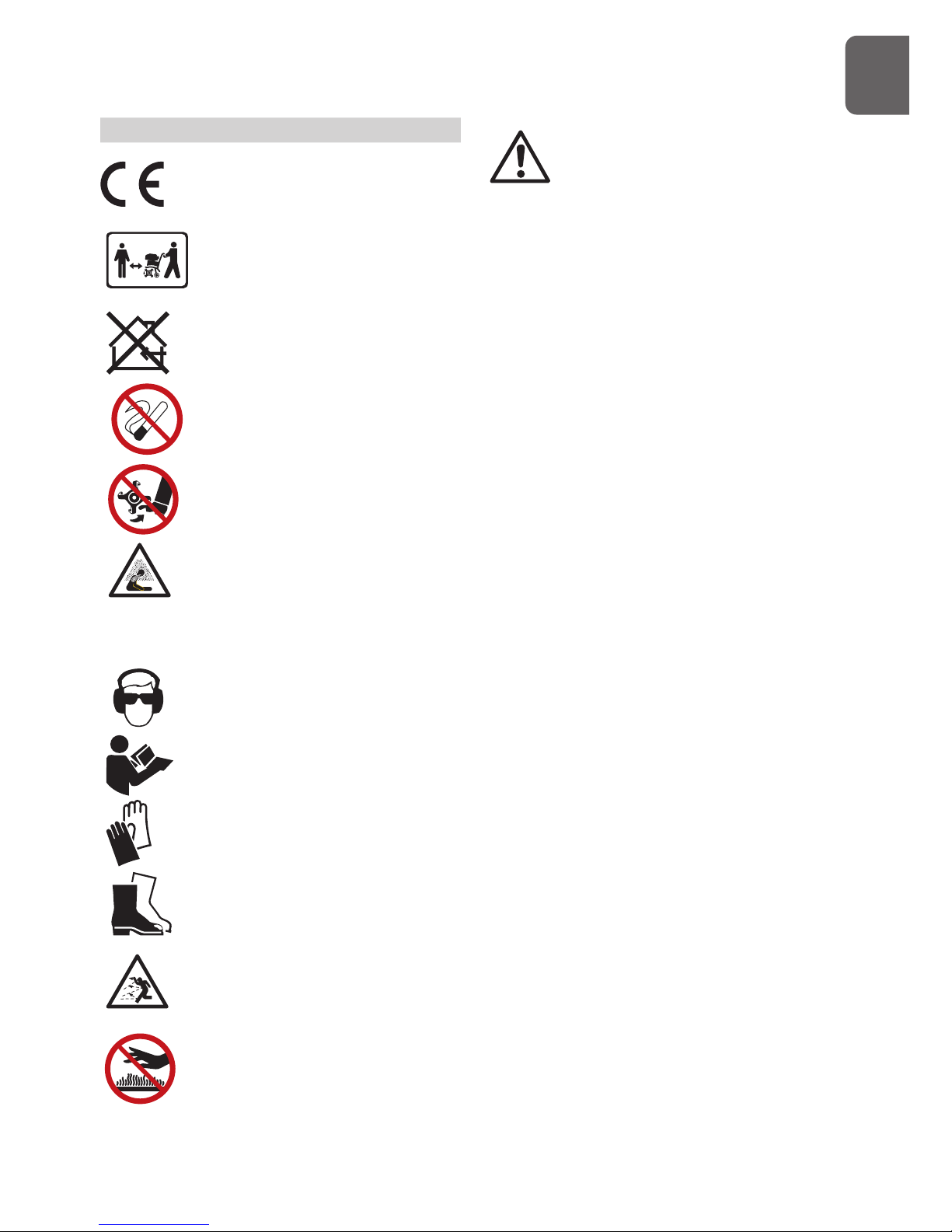

CONTENTS SUPPLIED

1.Tiller X1

2.Girder X1

3.Wheel assy X1

4.Right blade cover X1

5.Blade disc X2

6.Resistance rod X1

7.Safety plate X1

8.Right blade assy X1

9.Left blade assy X1

10. Resistance rod support X1

11.Pin X4

12.Cotter pin X5

13.Cable bandage X4

14.Bolt M 8*70 X2

15.Hex flange face locknut M8 X5

16.Bolt M 8*16 X2

17.Flat washer D8 X3

18.Bolt M 6*35 X2

19.Flat washer D6 X2

20.Hex locknut M6 X2

21.Hex bolt M 8*50 X1

22.Extension spring X1

23.Hex bolt M 8*70 X1

24.Handle lock lever X1

25.Hex locknut M8 X1

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

1

2

3

4

7

8

6

5

9

10

g.1

Page 7

7

7

G

B

ASSEMBLY

Following the assembly directions below, you will

assemble the front tine tiller in a few minutes.

1.Place tilling tines on the tine shaft on both sides

of the gear box. Line up the holes in the tine frame

sleeves and tine shaft. Insert clevis pins through

the holes in tine frames and tine shaft. Insert cotter

pins through the holes in the clevis pins to secure

them.(Fig.3)

11/12

5

9

8

5

g.2

2. Install the resistance rod support with clevis pin,

and tight them with cotter pin. Insert the resistance

rod in the hole of resistance

rod support, then lock them with lock lever in

desired position.(Fig.3)

g.3

6

10

3. Mount the girder on the tiller with 2

M8*70 screws and flange nuts.(Fig.4)

g4

2

14/15

4. Install the handle on the girder with M 8*70

screw, washer and flange nut, then insert the

lock lever in desired position to secure the top of

handle(Fig.5).

g.5

12/17/24

17/23/25

5. Install the safety plate with 2x M 6*35 screws,

washers and flange nuts.(Fig.6)

g.6

7

18/19/20

6. Mount the Wheel assy on the tiller with M 8*50

screw and flange nut, then hang extension spring

(Fig.7).

Page 8

8

8

g.7

3

15/21

22

7. Install the Cable bandage(See Fig.8)

g.8

13

8. Mount the blade cover and tight it on the

machine with 2x M 8*16 screws and flange

locknuts.(See Fig.9)

g.9

4

15/16

Engine oil

Engine is shipped from factory without

oil. You must add engine oil before

G

B

Page 9

9

9

G

B

7

2

3

4

5

6

9

8

1

Page 10

10

10

LAYOUT

1. Handle

2. Gasoline engine

3. Blade cover

4.Blade disc

5. Wheel

6. Chain box

7. Blade

8. Resistance rod

9. Belt cover

10.Oil dispstick

11. Choke Lever

12.ON/OFF Switch

13.Recoiling Handle

14. Forward control rod

15. Reverse control rod

16. Adjust Nut

17. Spark cap

18. Spark Plug

OPERATION INSTRUCTION

1. Checking/Adding Oil (Figure 10)

Place engine in a horizontal position and clean the

oil fill area of any debris before adding or checking

the oil.

1) Remove the dipstick (G) and swipe with a clean

cloth.

2) Insert the dipstick into the filler neck without

screwing it in.

3) Pull the dipstick out and check the oil lever. The

oil lever should be in between the MIN.and MAX.

levels.

4) If low, add oil slowly into the engine oil fill

tube(G). Do not overfill. After adding oil, wait one

minute and then recheck the oil level.

5) Replace and tighten the dipstick.

g.10

Warning:

If the level is too low, it may cause serious damage

to the engine. When the engine is working,

please use clean and good quality 4-stroke engine

oil. Run with other engine oil or dirty oil may

shorten the lifetime of the engine severely.

2. Adding fuel (Figure 11)

1) Clean the fuel cap area of dirt and debris.

Remove the fuel cap.

2) Fill the fuel tank with gasoline. To allow for

expansion of the gasoline, do not fill above the

bottom of the fuel tank neck.

3) Reinstall the fuel cap.

CAUTION:

1) Turn engine off and let engine cool at least 2

minutes before removing the fuel cap.

2) Fill fuel tank outdoors or in well-ventilated area.

3) Do not overfill fuel tank. Fill tank to approximately

1.5 inches (38mm) below top of neck to allow for

fuel expansion.

4) Gasoline is extremely flammable and is

explosive. Do not smoke and allow flames or sparks

G

B

Page 11

11

11

in the area where gasoline is stored or where the

fuel tank is refueled.

5) Check fuel lines, tank, cap and fittings frequently

for cracks or leaks. Replace if necessary.

6) If fuel spill,wait until it evaporates before starting

engine.

g.11

3. Starting engine

Starting is different due to different equipments. It

is optional according to your engine.

1) Check the engine oil lever. See the” Checking/

Adding Oil” section.

2) Push the choke lever to the CLOSE position (Fig.

12)

Note: It is not necessary to push to the CLOSE

position when the engine is warm or the air

temperature is high.

g.12

Open

Close

11

3) Push below switche to the “ON” position.(Fig. 13)

g.13

12

4) Pull the starting handle slowly until you feel

the resistance, and then pull it out suddenly and

quickly. (Fig.14)

g.14

13

Attention:

Send the starting handle back slowly. Or it may

cause the damage of the starting equipment and

other spare parts. Please don’t pull the starting

handle out when running, because it will affect the

engine.

5) If the choke lever is on the “CLOSE” position,

please turn the choke lever to the “OPEN” position

after engine runs 2 minutes. (Figure 12)

4. Shutting the engine down

Push the Engine switch to the “OFF” position.

(Figure 13)

5. Adjusting the clutch

If the main clutch cable is not adjusted well (too

G

B

Page 12

12

12

tight or loose), the clutch may not work well.

1) Starting the engine.

2) Take the clutch control rod to the middle position.

( Figure 15)

3) Turn the adjusting nut in figure 16 in a clockwise

direction to tighten the wheel clutch; or in a

anticlockwise direction to loosen it.

g.15

14

15

g.16

16

6. Using the rear resistance rod or adjusting the

tilling depth

Adjust the depth of rear resistance rod by changing

the hole. (Figure 17)

7. Adjusting the height of the handle

Loosen the bolt and then adjust the height of the

handle by moving the nut right or left. (Figure 18)

g.17

g.18

Tilling

Tilling is digging in, turning over and breaking up

garden soil and prepare a seedbed for planting.

Best tilling depth is 100mm (4”) to 150mm (6”). A

tiller will also clear the soil of unwanted vegetation.

The decomposition of this vegetation matter

enriches the soil.

Avoid tilling soil that is too dry as it will pulverize

and produce a dust that will not hold water. Water

a few days before tilling. Also, tilling soil that is

too wet will produce unsatisfactory clods. Wait a

day or two after heavy rain for the soil to dry.

Better growth will be obtained if an area is tilled

properly and used soon after tilling to preserve

the moisture content.

The type of soil and working conditions will

determine the actual setting of the tilling depth.

In some soils, the desired depth is reached first

pass over garden. In other soils, the desired depth

is obtained by going over the garden two or three

G

B

Page 13

13

13

times. In later case, the depth regulator rod should

be lowered before each succeeding pass over the

garden. Passes should be made across the length

and width of the garden alternately. Do not try to

dig too deeply in the first pass. If the machine

jumps or bucks, allow the unit to move forward

at a lightly faster rate.

If the tiller stops forward motion and tries to dig

in one spot, rock the handles from side to side to

start it moving forward again.

Rocks which are turned up should be removed

from the garden area.

Cultivating

Cultivating is loosening or digging around growing

plants to disrupt weeds and aerate soil. Less than

50mm (2”) depth is always desirable.

MAINTENANCE

CAUTION:

Stop the engine at the flat ground, and do not touch

the hot part or moving parts to avoid injury. If the

maintenance is required with the engine running,

be sure to keep good ventilation in the area. The

exhaust emissions from the engine contain toxic

carbon monoxide, breathing it may result injury and

even death.

Keeping your tiller in top running condition will

prolong its life, and help you obtain optimum

performance whenever you wish to till your garden.

Cleaning tine area

Clean the tiller underside of the tine shield after

each use. The dirt washes off tines easier if rinsed

off immediately instead of after it dries.

1. Turn off engine. Engine must be cool.

2. Keep the engine’s throttle control in its “STOP”

position, and remove spark plug wire from spark

plug and secure.

3. Remove all vegetation, string, wire, and other

materials that may have accumulated to the

axle between the inside set of tines and the

seals on the transmission housing.

4. Always towel dry the tiller afterwards and apply

a light coat of oil or silicone to prevent rusting

or water damage.

5. Replace spark plug wire.

Never use a “pressure washer” to clean

your tiller. Water can penetrate tight

areas of the tiller and its transmission

case and cause damage to spindles, pulleys,

bearings, or the engine. The use of pressure

washers will result in shortened life and reduce

serviceability.

Lubrication

Remove the tine assemblies to lubricate the tine

shafts at least once a season.

Change Oil

When the engine is hot, it is easy to drain the oil

out completely.

- Keep the engine in a horizontal position.

- Unscrew the oil filler (bolt). (Fig.19)

- Place a cup under the drain plug and then screw

off the drain plug to drain the oil out completely.

- After draining the oil thoroughly out , re- install

the drain plug.

- Fill engine oil up to the mark of top limit.

- Re-install the oil filler.

g.19

G

B

Page 14

14

14

Clean the air filter (Fig.20)

If the air cleaner is jam, it will output less enough

air and cause fuel consumption increase. Check

and clean it periodically.

Cleaning Period: Once 50 hours’ working.

If work in hervy dust area, check it every day or

once 10 hours.

Replace: each year or 300 hours’ running

1) Remove the air cleaner housing.

2) Remove paper element, paying attention to

prevent dust and foreign matter.

3) Check, clean or replace damaged air cleaner

parts.

4) Re-stall the air cleaner parts back.

g.20

Clean the sediment cup (Fig.21)

First check fuel tank for fuel, if having, drain the

fuel in the fuel tank completely.

1) Remove the fuel sediment cup and o-ring.

2) Wash the sediment cup and o-ring in nonflammable solvent and dry them thoroughly.

3) Place the o-ring in the fuel valve and install

the sediment cup. Then tighten the sediment cup

securely.

4) Move the fuel valve to the ON position and check

for leaks. And replace the o-ring if there is any

leakage.

G

B

Deposit Cup

O Seal Ring

g.21

Clear Spark Plug(Fig.22/23)

In order to ensure the engine normal running,

the gap of the spark plug must be correct and no

deposit around the spark plug.

5) Remove the spark cap

6) Clear away dirt around the spark plug base.

7) Dismantle the spark plug with a spark plug

wrench.

8) Visually check the spark plug. Clean with a steel

brush. If the insulator is damaged, replace the

spark plug .

9) Measure the spark plug clearance with

a thickness feeler. The clearance should be

0.6~0.7mm. If adjustment is necessary, bend the

side electrode carefully.

10) Check if the spark plug gasket is in good

condition.

11) Screw the spark plug to the bottom first by hand

and then screw up with a spark plug wrench and

compress the gasket.

g.22

17

Page 15

15

15

g.23

18

STORAGE

If the tiller will not be used for a period longer than

30 days, following the steps below to prepare your

tiller for storage.

1. Drain the fuel tank completely. Stored fuel

containing ethanol or MTBE can start to go stale

in 30 days. Stale fuel has a high gum content

and can clog the carburetor and restrict fuel

flow.

2. Start the engine and allow it to run until it stops.

This ensures no fuel is left in the carburetor.

This helps prevent gum deposits from forming

inside the carburetor and possible engine

damage.

3. While the engine is still warm, drain the oil from

the engine. Refill with fresh oil of the grade

recommended in the Engine Manual.

4. Allow the engine to cool. Remove the spark

plug and put 30 ml (1 oz.) of high quality motor

oil into the cylinder. Pull the starter rope slowly

to distribute the oil. Replace the spark plug.

Remove the spark plug and drain all

of the oil from the cylinder before

attempting to start the unit after

storage.

5. Use clean cloths to clean off the outside of the

tiller and to keep the air vents free of

obstructions.

Do not use strong detergents or

petroleum based cleaners when

cleaning plastic parts. Chemicals can

damage plastics.

6. Inspect for any loose or damaged parts. Repair

or replace damaged parts and tighten loose

screws, nuts or bolts.

7. Remove the tines. Clean and apply oil to the

tines and tine shafts to prevent rusting. Mount

the tines onto the tine shafts.

8. Oil the control cables and all visible moving

parts. Do not remove the engine cover.

9. To store with the handles folded down, loosen

the knobs that secure the upper handle to the

lower handles. Carefully fold the upper handle

down. Do not allow control cables to become

pinched or bent. Tighten the knobs.

Do not sore tiller with fuel in a

nonventilated area where fuel fumes may

reach flame, sparks, or any ignition

sources.

Use only approved fuel containers

.

Specification

Engine 4-stroke, air-cooled single cylinder, OHV

Max. Power (kw/rpm) 1.8/3600

Displacement (cc) 94

Fuel Tank Capacity (L) 1.5

Oil Capacity(L) 0.4

Tilling Width (mm) 450

Tilling diameter (mm) 260

Tine Speed (rpm) Forward 180/Reverse 100

Starting Type Recoil

Sound power level L

WA

91.2 dB(A), K=3dB

Sound pressure level LPA 87.8 dB (A), K=3dB

Garantierter Schallleistungspegel LWA: 93dB(A)

Vibrating level on handlebar grips

Left: 11.7 m/s2, K=1,5m/s2

Right: 10 m/s2, K=1,5m/s2

G

B

Page 16

16

16

G

B

Maintenance schedule

Frequency

Items

Each time First

month or

20hrs

Each

season

or 50hrs

Every 6

month or

100 hrs

Each year

or 300hrs

Engine Oil Oil level

check

○

Replace

○ ○

Reduction

Gear Oil

Oil level

check

○

Replace

○ ○

Air Cleaner Check

○

Clean

○ ○

Replace

○

Deposit Cup Clean

○

Spark Plug Clean, adjust

○

Replace

○

Valve

Clearance

Check-adjust

○

*

Fuel Tank &

Fuel Filter

Clean

○

Fuel Supply

Tube

Check Every two years( do a replacement if necessary)

Cylinder head Clean carbon Every 125hours*

Notice:

When it works in heavy dusty area, the air cleaner should be cleaned after 10 hours or once

a day.

Please check the machine periodically upon the schedule or the working time, which expires

first.

Page 17

17

17

Problem Cause Remedy

Engine fails to start.

1. Spark plug wire disconnected.

2.Out of fuel or stale fuel.

3. Throttle control lever not in correct

starting position.

4.Choke not in ON Position.

5.Blocked fuel line.

6.Fouled spark plug.

7.Engine flooding.

8. Tine clutch control not in neutral

position.

1. Attach spark plug wire securely to

spark plug.

2.Fill with clean, fresh gasoline.

3. Move throttle control lever to start

position.

4. Chock must be positioned at CHOKE

for a cold start.

5.Clean the fuel line.

6.Clean, adjust gap, or replace.

7. Wait a few minutes to restart, but do

not prime.

8. Tine clutch control lever must be released

to neutral to start the engine.

Engine runs erratically.

1. Spark plug wire loose.

2.Unit running on CHOKE.

3.Blocked fuel line or stale fuel.

4.Vent plugged.

5.Water or dirt in fuel system.

6.Dirty air cleaner.

7.Improper carburetor adjustment.

1. Connect and tighten spark plug wire.

2.Move choke lever to OFF.

3. Clean fuel line. Fill tank with clean,

fresh gasoline.

4.Clear vent.

5. Drain fuel tank. Refill with fresh fuel.

6.Clean or replace air cleaner.

7.Refer to Engine Manual.

Engine overheats.

1. Engine oil level low.

2.Dirty air cleaner.

3.Air flow restricted.

4.Carburetor not adjusted properly.

1. Fill crankcase with proper oil.

2.Clean air cleaner.

3.Remove blower housing and clean.

4.Refer to Engine Manual.

Engine will not stop when

throttle control is positioned

at stop, or engine speed

does not increase properly

when throttle control is

adjusted.

1. Debris interfering with throttle linkage.

2. Improper throttle linkage

adjustment.

1. Clean dirt and debris.

2. Refer to Engine Manual to check and

adjust throttle linkage.

Tiller moves forward during

starting.

Tine clutch control not in neutral

position.

Tine clutch control lever must be released

to neutral to start the engine.

Tiller is difficult to control

when tilling (machine jumps

or lurches forward).

1. Improper tilling depth setting.

2. Too high engine speed on hard

ground.

1. Raise the tines for shallower tilling

by raising the depth regulator rod.

2.Set the throttle lever at lower speed.

Tines do not engage.

1. Foreign object lodged in tines.

2.Tine clevis pin(s) missing.

3.Belt worn and/or stretched.

4. Pulley and idler not in correct

adjustment.

1. Stop tiller completely, check and

discard foreign object.

2.Replace tine clevis pin(s).

3.Replace belt.

4.Contact dealer.

TROUBLE SHOOTING

G

B

Page 18

18

18

Matrix GmbH

Postauer Str. 26

D-84109 Wörth/Isar

Germany

Fax: +49 (0) 8702/45338 98

E-Mail: info@matrix-direct.net

EN 709; EN ISO 14982; Geräuschemission 2000/14/EC, Anhang VI & 2005/88/EC

Garantierter Schallleistungspegel: LwA= 97 dB (A) Gemessener Schallleistungspegel: LwA= 93,5 dB (A)

Benannte Stelle , Name und Anschrift der beteiligten Stelle: TÜV SÜD China. 16F, West Building, New

Hua Lian Mansion, No. 775, Huaihai Road Shanghai 200020,P.R.China

Wörth/Isar, den 27.11.2017

Art.-Nr.: 604.400.020

The technical documentation is kept by our authorized representative:

Matrix GmbH

Postauer Str. 26

D-84109 Wörth/Isar

Germany

Front Tine Tiller /SGT-25-450-H

2006/42/EC

R&TTED 1999/5/EC

2000/14/EC_2005/88/EC

97/68/EC_ 2004/26/EC

97/68/EC_2012/46/EC

93/68/EEC

2014/30/EU

2002/96/EC

Joachim Lichtl (Geschäftsführer)

GB

hereby declares the following conformity

under the EU Directive and standards for

the following article

Original Declaration of Conformity

Page 19

19

19

GARANTIE

Guarantee

GB

This appliance is a quality product. It was designed in compliance with

current technical standards and made carefully using normal, good quality

materials.

The warranty period is 24 months and commences on the date of purchase,

which can be verified by the receipt, invoice or delivery note. During this

warranty period all functional errors, which, despite the careful treatment

described in our operating manual, are verifiably due to material aws, will

be rectified by our after-sales service staff.

The warranty takes the form that defective parts will be repaired or replaced

with perfect parts free of charge at our discretion. Replaced parts will

become our property. Repair work or the replacement of individual parts

will not extend the warranty period not will it result in a new warranty period

being commenced for the appliance. No separate warranty period will

commence for spare parts that may be fitted. We cannot offer a warranty for

damage and defects on appliances or their parts caused by the use of excessive

force, improper treatment and servicing.

This also applies for failures to comply with the operating manual and the

installation or spare and accessory parts that are not included in our range of

products. In the event of interference with of modifications to the appliance by unauthorised

persons, the warranty will be rendered void.

Damages that are attributable to improper handling, over loading, or natural wear and tear

are excluded from the guarantee.

Damages caused by the manufacturer or by a material defect will be corrected at no

charge by repair or by providing spare parts.

The prerequisite is that the equipment is handed over assembled, and complete with

the proof of sale and guarantee.

For a guarantee claim, only use the original packaging.

That way, we can guarantee quick and smooth guarantee processing.

Please send us the appliances post-paid or request a Freeway sticker.

Unfortunately we will be unable to accept appliances that are not postpaid.

The warranty does not cover parts that are subject to natural wear and tear.

If you wish to make a warranty claim, report faults or order spare parts or

accessories, please contact the after-sales centre below:

Subject to change without prior notice.

210 Bath Road; Slough, Berks SL1 3YD

www.stanleytools.co.uk

Tel: +44 (0)1753 511234

Fax: +44 (0)1753 512365

Page 20

20

20

Front Tine Tiller /SGT-25-450-H

GB

WARRANTY

Purchased at:

in (city, street):

Name of customer:

Street address:

Postal code, city:

Telephone:

Date, signature:

Fault description:

Loading...

Loading...