Page 1

SGS105

English Page 04

Russian Page 11

Ukrainian Page 21

Page 2

ENGLISH (Original instr uctions )

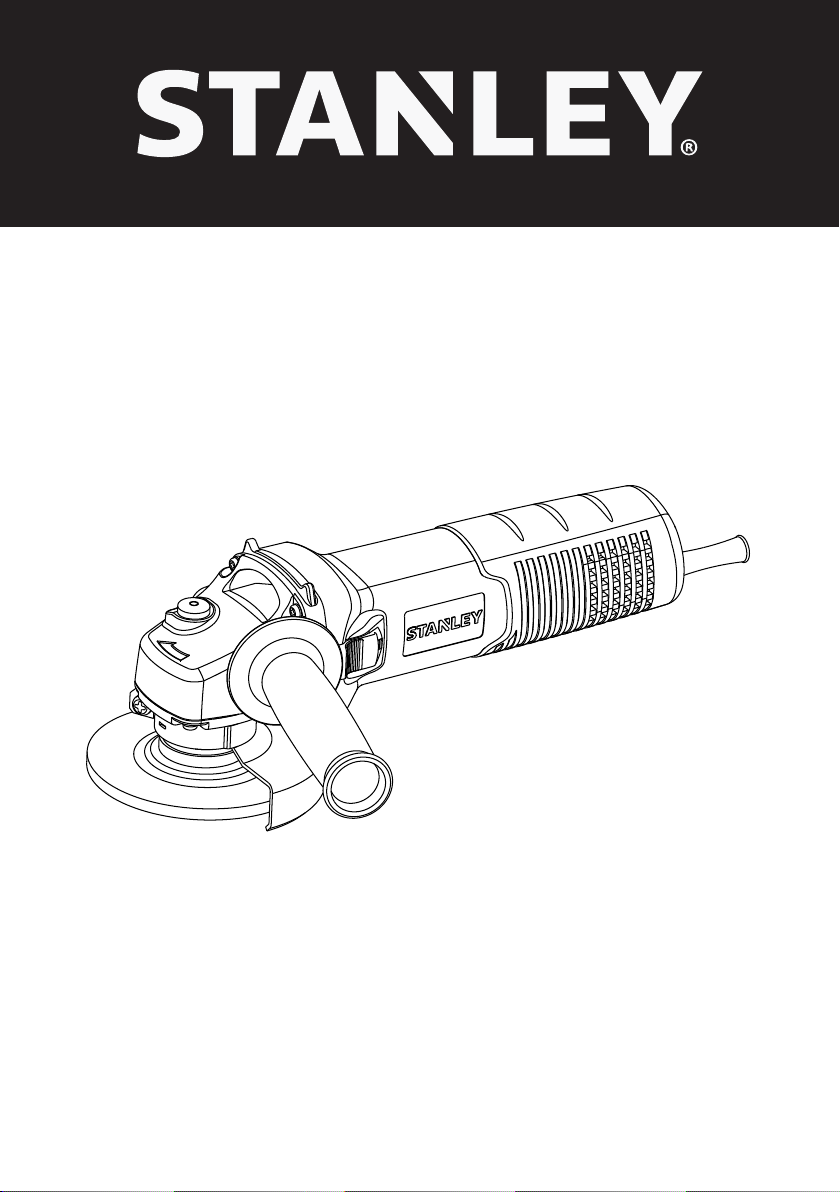

A

2

3

1

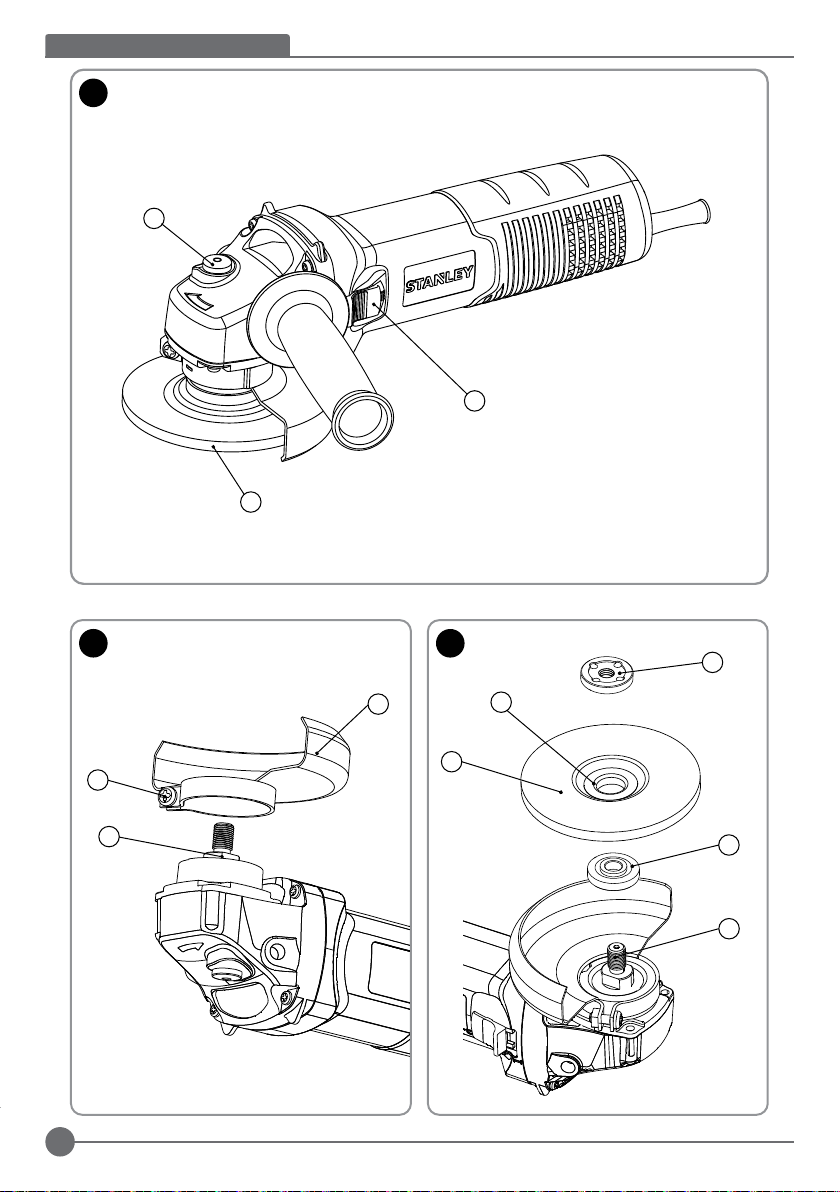

B

3

10

9

C

8

7

6

4

5

2

Page 3

(Or iginal instructions) ENGLISH

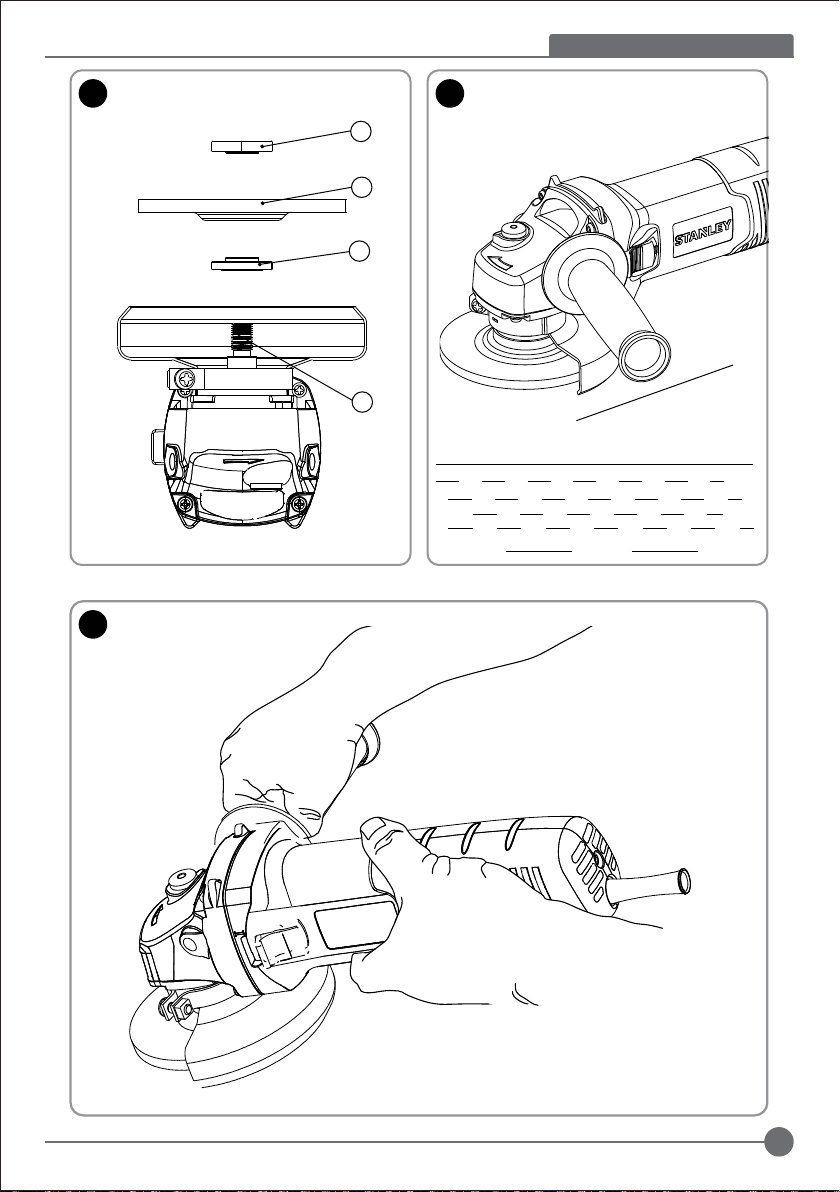

D

8

6

4

5

E

15º-30º

A B

F

* The picture may differ slightly to actual unit.

3

Page 4

ENGLISH (Original instr uctions )

Intended use

Your STANLEY angle grinder SGS105 has been designed for

grinding metal using the appropriate type of grinding disc. This

tool is intended for professional use.

Safety instructions

General Power Tool Safety Warnings

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered and dark

b. Do not operate power tools in explosive atmospheres,

c. Keep children and bystanders away while operating a

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify

b. Avoid body contact with earthed or grounded

c. Do not expose power tools to rain or wet conditions.

d. Do not abuse the cord. Never use the cord for

e. When operating a power tool outdoors, use an

f. If operating a power tool in a damp location is

3. Personal safety

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

areas invite accidents.

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

power tool. Distractions can cause you to lose control.

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

Water entering a power tool will increase the risk of electric

shock.

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock. NOTE: The term “residual current device

(RCD)” may be replaced by the term “ground fault circuit

interrupter (GFCI)” or “earth leakage circuit breaker

(ELCB)”.

4

a. Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention

while operating power tools may result in serious personal

injury.

b. Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

c. Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites

accidents.

d. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at

at all times. This enables better control of the power tool

in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices can

can reduce dust related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it was

designed.

b. Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

Page 5

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

5. Service

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

SAFETY INSTRUCTIONS FOR ALL OPERATIONS

Safety warnings common for grinding.

• This power tool is intended to function as a grinder.

Read all safety warnings, instructions, illustrations

and specifications provided with this power tool.

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury.

• Operations such as polishing are not recommended to

be performed with this power tool. Operations for which

the power tool was not designed may create a hazard and

cause personal injury.

• Do not use accessories which are not specifically

designed and recommended by the tool manufacturer.

Just because the accessory can be attached to your

power tool, it does not assure safe operation.

• The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated speed

can break and fly apart.

• The outside diameter and the thickness of your

accessory must be within the capacity rating of your

power tool. Incorrectly sized accessories cannot be

adequately guarded or controlled.

• Threaded mounting of accessories must match the

grinder spindle thread. For accessories mounted by

flanges, the arbour hole of the accessory must fit the

locating diameter of the flange. Accessories that do not

match the mounting hardware of the power tool will run out

of balance, vibrate excessively and may cause loss of

control.

• Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheel for

chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires. If

power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After

inspecting and installing an accessory, position

yourself and bystanders away from the plane of the

rotating accessory and run the power tool at

(Or iginal instructions) ENGLISH

maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test time.

• Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing

protectors, gloves and work shop apron capable of

stopping small abrasive or workpiece fragments. The

eye protection must be capable of stopping flying

debris generated by various operations. The dust mask

or respirator must be capable of filtrating particles

generated by your operation. Prolonged exposure to high

intensity noise may cause hearing loss.

• Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of workpiece

or of a broken accessory may fly away and cause injury

beyond immediate area of operation.

• Hold power tool by insulated gripping surfaces only,

when performing an operation where the cutting

accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may make

exposed metal parts of the power tool “live” and shock the

operator.

• Position the cord clear of the spinning accessory. If

you lose control, the cord may be cut or snagged and your

hand or arm may be pulled into the spinning accessory.

• Never lay the power tool down until the accessory has

come to a complete stop. The spinning accessory may

grab the surface and pull the power tool out of your

control.

• Do not run the power tool while carrying it at your

side. Accidental contact with the spinning accessory could

snag your clothing, pulling the accessory into your body.

• Regularly clean the power tool’s air vents. The motor’s

fan will draw the dust inside the housing and excessive

accumulation of powdered metal may cause electrical

hazards.

• Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

• Do not use accessories that require liquid coolants.

Using water or other liquid coolants may result in

electrocution or shock.

FURTHER SAFETY INSTRUCTIONS FOR ALL

OPERATIONS

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating

wheel, backing pad, brush or any other accessory. Pinching or

snagging causes rapid stalling of the rotating accessory which

in turn causes the uncontrolled power tool to be forced in the

direction opposite of the accessory’s rotation at the point of the

binding.

5

Page 6

ENGLISH (Original instr uctions )

For example, if an abrasive wheel is snagged or pinched by the

workpiece, the edge of the wheel that is entering into the pinch

point can dig into the surface of the material causing the wheel

to climb out or kick out. The wheel may either jump toward or

away from the operator, depending on direction of the wheel’s

movement at the point of pinching. Abrasive wheels may also

break under these conditions. Kickback is the result of tool

misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given below:

• Maintain a firm grip on the power tool and position

your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction

during start up. The operator can control torque reaction

or kickback forces, if proper precautions are taken.

• Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

• Do not position your body in the area where power

tool will move if kickback occurs. Kickback will propel

the tool in direction opposite to the wheel’s movement at

the point of snagging.

• Use special care when working corners, sharp edges

etc. Avoid bouncing and snagging the accessory.

Corners, sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of control or

kickback.

• Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent kickback

and loss of control.

Additional Safety Information

• Do not use Type 11 (flaring cup) wheels on this tool.

Using inappropriate accessories can result in injury.

• Always use side handle. Tighten the handle securely.

The side handle should always be used to maintain control

of the tool at all times.

• Use clamps or another practical way to secure and

support the work piece to a stable platform. Holding

the work by hand or against your body leaves it unstable

and may lead to loss of control.

Personal safety

• No children or pregnant women should enter the work rea

where the paint sanding is being done until all cleanup is

completed.

• A dust mask or respirator should be worn by all persons

entering the work area. The filter should be replaced daily

or whenever the wearer has difficulty breathing.

Note: only those dust masks suitable for working with lead paint

dust and fumes should be used. Ordinary painting masks do not

offer this protection. See your local hardware dealer for the NIOSH

approved proper mask.

6

Environmental safety

• Paint should be removed in such a manner as to minimize

the amount of dust generated.

• Areas where paint removal is occurring should be sealed

with plastic sheeting of 4 mils thickness.

• Sanding should be done in a manner to reduce tracking of

paint dust outside the work area.

Labels on tool

The label on your tool may include the following symbols:

WARNING! To reduce the risk of injury, the user

must read the instruction manual before use.

Wear ear protection.

Wear safety glasses or goggles.

/min.

Direct Current

Class II Construction

Earthing Terminal

Safety Alert Symbol

Revolutions or

Reciprocation per

minute

V Volts

A Amperes n0No-Load Speed

Hz Hertz

W Watts

min minutes

Alternating

Current

Position of Date Code (Fig. A)

The Date Code (10), which also includes the year of

manufacture, is printed into the housing.

Example:

Package Contents

The package contains:

1 Angle Grinder

1 Guard

1 Flange set

1 Spanner

1 Handle

1 Instruction Manual

• Check for damage to the tool, parts or accessories which

may have occurred during transport.

• Take the time to thoroughly read and understand this

manual prior to operation.

Electrical Safety

Your tool is double insulated; therefore no earth

wire is required. Always check that the main voltage

corresponds to the voltage on the rating plate.

2017 XX JN

Year of manufacturing

Page 7

Warning! If the power cord is damaged, it must be

replaced by the manufacturer, authorized Stanley

Service Center or an equally qualified person in

order to avoid damage or injury. If the power cord is

replaced by an equally qualified person, but not

authorized by Stanley, the warranty will not be valid.

Using an Extension Cable

If it is necessary to use an extension cable, please used an

approved extension cable that fits the tool’s power input

specifications. The minimum cross-sectional area of the

conducting wire is 1.5 sq. mm. Cables should be untangled

before reeling up.

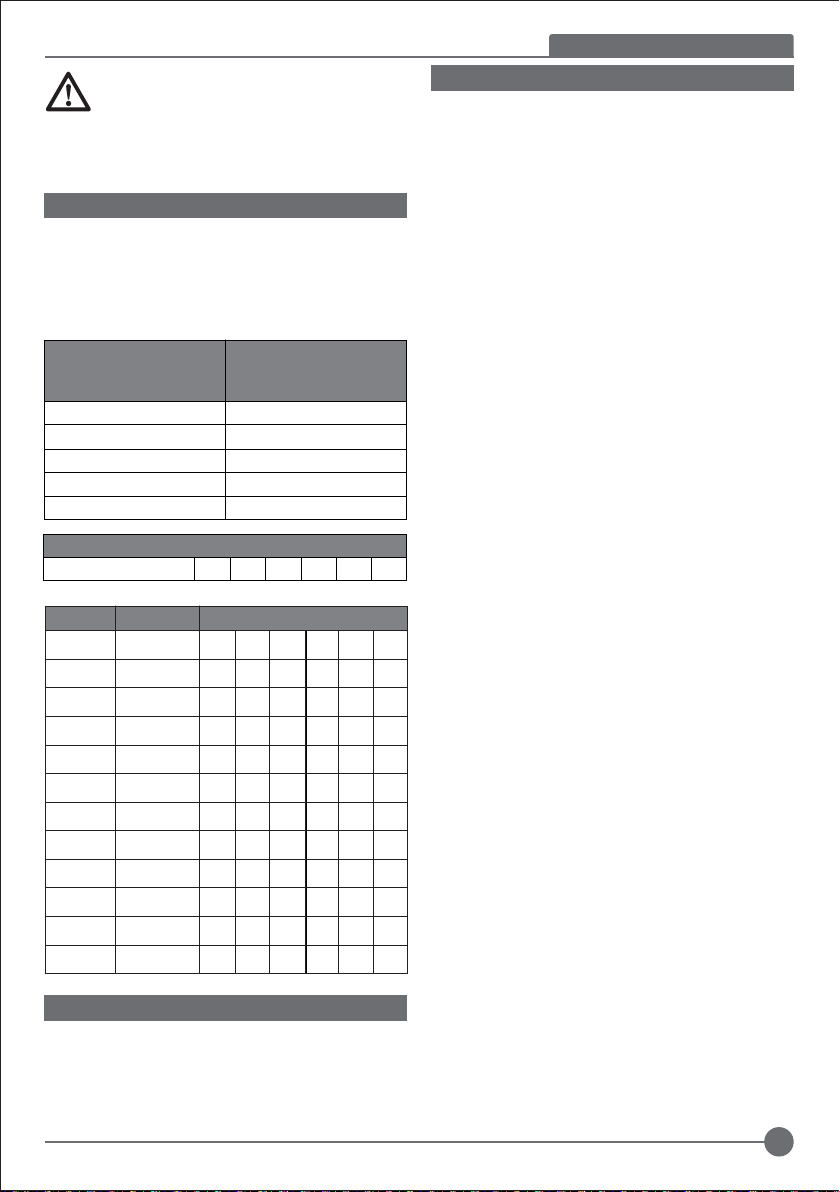

Cable cross-sectional

area (mm

2

) Cable rated

current (Ampere)

Cable cross-sectional

area (mm2) Cable rated

current (Ampere)

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rated current (Ampere)

110-127 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - -

220-240 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

(Or iginal instructions) ENGLISH

Assembly

WARNING! To prevent accidental operation, turn off and

unplug tool before performing the following operations. Failure

to do this could result in serious personal injury.

Attaching and Removing the Wheel Guard (Fig. B)

WARNING! To minimize the danger of serious personal injury,

please switch off the tool power and disconnect all plugs

before adjusting or removing/installing any accessory. Before

reassembling the tool, press and release the trigger switch to

make sure the tool is already switched off.

Attaching the Guard

1. Place the angle grinder on a work bench, groove facing

up.

2. Bring the flange of the guard (3) collar over the groove (9)

of the gear housing.

3. Turn the guard (3) counterclockwise by 150 degrees.

4. Make sure that the screws (10) are tightened.

Removing the Guard

1. Loosen the screws (10) on the guard collar.

2. Pull up the guard (3).

WARNING! Do not operate the tool when the safety guard is

not in place.

Note: Refer to the grinding accessories chart at the end of this

section for accessories that can be used together with this

angle grinder.

Attaching and Removing Grinding Wheels (Fig. C

and D)

WARNING! Do not use damaged grinding wheels.

1. Place the tool on a work bench, groove facing up.

2. Figure C: Attach the inner flange (4) correctly on the

output shaft (5).

3. Place the grinding wheel (6) on the inner flange (4).When

attaching a grinding wheel with a raised center,make sure

that the raised center (7) faces the innerflange (4).

4. Figure D: Tighten the outer flange (h) until the output shaft

(5).

4). When attaching the grinding wheel, the ring on top ofthe

outer flange (8) must face the wheel.

5. Press the spindle lock (2) and prevent the spindle (4)from

rotating until it locks in place.

6. Use the pin spanner to tighten the outer flange (8).

Features (Fig. A)

This tool includes some or all of the following features.

1. ON/OFF Switch

2. Spindle Lock

3. Guard

Preparation Before Use

• Attach the safety guard and appropriate abrasive or

grinding wheels. Do not use abrasive or grinding wheels

that are overly worn.

• Make sure that the inner and outer flanges are attached

correctly.

7

Page 8

ENGLISH (Original instr uctions )

• Make sure that the abrasive or grinding wheels are

rotating in the direction of the arrows on the accessories

and tool.

OPERATION

WARNING! Always observe the safety instructions and

applicable regulations.

WARNING! To minimize the danger of serious personal injury,

please switch off the tool power and disconnect all plugs

before adjusting or removing/installing any accessory. Before

reassembling the tool, press and release the trigger switch to

make sure the tool is already switched off.

WARNING!

• Make sure all materials to be grinded are secured in

position.

• Apply slight pressure to the tool. Do not apply side

pressure to the abrasive disc.

• Avoid overloading. If the tool becomes hot, let it spin for a

few minutes with no load.

• Be sure to hold the tool tightly with both hands (one hand

on housing, the other on side handle). Start the tool and

bring the grinding wheel on the workpiece.

• Keep the edge of the wheel tilted at angle from 15 to 30

degrees against the surface of the workpiece.

• When using a new grinding wheel, do not operate the

wheel in the B direction, otherwise, it will cut into the

workpiece. When the edge of wheel has been rounded off,

you are free to operate the grinder in either the A or B

direction.

Starting and Stopping (Fig. A)

WARNING! Before using the tool, check whether the handle is

tightened securely. Check whether the ON/OFF switch is

working normally.

Before plugging in the tool to the power supply, check whether

the switch is in the OFF (o) position when pressing the rear

end of the switch.

To start the tool, press the rear end of the switch and slide it

forward. Then press the front end of the switch to lock it.

Press the rear end of the switch to stop the tool.

WARNING! Do not switch the tool on or off while under load

conditions.

Proper Hand Position (Fig. F)

WARNING! To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING! To reduce the risk of serious personal injury,

ALWAYS hold securely in anticipation of a sudden reaction.

Proper hand position requires one hand on the side handle

(Figure A), with the other hand on the body of the tool, as

shown in Figure F.

Switches

Caution! Hold the body of the tool firmly to maintain control of

the tool at start up and during use and until the wheel or

accessory stops rotating. Make sure the wheel has come to a

complete stop be fore laying the tool down.

Note: To reduce unexpected tool movement, do not switch the

tool on or off while under load conditions. Allow the grinder to

run up to full speed before touching the work surface. Lift the

tool from the surface before turning the tool off. Allow the tool

to stop rotating before putting it down.

Slider switch (Fig. A)

WARNING! Before connecting the tool to a power supply, be

sure the slider switch is in the off position by pressing the rear

part of the switch and releasing. Ensure the slider switch is in

the off position as described above after any interruption in

power supply to the tool, such as the activation of a ground

fault interrupter, throwing of a circuit breaker, accidental

unplugging, or power failure. If the slider switch is locked on

when the power is connected, the tool will start unexpectedly.

To start the tool, slide the slider switch (1) toward the front of

the tool. To stop the tool, release the slider switch. For

continuous operation, slide the switch toward the front of the

tool and press the forward part of the switch inward. To stop

the tool while operating in continuous mode, press the rear

part of the slider switch and release.

Spindle lock (Fig. A)

The spindle lock (2) prevents the output shaft from rotating

when attaching or removing the grinding wheel. Only use the

spindle lock when the tool is switched off, power is unplugged,

and wheel stops completely.

Note: To minimize tool damages, don’t use the spindle lock

when the tool is operating.

Otherwise, it may damage the tool. The attached accessories

may come off and cause injury.

If using the spindle lock, press the spindle lock button and

rotate the output shaft until it stops.

Application on Metals

When applying the tool on metals, make sure that a

residual-current device (RCD) is inserted to prevent danger

from metal chips.

If the RCD causes power disconnection, have the tool sent to

an authorized Stanley dealer for repair.

WARNING! Under extreme working conditions, conductive

dust and grit may accumulate on the housing interior when

handling metal workpieces.

This could create an electric shock hazard as it weakens the

protective insulation in the grinder.

8

Page 9

To avoid accumulation of metal chips in the interior of the

grinder, we recommend cleaning the ventilation ducts

daily.Refer to Maintenance.

Using Grinding Wheels

WARNING! Metal powder accumulates. Excessive use of the

grinding wheel on metals may increase the risk of electric

shock. To reduce the risk, insert the RCD before use and

clean the ventilation ducts daily. Follow the maintenance

instructions below to blow dry compressed air into the

ventilation ducts.

GRINDING

Surface Grinding with Grinding Wheels

1. Allow the tool to reach full speed before touching the tool

to the work surface.

2. Apply minimum pressure to the work surface, allowing the

tool to operate at high speed. Grinding rate is greatest

when the tool operates at high speed.

3. Maintain a 20˚ to 30˚ angle between the tool and work

surface.

4. Continuously move the tool in a forward and back motion

to avoid creating gouges in the work surface.

5. Remove the tool from work surface before turning tool off.

Allow the tool to stop rotating before laying it down.

Precautions to Take when Sanding Paint

• Sanding of lead based paint is NOT RECOMMENDED

due to the difficulty of controlling the contaminated dust.

The greatest danger of lead poisoning is to children and

pregnant women.

• Since it is difficult to identify whether or not a paint

contains lead without a chemical analysis, we recommend

the following precautions when sanding any paint.

GENERAL INFORMATION

Helpful Hints

• Hold your angle grinder with one hand on the body and

the other hand firmly around the side handle as shown in

Fig. J.

• Always position the guard so that as much of the exposed

disc as possible is pointing away from you. ff Be prepared

for a stream of sparks when the disc touches the metal.

• Maintain an angle between the disc and work surface (Fig.

J) of approximately 30° when grinding and 10°- 15° when

sanding (Fig. K) for best tool control, material removal, and

minimal loading.

CAUTION! Use extra care when grinding into a corner as a

sudden, sharp movement of the grinder may be experienced

when the wheel contacts a secondary surface.

WARNING! Always wear eye protection while operating this

power tool.

(Or iginal instructions) ENGLISH

Maintenance

Your Stanley corded/cordless appliance/tool has been

designed to operate over a long period of time with a minimum

of maintenance. To ensure satisfactory operations, the tool

must be maintained and cleaned regularly

WARNING! To minimize the danger of serious personal

injury, please switch off the tool power and disconnect all

plugs before adjusting or removing/ installing any

accessory. Before reassembling the tool, press and release

the trigger switch to make sure the tool is already switched off.

WARNING! Before performing any maintenance on corded/

cordless power tools:

Lubrication

Stanley tools are properly lubricated at the factory

and are ready for use.

Tools should be lubricated regularly every year depending on

usage. (Tools used on heavy duty jobs and tools exposed to

heat may require more frequent lubrication.) This lubrication

should be attempted only by trained power tool repairperson’s

such as those at Stanley service centers or in other qualified

service personnel.

Cleaning

WARNING! Dust and grit from metal grinding often

accumulate on interior surfaces and could create an

electrical shock hazard if not cleaned out. Use only

mild soap and a damp cloth to clean the tool. Never

let any liquid get inside the tool; never immerse any

part of the tool into a liquid.

WARNING! Never use solvents or harsh chemicals

to clean non-metal parts of the tool. These

chemicals may weaken the material of the parts.

Use only mild soap and damp cloth to clean the

tool. Never let any liquid get inside the tool; never

immerse any part of the tool into liquid.

WARNING! Do not overload your angle grinder.

Overloading causes a reduction in speed and

efficiency, causing your angle grinder to become too

hot. If this happens, operate your angle grinder

under no load for one or two minutes until it has

cooled to normal operating temperature. Switching

your angle grinder off under load will reduce the life

of the switch.

¡IMPORTANT! To ensure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(other than those listed in this manual) should be

performed by authorized service centers or other

qualified organizations, always using identical

replacement parts. Unit contains no user service

able parts inside.

9

Page 10

ENGLISH (Original instr uctions )

Optional Accessories

WARNING! Since accessories, other than those

offered by Stanley, have not been tested with this

product, use of such accessories with this tool could

be hazardous. To reduce the risk of injury, only

Stanley, recommended accessories should be used

with this product.

The performance of any power tool is dependent upon the

accessory used. Stanley accessories are engineered to high

quality standards and are designed to enhance the

performance of power tool. By using Stanley accessories will

ensure that you get the very best from your Stanley tool.

Stanley offers a large selection of accessories available at our

local dealer or authorized service center at extra cost.

Remarks

Stanley’s policy is one of continuous improvement to our

products and, as such, we reserve the right to change product

specifications without prior notice. Standard equipment and

accessories may vary by country. Product specifications may

differ by country. Complete product range may not be

available in all countries. Contact your local Stanley dealers

for range availability.

Protecting the Environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your STANLEY product needs

replacement, or if it is of no further use to you, do not dispose

of it with household waste. Make this product available for

separate collection.

STANLEY provides a facility for the collection and

recycling of STANLEY products once they have

advantage of this service please return your product to any

authorised repair agent who will collect them on our behalf.

You can check the location of your nearest authorised repair

agent by contacting your local STANLEY office at the address

indicated in this manual. Alternatively, a list of authorised

STANLEY repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com.

reached the end of their working life. To take

Technical Data

GRINDER SGS105

Voltage V 220-240

Frecuency Hz 50/60

Power W 1050

No-load Speed /min 11000

Wheel Diameter mm 125

Spindle Size M14

Weight kg 2.3

10

Page 11

Назначение

Ваша угловая шлифмашина STANLEY SGS 105

пред назначена д ля шли фования металла с

исп ол ьз ов ан ие м шлиф ов ал ьн ых круго в

соответству ющего типа. Данный инстру мент

предназначен для профессионального использования.

Инструкции по технике безопасности

Общие правила безопасности при работе с

электроинструментами

ВНИМАНИЕ! Внимательно прочтите все

инструкции по безопасности и руководство

по эксп луатации. Несоблюдение всех

перечисленных ниже правил безопасности и

инструкций может привести к поражению

электрическим током, возникновению пожара

и/или получению тяжёлой травмы.

Сохраните все инструкции по безопасности и

руководство по эксплуатации для их дальнейшего

использования. Термин «Электроинструмент» во всех

привёденных ниже указаниях относится к Вашему

сетевому ( с кабелем ) или акк умулятор ному

(беспроводному) электроинструменту.

1. Безопасность рабочего места

а. Содержите рабочее место в чистоте и хорошо

освещенным. Беспорядок на рабочем месте или

отсутствие освещения рабочего места может

привести к аварии.

b. Не работайте с электроинструментом в месте

хранения взрывоопасных материалов, например,

в присутствии огнеопасных жидкостей, газов или

пыли. Электрические инструменты создают искры,

которые могут воспламенить пыль или пары.

с. Дети и посторонние лица должны находиться как

можн о да льше в о время ра боты с

электроинструментом. Вы можете отвлечься и

потерять контроль.

2. Электробезопасность

а. В ил ка эл ек тр ои нс тр ум ен та до лж на

со ответ ств оват ь розе тке . Нико гда н е

модифицируйте вилку каким-либо образом. Не

используйте ник акие вилки-переходни ки с

за земле нными (за мкнут ыми на з емлю)

электроинструментами. Вилки и розетки, которые

не подвергались никаким изменениям снижают риск

поражения электрическим током.

b. Избегайте контакта тела с заземленны ми

поверхностями, такими как трубы, радиаторы,

плиты и холодильники. Существует повышенный

риск поражения электрическим током, если ваше

тело заземлено.

с. Избегайте любого воздействия дождя или влаги

на элек троинструменты. Вода, попавшая в

электроинструмент, увеличивает риск поражения

электрическим током.

(Перевод с оригинала инструкции)

d. Аккуратно обращайтесь со шнуром питания.

Никогда не используйте шнур питания для

переноски, перемещения или извлечения вилки

из розетки. Держите шнур вдали от источников

тепла, масла, острых краев или движущихся частей.

Поврежденные или запутанные шнуры увеличивают

риск поражения электрическим током.

е. При работе с электроинструментом на улице,

используйте удлинитель, подходящий для

наружного использования. Использование кабеля,

пригодного для использования на открытом воздухе,

снижает риск поражения электрическим током.

f. П ри н ео бх од им ос ти р аб оты с

электроинструме нтом во влажной с реде,

используйте устройство защитного отключения

(УЗО). Использование УЗО снижает риск поражения

электрическим током. ПРИМЕЧАНИЕ: Термин

«устройство защитного отключения (УЗО)» может

быть заменён на «аварийный прерыватель

заземления» или «автоматический выключатель тока

утечки».

3. Личная безопасность

a. Будьте внимательны, смотрите, что вы делаете,

используйте здравый смысл при работе с

эл ектр оинст рум ент ом. Н е испо льзу йте

электроинструмент, если вы устали или находитесь

под влиянием наркотиков, алкоголя или лекарств.

Малейш ая неосторожность при работе с

электроинструментом может привести к серьезным

травмам.

b. Используйте средства индивидуальной защиты.

Всегда надевайте защитные очки. Другое

защитное оборудование, включая респиратор,

ботинки на нескользящей подошве, защитный

шлем или средства защиты органов слуха,

используемые в надлежащих условиях, уменьшат

риск получения травмы.

с. Для п редотвращения случа йного запуска,

убедитесь, что переключатель находится в

выключенном положении перед подключением к

источнику питания и/или аккумуляторной

батарее, поднятия или переноски инструмента. Не

переносите электроинструмент с пальцем на

выключателе и не включайте питание на инструмент с

включенным выключателем, что может привести к

несчастному случаю.

d. Перед включением электроинструмента снимайте

регулировочный или гаечный ключ. Гаечный или

регулировочный ключ, оставленный на вращающейся

части электроинструмента, может привести к травме.

е. Не тянитесь. Сохраняйте правильную стойку и

баланс в се время . Это позволяет лучше

контролировать инструмент в неожиданных

ситуациях.

РУССКИЙ

11

Page 12

РУССКИЙ

f. Одевайтесь правильно. Не надевайте свободную

одежду или украшения. Держите волосы, одежду

и перчатки вдали от движущихся частей.

Свободная одежда, украшения или длинные волосы

могут попасть в движущиеся части.

g. Если имеются устройства для подключения

пылесборника или вытяжки, убедитесь в том, что

они подсоединены и используются правильно.

Использование пылесборника снижает вероятность

возникновения рисков, связанных с пылью.

4. Использование и уход за электроинструментом

a. Н е п ерег ру жайт е э лектр ои нстру мент.

Используйте подход ящий элек триче ский

инструмент для соответствующего применения.

Правильно подо бранный электроинструмент

позволит выполнить работу лучше и безопаснее при

скорости, для которой он был разработан.

b. Не используйте электроинструм ент, если

переключатель не может его включить и

выключить. Любой электроинструмент, который

нельзя контролировать с помощью переключателя,

опасен и должен быть отремонтирован.

c. Отключите кабель питания от источника питания

и/или аккумуляторный блок от электрического

инструмента п еред выполнением любых

регулировок, замены принадлежностей или при

хра не нии эл ек трои нс труме нта. Та кие

профилактические меры безопасности уменьшают

риск непреднамеренного запуска электрического

инструмента.

d. Храните неиспользуемые электроинструменты в

недоступном для детей месте и не позволяйте

лицам, не знакомым с электроинструментом или

да нными инс трук циями, работа ть с

электроинструментом. Электроинструменты опасны в

руках неопытных пользователей.

е. Поддержание электроинструмента. Проверяйте

разрегулированность или cоединение подвижных

частей, поломки частей и любые другие условия,

кото рые мог ут по влия ть н а ра бот у

электроинструмента. При наличии повреждения,

отремонтируйте электроинс трумент перед

использованием. М н о г и е

несчастные случаи являются следствием плохого

ухода за электроинструментом.

f. Держите режущий инструмент острым и чистым.

Хорошо ухоженный режущий инструмент с острыми

режущими кромками легче контролировать.

g. И с по л ьз у йт е э л ек т ро и нс т ру м ен т,

принадлежности, насадки и т.д. в соответствии с

этими инструкциями, принимая во внимание

рабочие условия и характер выполняемой

работы Использование электроинструмента иным

способом может привести к опасным ситуациям.

(Перевод с оригинала инструкции)

5. Обслуживание

а. Обеспечьте, чтобы обслу живание и ремонт

ваш его электроинструмента проводился в

авторизованном сервисном центре по ремонту с

использованием только оригинальных запасных

час тей. Это станет гарантией безопасности

электроинструмента.

МЕРЫ БЕЗОПАСНОСТИ ПРИ ВЫПОЛНЕНИИ

ВСЕХ ОПЕРАЦИЙ

Общие правила б езоп асно сти при работе

шлифовальными машинами

• Данный электроинструмент предназначен для

шлифован ия. Вн имательно пр очтите все

инст рукции по испо льзо вани ю, пр авила

бе зопасн ост и, с пец ификац ии, а так же

рассмотрите все иллюстрации, входящие в

руко водст во по э ксплуат ации д анног о

эл ектроинст румента . Несоблю дение всех

перечисленных ниже инструкций может привести к

поражению электрическим током, возникновению

пожара и/или получению серьёзной травмы.

• Не рекомендуется выпо лнение данны м

инструментом работ по полировке. Использование

инструмента не по назначению может привести к

повреждению инструмента и получению телесной

травмы.

• Н е и с по ль зу йт е д оп ол ни те ль ные

принадлежнос ти и насадки, специально не

ра зработанн ые и не рек омендов анные

про изводителе м инструмента. Возможность

установки принадлежнос тей и насадок на

электроинструмент не обеспечивает безопасности

при его использовании.

• Номинальная скорость вращения насадок должна

соотв етство вать с коро сти, у казанной на

электроинструменте. Диски и прочие насадки при

вращении на скор ости, превышающей их

номинальную скорость, могут разрушиться и

сорваться с крепления.

• Внешний диаметр и толщина насадки должны

соответствовать диапазону мощности Вашего

электроинструмента. Насадка неправильного

размера не закрывается надлежащим образом

защитным кожухом и не обеспечивает контроля при

управлении инструментом.

• М онт ажна я резьб а наса док до лжна

соответствовать резьбе шпинделя шлифмашины.

Для насадок, устанавливаемых на фланцы:

посадочное отвер стие насадк и до лжно

соответствовать устан овоч ному ди аметру

фланца. Насадки, не соответствующие крепёжным

деталям электроинструмента, могут стать причиной

разбалансированности, повышенной вибрации и

потери контроля над электроинструментом.

12

Page 13

• Не используйте повреждённые насадки. Перед

каждым использованием проверяйте абразивные

диск и н а нал ичие сколов и трещ ин,

диски-подошвы - на наличие надрывов и трещин,

проволочные щётки - на наличие ослабленной

или сломанной проволоки. В случае падения

электроинструмента или насадки проверьте их на

на личие п овреж ден ий и ли уст анови те

неповреждённую насадку. После проверки и

установки насадки отведите электроинструмент

от себя и посторонних лиц в сторону и запустите

его на максимальной скорости без нагрузки в

течение одной минуты. Повреждённые насадки

отлетят в сторону в течение данного тестового

периода.

• Используйте средства индивидуальной защиты. В

зависимости от типа выполняемых работ

надевайте щиток для защиты лица, защитную

маску или защитные очки. В соответствии с

не обходи мос тью над евайт е респи рато р,

защитные наушники, перчатки и рабочий фартук,

способный защитить от отлетающих мелких

абр аз ив ных ч астиц и ф ра гменто в

обрабатываемой детали. Средства защиты для

глаз д олж ны останав лив ать час тиц ы,

вылетающие при выполнении различных видов

работ. Противопылевая маска или респиратор

должны обеспечивать фильтрацию твёрдых частиц,

образующихся в ходе работ. Длительное воздействие

шума высокой интенсивности может привести к

нарушениям слуха.

• Не подпускайте посторонних лиц близко к

рабочей зоне. Любое лицо, входящее в рабочую

зо ну, д олж но и спол ьзо ват ь сре дств а

индивидуальной защиты. Отлетающие фрагменты

обрабатываемой детали и л и

разрушенной насадки могут стать причиной

получения травмы даже за пределами рабочей зоны.

• Держи те эле ктрои нструме нт тол ько за

изолированные поверхности при выполнении

ра бот, в о в рем я к оторы х р ежущ ая

принадлежность может задеть скрытую проводку

или кабель подключения к электросети. При

контакте с находящимся под напряжением проводом,

на не изолированны х металлических час тях

инструмента также появляется напряжение, что

приводит к поражению электрическим током.

• Располагайте кабель подключения к электросети

на удалении от вращающейся насадки. В случае

потери контроля кабель может быть разрезан или

защемлён, а Ваша рука может быть затянута

вращающейся насадкой.

• Никогда не кладите электроинструмент, пока

насадка полностью не остановится. Вращающаяся

насадка может задеть за поверх ность, и

электроинструмент вырвется из Ваших рук.

(Перевод с оригинала инструкции)

• Не включайте электроинструмент, если насадка

направлена на Вас. Случайный контакт с

вращающейся насадкой может привести к захвату

насадкой Вашей одежды и получению телесной

травмы.

• Регулярно очищайте вентиляционные отверстия

электроинструмента. Вентилятор электродвигателя

затягивает пыль внутрь корпуса, а скопление

большого количе ства пыли на мета лле

электродвигателя повышает риск поражения

электротоком.

• Не используйте электроинс трумент вблизи с

пожаро опас ными матери алам и. Искровые

разряды могут привести к их воспламенению.

• Не используйте насадки, требующие жидкостного

охлаждения. Использование воды или других

жидких охлаждающих средств может привести к

поражению электрическим током вплоть до

смертельного исхода.

РУССКИЙ

ДОПОЛНИТЕЛЬНЫЕ МЕРЫ БЕЗОПАСНОСТИ

ПРИ ВЫПОЛНЕНИИ ВСЕХ ОПЕРАЦИЙ

Причины обратного удара и меры по его

предотвращению

Обратный удар является внезапной реакцией на

защемление или застревание вращающегося диска,

диска-подошвы, щётки или какой-либо другой насадки.

Защемление или застревание могут стать причиной

мгновенной остановки вращающейся насадки, что в

свою очередь приводит к потере контроля над

электроинструментом и его внезапному отбрасыванию

назад в направлении, противоположном вращению

насадки.

Например, если абразивный круг был защемлён или

застрял в заготовке, край круга в момент защемления

может врезаться в поверхность заготовки, в результате

чего круг поднимается или отскакивает назад. В

зависимости от направления движения круга в момент

защемления, круг может резко подняться в сторону или

от оператора. В этот момент абразивные круги могут

также сломаться. Обратный удар является результатом

использования инструмента не по назначению и/или

неправильных действий оператора и условий работы, и

его можно избежать, соблюдая следующие меры

безопасности:

• Крепко удерживайте элек троинструмент и

следите за положением тела и рук, чтобы

эффек тивно про тивос тоят ь воз действию

обратного удара. Для максимального контроля

силы обратного удара или реакции от крутящего

момента всегда используйте вспомогательную

рукоятку, ес ли она предусмотрена. При

со бл юде ни и со от ве тс тв ую щи х м ер

предосторожности оператор может контролировать

силу обратного удара и реакцию от крутящего

момента.

13

Page 14

РУССКИЙ

• Никогда не держите руки вблизи от вращающейся

насадки. При обратном ударе насадка может

поранить Ваши руки.

• Не стойте в зоне действия обратного удара

электроинструмента. В момент заклинивания сила

обратного удара отбросит инструмент в направлении,

обратном движению диска.

• Будьте особенно осторожны при обрабатывании

углов, острых кромок и пр. И збегайте

отскакивания и заклинивания насадки. Именно

при обработке углов, острых кромок или при

отскакивании высока вероятность заклинивания

вращающейся насадки, что может пос лужить

причиной потери контроля над инструментом или

образования обратного удара.

• Не устанавливайте на инструмент диск для

резьбы по дереву или зубчатый пильный диск.

Да нные ди ски уве личив ают вер оятно сть

возникновения обратного удара и потери контроля

над инструментом.

(Перевод с оригинала инструкции)

Дополнительные инструкции по безопасности

• Не используйте диски Тип 11 (конусные

чашеобразные) с данным ин струменто м.

Использование насадок несоответствующего типа

может привести к получению травмы.

• Всегда используйте боковую рукоятку.

Надёжно затягивайте боковую рукоятку. Для

обеспечения полного контроля над инструментом во

время работы всегда должна использоваться боковая

рукоятка.

• И спо льзу йте стру бцин ы ил и др уги е

приспособления для фиксации обрабатываемой

детали, устанавливая их только на неподвижной

поверхности. Если держать обрабатываемую деталь

руками или с упором в собственное тело, то можно

потерять контроль над инструментом или

обрабатываемой деталью.

Личная безопасность

• Не допускайте детей или беременных женщин в

рабочую зону, где выполняется шлифование

окрашенных поверхностей до тех пор, пока рабочая

зона не будет полностью очищена.

• Все люди, входящие в рабочую зону, должны надевать

пылезащитные маски или респираторы. Фильтр

следует заменять ежедневно или по мере его

загрязнения.

Примечание: Следует использовать только те

пылезащитные маски, которые предназначены для

работы с пылью и парами красок, содержащих

свинец. Обычные маски для лакокрасочных работ не

обеспечив ают достаточной защиты. Купите в

строительном магазине респиратор, утверждённого

Национальным институтом США по охране труда и

промышленной гигиене (NIOSH) типа.

Экологическая безопасность

• Краску следует снимать таким образом, чтобы свести

к минимуму количество образующейся пыли.

• Зоны, где выполняется удаление краски, должны быть

герметизированы пластиковыми панелями толщиной

4 мм.

• Шлифование поверхности должно выполняться

таким образом, чтобы свести к минимуму

проникновение пыли за пределы рабочей зоны.

Маркировка инструмента

На инструменте имеются следующие знаки:

ВНИМАНИЕ! Полное ознакомление с руководством

по эксплуатации перед использованием инструмента

снизит риск получения травмы.

Используйте средства защиты органов слуха.

Надевайте защитные очки или маску.

V

Вольт

A

Ампер

Hz

Герц

W

Ватт

min

минут

Переменный

ток

Место положения кода даты (Рис. А)

Код даты (10), который также включает в себя год

изготовления, отштампован на поверхности корпуса

инструмента.

Пример:

Комплект поставки

В упаковку входят:

1 Угловая шлифмашина

1 Защитный кожух

1 Набор дисковых фланцев

1 Ключ

1 Боковая рукоятка

1 Руководство по эксплуатации

• Проверьте инструмент, детали и дополнительные

приспособления на наличие повреждений, которые

могли произойти во время транспортировки.

2017 XX JN

Год изготовления

Постоянный ток

Скорость без нагрузки

n

0

Конструкция Класса II

Клемма заземления

Символ опасности

Кол-во оборотов или

шагов в минуту

/min.

14

Page 15

• Перед началом работы необходимо внимательно

прочитать настоящее руководство и принять к

сведению содержащуюся в нем информацию.

Электробезопасность

Данный инструмент защищён двойной

изоляцией, что исключает потребность в

заземляющем проводе. Всегда проверяйте,

соответствует ли напряжение, указанное на

табличке с техническими параметрами,

напряжению электросети.

Внимание! Во избежание повреждений или

получения травмы, замена повреждённого

кабеля питания должна производиться только

на заводе-изготовителе, в авторизованном

серв ис ном центр е Stanley или

квалифицированным персоналом. При замене

кабеля питания квалифицированным лицом, но

не имеющим авторизацию Stanley, гарантия на

продукт будет недействительной.

Использование удлинительного кабеля

При необходимости использования удлинительного

кабеля, используйте только утверждённые кабели

промышленного изготовления, рассчитанные на

мощность не меньшую, чем потребляемая мощность

данного инструмента. Минимальный р азмер

проводника должен состав лять 1,5 мм². При

использовании кабельного барабана, всегда полностью

разматывайте кабель.

Поперечное сечение

проводника (мм

Номинал кабеля (Ампер)

Напряжение Ампер Номинал кабеля (Ампер)

110-127 0 - 2,0 6 6 6 6 6 10

2

)

0,75 6

1,00 10

1,50 15

2,50 20

4,00 25

2,1 - 3,4 6 6 6 6 15 15

3,5 - 5,0 6 6 10 15 20 20

5,1 - 7,0 10 10 15 20 20 25

7,1 - 12,0 15 15 20 25 25 -

12,1 - 20,0 20 20 25 - - -

Поперечное сечение

проводника (мм2)

Номинал кабеля (Ампер)

Длина кабеля (м)

7,5 15 25 30 45 60

(Перевод с оригинала инструкции)

220-240 0 - 2,0 6 6 6 6 6 6

2,1 - 3,4 6 6 6 6 6 6

3,5 - 5,0 6 6 6 6 10 15

5,1 - 7,0 10 10 10 10 15 15

7,1 - 12,0 15 15 15 15 20 20

12,1 - 20,0 20 20 20 20 25 -

Описание (Рис. А)

Данный инструмент может содержать все или некоторые

из перечисленных ниже составных частей:

1. Клавиша пускового выключателя

2. Кнопка блокировки шпинделя

3. Защитный кожух

Сборка

ВНИМАНИЕ! Чтобы избежать случайного включения,

перед проведением нижеследующих дейс твий

выключите инструмент и отсоедините его от источника

питания. Несоблюдение этого требования может

привести к получению тяжёлой травмы.

РУССКИЙ

Установка и снятие защитного кожуха (Рис. В)

ВНИМАНИЕ! Для снижения риска получения серьёзной

травмы, перед регулировкой или снятием/установкой

насадок выключайте инструмент и отсоединяйте его от

электросети. Перед повторной сборкой инструмента

нажмите и отпустите пусковой выключатель, чтобы

убедиться, что инструмент действительно выключен.

Установка защитного кожуха

1. Положите угловую шлифмашину на рабочий стол

прорезью вверх.

2. Поместите фланец воротника защитного кожуха (3)

поверх прорези (9) на коробке редуктора.

3. Поверните защитный кожух (3) на 150 градусов

против часовой стрелки.

4. Убедитесь, что винты (10) затянуты.

Снятие защитного кожуха

1. Ослабьте винты (10) на воротнике защитного кожуха.

2. Снимите защитный кожух (3).

ВНИМАНИЕ! Не используйте инс трумент без

установленного защитного кожуха.

Примечание: В конце данного раздела Вы найдете

Таблицу принадлежностей для шлифования, в которой

обозначены дополнительные принадлежности и

аксессуары, которые могут быть использованы с данной

угловой шлифмашиной.

15

Page 16

РУССКИЙ

(Перевод с оригинала инструкции)

Установка и снятие шлифовальных кругов

(Рис. С и D)

ВНИМ АНИЕ! Не используйте повр еждённые

шлифовальные круги.

1. Положите инструмент на рабочий стол прорезью

вверх.

2. Рисунок С: Установите на шпиндель (5) проставочный

фланец (4).

3. Установите шлифовальный круг (6) на проставочный

фланец (4). При установке шлифовальных кругов с

выпуклым центром проследите, чтобы выпуклый

центр (7) примыкал к проставочному фланцу (4).

4. Рисунок D: Затяните внешний фланец (8) на шпинделе

(5).

4). При установке шлифовального круга кольцо в

верхней части внешнего фланца (8) должно быть

обращено к кругу.

5. Нажмите кнопку блокировки шпинделя (2) и

удерживайте шпиндель (4) от вращения до его

полной фиксации на месте.

6. Спецключом затяните внешний фланец (8).

Подготовка к использованию

• Установите защитный кожух и соответствующий

абразивный или шлифовальный круг. Не используйте

очень изношенные абразивные или шлифовальные

круги.

• Убедитесь в правильной установке наружного и

внутреннего фланцев.

• Проследите, чтобы абразивный или шлифовальный

круг вращался в соответствии с указательными

стрелками на шлифмашине и на самой насадке.

ЭКСПЛУАТАЦИЯ

ВНИМАНИЕ! Всегда следуйте указаниям действующих

норм и правил безопасности.

ВНИМАНИЕ! Для снижения риска получения серьёзной

травмы, перед регулировкой или снятием/установкой

насадок выключайте инструмент и отсоединяйте его от

электросети. Перед повторной сборкой инструмента

нажмите и отпустите пусковой выключатель, чтобы

убедиться, что инструмент действительно выключен.

ВНИМАНИЕ!

• Следите, чтобы все обрабатываемые заготовки были

надёжно зафиксированы на месте.

• Не прилагайте к инструменту чрезмерного усилия. Ни

в коем случае не прилагайте бокового усилия к

абразивному диску!

• Избегайте перегрузки. Если инструмент очень

нагрелся, дайте ему поработать несколько минут на

холостом ходу.

• Крепко удерживайте инструмент обеими руками

(одной рукой за корпус, другой рукой за боковую

рукоятку). Включите инструмент и опустите

шлифовальный круг на заготовку.

16

• Следите, чтобы край шлифовального круга находился

под углом 15-30º к поверхности заготовки.

• При использовании нового шлифовального круга, не

ведите шлифмашину в направлении В, иначе

шлифовальный круг врежется в заготовку. Когда край

шлифовального круга округлится, Вы сможете

свободно работать в любом направлении – А или В.

Включение и выключение (Рис. А)

ВНИМАНИЕ! Перед использованием инструмента

убедитесь, что рукоятка надёжно затянута. Проверьте

функциональность пускового выключателя.

Перед подключением инструмента к источнику питания

убедитесь, что пусковой выключатель находится в

положении «ВЫКЛ.» (о); для этого нажмите и отпустите

заднюю половину выключателя.

Чтобы запустить инструмент, нажмите на заднюю

половину выключателя и передвиньте её вперёд. Затем

нажмите на переднюю половину выключателя, фиксируя

выключатель во включённом положении.

Чтобы выключить инструмент, нажмите на заднюю часть

клавиши пускового выключателя.

ВНИМАНИЕ! Не включайте и не выключайте инструмент,

находящийся под нагрузкой.

Правильное положение рук во время работы

(Рис. F)

ВНИМАНИЕ! Для уменьшения риска получения тяжёлой

тр авмы , ВСЕ ГДА пра вильн о уд ержи вайт е

электроинструмент, как показано на рисунке.

ВНИМАНИЕ! Для уменьшения риска получения тяжёлой

травмы ВСЕГДА надёжно удерживайте инструмент,

предупреждая внезапные сбои в работе.

Правильное положение рук во время работы: одной

рукой возьмитесь за боковую рукоятку (Рисунок А),

другой рукой удерживайте корпус инструмента, как

показано на Рис. F.

Выключатели

Пре дупреждение! Крепко удерживайте корпус

инструмента для обеспечения контроля над

инструментом при запуске, во время работы и до тех пор,

пока диск или насадка не прекратит вращаться. Прежде

чем положить инструмент убедитесь, что диск полностью

остановился.

Примечание: Для предотвращения неожиданного

движения инструмента не включайте/не выключайте

инструмент, находящийся под нагрузкой. Перед началом

работы с заготовкой дождитесь, пока инструмент не

наберёт полную скорость. Перед вык лючением

инструмента, сначала поднимите его с заготовки. Прежде

чем положить инструмент, дождитесь полной остановки

двигателя.

Page 17

Передвижной пусковой выключатель (Рис. А)

ВНИМАНИЕ! Перед подключением инструмента к

источнику питания убедитесь, что передвижной

пусковой выключатель находится в положении «ВЫКЛ.»;

для этого нажмите и отпустите заднюю половину

вы ключа тел я. П осле л юбог о п реры вани я

электроснабжения инструмента, например, при

срабатывании аварийного прерывателя заземления или

автоматического выключателя, при случайном

отсоединении от источника питания или при нарушении

электропитания, всегда проверяйте, что передвижной

пусковой выключатель находится в положении «ВЫКЛ.»,

как было описано выше. Если передвижной пусковой

вык лючатель при подаче питания находится в

положении «ВКЛ.», инструмент внезапно начнёт

работать.

Чтобы включить инструмент, передвиньте пусковой

выключатель (1) в сторону передней части инструмента.

Чтобы выключить инструмент, отпустите клавишу

пускового выключателя. Для непрерывного режима

работы передвиньте пусковой выключатель в сторону

передней части инструмента и нажмите на переднюю

половину выключателя. Для выключения непрерывного

режима работы инструмента нажмите на заднюю

половину передвижного пускового выключателя и

отпустите.

Блокировка шпинделя (Рис. А)

Кнопка блокировки шпинделя (2) предотвращает

вращение шпинделя во время установки или снятия

шлифовального круга. Используйте кнопку блокировки

шпинделя только при выключенном инструменте,

отключённом от источника питания или при полностью

остановленном круге.

Примечание: Для сведения к минимуму повреждения

инструмента не нажимайте на кнопку блокировки

шпинделя при работающем инструменте.

Это действие может привести к поломке инструмента.

Установленная насадка может соскочить со шпинделя и

стать причиной получения травмы.

При использовании блокировки шпинделя нажмите на

кнопку блокировки шпинделя и поворачивайте

шпиндель до его полной фиксации на месте.

Обработка металла

При использовании инструмента для обработки металла

убедитесь, в наличии устройства защитного отключения

(УЗО), предотвращения опасности в связи с

металлической стружкой.

Если УЗО провоцирует отключение электроэнергии,

отнесите инструмент в авторизованный сервисный центр

Stanley для проведения ремонта.

(Перевод с оригинала инструкции)

ВНИМАНИЕ! В экс тремальных условиях работы

токопроводящая пыль и песок могут накапливаться на

внутренней поверхности корпуса при обработке

металлических деталей.

Это ослабляет изоляцию шлифмашины и может создать

опасность поражения электрическим током.

Во избежание скапливания внутри шлифмашины

металлической стружки рекомендуется ежедневная

очистка вентиляционных прорезей. См. раздел

«Техническое обслуживание».

РУССКИЙ

Использование шлифовальных кругов

ВНИМАНИЕ! Скапливание металлической пыли.

Чрезмерное использование шлифовального круга для

обработки металла может увеличить риск поражения

электрическим током. Для снижения риска, перед

использованием устанавливайте УЗО и ежедневно

прочищайте вентиляционные прорези. Для прочистки

вентиляционных прорезей сухим сжатым воздухом см.

инструкции по техническому обслуживанию.

ШЛИФОВАНИЕ

Шлифование поверхнос ти с использован ием

шлифовальных кругов

1. Дождитесь, пока инструмент не наберёт полную

скорость, прежде чем прикасаться им к

обрабатываемой поверхности.

2. Нажимайте на поверхность с минимальным усилием,

чтобы инструмент работал на высокой скорости.

Эффективность шлифования максимальна, когда

инструмент работает на высокой скорости.

3. Удерживайте инструмент под углом от 20° до 30° по

отношению к обрабатываемой поверхности.

4. Непрерывно перемещайте инструмент вперёд и

назад для предотвращения образования канавок на

обрабатываемой поверхности.

5. Прежде чем выключить инструмент поднимите его с

обрабатываемой поверхности. Прежде чем положить

инструмент, дождитесь полной остановки двигателя.

Меры предосторожности при шлифовании

лакокрасочных покрытий

• НЕ РЕКОМЕНДУЕТСЯ шлифование красок с

содержанием свинца, так как это приводит к

образованию вредной для здоровья пыли.

Наибольшую опасность отравление свинцом

представляет для детей и беременных женщин.

• Так как определить наличие свинца в краске без

проведения химического анализа достаточно сложно,

мы рекомендуем соблюдать следующие меры

предосторожности при выполнении шлифования

окрашенных поверхностей.

17

Page 18

РУССКИЙ

ОБЩАЯ ИНФОРМАЦИЯ

Рекомендации по оптимальному использованию

• Одной рукой держите угловую шлифмашину за

корпус, другой рукой крепко удерживайте боковую

рукоятку, как показано на Рисунке J.

• Всегда располагайте защитный кожух таким образом,

чтобы наиболее выступающая часть диска была

направлена в противоположную сторону от Вас.

Будьте готовы к сильному выбросу искр при

соприкосновении диска с металлом.

• Для наилучшего контроля над инструментом и

снижения нагрузки во время удаления материала

держите круг под углом приблизительно 30° к

обрабатываемой поверхности во время шлифования

(Рис. J) и под углом 10°- 15° во время зачистки (Рис. K).

ПРЕДУПРЕЖДЕНИЕ! Будьте особенно внимательны при

шлифовании углов - при контакте круга со вторичной

поверхностью шлифмашина может резко отскочить.

ВНИМАНИЕ ! Всегда при раб оте с д анны м

электроинструментом надевайте защитные очки.

Техническое обслуживание

Ваш электрический/аккумуляторный инструмент Stanley

рассчитан на работу в течение продолжительного

времени при минимальном техническом обслуживании.

Срок службы и надёжность инструмента увеличивается

при правильном уходе и регулярной чистке.

ВНИМАНИЕ! Для снижения риск а получения

серьёзной травмы, перед регулировкой или

сн ятие м/ус тан овко й нас адок в ык люч айт е

инструмент и отсоединяйте его от электросети. Перед

повторной сборкой инструмента нажмите и отпустите

пусковой выключатель, чтобы убедиться, что инструмент

действительно выключен.

ВНИМА НИЕ! Перед проведением технического

обслужива ния эле ктр ического/а ккумуляторн ого

инструмента:

(Перевод с оригинала инструкции)

Смазка

Инс трументы Stanley смазаны должным

образом на производс тве и готовы к

использованию.

Инструменты должны регулярно смазываться каждый

год, в зависимости от интенсивности использования.

(Инструменты, используемые в тяжёлом режиме, и

инструменты, подвергающиеся влиянии высоких

температур, должны смазываться более часто). Смазка

инструмента должна производиться только обученным

персоналом по ремонту электроинструментов,

например, в авторизованном сервисном центре Stanley.

Чистка

ВНИМАНИЕ! На внутренних поверхностях

инструмента часто собирается содержащая

металлические частицы пыль, повышая риск

поражения электрическим током. Для чистки

инструмента используйте только слабый

мыльный раствор и влажную ткань. Не

допускайте попадания какой-либо жидкости

внутрь инструмента; ни в коем случае не

погружайте какую-либо часть инструмента в

жидкость.

ВНИМАНИЕ! Н икогд а не и спользуйте

растворители или агрессивные химические

средства для очистки неметаллических деталей

инструмента. Эти химикаты могут ухудшить

свойства материалов, применённых в данных

деталях. Для чистки инструмента используйте

только слабый мыльный раствор и влажную

ткань. Не допускайте попадания какой-либо

жидкости внутрь инструмента; ни в коем случае

не погружайте какую-либо часть инструмента в

жидкость.

ВНИМАНИЕ! Избегайте перегрузки Вашей

угловой шлифмашины. Перегрузка приведёт к

снижению скорости и производительности, а

также перегреву угловой шлифмашины. Если

это произошло, дайте поработать шлифмашине

без нагрузки в течение одной-двух минут – это

позволить ей остыть до нормальной рабочей

температуры. Включение и выключение

угловой шлифмашины, находящейся под

нагрузкой, значительно снизит срок службы

выключателя.

ВАЖНО! В целях обеспечения БЕЗОПАСНОСТИ

и ДОЛГОВЕЧНОСТИ в использовании продукта

ремонт, техническое обс луживание и

регулировка (кроме перечисленных в данном

руководстве по эксплуатации) должны

производиться только в авторизованных

се рв исных ц ентрах ил и других

квалифицированных мастерских и только с

использованием идентичных запасных частей.

Внутри инструмента нет обслуживаемых

пользователем деталей.

Дополнительные принадлежности

ВНИМАНИЕ! Поскольку принадлежности,

отличные от тех, которые предлагает Stanley, не

проходили тесты на данном изделии, то

использование этих принадлежностей может

привести к опасной ситуации. Во избежание

риска получения травмы, с данным продуктом

дол жн ы ис по ль зо ва ть ся т ол ьк о

до по лн ите ль ны е пр ин ад ле жно ст и,

рекомендованные Stanley.

18

Page 19

Производительность любого электроинс трумента

напрямую зависит от того, какие дополнительные

принадлежности с ним используются. Принадлежности

Stanley изготовлены в соответствии с самыми высокими

стандартами качества и способны увеличить

производительность вашего электроинструмента.

Использование принадлежностей Stanley гарантирует

самые наилучшие результаты в работе Вашего

инструмента Stanley. Stanley предоставляет широкий

выбор насадок и дополнительных принадлежностей,

которые можно приобрести за дополнительную плату у

местного дилера или в авторизованном сервисном

центре.

Примечания

Политик а St anley н ацелена на пос тоян ное

усовершенствование нашей продукции, поэтому фирма

оставляет за собой право изменять технические

харак терис тики изделий без предварительного

уведо мления. Стан дартн ое о борудов ание и

дополнительные принадлежности могут меняться в

зависимости от страны продаж. Техн ические

характеристики продуктов могут различаться в

зависимости от страны продаж. Полная линия продуктов

присутствует на рынках не всех стран. Для получения

информации касательно линии продуктов в Вашей

стране обратитесь в ближайший сервисный центр

Stanley.

(Перевод с оригинала инструкции)

Технические характеристики

УГЛОВАЯ ШЛИФМАШИНА SGS105

Напряжение В 220-240

Частота Гц 50/60

Потребляемая мощность Вт 1050

Номинальная скорость об/мин. 11000

Диаметр диска мм 125

Размер шпинделя M14

Вес кг 2,3

РУССКИЙ

Защита окружающей среды

Раздельный сбор. Данное изделие нельзя

утилизировать вместе с обычными бытовыми

отходами.

Если одна жды В ы захотите за менить Ваш

электроинструмент STANLEY, или Вы больше в нем не

нуждаетесь, не выбрасывайте его вместе с бытовыми

отходами. Отнесите изделие в специальный приемный

пункт.

Фирма STANLEY обеспечивает прием и

переработку отслуживших свой срок изделий

STANLEY. Чтобы воспользоваться этой услугой,

Вы можете сдать Ваше изделие в любой авторизованный

сервисный центр, который собирает их по нашему

поручению. Вы можете узнать место нахождения Вашего

ближайшего авторизованного сервисного центра,

обратившись в Ваш местный офис STANLEY по адресу,

указанному в данном руководстве по эксплуатации.

Кроме того, список авторизованных сервисных центров

STANLEY и полную информацию о нашем

послепродажном обслуживании и контактах Вы можете

найти в интернете по адресу: www.2helpU.com.

19

Page 20

РУССКИЙ

(Перевод с оригинала инструкции)

Гарантийные условия

Уважаемый покупатель!

1. Поздравляем Вас с покупкой высококачественного изделия

STANLEY и выражаем признательность за Ваш выбор.

2. При покупке изделия требуйте проверки его комплектности

и исправности в Вашем присутствии, инструкцию по

эксплуатации и заполненный гарантийный талон на

русском языке.

В гарантийном талоне должны быть внесены: модель, дата

продажи, серийный номер, дата производства

инструмента; название, печать и подпись торговой

организации. При отсутствии у Вас правильно заполненного гарантийного талона, а также несоответствия

указанных в нем данных мы будем вынуждены откло- нить

Ваши претензии по качеству данного изделия.

3. Во избежание недоразумений убедительно просим Вас

перед началом работы с изделием внимательно

ознакомиться с инструкцией по его эксплуатации. Правовой

основой настоящих гарантийных условий является

действующее Законодательство. Гарантийный срок на

данное изделие составляет 24 месяца и исчисляется со

дня продажи. В случае устранения недостатков изделия,

гарантийный срок продлевается на период его нахождения

в ремонте. Срок службы изделия составляет 5 лет со дня

продажи.

4. В случае возникновения каких-либо проблем в про- цессе

эксплуатации изделия рекомендуем Вам обра- щаться

только в уполномоченные сервисные центры STANLEY,

адреса и телефоны которых Вы сможете найти в

гарантийном талоне, на сайте www.2helpU.com или узнать

в магазине. Наши сервисные станции - это не только

квалифицированный ремонт, но и широкий ассортимент

запчастей и принадлежностей.

5. Производитель рекомендует проводить периодическую

проверку и техническое обслуживание изделия в

уполномоченных сервисных центрах.

Изготовитель

Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

6. Наши гарантийные обязательства распространяются

только на неисправности, выявленные в течение гарантийного срока и вызванные дефектами производства и \

или материалов.

7. Гарантийные условия не распространяются на

неисправности изделия, возникшие в результате:

7.1. Несоблюдения пользователем предписаний инструкции по

эксплуатации изделия, применения изделия не по

назначению, неправильном хранении, использования

принадлежностей, расходных материалов и запчастей, не

предусмотренных производителем.

7.2. Механического повреждения (сколы, трещины и разрушения) внутренних и внешних деталей изделия,

основных и вспомогательных рукояток, сетевого электрического кабеля, вызванного внешним ударным или

любым иным воздействием

7.3 Попадания в вентиляционные отверстия и проник- новение

внутрь изделия посторонних предметов, материалов или

веществ, не являющихся отходами, сопровождающими

применение изделия по назначению, такими как: стружка,

опилки, песок, и пр.

7.4. Воздействий на изделие неблагоприятных атмосферных и

иных внешних факторов, таких как дождь, снег,

повышенная влажность, нагрев, агрессивные среды,

несоответствие параметров питающей электросети,

указанных на инструменте.

7.5. Стихийного бедствия. Повреждение или утрата изделия,

связанное с непредвиденными бедствиями, стихийными

явлениями, в том числе вследствие действия

непреодолимой силы (пожар, молния, потоп и другие

природные явления), а так же вследствие перепадов напряжения в электросети и другими причинами, которые

находятся вне контроля производителя.

8. Гарантийные условия не распространяются:

8.1. На инструменты, подвергавшиеся вскрытию, ремонту или

модификации вне уполномоченного сервисного центра.

8.2. На детали и узлы, имеющие следы естественного износа,

такие как:

приводные ремни и колеса, угольные щетки, смазка,

подшипники, зубчатое зацепление редукторов, рези- новые

уплотнения, сальники, направляющие ролики, муфты,

выключатели, бойки, толкатели, стволы, и т.п.

8.3. На сменные части: патроны, цанги, зажимные гайки и

фланцы, фильтры, аккумуляторные батареи, ножи,

шлифовальные подошвы, цепи, звездочки, пильные шины,

защитные кожухи, пилки, абразивы, пильные и абразивные

диски, фрезы, сверла, буры и т.п.

8.4. На неисправности, возникшие в результате перегрузки

инструмента (как механической, так и электрической),

повлекшей выход из строя одновременно двух и более

деталей и узлов, таких как: ротора и статора, обеих

обмоток статора, ведомой и ведущей шестерни ре- дуктора

или других узлов и деталей. К безусловным признакам

перегрузки изделия относятся, помимо прочих: появление

цветов побежалости, деформация или оплавление

деталей и узлов изделия, потемнение или обугливание

изоляции проводов электродвигателя под воздействием

высокой температуры.

20

Page 21

Призначення

Кутова шліфмашина STANLEY SGS105 розроблена для

обробки металу за допомогою кіл належного типу. Цей

ін струмент приз начен ий для п рофесі йного

використання.

ВКАЗІВКИ З ТЕХНІКИ БЕЗПЕКИ

Загальні правила техніки безпеки під час роботи з

електричним інструментом

Збережіть усі застереження та вказівки з техніки

безпеки для подальшого використання. Термін

«електричний інструмент», що використовується в

попереджувальних написах та вказівках щодо техніки

безпеки, відносяться до електричного інструмента, який

працює від мережі (зі шнуром електроживлення) або від