Page 1

18-bit enhanced port expander with keypad controller

Features

■ 18 GPIOs configurable as GPI, GPO, keypad

matrix, special key or dedicated key function

■ Operating voltage: 1.65 - 3.6 V

■ Hardware keypad controller (KPC)

(10 x 8 matrix with 4 optional dedicated keys

maximum)

■ Keypad controller capable of detecting

keypress in hibernation mode

■ Interrupt output (open drain) pin

■ Advanced power management system

■ Ultra-low standby mode current

■ Programmable pull-up resistors for all GPIO

pins

■ ESD performance on GPIO pins:

– ± 8 kV human body model

(JESD22 A114-C)

■ ESD performance on V

SCL, SDA pins:

– ± 3 kV human body model

(JESD22 A114-C)

, GND, INTB, R

CC

STB

STMPE1801

Xpander Logic™

Flip-chip CSP 25

(2.03 x 2.03 mm)

Description

The STMPE1801 is a GPIO (general purpose

input/output) port expander capable of interfacing

a main digital ASIC via the two-line bidirectional

2

bus (I

,

C). A separate GPIO expander IC is often

used in mobile multimedia platforms to resolve

the problem of the limited number of GPIOs

typically available on digital engines.

The STMPE1801 offers high flexibility, as each

I/O can be configured as input, output, special

key, keypad matrix or dedicated key function. This

device is designed to include very low quiescent

current, and a wakeup feature for each I/O, to

optimize the power consumption of the device.

Potential applications for the STMPE1801 include

portable media players, game consoles, mobile

and smart phones.

Table 1. Device summary

Order code Package Packaging

STMPE1801BJR

March 2011 Doc ID 17884 Rev 3 1/60

Flip-chip CSP 25 (2.03 x 2.03 mm)

0.4 mm pitch

Tape and reel

www.st.com

60

Page 2

Contents STMPE1801

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 GPIO pin functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Electrical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 DC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Input/Output DC electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Register address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 I2C specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 I2C related pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 I2C addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.3 Start condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4 Stop condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.5 Acknowledge bit (ACK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.6 Data input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.7 Memory addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.8 Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.9 General call address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 System controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 System level registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 States of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Auto-hibernate 20

7.2.2 . . . . . . . . . . . . . . . . . . . . . . . . Keypress detect in the Hibernate mode 21

2/60 Doc ID 17884 Rev 3

Page 3

STMPE1801 Contents

8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clocking system 22

8.0.1 Clock source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.0.2 Power mode programming sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9 Interrupt system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.1 Interrupt system register map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.2 Interrupt latency for the GPIO hot keys . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.3 Programming sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10 GPIO controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.1 GPIO control registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.1.1 Bit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.2 Hotkey feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2.1 Programming sequence for Hotkey . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.2.2 Minimum pulse width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11 Keypad controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11.1 Keypad configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.2 Keypad controller registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.3 Data registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11.4 Keypad combination key registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.5 Using the keypad controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.5.1 Ghost key handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.5.2 Key detection priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.5.3 Keypad wakeup from Hibernate mode . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.5.4 Keypad controller combination key interrupt . . . . . . . . . . . . . . . . . . . . . 52

12 Miscellaneous features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12.1 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Doc ID 17884 Rev 3 3/60

Page 4

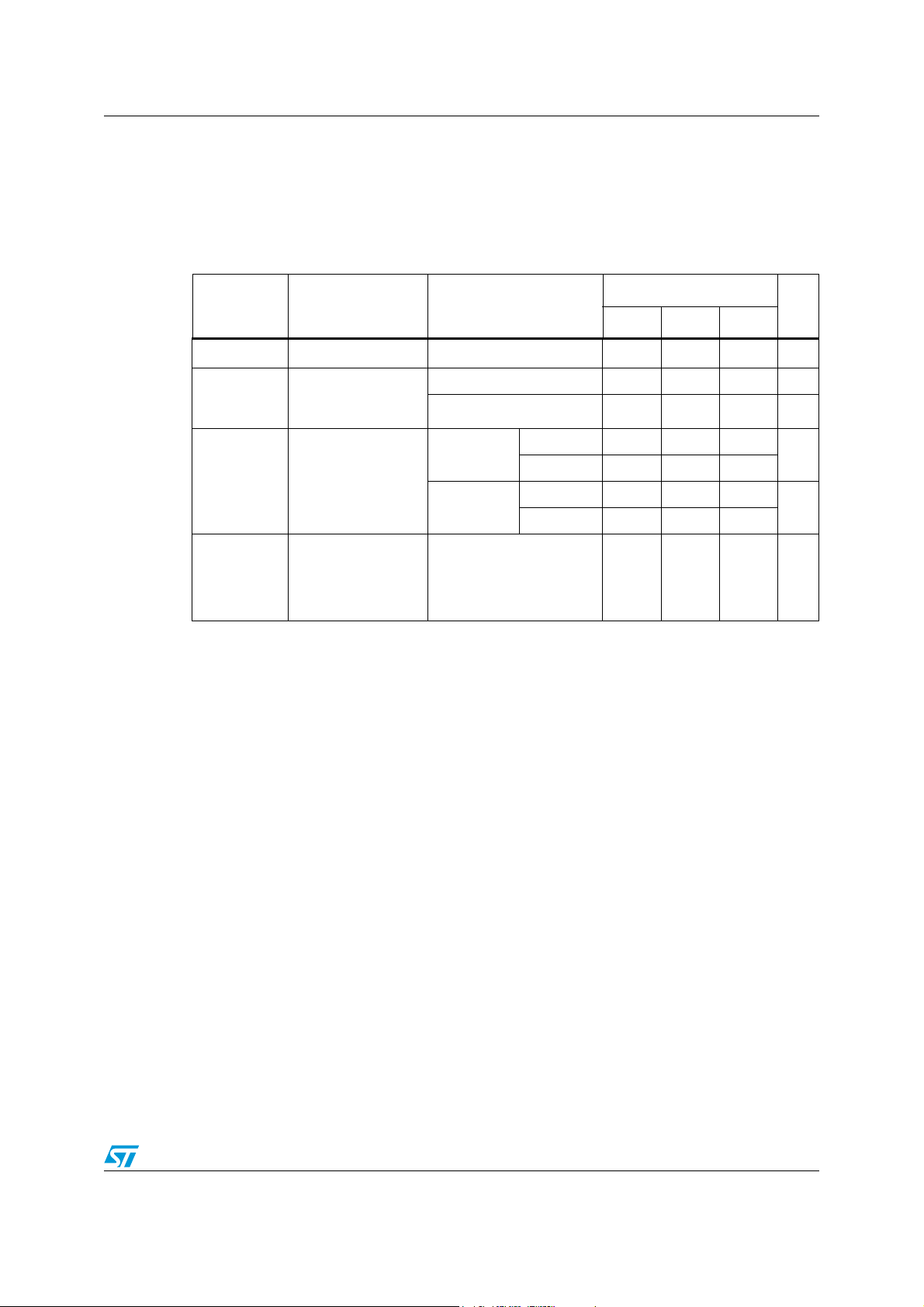

Block diagram STMPE1801

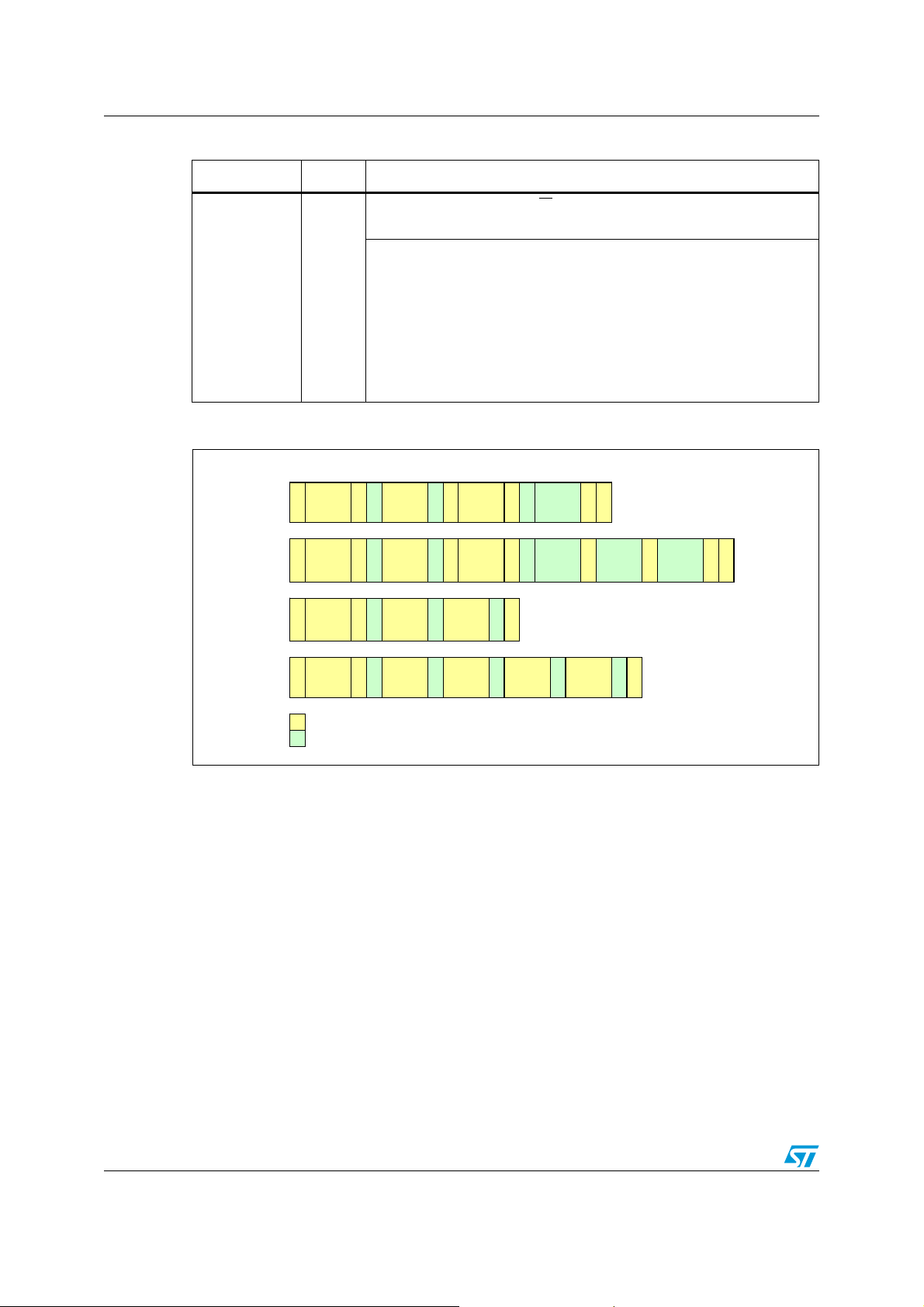

1 Block diagram

Figure 1. STMPE1801 block diagram

'.$

234"

).4"

3#,

3$!

+EYPADCONTROLLER

-AIN&307-

'0)/CONTROL

)#

)NTERFACE

0/2

-58

-58

+EYPADINPUT

2/72/7

'0)/

+EYPADOUTPUT

#/,#/,

'0)/

6

##

4/60 Doc ID 17884 Rev 3

Page 5

STMPE1801 Pin settings

_

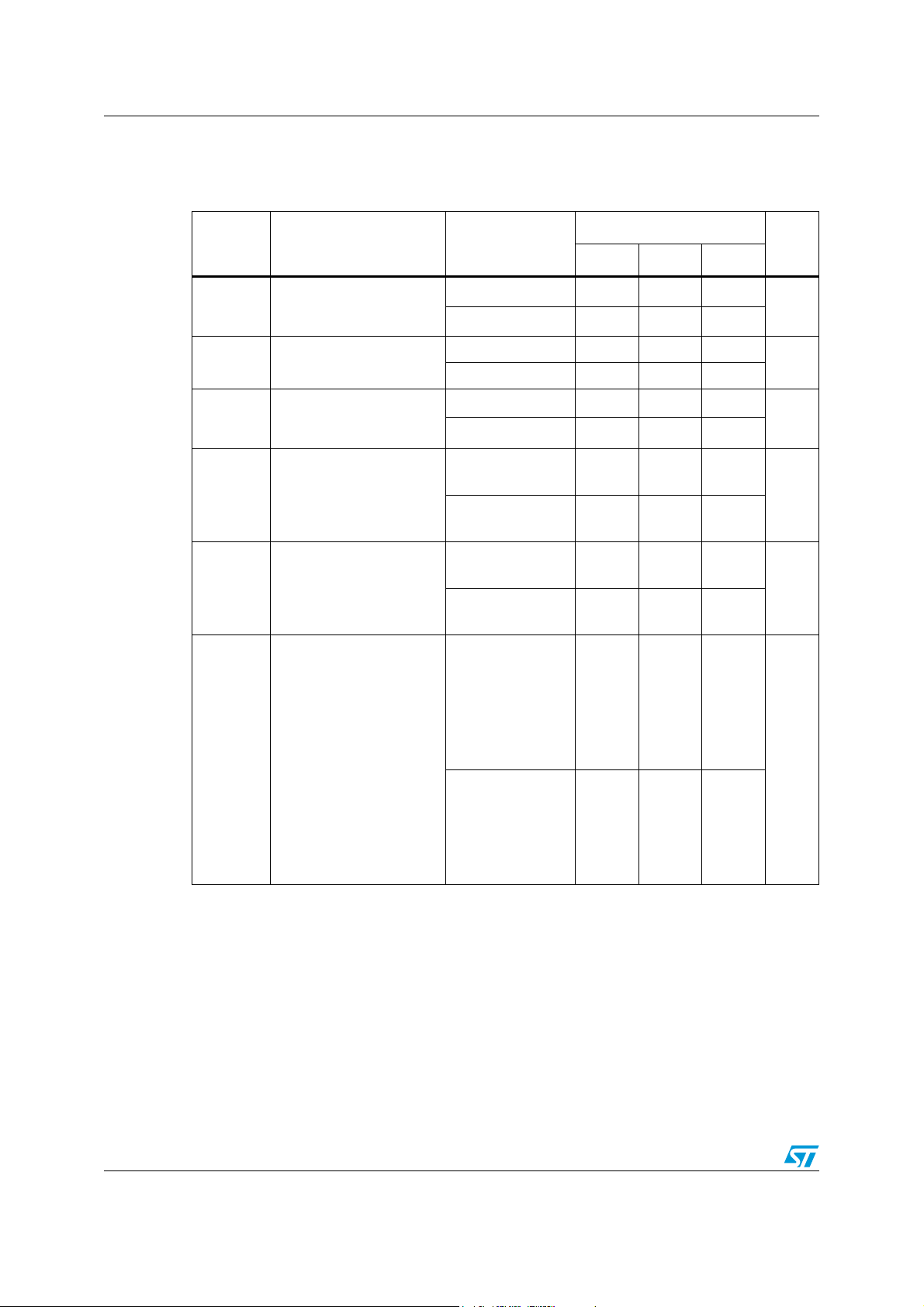

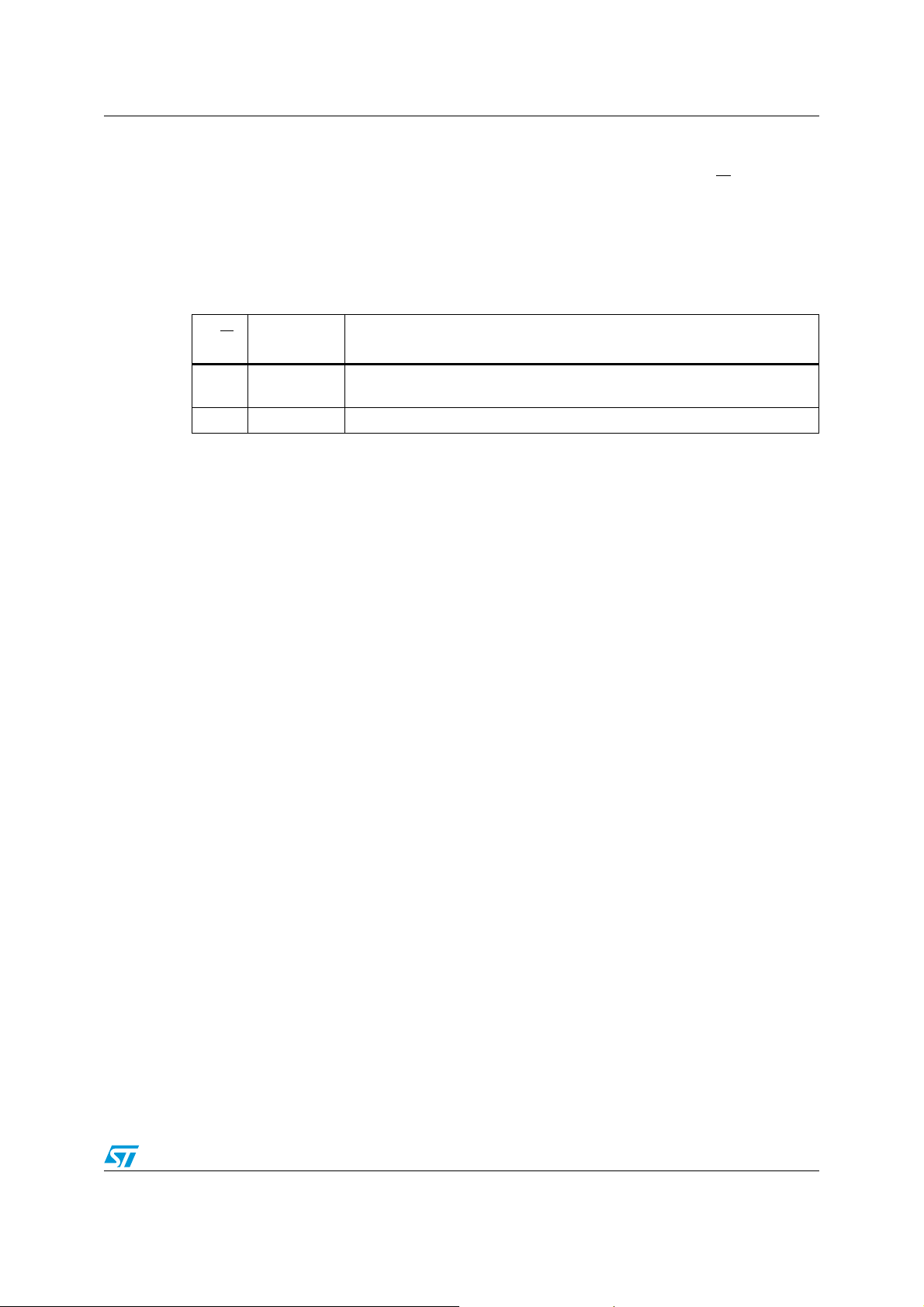

2 Pin settings

2.1 Pin connection

Figure 2. Pin connection (top-through view)

GPIO_14 GPIO9 GPIO2 GPIO7

!

"

RSTB

VCC

GPIO15 GPIO10 NC GPIO6

#

$

%

2.2 Pin description

Table 2. Pin description

Pin number Type Symbol Name and function

D4 I/O GPIO0 GPIO0/ROW0

C4 I/O GPIO1 GPIO1/ROW1

A4 I/O GPIO2 GPIO2/ROW2

E5 I/O GPIO3 GPIO3/ROW3

SDA GPIO16 GPIO1

GPIO17 GPIO0 GPIO4

SCL

INTB GND GPIO13 GPIO8 GPIO3

GPIO11

GPIO12

GPIO5

Flip-chip CSP 25

!-6

D5 I/O GPIO4 GPIO4/ROW4

C5 I/O GPIO5 GPIO5/ROW5

B5 I/O GPIO6 GPIO6/ROW6

A5 I/O GPIO7 GPIO7/ROW7

E4 I/O GPIO8 GPIO8/COL0

A3 I/O GPIO9 GPIO9/COL1

B3 I/O GPIO10 GPIO10/COL2

Doc ID 17884 Rev 3 5/60

Page 6

Pin settings STMPE1801

Table 2. Pin description (continued)

Pin number Type Symbol Name and function

C3 I/O GPIO11 GPIO11/COL3

D3 I/O GPIO12 GPIO12/COL4

E3 I/O GPIO13 GPIO13/COL5

A2 I/O GPIO14 GPIO14/COL6

B2 I/O GPIO15 GPIO15/COL7

C2 I/O GPIO16 GPIO16/COL8

D2 I/O GPIO17 GPIO17/COL9

Open drain interrupt output pin. Programmable active low

E1 O INTB

A1 I RSTB

C1 A SDA I

D1 A SCL I2C clock. Fail safe

(a pull-up resistor is required) or active high (a pull-down

resistor is required). Fail safe. Pull to V

if not in use.

CC

External reset input. Active low. Fail safe. Reset pulse

width must be more than 500 µs to be valid.

2

C data. Fail safe

B4 - NC No connect

B1 - V

E2 - GND Ground

2.3 GPIO pin functions

Table 3. GPIO pin function

Name Primary function Alternate function

GPIO0 GPIO Keypad row 0

GPIO1 GPIO Keypad row 1

GPIO2 GPIO Keypad row 2

GPIO3 GPIO Keypad row 3

GPIO4 GPIO Keypad row 4

GPIO5 GPIO Keypad row 5

GPIO6 GPIO Keypad row 6

GPIO7 GPIO Keypad row 7

GPIO8 GPIO Keypad column 0

GPIO9 GPIO Keypad column 1

CC

Power supply

GPIO10 GPIO Keypad column 2

GPIO11 GPIO Keypad column 3

GPIO12 GPIO Keypad column 4

6/60 Doc ID 17884 Rev 3

Page 7

STMPE1801 Pin settings

Table 3. GPIO pin function

Name Primary function Alternate function

GPIO13 GPIO Keypad column 5

GPIO14 GPIO Keypad column 6

GPIO15 GPIO Keypad column 7

GPIO16 GPIO Keypad column 8

GPIO17 GPIO Keypad column 9

The default function is always GPIO. As soon as the key scanning is enabled through the

keypad registers, the function is then switched to the key function and then any configuration

made in the GPIO registers is ignored.

Doc ID 17884 Rev 3 7/60

Page 8

Maximum ratings STMPE1801

3 Maximum ratings

Stressing the device above the rating listed in the “absolute maximum ratings” table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

3.1 Absolute maximum ratings

Table 4. Absolute maximum ratings

Symbol Parameter Value Unit

V

CC

Input voltage on GPIO pin 4.5 V

V

IN

V

ESD

V

ESD

Supply voltage 4.5 V

Minimum ESD protection on each GPIO

pin (HBM model - JESD22 A114-C)

ESD protection on other pins (HBM model -

JESD22 A114-C)

3.2 Thermal data

Table 5. Thermal data

Symbol Parameter Min Typ Max Unit

R

thJA

T

A

T

J

Thermal resistance junction-ambient – 100 – °C/W

Operating ambient temperature -40 25 85 °C

Operating junction temperature -40 25 125 °C

±8 kV

±3 kV

8/60 Doc ID 17884 Rev 3

Page 9

STMPE1801 Electrical specification

4 Electrical specification

4.1 DC electrical characteristics

Table 6. DC electrical characteristics

Val ue

Symbol Parameter Test conditions

Min Typ Max

Unit

V

CC

I

CC

I

HIBERNATE

I

NTB

Supply voltage - 1.65

Active current (core

and analog) - 1 key

press

Hibernate current

Open drain output

current

V

OL(max)

V

CC

V

OL(max)

VCC=3.3 V

1.8 V − 28 55 µA

3.3 V

25 °C

1.8 V

85 °C

25 °C

3.3 V

85 °C

=0.45 V at

=1.8 V

=0.83 V at

− 90 140 µA

−−0.5

−−1

−−0.5

−−1

− 4 − mA

−

3.6 V

µA

µA

Doc ID 17884 Rev 3 9/60

Page 10

Electrical specification STMPE1801

4.2 Input/Output DC electrical characteristics

Table 7. I/O DC electrical characteristics

Val ue

Symbol Parameter Test conditions

V

= 1.8 V −−0.2 V

V

Low level input voltage

IL

CC

= 3.3 V −−0.2 V

V

CC

VCC = 1.8 V 0.8 V

V

V

HYST

V

OL

V

OH

High level input voltage

IH

Schmitt trigger hysteresis

Low level output voltage

High level output voltage

= 3.3 V 0.8 V

V

CC

V

= 1.8 V − 0.10 −

CC

V

= 3.3 V − 0.20 −

CC

I

= 4 mA,

OL

= 1.8 V

V

CC

= 4 mA,

I

OL

= 3.3 V

V

CC

I

= -4 mA,

OH

= 1.8 V

V

CC

= -4 mA,

I

OH

= 3.3 V

V

CC

= 3.3 V.

V

CC

Active

implementation,

R value is

determined by the

R

Equivalent pull-up

UP

resistance

current measured

at 0 V

= 1.8 V. Active

V

CC

implementation,

R value is

determined by the

current measured

at 0 V

Min Typ Max

CC

CC

−−

−−

−−0.45

−−0.45

1.35

2.48

30 60 90

50 100 150

−−

−−

CC

CC

Unit

V

V

V

V

V

kΩ

10/60 Doc ID 17884 Rev 3

Page 11

STMPE1801 Register address

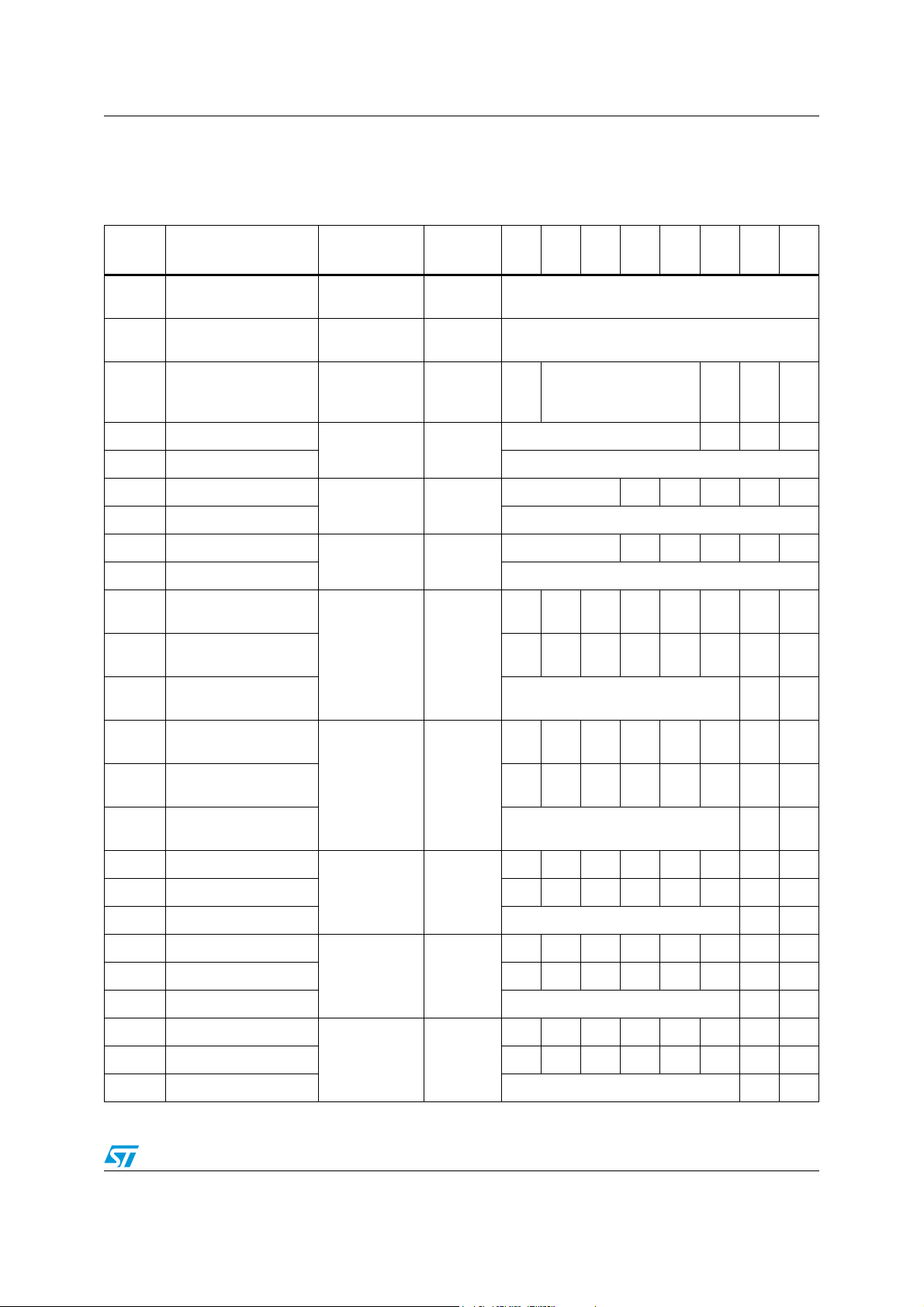

5 Register address

Table 8. STMPE1801 register summary table

Addres

s

00 CHIP_ID

01 VERSION_ID

02 SYS_CTRL System control No

04 INT_CTRL_LOW

05 INT_CTRL_HIGH RESERVED

06 INT_EN_MASK_LOW

07 INT_EN_MASK_HIGH RESERVED

08 INT_STA_LOW

09 INT_STA_HIGH RESERVED

0A

0B

0C

0D INT_STA_GPIO_LOW

0E INT_STA_GPIO_MID

Register name Description

identification

Version

identification

Interrupt

control

Interrupt

enable mask

Interrupt status Yes

INT_EN_GPIO_MASK

_LOW

INT_EN_GPIO_MASK

_MID

INT_EN_GPIO_MASK

_HIGH

Interrupt

enable GPIO

Interrupt status

Chip

mask

GPIO

Auto-

increment

No 8-bit CHIP ID

No 8-bit VERSION ID

Ye s

Ye s

Ye s

Ye s

76543210

SF_

RST

RESERVED IE4 IE3 IE2 IE1 IE0

RESERVED IE4 IE3 IE2 IE1 IE0

IEG7IEG6IEG5IEG4IEG3IEG2IEG1IEG

IEG15IEG14IEG13IEG12IEG11IEG10IEG9IEG

ISG7ISG6ISG

ISG15ISG14ISG13ISG12ISG11ISG10ISG9ISG

RESERVED

RESERVED IC2 IC1 IC0

RESERVED

ISG4ISG3ISG2ISG1ISG

5

GPI

_DB

1

GPI

RSV

_DB

IEG17IEG

D

0

0

8

16

0

8

0F INT_STA_GPIO_HIGH RESERVED

10 GPIO_SET_LOW

11 GPIO_SET_MID IO15 IO14 IO13 IO12 IO11 IO10 IO9 IO8

12 GPIO_SET_HIGH RESERVED IO17 IO16

13 GPIO_CLR_LOW

14 GPIO_CLR_MID IO15 IO14 IO13 IO12 IO11 IO10 IO9 IO8

15 GPIO_CLR_HIGH RESERVED IO17 IO16

16 GPIO_MP_LOW

17 GPIO_MP_MID IO15 IO14 IO13 IO12 IO11 IO10 IO9 IO8

18 GPIO_MP_HIGH RESERVED IO17 IO16

GPIO set pin

state

GPIO clear pin

state

GPIO monitor

pin state

Doc ID 17884 Rev 3 11/60

Ye s

Ye s

Ye s

IO7 IO6 IO5 IO4 IO3 IO2 IO1 IO0

IO7 IO6 IO5 IO4 IO3 IO2 IO1 IO0

IO7 IO6 IO5 IO4 IO3 IO2 IO1 IO0

ISG17ISG

16

Page 12

Register address STMPE1801

Table 8. STMPE1801 register summary table

Addres

s

19 GPIO_SET_DIR_LOW

1A GPIO_SET_DIR_MID IO15 IO14 IO13 IO12 IO11 IO10 IO9 IO8

1B

1C GPIO_RE_LOW

1D GPIO_RE_MID IO15 IO14 IO13 IO12 IO11 IO10 IO9 IO8

1E GPIO_RE_HIGH RESERVED IO17 IO16

1F GPIO_FE_LOW

20 GPIO_FE_MID IO15 IO14 IO13 IO12 IO11 IO10 IO9 IO8

21 GPIO_FE_HIGH RESERVED IO17 IO16

22

23 GPIO_PULL_UP_MID IO15 IO14 IO13 IO12 IO11 IO10 IO9 IO8

24

30 KPC_ROW

Register name Description

GPIO set pin

direction

GPIO_SET_DIR_HIG

H

GPIO_PULL_UP_LO

W

GPIO_PULL_UP_HIG

H

register

GPIO rising

edge

GPIO falling

edge

GPIO pull up Yes

Keypad row

scanning

Auto-

increment

Ye s

Ye s

Ye s

Ye s

76543210

IO7 IO6 IO5 IO4 IO3 IO2 IO1 IO0

RESERVED IO17 IO16

IO7 IO6 IO5 IO4 IO3 IO2 IO1 IO0

IO7 IO6 IO5 IO4 IO3 IO2 IO1 IO0

IO7 IO6 IO5 IO4 IO3 IO2 IO1 IO0

RESERVED IO17 IO16

ROW7ROW6ROW5ROW4ROW3ROW2ROW1RO

W0

31 KPC_COL_LOW

32 KPC_COL_HIGH RESERVED

33 KPC_CTRL_LOW

34 KPC_CTRL_MID DB6 DB5 DB4 DB3 DB2 DB1 DB0

35 KPC_CTRL_HIGH

36 KPC_CMD

37 KPC_COMB_KEY_0

38 KPC_COMB_KEY_1 C4 C3 C2 C1 C0 R2 R1 R0

39 KPC_COMB_KEY_2 C4 C3 C2 C1 C0 R2 R1 R0

Keypad column

scanning

Key config:

Scan count and

dedicated key

Keypad

command

Keypad

combination

key mask

Ye s

Ye s

Yes RESERVED

Ye s

COL7COL6COL5COL4COL3COL2COL1COL

0

COL9COL

8

SCAN_COUNT 0-3 DKEY 0-3

Rsv

d

CM

Rsv

B_K

d

EY

C4 C3 C2 C1 C0 R2 R1 R0

RESERVED

SCAN_FR

EQ

KPC

SCA

_LC

N

K

12/60 Doc ID 17884 Rev 3

Page 13

STMPE1801 Register address

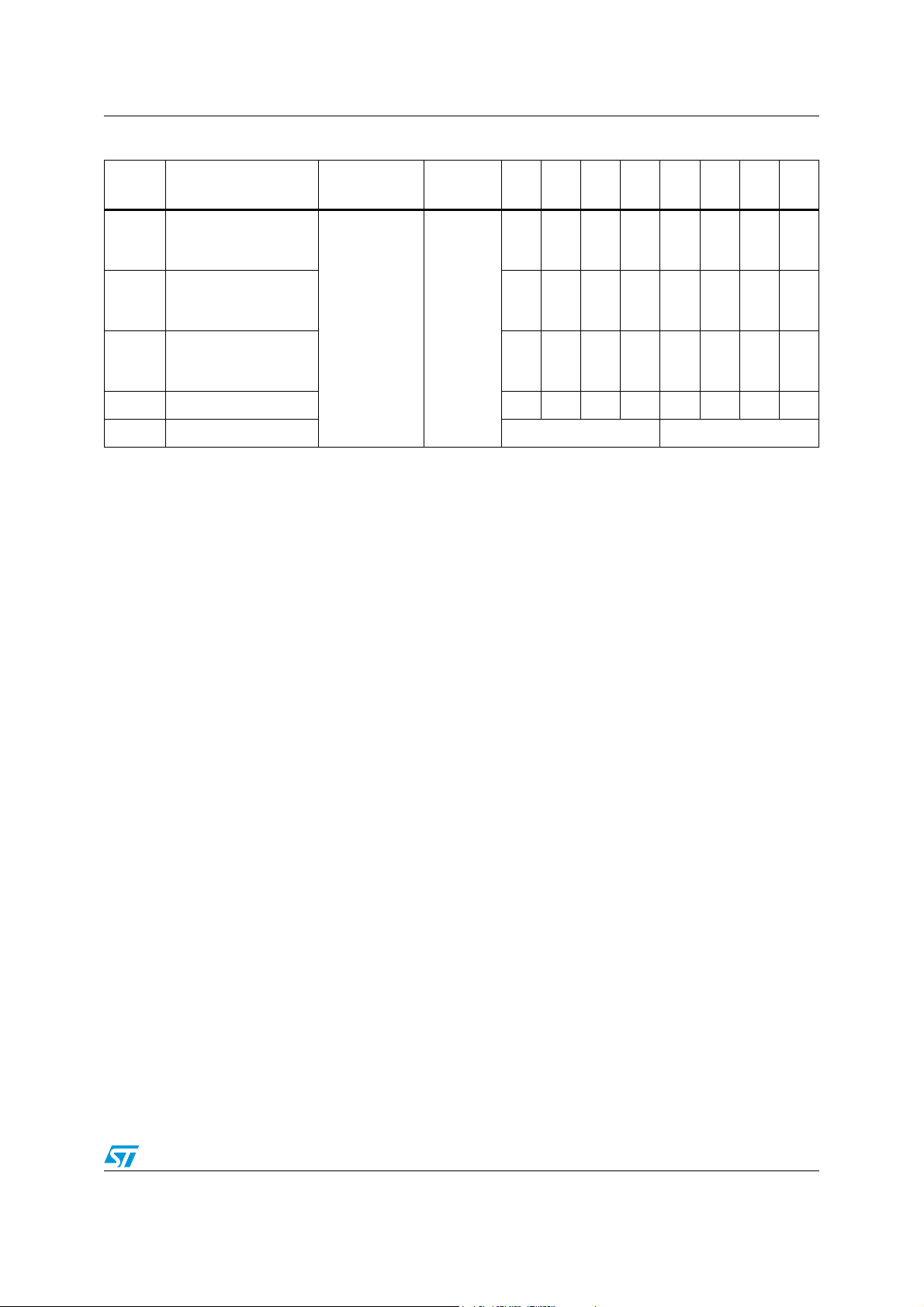

Table 8. STMPE1801 register summary table

Addres

s

Register name Description

Auto-

increment

76543210

UP/

3A KPC_DATA_BYTE0

DWNC3 C2 C1 C0 R2 R1 R0

UP/

3B KPC_DATA_BYTE1

DWNC3 C2 C1 C0 R2 R1 R0

Keypad data Yes

UP/

3C KPC_DATA_BYTE2

DWNC3 C2 C1 C0 R2 R1 R0

3D KPC_DATA_BYTE3 SF7 SF6 SF5 SF4 SF3 SF2 SF1 SF0

3E KPC_DATA_BYTE4 RESERVED Dedicated Key 0 - 3

Doc ID 17884 Rev 3 13/60

Page 14

I2C specification STMPE1801

6 I2C specification

The features supported by the I2C interface are listed below:

2

● I

C slave device

● Operates at V

● Compliant to Philips I

● Supports standard (up to 100 kbps) and fast (up to 400 kbps) modes

● 7-bit device addressing modes

● General call

● Start/Restart/Stop

6.1 I2C related pins

● SCL

● SDA

The device supports both 1.8 V I

Vpullup at SCL and SDA externally is greater or equal to V

(1.8 - 3.6 V)

CC

2

C specification version 2.1

2

C and 3.3 V I2C operations. It is recommended that

.

CC

6.2 I2C addressing

The STMPE1801 7-bit addressing is set to 40h.

6.3 Start condition

A Start condition is identified by a falling edge of SDA while SCL is stable at high state. A

Start condition must precede any data/command transfer. The device continuously monitors

for a Start condition and does not respond to any transaction unless one is encountered.

The first byte is scanned after the START command is detected to check for device ID.

Ensure that all state machines are flushed when START instruction is issued.

6.4 Stop condition

A Stop condition is identified by a rising edge of SDA while SCL is stable at high state. A

Stop condition terminates the communication between the slave device and bus master. A

read command that is followed by NoAck can be followed by a Stop condition to force the

slave device into idle mode. When the slave device is in idle mode, it is ready to receive the

2

next I

C transaction. A Stop condition at the end of a write command stops the write

operation to the registers.

Once the Stop condition is detected, the device should release the bus and go to Hibernate

mode if there is no more activity.

2

An I

C transaction with a START bit followed immediately by a STOP condition should not

cause any I

2

C lock-up.

14/60 Doc ID 17884 Rev 3

Page 15

STMPE1801 I2C specification

6.5 Acknowledge bit (ACK)

The acknowledge bit is used to indicate a successful byte transfer. The bus transmitter

releases the SDA after sending eight bits of data. During the ninth bit, the receiver pulls the

SDA low to acknowledge the receipt of the eight bits of data. The receiver may leave the

SDA in high state if it does not acknowledge the receipt of the data.

6.6 Data input

The device samples the data input on SDA on the rising edge of the SCL. The SDA signal

must be stable during the rising edge of SCL and the SDA signal must change only when

SCL is driven low.

6.7 Memory addressing

For the bus master to communicate to the slave device, the bus master must initiate a Start

condition and be followed by the slave device address. Accompanying the slave device

address, there is a Read/Write bit (R/W

operation.

If a match occurs on the slave device address, the corresponding device gives an

acknowledgement on the SDA during the 9th bit time. If there is no match, it deselects itself

from the bus by not responding to the transaction.

). The bit is set to 1 for Read and 0 for Write

6.8 Operation modes

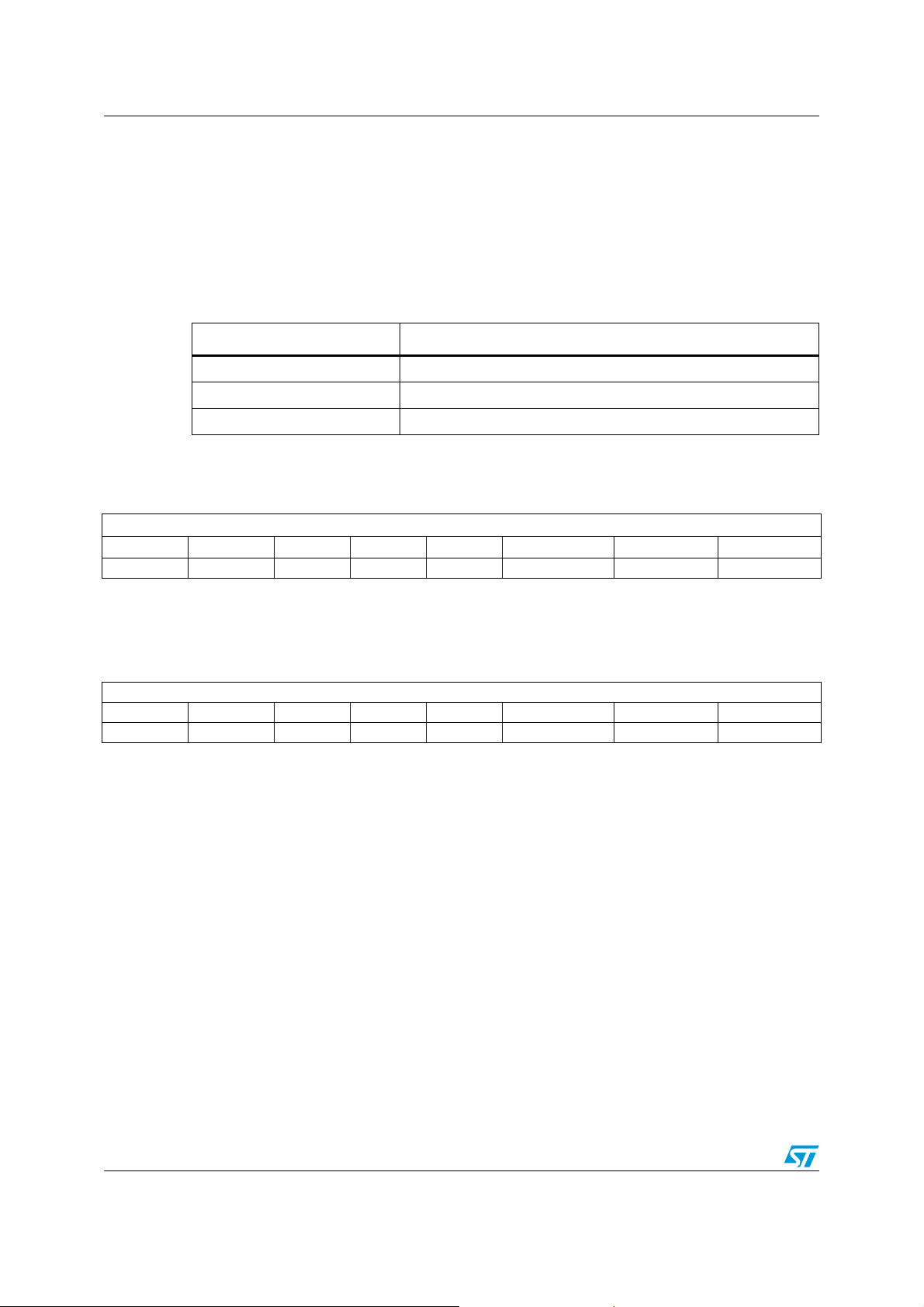

Table 9. Operating modes

Mode Byte Programming sequence

Read ≥1

START, Device address, R/W

=0, Register Address to be read

RESTART, Device Address, R/W

=1, Data Read, STOP

If no STOP is issued, the Data Read can be continuously performed. If

the register address falls within the range that allows address autoincrement, then register address auto-increments internally after every

byte of data being read. For register address that fails within a nonincremental address range, the address is kept static throughout the

entire read operation. Refer to Table 8.: STMPE1801 register summary

table for the address ranges that are auto-increment and non-increment.

An example of such a non-increment address is FIFO.

Doc ID 17884 Rev 3 15/60

Page 16

I2C specification STMPE1801

M

Table 9. Operating modes

Mode Byte Programming sequence

START, Device Address, R/W

=0, Register Address to be written, Data Write, STOP

If no STOP is issued, the Data Write can be continuously performed. If

the register address falls within the range that allows address autoincrement, then register address auto-increment internally after every

Write ≥1

byte of data being written. For those register addresses that fall within a

non-incremental address range, the address will be kept static

throughout the entire write operation. Refer to Table 8.: STMPE1801

register summary table for the address ranges that are auto-increment

and non-increment. An example of a non-increment address is Data

Port for initializing the PWM.

Figure 3. Operating modes

One B yte

Read

More than

One B yte

Read

One B yte

Write

ore than

One B yte

Write

Start

Start

Start

Start

Dev

Addr

Dev

Addr

Dev

Addr

Dev

Addr

Master

Slave

Reg

Addr

RnW=0

Ack

Reg

Addr

RnW=0

Ack

Reg

Addr

RnW=0

Ack

Reg

Addr

RnW=0

Ack

Ack

Ack

Ack

Ack

Dev

Addr

reStart

Dev

Addr

reStart

Data to

be

Written

Data to

Write

RnW=1

RnW=1

Ack

Stop

Data to

Write + 1

Ack

Dat a

Rea d

Ack

Ack

Dat a

Rea d

Data to

Write + 2

Ack

NoAck

Stop

Rea d + 1

Ack

Dat a

Ack

Stop

Rea d + 2

Ack

Dat a

NoAck

Stop

16/60 Doc ID 17884 Rev 3

Page 17

STMPE1801 I2C specification

6.9 General call address

A general call address is a transaction with the slave address of 0x00 and R/W =0. When a

general call address is asserted, the STMPE1801 responds to this transaction with an

acknowledgement and behaves as a slave-receiver mode. The meaning of a general call

address is defined in the second byte sent by the master-transmitter.

Table 10. General call address

R/W

Second byte

value

0 0x06

0 0x00 Not allowed as second byte.

A 2-byte transaction in which the second byte tells the slave device to reset

and write (or latch in) the 2-bit programmable part of the slave address.

Note: All other second byte values are ignored.

Definition

Doc ID 17884 Rev 3 17/60

Page 18

System controller STMPE1801

7 System controller

7.1 System level registers

The system controller is the heart of the STMPE1801. It contains the registers for power

control and chip identification.

The system registers are:

Address Register name

00 CHIP_ID

01 VERSION_ID

02 SYS_CTRL

CHIP_ID Chip identification register

76543 2 1 0

8-bit CHIP_ID

RRRRR R R R

11000 0 0 1

VERSION_ID Version identification register

76543 2 1 0

8-bit VERSION_ID

RRRRR R R R

00010 0 0 0

18/60 Doc ID 17884 Rev 3

Page 19

STMPE1801 System controller

SYS_CTRL System control register

76543 2 1 0

SF_RST RESERVED GPI_DB1 GPI_DB0 RSVD

WRRRR RW RW R

00000 1 1 0

Address: 02

Type: R/W

Reset: 0x06

Description: System control register.

[7] SF_RST: Soft Reset

Writing a ‘1’ to this bit will do a soft reset of the device. Once the reset is done, this bit is

cleared to ‘0’ by the HW.

[6:3] RESERVED

[2:1] GPI_DB [1:0]

GPI [17:0] operational mode de-bounce time

‘00’ = 30 µs

‘01’ = 90 µs

‘10’ = 150 µs

‘11’ = 210 µs (default)

[0] RESERVED

Doc ID 17884 Rev 3 19/60

Page 20

System controller STMPE1801

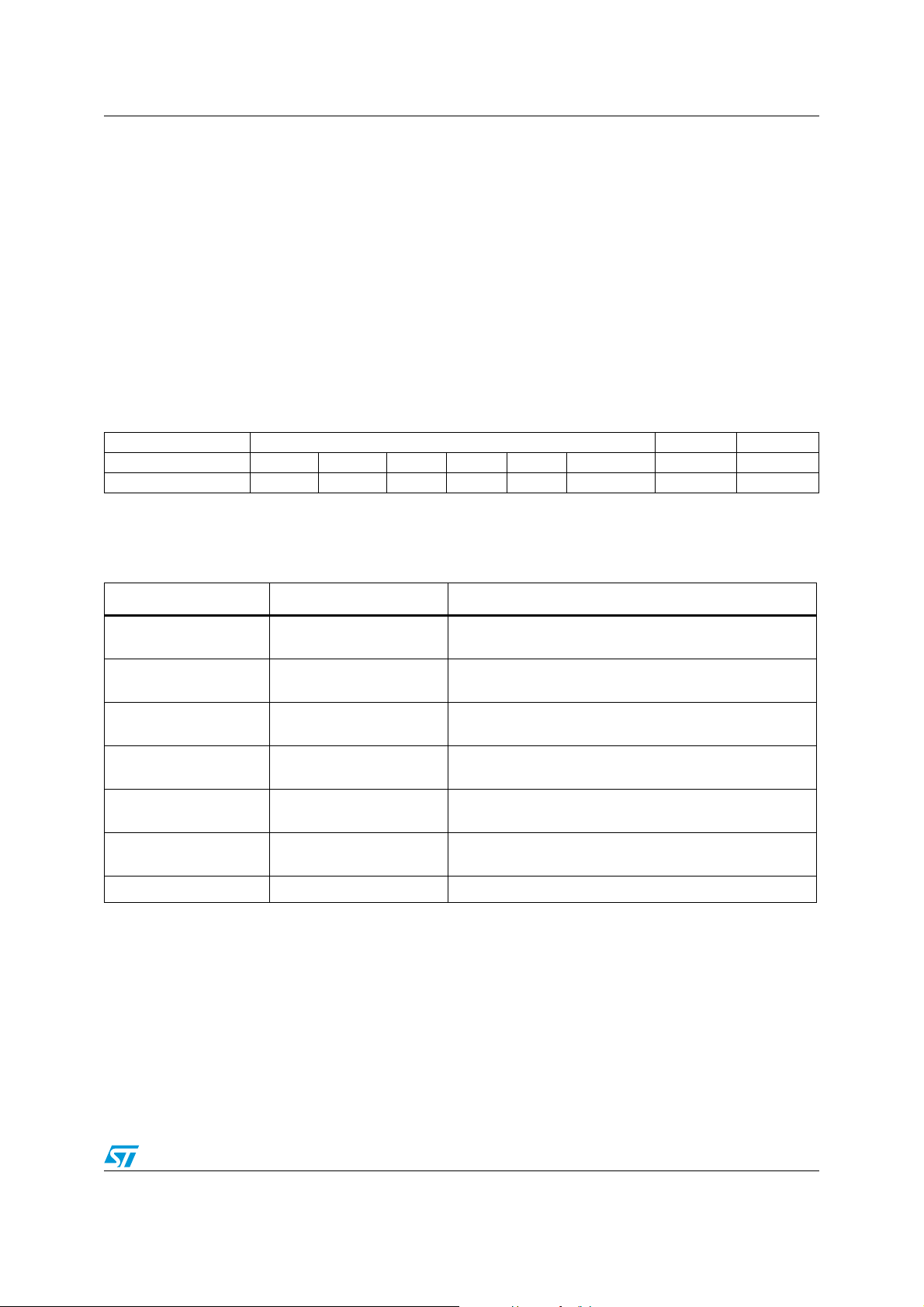

7.2 States of operation

Figure 4. States of operation

O perational

3 2 kHz: ON

No a ctivity

(~ 100 μs)

3 2 kHz: OFF

Hibernate

Keypad, interrupts

2

& I

C tran saction

(~ 48 μs)

Reset

AM04176V1

The device has two main modes of operation:

● Operational mode: This is the mode, whereby normal operation of the device takes

place. In this mode, the main finite state machine (FSM) unit routes 32 kHz clock to all

the device blocks.

● Hibernate mode: This mode is entered automatically in auto-hibernate mode. When the

device is in Hibernate mode, the 32 kHz clock is disabled. If there is a keypad activity,

interrupt event, hotkey activity or I

2

C transaction, the device switches to operational

mode. A reset event brings back the system to operational mode.

7.2.1 Auto-hibernate

The STMPE1801 is set to go into Hibernate mode automatically if there is a period of

inactivity (~ 100

STMPE1801 will continue counting down for hibernation mode activation even if there is an

2

I

C transaction sent by the host to other slave devices. Any I2C transaction from the host to

the STMPE1801 resets the hibernate counter.

Auto-hibernate mode occurs only when all the keys are released and FIFO is emptied

through reading. This is to prevent any loss of data.

The hibernate mode counter should start when any of the following conditions is detected:

– Once the I

– If the device ID in the I

When there is a keypad activity, the device should go into Hibernate mode ONLY when all

the previously pressed keys are released.

20/60 Doc ID 17884 Rev 3

µs) following the completion of I

2

C transaction is completed or a STOP condition is detected.

2

C transaction is invalid.

2

C transaction with the host. The

Page 21

STMPE1801 System controller

Any keypad activity, interrupt event, hotkey activity or VALID I2C transaction wakes up the

device from Hibernate mode and switches to operational mode automatically.

7.2.2 Keypress detect in the Hibernate mode

When in Hibernate mode, any keypress detected causes the system to go into operational

mode (~48

detected is valid, the system stays in operation mode. If the key detected is invalid, the

system goes back into Hibernate mode.

µs). The system will then de-bounce the key to detect a valid key. If the keypress

Doc ID 17884 Rev 3 21/60

Page 22

Clocking system STMPE1801

8 Clocking system

In order to reduce the power consumption, the STMPE1801 turns off the oscillator during

Hibernate mode.

Figure 5. Clocking system

K(Z

/3#

#LOCKCONTROL

3YSTEMCLOCK

8.0.1 Clock source

By default, when the STMPE1801 powers up, it derives a 32 kHz clock from the internal RC

oscillator for its operation.

There are 4 sources of reset:

● RSTB pin

● Low voltage detect (LVD) reset

● Soft reset bit of the SYS_CTRL register

2

● I

C reset from the I2C block.

3#,PIN

!-6

22/60 Doc ID 17884 Rev 3

Page 23

STMPE1801 Clocking system

8.0.2 Power mode programming sequence

The device enters auto Hibernate mode when there is inactivity for a fixed period of time.

To wake up the device, the host is required to:

– Send an I

To do a soft reset to the device, the host needs to do the following:

– Write a '1' to bit 7 of the SYS_CTRL register. This bit is automatically cleared upon

reset.

To come out of the Hibernate mode, the following needs to be done by the host:

– Assert a system reset

– Or put a wakeup on the I

– Interrupt activity

2

C transaction to the device.

2

C transaction

Doc ID 17884 Rev 3 23/60

Page 24

Interrupt system STMPE1801

9 Interrupt system

The STMPE1801 uses a highly flexible interrupt system. It allows the host system to

configure the type of system events that should result in an interrupt, and pinpoints the

source of interrupt by status registers. The INT pin can be configured as active high (a pulldown resistor is required), or active low (a pull-up resistor is required). If INT pin is not in

use, it is necessary to pull INT pin to V

Once asserted, the INT pin would de-assert when a read is done to the corresponding bit

either in the INT_STA register or INT_STA_GPIO register.

Figure 6. Interrupt system

CC

.

+EYPAD

CONTROLLER

'0)/

CONTROLLER

)NTERRUPT

ENABLE

'0)/

REGISTER

)NTERRUPTSTATUS

)NTERRUPTENABLE

REGISTER

REGISTER

)NTERRUPT

GENERATION

)NTERRUPTPOLARITYCONTROL

3YSTEMCONTROLREGISTER

!-6

24/60 Doc ID 17884 Rev 3

Page 25

STMPE1801 Interrupt system

9.1 Interrupt system register map

Table 11. Interrupt system register map

Address Register name Description

04 INT_CTRL_LOW

05 INT_CTRL_HIGH Yes

06 INT_EN_MASK_LOW

07 INT_EN_MASK_HIGH Yes

08 INT_STA_LOW

09 INT_STA_HIGH Yes

0A INT_EN_GPIO_MASK_LOW

0B INT_EN_GPIO_MASK_MID Yes

0C INT_EN_GPIO_MASK_HIGH Yes

0D INT_STA_GPIO_LOW

0E INT_STA_GPIO_MID Yes

0F INT_STA_GPIO_HIGH Yes

Interrupt control register

Interrupt enable mask register

Interrupt status register

Interrupt enable GPIO mask register

Interrupt status GPIO register

(during sequential R/W)

9.2 Interrupt latency for the GPIO hot keys

Auto-increment

Ye s

Ye s

Ye s

Ye s

Ye s

When the generation of interrupts by the GPIO as input is enabled for the hot keys, the

latency (time taken from actual transition at GPIO to time of INT pin assertion) is shown in

the following table:

Table 12. GPIO hot keys interrupt latency

State of operation Interrupt latency Comments

Hibernation >200 µs (default)

Active >200 µs (default)

Latency can be programmed by

the GPI_DB bits of SYS_CTRL

register

Doc ID 17884 Rev 3 25/60

Page 26

Interrupt system STMPE1801

INT_CTRL Interrupt control register

1514131211109876543 2 1 0

INT_CTRL_HIGH INT_CTRL_LOW

Reserved IC2 IC1 IC0

RRRRRRRRRRRRRRW RWRW

Address: 04, 05

Type: R, R/W

Reset: 0x00

Description: The interrupt control register is used to configure the interrupt controller. It has global

enable interrupt mask bit that controls the interruption to the host.

[15:3] RESERVED

[2] IC2: Output Interrupt polarity

‘0’ = Active low/falling edge

‘1’ = Active high/rising edge

[1] IC1: Output Interrupt type

‘0’ = Level interrupt

‘1’ = Edge interrupt (Pulse width of 200µs)

[0] IC0: Global interrupt mask bit

When this bit is written a ‘1’, it allows interruption to the host. If it is written with a ‘0’, then, it

disables all interruption to the host. Writing to this bit does not affect the INT_EN_MASK value.

26/60 Doc ID 17884 Rev 3

Page 27

STMPE1801 Interrupt system

INT_EN_MASK Interrupt enable mask register

1514131211109876543 2 1 0

INT_EN_MASK_HIGH INT_EN_MASK_LOW

RESERVED IE4 IE3 IE2 IE1 IE0

RRRRRRRRRRRRWRWRWRWRW

0000000000000 0 0 0

Address: 06, 07

Type: R, R/W

Reset: 0x00

Description: The interrupt enable mask register is used to enable the interruption from a particular

interrupt source to the host.

[15:4] RESERVED

[4:0] IE[x]:

Interrupt Enable Mask (where x = 3 to 0)

IE0: Default value is 0.

IE1: Keypad controller interrupt mask

IE2: Keypad controller FIFO overflow interrupt mask

IE3: GPIO controller interrupt mask

IE4: Combination key interrupt enable

Writing a ‘1’ to the IE[x] bit enables the interruption to the host.

Doc ID 17884 Rev 3 27/60

Page 28

Interrupt system STMPE1801

INT_STA Interrupt status register

1514131211109876543210

INT_STA_HIGH INT_STA _LOW

RESERVED IS4 IS3 IS2 IS1 IS0

RRRRRR RRRRRRRRRR

000000 0000000001

Address: 08, 09

Type: R

Reset: 0x00

Description: The interrupt status register monitors the status of the interruption from a particular

interrupt source to the host. The INT_STA bits are constantly updated regardless

whether the INT_EN bits are enabled or not.

[15:4] RESERVED

[4:0] IS[x]

Interrupt status (where x = 3 to 0)

Read:

IS0: Wake-up interrupt status

IS1: Keypad controller interrupt status

IS2: Keypad controller FIFO overflow interrupt status

IS3: GPIO controller interrupt status

IS4: Combination key interrupt status

Reading the INT_STA register clears all interrupt status bits to ‘0’ which had been set to ‘1’

prior to the read event.

28/60 Doc ID 17884 Rev 3

Page 29

STMPE1801 Interrupt system

INT_EN_GPIO_MASK Interrupt enabled GPIO mask register

76543 2 1 0

INT_EN_GPIO_MASK_LOW

IEG7 IEG6 IEG5 IEG4 IEG3 IEG2 IEG1 IEG0

RW RW RW RW RW RW RW RW

00000 0 0 0

15 14 13 12 11 10 9 8

INT_EN_GPIO_MASK_MID

IEG15 IEG14 IEG13 IEG12 IEG11 IEG10 IEG9 IEG8

RW RW RW RW RW RW RW RW

00000 0 0 0

23 22 21 20 19 18 17 16

INT_EN_GPIO_MASK_HIGH

Reserved IEG17 IEG16

R R R R R R RW RW

00000 0 0 0

Address: 0A, 0B, 0C

Type: R/W

Reset: 0x00

Description: The interrupt enable GPIO mask register is used to enable the interruption from a

particular GPIO interrupt source to the host. The IEG[17:0] bits are the interrupt

enable mask bits correspond to the GPIO[17:0] pins.

[17:0 IEG[x]: Interrupt enable GPIO mask (where x = 17 to 0)

Writing a ‘1’ to the IEG[x] bit enables the interruption to the host.

Doc ID 17884 Rev 3 29/60

Page 30

Interrupt system STMPE1801

NT_STA_GPIO Interrupt status GPIO register

76543 2 1 0

INT_STA_GPIO_LOW

ISG7 ISG6 ISG5 ISG4 ISG3 ISG2 ISG1 ISG0

RRRRR R R R

00000 0 0 0

15 14 13 12 11 10 9 8

INT_STA_GPIO_MID

ISG15 ISG14 ISG13 ISG12 ISG11 ISG10 ISG9 ISG8

RRRRR R R R

00000 0 0 0

23 22 21 20 19 18 17 16

INT_STA_GPIO_HIGH

Reserved ISG17 ISG16

RRRRR R R R

00000 0 0 0

Address: 0D, 0E, 0F

Type: R

Reset: 0x00

Description: The interrupt status GPIO register monitors the status of the interruption from a

particular GPIO pin interrupt source to the host. The INT_STA_GPIO bits are

constantly updated regardless whether the INT_EN_GPIO_MASK bits are enabled or

not. The ISG[17:0] bits are the interrupt status bits correspond to the GPIO[17:0] pins.

[17:0 ISG[x]

Interrupt status GPIO (where x = 17 to 0)

ISG[x] will be set to ‘1’ if an interrupt is detected on the corresponding GPIO pin.

Reading the INT_STA_GPIO register clears all interrupt status GPIO bits to ‘0’ which had been

set to ‘1’ prior to the read event.

30/60 Doc ID 17884 Rev 3

Page 31

STMPE1801 Interrupt system

9.3 Programming sequence

To configure and initialize the interrupt controller to allow interruption to host, observe the

following steps:

1. Set the INT_EN_MASK and INT_EN_GPIO_MASK registers to the desired values to

enable the interrupt sources that are to be expected to receive from.

2. Configure the output interrupt type and polarity and enable the global interrupt mask by

writing to the INT_CTRL.

3. Wait for interrupt.

4. Upon receiving an interrupt, the corresponding INT bit is asserted.

5. The host comes to read the INT_STA register through the I

INT_STA bits indicates that the corresponding interrupt source is triggered.

6. If the IS3 bit in INT_STA register is set, the interrupt is coming from the GPIO controller.

Then, a subsequent read is performed on the INT_STA_GPIO register to obtain the

interrupt status of all 18 GPIOs to locate the GPIO that triggers the interrupt. This is a

‘Hot Key’ feature.

7. After obtaining the interrupt source that triggers the interrupt, the host performs the

necessary processing and operations related to the interrupt source.

8. All IS[x] bits in INT_STA register and ISG[x] bits in INT_STA_GPIO register which are

set to ‘1’ prior to the read event are cleared to ‘0’ automatically once the reading of the

registers are completed.

9. Any interrupt inputs received between reading and auto clearing of the registers are

kept in a shadow register and updated into the INT_STA and INT_STA_GPIO registers

once the auto clearing is completed.

10. Once the interrupt is cleared, the INT pin is also de-asserted if the interrupt type is level

interrupt. An edge interrupt only asserts a pulse width of 200 µs.

11. When the interrupt function is no longer required, the IC0 bit in INT_CTRL may be set

to ‘0’ to disable the global interrupt mask bit.

2

C interface. A ‘1’ in the

Doc ID 17884 Rev 3 31/60

Page 32

GPIO controller STMPE1801

10 GPIO controller

A total of 18 GPIOs are available in the STMPE1801 port expander device. Most of the

GPIOs are sharing physical pins with alternate functions. The GPIO controller contains the

registers that allow the host system to configure each of the pins into either a GPIO, or one

of the alternate functions. Unused GPIOs should be configured as outputs to minimize the

power consumption.

Table 13. GPIO controller registers

Auto-increment

Address Register name Description

(during sequential

R/W)

10 GPIO_SET_LOW

11 GPIO_SET_MID Yes

12 GPIO_SET_HIGH Yes

13 GPIO_CLR_LOW

14 GPIO_CLR_MID Yes

15 GPIO_CLR_HIGH Yes

16 GPIO_MP_LOW

17 GPIO_MP_MID Yes

18 GPIO_MP_HIGH Yes

19 GPIO_SET_DIR_LOW

1A GPIO_SET_DIR_MID Yes

1B GPIO_SET_DIR_HIGH Yes

1C GPIO_RE_LOW

1D GPIO_RE_MID Yes

1E GPIO_RE_HIGH Yes

1F GPIO_FE_LOW

20 GPIO_FE_MID Yes

21 GPIO_FE_HIGH Yes

22 GPIO_PULL_UP_LOW

GPIO set pin state register

GPIO clear pin state register

GPIO monitor pin state register

GPIO set pin direction register

GPIO rising edge register

GPIO falling edge register

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

23 GPIO_PULL_UP_MID Yes

24 GPIO_PULL_UP_HIGH Yes

32/60 Doc ID 17884 Rev 3

GPIO pull up register

Page 33

STMPE1801 GPIO controller

10.1 GPIO control registers

A group of registers is used to control the exact function of each of the 18 GPIOs.

All the GPIO registers are named as GPIO_xxx_yyy, where:

– xxx represents the functional group

– yyy represents the byte position of the GPIO (LOW/MID/HIGH)

– LOW registers control GPIO[7:0]

– MID registers control GPIO[8:15]

– HIGH registers control GPIO[17:16]

10.1.1 Bit description

76543 2 1 0

GPIO_xxx_HIGH RESERVED IO-16 IO-17

GPIO_xxx_MID IO-15 IO-14 IO-13 IO-12 IO-11 IO-10 IO-9 IO-8

GPIO_xxx_LOW IO-7 IO-6 IO-5 IO-4 IO-3 IO-2 IO-1 IO-0

The function of each bit is shown in the following table:

Register name Description Function

GPIO_MP_yyy GPIO monitor pin state

GPIO_SET_yyy GPIO set pin state

GPIO_CLR_yyy GPIO clear pin state

GPIO_SET_DIR_yyy GPIO set pin direction

GPIO_RE_yyy GPIO rising edge

GPIO_FE_yyy GPIO falling edge

GPIO_PULL_UP_yyy GPIO pull up Set to ‘1’ enable internal pull-up resistor.

Reading this bit yields the current state of the bit. Writing

has no effect.

Writing ‘1’ to this bit causes the corresponding GPIO to go

to ‘1’ state. Writing ‘0’ has no effect.

Writing ‘1’ to this bit causes the corresponding GPIO to go

to ‘0’ state. Writing ‘0’ has no effect.

‘0’ sets the corresponding GPIO to input state, and ‘1’ sets

it to output state.

Set to ‘1’ enable rising edge detection on the

corresponding GPIO.

Set to ‘1’ enable falling edge detection on the

corresponding GPIO.

Doc ID 17884 Rev 3 33/60

Page 34

GPIO controller STMPE1801

10.2 Hotkey feature

A GPIO is known as ‘Hotkey’ when it is configured to trigger an interruption to the host

whenever the GPIO input is being asserted. This feature is applicable in operational mode

as well as in Hibernate mode.

10.2.1 Programming sequence for Hotkey

1. Configure the GPIO pin into input direction by setting the corresponding bit in the GPIO

set pin direction registers [GPIO_SET_DIR_yyy].

2. Set the GPIO rising edge registers [GPIO_RE_yyy] and GPIO falling edge registers

[GPIO_FE_yyy] to the desired values to enable the rising edge or falling edge

detection.

3. Configure and enable the interrupt controller to allow the interruption to the host.

4. Now, the GPIO expander may enter Hibernate mode if there is no activity.

5. Upon any hot-key being asserted, the device will wake up and issue an interrupt to the

host.

Below are the conditions to be fulfilled in order to configure a Hot Key:

1. The pin is configured into GPIO mode and as input pin.

2. The global interrupt mask bit is enabled.

3. The corresponding GPIO interrupt mask bit is enabled.

10.2.2 Minimum pulse width

The minimum pulse width of the assertion of the Hotkey is dependent on the de-bounce

time configured. It must be greater than the de-bounce value configured. Any pulse width

less than the stated value may not be registered.

34/60 Doc ID 17884 Rev 3

Page 35

STMPE1801 Keypad controller

11 Keypad controller

The keypad controller consists of:

– 4 dedicated key controllers that support up to 4 simultaneous dedicated key

presses;

– a keyscan controller support a maximum of 10 x 8 key matrix with detection of

three simultaneous key presses;

– 8 special function key controllers that support up to 8 simultaneous “special

function” key presses.

The key detection priority is dedicated, special function and normal keys.

Four of the row inputs can be configured as dedicated keys through the setting of Dkey0~3

bits of the KPC_CTRL register. The normal key matrix size can be configured through the

setting of KPC_ROW and KPC_COL registers. The scanning of each individual row input

and column output can be enabled or masked to support a key matrix of variable size from 1

x 1 to 10 x 8. It is allowed to have other 8 special function keys incorporated in the key

matrix.

The operation of the keypad controller is enabled by the SCAN bit of KPC_CTRL register.

Every key activity detected is de-bounced for a period set by the DB_1~7 bits of KPC_CTRL

register before a key press or key release is confirmed and updated into the output FIFO.

The key data, indicating the key coordinates and its status (up or down), is loaded into the

FIFO at the end of a specified number of scanning cycles (set by SCAN_COUNT0~3 bits of

KPC_CTRL_MID register). An interrupt is generated when a new set of key data is loaded.

The FIFO has a capacity for ten sets of key data. Each set of key data consists of 5 bytes of

information when any of the four dedicated keys is enabled. It is reduced to 4 bytes when no

dedicated key is involved. When the FIFO is full before its content is read, an overflow signal

is generated while the FIFO will continue to hold its content but forbid loading of new key

data set.

Doc ID 17884 Rev 3 35/60

Page 36

Keypad controller STMPE1801

Figure 7. Keypad controller

/UTPUT

COLUMN

-ATRIXKEYPAD

)NPUTROW

!-6

The keypad rows enabled by the KPC_ROW register are normally 'high', with the

corresponding input pins pulled up by resistors internally. After reset, all the keypad columns

enabled by the KPC_COL register are driven 'low' via weak-pull down resistors. The pulldown resistors on the column are weaker than the pull-up resistors on the rows. If a key is

pressed, the stronger pull-up drive on the corresponding row overwrites the weaker pulldown drive on the selected column thus allowing the keyscan controller to sense a "high"

input on the selected column.

Once the keyscan controller senses a "high" on the selected column, the output buffer for

the selected column drives the line low overwriting the pull-up resistor on the corresponding

row. The row that senses the "low" signal enables the key scan controller to decode the key

coordinates (its corresponding row number and column number), save the key data into a

de-bounce buffer if available, confirm if it is a valid key press after de-bouncing, and update

the key data into output data FIFO if valid.

The key press/release detection mechanism is listed below:

1. When the GPIO is configured as keypad, the ROWS have internal "strong" pull-up and

COLUMNS have internal "weak" pull-down. The initial states of the ROWS are Logic

High and the COLUMNS are Logic Low.

2. When a keypad is pressed, the corresponding Row and Column form a Resistor

Voltage Divider Network. Since the pull-up resistance of the ROW is stronger than the

pull-down resistance of the COLUMN, the COLUMN is pulled to Logic High.

3. Once the COLUMN's state changes to Logic High, the state machine initiates a keyscan cycle and drives the selected COLUMN to Logic Low. A low is detected on the

36/60 Doc ID 17884 Rev 3

Page 37

STMPE1801 Keypad controller

key-press ROW. This is because the row and column node of key press are shorted

together.

4. The state machine continues to poll while the key is still pressed and is reinitialized

once all the keys are released.

The key detection sequence is described below:

1. The column outputs are initially not driven.

2. Then the row inputs are checked for any special function keys.

3. Next, the columns are checked for any normal key presses.

4. With the internal pull-down resistor on the columns, the column senses a logic low. But

when there is a normal key press, the pull up on the row and pull down on the column

forms a resistor voltage divider. Since the pull up resistor is sized much smaller than

the pull down resistor, the voltage on the column is pulled to logic high state.

5. Then only the configured columns that sensed a high are driven low in turn and check

for normal key presses.

This eliminates the need to drive columns that do not have any key press. This in turn

reduces the switching amount and hence the reduction in noise and EMI.

Also the 4 mA IO during GPIO mode is 1 mA in keypad mode.

Doc ID 17884 Rev 3 37/60

Page 38

Keypad controller STMPE1801

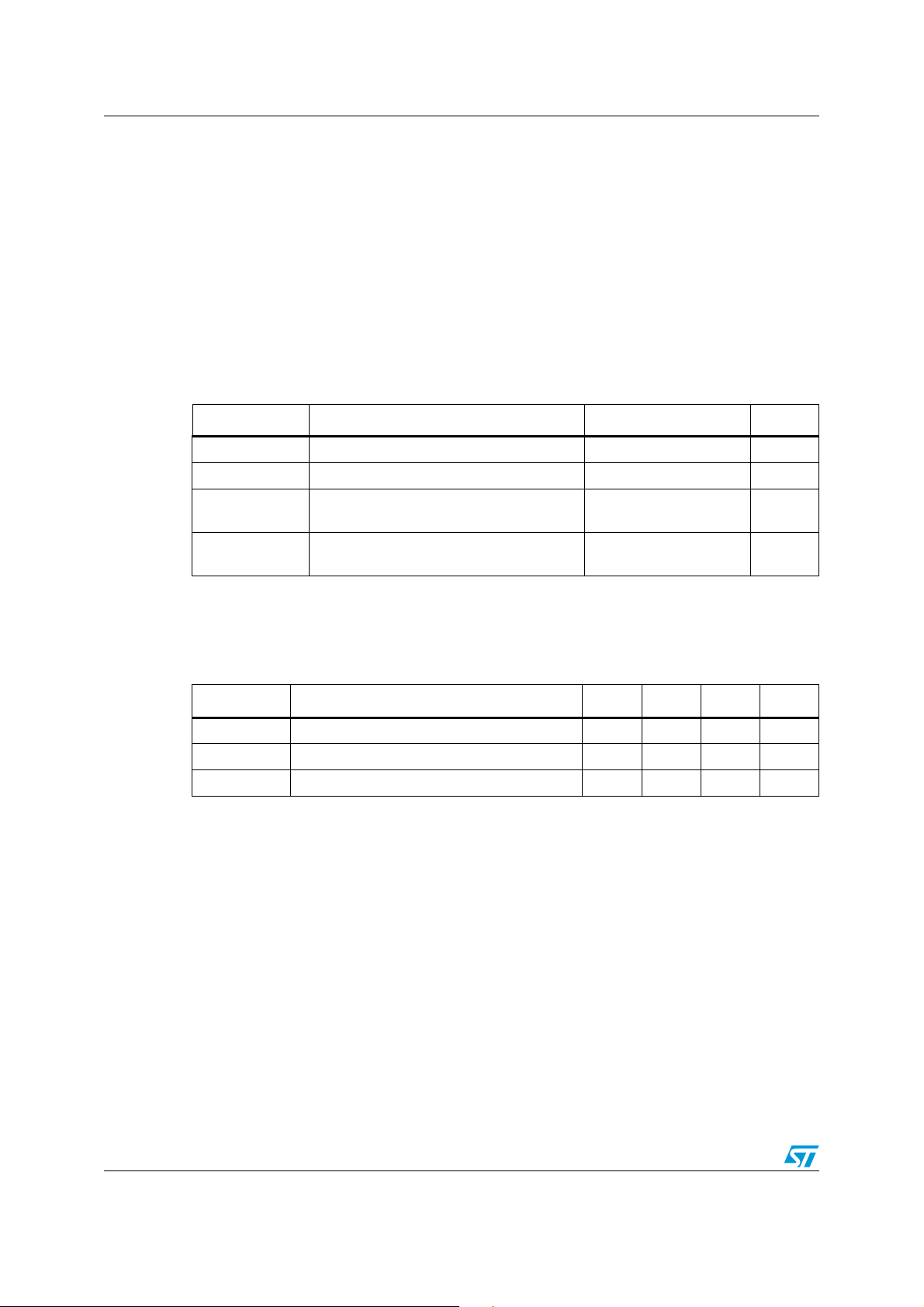

11.1 Keypad configurations

The keypad controller supports the following types of keys:

● Up to 10 columns * 8 rows matrix keys

● Up to 8 special function keys

● Up to 4 dedicated keys

Figure 8. Keypad configuration

Matrix keypad (10*8)

Input Row 0-7

10*8 (80) Matrix Keys

8 Special Function Keys

0 Dedicated Keys

STMPE1801

Output Column 0

-9

Special Function Keys

38/60 Doc ID 17884 Rev 3

!-6

Page 39

STMPE1801 Keypad controller

Figure 9. Keypad configurations

Matrix keypad (10*4)

STMPE1801

Output Column 0-9

Input Row 0-7

Dedicated Keys

Special Function Keys

10*4 (40) Matrix Keys

4 Special Function Keys

4 Dedicated Keys

!-6

Doc ID 17884 Rev 3 39/60

Page 40

Keypad controller STMPE1801

11.2 Keypad controller registers

The mapping between the keypad controller (rows and columns) and the GPIO is based on

Section 2.3.

Table 14. Keypad controller registers

Address Register name Description

30 KPC_ROW Keypad row register Yes

31 KPC_COL_LOW

32 KPC_COL_HIGH Yes

33 KPC_CTRL_LOW

34 KPC_CTRL_MID Yes

35 KPC_CTRL_HIGH Yes

36 KPC_CMD Key command register Yes

37 KPC_COMBI_KEY_0 Keypad combination key mask 0 Yes

38 KPC_COMBI_KEY_1 Keypad combination key mask 1 Yes

39 KPC_COMBI_KEY_2 Keypad combination key mask 2 Yes

3A KPC_DATA_BYTE0

3B KPC_DATA_BYTE1 Yes

3C KPC_DATA_BYTE2 Yes

3D KPC_DATA_BYTE3 Yes

3E KPC_DATA_BYTE4 Yes

Keypad column register

Keypad control register

Keypad data register

Auto-increment

(during sequential R/W)

Ye s

Ye s

Ye s

40/60 Doc ID 17884 Rev 3

Page 41

STMPE1801 Keypad controller

KPC_ROW Keypad controller row register

76543 2 1 0

Input Row 0 - 7

RW RW RW RW RW RW RW RW

00000 0 0 0

Address: 30

Type: R/W

Reset: 0x00

Description: Keypad row scanning

[7:0] Input row 0 – 7:

‘1’: Turn on scanning of the corresponding row

.‘0’: Turn off

KPC_COL_HIGH Keypad controller column (HIGH)

15 14 13 12 11 10 9 8

RESERVED Output Column 8 - 9

R R R R R R RW RW

00000 0 0 0

Address: 32

Type: R/W

Reset: 0x00

Description: Keypad column scanning register.

[15:10] RESERVED

[9:8] OUTPUT COLUMN 8-9:

‘1’: Turn on scanning of the corresponding column.

‘0’: Turn off

Doc ID 17884 Rev 3 41/60

Page 42

Keypad controller STMPE1801

KPC_COL_LOW Keypad controller column (LOW)

76543 2 1 0

Output Column 0 - 7

RW RW RW RW RW RW RW RW

00000 0 0 0

Address: 31

Type: R/W

Reset: 0x00

Description: Keypad column scanning register.

[7:0] OUTPUT COLUMN 0-7:

‘1’: Turn on scanning of the corresponding column.

‘0’: Turn off

KPC_CTRL_LOW Keypad controller control (Low)

76543 2 1 0

SCAN_COUNT 0 – 3 DKEY 0 – 3

RW RW RW RW RW RW RW RW

00000 0 0 0

Address: 33

Type: R/W

Reset: 0x00

Description: Keypad control register.

[7:4] SCAN_COUNT_0-3:

Number of key scanning cycles elapsed before a confirmed key data is updated into output

data FIFO (0-15 cycles)

[3] DKEY_3: Set ‘1’ to use input row 3 as dedicated key

[2] DKEY_2: Set ‘1’ to use input row 2 as dedicated key

[1] DKEY_1: Set ‘1’ to use input row 1 as dedicated key

[0] DKEY_0: Set ‘1’ to use input row 0 as dedicated key

42/60 Doc ID 17884 Rev 3

Page 43

STMPE1801 Keypad controller

KPC_CTRL_MID Keypad controller control (Mid)

76543 2 1 0

DB[7:2] DB0 RSVD

RW RW RW RW RW RW R RW

01100 0 1 0

Address: 34

Type: R/W

Reset: 0x31

Description: Keypad control register.

[7:1] DB[7:2] and DB0:

DB0 bit is fixed to ‘1’.

10-127ms of de-bounce time

De-bounce time range is from 10 ms to 127 ms with 50 ms as the default.

[0] RESERVED

Doc ID 17884 Rev 3 43/60

Page 44

Keypad controller STMPE1801

KPC_CTRL_HIGH Keypad controller control (High)

76543 2 1 0

RSVD CMB_KEY RESERVED SCAN_FREQ

RRWRRR R RW

01000 0 0 0

Address: 35

Type: R/W, R

Reset: 0x40

Description: Keypad data register.

[7:4] RESERVED

[6] CMB_KEY:

Combination key mode

1: AND function for combination-key interrupt (default).

0: OR function for combination-key interrupt.

[5:2] RESERVED

[1:0] SCAN_FREQ:

Scan frequency based on internal 32KHz clock

00: 60 Hz (default)

01: 30 Hz

10: 15 Hz

11: 275 Hz

KPC_CMD Keypad command register

76543 2 1 0

RSVD RSVD RSVD RSVD RSVD RSVD KPC_LOCK SCAN

R R R R R R RW RW

00000 0 0

Address: 36

Type: R/W, R

Reset: 0x00

Description: Keypad command register.

[7:2] RESERVED

[1] KPC_LOCK:

Keypad lock control bit

1: Writing 1 to enter key pad lock state when the key press stops.

44/60 Doc ID 17884 Rev 3

Page 45

STMPE1801 Keypad controller

The KPC_LOCK bit is only used when a combination key is configured in the device. If there

is no combination key programmed, then this bit is not used. This command is used in

conjunction with the combination keys. After the device has entered the keypad lock state,

all subsequent key presses are ignored until the combinational key(s) are detected.

Thereafter, the device exits the lock state, sets the combinational key wakeup status in the

interrupt status register bit IS[4] and sends out the interrupt if it was enabled.

0: Writing 0 aborts the key lock

Writing a 0 to this bit cancels any earlier key lock execution command. If the device has

already entered the lock state, writing 0 exits the lock state.

This bit is readable by the Host and the read status is described as follows:

Reading [1]: KPC lock execution is not completed. It is either waiting for the key press to

stop to enter the lock state or it is already in the lock state.

Reading [0]: KPC is already not in lock state, and not waiting to enter lock state.

[0]SCAN:

1: to start scanning

0: to stop

Note: All the key configurations and control must be completed before executing the scan

command. Any configuration and control change while scan is active is not supported.

Doc ID 17884 Rev 3 45/60

Page 46

Keypad controller STMPE1801

11.3 Data registers

The KPC_DATA register contains five bytes of information. The first three bytes store the key

coordinates and status of any three keys from the normal key matrix, while the fourth byte

stores the status of special function keys and the fifth byte consists of the status of

dedicated keys.

Note: When accessing the KPC DATA FIFO, it is mandatory to read all five bytes of KPC_Data

registers together consecutively.

46/60 Doc ID 17884 Rev 3

Page 47

STMPE1801 Keypad controller

KPC_DATA_BYTE0 Keypad data byte 0

76543 2 1 0

UP/DWN C3 C2 C1 C0 R2 R1 R0

RRRRR R R R

11111 0 0 0

Address: 3A

Type: R

Reset: 0xF8

Description: Keypad data register.

[7] UP/DWN:

0: key-down

1: key-up

[6:3] C[3:0]:

Column number of key 1 (valid range: 0000-1001)

0x1111: No key

[2:0] R[2:0]:

Row number of key 1 (valid range: 000-111)

KPC_DATA_BYTE1 Keypad data byte 1

76543 2 1 0

UP/DOWN C3 C2 C1 C0 R2 R1 R0

RRRRR R R R

11111 0 0 0

Address: 3B

Type: R

Reset: 0xF8

Description: Keypad data register.

[7] UP/DOWN:

0: key-down

1: key-up

[6:3] C[3:0]:

Column number of key 2 (valid range: 0000-1001)

0x1111: No key

[2:0] Row number of key 2 (valid range: 000-111)

Doc ID 17884 Rev 3 47/60

Page 48

Keypad controller STMPE1801

KPC_DATA_BYTE2 Keypad data byte 2

76543 2 1 0

UP/DOWN C3 C2 C1 C0 R2 R1 R0

RRRRR R R R

11111 0 0 0

Address: 3C

Type: R

Reset: 0xF8

Description: Keypad data register.

[7] UP/DOWN:

0: key-down

1: key-up

[6:3] C[3:0]: Column number of key 3 (valid range: 0000-1001)

0x1111: No key

[2:0] R[2:0]: Row number of key 3 (valid range: 000-111)

KPC_DATA_BYTE3 Keypad data byte 3

76543 2 1 0

SF7 SF6 SF5 SF4 SF3 SF2 SF1 SF0

RRRRR R R R

11111 1 1 1

Address: 3D

Type: R

Reset: 0xFF

Description: Keypad data register.

[7:0] SF[7:0]:

0: key-down

1: key-up

48/60 Doc ID 17884 Rev 3

Page 49

STMPE1801 Keypad controller

KPC_DATA_BYTE4 Keypad data byte 4

76543 2 1 0

RESERVED Dedicated Key 0 – 3

RRRRR R R R

00001 1 1 1

Address: 3E

Type: R

Reset: 0x0F

Description: Keypad data register.

[7:4] RESERVED

[3:0] Dedicated key [3:0]:

0: Key down

1: Key up

Doc ID 17884 Rev 3 49/60

Page 50

Keypad controller STMPE1801

11.4 Keypad combination key registers

The 3 keypad controller mask registers contains the key combination to be used to wake up

the KPC and send an interrupt to the host system.

KPC_COMB_KEY_n Keypad combination [n = 0-2]

76543 2 1 0

C4 C3 C2 C1 C0 R2 R1 R0

RW RW RW RW RW RW RW RW

11111 0 0 0

Address: 38, 39

Type: R/W

Reset: 0xF8

Description: Keypad combination key mask registers.

[7:3] C[4:0]: Column number of key n (valid range: 00000 – 01001)

[2:0] R[2:0]: Row number of key n (valid range: 000 – 111)

Valid key press value must be entered. The valid range for STMPE1801 is 00 to 4F. Any

other value outside this range is not accepted and a none value of F8 is returned.

50/60 Doc ID 17884 Rev 3

Page 51

STMPE1801 Keypad controller

11.5 Using the keypad controller

It is not necessary to explicitly enable the internal pull-up, pull-down and direction by

configuring the GPIO control registers. Once a GPIO is enabled for the keypad function, its

internal pull-up, pull-down and direction is controlled automatically.

The scanning of row inputs should then be enabled for those GPIO ports that are configured

as keypad inputs by writing '1's to the corresponding bits in the KPC_ROW register. If any of

the first four row inputs is to be used as dedicated key input, the corresponding bits in the

KPC_CTRL_MID register should be set to '1'. The bits in the KPC_COL_HIGH and

KPC_COL_LOW registers should also be set correctly to enable the column output

scanning for the corresponding GPIO ports programmed as keypad outputs.

The scan count and de-bounce count should also be programmed into the keypad control

registers before enabling the keypad controller operation. To enable the keypad controller

operation, the SCAN bit in the KPC_CTRL_LOW register must be set to '1'. The keypad

controller operation can be disabled by setting the SCAN bit back to '0'. The KPC interrupt

can be cleared upon status bit read, even if there is unread key-press in the KPC Data

register. It is the host responsibility to read the KPC Data register to access all key-press

data.

11.5.1 Ghost key handling

The ghost key is inherent in keypad matrix that is not equipped with a diode at each of the

keys. While it is not possible to avoid ghost key occurrence, the STMPE1801 allows the

detection of possible ghost keys by the capability of detecting 3 simultaneous key-presses in

the key matrix.

The ghost key is only possible if 3 keys are pressed and held down together in a keypad

matrix. If 3 keys are reported by the STMPE1801 keypad controller, it indicates a potential

ghost key situation. The system may check for the possibility of a ghost key by analyzing the

coordinates of the 3 keys. If the 3 keys form 3 corners of a rectangle, it could be a ghost key

situation.

A ghost key may also occur in the “special function keys”. The keypad controller does not

attempt to avoid the occurrence of ghost keys. However, the system should be aware that if

more than one special function key is reported, then there is a possibility of ghost keys.

11.5.2 Key detection priority

A dedicated key is always detected, if this is enabled. When a special function key is

detected, the matrix key scanning on the same input line is disabled.

Up to 3 matrix keys can be detected. Matrix keys that fall on activated special function keys

are not counted.

As a result of these priority rules, a matrix key is ignored by the keypad controller when the

special function key on the same input line is detected, even if the matrix key is being

pressed down before the special function key. Hence, when a matrix is reported "key-down"

and it is being held down while the corresponding special function is being pressed, a "no

key" status is reported for the matrix key when the special function key is reported "keydown". If the matrix key is released while the special function key is still being held down, no

"key-up" will be reported for the matrix key. On the other hand, if the matrix key is released

after the special function key is reported "key-up", then a new "key-down" is reported for the

matrix key, followed by "key-up".

Doc ID 17884 Rev 3 51/60

Page 52

Keypad controller STMPE1801

11.5.3 Keypad wakeup from Hibernate mode

The keypad controller is functional in Hibernate mode as long as it is enabled before

entering the Hibernate mode. It will then wake the system up into operational mode if a valid

key press is detected.

An asynchronous detection of the keypad column input activity is turned on during the

Hibernate mode. If any key activity is detected, the system wakes up into operational mode

for the de-bouncing of the key press to take place. If a valid key is detected, the system

stays in operational mode; otherwise, the device goes back into Hibernate mode.

11.5.4 Keypad controller combination key interrupt

The keypad controller (KPC) can be programmed to exit from Hibernate mode if a unique

combination keys is detected. These combination keys of up to 3 keys are specified in the

KPC combination set 0-2 registers.

There are 2 combination key operation modes. The modes can be set in the

COMB_KEY_MODE in the KPC_CTRL_HIGH register. In ‘OR’ mode, the device exits from

Hibernate mode on ANY of the 3 keys specified in the KPC combination set 0-2 registers. In

‘AND’ mode, the device exits from Hibernate mode ONLY if ALL of the 3 keys are pressed.

The sequence of the key pressed in not relevant as long as the 1-3 keys specified in the

KPC_COMB_KEY registers are detected, the KPC will exit from Hibernate mode and

interrupt the host. All the "active" keys must be pressed and held together, for the combi-key

interrupt to be generated.

If any other keys (beside those specified in the KPC_COMB_KEY_N registers) are pressed,

it would be considered an invalid combination and no interrupt will be generated.

52/60 Doc ID 17884 Rev 3

Page 53

STMPE1801 Miscellaneous features

12 Miscellaneous features

12.1 Reset

The STMPE1801 is equipped with an internal POR circuit that holds the device in reset

state, until the clock is steady and V

filter with minimum 180 ns at 1.8 V V

STMPE1801 by asserting the RSTB pin. The reset pin is also integrated with a filter of

minimum 200

µs duration and maximum 500 µs duration.

input is valid. The POR circuit is integrated with a

CC

. The host system may choose to reset the

CC

Doc ID 17884 Rev 3 53/60

Page 54

Package mechanical data STMPE1801

13 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

Figure 10. Package outline for Flip-chip CSP 25 (2.03 x 2.03 mm) - 0.4 mm pitch

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

54/60 Doc ID 17884 Rev 3

Page 55

STMPE1801 Package mechanical data

Table 15. Package mechanical data for Flip-chip CSP 25 (2.03 x 2.03 mm)

0.4 mm pitch

Millimeters

Symbol

Min Typ Max

A 0.55 0.605 0.660

A1 0.17 0.205 0.24

A2 0.38 0.4 0.42

b 0.215 0.255 0.295

D1.9722.03

D1 - 1.6 -

E1.9722.03

E1 - 1.6 -

e 0.36 0.4 0.44

f 0.190 0.200 0.210

ccc - 0.05 0.05

Figure 11. Footprint recommendation

Doc ID 17884 Rev 3 55/60

Page 56

Package mechanical data STMPE1801

Figure 12. Device marking

)DENTIFICATIONFOR

DEVICEFRONTEND

ANDBACKENDPLANT

Figure 13. Carrier tape information

6,.

977

'

)DENTIFICATIONFOR

(ALOGENFREE

)DENTIFICATIONFOR

TRACEABLEDATECODE

!-6

1. Pin A1 is at top left corner based on above tape orientation.

56/60 Doc ID 17884 Rev 3

Page 57

STMPE1801 Package mechanical data

Table 16. Carrier tape specifications

Millimeters

Symbol

Min Typ Max

A0 2.06 2.11 2.16

B0 2.06 2.11 2.16

K0 0.64 0.69 0.74

F 3.45 3.50 3.55

W 7.90 8.00 8.30

P2 1.95 2.00 2.05

P0 3.90 4.00 4.10

10P0 39.80 40.00 40.20

D0 1.50 1.55 1.60

T 0.185 0.200 0.215

P 3.90 4.00 4.10

Table 17. Tape width (millimeters)

A N W1 W2 W3

Tape width

max min max max min max

8 180 60 8,4 14.4 7.9 10.9

Doc ID 17884 Rev 3 57/60

Page 58

Package mechanical data STMPE1801

Figure 14. Reel drawing (front)

Figure 15. Reel drawing (back)

58/60 Doc ID 17884 Rev 3

Page 59

STMPE1801 Revision history

14 Revision history

Table 18. Document revision history

Date Revision Changes

15-Nov-2010 1 Initial release.

13-Dec-2010 2 Updated: Figure 12 and added footnote related to Figure 13.

09-Mar-2011 3 Updated: Pin A1 function in Ta b le 2 and Section 12.1.

Doc ID 17884 Rev 3 59/60

Page 60

STMPE1801

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

60/60 Doc ID 17884 Rev 3

Loading...

Loading...