www.DataSheet4U.com

查询STM32F101x6供应商查询STM32F101x6供应商

STM32F101x6

STM32F101x8 STM32F101xB

Access line, advanced ARM-based 32-bit MCU with Flash memory,

six 16-bit timers, ADC and seven communication interfaces

Preliminary Data

Features

■ Core: ARM 32-bit Cortex™-M3

– 36 MHz, 45 DMIPS with 1.25 DMIPS/MHz

– Single-cycle multiplication and hardware

division

– Nested interrupt controller with 43

maskable interrupt channels

– Interrupt processing (down to 6 CPU

cycles) with tail chaining

■ Memories

– 32-to -1 2 8 Kbytes of Flash me m ory

– 6-to- 16 Kbytes of SRAM

■ Clock, reset and supply management

– 2.0 to 3.6 V application supply and I/Os

– POR, PDR and programmable voltage

detector (PVD)

– 4-to-16 MHz high-speed quartz oscillator

– Internal 8 MHz factory-trimmed RC

– Internal 32 kHz RC

– PLL for CPU clock

– Dedicated 32 kHz oscillator for RTC with

calibration

■ Low power

– Sleep, Stop and Standby modes

–V

■ Debug mode

supply for RTC and backup registers

BAT

– Serial wire debug (SWD) and JTAG

interfaces

■ DMA

– 7-channel DMA controller

– Peripherals supported: timers, ADC, SPIs,

2

I

Cs and USARTs

■ 12-bit, 1 µs A/D converter (16-channel)

– Conversion range: 0 to 3.6 V

CPU

LQFP48

7 x 7 mm

LQFP64

10 x 10 mm

LQFP100

14 x 14 mm

– Temperature sensor

■ Up to 80 fast I/O ports

– 32/49/80 5 V-tolerant I/Os

– All mappable on 16 external interrupt

vectors

– Atomi c re ad /m o dif y/write operations

■ Up to 6 timers

– Up to three 16-bit timers, each with up to 4

IC/OC/PWM or pulse counter

– 2 x 16-bit watchdog timers (Independent

and Window)

– SysTick timer: 24-bit downcounter

■ Up to 7 communication interfaces

– Up to 2 x I

2

C interfaces (SMBus/PMBus)

– Up to 3 USARTs (ISO 7816 interface, LIN,

IrDA capability, modem control)

– Up to 2 SPIs (18 Mbit/s)

Table 1. Device summary

Reference Root part number

STM32F101x6 STM32F101C6, STM32F101R6

STM32F101x8

STM32F101xB STM32F101RB, STM32F101VB

STM32F101C8, STM32F101R8

STM32F101V8

July 2007 Rev 2 1/64

This is preliminary information on a new product now in development or undergoing ev aluation. Details are subject to

change without notice.

www.st.com

1

Contents STM32F101xx

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Memory mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.1 Minimum and maximum values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.2 Typical values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.3 Typical curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.4 Loading capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.5 Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1.6 Power supply scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.7 Current consumption measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.1 General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.2 Operating conditions at power-up / power-down . . . . . . . . . . . . . . . . . . 26

5.3.3 Embedded reset and power control block characteristics . . . . . . . . . . . 27

5.3.4 Embedded reference voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.5 Supply current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3.6 External clock source characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3.7 Internal Clock source characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3.8 PLL characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3.9 Memory characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3.10 EMC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.11 Absolute maximum ratings (electrical sensitivity) . . . . . . . . . . . . . . . . . 40

5.3.12 I/O port characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.13 NRST pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2/64

STM32F101xx Contents

5.3.14 TIM timer characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.3.15 Communications interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.16 12-bit ADC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.17 Temperature sensor characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6 Package characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.1 Thermal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.1 Future family enhancements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3/64

List of tables STM32F101xx

List of tables

Table 1. Device summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Device features and peripheral counts (STM32F101xx access line) . . . . . . . . . . . . . . . . . . 7

Table 3. Pin definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 4. Voltage characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 5. Current characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 6. Thermal characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 7. General operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 8. Operating conditions at power-up / power-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 9. Embedded reset and power control block characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 10. Embedded internal reference voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 11. Maximum current consumption in Run and Sleep modes (T

Table 12. Maximum current consumption in Stop and Standby modes . . . . . . . . . . . . . . . . . . . . . . . 29

Table 13. Typical current consumption in Run and Sleep modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 14. Typical current consumption in Stop and Standby modes . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 15. High-speed user external (HSE) clock characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 16. Low-speed user external clock characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 17. HSE 4-16 MHz oscillator characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 18. LSE oscillator characteristics (

= 32.768 kHz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

fLSE

Table 19. HSI oscillator characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 20. LSI oscillator characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 21. Low-power mode wakeup timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 22. PLL characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 23. Flash memory characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 24. Flash endurance and data retention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 25. EMS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 26. EMI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 27. ESD absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 28. Electrical sensitivities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 29. I/O static characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 30. Output voltage characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 31. I/O AC characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 32. NRST pin characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 33. TIMx characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 34. I

Table 35. SCL frequency (f

2

C characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

= 36 MHz, VDD = 3.3 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

PCLK1

Table 36. SPI characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 37. ADC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 38. ADC accuracy (f

PCLK2

= 10 MHz, f

= 10 MHz, R

ADC

AIN

Table 39. TS characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 40. LQPF100 – 100-pin low-profile quad flat package mechanical data . . . . . . . . . . . . . . . . . 58

Table 41. LQFP64 – 64-pin low-profile quad flat package mechanical data . . . . . . . . . . . . . . . . . . . 59

Table 42. LQFP48 – 48-pin low-profile quad flat package mechanical data . . . . . . . . . . . . . . . . . . . 60

Table 43. Thermal characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 44. Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 45. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

= 85 °C) . . . . . . . . . . . . . . . 28

A

< 10 kΩ, V

= 3.3 V) . . . . . . . . 55

DDA

4/64

STM32F101xx List of figures

List of figures

Figure 1. STM32F101xx access line block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

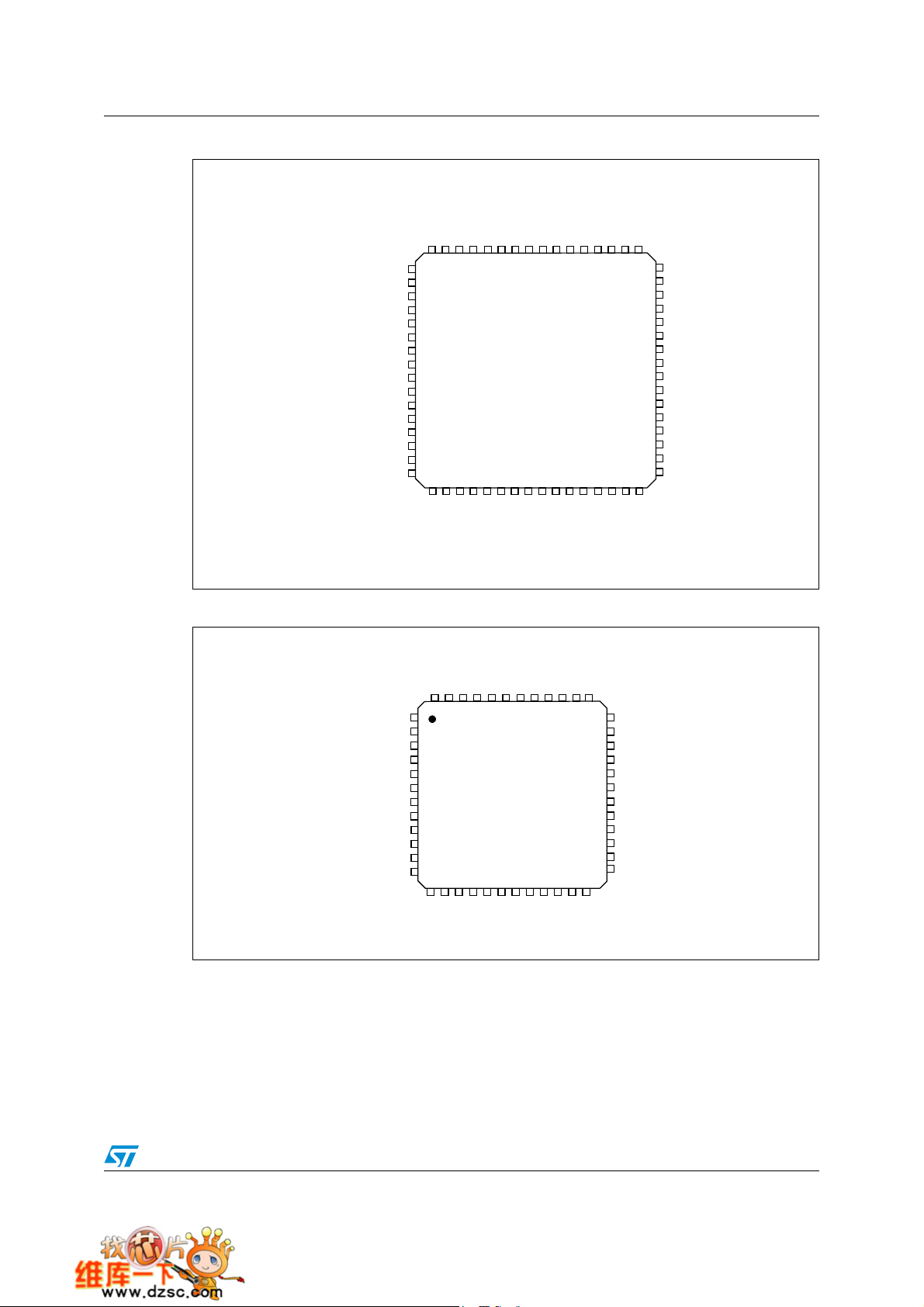

Figure 2. STM32F101xx access line LQFP100 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

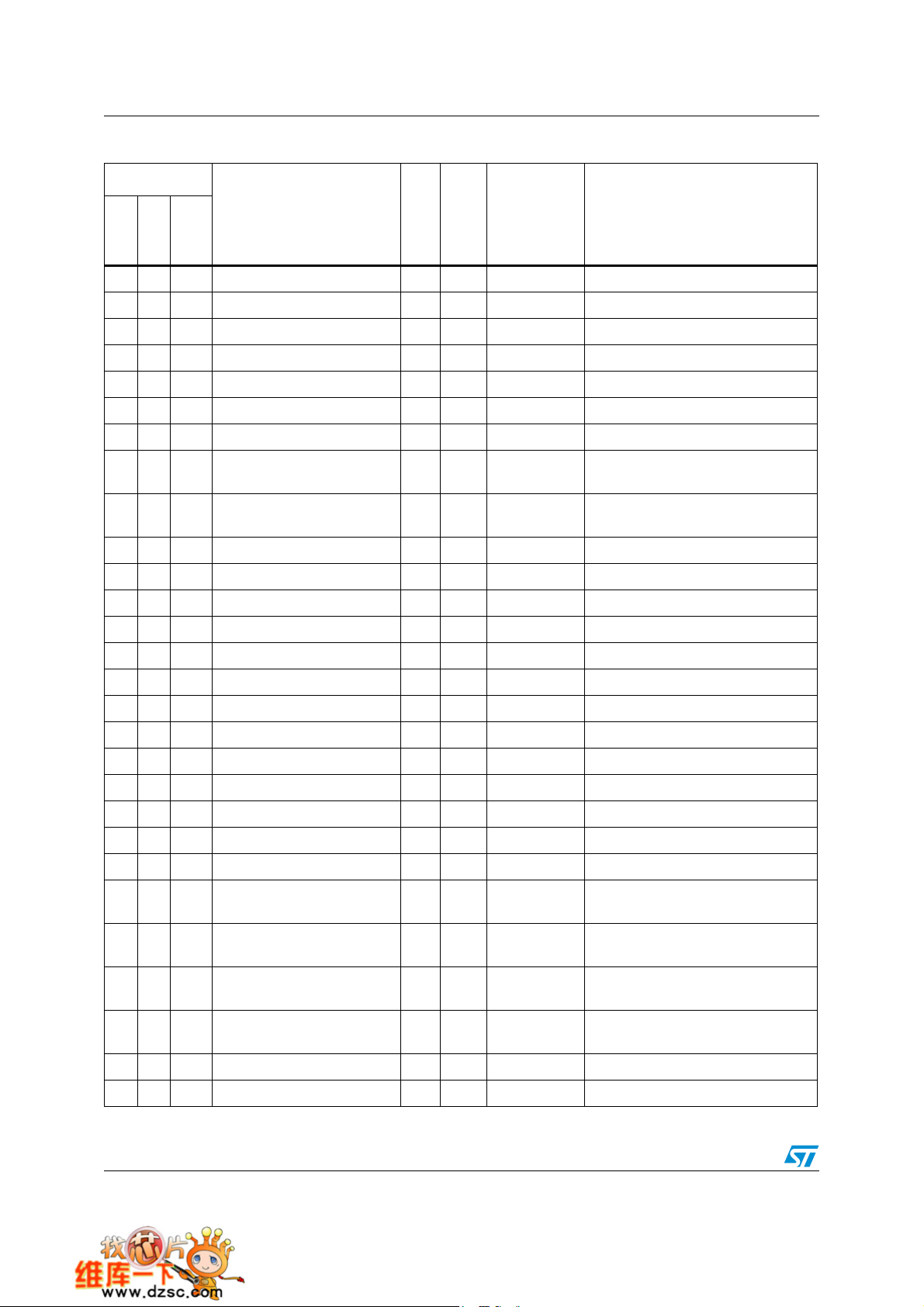

Figure 3. STM32F101xx access line LQFP64 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 4. STM32F101xx access line LQFP48 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 5. Memory map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 6. Pin loading conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 7. Pin input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 8. Power supply scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 9. Current consumption measurement scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10. High-speed external clock source AC timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 11. Low-speed external clock source AC timing diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 12. Typical application with an 8 MHz crystal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 13. Typical application with a 32.768 kHz crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 14. Unused I/O pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 15. I/O AC characteristics definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 16. Recommended NRST pin protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 17. I

Figure 18. SPI timing diagram - slave mode and CPHA=0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 19. SPI timing diagram - slave mode and CPHA=11). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 20. SPI timing diagram - master mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 21. ADC accuracy characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 22. Typical connection diagram using the ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 23. Power supply and reference decoupling (V

Figure 24. Power supply and reference decoupling (VREF+ connected to VDDA). . . . . . . . . . . . . . . 56

Figure 25. LQPF100 – 100-pin low-profile quad flat package outline . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 26. LQFP64 – 64-pin low-profile quad flat package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 27. LQFP48 – 48-pin low-profile quad flat package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2

C bus AC waveforms and measurement circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

not connected to V

REF+

). . . . . . . . . . . . . . 56

DDA

5/64

Introduction STM32F101xx

1 Introduction

This datasheet contains the description of the STM32F101xx access line family features,

pinout, Electrical Characteristics, Mechanical Data and Ordering information.

For information on programming, erasing and protection of the internal Flash memory

please refer to the STM32F10x Flash Programming Reference Manual

For information on the Cortex™-M3 core please refer to the Cortex™-M3 Technical

Reference Manual.

2 Description

The STM32F101xx access line family incorporates the high- performance ARM Cortex™-M3

32-bit RISC core operating at a 36 MHz frequency, high-speed embedded memories (Flash

memory up to 128Kbytes and SRAM up to 16 Kbytes), and an extensive ran ge of enhanced

peripherals and I/Os connected to tw o APB bu ses. All de vices off er standard comm unication

interfaces (two I

purpose 16-bit timers.

2

Cs, two SPIs, a nd up to three USARTs), one 12-bit ADC and three g ener al

The STM32F101 family oper at es in the −40 to +85°C temperature range , from a 2.0 to 3. 6 V

power supply. A comprehensive set of power-saving mode allows to design low-power

applications.

The complete STM32F101xx access line family includes devices in 3 different package

types: from 48 pins to 100 pins. Depending on the device chosen, different sets of

peripherals are included, the description below gives an overview of the complete range of

peripherals proposed in this family.

These features make the STM32F101xx access line microcontroller family suitable for a

wide range of applications:

● Application control and user interface

● Medical and handheld equipment

● PC peripherals, gaming and GPS platforms

● Industrial applications: PLC, inverters, printers, and scanners

● Alarm systems, Video intercom, and HVAC

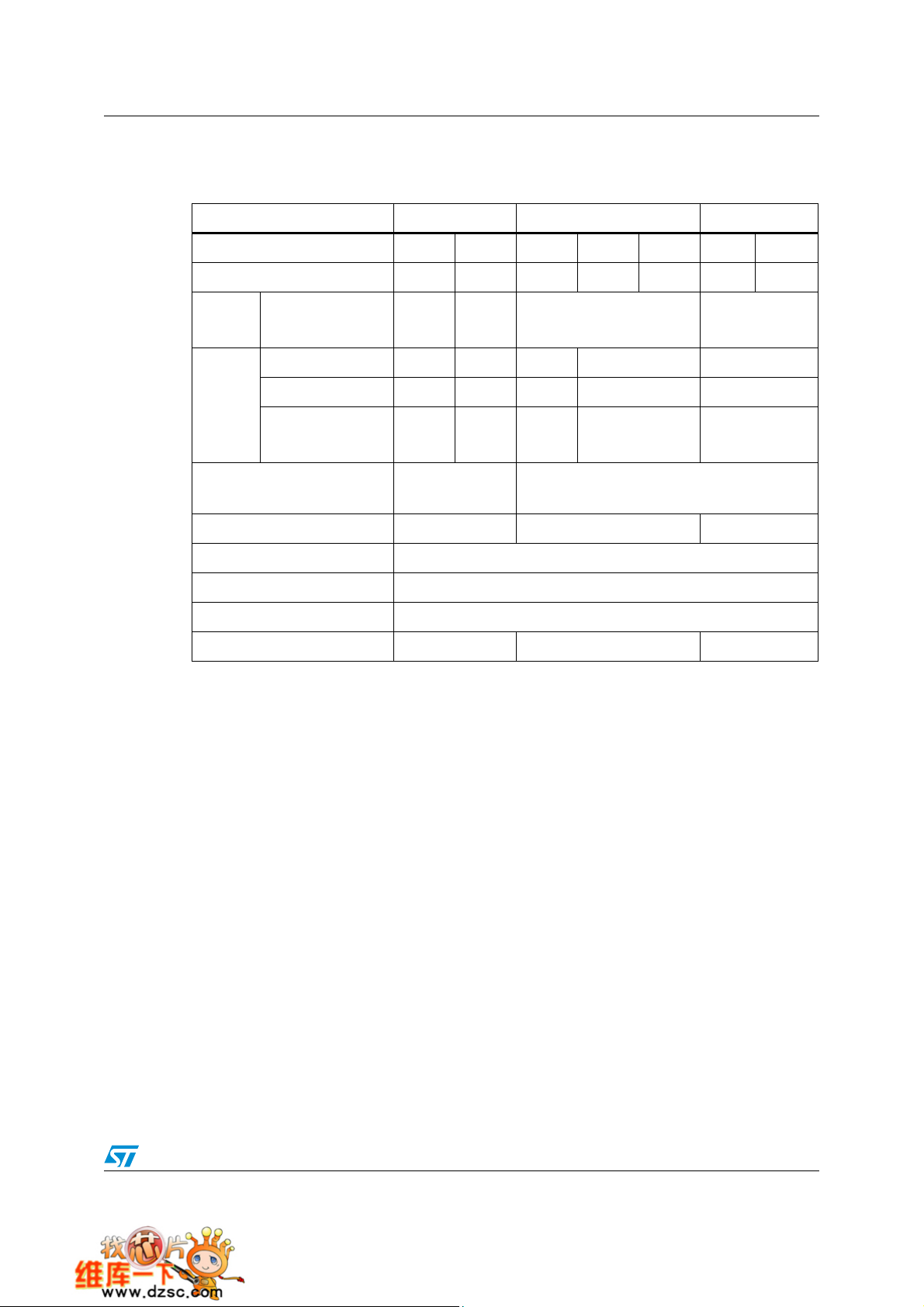

Figure 1 shows the general block diagram of the device family.

6/64

STM32F101xx Description

2.1 Device overview

Table 2. Device features and peripheral counts (STM32F101xx access line)

Peripheral

Flash - Kbytes 32 64 32 64 128 64 128

SRAM - Kbytes 610610161016

General purpose 23 3 3

Timers

SPI 121 2 2

2

C 121 2 2

I

USART 232 3 3

Communication

12-bit synchronized ADC

number of channels

GPIOs 32 49 80

STM32F101Cx STM32F101Rx STM32F101Vx

1

10 channels

1

16 channels

CPU frequency 36 MHz

Operating voltage 2.0 to 3.6 V

Operating temperature -40 to +85 °C

Packages LQFP48 LQFP64 LQFP100

7/64

Description STM32F101xx

2.2 Overview

ARM® CortexTM-M3 core with embedded Flash and SRAM

The ARM Cortex™-M3 processor is the latest generation of ARM processors for embedded

systems. It has been de v eloped t o prov ide a low- cost platform that meets the needs of MCU

implementation, with a reduced pin count and low-power consumption, while delivering

outstanding computational performance and an advanced system response to interrupts.

The ARM Cortex™-M3 32-bit RISC processor features exceptional code-efficiency,

delivering the high-performance expected from an ARM core in the memory size usually

associated with 8- and 16-bit devices.

The STM32F101xx access line family having an embedded ARM core, is therefore

compatible with all ARM tools and software.

Embedded Flash memory

Up to 128 Kbytes of embedded Flash is available for storing programs and data.

Embedded SRAM

Up to 16 Kbytes of embedded SRAM accessed (read/write) at CPU clock speed with 0 wait

states.

Nested vectored interrupt controller (NVIC)

The STM32F101xx access line embeds a nested vectored interrupt controller able to handle

up to 43 maskable interrupt channels (not including the 16 interrupt lines of Cortex™-M3)

and 16 priority levels.

● Closely coupled NVIC gives low latency interrupt processing

● Interrupt entry vector table address passed directly to the core

● Closely coupled NVIC core interface

● Allows early processing of interrupts

● Processing of late arriving higher priority inte r rupts

● Support for tail-chaining

● Processor state automatically saved

● Interrupt entry restored on interrupt exit with no instruction overhead

This hardware block provides flexible interrupt management features with minimal interrupt

latency.

8/64

STM32F101xx Description

External interrupt/event controller (EXTI)

The external interrupt/event controller consists of 19 edge detectors lines used to generate

interrupt/event requests. Each line can be independently configured to select the trigger

event (rising edge , falling edge, both) and ca n be mask ed ind ependently. A pending register

maintains the status of the interrupt requests. The EXTI can detect external line with pulse

width lower than the Internal APB2 clock period. Up to 80 GPIOs are connected to the 16

external interrupt lines.

Clocks and startup

System clock selection is performed on startup, however the internal RC 8 MHz oscillator is

selected as default CPU clock on reset. An external 4-16 MHz clock can be selected and is

monitored for failure. During such a scenario, it is disabled and software interrupt

management follo ws . Similarly, full interrupt management of the PLL clock entry is av ailable

when necessary (for example with failure of an indirectly used external oscillator).

Several prescalers allow the configuration of the AHB frequency, the High Speed APB

(APB2) and the low Speed APB (APB1) domains. The maximum frequency of the AHB and

the APB domains is 36 MHz.

Boot modes

At startup, boot pins are used to select one of five boot options:

● Boot from User Flash

● Boot from System Memory

● Boot from SRAM

The boot loader is located in System Memory. It is used to reprogram the Flash memory by

using the USART.

Power supply schemes

● V

● V

● V

= 2.0 to 3.6 V: External power sup ply for I/Os and the internal regulator.

DD

Provided externally through V

, V

SSA

and PLL. In V

BAT

= 2.0 to 3.6 V: External analog power sup plies for ADC, Reset b loc ks , RCs

DDA

range (ADC is limited at 2.4 V).

DD

= 1.8 to 3.6 V: Power supply for RTC, external clock 32 kHz oscillator and backup

registers (through power switch) when V

DD

pins.

is not present.

DD

Power supply supervisor

The device has an integrated power on reset (POR)/power down reset (PDR) circuitry. It is

always active, and ensures proper operation starting from/down to 2 V. The device remains

in reset mode when V

external reset circuit.

The device features an embedded Programmable voltage detector (PVD) that monitors the

V

power supply and compares it to the V

DD

when V

drops below the V

DD

interrupt service routine can then generate a warning message and/or put the MCU into a

safe state. The PVD is enabled by software.

Refer to Table 9: Embedded reset and power control block characteristics for the values of

V

POR/PDR

and V

PVD

is below a specified threshold, V

DD

and/or when VDD is higher than the V

PVD

PVD

.

POR/PDR

, without the need for an

threshold. An interrupt can be generated

threshold. The

PVD

9/64

Description STM32F101xx

Voltage regulator

The regulator has three operation modes: ma in (M R ), low power (LPR) and power down.

● MR is used in the nominal regulation mode (Run)

● LPR is used in the Stop modes

● Power down is used in Standby Mode: the regulator output is in high impedance: the

kernel circuitry is powered-down, inducing zero consumption (but the contents of the

registers and SRAM are lost)

This regulator is always enabled after RESET. It is disabled in Standby Mode, providing high

impedance output.

Low-power modes

The STM32F101xx access line supports three low-power modes to achieve the best

compromise between low power consumption, short startup time and available wakeup

sources:

● Sleep mode

In Sleep mode, only the CPU is stopped. All peripherals continue to operate and can

wake up the CPU when an interrupt/event occurs.

● Stop mode

Stop mode allows to achieve the lowest po we r consumption while re taining the co ntent

of SRAM and registers. All clocks in the 1.8 V domain are stopped, the PLL, the HSI

and the HSE RC oscillators are disabled. The voltage regulator can also be put either in

normal or in low power mode.

The device can be wok en up from Stop mode by any of the EXTI line. The EXTI line

source can be one of the 16 external lines, the PVD output or the RTC alarm.

● Standby mode

The Standby mode allows to achieve the lo west power consumption. The internal

voltage regulator is switched off so that the entire 1.8 V domain is powered off. The

PLL, the HSI and the HSE RC oscillators are also switched off. After entering Standby

mode, SRAM and registers content are lost except for registers in the Backup domain

and Standby circuitry.

The device exits Standby mode when an external reset (NRST pin), a IWDG reset, a

rising edge on the WKUP pin, or an RTC alarm occurs.

Note: The RTC , the IWDG, and t he corresponding cloc k sources ar e not stopped by e ntering Stop

or Standby mode.

DMA

The flexible 7-channel general-purpose DMA is able to manage memory-to-memory,

peripheral-to-memory and memory-to-peripheral transfers. The DMA controller supports

circular buffer management avoiding the generation of interrupts when the controller

reaches the end of the buffer.

Each channel is connected to dedicated hardware DMA requests, with support for software

trigger on each channel. Configuration is made by software and transfer sizes between

source and destination are independent.

The DMA can be used with the main peripherals: SPI, I

TIMx and ADC.

10/64

2

C, USART, general purpose timers

STM32F101xx Description

RTC (real-time clock) and backup registers

The RTC and the bac kup registers are supplied through a switch that takes po wer either on

V

supply when present or through the V

DD

can be used to store data when V

power is not present.

DD

pin. The backup registers (ten 16-bit registers)

BAT

The Real-Time Clock provides a set of continuously running counters which can be used

with suitable software to provide a clock calendar function, and provides an alarm interrupt

and a periodic interrupt. It is clocked by an external 32.768 kHz oscillator, the internal low

power RC oscillator or the high-speed external clock divided by 128. The internal low pow er

RC has a typical frequency of 32 kHz. The RTC can be calibrated using an external 512Hz

output to compensate for any natural quartz deviation. The RTC features a 32-bit

programmable counter for long term measurement using the Compare register to generate

an alarm. A 20-bit prescaler is used for the time base clock and is by default configured to

generate a time base of 1 second from a clock at 32.768 kHz.

Independent watchdog

The independent watchdog is based on a 12-bit downcounter and 8-bit prescaler. It is

clocked from an independent 32 kHz internal RC and as it operates independently from the

main clock, it can operate in Stop and Standby modes. It can be used as a watchdog to

reset the device when a problem occurs, or as a free running timer for application time out

management. It is hardware o r software configurable through the option bytes. The counter

can be frozen in debug mode.

Window watchdog

The window watchdog is based on a 7-bit downcounter that can be set as free running. It

can be used as a watchdog to reset the de vice when a prob lem occurs . It is clock ed from the

main clock. It has an early warning interrupt capability and the counter can be frozen in

debug mode.

SysTick timer

This timer is dedicated for OS, but could also be used as a standard down counter. It

features:

● A 24-bit down counter

● Autoreload capability

● Maskable system interrupt generation whe n th e co un te r re ach e s 0.

● Programmable clock source

General purpose timers (TIMx)

There are up to 3 synchronizable standard timers embedded in the STM32F101xx access

line devices. These timers are based on a 16-bit auto-reload up/down counter, a 16-bit

prescaler and feature 4 in dependent channels each f or input captu re, output compa re, PWM

or one pulse mode output. This give s u p to 12 input ca ptur es / o utpu t compar es / PWMs on

the largest packages. They can work together via the Timer Link feature for synchronization

or event chaining.

The counter can be frozen in debug mode.

Any of the standard timers can be used to generate PWM outputs. Each of the timers has

independent DMA request generations.

11/64

Description STM32F101xx

I²C bus

Up to two I²C bus interf aces can oper ate in multi-maste r and slav e modes . They can sup port

standard and fast modes.

They support dual slave addressing (7-bit only) and both 7/10-bit addressing in master

mode. A hardware CRC generation/verification is embedded.

They can be served by DMA and they support SM Bus 2.0/PM Bus.

Universal synchronous/asynchronous receiver transmitter (USART)

The available USART interfaces communicate at up to 2.25 Mbit/s. They provide hardware

management of the CTS and RTS signals, support IrDA SIR ENDEC, are ISO 7816

compliant and have LIN Master/Slave capability.

The USART interfaces can be served by the DMA controller.

Serial peripheral interface (SPI)

Up to two SPIs are able to communicate up to 18 Mbits/s in slave and master modes in fullduplex and simplex communication modes. The 3-bit prescaler gives 8 master mode

frequencies and the frame is configurable from 8-bit to 16-bit. The hardware CRC

generation/ve rification supports basic SD Card/MMC modes.

Both SPIs can be served by the DMA controller.

GPIOs (general purpose inputs/outputs)

Each of the GPIO pins can be configured b y softw are as output ( push-pull or open-dr ain), as

input (with or without pull-up or pull-down) or as Peripheral Alternate Function. Most of the

GPIO pins are shared with digital or analog alternate functions. All GPIOs are high currentcapable.

The I/Os alternate function configuration can be locked if needed following a specific

sequence in order to avoid spurious writing to the I/Os registers.

ADC (analog to digital converter)

The 12-bit Analog to Digital Converter has up to 16 external channels and performs

conversions in single-shot or scan modes. In scan mode, automatic conversion is performed

on a selected group of analog inputs.

The ADC can be served by the DMA controller.

An analog watchdog f eatur e allo ws very precise monitoring of the converted voltage of one ,

some or all selected channels. An interrupt is generated when the converted voltage is

outside the programmed thresholds.

Temperature sensor

The temperature sensor has to generate a linear voltage with any variation in temperature.

The conversion range is between 2V < V

connected to the ADC_IN16 input channel which is used to convert the sensor output

voltage into a digital value.

< 3.6V. The temperature sensor is internally

DDA

12/64

STM32F101xx Description

Serial wire JTAG debug port (SWJ-DP)

The ARM SWJ-DP Interface is embedded. and is a combined JTAG and serial wire debug

port that enables either a serial wire debug or a JTAG probe to be connected to the target.

The JTAG TMS and TCK pins are shared respectively with SWDIO and SWCLK and a

specific sequence on the TMS pin is used to switch between JTAG-DP and SW-DP.

Figure 1. STM32F101xx access line block diagram

JNTRST

JTDI

JTCK/SWCLK

JTMS/SWDIO

JTDO

as AF

80AF

PA[15:0]

PB[15:0]

PC[15:0]

PD[15:0]

PE[15:0]

MOSI,MISO,

SCK,NSS as AF

RX,TX, CTS, RTS,

SmartCard as AF

16AF

V

REF+

V

REF-

NRST

VDDA

VSSA

JTAG & SWD

Cortex M3 CPU

F

max

NVIC

NVIC

7 channels

SUPERVISION

POR / PDR

EXTI

WAKEUP

GPIOA

GPIOB

GPIOC

GPIOD

GPIOE

SPI1

USART1

@VDDA

12bit ADC1

Temp sensor

: 36 MHz

GP DMA

@VDDA

SUPPLY

PVD

IF

pbus

Dbus

System

Rst

Int

Ibus

= 36 MHz

max

APB2 : F

BusMatrix

Controller

AHB2

APB2

Trace

=36 MHz

max

AHB:F

obl

FLASH 128 KB

Interface

Flash

SRAM

16 KB

PCLK1

PCLK2

HCLK

FCLK

RC 8 MHz

RC 32 kHz

@VDDA

AHB2

APB1

64 bit

CLOCK

MANAGT

PLL &

=24 / 36 MHz

max

APB1 : F

@VBAT

Backup interface

2x(8x16bit)

POWER

VOLT. REG.

3.3V TO 1.8V

@VDD

@VDD

XTAL OSC

4-16 MHz

IWDG

Standby

interface

XTAL 32 kHz

Backup

RTC

AWU

TIM2

TIM3

TIM4

USART2

USART3

SPI2

I2C1

I2C2

W W D G

reg

V

= 2 to 3.6V

DD

V

SS

OSC_IN

OSC_OUT

V

BAT

OSC32_IN

OSC32_OUT

ANTI_TAMP

4 Channels

4 Channels

4 Channels

RX,TX, CTS, RTS,

SmartCard as AF

RX,TX, CTS, RTS,

SmartCard as AF

MOSI,MISO,SCK,NSS

as AF

SCL,SDA,SMBAL

as AF

SCL,SDA

as AF

1. AF = alternate function on I/O port pin.

2. TA = –40 °C to +85 °C (junction temperature up to 125 °C).

13/64

ai14385

Pin descriptions STM32F101xx

3 Pin descriptions

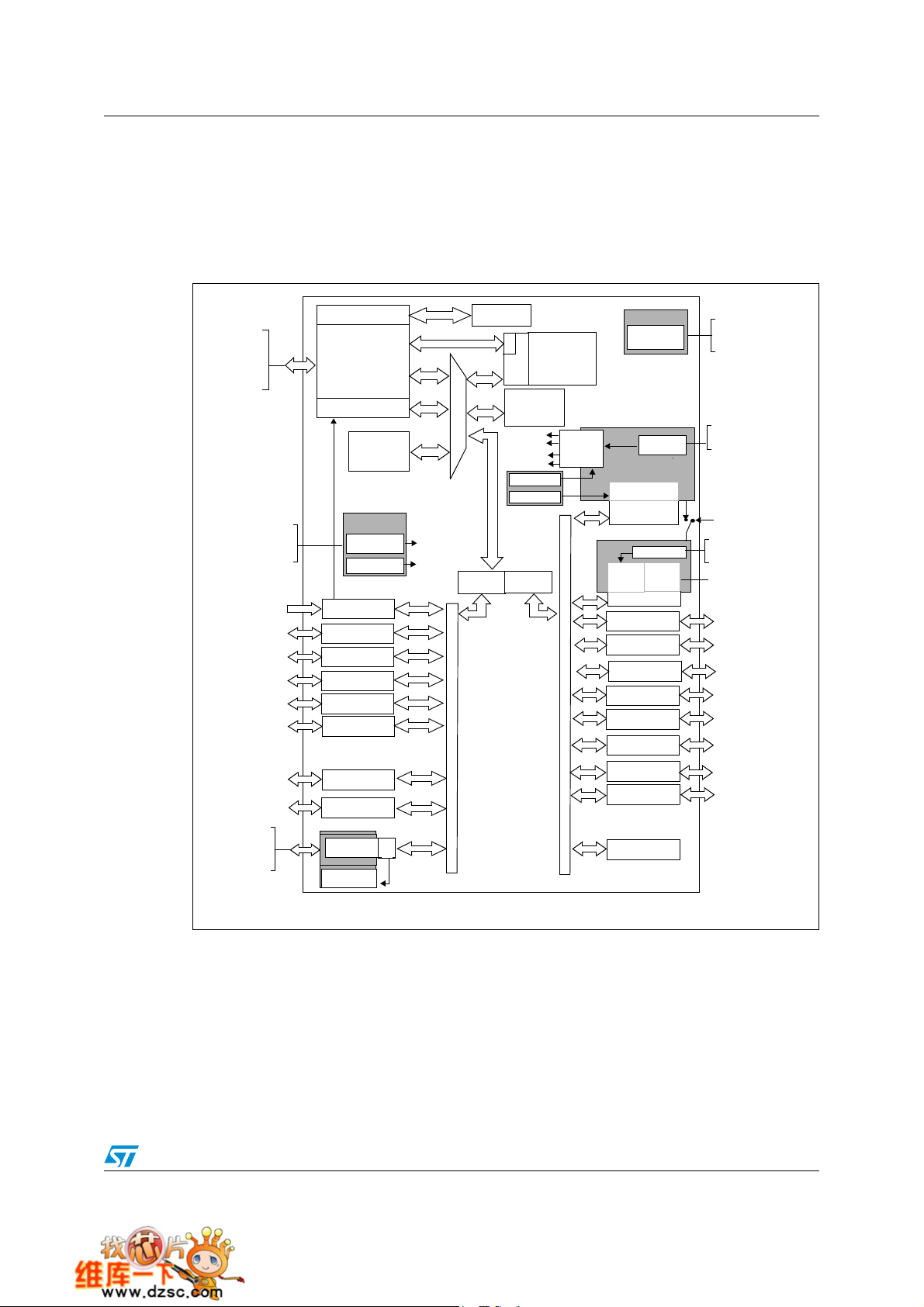

Figure 2. STM32F101xx access line LQFP100 pinout

VDD_3

VSS_3

PE1

PE0

PB9

PB8

BOOT0

PB7

PB6

PB5

PB4

PB3

PD7

PD6

PD5

PD4

PD3

PD2

PD1

PD0

PC12

PC11

PC10

PA15

PA14

PE2

PE3

PE4

PE5

PE6

VBAT

PC13-ANTI_TAMP

PC14-OSC32_IN

PC15-OSC32_OUT

VSS_5

VDD_5

OSC_IN

OSC_OUT

NRST

PC0

PC1

PC2

PC3

VSSA

VREF-

VREF+

VDDA

PA0-WKUP

PA1

PA2

100999897969594939291908988878685848382818079787776

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26272829303132333435363738394041424344454647484950

PA3

PA4

PA5

PA6

PA7

VSS_4

VDD_4

PC4

PC5

PB0

LQFP100

PB1

PB2

PE7

PE8

PE9

PE10

PE11

PE12

PE13

PE14

PE15

PB10

PB11

VSS_1

75

VDD_2

74

VSS_2

73

NC

72

PA 13

71

PA 12

70

PA 11

69

PA 10

68

PA 9

67

PA 8

66

PC9

65

PC8

64

PC7

63

PC6

62

PD15

61

PD14

60

PD13

59

PD12

58

PD11

57

PD10

56

PD9

55

PD8

54

PB15

53

PB14

52

PB13

51

PB12

VDD_1

14/64

ai14386

STM32F101xx Pin descriptions

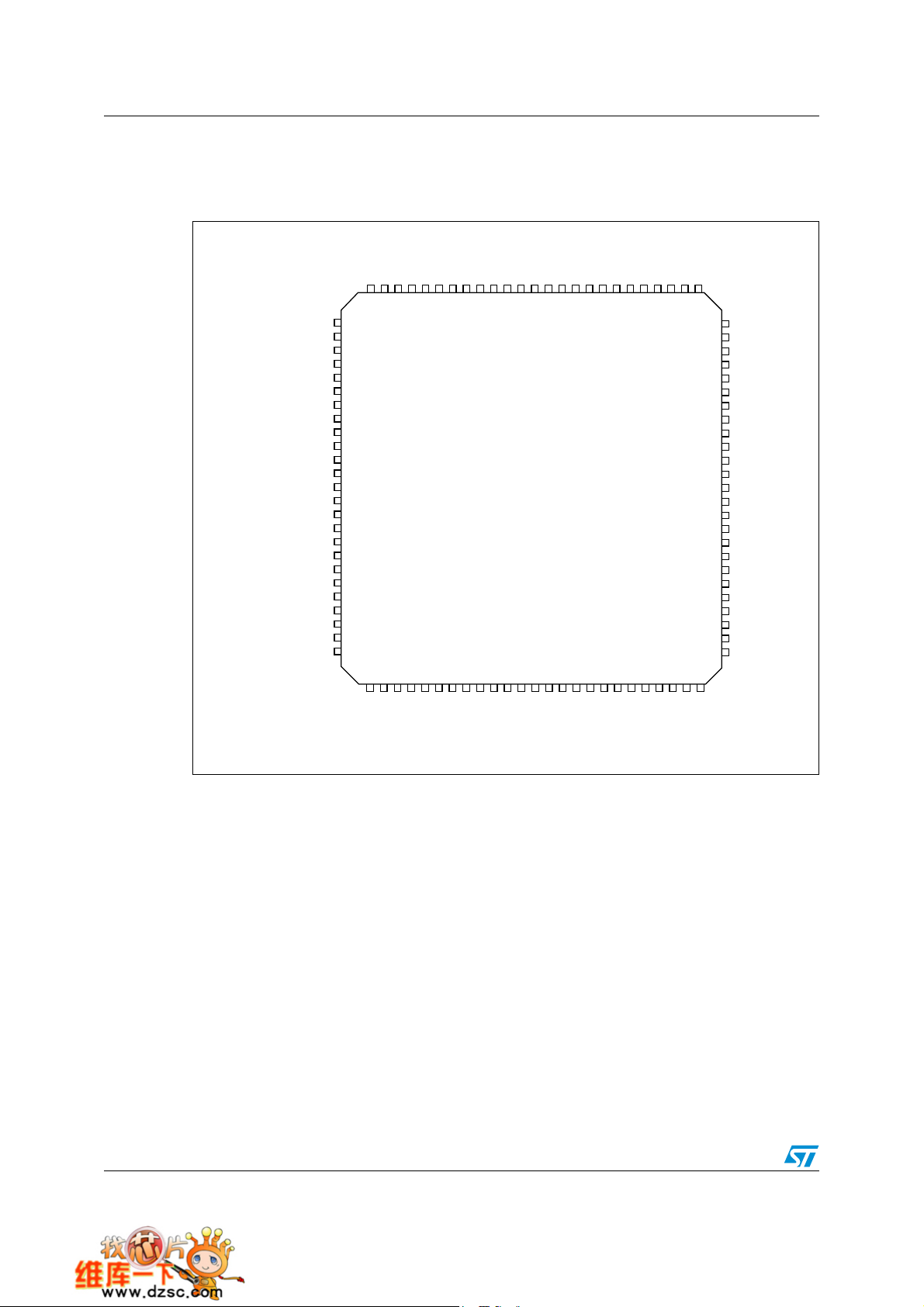

Figure 3. STM32F101xx access line LQFP64 pinout

VDD_3

VSS_3

PB9

PB8

BOOT0

PB7

PB6

PB5

PB4

PB3

PD2

PC12

PC11

PC10

PA15

PA14

PC13-ANTI_T AMP

VBAT

PC14-OSC32_IN

PC15-OSC32_OUT

PD0 OSC_IN

PD1 OSC_OUT

NRST

PC0

PC1

PC2

PC3

VSSA

VDDA

PA0-WKUP

PA1

PA2

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 29 30 31 3225 26 27 28

PA3

VSS_4

VDD_4

PA4

PA5

PA6

LQFP64

PA7

PC4

PC5

PB0

PB1

PB2

PB10

PB11

VDD_2

48

VSS_2

47

PA13

46

PA12

45

PA11

44

PA10

43

PA9

42

PA8

41

PC9

40

PC8

39

PC7

38

PC6

37

PB15

36

PB14

35

PB13

34

33

PB12

VSS_1

VDD_1

Figure 4. STM32F101xx access line LQFP48 pinout

VDD_3

VSS_3

PB9

PB8

BOOT0

PB7

PB6

PB5

PB4

PB3

PC13-ANTI_TAMP

VBAT

PC14-OSC32_IN

PC15-OSC32_OUT

PD0 OSC_IN

PD1 OSC_OUT

NRST

VSSA

VDDA

PA0-WKUP

PA1

PA2

48 47 46 45

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18

PA3

44 43 42 41 40 39 38 37

LQFP48

19 20 21 22

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB10

23

PB11

VSS_1

ai14387

PA15

PA14

VDD_2

36

VSS_2

35

PA13

34

PA12

33

PA11

32

PA10

31

PA9

30

PA8

29

PB15

28

PB14

27

26

PB13

25

PB12

24

VDD_1

ai14378

15/64

Pin descriptions STM32F101xx

LQFP64

(2)

(1)

Pin name

Type

LQFP100

SV

BAT

(4)

(4)

(4)

SS_5

DD_5

I/O PC13 ANTI_TAMP

I/O

I/O

SV

SV

I / O level

FT

FT

FT

FT

FT

Main

function

(after reset)

PE2 TRACECK

PE3 TRACED0

PE4 TRACED1

PE5 TRACED2

PE6 TRACED3

PC14-

OSC32_IN

PC15-

OSC32_OUT

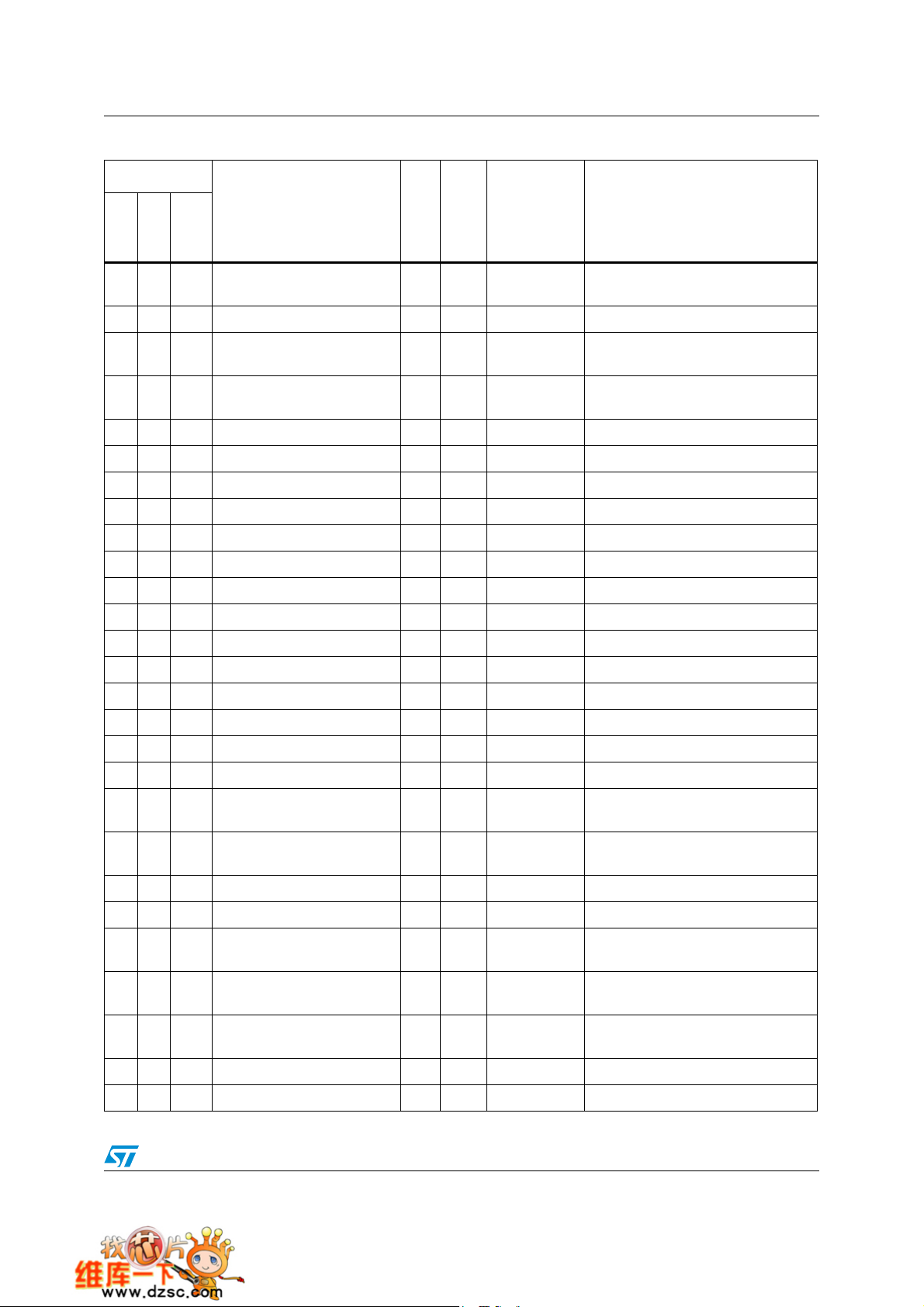

Table 3. Pin definitions

Pins

LQFP48

- - 1 PE2/TRACECK I/O

- - 2 PE3/TRACED0 I/O

- - 3 PE4/TRACED1 I/O

- - 4 PE5/TRACED2 I/O

- - 5 PE6/TRACED3 I/O

11 6 V

2 2 7 PC13-ANTI_TAMP

3 3 8 PC14-OSC32_IN

4 4 9 PC15-OSC32_OUT

--10 V

--11 V

5 5 12 OSC_IN I OSC_IN

BAT

SS_5

DD_5

(3)

Default alternate functions

(3)

6 6 13 OSC_OUT O OSC_OUT

7 7 14 NRST I/O NRST

- 8 15 PC0/ADC_IN10 I/O PC0 ADC_IN10

- 9 16 PC1/ADC_IN11 I/O PC1 ADC_IN11

- 10 17 PC2/ADC_IN12 I/O PC2 ADC_IN12

- 11 18 PC3/ADC_IN13 I/O PC3 ADC_IN13

81219 V

SSA

SV

SSA

- - 20 VREF- S VREF-

- - 21 VREF+ S VREF+

91322 V

10 14 23

11 15 24

12 16 25

13 17 26

PA0-WKUP/USART2_CTS/

ADC_IN0/TIM2_CH1_ETR

PA1/USART2_RTS/ADC_

PA2/USART2_TX/ADC_IN2/

PA3/USART2_RX/ADC_IN3/

-1827 V

-1928 V

DDA

IN1/TIM2_CH2

TIM2_CH3

TIM2_CH4

SS_4

DD_4

SV

I/O PA0

DDA

WKUP/USART2_CTS

I/O PA1

I/O PA2

I/O PA3

SV

SV

SS_4

DD_4

TIM2_CH1_ETR

USART2_RTS

TIM2_CH2

USART2_TX

TIM2_CH3

USART2_RX

TIM2_CH4

(7)

/ ADC_IN0/

(7)

/ADC_IN1/

(7)

(7)

/ADC_IN2/

(7)

(7)

/ADC_IN3/

(7)

(7)

16/64

STM32F101xx Pin descriptions

Table 3. Pin definitions (continued)

Pins

LQFP48

LQFP64

14 20 29

Pin name

LQFP100

PA4/SPI1_NSS/

USART2_CK/ADC_IN4

I/O PA4

(1)

(2)

Type

Main

function

(3)

(after reset)

Default alternate functions

I / O level

SPI1_NSS/USART2_CK

ADC_IN4

15 21 30 PA5/SPI1_SCK/ADC_IN5 I/O PA5 SPI1_SCK/ADC_IN5

16 22 31

17 23 32

PA6/SPI1_MISO/ADC_IN6/

TIM3_CH1

PA7/SPI1_MOSI/ADC_IN7/

TIM3_CH2

I/O PA6

I/O PA7

SPI1_MISO/ADC_IN6/

TIM3_CH1

SPI1_MOSI/ADC_IN7/

TIM3_CH2

(7)

(7)

- 24 33 PC4/ADC_IN14 I/O PC4 ADC_IN14

- 25 34 PC5/ADC_IN15 I/O PC5 ADC_IN15

18 26 35 PB0/ADC_IN8/TIM3_CH3 I/O PB0 ADC_IN8/TIM3_CH3

19 27 36 PB1/ADC_IN9/TIM3_CH4 I/O PB1 ADC_IN9/TIM3_CH4

(7)

(7)

20 28 37 PB2/BOOT1 I/O FT PB2/BOOT1

- - 38 PE7 I/O FT PE7

- - 39 PE8 I/O FT PE8

- - 40 PE9 I/O FT PE9

(7)

(3)

/

- - 41 PE10 I/O FT PE10

- - 42 PE11 I/O FT PE11

- - 43 PE12 I/O FT PE12

- - 44 PE13 I/O FT PE13

- - 45 PE14 I/O FT PE14

- - 46 PE15 I/O FT PE15

21 29 47

22 30 48

PB10/I2C2_SCL

USART3_TX

PB11/I2C2_SDA

USART3_RX

23 31 49 V

24 32 50 V

25 33 51

26 34 52

27 35 53

PB12/SPI2_NSS/

I2C2_SMBAl/USART3_CK

PB13/SPI2_SCK/

USART3_CTS

PB14/SPI2_MISO/

USART3_RTS

SS_1

DD_1

I/O FT PB10 I2C2_SCL

I/O FT PB11 I2C2_SDA

SV

SV

I/O FT PB12

SS_1

DD_1

SPI2_NSS

I/O FT PB13 SPI2_SCK

I/O FT PB14 SPI2_MISO

(5)

/USART3_TX

(5)

/USART3_RX

(5) (7)

/I2C2_SMBAl

USART3_CK

(5)(7)

/USART3_CTS

(5)(7)

/USART3_RTS

28 36 54 PB15/SPI2_MOSI I/O FT PB15 SPI2_MOSI

- - 55 PD8 I/O FT PD8

(5) (7)

(5) (7)

(5) (7)

(5) (7)

(5)

(5)(7)

(5)(7)

/

17/64

Pin descriptions STM32F101xx

Table 3. Pin definitions (continued)

LQFP48

Pins

LQFP64

Pin name

LQFP100

(1)

(2)

Type

Main

function

(3)

(after reset)

Default alternate functions

I / O level

- - 56 PD9 I/O FT PD9

- - 57 PD10 I/O FT PD10

- - 58 PD11 I/O FT PD11

- - 59 PD12 I/O FT PD12

- - 60 PD13 I/O FT PD13

- - 61 PD14 I/O FT PD14

- - 62 PD15 I/O FT PD15

- 37 63 PC6 I/O FT PC6

38 64 PC7 I/O FT PC7

39 65 PC8 I/O FT PC8

- 40 66 PC9 I/O FT PC9

29 41 67 PA8/USART1_CK/MCO I/O FT PA8 USART1_CK/MCO

30 42 68 PA9/USART1_TX I/O FT PA9 USART1_TX

31 43 69 PA10/USART1_RX I/O FT PA10 USART1_RX

(7)

(7)

32 44 70 PA11/USART1_CTS I/O FT P A11 USART1_CTS

(3)

33 45 71 PA12/USART1_RTS I/O FT PA12 USART1_RTS

34 46 72 PA13/JTMS/SWDIO I/O FT JTMS-SWDIO PA13

- - 73 Not connected

35 47 74 V

36 48 75 V

SS_2

DD_2

SV

SV

SS_2

DD_2

37 49 76 PA14/JTCK/SWCLK I/O FT JTCK/SWCLK PA14

38 50 77 PA15/JTDI I/O FT JTDI PA15

-5178 PC10 I/OFT PC10

-5279 PC11 I/OFT PC11

-5380 PC12 I/OFT PC12

5 5 81 PD0 I/O FT OSC_IN

6 6 82 PD1 I/O FT OSC_OUT

(6)

(6)

54 83 PD2/TIM3_ETR I/O FT PD2 TIM3_ETR

- - 84 PD3 I/O FT PD3

- - 85 PD4 I/O FT PD4

- - 86 PD5 I/O FT PD5

- - 87 PD6 I/O FT PD6

18/64

STM32F101xx Pin descriptions

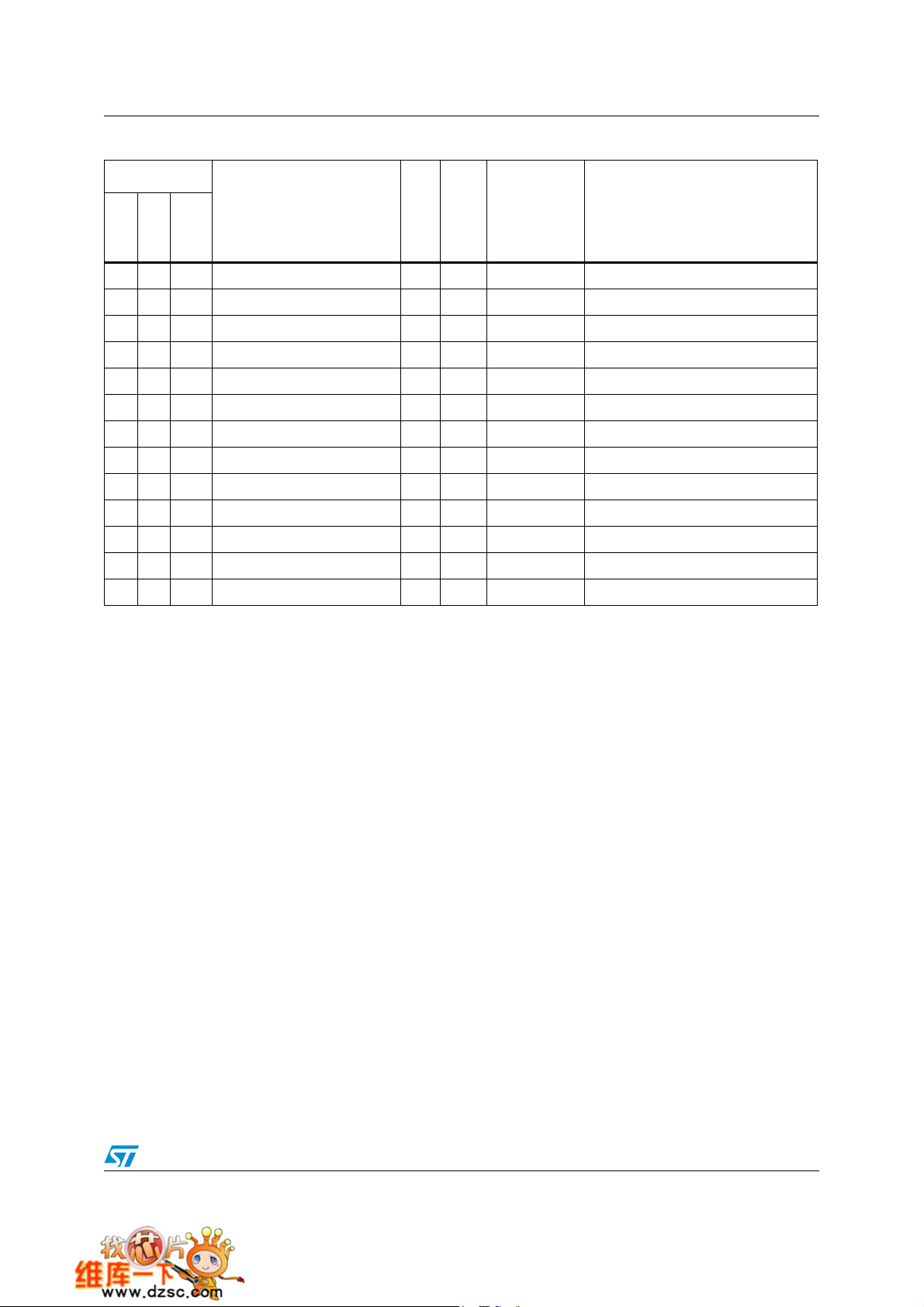

Table 3. Pin definitions (continued)

LQFP48

Pins

LQFP64

Pin name

LQFP100

(1)

(2)

Type

Main

function

(3)

(after reset)

Default alternate functions

(3)

I / O level

- - 88 PD7 I/O FT PD7

39 55 89 PB3/JTDO/TRACESWO I/O FT JTDO PB3/TRACESWO

40 56 90 PB4/JNTRST I/O FT JNTRST PB4

41 57 91 PB5/I2C1_SMBAl I/O PB5 I2C1_SMBAl

42 58 92 PB6/I2C1_SCL/TIM4_CH1 I/O FT PB6 I2C1_SCL

43 59 93 PB7/I2C1_SDA/TIM4_CH2 I/O FT PB7 I2C1_SDA

(7)

/TIM4_CH1

(7)

/TIM4_CH2

(5) (7)

(5) (7)

44 60 94 BOOT0 I BOOT0

45 61 95 PB8/TIM4_CH3 I/O FT PB8 TIM4_CH3

46 62 96 PB9/TIM4_CH4 I/O FT PB9 TIM4_CH4

- - 97 PE0/TIM4_ETR I/O FT PE0 TIM4_ETR

(5) (7)

(5) (7)

(5)

- - 98 PE1 I/O FT PE1

47 63 99 V

48 64 100 V

1. I = input, O = output, S = supply, HiZ= high impedance.

2. FT= 5 V tolerant.

3. Function availability depends on the chosen device. Refer to Table 2 on page 7.

4. PC13, PC14 and PC15 are supplied through the power switch, and so their use in ouptut mode is limited: they can be used

only in output 2 MHz mode with a maximum load of 30 pF and only one pin can be put in output mode at a time.

5. Available only on devices with a Flash memory density equal or higher than 64 Kbytes.

6. For the LQFP48 and LQFP64 packages, the pins number 5 and 6 are configured as OSC_IN/OSC_OUT after reset,

however the functionality of PD0 and PD1 can be remapped by software on these pins.

7. This alternate function can be remapped by software to some other port pins (if available on the used package). For more

details, refer to the Alternate function I/O and debug configuration section in the STM32F10xxx reference manual,

UM0306, available from the STMicroelectronics website: www.st.com.

SS_3

DD_3

SV

SV

SS_3

DD_3

19/64

Memory mapping STM32F101xx

4 Memory mapping

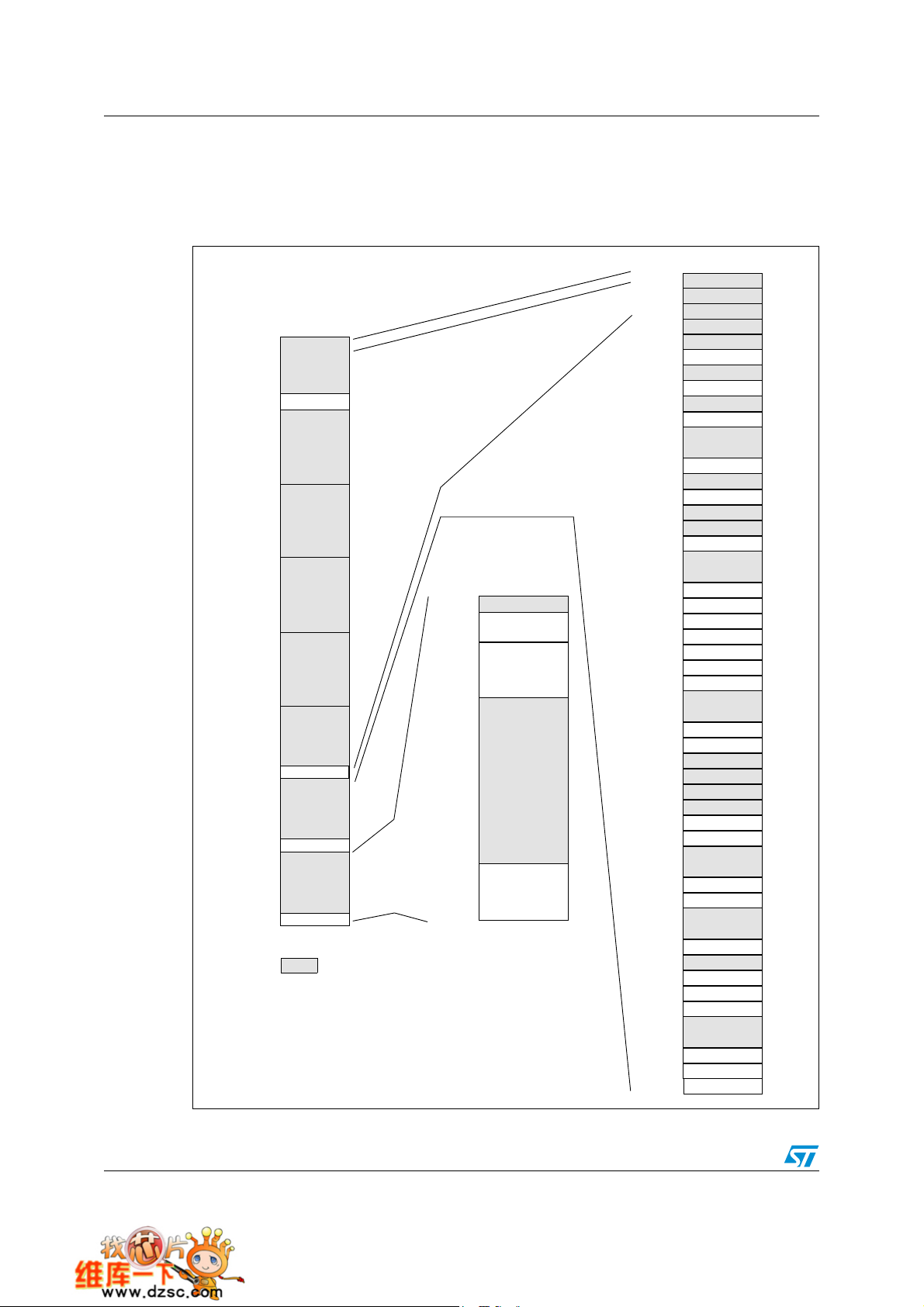

The memory map is shown in Figure 5.

Figure 5. Memory map

APB memory space

0xFFFF FFFF

0xFFFF F000

7

0xE010 0000

0xE000 0000

6

0xC000 0000

5

0xA000 0000

4

0x8000 0000

3

0x6000 0000

2

0x4000 0000

1

0x2000 0000

0

0x0000 0000

ai14379

Cortex-M3 internal

peripherals

Peripherals

SRAM

Code

Reserved

0x1FFF FFFF

0x1FFF F9FF

0x1FFF F800

0x1FFF F000

0x0801 FFFF

0x0800 0000

reserved

Option bytes

System memory

reserved

Flash memory

0xFFFF FFFF

0xE010 0000

0x6000 0000

0x4002 3400

0x4002 3000

0x4002 2400

0x4002 2000

0x4002 1400

0x4002 1000

0x4002 0400

0x4002 0000

0x4001 3C00

0x4001 3800

0x4001 3400

0x4001 3000

0x4001 2C00

0x4001 2800

0x4001 2400

0x4001 1C00

0x4001 1800

0x4001 1400

0x4001 1000

0x4001 0C00

0x4001 0800

0x4001 0400

0x4001 0000

0x4000 7400

0x4000 7000

0x4000 6C00

0x4000 6800

0x4000 6400

0x4000 6000

0x4000 5C00

0x4000 5800

0x4000 5400

0x4000 4C00

0x4000 4800

0x4000 4400

0x4000 3C00

0x4000 3800

0x4000 3400

0x4000 3000

0x4000 2C00

0x4000 2800

0x4000 0C00

0x4000 0800

0x4000 0400

0x4000 0000

reserved

reserved

reserved

reserved

reserved

Flash interface

reserved

RCC

reserved

DMA

reserved

USART1

reserved

SPI1

reserved

reserved

ADC1

reserved

Port E

Port D

Port C

Port B

Port A

EXTI

AFIO

reserved

PWR

BKP

reserved

reserved

reserved

reserved

I2C2

I2C1

reserved

USART3

USART2

reserved

SPI2

reserved

IWDG

WWDG

RTC

reserved

TIM4

TIM3

TIM2

4K

1K

3K

1K

3K

1K

3K

1K

1K

1K

1K

1K

1K

1K

1K

2K

1K

1K

1K

1K

1K

1K

1K

35K

1K

1K

1K

1K

1K

1K

1K

1K

2K

1K

1K

2K

1K

1K

1K

1K

1K

7K

1K

1K

1K

20/64

STM32F101xx Electrical characteristics

5 Electrical characteristics

5.1 Test conditions

Unless otherwise specified, all voltages are referred to VSS.

5.1.1 Minimum and maximum values

Unless otherwise specified the minimum and maximum values are guaranteed in the worst

conditions of ambient temperature , supply v olta ge and frequ encies b y tests in production on

100% of the devices with an ambient temperature at T

the selected temperature range ).

Data based on characterization results, design simulation and/or technology characteristics

are indicated in the table footnotes and are not tested in production. Based on

characterization, the minimum and maximum v alu es ref er to sample tests an d represent th e

mean value plus or minus three times the standard deviation (mean±3Σ).

5.1.2 Typical values

= 25 °C and TA = TAmax (given by

A

Unless otherwise specified, typical data are based on TA = 25 °C, V

2V≤V

tested.

Typical ADC accuracy values are determined by characterizati on of a batch of samples fr om

a standard diffusion lot over the full temperature range, where 95% of the devices have an

error less than or equal to the value indicated

≤3.6 V voltage range). They are given only as design guidelines and are not

DD

5.1.3 Typical curves

Unless otherwise specified, all typical curves are given only as design guidelines and are

not tested.

5.1.4 Loading capacitor

The loading conditions used for pin parameter measurement are shown in Figure 6.

5.1.5 Pin input voltage

The input voltage measurement on a pi n of the device is described in Figure 7.

(mean±2Σ).

= 3.3 V (for the

DD

21/64

Electrical characteristics STM32F101xx

Figure 6. Pin loading conditions Figure 7. Pin input voltage

C=50pF

5.1.6 P ower supply scheme

Figure 8. Power supply scheme

1.8-3.6V

V

DD

5 × 100 nF

+ 1 × 10 µF

V

DD

V

REF

10 nF

+ 1 µF

10 nF

+ 1 µF

STM32F101 PIN

ai14123

V

GP I/Os

V

1/2/3/4/5

1/2/3/4/5

BAT

V

3.3 V

DD

SS

3.3V

V

DDA

V

REF+

V

REF-

V

SSA

Power switch

OUT

IN

Regulator

ADC

Backup circuitry

(OSC32K,RTC,

Wake-up logic

Backup registers)

IO

Logic

Level shifter

Analog:

RCs, PLL,

...

V

IN

STM32F101 PIN

ai14124

Kernel logic

(CPU,

Digital

& Memories)

ai14125

22/64

STM32F101xx Electrical characteristics

5.1.7 Current consumption measurement

Figure 9. Current consumption measurement scheme

IDD_V

BAT

V

BAT

I

DD

V

DD

V

DDA

ai14126

23/64

Electrical characteristics STM32F101xx

5.2 Absolute maximum ratings

Stresses above the absolute maximum ratings listed in Table 4: Voltage characteristics,

Table 5: Current characteristics, and T able 6: Thermal characteristics may cause permanent

damage to the device. These are stress ratings only and functional operation of the device

at these conditions is not implied. Exposure to maximum rating conditions for extended

periods may affect device reliability.

Table 4. Voltage characteri stics

Symbol Ratings Min Max Unit

VDD−V

V

IN

|∆V

DDx

|V

− VSS|

SSX

V

ESD(HBM)

1. All 3.3 V power (VDD, V

supply.

2. I

INJ(PIN)

maximum is respected. If V

externally to the I

induced by VIN<VSS.

Table 5. Current characteristics

External 3.3 V supply voltage (including

SS

V

and VDD)

DDA

(1)

Input voltage on five volt tolerant pin

Input voltage on any other pin

(2)

(2)

−0.3 4.0

V

− 0.3 +5.5

SS

VSS − 0.3 VDD+0.3

| Variations between different power pins 50 50

Variations between all the different ground

pins

Electrostatic discharge voltage (human

body model)

) and ground (VSS, V

DDA

must never be exceeded (see Table 5: Current characteristics). This is implicitly insured if VIN

INJ(PIN)

maximum cannot be respected, the injection current must be limited

IN

value. A positive injection is induced by VIN>VDD while a negative injection is

) pins must always be connected to the external 3.3 V

SSA

50 50

see Section 5.3.11: Absolute

maximum ratings (electrical

sensitivity)

mV

Symbol Ratings Max. Unit

I

VDD

I

VSS

Total current into V

DD

Total current out of V

power lines (source)

ground lines (sink)

SS

(1)

(1)

150

150

Output current sunk by any I/O and control pin 25

I

IO

Output current source by any I/Os and control pin − 25

Injected current on NRST pin ± 5

(2)(3)

I

INJ(PIN)

ΣI

INJ(PIN)

1. All 3.3 V power (VDD, V

supply.

2. I

3. Negative injection disturbs the analog performance of the device. See note in Section 5.3.16: 12-bit ADC

4. When several inputs are submitted to a current injection, the maximum ΣI

must never be exceeded. This is implicitly insured if VIN maximum is respected. If VIN maximum

INJ(PIN)

cannot be respected, the injection current must be limited externally to the I

injection is induced by VIN>VDD while a negative injection is induced by VIN<VSS.

characteristics.

positive and negative injected currents (instantaneous values). These results are based on

characterization with ΣI

Injected current on High-speed external OSC_IN and Lowspeed external OSC_IN pins

Injected current on any other pin

(2)

Total injected current (sum of all I/O and control pins)

) and ground (VSS, V

DDA

maximum current injection on four I/O port pins of the device.

INJ(PIN)

(4)

) pins must always be connected to the external 3.3 V

SSA

(4)

INJ(PIN)

is the absolute sum of the

INJ(PIN)

± 25

value. A positive

± 5

± 5

V

mA

24/64

STM32F101xx Electrical characteristics

Table 6. Thermal characteristics

Symbol Ratings Value Unit

T

STG

T

J

Storage temperature range –65 to +150 °C

Maximum junction temperature (see Thermal characteristics)

25/64

Electrical characteristics STM32F101xx

5.3 Operating conditions

5.3.1 General operating conditions

Table 7. General operating conditions

Symbol Parameter Conditions Min Max Unit

f

HCLK

PCLK1

f

PCLK2

V

DD

V

BAT

T

A

Internal AHB clock frequency 0 36

Internal APB1 clock frequency 0 36

Internal APB2 clock frequency 0 36

Standard operating voltage 2 3.6 V

Backup operating voltage 1.8 3.6 V

Ambient temperature range −40 85 °C

5.3.2 Operating conditions at power-up / power-down

The parameters given in Table 8 are derived from tests performed under the ambient

temperature condition summarized in Table 7.

Table 8. Operating conditions at power-up / power-down

Symbol Parameter Conditions Min Typ Max Unit

t

VDD

VDD rise/fall time

MHzf

20 µs/V

20 ms/V

26/64

STM32F101xx Electrical characteristics

5.3.3 Embedded reset and power control block characteristics

The parameters given in Table 9 are derived from tests performed under ambient

temperature and V

.

Table 9. Embedded reset and power control block characteristics

Symbol Parameter Conditions Min Typ Max Unit

supply voltage conditions summarized in Table 7.

DD

PLS[2:0]=000 (rising edge) 2.1 2.18 2.26 V

PLS[2:0]=000 (falling edge) 2 2.08 2.16 V

PLS[2:0]=001 (rising edge) 2.19 2.28 2.37 V

PLS[2:0]=001 (falling edge) 2.09 2.18 2.27 V

PLS[2:0]=010 (rising edge) 2.28 2.38 2.48 V

PLS[2:0]=010 (falling edge) 2.18 2.28 2.38 V

PLS[2:0]=011 (rising edge) 2.38 2.48 2.58 V

V

PVD

V

PVDhyst

V

POR/PDR

V

PDRhyst

t

RSTTEMPO

Programmable voltage

detector level selection

PVD hysteresis 100 mV

Power on/power down reset

threshold

PDR hysteresis 40 mV

Reset temporization 1.5 2.5 3.5 ms

5.3.4 Embedded reference voltage

The parameters given in Table 10 are derived from tests performed under ambient

temperature and V

Table 10. Embedded internal reference voltage

supply voltage conditions summarized in Table 7.

DD

PLS[2:0]=011 (falling edge) 2.28 2.38 2.48 V

PLS[2:0]=100 (rising edge) 2.47 2.58 2.69 V

PLS[2:0]=100 (falling edge) 2.37 2.48 2.59 V

PLS[2:0]=101 (rising edge) 2.57 2.68 2.79 V

PLS[2:0]=101 (falling edge) 2.47 2.58 2.69 V

PLS[2:0]=110 (rising edge) 2.66 2.78 2.9 V

PLS[2:0]=110 (falling edge) 2.56 2.68 2.8 V

PLS[2:0]=111 (rising edge) 2.76 2.88 3 V

PLS[2:0]=111 (falling edge) 2.66 2.78 2.9 V

Falling edge 1.8 1.88 1.96 V

Rising edge 1.84 1.92 2.0 V

Symbol Parameter Conditions Min Typ Max Unit

V

REFINT

Internal reference voltage -45 °C < TA < +85 °C 1.16 1.20 1.24 V

27/64

Electrical characteristics STM32F101xx

5.3.5 Supply current characteristics

The current consumption is measured as described in Figure 9: Current consumption

measurement scheme.

Maximum current consumption

The MCU is placed under the following conditions:

● All I/O pins are in input mode with a static value at V

● All peripherals are disabled except if it is explicitly mentioned

● The Flash access time is adjusted to f

frequency (0 wait state from 0 to 24 MHz, 1

HCLK

wait state from 24 to 36 MHz)

The parameters given in Table 11 are derived from tests performed under ambient

temperature and V

Table 11. Maximum current consumption in Run and Sleep modes (TA = 85 °C)

Symbol Parameter Conditions F

I

DD

1. TBD stands for to be determined.

2. Typical values are measured at T

3. Data based on characterization results, tested in production at V

Supply current in

Run mode

Supply current in

Sleep mode

supply voltage conditions summarized in Table 7.

DD

External clock with PLL, code running from

Flash, all peripherals enabled (see RCC register

= f

description): f

PCLK1

HCLK

/2, f

PCLK2=fHCLK

External clock, PLL stopped, code running from

Flash, all peripherals enabled (see RCC register

description): f

PCLK1

= f

HCLK

/2, f

PCLK2=fHCLK

External clock with PLL, code running from RAM,

all peripherals enabled (see RCC register

= f

description): f

PCLK1

HCLK

/2, f

PCLK2=fHCLK

External clock, PLL stopped, code running from

RAM, all peripherals enabled (see RCC register

= f

description): f

PCLK1

HCLK

/2, f

PCLK2=fHCLK

External clock with PLL, code running from RAM

or Flash, all peripherals enabled (see RCC

register description): f

f

PCLK2=fHCLK

PCLK1

= f

HCLK

/2,

External clock, PLL stopped, code running from

RAM or Flash, all peripherals enabled (see RCC

register description): f

f

PCLK2=fHCLK

= 25 °C, and VDD = 3.3 V.

A

PCLK1

= f

HCLK

Dmax

, f

/2,

HCLK

max. T

or VSS (no load)

DD

(1)

HCLK

Typ

36 MHz 22 TBD

24 MHz 21 TBD

8 MHz 10 TBD

36 MHz 13 18

24 MHz 11 15

8 MHz 4.5 TBD

36 MHz 13 22

24 MHz 10 17

8 MHz 3.5 TBD

and code executed from RAM.

Amax,

(2)

Max

(3)

Unit

mA

28/64

STM32F101xx Electrical characteristics

Table 12. Maximum current consumption in Stop and Standby modes

Typ

Symbol Parameter Conditions

Regulator in Run mode,

Low-speed and high-speed internal

RC oscillators and high-speed

oscillator OFF (no independent

Supply current in

Stop mode

I

DD

Regulator in Low Power mode,

Low-speed and high-speed internal

watchdog)

RC oscillators and high-speed

oscillator OFF (no independent

watchdog)

Supply current in

Standby mode

I

DD_VBA

T

1. TBD stands for to be determined.

2. Typical values are measured at T

3. Data based on characterization results, tested in production at V

4. Values expected for next silicon revision.

5. To have the Standby consumption with RTC ON, add I

V

DD

Backup domain

supply current

is present the Backup Domain is powered by VDD supply).

Low-speed internal RC oscillator and

(5)

independent watchdog OFF, low-

speed oscillator and RTC OFF

Low-speed oscillator and RTC ON 1

= 25 °C, V

A

= 3.3 V, unless otherwise specified.

DD

DD_VBAT

DD max

(Low-speed oscillator and RTC ON) to IDD Standby (when

VDD/ V

= 2.4 V

TBD

TBD

, f

max. and TA max.

HCLK

BAT

TBD 24 TBD

(4)

(4)

(4)

(1)

(2)

VDD/

= 3.3 V

1.4

14

2

VBAT

(4)

(4)

(4)

Max

= 85 °C

T

A

TBD

TBD

TBD

(3)

(4)

(4)

(4)

Unit

µA

29/64

Electrical characteristics STM32F101xx

Typical current consumption

The MCU is placed under the following conditions:

● All I/O pins are in input mode with a static value at V

● All peripherals are disabled except if it is explicitly mentioned

● The Flash access time is adjusted to f

frequency (0 wait state from 0 to 24 MHz, 1

HCLK

wait state from 24 to 36 MHz)

The parameters given in Table 13 are derived from tests performed under ambient

temperature and V

Table 13. Typical current consumption in Run and Sleep modes

Symbol Parameter Conditions f

I

DD

Supply current in

Run mode

supply voltage conditions summarized in Table 7.

DD

Oscillator running at 8 MHz with PLL, code running

from Flash, all peripheral disabled (see RCC register

description): f

PCLK1

= f

HCLK

/2, f

PCLK2

= f

HCLK

Running on HSI clock, code running from Flash, all

peripheral disabled (see RCC register description):

= f

f

PCLK1

HCLK

/2, f

PCLK2

= f

AHB pre-scaler used

HCLK.

to reduce the frequency

Running on HSI clock, code running from RAM, all

peripheral disabled (see RCC register description):

= f

f

PCLK1

HCLK

/2, f

PCLK2

= f

AHB pre-scaler used

HCLK.

to reduce the frequency

or VSS (no load)

DD

(1)

HCLK

36 MHz TBD

16 MHz TBD

8 MHz 7.8

4 MHz 7

2 MHz 6.3

1 MHz 6.2

500 kHz 6.1

125 kHz 5.95

8 MHz 2.3

4 MHz 1.6

2 MHz 1.2

1 MHz 1

500 kHz 0.88

Typ

(2)

Unit

mA24 MHz 13

mA

mA

Oscillator running at 8 MHz with PLL, code running

from Flash, all peripheral disabled (see RCC register

description): f

PCLK1

= f

HCLK

Supply current in

Sleep mode

Running on HSI clock, code running from Flash, all

peripheral disabled (see RCC register description):

= f

f

PCLK1

HCLK

/2, f

PCLK2

= f

to reduce the frequency

1. TBD stands for to be determined.

2. Typical values are measures at T

= 25 °C, V

A

DD

= 3.3 V.

30/64

/2, f

HCLK.

= f

PCLK2

HCLK

AHB pre-scaler used

125 kHz 0.82

36 MHz TBD

16 MHz 1

8 MHz TBD

4 MHz TBD

2 MHz TBD

1 MHz TBD

500 kHz TBD

mA24 MHz TBD

mA

STM32F101xx Electrical characteristics

Table 14. Typical current consumption in Stop and Standby modes

Symbol Parameter Conditions

Regulator in Run mode,

Low-speed and high-speed internal RC

oscillators OFF

High-speed oscillator OFF (no

Supply current in Stop

mode

I

DD

Supply current in

Standby mode

I

DD_VBAT

1. TBD stands for to be determined.

2. Typical values are measures at T

3. Values expected for next silicon revision.

4. To obtain Standby consumption with RTC ON, add I

Backup domain

supply current

independent watchdog)

Regulator in Low Power mode,

Low-speed and high-speed internal RC

oscillators OFF,

High-speed oscillator OFF (no

independent watchdog)

Low-speed internal RC oscillator and

independent watchdog OFF

Low-speed internal RC oscillator and

(4)

independent watchdog ON

Low-speed internal RC oscillator ON,

independent watchdog OFF

Low-speed oscillator and RTC ON

Low-speed oscillator OFF, RTC ON

= 25 °C, V

A

DD

= 3.3 V.

DD_VBAT

(Low-speed oscillator, RTC ON) to IDD Standby.

(1)

V

DD

3.3 V 24

2.4 V TBD

3.3 V 14

2.4 V TBD

3.3 V 2

2.4 V TBD

3.3 V 3.1

2.4 V TBD

3.3 V 2.9

2.4 V TBD

3.3 V 1.4

2.4 V 1

3.3 V 0.5

2.4 V TBD

Typ

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(2)

(3)

(3)

(3)

(3)

(3)

Unit

µA

µA

µA

31/64

Electrical characteristics STM32F101xx

5.3.6 External clock source characteristics

High-speed user external clock

The characteristics given in Table 15 result from tests performed using an high-speed

external clock source, and under ambient temperature and supply voltage conditions

summarized in Table 7.

Table 15. High-speed user external (HSE) cloc k characteristics

Symbol Parameter Conditions Min Typ Max Unit

f

HSE_ext

V

HSEH

V

HSEL

t

w(HSE)

t

w(HSE)

t

r(HSE)

t

f(HSE)

I

1. Value based on design simulation and/or technology characteristics. It is not tested in production.

User external clock source

frequency

(1)

OSC_IN input pin high level

voltage

OSC_IN input pin low level

voltage

OSC_IN high or low time

OSC_IN rise or fall time

OSC_IN Input leakage

L

current

(1)

(1)

V

SS

≤ VIN≤ V

DD

0.7V

V

16

SS

DD

825MHz

V

DD

0.3V

DD

5

±1 µA

Low-speed user external clock

The characteristics given in Table 16 result from tests performed using an low-speed

external clock source, and under ambient temperature and supply voltage conditions

summarized in Table 7.

Table 16. Low-speed user external clock characteristics

Symbol Parameter Conditions Min Typ Max Unit

f

LSE_ext

V

LSEH

V

LSEL

t

w(LSE)

t

w(LSE)

t

r(LSE)

t

f(LSE)

I

1. Value based on design simulation and/or technology characteristics. It is not tested in production.

User external clock source

frequency

(1)

OSC32_IN input pin high level

voltage

OSC32_IN input pin low level

voltage

OSC32_IN high or low time

OSC32_IN rise or fall time

OSC32_IN Input leakage

L

current

(1)

(1)

V

SS

≤ VIN≤ V

DD

0.7V

V

450

32.768 1000 kHz

DD

SS

V

DD

0.3V

DD

5

±1 µA

V

ns

V

ns

32/64

STM32F101xx Electrical characteristics

Figure 10. High-speed external clock source AC timing diagram

V

HSEH

V

HSEL

90%

10%

t

r(HSE)

EXTERNAL

CLOCK SOURC E

T

f

HSE_ext

HSE

t

f(HSE)

OSC _I N

t

W(HSE)

I

L

STM32F101

t

W(HSE)

t

ai14127

Figure 11. Low-speed external clock source AC timing diagram

V

LSEH

V

LSEL

90%

10%

t

r(LSE)

EXTERNAL

CLOCK SOURC E

f

LSE_ext

T

LSE

t

f(LSE)

OSC32_IN

t

W(LSE)

I

L

STM32F101

t

W(LSE)

t

ai14140b

33/64

Electrical characteristics STM32F101xx

High-speed external clock

The high-speed external (HSE) clock can be supplied with a 4 to 16 MHz crystal/ceramic

resonator oscillator. All the inf ormation given in this paragraph are based on characterization

results obtained with typical external components specified in Table 17. In the application,

the resonator and the load capacitors have to be placed as close as possible to the oscillator

pins in order to minimize output distortion and startup stabilization time. Refer to the crystal

resonator manufacturer for more details on the resonator characte ristics (frequency,

package, accuracy).

Table 17. HSE 4-16 MHz oscillator characteristics

Symbol Parameter Conditions Min Typ Max Unit

(1)

f

OSC_IN

R

C

C

L2

Oscillator frequency 4 8 16 MHz

Feedback resistor 200 kΩ

F

Recommended load capacitance

L1

versus equivalent serial

(2)

resistance of the crystal (R

i

HSE driving current

2

(3)

)

S

RS = 30 Ω 30 pF

V

= 3.3 V

DD

VIN = V

with 30 pF

SS

1mA

load

g

t

SU(HSE)

(4)

1. Resonator characteristics given by the crystal/ceramic resonator manufacturer.

2. For CL1 and C

designed for high-frequency applications, and selected to match the requirements of the crystal or

resonator. C

capacitance which is the series combination of CL1 and CL2. PCB and MCU pin capacitance must be

included when sizing C

capacitance).

3. The relatively low value of the RF resistor offers a good protection against issues resulting from use in a

humid environment, due to the induced leakage and the bias condition change. However, it is

recommended to take this point into account if the MCU is used in tough humidity conditions.

4. t

SU(HSE)

oscillation is reached. This value is measured for a standard crystal resonator and it can vary significantly

with the crystal manufacturer

Oscillator transconductance Startup 25 mA/V

m

Startup time VSS is stabilized 2 ms

it is recommended to use high-quality ceramic capacitors in the 5 pF to 25 pF range (typ.),

L2

and C

L1

is the startup time measured from the moment it is enabled (by software) to a stabilized 8 MHz

are usually the same size. The crystal manufacturer typically specifies a load

L2,

and C

L1

(10 pF can be used as a rough estimate of the combined pin and board

L2

Figure 12. Typical application with an 8 MHz crystal

RESONATOR WITH

INTEGRATED CAPACITORS

C

1. R

L1

8 MHz

resonator

R

C

L2

value depends on the crystal characteristics. Typical value is in the range of 5 to 6RS.

EXT

EXT

(1)

OSC_IN

OSC_OUT

34/64

R

F

Bias

controlled

gain

f

HSE

STM32F101xx

ai14128

STM32F101xx Electrical characteristics

Low-speed external clock

The low-speed external (LSE) clock can be supplied with a 32.768 kHz crystal/ceramic

resonator oscillator. All the inf ormation given in this paragraph are based on characterization

results obtained with typical external components specified in Table 18. In the application,

the resonator and the load capacitors have to be placed as close as possible to the oscillator

pins in order to minimize output distortion and startup stabilization time. Refer to the crystal

resonator manufacturer for more details on the resonator characte ristics (frequency,

package, accuracy).

Table 18. LSE oscillator characteristics (

Symbol Parameter Conditions Min Typ Max Unit

= 32.768 kHz)

LSE

f

R

C

L1

C

L2

I

2

g

m

t

SU(LSE)

1. The oscillator selection can be optimized in terms of supply current using an high quality resonator with

small RS value for example MSIV-TIN32.768 kHz. Refer to crystal manufacturer for more details

2. t

SU(LSE)

32.768 kHz oscillation is reached. This value is measured for a standard crystal resonator and it can vary

significantly with the crystal manufacturer

Feedback resistor 5 MΩ

F

Recommended load capacitance

versus equivalent serial

resistance of the crystal (R

LSE driving current

(1)

)

S

RS = 30 KΩ 15 pF

= 3.3 V

V

DD

= V

V

IN

SS

Oscillator transconductance 5 µA/V

(2)

Startup time VSS is stabilized 3 s

is the startup time measured from the moment it is enabled (by software) to a stabilized

1.4 µA

Figure 13. Typical application with a 32.768 kHz crystal

RESONATOR WITH

INTEGRATED CAPACITORS

C

L1

32.768 KHz

resonator

C

L2

OSC32_IN

OSC32_OUT

R

F

Bias

controlled

gain

f

LSE

STM32F101xx

ai14129

35/64

Electrical characteristics STM32F101xx

5.3.7 Internal Clock source characteristics

The parameters given in Table 19 are derived from tests performed under ambient

temperature and V

High-speed internal (HSI) RC oscillator

Table 19. HSI oscillator characteristics

Symbol Parameter Conditions Min Typ Max

supply voltage conditions summarized in Table 7.

DD

(1)(2)

(3)

Unit

f

ACC

t

su(HSI)

I

DD(HSI)

1. V

2. TBD stands for to be determined.

3. Values based on device characterization, not tested in production.

Frequency 8 MHz

HSI

T

= –40 to 85 °C TBD ±3TBD%

Accuracy of HSI oscillator

HSI

A

= 25 °C TBD ±1TBD%

at T

A

HSI oscillator startup time 1 2 µs

HSI oscillator power

consumption

= 3.3 V, TA = −40 to 85 °C unless otherwise specified.

DD

LSI Low Speed Internal RC Oscillator

Table 20. LSI oscillator characteristics

Symbol Parameter Conditions Min Typ

f

t

su(LSI)

I

DD(LSI)