查询STM1810供应商

STM1810, STM1811, STM1812, STM1813

STM1815, STM1816, STM1817, STM1818

FEAT URES SUM MARY

■ PRECISION MONITORING OF 3V, 3.3V,

AND 5V SUPPLY VOLTAGES

■ FOUR OUTPUT CONFIGURATIONS

– Push-Pull, Active-High (STM1812,1817)

– Push-Pull, Active-Low (STM1810,1815)

– Open Drain, Active-Low (STM1811,1816)

– Open Drain, Active-Low with Push-Button

Detect (STM1813,1818)

■ RESET PULSE WIDTH - 100ms (min)

■ LOW SUPPLY CURRENT - 4uA (typ)

■ GUARANTEED ASSERTION DOWN TO

= 1.0V (0°C to 105°C)

V

CC

■ FACTORY-TRIMMED RESET

THRESHOLDS OF 2.55V, 2.88V, 3.06V,

4.37V, and 4. 62V (typ)

■ POWER SUPPLY TRANSIENT IMMUNITY

■ PUSH-BUTTON/MANUAL RESET DETECT

(STM1813/1818)

■ OPERATING TEMPERAT UR E:

–40°C TO 105°C

■ ±2.5% RESET THRESHOLD ACCURACY

(–40°C TO 105°C)

■ AVAILABLE IN THE SOT23-3 PACKAGE

■ FULLY COMPATIBLE WITH DS181x AND

MXD181x PRODUCTS

Low Power Reset Circu it

PRELIMINARY DATA

Figure 1. Packages

SOT23-3 (WX)

Table 1. Device Options

3.3V/

5V

3.0V

STM1810L/M ✔✔

STM1811L/M ✔

STM1812L/M ✔✔

STM1813L/M ✔ ✔

STM1815T/S/R ✔✔

STM1816T/S/R ✔

STM1817T/S/R ✔✔

STM1818T/S/R ✔✔

Note: 1. Active-low RST with inter nal pull-up resistor

June 2005

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

Active-Low

RESET

(Push-Pull)

Active-Low

RESET

(Open Drain)

(1)

✔

(1)

✔

Active-High

RESET

(Push-Pull)

Active-Low RESET

(Open Drain,

Bi-directional, with MR

Detect)

Rev 5

1/20

STM1810/1811/1812/1813/1815/1816/1817/1818

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. P ack ages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 1. Device Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

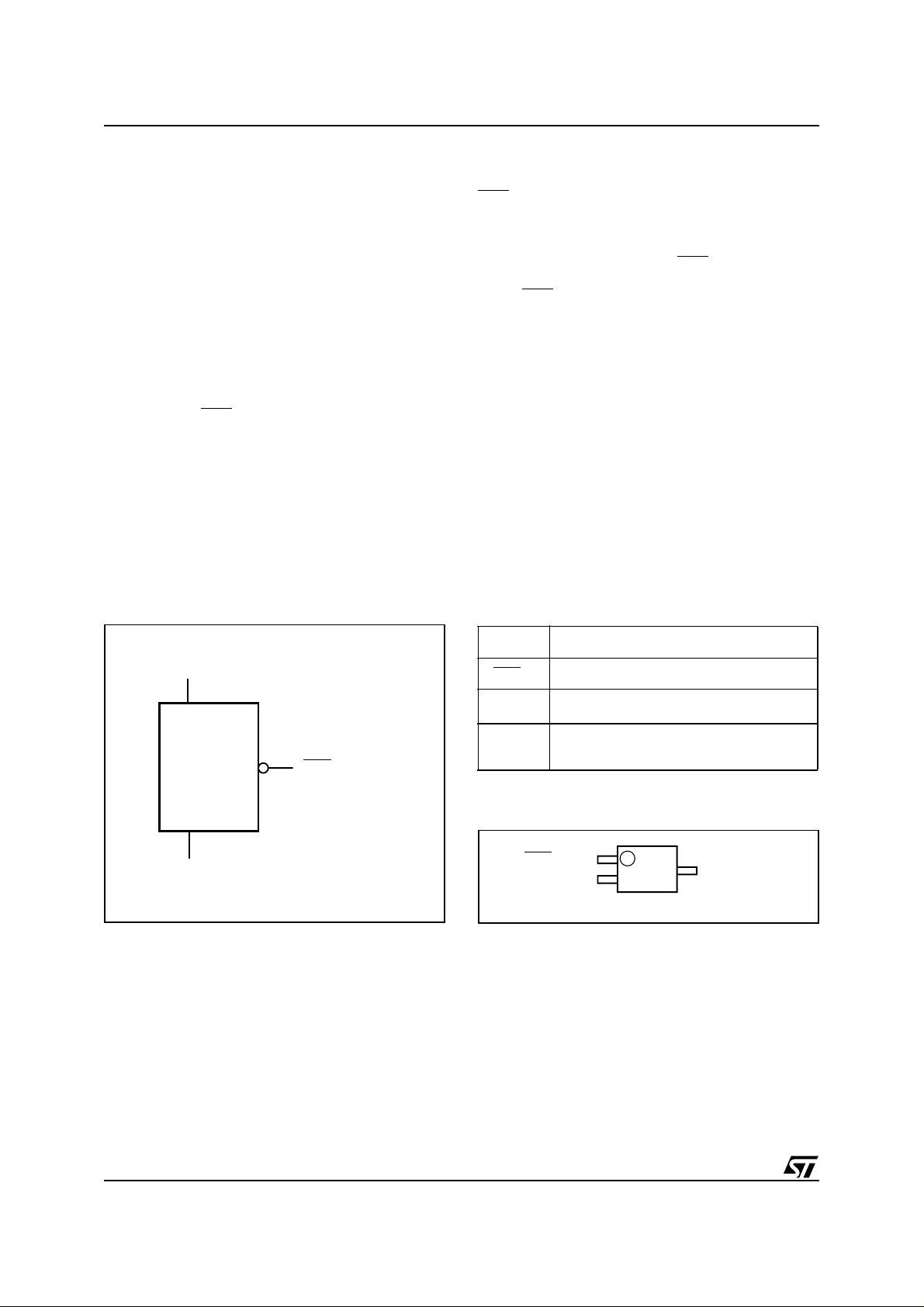

Figure 2. Logi c Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 2. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. S OT 23-3 Connect ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4. Hardware Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

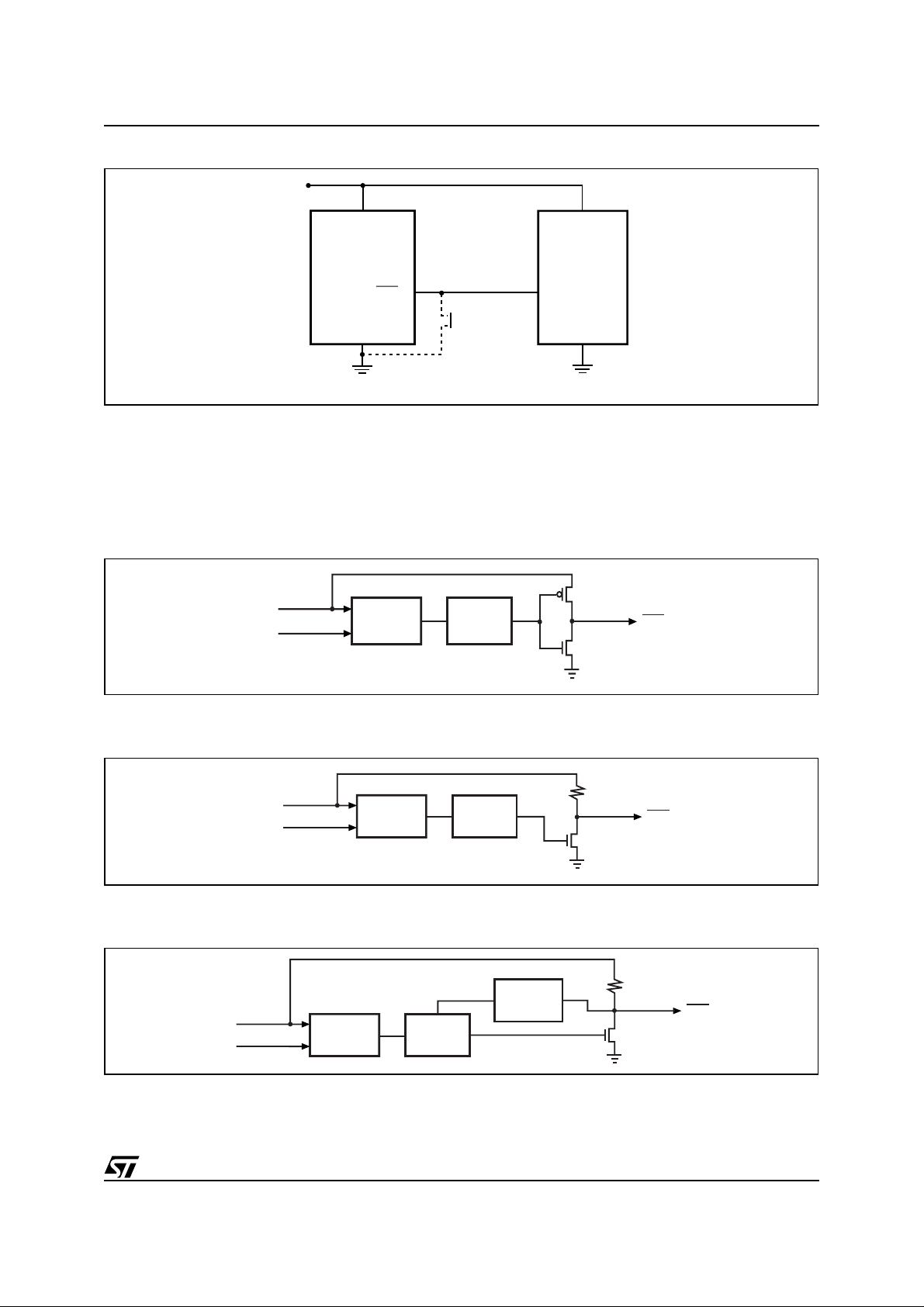

FUNCTIONAL BLOCK DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 5. P ush-pull Active-Low Output (STM1810/ 1812/1815/1817) . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 6. Open Drain, Active-Low Output (STM1811/1816). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 7. Open Drain, Active-Low Output (Bi-directional, Manual Reset Detect, STM1813/1818) . . 5

PIN DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. S TM 1810 /STM 181 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4. S TM 1811 /STM 181 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 5. S TM 1812 /STM 181 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 6. S TM 1813 /STM 181 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reset Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Push-Button Detect Reset (STM1813/1818) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Interfacing to Bidirectional Microcontrollers (MCU’s). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Negative Going V

Valid RST

Output Down to VCC = 0V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CC

Figure 8. Reset Timing Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 9. P ush-Button Ma nual Reset with MR

Detect (STM1813/1818) . . . . . . . . . . . . . . . . . . . . .8

Figure 10.Manual Reset Timing Diagram, Switch Bounce/Debounce (S TM1813/ 1818). . . . . . . . . . 8

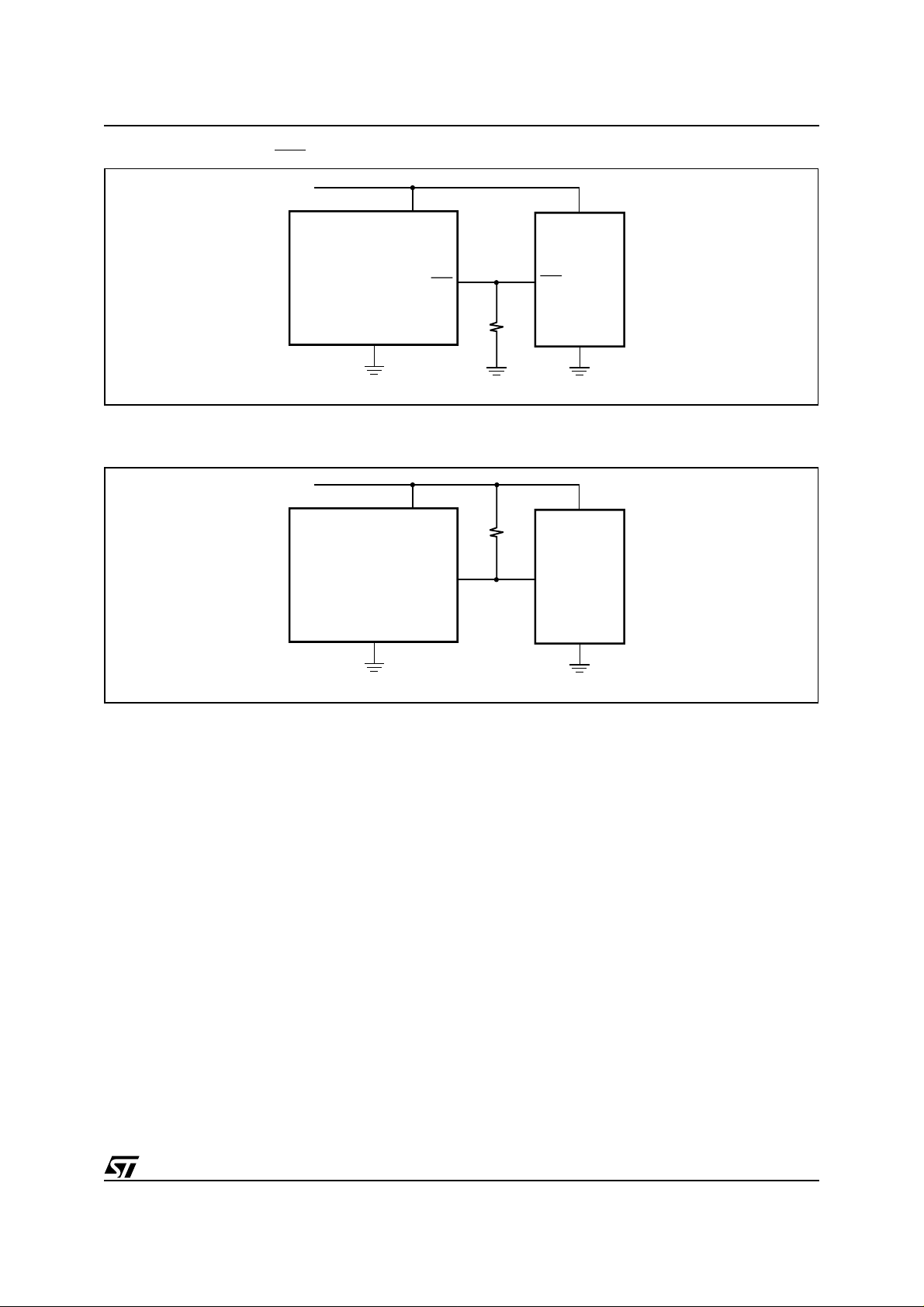

Figure 11.Interfacing MCUs with Bi-Directional Reset Pins (RST

Figure 12.Valid Reset (RST

Figure 13.Valid Reset (RST) Output Down to V

) Output Down to VCC = 0V (Push-pull). . . . . . . . . . . . . . . . . . . . . . . . .9

= 0V (Push-pull). . . . . . . . . . . . . . . . . . . . . . . . .9

CC

, Open Drain, STM1811/1816). . . 8

TYPICAL OPERATING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 14.Supply Current vs. Temperature (no load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 15.Normalized Reset Time-out Period (t

Figure 16.V

Figure 17.Voltage Output Low vs. I

Figure 18.Voltage Output High vs. I

-to-Reset Output Delay vs. Temperature - VOD = VTH – VCC . . . . . . . . . . . . . . . . . 11

CC

SINK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SOURCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

) vs. Temperature - VOD = VTH – VCC . . . . . . . 10

rec

Figure 19.Normalized Reset Threshold vs. Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 20.Max Transient Duration NOT Causing Reset Pulse vs. Reset Threshold Overdrive . . . 13

2/20

STM1810/1811/1812/1813/1815/1816/1817/1818

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DC AND AC PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 8. Operating and AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 21.AC Testing Input/Output Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 9. DC and A C Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 22.SOT23-3 – 3-lead Small Outline Transistor Package Outline. . . . . . . . . . . . . . . . . . . . . 16

Table 10. SOT23-3 – 3-lead Small Outline Transistor Package Mechanical Data . . . . . . . . . . . . . 16

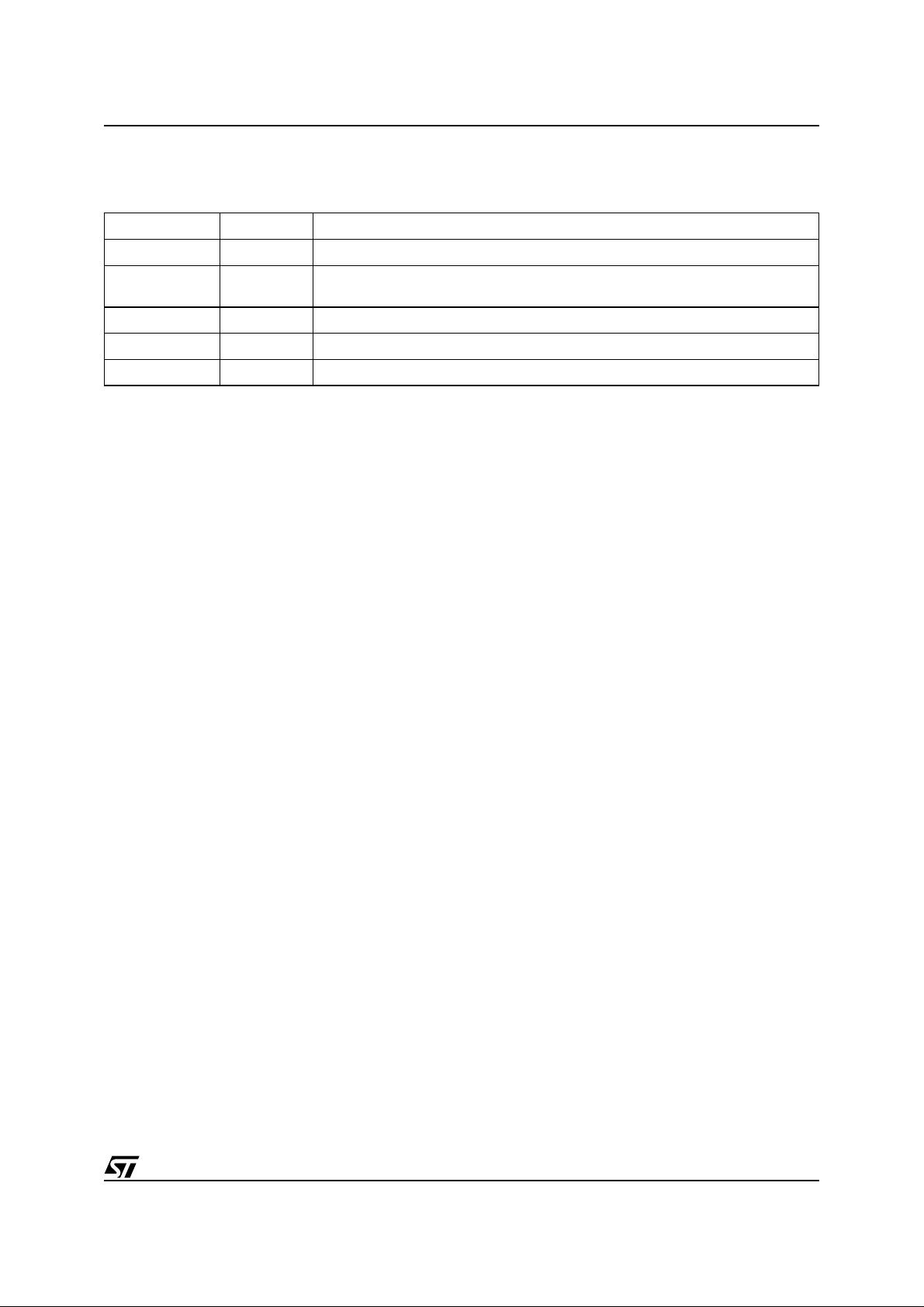

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 11.Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Table 12.Marking Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 13.Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3/20

STM1810/1811/1812/1813/1815/1816/1817/1818

SUMMARY DESCRIPTION

STM181x devices are low power reset devices

used to monitor power supplies for microcont rollers. They perform a single function: as serting a

reset signal whenever V

below a preset value and keeping it asserte d unt il

has risen above the preset threshold for a

V

CC

minimum period of time (t

lent circuit reliability without additional external

components when used with +3.0V/+3.3V

(STM1815–STM1818), and +5V (STM1810–

STM1813) power supply systems.

A precision voltage reference and comparator

monitors the V

input for an out-of-tolerance con-

CC

dition. When an invalid V

reset output (RST

) is forced low (or high in the

case of RST) and remains asserted for t

rises above the reset threshold. The

V

CC

STM1813/1818 also keep reset asserted for t

after the output is momentarily pulled to ground by

an external push-button switch.

The STM1812 and STM1817 have an active-high,

push-pull output. The STM1810 and STM1815

(push-pull) and STM1811, STM1813, STM1816,

supply voltage drops

CC

). They provide excel-

rec

condition occurs, the

CC

rec

after

rec

and STM1818 (open drain) have an active-low

output. The open drain devices (STM1811/

RST

STM1813/STM1816/STM1818) also have an internal pull-up resistor to V

. The STM1813 and

CC

STM1818 feature a debounced manual reset feature that asserts a reset if the RST

pin is pulled low

for more than 1.5µs. When used to initiate manual

reset, RST

debounces s ignals from device s such

as mechanical switches. For devices with this feature, the release of the external switch triggers the

reset period.

The STM181x devices are guaranteed to output

the correct logic state for V

down to 1.0V (0°C

CC

to +105°C). They also provide a reset comparator

designed to ignore fast transients on V

CC

.

Reset thresholds are available between +2.55V

and +4.62V These small, low power devices are

ideal for use in port able equipment. All are available in the space-saving 3-pin SOT23 package,

and are specified from –40°C to +105°C. Figure

4., page 5 shows a typical hardware hookup for

STM181x devices to a Microcontroller.

Figure 2. Logic Diagram

V

CC

STM181x

V

SS

Note: 1. For STM1812, STM1817

RST (RST)

AI09648

(1)

Table 2. Signal Names

V

SS

RST

RST

V

CC

Note: 1. For STM1812, STM1817

Ground

Active-low Reset Output

(1)

Active-high Reset Output

Supply Voltage and Input for Reset

Threshold Monitor

Figure 3. SOT23-3 Connections

RST (RST)

V

CC

Note: RST for STM1812 and STM1817

1

3

2

AI09649

V

SS

4/20

Figure 4. Hardware Hookup

V

CC

STM1810/1811/1812/1813/1815/1816/1817/1818

V

CC

STM181x

(1)

RST

Push-button

V

SS

Note: 1. RST for STM1812 and S TM1817 (see Ta bl e 1. , Device Opti ons)

2. Only valid for STM1813 and STM1818.

RESET

(2)

MCU

RESET

Input

FUNCTI ONAL BLOCK DIAGRAMS

Figure 5. Push-pull Active-Low Output (STM1810/1812/ 181 5/18 17)

V

CC

V

RST

COMPARE

t

rec

Generator

V

CC

V

SS

AI09652a

(1)

RST

AI09651a

Note: 1. RST for STM 1812 and STM 1817.

Figure 6. Open Drain, Active-Low Output (STM1811/1816)

(1)

V

CC

Note: 1. 5.5kΩ inter n al pull- up resist or

t

V

RST

COMPARE

rec

Generator

5.5kΩ

RST

AI09672

Figure 7. Open Drain, Active-Low Output (Bi-directional, Manual Reset Detect, STM1813/1818)

(1)

5.5kΩ

RST

AI09673

V

CC

V

RST

Note: 1. 5.5kΩ inter n al pull- up resist or

COMPARE

t

rec

Generator

Push-button

Detect

5/20

STM1810/1811/1812/1813/1815/1816/1817/1818

PIN DES CRIPTIONS

See Figure 2., Logic Diagram and Table 2., Signal

Names for a brief overview of the signals connect-

ed to this de vice.

Active-Low RST

low when V

long as V

CC

mains low for t

Output (Push-pull). Pulses

drops below V

CC

, and stays low as

RST

is below the reset threshold. It re-

after VCC rises above the reset

rec

threshold.

Active-Low RST

low when V

long as V

CC

mains low for t

thres ho ld. R ST

Output (Open D rain) . Pulses

drops below V

CC

, and stays low as

RST

is below the reset threshold. It re-

after VCC rises above the reset

rec

output has a n internal 5.5k Ω p ull-

up resistor.

Table 3. STM1810/STM1815

Pin Name Function

1RST

2

3

V

V

Active-low Reset Output (Push-pull)

Supply Voltage and Input for Reset Threshold Monitor

CC

Ground

SS

Active-hi gh R S T Ou t put (P us h -p ul l ). Pulses

high when V

as long as V

mains high for t

threshold.

Active-Low RST

nal 5.5kΩ pull-up) with Manual Reset Detect.

Pulses low when V

is externally pulled low for at least 1.5µs. It remains low for t

set threshold, or after the external manual reset is

released (see Figure 10., page 8). RST

an internal 5.5kΩ pull-up resistor.

V

CC

tor.

V

SS

ply. It must be connected to the system ground.

drops below V

CC

is below the reset threshold. It re-

CC

after VCC rises above the reset

rec

, and stays high

RST

Output (Open Drain with inter-

drops below V

CC

after VCC rises above the re-

PBRST

RST

, or RST

output has

. Supply voltage and input for V

compara-

RST

. Ground, is the reference for the power sup-

Table 4. STM1811/STM1816

Pin Name Function

1RST

2

3

V

V

Active-low Reset Output (Open Drain, with internal 5.5kΩ pull-up resistor)

Supply Voltage and Input for Reset Threshold Monitor

CC

Ground

SS

Table 5. STM1812/STM1817

Pin Name Function

1 RST Active-high Reset Output (Push-pull)

2

3

V

V

Supply Voltage and Input for Reset Threshold Monitor

CC

Ground

SS

Table 6. STM1813/STM1818

Pin Name Function

1RST

2

3

V

V

Active-low Reset Output (Open Drain, with internal 5.5kΩ pull-up) with Push-Button/Manual

Reset Detect

Supply Voltage and Input for Reset Threshold Monitor

CC

Ground

SS

6/20

OPERATION

Reset Output

The STM181x asserts a reset signa l to t he M icrocontroller (MCU) whenever V

reset threshold (V

down to V

= 1.0V (0° to 105°C). A microcontrol-

CC

), and is guaranteed valid

RST

ler’s (MCU) reset input starts the MCU in a known

state. The STM1810 - STM1813/ STM1815 STM1818 Low Power Reset circuits assert reset to

prevent code-execution errors during power-up,

power-down, and brownout conditions (Figure

8., page 7).

During power-up, once V

threshold an internal timer keeps RST

reset time-out period, t

. After this interval, RST

rec

returns high.

If V

drops below the reset threshold, RST goes

CC

low. Each time RST

is asserted, it stays low for at

least the reset time-out period. Any time V

below the reset threshold, the internal timer clears.

The reset timer starts when V

reset threshold. Reset t

rec

externally initiated rising edge on the RST

(STM1813/STM1818), following a low signal of

1.5µs minimum duration.

Push-Button Detect Reset (STM1813/1818)

Many systems require push-button re set capabil ity

(Figure 9., page 8), allowing the user or external

logic circuitry to initiate reset. On the STM1813/

STM1818, a logic low on RST

1.5µs asserts a reset. RST

100ms minimum reset time-out delay (t

manual reset input shorter than 1.5µs may release

without the 1 00ms minimum reset time-out

RST

delay. To fac ilitate us e with mechanic al s witche s,

the STM1813/STM1818 contain internal debounce circuitry. A debounced waveform is shown

in Fi gur e 10. ,page 8 The RST

nal 5.5kΩ pull-up resistor.

Interfacing to Bidirectional Microcontrollers

(MCU’s)

As the RST

output on the STM1811/STM1816 is

open drain, these devices interface easily with

MCU’s that have bidirectional reset pins. Connect-

goes below the

CC

exceeds the reset

CC

low for the

goes

CC

returns above the

CC

is also triggered by an

pin

held for greater than

deasserts following a

). A

rec

output has an inter-

STM1810/1811/1812/1813/1815/1816/1817/1818

ing the µP supervisor’s reset (RST

to the microcontroller’s reset (RST

ther device to asse rt reset (Figure 11., page 8). No

externa l pull-up resistor is require d, as it is w ithin

the STM1811/STM1816.

Negative Go in g V

Transients

CC

The STM181x are relatively immune to negativegoing V

transients (glitches). Figure

CC

20., page 13 shows typical transient duration ver-

sus reset comparator overdrive (for which the

STM181x will NOT generate a reset pulse). The

graph was gene rated using a negative pul se applied to V

starting at 0.5V above the actual re-

CC,

set threshold and ending below it by the

magnitude indicated (comparator ov erdrive). The

graph indicates the maximum pulse width a negative V

transient can ha ve without cau sing a re-

CC

set pulse. As the magnitude of the transient

increases (further below the thres hold), the maximum allowable pulse width decreases . Any combination of duration and overdrive which lies under

the curve will NOT generate a reset signal. Typically, a V

transient that goes 100mV below the

CC

reset threshold and lasts 20µs or less will not

cause a reset pulse. A 0.1µF bypass capacitor

mounted as close as possibl e to the V

vides additional transient immunity.

Valid R ST

When V

Output Down to VCC = 0V

falls below 1V, the RST output no long-

CC

er sinks current, but becomes an open circuit. In

most systems this is not a problem, as most MCUs

do not operate below 1V. However, in applications

where RST

output must be valid down to 0V, a

pull-down resistor may be added t o hold the RST

output low (see Figure 12., page 9). This resi stor

must be large enough to not load the RST

and still be small enough to pull the output to

ground. A 100kΩ res istor is recommended .

Note: The same situation applies for the activehigh RST of the STM1810/1812. A 100kΩ pul l-up

resistor to V

valid for V

should be used if RST must remain

CC

< 1.0V .

CC

) output directly

) pin allows ei-

pin pro-

CC

output,

Figure 8. Reset Timing Diagram

V

CC

V

RST

(1)

RST

Note: 1. RST for STM1812 and S TM1817

CC

(min)

V

RST

t

t

rec

rec

AI09653

7/20

STM1810/1811/1812/1813/1815/1816/1817/1818

Figure 9. Push-Button Manual Reset with MR Detect (STM1813/1818)

V

CC

STM1813

STM1818

V

CC

5.5kΩ

Reset

Monitor

V

SS

RST

Micro RESET

Push-button RESET

AI09654

Figure 10. Manual Reset Timing Diagram, Switch Bounce/Debou nce (STM1813/ 1818)

V

CC

(Open)

External

Push-button

tPBRST

Switch Bounce

(Closed)

RST

Figure 11. Interfacing MCUs with Bi-Directional Reset Pins (RST

V

CC

tPBRST

, Open Drain, STM1811/1816)

AI09655

STM1811

STM1816

V

CC

5.5kΩ

RST

V

SS

RST

Input

V

CC

MCU

V

SS

AI09656

8/20

STM1810/1811/1812/1813/1815/1816/1817/1818

Figure 12. Va lid R eset (RST) Output Down to VCC = 0V (Push-pull)

V

CC

STM1810

V

CC

V

STM1815

MCU

RST

V

SS

RST

Input

(1)

R

P

V

Note: 1. ~100 kΩ re sistor reco m m ended.

Figure 13. Vali d Re set (RST) Outp ut Down to VCC = 0V (Push-pull)

V

CC

STM1812

STM1817

V

CC

(1)

R

P

V

MCU

RST

RST

Input

V

SS

V

CC

SS

AI09657

CC

SS

Note: 1. ~100 kΩ re sistor reco m m ended.

AI09658

9/20

STM1810/1811/1812/1813/1815/1816/1817/1818

TYPICAL OPERATING CHARACTERISTICS

Note: Typical values are at TA = 25°C .

Figure 14. Supply Current vs. Temperature (no load )

5

4

3

2

Supply Current (µA)

1

VCC = 1.8V

VCC = 3V

VCC = 5V

0

–40 –20 0 20 40 60 80 100

Temperature (˚C)

Figure 15. Normalized Re set Time- o ut Period (t

1.07

1.05

)

rec

1.03

Period (t

1.01

Normalized Reset Time-out

0.99

–40 –20 0 20 40 60 80 100

Temperature (°C)

) vs. Temperature - VOD = VTH – VCC

rec

AI10403

AI10402

10/20

STM1810/1811/1812/1813/1815/1816/1817/1818

Figure 16. VCC-to-Reset Output Delay vs. Temperature - VOD = VTH – VCC

3.0

2.5

2.0

1.5

1.0

-to-Reset Output Delay (µs)

CC

V

0.5

0.0

–40 –20 0 20 40 60 80 100

Temperature (°C)

AI10404

Figure 17. Voltage Output Low vs. I

0.10

0.08

0.06

(V)

OUT

V

0.04

0.02

0.00

0123456

SINK

I

SINK

(mA)

VCC = 3V

AI10406

11/20

STM1810/1811/1812/1813/1815/1816/1817/1818

Figure 18. Voltage Output High vs. I

1.20

1.00

0.80

SOURCE

CC

/ V

0.60

OUT

V

0.40

0.20

0.00

0.0 1.0 2.0 3.0 4.0 5.0 6.0

I

SOURCE

(mA)

Figure 19. Nor m a liz ed R es et Threshol d vs . Tem perature

1.010

VCC = 3V

AI10407

1.005

1.000

0.995

Normalized Reset Threshold Voltage

0.990

–40 –20 0 20 40 60 80 100

Temperature (°C)

AI10405

12/20

STM1810/1811/1812/1813/1815/1816/1817/1818

Figure 20. Max Transient Duration NOT Causing Reset Pulse vs. Reset Threshold Overdrive

30

25

20

15

10

Transient Duration (µs)

5

0

10 100 1000

Reset Threshold Overdrive (mV)

Note: Reset occurs above the li ne.

AI10408

13/20

STM1810/1811/1812/1813/1815/1816/1817/1818

MAXIMUM RA T ING

Stressing the device above the rating l isted in the

Absolute Maximum Ratings” table may cause permanent damage to the device. These are stress

ratings only and operation of the device at t hese or

any other conditions ab ove those i ndicated in t he

Operating sections of this specificat ion is not im-

Table 7. Absolute Maximum Ratings

Symbol Parameter Value Unit

plied. Exposure to Absolute Maximum Rating conditions for extended periods may affect device

reliability. Refer also to the STMicroelectronics

SURE Program and other relevan t quality documents.

T

STG

(1)

T

SLD

V

IO

V

CC

I

O

P

D

Note: 1. Reflow at peak temperature of 2 55°C to 260° C f or < 30 seconds (total thermal budg et not to exce ed 180°C for between 90 t o 150

seconds).

Storage Temperature (VCC Off)

Lead Solder Temperature for 10 seconds 260 °C

Input or Output Voltage

Supply Voltage –0.3 to 7.0 V

Output Current 20 mA

Power Dissipation 320 mW

–55 to 150 °C

–0.3 to V

CC

+0.3

V

DC AND AC PARAMETERS

This section summarizes t he operating m easurement conditions, and the DC and AC characteristics of the device. The parameters in the D C and

AC characteristics Tables that follow, are derived

from tests performed under the Measurement

Table 8. Operating and AC Measurement Conditions

Parameter STM1810 - 1818 Unit

V

Supply Voltage

CC

Ambient Operating Temperature (T

Input Rise and Fall Times ≤ 5ns

Input Pulse Voltages

Input and Output Timing Ref. Voltages

)

A

Conditions summarized in Table 8, Operating and

AC Measurement Conditions. Designers should

check that the operating cond itions in their circuit

match the operating conditions when relying on

the quoted parameters.

1.0 to 5.5 V

–40 to 105 °C

0.2 to 0.8V

0.3 to 0.7V

CC

CC

V

V

Figure 21. AC Testing Input/Output Waveforms

0.8V

0.2V

14/20

CC

CC

0.7V

0.3V

AI02568

CC

CC

STM1810/1811/1812/1813/1815/1816/1817/1818

Table 9. DC and AC Characteristics

Sym

V

V

Alter-

native

CC

I

CC

V

IH

V

IL

OH

Operating Voltage

VCC Supply Current

Input High Voltage STM1813/1818 only

Input Low Voltage STM1813/1818 only

Output High Voltage 0 < IOH < 500µA

RST Output Source Current

I

OH

RST Output Source Current

Description

Test Condition

T

= 0 to +105°C

A

= –40 to +105°C

T

A

= 3.6V, No load

V

CC

= 5.5V, No load

V

CC

≥ V

V

CC

(max), Reset not

RST

asserted (STM1810/STM1815)

V

≤ V

CC

(min), Reset asserted

RST

(STM1812/STM1817)

VCC ≥ 2.7V, Reset asserted,

C

I

OL

OUT

RST Output Sink Current

RST Output Sink Current

Output Capacitance

(2)

V

= 0.4V (STM1810/1811/

OUT

1813/1815/1816/1818)

V

≥ 2.7V, Reset not asserted,

CC

V

= 0.4V, (STM1812/1817)

OUT

Reset Thresholds

STM181xL

STM181xM

V

RST

Reset Threshold

STM181xT

STM181xS

STM181xR

V

= (VTH + 100mV) falling to

t

RD

t

rec

VCC to RST Delay

RST Pulse Width

CC

(VTH – 200mV)

V

CC

Rising

Push-Button Reset Detect (STM1813, STM1818)

t

PB

t

PBRST

Note: 1. Valid for A m bi ent Operat in g T em perature: TA = –40 to 105°C; VCC = 1.2V to 5.5V (except where noted).

2. T he STM1811/1813/1816/1818 have an internal pul l -up resist or which may si nk 1mA of current.

Push-button Detect to RST STM1813/1818 1.5 µs

Push-button RST Time-out From Rising Edge

Internal Pull-up Resistance

STM1811/1816 3.5 5.5 7.5 kΩ

STM1813/1818 3.1 5.5 7.5 kΩ

(1)

Min Typ Max Unit

1.0 5.5 V

1.2 5.5 V

0.7V

CC

V

–

CC

0.5

10 mA

10 mA

25°C 4.62 V

–40 to 105°C 4.50 4.75 V

25°C 4.37 V

–40 to 105°C 4.25 4.49 V

25°C 3.06 V

–40 to 105°C 2.98 3.15 V

25°C 2.88 V

–40 to 105°C 2.80 2.97 V

25°C 2.55 V

–40 to 105°C 2.47 2.64 V

100 150 200 ms

100 150 200

410µA

916µA

V

0.4

VCC

– 0.1

V

V

350 µA

350 µA

10 pF

25µs

ms

15/20

STM1810/1811/1812/1813/1815/1816/1817/1818

PACKAG E MECHANICAL

Figure 22. SOT23-3 – 3-lead Small Outline Transistor Package Outline

E

E1

B

1

e1

0.15

e

M

D

CAB

A1

0.20 C A B

3X b

C

M

A

θ

C

L1

3X

0.10 C

C

A2

L

SOT23-3

Note: Drawing is not to scale.

Table 10. SOT23-3 – 3-lead Small Outline Transistor Package Mechanical Data

Symbol

Typ Min Max Typ Min Max

A 0.89 1.12 0.035 0.044

A1 0.01 0.10 0.001 0.004

A2 0.88 1.02 0.035 0.042

b 0.30 0.50 0.012 0.020

C 0.08 0.20 0.003 0.008

D 2.80 3.04 0.110 0.120

mm inches

A

E 2.10 2.64 0.083 0.104

E1 1.20 1.40 0.047 0.055

e 0.89 1.03 0.035 0.041

e1 1.78 2.05 0.070 0.081

L 0.54 0.021

L1 0.40 0.60 0.016 0.024

Θ 0° 8° 0° 8°

N3 3

16/20

STM1810/1811/1812/1813/1815/1816/1817/1818

PART NUMBERING

Table 11. Ordering Information Scheme

Example: STM1810 L WX 7 F

Device Type

STM181x

Reset Threshold Voltage

STM1810 - 1813:

L = V

M = V

STM1815 - 1818:

T = V

S = V

R = V

= 4.50V to 4.75V (4.62 typ)

RST

= 4.25V to 4.49V (4.37 typ)

RST

= 2.98V to 3.15V (3.06 typ)

RST

= 2.80V to 2.97V (2.88 typ)

RST

= 2.47V to 2.64V (2.55 typ)

RST

Package

WX = SOT23-3

Temperature Range

7 = –40 to 105°C

Shipping Method

F = Pb-Free Package, Tape & Reel

Note: 1. Contact the local ST sales office for availability.

For other options, or for more information on any aspect of this device, please contact the ST Sales Office

nearest you.

17/20

STM1810/1811/1812/1813/1815/1816/1817/1818

Table 12. Marking Description

Part Number Reset Threshold Output Topside Marking

STM1810L 4.62V Push -Pull R ST

STM1810M 4.37V Push -Pull R ST

STM1811L 4.62V Open Drain RST

STM1811M 4.37V Open Drain RST

STM1812L 4.62V Push-Pull RST

STM1812M 4.37V Push-Pull RST

STM1813L 4.62V Open Drain RST

STM1813M 4.37V Open Drain RST

STM1815T 3.06V Push-Pull R ST

STM1815S 2.88V Push-Pull RST

STM1815R 2.5 5V Push-Pull RST

STM1816T 3.06V Open Drain RST

STM1816S 2.88V Open Drain RST

STM1816R 2.55V Open Drain RST

STM1817T 3.06V Push-Pull RST

STM1817S 2.88V Push-Pull RST

STM1817R 2.55V Push-Pull RST

STM1818T 3.06V Open Drain RST

STM1818S 2.88V Open Drain RST

STM1818R 2.55V Open Drain RST

18/20

STM1810/1811/1812/1813/1815/1816/1817/1818

REVISION HISTORY

Table 13. Document Revision History

Date Revision Revision Details

26-Aug-04 1.0 First Issue

05-Oct-04 2.0

19-Nov-04 3.0 Update dimensions (Table 10)

07-Dec-04 4.0 Remove some voltage options (Table 1, 9, 11, 12)

29-Jun-05 5 Temperature range change (Figure 14, 15, 16, 19; Table 8, 9, 11)

Update reset characteristics, add typical graphs, remove SC70 references (Figure

1, 2, 4, 7, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20; Table 9, 11, 12)

19/20

STM1810/1811/1812/1813/1815/1816/1817/1818

Information furnished is believed to be accurate and reliable. However, STMicroelectronics a ssumes no responsibility fo r the c onsequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authori zed for use as crit i cal compon ents in life support devic es or systems w i thout express written approval of STMicroele ct ronics.

The ST logo is a registered trademark o f STM i croelectronics.

All other nam es are the pro perty of their respective owners

© 2005 STMi croelectro ni cs - All righ ts reserved

Australi a - Belgium - B razil - Canad a - China - Cze ch Republic - F i nl and - Franc e - Germany - Hong Kong - Ind ia - Is rael - Italy - Japan -

Malaysia - M al ta - Morocco - Singapore - Spain - Swe den - Switzerland - Uni ted Kingdom - United Sta tes of Americ a

STMicroelectron ics group of com panies

www.st.com

20/20

Loading...

Loading...