Page 1

1/17

PRELIMINARY DATA

February 1999

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

M28C16B

M28C17B

16 Kbit (2K x 8) Parallel EEPROM

With Software Data Protection

■ Fast Access Time: 90 ns at V

CC

=5V

■ Single Supply Voltage:

– 4.5 V to 5.5 V for M28CxxB

– 2.7 V to 3.6 V for M28CxxB-W

■ Low Power Consumption

■ Fast BYTE and PAGE WRITE (up to 64 Bytes)

–3ms at V

CC

=4.5 V

–5ms at V

CC

=2.7 V

■ Enhanced Write Detection and Monitoring:

– Data Po lling

– Toggle Bit

– Page Load Timer Status

■ JEDEC Approved Bytewide Pin-Out

■ Software Data Protection

■ 100000 Erase/Write Cycles (minimum)

■ Data Retention (minimum): 40 Years

DESCRIPTION

The M28C16B an d M28C17B devices consist of

2048x8 bits of low power, parallel EEPROM, fabricated with STMicroelectronics’ proprietary single

polysilicon CMOS technology. The devices offer

fast access time, with low power dissipation , and

require a single voltage supply.

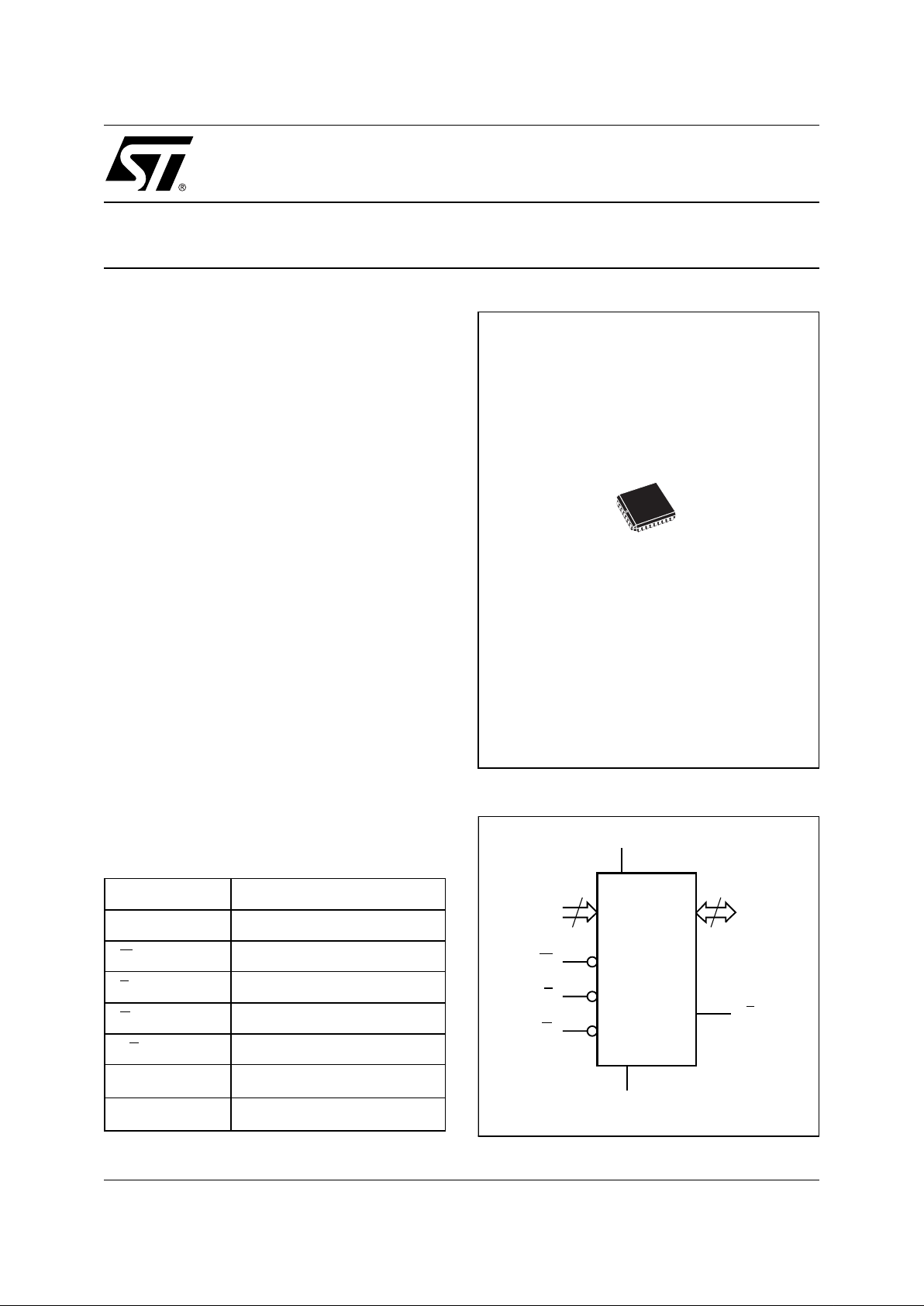

Figure 1. Logic Diagram

AI02816

11

A0-A10

W

DQ0-DQ7

V

CC

M28C16B

M28C17B

G

E

V

SS

8

RB

(M28C17B only)

Table 1. Signal Names

A0-A10 Address Input

DQ0-DQ7 Data Input / Output

W

Write Enable

E

Chip Enable

G

Output Enable

RB

Ready/Busy (M28C17B only)

V

CC

Supply Voltage

V

SS

Ground

PLCC32 (K)

Page 2

M28C16B, M28C17B

2/17

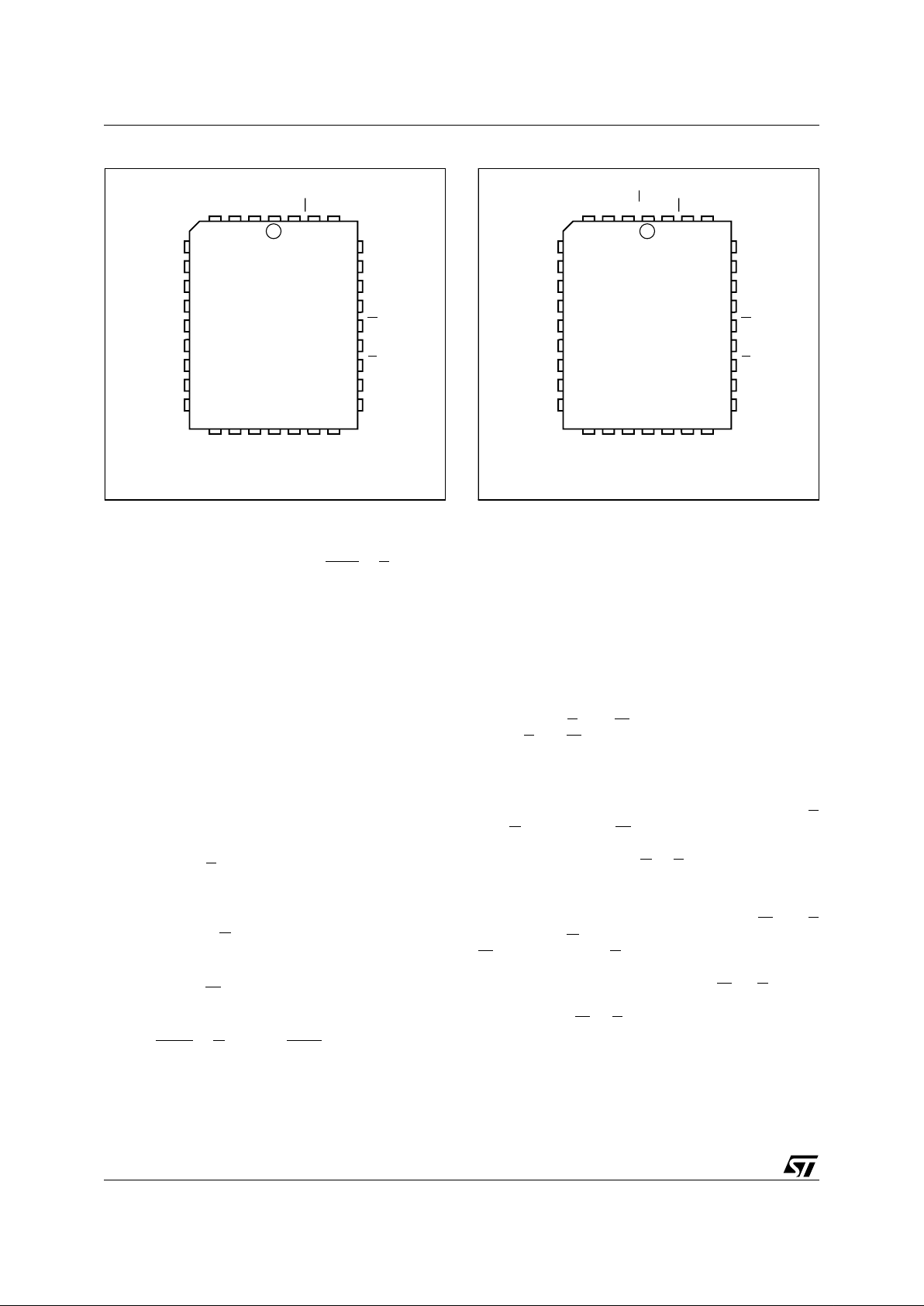

Figure 2A. PLLC Connections

Note: 1. NC = Not Connected

AI02817

NC

A8

A10

DQ4

17

A0

NC

DQ0

DQ1

DQ2NCDQ3

A6

A3

A2

A1

A5

A4

9

W

A9

1

NC

NC

DQ6

A7

DQ7

32

NC

V

CC

M28C16B

NC

NC

DQ5

G

E

25

V

SS

Figure 2B. PLLC Connections

Note: 1. NC = Not Connected

AI02830

NC

A8

A10

DQ4

17

A0

NC

DQ0

DQ1

DQ2NCDQ3

A6

A3

A2

A1

A5

A4

9

W

A9

1

NC

NC

DQ6

A7

DQ7

32

RB

V

CC

M28C17B

NC

NC

DQ5

G

E

25

V

SS

The M28C17B is like the M28C16B in every way,

except that it has an extra ready/busy

(RB) output.

The device has been designed to offer a flexible

microcontroller interface, featuring software handshaking, with Data Polling and Toggle Bit. The device supports a 64 byte Page Write operation.

Software Data Protection (SDP) is also supported,

using the standard JEDEC algorithm.

SIGNAL DESCRIPTION

The external connections to the device are summarized in Table 1, and their use in Table 3.

Addresses (A0-A10). The address inputs are

used to select one byte from the memory array

during a read or write operation.

Data In/Out (DQ0-DQ7). The contents of the data

byte are written to, or read from, the memory array

through the Data I/O pins.

Chip Enable (E

). The chip enable input must be

held low to enable read and write operations.

When Chip Enable is high, p ower consumpti on is

reduced.

Output Enable (G

). The Output Enable input con-

trols the data output buffers, and is used to initiate

read operations.

Write Enable (W

). The Write Enable input controls

whether the addressed location is to be read, from

or written to.

Ready/Busy

(RB). Ready/Busy (on the M28C17B

only) is an open drain output that can be us ed to

detect the end of the internal write cycle.

DEVICE OPERATION

In order to prevent data corruption and inadvertent

write operations, an internal V

CC

comparator in-

hibits the Write operations if the V

CC

voltage is

lower than V

WI

(see Table 4A). Once the voltage

applied on the V

CC

pin goes over the VWI thresh-

old (V

CC>VWI

), write access to the memory is al-

lowed after a time-out t

PUW

, as specified in Table

4A.

Further protection against data corruption is of-

fered by the E

and W low pass filters: any glitch,

on the E

and W inputs, with a pulse width less than

10 ns (typical) is inte rnally filtered out to prevent

inadvertent write operations to the memory.

Read

The device is accessed like a static RAM. When E

and G are low, and W is high, the contents of the

addressed location are presented on the I/ O pi ns.

Otherwise, when either G

or E is high, the I/O pins

revert to their high impedance state.

Write

Write operations are initiated when both W

and E

are low and G i s high. The device supports both

W

-controlled and E-controlled write cycles (as

shown in Figure 11 and Figure 12). The address is

latched during the falling edge of W

or E (which

ever occurs later) and the data is latche d on the

rising edge of W

or E (which ever occurs first). Af-

ter a delay, t

WLQ5H

, that cannot be shorter than the

value specified in Table 10A, the internal write cycle starts. It continues, under internal timing control, until the write operation is complete. The

commencement of this period can be det ecte d by

reading the Page Load Timer Status on DQ5. The

Page 3

3/17

M28C16B, M28C17B

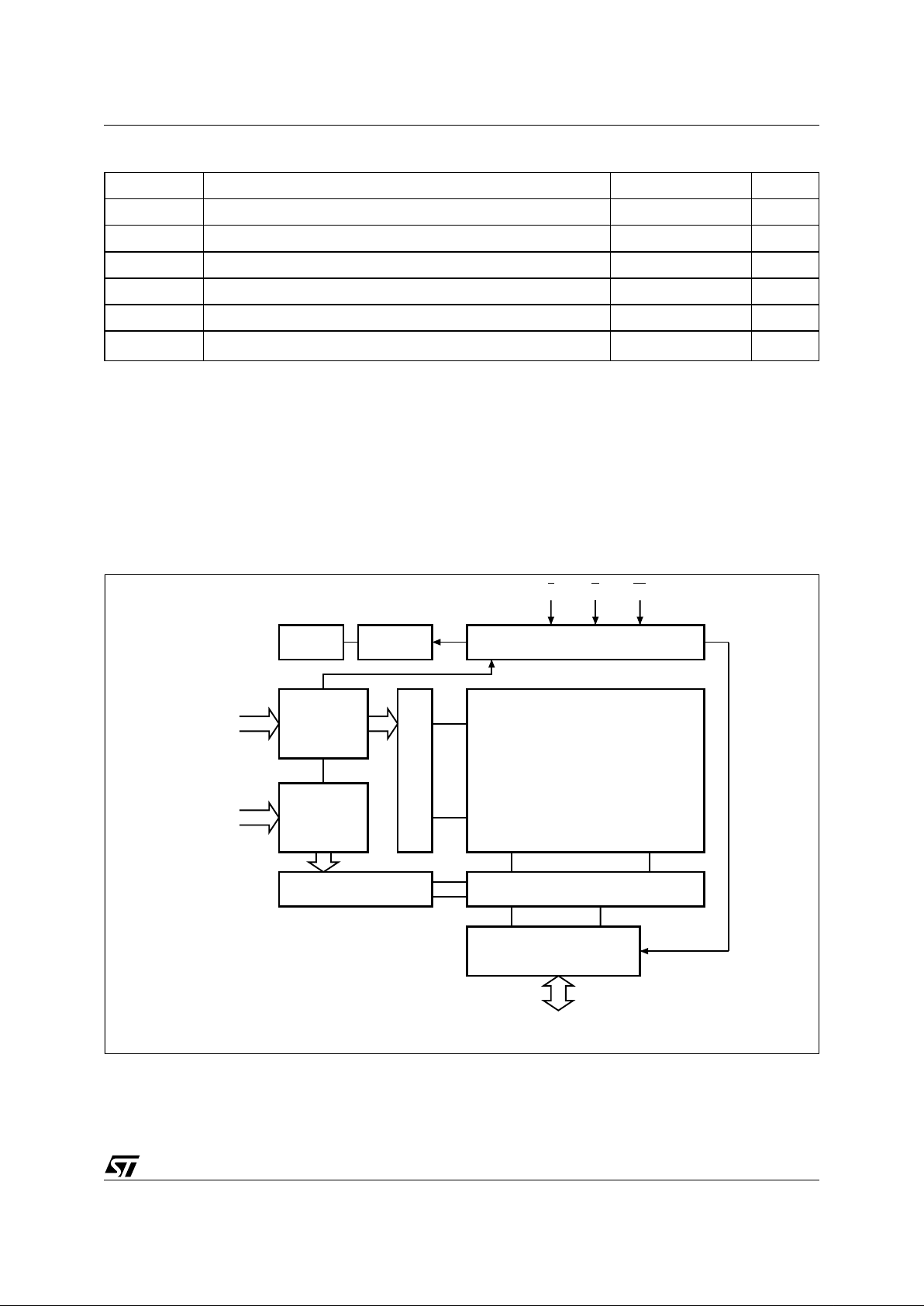

Figure 3. Block Diagram

AI02818

ADDRESS

LATCH

A6-A10

(Page Address)

X DECODE

CONTROL LOGIC

16K ARRAY

ADDRESS

LATCH

A0-A5

Y DECODE

VPP GEN RESET

SENSE AND DATA LATCH

I/O BUFFERS

EGW

PAGE LOAD

TIMER STATUS

TOGGLE BIT

DATA POLLING

DQ0-DQ7

Table 2. Absolute Maximum Ratings

1

Note: 1. Except for the rating “Operat i ng Temperature Ra nge”, stresses above those listed in t he Table “A bsolute Maximum Ratings” m ay

cause permanent damage to the device. These are stress ratings only, and operation of the device at these or any other conditions

above those indi cated in t he Operating sect i ons of thi s specifi cation i s not impl i ed. Exposure to Absolute M aximum Rating c onditions for extended periods may affect device reliability. Refer also to the ST SURE Program and other relevant quality documents.

2. MIL-ST D-883C, 3015.7 (100 pF, 15 00 Ω)

Symbol Parameter Value Unit

T

A

Ambient Operating Temperature -40 to 125 °C

T

STG

Storage Temperature -65 to 150 °C

V

CC

Supply Voltage -0.3 to 6.5 V

V

IO

Input or Output Voltage

-0.6 to V

CC

+0.6

V

V

I

Input Voltage -0.3 to 6.5 V

V

ESD Electrostatic Discharge Voltage (Human Body model)

2

4000 V

Page 4

M28C16B, M28C17B

4/17

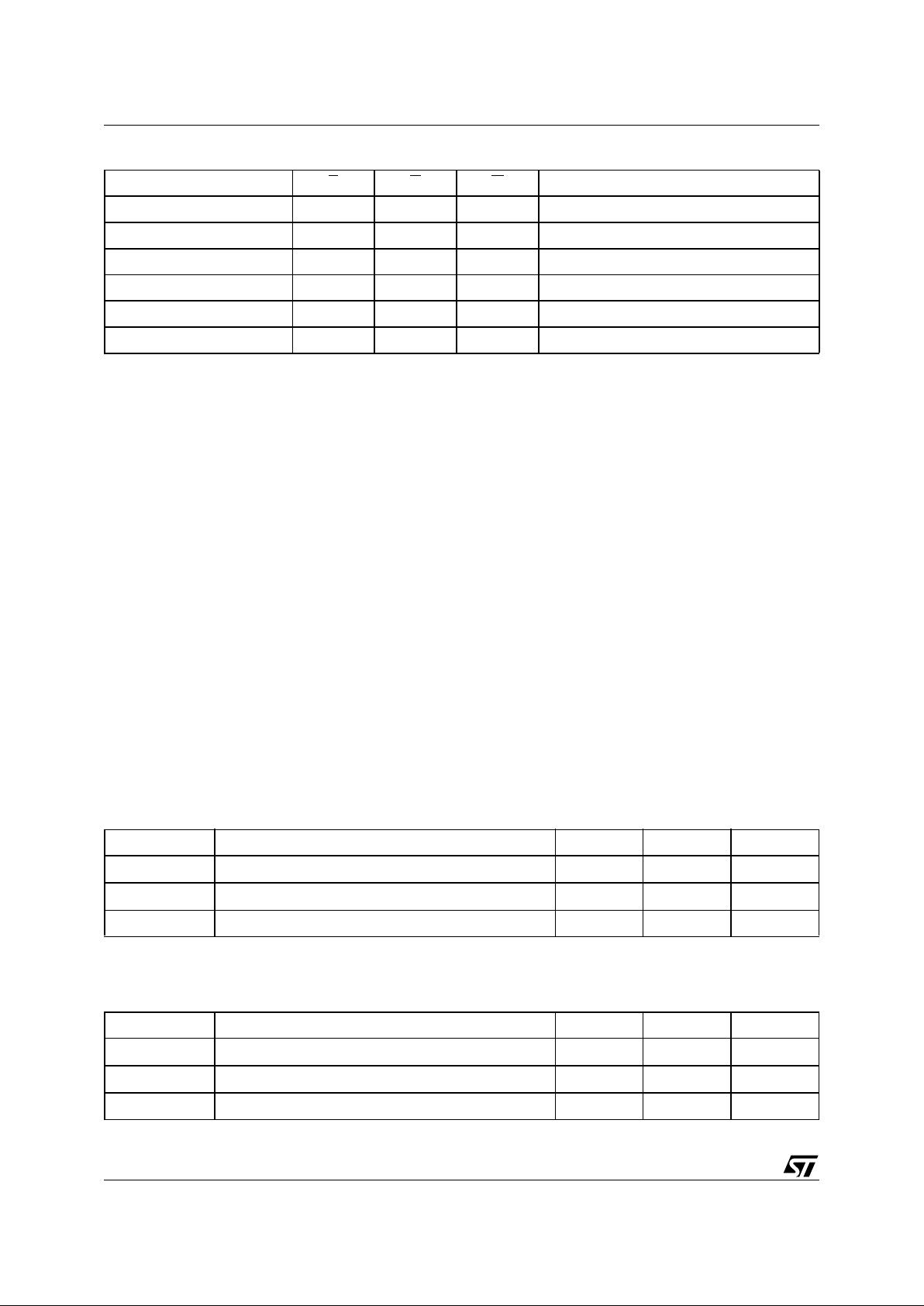

Table 3. Operating Modes

1

Note: 1. 0=VIL; 1=VIH; X = V

IH

or V

IL

; V=12V ± 5%.

Mode E G W DQ0-DQ7

Stand-by 1 X X Hi-Z

Output Disable X 1 X Hi-Z

Write Disable X X 1 Hi-Z

Read 0 0 1 Data Out

Write 0 1 0 Data In

Chip Erase 0 V 0 Hi-Z

end of the cycle can be detected by reading the

status of the Data Polling and the Toggle Bit functions on DQ7 and DQ6.

Page Write

The Page Write mode allows u p to 64 by tes to be

written on a single page in a single go. This is

achieved through a series of successive Write operations, no two of which are separated by more

than the t

WLQ5H

value (as specified in Table 10A).

The page write can be initiated during any byte

write operation. Following the first byte write instruction the host may send another address and

data with a minimum data transfer rate of:

1/t

WLQ5H

.

The internal write cycle can start at any instant after t

WLQ5H

. Once initiated, the write operation is internally timed, and continues, uninterrupt ed, until

completion.

All bytes must be located on the same page address (A10-A6 must be the same for all bytes).

Otherwise, the Page Write operation is not executed.

As with the single byte Write operation, described

above, the DQ5, DQ6 and DQ7 lines can be used

to detect the beginning and end of the internally

controlled phase of the Page Write cycle.

Software Data Protection (SDP)

The device offers a software-controlled write-protection mechanism that allows the user to inhibit all

write operations to the device. This c an be usef ul

for protecting the memory f rom inadvertent write

cycles that may occur during periods of instability

(uncontrolled bus conditions when excessive

noise is detected, or when power supply levels are

outside their specified values).

By default, the device is shipped in the “unprotected” state: the memory contents can be freely

changed by the user. Once the Software Data Protection Mode is enabled, all write com mands are

Table 4A. Power-Up Timing

1

for M28CxxB (5V range)

(T

A

= 0 to 70 °C or -40 to 85 °C; VCC = 4.5 to 5.5 V)

Note: 1. Sampled only, not 100% tested.

Table 4B. Power-Up Timing1 for M28CxxB-W (3V range)

(T

A

= 0 to 70 °C or -40 to 85 °C; VCC = 2.7 to 3.6 V)

Note: 1. Sampled only, not 100% tested.

Symbol Parameter Min. Max. Unit

t

PUR

Time Delay to Read Operation 1 µs

t

PUW

Time Delay to Write Operation (once VCC ≥ VWI)

10 ms

V

WI

Write Inhibit Threshold 3.0 4.2 V

Symbol Parameter Min. Max. Unit

t

PUR

Time Delay to Read Operation 1 µs

t

PUW

Time Delay to Write Operation (once VCC ≥ VWI)15ms

V

WI

Write Inhibit Threshold 1.5 2.5 V

Page 5

5/17

M28C16B, M28C17B

ignored, and have no effect on the memory contents .

The device remains in this mode until a valid Software Data Protection disable sequence is re-

ceived. The device reverts to its “unprotected”

state.

The status of the Software Data Protection (enabled or disabled) is represented by a non-volatile

latch, and is remembered across periods of the

power being off.

The Software Data Protection Enable command

consists of the writing of three specific data bytes

to three specific memory locations (each location

being on a different page), as shown in Figure 4.

Similarly to disable the Software Data Protection,

the user has to write specific data bytes into six dif-

ferent locations, as shown in Figure 6. This complex series of operations protects against the

chance of inadvertent enabling or disabling of the

Software Data Protection mechanism.

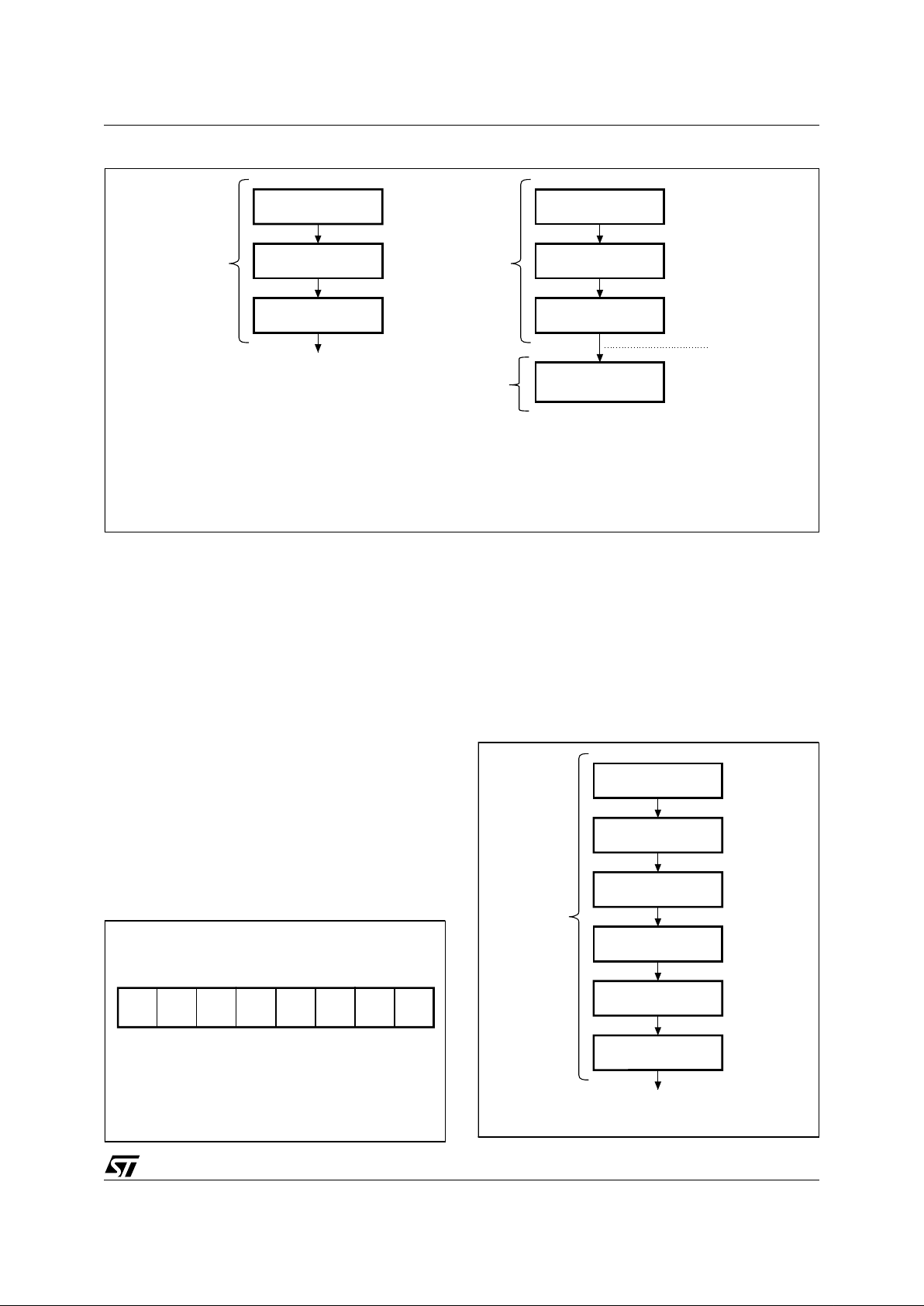

Figure 4. Software Data Protection Enable Algorithm and Memory Write

Note: 1. The most sign i ficant addre ss bits (A1 0 to A6) differ during the se specific Page Write operations.

AI02819

Write AAh in

Address 555h

Write 55h in

Address 2AAh

Write A0h in

Address 555h

SDP is set

Write AAh in

Address 555h

Write 55h in

Address 2AAh

Write A0h in

Address 555h

Page Write

(1 up to 64 bytes)

Write to Memory

When SDP is SET

SDP Enable Algorithm

Page Write

Timing

(see note 1)

Page Write

Timing

(see note 1)

Write

is Enabled

Physical

Page Write

Instruction

Figure 5. Sta tu s B it As si gnment

AI02815

DP TB PLTS Hi-Z Hi-Z Hi-Z Hi-Z Hi-Z

DP

TB

PLTS

Hi-Z

DQ7 DQ6 DQ5 DQ4 DQ3 DQ2 DQ1 DQ0

= Data Polling

= Toggle Bit

= Page Load Timer Status

= High impedance

Figure 6. Software Data Protection Disable

Algorithm

AI02820

Write AAh in

Address 555h

Write 55h in

Address 2AAh

Write 80h in

Address 555h

Unprotected State

Write AAh in

Address 555h

Write 55h in

Address 2AAh

Write 20h in

Address 555h

Page Write

Timing

Page 6

M28C16B, M28C17B

6/17

Table 5. Chip Erase AC Characteristics

1

(TA = 0 to 70 °C or -40 to 85 °C; VCC = 4.5 to 5.5 V or 2.7 to 3.6 V)

Note: 1. Sampled only, not 100% tested.

Symbol Parameter Test Condition Min. Max. Unit

t

ELWL

Chip Enable Low to Write Enable Low

G

= VCC + 7V

1 µs

t

WHEH

Write Enable High to Chip Enable High G = VCC + 7V 0 ns

t

WLWH2

Write Enable Low to Write Enable High G = VCC + 7V 10 ms

t

GLWH

Output Enable Low to Write Enable High

G

= VCC + 7V

1µs

t

WHRH

Write Enable High to Write Enable Low G = VCC + 7V 3 ms

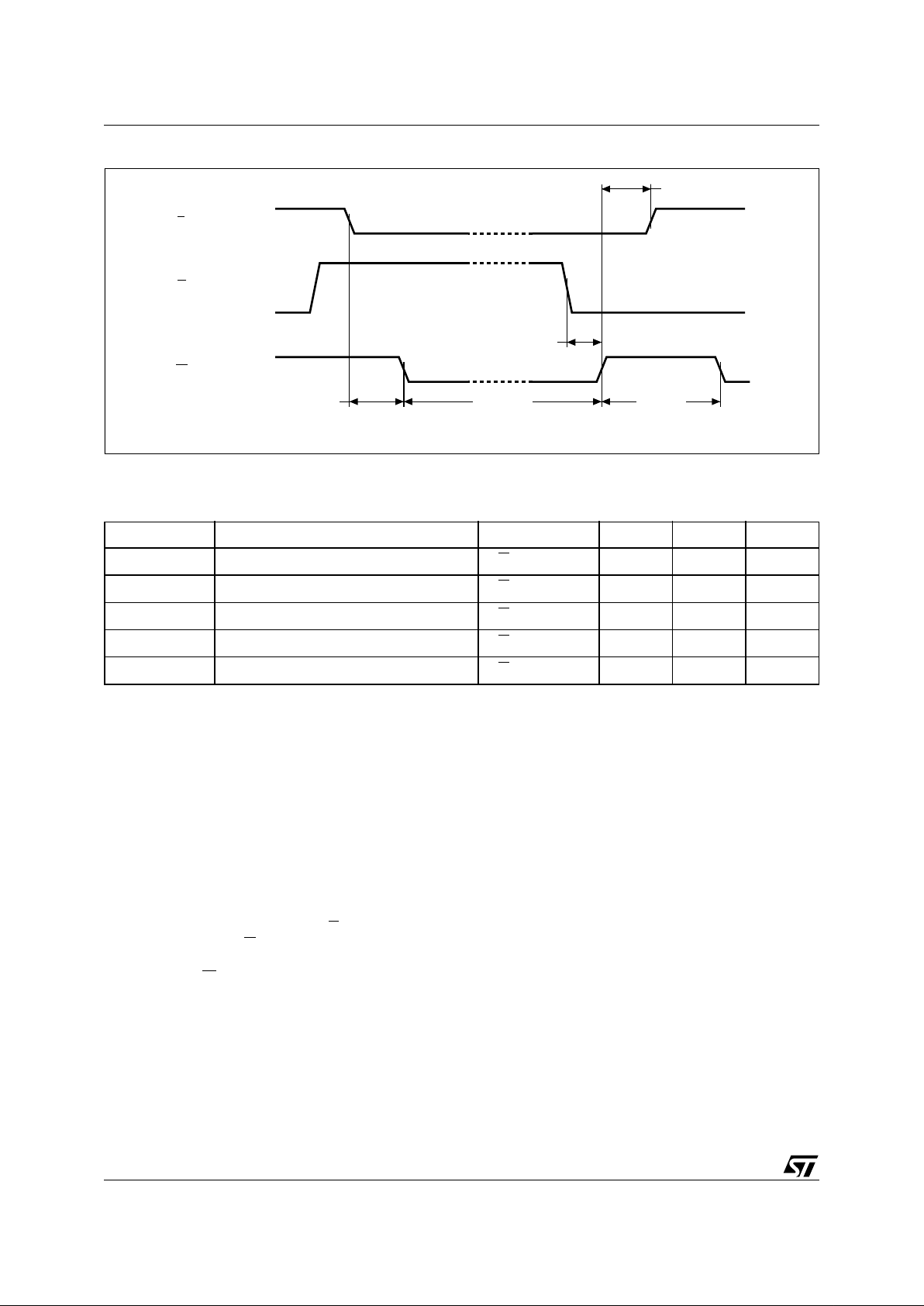

Figure 7. Chip Erase AC Waveforms

AI01484B

E

G

W

tWLWH2tELWL

tGLWH

tWHRH

tWHEH

When SDP is enabled, the memory array can still

have data written to it, but the sequence is more

complex (and hence better protected from inadvertent use). The seque nce is as shown in Figure

4. This consists of an unlock key, to enable the

write action, at the end of which the SDP continues

to be enabled. This allows the SDP to be enabled,

and data to be written, within a single Write cycle

(t

WC

).

Software Chip Erase

The contents of the entire memory are erased ( set

to FFh) by holding Chip Enable (E

) low, and hold-

ing Output Enable (G

) at VCC+7.0V. The chip is

cleared when a 10 ms low pulse is applied to the

Write Enable (W

) signal (see Figure 7 and Table 5

for details).

Status Bits

The devices provide three status bits (DQ7, DQ6

and DQ5), for use d uring write operation s. These

allow the application to use t he write time la tency

of the device for getting on with other work. These

signals are available on the I/O port bits DQ7, DQ6

and DQ5 (but only during programming cycle,

once a byte or more has been latched into the

memory).

Data Polling bit (DQ7). The internally timed write

cycle starts after t

WLQ5H

(defined in Table 10A)

has elapsed since the previous byte was latched in

to the memory. The value of the DQ7 bit of this last

byte, is used as a signal throughout this write operation: it is inverted while the internal write operation is underway, and is inverted back to its

original value once the operation is complete.

Toggle bit (DQ6). The device offers another way

for determining when the internal write cycle is

completed. During the internal E rase/Write cycle,

DQ6 toggles from ’0’ to ’1’ and ’1’ to ’0’ (the first

read value being ’0’) on subsequent att empts to

read any byte of the memory. When the internal

write cycle is complete, the toggling is stopped,

and the values read on DQ7-DQ0 are those of the

addressed memory byte. This indicates that the

device is again avai lable for new Read and Write

operations.

Page Load Timer Status bit (DQ5). An internal

timer is used to measure the period bet ween suc -

Page 7

7/17

M28C16B, M28C17B

Table 6A. Read Mode DC Characteristics for M28CxxB (5V range)

(T

A

= 0 to 70 °C or -40 to 85 °C; VCC = 4.5 to 5.5 V)

Note: 1. All inputs and outputs op en circuit.

Table 6B. Read Mode DC Characteristics for M28CxxB-W (3V range)

(T

A

= 0 to 70 °C or -40 to 85 °C; VCC = 2.7 to 3.6 V)

Note: 1. All inputs and outputs op en circuit.

Symbol Parameter Test Condition Min. Max. Unit

I

LI

Input Leakage Curren t

0V ≤ V

IN

≤ V

CC

10 µA

I

LO

Output Leakage Current 0 V ≤ V

OUT

≤ V

CC

10 µA

I

CC

1

Supply Current (TTL inputs) E = VIL, G = VIL , f = 5 MHz 30 mA

Supply Current (CMOS inputs) E

= VIL, G = VIL , f = 5 MHz 25 mA

I

CC1

1

Supply Current (Stand-by) TTL

E

= V

IH

1mA

I

CC2

1

Supply Current (Stand-by) CMOS E > VCC - 0.3V 100 µA

V

IL

Input Low Voltage -0.3 0.8 V

V

IH

Input High Voltage 2

V

CC

+ 0.5

V

V

OL

Output Low Voltage

I

OL

= 2.1 mA

0.4 V

V

OH

Output High Voltage

I

OH

= -400 µA

2.4 V

Symbol Parameter Test Condition Min. Max. Unit

I

LI

Input Leakage Curren t

0V ≤ V

IN

≤ V

CC

10 µA

I

LO

Output Leakage Current

0V ≤ V

OUT

≤ V

CC

10 µA

I

CC

1

Supply Current (CMOS inputs)

E

= VIL, G = VIL , f = 5 MHz, VCC = 3.3V 8 mA

E

= VIL, G = VIL , f = 5 MHz, VCC = 3.6V 10 mA

I

CC2

1

Supply Current (Stand-by) CMOS E > VCC - 0.3V 20 µA

V

IL

Input Low Voltage -0.3 0.6 V

V

IH

Input High Voltage 2 VCC + 0.5 V

V

OL

Output Low Voltage

I

OL

= 1.6 mA 0.2 V

CC

V

V

OH

Output High Voltage

I

OH

= -400 µA 0.8 V

CC

V

cessive Write operations, up to t

WLQ5H

(defined in

Table 10A). The DQ5 line is held low to show

when this timer is running (hence showing that the

device has received one write operation, and is

waiting for the next). The DQ5 line is held high

when the counter has overflowed (hence showing

that the device is now starting the internal write to

the memory array).

Page 8

M28C16B, M28C17B

8/17

Table 7. Input and Ou t put Parameters1 (TA = 25 °C, f = 1 MHz)

Note: 1. Sampled only, not 100% tested.

Table 8. AC Measurement Conditions

Symbol Parameter Test Condition Min. Max. Unit

C

IN

Input Capacitance VIN = 0 V 6 pF

C

OUT

Output Capacitance

V

OUT

= 0 V

12 pF

Input Rise and Fall Times ≤ 20 ns

Input Pulse Voltages 0.4 V to 2.4 V

Input and Output Timing Reference Voltages 0.8 V to 2.0 V

Figure 8. AC Testing Input Output Waveforms

AI02821

2.4V

0.4V

2.0V

0.8V

Figure 9. AC Testing Equivalent Lo ad Circuit

AI02102B

OUT

CL = 100pF

CL includes JIG capacitance

I

OL

DEVICE

UNDER

TEST

I

OH

Page 9

9/17

M28C16B, M28C17B

Table 9A. Read Mode AC Characteristics for M28CxxB (5V range)

(T

A

= 0 to 70 °C or -40 to 85 °C; VCC = 4.5 to 5.5 V)

Note: 1. Output Hi-Z i s defined as th e poi nt at which data is no longer drive n.

Table 9B. Read Mode AC Characteristics for M28CxxB-W (3V range)

(T

A

= 0 to 70 °C or -40 to 85 °C; VCC = 2.7 to 3.6 V)

Note: 1. Output Hi-Z i s defined as th e poi nt at which data is no longer drive n.

Symbol Alt. Parameter

Test

Condition

M28CxxB

Unit-90 -12

Min Max Min Max

t

AVQV

t

ACC

Address Valid to Output Valid

E

= VIL,

G

= V

IL

90 120 ns

t

ELQV

t

CE

Chip Enable Low to Output Valid

G

= V

IL

90 120 ns

t

GLQV

t

OE

Output Enable Low to Output Valid

E

= V

IL

40 45 ns

t

EHQZ

1

t

DF

Chip Enable High to Output Hi-Z

G

= V

IL

040045ns

t

GHQZ

1

t

DF

Output Enable High to Output Hi-Z

E

= V

IL

040045ns

t

AXQX

t

OH

Address Transition to Output Transition

E

= VIL,

G

= V

IL

00ns

Symbol Alt. Parameter

Test

Condition

M28CxxB-W

Unit-12 -15

Min Max Min Max

t

AVQV

t

ACC

Address Valid to Output Valid

E

= VIL,

G

= V

IL

120 150 ns

t

ELQV

t

CE

Chip Enable Low to Output Valid

G

= V

IL

120 150 ns

t

GLQV

t

OE

Output Enable Low to Output Valid

E

= V

IL

80 80 ns

t

EHQZ

1

t

DF

Chip Enable High to Output Hi-Z

G

= V

IL

045050ns

t

GHQZ

1

t

DF

Output Enable High to Output Hi-Z

E

= V

IL

045050ns

t

AXQX

t

OH

Address Transition to Output Transition

E

= VIL,

G

= V

IL

00ns

Page 10

M28C16B, M28C17B

10/17

Table 10A. Write Mode AC Characteristics for M28CxxB (5V range)

(T

A

= 0 to 70 °C or -40 to 85 °C; VCC = 4.5 to 5.5 V)

Symbol Alt. Parameter Test Condition

M28C17B

Unit

Min Max

t

AVWL

t

AS

Address Valid to Write Enable Low

E

= VIL, G = V

IH

0ns

t

AVEL

t

AS

Address Valid to Chip Enable Low

G

= VIH, W = V

IL

0ns

t

ELWLtCES

Chip Enable Low to Write Enable Low

G

= V

IH

0ns

t

GHWLtOES

Output Enable High to Write Enable Low

E

= V

IL

0ns

t

GHELtOES

Output Enable High to Chip Enable Low

W

= V

IL

0ns

t

WLELtWES

Write Enable Low to Chip Enable Low

G

= V

IH

0ns

t

WLAX

t

AH

Write Enable Low to Address Transition 50 ns

t

ELAX

t

AH

Chip Enable Low to Address Transition 50 ns

t

WLDV

t

DV

Write Enable Low to Input Valid

E

= VIL, G = V

IH

1 µs

t

ELDV

t

DV

Chip Enable Low to Input Valid

G

= VIH, W = V

IL

1µs

t

ELEH

t

WP

Chip Enable Low to Chip Enable High 50 ns

t

WHEHtCEH

Write Enable High to Chip Enable High 0 ns

t

WHGLtOEH

Write Enable High to Output Enable Low 0 ns

t

EHGLtOEH

Chip Enable High to Output Enable Low 0 ns

t

EHWHtWEH

Chip Enable High to Write Enable High 0 ns

t

WHDX

t

DH

Write Enable High to Input Transition 0 ns

t

EHDX

t

DH

Chip Enable High to Input Transition 0 ns

t

WHWLtWPH

Write Enable High to Write Enable Low 50 ns

t

WLWHtWP

Write Enable Low to Write Enable High 50 ns

t

WLQ5HtBLC

Time-out After the Last Byte Write 100 µs

t

Q5HQ5XtWC

Write Cycle Time 3 ms

t

DVWH

t

DS

Data Valid before Write Enable High 50 ns

t

DVEH

t

DS

Data Valid before Chip Enable High 50 ns

Page 11

11/17

M28C16B, M28C17B

Table 10B. Write Mode AC Characteristics for M28CxxB-W (3V range)

(T

A

= 0 to 70 °C or -40 to 85 °C; VCC = 2.7 to 3.6 V)

Symbol Alt. Parameter Test Condition

M28C17B-xxW

Unit

Min Max

t

AVWL

t

AS

Address Valid to Write Enable Low

E

= VIL, G = V

IH

0ns

t

AVEL

t

AS

Address Valid to Chip Enable Low

G

= VIH, W = V

IL

0ns

t

ELWLtCES

Chip Enable Low to Write Enable Low

G

= V

IH

0ns

t

GHWLtOES

Output Enable High to Write Enable Low

E

= V

IL

0ns

t

GHELtOES

Output Enable High to Chip Enable Low

W

= V

IL

0ns

t

WLELtWES

Write Enable Low to Chip Enable Low

G

= V

IH

0ns

t

WLAX

t

AH

Write Enable Low to Address Transition 100 ns

t

ELAX

t

AH

Chip Enable Low to Address Transition 100 ns

t

WLDV

t

DV

Write Enable Low to Input Valid

E

= VIL, G = V

IH

1 µs

t

ELDV

t

DV

Chip Enable Low to Input Valid

G

= VIH, W = V

IL

1µs

t

ELEH

t

WP

Chip Enable Low to Chip Enable High 100 1000 ns

t

WHEHtCEH

Write Enable High to Chip Enable High 0 ns

t

WHGLtOEH

Write Enable High to Output Enable Low 0 ns

t

EHGLtOEH

Chip Enable High to Output Enable Low 0 ns

t

EHWHtWEH

Chip Enable High to Write Enable High 0 ns

t

WHDX

t

DH

Write Enable High to Input Transition 0 ns

t

EHDX

t

DH

Chip Enable High to Input Transition 0 ns

t

WHWLtWPH

Write Enable High to Write Enable Low 50 1000 ns

t

WLWHtWP

Write Enable Low to Write Enable High 100 ns

t

WLQ5HtBLC

Time-out after the last byte write 100 µs

t

Q5HQ5XtWC

Write Cycle Time 5 ms

t

DVWH

t

DS

Data Valid before Write Enable High 50 ns

t

DVEH

t

DS

Data Valid before Chip Enable High 50 ns

Page 12

M28C16B, M28C17B

12/17

Figure 10. Read Mode AC Waveforms (with Write Enable, W, high)

Note: 1. Write Enable (W) = V

IH

Figure 11. Write Mode AC Waveforms (Write Enable, W, controlled)

AI02822

VALID

tAVQV tAXQX

tGLQV tEHQZ

tGHQZ

DATA OUT

A0-A10

E

G

DQ0-DQ7

tELQV

Hi-Z

AI02823

VALID

tAVWL

A0-A10

E

G

DQ0-DQ7

DATA IN

W

tWLAX

tELWL

tGHWL

tWLDV

tWHEH

tWHGLtWLWH

tWHWL

tWHDXtDVWH

RB

tWHRL

Page 13

13/17

M28C16B, M28C17B

Figure 12. Write Mode AC Waveforms (Chip Enable, E, controlled)

Figure 13. Page Write Mode AC Waveforms (Write Enable, W

, controlled)

AI02824

VALID

tAVEL

A0-A10

E

G

DQ0-DQ7

DATA IN

W

tELAX

tGHEL

tWLEL

tELDV

tEHGL

tEHDXtDVEH

RB

tEHRL

tELEH

tEHWH

tQ5HQ5X

AI02825

A0-A10

E

G

DQ0-DQ7 (in)

W

Addr 0

DQ5 (out)

RB

Addr 1 Addr 2 Addr n

tWLQ5H

tWLWH

tWHWL

tWHRL

Byte 0 Byte 1 Byte 2 Byte n

Page 14

M28C16B, M28C17B

14/17

Figure 14. Software Protected Write Cycle Waveforms

Note: 1. A10 to A6 must specify the same pa ge address dur i ng each high-to-low trans i tion of W (or E). G must be high on l y wh en W and E

are both low.

Figure 15. Data Polling Sequence Waveforms

AI02826

A0-A5

E

G

DQ0-DQ7

W

tWLWH

tDVWH

Byte 0

tWHWL

A6-A10

tWLAX

tWHWH

tWHDX

tAVEL

555h 2AAh 555h

Byte 62 Byte 63AAh 55h A0h

Byte Address

Page Address

AI02827

A0-A10

E

G

DQ7

W

DQ7 DQ7DQ7 DQ7DQ7

Ready

Last WRITE Internal Write Sequence

Address of the last byte of the Page Write instruction

Page 15

15/17

M28C16B, M28C17B

Table 11. Ordering Information Scheme

Example: M28C16 – 120 W K 6 TR

Ready/Busy

Option

16 Pin 1 = Not Connected TR Tape and Reel Packing

17 Pin 1 = Ready/Busy

Speed Temperature Range

90 90 ns (5V range only) 1 0 °C to 70 °C

120 120 ns 6 –40 °C to 85 °C

150 150 ns (3V range only)

Operating Voltage Package

blank 4.5 V to 5.5 V K PLCC32

W

2.7 V to 3.6 V

ORDERING INFORMATION

Devices are shipped from the factory with the

memory content set at all ‘1’s (FFh).

The notation used for the device number is as

shown in Table 11. For a list of available options

(speed, package, etc.) or for further information on

any aspect of this device, please contact the ST

Sales Office nearest to you.

Figure 16. Toggle Bit Sequence Waveforms

Note: 1. The Toggle Bit is first set to ‘0’.

AI02828

A0-A10

E

G

DQ6

W

ReadyLast WRITE

Internal Write Sequence

(1)

TOGGLE

Page 16

M28C16B, M28C17B

16/17

Figure 17. PLCC (K)

Note: 1. Drawing is not to scal e.

PLCC

D

Ne E1 E

1 N

D1

Nd

CP

B

D2/E2

e

B1

A1

A

R

0.51 (.020)

1.14 (.045)

F

A2

Table 12. PLCC32 - 32 lead Plastic Leaded Chip Carrier, rectangular

Symbol

mm inches

Typ. Min. Max. Typ. Min. Max.

A 2.54 3.56 0.100 0.140

A1 1.52 2.41 0.060 0.095

A2 – 0.38 – 0.015

B 0.33 0.53 0.013 0.021

B1 0.66 0.81 0.026 0.032

D 12.32 12.57 0.485 0.495

D1 11.35 11.56 0.447 0.455

D2 9.91 10.92 0.390 0.430

E 14.86 15.11 0.585 0.595

E1 13.89 14.10 0.547 0.555

E2 12.45 13.46 0.490 0.530

e 1.27 – – 0.050 – –

F 0.00 0.25 0.000 0.010

R 0.89 – – 0.035 – –

N32 32

Nd 7 7

Ne 9 9

CP 0.10 0.004

Page 17

17/17

M28C16B, M28C17B

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or p atent rights of STMi croelectr oni cs. Spec i fications mentioned i n this publicatio n are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi t hout expres s written approval of STMi croelectr o nics.

© 1999 STMicroelectronics - All Rights Reserved

The ST logo is a registered trademark of STMicroelectr oni cs.

All other na m es are the prop erty of their respectiv e owners.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands - Singapore -

Spain - Sweden - Switze rl and - Taiwan - Thailand - United Ki ngdom - U.S. A.

http://www.s t. com

Loading...

Loading...