ST M24C64, M24C32 User Manual

M24C64

M24C32

64Kbit and 32Kbit Serial I²C Bus EEPROM

FEATURES SUMMARY

M24C64

M24C32

2

C Serial Interface

M24C64

M24C64-W

M24C64-R

M24C32

M24C32-W

M24C32-R

■ Two-Wire I

Supports 400kHz Protocol

■ Single Supply Voltage:

– 4.5 to 5.5V for M24Cxx

– 2.5 to 5.5V for M24Cxx-W

– 1.8 to 5.5V for M24Cxx-R

■ Write Control Input

■ BYTE and PAGE WRITE (up to 32 Bytes)

■ RANDOM and SEQUENTIAL READ Modes

■ Self-Timed Programming Cycle

■ Automatic Address Incr em ent ing

■ Enhanced ESD/Latch-Up Protection

■ More than 1 Million Erase/Write Cycles

■ More than 40-Year Data Retention

Table 1. Product List

Reference Part Number

Figure 1. Packages

8

1

PDIP8 (BN)

8

1

SO8 (MN)

150 mil width

TSSOP8 (DW)

169 mil width

UFDFPN8 (MB)

2x3mm² (MLP)

1/26January 2005

M24C64, M24C32

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 1. Product List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 2. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power On Reset: VCC Lock-Out Write Protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. DIP, SO, TSSOP and UFDFPN Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SIGNAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Clock (SCL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Data (SDA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chip Enable (E0, E1, E2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Write Control (WC

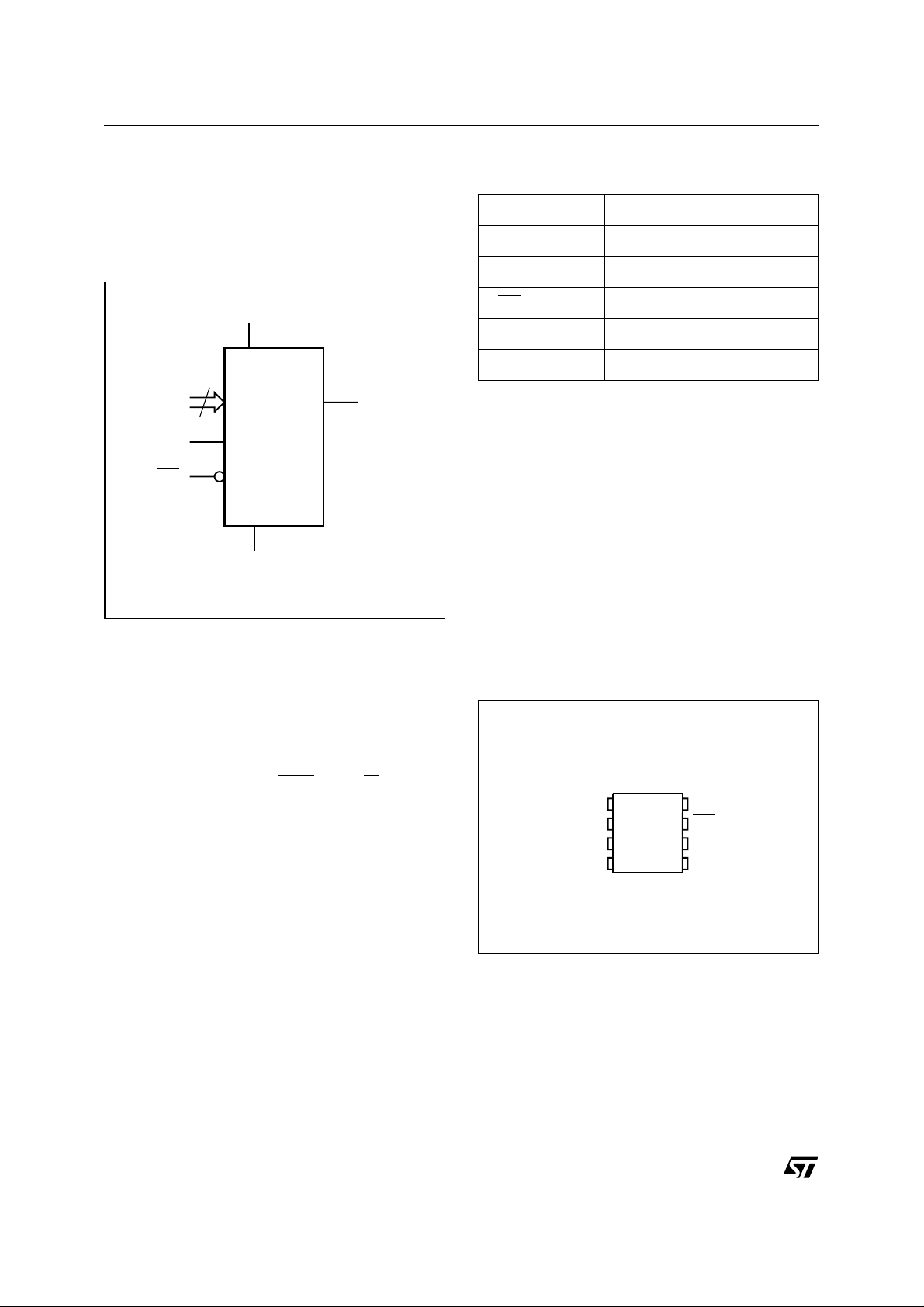

Figure 4. Maximum R

Figure 5. I

2

Table 3. Device Select Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4. Most Significant Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 5. Least Significant Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Value versus Bus Capacitance (C

L

) for an I2C Bus . . . . . . . . . . . . . . . . 5

BUS

C Bus Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MEMORY ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 6. Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DEVICE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Start Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Stop Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Acknowledge Bit (ACK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Memory Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 6. Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

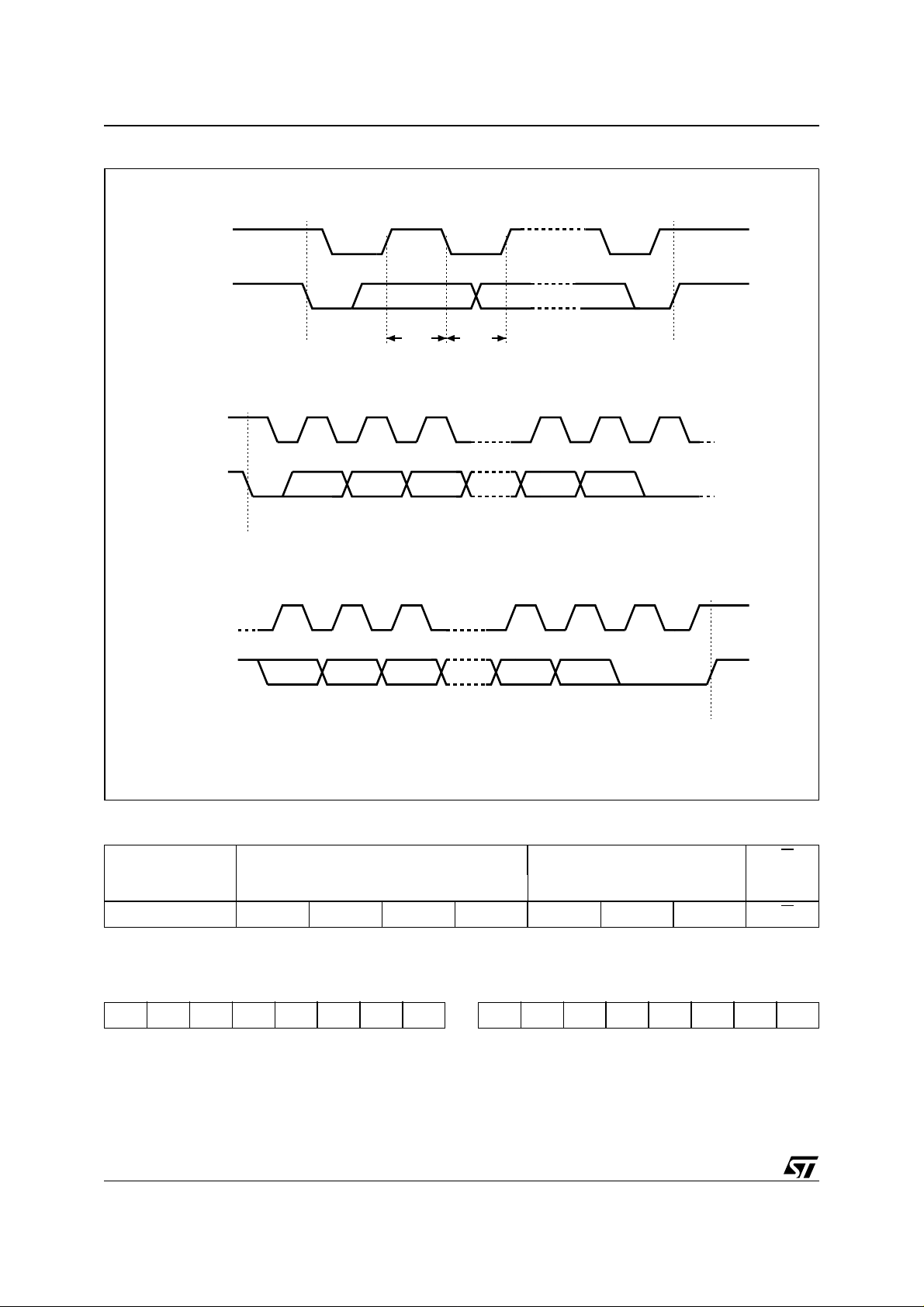

Figure 7. Write Mode Sequences with WC

=1 (data write inhibited) . . . . . . . . . . . . . . . . . . . . . . . . . 9

Write Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Byte Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Page Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8. Write Mode Sequences with WC

=0 (data write enabled) . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 9. Write Cycle Polling Flowchart using ACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Minimizing System Delays by Polling On ACK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

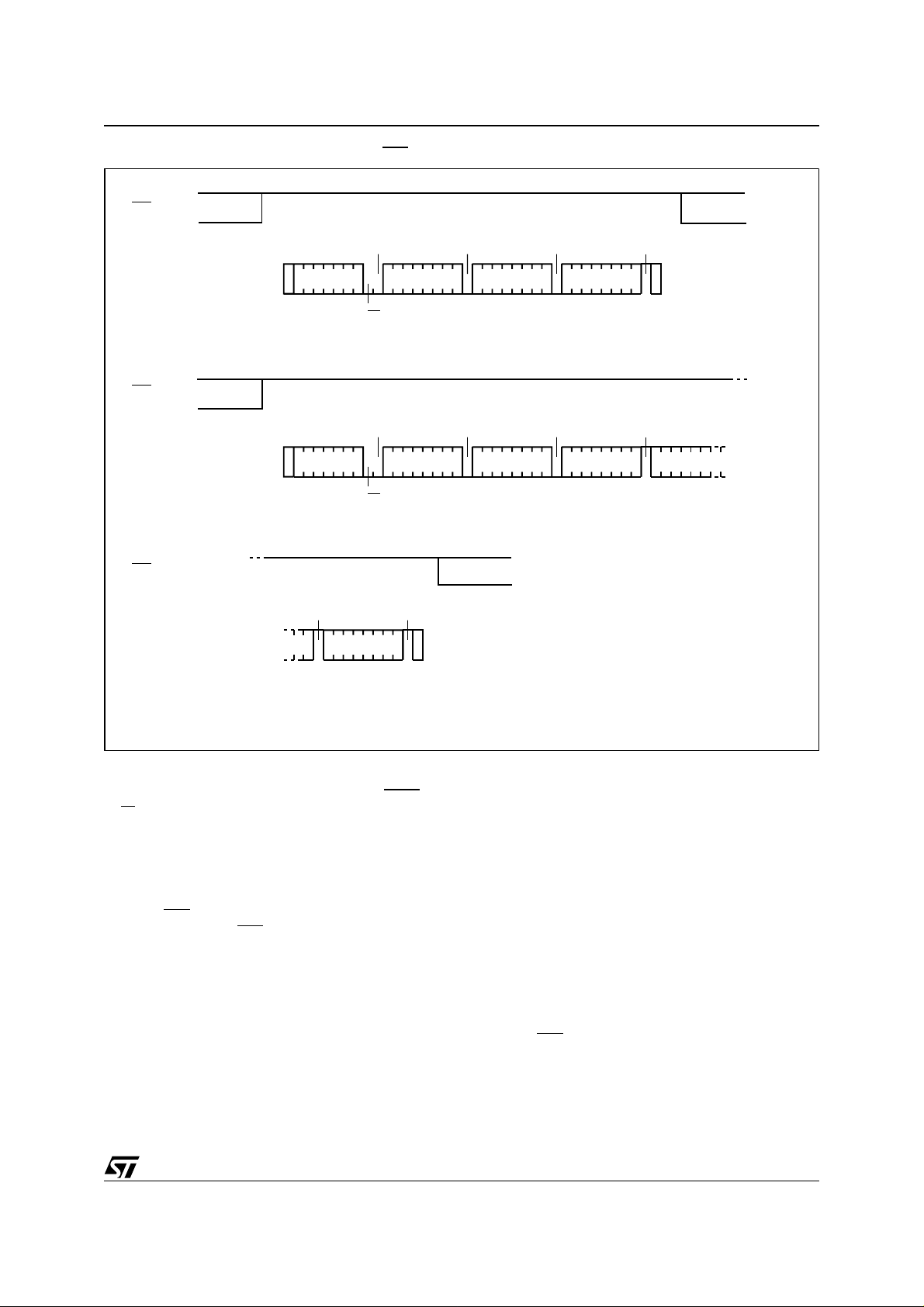

Figure 10.Read Mode Sequences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Read Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Random Address Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Current Address Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sequential Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/26

M24C64, M24C32

Acknowledge in Read Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

INITIAL DELIVERY STATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DC AND AC PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 8. Operating Conditions (M24Cxx-6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 9. Operating Conditions (M24Cxx-W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 10. Operating Conditions (M24Cxx-R). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 11. AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11.AC Measurement I/O Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 12. Input Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 13. DC Characteristics (M24Cxx

Table 14. DC Characteristics (M24Cxx-W6 and M24Cxx-W3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 15. DC Characteristics (M24Cxx-R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 16. AC Characteristics (M24Cxx-6, M24Cxx-W6 and M24Cxx-W3) . . . . . . . . . . . . . . . . . . . 18

Table 17. AC Characteristics (M24Cxx-R). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 12.AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

(1)

, M24Cxx-W6 and M24Cxx-W3). . . . . . . . . . . . . . . . . . . 16

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 13.PDIP8 – 8 pin Plastic DIP, 0.25mm lead frame, Package Outline . . . . . . . . . . . . . . . . . 20

Table 18. PDIP8 – 8 pin Plastic DIP, 0.25mm lead frame, Package Mechanical Data . . . . . . . . . . 20

Figure 14.SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Outline . . . . 21

Table 19. SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width,

Package Mechanical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 15.TSSOP8 – 8 lead Thin Shrink Small Outline, Package Outline . . . . . . . . . . . . . . . . . . . 22

Table 20. TSSOP8 – 8 lead Thin Shrink Small Outline, Package Mechanical Data . . . . . . . . . . . . 22

Figure 16.UFDFPN8 (MLP8) – 8-lead Ultra thin Fine pitch Dual Flat Package No lead 2x3mm. . . 23

Table 21. UFDFPN8 (MLP8) – 8-lead Ultra thin Fine pitch Dual Flat Package No lead 2x3mm,

Package Mechanical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 22. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 23. Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3/26

M24C64, M24C32

SUMMARY DESCRIPTION

These I2C-compatible electrically erasable programmable memory (EEPROM) devices are organized as 8192 x 8 bits (M24C64) and 4096 x 8 bits

(M24C32).

Table 2. Signal Names

E0, E1, E2 Chip Enable

SDA Serial Data

Figure 2. Logic Diagram

V

CC

3

E0-E2 SDA

SCL

WC

2

I

C uses a two-wire serial interf ace, comprisi ng a

M24C64

M24C32

V

SS

AI01844B

bi-directional data line and a clock line. The devices carry a built-in 4-bit Device Type Identifier code

(1010) in accordance with the I

The device behaves as a slave in the I

2

C bus definition.

2

C protocol,

with all memory operations synchronized by the

serial clock. Read and Write operations are initiated by a Start condition, generated by the bus master. The Start condition is followed by a Device

Select Code and Read/Write

bit (RW) (as described in Table 3.), terminated by an acknowledge bit.

When writing data to the memory , the device inserts an acknowled ge bit during the 9

th

bit time,

following the bus master’s 8-bit transmission.

When data is read by the bus master, the bus

master acknowledge s the rec eipt o f the d ata by te

in the same way. Data transfers are terminated by

a Stop condition after an Ack for Write, and after a

NoAck for Read.

SCL Serial Clock

WC

V

CC

V

SS

Power On Reset: V

Write Control

Supply Voltage

Ground

Lock-Out Write Protect

CC

In order to prevent data corruption and inadvertent

Write operations during Power-up, a Power On

Reset (POR) circuit is included . At Power-up, the

internal reset i s he ld a cti ve unti l V

has reached

CC

the Power On Reset (POR) threshold voltage, and

all operations are disabled – the device will not respond to any command. In the sam e way, when

V

drops from the operat ing voltage, below the

CC

Power On Reset (PO R) threshold voltage, a ll operations are disabl ed and the device will not respond to any command.

A stable and valid V

(as defined in Table 9. and

CC

Table 10.) must be applied before applying any

logic signal.

Figure 3. DI P, SO, TSSOP and UFDFPN Connections

M24C64

M24C32

E0 V

1

2

E2

3

4

SS

Note: See PACKA GE MECHANICAL section for package dimen-

sions, and how to identify pin-1.

8

7

6

5

AI01845C

CC

WCE1

SCL

SDAV

4/26

SIGNAL DESCRIPTION

Serial Clock (SCL). This input signal is used to

strobe all data in and out of the device. In applications where this signal is used by slave devices to

synchronize the bus to a slower clock, the bus

master must have an open drain output, and a

pull-up resistor must be connected from Serial

Clock (SCL) to V

value of the pull- up resi stor can be calc ulate d). In

most applications, though, this method of synchronization is not employed, and so the pull-up resistor is not necessary, pro vided that the bus master

has a push-pull (rather than open drain) output.

Serial Data (SDA). This bi-directional signal is

used to transfer data in or out of the device. It is an

open drain output that may be wire-OR’ed with

other open drain or ope n collector signals on the

bus. A pull up resistor must be connected from Se-

. (Figure 4. indicates how the

CC

M24C64, M24C32

rial Data (SDA) to V

the value of the pull-up resistor can be calculated).

Chip Enable (E0, E1, E2). These input signals

are used to set the value that is to be looked for on

the three least significant bits (b3, b2, b1) of the 7bit Device Select Code. These inputs must be tied

to V

or VSS, to establish the Device Select

CC

Code.

Write Control (WC

for protecting the entire content s of the memory

from inadvertent write operations. Write operations are disabled to the entire memory array when

Write Control (WC

nected, the signal is internally read as V

Write operations are allowed.

When Write Contr ol (WC

Select and Address bytes are acknowledged,

Data bytes are not acknowledged.

. (Figure 4. indicates how

CC

). This input signal is useful

) is driven High. When uncon-

, and

IL

) is driven High, Device

Figure 4. Maximum R

20

16

12

8

Maximum RP value (kΩ)

4

0

10

Value versus Bus Capacitance (C

L

fc = 100kHz

fc = 400kHz

100

C

(pF)

BUS

) for an I2C Bus

BUS

MASTER

1000

V

CC

R

SDA

SCL

R

L

C

BUS

L

C

BUS

AI01665

5/26

M24C64, M24C32

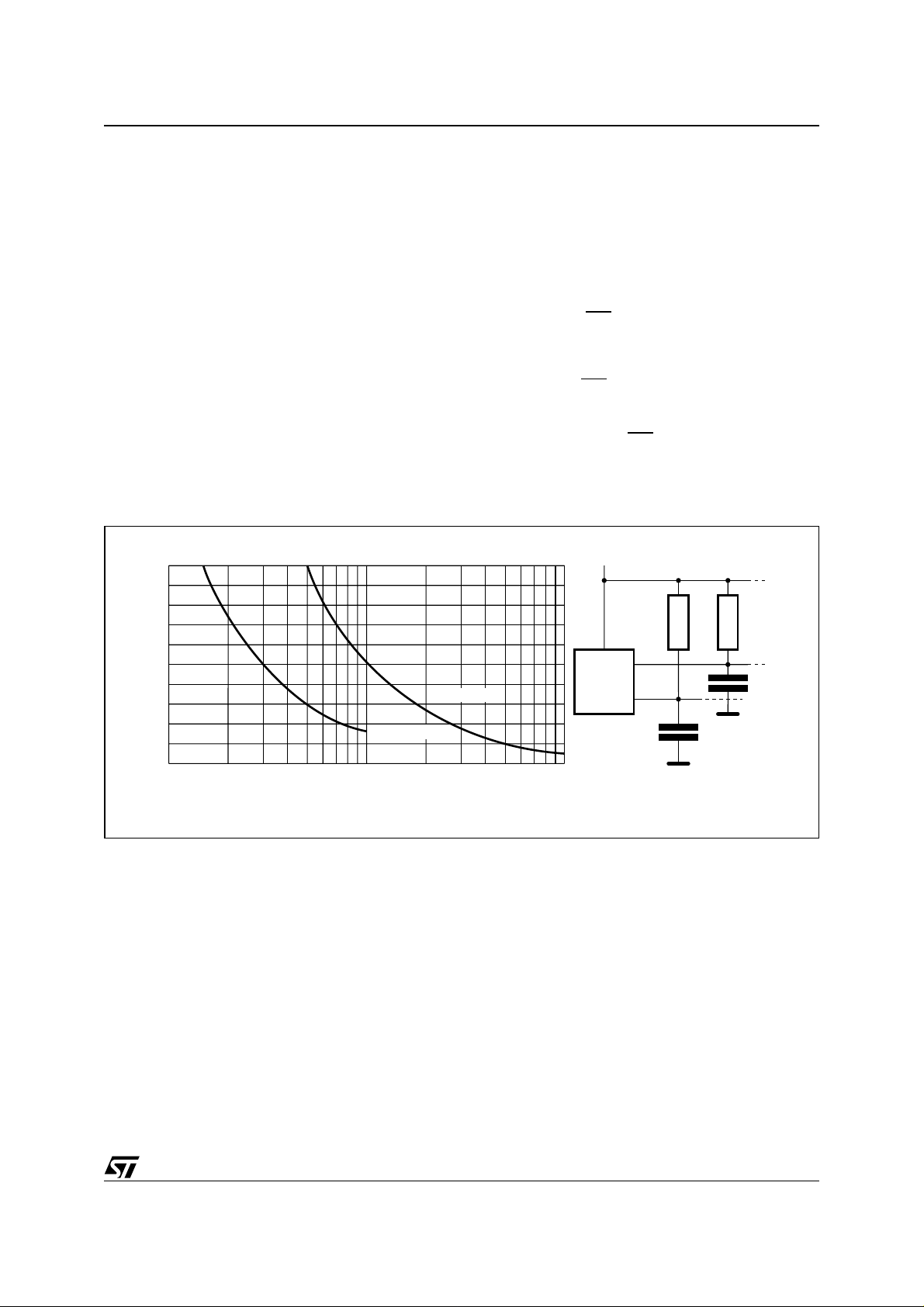

Figure 5. I2C Bus Protocol

SCL

SDA

SCL

SDA

SCL

SDA

START

Condition

START

Condition

1 23 7 89

MSB

1 23 7 89

MSB

SDA

Input

SDA

Change

STOP

Condition

ACK

ACK

STOP

Condition

AI00792B

Table 3. Device Select Code

Device Type Identifier

1

Chip Enable Address

b7 b6 b5 b4 b3 b2 b1 b0

Device Select Code1010E2E1E0RW

Note: 1. The most significant bit, b7, is sent first.

2. E0, E1 and E2 are compared against the respective exte rnal pins on the memory device.

2

RW

Table 4. Most Significant Byte Table 5. Least Significant Byte

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

6/26

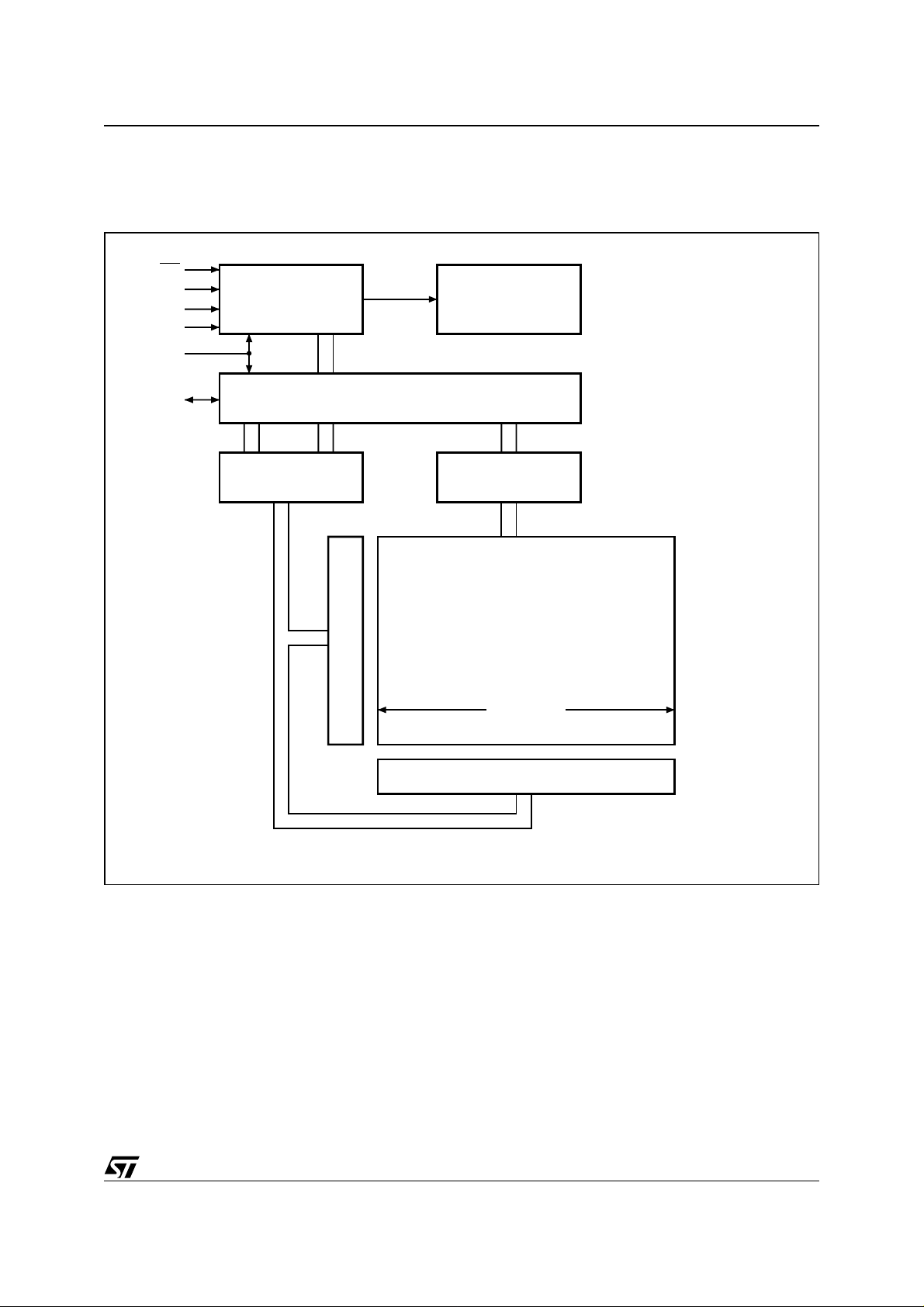

MEMORY ORGANIZATION

The memory is organized as shown in Figure 6..

Figure 6. Block Diagram

WC

E0

E1

E2

SCL

Control Logic

M24C64, M24C32

High Voltage

Generator

SDA

Address Register

and Counter

I/O Shift Register

Data

Register

Y Decoder

1 Page

X Decoder

AI06899

7/26

M24C64, M24C32

DEVICE OPERATION

The device supports the I2C protocol. This is summarized in Figure 5.. Any device that sends d ata

on to the bus is defined to be a transmitter, and

any device that reads the data to be a rec eiver.

The device that controls the data transfer is known

as the bus master, an d th e other a s the s lave device. A data transfer can only be initiated by the

bus master, which will also provide the serial clock

for synchr oniz atio n. Th e M24C xx de vice is alwa ys

a slave in all communication.

Start Condition

Start is identified by a falling edge of Serial Data

(SDA) while Serial Clock (SCL) is stable in the

High state. A Start condition must precede any

data transfer command . The device continuou sly

monitors (except during a Write cycle) Serial Data

(SDA) and Serial Clock (SCL) for a Start condition,

and will not respond unless one is given.

Stop Condition

Stop is identified by a rising edge of Serial Data

(SDA) while Serial Cloc k (S CL) is s tab le a nd d ri ven High. A Stop condition t ermi nate s co mm uni ca tion between the device and the bus master. A

Read command that is follow ed by NoA ck can be

followed by a Sto p condition to force the device

into the Stand-by mode. A S top condition at the

end of a Write command triggers the internal Write

cycle.

Acknowledge Bit (ACK)

The acknowledge bit is used to indicate a successful byte transfer. The bus transmitter, whether it be

bus master or sl ave device, releas es Serial Data

(SDA) after sending ei ght bits of da ta. During the

th

9

clock pulse period, the receiver pulls Serial

Data (SDA) Low to acknowledge the receipt of the

eight data bits.

Data Input

During data input, the device samples Serial Data

(SDA) on the rising edge of Serial Clock (SCL).

For correct device operation, Serial Data (SDA)

must be stable during the rising edge of Serial

Clock (SCL), and the Serial Data (SDA) signal

must change

only

when Serial Cl ock ( SCL ) i s dr iv-

en Low.

Memory Addressing

To start communica tion between the bus master

and the slave device, the b us mas ter m u st ini ti ate

a Start condition. Following this, the bus master

sends the Device Select Code, shown in Table 3.

(on Serial Data (SDA), most significant bit first).

The Device Select Code consists of a 4-bit Device

Type Identifier, and a 3-bit Chip Enable “Address”

(E2, E1, E0). To address the memory array, the 4bit Device Type Identifier is 1010b.

Up to eight memory devices can be connected on

a single I

2

C bus. Each one is gi ven a un ique 3-bit

code on the Chip Enable (E0, E1, E2) inputs.

When the Device Select Code is received, the device only respond s if the Chip Enabl e Address is

the same as the value on the Chip Enable (E0, E1,

E2) inputs.

th

The 8

bit is the Read/Write bit (RW). This bit is

set to 1 for Read and 0 for Write operations.

If a match occurs on the Device Select code, the

corresponding device gives an acknowledgment

on Serial Data (SDA) du ring the 9

th

bit time. If the

device does not match the Devic e Select code, it

deselects itself from the bus, and goes into Standby mode.

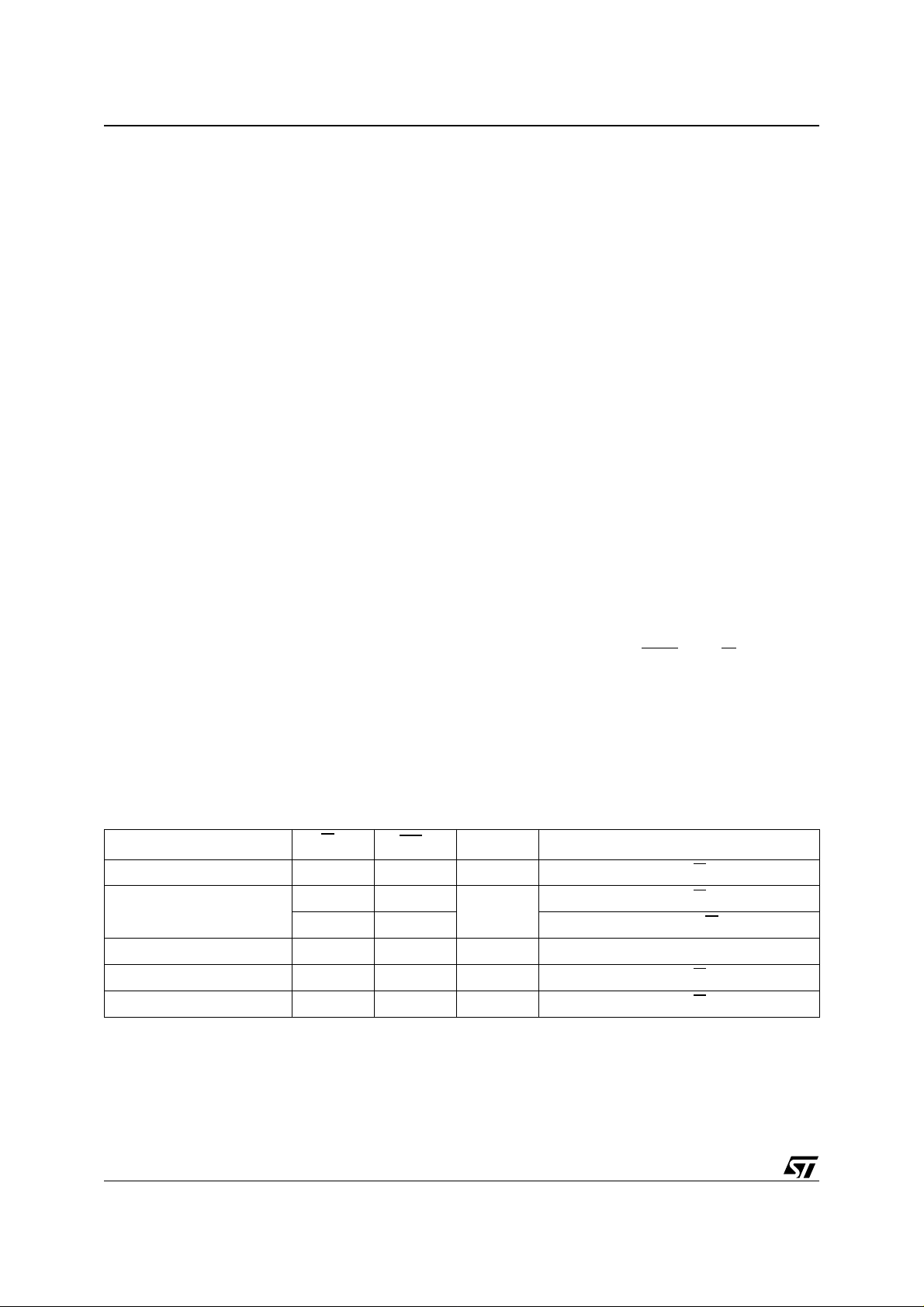

Table 6. Operating Modes

Mode RW bit

Current Address Read 1 X 1 START, Device Select, RW

Random Address Read

Sequential Read 1 X ≥ 1 Similar to Current or Random Address Read

Byte Write 0

Page Write 0

Note: 1. X = V

8/26

IH

or V

.

IL

0X

1 X reSTART, Device Select, RW

WC

V

V

1

IL

IL

Bytes Initial Sequence

= 1

1

START, Device Select, RW

1 START, Device Select, RW = 0

≤ 32 START, Device Select, RW = 0

= 0, Address

= 1

Figure 7. Write Mode Sequences with WC=1 (data write inhibited)

WC

ACK ACK ACK NO ACK

BYTE WRITE DEV SEL BYTE ADDR BYTE ADDR DATA IN

M24C64, M24C32

R/W

START

WC

ACK ACK ACK NO ACK

PAGE WRITE DEV SEL BYTE ADDR

R/W

START

WC (cont'd)

NO ACK NO ACK

PAGE WRITE

(cont'd)

DATA IN N

STOP

Write Operations

Following a Start co ndition the bus mas ter sends

a Device Select Code with the Read/Write

(RW

) reset to 0. The device acknowledges this, as

bit

shown in Figure 8., and waits for two address

bytes. The devi ce res ponds to e ach addres s by te

with an acknowledge bit, and then waits for the

data byte.

Writing to the memory may be inhibited if Write

Control (WC

with Write Control (WC

) is driven Hi gh. Any W rite instruction

) driven High (duri ng a pe riod of time from the Start condition until the end of

the two address bytes) will not modify the memory

contents, and the accompanying data bytes are

not

acknowledged, as shown in Figure 7..

Each data byte in the memory ha s a 16-bit (two

byte wide) address. The Most Significant Byte (Ta-

ble 4.) is sent first, foll owed by the Least Signifi-

cant Byte (Table 5.). Bits b15 to b0 form the

address of the byte in memory.

When the bus master gener ates a Stop conditi on

immediately after t he Ac k bi t (i n th e “1 0

th

bit” time

STOP

BYTE ADDR DATA IN 1

DATA IN 2

AI01120C

slot), either at the end of a Byte Write or a Page

Write, the internal W rite c ycle is tri ggered. A Stop

condition at any other time slot does not trigger the

internal Write cycle.

After the Stop condition, the delay t

, and the suc-

W

cessful completion of a Write operation, the device’s internal address counter is incremented

automatically, to point to the next byte address after the last one that was modified.

During the internal Write cycl e, Serial Data (SDA)

is disabled intern ally, a nd the devic e does n ot respond to any requests.

Byte Write

After the Device Select code and the address

bytes, the bus mas ter sends one d ata byte. If the

addressed location is Write-protected, by Write

Control (WC

) being driven High, the device replies

with NoAck, and the location is not modified. If, instead, the addressed location is not Write-protected, the device replies with Ack. The bus master

terminates the transf er by gener ating a St op condition, as shown in Figure 8..

9/26

Loading...

Loading...