3D accelerometer and 3D gyroscope

Features

■ Analog supply voltage: 2.4 V to 3.6 V

■ Digital supply voltage IOs: 1.8 V

■ Low power mode

■ Power-down mode

■ 3 independent acceleration channels and 3

angular rate channels

■ ±2 g/±4 g/±8 g/±16 g dynamically selectable

full scale

■ ±250/±500/±2000 dps dynamically selectable

full scale

■ SPI/I

■ Programmable interrupt generator for free-fall

■ ECOPACK

2

C serial interface (16-bit data output)

and motion detection

®

RoHS and “Green” compliant

LSM330DLC

iNEMO inertial module:

Preliminary data

LGA-28L (4x5x1.1 mm)

ST’s family of MEMS sensor modules leverages

the robust and mature manufacturing processes

already used for the production of micromachined

accelerometers.

The various sensing elements are manufactured

using specialized micromachining processes,

while the IC interfaces are developed using a

CMOS technology that allows the design of a

dedicated circuit which is trimmed to better match

the sensing element characteristics.

The LSM330DLC has dynamically user-

Application

■ GPS navigation systems

■ Impact recognition and logging

■ Gaming and virtual reality input devices

■ Motion activated functions

■ Intelligent power saving for handheld devices

■ Vibration monitoring and compensation

■ Free-fall detection

■ 6D orientation detection

selectable full scale acceleration range of

±2 g/±4 g/±8 g/±16 g and angular rate of

±250/±500/±2000 deg/sec.

The accelerometer and gyroscope sensors can

be either activated or separately put in Low

power/Power-down mode for applications

optimized for power saving.

The LSM330DLC is available in a plastic land grid

array (LGA) package.

Description

The LSM330DLC is a system-in-package

featuring a 3D digital accelerometer and a 3D

digital gyroscope.

Table 1. Device summary

Part number Temperature range [°C] Package Packing

LSM330DLC -40 to +85

LSM330DLCTR -40 to +85 Tape and reel

LGA-28L (4x5x1.1 mm)

Tr ay

September 2011 Doc ID 022162 Rev 1 1/67

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

www.st.com

67

Contents LSM330DLC

Contents

1 Block diagram and pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Module specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Mechanical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Temperature sensor characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Communication interface characteristics . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4.1 SPI - serial peripheral interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4.2 I2C - inter IC control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Zero-g level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Normal mode, Low power mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1 Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 6D/4D orientation detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.3 “Sleep-to-wake” and “Return to sleep” . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Linear acceleration digital main blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.1 FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.2 Bypass mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.3 FIFO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.4 Stream mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2.5 Stream-to-FIFO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.6 Retrieve data from FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Gyroscope digital main blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4 FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.1 Bypass mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.2 FIFO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/67 Doc ID 022162 Rev 1

LSM330DLC Contents

4.4.3 Stream mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.4 Bypass-to-stream mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.5 Stream-to-FIFO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.6 Retrieve data from FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.5 Level-sensitive / Edge-sensitive data enable . . . . . . . . . . . . . . . . . . . . . . 25

4.5.1 Level-sensitive trigger stamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.5.2 Edge-sensitive trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6 Factory calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Application hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 External capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Soldering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Digital interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 I2C serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1.1 I2C operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 SPI bus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2.1 SPI read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.2 SPI write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2.3 SPI read in 3-wire mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7 Register mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8 Register descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.1 CTRL_REG1_A (20h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2 CTRL_REG2_A (21h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.3 CTRL_REG3_A (22h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.4 CTRL_REG4_A (23h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.5 CTRL_REG5_A (24h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.6 CTRL_REG6_A (25h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.7 REFERENCE/DATACAPTURE_A (26h) . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.8 STATUS_REG_A (27h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.9 OUT_X_L_A (28h), OUT_X_H_A (29h) . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.10 OUT_Y_L_A (2Ah), OUT_Y_H_A (2Bh) . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.11 OUT_Z_L _A (2Ch), OUT_Z_H_A (2Dh) . . . . . . . . . . . . . . . . . . . . . . . . . 44

Doc ID 022162 Rev 1 3/67

Contents LSM330DLC

8.12 FIFO_CTRL_REG_A (2Eh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.13 FIFO_SRC_REG_A (2Fh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.14 INT1_CFG_A (30h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.15 INT1_SRC_A (31h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.16 INT1_THS_A (32h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.17 INT1_DURATION_A (33h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.18 CLICK_CFG _A (38h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.19 CLICK_SRC_A (39h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.20 CLICK_THS_A (3Ah) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.21 TIME_LIMIT_A (3Bh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.22 TIME_LATENCY_A (3Ch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.23 TIME WINDOW_A (3Dh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.24 Act_THS (3Eh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.25 Act_DUR (3Fh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.26 WHO_AM_I_G (0Fh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.27 CTRL_REG1_G (20h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.28 CTRL_REG2_G (21h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.29 CTRL_REG3_G (22h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.30 CTRL_REG4_G (23h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.31 CTRL_REG5_G (24h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.32 REFERENCE_G (25h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.33 OUT_TEMP_G (26h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.34 STATUS_REG_G (27h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.35 OUT_X_L_G (28h), OUT_X_H_G (29h) . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.36 OUT_Y_L_G (2Ah), OUT_Y_H_G (2Bh) . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.37 OUT_Z_L_G (2Ch), OUT_Z_H_G (2Dh) . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.38 FIFO_CTRL_REG_G (2Eh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.39 FIFO_SRC_REG_G (2Fh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.40 INT1_CFG_G (30h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.41 INT1_SRC_G (31h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.42 INT1_THS_XH_G (32h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.43 INT1_THS_XL_G (33h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.44 INT1_THS_YH _G (34h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4/67 Doc ID 022162 Rev 1

LSM330DLC Contents

8.45 INT1_THS_YL_G (35h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.46 INT1_THS_ZH_G (36h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.47 INT1_THS_ZL_G (37h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.48 INT1_DURATION_G (38h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Doc ID 022162 Rev 1 5/67

List of tables LSM330DLC

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

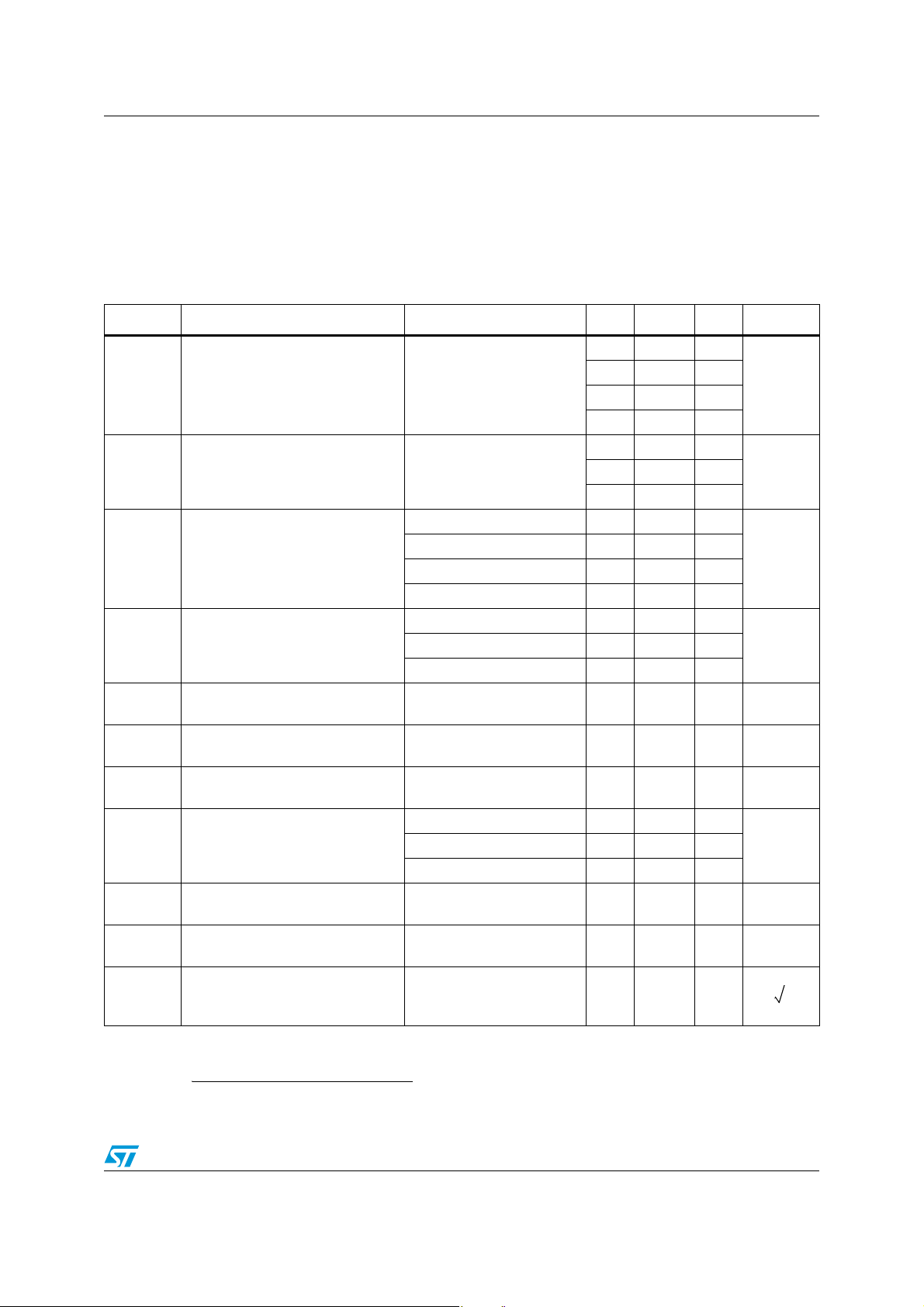

Table 3. Mechanical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

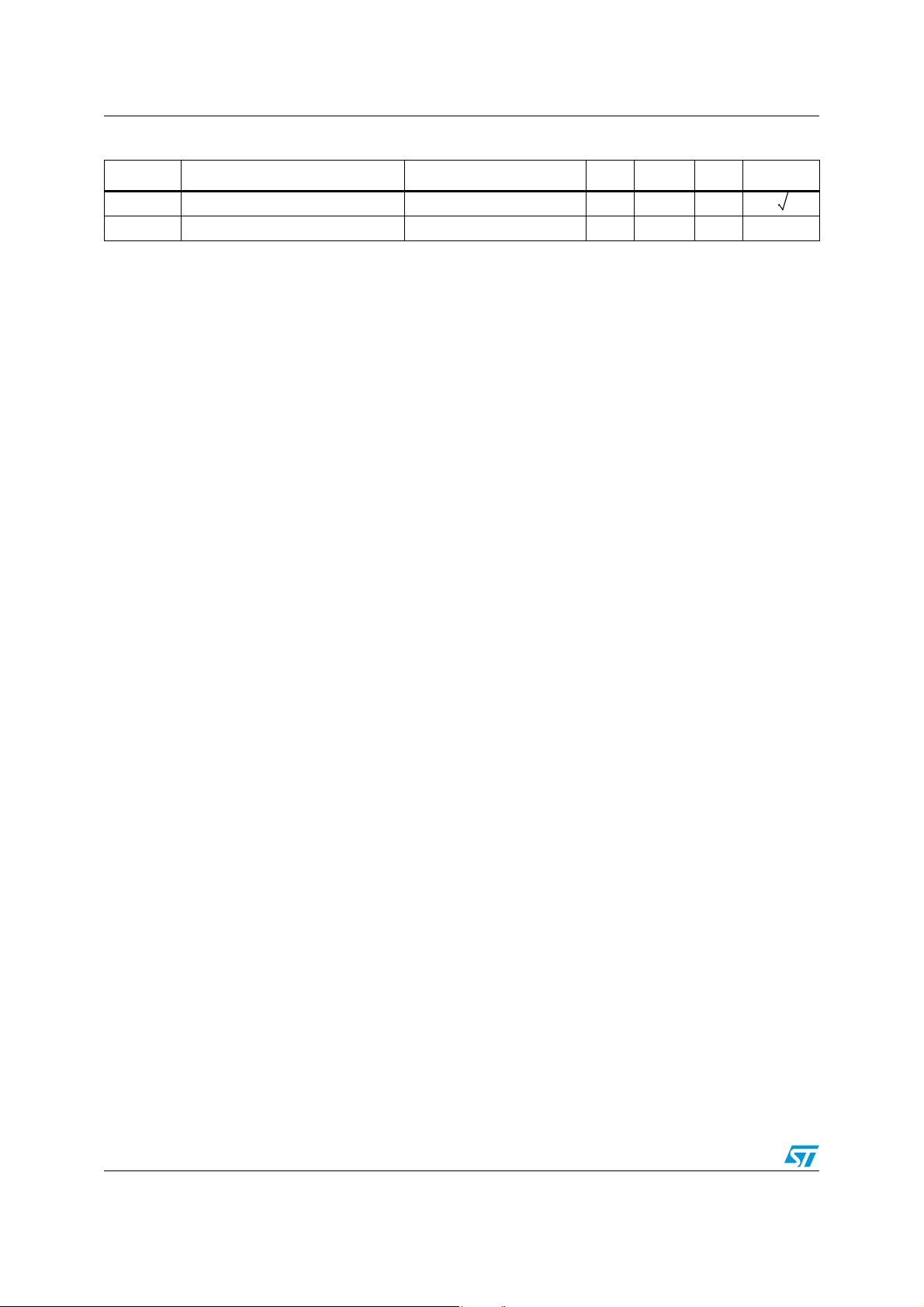

Table 4. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

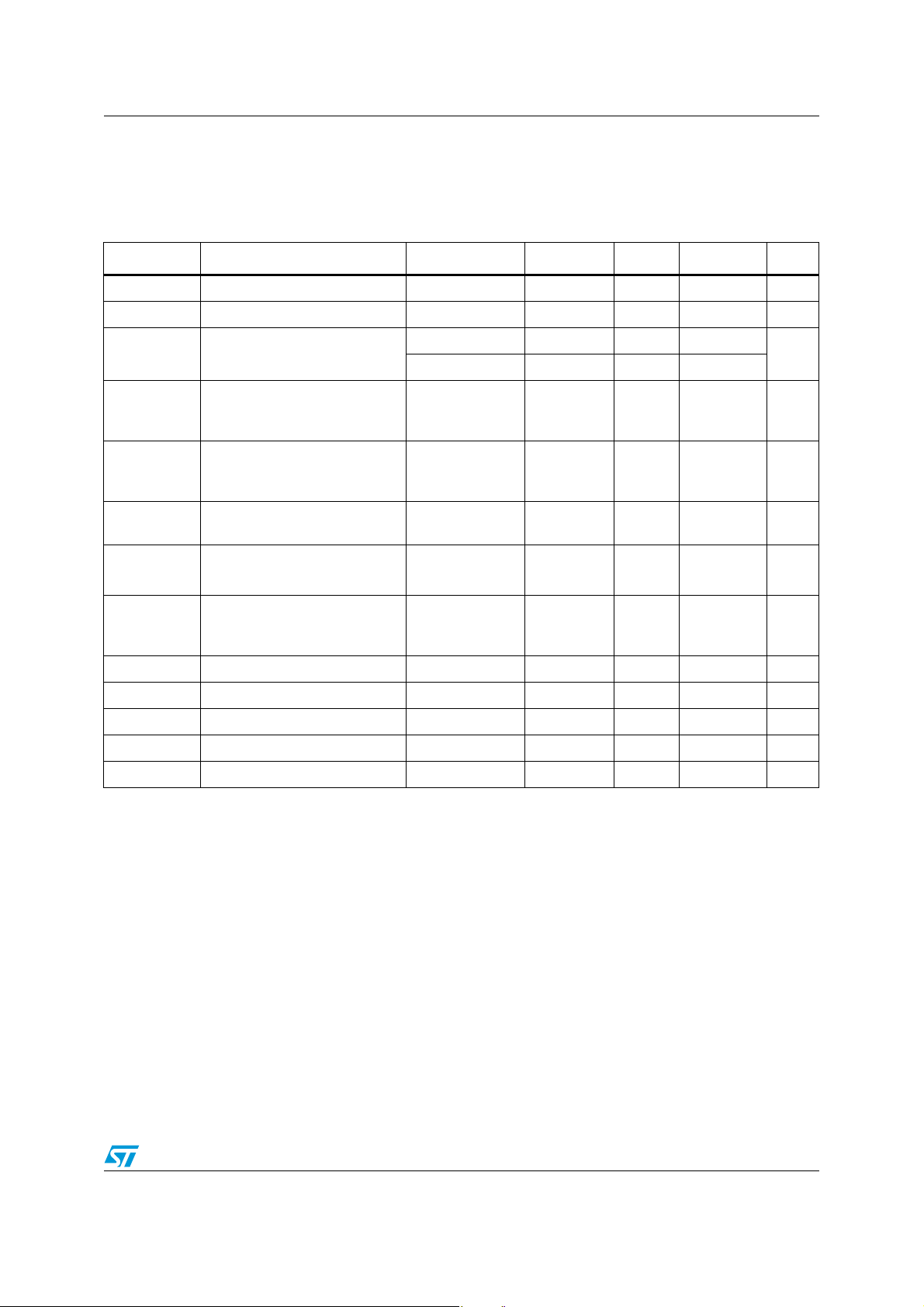

Table 5. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

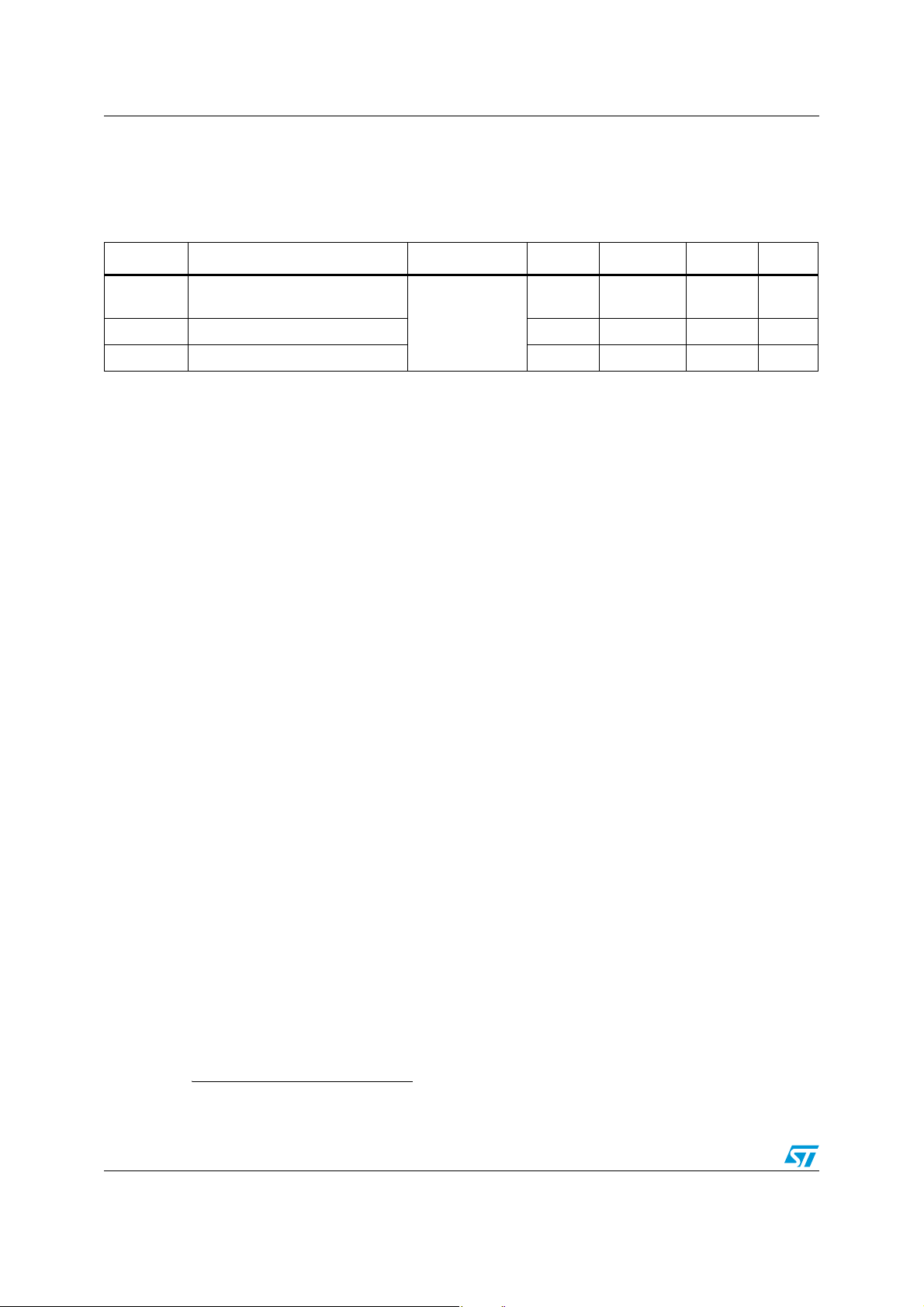

Table 6. SPI slave timing values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 7. I2C slave timing values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 8. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 9. Operating mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 10. Serial interface pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 11. Serial interface pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 12. Transfer when master is writing one byte to slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 13. Transfer when master is writing multiple bytes to slave . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 14. Transfer when master is receiving (reading) one byte of data from slave . . . . . . . . . . . . . 32

Table 15. Transfer when master is receiving (reading) multiple bytes of data from slave . . . . . . . . . 32

Table 16. Linear acceleration SAD+Read/Write patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 17. Angular rate SAD+Read/Write patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 18. Register address map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 19. CTRL_REG1_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 20. CTRL_REG1_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 21. Data rate configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 22. CTRL_REG2_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 23. CTRL_REG2_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 24. High-pass filter mode configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 25. CTRL_REG3_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 26. CTRL_REG3_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 27. CTRL_REG4_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 28. CTRL_REG4_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 29. CTRL_REG5_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 30. CTRL_REG5_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 31. CTRL_REG6_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 32. CTRL_REG6 description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 33. REFERENCE_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 34. REFERENCE register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 35. STATUS_REG_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 36. STATUS_REG_A register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 37. FIFO_CTRL_REG_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 38. FIFO_CTRL_REG_A register description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 39. FIFO mode configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 40. FIFO_SRC_REG_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 41. FIFO_SRC_REG_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 42. INT1_CFG_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 43. INT1_CFG_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 44. Interrupt mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 45. INT1_SRC_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 46. INT1_SRC_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 47. INT1_THS_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 48. INT1_THS_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6/67 Doc ID 022162 Rev 1

LSM330DLC List of tables

Table 49. INT1_DURATION_Aregister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 50. INT1_DURATION_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 51. CLICK_CFG_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 52. CLICK_CFG_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 53. CLICK_SRC_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 54. CLICK_SRC_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 55. CLICK_THS_A register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 56. CLICK_SRC_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 57. TIME_LIMIT_A register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 58. TIME_LIMIT_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 59. TIME_LATENCY_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 60. TIME_LATENCY_A description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 61. TIME_WINDOW_A register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 62. TIME_WINDOW_A description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 63. Act_THS register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 64. Act_THS description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 65. Act_DUR register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 66. Act_DUR description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 67. WHO_AM_I_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 68. CTRL_REG1_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 69. CTRL_REG1_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 70. DR and BW configuration setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 71. Power mode selection configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 72. CTRL_REG2_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 73. CTRL_REG2_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 74. High-pass filter mode configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 75. High-pass filter cut-off frequency configuration [Hz] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 76. CTRL_REG3_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 77. CTRL_REG3_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 78. CTRL_REG4_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 79. CTRL_REG4_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 80. CTRL_REG5_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 81. CTRL_REG5_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 82. REFERENCE_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 83. REFERENCE_G register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 84. OUT_TEMP_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 85. OUT_TEMP_G register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 86. STATUS_REG_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 87. STATUS_REG description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 88. FIFO_CTRL_REG_G register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 89. FIFO_CTRL_REG_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 90. FIFO mode configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 91. FIFO_SRC_REG_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 92. FIFO_SRC_REG_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 93. INT1_CFG_G register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 94. INT1_CFG_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 95. INT1_SRC_G register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 96. INT1_SRC_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 97. INT1_THS_XH_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 98. INT1_THS_XH_G description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 99. INT1_THS_XL_G register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 100. INT1_THS_XL_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Doc ID 022162 Rev 1 7/67

List of tables LSM330DLC

Table 101. INT1_THS_YH_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 102. INT1_THS_YH_G description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 103. INT1_THS_YL_G register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 104. INT1_THS_YL_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 105. INT1_THS_ZH_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 106. INT1_THS_ZH_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 107. INT1_THS_ZL_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 108. INT1_THS_ZL_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 109. INT1_DURATION_G register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 110. INT1_DURATION_G description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 111. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8/67 Doc ID 022162 Rev 1

LSM330DLC List of figures

List of figures

Figure 1. LSM330DLC block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2. Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3. SPI slave timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 4. I2C slave timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 5. Gyroscope block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 6. Bypass mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 7. FIFO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 8. Stream mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 9. Bypass-to-stream mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 10. Trigger stream mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 11. Level-sensitive trigger stamping (LVLen = 1; EXTRen = 0) . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 12. Edge-sensitive trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 13. LSM330DLC electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 14. Read and write protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 15. SPI read protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 16. Multiple-byte SPI read protocol (2-byte example). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 17. SPI write protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 18. Multiple bytes SPI write protocol (2 bytes example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 19. SPI read protocol in 3-wire mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 20. INT1_Sel and Out_Sel configuration block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 21. Wait disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 22. Wait enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 23. LGA-28 (4x5x1.1 mm): mechanical data and package dimensions . . . . . . . . . . . . . . . . . . 65

Doc ID 022162 Rev 1 9/67

Block diagram and pin description LSM330DLC

1 Block diagram and pin description

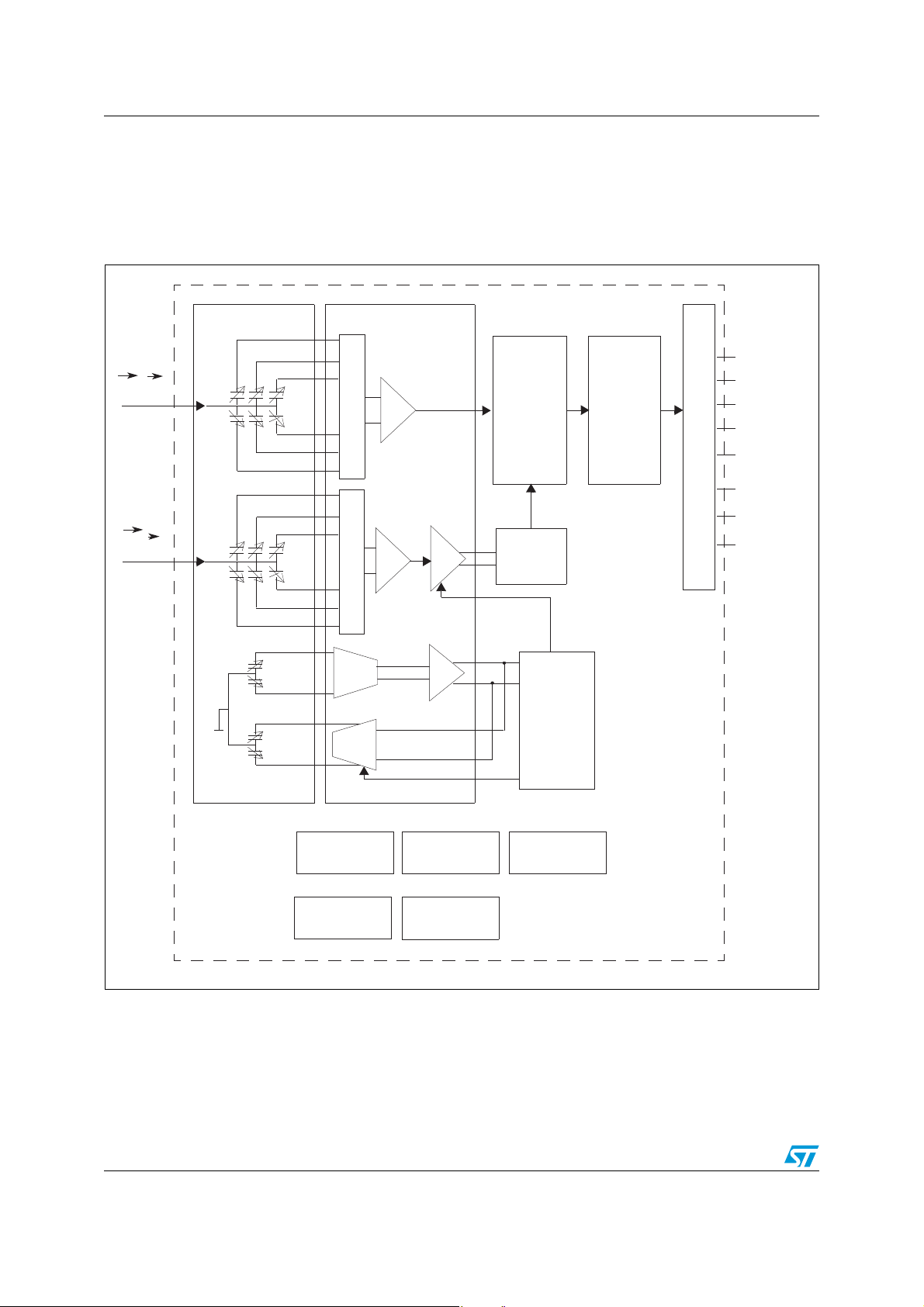

1.1 Block diagram

Figure 1. LSM330DLC block diagram

I (a)

I (

Ω)

Sensing Block

Feedback+

Feedback-

Drive-

Drive+

X+

Sensing Interface

Y+

Z+

Z-

Y-

X-

X+

Y+

Z+

Z-

Y-

X-

MUX

MUX

VOLTAGE

GAIN

AMPLIFIER

CHARGE

AMPLIFIER

+

-

CHARGE

AMPLIFIER

+

-

DEMODULATOR

ANALOG

CONDITIONING

A/D Control

LOW-PASS

FILTER

AUTOMATIC

GAIN

CONTROL

Logicconverter

I2C/SPI

CS_A/G

SDA/SDI_A/G

SDO_A/G

INT1_A

INT2_A

INT1_G

DRDY_G\INT2_

SCL_A/G

REFERENCE

CONTROL LOGIC

&

INTERRUPT GEN.

TRIMMING

CIRCUITS

PHASE

GENERATOR

10/67 Doc ID 022162 Rev 1

CLOCK

AM10160V1

LSM330DLC Block diagram and pin description

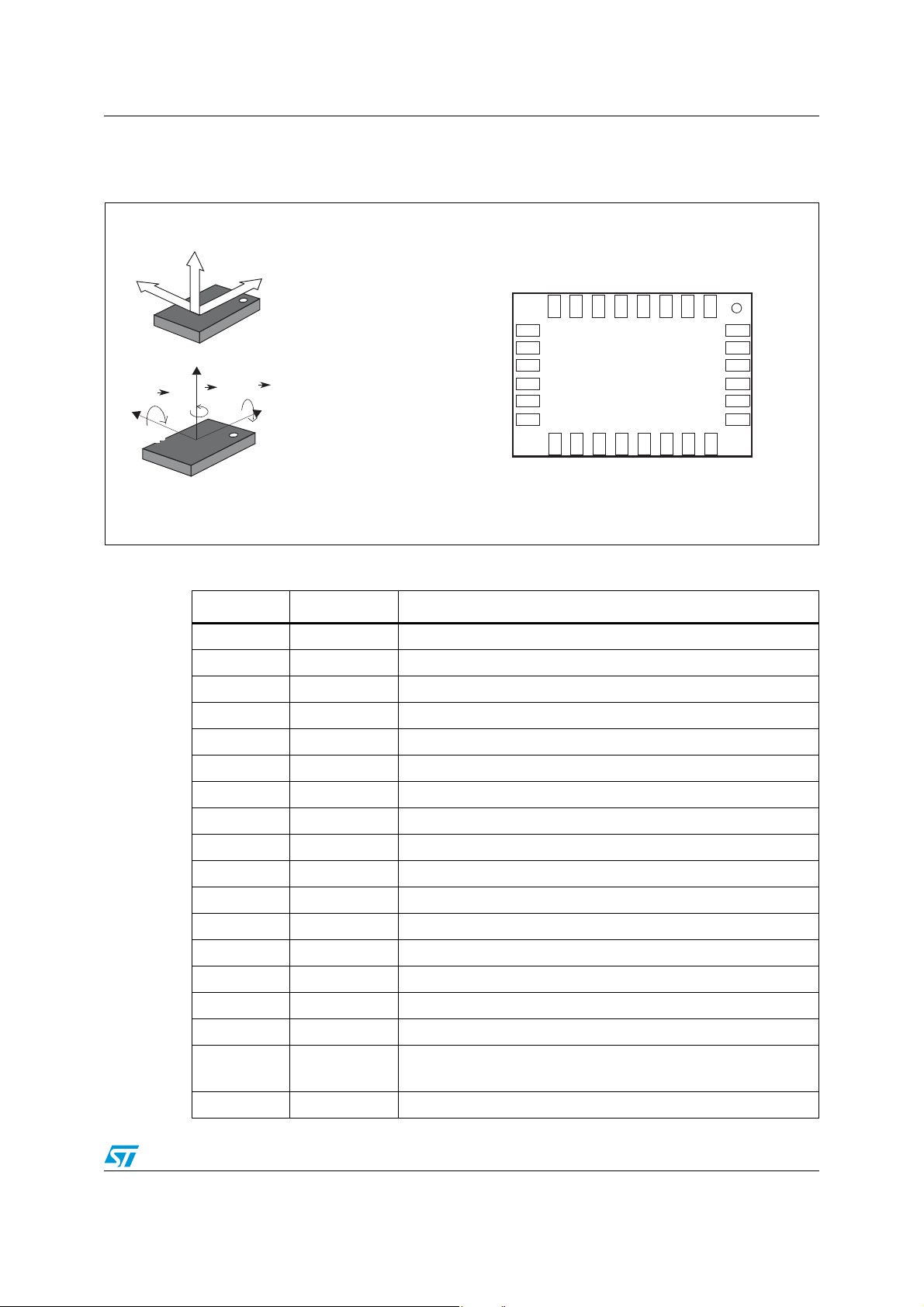

1.2 Pin description

Figure 2. Pin connection

Z

Y

X

1

+Ω

Y

X

DIRECTION OF

DETECTABLE

ACCELERATIONS

Z

+Ω

+Ω

z

1

X

X

INT1_A

INT2_A

INT1_G

DRDY_G/INT2_G

DEN_G

CAP

DIRECTION OF

DETECTABLE

VDD_IO

CS_A

SCL_A/G

CS_G

21

20

(BOTTOM VIEW)

15

14

SDO_A

VDD_IO

SDO_G

28

FILTVDD

FILTIN Y

FILTOUT Y/ OUT Y

SDA_A/G

GND

1

RES

RES

RES

RES

GND

6

7

ANGULAR RATES

RES

RES

RES

RES

RES

VDD

VDD

VDD

AM10161V1

Table 2. Pin description

Pin# Name Function

1 GND 0 V supply

2 Res Reserved. Connect to GND

3 Res Reserved. Connect to GND

4 Res Reserved. Connect to GND

5 Res Reserved. Connect to GND

6 GND 0 V supply

7VddPower supply

8VddPower supply

9VddPower supply

10 Res Reserved. Connect to Vdd

11 Res Reserved. Connect to Vdd

12 Res Reserved. Connect to Vdd

13 Res Reserved. Connect to Vdd

14 Res Reserved. Connect to Vdd

15 Cap Connect to GND with ceramic capacitor, 10 nF (+/-10%), 25 V

16 DEN_G Gyroscope data enable

17

DRDY_G/

INT2_G

Gyroscope data ready/interrupt signal 2

18 INT1_G Gyroscope interrupt signal

Doc ID 022162 Rev 1 11/67

Block diagram and pin description LSM330DLC

Table 2. Pin description (continued)

Pin# Name Function

19 INT2_A Accelerometer interrupt signal

20 INT1_A Accelerometer interrupt signal

21 Vdd_IO Power supply for IO pins

Gyroscope: SPI enable

22 CS_G

23 CS_A

24 SCL_A/G I

25 Vdd_IO Power supply for IO pins

26 SDO_G

27 SDO_A

28 SDA_A/G

2

C/SPI mode selection (1: SPI idle mode / I2C communication

I

enabled; 0: SPI communication mode / I2C disabled)

Accelerometer: SPI enable

2

C/SPI mode selection (1: SPI idle mode / I2C communication

I

enabled; 0: SPI communication mode / I

2

C serial clock (SCL)/SPI serial port clock (SPC)

2

C disabled)

Gyroscope:

SPI serial data output (SDO)

2

C least significant bit of the device address (SA0)

I

Accelerometer:

SPI serial data output (SDO)

I2C least significant bit of the device address (SA0)

2

I

C serial data (SDA)

SPI serial data input (SDI)

3-wire interface serial data output (SDO)

12/67 Doc ID 022162 Rev 1

LSM330DLC Module specifications

z

2 Module specifications

2.1 Mechanical characteristics

@ Vdd = 3V, T = 25 °C unless otherwise noted

Table 3. Mechanical characteristics

Symbol Parameter Test conditions Min. Typ.

LA_FS

G_FS

LA_So Linear acceleration sensitivity

G_So Angular rate sensitivity

LA_So

G_SoDr

LA_TyOff

G_TyOff

LA_TCOff

G_TCOff

An Acceleration noise density

Linear acceleration measurement

(2)

range

Angular rate

measurement range

Linear acceleration sensitivity

change vs. temperature

Angular rate sensitivity change vs.

temperature

Linear acceleration typical zero-g

level offset accuracy

Angular rate typical zero-rate

(4)

level

Linear acceleration zero-g level

change vs. temperature

Zero-rate level change vs.

temperature

(3)

(3)

User-selectable

User-selectable

FS = ±2 g 1

FS = ±4 g 2

FS = ±8 g 4

FS = ±16 g 12

FS = ±250 dps 8.75

FS = ±500 dps 17.50

FS = ±2000 dps 70

FS = ±2 g ±0.05 %/°C

From -40 °C to +85 °C ±2 %

FS bit set to 00 ±60 mg

FS = 250 dps ±10

FS = 2000 dps ±25

Max delta from 25 °C ±0.5 mg/°C

FS = ±2 g, Normal mode

Ta bl e 9 , ODR bit set to

1001 Ta b le 1 9

(a)

(1)

Max. Unit

±2

±4

±8

±16

±250

±2000

±0.2 dps/°C

220 µg/

g

dps±500

mg/digit

mdps/

digit

dpsFS = 500 dps ±15

H

a. The product is factory calibrated at 3.0 V. The operational power supply range is from 2.4 V to 3.6 V.

Doc ID 022162 Rev 1 13/67

Module specifications LSM330DLC

z

Table 3. Mechanical characteristics (continued)

Symbol Parameter Test conditions Min. Typ.

(1)

Max. Unit

Rn Rate noise density FS = ±250 dps, BW = 50 Hz 0.03 dps/

Top Operating temperature range -40 +85 °C

1. Typical specifications are not guaranteed.

2. Verified by wafer level test and measurement of initial offset and sensitivity.

3. Typical zero-g level offset value after MSL3 preconditioning.

4. Offset can be eliminated by enabling the built-in high-pass filter.

H

14/67 Doc ID 022162 Rev 1

LSM330DLC Module specifications

2.2 Electrical characteristics

@ Vdd = 3 V, T = 25 °C unless otherwise noted

Table 4. Electrical characteristics

Symbol Parameter Test conditions Min. Typ.

Vdd Supply voltage 2.4 3.6 V

Vdd_IO Power supply for I/O 1.71 Vdd+0.1 V

LA_Idd

LA_IddLowP

LA_IddPdn

G_Idd

Accelerometer current

consumption in Normal mode

Accelerometer current

consumption in Low power

mode

Accelerometer current

consumption in Power-down

mode

Gyroscope current

consumption in Normal mode

ODR = 50 Hz 11

ODR = 1 Hz 2

ODR = 50 Hz 6 µA

(1)

0.5 µA

6.1 mA

Max. Unit

µA

G_IddLowP

G_IddPdn

VIH Digital high level input voltage 0.8*Vdd_IO V

VIL Digital low level input voltage 0.2*Vdd_IO V

VOH High level output voltage 0.9*Vdd_IO V

VOL Low level output voltage 0.1*Vdd_IO V

Top Operating temperature range -40 +85

1. Typical specifications are not guaranteed.

2. Sleep mode introduces a faster turn-on time compared to Power-down mode.

Gyroscope supply current

in Sleep mode

Gyroscope current

consumption in Power-down

mode

(2)

2mA

5µA

°C

Doc ID 022162 Rev 1 15/67

Module specifications LSM330DLC

2.3 Temperature sensor characteristics

@ Vdd = 3V, T = 25 °C unless otherwise noted

Table 5. Electrical characteristics

Symbol Parameter Test condition Min. Typ.

(b)

(1)

Max. Unit

TSDr

TODR Temperature refresh rate 1 Hz

Top Operating temperature range -40 +85 °C

1. Typical specifications are not guaranteed.

Temperature sensor output

change vs. temperature

-1 °C/digit

-

b. The product is factory calibrated at 3.0 V.

16/67 Doc ID 022162 Rev 1

LSM330DLC Module specifications

t

t

t

t

t

t

t

t

2.4 Communication interface characteristics

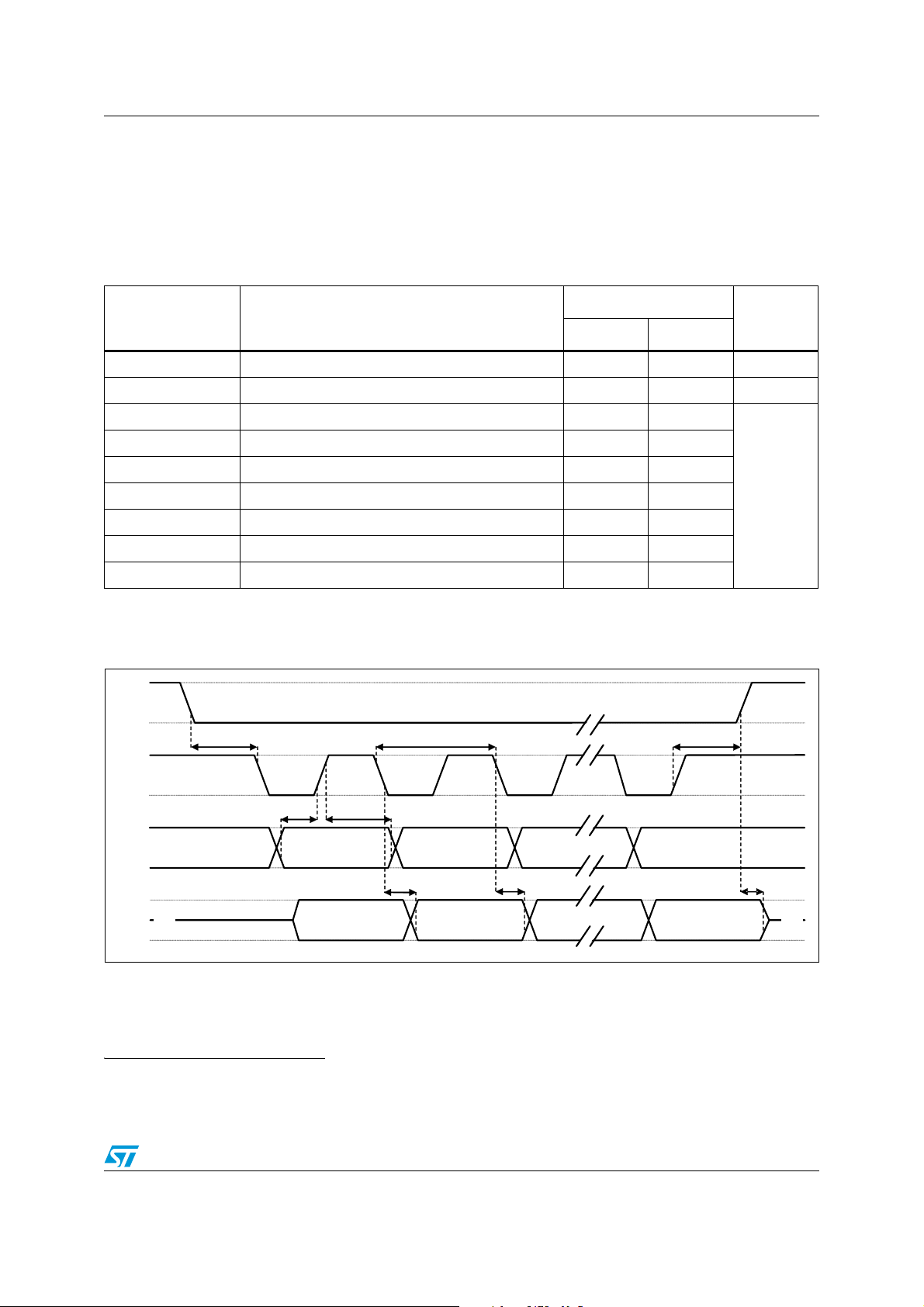

2.4.1 SPI - serial peripheral interface

Subject to general operating conditions for Vdd and TOP.

Table 6. SPI slave timing values

(1)

Val u e

Symbol Parameter

Min Max

tc(SPC) SPI clock cycle 100 ns

fc(SPC) SPI clock frequency 10 MHz

tsu(CS) CS setup time 6

th(CS) CS hold time 8

tsu(SI) SDI input setup time 5

th(SI) SDI input hold time 15

tv(SO) SDO valid output time 50

th(SO) SDO output hold time 9

tdis(SO) SDO output disable time 50

Unit

ns

1. Values are guaranteed at 10 MHz clock frequency for SPI with both 4 and 3 wires, based on characterization results. Not

tested in production.

(c)(d)

Figure 3. SPI slave timing diagram

CS

(3)

su(CS)

SPC

(3)

h(SI)

MSB IN

MSB OUT

SDI

SDO

su(SI)

(3)

(3)

v(SO)

c(SPC)

h(SO)

h(CS)

LSB IN

LSB OUT

dis(SO)

3. Data on CS, SPC, SDI and SDO refer to pins: CS_A, CS_G, SCL_A/G, SDA_A/G, SDO_A / SDO_G.

(3)

(3)

(3)

(3)

c. The SDO output line features an internal pull-up.

d. Measurement points are done at 0.2·Vdd_IO and 0.8·Vdd_IO, for both input and output ports.

Doc ID 022162 Rev 1 17/67

Module specifications LSM330DLC

W

W

W

W

W

W

W

W

W

W

W

W

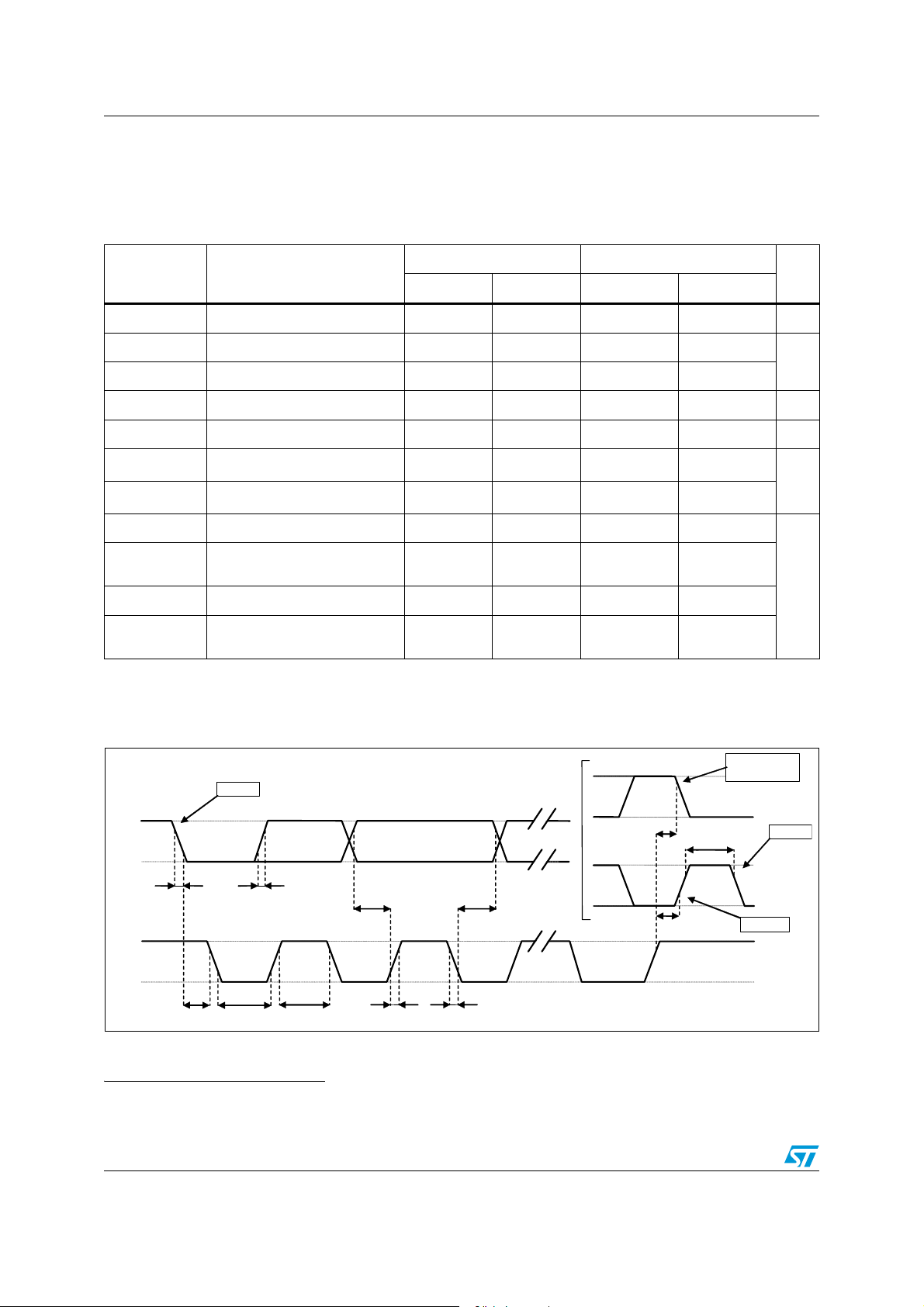

2.4.2 I2C - inter IC control interface

Subject to general operating conditions for Vdd and TOP.

Table 7. I2C slave timing values

Symbol Parameter

(1)

I2C standard mode

(1)

I2C fast mode

Min Max Min Max

(1)

Unit

f

(SCL)

t

w(SCLL)

t

w(SCLH)

t

su(SDA)

t

h(SDA)

t

r(SDA) tr(SCL)

t

f(SDA) tf(SCL)

t

h(ST)

t

su(SR)

t

su(SP)

t

w(SP:SR)

1. SCL (SCL_A/G pin), SDA (SDA_A/G pin)

2. Cb = total capacitance of one bus line, in pF

Figure 4. I

SCL clock frequency 0 100 0 400 KHz

SCL clock low time 4.7 1.3

SCL clock high time 4.0 0.6

SDA setup time 250 100 ns

SDA data hold time 0.01 3.45 0 0.9 µs

SDA and SCL rise time 1000

SDA and SCL fall time 300

START condition hold time 4 0.6

Repeated START condition

setup time

STOP condition setup time 4 0.6

Bus free time between STOP

and START condition

2

C slave timing diagram

67$57

(e)

20 + 0.1C

20 + 0.1C

4.7 0.6

4.7 1.3

µs

(2)

b

(2)

b

300

ns

300

µs

5(3($7('

67$57

6'$

I6'$

U6'$

VX6'$

K6'$

6&/

Z6&//

K67

e. Measurement points are done at 0.2·Vdd_IO and 0.8·Vdd_IO, for both ports

Z6&/+

U6&/

I6&/

18/67 Doc ID 022162 Rev 1

VX65

VX63

Z6365

67$57

6723

!-V

LSM330DLC Module specifications

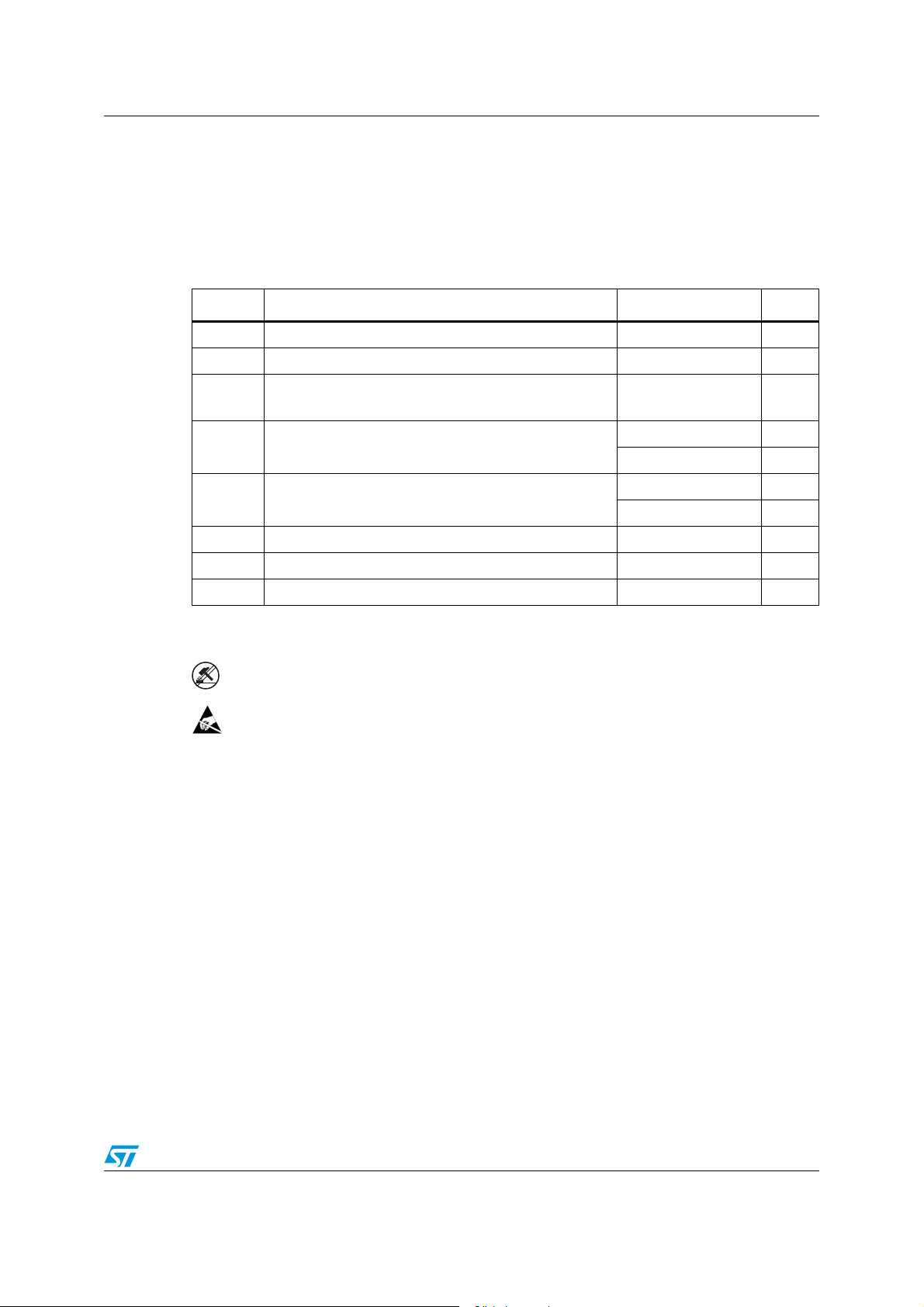

2.5 Absolute maximum ratings

Stresses above those listed as “absolute maximum ratings” may cause permanent damage

to the device. This is a stress rating only and functional operation of the device under these

conditions is not implied. Exposure to maximum rating conditions for extended periods may

affect device reliability.

Table 8. Absolute maximum ratings

Symbol Ratings Maximum value Unit

Vdd Supply voltage -0.3 to 4.8 V

Vdd_IO I/O pins supply voltage -0.3 to 4.8 V

Input voltage on any control pin (SCL_A/G, SDA_A/G,

SDO_A, SDO_G, CS_A, CS_G, DEN_G)

Acceleration (any axis, powered, Vdd = 3 V)

Acceleration (any axis, unpowered)

Operating temperature range -40 to +85 °C

OP

Storage temperature range -40 to +125 °C

A

A

T

T

Vin

POW

UNP

STG

ESD Electrostatic discharge protection 2 (HBM) kV

1. Supply voltage on any pin should never exceed 4.8 V.

(1)

-0.3 to Vdd_IO +0.3 V

3000 g for 0.5 ms

10000 g for 0.1 ms

3000 g for 0.5 ms

10000 g for 0.1 ms

This is a mechanical shock sensitive device, improper handling can cause permanent

damage to the part.

This is an ESD sensitive device, improper handling can cause permanent damage to

the part.

Doc ID 022162 Rev 1 19/67

Terminology LSM330DLC

3 Terminology

3.1 Sensitivity

Linear acceleration sensitivity can be determined e.g. by applying 1 g acceleration to the

device. Because the sensor can measure DC accelerations, this can be done easily by

pointing the selected axis towards the ground, noting the output value, rotating the sensor

180 degrees (pointing towards the sky) and noting the output value again. By doing so, ±1 g

acceleration is applied to the sensor. Subtracting the larger output value from the smaller

one, and dividing the result by 2, leads to the actual sensitivity of the sensor. This value

changes very little over temperature and over time. The sensitivity tolerance describes the

range of sensitivities of a large number of sensors.

Angular Rate Sensitivity describes the angular rate gain of the sensor and can be

determined by applying a defined angular velocity to it. This value changes very little over

temperature and also very little over time.

3.2 Zero-g level

Linear acceleration zero-g level offset (TyOff) describes the deviation of an actual output

signal from the ideal output signal if no acceleration is present. A sensor in a steady state on

a horizontal surface will measure 0 g on both the X axis and Y axes, whereas the Z axis will

measure 1 g. Ideally, the output is in the middle of the dynamic range of the sensor (content

of OUT registers 00h, data expressed as 2’s complement number). A deviation from the

ideal value in this case is called zero-g offset.

Offset is to some extent a result of stress to MEMS sensor and therefore the offset can

slightly change after mounting the sensor onto a printed circuit board or exposing it to

extensive mechanical stress. Offset changes little over temperature, see “Linear

acceleration zero-g level change vs. temperature” in Ta bl e 3 . The zero-g level tolerance

(TyOff) describes the standard deviation of the range of zero-g levels of a group of sensors.

Angular rate zero-rate level describes the actual output value if there is no angular rate

present. zero-rate level of precise MEMS sensors is, to some extent, a result of stress to the

sensor and therefore zero-rate level can slightly change after mounting the sensor onto a

printed circuit board or after exposing it to extensive mechanical stress. This value changes

very little over temperature and over time.

20/67 Doc ID 022162 Rev 1

LSM330DLC Functionality

4 Functionality

The LSM330DLC is a system-in-package featuring a 3D digital accelerometer and a 3D

digital gyroscope.

The device includes specific sensing elements and two IC interfaces capable to measuring

both the acceleration and angular rate applied to the module and to provide a signal to

external applications through an SPI/I

The various sensing elements are manufactured using specialized micromachining

processes, while the IC interfaces are developed using a CMOS technology that allows the

design of a dedicated circuit which is trimmed to better match the sensing element

characteristics.

The LSM330DLC may also be configured to generate an inertial wakeup and free-fall

interrupt signal according to a programmed acceleration event along the enabled axes.

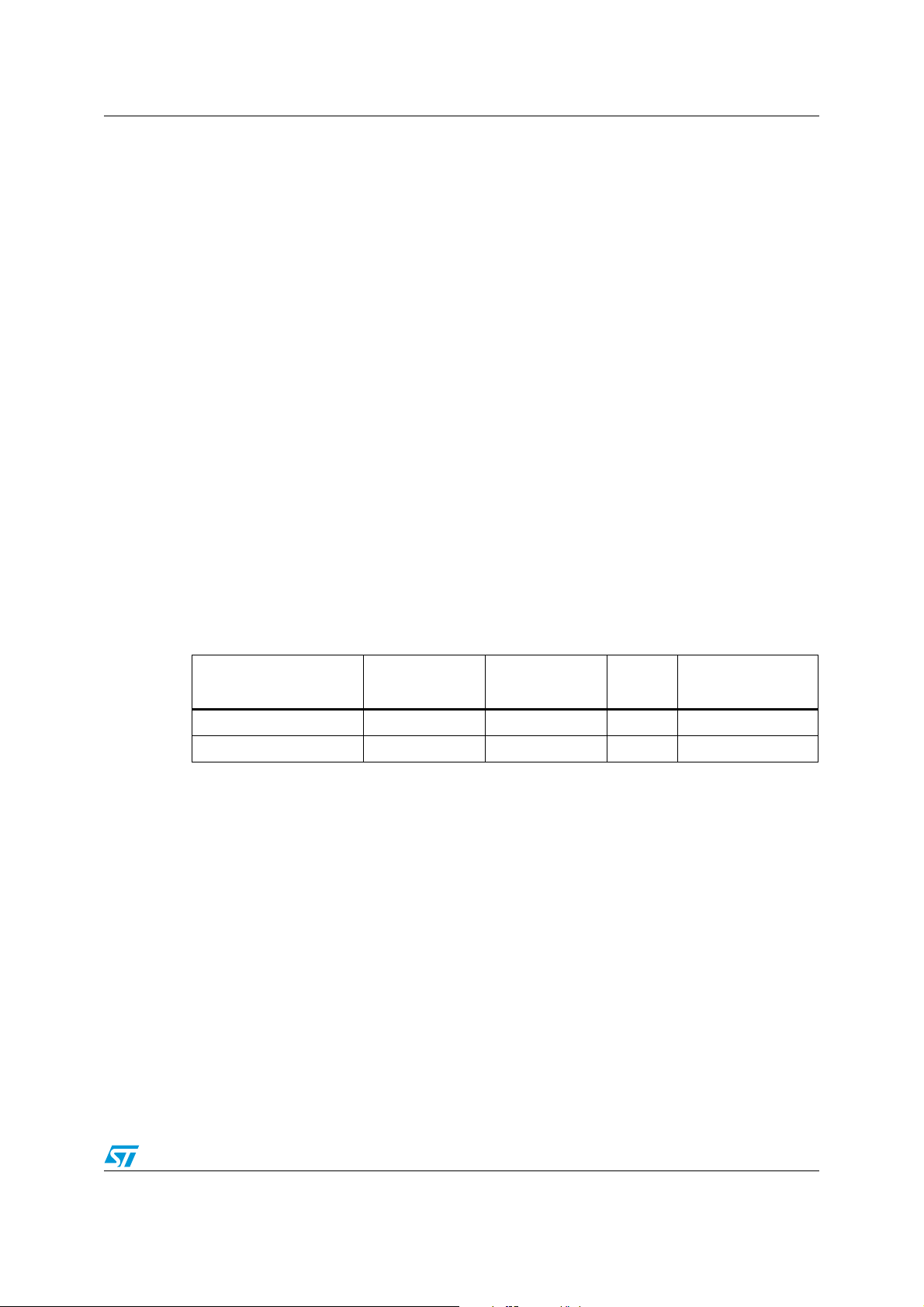

4.1 Normal mode, Low power mode

The LSM330DLC provides two different operating modes: Normal mode and Low power

mode. Normal mode guarantees high resolution, while Low power mode further reduces

current consumption.

2

C serial interface.

The table below summarizes how to select the operating mode and the corresponding

characteristics.

Table 9. Operating mode selection

Operating mode

Low power mode (8-bit) 1 0 ODR/2 1

Normal mode (12-bit) 0 1 ODR/9 7/ODR(kHz)

CTRL_REG1[3]

(LPen bit)

4.1.1 Self-test

Self-test allows the checking of sensor functionality without moving it. The self-test function

is off when the self-test bit (ST) is programmed to ‘0’. When the self-test bit is programmed

to ‘1’ an actuation force is applied to the sensor, simulating a definite input acceleration. In

this case, the sensor outputs exhibit a change in their DC levels which are related to the

selected full scale through the device sensitivity. When self-test is activated, the device

output level is given by the algebraic sum of the signals produced by the acceleration acting

on the sensor and by the electrostatic test-force. If the output signals change within the

amplitude specified in Ta bl e 3 , then the sensor is working properly and the parameters of

the interface chip are within the defined specifications.

4.1.2 6D/4D orientation detection

CTRL_REG4[3]

(HR bit)

BW [Hz] Turn-on time [ms]

The LSM330DLC includes 6D/4D orientation detection. In this configuration the interrupt is

generated when the device is stable in a known direction. In 4D configuration, Z axis

position detection is disabled.

Doc ID 022162 Rev 1 21/67

Loading...

Loading...