LD49150XX10, LD49150XX12

1.5 A very low drop for low output voltage regulator

Features

■ Input voltage range:

–V

= 1.4 V to 5.5 V

I

–V

■ Stable with ceramic capacitor

■ ±1.5 % initial tolerance

■ Maximum dropout voltage (V

over temperature

■ Adjustable output voltage down to 0.8 V

■ Ultra fast transient response (up to 10 MHz

bandwidth)

■ Excellent line and load regulation

specifications

■ Logic controlled shutdown option

■ Thermal shutdown and current limit protection

■ Junction temperature range: - 25 °C to 125 °C

Applications

■ Graphics processors

■ PC add-in cards

■ Microprocessor core voltage supply

■ Low voltage digital ICs

■ High efficiency linear power supplies

■ SMPS post regulators

= 3 V to 6 V

BIAS

- VO) of 200 mV

I

LD49150XX08

PPAK

Description

The LD49150xx is a high-bandwidth, low-dropout,

1.5 A voltage regulator, ideal for powering core

voltages of low-power microprocessors. The

LD49150xx implements a dual supply

configuration allowing for very low output

impedance and very fast transient response. The

LD49150xx requires a bias input supply and a

main input supply, allowing for ultra-low input

voltages on the main supply rail. The input supply

operates from 1.4 V to 5.5 V and the bias supply

requires between 3 V and 6 V for proper

operation. The LD49150xx offers fixed output

voltages from 0.8 V to 1.8 V and adjustable output

voltages down to 0.8 V. The LD49150xx requires a

minimum output capacitance for stability, and

work optimally with small ceramic capacitors.

DFN6 (3x3 mm)

Table 1. Device summary

Order codes

PPAK (tape and reel) DFN6 (tape and reel)

LD49150PT08R 0.8 V

LD49150PT10R LD49150PU10R 1.0 V

LD49150PT12R LD49150PU12R 1.2 V

1. Available on request.

2. Adjustable version.

June 2010 Doc ID 13446 Rev 3 1/22

(1)

Output voltages

(2)

www.st.com

22

Contents LD49150XX08, LD49150XX10, LD49150XX12

Contents

1 Typical application circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Alternative application circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

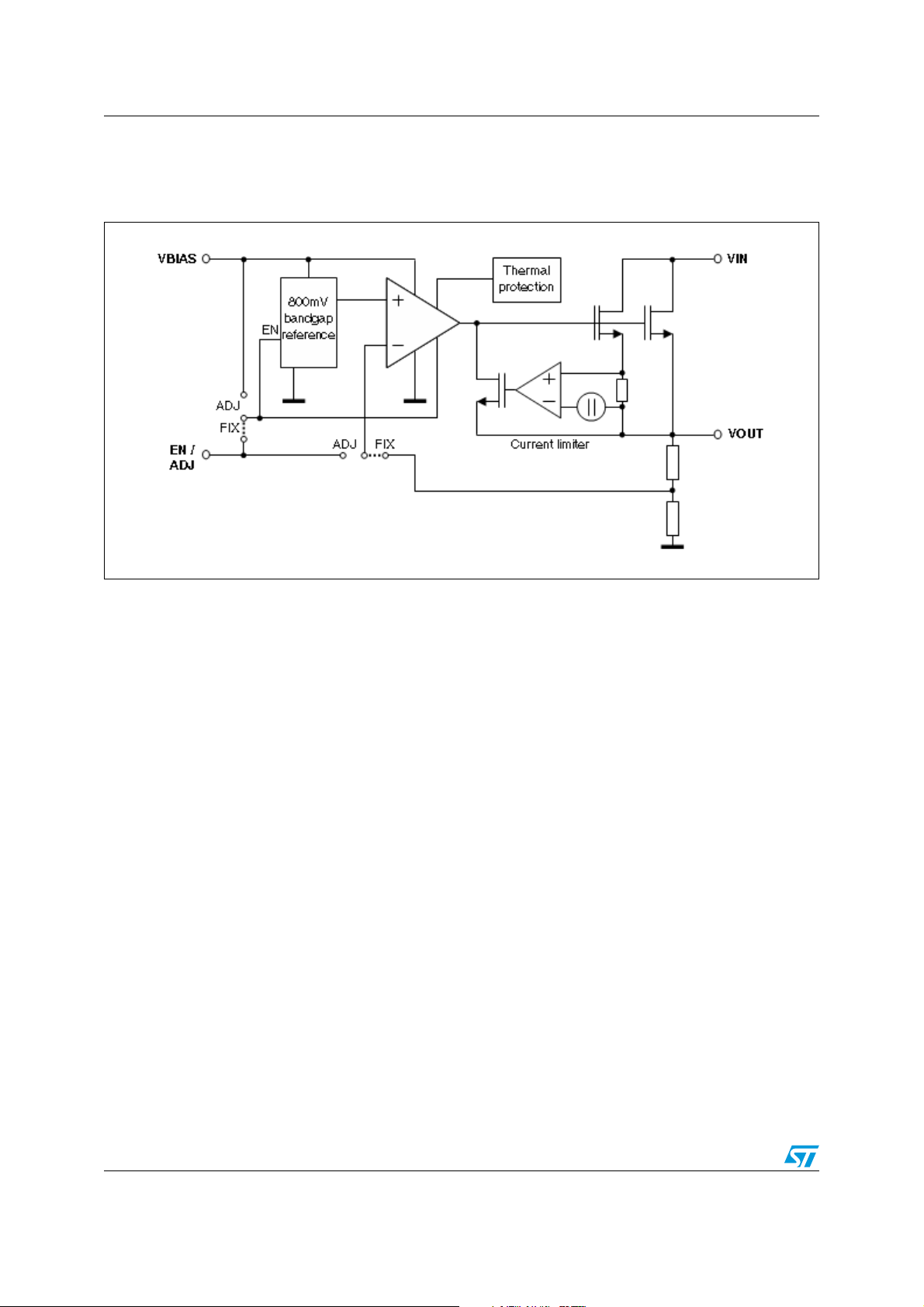

4 Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Typical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 Application hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.1 Input supply voltage (VIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.2 Bias supply voltage (V

8.3 External capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.4 Output capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.5 Minimum load current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.6 Power sequencing recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.7 Power dissipation/heatsinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.8 Heatsinking PPAK package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.9 Adjustable regulator design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.10 Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

BIAS

9 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22 Doc ID 13446 Rev 3

LD49150XX08, LD49150XX10, LD49150XX12 Typical application circuits

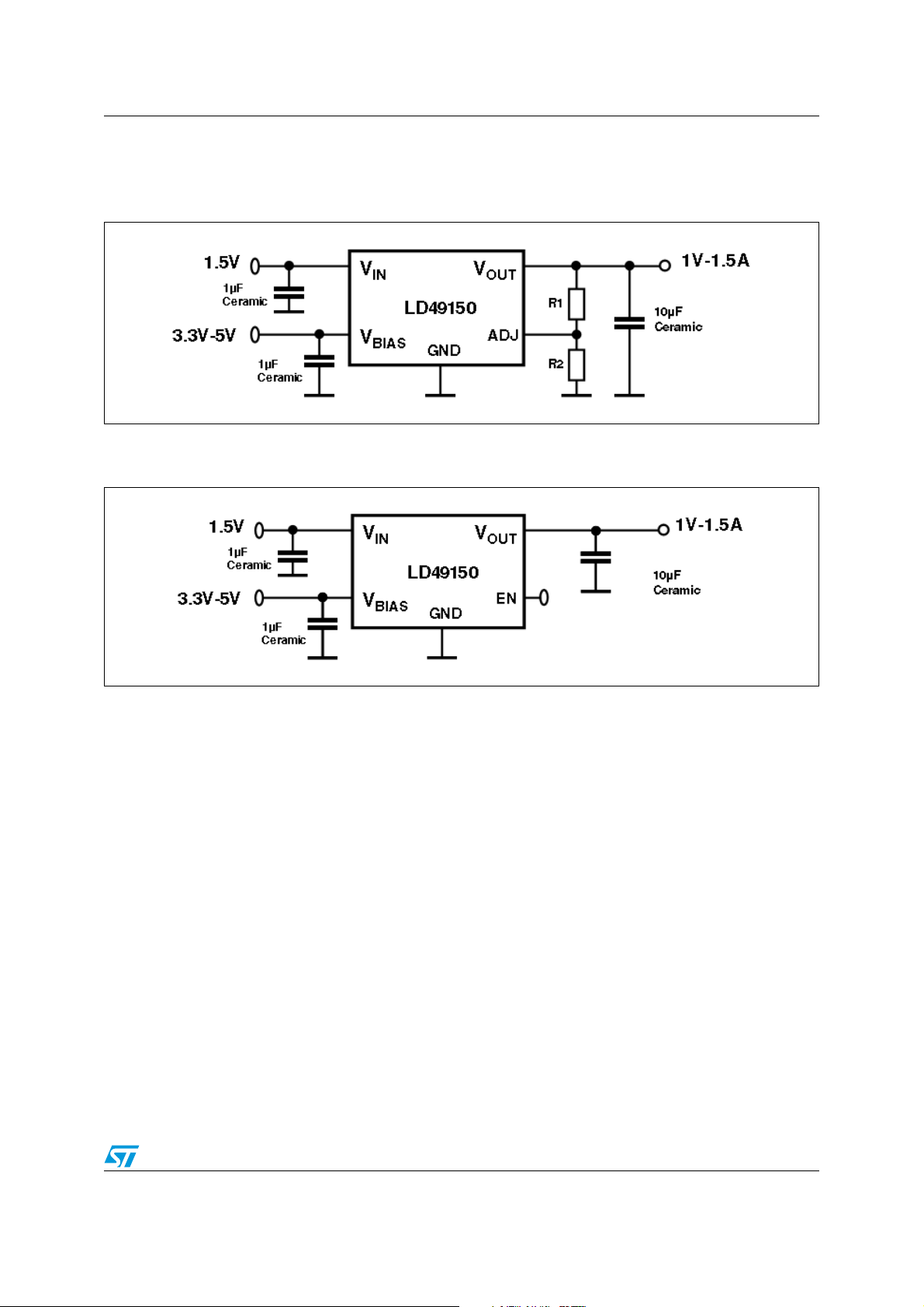

1 Typical application circuits

Figure 1. Adjustable version

Figure 2. Fixed version with Enable

Doc ID 13446 Rev 3 3/22

Alternative application circuits LD49150XX08, LD49150XX10, LD49150XX12

2 Alternative application circuits

Figure 3. Single supply voltage solution

Figure 4. LD49150xx plus DC-DC pre-regulator to reduce power dissipation

4/22 Doc ID 13446 Rev 3

LD49150XX08, LD49150XX10, LD49150XX12 Pin configuration

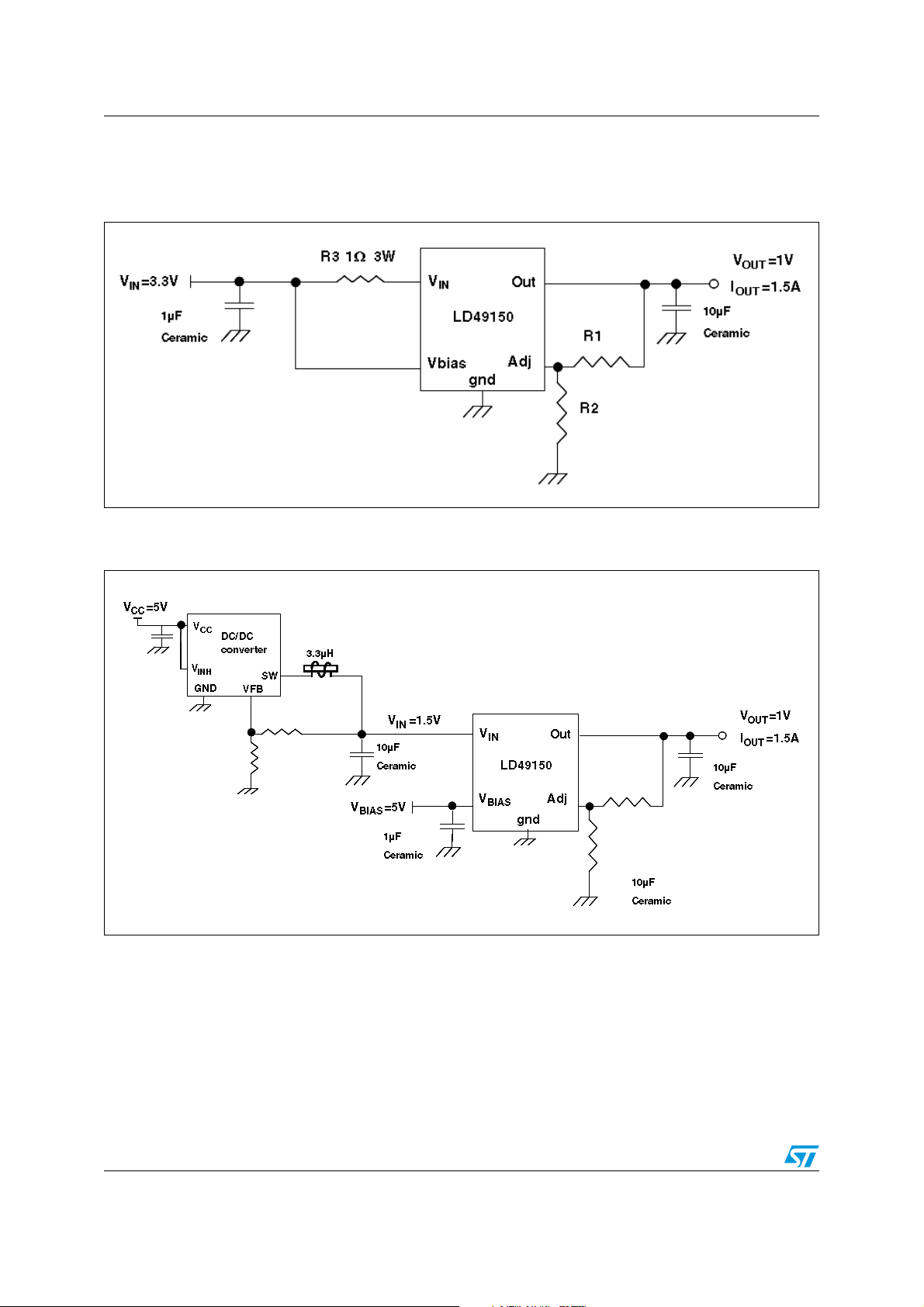

3 Pin configuration

Figure 5. Pin connections (top view for PPAK, bottom view for DFN)

DFN6 (3 x 3 mm)

Table 2. Pin description

Pin n° for

PPAK

12

23V

3 1 GND Ground (TAB is connected to ground).

44V

56V

Pin n° for

DFN

Symbol Note

EN

ADJ

OUT

BIAS

For fixed versions: Enable (Input) - Logic High = Enable, Logic Low =

Shutdown.

For adjustable versions: Adjustable regulator feedback input. Connect to

resistor voltage divider.

Input voltage which supplies current to the output power device.

IN

Regulator output.

Input bias voltage for powering all circuitry on the regulator with the

exception of the output power device.

5 N.C. Not connect.

PPAK

Doc ID 13446 Rev 3 5/22

Diagram LD49150XX08, LD49150XX10, LD49150XX12

4 Diagram

Figure 6. Block diagram

6/22 Doc ID 13446 Rev 3

LD49150XX08, LD49150XX10, LD49150XX12 Maximum ratings

5 Maximum ratings

Table 3. Absolute maximum ratings

(1)

Symbol Parameter Value Unit

V

IN

V

OUT

V

BIAS

V

EN

P

D

T

STG

1. All the values are referred to ground.

Supply voltage -0.3 to 7 V

Output voltage

-0.3 to V

-0.3 to V

IN

BIAS

+ 0.3

+ 0.3

V

BIAS supply voltage -0.3 to 7 V

Enable input voltage -0.3 to 7 V

Power dissipation Internally limited

Storage temperature range -50 to 150 °C

Note: Absolute maximum ratings are those values beyond which damage to the device may occur.

Functional operation under these conditions is not implied.

Table 4. Operating ratings

Symbol Parameter Value Unit

V

V

V

OUT

BIAS

V

EN

T

IN

J

Supply voltage 1.4 to 5.5 V

Output voltage 0.8 to 4.5 V

BIAS supply voltage 3 to 6 V

Enable input voltage 0 to V

BIAS

V

Junction temperature range -25 to 125 °C

Doc ID 13446 Rev 3 7/22

Electrical characteristics LD49150XX08, LD49150XX10, LD49150XX12

6 Electrical characteristics

TJ = - 25 °C to 125 °C, V

1 µF; C

= 10 µF; C

O

BIAS

= 1 µF; unless otherwise specified.

BIAS

Typical values are referred to T

Table 5. Electrical characteristics

= VO + 2.1 V

= 25 °C.

J

(1)

; VI = VO+1 V; VEN = V

BIAS

(2)

, IO = 10 mA; CI =

Symbol Parameter Test conditions Min. Typ. Max. Unit

T

= 25 °C, fixed voltage options -1.5 1.5

V

O

V

LINE

V

LOAD

V

DROP

V

DROP

I

GND

I

GND_SHD

Output voltage accuracy

Line regulation VI = VO + 1 V to 5.5 V -0.1 0.1 %/V

Load regulation IL = 0 mA to 3 A, V

Dropout voltage (VI - VO)I

Dropout voltage (V

- VO)I

BIAS

Ground pin current

Ground pin current in shutdown VEN ≤ 0.4 V

J

Over temperature range -3 3

≥ 3 V 1 %

BIAS

= 1.5 A 200 mV

L

= 1.5 A

L

I

= 0 mA 4 6

L

= 1.5 A 4 6

I

L

(1)

(2)

1.5 2.1 V

5µA

IL = 0 mA 3 5

I

VBIAS

I

Enable input

Current through V

Current limit VO = 0 V 2.5 A

L

(2)

BIAS

= 1.5 A 3 5

I

L

%

mA

mA

V

I

EN

Enable input threshold (fixed

EN

voltage only)

Enable pin input current 0.1 1 µA

Reference

V

REF

Reference voltage

SVR Supply voltage rejection

1. For VO ≤ 1 V, V

2. Fixed output voltage version only.

dropout specification does not apply due to a minimum 3 V V

BIAS

Regulator Enable 1.4

Regulator Shutdown 0.4

T

= 25 °C 0.788 0.8 0.812

J

Over temperature range 0.776 0.8 0.824

= 2.5 V ± 0.5 V, VO = 1 V,

V

I

F = 120 Hz, V

BIAS

= 3.3 V

BIAS

input.

68 dB

V

V

8/22 Doc ID 13446 Rev 3

LD49150XX08, LD49150XX10, LD49150XX12 Typical characteristics

7 Typical characteristics

Figure 7. Reference voltage vs. temperature Figure 8. Output voltage vs. temperature

Figure 9. Load regulation vs. temperature Figure 10. Line regulation vs. temperature

Figure 11. Output voltage vs. input voltage Figure 12. Dropout voltage (VIN-V

Doc ID 13446 Rev 3 9/22

temperature

OUT

) vs.

Typical characteristics LD49150XX08, LD49150XX10, LD49150XX12

Figure 13. Dropout voltage (VIN-V

Figure 15. Noise vs. frequency Figure 16. Quiescent current vs. temperature

temperature

OUT

) vs.

Figure 14. V

pin current vs. temperature

BIAS

Figure 17. Supply voltage rejection vs. output

current

Figure 18. Stability region vs. C

10/22 Doc ID 13446 Rev 3

ESR

OUT

& High

LD49150XX08, LD49150XX10, LD49150XX12 Typical characteristics

Figure 19. Stability region vs. C

& low ESR Figure 20. V

OUT

Figure 21. VIN start up transient response

(V

start up before VIN)

BIAS

VIN=V

BIAS=VINH

Figure 22. V

& VIN start up transient

BIAS

response (V

and V

IN

BIAS

the same time)

=3.1V, V

start up transient response

IN

(V

BIAS

OUT

=1V, C

OUT

=1µF

start up before VIN)

start up at

VIN=2.5V, V

BIAS=VINH

=3.1V, V

OUT

=1V, C

OUT

=1µF

VIN=2.5V, V

BIAS=VINH

=3.1V, V

OUT

=1V, C

OUT

=1µF

Doc ID 13446 Rev 3 11/22

Typical characteristics LD49150XX08, LD49150XX10, LD49150XX12

Figure 23. VIN start up transient response

(V

start up before V

BIAS

V

INH=VIN

)

IN

and

VIN=V

=2.5V, V

INH

BIAS

=3.1V, V

OUT

=1V, C

OUT

=1µF

12/22 Doc ID 13446 Rev 3

LD49150XX08, LD49150XX10, LD49150XX12 Application hints

8 Application hints

The LD49150xx is an ultra-high performance, low dropout linear regulator, designed for high

current application that requires fast transient response. The LD49150xx operates from two

input voltages, to reduce dropout voltage. The LD49150xx is designed so that a minimum of

external component are necessary.

8.1 Input supply voltage (VIN)

VIN provides the power input current to the LD49150xx. The minimum input voltage can be

as low as 1.4 V, allowing conversion from very low voltage supplies to achieve low output

voltage levels with very low power dissipation.

8.2 Bias supply voltage (V

The LD49150xx control circuitry is supplied the V

current (3 mA typ.) even at the maximum output current level (1.5 A). A bypass capacitor on

the bias pin is recommended to improve the performance of the LD49150xx during line and

load transient. The small ceramic capacitor from V

noise that could be injected into the control circuitry from the bias rail. In typical applications

a 1 µF ceramic chip capacitor may be used. The V

the output voltage, with a minimum V

8.3 External capacitors

To assure regulator stability, input and output capacitors are required as shown in the 1:

Typical application circuits.

8.4 Output capacitor

The LD49150xx requires a minimum output capacitance to maintain stability. A ceramic chip

capacitor of at least 1 µF is required. However, specific capacitor selection could be needed

to ensure the transient response. A 1 µF ceramic chip capacitor satisfies most applications

but 10 µF is recommended to ensure better transient performances. In applications where

the V

recommended to use an output capacitors of, at least, 10 µF in order to avoid over-voltage

stress on the Input/output power pins during short circuit conditions due to parasitic

inductive effect. The output capacitor must be located as close as possible to the output pin

of the LD49150xx. The ESR (equivalent series resistance) of the output capacitor must be

within the "stable" region as shown in the typical characteristics figures. Both ceramic and

tantalum capacitors are suitable.

level is close to the maximum operating voltage (V

IN

BIAS

BIAS

)

pin which requires a very low bias

BIAS

to ground reduces high frequency

BIAS

input voltage must be 2.1 V above

input voltage of 3 V.

BIAS

> 4 V), it is strongly

IN

8.5 Minimum load current

The LD49150xx does not require a minimum load to maintain output voltage regulation.

Doc ID 13446 Rev 3 13/22

Application hints LD49150XX08, LD49150XX10, LD49150XX12

8.6 Power sequencing recommendations

In order to ensure the correct biasing and settling of the regulator internal circuitry during the

startup phase, as well as to avoid overvoltage spikes at the output, it is recommended to

provide for the correct power sequencing.

As a general rule the V

and V

IN

signals timings at startup should be chosen properly, so

INH

that they are applied to the device after the V

operative value (see paragraph 8.2: Bias supply voltage (VBIAS)). This can be achieved, for

instance, by avoiding too slow V

rising edges (Tr >10 ms).

BIAS

Provided that the above condition is satisfied, when fast V

present, a smooth startup, with limited overvoltage on the output, can be obtained by

applying V

voltage at the same time as the V

IN

and Figure 22 on page 11).

In the fixed voltage versions it is possible to reduce overvoltage spikes during very fast

startup (T

<< 100 µs) by pulling the V

r

pin up to VIN voltage (see Figure 23 on page 12).

INH

8.7 Power dissipation/heatsinking

A heatsink may be required depending on the maximum power dissipation and maximum

ambient temperature of the application. Under all possible conditions, the junction

temperature must be within the range specified under operating conditions. The total power

dissipation of the device is given by:

P

= VIN x IIN + V

D

Where:

● V

● V

● V

● I

, input supply voltage

IN

, bias supply voltage

BIAS

, output voltage

OUT

, load current

OUT

From this data, we can calculate the thermal resistance (

using the following formula:

BIAS

x I

BIAS

- V

OUT

x I

OUT

voltage is already settled at its minimum

BIAS

transient input (Tr < 100 µs) is

IN

voltage (refer to Figure 20, Figure 21

BIAS

θ

) required for the heat sink

SA

θ

= (TJ - TA/PD) - (θJC + θCS)

SA

The maximum allowed temperature rise (T

temperature (T

(T

):

Jmax

T

= T

Rmax

Jmax

) of the application, and the maximum allowable junction temperature

Amax

- T

Amax

Rmax

The maximum allowable value for junction to ambient thermal resistance, θJA, can be

calculated using the formula:

θ

JAmax

= T

Rmax

/ P

D

This part is available for the PPAK package.

The thermal resistance depends on the amount of copper area or heat sink, and on air flow.

If the maximum allowable value of

θ

calculated above is ≥ 100 °C/W for the PPAK

JA

package, no heatsink is needed since the package can dissipate enough heat to satisfy

these requirements. If the value for allowable

θ

required as described below.

14/22 Doc ID 13446 Rev 3

) depends on the maximum ambient

falls below these limits, a heat sink is

JA

LD49150XX08, LD49150XX10, LD49150XX12 Application hints

8.8 Heatsinking PPAK package

The PPAK package uses the copper plane on the PCB as a heatsink. The tab of these

packages is soldered to the copper plane for heat sinking. It is also possible to use the PCB

ground plane a heatsink. This area can be the inner GND layer of a multi-layer PCB, or, in a

dual layer PCB, it can be an unbroken GND area on the opposite side where the IC is

situated with a dissipating area thermally connected through vias holes, filled by solder.

Figure 26 shows a curve for

θ

of the PPAK package for different copper area sizes, using

JA

a typical PCB with 1/16 in thick G10/FR4.

θ

Figure 24.

vs. copper area for PPAK package

JA

8.9 Adjustable regulator design

The LD49150xx adjustable version allows fixing output voltage anywhere between 0.8 V and

4.5 V using two resistors as shown in the typical application circuit. For example, to fix the

R

resistor value between V

1

(R

) is calculated by:

2

R

= R1 [0.8/(V

2

Where V

It is suggested to use R1 values lower than 10 kΩ to obtain better load transient

performances. Even, higher values up to 100 kΩ are suitable.

8.10 Enable

The fixed output voltage versions of LD49150xx feature an active high Enable input (EN)

that allows on-off control of the regulator. The EN input threshold is guaranteed between 0.4

V and 1.4 V, for simple logic interfacing. The regulator is set in shut down mode when V

0.4 V and it is in operating mode (V

must be tied directly to the V

not be left at high impedance.

and the ADJ pin, the resistor value between ADJ and GND

OUT

- 0.8)]

OUT

is the desired output voltage.

OUT

to keep the regulator continuously activated. The En pin must

IN

Doc ID 13446 Rev 3 15/22

activated) when V

OUT

> 1.4 V. If not in use, the EN pin

EN

EN

<

Package mechanical data LD49150XX08, LD49150XX10, LD49150XX12

9 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

16/22 Doc ID 13446 Rev 3

LD49150XX08, LD49150XX10, LD49150XX12 Package mechanical data

PPAK mechanical data

Dim.

Min. Typ. Max. Min. Typ. Max.

A 2.2 2.4 0.086 0.094

A1 0.9 1.1 0.035 0.043

A2 0.03 0.23 0.001 0.009

B 0.4 0.6 0.015 0.023

B2 5.2 5.4 0.204 0.212

C 0.45 0.6 0.017 0.023

C2 0.48 0.6 0.019 0.023

D 6 6.2 0.236 0.244

D1 5.1 0.201

E 6.4 6.6 0.252 0.260

E1 4.7 0.185

e 1.27 0.050

G4.9 5.25 0.193 0.206

G1 2.38 2.7 0.093 0.106

H 9.35 10.1 0.368 0.397

L2 0.8 1 0.031

L4 0.6 1 0.023 0.039

L5 1

L6 2.8 0.110

mm. inch.

0.039

0.039

0078180-E

Doc ID 13446 Rev 3 17/22

Package mechanical data LD49150XX08, LD49150XX10, LD49150XX12

DFN6 (3x3 mm) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A0.800.90 1.00 0.031 0.035 0.039

A1 0 0.02 0.05 0 0.001 0.002

A3 0.20 0.008

b 0.23 0.300.38 0.009 0.012 0.015

D2.90 3.00 3.10 0.114 0.118 0.122

D2 2.23 2.38 2.48 0.088 0.094 0.098

E2.90 3.00 3.10 0.114 0.118 0.122

E2 1.50 1.65 1.75 0.059 0.065 0.069

e0.950.037

L0.30 0.40 0.50 0.012 0.016 0.020

18/22 Doc ID 13446 Rev 3

7946637A

LD49150XX08, LD49150XX10, LD49150XX12 Package mechanical data

Tape & reel DPAK-PPAK mechanical data

Dim.

Min. Typ. Max. Min. Typ. Max.

A 330 12.992

C12.8 13.0 13.2 0.504 0.512 0.519

D 20.2 0.795

N60 2.362

T22.40.882

Ao 6.806.90 7.00 0.268 0.272 0.2.76

Bo 10.40 10.50 10.60 0.409 0.413 0.417

Ko 2.55 2.65 2.75 0.100 0.104 0.105

Po 3.9 4.0 4.1 0.153 0.157 0.161

P7.98.0 8.1 0.311 0.315 0.319

mm. inch.

Doc ID 13446 Rev 3 19/22

Package mechanical data LD49150XX08, LD49150XX10, LD49150XX12

Tape & reel QFNxx/DFNxx (3x3) mechanical data

mm. inch.

Dim.

Min. Typ. Max. Min. Typ. Max.

A180 7.087

C 12.8 13.2 0.504 0.519

D 20.2 0.795

N60 2.362

T 14.4 0.567

Ao 3.3 0.130

Bo 3.3 0.130

Ko 1.1 0.043

Po 4 0.157

P 8 0.315

20/22 Doc ID 13446 Rev 3

LD49150XX08, LD49150XX10, LD49150XX12 Revision history

10 Revision history

Table 6. Document revision history

Date Revision Changes

18-Apr-2007 1 Initial release.

12-Jan-2009 2 Added new package DFN6 (3x3 mm) and mechanical data.

29-Jun-2010 3 Modified Section 8.6: Power sequencing recommendations on page 14.

Doc ID 13446 Rev 3 21/22

LD49150XX08, LD49150XX10, LD49150XX12

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22 Doc ID 13446 Rev 3

Loading...

Loading...