SPYDER ELECTRA User Manual

USER MANUAL

English

Français

Español

TABLE OF CONTENTS

IMPOR TANT S AFET Y GUID ELIN ES 1

OPERATION GUI DE / S TART U P 2

CO2 / COM PRES SED AI R TANK WA RNIN GS 3

INSTALLIN G A CO2 / CO MPRESS ED A IR TANK 4

PROPE R USE OF B ARRE L BLOCK ING DE VICE 4

BATT ERY INSTALLATION / O PTIO NAL ACCESSO RY C HARGIN G IN STRU CTIONS 5-6

LEAP™ CI RCUIT BOARD w/CAMD SETT INGS 7

TRIGG ER ADJUST MENT 8

VELOCITY ADJ USTM ENT 8

C/A ON/OFF ADAPTER 9

REGUL ATOR ADJUST MENT 9-10

DISAS SEMBLE / R EASS EMBLE AND CLEANI NG O F RE AR INT ERNA LS 11-12

A JAMMED PAIN TBAL L 12

ANTI CHOP E YES / CH ANGING BAL L STOPP ERS 13

CUP S EAL RE MOVAL 14

TROUB LESHOOT ING / AIR LEAKS 15

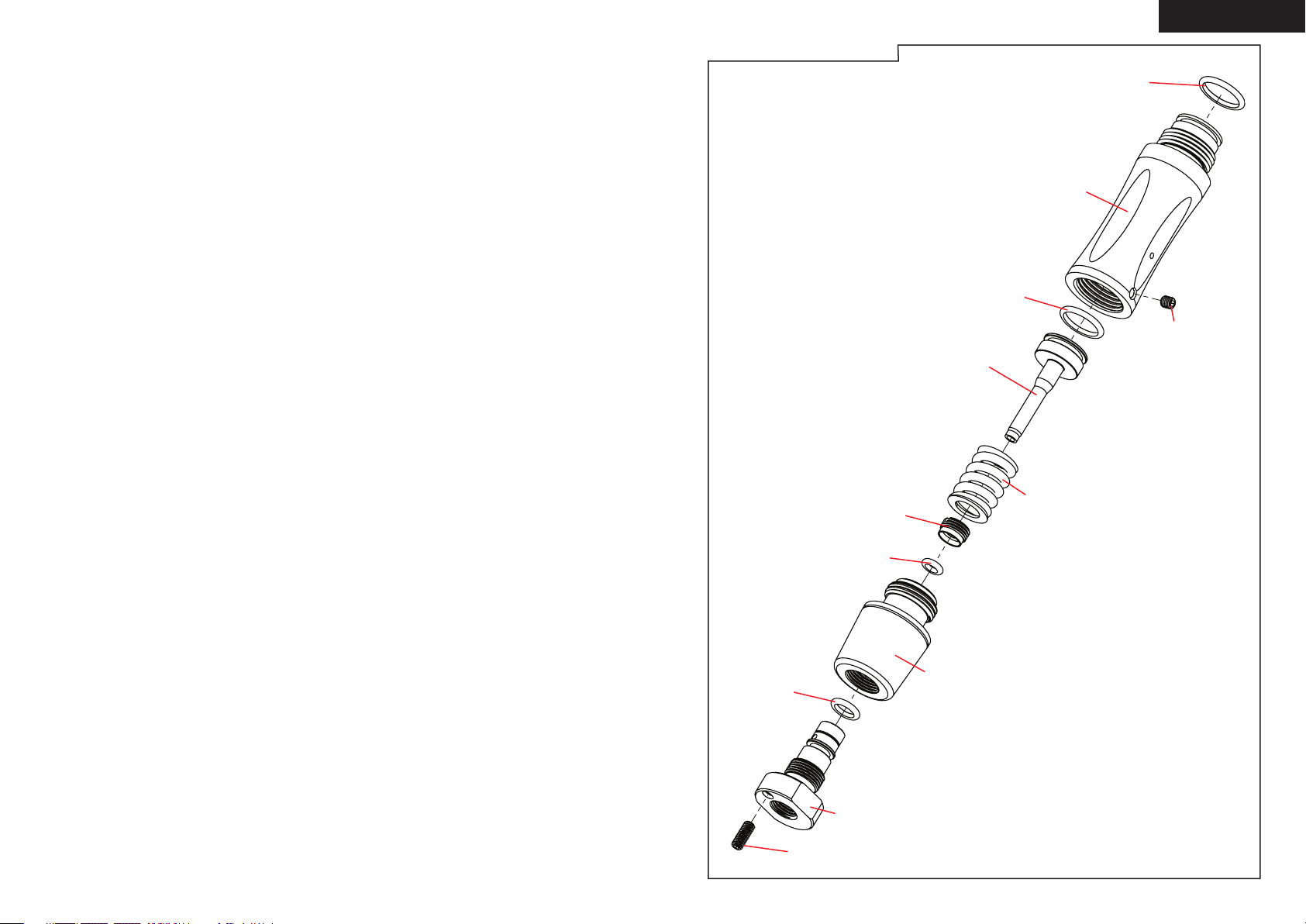

REGUL ATOR SCH EMATIC 16

ELECT RA w/Ey e PAR TS LIS T 17

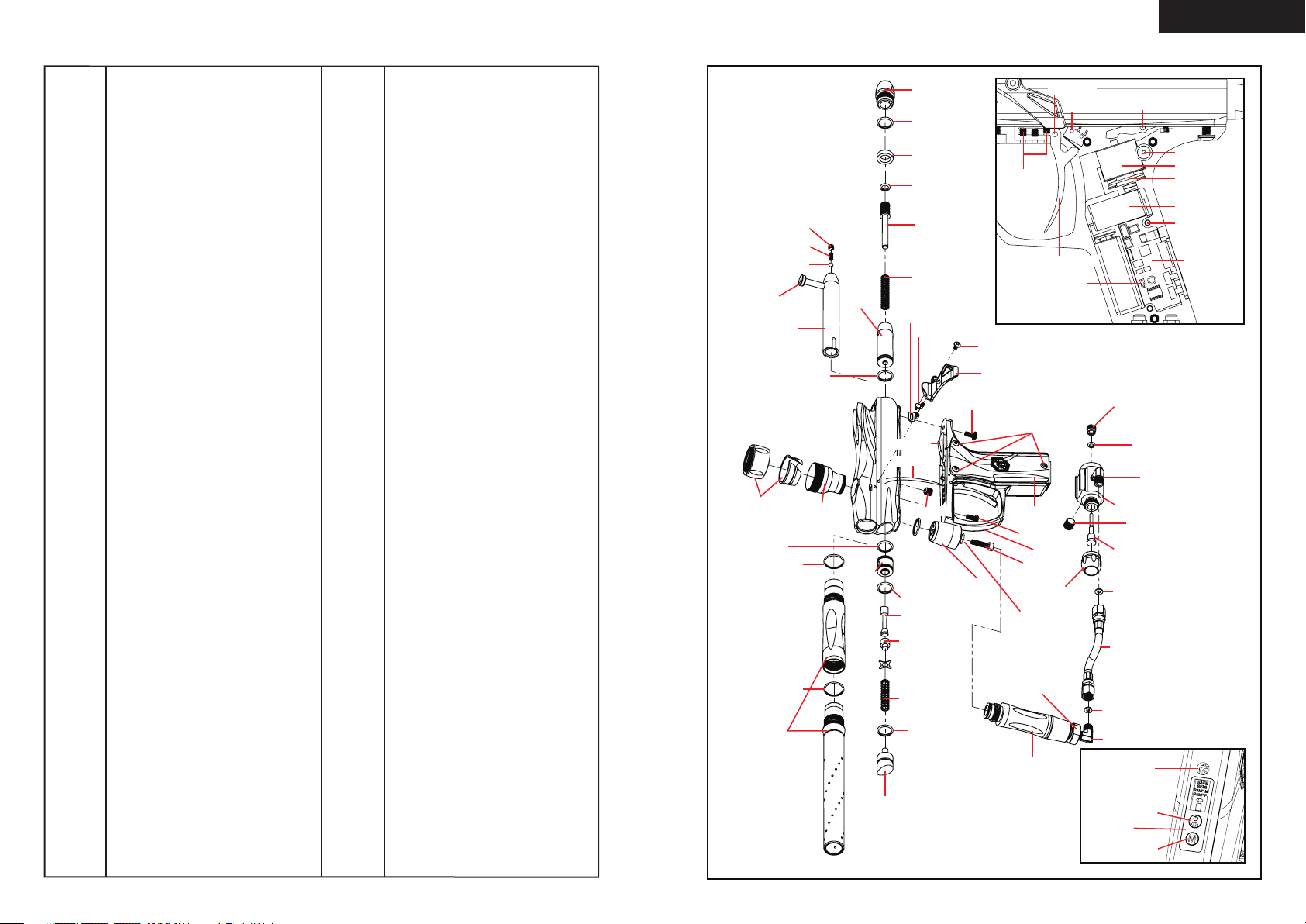

ELECT RA w/Ey e SCHE MATIC 18

WARRAN TY STATEMENT 19

.68 Calib er E lectronic Pai ntba ll M arke r

English

1

2

IMPORTANT SAFETY GUIDELINES

WARNING

This paintball marker is NOT a toy. It can cause serious injury or death.

Kingman recommends that the customer be at least 18 years of age to purchase this product.

Read this manual and air tank warnings before using this product.

Any modications or tampering of original factory parts will void all warranties and liabilities

from Kingman.

Kingman recommends using a barrel blocking device when the marker is not in operation.

To ensure proper adjustment of velocity Feet Per Second (fps), Kingman strongly recommends

using a chronograph for paintball use located at most paintball stores and paintball elds.

Before / after use of the marker, make sure to fasten all screws. Screws may become loose due to

vibration. Loose screws can be dangerous and cause injury.

Kingman STRONGLY recommends that any person using this product or within range of this

product while it is in use MUST wear EYE/FACE PROTECTION designed specically for the sport

of paintball. This includes, but is not limited to, performing a maintenance check and during target

practice.

Kingman reminds the user that it is YOUR RESPONSIBILITY to protect your eyes/face at

all times, and will not be held liable for injuries sustained when failing to wear the appropriate

protection.

Never shoot or point your marker at a person that is not in a designated paintball facility and

without proper paintball protection.

Treat every paintball marker as if it were loaded.

Never look down the barrel of a loaded or unloaded marker.

Always keep the paintball marker in SAFE or OFF mode until ready to operate.

Always remove the gas and all paintballs before disassembly.

Fire only 0.68 caliber paintballs with this product.

Always make certain the bolt is in the un-cocked position when marker is not in use.

Using a paintball marker outside of a non designated paintball eld can be illegal, and is

subject to law enforcement penalties if property damage is caused by the user.

Never point or shoot your marker at an animal.

Transfer this instruction manual upon change of marker ownership.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

English

OPERATION GUIDE / START UP

WARNING: Always keep the marker powered OFF or on SAFE until you are ready to re.

Always attach a barrel blocking device over the tip of the barrel for safety precautions when the marker is not in use.

Install and charge the battery see pages (See Battery Installation)

Attach a CO2 / Compressed Air Tank to the C/A On/Off Adapter. HELPFUL TIP: Make sure to have the CO2 /

Compressed Air Tank lled before attaching to the marker. Hand tighten the tank clockwise in the markers C/A

On/Off adapter until it is snug. If an air leak occurs between the tank and the C/A On/Off adapter, replace the

urethane O-ring. NOTE: O-rings in the markers parts kit are not supplied to attach with a CO2 / Compressed Air

Tank. IMPORTANT: You should never need to use any hand tool to attach a CO2 / Compressed Air Tank to the

C/A On/Off adapter.

Attach an electronic paintball loader and elbow to the markers Feed Neck. Only use .68 caliber paintballs

through the electronic loader. NOTE: Kingman recommends that you use a force feed / high speed electronic

loader to reach optimum performance.

Turn Power On for the electronic trigger frame (See LEAP™ Circuit Board w/CAMD Settings).

Cocking the marker. Pull the Top Cocking Knob rearward until the Delrin Bolt latches. CAUTION: Should you

let go of the Top Cocking Knob before it latches, your marker may re.

Remove the barrel blocking device. CAUTION: With the power switch turned ON the marker is LIVE. Pulling the

trigger will re a paintball. IMPORTANT: Only test your marker in a safe direction or in a designated playing eld.

Performing a velocity (fps) check. Turning the velocity adjuster & spring guide clockwise will increase the

velocity (fps) while turning counter-clockwise will decrease the velocity (fps). NOTE: Your marker is intended

to be used in a paintball facility with the proper paintball protection. IMPORTANT: Kingman recommends using

a chronograph to ensure that the maker’s velocity is under 300 (fps).

When nished playing, remove all paintballs from the paintball loader before detaching from the markers feed

neck. CAUTION: There may be paintballs in the marker’s breach; take a couple of shots in a safe direction to

make sure the barrel and receiver are empty.

Place the barrel blocking device over the barrel tip. This will help avoid any accidental discharge.

Kingman recommends having the marker in the “SAFE or OFF” position after use.

Unscrew the CO2 / Compressed Air Tank from the marker’s C/A adapter. Firmly hand loosen the tank counter-

clockwise will detach it from the marker’s C/A adapter. CAUTION: Never expose any skin underneath the C/A

adapters bleed hole when removing the tank. This can run the risk of getting skin burn from the releasing of

the GAS. IMPORTANT: You should never need to use any hand tool to detach a CO2 / Compressed Air Tank.

Store the marker in a paintball bag or in a safe place. WARNING: Before / after use of the marker, make sure

to fasten all screws. Screws can become loose due to vibration. Loose screws can be dangerous and cause

injury. HELPFUL TIP: It’s a good practice to lubricate your marker before and after each use, especially when

storing the marker for an extended period of time. Add a few drops of paintball gun oil on the Striker O-ring

(see Disassemble / Reassemble). Before storing the marker, make sure the marker is in the un-cocked position.

This will help the main spring maintain its tension.

IMPORTANT

Firing velocity may vary according to altitude and climate conditions.

Before using your marker in play, you must always rst perform a “SAFE VELOCITY TEST”. This can only be

accomplished by using a testing device called a “Velocity Chronograph“ and can be performed at a paintball

dealership or local playing eld. NOTE: This product is intended to be used at a velocity no greater than 300

feet per second (fps). Paintball markers are not intended to shoot any person less than 25 feet away without

EYE/FACE PROTECTION.

This paintball marker may have excess gas after the removal of the CO2 / Compressed Air Tank. Please

remove all paintballs and discharge the remaining gas safely.

Never store a CO2 / Compressed Air Tank attached on the marker while not supervised.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

•

•

•

•

3

4

CO2 / COMPRESSED AIR TANK WARNINGS

CO2 / COMPRESSED AIR TANK WARNINGS

All valves must only be installed or removed by a qualied airsmith.

See CO2 / Compressed Air tank labels for retest dates. Cylinder tanks must be retested periodically.

Improper use, lling, storage or disposal of all air cylinders may result in death, personal injury and/or property

damage.

Always keep cylinders out of reach from children or any inexperienced person(s).

Only properly trained personnel in accordance with CGA Pamphlets P.1 and G-6.3 must ll all air cylinders.

Pamphlets are available from the Compressed Gas Association or www.CGANET.com.

Never alter the cylinder in any way.

DO NOT expose pressurized cylinders to temperatures in excess of 130˚F (54˚C).

Cylinders heated to an excess of 250˚F (121˚C) must be condemned or requalied in accordance with test

dened in CFR-49.

The valve should NEVER be detached from the canister. Please seek immediate assistance from a trained

airsmith should this occur.

Any tank packed with the product is intended for paintball use only.

Conrm that there is an attached urethane O-ring on the CO2 / Compressed Air tank valve before attaching

the tank to the marker. The tank will leak air as soon as it is secured to the marker, if the O-ring is missing from

the valve.

A urethane O-ring is highly recommended before attaching any air supply to the marker.

NEVER over pressurize a CO2 / Compressed Air cylinder.

Avoid any direct skin exposure to the escaping gas, when installing or removing any air supply.

Never expose cylinders to corrosive materials or clean with any caustic cleaners.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

The CO2 or Compressed Air Tank can y off with enough force to cause serious

injury or death if the Valve unscrews from the cylinder head. LOOK at the Valve

when removing the cylinder from the marker. Be sure that the valve is turning

with the cylinder rather than remaining stationary with the marker. STOP if the

Valve starts to unscrew from the cylinder. If in doubt, screw the cylinder back

onto the marker and contact a trained person for repair.

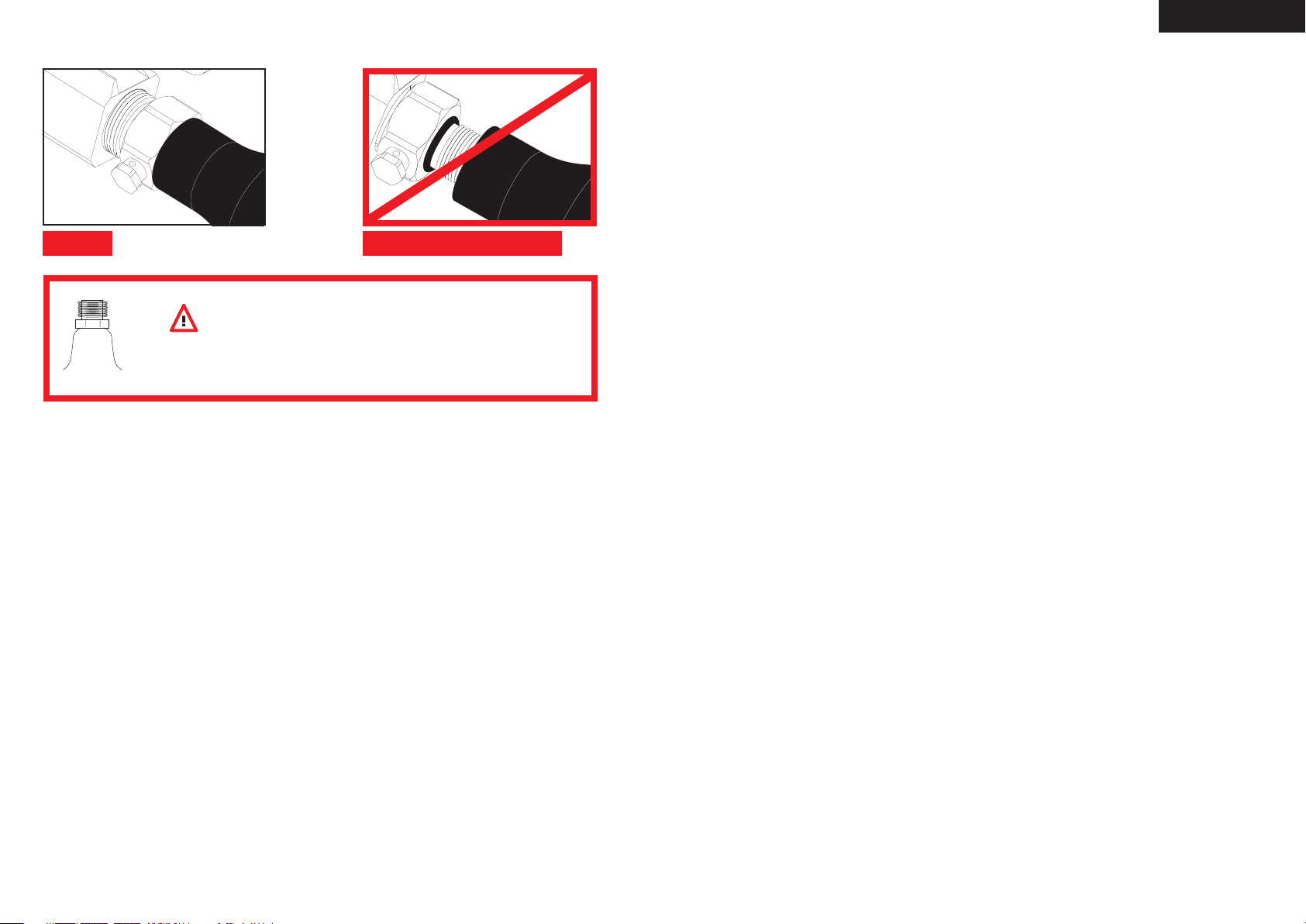

SAFE

DA N G E R

WARNING:UNSAFE

English

INSTALLING A CO2 / COMPRESSED AIR TANK

Firmly hand tighten the CO2 / Compressed Air Tank clockwise into the markers C/A On/Off adapter.

HELPFUL TIP: Before installing a CO2 / Compressed Air Tank, make sure that the tank is full and that it has a

urethane bottle o-ring on the top of the valve to prevent air leaks.

IMPORTANT: You should never need to use any hand tool to attach a CO2 / Compressed Air Tank to the C/A

On/Off adapter.

REMOVING A CO2 / COMPRESSED AIR TANK

With a rm grip holding the CO2 / Compressed Air Tank remove the cylinder by hand turn counter-clockwise until it

comes out of the C/A On/Off adapter. HELPFUL TIP: After ring the marker, you should ALWAYS remove the CO2

/ Compressed Air Tank before storing. When the tank is being removed, excess air will release from the C/A On/Off

adapter. CAUTION: Never expose any skin to the C/A On/Off adapters bleed hole when removing the tank. This is to

avoid the risk of getting skin burn from the escaping GAS.

IMPORTANT: You should never need to use any hand tool to detach a CO2 / Compressed Air Tank from the C/A

On/Off adapter. If you cannot remove a tank by hand please see a certied airsmith for assistance.

PROPER USE OF YOUR BARREL BLOCKING DEVICE

A Barrel Blocking Device or “BBD” is an essential part of your paintball safety equipment. The Barrel Blocking

Device is designed to stop a paintball from exiting a paintball marker accidentally. Improper use of the Barrel

Blocking Device will render this device useless.

BARREL SOCK/BAG TYPE DEVICE

Place the bag/sock part of the Barrel Blocking Device over the end of your barrel and wrap the elastic cord around

the back end of your marker.

Adjust the length of the elastic cord to make sure your Barrel Blocking Device ts securely over your markers barrel.

NOTE: If the elastic cord is too long you can tie a couple of knots around the cord to shorten its length.

BARREL PLUG TYPE DEVICE

Insert the barrel plug securely into the end of your markers barrel before proceeding to load paintballs and screwing

in your tank to your marker.

The barrel plug should t rmly into the barrel with a signicant amount of resistance. NOTE: The barrel plug should

not be easy to remove and always inspect the O-rings to make sure they are not worn or cut.

Remove the Barrel Blocking Device only when you are getting ready to begin play or have been instructed to do so

by a eld safety ofcial.

Always keep your Barrel Blocking Device on your marker after you have nished playing. Keep it in place even after

you have emptied all paintballs and removed your air tank from your paintball marker.

WARNING

Inspect your Barrel Blocking Device regularly for wear and any tear if it is worn, replace it immediately.

Always have your Barrel Blocking Device in place on your markers barrel to insure safety and prevent accidents that

may cause permanent injury or even death.

5

6

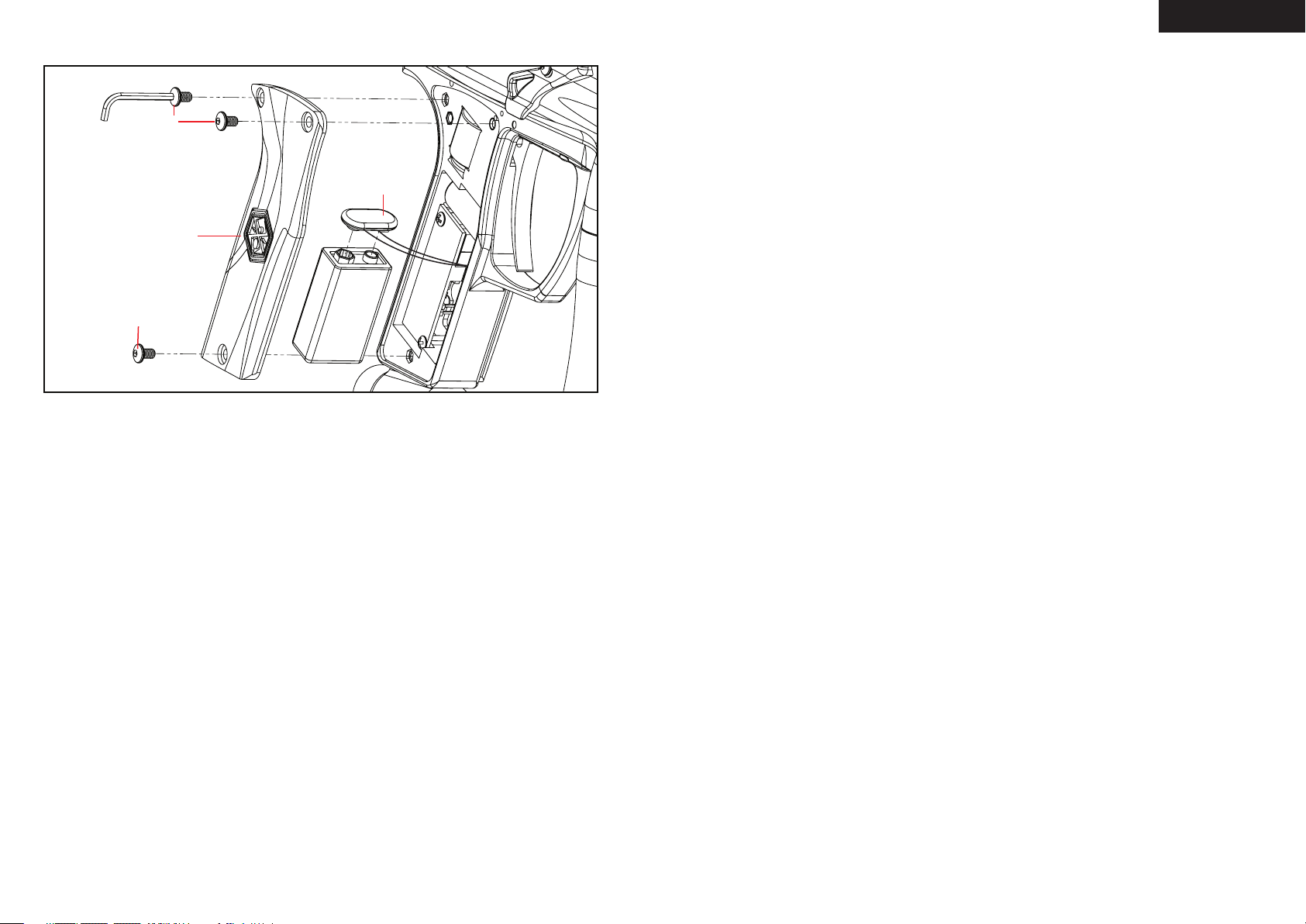

BATTERY INSTALLATION

BATTERY INSTALLATION

NOTE: This marker is compatible with the use of 9volt Alkaline batteries. Use only premium brand Alkaline batteries

for best performance. (Battery Not Included)

Shot counts will vary depending on the type of 9volt Alkaline battery used (2300 to 3200), choosing a premium

brand battery will give the best results.

Kingman Group recommends using a Spyder 9.6volt NiMH Rechargeable Battery as a power source for optimum

performance and will provide a superior shot count of around 5000 to 6000 rounds. (Spyder Battery and Charger

Sold Separately)

IMPORTANT: Performance will vary depending on the mode used and rate of re achieved.

STEP 1 Re move the three M4x 8 Screws fr om the Right side g rip panel. NOTE : Allen wrench p rovid ed in

the spare parts k it.

ST EP 2 Atta ch t he battery to the ba ttery harn ess.

ST EP 3 Re-tighten the three M4x 8 Screws.

HELPFUL TIP : Please note ho w the part s are re moved for easy reas semb ly.

CHARGING INSTRUCTIONS

Spyder 9.6volt Battery (US LED) optional accessory

To charge a Spyder 9.6 NiMH battery, the circuit board must be in the OFF position. Spyder batteries (JE1015) are not

fully charged when purchased. Using the supplied Spyder LED A/C Charger (JE1029), plug the charger into the charger

port located at the rear of the trigger frame. For a complete charge, Kingman recommends a charging time of 6-8 hours.

STEP 1 Plug the Spyder LED A/C charger into a power outlet.

STEP 2 Connect the Spyder A/C charger cord to the rear of the markers trigger frame’s charging port..

STEP 3 The LED indicator on the Spyder LED A/C charger will display RED when the battery is charging.

STEP 4 The LED indicator on the Spyder LED A/C charger will display GREEN when the battery is fully charged.

STEP 5 Unplug the Spyder LED A/C charger cord from the rear of the markers trigger frame’s charging port

after charging.

STEP 6 Remove the Spyder LED A/C charger from the power outlet.

IMPORTANT: Never charge the battery for over 24 hours, as you will risk damaging the battery and/or electronics.

HELPFUL TIP: It is recommended that the battery be charged prior to use in order to ensure maximum performance,

especially if the battery has not been used in over a week. NOTE: A fully charged Spyder battery will last about

5000-6000 shots, depending on your ring methods or ring mode in use. Under normal use and charging

conditions the expected life of the Spyder battery is approximately 700-1000 charging cycles.

To avoid any risks of having the Battery explode or the Circuit Board burned: charge only Spyder 9.6volt NiMH

Batteries in Spyder electronic frames.

IMPORTANT

DO NOT attempt to recharge any Alkaline or any other type of battery in the Spyder electronic frame.

DO NOT try to recharge batteries that are rusted, corroded, damaged or leaking.

FAILURE to follow any of the instructions will VOID ALL WARRANTIES AND LIABILTIES from Kingman.

Kingman will not be held liable for any injury or damages from the improper use of this product. This accessory is not

intended for use with any other product other than what Kingman designed it for.

Spyder 9.6volt Battery (EU) optional accessory

To charge a Spyder 9.6 NiMH battery, the circuit board must be in the OFF position. Spyder batteries (JE1015) are

not fully charged when purchased. Using the supplied A/C Charger (JE1025), plug the charger into the charger port

located at the rear of the trigger frame. For a complete charge, Kingman recommends a charging time of 6-8 hours.

IMPORTANT: Never charge the battery for over 24 hours, as you will risk damaging the battery and/or electronics.

HELPFUL TIP: It is recommended that the battery be charged prior to use in order to ensure maximum performance,

especially if the battery has not been used in over a week.

NOTE: A fully charged Spyder battery will last about 5000-6000 shots, depending on your ring methods or ring

mode in use. Under normal use and charging conditions the expected life of the Spyder battery is approximately

700-1000 charging cycles.

To avoid any risks of having the Battery explode or the Circuit Board burned: charge only Spyder 9.6volt NiMH

Batteries in Spyder electronic frames.

IMPORTANT

DO NOT attempt to recharge any Alkaline or any other type of battery in the Spyder electronic frame.

DO NOT try to recharge batteries that are rusted, corroded, damaged or leaking.

FAILURE to follow any of the instructions will VOID ALL WARRANTIES AND LIABILTIES from Kingman.

Kingman will not be held liable for any injury or damages from the improper use of this product. This accessory is not

intended for use with any other product other than what Kingman designed it for.

•

•

•

•

•

•

English

GR P005

SC R002

SC R002

WR H002

Part Names and Numbers described in this section:

Dual Texture Grip Panel (#GRP005)

M4 x 8 Screw (A) (#SCR002)

Battery Harness (#WRH002)

7

8

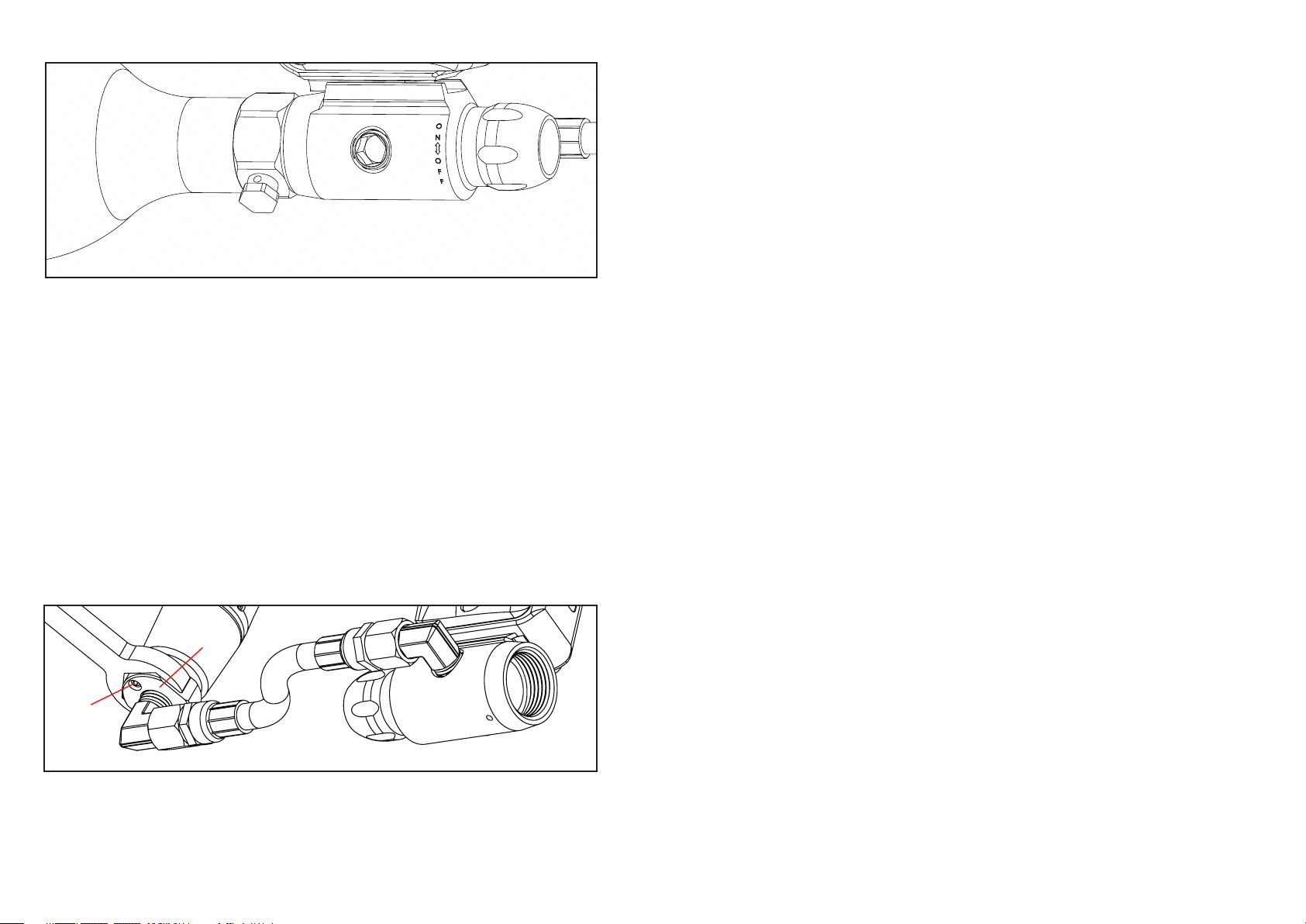

TRIGGER ADJUSTMENT

Magnetic Response “Saber” Trigger

There are 3 adjuster set screws that allows the adjustment for the trigger pull, the micro switch actuation, a post

travel stop and the magnetic response strength.

The rst set screw furthest from the micro switch is for adjusting the amount of resistance force the magnet applies

on the trigger. Adjusting the set screw in will increase resistance and out will reduce it for a lighter trigger pull.

The middle set screw is for adjusting the distance between the trigger and the micro switch. Adjusting the set screw

in will bring the trigger actuation closer giving the trigger a short trigger pull.

HELPFUL TIP: Remember not to over adjust this set screw as you may have the trigger rest against the micro

switch and not allow the micro switch to reset for the next trigger pull.

The third set screw closest to the micro switch is for the post travel of the trigger. It is to stop the trigger from

further back travel after it has actuated the micro switch

VELOCITY ADJUSTMENT INCREASE / DECREASE

To INCREASE your velocity fps using the Allen wrench, turn the Velocity Adjuster / Spring Guide clockwise.

To DECREASE your velocity fps using the Allen wrench, turn the Velocity Adjuster / Spring Guide counter-

clockwise. NOTE: Allen wrench provided in the spare parts kit. NOTE: Velocity Adjuster / Spring Guide doesn’t

remove from the rear of the Sticker Plug.

NOTE: The velocity of this paintball marker ranges from approximately 240 – 300 feet per second (fps). Velocities

will uctuate or vary due to paintball size, climate condition, altitude, type of air source and variance in spring

tension from manufacturing.

WARNING

The recommended Velocity speed should be no greater then 300 fps. Not doing so can cause serious injury or death

if the velocity is set dangerously high.

Paintball markers are not intended to shoot any person less then 25 feet without eye/face protection.

Never point a loaded marker at any person who is not wearing the proper face protection.

Never at any point should you look down the barrel, whether the marker is loaded or not.

Using a paintball marker outside a non designated paintball eld can be illegal, and is subject to law

enforcement penalties if property damage is caused by the user.

•

•

•

•

•

English

SC R029

ST P028

ST P029

VTA0 28

VTA0 29

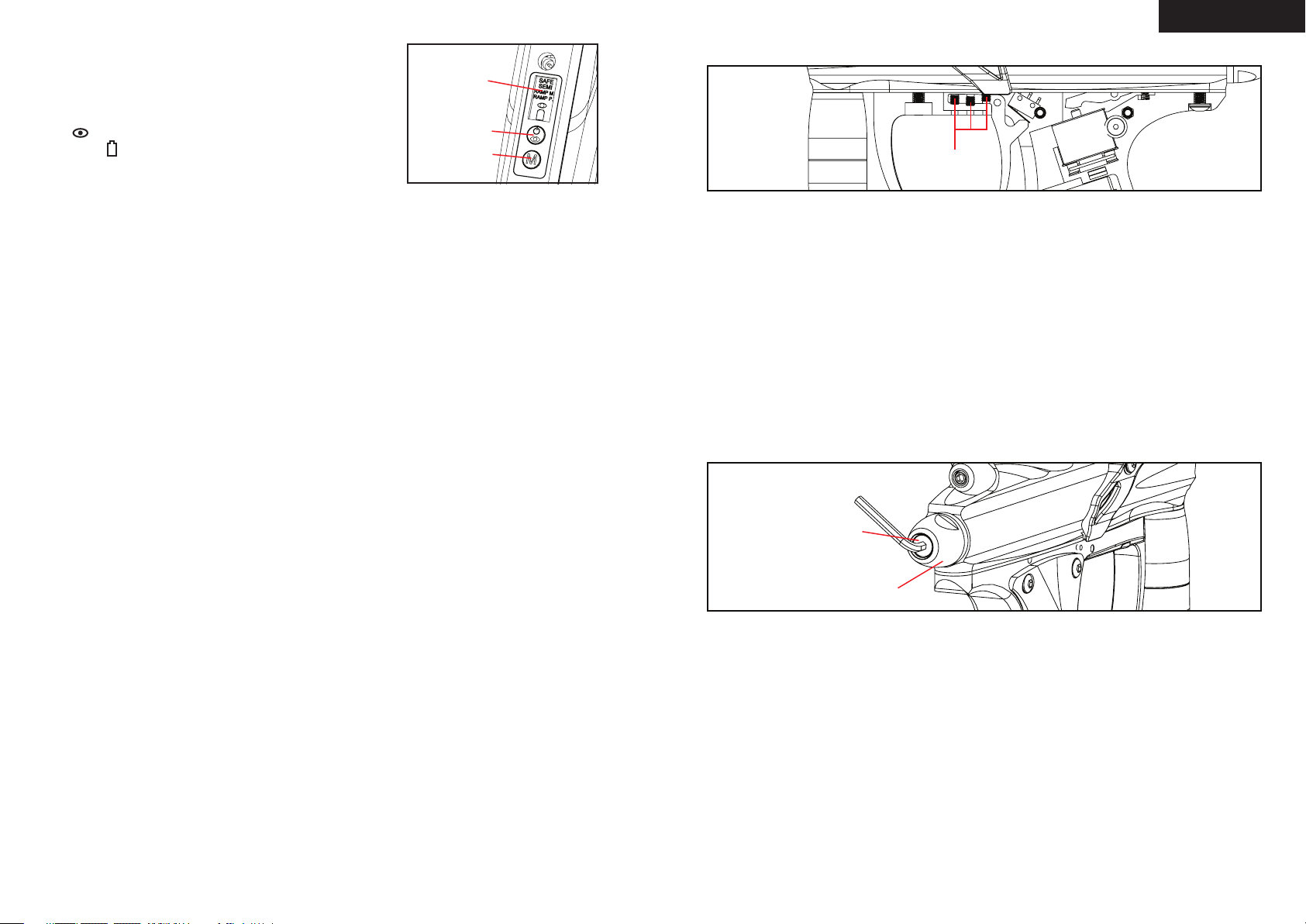

LEAP™ CIRCUIT BOARD w/CAMD SETTINGS

SAFE – Red LED

SEMI – Green LED

RAMP P – Blue LED (PSP RAMP) 13 Balls Per Second

RAMP M – Blue LED (Millennium RAMP) 12 Balls Per Second

EYE – Orange LED (LED ON = Eyes ON, LED OFF = Eyes OFF)

BATTERY – Yellow LED (Solid LED = Good, Flashing LED = Low)

2 Button Access Operations

Press and release the Upper “Power/Eye” Button to turn the marker on. The CAMD will display the Red “Safe”

indicator “ON” meaning that the marker is in safety mode and will not allow the marker to shoot. After turning the

Power “ON” you will need to choose a ring mode.

Press and hold the Lower “Mode” Button until the Green “Semi” indicator begins to ash you are now in the mode

selection menu. To select a ring mode press and release the Lower “Mode” Button until the CAMD mode indicator

displays the desired ring mode. Press and hold the Lower “Mode” Button until the mode indicator stops ashing,

the ring mode is now selected and the Red “Safe” indicator will remain “On”, to turn the safety mode “Off” press

and release the Lower “Mode” Button and the Red “Safe” indicator will turn off, the marker is now capable of ring.

To turn the Power “OFF” press and hold the “Power/Eye” Button until all CAMD LED indicator powers down

completely.

Changing Modes

To change the ring mode, Press and hold the Lower Button until the ring mode indicator on the CAMD start

ashing. While the indicator is ashing press and release the Lower Button to scroll through the desired mode

setting. When the desired ring mode has been selected, press and hold the Lower Button until the indicator stops

ashing. The marker will now operate in the ring mode that has been selected and the Red “Safe” indicator is will

remain “On”, to turn the safety mode “Off” press and release the Lower “Mode” Button and the Red “Safe” indicator

will turn off, the marker is now capable of ring.

IMPORTANT: The safety may be enabled in any mode by pressing and releasing the Lower “Mode” Button, the Red

“Safe” LED indicator will turn on and keep the marker from accidentally shooting while the Power is “ON”.

Firing Mode Lock

To lock the operations of the marker in Semi-Auto Mode remove the lock switch from the circuit board while the

Power is “Off” this will default the marker operation and shoot in Semi-Auto Mode Only.

To lock the operation in Ramp P (PSP) Mode turn the marker Power “ON”, select Ramp P on the CAMD indicator,

remove the tournament lock switch from the circuit board to lock in Ramp P Mode. NOTE: Following the same steps

on selecting the Ramp P Mode will allow you to lock the marker operation in Ramp M (Millennium) mode. NOTE: Use

the lock switch when the playing eld requires it.

Anti Chop Eye Operation

To turn off the Anti Chop Eye feature press and release the Upper “Power/Eye” Button, the “Orange” Eye indicator

will turn off indicating that the eyes are off. NOTE: This feature is useful if you need to cycle the marker without

paintballs for a clearing shot.

To turn the eyes back on press and release the Top “Power/Eye” Button again and the Eye indicator will light back

up indicating that the eyes are on. NOTE: Semi-Auto mode maybe the only allowable ring mode permitted in your

country. Check with your local ofcials regarding this application. For example select European countries, Australia

and New Zealand are restricted to use Semi-Auto model only.

NOTE: European Edition “Semi-Auto Mode Only”

WARN ING

Spyder Elec troni c Markers are not wate r res ista nt.

Extreme moistu re ca n ca use seriou s damage t o any Spyd er Electronic Marker.

Always clean any dirt or pa int inside th e marker s el ectronics.

Never attemp t to modif y the elec tronics circuitry, doi ng so will VOID all el ectro nic warranties and

liabilities from Kingman.

•

•

•

•

CA MD D ispl ay

UP PER Butt on

LOW ER B utto n

9

10

C/A ON/O FF ADA PTER

HELPF UL TIP : Ma ke sure to have the C02 / Compre ssed Air Tank f illed befo re use.

• Firm ly, ha nd t ight en the CO2 / Comp ress ed Air Tank c lockwi se i nto the markers C /A On/Off

ad apte r.

• Tighte n th e ta nk clo ckwi se in the mark ers C/A On/Off adap ter until it is snu g. If an air leak occu rs

be twee n th e tank and the C /A O n/Of f ad apte r, rep lace the ure than e o-ri ng.

• To p ress uriz e th e marker turn the a dapt er k nob to ward s th e ON posit ion to pie rce the pin val ve o n

th e ta nk.

• To rele ase the press ure turn the d ial knob t owards the OF F po sition . Th is w ill relea se t he pressu re

in the hos e line and stop the air flow i n th e marker.

IMPOR TANT: Ma rkers t hat are e quip ped wi th r egul ator s may stor e resid ual ai r af ter th e C0 2/

Compress ed A ir Tank h as b een removed. To ful ly r emove a ny r esid ual air st ored in the marker, turn the

C/A On/Off adapte r kn ob c ount er-c lock wise t o sh ut off the air suppl ied from th e tank . Take several dry

fire shot s wi th the mar ker poin ted in a s afe directi on until the ma rker ha s no rema ining air.

IMPOR TANT: You shou ld neve r need to use an y ha nd t ool to att ach a Compres sed Air Tank to the C /A

On/Off a dapt er.

NOT E: O -rings in the ma rkers p arts k it a re n ot s upplie d to att ach wi th a C02/ Compres sed Air Tank.

NOT E: T he hos e li ne ada pter sup plied on t he C/A O n/Of f is Ame rican thread 1/8” (N PT).

C/A ON/OFF Adap ter

REGULATO R ADJUSTMENT

WARNIN G: Neve r at any t ime should you att empt t o un scre w th e Ver tica l Re gula tor wh ile the marker is

press uriz ed. Doin g so c an c ause s erio us i njury or d eath .

The E lectra w/Eye is equip ped with t he Fast Cha rge Inli ne R egul ator that impr oves th e ma rker s

veloc ity cons iste ncy an d ai r effi cien cy. Once the C 02/ Comp ress ed A ir tan k ha s be en ins tall ed and

tank valv e is ope ned by tur ning t he C /A On/Off ada pter knob cloc kwise, th e ma rker is potential ly

capab le and ready to f ire.

Adj ustment t o the regu lato r ou tput p ress ure is done t hrou gh t he r egul ator a djus ter knob l ocat ed at the

botto m of t he regu lator with the u se o f th e wrench provide d with the spare pa rts kit.

ST EP 1 Loose n th e Re gula tor Adjus ter Lock Scr ew l ocat ed on the on the Reg ulat or A djus ter Knob.

ST EP 2 Us ing the Op en E nd Wr ench provid ed w ith th e sp are part s kit, tur ning t he a djus ter kn ob

clock wise w ill decr ease the reg ulat or out put pres sure and turni ng t he a djuste r kn ob counte r cl ockwis e

will increase the outp ut pressu re o f th e re gulato r. T he regula tor ou tput sho uld be no less t han 300p si

or at lea st one and a h alf tu rn c ount er c lockwi se o f th e Re gulato r Adjus ter Kn ob from the botto m of

the r egul ator.

NOT E: Too lo w of a n ou tput setti ng f rom the reg ulator wil l re sult in very low velo city a nd s ome re-

cocki ng i ssue w ith the marker. You must hav e ad equate out put air press ure from th e re gula tor to avo id

starv ing th e ma rker for air. Too hig h of an output set ting o f th e re gula tor wi ll resu lt in excessi ve air

consu mpti on and poo r ai r effi cien cy. Th is m ay a lso resul t in d ange rous ly h igh veloc itie s ex ceed ing the

recommen ded sa fety lim its for playin g pa intb all.

ST EP 3 Af ter each adj ustment t o the regu lato r, you mus t fi re t he mar ker a f ew t imes t o le t th e

regul ator set tle to its new o utpu t se tting.

ST EP 4 Se curi ng the Reg ulat or A djus ter Lock Scr ew w ill prevent the adj uster knob from t urning due

to vi brat ions kee ping the regu lato r outp ut s etting sta ble and lo cked.

IMPOR TANT: An y ad justme nt t o th e inli ne regu lator outp ut pressu re w ill affe ct the mar kers veloci ty

setti ng, al ways chr onog raph the marker a fter eac h adju stme nt. NOTE: T he Fast Charge I nlin e

Regul ator is tuned from th e fa ctor y to h ave an output pre ssure o f approxi mate ly 3 50 psi .

When adju sting the Regu lato r to “ Decreas e” t he o utpu t pressur e, you will n eed to f ire the ma rker a

few t imes to ge t th e ne w sett ing. IMPOR TANT: (Ma ke s ure you have you r marker poin ted in a s afe

direc tion and you a re foll owing all safe ty g uideli nes set wi th t he u se of this pro duct .)

IMPOR TANT: Ma rkers t hat are e quip ped wi th r egul ator s may stor e resid ual ai r af ter th e Compr esse d

Air Tan k ha s been removed. To full y re move an y re sidu al air sto red in t he mar ker, t urn the C/A On /Off

adapt er kno b c ount er-c lock wise to sh ut o ff the air sup plied from th e ta nk.

IMPOR TANT: Do not attem pt t o serv ice the regu lato r unle ss y ou h ave rece ived pr oper tra inin g from a

quali fied K ingm an G roup servi ce t echn icia n. Doi ng s o will VOID a ll r egul ator w arran ties and l iabi lities

fro m Ki ngman Grou p. If y ou experi ence any lea ks or prob lem with the regu lator, c onta ct K ingman Gro up

Techn ical Suppo rt S ervice De partme nt.

IMPOR TANT: Al ways rem ove all paintbal ls and C02 / Compresse d Air Tank from your m arker a nd

remem ber to k eep the marker in its un-cocke d po siti on before pla cing i t in sto rage.

SC R026

RE G012

RE G013

11

12

REASSEMBLY REAR INTERNALS

STEP 1 Reinsert the Striker Bolt with Striker O-ring facing toward the front of the marker with the at spot of the

Striker Bolt facing down. NOTE: Having the Power Switch ON will ease reentry of the Striker Bolt. Apply thumb

pressure behind the Bolt and at the same time pull on the Trigger. Repeat this process until the Bolt is fully inserted.

NOTE: The hole on the Striker Bolt should be facing upright when looking thru the Receiver. NOTE: The images

above display the Delrin Bolt “connected” to and “disconnected” from the Striker Bolt.

STEP 2 Insert the Striker Buffer ush with the receiver and place the Striker Spring thru the Striker Buffer.

STEP 3 Tighten rmly the Striker Plug w / Velocity Adjuster & Spring Guide to the rear of the Receiver.

STEP 4 Insert the Delrin Bolt thru the rear of the Receiver with the Top Cocking Pin. Press downward on the Top

Cocking Pin to gain entry with the Striker Bolt. NOTE: If the Striker Bolt hole is not aligned upright, the Top Cocking

Pin will not fasten correctly.

WARNING: Before / after use of the marker, make sure to fasten all screws. Screws may become loose due to

vibration. Loose screws can be dangerous and cause injury.

To assure that the marker is assembled properly, follow the schematic drawing or position parts in order during

disassembly. Parts assembled backwards or improper parts installed will / can cause the marker to malfunction.

A JAMMED PAINTBALL IN THE BREACH

In the event of a paintball break and the Delrin Bolt jams, follow these steps to help un-jam the marker. The markers

breach is located where the barrel starts to thread in the receiver and underneath the markers feed neck. Before

attempting to un-jam the Delrin Bolt you should always have your Goggles or Safety Glasses on. Make sure the

marker is in the SAFE / OFF position before attempting to un-jam the Delrin Bolt. Remove the CO2 / Compressed

Air Tank before attempting to un-jam the marker. Remove all paintballs and the loader from the feed neck. Have the

barrel removed from the receiver to allow the paintball (s) to exit. With enough force on the Cocking Knob, pull back

to release the Delrin Bolt from the jammed position. Another method is to use a “Straight Shot Squeegee” or the end

of a wood dowel rod; push against the face of the Delrin Bolt with enough force to release the jammed Bolt. Always

clean the paint from the breach and barrel to enhance the performance of your marker.

IMPORTANT: Never look down the barrel of the marker when loaded or unloaded. Remove the attached CO2 /

Compressed Air Tank before attempting to un-jam the Delrin Bolt.

NOTE: Never use a metal rod or screwdriver as a tool to push on the Delrin Bolt, anything metal will scratch and

damage the inside of the marker.

English

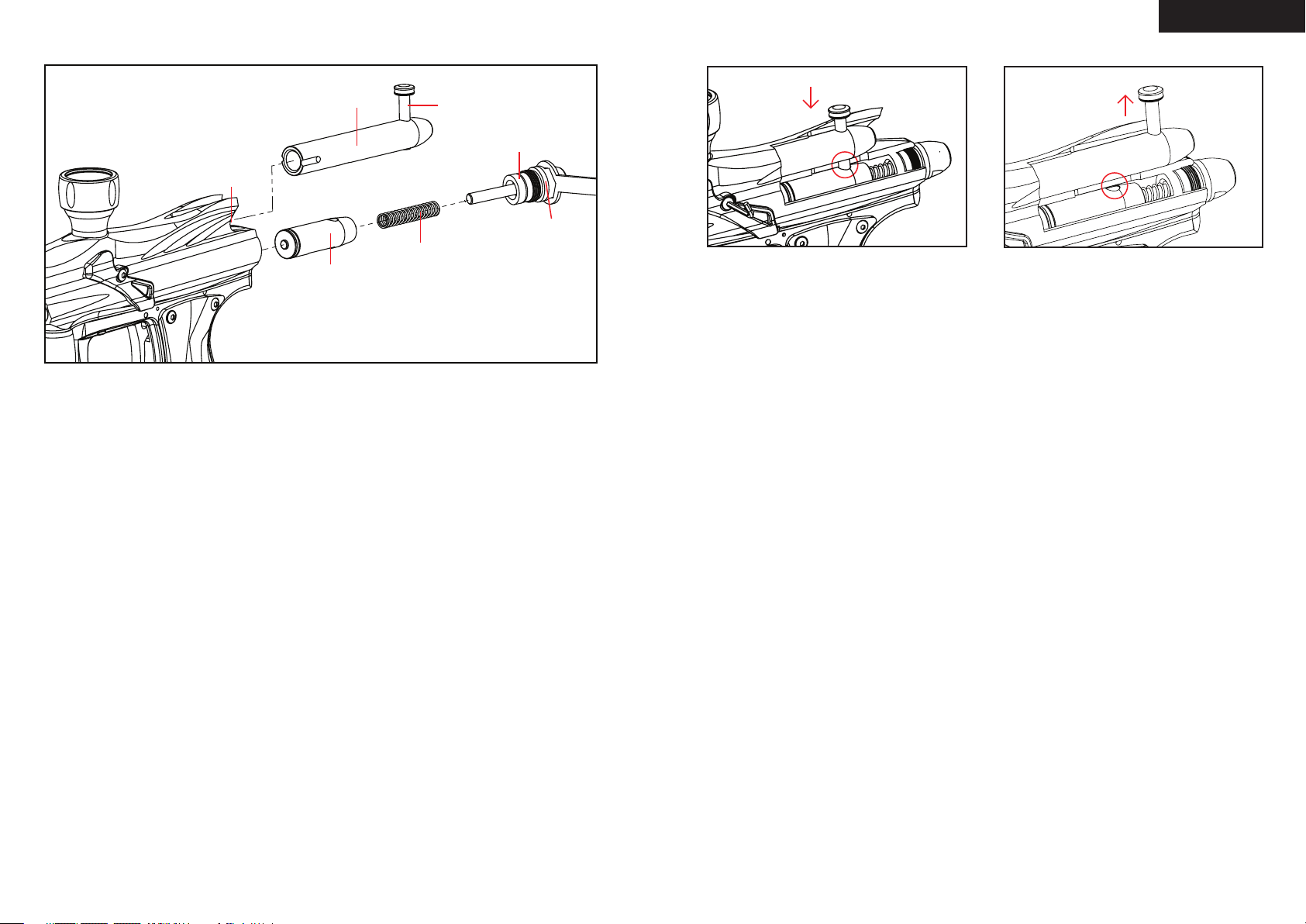

DISASSEMBLE / REASSEMBLE AND CLEANING OF REAR INTERNALS

QUICK CLEAN DISASSEMBLY

Lift upward on the Top Cocking Knob to disconnect the Delrin Bolt from the Striker Bolt. This will allow the Delrin Bolt to slide

out from the rear of the Receiver. HELPFUL TIP: Removing the Delrin Bolt from the Receiver will allow easy access

to clean with a squeegee. NOTE: Make sure the hole on the Striker Bolt is facing upright when looking thru the

Receiver. This will allow the Top Cocking Pin to correctly fasten with the Striker Bolt.

IMPORTANT: The air passage hole located in the middle of the Delrin Bolt should always be facing downward when

reinstalling. If the Delrin Bolt is not installed correctly, paintballs will not exit out of the barrel normally.

DISASSEMBLE OF REAR INTERNALS

STEP 1 Lift upward on the Top Cocking Knob to disconnect the Delrin Bolt from the Striker Bolt. This will allow the

Delrin Bolt to slide out from the rear of the Receiver.

STEP 2 Using an adjustable wrench turn the Striker Plug counter clockwise located at the rear of the Receiver. This

will allow all internal parts such as the Velocity Adjuster & Spring Guide, Striker Spring, Striker Buffer and Striker

Bolt to slide from the rear of the Receiver.

NOTE: Remove the Striker Plug only with the marker in the un-cocked position this will prevent the internals from

springing out because the Striker Spring is compressed. HELPFUL TIP: Placing your nger behind the Striker Plug

before removing this will prevent the markers internals from springing out.

STEP 3 Remove items in order; Striker Plug w/Velocity Adjuster, Striker Spring and Striker Buffer.

STEP 4 Slide the Striker Bolt out of the rear of the Receiver. HELPFUL TIP: When the internals are removed it

would be wise to clean any dirt or paint from the inside of the Receiver with a squeegee and wipe the Delrin Bolt

clean with a rag or paper towel. Apply some paintball gun oil on Striker O-ring periodically.

IMPORTANT: It is not necessary to disassemble the rear internals for basic maintenance unless the Striker O-ring

needs to be replaced.

Part Names and Numbers described in this section:

Top Cocking Knob (#STK008)

Delrin Bolt (#VBT008)

Striker Bolt (#STB002)

Striker Plug (#STP028/STP029)

Striker Spring (#SPR004)

Striker Buffer (#STF001)

Receiver (#REC028/REC029)

CONNECTED DISCONNECTED

RE C028

RE C029

VB T008

ST K008

ST B002

SP R004

ST P028

ST P029

ST F001

13

14

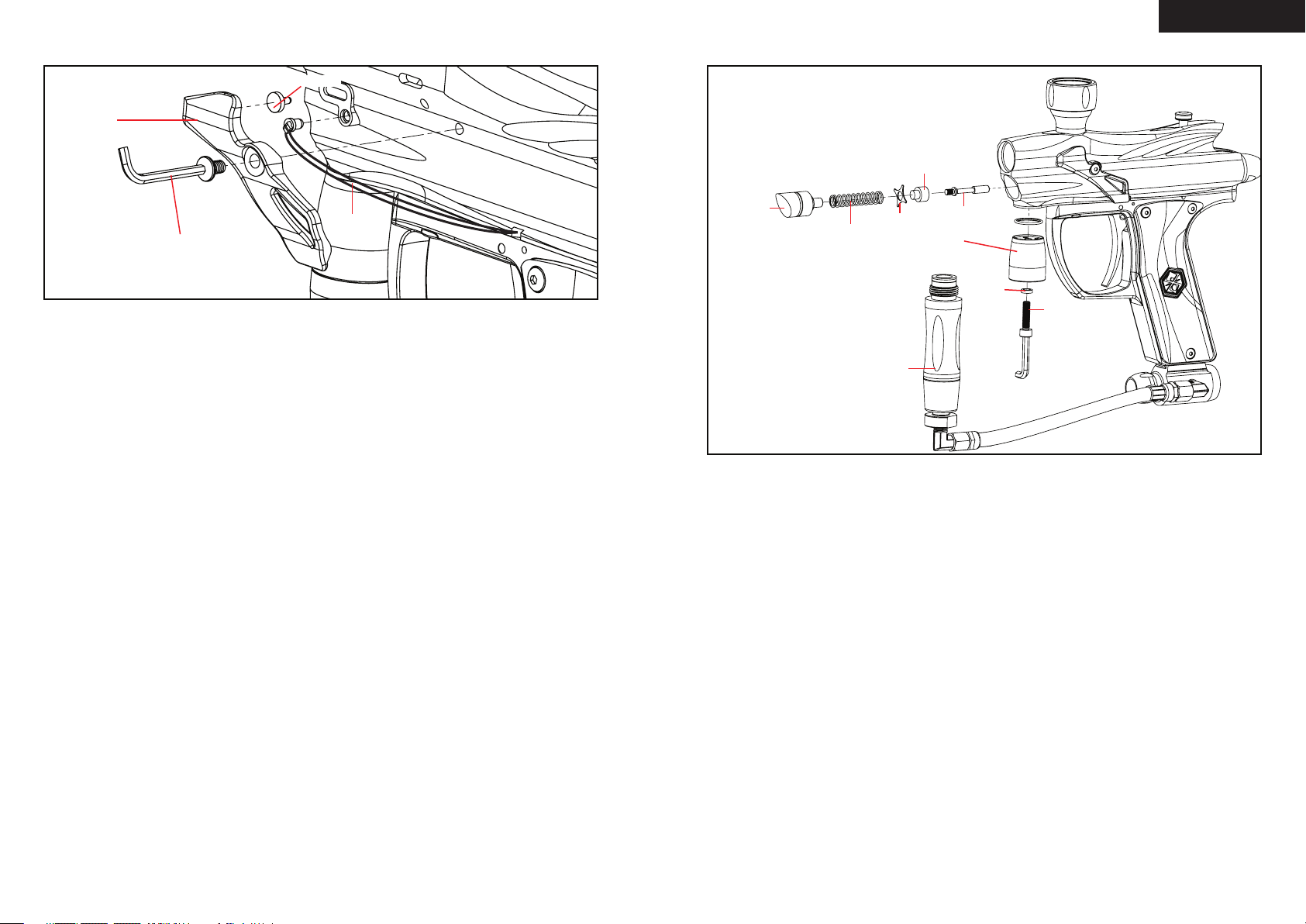

CUP SEAL REMOVAL

STEP BY STEP CUP SEAL ACCESS

Access of the cup seal for service or replacement requires the removal of the Front Plug and Vertical CA Adapter.

STEP 1 Unscrew the Regulator from the Vertical CA Adapter.

STEP 2 Remove the Vertical CA Adapter by unscrewing the Vertical CA Adapter Mounting Screw, be sure to keep a

nger over the Front Plug to prevent it from springing out.

NOTE: The Front Plug and Vertical CA Adapter are both held in place by the Vertical CA Adapter Mounting Screw.

STEP 3 Pull the Front Plug out and it should come out with the Valve Spring, Cup Seal Guide, Cup Seal and Valve

Pin all together.

STEP 4 Unscrew the Cup Seal from the Valve Pin and replace with the spare provided with your spare parts kit.

STEP 5 Follow the previous steps in reverse to re-install all components properly. Make sure the Front Plug screw

hole is lined up with the vertical adapter screw hole.

IMPORTANT: Always make sure all air sources have been removed from your marker and any residual air has been

vented out completely before servicing your marker.

NOTE: Service or replacement of the Cup Seal should only be done if a leak is present and can be heard from the

breach after the removal of the Delrin Bolt.

Part Names and Numbers described in this section:

Regulator (#REG028/REG029)

Cup Seal Guide (#ITP011)

Cup Seal (#ITP012)

Valve Pin (#ITP017)

M5x20 Vertical Washer (#ITP019)

Front Plug (#LPC028/LPC029)

Valve Spring (#SPR013)

Vertical Adapter (#VRT028/VRT029)

Vertical Adapter Mounting Screw (#SCR027)

English

LP C028

LP C029

SP R013

IT P011

IT P012

IT P017

VR T028

VR T029

RE G028

RE G029

SC R027

ANTI CHOP EYES

ANTI CHOP EYES

The Anti Chop Eyes help prevent the chopping of paint by not allowing the marker to re until a paintball is properly

chambered in the breach. The Eyes transmit a beam across the inside of the breech. The circuit board is preset from

the factory and does not need to be adjusted or altered. (If the Eyes are ON and do not see each other when ring

your marker, you will have to clean the Eyes.) NOTE: The Anti Chop Eyes system reduces the likelihood of chopping

paintballs but do not completely eliminate it from happening, keep the Anti Chop Eyes clean for best and reliable

performance.

CLEANING THE ANTI CHOP EYES

Using a squeegee or swab thru the breech should clean the Eyes enough for the Eyes to detect each other. Another

way is to use an aerosol can of air thru the breech to remove any paint or dirt. To thoroughly clean the Eyes using

the supplied Allen wrench remove both Eye Panel Screws and Eye Panels . Once the Eye Panel Screws & Eye

Panels are removed, proceed with a soft pinch to remove the Eye Wire Harness from the receiver. Use a cloth or

paper towel to remove any paint or dirt that is blocking the Eyes.

IMPORTANT: Cleaning the Eyes often will help reduce dirt, paint or oil residue that blocks the Eyes

NOTE: Never attempt to rush the cleaning process or you can pinch the wires and cause the marker to malfunction

with the Eye Mode ON. Take precaution not to over tighten the Eye Panel Screws or this can lead to stripping the

head. NOTE: When the Eye Panels are removed the Ball Stopper(s) may be attached to the Eye Panels and can

cause them to fall out. HELPFUL TIP: Please note how the parts are removed for easy reassembly.

IMPORTANT: Before removing both Eye Panels use a needle or dental pick through the hole of the Eye Panel to

remove any dirt that may have built up and prevent the Allen wrench from loosening the screw. It’s possible if the

dirt is not removed you can strip the Eye Panel Screw.

NOTE: Maintenance cleaning of the Anti Chop Eyes should only be done if a paintball break in the breach has

occurred and affected the detection of the paintballs. Removing the Delrin Bolt and pushing a swab type squeegee

through the breach may be adequate in cleaning the Anti Chop Eyes.

CHANGING THE BALL STOPPERS

Experiencing paint rolling through the barrel can be related to small diameter paintballs or the loss of a Ball

Stopper(s) . When removing Eye Panel Screws and Eye Panels the Ball Stopper(s) will be accessible for cleaning or

replacement.

HELPFUL TIP: Please note how the parts are removed for easy reassembly.

IMPORTANT: Before removing both Eye Panels use a needle or dental pick thru the hole of the Eye Panel to remove

any dirt that can build up and block the Allen screw from loosing. It’s possible if the dirt is not removed you can stripe

the Eye Panel Screw.

NOTE: Take precaution not to over tighten the Eye Panel Screws or this can strip the head. NOTE: Maintenance is

not required for the Ball Stoppers unless they have completely worn out or is unable to keep a paintball from rolling

out the breach of the marker when the marker is pointed down.

Part Names and Numbers described in this section:

Eye Panel (#BLS011/BLS012/ BLS014/BLS015)

Ball Stopper (#BLS003)

Eye Panel Screw (#SCR002)

Eye Wire Harness (#WRH008)

BL S 01 1

BL S012

BL S014

BL S015

SC R002

BL S003

WR H008

IT P019

15

16

English

SC R026

RE G012

RE G013

OR G024

RE G010

RE G011

OR G024

RE G014

RE G004

RE G003

OR G022

SC R025

RE G008

RE G009

OR G025

REGULATOR SCHEMATIC

TROUBLESHOOTING

ONE OR MORE OF THE FOLLOWING MAY CAUSE RECOCKING RELATED ISSUES:

Need lubrication on the following O-ring (#ORG001) (see Disassemble / Reassemble).

The pressure in the tank is too low and possibly needs to be relled.

Striker O-ring (#ORG001) is damaged or missing. Replace with a new Kingman approved Striker O-ring.

NOTE: The Striker O-ring can not be substituted with a black or urethane bottle o-ring.

Dirt or broken paint shell fragments in the receiver can cause the marker to have recocking issues. Using a

squeegee thru the upper portion of the receiver will remove most of the dirt or broken shell fragments. Should

this issue continue, (see Disassemble / Reassemble) remove the markers internals for complete cleaning.

Using low quality paintballs can cause the marker to experience recocking issues because of the shape of

the paintballs. HELPFUL TIP: Paintballs have a shelf life and can become too fragile for use. HELPFUL TIP:

Paintballs can take a different shape over time, so it would be wise to size the paintball with your barrel.

ELECTRONIC TRIGGER FRAME TROUBLESHOOTING

• If your marker is not shooting it may be due to one of the following problems:

• Battery may need to be recharged.

• The Battery Wire Harness is not properly attached to the circuit board.

• The Coil Set Harness is not properly attached to the circuit board.

• The Touch Switch Harness is not properly attached to the circuit board. NOTE: If the Markers Electronics have

any dirt or paint, Kingman recommends using an aerosol can of air. Apply the can of air directly at the

components that need cleaning.

AIR LEAKS

IMPORTANT: Always remove the air tank and paintballsbefore any disassembly of the marker.

Air leaking from the Front Plug means the O-ring (#ORG002) will need to be oiled or replaced.

Air leaking from the Vertical Adapter means the O-ring (#ORG023) will need to be oiled or replaced.

Air leaking down the barrel is usually caused by a worn or damaged cup seal (#ITP012). (see Cup Seal

Removal) should the cup seal need to be exchanged.

Never remove Valve Body (#ITP018) unless specic repairs are needed.

A nick or scratch on the lip of the Valve Body can cause an internal air leak (see Cup Seal Removal). The Valve

Body may need to be replaced.

Air leaking thru the Receiver and out of the Trigger Frame would indicate the Valve Body O-rings (#ORG002)

will need to be replaced.

If air is leaking thru the opposite end of the hose ttings, please check the following:

The female end of the hose must have a plastic washer (#HSF004) installed inside the hose collar and be

tightened properly.

IMPORTANT: The hose line supplied has metric female ends. This will not install into American 1/8” (NPT) threaded

ttings. If installed incorrectly, it is possible to damage the attachment ttings and hose line.

HELPFUL TIP: To assure marker is assembled properly, follow the schematic drawing or position parts in order

during disassembly. Parts assembled backwards or improper parts installed will / can cause the marker to

malfunction.

•

•

•

•

•

•

•

•

•

•

•

•

•

17

18

EL ECTRA w/ Eye SCHEMATIC S

English

OR G003

LP C028

LP C029

FN D019

FN D020

RE C028

RE C029

VB T008

ST K008

VB T003

VB T004

VB T013

OR G002

ST F001

OR G008

ST P028

ST P029

VTA0 28

VTA0 29

SP R004

OR G001

ST B002

OR G002

SP R013

IT P011

IT P012

IT P017

OR G023

IT P018

SC R027

VR T028

VR T029

OR G002

BAR 028

BAR 029

SC R007

WR H008

BL S009

BL S010

BL S011 BLS 012

BL S014 BLS0 15

BL S003

SC R028

GR P005

SC R002

SC R028

TR S008

TR F009

RE G028

RE G029

HS F009

HS F004

HS E010

AS A012

AS A028

AS A029

HS F001

SE R001

RP N001

SC R003

SC R003

EL M003

EL M004

EL M002

SC R011

EL M001

RP N002

SC R029

HS F009

EC B008

OR G002

SC R002

FN D028

FN D029

OR G003

RE G012

RE G013

AS A010

AS A014

AS A013

OR G018

AS A018

EL ECTRA w/ Eye PARTS LIST

AS A010 C/A On/O ff Ad apt er K nob (pol ishe d b lack )

AS A012 C /A On/Of f De pres sin g Pi n

AS A013 C /A On /Off Ret aini ng S crew

ASA014 C/A On/Off Adapter Knob (polished titanium)

AS A018 C/A On/O ff 1/8 H ose Plug

AS A028 C/A On/O ff A dapt er ( poli she d bl ack)

AS A029 C/A On/O ff A dapt er ( pol ishe d ti tani um)

BAR 028 12” 2PC S Ba rrel (po lish ed b lack )

BAR 029 12” 2PC S Ba rrel (po lish ed t ita nium)

BL S003 B all Stop per

BLS00 9 B all Stoppe r / Eye Wire Insert - right (bla ck)

BLS01 0 Ball Stopper / E ye Wire Inse rt - left (black)

BLS 011 A lumi num E ye Pa nel - righ t (po lishe d bl ack)

BL S012 Al umin um E ye P anel - l eft (pol ish ed b lack )

BLS014 Al uminum Eye Panel - rig ht (polished titaniu m)

BLS01 5 A luminum Ey e Panel - left (poli shed tita nium)

EC B008 LE AP™ Circu it Boar d

EL M001 C oil Set

EL M002 Coil Pin

EL M003 Tour name nt L ock Swit ch

EL M004 Ca paci tor

EL M008 LE AP™ Touch Sw itch Mem bran e

EL M009 CA MD D ispl ay Cover

FND0 19 Twist Clamp & C Cl ip Inse rt (po lished black)

FND020 Twist Clamp & C Clip Insert (polishe d titanium)

FN D028 Feed Nec k ( poli shed bla ck)

FN D029 Fee d Ne ck ( poli shed tit ani um)

GR P005 D ual Text ure Grip Pan el ( blac k)

HS E010 Di scon nect Hos e (f emal e x fema le)

HS F004 P last ic Wa sher

HS F009 9 0d Male to Male Ada pter (ST D x MET)

IT P011 Cu p Se al G uide

IT P012 Cu p S eal

IT P017 Va lve Pin (sli m)

IT P018 Valv e Bo dy (bli nd h ole)

IT P019 M5 x20 Verti cal Washe r

LP C028 Fro nt P lug (pol ishe d bl ack)

LP C029 Fro nt P lug (pol ishe d t itan ium)

OR G001 St riker O- ring #14. 3 1.7 60p u

OR G002 O-r ing #01 5 80

OR G003 Ba rrel O-r ing #22 1.5 80

OR G008 O-r ing #010 80

OR G018 O -rin g #0 8 80

OR G021 R eg P isto n #1 4 70p u

OR G022 Re g Ad just er O-ri ng # 11 8 0pu

OR G023 Ve rtic al O -rin g #1 7 1. 5 80

OR G024 Pi ston Sha ft O -rin g # 08 8 0pu

PAK0 05 Sp are Part s Ki t

REC 028 Ele ctra w /Eye Receiv er (p olis hed b lack)

* Item Not Pictured (+) Cross-head Screw (A) Allen-head Screw

REC0 29 Elec tra w/Ey e Recei ver (po lished titani um)

RE G003 Reg Pis ton

RE G004 Re g Sp ring

RE G008 Re g Top Body (po lis hed blac k)

RE G009 R eg Top Body (p olis hed tita nium )

RE G010 Reg Mid Bod y (p olis hed bla ck)

RE G011 Re g Mi d B ody (pol ishe d ti tan ium)

RE G012 Re g Ad just er ( pol ishe d bl ack)

RE G013 R eg A djus ter (pol ishe d t itan ium)

RE G014 Re g O- rin g Ho usin g (F )

RE G028 Reg ulat or (comp lete) (p olis hed blac k)

REG02 9 Reg ulator (comp lete) (poli shed titan ium)

RP N001 S ear Roll Pin

RP N002 Trig ger/Tou ch S witc h Ro ll P in

SC R002 M4 x 8 Sc rew (A)

SC R003 C ircu it B oard Scr ew ( +)

SC R007 M8 x 8 Valve Bod y Sc rew (A)

SC R011 Co il S et S crew

SC R025 M4 x 4 Reg Scr ew (A )

SC R026 M 4 x 10 Reg Adjus ter Scr ew (A )

SC R027 M5 x 2 0 Ver tica l Sc rew (A)

SC R028 M 5 x 10 Trig ger Frame Scr ew ( A)

SCR 029 M4 x 6 Tri gger Adjus tment Scre w (A)

SE R001 Se ar

SP R004 St rike r Sp ring

SP R009 E SP S ear Spri ng

SP R013 Va lve Spri ng

ST B002 St rike r Bo lt

ST F001 Str iker Buf fer

ST K008 Top Cock ing Knob

ST P028 S trik er P lug Thre aded (po lis hed blac k)

STP02 9 Striker Plug Thre aded (poli shed tita nium)

TR F009 El ectr onic Trigg er Frame (M)

TRS0 08 Ma gnetic Saber Trigge r (pol ished black)

VB T003 D elri n Bo lt L ocki ng B eari ng

VB T004 Del rin Bol t Loc king Sp ring

VB T008 Del rin Bol t w/ Lock ing Kno b

VB T013 Del rin Bol t Lo ckin g Sc rew

VR T028 Ver tica l Ad apte r ( poli shed bla ck)

VR T029 Ver tic al Ad apt er ( poli shed tit ani um)

VTA028 Velocity Adjuster & Spring Guide (polished black)

VTA0 29 Velocity Adjuster & Spring Guide (polished titanium)

WR H002 Ba tter y Ha rnes s

WR H007 Touc h Sw itch (3P )

WR H008 Eye Wire Har ness

WR H007

IT P019

CAM D Di spl ay

UPP ER B utt on

LOWE R B utto n

Cha rgin g Po rt

ELM 008

*

Loading...

Loading...