Page 1

EPX2255

SprayTECH

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

Piston Pump

Owner’s Manual

Printed in the U. S. A.

Model Numbers:

0551050 Stand

0551060 Upright Cart

0551070 Low Boy Cart

1104 © 2004 SprayTECH. All rights reserved. Form No. 0551545A

Page 2

Table of Contents

WARNING

CAUTION

WARNING

Safety Precautions.................................................................2

Specifications .........................................................................3

General Description ...............................................................4

Operation ................................................................................4

Setup ....................................................................................4

Preparing to Paint.................................................................4

Painting.................................................................................5

Pressure Relief Procedure ...................................................5

Spraying ..................................................................................6

Spraying Technique ..............................................................6

Practice.................................................................................6

Cleanup ...................................................................................6

Cleaning the Spray Tip.........................................................7

Maintenance............................................................................7

General Repair and Service Notes.......................................7

Replacing the PRIME/SPRAY Valve.....................................7

Replacing the Filters.............................................................8

Replacing the Motor Assembly.............................................8

Replacing the Gears.............................................................9

Replacing the Transducer.....................................................9

Servicing the Fluid Section.................................................10

Troubleshooting ...................................................................12

Parts List...............................................................................18

Main Assembly....................................................................18

Motor Assembly ..................................................................19

Suction Set Assembly.........................................................19

Labels .................................................................................19

Gear Box Assembly............................................................20

Stand Assembly..................................................................21

Upright Cart Assembly........................................................21

Fluid Section Assembly ......................................................22

Low Boy Cart Assembly......................................................23

Electrical Schematic ...........................................................23

Limited Warranty..................................................................24

Safety Precautions

This manual contains information that must be read and

understood before using the equipment. When you come to an

area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information will

follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information which should

HAZARD: Injection injury - A

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE

CUT! Injection can lead to amputation. See a physician

immediately.

The maximum operating range of the sprayer is 3100 PSI/

21.4 MPa fluid pressure.

PREVENTION:

be given special attention.

high pressure fluid stream

produced by this equipment can pierce the

skin and underlying tissues, leading to serious

injury and possible amputation. See a

physician immediately.

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the fluid stream.

DO NOT allow body to touch a leak in the fluid hose.

• NEVER put hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock gun trigger, shut pump off, and release all

pressure before servicing, cleaning tip or guard, changing

tip, or leaving unattended. Pressure will not be released

by turning off the motor. The PRIME/SPRAY valve handle

must be turned to PRIME to relieve the pressure. Refer to

the PRESSURE RELIEF PRESSURE described in the

pump manual.

• ALWAYS keep tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning

device.

• ALWAYS remove the spray tip before flushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking and

abuse. A leak can inject material into the skin. Inspect

the hose before each use.

• NEVER use a spray gun without a working trigger lock

and trigger guard in place.

• All accessories must be rated at or above the maximum

operating pressure range of the airless sprayer. This

includes spray tips, guns, extensions, and hose.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is

important to treat the injury as soon as possible. DO

NOT delay treatment to research toxicity. Toxicity is a

concern with some coatings injected directly into the

blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

HAZARD: EXPLOSION AND FIRE - Solvent and paint

PREVENTION:

• Provide extensive exhaust and fresh air introduction to

•

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

• Place pump at least 25 feet (7.6 m) from the spray object

• The equipment and objects in and around the spray area

• Use only conductive or grounded high-pressure fluid hose.

• Power cord must be connected to a grounded circuit.

• Always flush unit into separate metal container, at low

• Follow material and solvent manufacturer's warnings and

• Use extreme caution when using materials with a

• Plastic can cause static sparks. Never hang plastic to

• Use lowest possible pressure to flush equipment.

fumes can explode or ignite. Severe injury

and/or property damage can occur.

keep the air within the spray area free from accumulation

of flammable vapors.

Avoid all ignition sources such as static electricity sparks,

electrical appliances, flames, pilot lights, hot objects, and

sparks from connecting and disconnecting power cords or

working light switches.

order.

in a well ventilated area (add more hose if necessary).

Flammable vapors are often heavier than air. Floor area

must be extremely well ventilated. The pump contains

arcing parts that emit sparks and can ignite vapors.

must be properly grounded to prevent static sparks.

Gun must be grounded through hose connections.

pump pressure, with spray tip removed. Hold gun firmly

against side of container to ground container and prevent

static sparks.

instructions.

flashpoint below 70° F (21° C). Flashpoint is the

temperature at which a fluid can produce enough vapors

to ignite.

enclose spray area. Do not use plastic drop cloths when

spraying flammable materials.

2 © SprayTECH. All rights reserved.

Page 3

GAS ENGINE (WHERE APPLICABLE)

CAUTION

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Always place sprayer outside of structure in fresh air

solvents away from engine exhaust. Never fill fuel tank with a

running or hot engine. Hot surface can ignite spilled fuel.

Always attach ground wire from pump to a grounded object.

Refer to engine owner’s manual for complete safety

information.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as

• Contact your coating supplier about the compatibility of

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read

• W

• Wear protective clothing as required by coating

HAZARD: GENERAL - Can cause severe injury or

PREVENTION:

• Read all instructions and safety precautions before

• Follow all appropriate local, state, and national codes

• The United States Government Safety Standards have

• Use only manufacturer authorized parts. User assumes

• Before each use, check all hoses for cuts, leaks, abrasion

• All hoses, swivels, guns, and accessories must be

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

• Always unplug cord from outlet before working on

MATERIALS - will cause severe injury or

property damage.

bleach, mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

material with aluminum.

insecticides, and other materials can be

harmful if inhaled or come in contact with body.

Vapors can cause severe nausea, fainting, or

poisoning.

all instructions supplied with the mask to be sure it will

provide the necessary protection.

ear protective eyewear.

manufacturer.

property damage.

operating equipment.

governing ventilation, fire prevention, and operation.

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards, should be consulted.

all risks and liabilities when using parts that do not meet

the minimum specifications and safety devices of the

pump manufacturer

or bulging of cover. Check for damage or movement of

couplings. Immediately replace hose if any of those

conditions exist. Never repair a paint hose. Replace with

a grounded high-pressure hose.

pressure rated at or above the maximum operating

pressure range of the airless sprayer.

equipment.

.

. Keep all

Grounding Instructions

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER — Improper installation of the grounding plug can

result in a risk of electric shock. If repair or replacement of the

cord or plug is necessary, do not connect the green grounding

wire to either flat blade terminal. The wire with insulation

having a green outer surface with or without yellow stripes is

the grounding wire and must be connected to the grounding

pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the

plug on the product. Make sure your extension cord is in

good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your

product will draw

in line voltage resulting in loss of power and overheating.

A 12 gauge cord is recommended. If an extension cord is

to be used outdoors, it must be marked with the suffix WA after the cord type designation. For example, a

designation of SJTW-A would indicate that the cord would

be appropriate for outdoor use.

. An undersized cord will cause a drop

Specifications

Gallons per minute (GPM)...............0.56 (2.1 LPM)

Maximum tip sizes ...........................0.023”

Maximum pressure ..........................3100 PSI (21.4 MPa)

Power...............................................1.35 HP DC motor,

Weight..............................................33 lbs. (15 kg)

Maximum hose length......................300’ (91.4 m)

120VAC

© SprayTECH. All rights reserved. 3

Page 4

General Description

CAUTION

WARNING

WARNING

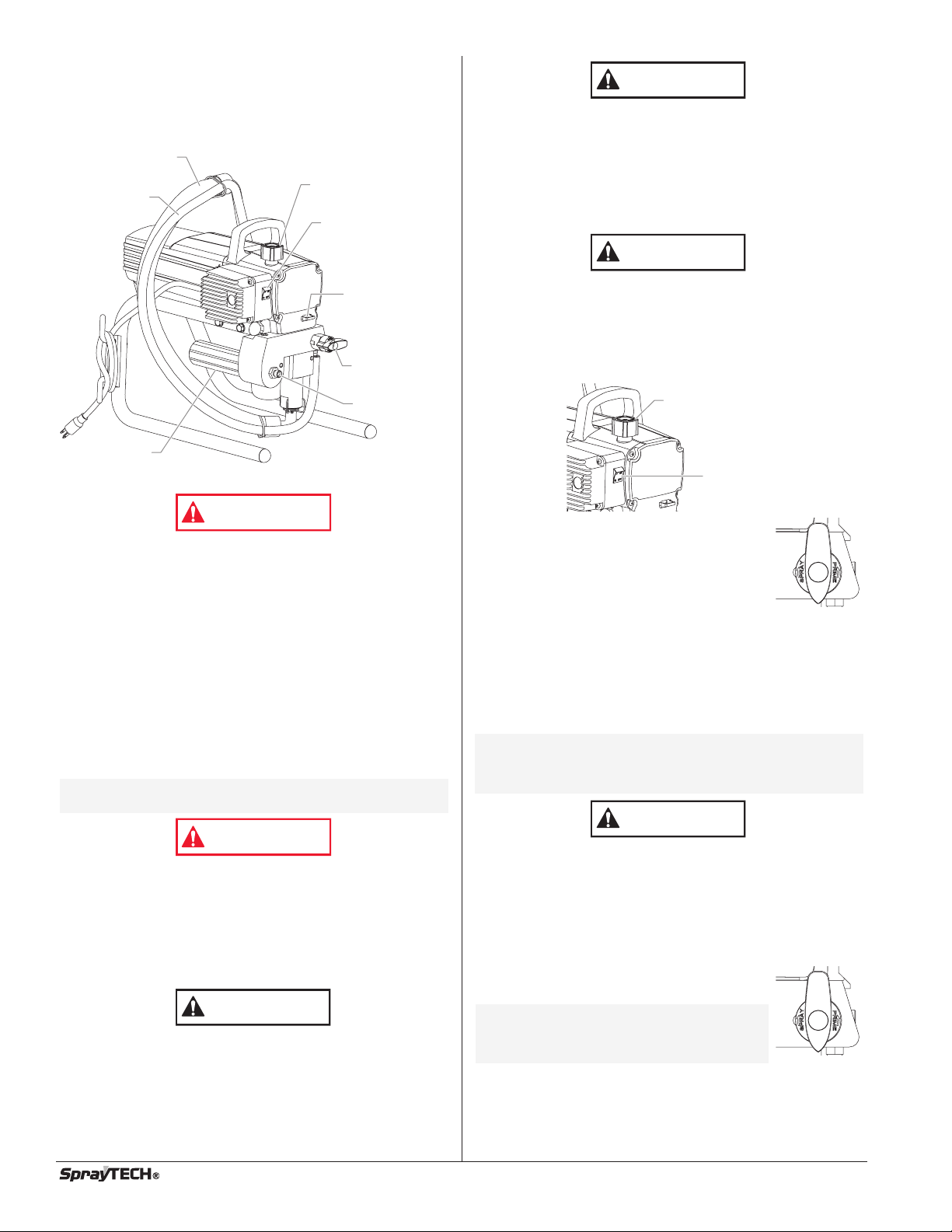

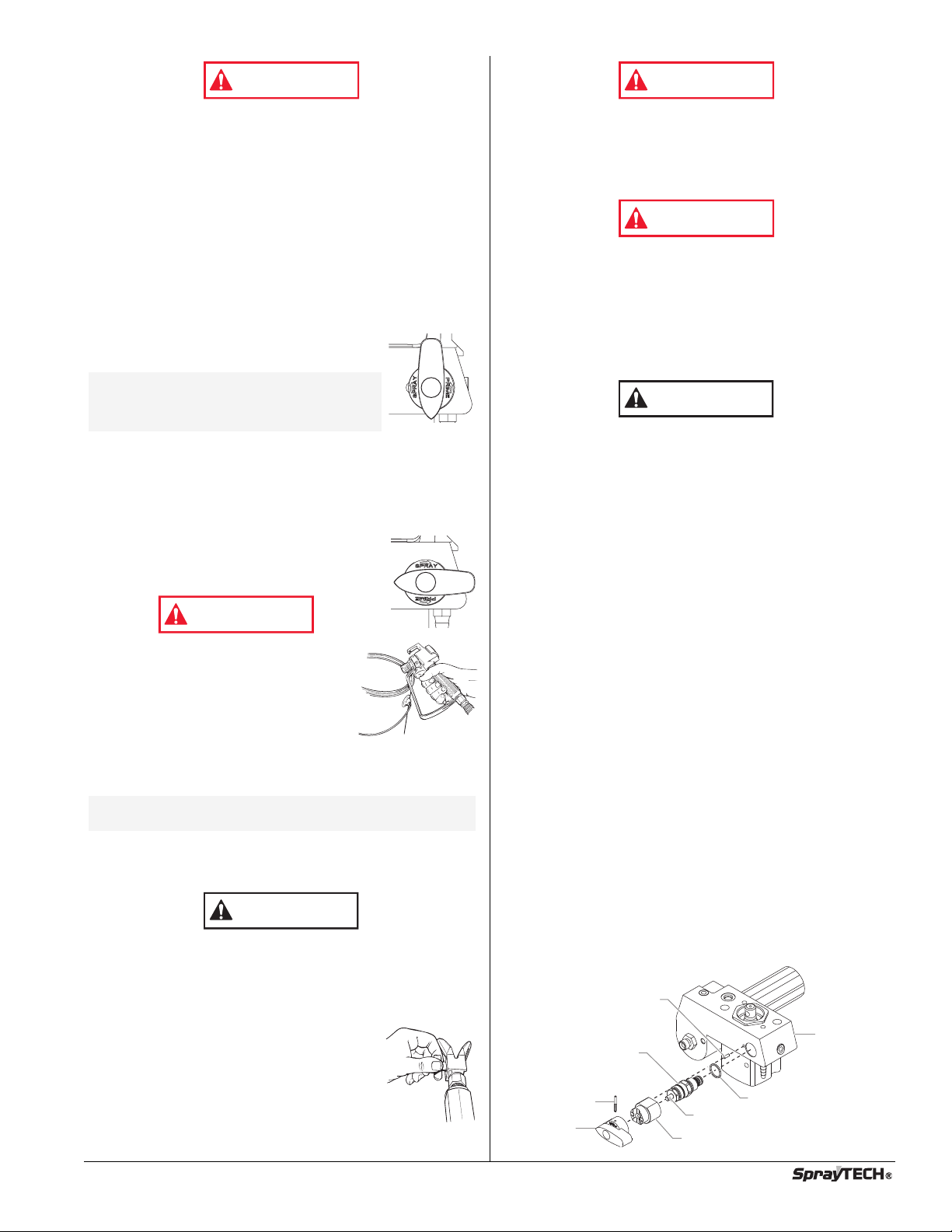

Pressure Control

Knob

ON/OFF

Switch

PRIME/SPRAY

Valve

Outlet Fitting

Oil Cup

Siphon

Tube

Return

Hose

Filter

CAUTION

Pressure Control

Knob

ON/OFF

Switch

CAUTION

CAUTION

This airless sprayer is a precision power tool used for spraying

many types of materials. Read and follow this Owner’s

Manual carefully for proper operating instructions,

maintenance, and safety information.

Operation

Always use a minimum 12 gauge, three-wire extension

cord with a grounded plug. Never remove the third prong

or use an adapter.

Preparing a New Sprayer

If this sprayer is new, it is shipped with test fluid in the fluid

section to prevent corrosion during shipment and storage.

This fluid must be cleaned out of the system thoroughly with

mineral spirits before spraying paint.

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

Place the siphon tube into a container of mineral spirits.

1.

2. Place the return hose into a metal waste container.

3. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

This equipment produces a fluid stream at extremely high

pressure. Read and understand the warnings in the

Safety Precautions section at the front of this manual

before operating this equipment.

Setup

Perform the following procedure before plugging in the power

cord of an electric sprayer.

1. Ensure that the siphon tube and the return hose are

attached and secure.

2. Using a wrench, attach a minimum of 50’ of 1/4” nylon

airless spray hose to the outlet fitting on the sprayer.

Tighten securely.

3. Attach an airless spray gun to the spray hose. Using two

wrenches (one on the gun and one on the hose), tighten

securely.

NOTE: Do not attach the tip to the spray gun yet.

Make sure all airless hoses and spray guns are electrically

grounded and rated at or above the maximum operating

pressure range of the airless sprayer

4. Make sure the pressure control knob is turned fully

5. Make sure the ON/OFF switch is in its OFF position.

6. Fill the oil cup with approximately one tablespoon of

Never operate unit for more than ten seconds without

fluid. Operating this unit without fluid will cause

unnecessary wear to the packings.

7. Make sure the electrical service is 120V, 15 amp

8. Plug the power cord into a properly grounded outlet at

Remove the tip if it is already attached.

.

counterclockwise to its lowest pressure setting.

separating oil (P/N 0279920).

minimum.

least 25’ from the spray area.

4. Move the PRIME/SPRAY valve down to the

PRIME position.

5. Turn on the unit by moving the ON/OFF

switch to the ON position.

6. Allow the sprayer to run for 15–30 seconds

to flush the test fluid out through the return

hose and into the waste container.

7. Turn off the unit by moving the ON/OFF switch to the OFF

position.

Preparing to Paint

Before painting, it is important to make sure that the fluid in the

system is compatible with the paint that is going to be used.

NOTE: Incompatible fluids and paint may cause the

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

1. Place the siphon tube into a container of the appropriate

2. Place the return hose into a metal waste container.

3.

4. Move the PRIME/SPRAY valve down to the

NOTE: Hold the return hose in the waste

5. Turn on the sprayer by moving the ON/OFF switch to the

6. Allow the sprayer to run for 15–30 seconds to flush the old

4 © SprayTECH. All rights reserved.

valves to become stuck closed, which would

require disassembly and cleaning of the

sprayer’s fluid section.

solvent. Examples of the appropriate solvent are water for

latex paint or mineral spirits for oil-based paints.

Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

PRIME position.

container when moving the

PRIME/SPRAY valve to PRIME in

case the sprayer is pressurized.

ON position.

solvent out through the return hose and into the metal

waste container.

Page 5

7. Turn off the sprayer by moving the ON/OFF switch to the

Pressure Control

Knob

ON/OFF

Switch

WARNING

WARNING

WARNING

WARNING

WARNING

OFF position.

NOTE: Make sure that the spray gun does not have a

8. Move the PRIME/SPRAY valve up to the

9. Turn on the sprayer.

10. Unlock the gun by turning the gun trigger

Ground the gun by holding it against

the edge of the metal container while

flushing. Failure to do so may lead to a

static electric discharge, which may

cause a fire.

11. Trigger the gun into the metal waste

12.

13. Set down the gun and increase the pressure by turning

14. Check the entire system for leaks. If leaks occur, turn the

15. Follow the “Pressure Relief Procedure” in this manual

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

tip or tip guard installed.

SPRAY position.

lock to the unlocked position.

container until the old solvent is gone

and fresh solvent is coming out of the gun.

Lock the gun by turning the gun trigger lock to the locked

position.

the pressure control knob slowly clockwise.

unit off and follow the “Pressure Relief Procedure” in this

manual before tightening any fittings or hoses.

before changing from solvent to paint.

Painting

1. Place the siphon tube into a container of paint.

2. Place the return hose into a metal waste container.

3. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

9. Move the PRIME/SPRAY valve up to the

SPRA

Y position.

10. Turn on the sprayer.

11. Unlock the gun by turning the gun trigger

lock to the unlocked position.

Ground the gun by holding it against

the edge of the metal container while

flushing. Failure to do so may lead to a

static electric discharge, which may

cause a fire.

12. Trigger the gun into the metal waste

container until all air and solvent is

flushed from the spray hose and paint is flowing freely

from the gun.

13.

Lock the gun by turning the gun trigger lock to the locked

position.

14. Turn off the sprayer.

15. Attach tip guard and tip to the gun as instructed by the tip

guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is

in either the spray or the unclog position.

the gun trigger lock before removing, replacing or

cleaning tip.

16. Turn on the sprayer.

17. Increase the pressure by turning the pressure control

knob slowly clockwise and test the spray pattern on a

piece of cardboard. Adjust the pressure control knob until

the spray from the gun is completely atomized. Try to

keep the pressure control knob at the lowest setting that

maintains good atomization.

NOTE: Turning the pressure up higher then needed to

atomize the paint will cause premature tip wear

and additional overspray.

Always engage

Pressure Relief Procedure

4. Move the PRIME/SPRAY valve down to the

PRIME position.

NOTE: Hold the return hose in the waste

5. Turn on the sprayer by moving the ON/OFF switch to the

ON position.

6. Allow the sprayer to run until paint is coming through the

return hose into the metal waste container.

7. Turn off the sprayer by moving the ON/OFF switch to the

OFF position.

8. Remove the return hose from the waste container and

place it in its operating position above the container of

paint.

© SprayTECH. All rights reserved. 5

container when moving the

PRIME/SPRAY valve to PRIME in

case the sprayer is pressurized.

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

1. Lock the gun by turning the gun trigger lock to the locked

position.

2. Turn off the sprayer by moving the ON/OFF switch to the

OFF position.

3. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

4. Unlock the gun by turning the gun

trigger lock to the unlocked position.

5. Hold the metal part of the gun firmly to

the side of a metal container to ground

the gun and avoid a build up of static

electricity.

6. Trigger the gun to remove any pressure that may still be in

the hose.

7. Lock the gun by turning the gun trigger

lock to the locked position.

8. Move the PRIME/SPRAY valve down to the

PRIME position.

Page 6

Spraying

Approximately

10 to 12 inches

Right way

Wrong way

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

Keep stroke smooth and at an even speed.

Even coat throughout

Approximately

10 to 12 inches

CAUTION

WARNING

WARNING

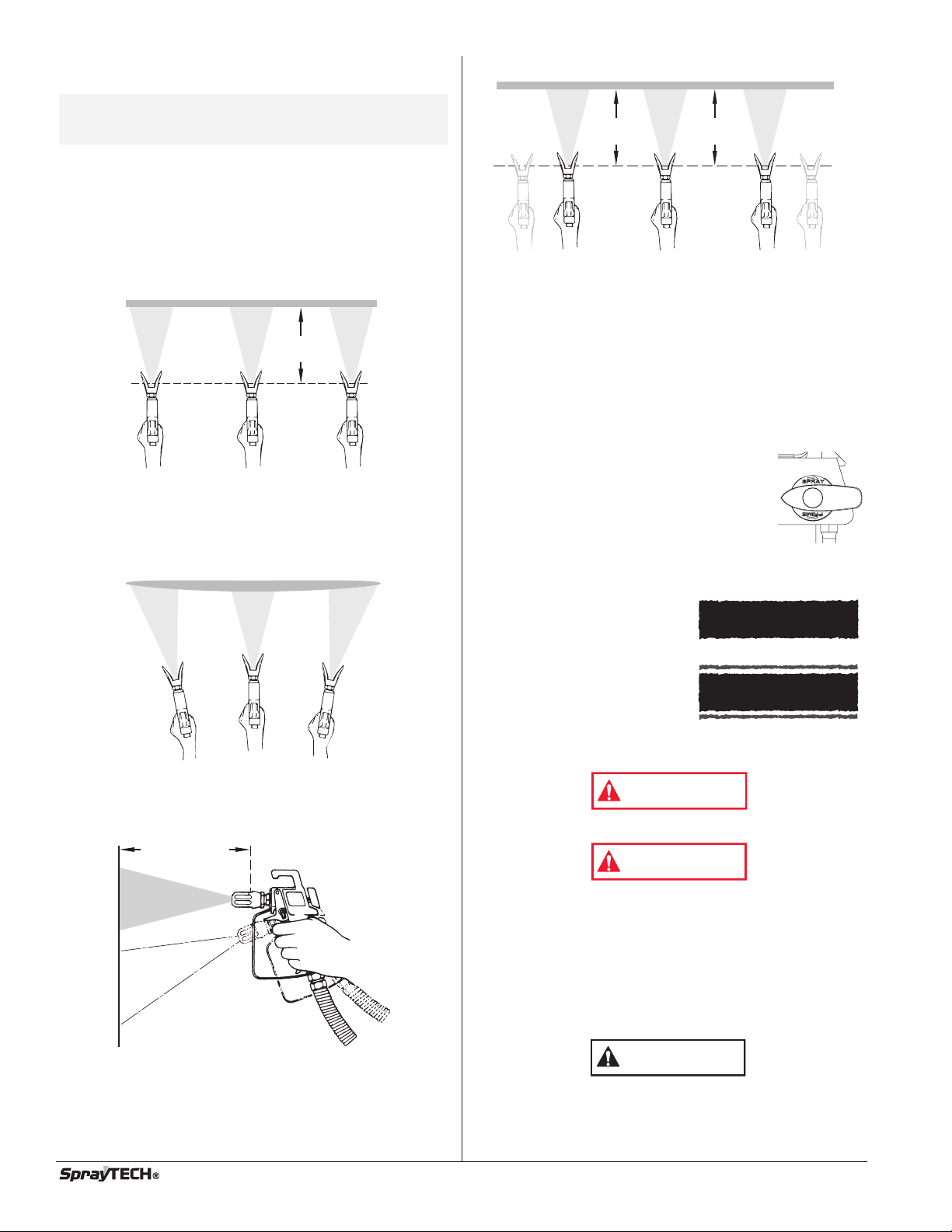

Good spray pattern

Paint tailing pattern

Proper way to trigger the spray gun

Approximately

10 to 12 inches

Keep stroke

even

Start stroke End strokePull trigger Release triggerKeep steady

NOTE: When spraying block filler, mastics or high

solid coating, remove the gun filter and high

pressure filter screens.

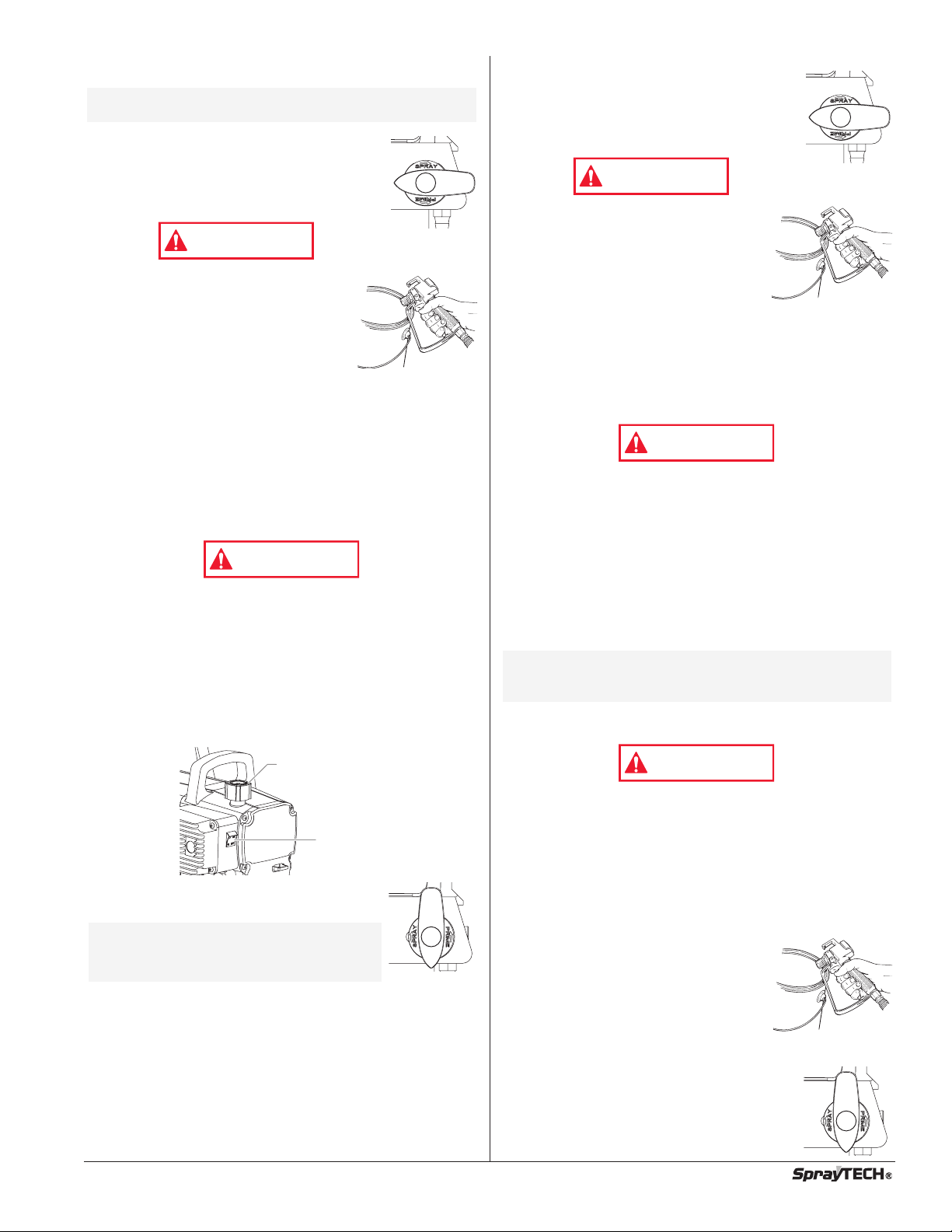

Spraying Technique

The key to a good paint job is an even coating over the entire

surface. This is done by using even strokes. Keep your arm

moving at a constant speed and keep the spray gun at a

constant distance from the surface. The best spraying

distance is 10 to 12 inches between the spray tip and the

surface.

Keep the spray gun at right angles to the surface. This means

moving your entire arm back and forth rather than just flexing

your wrist.

Overlap each stroke by about 30%. This will ensure an even

coating.

When you stop painting, lock the gun trigger lock, turn the

pressure control knob counterclockwise to its lowest setting

and set the PRIME/SPRAY valve to PRIME. Turn the ON/OFF

switch to the OFF position and unplug the sprayer.

Practice

1. Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its to

its lowest setting.

3. Move the PRIME/SPRAY valve up to the

SPRAY position.

4. Turn the pressure control knob clockwise to

its highest setting. The paint hose should

stiffen as paint begins to flow through it.

5. Unlock the gun trigger lock.

6. Trigger the spray gun to bleed air out of the hose.

7. When paint reaches the spray tip, spray a test area to

check the spray pattern.

8. Use the lowest pressure

setting necessary to get a

good spray pattern. If the

pressure is set too high, the

spray pattern will be too light.

If the pressure is set too low,

tailing will appear or the paint

will spatter out in gobs rather

than in a fine spray.

Keep the spray gun perpendicular to the surface, otherwise

one end of the pattern will be thicker than the other.

The spray gun should be triggered by turning it on and off with

each stroke. This will save paint and avoid paint buildup at the

end of the stroke. Do not trigger the gun during the middle of

a stroke. This will result in an uneven spray and splotchy

coverage.

Cleanup

Do not use gasoline to clean the sprayer.

Special cleanup instructions for use with flammable

solvents:

• Always flush spray gun preferably outside and at least one

hose length from spray pump.

•

If collecting flushed solvents in a one gallon metal

container, place it into an empty five gallon container, then

flush solvents.

• Area must be free of flammable vapors.

• Follow all cleanup instructions.

The sprayer, hose, and gun should be cleaned thoroughly

after daily use. Failure to do so permits material to build

up, seriously affecting the performance of the unit.

6 © SprayTECH. All rights reserved.

Page 7

Always spray at minimum pressure with the gun nozzle tip

CAUTION

WARNING

WARNING

Dowel Pin

Groove Pin

Valve Stem

Gasket

Pump

Manifold

Valve Housing

Assembly

Valve

Handle

Cam Base

CAUTION

WARNING

WARNING

removed when using mineral spirits or any other solvent

to clean the sprayer, hose, or gun. Static electricity

buildup may result in a fire or explosion in the presence of

flammable vapors.

1. Follow the “Pressure Relief Procedure” found in the

2. Remove the gun tip and tip guard and clean with a brush

3. Place the siphon tube into a container of the appropriate

4. Place the return hose into a metal waste container.

5. Set the pressure to minimum by turning the pressure

6. Move the PRIME/SPRAY valve down to its

NOTE: Hold the return hose in the waste

7. Turn on the sprayer by moving the ON/OFF switch to the

8. Allow the solvent to circulate through the sprayer and

9. Turn off the sprayer by moving the ON/OFF switch to the

10. Move the PRIME/SPRAY valve up to its

11. Turn on the sprayer.

Ground the gun by holding it against

the edge of the metal container while

flushing. Failure to do so may lead to a

static electric discharge, which may

cause a fire.

12. Trigger the gun into the metal waste

13.

NOTE: For long-term or cold weather storage, pump

14. Follow the “Pressure Relief Procedure” found in the

15. Unplug the sprayer and store in a clean, dry area.

Do not store the sprayer under pressure.

Cleaning the Spray Tip

1. Flush the gun with solvent immediately after the work is

2. Oil the sliding pins to prevent them from seizing up.

Should the spray tip become clogged, reverse

the spray tip with the lever and pull the trigger.

Once the obstruction comes out of the spray tip,

release the trigger, reverse the spray tip back to

the spray pattern setting, and resume spraying.

Operation section of this manual.

using the appropriate solvent.

solvent. Examples of the appropriate solvent are water for

latex paint or mineral spirits for oil-based paints.

control knob fully counterclockwise.

PRIME position.

container when moving the

PRIME/SPRAY valve to PRIME in

case the sprayer is pressurized.

ON position.

flush the paint out of the return hose into the metal waste

container.

OFF position.

SPRAY position.

container until the paint is flushed out

of the hose and solvent is coming out of the gun.

Continue to trigger the spray gun into the waste container

until the solvent coming out of the gun is clean.

mineral sprits through the entire system.

Operation section of this manual.

completed.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to

clean the tip. The hard tungsten carbide is brittle and can

be chipped.

Maintenance

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual. Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always unplug

the sprayer before servicing!

General Repair and Service Notes

1. Before repairing any part of the sprayer, read the

instructions carefully, including all warnings.

Never pull on a wire to disconnect it. Pulling on a wire

could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to be

sure that the problem is corrected. If the sprayer does not

operate properly

everything was done correctly. Refer to the Troubleshooting

section to help identify other possible problems.

3. Make sure that the service area is well ventilated in case

solvents are used during cleaning. Always wear

protective eyewear while servicing. Additional protective

equipment may be required depending on the type of

cleaning solvent. Always contact the supplier of solvents

for recommendations.

4. If you have any further questions concerning your

SprayTECH Airless Sprayer, call SprayTECH:

Technical Service...................................1-800-292-4637

Fax ................................................1-800-525-9501

Replacing the PRIME/SPRAY Valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 0507690.

1. Drive the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly from the pump manifold.

4. Make sure the gasket is in place and thread the new valve

housing assembly into the pump manifold. Tighten

securely with a wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam

with the pump manifold using the dowel pin.

6. Line up the hole on the valve stem with the hole in the

valve handle.

7. Insert the groove pin into the valve handle and through

the valve stem to secure the valve handle in position.

, review the repair procedure to determine if

© SprayTECH. All rights reserved. 7

Page 8

Replacing the Filters

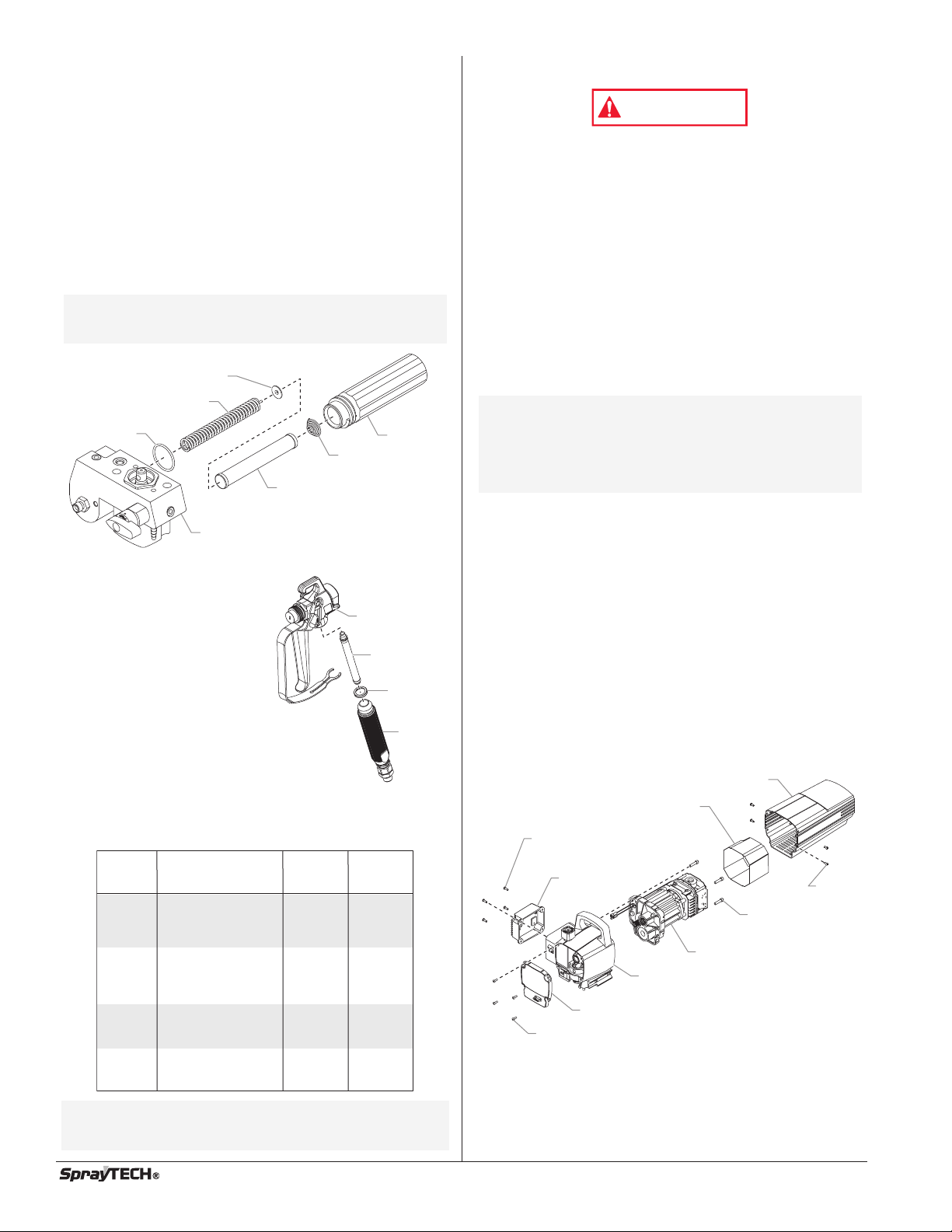

Part

Number

Application Filter

Type

Color of

Filter

Body

0089960 Synthetic resin,

enamels, clean

varnishes, stains

azures

Extrafine red

0089959 Base coat enamels,

primer enamels,

fillers, marking paints,

textured enamels

Fine yellow

0089958 Emulsions,

latex paints,

acrylic paints

Medium white

0089957 Heavy bodied latex,

blockfillers,

elastometrics

Coarse green

Gun

Housing

Filter

Handle

Handle

Seal

Filter

Spring

Adapter

Filter Support Spring

Filter Seal

Pump Manifold

Filter

Filter

Housing

Motor

Cover

Screw

Motor

Mounting

Screw

Electronic

Cover

Heat Sink

Assembly Screw

Heat Sink

Assembly

Motor

Gear Box

Housing

Front Cover

Front Cover Screw

Motor Cover

WARNING

Pump Filter

1. Loosen and remove the filter housing by hand. Pull the

filter out of the pump manifold.

2. Slip the filter off of the filter support spring.

3. Inspect the filter. Based on inspection, clean or replace

the filter.

4. Inspect the filter seal. Based on inspection, clean or

replace the filter seal.

5. Slide the new or cleaned filter over the filter support

spring with the adapter in place. Push the filter into the

center of the pump manifold.

6. Slide the filter housing over the filter and thread it into the

pump manifold until secure.

NOTE: The filter housing should be hand-tightened,

but make sure the filter housing is seated fully

into the pump manifold.

Gun Filter

1. Pull the bottom of the trigger

guard forward so that it

comes loose from the handle

assembly.

2. Loosen and remove the

handle assembly from the

gun head.

3. Pull the old filter out of the

gun head.

4. Slide the new filter, tapered

end first, into the gun head.

5. Make sure the handle seal is

in position and thread the

handle assembly into the gun

head until secure.

6. Snap the trigger guard back onto the handle assembly.

Gun Filter Chart

Replacing the Motor Assembly

Electrostatic discharge (ESD) potential could cause

damage to electronic control. Use SprayTECH ESD wrist

strap P/N 0507958 or equivalent when working on

electronic control with electronic cover removed.

1. Perform the Pressure Relief Procedure and unplug the

sprayer.

2. Remove the four motor cover screws. Remove the motor

cover.

3. Slide the electronic cover off of the electronic control

assembly on the motor.

4. Remove the four heat sink assembly screws. Pull back

the heat sink assembly to access and disconnect the two

wires coming from the motor.

5. At the electronic control assembly, disconnect the two

black wires coming from the microswitch.

6. Loosen and remove the four motor mounting screws.

7. Pull the motor out of the gear box housing.

NOTE: If the motor will not dislodge from the gear

box housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the slider assembly.

8. With the motor removed, inspect the gears in the gear box

housing for damage or excessive wear. Replace the

gears, if necessary.

9. Install the new motor into the gear box housing.

10. Secure the motor with the four motor mounting screws.

11. Reconnect the wires to the electronic control assembly

(refer to the electrical schematic in the Parts List section

of this manual).

12. Connect one of the motor wires to the power cord and the

other to the ON/OFF switch.

13. Position the electronic cover over the electronic control

assembly.

14. Position the heat sink assembly on the gear box housing

and secure in position with the four heat sink assembly

mounting screws

15. Slide the motor cover over the motor. Secure the motor

cover with the four motor cover screws.

NOTE: For more detail, part number information, and an

assembly drawing, please see the G-10 XL Airless

Spray Gun Owner's Manual (P/N 0296237).

8 © SprayTECH. All rights reserved.

Page 9

Replacing the Gears

Front Cover

Gear Box Housing

Front Cover Screw

2nd Stage Gear

Thrust Washer

Motor

Crankshaft/Gear

Assembly

Rotor Gear

Motor Mounting Screw

Motor Cover

Motor Cover Screw

WARNING

Gear Box

Housing

Slider

Assembly

Pump

Manifold

Pump

Manifold

Mounting

Screw

Front

Cover

Front

Cover

Screw

Transducer

Assembly

Connecting Pin

Retaining Ring

CAUTION

WARNING

Electrostatic discharge (ESD) potential could cause

damage to electronic control. Use SprayTECH ESD wrist

strap P/N 0507958 or equivalent when working on

electronic control with electronic cover removed.

1. Perform the Pressure Relief Procedure and unplug the

sprayer

2. Remove the four motor cover screws. Remove the motor

3. Slide the electronic cover off of the electronic control

4. Remove the four heat sink assembly mounting screws.

5. At the electronic control assembly, disconnect the two

6. Loosen and remove the four motor mounting screws.

7. Pull the motor out of the gear box housing.

NOTE: If the motor will not dislodge from the gear

8. Inspect the rotor gear on the end of the motor for damage

9. Remove and inspect the 2nd stage gear assembly for

10. Remove and inspect the crankshaft/gear assembly for

11. Reassemble the pump by reversing the above steps.

NOTE: Refill the gear box with five ounces of

.

cover.

assembly on the motor.

Pull back the heat sink assembly to access and

disconnect the two wires coming from the motor.

black wires coming from the microswitch.

box housing:

• Remove the front cover plate.

• Using a rubber mallet, carefully tap on the

front of the motor crankshaft that extends

through the slider assembly.

or excessive wear. If this gear is completely worn out,

replace the motor.

damage or excessive wear. Replace, if necessary.

damage or excessive wear. If damaged or worn, replace

the crankshaft/gear assembly.

During reassembly, make sure the thrust washers is in

place.

Lubriplate (P/N 9870307).

Replacing the Transducer

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Stop the sprayer at the bottom of its stroke so that the

piston is in its lowest position.

3. Perform the Pressure Relief Procedure and unplug the

sprayer.

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual.

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always unplug

the sprayer before servicing!

4. Tilt the sprayer back for easy access to the fluid section.

5.

Slide the retaining ring up on the slider assembly to

expose the connecting pin.

6. Push the connecting pin forward through the slider

assembly and piston. The connecting pin will fall into a

recessed area of the gear box housing where it can be

retrieved.

7. Using 3/8” a hex wrench, loosen and remove the two

pump manifold mounting screws.

8. Pull the pump manifold down off of the gear box housing.

9. Using a wrench, remove the transducer assembly from

the pump manifold.

10. Thread the new transducer assembly into the pump

manifold. Tighten securely with a wrench.

11. Reassemble the pump by reversing steps 1–8.

Make sure the transducer is aligned properly with the hole

in the pump manifold during reassembly. Improper

alignment may cause damage to the transducer o-ring.

Additionally, follow all

© SprayTECH. All rights reserved. 9

Page 10

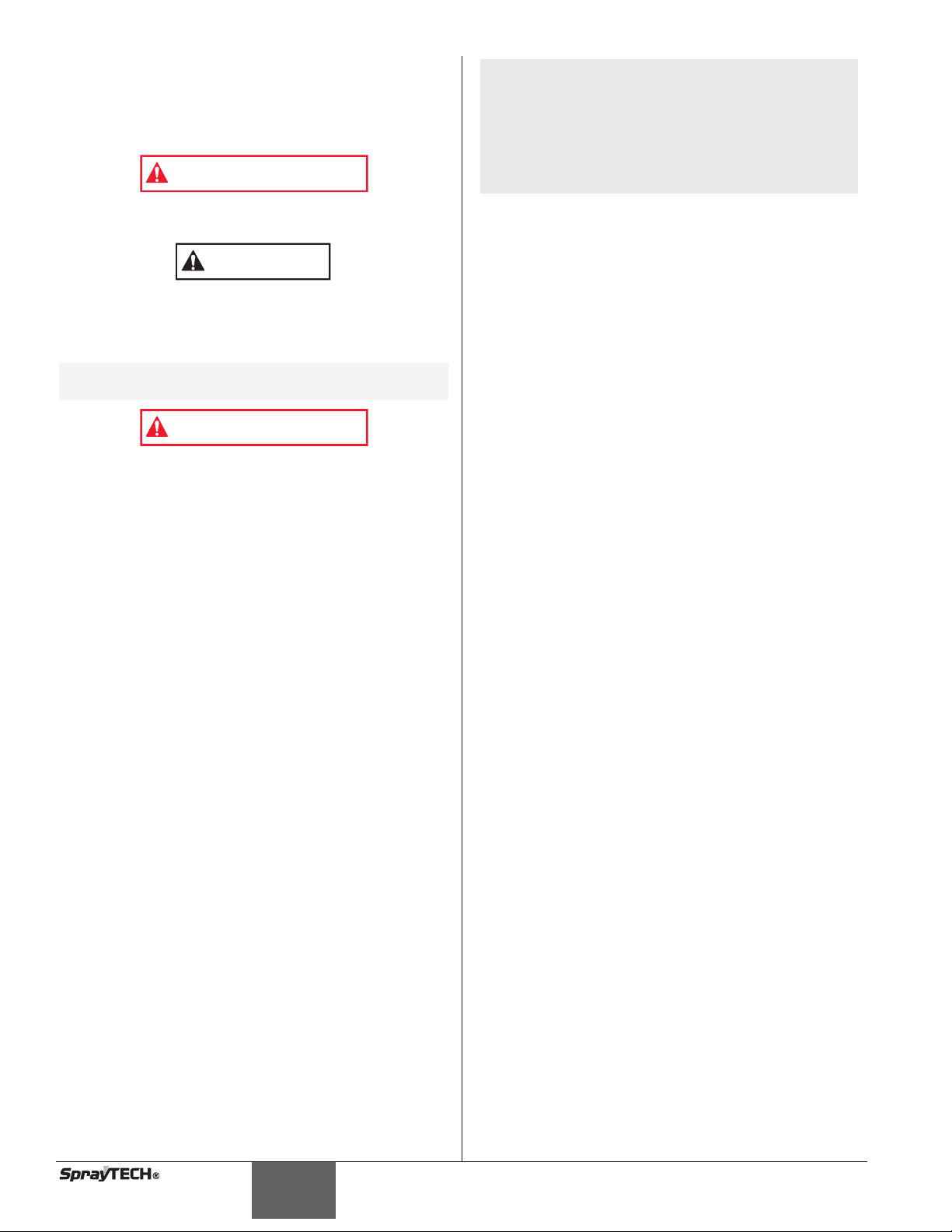

Servicing the Fluid Section

WARNING

Install lower packings

with raised lip and O-ring

facing up.

Install upper packing

with raised lip and O-ring

facing down.

O-Ring

O-Ring

Raised Lip

Raised Lip

Slider Assembly

Connecting Pin

Retaining Ring

Retainer Nut

Piston Guide

Upper Packing

Assembly

Pump Manifold

Pump Manifold

Mounting Screw

Piston Rod

Lower Packing

Assembly

Spacer

Use the following procedures to service the valves and repack

the fluid section. Perform the following steps before

performing any maintenance on the fluid section.

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Position the slider assembly at the bottom, dead-center of

its stroke so that the connecting pin and retaining ring are

visible below the slider assembly. This is done by turning

the sprayer on and off in short bursts until the connecting

pin is visible below the slider housing.

3. Perform the Pressure Relief Procedure and unplug the

sprayer.

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual.

other warnings to reduce the risk of an injection injury,

injury from moving parts or electric shock. Always

unplug the sprayer before servicing!

4. For Upright Cart units, remove the return hose from the

hose clip on the siphon tube. Unscrew the siphon tube

from the inlet valve housing.

5. For Low Boy cart units, remove the retaining ring from the

bottom of the inlet valve housing using a snap ring pliers.

Remove the return hose clamp and pull the return hose

from its fitting on the pump manifold. Remove the suction

set assembly.

6. Loosen and remove the high-pressure hose from the

outlet fitting on pump manifold.

Servicing the Valves

The design of the fluid section

allows access to the inlet valve and

seat as well as the outlet valve and

seat without completely

disassembling the fluid section. It

is possible that the valves may not

seat properly because of debris

stuck in the foot valve seat or outlet

valve seat. Use the following

instructions to clean the valves and

reverse or replace the seats.

1. Using a wrench, loosen and

remove the inlet valve housing

from the pump manifold.

2. Clean out any debris in the

inlet valve housing and

examine the valve housing and

seat. If the seat is damaged,

reverse or replace the seat.

3. Using a 5/16" hex wrench, loosen and remove the outlet

NOTE: Always service the

4. Clean out any debris and

5. Remove, clean, and inspect the outlet valve cage and

6. Reassemble the valves by reversing the steps above.

valve retainer from the piston rod.

outlet valve with the

piston rod attached to

the pump. This will

prevent the piston rod

from rotating during

disassembly of the

outlet valve.

examine the valve housing and

seat. If the seat is damaged, reverse or replace the seat.

outlet valve ball. Replace if they are worn or damaged.

Additionally

, follow all

Pump

Manifold

Piston

Bushing

Nylon

Washer

Inlet Valve

Cage

Inlet Valve

Ball

Inlet Valve

Seat

PTFE

O-Ring

Inlet Valve

Housing

Piston Rod

Outlet Valve

Cage

Outlet Valve

Ball

Outlet Valve

Seat

Outlet Valve

Retainer

Repacking the Fluid Section

1. Remove the inlet valve assembly using the steps in the

“Servicing the Valves” procedure above.

NOTE: The outlet valve does not need to be

disassembled from the piston rod for this

procedure.

2. Slide the retaining

ring up on the slider

assembly to expose

the connecting pin.

3. Push the connecting

pin forward through

the slider assembly

and piston. The

connecting pin will

fall into a recessed

area of the gear box

housing where it

can be retrieved.

4. Using 3/8” a hex

wrench, loosen and

remove the two

pump manifold

mounting screws.

5. Pull the pump

manifold down off of

the gear box

housing.

6. Slide the piston rod

out through the

bottom of the pump

manifold.

7. Loosen and remove

the retainer nut and

piston guide from

the pump manifold.

8. Remove the upper

and lower packings

from the pump

manifold.

9. Clean the pump manifold and install the new upper and

lower packings. Refer to the illustration below for proper

packing orientation.

10. Inspect the piston rod for wear and replace if necessary.

11. Insert the piston guide into the retainer nut. Thread the

retainer nut into the pump manifold until it is hand tight.

12. Slide the piston guide tool (included in the repacking kit)

over the top of the piston rod and insert the piston rod

through the bottom of the pump manifold. Using a rubber

mallet, tap the bottom of the piston rod lightly until the

piston rod is in position in the pump manifold.

NOTE: Coat the piston guide tool and the piston rod

with grease before inserting them into the

pump manifold.

13. Using a wrench, tighten the retainer nut securely.

14. Position the pump block underneath the pump housing

and push up until it rests against the pump housing.

When the connecting pin hole on the piston rod lines up

with the hole in the slider assembly, insert the connecting

pin.

15. Slide the retaining ring down over the connecting pin.

10 © SprayTECH. All rights reserved.

Page 11

Make sure the transducer is aligned properly with the hole

CAUTION

in the pump manifold during reassembly. Improper

alignment may cause damage to the transducer gasket.

16. Thread the pump manifold mounting screws through the

pump manifold and into the gear box housing. T

securely.

17. Reassemble the inlet valve assembly into the pump

manifold.

18. For Upright Cart units, thread the siphon tube into the inlet

valve and tighten securely. Make sure to wrap the threads on

the down tube with PTFE tape before assembly. Replace

the return hose into the hose clip on the siphon tube.

19. For Low Boy cart units, insert the elbow on the suction set

assembly into the bottom of the inlet valve housing. Push

the retaining ring up into the groove inside the inlet valve

housing to secure the suction set assembly in position.

Push the return hose onto the return hose fitting on the

pump manifold and secure in position with the return hose

clamp.

20. Place the front cover on the gear box housing and secure

in position using the four front cover screws.

21. Turn on the sprayer by following the procedure in the

“Operation” section of this manual and check for leaks.

NOTE: Repacking kit P/N 0551533 is available. For

best results use all parts supplied in this kit.

ighten

© SprayTECH. All rights reserved. 11

Page 12

Problem

The unit will not run.

Troubleshooting

Cause

1. The unit is not plugged in.

2. Tripped breaker.

3. The pressure is set too low (pressure

control knob set at minimum setting

does not supply power to unit).

4. Faulty or loose wiring.

5. Excessive motor temperature.

Solution

1. Plug the unit in.

2. Reset the breaker.

3. Turn the pressure control knob clockwise to

supply power to the unit and increase the

pressure setting.

4. Inspect or take to a SprayTECH authorized

service center.

5. Allow motor to cool.

The unit will not prime.

The unit will not build or

maintain pressure.

1. The PRIME/SPRAY valve is in the

SPRAY position.

2. Air leak in the siphon tube/suction set.

3. The pump filter and/or inlet screen is

clogged.

4. The siphon tube/suction set is clogged.

1. The spray tip is worn.

2. The spray tip is too large.

3. The pressure control knob is not set

properly.

4. The pump filter, gun filter, or inlet

screen is clogged.

5. Material flows from the return hose

when the PRIME/SPRAY valve is in the

SPRAY position.

6. Air leak in the siphon tube/suction set.

7. There is external fluid leak.

8. There is an internal fluid section leak

(packings are worn and/or dirty, valve

balls are worn).

9. Worn valve seats

10. Motor powers but fails to rotate

1. Rotate the PRIME/SPRAY valve clockwise

to the PRIME position.

2. Check the siphon tube/suction set

connection and tighten or re-tape the

connection with PTFE tape.

3. Remove the pump filter element and clean.

Remove the inlet screen and clean.

4. Remove the siphon tube/suction set and

clean.

1. Replace the spray tip following the

instructions that came with the spray gun.

2. Replace the spray tip with a tip that has a

smaller orifice following the instructions that

came with the spray gun.

3. Turn the pressure control knob clockwise to

increase the pressure setting.

4. Remove the pump filter element and clean.

Remove the gun filter and clean. Remove

the inlet screen and clean.

5. Clean or replace the PRIME/SPRAY valve.

6. Check the siphon tube/suction set

connection and tighten or re-tape the

connection with PTFE tape.

7. Check for external leaks at all connections.

Tighten connections, if necessary.

8. Clean the valves and service the fluid

section following the “Servicing the Fluid

Section” procedure in the Maintenance

section of this manual.

9. Reverse or replace the valve seats

following the “Servicing the Fluid Section”

procedure in the Maintenance section of

this manual.

10. Take unit to a SprayTECH authorized

service center.

Fluid leakage at the upper end

of the fluid section.

1. The upper packings are worn.

2. The piston rod is worn.

12 © SprayTECH. All rights reserved.

1. Repack the pump following the “Servicing

the Fluid Section” procedure in the

Maintenance section of this manual.

2. Replace the piston rod following the

“Servicing the Fluid Section” procedure in

the Maintenance section of this manual.

Page 13

Problem

Excessive surge at the spray

gun.

Troubleshooting

Cause

1. Wrong type of airless spray hose.

2. The spray tip worn or too large.

3. Excessive pressure.

Solution

1. Replace hose with a minimum of 50’ of 1/4”

grounded textile braid airless paint spray

hose.

2. Replace the spray tip following the

instructions that came with the spray gun.

3. Rotate the pressure control knob

counterclockwise to decrease spray

pressure.

Poor spray pattern.

The unit lacks power.

1. The spray tip is too large for the

material being used.

2. Incorrect pressure setting.

3. Insufficient fluid delivery.

4. The material being sprayed is too

viscous.

1. The pressure adjustment is too low.

2. Improper voltage supply.

1. Replace the spray tip with a new or smaller

spray tip following the instructions that

came with the spray gun.

2. Rotate the pressure control knob to adjust

the pressure for a proper spray pattern.

3. Clean all screens and filters.

4. Add solvent to the material according to the

manufacturer's recommendations.

1. Rotate the pressure control knob clockwise

to increase the pressure setting.

2. Reconnect the input voltage for 120V AC.

© SprayTECH. All rights reserved. 13

Page 14

Consignes de sécurité

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

Le présent manuel comprend des renseignements devant être

lus attentivement avant toute utilisation de l'appareil. Lorsque

l'un des symboles suivants apparaît, il est recommandé d'être

particulièrement attentif et de tenir compte des mesures de

sécurité indiquées.

Ce symbole indique un danger potentiel pouvant causer des

blessures graves ou même mortelles. Des renseignements

importants sur la sécurité sont également indiqués.

Ce symbole indique un danger potentiel pouvant causer des

blessures corporelles ou des dommages à l'équipement. Des

renseignements importants sur la façon de prévenir tout

dommage à l'équipement ou toute blessure corporelle mineure

sont également indiqués.

NOTA : Les remarques donnent des renseignements

DANGER: BLESSURES PAR PERFORATION - Le jet de

NE P

COMME UNE SIMPLE COUPURE! Une perforation peut

entraîner des risques d'amputation. Consultez

immédiatement un médecin.

Pression de service maximale du fluide dans l’appareil :

3100 lb/po2 / 21.4 MPa.

MESURES PRÉVENTIVES:

importants requérant une attention particulière.

peinture à haute pression produit par cet

appareil peut perforer la peau et les tissus

sous-jacents et entraîner de sévères blessures

pouvant nécessiter une amputation. Consultez

immédiatement un médecin.

AS TRAITER UNE BLESSURE PAR PERFORATION

• NE JAMAIS diriger le pistolet vers une quelconque partie

du corps.

• NE JAMAIS mettre une quelconque partie du corps en

contact avec le jet de liquide. NE JAMAIS se mettre au

contact d'un jet de liquide provenant d'une fuite du flexible

d'alimentation en liquide.

• NE JAMAIS placer votre main devant le pistolet. Des

gants ne vous protégeront pas contre les risques de

blessures par perforation.

• TOUJOURS verrouiller la gâchette du pistolet, fermer la

pompe à liquide et décompresser l'appareil lorsque vous

travaillez sur celui-ci, nettoyez le protecteur de tête,

remplacez la tête de pulvérisation ou vous éloignez de

l'appareil. Couper le moteur ne décompresse pas l'appareil.

Vous devez, pour le décompresser, placer le bouton

AMORÇAGE/PULVÉRISATION en position AMORÇAGE.

Reportez-vous, pour cela, à la PROCÉDURE DE

DÉCOMPRESSION décrite dans de ce manuel.

• TOUJOURS s'assurer que le protecteur de tête est en

place lorsque vous pulvérisez. Le protecteur de tête offre

une certaine protection contre les blessures par perforation

mais sa principale fonction est d'ordre préventif.

• TOUJOURS ôter la tête de pulvérisation avant de purger

ou nettoyer l'appareil.

• Le flexible d'alimentation en peinture peut fuir à la suite

d'une usure, de chocs ou de mauvais traitements. Une

fuite peut entraîner une perforation de la peau. Inspecter

le flexible avant chaque utilisation.

• NE JAMAIS utiliser un pistolet dont la gâchette n'est pas

munie d'un loquet ou un cran de sécurité qui soit en état

de fonctionner.

• Tous les accessoires doivent être homologués pour une

pression égale ou supérieure à 3100 lb/po2 / 21.4 MPa.

Cela s'applique, entre autres, aux têtes de pulvérisation,

aux accessoires du pistolet et aux flexibles.

Français

AVERTISSEMENT AUX MÉDECINS : Une perforation

sous-cutanée constitue un traumatisme. Il est

important de traiter la blessure de façon chirurgicale

aussitôt que possible. NE RETARDEZ PAS ce traitement

pour des recherches de toxicité. La toxicité n'est un

risque que dans les cas où certains produits de

revêtement pénètrent dans le flux sanguin. Il peut être

nécessaire de faire appel à des soins de chirurgie

plastique ou de reconstruction de la main.

DANGER: RISQUES D'EXPLOSION OU D'INCENDIE - Les

MESURES PRÉVENTIVES:

• V

• Veiller à éviter la présence de toute source incandescente

• Ne pas fumer dans la zone d’épandage.

• Toujours avoir un extincteur en état de fonctionner à

• Placer la pompe à peinture à une distance d’au moins un

• Le matériel utilisé, ainsi que les objets se trouvant à

• N'utiliser que des flexibles d'alimentation en liquide à

• Le cordon d’alimentation doit être raccordé à un circuit

• Toujours purger l’appareil dans un contenant métallique

• Se conformer aux consignes et recommandations de

• S’entourer de toutes les précautions possibles lorsqu’on

• Le plastique peut être une source d’étincelles provoquées

• Lorsque vous purgez l'appareil, veillez à utiliser à la

14 © SprayTECH. Tous droits réservés.

vapeurs dégagées par le solvant ou la peinture

sont explosives et inflammables et peuvent

causer des corporels sérieux ou dommages

matériels.

eiller à éviter toute accumulation de vapeurs

inflammables en vous assurant que la zone où la

pulvérisation a lieu est suffisamment ventilée.

telle qu'étincelle électrostatique, flamme nue, flammepilote, objet brûlant, cigarette et étincelle provenant du

branchement ou du débranchement d'un cordon

d'alimentation électrique ou d'un commutateur.

portée de la main.

mètre (3 pi) (on recommande d’ailleurs une plus grande

distance) de l’objet qui doit être vaporisé dans une pièce

séparée bien aérée, ou à une distance d’au moins six

mètres (20 pi) de celui-ci dans une zone bien aérée

(utiliser d’autres tuyaux si nécessaires). Les vapeurs

inflammables sont souvent plus lourdes que l’air. Le

plancher doit être extrêmement bien aéré. La pompe à

peinture contient des pièces pouvant créer des étincelles

et enflammer les vapeurs présentes dans l’air.

proximité de la zone de pulvérisation, doivent être

convenablement reliés à la terre afin d'éviter toute

étincelle ou toute décharge électrostatique.

haute pression conducteurs ou reliés à la terre dans les

cas d'utilisation sans air comprimé. S'assurer que le

pistolet est convenablement relié à la terre par

l'intermédiaire du flexible.

mis à la terre.

séparé, en s’assurant que la pompe soit à basse pression

et que le chapeau soit retiré. Tenir le pistolet fermement

contre la paroi du contenant pour mettre celui-ci à la terre

et empêcher l’émission d’étincelles causées par

l’électricité statique.

sécurité du fabricant du solvant ou du produit.

utilise des produits ayant un point d’éclair inférieur à 21

°C (70 °F). Le point d’éclair d’un fluide est la température

à laquelle les vapeurs émanant du fluide peuvent

s’enflammer au contact d’une flamme ou d’une étincelle.

par l’électricité statique. Ne jamais utiliser une couverture

en plastique pour fermer une zone d’épandage ni utiliser

des toiles de protection en plastique lors de la

pulvérisation de matières inflammables.

pression minimale.

Page 15

MOTEUR À ESSENCE

ATTENTION

Prise de terre

Goupille de mise à la terre

Couvercle du boîtier de prise de terre

(DANS LES CAS OÙ CELA S’APPLIQUE)

Toujours placer la pompe à l’extérieur de la structure à l’air

frais. Garder tous les solvants loin de l’échappement du

moteur. Ne jamais remplir le réservoir à carburant lorsque le

moteur est en marche ou lorsqu’il est chaud ; les surfaces

chaudes risquent d’enflammer le carburant déversé

accidentellement. Toujours raccorder un fil de mise à la terre

entre la pompe et un objet mis à la terre, tel qu’une conduite

d’eau métallique. Se reporter au guide d’utilisation du moteur

pour obtenir de plus amples renseignements concernant la

sécurité.

DANGER: RISQUES D'EXPLOSION PAR INCOMPATIBILITÉ

MESURES PRÉVENTIVES:

• Ne pas utiliser de matériaux contenant des agents de

• Ne pas utiliser des solvants à base d’hydrocarbure

• Communiquer avec votre fournisseur de revêtement pour

DANGER: VAPEURS NOCIVES – la peinture, les solvants,

MESURES PRÉVENTIVES:

• Utiliser un respirateur ou un masque chaque fois qu'il y a

• Porter des lunettes de protection.

• Porter des vêtements de protection, conformément aux

DANGER: GÉNÉRALITÉS - Peut causer des dommages

MESURES PRÉVENTIVES:

• Avant d'utiliser tout équipement, lire attentivement toutes

• Toujours débrancher le moteur de l’alimentation électrique

• Se conformer à la législation locale, provinciale ou fédérale

• Les normes de sécurité du Gouvernement américain sont

• N’utiliser que les pièces autorisées par le fabricant.

• Vérifier, avant toute utilisation, que les flexibles ne

• Tout flexible, raccord orientable, pistolet et accessoire

• Ne jamais pulvériser lorsqu'il vente.

• Porter des vêtements pour protéger la peau et les

DES MATÉRIAUX - Peuvent être à l'origine de

corporels sérieux ou dommages matériels.

blanchiment ou du chlore.

halogéné tels que l’agent anticryptogamique, le chlorure

de méthylène et le trichloro-éthane-1,1,1. Ces produits ne

sont pas compatibles avec l’aluminium

connaître la compatibilité du matériau avec l’aluminium.

les insecticides et autres matériaux peuvent

être nocifs lorsqu’ils sont inhalés ou en contact

avec le corps. Les vapeurs peuvent causer une

nausée importante, des évanouissements ou

un empoisonnement.

des risques d'inhalation de vapeurs. Lire attentivement

toutes les instructions se rapportant au masque pour

vérifier que celui-ci vous assure une protection suf

contre les vapeurs toxiques.

directives du fabricant de revêtement.

matériels ou corporels sérieux.

les instructions et les consignes de sécurité

avant d’effectuer des travaux sur l’appareil.

pour tout ce qui concerne la ventilation, la prévention des

incendies et les conditions générales d'utilisation.

régies par le Occupational Safety and Health Act (OSHA).

Il est important de consulter ces normes, en particulier la

section 1910 sur le normes générales et la section 1926

sur les des normes de la construction.

L’utilisateur assume tous les risques et responsabilités

lorsqu’il utilise des pièces qui ne sont pas conformes aux

caractéristiques techniques minimales ainsi qu’aux

dispositifs de sécurité du fabricant de la pompe.

présentent pas d'entaille ou de fuite, que le couvercle ne

soit pas gonflé et que les raccords ne soient pas

endommagés. Si le flexible a subi l'un des dommages

précités, remplacez-le immédiatement. Ne jamais réparer

un flexible d'alimentation en peinture. Le remplacer par un

autre flexible mis à la terre.

utilisé avec cet appareil doit pouvoir fonctionner à une

pression égale ou supérieure à 3100 lb/po2 / 21.4 MPa.

cheveux contre tout contact avec la peinture.

fisante

Instructions de mise à la terre

Cet appareil doit être mis à la terre. La mise à la terre réduit

les risques d'électrocution lors d'un court-circuit en permettant

au courant de s'écouler par le fil de mise à la terre. Cet

appareil est muni d'un cordon électrique avec fil de mise à la

terre ainsi que d'une fiche de terre. La fiche doit être branchée

sur une prise installée correctement et mise à la terre

conformément à la réglementation et aux codes en vigueur.

DANGER — Une prise de terre mal branchée peut être à

'origine d'électrocutions. S'il s'avère nécessaire de réparer ou

l

de remplacer le cordon électrique ou la fiche, ne pas brancher le

fil vert de mise à la terre sur l'une ou l'autre des bornes à broche

plate. Le fil recouvert d'un isolant vert avec ou sans rayures

jaunes est le fil de mise à la terre et doit être branché sur la

broche de mise à la terre.

Si vous ne comprenez pas les instructions de mise à la terre

ou si vous n'êtes pas sûr que l'appareil est correctement mis à

la terre, contactez un électricien agréé. Ne pas modifier la

fiche d'origine. Si la prise ne convient pas à la fiche, faites

installer la prise adéquate par un électricien agréé.

Utiliser uniquement une rallonge à trois fils munie d'une

fiche de terre dans une prise secteur mise à la terre

correspondant au type de fiche de l'appareil. S'assurer que

votre rallonge est en bon état. Lorsque vous utilisez une

rallonge, assurez-vous qu'elle soit d'un calibre suffisant

pour supporter l'intensité du courant requise par l'appareil.

Une rallonge trop mince entraîne une chute de tension, une

diminution de l'intensité et une surchauffe. Une rallonge de

calibre 12 est recommandée. Si vous devez utiliser une

rallonge à l’extérieur

A après la désignation indiquant le type de cordon. Par

exemple, la désignation SJTW-A indique que le cordon est

conçu pour être utilisé à l’extérieur.

, celle-ci doit comprendre la marque W-

© SprayTECH. Tous droits réservés. 15

Français

Page 16

Precauciones de seguridad

ADVERTENCIA

PRECAUCION

ADVERTENCIA

Este manual contiene información que debe leer y comprender

antes de usar el equipo. Cuando se encuentre con uno de los

siguientes símbolos, asegúrese de observar sus indicaciones

de seguridad.

NOTA PARA EL MÉDICO: La inyección dentro de la piel

es una lesión traumática. Es importante que la lesión

se trate quirúrgicamente tan pronto como sea posible .

NO retrase el tratamiento por investigar la toxicidad.

La toxicidad es motivo de preocupación con algunos

revestimientos que se inyectan directamente en la

corriente sanguínea. Es recomendable consultar a un

cirujano plástico o reconstructor de manos.

Este símbolo indica la existencia de un peligro potencial que

puede causar lesiones graves o la muerte. Después del

mismo se incluye información de seguridad importante.

Este símbolo indica la existencia de un peligro potencial para

usted o el equipo. Después del mismo se incluye información

importante que indica la forma de evitar daños al equipo o la

forma de prevenir lesiones menores.

NOTA: los avisos contienen información importante,

PELIGRO: LESIÓN POR INYECCIÓN - La corriente de

NO TRA

FUERAN SIMPLES CORTADAS! Una inyección puede

conducir a una amputación. Consulte de inmediato a un

médico.

El rango de operación máximo de la unidad es 3100 PSI /

21.4 MPa de presión de fluidos.

PARA PREVENIR:

présteles especial atención.

pintura de alta presión que produce este

equipo puede perforar la piel y tejidos

subyacentes, lo que conduciría a lesiones

serias y una posible amputación. Consulte de

inmediato a un médico.

TE LAS LESIONES POR INYECCIÓN COMO SI

• NO dirija NUNCA la punta de la pistola hacia alguna parte

del cuerpo.

• NO permita NUNCA que alguna parte del cuerpo tenga

contacto con la corriente del fluido. EVITE tener contacto

con corrientes de fluido que salgan de fugas que haya en

la manguera.

• NO ponga NUNCA la mano enfrente de la manguera. Los

guantes no ofrecen ninguna protección contra lesiones

por inyección.

• Bloquee SIEMPRE el gatillo de la pistola, apague la

bomba de fluido y libere toda la presión antes de dar

mantenimiento, limpiar el protector de la boquilla, cambiar

la boquilla o dejar desatendido el equipo. La presión no

se liberará al apagar el motor. Para liberar la presión

debe girarse la perilla PRIME/SPRAY (cebar/atomizar)

hasta la posición PRIME. Consulte el PROCEDIMIENTO

PARA LIBERAR LA PRESIÓN que se describe en este

manual.

• Mantenga puesto SIEMPRE el protector de la boquilla

mientras atomice. El protector de la boquilla ofrece cierta

protección contra lesiones por inyección pero es

principalmente un dispositivo de advertencia.

• Quite SIEMPRE la boquilla del atomizador antes de

enjuagar o limpiar el sistema.

• Pueden desarrollarse fugas en la manguera de pintura

por causa del desgaste, retorcimientos o el abuso. Una

fuga es capaz de inyectar el material en la piel. Cada vez

que use la manguera de pintura, inspecciónela antes.

• NO use nunca una pistola de atomización que no tenga

un bloqueador o un protector de gatillo puesto y que

funcione.

• Todos los accesorios deben tener una capacidad de 3100

lb/pulg2 / 21.4 MPa o mayor. Esto incluye las boquillas

de atomizador, pistolas, extensiones y mangueras.

PELIGRO: EXPLOSIÓN O INCENDIO - Los vapores de

PARA PREVENIR:

• Debe proveerse un escape y aire fresco para hacer que el

• Evite todas las fuentes de ignición como son las chispas

• No fume en la zona de trabajo.

• Debe haber un equipo para extinguir incendios

• Coloque la bomba para pintar a un mínimo de 1 m (de

• El equipo que se utilice, así como los objetos que estén

• Use solamente mangueras para fluidos de alta presión,

• El cable de alimentación debe enchufarse a un circuito

• Siempre enjuague la unidad en un recipiente de metal por

• Siga las advertencias y avisos de seguridad del fabricante

• Tenga muchísimo cuidado al usar materiales cuyo punto

• El plástico puede causar chispas estáticas. Nunca

• Cuando enjuague el equipo utilice la presión más baja

MOTOR DE GAS (SEGÚN CORRESPONDA)

Coloque siempre la bomba fuera del edificio, al aire libre.

Mantenga todo solvente alejado del escape del motor

llene el tanque de combustible si el motor está encendido o

caliente. La superficie caliente puede encender el combustible

derramado. Conecte siempre un conductor de tierra desde la

unidad de la bomba a un objeto puesto a tierra, por ejemplo

una tubería de agua metálica. Consulte el manual del motor

para obtener información completa de seguridad.

solventes y pintura pueden explotar o

incendiarse, causando con esto lesiones

severas y/o daños en la propiedad.

aire que está dentro del área de atomización se mantenga

libre de acumulaciones de vapores inflamables.

electrostáticas, llamas abiertas, flamas de piloto, objetos

calientes, cigarros, y chispas que se generan al conectar

y desconectar las extensiones o de apagadores de luz

que estén funcionando.

permanentemente y en buenas condiciones.

preferencia más) en una habitación aparte, bien ventilada,

alejada del objeto que va a pintar o a por lo menos 6 m

de dicho objeto, en una zona bien ventilada (utilice una

manguera más larga, si es necesario). Los gases

inflamables a menudo son más pesados que el aire. La

zona del piso debe tener la debida ventilación. La bomba

para pintar contiene piezas que forman arcos que emiten

chispas y pueden encender los gases.

dentro y alrededor del área de atomización, deben

conectarse a tierra de manera apropiada para prevenir las

descargas eléctricas y las chispas.

conductoras o conectadas a tierra, para aplicaciones sin

aire. Asegúrese de que la pistola esté conectada a tierra

de manera apropiada, mediante conexiones de

manguera.

aterrado.

separado, con presión baja en la bomba y sin la boquilla.

Sostenga la pistola firmemente contra el recipiente para

ponerlo a tierra y evitar chispas estáticas.

de los materiales y solventes.

de ignición sea inferior a 70° F (21° C). El punto de

ignición es la temperatura a la cual pueden encenderse

los vapores emanados por un fluido al exponerlos a

llamas o chispas.

cuelgue plástico en las ventanas ni en las puertas del

área donde va a pintar. No utilice plástico para proteger

el piso cuando pinte materiales inflamables.

posible.

. Nunca

Español

16 © SprayTECH. Todos los derechos reservados.

Page 17

PELIGRO: PELIGRO DE EXPLOSIÓN DEBIDO A

PRECAUCION

Tomacorriente aterrado

Terminal de tierra

Tapa de la caja del tomacorriente aterrado

PARA PREVENIR:

• No utilice materiales que contengan blanqueador o cloro.

• No use solventes con hidrocarburos halogenados, tales

• Comuníquese con el proveedor del producto para obtener

PELIGRO: GASES PELIGROSOS - Las pinturas, solventes,

PARA

• Use una mascarilla respiratoria o careta siempre que

• Use gafas protectoras.

• Use ropa de protección, según lo requiera el fabricante

PELIGRO: GENERAL - Puede causar daños en la

PARA PREVENIR:

• Lea todas las instrucciones y advertencias de seguridad

• Desconecte siempre el motor del suministro eléctrico

• Observe todos los códigos locales, estatales y nacionales

• Los Estándares de Seguridad del Gobierno de los

• Utilice únicamente piezas autorizadas por el fabricante.

• Antes de usarla cada vez, revise todas las mangueras para

• Todas las mangueras, soportes giratorios, pistolas y

• No atomice en días con viento.

• Use ropa que evite el contacto de la pintura con la piel y

MATERIALES INCOMPATIBLES - Podría

causar lesiones severas o daños en la

propiedad.

como productos para eliminar el moho, cloruro de

metileno y 1,1,1 - tricloroetano. Estos no son compatibles

con el aluminio.

información de compatibilidad con materiales de aluminio.

insecticidas y otros materiales pueden ser

perjudiciales si se inhalan o entran en contacto

con el cuerpo. Los gases pueden causar

náusea, desmayos o envenenamiento graves.

PREVENIR:

exista la posibilidad de que se puedan inhalar vapores.

Lea todas las intrucciones que vengan con la careta para

estar seguro de que se tendrá la protección necesaria

contra la inhalación de vapores dañinos.

del producto.

propiedad o lesiones severas.

antes de hacer funcionar cualquier equipo.

antes de dar servicio al equipo.

apropiados que rigen las medidas de ventilación,

prevención de incendios y operación.

Estados Unidos se han adoptado bajo el Acta de

Seguridad y Salud Ocupacionales (OSHA por sus siglas

en inglés). Deben consultarse estos estándares,

particularmente la parte 1910 de los Estándares

Generales y la parte 1926 de los Estándares de la

Construcción.

El usuario asume todos los riesgos y responsabilidades si

usa piezas que no cumplen con las especificaciones

mínimas y dispositivos de seguridad del fabricante de la

bomba.

ver que no tengan cortadas, fugas, una cubierta desgastada

por abrasión o con abolladuras, así como uniones dañadas

o que se hayan movido. Si existiera cualquiera de estas

condiciones, reemplace la manguera inmediatamente. No

repare nunca una manguera de pintura. Reemplácela con

otra manguera conectada a tierra.

accesorios que se usen con esta unidad deben tener una

capacidad de presión de 3100 lb/pulg2 / 21.4 MPa o

mayor.

el cabello.

Instrucciones para conectar a tierra

Este producto se debe conectar a tierra. En caso de que

ocurra un corto circuito, la conexión a tierra reduce el riesgo

de choque eléctrico al proporcionar un alambre de escape

para la corriente eléctrica. Este producto está equipado con

un cable que tiene un alambre de conexión a tierra con un

enchufe de conexión a tierra apropiado. El enchufe se debe

enchufar en una toma de corriente que se haya instalado y

conectado a tierra debidamente, de acuerdo con todos los

códigos y estatutos locales.

PELIGRO — Una instalación inapropiada del enchufe de

conexión a tierra puede dar como resultado el que exista un

riesgo de choque eléctrico. Si es necesario reparar o

reemplazar el cable o el enchufe, no conecte el alambre de

conexión a tierra a ninguno de los terminales de hoja planos.

El alambre con aislamiento que tiene la superficie exterior de

color verde con franjas amarillas o sin ellas es el alambre de

conexión a tierra que debe conectarse al conector de conexión

a tierra.

Verifique con un electricista o técnico de servicio calificado si

las instrucciones para conectar a tierra no le han quedado

completamente claras, o si duda que el producto haya

quedado conectado a tierra de manera apropiada. No