Page 1

LCX 130

SprayTECH

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

Line Striper

Do not use this equipment before reading this manual!

Owner’s Manual

NOTE: This manual contains important warnings and

Printed in the U. S. A.

instructions. Please read and retain for reference.

Model Number 0509040

0306 © 2006 SprayTECH. All rights reserved. Form No. 0555887A

Page 2

Table of Contents

WARNING

CAUTION

WARNING

WARNING

Safety Precautions.................................................................2

Français ..............................................................................18

Español...............................................................................20

General Description ...............................................................4

Operation ................................................................................4

Setup ....................................................................................4

Preparing to Paint.................................................................5

Painting.................................................................................6

Operating the Front Caster...................................................6

Pressure Relief Procedure ...................................................7

Cleanup ...................................................................................7

Maintenance............................................................................8

General Repair and Service Notes.......................................8

Maintaining the Engine .........................................................8

Replacing the Filter...............................................................8

Replacing the PRIME/SPRAY Valve.....................................8

Replacing the Potentiometer ................................................9

Replacing the sprayer ON/OFF switch.................................9

Replacing the Transducer...................................................10

Replacing the Electronic Pressure Control (EPC) Board ...10

Replacing the Slider Assembly and Slider Housing............11

Replacing the Gears...........................................................12

Servicing the Clutch Assembly...........................................12

Servicing the Fluid Section.................................................14

Troubleshooting ...................................................................17

Parts Listings........................................................................22

Main Assembly....................................................................22

Drive Assembly...................................................................23

Cart Assembly.....................................................................24

Fluid Section Assembly ......................................................26

Electrical Schematic ...........................................................26

Filter Assembly ...................................................................27

PRIME/SPRAY Assembly ...................................................27

Caster Assembly.................................................................27

Siphon Set ..........................................................................28

Return Hose Assembly.......................................................28

Labels .................................................................................28

Accessories ..........................................................................28

Limited Warranty..................................................................32

Safety Precautions

This manual contains information that must be read and

understood before using the equipment. When you come to

an area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information

will follow

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to

prevent damage to the equipment or how to avoid causes

of minor injuries will follow.

.

B. WARNING – To reduce the risk of fire or explosion:

1. Do not spray flammable or combustible materials near

an open flame, pilot lights or sources of ignition such as

hot objects, cigarettes, motors, electrical equipment and

electrical appliances. Avoid creating sparks from

connecting and disconnecting power cords.

2. For units intended for use with only water-based

materials — Do not spray or clean with flammable

liquids. For use with water-based liquids only.

3. For units intended for use with only water-based or

mineral spirit-type materials with a minimum flash point

of 21ºC (69.8ºF) — Do not spray or clean with liquids

having a flash point of less than 21ºC (69.8ºF). Flash

point is the temperature at which a fluid can produce

enough vapor to ignite.

4. Paint or solvent flowing through the equipment is able

to result in static electricity. Static electricity creates a

risk of fire or explosion in the presence of paint or

solvent fumes. All parts of the spray system, including

the pump, hose assembly, spray gun and objects in and

around the spray area shall be properly grounded to

protect against static discharge and sparks. Use only

conductive or grounded high-pressure airless paint

sprayer hoses specified by the manufacturer.

5. Verify that all containers and collection systems are

grounded to prevent static discharge.

6. For electric units — connect to a grounded outlet and use

grounded extension cords. Do not use a 3 to 2 adapter.

7. Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating

supplier about compatibility of material with aluminum.

8. Keep spray area well ventilated. Keep a good supply of

fresh air moving through the area to keep the air within

the spray area free from accumulation of flammable

vapors. Keep pump assembly in well ventilated area.

Do not spray pump assembly.

9. Do not smoke in the spray area.

10. Do not operate light switches, engines, or similar spark

producing products in the spray area.

11. Keep area clean and free of paint or solvent

containers, rags, and other flammable materials.

12. Know the contents of the paint and solvents being

sprayed. Read all Material Safety Data Sheets (MSDS)

and container labels provided with the paints and

solvents. Follow the paint and solvent manufacture’s

safety instructions.

13. Place pump at least 25 feet (7.62 meters) from the

spray object in a well ventilated area (add more hose if

necessary). Flammable vapors are often heavier than

air. Floor area must be extremely well ventilated. The

pump contains arcing parts that emit sparks and can

ignite vapors.

14. Plastic can cause static sparks. Never hang plastic to

enclose spray area. Do not use plastic drop cloths

when spraying flammable material.

15. Fire extinguisher equipment shall be present and working.

NOTE: Notes give important information that should

A. SAVE THESE INSTRUCTIONS – To reduce the risks of

be given special attention.

IMPORTANT SAFETY INSTRUCTIONS

fire or explosion, electrical shock, and the injury to

persons, read and understand all instructions

included in this manual. Be familiar with the controls

and the proper usage of the equipment.

C. WARNING – To reduce the risk of skin injection:

HAZARD:

Injection injury – A high pressure fluid stream produced

by this equipment can pierce the skin and underlying

tissues, leading to a serious injury and possible

amputation. See a physician immediately. DO NOT

TREAT AN INJECTION AS A SIMPLE CUT.

1. Do not aim the gun at, or spray any person or animal.

2. Keep hands and other body parts away from the

discharge. For example, do not try to stop leaks with

any part of the body.

2 © SprayTECH. All rights reserved.

Page 3

3. Always use the nozzle tip guard. Do not spray without

WARNING

WARNING

CAUTION

the nozzle tip guard in place.

4. Only use a nozzle tip specified by the manufacturer.

5. Use caution when cleaning and changing nozzle tips.

In the case where the nozzle tip clogs while spraying,

ALWAYS lock gun trigger, shut pump off, and release

all pressure before servicing, cleaning tip or guard, or

changing tip. Pressure will not be released by turning

off the motor. The PRIME/SPRAY valve handle must

be turned to PRIME to relieve the pressure. Refer to

PRESSURE RELIEF PROCEDURE described in the

pump manual.

6. Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the unit

and relieve the pressure in accordance with the

manufacturer’s instructions.

7. High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. In the event that

injection occurs, seek medical attention immediately.

8. Check hoses and parts for signs of damage, a leak can

inject material into the skin. Inspect hose before each

use. Replace any damaged hoses or parts.

9. This system is capable of producing 3300 PSI / 22.8

MPa. Only use replacement parts or accessories that

are specified by the manufacturer and that are rated a

minimum of 3300 PSI. This includes spray tips, nozzle

guards, guns, extensions, fittings, and hose.

10. Always engage the trigger lock when not spraying.

Verify the trigger lock is functioning properly.

11. Verify that all connections are secure before operating

the unit.

12. Know how to stop the unit and bleed pressure quickly.

Be thoroughly familiar with the controls. Pressure will

not be released by turning off the motor. The

PRIME/SPRAY valve handle must be turned to PRIME

to relieve the pressure. Refer to PRESSURE RELIEF

PROCEDURE described in the pump manual.

13. Always remove the spray tip before flushing or cleaning

the system.

D. WARNING – To reduce the risk of injury:

1. Always wear appropriate gloves, eye protection,

clothing and a respirator or mask when painting.

Hazardous vapors – Paints, solvents, insecticides, and

other materials can be harmful if inhaled or come in

contact with body. Vapors can cause severe nausea,

fainting or poisoning.

2.

Do not operate or spray near children. Keep children

away from equipment at all times.

3. Do not overreach or stand on an unstable support.

Keep effective footing and balance at all times.

4. Stay alert and watch what you are doing.

5. Do not operate the unit when fatigued or under the

influence of drugs or alcohol.

6. Do not kink or over-bend the hose. Airless hose can

develop leaks from wear, kinking and abuse. A leak

can inject material into the skin.

7. Do not expose the hose to temperatures or pressures in

excess of those specified by manufacturer.

8. Do not use the hose as a strength member to pull or lift

the equipment.

9. Use lowest possible pressure to flush equipment.

10. Follow all appropriate local, state and national codes

governing ventilation, fire prevention and operation.

11. The United States Government Safety Standards have

been adopted under the Occupational Safety and

Health Act (OSHA). These standards, particularly part

1910 of the General Standards and part 1926 of the

Construction Standards should be consulted.

12. Before each use, check all hoses for cuts, leaks,

abrasion or bulging of cover. Check for damage or

movement of couplings. Immediately replace hose if

any of those conditions exist. Never repair a paint hose.

Replace with a conductive high-pressure hose.

13. Do not spray outdoors on windy days.

14. Always unplug cord from outlet before working on

equipment.

Do not lift by cart handle when loading or unloading.

Gasoline Engine Safety

The engine exhaust from this unit contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

1. Gas engines are designed to give safe and dependable

service if operated according to instructions. Read and

understand the engine Owner's Manual before operating

the engine. Failure to do so could result in personal injury

or equipment damage.

To prevent fire hazards and to provide adequate

2.

ventilation, keep the engine at least 1 meter (3 feet) away

from buildings and other equipment during operation. Do

not place flammable objects close to the engine.

3. Children and pets must be kept away from the area of

operation due to a possibility of burns from hot engine

components or injury from any equipment the engine may

be used to operate.

4. Know how to stop the engine quickly, and understand the

operation of all controls. Never permit anyone to operate

the engine without proper instructions.

5. Gasoline is extremely flammable and is explosive under

certain conditions.

6. Refuel in a well-ventilated area with the engine stopped.

Do not smoke or allow flames or sparks in the refueling

area or where gasoline is stored.

7. Do not overfill the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

8. Be careful not to spill fuel when refueling. Fuel vapor or

spilled fuel may ignite. If any fuel is spilled, make sure the

area is dry before starting the engine.

9. Never run the engine in an enclosed or confined area.

Exhaust contains poisonous carbon monoxide gas;

exposure may cause loss of consciousness and may lead

to death.

10. The muffler becomes very hot during operation and

remains hot for a while after stopping the engine. Be

careful not to touch the muffler while it is hot. To avoid

severe burns or fire hazards, let the engine cool before

transporting it or storing it indoors.

11. Never ship/transport unit with gasoline in the tank.

Specifications

Gallons per minute (GPM)...............1.30 (4.92 LPM)

Maximum tip size .............................one gun = 0.035”

Maximum pressure ..........................3300 PSI (22.8 MPa)

Power...............................................6.0 HP gas engine

Weight..............................................272 lbs. (123.4 kg)

two guns = 0.025”

© SprayTECH. All rights reserved. 3

Page 4

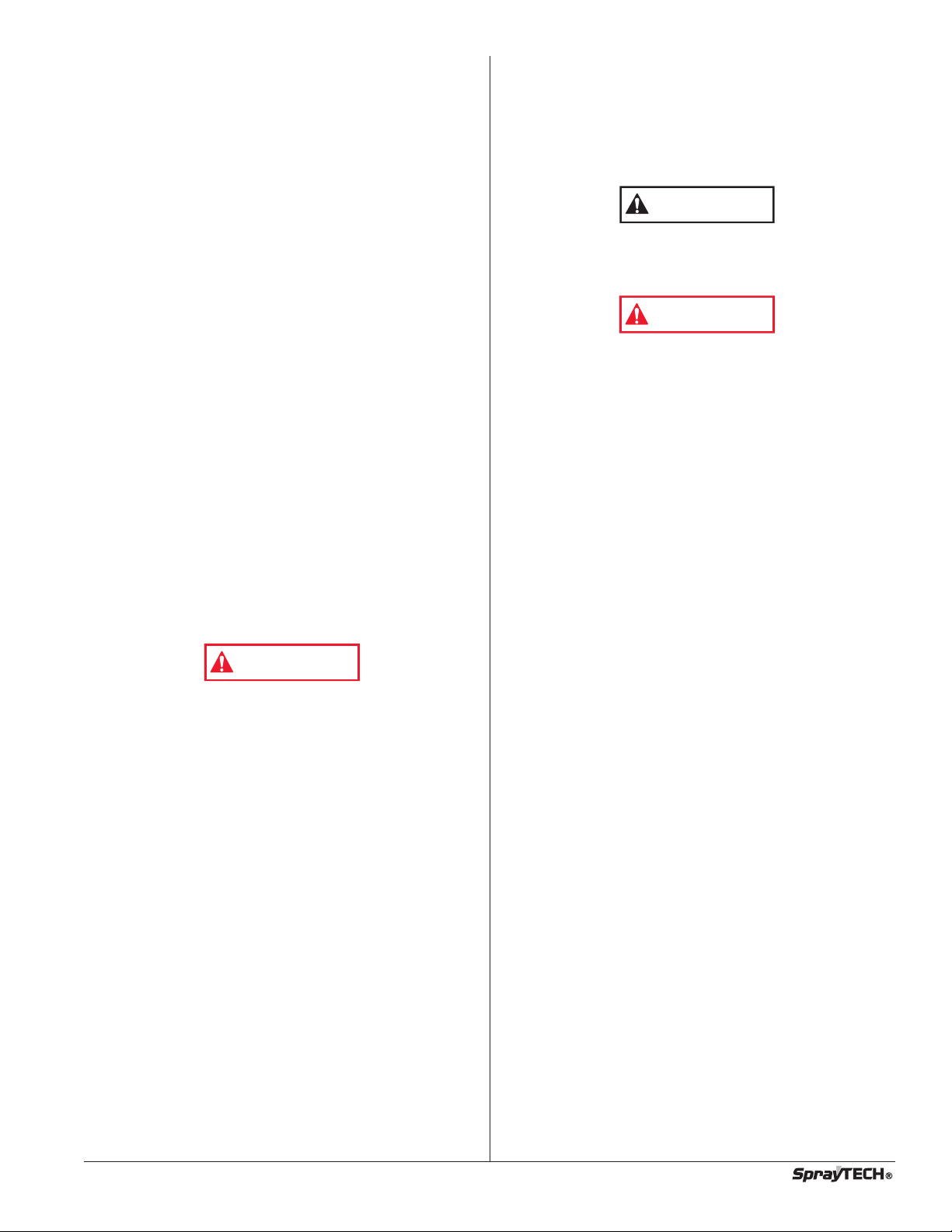

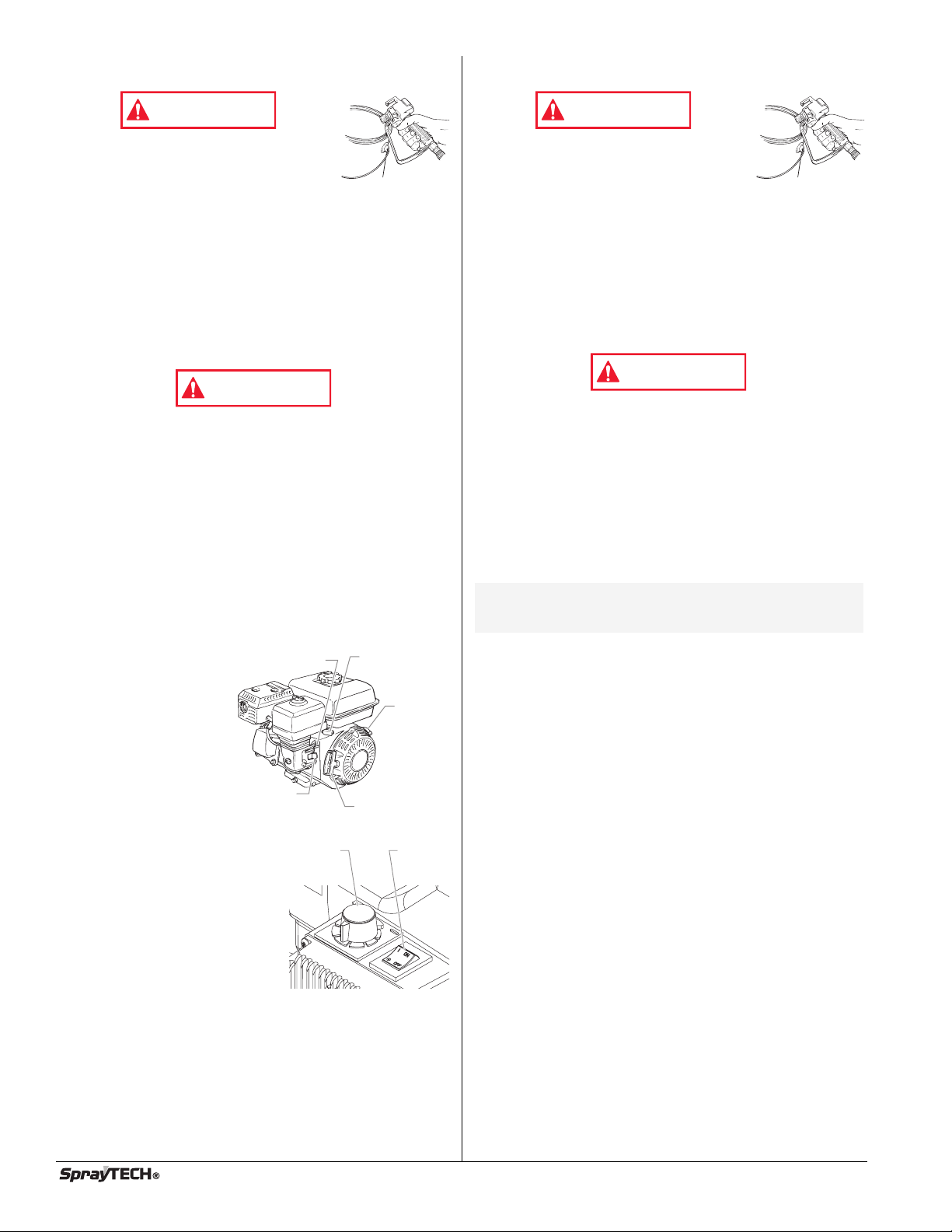

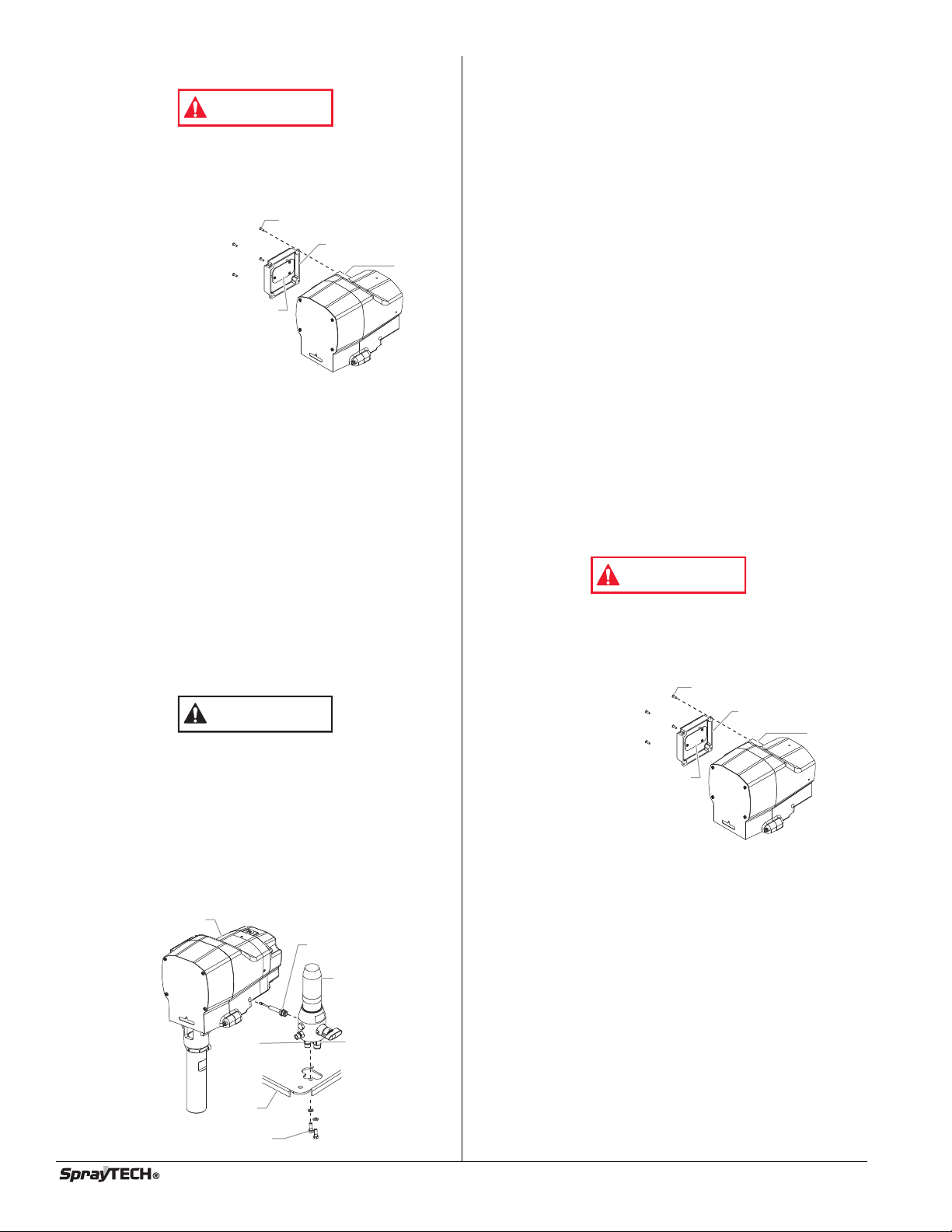

General Description

WARNING

WARNING

Throttle

Front Caster

Trigger

Gun

Trigger

Fluid

Section

Oil Cup

Tip Assembly

Gun

Support Bar

Airless Spray Gun

Gun Riser

Filter

Assembly

PRIME/

SPRAY

Valve

Outlet

Fitting

Engine

Return Hose

Siphon Tube

CAUTION

CAUTION

CAUTION

This airless line striper is a precision power tool used to spray

many types of material for many types of applications including

parking lots, curbs, and athletic fields. Read and follow this

instruction manual carefully for proper operating instructions,

maintenance, and safety information.

Operation

This equipment produces a fluid stream at extremely high

pressure. Read and understand the warnings in the

Safety Precautions section at the front of this manual

before operating this equipment.

Setup

Perform the following procedure before starting the engine of a

gas-powered sprayer.

1. Ensure that the siphon tube and the return hose are

2. Using a wrench, attach a minimum of 50’ of 1/4” nylon

3. Install the gun support bar.

NOTE: The spray gun, hose, and cables are mounted to

NOTE: The gun support bar and the spray gun(s) can

attached and secure.

airless spray hose to the outlet fitting on the filter

assembly of the sprayer. Tighten securely.

the gun support bar at the factory.

a. Loosen the support bar clamps on each side of the

cart.

b. Slide the gun support bar through the cart.

c. Tighten the support bar clamps to secure the gun

support bar in position.

be mounted on either side of the sprayer.

Always disengage the trigger cable from the tensioning

clamp before making any adjustments to the spray gun

position.

b. Loosen the support bar clamps and slide the gun

support bar to the desired horizontal position.

Loosen the gun riser clamp and slide the spray gun to

c.

the desired vertical position.

NOTE: The height of the spray gun affects the width of

4. Install the second gun assembly, if desired. Refer to the

5. Set the trigger selector for proper spray gun operation.

Always turn the trigger lock on the spray gun to the

locked position before making any adjustments to the

trigger selector. Also, release the trigger cable from its

block by lifting the cable up and out of the block. There

will be a brief triggering of the gun while releasing the

trigger cable.

4. Turn the pressure control knob fully counterclockwise to

5

6. Fill the fluid section oil cup with approximately one

the spray pattern (i.e., the lower the gun, the

smaller the line width). Tip size also affects

line width.

installation instructions that come with the second gun

assembly accessory.

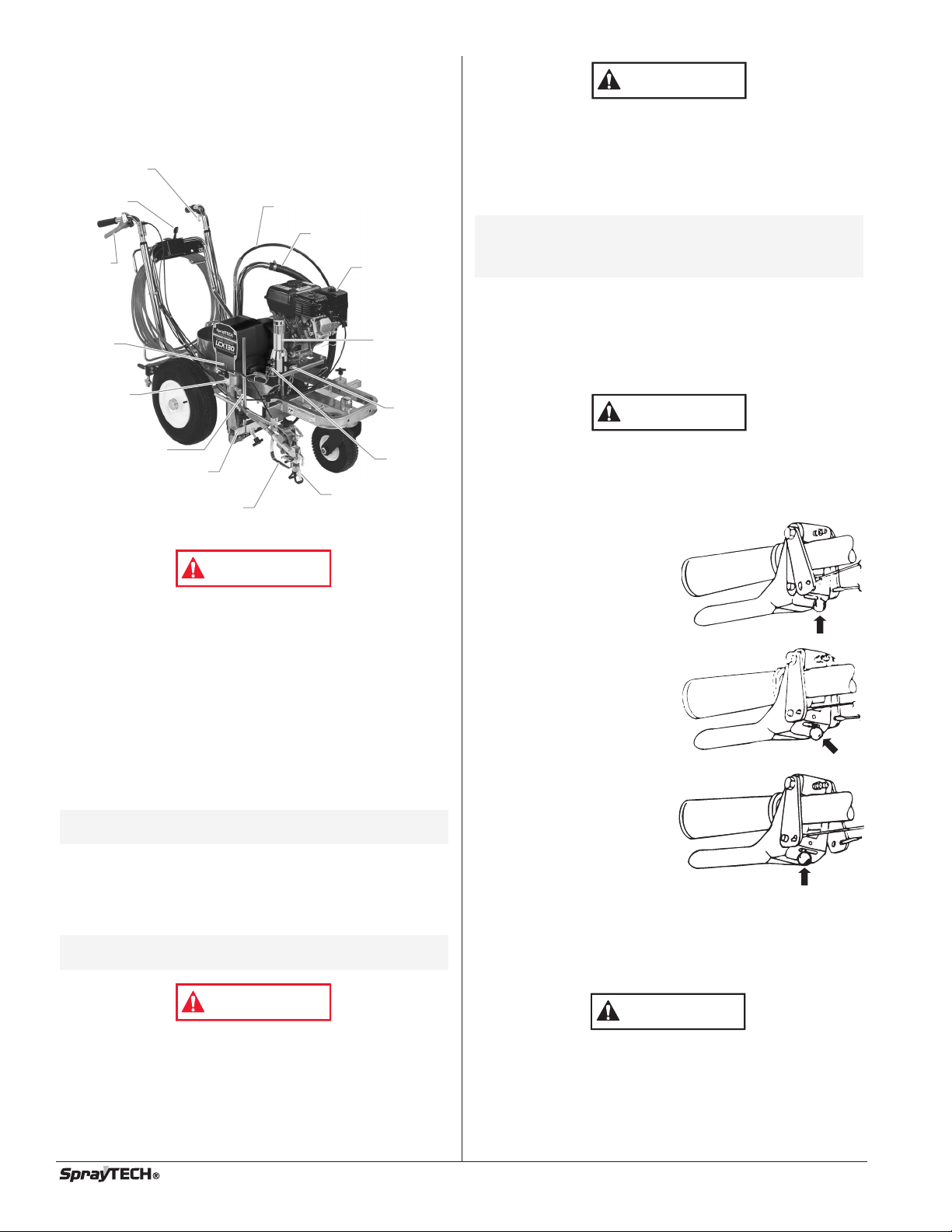

The right handlebar triggers the gun or guns. The selector

on the trigger must be set for the first gun, both guns, or

the second gun .

a. First Gun — The first

gun position is with the

selector in the left

position. Push the lever

toward the inside of the

frame until the pin

engages the left plate.

b. Both Guns — The dual

gun position is with the

selector in the center

position. Push the lever

toward the center

position until the pin

engages both plates.

The pin must engage

both plates.

c. Second Gun — The

second gun position is

with the selector in the

right position. Push the

lever away from the

inside of the frame until

the pin engages the right

plate.

its lowest pressure setting.

. Make sure the sprayer ON/OFF switch is in the OFF

position.

tablespoon of separating oil (P/N 0279920).

Always follow the Pressure Relief Procedure when

shutting the sprayer down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

4. Position the first spray gun.

a. Disengage the trigger cable from the tensioning clamp.

Never operate unit for more than ten seconds without

fluid. Operating this unit without fluid will cause

unnecessary wear to the packings.

7. Check the engine oil level. The gasoline engine oil level

is determined by the manufacturer. Refer to the engine

manufacturer's service manual (supplied).

Close the fuel shut-off lever and fill the gas tank with

8.

gasoline. Use only high quality, unleaded gasoline.

4 © SprayTECH. All rights reserved.

Page 5

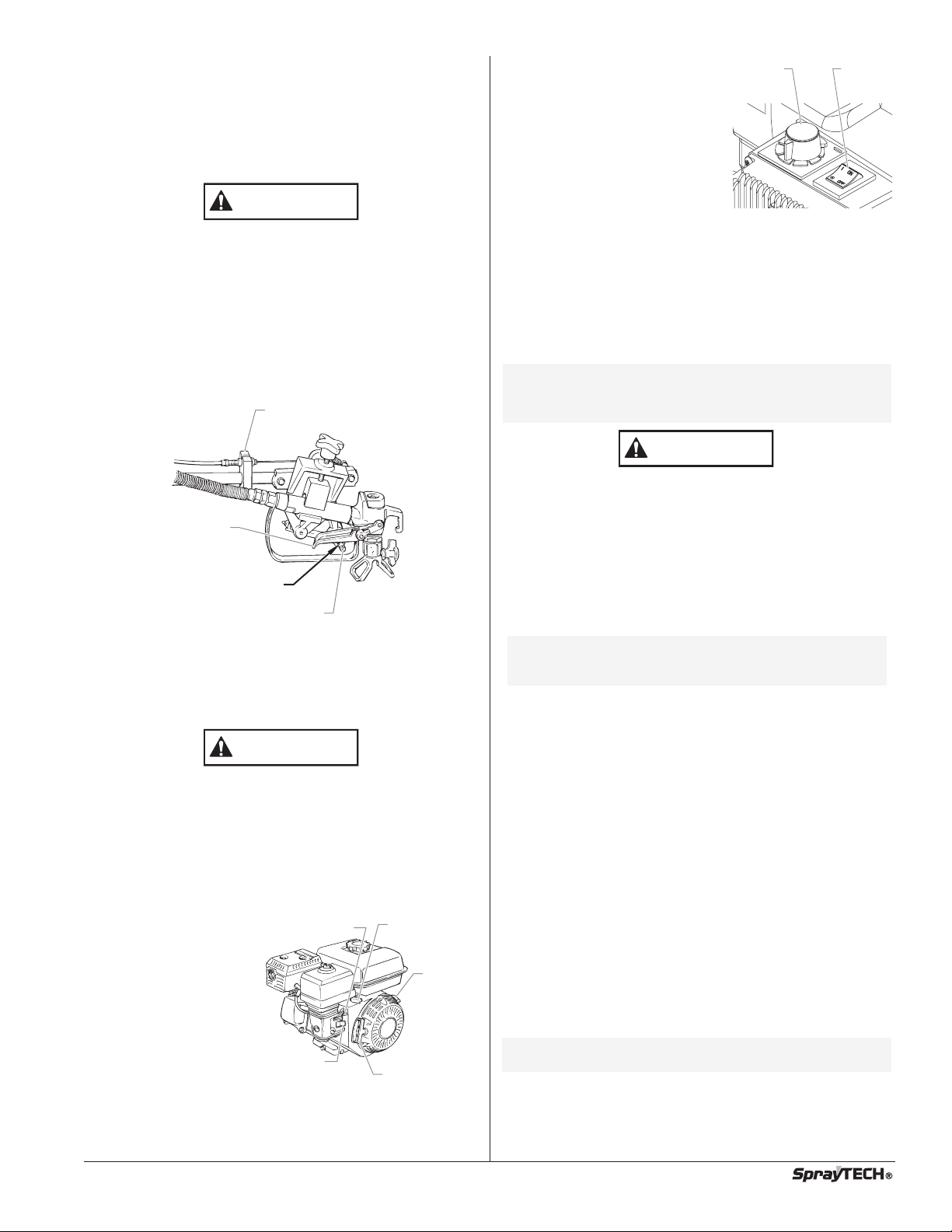

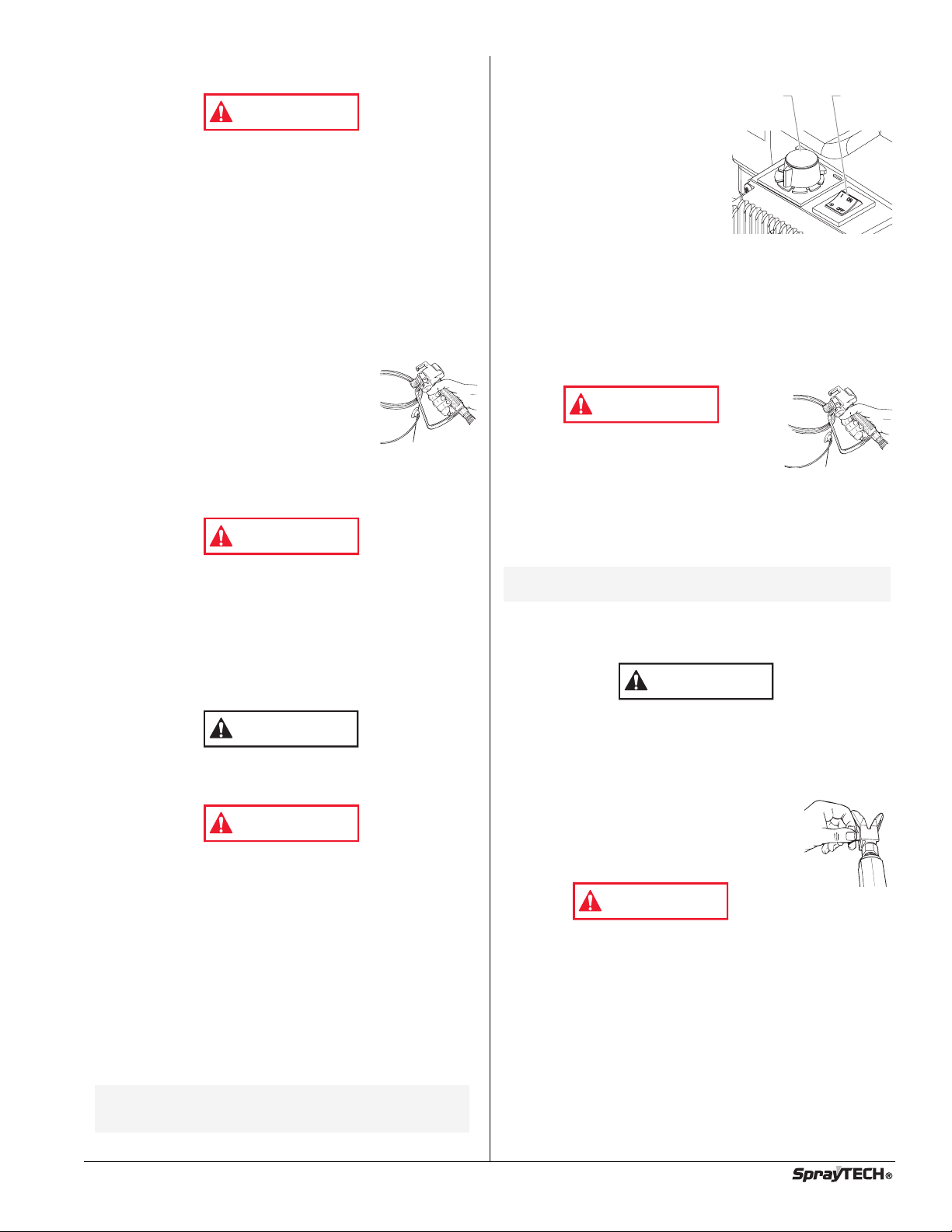

Adjusting the Trigger Tension

Fuel Valve

Lever

Choke Lever

Engine

ON/OFF

Switch

Throttle

Lever

Starter Rope

CAUTION

Spray Gun

Trigger

Trigger Lever

1/32" to 1/16" Gap

Cable Block

(set screw on back)

CAUTION

CAUTION

Pressure

Control

Knob

Pump

ON/OFF

Switch

Use the following procedure to adjust the spring tension of the

trigger lever on the gun holder assembly. The trigger lever

pulls and releases the spray gun trigger when operated from

the trigger on the cart. The proper tension ensures that the

gun will shut off when the gun trigger is released. To ensure

proper tension, there should be approximately a 1/32” to 1/16”

gap between the trigger lever and the spray gun trigger.

Always keep the trigger lock on the spray gun in the

locked position while making adjustments to the system.

1. Using a 5/32” hex wrench, loosen the set screw on the

2.

3. Tighten the set screw securely.

Preparing a New Sprayer

If this unit is new, it is shipped with test fluid in the fluid section

to prevent corrosion during shipment and storage. This fluid

must be thoroughly cleaned out of the system with mineral

spirits before you begin spraying.

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

1. Place the siphon tube into a container of mineral spirits

2.

3. Turn the pressure control knob fully counterclockwise to

4. Move the PRIME/SPRAY valve to the PRIME position.

5. Move the engine ON/OFF switch to the ON position.

6. Start the engine:

© SprayTECH. All rights reserved. 5

cable block.

Move the cable block in the appropriate direction to create

a gap of 1/32” to 1/16” between the trigger lever and spray

gun trigger.

a. Slide the cable block toward the gun to increase the

gap between the trigger lever and spray gun trigger.

b. Slide the cable block away from the gun to decrease

the gap between the trigger lever and spray gun trigger.

that has a flash point of 60ºC (140ºF) or above.

Place the return hose into a metal waste container.

its lowest pressure setting.

a. Open the fuel valve

lever.

b. Move the throttle

lever away from the

gas tank.

c. Close the engine

choke lever.

d. Holding the frame

with one hand, pull

the starter rope

rapidly and firmly. Continue to hold the rope as you let

it return. Pull and return the rope until the engine

starts.

7. Turn on the sprayer by moving

the sprayer ON/OFF switch to

the ON position.

8. Slowly turn the pressure control

knob clockwise to increase the

pressure until fluid starts to

come out of the return hose.

Use only enough pressure to

keep the fluid coming out.

9. Allow the sprayer to run for

15–30 seconds to flush the test fluid out through the

return hose and into the waste container.

10. Turn the pressure control knob fully counterclockwise to

its lowest setting.

11. Turn off the sprayer by moving the sprayer ON/OFF

switch to the OFF position.

Preparing to Paint

Before painting, it is important to make sure that the fluid in the

system is compatible with the paint that is going to be used.

NOTE: Incompatible fluids and paint may cause the

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

1. Place the siphon tube into a container of the appropriate

2. Place the return hose into a metal waste container.

3. Turn the pressure control knob fully counterclockwise to

4. Move the PRIME/SPRAY valve to the PRIME position.

5. Move the engine ON/OFF switch to the ON position.

6. Start the engine:

7. Turn on the sprayer by moving the sprayer ON/OFF

8. Slowly turn the pressure control knob clockwise to

9. Allow the sprayer to run for 15–30 seconds to flush the old

10. Turn the pressure control knob fully counterclockwise to

11. Turn off the sprayer by moving the sprayer ON/OFF

NOTE: Make sure that the spray gun does not have a

12. Move the PRIME/SPRAY valve to the SPRAY position.

13. Turn on the sprayer.

14. Turn the pressure control knob slowly clockwise to

valves to become stuck closed, which would

require disassembly and cleaning of the

sprayer’s fluid section.

solvent for the material being sprayed (refer to

recommendations of the material manufacturer).

example of the appropriate solvent is water for latex paint.

its lowest pressure setting.

NOTE: Hold the return hose in the waste container

when moving the PRIME/SPRAY valve to

PRIME in case the sprayer is pressurized.

a. Open the fuel valve lever.

b. Move the throttle lever away from the gas tank.

c. Close the engine choke lever.

d. Holding the frame with one hand, pull the starter rope

rapidly and firmly. Continue to hold the rope as you let

it return. Pull and return the rope until the engine

starts.

switch to the ON position.

increase the pressure until fluid starts to come out of the

return hose. Use only enough pressure to keep the fluid

coming out.

solvent out through the return hose and into the metal

waste container.

its lowest setting.

switch to the OFF position.

tip or tip guard installed.

increase pressure.

An

Page 6

15. Unlock the gun by turning the gun trigger lock to the

Pressure

Control

Knob

Pump

ON/OFF

Switch

Fuel Valve

Lever

Choke Lever

Engine

ON/OFF

Switch

Throttle

Lever

Starter Rope

WARNING

WARNING

WARNING

WARNING

unlocked position.

16. Unlock the gun by turning the gun trigger lock to the

unlocked position.

Ground the gun by holding it against the

edge of the metal container while flushing.

Failure to do so may lead to a static

electric discharge, which may cause a fire.

Trigger the gun into the metal waste container until the old

16.

solvent is gone and fresh solvent is coming out of the gun.

17. Lock the gun by turning the gun trigger lock to the locked

position.

18. Set down the gun and increase the pressure by turning the

pressure control knob slowly clockwise to its highest setting.

19. Check the entire system for leaks. If leaks occur, turn the

sprayer off and follow the “Pressure Relief Procedure” in

this manual before tightening any fittings or hoses.

20. Follow the “Pressure Relief Procedure” in this manual

before changing from solvent to paint.

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

Painting

1. Place the siphon tube into a container of paint.

2. Place the return hose into a metal waste container.

3. Turn the pressure control knob fully counterclockwise to

its lowest pressure setting.

4. Move the PRIME/SPRAY valve to the PRIME position.

5. Move the engine ON/OFF switch to the ON position.

6. Start the engine:

a. Open the fuel valve lever.

b. Move the throttle lever away from the gas tank.

c. Close the engine

choke lever.

d. Holding the frame

with one hand, pull

the starter rope

rapidly and firmly.

Continue to hold

the rope as you let

it return. Pull and

return the rope until

the engine starts.

7. Turn on the sprayer

by moving the sprayer ON/OFF switch to the ON position.

8. Slowly turn the pressure control

knob clockwise to increase the

pressure until fluid starts to

come out of the return hose.

Use only enough pressure to

keep the fluid coming out.

9. Allow the sprayer to run until

paint is coming through the

return hose into the metal

waste container.

10. Turn the pressure control knob fully counterclockwise to

its lowest setting.

11. Turn off the sprayer by moving the sprayer ON/OFF

switch to the OFF position.

12. Remove the return hose from the waste container and place

it in its operating position above the container of paint.

13. Move the PRIME/SPRAY valve to the SPRAY position.

14. Turn on the sprayer.

15. Turn the pressure control knob slowly clockwise to

increase pressure.

Ground the gun by holding it against the

edge of the metal container while flushing.

Failure to do so may lead to a static

electric discharge, which may cause a fire.

Trigger the gun into the metal waste container until all air

17.

and solvent is flushed from the spray hose and paint is

flowing freely from the gun.

18. Lock the gun by turning the gun trigger lock to the locked

position.

19. Turn the pressure control knob fully counterclockwise to

its lowest setting.

20. Turn off the sprayer.

21. Attach tip guard and tip to the gun as instructed by the tip

guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is in

either the spray or the unclog position.

gun trigger lock before removing, replacing or cleaning tip.

22. Turn on the sprayer.

23. Increase the pressure by turning the pressure control

knob slowly clockwise. Test the spray pattern and line

position on a long piece of roofing felt or cardboard.

a. Adjust the pressure control knob until the spray from

the gun is completely atomized. Try to keep the

pressure control knob at the lowest setting that

maintains good atomization.

NOTE: Turning the pressure up higher than needed to

atomize the paint will cause premature tip wear

and additional overspray.

b. Check for proper line width and position. If adjustment

to the position of the spray gun is required, refer to the

“Setup” procedure earlier in this section.

24. Make sure that the spray gun shuts off completely when

the gun trigger is released. If adjustment to the trigger

tension is required, refer to the “Adjusting the Trigger

Tension” procedure earlier in this section.

Always engage the

Operating the Front Caster

The front caster on the cart is designed to track the sprayer in

either a straight line or allow free motion. Standing behind the

sprayer, the trigger on the left handle of the cart controls the

operation of the front caster.

1. To lock the front caster in the straight line position,

squeeze then release the caster trigger and move the

sprayer forward.

2. To allow free motion of the front caster, squeeze and hold

the caster trigger.

6 © SprayTECH. All rights reserved.

Page 7

WARNING

CAUTION

WARNING

WARNING

WARNING

CAUTION

WARNING

Pressure

Control

Knob

Pump

ON/OFF

Switch

Pressure Relief Procedure

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

1. Lock the gun by turning the gun trigger lock to the locked

position.

2. Turn off the sprayer by moving the sprayer ON/OFF

switch to the OFF position.

3. Turn off the engine by moving the engine ON/OFF switch

to the OFF position.

4. Turn the pressure control knob counterclockwise to its

lowest setting.

5. Unlock the gun by turning the gun trigger lock to the

unlocked position.

4. Hold the metal part of the gun firmly to the

side of a metal container to ground the gun

and avoid a build up of static electricity.

5. Trigger the gun to remove any pressure

that may still be in the hose.

6. Lock the gun by turning the gun trigger

lock to the locked position.

7. Move the PRIME/SPRAY valve to the PRIME position.

Cleanup

Special cleanup instructions for use with flammable

solvents:

• Always flush spray gun preferably outside and at least one

hose length from spray pump.

• If collecting flushed solvents in a one gallon metal

container, place it into an empty five gallon container, then

flush solvents.

• Area must be free of flammable vapors.

• Follow all cleanup instructions.

The sprayer, hose, and gun should be cleaned thoroughly

after daily use. Failure to do so permits material to build

up, seriously affecting the performance of the unit.

Always spray at minimum pressure with the gun nozzle tip

removed when using mineral spirits or any other solvent

to clean the sprayer

buildup may result in a fire or explosion in the presence of

flammable vapors.

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

2. Remove the gun tip and tip guard and clean with a brush

using the appropriate solvent.

Place the siphon tube into a container of the appropriate

3.

solvent (refer to recommendations of the material

manufacturer). An example of the appropriate solvent is

water for latex paint.

4. Place the return hose into a metal waste container.

5. Move the PRIME/SPRAY valve to its PRIME position.

NOTE: Hold the return hose in the waste container

when moving the PRIME/SPRAY valve to

PRIME in case the sprayer is pressurized.

, hose, or gun. Static electricity

6. Move the engine ON/OFF switch to the ON position and

start the engine.

7. Turn on the sprayer by moving

the sprayer ON/OFF switch to

the ON position.

8. Slowly turn the pressure control

knob clockwise to increase the

pressure until fluid starts to

come out of the return hose.

9. Allow the solvent to circulate

through the sprayer and flush

the paint out of the return hose

into the metal waste container.

10. Turn the pressure control knob fully counterclockwise to

its lowest setting.

11. Turn off the sprayer by moving the ON/OFF switch to the

OFF position.

12. Move the PRIME/SPRAY valve to its SPRAY position.

13. Turn on the sprayer.

14. Turn the pressure control knob slowly clockwise to

increase pressure.

Ground the gun by holding it against the

edge of the metal container while flushing.

Failure to do so may lead to a static

electric discharge, which may cause a fire.

15. Trigger the gun into the metal waste container until the

paint is flushed out of the hose and solvent is coming out

of the gun.

Continue to trigger the spray gun into the waste container

16.

until the solvent coming out of the gun is clean.

NOTE: For long-term or cold weather storage, pump

17. Follow the “Pressure Relief Procedure” found in the

18. Store the sprayer in a clean, dry area.

Do not store the sprayer under pressure.

mineral sprits through the entire system.

Operation section of this manual.

Cleaning the Spray Tip

1. Flush the gun with solvent immediately after the work is

completed.

2. Oil the sliding pins to prevent them from seizing up.

Should the spray tip become clogged, reverse

the spray tip with the lever and pull the trigger.

Once the obstruction comes out of the spray tip,

release the trigger, reverse the spray tip back to

the spray pattern setting, and resume spraying.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to

clean the tip. The hard tungsten carbide is brittle and can

be chipped.

© SprayTECH. All rights reserved. 7

Page 8

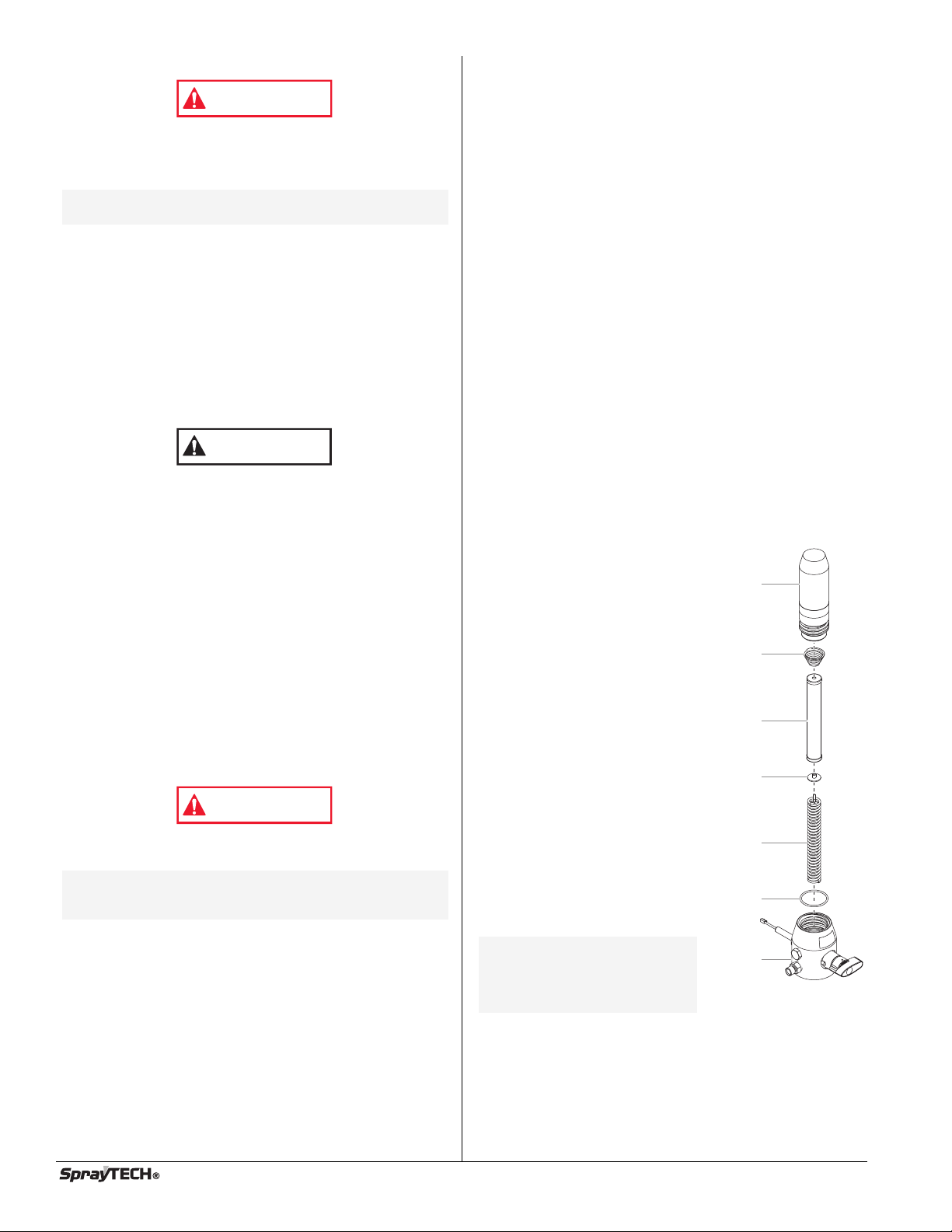

WARNING

CAUTION

WARNING

Filter

Spring

Filter

Body

Filter

Support

Spring

Filter

Adapter

Filter

Housing

O-ring

Filter

Housing

Maintenance

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual. Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts, or electric shock.

NOTE: All engine work should be performed by an

authorized service center.

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

Phillips screwdriver 3/8" hex wrench

needle-nose pliers 5/16" hex wrench

adjustable wrench 1/4" hex wrench

rubber mallet 3/16" hex wrench

flat-blade screwdriver 1/8” hex wrench

1/2” open-end wrench 7/8” open-end wrench

1. Before repairing any part of the sprayer, read the

instructions carefully, including all warnings.

Never pull on a wire to disconnect it. Pulling on a wire

could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to

be sure that the problem is corrected. If the sprayer does

not operate properly, review the repair procedure to

determine if everything was done correctly. Refer to the

Troubleshooting section to help identify other possible

problems.

3. Make certain that the service area is well ventilated in

case solvents are used during cleaning. Always wear

protective eyewear while servicing. Additional protective

equipment may be required depending on the type of

cleaning solvent. Always contact the supplier of solvents

for recommendations.

4. If you have any further questions concerning your

SprayTECH airless sprayer, call SprayTECH:

Technical Service...................................1-800-292-4637

Fax ................................................1-800-525-9501

Maintaining the Engine

When transporting a sprayer with a gas engine, make sure

the fuel is shut off.

NOTE: For detailed engine specifications and

maintenance, refer to the separate engine

manual supplied with this sprayer.

Important Facts Concerning this Sprayer

This gas-powered sprayer contains a clutch that engages

when the sprayer is pumping. The sprayer’s pressure control

system engages and disengages the clutch to control

pressure. To prevent unnecessary wear to the clutch, it is

advisable to adjust the engine speed and pressure setting to

limit the amount of times the clutch engages and disengages.

To reduce clutch wear, refer to the following examples.

Example:

Operating one gun with a .019 tip — reduce the engine speed

by adjusting the throttle to a low or medium setting and

increase pressure only until the heavy ends of the spray

pattern have been eliminated.

Example:

Operating one gun with .023 tip — increase engine speed to a

high setting and increase pressure until the heavy ends of the

spray pattern have been eliminated.

Example:

Spraying light-bodied materials at low pressure — to reduce

surging at the gun and to decrease clutch wear

engine speed to idle and reduce pressure until the desired

spray pattern is achieved.

, reduce the

Routine Engine Maintenance

Daily

• Check and fill the gas tank.

After the first 20 hours of operation, drain the oil and refill

•

with clean oil. Check the engine oil level and fill as

necessary.

Weekly

• Remove the cover of the air filter and clean the element.

Replace the element if necessary. If operating in an

unusually dusty environment, check the filter daily and

replace if necessary. (Replacement elements can be

purchased from your local SprayTECH dealer.)

• After each 50 hours of operation: Change the engine oil.

Spark Plug

• Use only a (NKG) BP6ES plug.

• Gap the plug 0.025” – 0.030” (0.7 – 0.8 mm).

• Make sure to use a spark plug wrench when installing and

removing the plug.

Replacing the Filter

1. Loosen and remove the filter

body by hand.

2. Remove the filter and filter

support spring spring from the

filter housing.

3. Remove the filter support spring

and adapter from inside the

filter.

4. Inspect the filter. Based on

inspection, clean or replace the

filter.

5. Inspect the filter housing o-ring.

Based on inspection, clean or

replace the o-ring.

6. Slide the new or cleaned filter

over the adapter and filter

support spring. Place the filter

and filter support spring into the

center of the filter housing.

7. Clean the inside of the filter

body.

8. Slide the filter body over the

filter and thread it into the filter

housing until secure. Make

sure the filter spring is in

position on top of the filter.

NOTE: The filter body should

be hand-tightened,

but make sure it is

seated fully into the

filter housing.

Replacing the PRIME/SPRAY Valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 0507690.

1. Drive the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly.

8 © SprayTECH. All rights reserved.

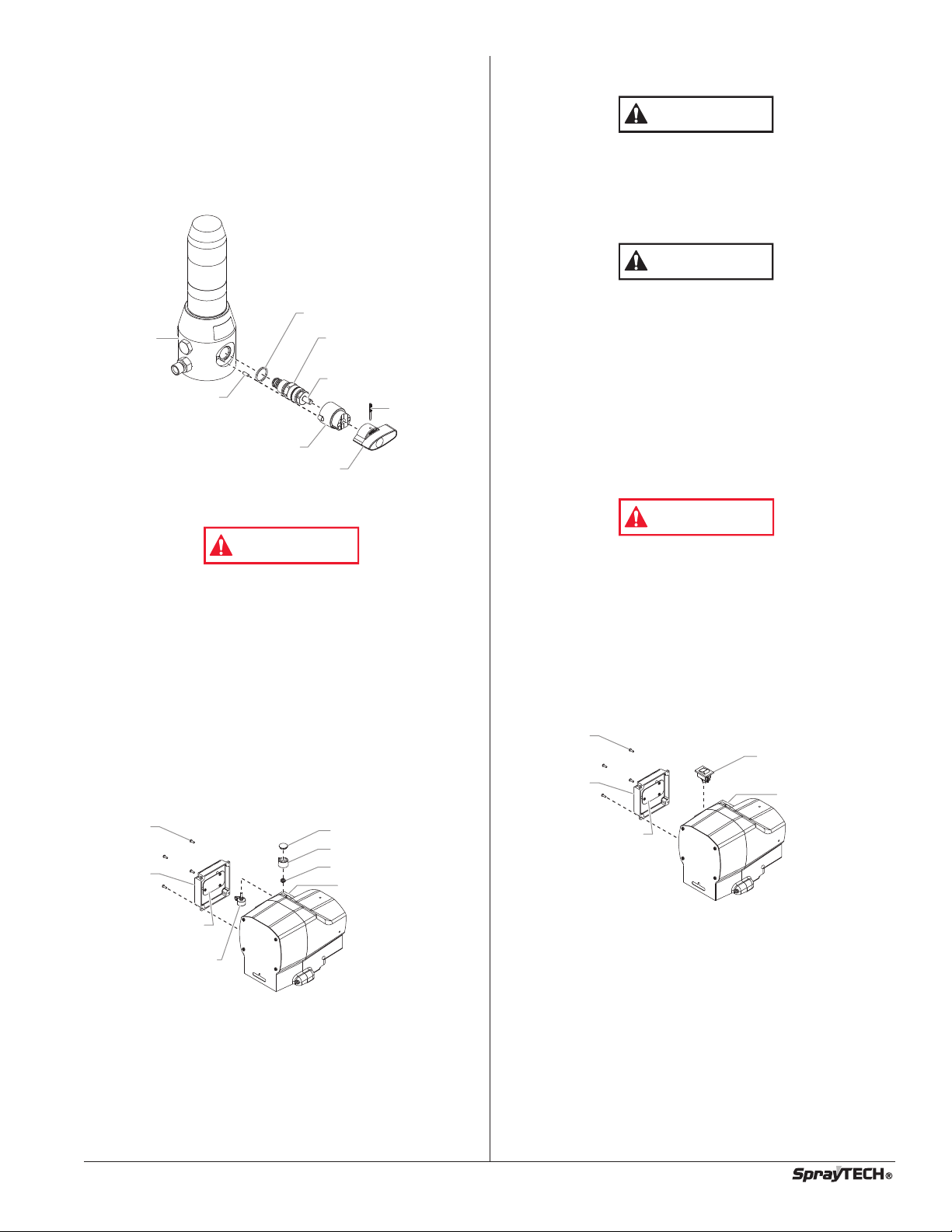

Page 9

4. Make sure the gasket is in place and thread the new valve

EPC

Housing

Pressure Control Knob

Seal Nut

Cap

EPC

Board

EPC

Assembly

EPC

Assembly

Screw

Potentiometer

WARNING

Dowel Pin

Cam Base

Valve Stem

Filter

Housing

Valve Housing

Assembly

Gasket

Valve Handle

Groove Pin

EPC

Housing

Sprayer ON/OFF

Switch

EPC

Board

EPC

Assembly

EPC

Assembly

Screw

WARNING

CAUTION

CAUTION

housing assembly into the filter housing. Tighten securely

with a wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam

with the filter block using the dowel pin.

6. Line up the hole on the valve stem with the hole in the

valve handle.

7. Insert the groove pin into the valve handle and through

the valve stem to secure the valve handle in position.

9. Thread the seal nut onto the threaded portion of the stem

and tighten using a 1/2” thin wall socket.

Do not over-tighten the seal nut.

10. Turn the potentiometer stem fully counterclockwise.

Place the pressure control knob on the potentiometer

11.

stem with the indicator tab resting at the “minimum

pressure” tab on the mounting plate.

12. Tighten the knob tension nut using a 5/16” socket.

Replacing the Potentiometer

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

2. Pry off the pressure control knob cap to expose the knob

tension nut.

3. Turn the pressure control knob fully counterclockwise to

the minimum pressure setting.

4. Using a 5/16” socket, loosen the tension nut in the center

of the knob. Remove the knob.

5. Using a Phillips screwdriver, remove the four screws that

secure the electronic pressure control (EPC) assembly to

the EPC housing. Carefully remove the EPC assembly from

the housing. Gently move the assembly away from the

sprayer and allow the assembly to hang from the housing.

Do not over-tighten the knob tension nut. Over-tightening

will damage the potentiometer

13. Connect the potentiometer wires to the EPC board. The

protruding tab on the EPC board connector will mate with

the slot on the potentiometer wires connector. The

connector on the end of the potentiometer wires and the

connector on the EPC board will mate only one way. Do

not force the connectors together.

14. Carefully place the EPC assembly over the EPC housing

taking care not to pinch any wires.

15. Install the four screws that secure the EPC assembly to

the EPC housing. Tighten securely.

.

Replacing the Sprayer ON/OFF Switch

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

2. Using a Phillips screwdriver, remove the four screws that

secure the electronic pressure control (EPC) assembly to

the EPC housing. Carefully remove the EPC assembly from

the housing. Gently move the assembly away from the

sprayer and allow the assembly to hang from the housing.

3. Locate the bottom of the sprayer ON/OFF switch inside

the EPC housing.

6. Hold the potentiometer inside the EPC housing while

using a 1/2” thin wall socket to remove the seal nut that

secures the potentiometer to the mounting plate. Remove

the potentiometer from the EPC housing.

7. Carefully remove the potentiometer wires from their

connection point on the EPC board.

8. Insert the stem of the new potentiometer through the hole

in the mounting plate from inside the EPC housing.

Position the protruding tab on the potentiometer face into

the hole on the underside of the mounting plate (the wires

will face the open side of the EPC housing).

© SprayTECH. All rights reserved. 9

4. Disconnect the switch wires from the sprayer ON/OFF

switch. Remember the locations of each of the two wires

(label the wires, if necessary).

5. Depress the mounting tabs on each corner of the sprayer

ON/OFF switch inside the EPC housing and remove the

switch through the top of the housing.

6. Snap the new sprayer ON/OFF switch into the switch hole

in the EPC housing.

7. Connect the two switch wires to the new sprayer ON/OFF

switch. Make sure the wires are connected to the

corresponding terminals from which they were removed

(refer to the labels created earlier in this procedure or the

electrical schematic in the Parts List section of this manual).

8. Carefully place the EPC assembly over the EPC housing

taking care not to pinch any wires.

9. Install the four screws that secure the EPC assembly to

the EPC housing. Tighten securely.

Page 10

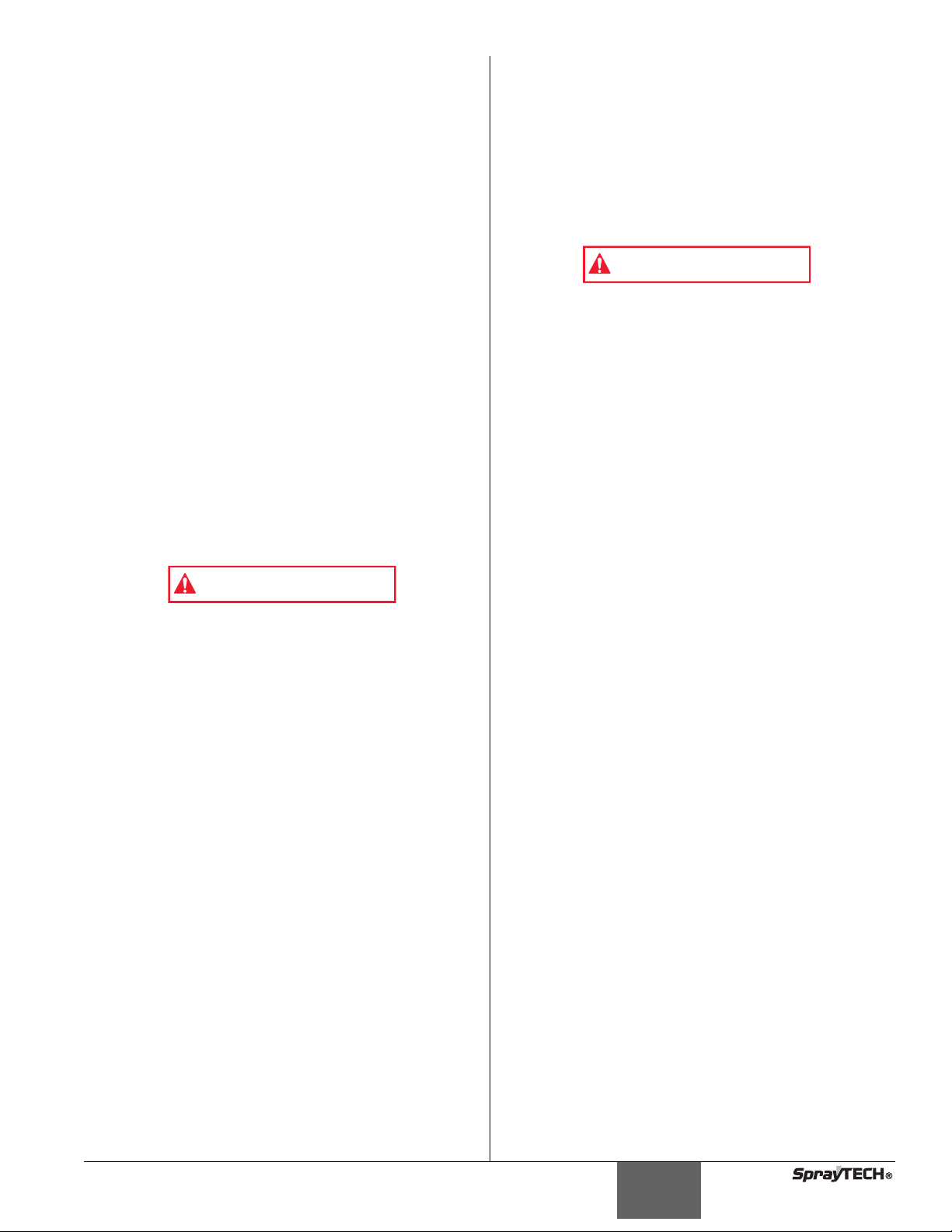

Replacing the Transducer

Transducer

Filter Assembly

Hex Screw

Gear Housing

Filter

Assembly

Fluid

Hose

Fitting

Cart

Return

Hose

Fitting

CAUTION

EPC

Housing

EPC Assembly Screw

EPC Assembly

EPC

Board

WARNING

EPC

Housing

EPC Assembly Screw

EPC Assembly

EPC

Board

WARNING

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

2. Using a Phillips

3. Locate the transducer wire in the EPC housing. This wire

4. Break off the locking tab from the phone jack-style

5. Using a 7/8” open-end wrench, loosen and remove the

6. Remove the return hose from the fitting on the bottom of

7. Using a 1/2” socket, remove the two hex screws that

8. Lift the filter assembly off the cart so that the transducer

9. Mount the filter assembly in a vise for easy access to the

Do not over-tighten the vise.

10. Using a 3/4” open-end wrench, turn the transducer nut

11. Locate the new transducer. Make sure that there is a

12. Insert the transducer into the filter housing port. Rotate

13. Remove the filter assembly from the vise.

screwdriver, remove

the four screws that

secure the electronic

pressure control

(EPC) assembly to the

EPC housing.

Carefully remove the

EPC assembly from

the housing. Gently

move the assembly

away from the sprayer

and allow the assembly to hang from the housing.

will be protruding from a hole in the lower left hand corner

of the EPC housing. Disconnect this wire from the EPC

board (it has a phone jack-style connector).

connector at the end of the transducer wire.

fluid hose from the fitting on the bottom of the filter

assembly.

the filter assembly.

secure the filter assembly to the cart.

tube moves out of the hole in the gear housing. Gently

pull the transducer wire through the housing until it is fully

disengaged from the hole.

transducer.

counterclockwise to remove the transducer from the filter

housing.

white, 37)( o-ring on the end of the transducer that gets

inserted into the filter housing.

the transducer nut clockwise to tighten it into the filter

housing.

Torque the nut to 360–400 in./lbs.

14. Insert the phone jack-style connector on the new

transducer wire into the hole in the gear housing from

which the old transducer wire was removed. Push the

wire and connector until the connector is visible in the

EPC housing.

15. Gently pull the wire into the EPC housing while moving

the filter assembly to its mounting point on the cart. Guide

the end of the transducer tube into the hole in the gear

housing.

16. Mount the filter assembly to the cart using the two hex

screws and lock washers. Torque the screws to 100–130

in./lbs.

17. Using a 7/8” open-end wrench, attach the fluid hose to the

fitting on the bottom of the filter assembly. Tighten

securely.

18. Push the return hose firmly into the fitting on the bottom of

the filter assembly. Pull on the hose to make sure it has

engaged within the fitting.

19. Plug the phone jack-style connector on the transducer

wire into the socket on the EPC board from which the old

connector was removed.

20. Carefully place the EPC assembly over the EPC housing

taking care not to pinch any wires.

21. Install the four screws that secure the EPC assembly to

the EPC housing. Tighten securely.

22. Take the sprayer to a SprayTECH Authorized Service

Center for re-calibration.

23. After re-calibration, pressurize the system and check for

leaks.

Replacing the Electronic Pressure

Control (EPC) Assembly

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

2. Using a Phillips

screwdriver, remove

the four screws that

secure the electronic

pressure control

(EPC) assembly to

the EPC housing.

Carefully remove the

EPC assembly from

the housing. Gently

move the assembly

away from the sprayer

and allow the assembly to hang from the housing.

3. Remember the locations of all the wire connections on the

EPC board (refer the electrical schematic located in the

Parts List section of this manual). If necessary, label all

the connections so that they can be replaced in their exact

location when the assembly is replaced.

4. Disconnect all the wires from the EPC board.

5. Connect all the wires to the new EPC assembly board

(refer to the labels created earlier in this procedure or the

electrical schematic in the Parts List section of this

manual).

6. Carefully place the EPC assembly over the EPC housing

taking care not to pinch any wires.

7. Install the four screws that secure the EPC assembly to

the EPC housing. Tighten securely.

8. Take the sprayer to a SprayTECH Authorized Service

Center for re-calibration.

10 © SprayTECH. All rights reserved.

Page 11

Connecting

Pin

Fitting

Retaining

Ring

Slider

Assembly

Pump

Housing

Front

Cover

Screw

Slider

Housing

Jam Nut

Fluid

Section

Front

Cover

Crankshaft

Dowel Pin

Connecting Rod

Slider Housing

Socket Screw

Pump

Housing

Slider Housing

Slider Assembly

Replacing the Slider Assembly and

Slider Housing

1. Start the engine (refer to the procedures in the Operation

section of this manual). Turn the pressure control knob

clockwise to its maximum pressure setting.

2. Toggle the sprayer ON/OFF switch between the ON and

OFF positions in short bursts until the slider assembly

stops in a position where the fluid section connecting pin

and retaining ring are visible through the slot in the slider

housing.

3. Turn off the engine and perform the Pressure Relief

Procedure.

4. Using a Phillips

screwdriver,

remove the four

front cover

screws. Remove

the front cover.

5. Slide the retaining

ring up on the

slider assembly to

expose the

connecting pin.

6. Push the

connecting pin

forward through

the slider

assembly and

piston. The

connecting pin

will fall out from

the rear window of the slider housing where it can be

retrieved.

7. Using a 7/8” open-end wrench, loosen and remove the

fluid hose from the fitting on the back of the fluid section.

8. Using a 2 1/4” wrench, loosen the fluid section jam nut.

Turn the fluid section counterclockwise by until it

disengages from the slider housing.

9. Using a 5/16” hex wrench, remove the four socket screws

and lock washers that secure the slider housing to the

pump housing.

10. Remove the slider housing and slider assembly by pulling it

straight out from the pump housing. The slider housing

assembly will disengage from the pump housing dowel pins

and the connecting rod will disengage from the crankshaft.

11. Remove the slider assembly from the slider housing by

grasping the bearing end of the connecting rod and lifting

it straight out from the slider housing.

12. Check the parts for wear.

a. If the slider housing bushing is scored or out of round it

should be replaced.

b. If the slider assembly is scored or the connection

between the connecting rod and slider assembly

exhibits movement other than pivoting movement, the

slider assembly should be replaced. The slider

assembly also should be replaced if the connecting rod

bearing shows signs of wear.

c. Any parts that will be reused should be cleaned

thoroughly, including the connecting rod. Also, clean the

crankshaft pin that the connecting rod bearing rides on.

d. If a new slider assembly will be used, remove the

13. Lubricate the inside diameter of the slider housing and the

outside diameter of the slider assembly with oil. Fill the

slider cup with Lubriplate 3000W grease (the slider cup is

the area on the slider assembly where the connecting rod

and slider housing join and pivot).

14. Insert the slider assembly into the bushing end of the

slider housing.

© SprayTECH. All rights reserved. 11

retaining ring from the bottom of the old slider assembly

and slide it onto the new assembly so that it rests

above the connecting pin hole.

15. Hold the assembly up to the pump housing, lining up the

connecting rod with the crankshaft pin and the pump

housing dowel pins with their mating holes on the slider

housing. Slide the assembly onto the crankshaft pin and

pump housing dowel pins until the slider housing bottoms

out on the pump housing. Make sure the grease fitting on

the connecting rod is facing the open side of the pump

housing.

16. Install the the four socket screws and lock washers that

secure the slider housing to the pump housing. Tighten in

a diagonal pattern and torque to 400–440 in./lbs.

17. Lubricate the connecting rod bearing with Lubriplate 1242

grease by inserting the end of a grease gun onto the

grease fitting on the end of the crankshaft pin. Lubricate

the main housing bearing by inserting the end of a grease

gun onto the grease fitting in the center of the crankshaft.

Also, lubricate the connecting rod bushing by inserting the

end of a grease gun onto the grease fitting on the

connecting rod.

18. Position the front cover over the pump housing. Secure

the front cover using the four front cover screws.

19. Apply blue Loctite to the bottom 3–4 threads on the fluid

section cylinder.

20. Turn the fluid section jam nut clockwise until it is flush

against the top of the cylinder.

21. Lubricate the first several threads at the top of the cylinder

with anti-seize compound.

22. Thread the cylinder into the pump housing, turning

clockwise. When the connecting pin hole on the piston

rod lines up with the hole in the slider assembly, insert the

connecting pin.

23. Slide the retaining ring down on the slider assembly to

cover the connecting pin.

24. Continue to turn the cylinder clockwise until the jam nut is

flush against the slider housing.

NOTE: If the nipple on the cylinder does not face the

back of the unit, turn the cylinder

counterclockwise until the nipple faces the

back of the unit. Do not turn the cylinder more

than one full turn.

25. Once the nipple is positioned, turn the jam nut clockwise

until it contacts the pump housing.

26. Tighten the jam nut with a wrench to tighten it against the

slider housing.

27. Using a 7/8” open-end wrench, attach the fluid hose to the

fitting on the back of the fluid section. Tighten securely.

Page 12

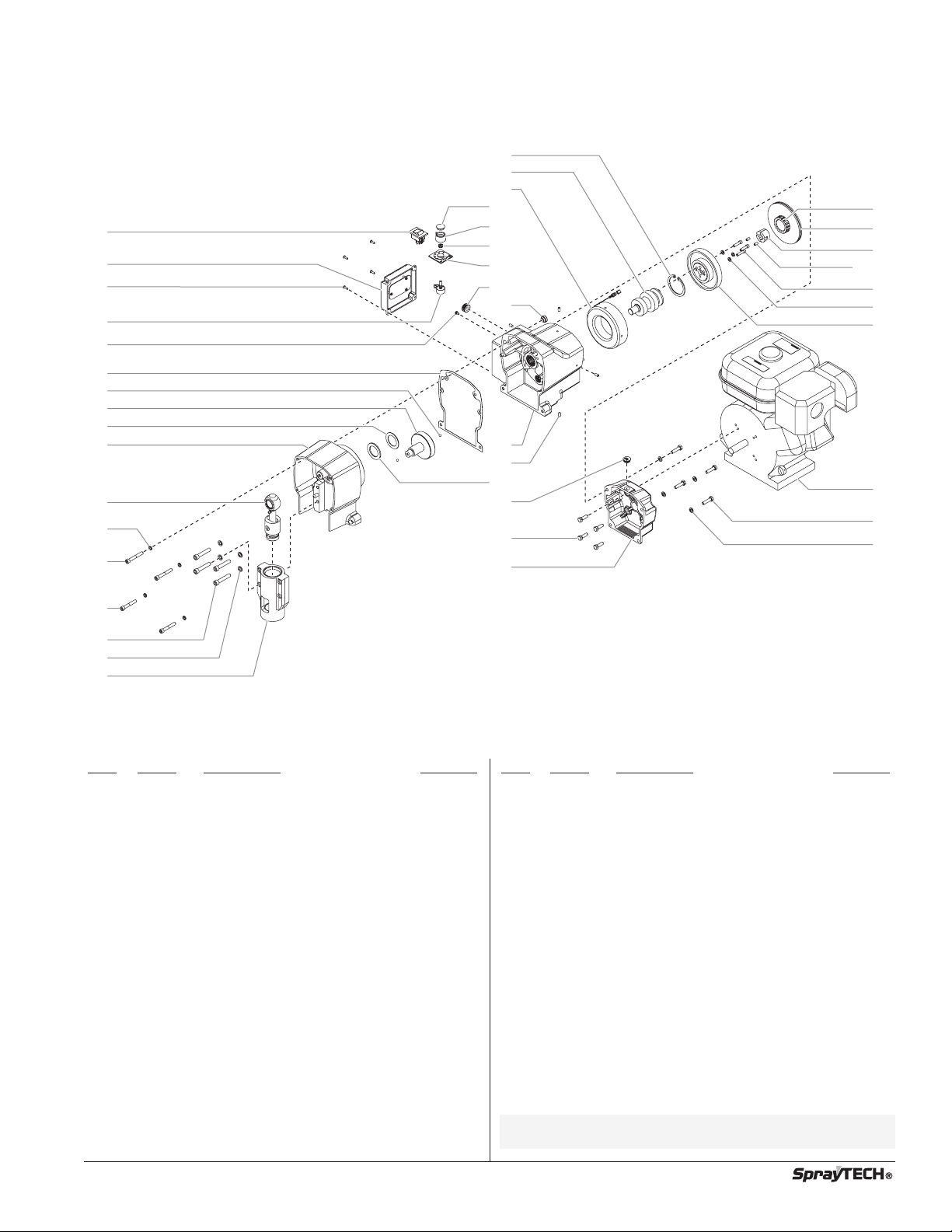

Replacing the Gears

Housing Gasket

Gear Housing

Thrust Ball

Thin Thrust Washer

Thrust Ball

Front

Cover

Pump Housing

Gear

Assembly

Thick Thrust

Washer

Pump Housing

Socket Screw

Front Cover

Screw

Clutch Armature

Clutch Hub

Taper Lock Bushing

Gear

Housing

Pump

Housing

Lock

Washer

Clutch

Housing

Clutch Housing

Hex Screw

Engine Shaft

Gear Housing

Hex Screw

Set Screw

CAUTION

1. Perform the Pressure Relief Procedure.

2. Using a Phillips screwdriver, remove the four front cover

screws. Remove the front cover..

3. Using a 7/8” open-end wrench, loosen and remove the

fluid hose from the fitting on the back of the fluid section.

4. Locate the four socket screws that secure the pump

housing to the gear housing. Two are at the inside top of

the pump housing and two are located on the external

bosses at the bottom of the pump housing.

5. Using a 1/4” hex wrench, remove the four socket screws

that secure the pump housing to the gear housing.

6. Slide the pump housing assembly away from the gear

housing.

7. Remove and clean the housing gasket. Replace if

damaged.

8. Remove the gear assembly and the 1/4” thrust balls from

within the bearing bores that support the gear.

16. Place the thick thrust washer onto the crankshaft up

against the gear hub. Next, place the thin thrust washer

up against the thick washer on the crankshaft.

17. Place the housing gasket over the gear housing dowel pins.

18. Carefully place the pump housing assembly in front of the

gear housing assembly, lining up the gear housing dowel

pins with their corresponding holes in the pump housing.

Slide the pump housing onto the gear housing until there

is no gap between the housings and gasket.

Do not force the pump housing and gear housing together.

19. Locate the four socket screws and lock washers that secure

the pump housing to the gear housing. The longer screws

(2.25”) are fastened into the top internal holes. The shorter

screws (2”) are fastened into the bottom external bosses.

20. Using a 1/4” hex wrench, snug and tighten the socket

screws in a crossing pattern. Torque to 200–230 in./lbs.

21. If the slider, slider housing, and fluid section were

removed, reinstall by following the steps in the “Replacing

the Slider and Slider Housing” procedure in this section.

22. Position the front cover over the pump housing. Secure

the front cover using the four front cover screws.

23. Using a 7/8” open-end wrench, attach the fluid hose to the

fitting on the back of the fluid section. Tighten securely.

Servicing the Clutch Assembly

NOTE: When replacing the clutch armature, the clutch

hub and clutch rotor must be replaced also.

This will allow for even wear and maximum life

on clutch parts.

9. Inspect the gears for excessive wear and replace if

10. Inspect the pinion gear on the end of the drive shaft for

11. Inspect the output gear and the two thrust washers on the

NOTE: If replacing the pump housing , first remove

12. Replace the thrust washers if worn. If the pump housing

NOTE: If any of the gears are worn and require

13. Coat each of the thrust balls with a generous amount of

14. Coat the gear assembly with fresh Lubriplate GR-132

15. Generously coat both faces of each of the crankshaft

damaged or worn. If the gear assembly is replaced,

replace the two thrust balls as well.

wear. Replace if damaged or worn (refer to the “Servicing

the Clutch Assembly” procedure in this section).

end of the crankshaft in the pump housing for wear. This

gear is permanently attached to the crankshaft and pump

housing. If this gear is worn, the pump housing must be

replaced.

the fluid section, slider housing, and slider

assembly from the pump housing (refer to the

“Replacing the Slider and Slider Housing”

procedure in this section).

assembly is replaced, replace the thrust washers as well.

replacement, check the grease in the gear

housing for metal particles or shavings.

Remove the contaminated grease. Replace the

grease that has been removed with fresh

Lubriplate GR-132 grease.

grease. Install the thrust balls — one in the gear housing

bore and one in the pump housing bore.

grease. Insert the gear assembly into the bore in the

pump housing, pinion end first.

thrust washers with grease.

Removing/Replacing the Clutch Hub and

Armature Assembly

1. Perform the Pressure Relief Procedure.

2. Using a 7/8” open-end wrench, loosen and remove the

fluid hose from the fitting on the back of the fluid section.

3. Hold the transducer tube with a pliers to prevent it from

rotating and turn the transducer nut counterclockwise

using a 3/4” open-end wrench. When the nut disengages

the filter housing, carefully remove the transducer from the

filter housing.

4. Locate the wire that exits the rear of the electronic

pressure control (EPC) housing and connects to the wire

harness on the engine. Disconnect this wire from its

connector at the engine wire harness.

5. Using a 1/2” wrench, remove the four hex screws and lock

washers that secure the clutch housing to the gear housing.

6. Using a 9/16” socket, remove the two hex screws that

secure the gear housing to the cart.

7. Slide the pump and gear housings away from the engine

to disengage them from the clutch housing.

12 © SprayTECH. All rights reserved.

Page 13

Removing the Clutch Rotor, Clutch Field, and

WARNING

Clutch

Housing

0.20"

Engine

Set

Screw

Straight

Edge

Taper

Lock

Bushing

0.20"

Clutch

Hub

Flat

Surface

Set-Up

To ol

Clutch

Armature

CAUTION

Clutch Rotor

Socket Screw

Retaining Ring

Clutch Field Wires

Drive Shaft

Assembly

Clutch

Field

Clutch Field

Set Screw

EPC

Housing

Lock

Washer

Clutch

Rotor

Drive Shaft Assembly

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

© SprayTECH. All rights reserved. 13

8. Locate the clutch hub and armature assembly on the end

of the engine shaft. Note the two set screws as well as

the unused, threaded hole in the taper lock bushing at the

center of the clutch hub.

9. Using an 1/8” hex wrench, remove the two set screws

from the taper lock bushing

10. Thread one of the set screws into the unused, threaded hole

on the taper lock bushing. As the screw tightens, the bushing

will loosen. Once the bushing has loosened enough, slide the

clutch hub and armature assembly off the engine shaft.

11. Before replacing the clutch

hub and armature assembly

the proper “set back” must

be created. Using the

SprayTECH hub set-up tool

(P/N 0509925), create a “set

back” of 0.20” between the

friction surface of the clutch

armature and the forward face of the clutch hub.

NOTE: A new clutch hub and

12. Line up the three holes in the taper lock bushing with the

13. Line up the key on the taper lock bushing with the keyway

14. Apply blue Loctite to the

15. Line up the forward face

NOTE: To ensure the clutch hub and the clutch

16. Make sure the friction surface of the clutch armature is

1. Follow steps 1–7 in “Removing/Replacing the Clutch Hub

2. Locate the clutch rotor assembly on the end of the drive shaft

3. Using a 3/16” hex wrench, remove the three socket

4. Thread two of the socket screws into the empty, threaded

armature assembly will

come pre-assembled, but

the “set back” will not be

correct. The “set back”

must still be created using

the hub set-up tool.

three holes in the clutch hub and insert the bushing into

the center of the clutch hub.

on the engine shaft and slide the assembly onto the shaft

with the holes facing out.

two set screws and insert

the screws into the taper

lock bushing. Tighten the

set screws only two turns

at this time.

of the clutch hub with the

front face of the clutch

housing. Using an 1/8”

hex wrench, alternately

tighten the set screws

into the taper lock bushing. Torque to 65–75 in/lbs.

housing are aligned, hold a straight edge

across the face of the clutch housing and then

hold the clutch hub against the back of the

straight edge while tightening the two set

screws into the taper lock bushing.

clean and free from oil or grease.

and Armature Assembly.”

assembly. Note the locations of the three socket screws and

the two empty, threaded holes on the clutch rotor.

screws and lock washers that secure the clutch rotor to

the drive shaft assembly.

holes and tighten alternately. This will push the clutch

rotor away from the drive shaft assembly and pinion.

5. Using a Phillips screwdriver, remove the four screws that

secure the EPC assembly to the EPC housing. Carefully

remove the EPC assembly from the housing.

6. Locate the two clutch field wires that pass from the gear

housing into the EPC housing through a grommet in the

back of the EPC housing. Remember the wire connection

terminals on the EPC assembly (label if necessary) and

disconnect the wires. Gently move the EPC assembly

away from the housing and rest it on the work surface by

the control housing.

7. Locate the four set screws that secure the clutch field to

the gear housing. They are located on the exterior of the

gear housing at the 12, 3, 6, and 9 o’clock positions while

facing the clutch field end of the gear housing. Using an

1/8” hex wrench, remove the setscrews. Remember the

location of the two clutch field wires with respect to the

grommet and EPC housing.

8. Carefully slide the clutch field out of the gear housing,

keeping the field square to the gear housing so it does not

bind.

9. Remove the retaining ring in front of the ball bearing

within the center bore of the gear housing.

10. Follow steps 2–6 in the “Replacing the Gears” procedure

to remove the pump housing from the gear housing.

11. From the gear side of the gear housing, use a soft

hammer to tap the gear end of the drive shaft through the

gear housing.

12. Carefully slide the drive shaft assembly out from the gear

housing, keeping the shaft square to the housing so it

does not bind.

13. Remove the o-ring from inside the center bore of the gear

housing from which the small ball bearing on the drive

shaft assembly was removed.

14. Clean the inside of the gear housing.

Installing the Clutch Rotor Assembly, Clutch

Field and Drive Shaft Assembly

1. Install a new o-ring into the center bore of the gear housing.

2. Apply Loctite retaining compound #635 to the outside

diameter of the large bearing on the drive shaft. Do not get

retaining compound on the faces of the bearing.

3. Install the drive shaft assembly into the center bore of the

gear housing, keeping it square to the housing so it does

not bind. Once the large ball bearing on the drive shaft

assembly is half way into its bore, a soft hammer may be

used to gently tap the assembly into position.

Do not force the drive shaft assembly into position.

4. Install the retaining ring into its groove next to the large

ball bearing.

Line up the four holes around the outside of the clutch

5.

field with the four set screw holes in the gear housing.

The clutch field wires should be at approximately the 1 or

2 o’clock position.

Page 14

6. Route the two clutch field wires through the grommet and

WARNING

CAUTION

Connecting

Pin

Fitting

Retaining

Ring

Slider

Assembly

Jam Nut

Cylinder

WARNING

into the EPC housing.

7. Carefully slide the clutch field into its bore in the gear

housing until it “bottoms out” within the housing. Do not

pinch the clutch field wires during installation.

NOTE: Apply blue Loctite to the four clutch field set

8. Thread one of the set screws into its hole. Using an 1/8”

9.

10. Using a crossing pattern, tighten each of the setscrews

It is very important to evenly snug, tighten, and torque the

clutch field set screws in a crossing pattern. This ensures

the clutch field will stay centered in the gear housing.

11. Line up the three screw holes and dowel pin hole on the

12. Using a 3/16” hex wrench, thread the three socket screws

13.

14. Follow steps 17–20 in the “Replacing the Gears” procedure

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

15. Locate the two clutch field wires in the EPC housing.

16. Carefully place the EPC assembly over the EPC housing

17.

screws prior to installation.

hex wrench, rotate the screw slowly until it contacts the

clutch field. Do not tighten the set screw. The tip of the

set screw should mate with the drill point hole in the field.

Check the clutch field for rotation. If it rotates within its

bore, the set screw is not seated within the drill point.

When the set screw is properly seated, install the remaining

three set screws. Do not tighten the set screws.

until they are snug. Once all four set screws are snug,

use a crossing pattern to tighten and torque the set

screws to 30–40 in./lbs.

clutch rotor with the screw holes and dowel pin on the drive

shaft assembly hub. Place the clutch rotor onto the hub.

and lock washers through the clutch rotor and into the

drive shaft assembly hub. Evenly snug, tighten, and

torque the socket screws to 75–85 in/lbs.

Make sure the friction surface of the clutch rotor is clean

and free from oil or grease.

to mate the pump housing with the gear housing.

Gently pull the wires fully into the EPC housing so that

there is no slack in the gear housing. Connect the wires

to their proper terminals on the EPC board (refer to the

labels created earlier in this procedure or the electrical

schematic in the Parts List section of this manual).

taking care not to pinch any wires.

Install the four screws that secure the EPC assembly to

the EPC housing. Tighten securely.

Mating the Gear Housing and the Clutch

Housing

1. Place the gear housing assembly onto the cart in front of

the clutch housing. Line up the dowel pins in the gear

housing with their corresponding holes in the clutch

housing. Slide the gear housing assembly onto the clutch

housing until there is no gap between the housings.

2. Thread the four hex screws and lock washers through the

clutch housing and into the gear housing.

3. Using a 1/2” wrench, snug and tighten the hex screws in a

crossing pattern. Torque to 140–155 in./lbs.

4. Using a 9/16” socket, thread the two hex screws that secure

the gear housing to the cart through the underside of the

cart and into the gear housing. Torque to 100–120 in./lbs.

5. Connect the wire from the EPC housing to its mating

connector on the engine wire harness.

6. Make sure that there is a white 37)( o-ring on the end of

the transducer that gets inserted into the filter housing.

Insert the transducer into the filter housing port.

7. Hold the transducer tube with a pliers to prevent it from

rotating, and turn the transducer nut clockwise with a 3/4”

open-end wrench to tighten it into the filter housing.

Torque the nut to 360–400 in./lbs.

Checking the Clutch Gap

1. Remove the plastic plug from the top of the clutch

housing. Look through the port to locate the clutch

armature and the clutch rotor.

2. Check the gap between the clutch armature and the clutch

rotor using a .016” feeler gauge and a .035” feeler gauge.

a. Insert each feeler gauge through the port and into the

gap between the clutch armature and the clutch rotor.

The .016” feeler gauge should fit in the gap. The .035”

feeler gauge should not fit in the gap.

b. Pull the engine pull cord several times to rotate the

clutch armature, checking the gap with each feeler

gauge between each pull.

c. If the .016” gauge does not fit or the .035” gauge does

fit at any checkpoint, the gap must be readjusted. This

is done by relocating the clutch hub and armature

assembly on the engine shaft. Refer to the

“Removing/Replacing the Clutch Hub and Armature

Assembly” procedure.

Servicing the Fluid Section

Use the following procedures to service the valves and repack

the fluid section.

1. Start the engine (refer to the procedures in the Operation

section of this manual). Turn the pressure control knob

clockwise to its maximum pressure setting.

2. Toggle the sprayer ON/OFF switch between the ON and

OFF positions in short bursts until the slider assembly stops

in a position where the fluid section connecting pin and

retaining ring are visible through the slot in the slider

housing.

3. Turn off the engine and perform the Pressure Relief