210

C

oX

Contents

General information, 1-2-3-4-5

Technical Information, 2-3

For your safety, 4

Introduction, 5

Installation requirements, 6-7

Attention / Grounding instructions, 6

Electrical, location and draining, 7

Installing the washer-dryer, 8-9-10-11

Unpacking the washer-dryer, 8

Removing the transit screws, 8

Connecting the water inlets, 9

Connecting the drain hose, 9

Installing the exhaust ducting, 10

Leveling the washer-dryer, 10

Completing the installation, 11

About your appliance, 12-13-14-15

Washer-dryer special features, 12

Control panel, 13

Option buttons, 14

Program key, 14

Detergent and laundry aids, 15

Dispenser drawer, 15

Washing and drying, 16-17-18-19

Cycle Description Chart, 16

Before starting a cycle, 17

Determining load sizes, 17

Setting a ‘wash’, ‘dry’ or ‘wash-to-dry’ cycle, 17

Splendide laundry tips, 18

For best results, 18

Combo laundry FAQ’s / Sample loads, 19

Care and maintenance, 20-21

Turning off the water or electricity supply, 20

Cleaning the dispenser drawer, 20

Checking the water inlet hoses, 20

Cleaning the pump pre-chamber, 21

Checking the dryer vent, 21

No lint filter to clean, 21

Troubleshooting, 22-23

Troubleshooting Chart, 22

If you need assistance, 23

Quick Reference Guide / Winterization 25

General Information

As an Energy Star Partner,

Splendide Division of Westland

Sales has determined that Energy

Star labeled models meet the

Energy Star guidelines for energy

efficiency.

2 General Information

This appliance was tested by UL and

conforms with both Canadian and

U.S. UL safety requirements and

displays their mark.

Technical information

Model WD2100XC(P) Splendide 2100XC, Splendide 2100XCP

Weight

Dimensions

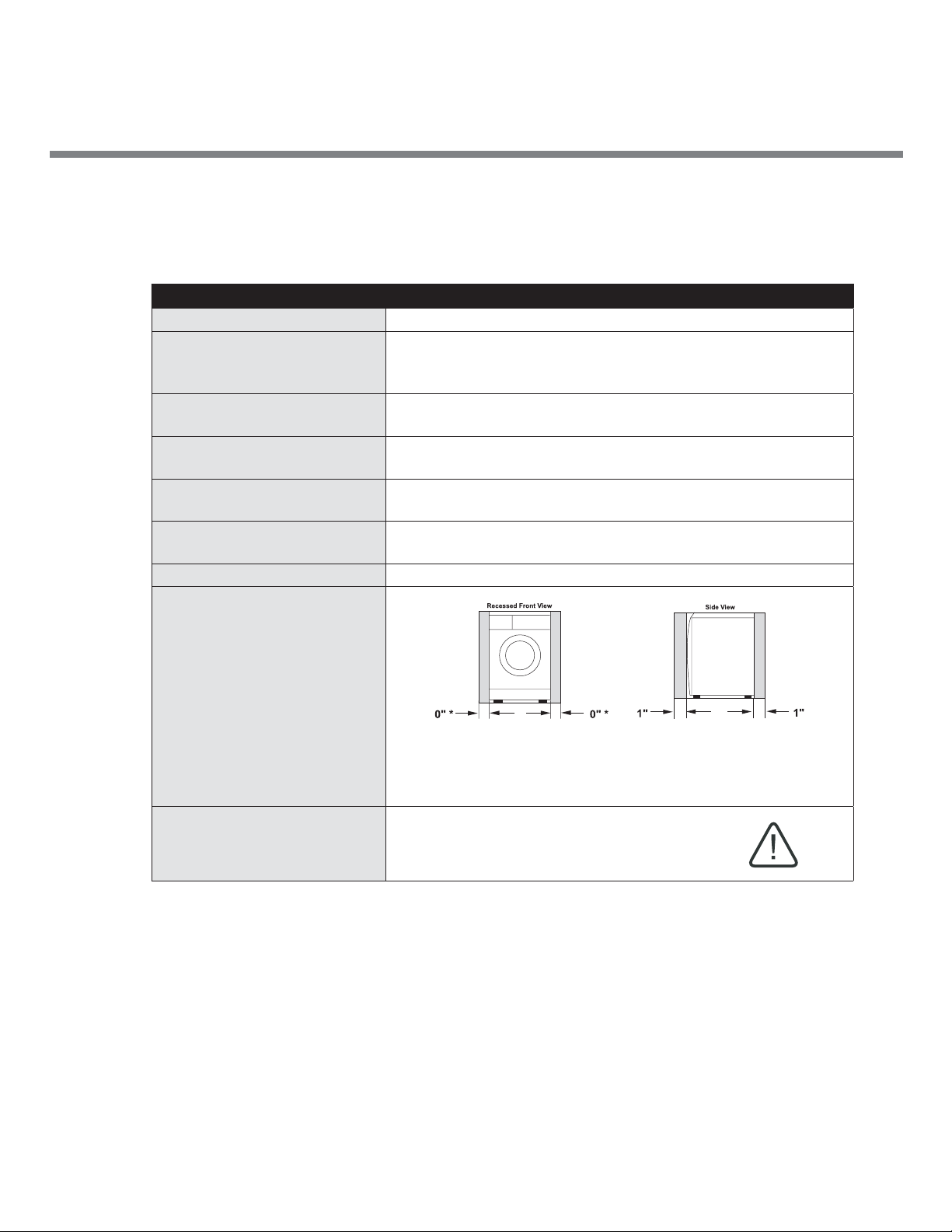

Minimum Installation

Clearances

Capacity

Electrical Connection

Water Connection

Max. Spin Speed

Min. Installation Spacing

148 lbs.

W

idth: 23.4” (59.5 cm)

Height: 33.25”-33.75” (84.5-85.7 cm)

Depth: 22” (55.9 cm)

Sides: 0”

Front / Back: 1”

Washing: 2 to 15 lbs. (1 to 7 kg)

Drying: 2 to 11 lbs. (1 to 5 kg)

Voltage: 120 Volts, 10.5 Amp, 60 Hz

Max. Absorbed Power: 1300 Watts

Max. Pressure: .69 MPa (6.9 bar), 100 PSI

Min. Pressure: 0.05 MPa (0.5 bar), 7.5 PSI

Up to 1200 RPM

This appliance may be installed in a recessed area, closet or alcove. The installation

spacing is in inches and is the minimum acceptable. *Additional spacing should be

considered for easy installation, servicing and compliance with local codes and

ordinances. Installations must conform with the minimum dimensions indicated.

Dryer Exhaust

Requirements

NOTE: The manufacturer reserves the right to make any improvements to its appliances without giving prior notice.

WARNING! To reduce the risk of fire, this

appliance must be exhausted to the outdoors.

General Information 3

For Your Safety

Save These Instructions

Your washer-dryer has been built in compliance with the

strictest international safety regulations. However, for your

safety, the information in this manual must be followed to

minimize the risk of fire or explosion, electric shock, or to

prevent property damage, personal injury, or loss of life.

Read all instructions before using any appliance.

• Do not wash or dry articles that have been previously

cleaned in, washed in, or spotted in gasoline, dry cleaning

solvents, other flammable/explosive substances as they

emit vapors that could ignite or explode.

• Before the appliance is removed from service or

discarded, remove the door to the washing/drying

compartment.

• Do not repair or replace any part of the appliance or

attempt any servicing unless specifically recommended in

the user-maintenance instructions or in published userrepair instructions that you understand and have the skills

to perform.

• Do not allow children to play on or in the appliance.

• Do not add gasoline, dry cleaning solvents, items

contaminated with cooking oil or other flammable or

explosive substances to the wash water. Do not install or

store this appliance where it will be exposed to weather

or in an area where gasoline or other flammables are

stored.

• Under certain conditions, Hydrogen gas may be

produced in a hot water system that has not been used

for 2 weeks or more. HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been used for such a

period, before using the appliance, turn on all hot water

faucets and let the water flow from each for several

minutes. This will release any accumulated hydrogen.

• Do not use heat to dry articles containing foam rubber or

similar textured rubber-like materials.

• Turn off water faucets to relieve pressure on hoses and

valves and to minimize leakage if a break or rupture

occurs.

• Do not reach into the appliance if the drum is moving.

• Do not tamper with controls.

• Repair or replacement of a part should be made only by

a qualified service technician to prevent personal injury or

damage to the machine. Contact Splendide to locate an

authorized repair service company near you.

• Disconnect power to the washer at the circuit breaker or

fuse box, or unplug the machine in an emergency or

when servicing is required. Have the installer show you

and label the proper switch or fuse at the electrical

disconnect box.

• Good, safe practices and caution MUST be applied when

installing, operating, and maintaining any appliance.

Follow basic precaution.

• Before loading the washer, make sure the drum is empty.

4 General information

Congratulations

Introduction

Congratulations on your purchase of a

Splendide. Your Spendide washer-dryer takes

the drudgery out of doing laundry - simply toss

dirty laundry in and get clean, dry laundry out!

Whether it’s installed in a luxury RV, yacht, or

apartment closet, your new Splendide is

designed to fit where others won’t and deliver

outstanding washing and drying performance

(all while conserving more energy and water

than other brands). Enjoy your new Splendide!

Read this manual

Please read this manual carefully. If you need

further assistance, please contact Splendide

Laundry Centers (Mon-Fri 7am-5pm PST)

For your records

Write model and serial numbers here. You can find

them on the front of the machine and inside of the

door opening.

Model: (i.e. WD2100XP)

Serial No:

S/N

1-800-356-0766

General information 5

Installation Requirements

ATTENTION!

For your own protection and to prevent

accidents, injury, and fire, please read the

following carefully before installing the

washer-dryer.

• Installation and grounding must be done in

accordance with local codes and by a qualified

installer. Installation Instructions provided in

this booklet are for the installers’ reference.

• Washer-dryer MUST be installed on a strong,

level floor and in a protected dry and wellventilated areaclose to a power supply and

drain outlet of sufficient capacity. DO NOT

install on carpet.

IMPORTANT: Installation on

carpet floors will cause the

machine to vibrate and may

result in excessive machine

vibration

and loss of performance.

• The washer-dryer should be plugged into a

properly grounded (3) prong electrical outlet

capable of 120 Volt, 60 Hz, 1300 W, and

10.5 Amp. It shouldn’t be controlled by a

wall switch or pull cord which could be

turned off accidentally. For your safety, the

third or round grounding prong must never

be removed. DO NOT USE AN EXTENSION

CORD.

• DO NOT install or store this appliance where

it will be exposed to weather or in an area

where gasoline or other flammables are

stored.

during the spin cycles

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the

event of malfunction, or breakdown,

grounding will reduce the risk of electric

shock by providing a path of least resistance

for electriccurrent. This appliance is

equipped with acord having an equipment

grounding conductor and grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes

and ordinances. DO NOT modify the plug

provided with the appliance. If it will not fit

the outlet, have a proper outlet installed by a

qualified electrician.

WARNING! Improper

connection of the equipment

-grounding conductor can

result in a risk of electric

shock. Check with a qualified

electrician or serviceman if you

are in doubt as to whether the

appliance is properly

grounded.

!

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so can result in death

or electrical shock.

6 Installation requirements

Electrical

• Machine Voltage/Amperage - 120V, 60 Hz,

1300 W, 10.5 Amp.

• Connection - 3-prong plug with 6’ cord is

provided with the machine.

• Circuit/Protector - 3-wire single phase, 120V,

60 Hz, AC, on a separate 15 Amp circuit.

Location

• This machine may be installed free

standing as well as in a recessed area,

closet, or alcove

• Minimum Installation Spacing - 0” on

sides and 1” in front and back. NOTE:

Additional installation spacing needs to be

considered for easy installation, servicing,

and compliance with state and federal

codes.

• Floor - Must support at least 280 lbs. and

be a solid, level surface. DO NOT install on

carpet.

• RV/Marine Installations - When locating

the appliance in a towable trailer or

watercraft, position the machine over the

axles or mid-ship where movement is at a

minimum. Block the machine to prevent

extreme movement.

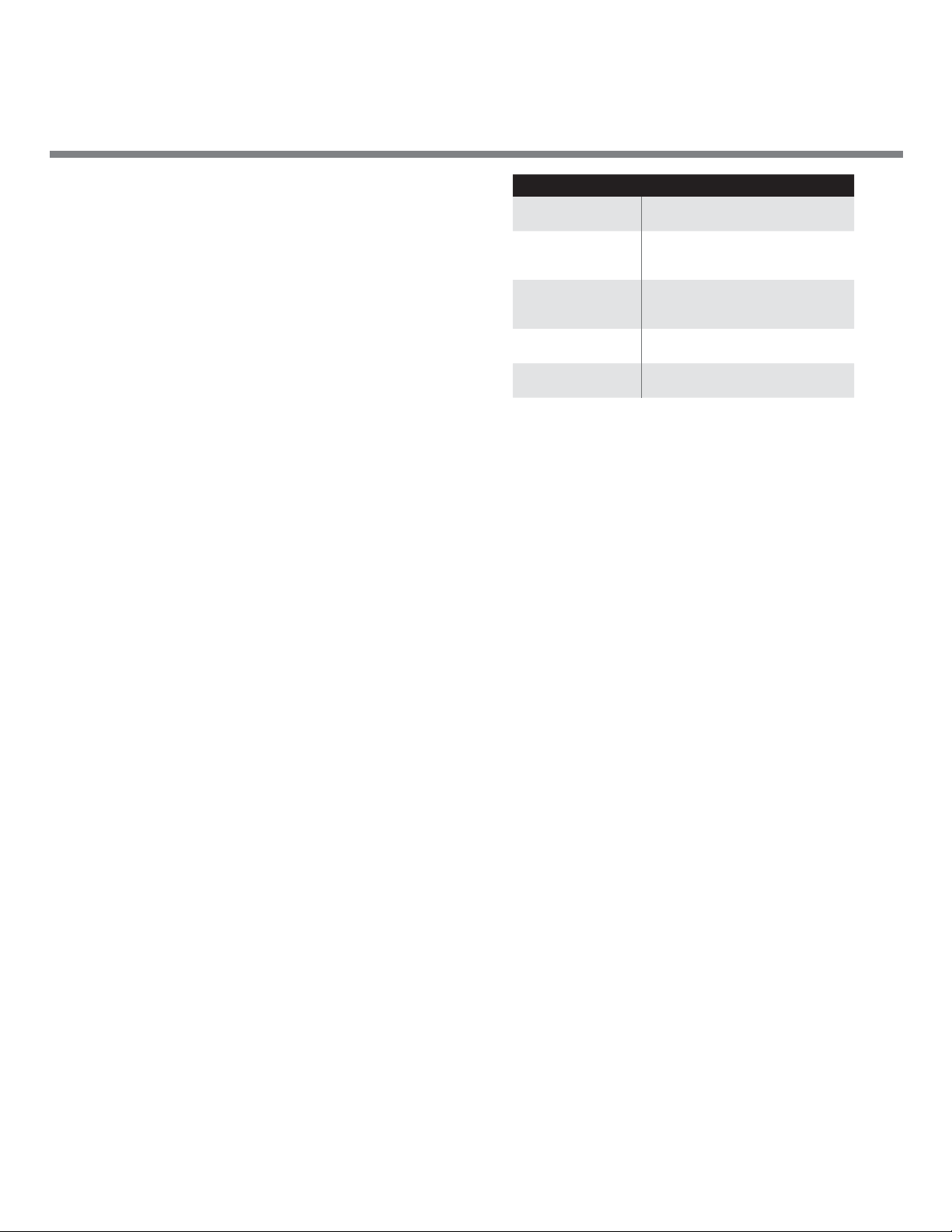

If you have... You’ll need...

no access to Hot/Cold

water hookups

to install a dryer vent

ducting in your

and

RV or boat

concerns about the

appliance shifting in

your RV or boat

water damage

concerns

to make a 90” duct

turn in less than 4.5”

Splendide Faucet Adapter

Kit, or equivalent.

Splendide Vent Kit, or

equivalent.

Splendide SecureFit bracket

kit, or equivalent.

Splendide Drain-A-Way Pan,

or equivalent.

Splendide 90˚ offset elbow, or

equivalent.

Drainage

Standpipe Diameter/Capacity - Needs a 1 ¼”

minimum diameter standpipe with a minimum

carry-away capacity of 7 gallons per minute.

Top of Standpipe - Must be between 25” and 34”

high from the bottom of the machine.

Outlet End of Drain Hose (provided with the unit)

- Must be at least 20” above the bottom of the

washer-dryer. An air break must be available at the

standpipe to avoid siphoning. No more than 6” of

the drain hose should be inserted into the drain

pipe to prevent siphoning.

• Exhaust Requirements - Rigid or flexible

metallic duct required. Ducting should be

as short and straight as possible. DO NOT

exhaust dryer into a chimney, furnace, cold

air duct, attic crawl space, or another duct

used for venting. If a cabinet door is

installed, a minimum of 8 sq. in. should be

provided for make up air. Louvered doors

with equivalent air openings are

acceptable. Allow clearances behind

door(s) to avoid rubbing between back of

cabinet door(s) and front of unit control

panel. Additional clearances for wall, door

and floor moldings may be required.

Installation requirements 7

Installing the washer-dryer

Unpacking the washer-dryer

• Carefully remove the packing materials with care

not to damage the drain hose and power cord

that are shipped installed on the machine.

Check that the machine is intact. Report any

damage immediately.

• Position the washer-dryer near the desired

installation position.

WARNING! Plastic bags, styrofoam, nails

and other packaging parts are not

children’s toys and can be potentially

dangerous. Destroy the carton and plastic

bags after the washer-dryer has been

unpacked.

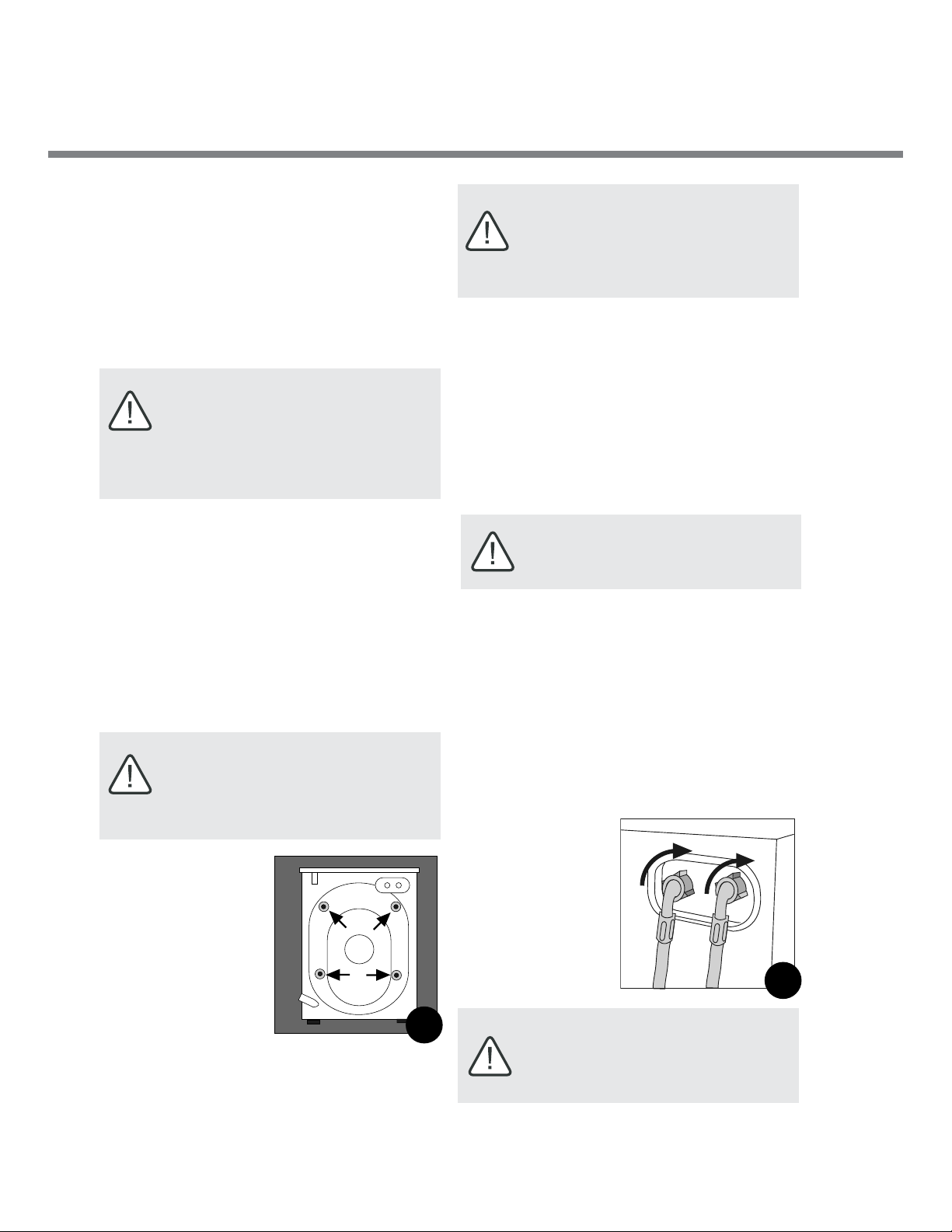

Removing the transit screws

For transportation, the inside of the machine is

supported by screws, rubber grommets and spacers

on the back panel. Before using the washer-dryer,

these items MUST be removed.

IMPORTANT: Transit screws and spacers

must be removed before operating the

machine to allow proper operation of the

machine and to prevent damage to the

appliance.

• After positioning

the washer-dryer

near the

installation

location, remove

the four screws

(Fig.1), with the

rubber grommets

and plastic spacers

that are attached

to them.

• Use the plastic plugs (provided in the accessories

bag) to fill in the holes.

Fig 1

IMPORTANT: Retain the transit screws,

spacers and rubber tubes. These items

should be reinstalled to prevent damage if

or when you transport the machine in the

future.

Connecting the water inlets

If the water pipes you will be connecting to are new

or unused, run the water until clear to remove any

debris that could clog the water valve screens or

valves before connecting the machine. NOTE: Supply

shut-off valves should be easily accessible.

IMPORTANT: Water pressure MUST range

within the values indicated on the

“Technical Data” chart

• Included in the accessories supplied with your

machine are 2 inlet hoses with 4 rubber washers

pre installed. Check that the rubber washers are

installed in the ends of the inlet hoses to make a

water tight seal at each connection point.

• Connect the straight ends of the water inlet

hoses to the supply taps that have ¾” BSP

thread (standard hose bib).

• Connect the 90º angled ends (20 mm thread) of

these hoses to

the inlet valves

on the back of

the machine (Fig.

2). NOTE: Water

Inlet valves are

color coded:

Red (Hot) &

White (Cold).

IMPORTANT: Do not use excessive force.

Damage to the couplings can result. The

couplings should be tightened by hand; a

tool should only be used if a leak occurs.

H

C

Fig 2

8 Installing the washer-dryer

Loading...

Loading...