Page 1

Production

Housing P/N On

Production

Brackets Welded

Spicer

®

Axles & Brakes

P/N: SHAIS132

DS404 Housing Cover Weld Reinforcing Instructions

Subject of Instruction Sheet: The procedure below has been created to assist a mechanical technician in the proper

repair of a cracked rear cover weld and the installation of a reinforcement bracket on DS404 housings in Peterbilt vehicles

using an Air Leaf Suspension. This is the only approved method for this repair. Any other method of repair may result in

damage to the axle, axle housing, or other vehicle components and could affect performance and safety. Failure to follow

all steps of this procedure will result in a poor repair and the crack could occur again.

Affected Models: DS404 Drive Housing Used in Peterbilt Air Leaf Suspension Vehicles. See chart below.

Wall

Axle Model

DS404 3/8" (9.5mm) Air Leaf - Before 3/99 319402 Peterbilt

DS404 3/8" (9.5mm) Air Leaf - From 3/99 - 6/00 319954 Dana

Thickness

Reinforcing Bracket Part Number 302527

Suspension Type and

Timing

Tag

By:

Welding Equipment and Specifications:

Mig (wire) Welding

Welding Gas – recommended – 80% Argon, 20% C-O2 Gas Flow Setting – 50-60 cfh.

Wire Size – ER70S-3 or ER70S-6 .035”

First and second passes cover weld, approximate settings – 30 volts, 180 amps.

Third filler pass, cover weld, approximate settings – 26 volts, 140 amps.

Apply three weld passes to the cover and two to the bracket. The first pass should be centered over the fit-up line and

penetrate the failure area. The second pass should be placed slightly above the first. Blend the weld smoothly ( without

significant cross section enlargement ) with the housing and first pass. The third pass should penetrate the lower half of

the second pass to the edge of the housing cover. Avoid any significant overlap of weld or undercut. When making the

second and third passes the weld direction should be reversed. Always start the weld at one end, never in the middle the

intended weld area. See illustrations below for more information.

Arc (stick) Welding

Miller DC type stick welder set at 140 -150 amp setting.

Use E7018 1/8 inch Electrode for all three passes. Note** Remove slag between passes. E7018 rod must be stored in

heated rod oven. Apply three weld passes to the cover and two to the bracket. The first pass should be centered over the

fit-up line and penetrate the failure area. The second pass should be placed slightly above the first. Blend the weld

smoothly ( without significant cross section enlargement ) with the housing and first pass. The third pass should penetrate

the lower half of the second pass to the edge of the housing cover. Avoid any significant overlap of weld or undercut.

When making the second and third passes the weld direction should be reversed. Always start the weld at one end, never

in the middle the intended weld area. See illustrations below for more information. When welding the second and third

passes, reverse the direction of the weld. Never start or stop a weld close to the 12:00 position.

Page 2

When using an Arc welder you may have to start the weld at the 11:00 position so that you do not run out of electrode at

12:00 Position

the 12:00 position. You can then go back and fill in the ends of the weld area.

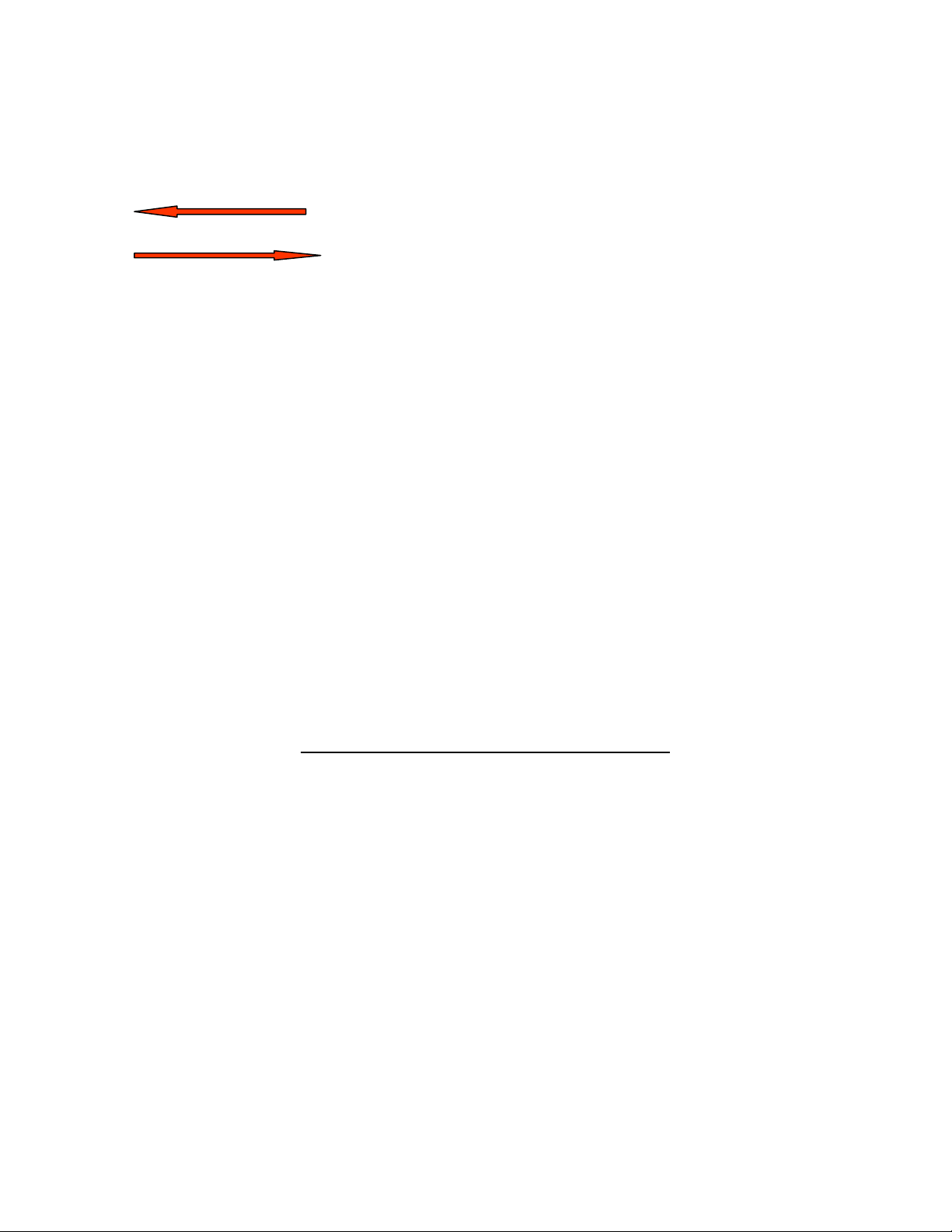

Second Pass Direction

First Pass Direction

First Electrode

Weld Direction

Never Start or Stop at 12:00

Repair Instructions:

Important : Before starting, always wear the proper safety equipment for your protection.

1. Disconnect the battery grounds and oil temperature sensor wire. Caution*** If the battery ground is not

disconnected, vehicle electronic control modules may be damaged.

2. Block front and back of steer axle tires.

3. Jack-up driver’s side forward rear drive axle and support with jack stand.

4. Remove driver’s side forward rear drive axle tires and rims only.

5. Remove inter axle driveline.

6. Disconnect and remove tracking rod assembly.

7. For the repair of the cover weld crack, locate the ends of the crack, mark 2 inches either side of the crack. These

marks are ONLY for reference! You must grind until the entire crack is eliminated

inches on either side of the crack.

. Then grind an additional two-

Locate Crack Mark 2” Both Sides of Crack

Page 3

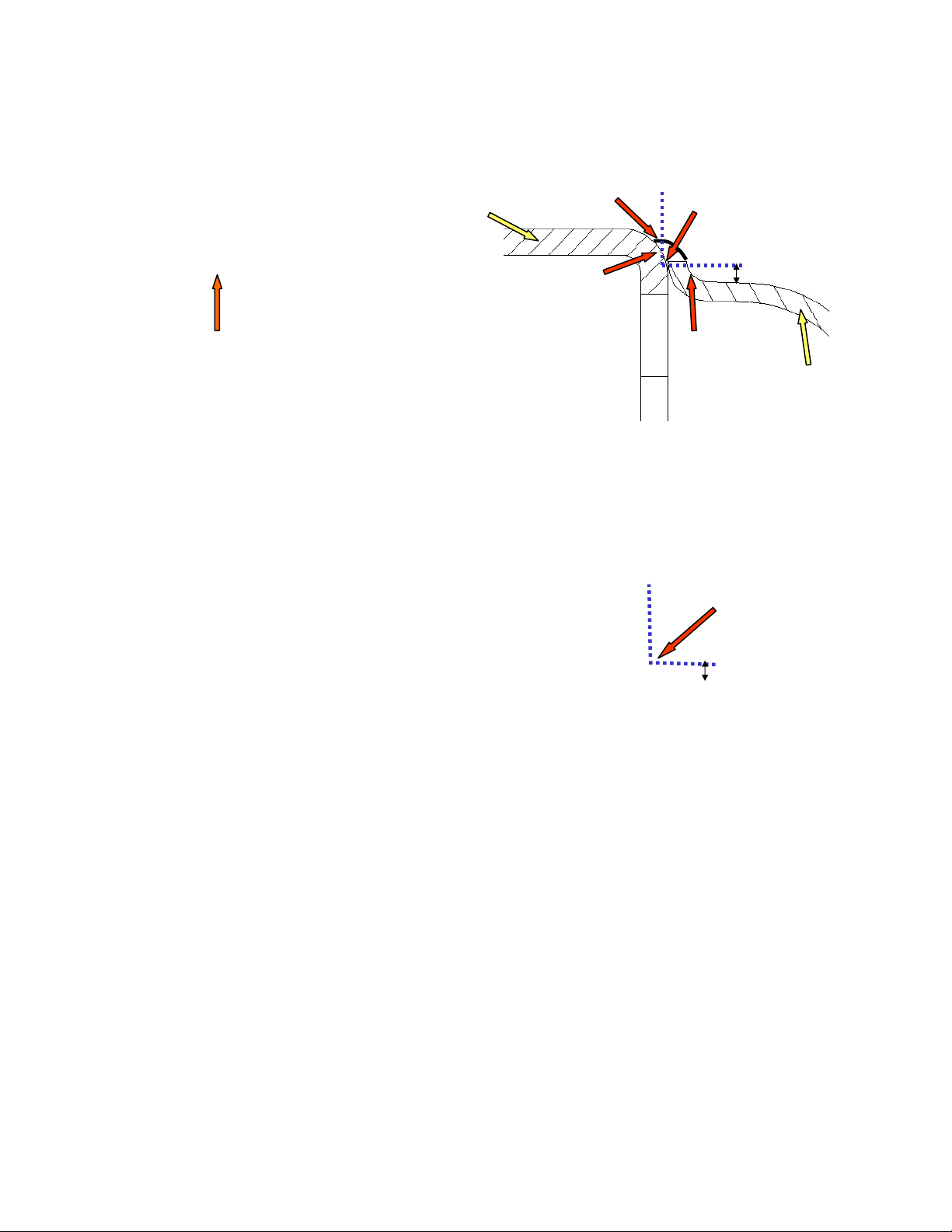

8. If the cover weld is NOT cracked on the outside of the weld, mark the housing 2 inches either side of the 12:00

Grind Profile

Fit-Up Line

Cover

1/4”

Area To Be

position. Remember these cracks start on the inside of the housing and work their way out. You will need to grind

through the old weld to the fit-up line, this is where the cover meets the axle housing. You should have approximately

¼” of distance between the top of the cover to the bottom of the ground area. The blue dotted lines below represent

the area to be ground.

Housing

Old Weld

Ground

Radius

Cover

12:00 Position

No Crack Outside Of Weld

9. Use a 4 inch angle grinder to grind away the crack. You must grind just below the old weld, down to the fit-up line.

Use the drawing above and the photo below as a guide. It’s very important that you recognize the difference between

the crack and the point where the cover meets the axle housing. Caution*** Be careful to not break completely

through as this will contaminate the axle’s lubricant with grinding material.

Use a wire wheel to remove paint from area to be welded.

Approximate

1/4”

Grind Away Crack Side view of Grind

10. For All Weld Passes Cover Weld – When using a Mig Welder use approximate setting of 30 volts and 180 amps. If

using an Arc welder, use E7018 1/8 inch electrode.

Important** The ground from the welder must be connected to the torque rod bracket. See figure below.

Ground Connection

Page 4

11. Important: The first weld pass must be centered over the fit-up line and penetrate the failed area. Remove all

Top of Repair

Top of Bracket

First Weld Pass

Cover

Housing

slag. The first pass must cool before the second pass can be applied. While weld is cooling move to step 12 to

prepare housing for bracket.

(Centered over

fit-up line)

First Pass

12. Before the reinforcing bracket is located the housing surface must be clean and paint removed in weld area.

Remove Paint From Housing Remove Paint From Bracket

13. Position the reinforcing bracket so that the bracket edge is flush with the surface between the tracking arm bracket

lugs.

Bracket Lugs

Bracket

Align Top Of Repair Bracket Align Bottom Of Bracket

Between Lugs

Page 5

Cover

Housing

Second Weld Pass

14. Tack weld at housing and bracket interface.

Two At Bottom Two At Top

15. Second Pass Cover Weld – Remember, do not start or stop at the 12:00 position. The second pass will be placed

slightly above the initial pass. See drawing below. When making the second pass the weld direction should be

reversed. When using an Arc welder you may have to start the weld at the 1:00 position so that you do not run out of

electrode at the 12:00 position. You can then go back and fill in the ends of the weld area. When the second pass

cools, apply the third weld pass as show on the diagram below.

Second Pass Cover

16. Third Pass Cover Weld – The third pass should cover the lower half of the second pass and stop at the housing

covers edge. Again, reverse the direction of the weld. Remember, do not start or stop at the 12:00 position.

Housing

Third Pass Cover

Third Weld Pass

Cover

Page 6

17. Bracket Weld – Weld first pass, apply second or third passes as needed. When using a Mig Welder use approximate

setting of 30 volts and 180 amps. If using an Arc welder, use 1/8 inch, E7018 electrode.

Weld First Pass, Bottom of Bracket First Pass, Top Of Bracket

18. Clean and paint the repaired area.

Clean And Paint

19. Reinstall the torque rod, use same spacers.

Install Torque Rod Bracket

20. Reinstall inter axle driveline.

21. Reinstall tires and rims.

Reconnect grounds and oil temperature wire.

22.

If you have any questions about this procedure call the Spicer C

all Center at 1-800-621-8084.

Page 7

For spec’ing or service assistance, call 1-800-621-8084 24 hours a day, 7 days a week.

Or visit our web site at: http://www.spicerparts.com

SHAIS132 Copyright Dana Corporation, 2001 Commercial Vehicle Axle Division

August 2001 All Rights Reserved. P.O. Box 321

Printed in U.S.A. www.dana.com Toledo, Ohio 43697-0321

Dana Corporation

Loading...

Loading...