Page 1

Dodge 1999-2001

Light Duty Axle Applications

X510-5

September, 2001

Supersedes X510-5DSD

dated January 1999

Page 2

SAFETY INFORMATION

WARNING - Failure to follow these instructions could affect vehicle performance and/or

safety and result in personal injury or death.

• Do not convert or alter Spicer axles except in accordance with vehicle manufacturer's

instructions.

Spicer axles are designed to meet OEM vehicle manufacturer's design and performance

specifications. Improper conversion or alteration of these axles can damage the axles and/or

other vehicle systems. Contact the OEM manufacturer for specific directions and guidelines.

• Do not change axle gear ratios on vehicles with anti-lock braking systems except in

accordance with the vehicle manufacturer's instructions.

Vehicles with anti-lock braking systems may utilize sensors and tone rings within the axle

housings to ensure the functioning of the anti-lock brakes. Improperly changing the axle

ratios may defeat the anti-lock braking system. If changing axle ratios will require changing

the location of the tone ring on the ring gear flange relative to the location of the sensor in

the axle housing, contact the OEM manufacturer for specific directions and guidelines.

• Do not reuse or substitute ring gear bolts.

If you reuse a ring gear bolt or substitute an inferior quality bolt, the bolt may loosen or back

out of its threaded hole, causing severe damage to the axle gears and other components and

possibly resulting in a sudden "locking up" of the axle and loss of control of the vehicle.

Always use new bolts specifically recommended for the application and install bolts using

proper tools and torquing to the proper specifications.

CAUTION - Do not substitute parts not of Spicer quality.

Spicer axles are designed for each model vehicle, and manufactured and tested for safety and best

performance. Replacement parts from other manufacturers may not be made to Spicer's rigid quality

standards. To be sure you're getting Spicer quality, always use genuine Spicer parts.

This symbol warns of possible personal injury.

Page 3

X510-5

Contents

How to Use This Catalog ........................................ 2

General Information ................................................. 4

Axle Kits ................................................................... 6

Model 35/194 Front

Dakota

Exploded View & Parts Listing ..................................... 8

Bill of Material Table ...................................................... 9

Model 44/216 Front Disconnect

W1500 & W2500 Ram

Exploded View & Parts Listing ................................... 12

Bill of Material Table .................................................... 14

Variable Parts Table ................................................... 15

Model 60/248 Front Disconnect

W2500HD, W3500 & Non-ABS Air Force Tow

Exploded View & Parts Listing ................................... 18

Bill of Material Table .................................................... 20

Variable Parts Table ................................................... 22

Model 44/216 ICA Rear

Viper

Exploded View & Parts Listing ................................... 26

Bill of Material Table .................................................... 27

Model 60/248 Rear

B-300 Maxivan HD

Exploded View & Parts Listing ................................... 30

Bill of Material Table .................................................... 32

Variable Parts Table ................................................... 32

Model 60/248 Rear

D2500 & W2500 Ram

Exploded View & Parts Listing ................................... 34

Variable Parts Table ................................................... 35

Bill of Material Table .................................................... 36

Model 70/267 Rear

D2500 & W2500 Ram

Exploded View & Parts Listing ................................... 40

Bill of Material Table .................................................... 42

Variable Parts Table ................................................... 44

Model 80/286 Rear

D2500, D3500, W2500 & Sweptline

Exploded View & Parts Listing ................................... 46

Bill of Material Table .................................................... 48

Variable Parts Table ................................................... 52

Shim Table ............................................................. 54

1

Page 4

X510-5

How to Use This Catalog

This catalog contains applications and part listings for front and rear axles which fit Chrysler/Dodge

vehicles from model years 1999-2001. For information on model years between 1967-1978, please refer

to catalog X510-8DSD; Ford model years 1979-1999 refer to X510-9. For miscellaneous models from

years 1979-1984, please refer to X510-7DSD.

The data in this publication is arranged by make, then in numerical order by model for front axles and then

for rear axles. Each model contains the following three sections as appropriate:

• Parts Listing and Exploded View

This section contains an exploded view of the axle and lists all the part numbers for those parts illustrated.

The parts that do not have a common part number have a footnote reference indicating where to find the

correct part number for each Bill of Material.

• Bill of Material Table

This section contains vehicle applications listed in order by year. Included in the table are the major kits

and assemblies for each Bill of Material number.

2

Page 5

X510-5

• Variable Parts Table

This section contains the individual part numbers that vary by Bill of Material number for a given model.

Note: Additional information on Spicer axles can be found in our General Information catalog number

XGI. It contains the following sections:

• Bill of Material Numerical Listing

• Ring and Pinion Kits

• Differential Case Assembly Kits

• Axle Shaft Dimension and Components

3

Page 6

X510-5

General Information

How To Identify A Spicer Axle

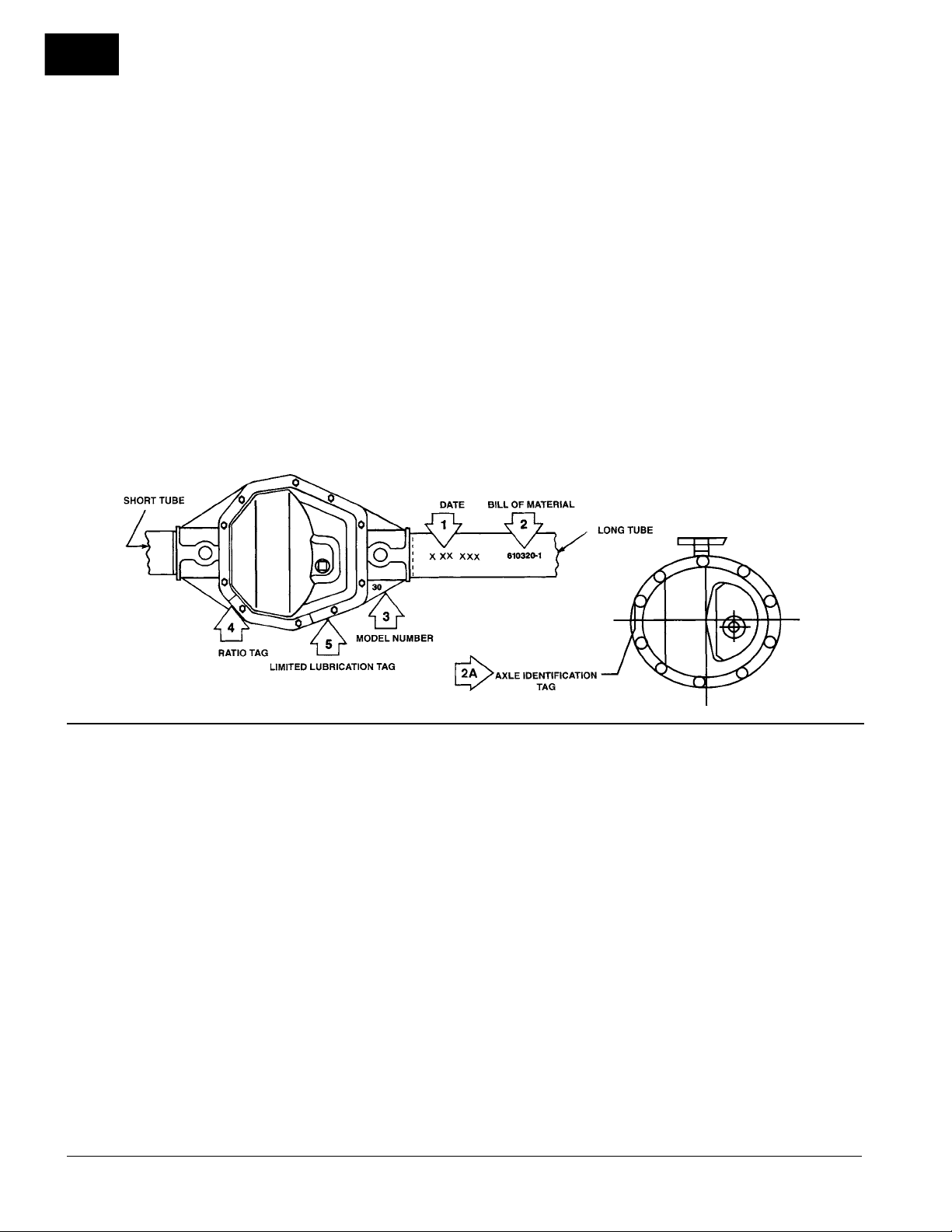

All Spicer Carrier Type axles are identified with a manufacturing date (1) and Bill of Material number (2)

stamped on the right or left hand tube on driving axles. The Bill of Material number may also be found on the

carrier in some models as shown in illustration (2A). For independent front suspension (IFS) axles, the B/M

number may be located at one of three locations: 1). A vertically positioned tag near the center of the right

hand side support arm, 2) stamped into the left hand side support arm (opposite end of the camber adjuster), or 3) stamped into the "nose end" of the axle carrier. The location of the information will depend on

the manufacturing date of the axle.

The axle model number will be cast into one of the webs as shown (3), or it can be on the nose.

Each axle contains a gear ratio tag (4), and if the axle is equipped with a limited slip differential, it will have a

tag specifying the type of limited slip lubricant to be used (5).

Refer to the appropriate model number section for parts identification and a breakdown of the Bill of Material.

How To Change Gear Ratios

To increase or decrease a gear ratio, there are certain steps that must be taken. The differential case depends upon the ratio

desired. For each axle model, there is a high-ratio and a low-ratio case as illustrated below:

Axle Model Low Ratio Case High Ratio Case Axle Model Low Ratio CaseHigh Ratio Case

Model 27 3.73 and Down 3.92 and Up Model 50 4.10 and Down ............. —

Model 28 3.45 and Down 3.73 and Up Model 60 4.10 and Down .... 4.56 and Up

Model 28 IFS Aerostar 2.27, 3.73 — Model 61

Model 30 3.55 and Down 3.73 and Up Semi Float 3.00 and 3.07 only

Model 35 2.35 only — Model 61

Model 35 2.73 - 3.31 3.54 and Up Full Float 3.31 and Down .... 3.54 and Up

Model 36 ICA 2.73 and Down 3.07 and Up Model 70 4.10 and Down .... 4.56 and Up

Model 44 3.73 and Down 3.92 and Up Model 70-3HD 3.42 and Down .... 3.73 and Up

Model 44 ICA Model 70-2UA 3.07 only ....................... —

1984 & earlier 3.73 and Down 3.92 and Up Model 80 3.73 and Down .... 4.10 and Up

Model 44 ICA

1985 & later 2.87 and Down 3.07 and Up

Example - If you have a model 44 Rear Axle with a 3.54 ratio and wish to change to a 3.73 ratio, you change only the ring gear

and pinion assembly. If you change the ratio to a 4.09, you must change to a high-ratio case in addition to changing the ring

gear and pinion. The application section will show you what case to use. When the vehicle is equipped with both front and

rear driving axles, the gear ratios must be the same in both axles. The drive gear screws are self-locking and must be

replaced with new screws each time that they are removed.

4

Page 7

X510-5

How Limited Slip Differentials Operate

A conventional differential transmits all the ring gear torque through the differential gears to the axle shafts.

Torque is at all times equal on the axle shafts, and if one wheel slips, the other wheel can only put out as much

torque as the slipping wheel.

The Spicer Limited Slip differential has the same power flow as a conventional differential, plus a more direct flow

which automatically takes effect as driving conditions demand. This more direct power flow is from the differential case to each axle shaft through a clutch plate and disc arrangement.

Arrangement of these plates and discs is at the option of the vehicle manufacturer, so care should be taken

during disassembly to note the arrangement of these components.

The Limited Slip construction permits differential action when required for turning corners and transmits equal

torque to both wheels when driving straight ahead. However, when one wheel tries to spin due to leaving the

ground, a patch of ice, etc., the clutch packs automatically provide more torque to the wheel which is not trying

to spin.

The Limited Slip differential resists wheel spin on bumpy roads and provides more pulling power when one wheel

tries to slip. In many cases of differences in traction, pulling power will be automatically provided until both

wheels start to slip.

In diagnosis of vehicle operators' complaints, it is important to recognize two things.

1. If, with unequal traction, both wheels slip, the Limited Slip Differential has done all it can pssibly do.

2. In extreme cases of differences in traction, the wheel with the least traction may spin after the Limited . Slip

has transferred as much torque as possible to the non-slipping wheel.

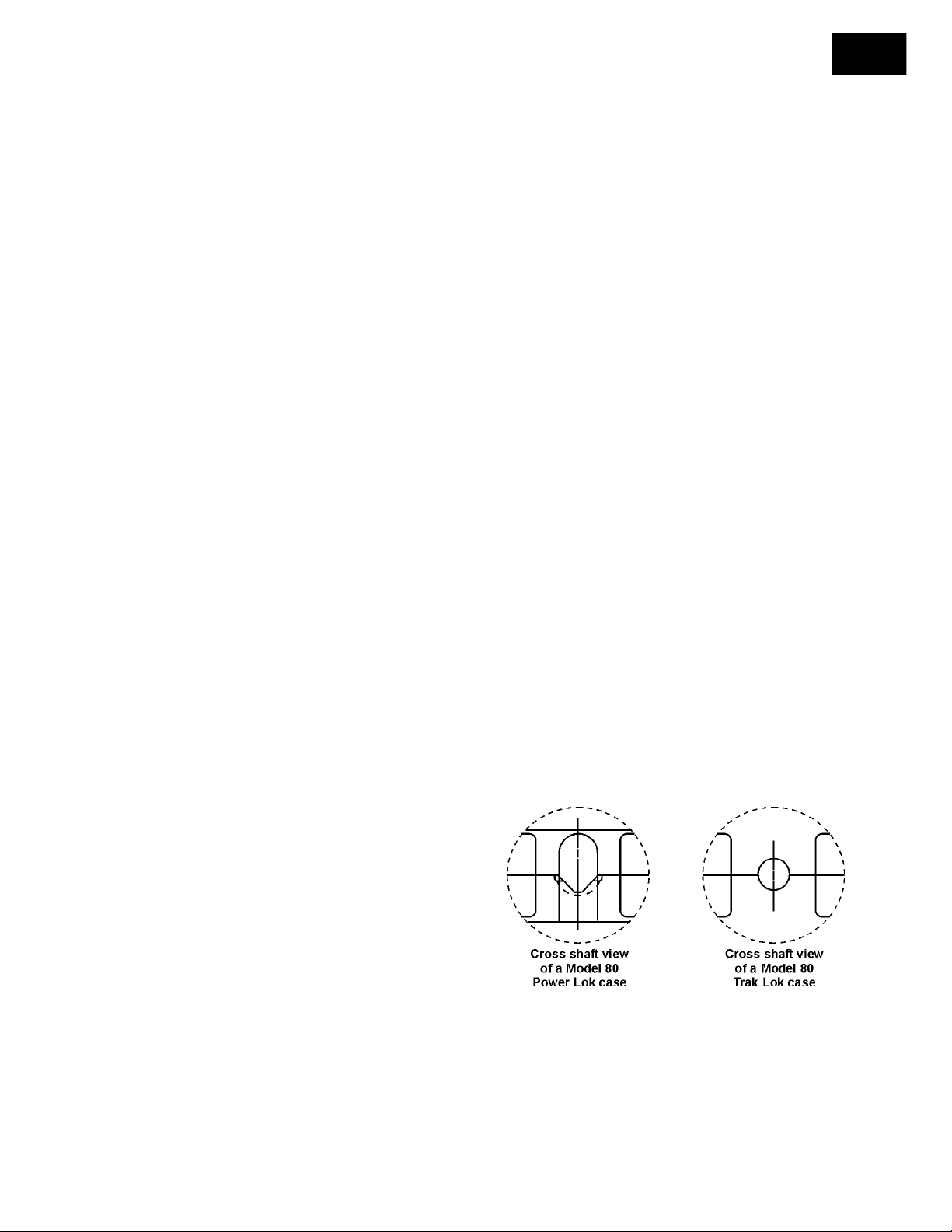

How To Distinguish a Powr-Lok™ from a Trac-Lok™

All Models except Model 80 /286: The Powr-Lok

design is identified by its 2-piece case. The Trac-Lok

design is identified by its 1-piece case.

Model 80 /286 only: Both the Powr-Lok and the TracLok use 2-piece cases in the model 80 (286) axle. The

difference between the two is in the shape of the holes

for the cross shaft. The Powr-Lok case will have cross

POWR-LOK™

2-Piece Case

4 Pinion Mate Gears

shaft holes that are "U" shaped in one case half and "V"

shaped in the other case half. The Trac-Lok case will

have cross shaft holes that are semicircles in both case

halves.

It is also possible to replace an existing Powr-Lok unit

with a complete Trac-Lok unit. For this purpose, the

differential case assembly must be replaced.

How To Obtain Special Service Tools

Special service tools (see service manuals) can be obtained from the following company:

Kent-Moore

OE Tool and Equipment Group

SPX Corporation

28635 Mound Road

Warren MI 48092-3499

(800) 345-2233

TRAC-LOK™

1 or 2-Piece Case

2 Pinion Mate Gears

5

Page 8

Light Axle Kits

X510-5

DIFFERENTIAL CASE KIT

DIFFERENTIAL CASE ASSEMBLY KIT

SHAFT ASSEMBLY KIT

DRIVE PINION & GEAR ASSEMBLY KIT

CARRIER COVER KIT

6

DIFFERENTIAL INNER PARTS KIT

Page 9

X510-5

Model 35 /194

Front Axles for

Dakota and Durango

7

Page 10

Chrysler/Dodge 35/194 Front

Exploded View

X510-5

8

Page 11

X510-5

Chrysler/Dodge 35/194 Front

Parts Listing

ITEM PART

NO. NUMBER

DESCRIPTION

1 -(3) Housing - Axle Service

2 -(1) Drive Pinion & Gear Assembly

3 701130X PKG - Inner Pinion Shim

4 707162X KIT - Inner Pinion Bearing

5 42102 Collapsible Spacer

6 706894X KIT - Outer Pinion Bearing

7 42778 Slinger - Outer Pinion Bearing

8 48009 Seal - Pinion Oil

9 48008 Seal - End Yoke

10 2-4-8131-1 End Yoke

11 44189 Pinion Nut

707438X KIT - Carrier Cover

12 -(4) Carrier Cover

13 41356 Plug - Carrier Cover

14 40286-5 Bolt - Carrier Cover (qty 10)

15 38615 RTV Silicone Sealant

16 -(3) Differential Bearing Cap

ITEM PART

NO. NUMBER

DESCRIPTION

17 40284-1 Bolt - Differential Bearing Cap

18 706016X Differential Bearing Kit

19 701004X PKG - Differential Bearing Shim

20 -(1) Case - Differential (std)

21 41221 Bolt - Drive Gear (qty 10)

22 42570 Snap Ring

23 46504 Pinion - Differential

24 47559 Gear - Differential

25 34096 Thrustwasher - Differential Pinion

26 34095 Thrustwasher - Differential Gear

27 41648 Shaft - Differential Pinion

28 13449 Roll Pin - Differential Shaft

29 565977 Bearing

30 46485 Oil Seal

31 47067 Axle Shaft (LH)

32 47065 Axle Shaft (RH)

33 41962 Vent - Axle Shaft (RH)

(1) See "Bill of Material Table" below

(2) See "Variable Parts Table" within this section

(3) Contact Vehicle Manufacturer

(4) Not Sold Separately

N.I. = Not Illustrated

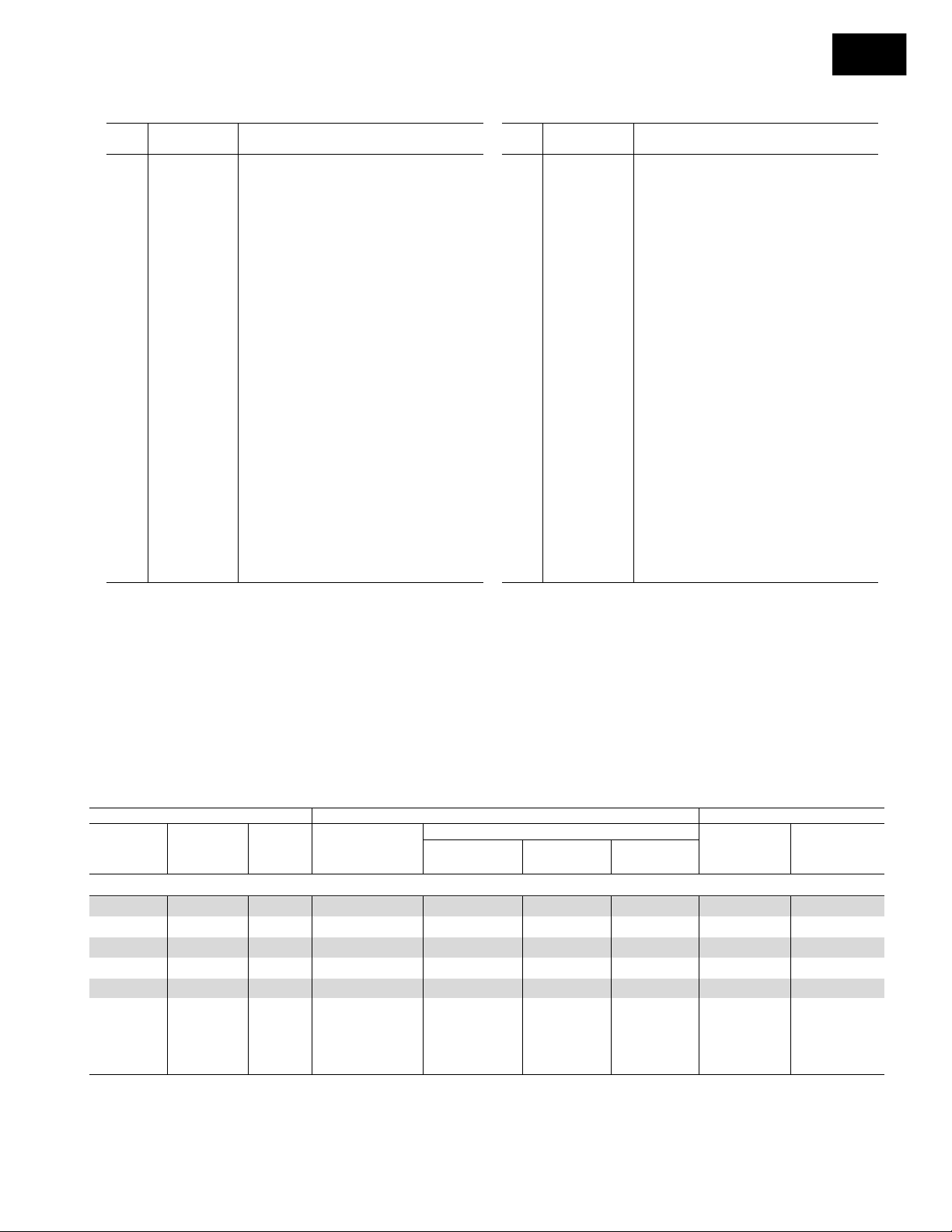

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

1997-99 Dakota & Durango

610576-1 Standard 3.21 75812-5X 75935X 47071 707436X

610576-2 Standard 3.55 74346-5X 75934X 47069 707436X

610576-3 Standard 3.92 75813-5X 75934X 47069 707436X

610576-4 Standard 3.21 75812-5X 75935X 47071 707436X

610576-5 Standard 3.55 74346-5X 75934X 47069 707436X

610576-6 Standard 3.92 75813-5X 75934X 47069 707436X

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

NOTE: All Ring & Pinion Kits with base number 706930 are reverse spiral bevel

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

9

Page 12

Notes

X510-5

10

Page 13

X510-5

Model 44 /216

Front Disconnect Axles for

W1500 & W2500 Ram

11

Page 14

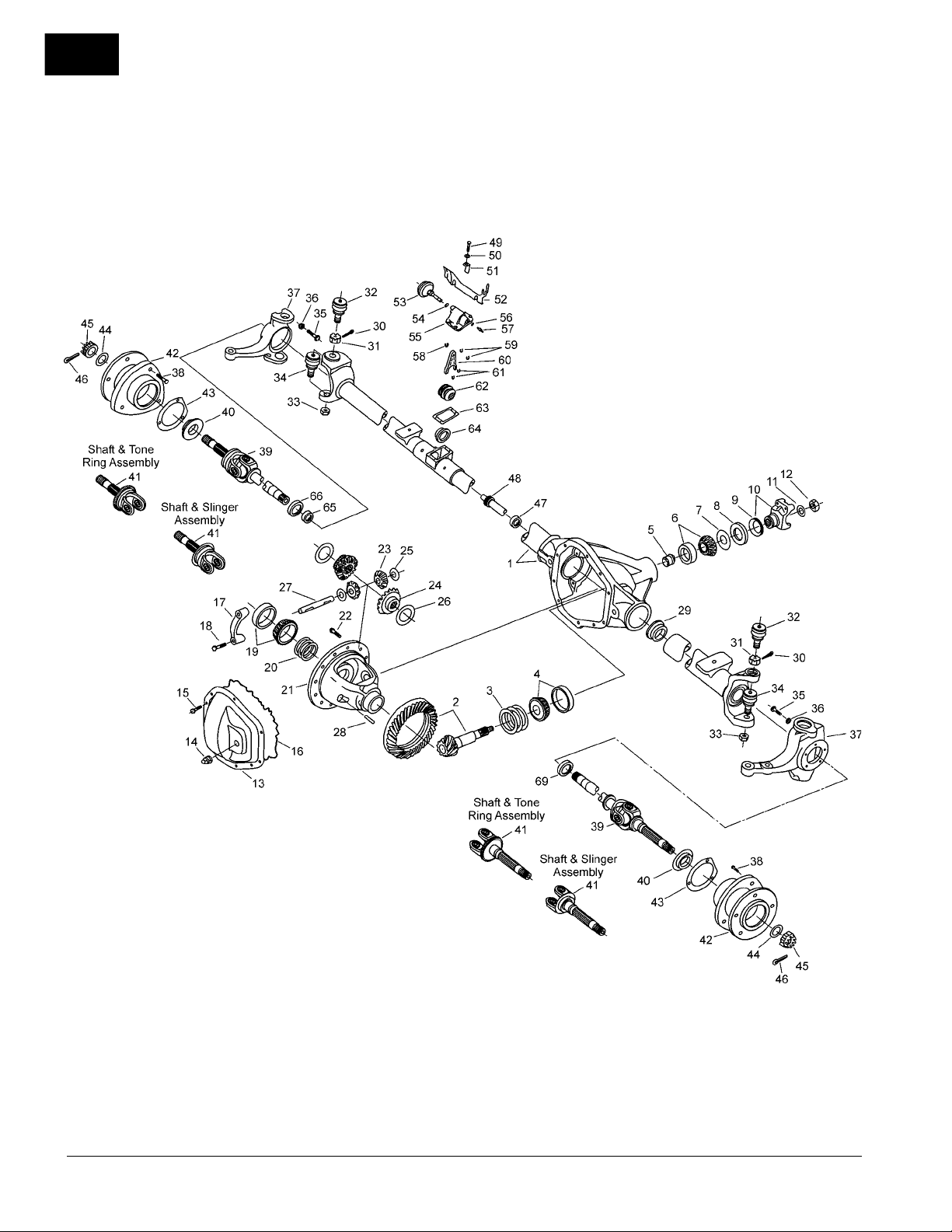

Chrysler/Dodge 44/216 Disconnect Front

Exploded View

X510-5

12

Page 15

X510-5

Chrysler/Dodge 44/216 Disconnect Front

Parts Listing

ITEM PART

NO. NUMBER

1 -(3) Housing - Axle Service

2 -(1) Drive Pinion & Gear Assembly

3 701112X PKG - Inner Pinion Bearing Shim

4 706015X KIT - Inner Pinion Bearing

5 44896 Collapsible Spacer

6 706030X KIT - Outer Pinion Bearing

7 13575 Slinger - Outer Pinion Bearing

8 -(2) Seal - Pinion Oil

9 -(2) Seal - End Yoke

10 -(2) End Yoke Assembly (inc 9)

11 30186 Washer - Pinion Nut

12 30185 Pinion Nut

707192X KIT - Carrier Cover (inc 13,14,15)

13 -(4) Carrier Cover

14 36472 Plug - Carrier

15 34279 Bolt - Carrier Cover (qty 10)

16 38615 RTV Silicone Sealant

17 -(3) Differential Bearing Cap

18 48632-1 Bolt - Diff Bearing Cap

19 706032X KIT - Differential Bearing

20 706086X PKG - Differential Bearing Shim

21 -(1) Case - Differential

22 41221 Bolt - Drive Gear (qty 10)

23 45872 Pinion - Differential

24 45870 Gear - Differential

25 13338-3 Thrustwasher - Differential Pinion

26 32121 Thrustwasher - Differential Gear

27 39194 Shaft - Differential

28 13449 Lock - Differential Shaft

29 48489 Seal - Tube (left side)

-(2) KIT - Socket Assembly

30 500024-6 Cotter Pin

31 40584 Slotted Nut

32 40916 Upper Socket

33 -(2) Lock Nut

34 -(2) Lower Socket

DESCRIPTION

(inc items 30, 31, 32, 33, 34)

ITEM PART

NO. NUMBER

35 -(2) Stop Screw

36 -(2) Jam Nut

37 -(3) Knuckle (RH)

-(3) Knuckle (LH)

38 44993-1 Bolt - Knuckle (if required)

39 -(1) Shaft & Joint Assembly

40 45942 Slinger

41 -(2) Shaft & Slinger/Tone Ring Assy.

42 -(3) Hub Assembly

43 -(2) Spacer - Flat

44 45523 Washer - Flat

45 46085 Slotted Nut

46 500025-10 Cotter Pin

47 50429(6) Bushing - Synthetic

48 45770 Output Shaft

75265X KIT - Front Axle Shaft (inc 48, 65)

49 500396-10 Bolt - Disconnect Assembly

50 500357-9 Lock Washer

51 -(3) Brake Line Clip

52 43424 Protection Shield

-(3) Cover & Motor Assembly

53 -(4) Motor Assembly

54 -(4) O-Ring

55 -(4) Cover - Housing

56 -(4) O-Ring

57 -(4) Switch Assembly

58 -(4) Snap Ring

59 -(4) Snap Ring

60 -(4) Shift Fork

61 -(4) Clip

62 46401 Clutch Collar

63 41494 Gasket

64 48488 Seal - Tube (right side)

65 43337 Bushing

66 50382 Oil Seal

DESCRIPTION

(inc 53,54,55,56,57,58,59,60,61)

(1) See "Bill of Material Table" on next page

(2) See "Variable Parts Table" within this section

(3) Contact Vehicle Manufacturer

(4) Not Sold Separately

(5) Bearing Assembly 566008 was used in older models and is still available for service.

13

Page 16

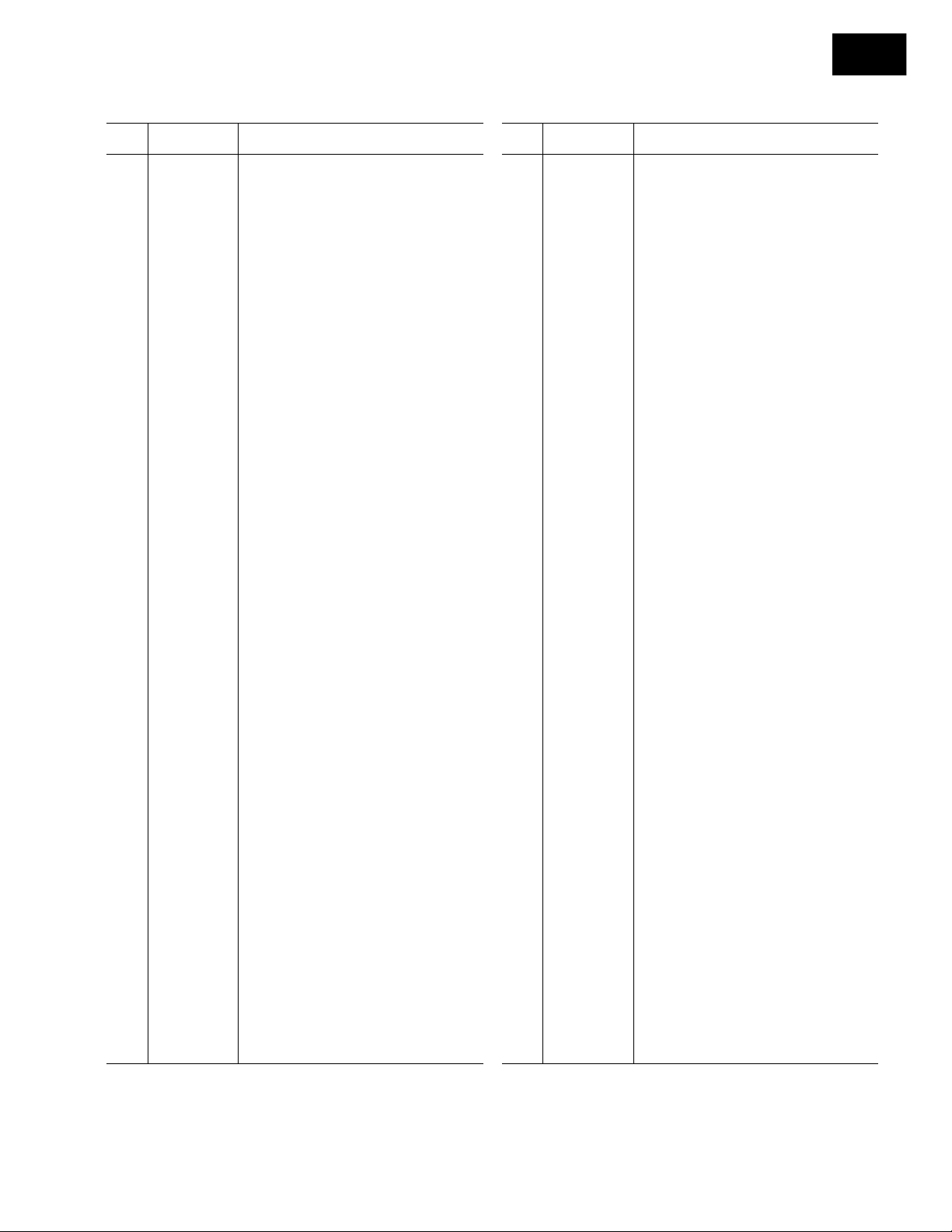

Chrysler/Dodge 44/216 Disconnect Front

X510-5

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

1999 W1500

610786-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 76812-1X 76813-1X

610786-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 76812-1X 76813-1X

610787-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 76812-1X 76813-1X

610787-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 76812-1X 76813-1X

610826-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 76812-1X 76813-1X

610826-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 76812-1X 76813-1X

610827-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 76812-1X 76813-1X

610827-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 76812-1X 76813-1X

610834-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

610834-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 708060 708061

610835-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

610835-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 708060 708061

2000 W1500

610800-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 76812-1X 76813-1X

610800-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 76812-1X 76813-1X

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

610801-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 76812-1X 76813-1X

610801-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 76812-1X 76813-1X

610847-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

610847-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 708060 708061

610847-3 Standard 4.10 707338-5X 707021-1X 706024X 707025-1X 708060 708061

610848-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

610848-2 Standard 3.92 707338-2X 707021-1X 706024X 707025-1X 708060 708061

610938-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

610938-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 708060 708061

610939-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

610939-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 708060 708061

2000 W1500 Off Road Axle

610911-1 Standard 4.10 707338-5X 707021-1X 706024X 707025-1X 708060 708061

610940-1 Standard 4.10 707338-5X 707021-1X 706024X 707025-1X 708060 708061

2000-01 W1500

611048-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

611048-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 708060 708061

611049-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

611049-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 708060 708061

611050-1 Standard 4.10 707338-5X 707021-1X 706024X 707025-1X 708060 708061

2001 W1500

611149-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

611149-2 Standard 3.92 707338-2X 707022-1X 706024X 707025-1X 708060 708061

611150-1 Standard 3.54 707338-1X 707021-1X 706024X 707025-1X 708060 708061

611150-2 Standard 3.92 707338-2X 707022-1X 706025X 707025-1X 708060 708061

611151-1 Standard 4.10 707338-5X 707021-1X 706024X 707025-1X 708060 708061

14

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

Page 17

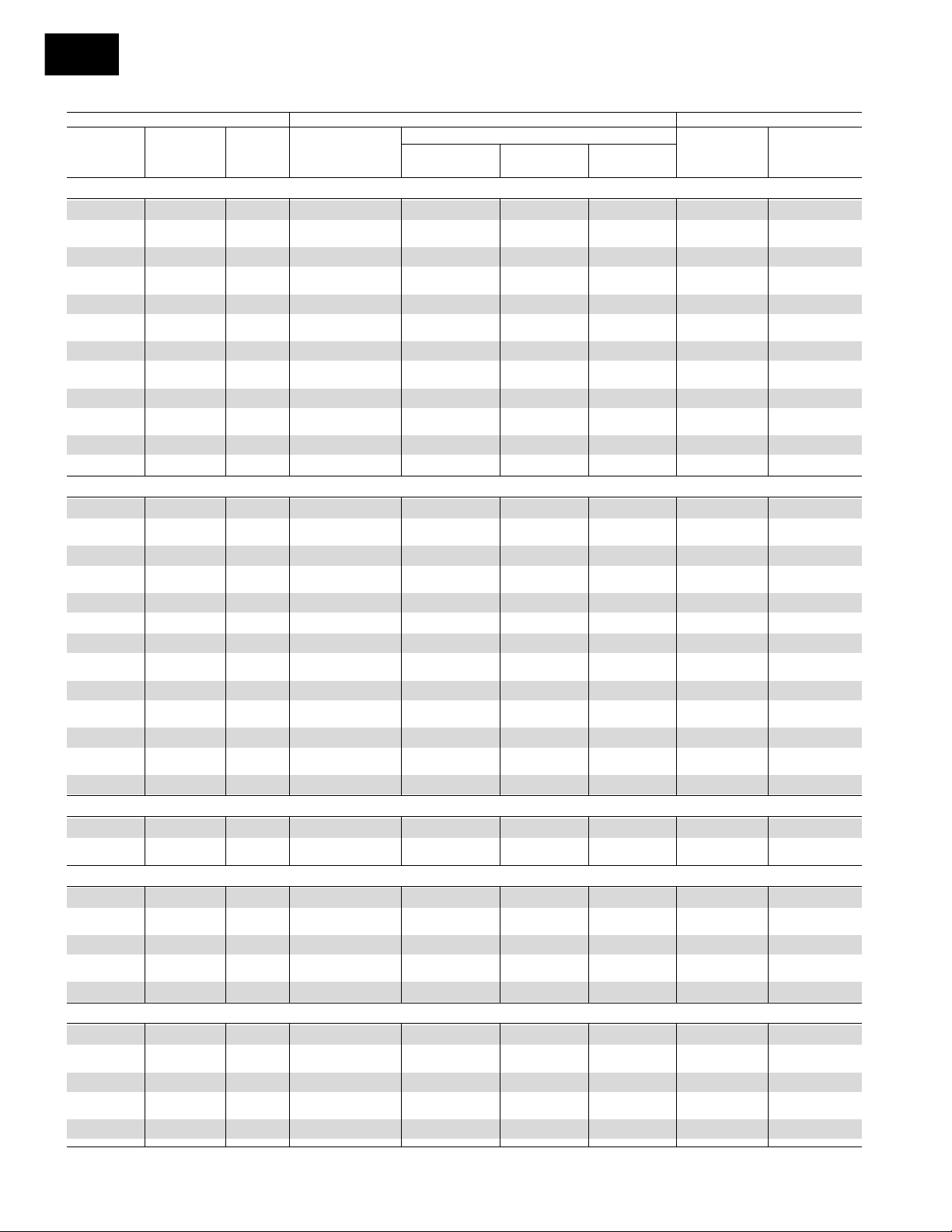

X510-5

Chrysler/Dodge 44/216 Disconnect Front

Variable Parts Listing

Kits & Parts - Use With All Applications

Description & Item Number (Refer to the

"Exploded View" at the front of this section)

1 Seal - Pinion Oil 8 44895 44895 47761 44895 44895

2 Seal - End Yoke 9 232549 232549 47762 232549 232549

3 End Yoke Assembly (inc 9) 10 2-4-7651-1X 2-4-7651-1X - (10) 2-4-7651-1X 2-4-7651-1X

4 KIT - Socket Assembly - 707315X 707315X 707315X 707315X 707315X

5 Lock Nut 33 35566 35566 35566 35566 35566

6 Lower Socket 34 40113 40113 40113 40113 40113

7 Stop Screw 35 31026-3 31026-3 - 31026-3 31026-3

8 Jam Nut 36 49270 49270 - 49270 49270

9 Shaft & Tone Ring/Slinger Assembly 41 74917X (11) 74917X (11) 74917X (11) 74917X (11) 74917X (11)

10 Spacer - Flat 43 44997 48352 - 44997 48352

1 Seal - Pinion Oil 8 44895 44895 50092 50092 50092

2 Seal - End Yoke 9 232549 232549 47762 47762 47762

3 End Yoke Assembly (inc 9) 10 2-4-7651-1X 2-4-7651-1X 2-4-8431-1 2-4-8431-1 2-4-8431-1

4 KIT - Socket Assembly - 707315X 707315X 708072 708072 708072

5 Lock Nut 33 35566 35566 50153 50153 50153

6 Lower Socket 34 40113 40113 50154 50154 50154

7 Stop Screw 35 31026-3 31026-3 - 49501 8 Jam Nut 36 49270 49270 - - 9 Shaft & Slinger Assembly 41 80566 80566 80566 80566 80566

10 Spacer - Flat 43 44997 48352 - - -

610786 610787 610800 610826 610827

610834 610835 610847 610911 610939

Bills of Material

610801

610848 610938

610940 611149

611048 611150

611049 611151

611050

1 Seal - Pinion Oil 8 50092 50092

2 Seal - End Yoke 9 47762 47762

3 End Yoke Assembly (inc 9) 10 2-4-8431-1 2-4-8431-1

4 KIT - Socket Assembly - 708072 708072

5 Lock Nut 33 50153 50153

6 Lower Socket 34 50154 50154

7 Stop Screw 35 49501 50752

8 Jam Nut 36 - 9 Shaft & Slinger Assembly 41 80566 80566

10 Spacer - Flat 43 - -

(10) 7290 Series used in vehicle. Service 1330 Series using 2-4-8431-1, 5-637X and 2-70-18X

(11) 74917X is used in some non-ABS applications; check tone ring for interference fit.

15

Page 18

Notes

X510-5

16

Page 19

X510-5

Model 60 /248

Front Disconnect Axles for

W2500HD, W3500 &

Non-ABS Air Force Tow Vehicle

17

Page 20

Chrysler/Dodge 60/248 Front Disconnect

Exploded View

X510-5

18

Page 21

X510-5

Chrysler/Dodge 60/248 Front Disconnect

Parts Listing

ITEM PART

NO. NUMBER

1 -(3) Housing - Axle Service

2 -(1) Drive Pinion & Gear Assembly

3 701126X PKG - Inner Pinion Bearing Shim

4 706046X KIT - Inner Pinion Bearing

5 45658 Collapsible Spacer

6 706045X KIT - Outer Pinion Bearing

7 42737 Thrustwasher - Bearing

8 -(2) Seal - Pinion Oil

9 -(2) Seal - End Yoke

10 -(2) End Yoke Assy (inc 9) or Flange

11 30275 Washer - Pinion Nut

12 30271 Pinion Nut

-(2) KIT-Carrier Cover (inc 13,14,15,16)

13 -(4) Carrier Cover

14 43180 Plug - Carrier Cover

15 34822 Bolt - Carrier Cover (qty 10)

16 38615 RTV Silicone Sealant

17 -(3) Differential Bearing Cap

18 48632-1 Bolt - Differential Bearing Cap

19 706047X KIT - Differential Bearing

20 708012 PKG - Diff & Pinion Bearing Shim

21 -(1) Case - Differential

22 40638 Bolt - Drive Gear (qty 12)

23 -(2) Pinion - Differential

24 -(2) Gear - Differential

25 34730 Thrustwasher - Differential Pinion

26 -(2) Thrustwasher - Differential Gear

27 30263 Shaft - Differential

28 44810 Lock - Differential Shaft

29 -(2) Seal - Tube (Left Side)

-(2) KIT - Socket Assembly

30 500024-9 Cotter Pin

31 -(2) Nut - Slotted

32 -(2) Bushing - 0º Caster

33 -(2) Upper Socket

DESCRIPTION

ITEM PART

NO. NUMBER

34 -(2) Lock Nut

35 -(2) Lower Socket

36 -(2) Snap Ring

37 -(3) Knuckle (RH)

38 -(3) Knuckle (LH)

39 -(2) Bolt - Knuckle/Hub

40 -(1) Shaft & Joint Assembly

41 -(4) Slinger

42 -(2) Outer Shaft & Slinger Assembly

43 -(3) Hub Assembly

44 -(2) Spacer - Flat

45 45523 Washer - Flat

46 46085 Nut - Slotted

47 500025-10 Cotter Pin

48 -(2) Oil Seal - Outer Tube

49 43337 Bushing

50 500396-10 Bolt - Disconnect Assembly

51 500357-9 Lockwasher - Disconnect Assembly

52 43424 Protection Shield

-(3) Disconnect Cover & Motor Assembly

53 -(4) Motor Assembly

54 -(4) O-Ring

55 -(4) Cover - Housing

56 -(4) O-Ring

57 -(4) Switch Assembly

58 -(4) Snap Ring

59 -(4) Snap Ring

60 -(4) Shift Fork

61 -(4) Clip

62 -(2) Clutch Collar

63 41494 Gasket

64 -(2) Seal - Tube (right side)

65 -(2) Output Shaft

66 -(2) Bearing Assy or Synthetic Bushing

DESCRIPTION

(1) See "Bill of Material Table" on next page

(2) See "Variable Parts Table" within this section

(3) Contact Vehicle Manufacturer

(4) Not Sold Separately

19

Page 22

Chrysler/Dodge 60/248 Front Disconnect

X510-5

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

1999 Air Force Tow Vehicle

610832-1 Standard 7.17 707345-3X 706037X 706041X 706043X 76471X 76472X

1999 D3500 (Dead Front)

610840

1999 D3500 (Dead Front) w/ABS

610831

1999 W2500 HD

610788-1 Standard 3.54 708009-1 707339-1X 706040X 707340-1X 76471X 76472X

610788-2 Standard 4.10 708009-2 707339-1X 706040X 707340-1X 76471X 76472X

610828-1 Standard 3.54 708009-1 707339-1X 706040X 707340-1X 76471X 76472X

610828-2 Standard 4.10 708009-2 707339-1X 706040X 707340-1X 76471X 76472X

1999 W2500 HD w/ABS

610829-1 Standard 3.54 708009-1 707339-1X 706040X 707340-1X 76471X 76472X

610829-2 Standard 4.10 708009-2 707339-1X 706040X 707340-1X 76471X 76472X

1999 W3500

610789-1 Standard 3.54 708009-1 707339-1X 706040X 707340-1X 76471X 76472X

610789-2 Standard 4.10 708009-2 707339-1X 706040X 707340-1X 76471X 76472X

610791-1 Standard 3.54 708009-1 707339-1X 706040X 707340-1X 76471X 76472X

610791-2 Standard 4.10 708009-2 707339-1X 706040X 707340-1X 76471X 76472X

610830-1 Standard 3.54 708009-1 707339-1X 706040X 707340-1X 76471X 76472X

610830-2 Standard 4.10 708009-2 707339-1X 706040X 707340-1X 76471X 76472X

2000 Air Force Tow Vehicle

610899-1 Standard 7.17 707345-3X 708048-1 706041X 708049 708063 708064

2000 D3500 (Dead Front)

610898

611058

611079

2000 D3500 (Dead Front) w/ABS

610839

610943

611057

610794

611078

2000 W2500 HD

610836-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

610836-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

611075-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611075-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2000 W2500 HD w/ABS

610837-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

610837-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

610941-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

610941-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

611076-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611076-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

20

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

Page 23

X510-5

Chrysler/Dodge 60/248 Front Disconnect

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

2000 W3500

610838-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

610838-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

610942-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

610942-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

611077-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611077-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2000-01 W2500 Air Force Tow Vehicle

611059-1 Standard 7.17 707345-3X 708048-1 706041X 708049 708063 708064

2000-01 W2500 HD

611054-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611054-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2000-01 W2500 HD w/ABS

611055-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611055-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2000-01 W3500

611056-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611056-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2001 D3500 (Dead Front)

611157

2001 D3500 (Dead Front) w/ABS

611156

2001 W2500 HD

611153-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611153-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2001 W2500 HD w/ABS

611154-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611154-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2001 W3500

611155-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611155-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2001 1/2 D3500 (Dead Front)

611172

2001 1/2 W2500 HD

611176-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611176-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2001 1/2 W2500 HD w/ABS

611173-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611173-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2001 1/2 W3500

611174-1 Standard 3.54 708009-1 708048 706040X 708049 708063 708064

611174-2 Standard 4.10 708009-2 708048 706040X 708049 708063 708064

2001 1/2 D3500 (Dead Front) w/ABS

611175

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

21

Page 24

Chrysler/Dodge 60/248 Front Disconnect

X510-5

Variable Parts Listing

Kits & Parts - Use With All Applications

Description & Item Number (Refer to the

"Exploded View" at the front of this section)

610788 610791 610794 610828 610829

610789

1 Seal - Pinion Oil 8 42449 42449 - 42449 42449

2 Seal - End Yoke 9 34592 34592 - 34592 34592

3 End Yoke Assy (inc 9) or Flange 10 2-4-7681-1X 2-4-7681-1X - 2-4-7681-1X 2-4-7681-1X

4 KIT - Carrier Cover - 707335X 707335X - 707335X 707335X

5 Pinion - Differential 23 46354 46354 - 46354 46354

6 Gear - Differential 24 46355 46355 - 46355 46355

7 Thrustwasher - Differential Gear 26 46146 46146 - 46146 46146

8 Seal - Tube (Left Side) 29 620216 620216 - 620216 620216

9 KIT - Socket Assembly - 707469X 707469X 708047 707469X 707469X

10 Nut - Slotted 31 44101 44101 41864 44101 44101

11 Bushing - 0º Caster 32 44507 44507 - 44507 44507

12 Upper Socket 33 40126 40126 49476 40126 40126

13 Lock Nut 34 44133 44133 35566 44133 44133

14 Lower Socket 35 44627 44627 49477 44627 44627

15 Snap Ring 36 620343 620343 49478 620343 620343

16 Bolt - Knuckle/Hub 39 45524 45524 - 45524 45524

17 Outer Shaft & Slinger Assembly 42 75689X - 80113 75689X 75689X

18 Spacer - Flat 47 45935 48355 - 45935 48355

19 Oil Seal 51 - - - - 20 Clutch Collar 65 46401 46401 - 46401 46401

21 Seal - Tube (right side) 67 43154 43154 - 43154 43154

22 Output Shaft 68 45531 45531 - 45531 45531

23 Bearing Assy or Synthetic Bushing 69 566008 566008 - 566008 566008

Bills of Material

610830 610831 610832 610836 610839

610837

610838

1 Seal - Pinion Oil 8 42449 - 42449 47885 -

2 Seal - End Yoke 9 34592 - 34592 47886 -

3 End Yoke Assy (inc 9) or Flange 10 2-4-7681-1X - 2-4-7681-1X 2-4-8421-1 -

4 KIT - Carrier Cover - 707335X - 707335X 708050 -

5 Pinion - Differential 23 46354 - 34367 46354 -

6 Gear - Differential 24 46355 - 34394 49482 -

7 Thrustwasher - Differential Gear 26 46146 - 34729 46146 -

8 Seal - Tube (Left Side) 29 620216 - 620216 49489 -

9 KIT - Socket Assembly - 707469X 707469X 707469X 708047 708047

10 Nut - Slotted 31 44101 44101 44101 41864 41864

11 Bushing - 0º Caster 32 44507 44507 44507 - 12 Upper Socket 33 40126 40126 40126 49476 49476

13 Lock Nut 34 44133 44133 44133 35566 35566

14 Lower Socket 35 44627 44627 44627 49477 49477

15 Snap Ring 36 620343 620343 620343 49478 49478

16 Bolt - Knuckle/Hub 39 45524 45524 45524 49466 49466

17 Outer Shaft & Slinger Assembly 42 75689X 74777X 75689X 80375 80113

18 Spacer - Flat 47 48355 48355 45935 - 19 Oil Seal 51 - - - 50381 20 Clutch Collar 65 46401 - 46401 49495 21 Seal - Tube (right side) 67 43154 - 43154 49485 22 Output Shaft 68 45531 - 45531 49490 23 Bearing Assy or Synthetic Bushing 69 566008 - 566008 49488 -

22

Page 25

X510-5

Chrysler/Dodge 60/248 Front Disconnect

Variable Parts Listing

Kits & Parts - Use With All Applications

Description & Item Number (Refer to the

"Exploded View" at the front of this section)

610840 610898 610899 610943 611054

1 Seal - Pinion Oil 8 - - 47885 - 47885

2 Seal - End Yoke 9 - - 47886 - 47886

3 End Yoke Assy (inc 9) or Flange 10 - - 2-4-8421-1 - 2-4-8421-1

4 KIT - Carrier Cover - - - 708050 - 708050

5 Pinion - Differential 23 - - 46354 - 46354

6 Gear - Differential 24 - - 49482 - 49482

7 Thrustwasher - Differential Gear 26 - - 46146 - 46146

8 Seal - Tube (Left Side) 29 - - 49489 - 49489

9 KIT - Socket Assembly - 707469X 708047 708047 708047 708047

10 Nut - Slotted 31 44101 41864 41864 41864 41864

11 Bushing - 0º Caster 32 44507 - - - 12 Upper Socket 33 40126 49476 49476 49476 49476

13 Lock Nut 34 44133 35566 35566 35566 35566

14 Lower Socket 35 44627 49477 49477 49477 49477

15 Snap Ring 36 620343 49478 49478 49478 49478

16 Bolt - Knuckle/Hub 39 45524 49466 49466 49466 49466

17 Outer Shaft & Slinger Assembly 42 74777X 80113 80375 80113 80375

18 Spacer - Flat 47 48355 - - - 19 Oil Seal 51 - - 50381 - 50381

20 Clutch Collar 65 - - 49495 - 49495

21 Seal - Tube (right side) 67 - - 49485 - 49485

22 Output Shaft 68 - - 49490 - 49490

23 Bearing Assy or Synthetic Bushing 69 - - 49488 - 49488

Bills of Material

610941 611055

610942 611056

611057 611059 611075 611078 611153

611058 611076 611079 611154

611077 611155

1 Seal - Pinion Oil 8 - 47885 47885 - 47885

2 Seal - End Yoke 9 - 47886 47886 - 47886

3 End Yoke Assy (inc 9) or Flange 10 - 2-4-8421-1 2-4-8421-1 - 2-4-8421-1

4 KIT - Carrier Cover - - 708050 708050 - 708050

5 Pinion - Differential 23 - 46354 46354 - 46354

6 Gear - Differential 24 - 49482 49482 - 49482

7 Thrustwasher - Differential Gear 26 - 46146 46146 - 46146

8 Seal - Tube (Left Side) 29 - 49489 49489 - 49489

9 KIT - Socket Assembly - 708047 708047 708047 708047 708047

10 Nut - Slotted 31 41864 41864 41864 41864 41864

11 Bushing - 0º Caster 32 - - - - 12 Upper Socket 33 49476 49476 49476 49476 49476

13 Lock Nut 34 35566 35566 35566 35566 35566

14 Lower Socket 35 49477 49477 49477 49477 49477

15 Snap Ring 36 49478 49478 49478 49478 49478

16 Bolt - Knuckle/Hub 39 49466 49466 49466 49466 49466

17 Outer Shaft & Slinger Assembly 42 80113 80375 80375 80113 80375

18 Spacer - Flat 47 - - - - 19 Oil Seal 51 - 50381 50381 - 50381

20 Clutch Collar 65 - 49495 49495 - 49495

21 Seal - Tube (right side) 67 - 49485 49485 - 49485

22 Output Shaft 68 - 49490 49490 - 49490

23 Bearing Assy or Synthetic Bushing 69 - 49488 49488 - 49488

23

Page 26

Chrysler/Dodge 60/248 Front Disconnect

Variable Parts Listing

Kits & Parts - Use With All Applications

Description & Item Number (Refer to the

"Exploded View" at the front of this section)

611156 611173 611175 611176

611157 611174

611172

1 Seal - Pinion Oil 8 - 47885 - 47885

2 Seal - End Yoke 9 - 47886 - 47886

3 End Yoke Assy (inc 9) or Flange 10 - 2-4-8421-1 - 2-4-8421-1

4 KIT - Carrier Cover - - 708050 - 708050

5 Pinion - Differential 23 - 46354 - 46354

6 Gear - Differential 24 - 49482 - 49482

7 Thrustwasher - Differential Gear 26 - 46146 - 46146

8 Seal - Tube (Left Side) 29 - 49489 - 49489

9 KIT - Socket Assembly - 708047 708047 708047 708047

10 Nut - Slotted 31 41864 41864 41864 41864

11 Bushing - 0º Caster 32 - - - 12 Upper Socket 33 49476 49476 49476 49476

13 Lock Nut 34 35566 35566 35566 35566

14 Lower Socket 35 49477 49477 49477 49477

15 Snap Ring 36 49478 49478 49478 49478

16 Bolt - Knuckle/Hub 39 49466 49466 49466 49466

17 Outer Shaft & Slinger Assembly 42 80113 80375 80113 80375

18 Spacer - Flat 47 - - - 19 Oil Seal - 51 - 50381 - 50381

20 Clutch Collar 65 - 49495 - 49495

21 Seal - Tube (right side) 67 - 49485 - 49485

22 Output Shaft 68 - 49490 - 49490

23 Bearing Assy or Synthetic Bushing 69 - 49488 - 49488

Bills of Material

X510-5

24

Page 27

X510-5

Model 44 /216 ICA

Rear Axles for

Viper

25

Page 28

Chrysler/Dodge 44/216 ICA Rear

Exploded View

X510-5

26

Page 29

X510-5

Chrysler/Dodge 44/216 ICA Rear

Parts Listing

ITEM PART

NO. NUMBER

DESCRIPTION

1 -(3) Housing - Axle Service

2 -(1) Drive Pinion & Gear Assembly

3 - PKG - Inner Pinion Bearing Shim

(select pkg. based on thickness req)

72922-1X Inner Pinion Shim (.030 to .034)

72922-2X Inner Pinion Shim (.035 to .039)

72922-3X Inner Pinion Shim (.040 to .044)

72922-4X Inner Pinion Shim (.045 to .049)

72922-5X Inner Pinion Shim (.050 to .054)

4 707064X KIT - Inner Pinion Bearing

5 43916 Collapsible Spacer

6 706123X KIT - Outer Pinion Bearing

7 42737 Thrustwasher - Bearing

8 42449 Seal - Pinion Oil

9 42501 Seal - End Yoke

10 3-4-12211-1 End Yoke Assembly (inc 9)

11 30275 Washer - Pinion Nut

12 30271 Pinion Nut

13 38615 RTV Silicone Sealant

14 -(3) Arm - Carrier Cover Support

15 44300 Screw - Carrier Cover

16 39527 Fill Plug

17 44780 Breather Vent

ITEM PART

NO. NUMBER

DESCRIPTION

18 44467-2 Bushing - Carrier Cover

19 -(3) Differential Bearing Cap

20 41212 Bolt - Differential Bearing Cap

21 706988X KIT - Differential Bearing

22 701005X PKG - Differential Bearing Shim

23 -(1) Case - Differential

24 41221 Bolt - Drive Gear (qty 10)

25 41193 Pinion - Differential

26 46618 Gear - Differential

27 13338-3 Thrustwasher - Differential Pinion

28 41219 Shaft - Differential

29 13449 Lock - Differential Shaft

707018X KIT - Differential Plate & Disc

(inc items 30, 31, 32, 33)

30 -(4) Disc - Differential

31 -(4) Plate - Differential Pressure

32 -(4) Plate - Differential Dished

33 40835 Clip - Diff Clutch Retainer

34 -(1) Shaft - Inner Yoke (inc 35)

35 41218 Seal Defector - Inner Yoke Shaft

36 45670 Oil Seal

37 566002 Bearing - Yoke Shaft

38 41323-8 Snap Ring

(1) See "Bill of Material Table" below

(2) See "Variable Parts Table" within this section

(3) Contact Vehicle Manufacturer

(4) Not Sold Separately

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

1998-2000 Viper

606014-1 Trac Lok 3.07 75402-5X 75499X - - 74788-1X 74788-2X

2000 1/2 Viper

606521-1 Trac Lok 3.07 80739-5 80740 - - 74788-1X 74788-2X

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

27

Page 30

Notes

X510-5

28

Page 31

X510-5

Model 60 /248

Rear Axles for

B-300 Maxivan HD

29

Page 32

Chrysler/Dodge 60/248 Rear

Exploded View

X510-5

30

Page 33

X510-5

Chrysler/Dodge 60/248 Rear

Parts Listing

ITEM PART

NO. NUMBER

1 -(3) Housing - Axle Service

2 -(1) Drive Gear & Pinion Assembly

3 706046X KIT - Inner Pinion Bearing

-(2) PKG - Diff & Pinion Bearing Shim

-(2) PKG - Pinion Bearing Shim

4 -(2) Inner Pinion Bearing Shims

5 -(2) Outer Pinion Bearing Shims

5A -(2) Collapsible Spacer

6 706045X KIT - Outer Pinion Bearing

7 42737 Thrustwasher

8 -(2) Seal - Pinion Oil

9 34592 Slinger - End Yoke

10 3-4-11891-1X End Yoke (inc 9)

11 30275 Washer - Pinion Nut

12 30271 Pinion Nut

707183X KIT - Carrier Cover

13 43788 Carrier Cover

14 43180 Plug - Carrier Cover

15 34822 Bolt - Carrier Cover (qty 10)

16 34687 Gasket - Carrier Cover

38615 RTV Silicone Sealant

17 -(3) Cap - Differential Bearing

18 48632-1 Bolt - Differential Bearing Cap

19 706047X KIT - Differential Bearing

20 708012 KIT - Diff Bearing Shim (inc 16)

DESCRIPTION

(inc items 4, 5, 12, 16, 20)

(inc items 4, 5, 11, 12, 16)

(inc items 13, 14, 15, 16)

ITEM PART

NO. NUMBER

21 -(1) Case - Differential (std)

22 40638 Bolt - Drive Gear (qty 12)

23 34367 Pinion - Differential

24 34394 Gear - Differential (std)

25 34730 Thrustwasher - Differential Pinion

26 34729 Thrustwasher - Diff Gear (std)

27 30263 Shaft - Differential

28 44810 Lock - Differential Shaft

29 42928 Tone Ring (ABS)

30 44835 Bolt - Brake Mounting

31 44836 Nut - Brake Mounting

32 -(2) Hub Seal

33 -(3) KIT - Inner Wheel Bearing

34 -(3) KIT - Outer Wheel Bearing

35 -(3) Wheel Hub

36 47163 Spindle Nut

37 46545 Lockwasher / Locking Wedge

38 -(1) Shaft - Axle Flanged Drive

39 -(1) Case - Differential (t/l)

40 35803 Gear - Differential (t/l)

707083X KIT - Disc & Plate (t/l)

41 -(4) Plate - Differential Pressure

42 -(4) Disc - Differential

43 -(4) Plate - Diff(selective thickness)

44 -(4) Plate - Preload Spacer

45 40835 Clip - Diff Clutch Retainer

46 45720 Cap Screw

47 39697 Gasket

DESCRIPTION

(1) See "Bill of Material Table" on next page

(2) See "Variable Parts Table" within this section

(3) Contact Vehicle Manufacturer

(4) Not Sold Separately

(6) See Shim Table in the back of this catalog

31

Page 34

Chrysler/Dodge 60/248 Rear

X510-5

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

1999 B-300 Van w/ABS

606155-2 Trac Lok 4.09 708021-1 708013 708014 707084X 43965-2 43965-3

606156-1 Standard 4.09 708021-1 708010 708011 706043X 43965-2 43965-3

606205-2 Trac Lok 4.10 708009-2 708013 708014 707084X 43965-2 43965-3

606206-1 Standard 4.10 708009-2 708010 708011 706043X 43965-2 43965-3

606206-2 Trac Lok 4.10 708009-2 708013 708014 707084X 43965-2 43965-3

2001 B-300 Van w/ABS

606714-2 Trac Lok 4.10 708148-2 708013 708014 707084X 43965-2 43965-3

NOTE: All Ring & Pinion Kits with base number 706930 are reverse spiral bevel

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

Variable Parts Listing

Kits & Parts - Use With All Applications

Description & Item Number (Refer to

"Exploded View" at the front of this section)

606155 606156 606205 606206 606714

1 PKG - Diff & Pinion Bearing Shim - 708020 708020 - - 2 PKG - Pinion Bearing Shim - 706359X 706359X - - 3 Inner Pinion Bearing Shims 4 701012X 701012X 703018 703018 703018

4 Outer Pinion Bearing Shims 5 701012X 701012X - - 5 Collapsible Spacer 5A - - 45658 45658 45658

6 Seal - Pinion Oil 8 42449 42449 42449 42449 50637

7 Hub Seal 32 35313 43146 35313 43146 35313

Bills of Material

32

Page 35

X510-5

Model 60 /248

Rear Axles for

D2500 & W2500 Ram

33

Page 36

Chrysler /Dodge 60/248 Rear - Ram

Exploded View

X510-5

34

Page 37

X510-5

Chrysler /Dodge 60/248 Rear - Ram

Parts Listing

ITEM PART

NO. NUMBER

1 -(3) Housing - Axle Service

2 -(1) Drive Gear & Pinion Assembly

3 706046X KIT - Inner Pinion Bearing

4 701126X PKG - Inner Pinion Bearing Shim

5 45658 Collapsible Spacer

6 706045X KIT - Outer Pinion Bearing

7 42737 Thrustwasher

8 -(2) Seal - Pinion

9 -(2) Slinger - End Yoke

10 -(2) End Yoke Assembly (inc 9)

11 44167 Washer - Pinion Nut

12 30271 Pinion Nut

-(2) KIT - Carrier Cover (inc. 13, 14, 15)

13 -(2) Carrier Cover

14 43180 Plug - Carrier Cover

15 34822 Bolt - Carrier Cover (qty 10)

16 34687 Gasket - Carrier Cover

38615 RTV Silicone Sealant

17 -(3) Differential Bearing Cap

18 48632-1 Bolt - Differential Bearing Cap

19 706047X KIT - Differential Bearing

20 708012 KIT - Diff Bearing Shim (inc 16)

21 -(1) Case - Differential

22 40638 Bolt - Drive Gear (qty 12)

23 34367 Pinion - Differential

DESCRIPTION

ITEM PART

NO. NUMBER

24 34394 Gear - Differential (std)

25 34730 Thrustwasher - Differential Pinion

26 34729 Thrustwasher - Diff Gear (std)

27 30263 Shaft - Differential

28 44810 Lock - Differential Shaft

29 42928 Tone Ring (ABS Only)

30 -(2) Bolt - Brake Mounting

31 -(2) Nut - Brake Mounting

32 -(2) Seal - Hub

33 -(3) KIT - Inner Wheel Bearing

34 -(3) KIT - Outer Wheel Bearing

35 -(3) Wheel Hub

36 47163 Spindle Nut

37 46545 Locking Wedge

38 -(1) Shaft - Axle Flanged Drive

39 39697 Gasket

40 45720 Cap Screw

41 35803 Gear - Differential (t/l)

707083X KIT - Diff Plate & Disc (t/l)

42 -(4) Plate - Differential Pressure

43 -(4) Disc - Differential

44 -(4) Plate - Diff (selec. thickness)

45 -(4) Plate - Preload Spacer

46 40835 Clip - Diff Clutch Retainer

DESCRIPTION

(1) See "Bill of Material Table" on next page

(2) See "Variable Parts Table" within this section

(3) Contact Vehicle Manufacturer

(4) Not Sold Separately

35

Page 38

Chrysler /Dodge 60/248 Rear - Ram

X510-5

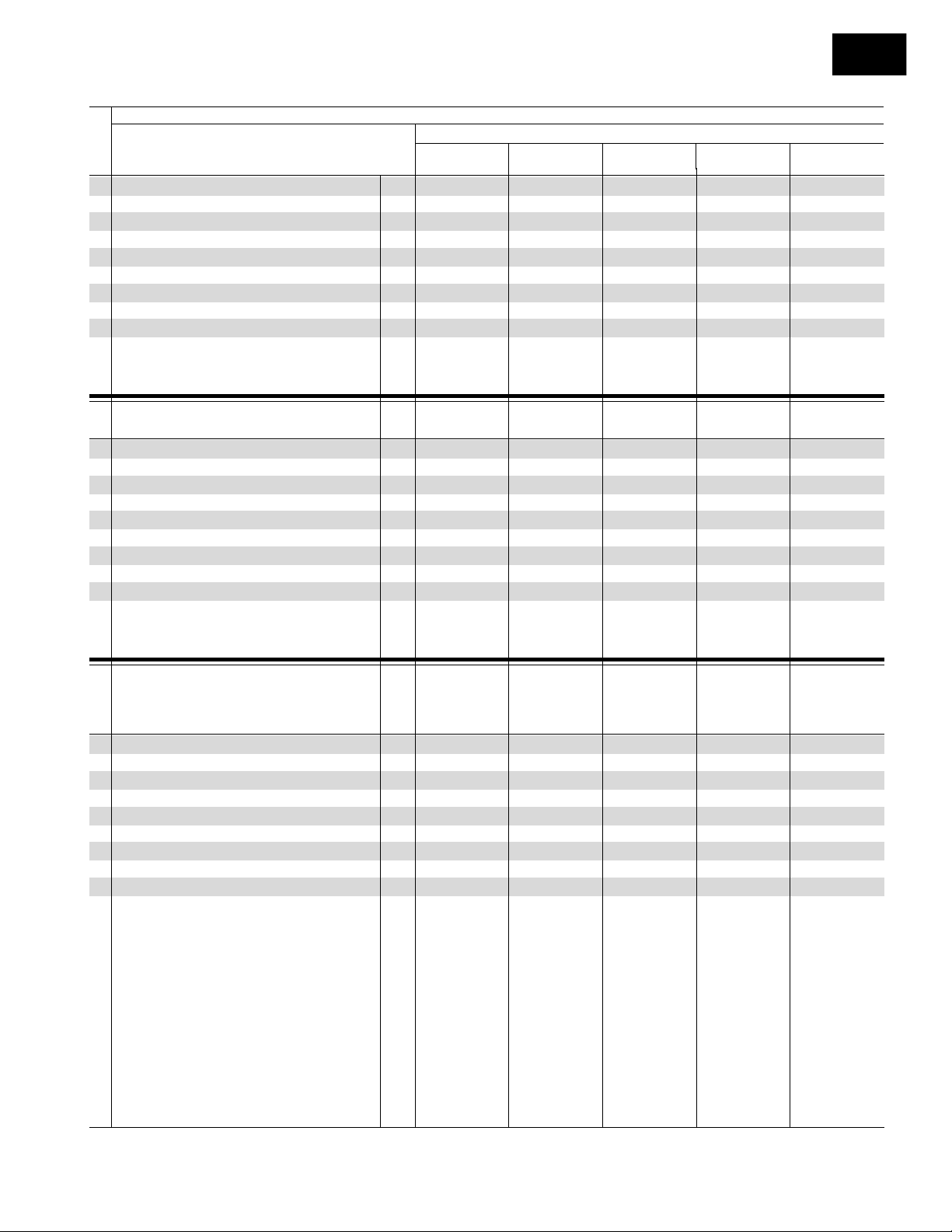

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

1999 D2500 w/ABS

606146-1 Standard 3.55 708009-1 708010 708011 706043X 43965-4 43965-4

606146-2 Trac Lok 4.10 708009-2 708013 708014 707084X 43965-4 43965-4

1999 W2500

606147-1 Standard 3.55 708009-1 708010 708011 706043X 43965-4 43965-4

606147-2 Trac Lok 4.10 708009-2 708013 708014 707084X 43965-4 43965-4

2000 D2500 w/ABS

606117-1 Standard 3.55 708009-1 708010 708011 706043X 43965-4 43965-4

606117-2 Trac Lok 4.10 708009-2 708013 708014 707084X 43965-4 43965-4

606239-1 Standard 3.55 708009-3 708010 708011 706043X 43965-4 43965-4

606239-2 Trac Lok 4.10 708009-4 708013 708014 707084X 43965-4 43965-4

606541-1 Standard 3.55 708009-3 708010 708011 706043X 43965-4 43965-4

606541-2 Trac Lok 4.10 708009-4 708013 708014 707084X 43965-4 43965-4

2000 W2500

606118-1 Standard 3.55 708009-1 708010 708011 706043X 43965-4 43965-4

606118-2 Trac Lok 4.10 708009-2 708013 708014 707084X 43965-4 43965-4

606240-1 Standard 3.55 708009-3 708010 708011 706043X 43965-4 43965-4

606240-2 Trac Lok 4.10 708009-4 708013 708014 707084X 43965-4 43965-4

606542-1 Standard 3.55 708009-3 708010 708011 706043X 43965-4 43965-4

606542-2 Trac Lok 4.10 708009-4 708013 708014 707084X 43965-4 43965-4

2001 D2500 w/ABS

606264-1 Standard 3.55 708009-3 708010 708011 706043X 43965-4 43965-4

606264-2 Trac Lok 4.10 708009-4 708013 708014 707084X 43965-4 43965-4

606705-1 Standard 3.55 708148-1 708010 708011 706043X 43965-4 43965-4

606705-2 Trac Lok 4.10 708148-2 708013 708014 707084X 43965-4 43965-4

2001 W2500

606265-1 Standard 3.55 708009-3 708010 708011 706043X 43965-4 43965-4

606265-2 Trac Lok 4.10 708009-4 708013 708014 707084X 43965-4 43965-4

606706-1 Standard 3.55 708148-1 708010 708011 706043X 43965-4 43965-4

606706-2 Trac Lok 4.10 708148-2 708013 708014 707084X 43965-4 43965-4

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

36

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

Page 39

X510-5

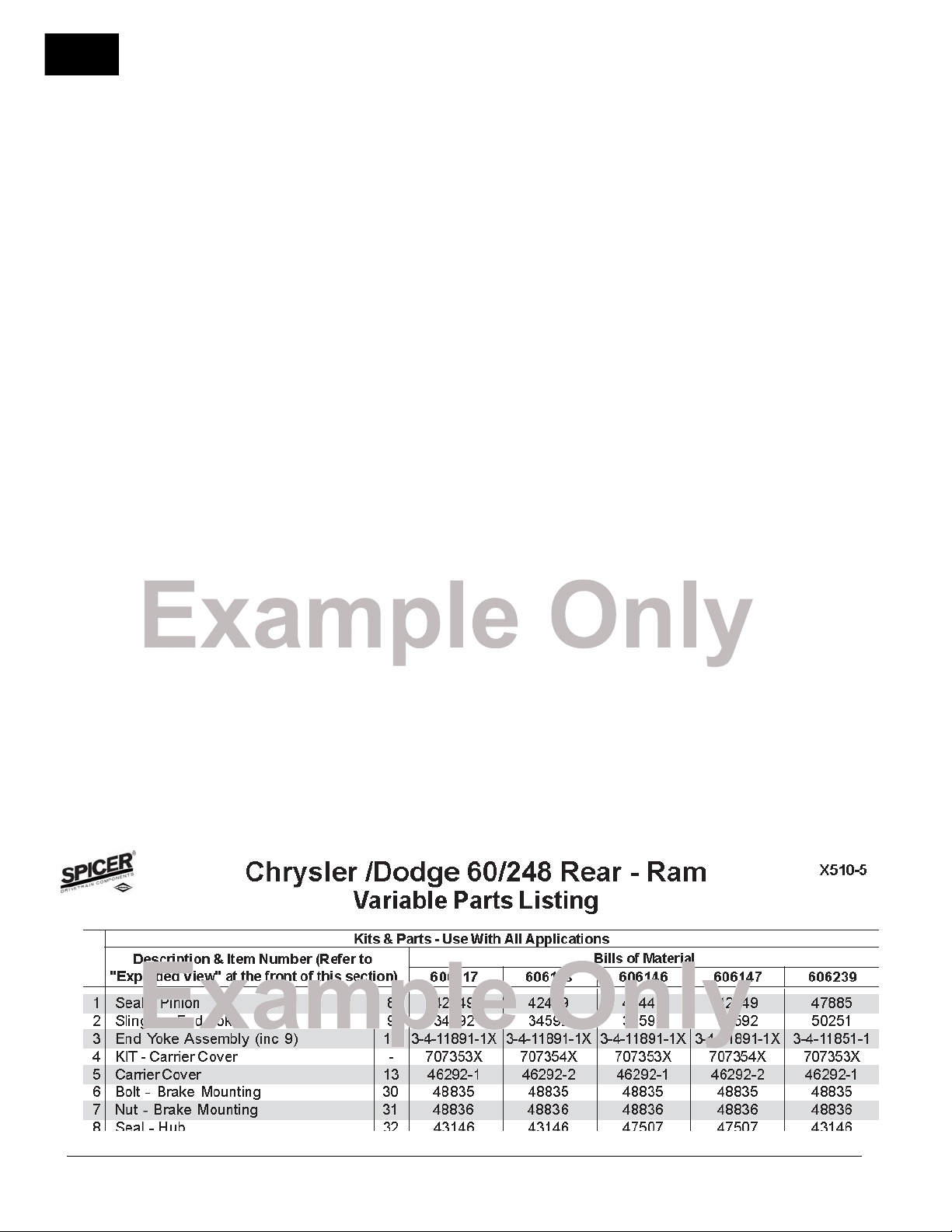

Chrysler /Dodge 60/248 Rear - Ram

Variable Parts Listing

Kits & Parts - Use With All Applications

Description & Item Number (Refer to

"Exploded View" at the front of this section)

1 Seal - Pinion 8 42449 42449 42449 42449 47885

2 Slinger - End Yoke 9 34592 34592 34592 34592 50251

3 End Yoke Assembly (inc 9) 10 3-4-11891-1X 3-4-11891-1X 3-4-11891-1X 3-4-11891-1X 3-4-11851-1

4 KIT - Carrier Cover - 707353X 707354X 707353X 707354X 707353X

5 Carrier Cover 13 46292-1 46292-2 46292-1 46292-2 46292-1

6 Bolt - Brake Mounting 30 48835 48835 48835 48835 48835

7 Nut - Brake Mounting 31 48836 48836 48836 48836 48836

8 Seal - Hub 32 43146 43146 47507 47507 43146

1 Seal - Pinion 8 47885 47885 47885 47885 47885

2 Slinger - End Yoke 9 50251 50251 50251 50251 50251

3 End Yoke Assembly (inc 9) 10 3-4-11851-1 3-4-11851-1 3-4-11851-1 3-4-11851-1 3-4-11851-1

4 KIT - Carrier Cover - 707354X 707353X 707354X 707353X 707354X

5 Carrier Cover 13 46292-2 46292-1 46292-2 46292-1 46292-2

6 Bolt - Brake Mounting 30 48835 - - 48835 48835

7 Nut - Brake Mounting 31 48836 47892 47892 48836 48836

8 Seal - Hub 32 43146 43146 43146 43146 43146

606117 606118 606146 606147 606239

606240 606264 606265 606541 606542

Bills of Material

606705 606706

1 Seal - Pinion 8 50574 50574

2 Slinger - End Yoke 9 50251 50251

3 End Yoke Assembly (inc 9) 10 3-4-11851-1 3-4-11851-1

4 KIT - Carrier Cover - 707353X 707354X

5 Carrier Cover 13 46292-1 46292-2

6 Bolt - Brake Mounting 30 - 7 Nut - Brake Mounting 31 47892 47892

8 Seal - Hub 32 43146 43146

37

Page 40

Notes

X510-5

38

Page 41

X510-5

Model 70 /267

Rear Axles for

D2500 & W2500 Ram

39

Page 42

Chrysler/Dodge 70/267 Rear - Ram

Exploded View

X510-5

40

Page 43

X510-5

Chrysler/Dodge 70/267 Rear - Ram

Parts Listing

ITEM PART

NO. NUMBER

1 -(3) Housing - Axle Service

2 -(1) Drive Gear & Pinion Assembly

3 47520(6) PKG - Inner Pinion Bearing Shim

4 706861X Kit - Inner Pinion Bearing

5 46176 Flat Spacer - Outer Pinion

6 34801(6) Outer Pinion Bearing Shims

7 706045X KIT - Outer Pinion Bearing

8 42737 Thrustwasher - Bearing

9 -(2) Seal - Pinion Oil

10 -(2) Slinger - End Yoke

11 -(2) End Yoke Assembly (inc 10)

12 44167 Washer - Pinion Nut

13 30271 Pinion Nut

-(2) Kit - Carrier Cover

14 -(2) Carrier Cover

15 43180 Plug - CarrierCover

16 34822 Bolt - Carrier Cover (qty 10)

17 34687 Gasket - Carrier Cover

18 42929 Tone Ring (ABS)

19 -(3) Differential Bearing Cap

20 48632-1 Bolt - Differential Bearing Cap

21 706047X KIT - Differential Bearing

22 708012(6) PKG - Diff Bearing Shim (inc 17)

23 -(1) Case - Differential (std)

24 40638 Bolt - Drive Gear (qty 12)

25 35080 Pinion - Differential (std)

DESCRIPTION

ITEM PART

NO. NUMBER

26 43913 Gear - Differential (std)

27 35082 Thrustwasher - Diff Pinion (std)

28 34729 Thrustwasher - Diff Gear (std)

29 46640 Shaft - Differential (std)

30 47024 Lock - Differential Shaft

31 -(2) Bolt - Brake Mounting

32 -(2) Nut - Brake Mounting

33 -(2) Seal - Hub

34 -(3) KIT - Inner Wheel Bearing

35 -(3) Wheel Hub

36 -(3) KIT - Outer Wheel Bearing

37 47163 Spindle Nut

38 46545 Locking Wedge

39 39697 Gasket - Axle Shaft

40 -(1) Shaft - Axle Flange Drive

41 -(1) Case - Differential (p/l)

42 42522 Ring - Differential Gear

707075X KIT - Disc & Plate (p/l)

43 -(4) Plate - Differential

44 -(4) Disc - Differential Dished

45 -(4) Plate - Differential

46 43914 Gear - Differential (p/l)

47 31040 Pinion - Differential (p/l)

48 31041 Shaft - Differential (p/l)

49 45720 Screw - Axle Shaft

50 41610-1 Flange Head Screw

DESCRIPTION

(1) See "Bill of Material Table" on next page

(2) See "Variable Parts Table" within this section

(3) Contact Vehicle Manufacturer

(4) Not Sold Separately

(6) See Shim Table in the back of this catalog

41

Page 44

Chrysler/Dodge 70/267 Rear - Ram

X510-5

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

1999 D2500 Air Force Tow Vehicle w/ABS

606164-2 Powr Lok 7.17 708015-3 708024 708025 707254X 43811-12 43811-12

606165-2 Powr Lok 7.17 708015-3 708024 708025 707254X 43811-12 43811-12

1999 D2500 w/ABS

606149-1 Standard 3.54 708015-1 708016 708017 707252X 43811-12 43811-12

606149-2 Powr Lok 3.54 708015-1 708018 708019 707254X 43811-12 43811-12

606149-3 Standard 4.10 708015-2 708016 708017 707252X 43811-12 43811-12

606149-4 Powr Lok 4.10 708015-2 708018 708019 707254X 43811-12 43811-12

1999 W2500

606148-1 Standard 3.54 708015-1 708016 708017 707252X 43811-12 43811-12

606148-2 Powr Lok 3.54 708015-1 708018 708019 707254X 43811-12 43811-12

606148-3 Standard 4.10 708015-2 708016 708017 707252X 43811-12 43811-12

606148-4 Powr Lok 4.10 708015-2 708018 708019 707254X 43811-12 43811-12

2000 D2500 w/ABS

606120-1 Standard 3.54 708015-1 708016 708017 707252X 43811-12 43811-12

606120-2 Powr Lok 3.54 708015-1 708018 708019 707254X 43811-12 43811-12

606120-3 Standard 4.10 708015-2 708016 708017 707252X 43811-12 43811-12

606120-4 Powr Lok 4.10 708015-2 708018 708019 707254X 43811-12 43811-12

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

606241-1 Standard 3.54 708015-4 708016 708017 707252X 43811-12 43811-12

606241-2 Powr Lok 3.54 708015-4 708018 708019 707254X 43811-12 43811-12

606241-3 Standard 4.10 708015-5 708016 708017 707252X 43811-12 43811-12

606241-4 Powr Lok 4.10 708015-5 708018 708019 707254X 43811-12 43811-12

606543-1 Standard 3.54 708015-4 708016 708017 707252X 43811-12 43811-12

606543-2 Powr Lok 3.54 708015-4 708018 708019 707254X 43811-12 43811-12

606543-3 Standard 4.10 708015-5 708016 708017 707252X 43811-12 43811-12

606543-4 Powr Lok 4.10 708015-5 708018 708019 707254X 43811-12 43811-12

2000 D2500 Air Force Tow Vehicle w/ABS

606249-1 Standard 7.17 708015-6 708022 708023 707252X 43811-12 43811-12

606249-2 Powr Lok 7.17 708015-6 708024 708025 707254X 43811-12 43811-12

2000 W2500

606119-1 Standard 3.54 708015-1 708016 708017 707252X 43811-12 43811-12

606119-2 Powr Lok 3.54 708015-1 708018 708019 707254X 43811-12 43811-12

606119-3 Standard 4.10 708015-2 708016 708017 707252X 43811-12 43811-12

606119-4 Powr Lok 4.10 708015-2 708018 708019 707254X 43811-12 43811-12

606242-1 Standard 3.54 708015-4 708016 708017 707252X 43811-12 43811-12

606242-2 Powr Lok 3.54 708015-4 708018 708019 707254X 43811-12 43811-12

606242-3 Standard 4.10 708015-5 708016 708017 707252X 43811-12 43811-12

606242-4 Powr Lok 4.10 708015-5 708018 708019 707254X 43811-12 43811-12

606544-1 Standard 3.54 708015-4 708016 708017 707252X 43811-12 43811-12

606544-2 Powr Lok 3.54 708015-4 708018 708019 707254X 43811-12 43811-12

606544-3 Standard 4.10 708015-5 708016 708017 707252X 43811-12 43811-12

606544-4 Powr Lok 4.10 708015-5 708018 708019 707254X 43811-12 43811-12

42

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

Page 45

X510-5

Chrysler/Dodge 70/267 Rear - Ram

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

2000 W2500 Air Force Tow Vehicle w/ABS

606250-1 Standard 7.17 708015-6 708022 708023 707252X 43811-12 43811-12

606250-2 Powr Lok 7.17 708015-6 708024 708025 707254X 43811-12 43811-12

2001 D2500 w/ABS

606266-1 Standard 3.54 708015-4 708016 708017 707252X 43811-12 43811-12

606266-2 Powr Lok 3.54 708015-4 708018 708019 707254X 43811-12 43811-12

606266-3 Standard 4.10 708015-5 708016 708017 707252X 43811-12 43811-12

606266-4 Powr Lok 4.10 708015-5 708018 708019 707254X 43811-12 43811-12

606707-1 Standard 3.54 708149-1 708016 708017 707252X 43811-12 43811-12

606707-2 Powr Lok 3.54 708149-1 708018 708019 707254X 43811-12 43811-12

606707-3 Standard 4.10 708149-2 708016 708017 707252X 43811-12 43811-12

606707-4 Powr Lok 4.10 708149-2 708018 708019 707254X 43811-12 43811-12

2001 D2500 Air Force Tow Vehicle w/ABS

606274-1 Standard 7.17 708015-6 708022 708023 707252X 43811-12 43811-12

606274-2 Powr Lok 7.17 708015-6 708024 708025 707254X 43811-12 43811-12

2001 W2500

606267-1 Standard 3.54 708015-4 708016 708017 707252X 43811-12 43811-12

606267-2 Powr Lok 3.54 708015-4 708018 708019 707254X 43811-12 43811-12

606267-3 Standard 4.10 708015-5 708016 708017 707252X 43811-12 43811-12

606267-4 Powr Lok 4.10 708015-5 708018 708019 707254X 43811-12 43811-12

606708-1 Standard 3.54 708149-1 708016 708017 707252X 43811-12 43811-12

606708-2 Powr Lok 3.54 708149-1 708018 708019 707254X 43811-12 43811-12

606708-3 Standard 4.10 708149-2 708016 708017 707252X 43811-12 43811-12

606708-4 Powr Lok 4.10 708149-2 708018 708019 707254X 43811-12 43811-12

2001 W2500 Air Force Tow Vehicle w/ABS

606273-1 Standard 7.17 708015-6 708022 708023 707252X 43811-12 43811-12

606273-2 Powr Lok 7.17 708015-6 708024 708025 707254X 43811-12 43811-12

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

43

Page 46

Chrysler/Dodge 70/267 Rear - Ram

X510-5

Variable Parts Listing

Kits & Parts - Use With All Applications

Description & Item Number (Refer to the

"Exploded View" at the front of this section)

1 Seal - Pinion Oil 9 42449 42449 42449 42449 42449

2 Slinger - End Yoke 10 34592 34592 34592 34592 34592

3 End Yoke Assembly (inc 10) 11 3-4-11891-1X 3-4-11891-1X 3-4-11891-1X 3-4-11891-1X 3-4-11891-1X

4 Kit - Carrier Cover - 707351X 707352X 707351X 707352X 707351X

5 Carrier Cover 14 46293-2 46293-1 46293-2 46293-1 46293-2

6 Bolt - Brake Mounting 31 48835 48835 48835 48835 48835

7 Nut - Brake Mounting 32 48836 48836 48836 48836 48836

8 Seal - Hub 33 43146 43146 47507 47507 47507

1 Seal - Pinion Oil 9 42449 47885 47885 47885 47885

2 Slinger - End Yoke 10 34592 50251 50251 50251 50251

3 End Yoke Assembly (inc 10) 11 3-4-11891-1X 3-4-11851-1 3-4-11851-1 3-4-11851-1 3-4-11851-1

4 Kit - Carrier Cover - 707352X 707352X 707351X 707352X 707351X

5 Carrier Cover 14 46293-1 46293-1 46293-2 46293-1 46293-2

6 Bolt - Brake Mounting 31 48835 48835 48835 48835 48835

7 Nut - Brake Mounting 32 48836 48836 48836 48836 48836

8 Seal - Hub 33 47507 43146 43146 43146 43146

606119 606120 606148 606149 606164

606165 606241 606242 606249 606250

Bills of Material

606266 606267 606273 606274 606543

1 Seal - Pinion Oil 9 47885 47885 47885 47885 47885

2 Slinger - End Yoke 10 50251 50251 50251 50251 50251

3 End Yoke Assembly (inc 10) 11 3-4-11851-1 3-4-11851-1 3-4-11851-1 3-4-11851-1 3-4-11851-1

4 Kit - Carrier Cover - 707352X 707351X 707351X 707352X 707352X

5 Carrier Cover 14 46293-1 46293-2 46293-2 46293-1 46293-1

6 Bolt - Brake Mounting 31 - - - - 48835

7 Nut - Brake Mounting 32 47892 47892 47892 47892 48836

8 Seal - Hub 33 43146 43146 43146 43146 43146

606544 606707 606708

1 Seal - Pinion Oil 9 47885 50574 50574

2 Slinger - End Yoke 10 50251 50251 50251

3 End Yoke Assembly (inc 10) 11 3-4-11851-1 3-4-11851-1 3-4-11851-1

4 Kit - Carrier Cover - 707351X 707352X 707351X

5 Carrier Cover 14 46293-2 46293-1 46293-2

6 Bolt - Brake Mounting 31 48835 - 7 Nut - Brake Mounting 32 48836 47892 47892

8 Seal - Hub 33 43146 43146 43146

44

Page 47

X510-5

Model 80 /286

Rear Axles for

D2500, D3500, W2500 & Sweptline Vehicle

45

Page 48

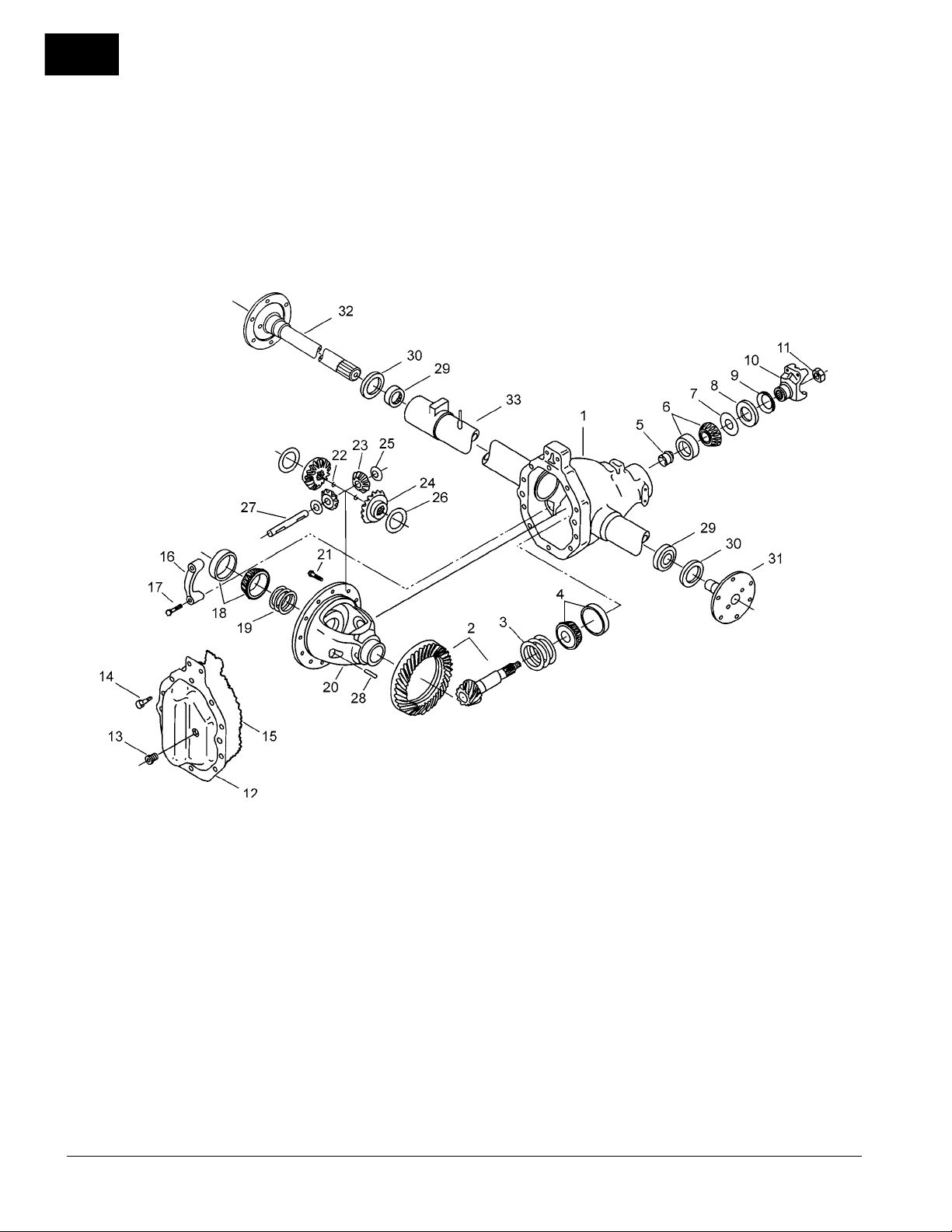

Chrysler/Dodge 80/286 Rear

Exploded View

X510-5

46

Page 49

X510-5

Chrysler/Dodge 80/286 Rear

Parts Listing

ITEM PART

NO. NUMBER

1 -(3) Housing - Axle Service

2 -(1) Drive Pinion & Gear Assembly

3 707065X KIT - Inner Pinion Bearing

707066X PKG - Pinion Bearing Shim

708036 PKG - Diff & Pinion Bearing Shim

4 -(4) Inner Pinion Bearing Shims

5 -(4) Outer Pinion Bearing Shims

6 707064X KIT - Outer Pinion Bearing

7 42430 Thrustwasher - Bearing

8 -(2) Seal - Pinion Oil

9 -(2) Seal - Deflector

9A -(2) Seal - V-Ring

10 -(2) End Yoke Assembly

11 37104 Washer - Pinion Nut

12 37082 Pinion Nut

-(2) KIT - Carrier Cover

13 -(2) Carrier Cover

14 38637 Plug - Carrier Cover

15 -(2) Bolt - Carrier Cover

16 38615 RTV Silicone Sealant

17 -(3) Differential Bearing Cap

18 48632-1 Bolt - Differential Bearing Cap

19 707069X KIT - Outboard Bearing Spacer

20 706070X KIT - Differential Bearing

21 708035(6) PKG - Differential Bearing Shim

22 -(1) Case - Differential (std)

DESCRIPTION

(inc items 4, 5, 11, 12)

(inc items 4, 5, 11, 12, 21)

(inc items 13, 14, 15, 16)

ITEM PART

NO. NUMBER

23 42413 Pinion - Differential (std)

24 35082 Thrustwasher - Differential Pinion

25 42411 Gear - Differential (std)

26 34729 Thrustwasher - Differential Gear

27 46640 Shaft - Differential

28 47024 Lock - Differential Shaft

29 42433 Bolt - Drive Gear

30 42414 Tone Ring (ABS)

31 -(2) Seal - Inner Wheel

32 -(3) Bearing - Inner Wheel

33 -(3) Hub Assembly

34 -(3) Bearing - Outer Wheel

35 47163 Spindle Nut

36 46545 Locking Wedge

37 39697 Gasket

38 -(1) Axle Shaft

39 45720 Screw - Flange Head

40 -(1) Case - Differential

41 41610-1 Screw - Flange Head

42 47802 Shaft - Differential (t/l)

43 47798 Pinion - Differential (t/l)

44 47796 Gear - Differential (t/l)

701129X KIT - Diff Plate & Disc (p/l)

2003819 KIT - Diff Plate & Disc (t/l)

45 -(4) Disc - Differential Dished

46 -(4) Plate - Diff Pressure

47 -(4) Disc - Diff Clutch

48 47800 Thrustwasher - Pinion Diff (t/l)

DESCRIPTION

(1) See "Bill of Material Table" on next page

(2) See "Variable Parts Table" within this section

(3) Contact Vehicle Manufacturer

(4) Not Sold Separately

(6) See Shim Table in the back of this catalog

(9) NOTE: When replacing a model 80/286 Power-Lok component or case assembly, the complete Power-Lok case assembly or

component must be replaced with a Track-Lok case assembly. The only Power-Lok component currently available is disc and

plate kit 701129X.

47

Page 50

Chrysler/Dodge 80/286 Rear

X510-5

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Axle Axle Kits Shaft & Joint Assy.

Differential

Bill of

Bill of

Material

Material

Diff.

Diff.

Type

Type

Ratio

Ratio

Ring Gear &

Ring Gear &

Pinion Kit

Pinion Kit

(7)

(7)

Case Assy.

Case Assy.

(8)

(8)

Kit

Kit

1999 D2500 w/ABS

606150-1 Standard 3.54 708026-1 708027 708028 707063X 45553-1 45553-1

606150-2 Trac Lok 3.54 708026-1 2011842(9) 708055(9) 2003857(9) 45553-1 45553-1

606150-3 Standard 4.10 708026-2 708031 708032 707063X 45553-1 45553-1

606150-4 Trac Lok 4.10 708026-2 2011841(9) 708053(9) 2003857(9) 45553-1 45553-1

1999 D3500 w/ABS

606152-1 Standard 3.54 708026-1 708027 708028 707063X 45553-2 45553-2

606152-2 Trac Lok 3.54 708026-1 2011842(9) 708055(9) 2003857(9) 45553-2 45553-2

606152-3 Standard 4.10 708026-2 708031 708032 707063X 45553-2 45553-2

606152-4 Trac Lok 4.10 708026-2 2011841(9) 708053(9) 2003857(9) 45553-2 45553-2

1999 D/W3500 w/ABS

606154-1 Standard 3.54 708026-1 708027 708028 707063X 45553-3 45553-3

606154-2 Trac Lok 3.54 708026-1 2011842(9) 708055(9) 2003857(9) 45553-3 45553-3

606154-3 Standard 4.10 708026-2 708031 708032 707063X 45553-3 45553-3

606154-4 Trac Lok 4.10 708026-2 2011841(9) 708053(9) 2003857(9) 45553-3 45553-3

1999 W2500

606151-1 Standard 3.54 708026-1 708027 708028 707063X 45553-1 45553-1

606151-2 Trac Lok 3.54 708026-1 2011842(9) 708055(9) 2003857(9) 45553-1 45553-1

606151-3 Standard 4.10 708026-2 708031 708032 707063X 45553-1 45553-1

606151-4 Trac Lok 4.10 708026-2 2011841(9) 708053(9) 2003857(9) 45553-1 45553-1

1999 W3500

606153-1 Standard 3.54 708026-1 708027 708028 707063X 45553-2 45553-2

606153-2 Trac Lok 3.54 708026-1 2011842(9) 708055(9) 2003857(9) 45553-2 45553-2

606153-3 Standard 4.10 708026-2 708031 708032 707063X 45553-2 45553-2

606153-4 Trac Lok 4.10 708026-2 2011841(9) 708053(9) 2003857(9) 45553-2 45553-2

2000 D2500 w/ABS

606114-1 Standard 3.54 708026-1 708027 708028 707063X 45553-1 45553-1

606114-2 Trac Lok 3.54 708026-1 2011842 708055 2003857 45553-1 45553-1

606114-3 Standard 4.10 708026-2 708031 708032 707063X 45553-1 45553-1

606114-4 Trac Lok 4.10 708026-2 2011841 708053 2003857 45553-1 45553-1

606243-1 Standard 3.54 708026-3 708027 708028 707063X 45553-1 45553-1

606243-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-1 45553-1

606243-3 Standard 4.10 708026-4 708031 708032 707063X 45553-1 45553-1

606243-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-1 45553-1

606545-1 Standard 3.54 708026-3 708027 708028 707063X 45553-1 45553-1

606545-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-1 45553-1

606545-3 Standard 4.10 708026-4 708031 708032 707063X 45553-1 45553-1

Differential

Case Kit

Case Kit

Inner Parts

Inner Parts

Kit

Kit

Right Hand

Right Hand

Shaft Assy.

Shaft Assy.

Left Hand

Left Hand

Shaft Assy.

Shaft Assy.

48

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

(9) NOTE: When replacing a model 80/286 Power-Lok component or case assembly, the complete Power-Lok case assembly or

component must be replaced with a Track-Lok case assembly. The only Power-Lok component currently available is disc and

plate kit 701129X.

Page 51

X510-5

Chrysler/Dodge 80/286 Rear

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

2000 D3500 w/ABS

606112-1 Standard 3.54 708026-1 708027 708028 707063X 45553-2 45553-2

606112-2 Trac Lok 3.54 708026-1 2011842 708055 2003857 45553-2 45553-2

606112-3 Standard 4.10 708026-2 708031 708032 707063X 45553-2 45553-2

606112-4 Trac Lok 4.10 708026-2 2011841 708053 2003857 45553-2 45553-2

606245-1 Standard 3.54 708026-3 708027 708028 707063X 45553-2 45553-2

606245-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-2 45553-2

606245-3 Standard 4.10 708026-4 708031 708032 707063X 45553-2 45553-2

606245-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-2 45553-2

606547-1 Standard 3.54 708026-3 708027 708028 707063X 45553-2 45553-2

606547-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-2 45553-2

606547-3 Standard 4.10 708026-4 708031 708032 707063X 45553-2 45553-2

606547-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-2 45553-2

2000 D/W3500 w/ABS

606113-1 Standard 3.54 708026-1 708027 708028 707063X 45553-3 45553-3

606113-2 Trac Lok 3.54 708026-1 2011842 708055 2003857 45553-3 45553-3

606113-3 Standard 4.10 708026-2 708031 708032 707063X 45553-3 45553-3

606113-4 Trac Lok 4.10 708026-2 2011841 708053 2003857 45553-3 45553-3

606247-1 Standard 3.54 708026-3 708027 708028 707063X 45553-3 45553-3

606247-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-3 45553-3

606247-3 Standard 4.10 708026-4 708031 708032 707063X 45553-3 45553-3

606247-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-3 45553-3

606549-1 Standard 3.54 708026-3 708027 708028 707063X 45553-3 45553-3

606549-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-3 45553-3

606549-3 Standard 4.10 708026-4 708031 708032 707063X 45553-3 45553-3

606549-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-3 45553-3

2000 W2500

606115-1 Standard 3.54 708026-1 708027 708028 707063X 45553-1 45553-1

606115-2 Trac Lok 3.54 708026-1 2011842 708055 2003857 45553-1 45553-1

606115-3 Standard 4.10 708026-2 708031 708032 707063X 45553-1 45553-1

606115-4 Trac Lok 4.10 708026-2 2011841 708053 2003857 45553-1 45553-1

606244-1 Standard 3.54 708026-3 708027 708028 707063X 45553-1 45553-1

606244-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-1 45553-1

606244-3 Standard 4.10 708026-4 708031 708032 707063X 45553-1 45553-1

606244-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-1 45553-1

606546-1 Standard 3.54 708026-3 708027 708028 707063X 45553-1 45553-1

606546-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-1 45553-1

606546-3 Standard 4.10 708026-4 708031 708032 707063X 45553-1 45553-1

606546-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-1 45553-1

Differential

Case Kit

Inner Parts

Kit

Right Hand

Shaft Assy.

Left Hand

Shaft Assy.

(7) See Ring Gear & Pinion Kits in XGI Catalog for ratio & tooth combinations.

(8) See Differential Case Assy Kits in XGI Catalog for spline data & ratios.

49

Page 52

Chrysler/Dodge 80/286 Rear

X510-5

Bill of Material Table

Axle Axle Kits Shaft & Joint Assy.

Bill of

Material

Diff.

Type

Ratio

Ring Gear &

Pinion Kit

(7)

Case Assy.

(8)

Kit

2000 W3500

606111-1 Standard 3.54 708026-1 708027 708028 707063X 45553-2 45553-2

606111-2 Trac Lok 3.54 708026-1 2011842 708055 2003857 45553-2 45553-2

606111-3 Standard 4.10 708026-2 708031 708032 707063X 45553-2 45553-2

606111-4 Trac Lok 4.10 708026-2 2011841 708053 2003857 45553-2 45553-2

606246-1 Standard 3.54 708026-3 708027 708028 707063X 45553-2 45553-2

606246-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-2 45553-2

606246-3 Standard 4.10 708026-4 708031 708032 707063X 45553-2 45553-2

606246-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-2 45553-2

606548-1 Standard 3.54 708026-3 708027 708028 707063X 45553-2 45553-2

606548-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-2 45553-2

606548-3 Standard 4.10 708026-4 708031 708032 707063X 45553-2 45553-2

606548-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-2 45553-2

2001 W2500

606272-1 Standard 3.54 708026-3 708027 708028 707063X 45553-1 45553-1

606272-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-1 45553-1

606272-3 Standard 4.10 708026-4 708031 708032 707063X 45553-1 45553-1

606272-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-1 45553-1

606710-1 Standard 3.54 708150-1 708027 708028 707063X 45553-1 45553-1

606710-2 Trac Lok 3.54 708150-1 2011842 708055 2003857 45553-1 45553-1

606710-3 Standard 4.10 708150-2 708031 708032 707063X 45553-1 45553-1

606710-4 Trac Lok 4.10 708150-2 2011841 708053 2003857 45553-1 45553-1

2001 W3500

606268-1 Standard 3.54 708026-3 708027 708028 707063X 45553-2 45553-2

606268-2 Trac Lok 3.54 708026-3 2011842 708055 2003857 45553-2 45553-2

606268-3 Standard 4.10 708026-4 708031 708032 707063X 45553-2 45553-2

606268-4 Trac Lok 4.10 708026-4 2011841 708053 2003857 45553-2 45553-2

606712-1 Standard 3.54 708150-1 708027 708028 707063X 45553-2 45553-2

606712-2 Trac Lok 3.54 708150-1 2011842 708055 2003857 45553-2 45553-2

606712-3 Standard 4.10 708150-2 708031 708032 707063X 45553-2 45553-2

606712-4 Trac Lok 4.10 708150-2 2011841 708053 2003857 45553-2 45553-2

2001 D2500 w/ABS