Page 1

Datalogging Manometer

840086, 840098 and 840099

Instruction Manual

Page 2

TABLE OF CONTENTS

Introduction ………………………….. 3

Front Panel Descriptions

Set-up ………………………….. 5-6

Calibration ………………………….. 7

Measurement Procedures ………………………….. 8-14

Error Codes ………………………….. 14

Auto Power Off ………………………….. 14

Battery Replacement ………………………….. 15

Specifications ………………………….. 15-16

Software Configuration ………………………….. 17-19

Accessories ………………………….. 19

………………………….. 4

FIRST TIME USE

Before using the Manometer the first time ensure that the

user-defined settings have been configured (see page 5),

and that the meter has been calibrated (see page 7)

Page 3

INTRODUCTION

This Manometer is ideal for measuring gauge pressure and

low differential pressure in clean rooms, test and balance,

medical equipment, HVAC, pneumatic

systems and computer peripherals.

Features a user-friendly interface with a large backlight

display, automatic data logging, measurement of single

and multiple points and a tripod mount.

The RS232 port, cable and software enable

communication with a

computer.

Powered by 4-AAA batteries (included), or an optional 9V

adaptor.

Gauge Pressure:

A measure of pressure in PSI that refers to ambient

pressure.

Differential Pressure: Measurement of the difference

between two pressures.

3

Page 4

View

previous/

next

record

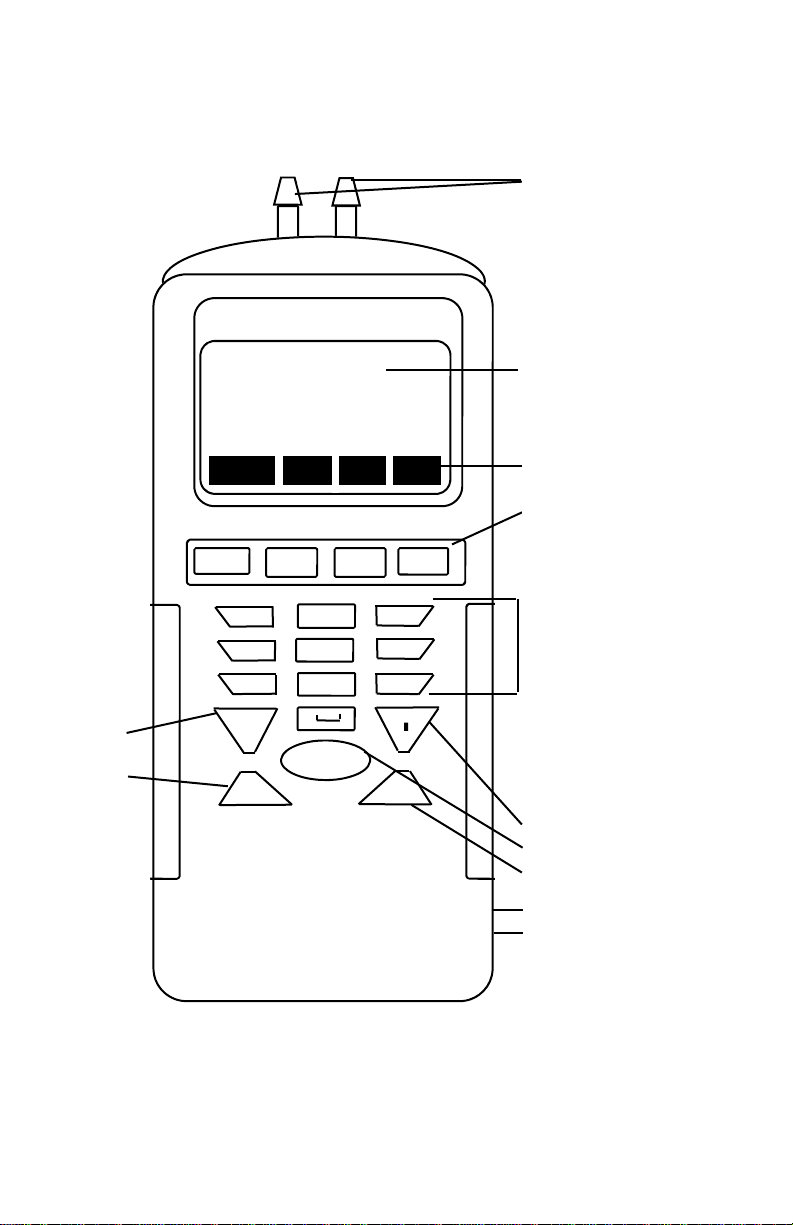

FRONT PANEL DESCRIPTION

Connectors

Welcome

MEAS MEM LOG SET

F1 F2 F3 F4

1 SYM. 2 ABC DEF 3

4 GHI 5 JKL MN0 6

7 PQRS 8 TUV WXYZ 9

0 ☼

▲

ON/OFF

▼

Display

On Screen prompts

correspond to the

F1-F4 buttons.

Keypad, press:

1 for 1*:$+-=,

2 for 2abcABC

3 for 3defDEF

4 for 4ghiGHI

5 for 5jklJKL

6 for 6mnoMNO

7 for 7pqrsPQRS

8 for 8tuvTUV

9 for 9wxyzWXYZ

0 for 0 and space

Backlight

On/Off

Not Applicable

DC 9V Adaptor Port

RS232 Port

4

Page 5

SET-UP PROCEDURE

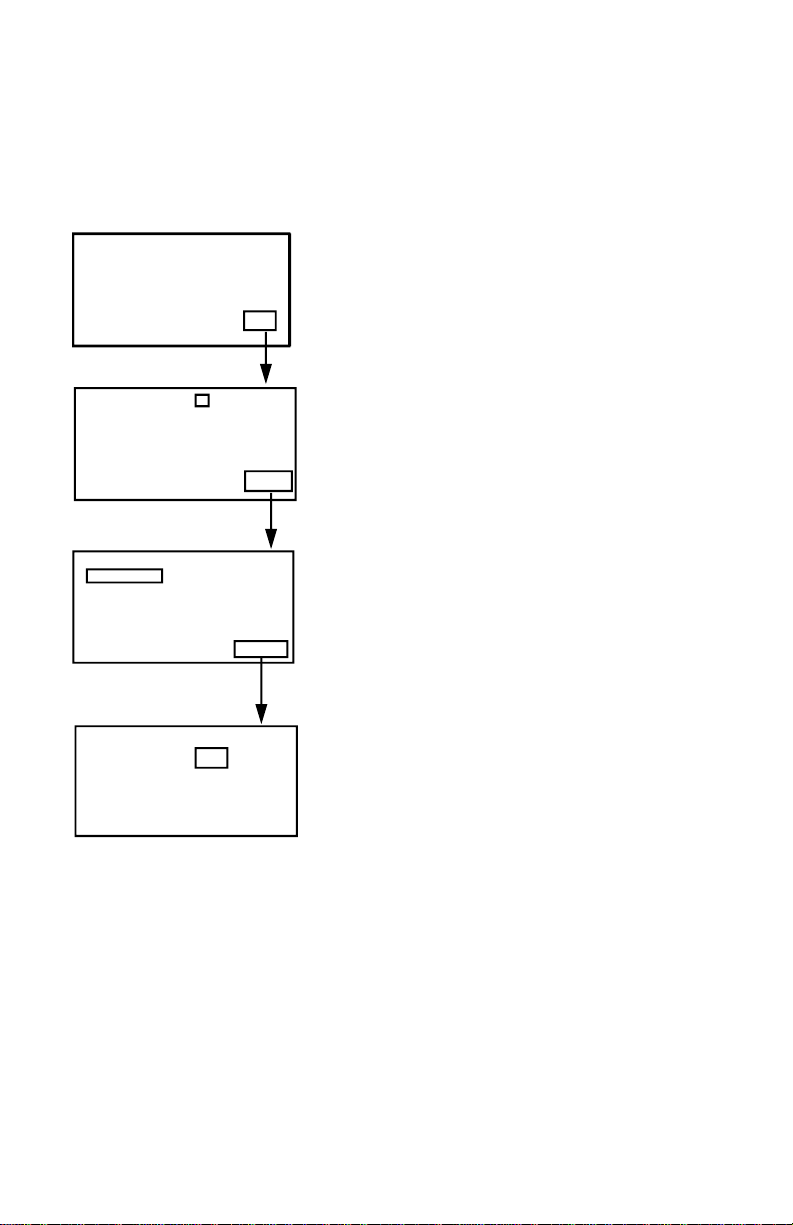

Turn the meter on using the ON/OFF button. You will see

the Welcome menu shown below.

Welcome

MEAS MEM LOG SET

LCD Cont. (1-5): 3

Prn Cont. (1-9): 5

Auto Off: 20mins

Enable

EXIT EDIT NEXT

Set Clock:

MM-DD-YY HH:MM:SS

06-30-05 18 : 29 : 20

Set ID: Disable

ID: User Name

EXIT EDIT NEXT

1. Press F4 (SET) to enter the set-

up mode.

2. Use the ▲ or ▼ buttons to move

the on-screen cursor, F2 (EDIT),

and the Keypad to input chang-

es.

3. If changes are made, press the

F4 (Enter) button to save the new

settings or F1 (ABORT) to cancel

the change.

4. Press F4 (NEXT) to access the

next page.

Select Item

P psi

EXIT EDIT BACK

5. Press F1 (EXIT) to return to the

Welcome menu.

5

Page 6

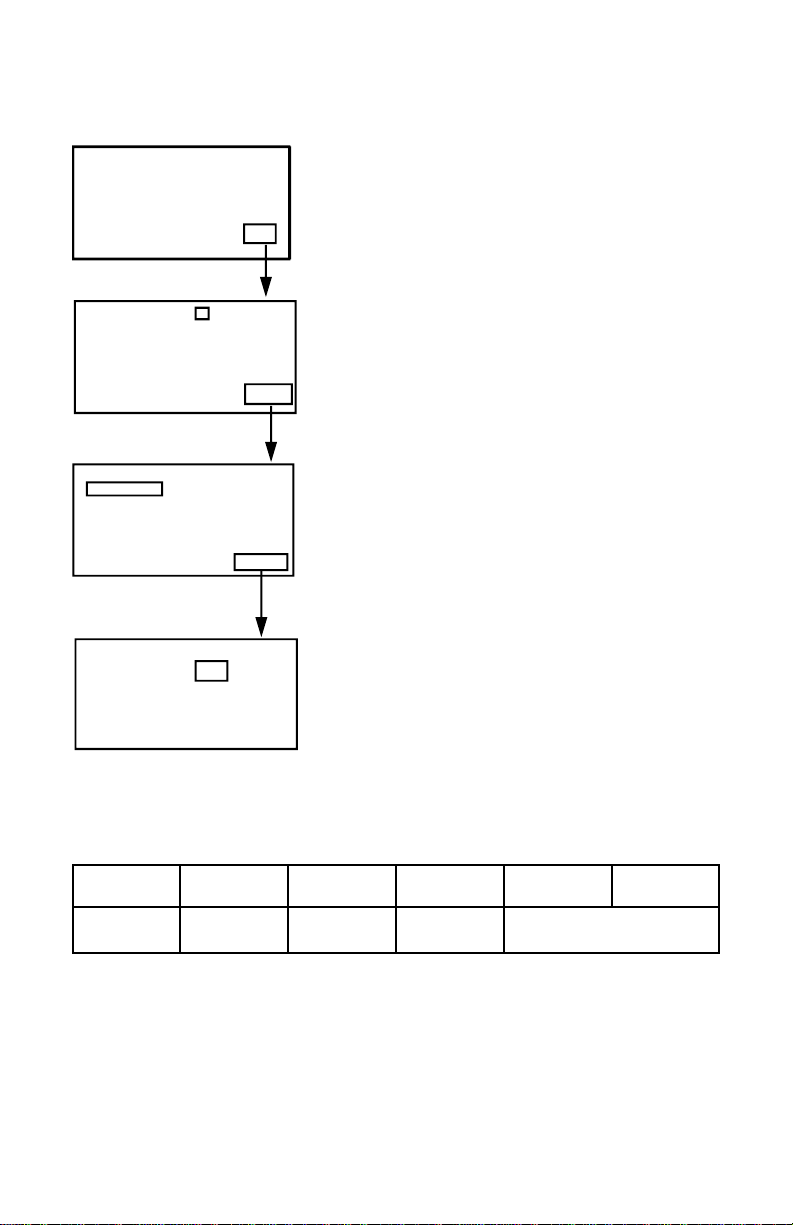

SET-UP PROCEDURE

Welcome

MEAS MEM LOG SET

LCD Cont. (1-5): 3

Prn Cont. (1-9): 5

Auto Off: 20mins

Enable

EXIT EDIT NEXT

Set Clock:

MM-DD-YY HH:MM:SS

06-30-05 18 : 29 : 20

Set ID: Disable

ID: User Name

EXIT EDIT NEXT

Select Item

P psi

EXIT EDIT BACK

1.LCD Cont. (1-5): Display con-

trast, 5 = least contrast.

2.Auto Off: 1~20 minutes, Enable/

Disable.

3.Set Clock: Select the date mode

MM-DD-YY, DD-MM-YY or

YY-MM-DD and set local time.

4.Set ID: Enable/Disable datalog-

ging.

5.ID: Alpha/numeric user name.

6.Select Item: Press F2 (EDIT) to

select X = not selected,

√ = selected.

7.Press the F2 (EDIT), ▲ or ▼

buttons to cycle through the 11

units of measure shown below:

PSI inH2 kPa ftH2 inHg cmH2

mbar bar mmHg ozin kgcm

6

Page 7

CALIBRATION

Calibration

1. Full (HI-LOW) calibration requires a standard manometer calibrator and should be performed by a professional

calibration laboratory. Contact Sper Scientific.

2. To perform a ZERO calibration, disconnect all tubes and

do not apply pressure to the connectors.

3. Press F1 (MEAS) followed by F3 (Cali) - “Calibration” is

displayed.

3. Press F4 (ZER0) and “Cali: 0.000 PSI” will be displayed.

4. Press F4 (ENTER) again - after approximately 3 se-

conds the meter will display “OK” to indicate that the

calibration was successful.

5. If NG (No Good) is displayed, perform the calibration

again. If the meter fails to calibrate after three (3)

attempts, it should be returned to Sper Scientific.

7

Page 8

MEASUREMENT PROCEDURES

Measurement Modes

The unit offers three (3) measurement modes:

1. F1 (MEAS) Single Measurement

2. F2 (MEM) Multiple Measurement

3. F3 (LOG) Auto Logging

Single Measurement

Welcome

MEAS MEM LOG SET

EXIT REC Cali

Max: 1.2psi

Min: -1.2psi

Avg: 0.4psi

Curr: 0.1psi

EXIT

P: 0.1 psi

Pressure

1. Ensure the tubing is connected

and not leaking or damaged.

2. Press F1 (MEAS) to take a

single pressure measurement.

3. Once a pressure is detected

the reading is displayed.

4. If desired, press F2 (REC) to

display the real-time Max., Min.

and Avg. pressure and last

pressure readings.

5. Press F1 (EXIT) to return to the

Welcome menu.

8

Page 9

MEASUREMENT PROCEDURES

Multiple Measurement

Manually record up to 99 data points with time & date and

your filename.

Welcome

MEAS MEM LOG

0.

P.

1

P.

02

P.

EXIT MEAS EDIT

0.1

0.

P.

1

P.

02

P.

EXIT CLR BACK

P. 0.100psi

ABORT SAVE

06:30:23:56:49

0.

1

P. 100psi

P.

02

P.

EXIT MEAS EDIT NEXT

06:30:23:56:49

0.

1

P. 100psi

P.

02

P.

EXIT CLR BACK

1. Press F2 (MEM) to enter Multiple Measurement mode.

2. Press F2 (MEAS) to take a measurement.

3. Once a pressure is detected the reading is displayed.

4. Press F4 (SAVE) to save the reading or press F1

(ABORT) to exit the current reading.

9

Page 10

MEASUREMENT PROCEDURES

5. By default, the first reading will be stored in memory

location 01: using the date & time as the filename. The

pressure reading is displayed next to the P: (for exam-

ple: 0.025 psi).

6. If desired, press F3 (EDIT) to edit the filename. Then,

use the Keypad to edit the filename. Cycle through the

characters by depressing the key until the desired character is highlighted. Once the filename has been de-

fined, press F4 (ENTER).

7. To take another reading, press the button to advance

to the next memory location and continue with the next

reading.

8. Press F1 (EXIT) to return to the Welcome menu.

10

Page 11

MEASUREMENT PROCEDURES

Clear Single Memory Record

1. Press F2 (MEM) to enter Multiple Measurement mode.

2. Use the ▲ or buttons to move to the desired memory

location.

3. Press F4 (NEXT) then press F2 (CLR). Once F2 is

pressed the “Clear ?” message is displayed. Press F2

(YES) again to clear the highlighted memory location or

F3 (NO) to cancel the clear function.

4. Press F1 (EXIT) to return to the Welcome menu.

Clear All Memory Records

1. Press F2 (MEM) to enter Multiple Measurement mode.

2. Press F4 (NEXT) then press F2 (CLR) for two (2) se-

conds. After two (2) seconds the “Clear All?” message

is displayed. Press F2 (YES) again to clear all 99

memory locations or F3 (NO) to cancel the clear func-

tion.

3. Press F1 (EXIT) to return to the Welcome menu.

11

Page 12

MEASUREMENT PROCEDURES

Run Auto Logger

Welcome

06-30 02:28:55

0.1 psi

MEAS MEM LOG SET

0023:

P:

0024:

P:

0025:

P:

EXIT START SET NEXT

1. Press F3 (LOG) to enter log

mode.

2. Press F3 (SET) to modify the us-

er-defined parameters.

0023: 06-30. 02:28:55

P: 0.1 psi

0024:

P:

0025:

P:

P-PG N-PG BACK

Begin: 30-06-06

Start: 02:28:06

End: 02-07-05

Suspend: 03:28:55

Rate: 60Sec(s)

Expect: 12000Point(s)

Remain: 11977Point(s)

EXIT EDIT VIEW NEXT

Begin: 30-06-06

Start: 02:28:06

End: 02-07-05

Suspend: 03:28:55

Rate: 60Sec(s)

Expect: 12000Point(s)

Remain: 11977Point(s)

START CLR BACK

Logging. . .

STOP MEAS VIEW

0023: 06-30 02:28:55

P: 0.100 psi

0024:

P:

0025:

P:

STOP MEAS ESC

3. Use the ▲ and buttons to se-

lect an auto log parameter and

press F2 (EDIT) to edit.

“Begin” date*

“Start” time

“End” date*

“Rate” (1 to 7200 seconds)

“Suspend” time

For 24 hour logging, set the Start

time to 00:00:00 and the Suspend time to 23:59:59.

“Expect” is the total number of

memory points (12,000).

Remain” shows the number of

available memory points (12,000

minus the number already

recorded).

ESC

P: 0.100 psi

* Ensure date formats are consistent

12

Page 13

MEASUREMENT PROCEDURES

4. Press F4 (ENTER) after modifying a parameter.

5. Once the parameters have been set press F4 (NEXT)

and F1 (START) to start the auto logger. The word

“Logging…” will be displayed.

The meter will automatically start and stop logging ac-

cording to your chosen parameters. Once the required

number of data points is reached, logging stops and the

records are held in the data logger.

6. During the auto logging press F2 (MEAS) to take a realtime reading or F4 (VIEW) to view memory record.

7. To stop auto logging press F1 (STOP).

8. Use the ▲ and buttons to scroll through the memory

records.

9. Press F4 (NEXT) to access the previous and next page

buttons. Press F1 (P-PG) or F2 (N-PG) to review previ-

ous or next 100 data points.

10. Press F4 (BACK) to access the auto log main menu and

press F2 (Start) to continue auto logging or F1 (EXIT).

13

Page 14

MEASUREMENT PROCEDURES

Clear Auto Log Data

1. Press F3 (LOG) to enter log mode.

2. Press F3 (SET) to enter auto log parameter set-up.

3. Press F4 (NEXT) to access the clear option.

4. Press F2 (CLR) for two (2) seconds and the “Clear All?”

message is displayed.

5. Press F2 (YES) to clear all auto log data, or F3 (NO) to

cancel clear function.

6. After clearing all auto log data, press F4 (BACK) to re-

turn to auto log parameter set-up.

7. Press F1 (EXIT) to return to the Welcome display.

ERROR CODES

E2: The value is under-range

E3: The value is over-range

E4: Error reading sample

AUTO POWER OFF

To prolong battery life, the meter will turn off automatically if

no buttons are pressed for your preset (1~20 minutes). To

edit or disable this feature, press F4 (SET) to access the

setup mode, then use the F2 (EDIT), ▲ or ▼ buttons and

Keypad to make changes.

14

Page 15

BATTERY REPLACEMENT

When the low battery icon is displayed, open the battery

cover, install 4-AAA Alkaline batteries and replace the cover. Remove the batteries during prolonged periods of nonuse.

840086 SPECIFICATIONS

Unit of Measure Range Resolution

PSI ±5 0.001

inH2O ±138 0.1

kPa ±34.5 0.01

ftH2O ±11.5 0.01

inHg ±10.2 0.01

cmH2O ±352 0.1

mbar ±345 0.1

Bar ±0.345 0.001

mmHg ±259 0.1

oz / inch2 ±80 0.01

Kg / cm2 ±0.35 0.001

Max Pressure 20 PSI

Accuracy

Repeatability ± 0.2% typ, max ± 0.5% fs

Combined linearity & hysteresis ± 0.29% typ, max ± 1.0% fs

Manual Memory 99

Auto Log Memory 1200

Battery 4-AAA Alkaline

Weight 9 oz (255g)

Dimensions 208x70x53 mm

15

± 0.3% fs @ 25 ºC

Page 16

840098 SPECIFICATIONS

Unit of Measure

PSI ±2 0.001

inH2O ±55.36 0.01

kPa ±13.79 0.01

ftH2O ±4.614 0.01

inHg ±4.072 0.01

cmH2O ±140.6 0.1

mbar ±137.9 0.1

Bar ±0.138 0.001

mmHg ±103.4 0.1

oz / inch2 ±32.48 0.01

Kg / cm2 ±0.141 0.001

Max Pressure 20 PSI

Range Resolution

840099 SPECIFICATIONS

Unit of Measure

PSI ±15 0.01

inH2O ±415.2 0.1

kPa ±103.4 0.1

ftH2O ±34.6 0.01

inHg ±30.54 0.01

cmH2O ±1054 1

mbar ±1034 1

Bar ±1.034 0.001

mmHg ±775.7 0.1

oz / inch2 ±240 0.1

Kg / cm2 ±1.055 0.001

Max Pressure 30 PSI

Range Resolution

16

Page 17

SOFTWARE CONFIGURATION

Use the included USB 2.0-P cable and software to download saved data to a PC for further analysis, or to upload

pre-edited filenames to save set-up time.

PC requirements: Win98 or above.

Main Menu Options (see Figure 1)

File

Mode

Port

Command

About

Main Menu Options

Figure 1.

Mode Menu Option

1. There are two (2) data modes: Memory and Logger.

2. Select the data mode from Mode on the main menu or

the drop-down menu. (see Figure 2)

3. In Logger mode, select “GoTo” to choose the logged data range you wish to display.

17

Page 18

SOFTWARE CONFIGURATION

Figure 2.

Com Port

1. Select the Com port and ensure that the meter is communicating with the PC.

2. The selected Com port is displayed in the bottom-left hand

corner of the software screen.

Com1

3. When connected, “PC Mode” and the Com port number

(1-8) are displayed on the meter.

Command Options

There are four (4) command options supported by the software. Choose the correct mode before uploading or downloading data. (see Figure 3)

1. Download Memory Data

2. Download Logger Data

3. Download All Data

4. Upload Memory Description

18

Page 19

SOFTWARE CONFIGURATION

Figure 3.

Print Options

Select the data to be printed from the following three (3)

choices: (see Figure 4)

1. All Data ( Memory and Logger Data printed in sequential

order).

2. Memory Data

3. Logger Data

ACCESSORIES

840089 Rubber Holster

840090 Water Resistant Pouch

840096 AC Adapter

19

Figure 4.

Page 20

Sper Scientific warrants this product against defects in materials

and workmanship for a period of ONE (1) year from the date of

purchase, and agrees to repair or replace any defective unit without

charge. If your model has since been discontinued, an equivalent

Sper Scientific product will be substituted if available. This warranty

does not cover probes, batteries, battery leakage, or damage

resulting from accident, tampering, misuse, or abuse of the product.

Opening the meter to expose its electronics will void the warranty.

To obtain warranty service, ship the unit postage prepaid to:

SPER SCIENTIFIC LTD

7720 E Redfield Rd, Suite 7

Scottsdale, AZ 85260

WWW.SPERSCIENTIFIC.COM

INFO@SPERSCIENTIFIC.COM

The defective unit must be accompanied by a description of the

problem and your return address. Register your product online or

return your warranty card within 10 days of purchase.

Revised 5/2/2012

Loading...

Loading...