Page 1

FAST Survey

Reference Manual

Page 2

Copyright Notice

Copyright 2010 Ashtech. All rights reserved. This manual is derived

from the Carlson SurvCE Reference Manual, last revised Oct 13, 2010.

Trademarks

All product and brand names mentioned in this publication are trademarks of their respective holders.

Ashtech Products - Limited Warranty (North, Central and South America)

Ashtech warrants their GPS receivers and hardware accessories to be

free of defects in material and workmanship and will conform to our

published specifications for the product for a period of one year from

the date of original purchase. THIS WARRANTY APPLIES ONLY TO

THE ORIGINAL PURCHASER OF THIS PRODUCT.

In the event of a defect, Ashtech will, at its option, repair or replace the

hardware product with no charge to the purchaser for parts or labor. The

repaired or replaced product will be warranted for 90 days from the

date of return shipment, or for the balance of the original warranty,

whichever is longer. Ashtech warrants that software products or software included in hardware products will be free from defects in the media for a period of 30 days from the date of shipment and will

substantially conform to the then-current user documentation provided

with the software (including updates thereto). Ashtech's sole obligation

shall be the correction or replacement of the media or the software so

that it will substantially conform to the then- current user documentation. Ashtech does not warrant the software will meet purchaser's requirements or that its operation will be uninterrupted, error-free or

virus-free. Purchaser assumes the entire risk of using the software.

PURCHASER'S EXCLUSIVE REMEDY UNDER THIS WRITTEN WARRANTY OR ANY IMPLIED WARRANTY SHALL BE LIMITED TO THE

REPAIR OR REPLACEMENT, AT ASHTECH'S OPTION, OF ANY DEFECTIVE PART OF THE RECEIVER OR ACCESSORIES WHICH ARE COVERED BY THIS WARRANTY. REPAIRS UNDER THIS WARRANTY

SHALL ONLY BE MADE AT AN AUTHORIZED ASHTECH SERVICE

CENTER. ANY REPAIRS BY A SERVICE CENTER NOT AUTHORIZED

BY ASHTECH WILL VOID THIS WARRANTY.

To obtain warranty service the purchaser must obtain a Return Materials Authorization (RMA) number prior to shipping by calling 1-800229-2400 (North America) or 1-408-572-1134 (International) and

leaving a voice mail at option 3, or by submitting a repair request online at: http://ashtech.com (fill out the RMA request from under the

Support tab). The purchaser must return the product postpaid with a

copy of the original sales receipt to the address provided by Ashtech

with the RMA number. Purchaser’s return address and the RMA number

must be clearly printed on the outside of the package.

Ashtech reserves the right to refuse to provide service free-of-charge if

the sales receipt is not provided or if the information contained in it is

incomplete or illegible or if the serial number is altered or removed.

Ashtech will not be responsible for any losses or damage to the product

incurred while the product is in transit or is being shipped for repair.

Insurance is recommended. Ashtech suggests using a trackable shipping method such as UPS or FedEx when returning a product for service.

EXCEPT AS SET FORTH IN THIS LIMITED WARRANTY, ALL OTHER

EXPRESSED OR IMPLIED WARRANTIES, INCLUDING THOSE OF FITNESS FOR ANY PARTICULAR PURPOSE, MERCHANTABILITY OR

NON-INFRINGEMENT, ARE HEREBY DISCLAIMED AND IF APPLICABLE, IMPLIED WARRANTIES UNDER ARTICLE 35 OF THE UNITED

NATIONS CONVENTION ON CONTRACTS FOR THE INTERNATIONAL

SALE OF GOODS. Some national, state, or local laws do not allow limitations on implied warranty or how long an implied warranty lasts, so

the above limitation may not apply to you.

The following are excluded from the warranty coverage: (1) periodic

maintenance and repair or replacement of parts due to normal wear and

tear; (2) batteries and finishes; (3) installations or defects resulting

from installation; (4) any damage caused by (i) shipping, misuse,

abuse, negligence, tampering, or improper use; (ii) disasters such as

fire, flood, wind, and lightning; (iii) unauthorized attachments or modification; (5) service performed or attempted by anyone other than an

authorized Ashtechs Service Center; (6) any product, components or

parts not manufactured by Ashtech; (7) that the receiver will be free

from any claim for infringement of any patent, trademark, copyright or

other proprietary right, including trade secrets; and (8) any damage due

to accident, resulting from inaccurate satellite transmissions. Inaccurate transmissions can occur due to changes in the position, health or

geometry of a satellite or modifications to the receiver that may be required due to any change in the GPS. (Note: Ashtech GPS receivers use

GPS or GPS+GLONASS to obtain position, velocity and time information. GPS is operated by the U.S. Government and GLONASS is the

Global Navigation Satellite System of the Russian Federation, which

are solely responsible for the accuracy and maintenance of their systems. Certain conditions can cause inaccuracies which could require

modifications to the receiver. Examples of such conditions include but

are not limited to changes in the GPS or GLONASS transmission.)

Opening, dismantling or repairing of this product by anyone other than

an authorized Ashtech Service Center will void this warranty.

ASHTECH SHALL NOT BE LIABLE TO PURCHASER OR ANY OTHER

PERSON FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

WHATSOEVER, INCLUDING BUT NOT LIMITED TO LOST PROFITS,

DAMAGES RESULTING FROM DELAY OR LOSS OF USE, LOSS OF OR

DAMAGES ARISING OUT OF BREACH OF THIS WARRANTY OR ANY

IMPLIED WARRANTY EVEN THOUGH CAUSED BY NEGLIGENCE OR

OTHER FAULT OFASHTECH OR NEGLIGENT USAGE OF THE PRODUCT. IN NO EVENT WILL ASHTECH BE RESPONSIBLE FOR SUCH

DAMAGES, EVEN IF ASHTECH HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

This written warranty is the complete, final and exclusive agreement

between Ashtech and the purchaser with respect to the quality of performance of the goods and any and all warranties and representations.

This warranty sets forth all of Ashtech's responsibilities regarding this

product. This limited warranty is governed by the laws of the State of

California, without reference to its conflict of law provisions or the U.N.

Convention on Contracts for the International Sale of Goods, and shall

benefit Ashtech, its successors and assigns.

This warranty gives the purchaser specific rights. The purchaser may

have other rights which vary from locality to locality (including Directive

1999/44/EC in the EC Member States) and certain limitations contained in this warranty, including the exclusion or limitation of incidental or consequential damages may not apply.

For further information concerning this limited warranty, please call or

write:

Ashtech LLC, El Camino Real 451, Suite 210, CA 95050, Santa Clara,

USA, Phone: +1 408 572 1103, Fax: +1 408 572 1199 or

Ashtech - ZAC La Fleuriaye - BP 433 - 44474 Carquefou Cedex France Phone: +33 (0)2 28 09 38 00, Fax: +33 (0)2 28 09 39 39.

Ashtech Products Limited Warranty (Europe, Middle East, Africa)

All Ashtech global positioning system (GPS) receivers are navigation

aids, and are not intended to replace other methods of navigation. Purchaser is advised to perform careful position charting and use good

judgment. READ THE USER GUIDE CAREFULLY BEFORE USING THE

ODUCT.

PR

1. ASHTECH WARRANTY

Ashtech warrants their GPS receivers and hardware accessories to be

free of defects in material and workmanship and will conform to our

published specifications for the product for a period of one year from

the date of original purchase or such longer period as required by law.

Page 3

THIS WARRANTY APPLIES ONLY TO THE ORIGINAL PURCHASER OF

THIS PRODUCT.

In the event of a defect, Ashtech will, at its option, repair or replace the

hardware product with no charge to the purchaser for parts or labor. The

repaired or replaced product will be warranted for 90 days from the

date of return shipment, or for the balance of the original warranty,

whichever is longer. Ashtech warrants that software products or software included in hardware products will be free from defects in the media for a period of 30 days from the date of shipment and will

substantially conform to the then-current user documentation provided

with the software (including updates thereto). Ashtech's sole obligation

shall be the correction or replacement of the media or the software so

that it will substantially conform to the then- current user documentation. Ashtech does not warrant the software will meet purchaser's requirements or that its operation will be uninterrupted, error-free or

virus-free. Purchaser assumes the entire risk of using the software.

2. PURCHASER'S REMEDY

PURCHASER'S EXCLUSIVE REMEDY UNDER THIS WRITTEN WARRANTY OR ANY IMPLIED WARRANTY SHALL BE LIMITED TO THE

REPAIR OR REPLACEMENT, AT ASHTECH'S OPTION, OF ANY DEFECTIVE PART OF THE RECEIVER OR ACCESSORIES WHICH ARE COVERED BY THIS WARRANTY. REPAIRS UNDER THIS WARRANTY

SHALL ONLY BE MADE AT AN AUTHORIZED ASHTECH SERVICE

CENTER. ANY REPAIRS BY A SERVICE CENTER NOT AUTHORIZED

BY ASHTECH WILL VOID THIS WARRANTY.

3. PURCHASER'S DUTIES

To obtain service, contact and return the product with a copy of the

original sales receipt to the dealer from whom you purchased the product.

Ashtech reserves the right to refuse to provide service free-of-charge if

the sales receipt is not provided or if the information contained in it is

incomplete or illegible or if the serial number is altered or removed.

Ashtech will not be responsible for any losses or damage to the product

incurred while the product is in transit or is being shipped for repair.

Insurance is recommended. Ashtech suggests using a trackable shipping method such as UPS or FedEx when returning a product for service.

4. LIMITATION OF IMPLIED WARRANTIES

EXCEPT AS SET FORTH IN ITEM 1 ABOVE, ALL OTHER EXPRESSED

OR IMPLIED WARRANTIES, INCLUDING THOSE OF FITNESS FOR

ANY PARTICULAR PURPOSE OR MERCHANTABILITY, ARE HEREBY

DISCLAIMED AND IF APPLICABLE, IMPLIED WARRANTIES UNDER

ARTICLE 35 OF THE UNITED NATIONS CONVENTION ON CONTRACTS FOR THE INTERNATIONAL SALE OF GOODS.

Some national, state, or local laws do not allow limitations on implied

warranty or how long an implied warranty lasts, so the above limitation

may not apply to you.

5. EXCLUSIONS

The following are excluded from the warranty coverage:

(1) periodic maintenance and repair or replacement of parts due to normal wear and tear;

(2) batteries;

(3) finishes;

(4) installations or defects resulting from installation;

(5) any damage caused by (i) shipping, misuse, abuse, negligence,

tampering, or improper use; (ii) disasters such as fire, flood, wind, and

lightning; (iii) unauthorized attachments or modification;

(6) service performed or attempted by anyone other than an authorized

Ashtechs Service Center;

(7) any product, components or parts not manufactured by Ashtech,

(8) that the receiver will be free from any claim for infringement of any

patent, trademark, copyright or other proprietary right, including trade

secrets

(9) any damage due to accident, resulting from inaccurate satellite

transmissions. Inaccurate transmissions can occur due to changes in

the position, health or geometry of a satellite or modifications to the receiver that may be required due to any change in the GPS. (Note:

Ashtech GPS receivers use GPS or GPS+GLONASS to obtain position,

velocity and time information. GPS is operated by the U.S. Government

and GLONASS is the Global Navigation Satellite System of the Russian

Federation, which are solely responsible for the accuracy and maintenance of their systems. Certain conditions can cause inaccuracies

which could require modifications to the receiver. Examples of such

conditions include but are not limited to changes in the GPS or

GLONASS transmission.).

Opening, dismantling or repairing of this product by anyone other than

an authorized Ashtech Service Center will void this warranty.

6. EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES

ASHTECH SHALL NOT BE LIABLE TO PURCHASER OR ANY OTHER

PERSON FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES WHATSOEVER, INCLUDING BUT NOT LIMITED TO LOST

PROFITS, DAMAGES RESULTING FROM DELAY OR LOSS OF USE,

LOSS OF OR DAMAGES ARISING OUT OF BREACH OF THIS WARRANTY OR ANY IMPLIED WARRANTY EVEN THOUGH CAUSED BY

NEGLIGENCE OR OTHER FAULT OFASHTECH OR NEGLIGENT USAGE OF THE PRODUCT. IN NO EVENT WILL ASHTECH BE RESPONSIBLE FOR SUCH DAMAGES, EVEN IF ASHTECH HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Some national, state, or local laws do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

7. COMPLETE AGREEMENT

This written warranty is the complete, final and exclusive agreement

between Ashtech and the purchaser with respect to the quality of performance of the goods and any and all warranties and representations.

THIS WARRANTY SETS FORTH ALL OF Ashtech'S RESPONSIBILITIES REGARDING THIS PRODUCT.

THIS WARRANTY GIVES YOU SPECIFIC RIGHTS. YOU MAY HAVE

OTHER RIGHTS WHICH VARY FROM LOCALITY TO LOCALITY (including Directive 1999/44/EC in the EC Member States) AND CERTAIN

LIMITATIONS CONTAINED IN THIS WARRANTY MAY NOT APPLY TO

YOU.

8. CHOICE OF LAW.

This limited warranty is governed by the laws of France, without reference to its conflict of law provisions or the U.N. Convention on Contracts for the International Sale of Goods, and shall benefit Ashtech, its

successors and assigns.

THIS WARRANTY DOES NOT AFFECT THE CUSTOMER'S STATUTORY

RIGHTS UNDER APPLICABLE LAWS IN FORCE IN THEIR LOCALITY,

NOR THE CUSTOMER'S RIGHTS AGAINST THE DEALER ARISING

FROM THEIR SALES/PURCHASE CONTRACT (such as the guarantees

in France for latent defects in accordance with Article 1641 et seq of

the French Civil Code).

For further information concerning this limited warranty, please call or

write:

Ashtech SAS - ZAC La Fleuriaye - BP 433 - 44474 Carquefou Cedex France.

Phone: +33 (0)2 28 09 38 00, Fax: +33 (0)2 28 09 39 39

Page 4

Page 5

Table of Contents

Installation

6

Using the Manual

6

System Requirements

6

Microsoft ActiveSync

6

Installing FAST Survey

9

Authorizing FAST Survey

12

Hardware Notes

13

Color Screens

13

Memory

14

Battery Status

14

Save System

14

User Interface

15

Graphic Mode

15

View Options

17

Quick Calculator

18

Hot Keys & Hot List

19

Instrument Selection

22

Input Box Controls

22

Keyboard Operation

24

Abbreviations

25

FILE

27

Job

27

Job Settings (New Job)

28

Job Settings (System)

29

Job Settings (Format)

30

Job Settings (Options)

31

Job Settings (Stake)

34

List Points

40

Raw Data

42

Feature Code List

49

Data Transfer

66

Import/Export

70

Delete File

73

Add Job Notes

74

Exit

74

EQUIP

75

Total Station

75

GPS Setup

80

GPS Base

84

GPS Rover

90

GPS Utilities

95

Configure (General)

97

Configure (View Pt)

99

Configure (Sets)

100

Localization

101

Monitor/SkyPlot (GPS)

112

Check Level (Total Station)

114

Tolerances

114

Peripherals

116

p3

Page 6

About FAST Survey

119

SURV

120

Orientation (Instrument Setup)

120

Orientation (Backsight)

122

Orientation (Remote Benchmark)

123

Orientation (Advanced Occupation)

124

Orientation (Robotics)

133

Store Points (TS)

135

Store Points (TS Offsets)

138

Store Points (GPS)

140

Store Points (GPS Offsets)

142

Stake Points

145

Stake Line/Arc

155

Stake Offset

169

Elevation Difference

172

Grid/Face

176

Resection

178

Set Collection

182

Leveling

188

Auto By Interval

195

Remote Elevation

197

Log Raw GPS

198

COGO

202

Keyboard Input

202

Inverse

203

Areas

204

Intersections

206

Point Projection

209

Station Store

211

Transformation

213

Calculator

216

Manual Traverse

220

Point Average

222

ROAD

224

Centerline Editor

224

Draw Centerline

229

Profile Editor

229

Draw Profile

231

Template Editor

231

Draw Template

235

Utilities

236

Stake Slope

253

Store Sections

268

Stake Road

277

MAP

283

Basics

283

FILE

285

VIEW

297

DRAW

300

COGO

314

TOOLS

323

p4

Page 7

Tutorials

332

Tutorial 1: Calculating a Traverse (By Hand) with FAST Survey

332

Tutorial 2: Performing Math Functions in FAST Survey Input Boxes

333

Tutorial 3: Performing a Compass Rule Adjustment

333

Tutorial 4: Defining Field Codes, Line/Layer Properties & GIS Prompting

337

Tutorial 5: Standard Procedures for Conducting GPS Localizations

350

Instrument Setup by Manufacturer

357

Total Station (Geodimeter/Trimble)

357

Total Station (Leica TPS Series)

360

Total Station (Leica Robotic)

363

Total Station (Leica/Wild Older Models)

368

Total Station (Nikon)

369

Total Station (Pentax)

369

Total Station (Sokkia Set)

370

Total Station (Sokkia Robotic)

373

Total Station (Topcon 800/8000/APL1)

374

Total Station (Topcon GTS)

378

GPS (Ashtech)

378

GPS (NMEA)

381

GPS Utilities by Manufacturer

383

GPS Utilities (Magellan/Ashtech)

383

Troubleshooting

386

GPS Heights

386

Handheld Hardware

386

Miscellaneous Instrument Configuration

387

Supported File Formats

387

Raw Data

389

File Format

389

p5

Page 8

Installation

This chapter describes the system requirements and installation instructions for FAST Survey.

Using the Manual

This manual is designed as a reference guide. It contains a complete description of all commands in the FAST Survey

product.

The chapters are organized by program menus, and they are arranged in the order that the menus typically appear in

FAST Survey. Some commands are only applicable to either GPS or total station use and may not appear in your menu.

Look for the icons for either GPS mode and/or total station mode, found at the start of certain chapters. These icons will

be located at the top (header) of these pages, or at the start of a chapter.

For some commands both icons will be shown, indicating that the FAST Survey command can be used in both GPS and

total station modes.

System Requirements

The information below describes the system requirements and installation instructions for FAST Survey.

Software

Windows CE® or Windows Mobile version 4.0 or later. Handheld PC.

Microsoft ActiveSync 3.7 and later.

RAM and Hard Disk Space Requirements

64 MB of RAM (recommended)

16 MB of hard disk space (minimum)

Hardware (Required)

StrongARM, XScale or compatible processor (hardware must be supported by the Microsoft operating system being

used)

Hardware (Optional)

Serial cable for uploading and downloading data.

Microsoft ActiveSync

If you use Windows XP or an earlier version of the Windows Operating System on your computer, Microsoft®

ActiveSync® provides support for synchronizing data between a Windows-based desktop computer and Microsoft®

Windows® CE or Windows® Mobile based portable devices.

ActiveSync is only compatible with Windows XP or earlier. If you are running Windows Vista or Windows 7, you will

need to download and install Windows Mobile Device Center from Microsoft.

You should have a USB cable or 9-pin null modem cable that was included with your mobile device. Attach this cable

from your desktop PC to the mobile device. Before you can install FAST Survey, your desktop PC must have Microsoft

ActiveSync or Windows Mobile Device Center installed and running depending on what version of Windows is running

on your computer. If you have ActiveSync on your desktop PC, you should see the ActiveSync icon in your system tray.

If you do not see this icon in the tray, choose the Windows Start button, choose Programs and then choose Microsoft

p6

Page 9

ActiveSync. If you do not have ActiveSync installed, insert the FAST Survey CD-ROM and choose “Install ActiveSync

”. You may also choose to download the latest version from Microsoft. After the ActiveSync installation starts, follow

the prompts. If you need more assistance to install ActiveSync, visit Microsoft’s web site for the latest install details.

Auto Connection

If the default settings are correct, ActiveSync should automatically connect to the mobile device. When you see a dialog

on the mobile device that asks you if you want to connect, press Yes.

Manual Connection

If nothing happens when you connect the cable, check to see if you have the ActiveSync icon in your system tray. If you

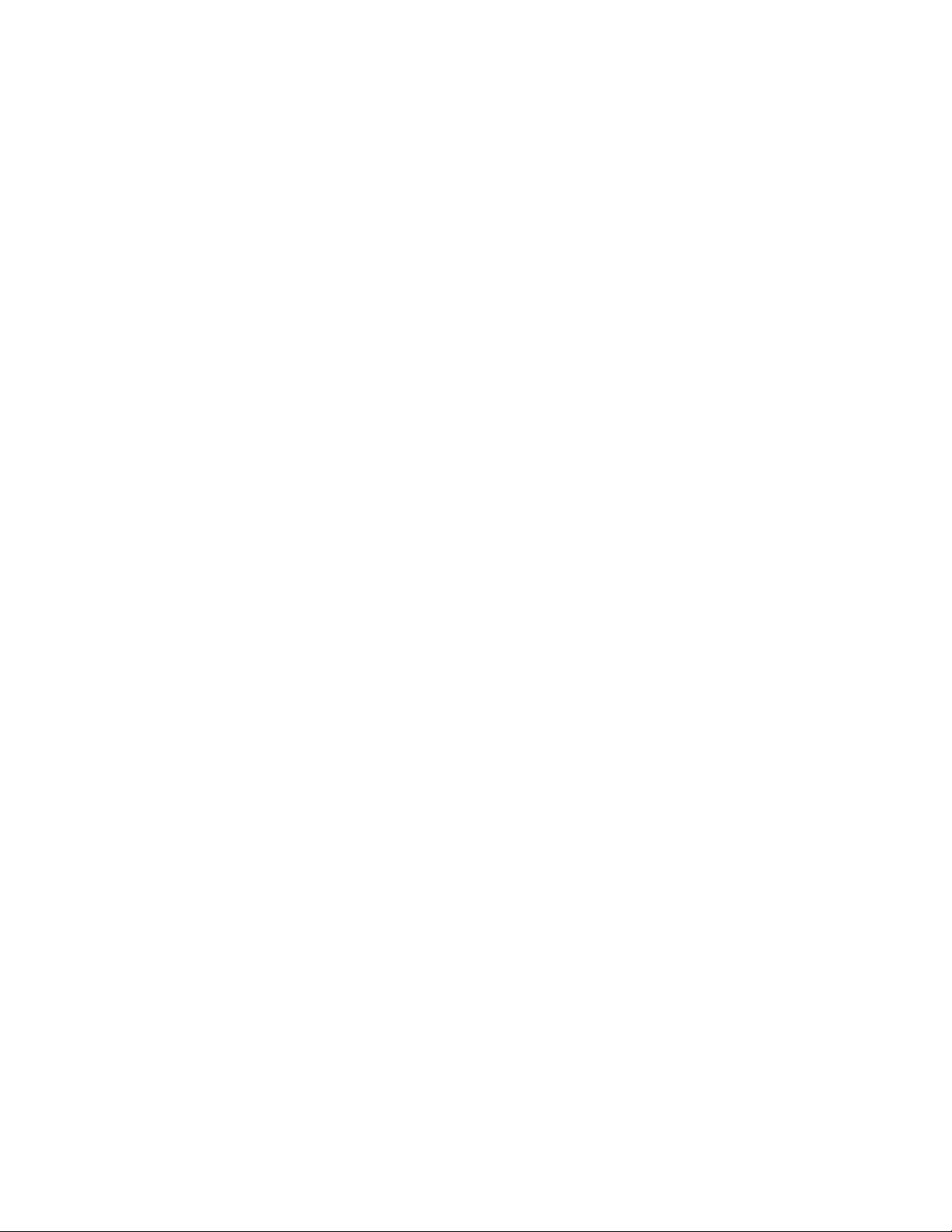

see this icon, right click on it and choose “Connection Settings”. You should see the following dialog:

Be sure that you have selected the appropriate COM port or USB options. Assuming that you are using a COM port

connection, you will choose the COM port (usually this will be COM1). Click Connect at the top right. You will now

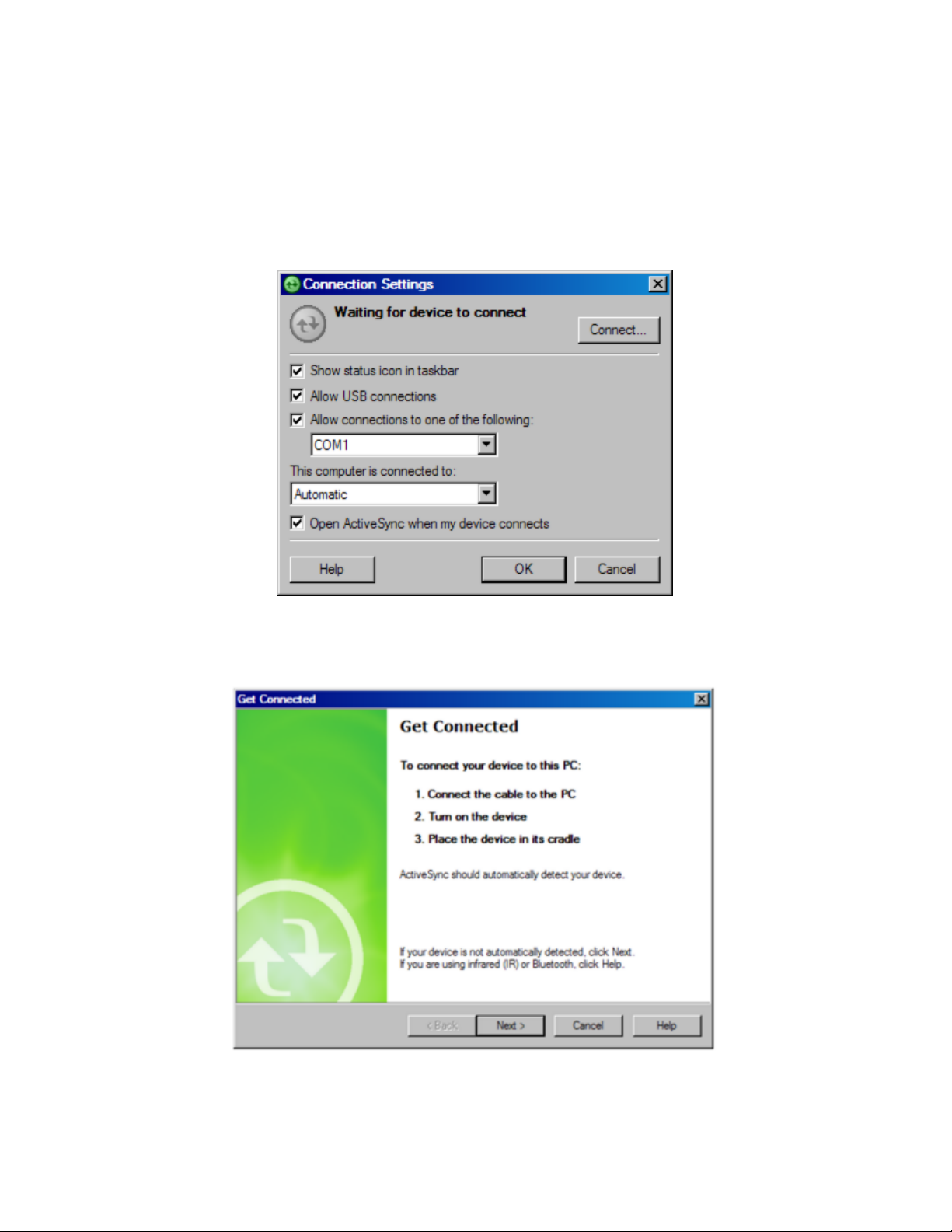

see the Get Connected dialog.

You now need to manually "link" to the remote device. Focus on the mobile device while still observing your PC screen.

Observe the above dialog and, with your device properly connected to the PC, be prepared to click the Next button at

the bottom. Now look at the mobile device screen for the "PC Link" icon.

First, click Next on the PC. Then immediately double-tap the PC Link icon. (You may have to do the double-tap more

p7

Page 10

than once.) If successful, after you press Next, the following screen will appear and the connection will be made.

In ActiveSync, you will then see the New Partnership dialog. Click No to setting up a partnership, and click Next.

When you see the icon in the system tray, and it is green with no "x" through it, you are connected. Once you are

connected, you should see the following dialog. It should say "Connected":

Troubleshooting

If you cannot get connected, make sure that no other program is using the COM port. Programs to check for include any

Fax/Modem software and other data transfer software. If you see anything you think may be using the COM port, shut it

down and retry the connection with ActiveSync.

Enabling COM Port Communication for ActiveSync on Allegro, Panasonic Toughbook 01 and other CE devices

In order for ActiveSync to communicate, it may be necessary to direct the CE device to utilize the COM port as a

default. Some may come set default to USB. Go to Start (on Allegro, blue key and Start button), then Settings, and

open the Control Panel. Next choose the Communications icon, then PC Connection. Choose COM1 at a high baud

rate, such as 57,600 baud. This will download programs and files at a high rate of speed. On the Allegro, use PC Link

to connect to PC with ActiveSync. On the Panasonic Toughbook, do Start, Run, and in the Open window, type in

“autosync –go” (autosync then spacebar then “minus” go). Then go to Start, then Settings, and open the Control Panel.

Choose the Communications icon, then PC Connection. Change Connection to Serial Port @ 115K. Make sure “Enable

p8

Page 11

direct connections to the desktop computer” is checked.

Note:

When using FAST Survey’s Data Transfer option, you will need to disable Serial Port Connection (uncheck

Allow Serial Cable). This is done in the Connection Settings in ActiveSync. This option must be enabled again in order

to use ActiveSync.

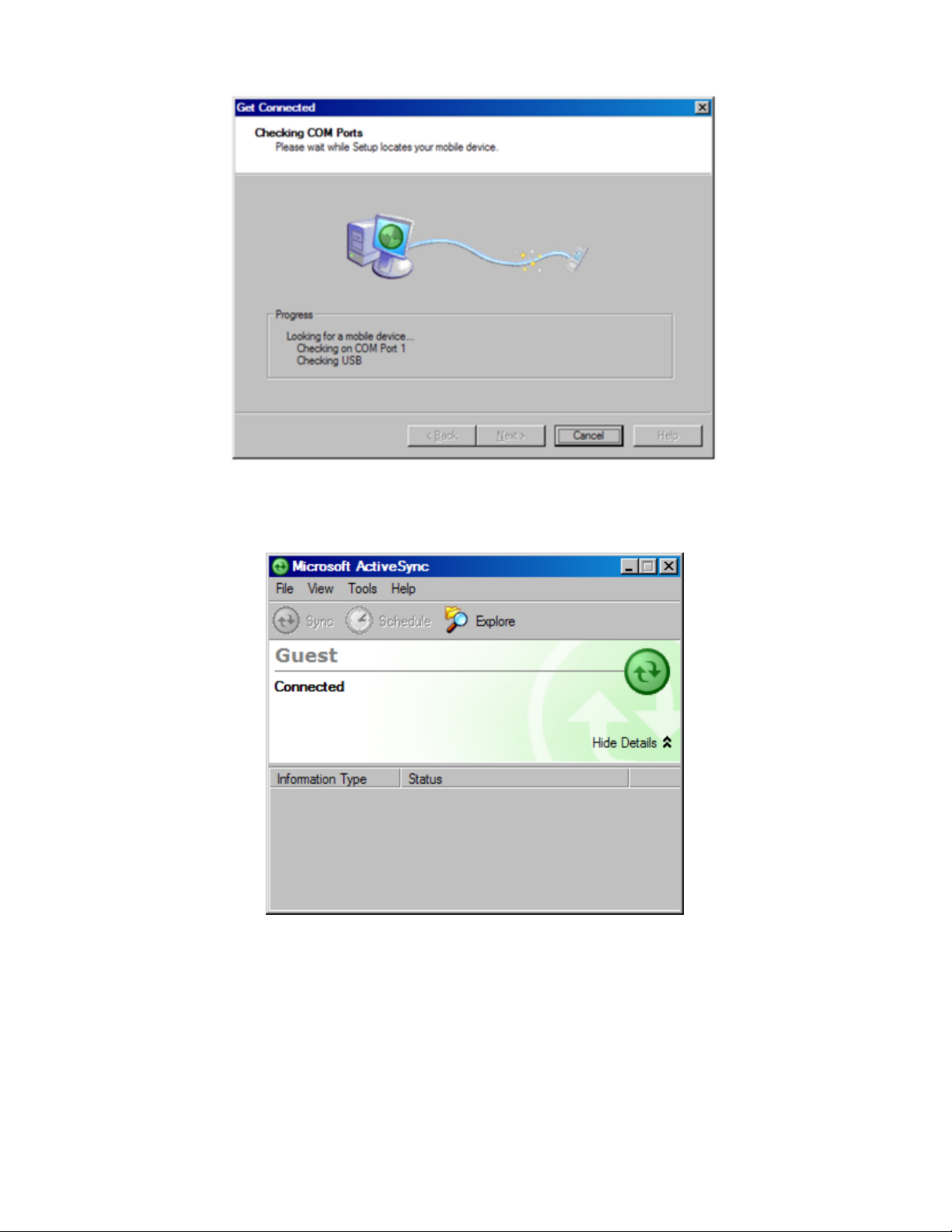

Installing FAST Survey

Before you install FAST Survey, close all running applications on the mobile device.

Connect the mobile device to the desktop PC and ensure that the ActiveSync connection is made.

1.

Insert the CD into the CD-ROM drive on the desktop PC. If Autorun is enabled, the startup program begins. The

2.

startup program lets you choose the version of FAST Survey to install. To start the installation process without

using Autorun, choose Run from the Windows Start Menu. Enter the CD-ROM drive letter, and setup. For example,

enter d:\setup (where d is your CD-ROM drive letter).

On the desktop PC, a Welcome dialog will appear. Click Next.

3.

p9

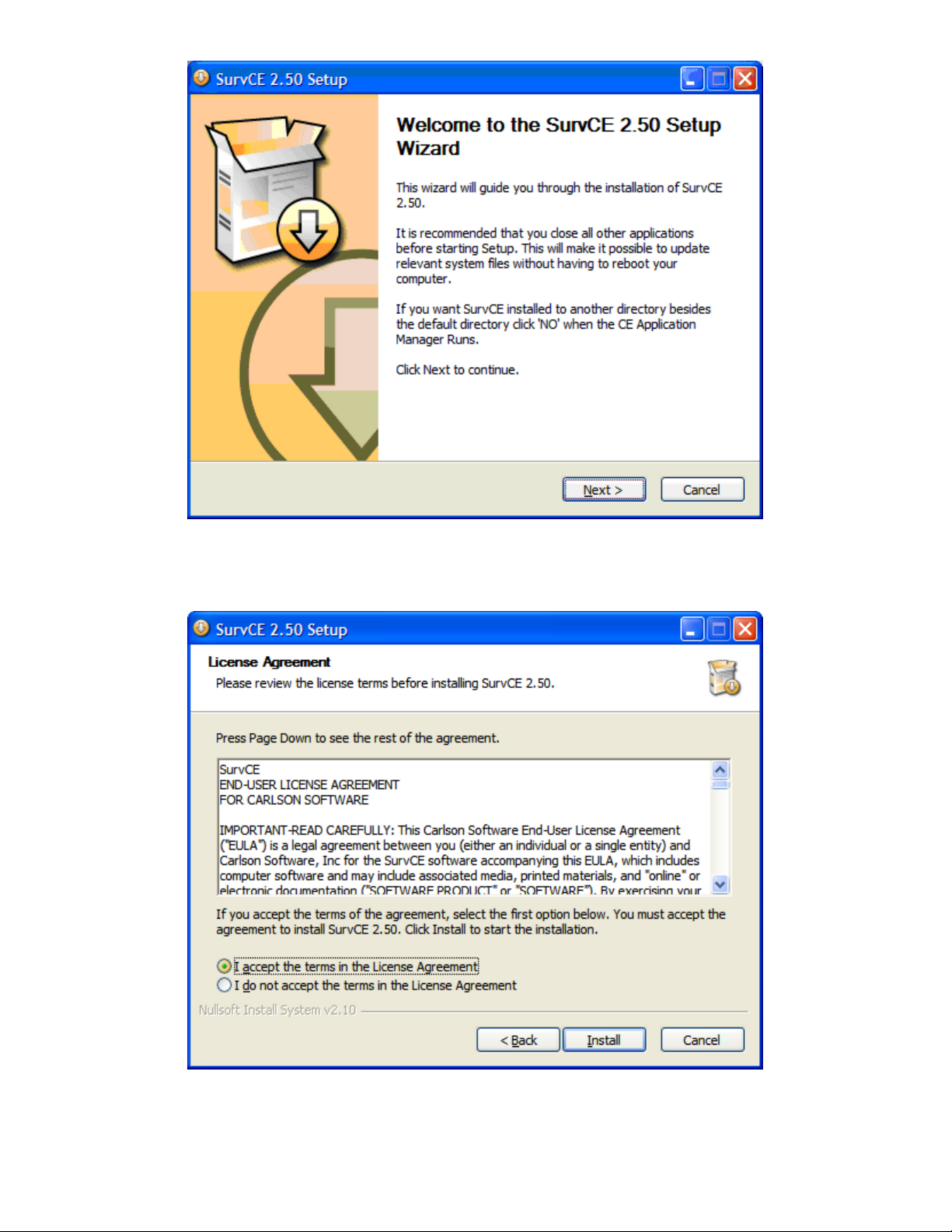

Page 12

On the next dialog, you must read and accept the FAST Survey End-User License Agreement (EULA). If you agree

4.

with the EULA, click "I accept ..." and then select Install. If you do not agree with the EULA, click "I do not accept

..." and the installation program will quit.

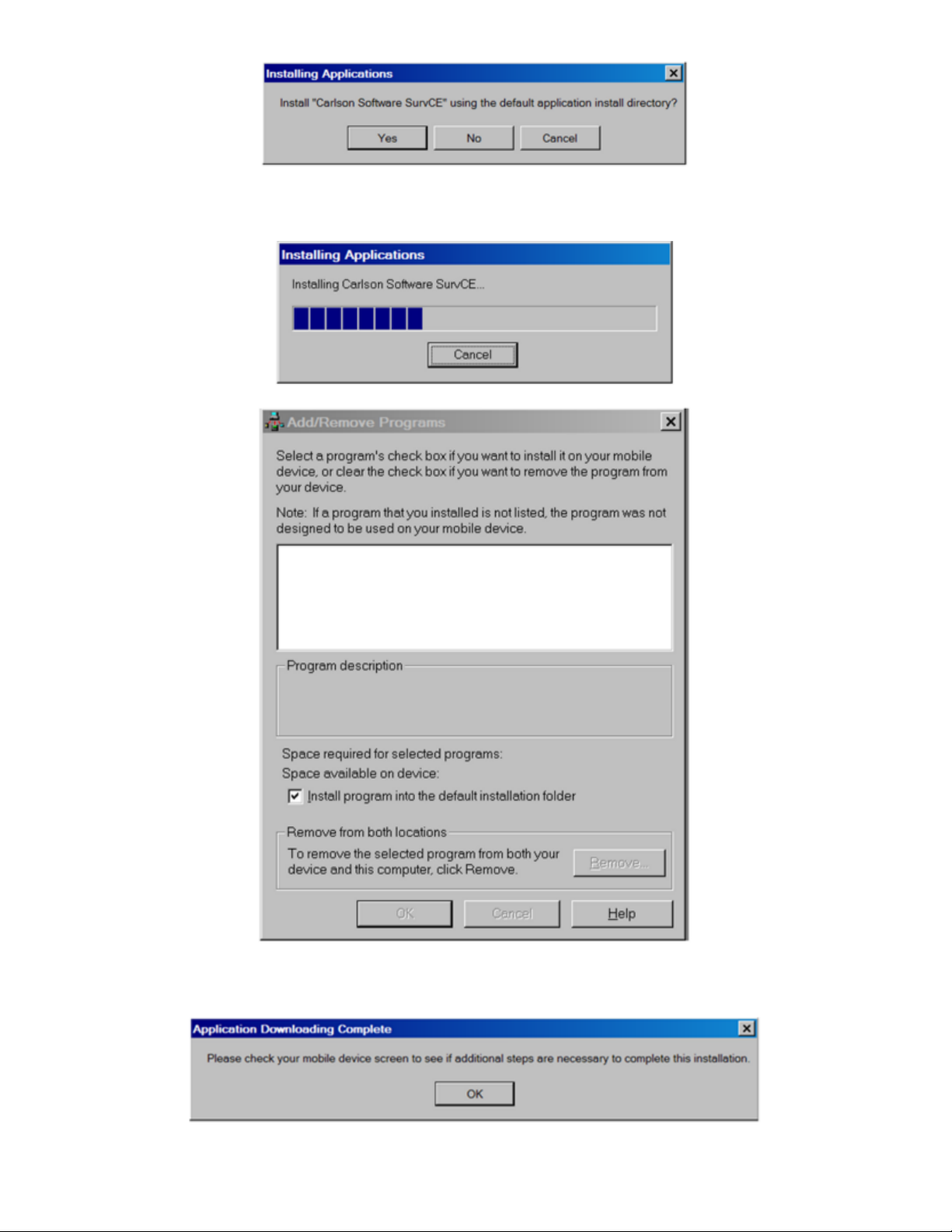

The next dialog asks you to confirm the installation directory. Press Yes.

5.

p10

Page 13

At this point, the necessary files will be copied to the mobile device. A dialog will appear to show installation

6.

progress.

You are given a final chance to check your mobile device. Click OK when you are ready, then click Finish on the

7.

desktop PC.

p11

Page 14

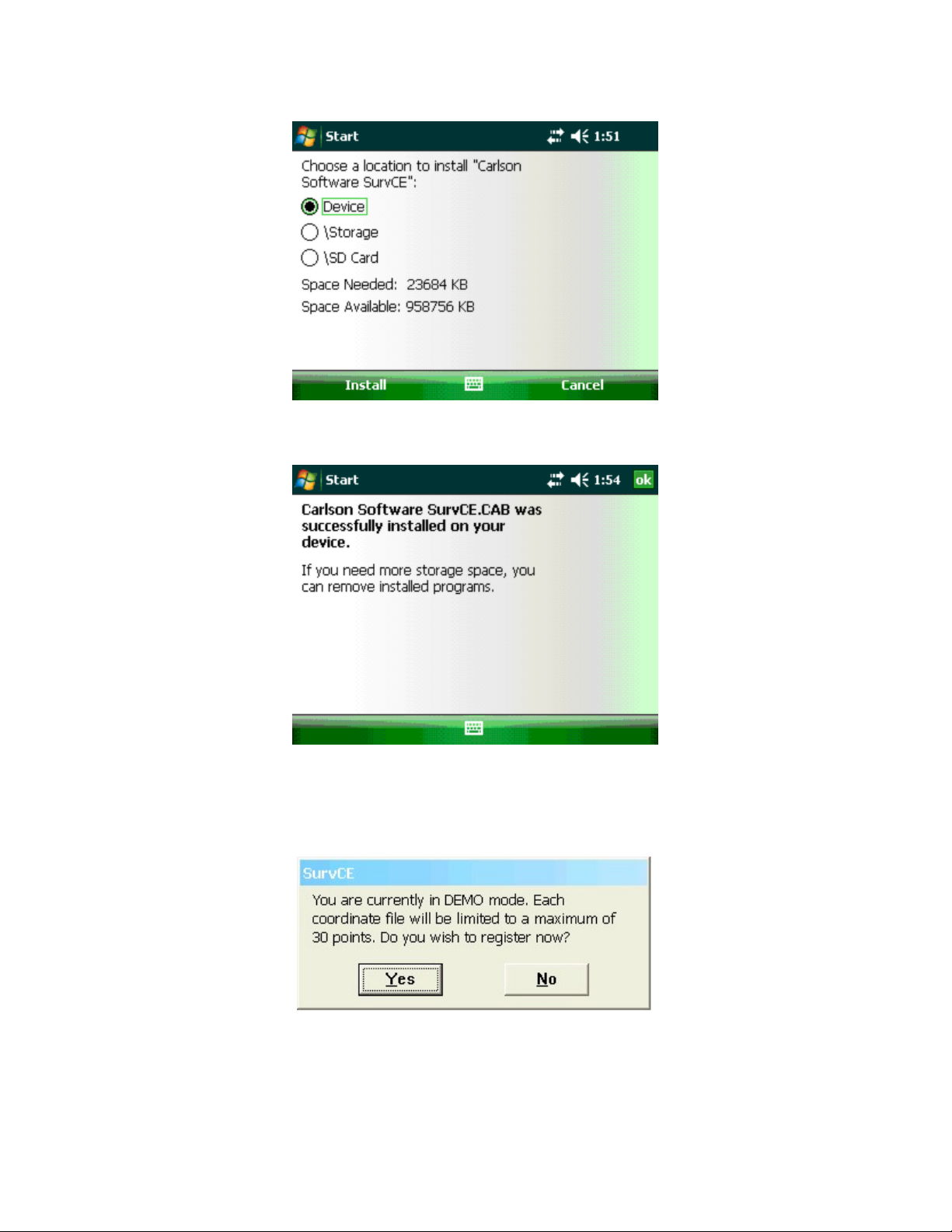

On the Data Collector - Tap “Install” in the bottom left to install FAST Survey to the default location of “Device”.

8.

After tapping Install you will see an hourglass with a progress bar showing the installation progress.

Once the Status Bar finishes on the data collector it will say “Software was successfully installed”. Tap OK in the

9.

upper right to complete the installation of FAST Survey.

Authorizing FAST Survey

The first time you start FAST Survey, you are prompted to register your license of the software. If you do not register,

FAST Survey will remain in demo mode, limiting each job file to a maximum of 30 points.

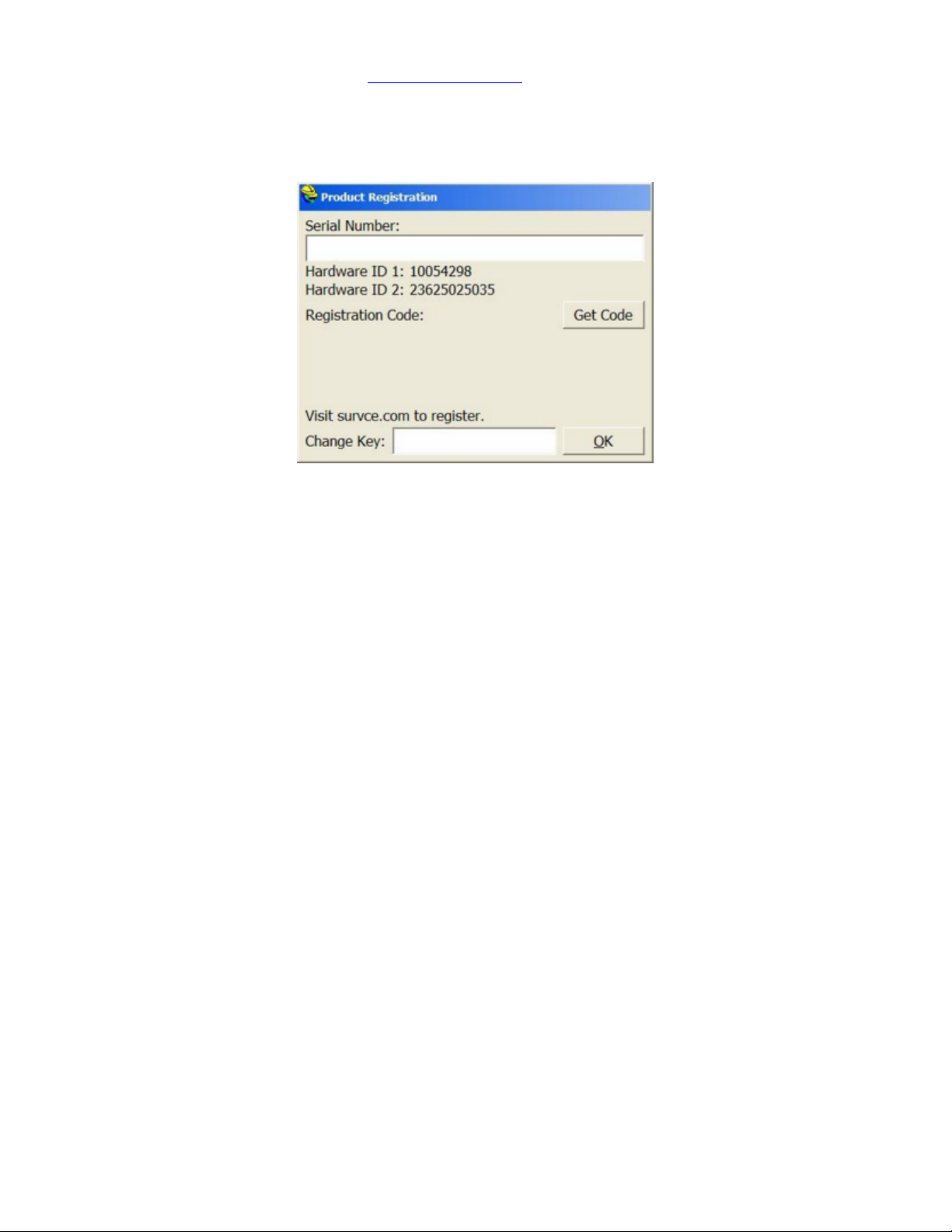

1) If you open FAST Survey and it says you are in “Demo Mode”, tap Yes to register now. If you are at the Main menu

of FAST Survey already you can tap the Equip tab / About FAST Survey and tap Change Registration to access this

screen.

2) Type in your FAST Survey Serial number into the Serial Number box at the top

3) Tap the “Get Code” button

p12

Page 15

4) Now go to the FAST Survey website at www.survce.com/ashtech to complete your registration via the Internet

PLEASE NOTE: If you do not have access to the Internet, you may fax your company name, phone number, email

address, your FAST Survey serial number, Hardware #1, Hardware #2 and the registration code to 606-564-9525.

Your registration information will be faxed back to you within 48 hours.

5) Click on the “Registration Page” icon under Version 2.0/2.5

6) Fill out this form with your Name and Company information / type in your FAST Survey Serial number in the “Serial

Number” box and make sure to include the Dashes

7) Fill in the Hardware #1 and Hardware #2 boxes with the Values displayed on your Data Collector Screen {If you

have trouble finding them click the “where is it located link”}

8) Choose the Reason for Install of “Initial Installataion” if this is your First time registering FAST Survey

9) Fill in the Registration Code from the screen of your Data Collector and make sure to include the Dash

10) Click the Submit Registration Button

11) If this is your first time Registering FAST Survey you may need to fill in Some Contact Details then click “Submit

Contact Information”

12) If this is your first time Registering this Data Collector with FAST Survey please Select the “Device Model” from

the List and fill in the “Device Serial Number” and click the “Register Device to Complete Registration” button

13) Your Change Key will be displayed in a BOX in the Top Left of the FAST Survey Registration summary. Type this

change key in on the “Change Key” box on your Data Collector then tap OK

14) You should receive a message saying “Successful FAST Survey Registration!”. Tap OK

15) Your FAST Survey Software is now Fully Registered. Your change key will also be emailed to the address that you

submit. Keep a copy of this email for your permanent records.

Hardware Notes

If FAST Survey quits responding, you can reset the hardware by following the applicable procedures described in the

hardware documentation.

Color Screens

FAST Survey enables viewing of color. Any red, green, blue or other colored entities in DXF files will retain their color

when viewed within FAST Survey. Points will appear with black point numbers, green descriptions and blue elevations.

Dialogs and prompting will utilize color throughout FAST Survey.

p13

Page 16

Memory

Memory is NOT an issue with newer data collectors running Windows Mobile. Please ignore this section of you have a

Windows Mobile device. For all Windows Mobile users, there is no need to do any memory allocation. This section

applies only to older, Windows CE devices like the early Rangers and Allegros.

Memory on most Windows CE devices (excluding Windows Mobile), can be allocated directly by the user for best

results when running or installing FAST Survey. We recommend setting “Storage Memory” to a minimum of 16,000

KB. The following discussion is an example for setting that memory . An equivalent process should be used for other

CE devices, as available.

The FAST Survey controller will function better during topo and stakeout with the "Storage Memory" set to around

18,000 KB. Use the following process to check and/or change the settings:

Go to the start menu by simultaneously hitting the

double click on

side, so that

Keep in mind that to upgrade software, this setting may need to be changed back, so that the Program Memory has more

available. To change, do as above but slide the pointer toward the right, which is the Program side, so that

18,000 KB

around

Once the upgrade or additional software is added, you can change it back so that the pointer is more toward the Storage

Memory -- around 18,000 KB.

After changing these settings, or updating software, it's a good idea to do a "Save System".

System

. Touch the

Allocated

. This assures that there is enough Program memory, so that the new updates can be saved.

is around

Memory tab

18,000 KB

Blue Key

and slide the pointer toward the left, which is the Storage Memory

.

and

Start

. Choose

Settings,

Control Panel,

then

Allocated

then

is

Battery Status

Battery Status of Data Collector

status of the data collector itself. Full black should indicate full battery. As battery levels decrease the black recedes to

full white (out of battery).

Most Windows Mobile devices show an accurate battery status. If you tap the battery icon, it will display the exact

battery percent available, as in 73% (for example). On some CE devices, there is no way to detect battery status, so the

battery icon does not change. On other devices such as the Jett CE, a partial indication of battery status is detected as

follows:

: The black icon that appears at the top of every screen is designed to indicate battery

Good - 100%

Low - 50%

Critical – 10%

Save System

On older Windows CE devices, its highly recommended that you perform a Save System on the device after installing

FAST Survey or making any system level changes (eg. memory settings).

Examples:

Allegro

Start Programs Utilities Save System

This is not necessary (or even possible) on most Windows Mobile data controllers. Windows Mobile itself protects

against loss of registries and data when the power is low or disrupted.

p14

Page 17

User Interface

This chapter describes the general user interface features of FAST Survey.

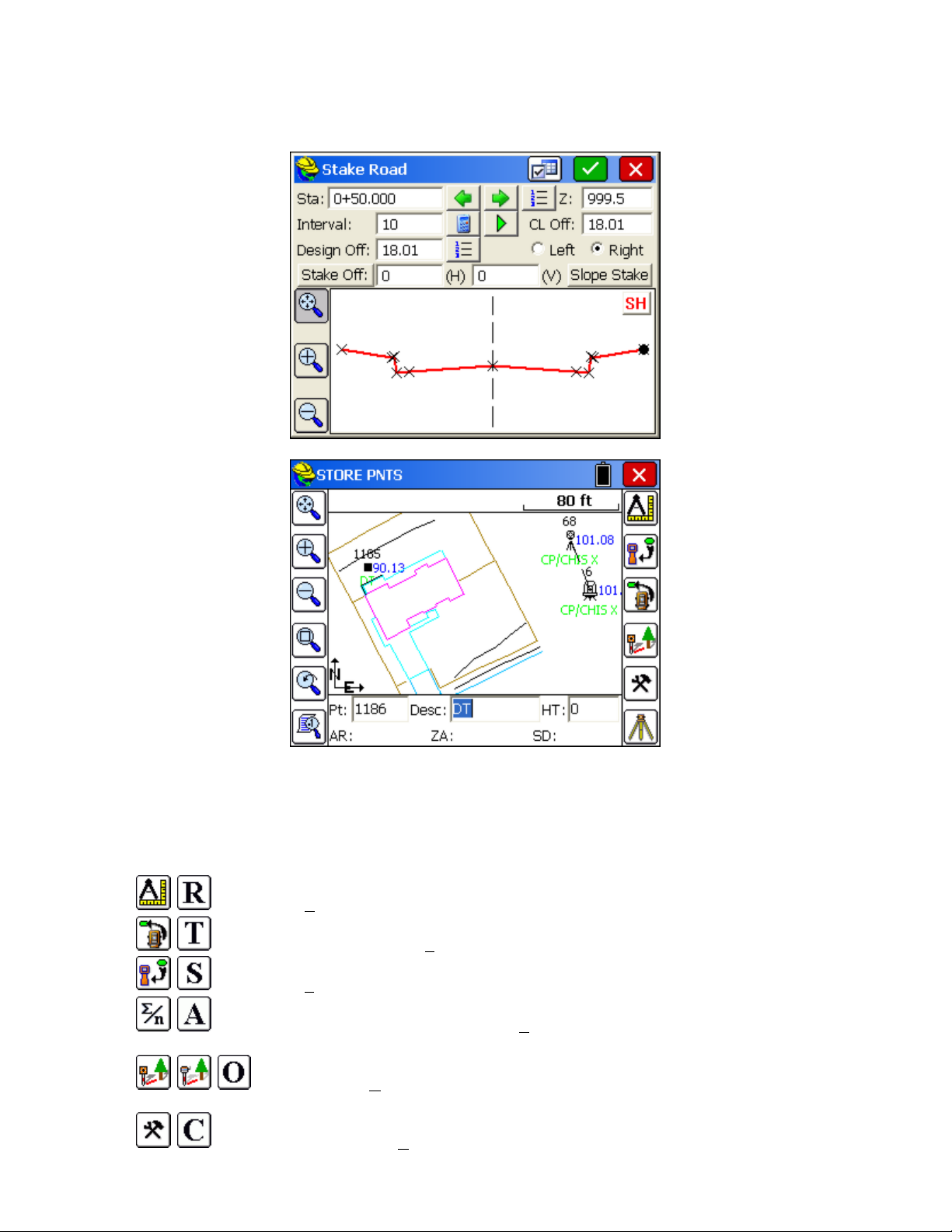

Graphic Mode

Icons

FAST Survey can be configured to show either the traditional letter icons or graphical icons for several functions. To set

this option, go to the EQUIP tab, select Configure and toggle the "Use Graphic Icons" check box.

(ALT-A).

taken by laser and hydrographic devices that measure distance only, or distance and azimuth (ALT-O).

preferences in FAST Survey such as the number of readings to average, function of the Store icon, and whether to

This icon will Read a measurement (ALT-R).

Total Station Only. This icon will Traverse to the measured point by advancing your setup (ALT-T).

This icon will Store a point. This function is also performed via the Enter key. (ALT-S).

This icon will lead to a dialog where the user can

This icon leads to

This icon will take you to the

O

ffset reading screens with options for keyed-in offsets as well as offsets

C

onfigure dialog, also found on the EQUIP tab. Here you set many

p15

A

verage up to 999 epochs of GPS readings

Page 18

display the Hgt/Desc prompt on Save (ALT-C).

stake data.

the instrument in search mode when then leads to lock mode when the prism is found.

the robotic total station in Standby mode, meaning it will suspend tracking mode (e.g. allows you to place the pole

down, drive a stake, then resume work).

(tracking) and when pressed will stop the EDM.

distances (not tracking) and when pressed will start the EDM.

will switch the instrument to reflectorless mode.

This icon will advance stake location incrementally to the

This icon returns to the previous stakeout settings dialog where you can

This icon allows the user to override the design

OK:

This icon will accept the dialog.

Back:

This icon will return you to the previous dialog.

Exit:

This icon will return you to the main menu and dismiss any changes (ALT-X).

Standby/Search:

Locked:

Tracking is On:

Tracking is Off:

Prism Mode:

Robotics only. This icon shows that the instrument is locked on the prism, and when pressed, places

Robotics only. This status icon shows the instrument is in standby and when pressed, puts

Robotics only. This icon shows that the instrument is continuously measuring distances

Robotics only. This icon shows that the instrument is NOT continuously measuring

This icon shows that the instrument is currently configured to read a prism and when pressed

El

evation (ALT-E).

N

ext point or station (ALT-N).

M

odify the current design

Reflectorless Mode:

will switch the instrument to prism mode.

Stop/Go:

(ALT-G).

Monitor/SkyPlot:

Lat/Long display (ALT-D).

Tripod:

and Remote Benchmark (ALT B).

Zoom Extents:

Zoom In:

Zoom Out:

Zoom Window:

Zoom Previous:

View Options:

symbol, the style of the plot and the freezing or thawing of attributes such as descriptions and elevations. To avoid

“point clutter”, you can even set it to show only the last stored point along with setup and BS. See the View Options

section of this manual.

This will take you to the Instrument Setup dialog. This dialog contains Backsight, Setup, Robotics

Zooms in 25%.

Zooms out 25%

This icon shows that the instrument is currently in reflectorless mode and when pressed

This icon, inside of Auto By Interval, begins and pauses the action of recording points

This icon will take you to the Monitor/SkyPlot screen for GPS status and Coordinate and

This zooms the entire drawing to fit the screen.

Zooms into a rectangular area that you pick on the map screen.

Zooms to the previous view. FAST Survey remembers up to 50 views.

Displays the View Options dialog box, where you can control aspects of points such as the

Pan

Settings

: This icon leads to settings associated with the current command or option.

p16

Page 19

You can also pan the screen simply by touching it, then holding and dragging your finger or stylus along the screen

surface. Pan is automatic and needs no prior command.

View/Edit Points by Touch

You can edit or delete any point by simply clicking on it graphically. In the Store Points command, clicking on a point

also allows you to Re-Measure the point location, both in GPS and Total Station mode.

Text Mode

The Text screen uses a large character size for easy viewing, and limits options to Monitor/Skyplot, Offset and Store.

Select the Text mode by clicking on the Helmet in the upper left of the screen, in most active survey commands,

choosing Text. You can return to the Graph view by tapping the Helmet icon and choosing Graph. You can also

temporarily view your points on the screen by tapping

screen. Note that the program will remember which screen you were in last (Graph or Text) and return to that mode of

data collection automatically.

Map

, then tap

Back

to return to the text-based data collection

View Options

The graphic view has all of the standard zoom icons as well as a View Setting Icon in the lower left. This icon allows

you to change the way the graphical items will be displayed. The View Setting Icon will show more options such as the

"Alt-F" (store last point only) option when clicked during commands such as Store Points and Stake Points (active

survey commands).

Freeze All:

Each attribute can be toggled off separately as well.

Font Size

Use Decimal as Point Location:

point of the elevation. It applies if the "dot" symbol is used.

Set Attribute Colors:

Only Display Last Stored Point (ALT-F):

collected, the instrument and backsight points, and the last point collected. This is a popular setting to reduce the

clutter of numerous points displayed all at once.

Auto Zoom

magnification, and in stakeout commands, the zoom includes your target and current location. If turned off, the

program holds the current window.

Draw Trail

direction of movement is shown by an added trail or tail associated with the arrowhead (current position).

WCS Icon

The Data tab goes to a secondary screen which normally shows only the Intelligent Zoom option, but when selected

from the Map screen (globe icon), also includes Traverse Defaults:

This toggle will freeze (hide from view) the point attributes (e.g. Point ID, Elevation and Description).

: Points can be small (default setting) or large and bold for easier readability.

This toggle will adjust the text location so that the point location is the decimal

This button will allow users to specify the colors of the point text (color units only).

This toggle will result in FAST Survey only displaying the linework

: Normally clicked on, this setting zooms to your location in survey commands at the current zoom

: For GPS and robotic total station work where the current position is updated continuously, the

: This shows the N/E icon on the graphic screen, for orientation.

p17

Page 20

Intelligent Zoom

"Intelligent Zoom" allows you to pick the point from the screen in a condensed area of points, and the program will

auto-zoom allowing you to pick again and obtain the precise point that you want. If Intelligent Zoom is off, you

would instead see a list of points and must pick from the list or return to the Map screen and zoom in closer using

the Zoom + or Zoom Window options.

Traverse Defaults

instrument height, rod height and zenith angles as set in this dialog, and will optionally store to the raw file for

processing. This allows for very fast manual entry of raw field data.

: When selecting points "From Map" in commands such as Inverse or Stake Points, the

: The T for Traverse and S for Sideshot commands, within the Map screen, will prompt for

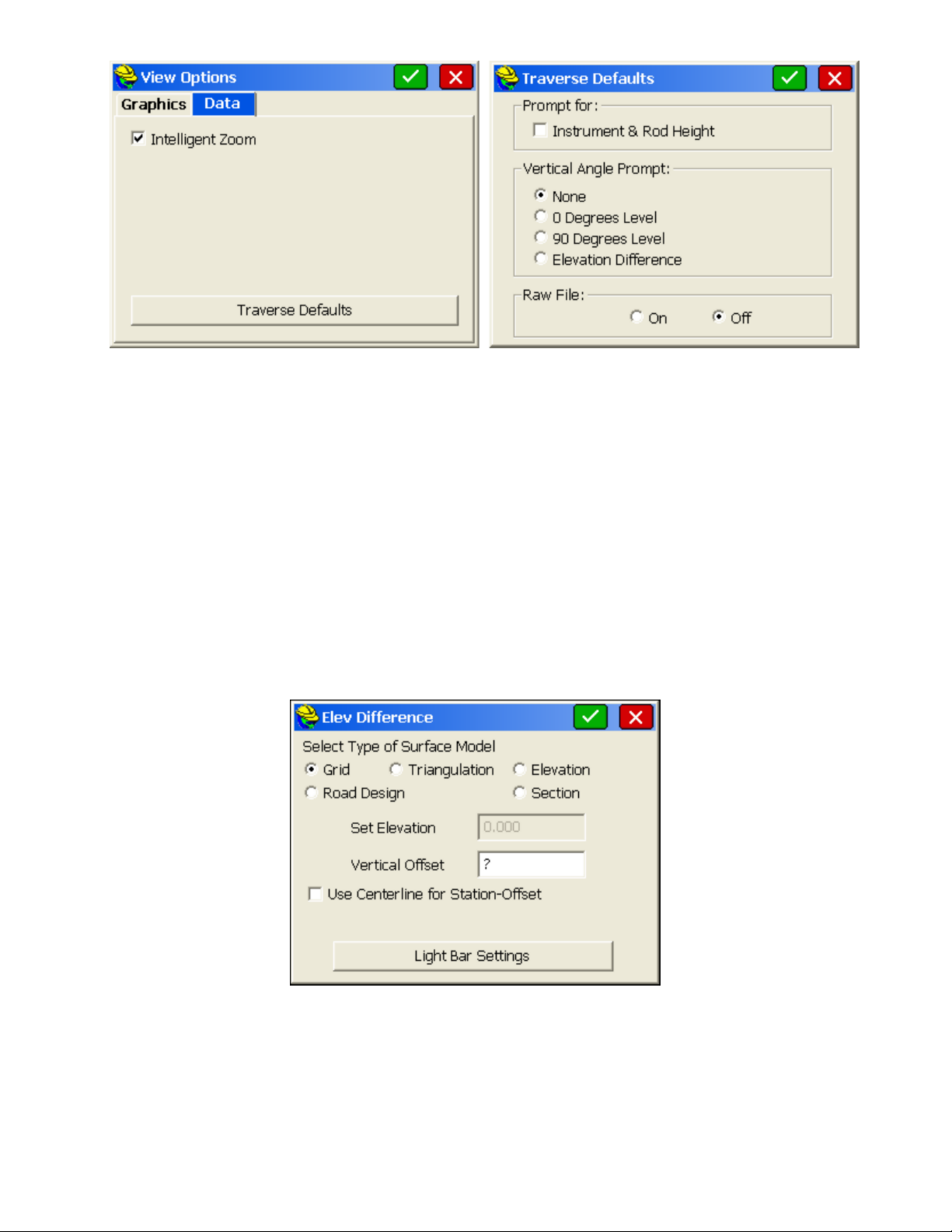

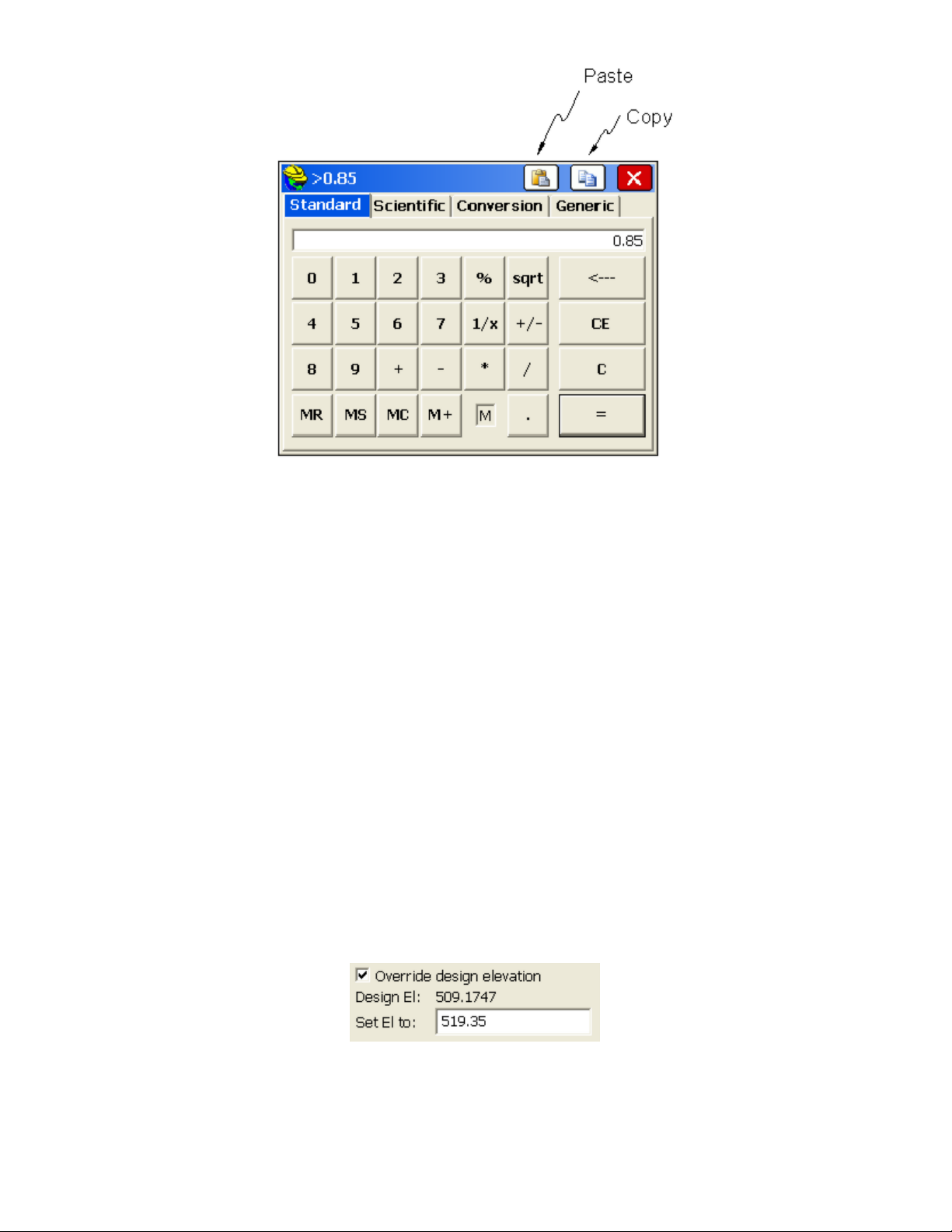

Quick Calculator

From virtually any dialog entry line in the program, the ? command will go to the Calculator routines and allow copying

and pasting of any selected calculation result back into the dialog entry line.

For example, if you were grading a site that had 4 subgrades, and had modeled the top surface, you need to grade to the

lowest subgrade surface with a vertical offset of (0.12+0.15+0.33+0.25). You could quickly obtain the value by

entering ? in the Vertical Offset field within the

Elevation Difference

dialog, as shown in this next figure.

This leads immediately to the

Standard tab, we can enter 0.12+0.15+0.33+0.25 and then "=" . Then select the

the banner line at the very top of the screen. Then choose

edit box. Change the sign to "-" for negative, as needed. Calculations can also be done directly from the edit box

within the

units setting. In this same edit box, you could also enter 19.5/12, which would do the division directly in the edit box.

Vertical Offset

Calculator

dialog. You could enter "19.5 in" for inches, which would auto-convert to feet or the current

dialog, with its four tabs, or options, many with sub-options. Using the

Copy

button, which places the value in

Paste

to paste the value back into the

p18

Vertical Offset

dialog

Page 21

Hot Keys & Hot List

The ALT key commands take the form ALT-C (Configure Reading) or ALT-N (Next Point). The ALT key and the

subsequent "Hot Key" (“C” or “N”, as mentioned here) can be entered at nearly the same time or with any delay desired.

If you press ALT and delay the entry of the hot key, you will see a text instruction: “Waiting for HotKey… Press Alt

again to return”. A second ALT returns to the previous position in the program without executing any command. ALT< and ALT- > will brighten or darken screens on “At Work” brand CE data collectors.

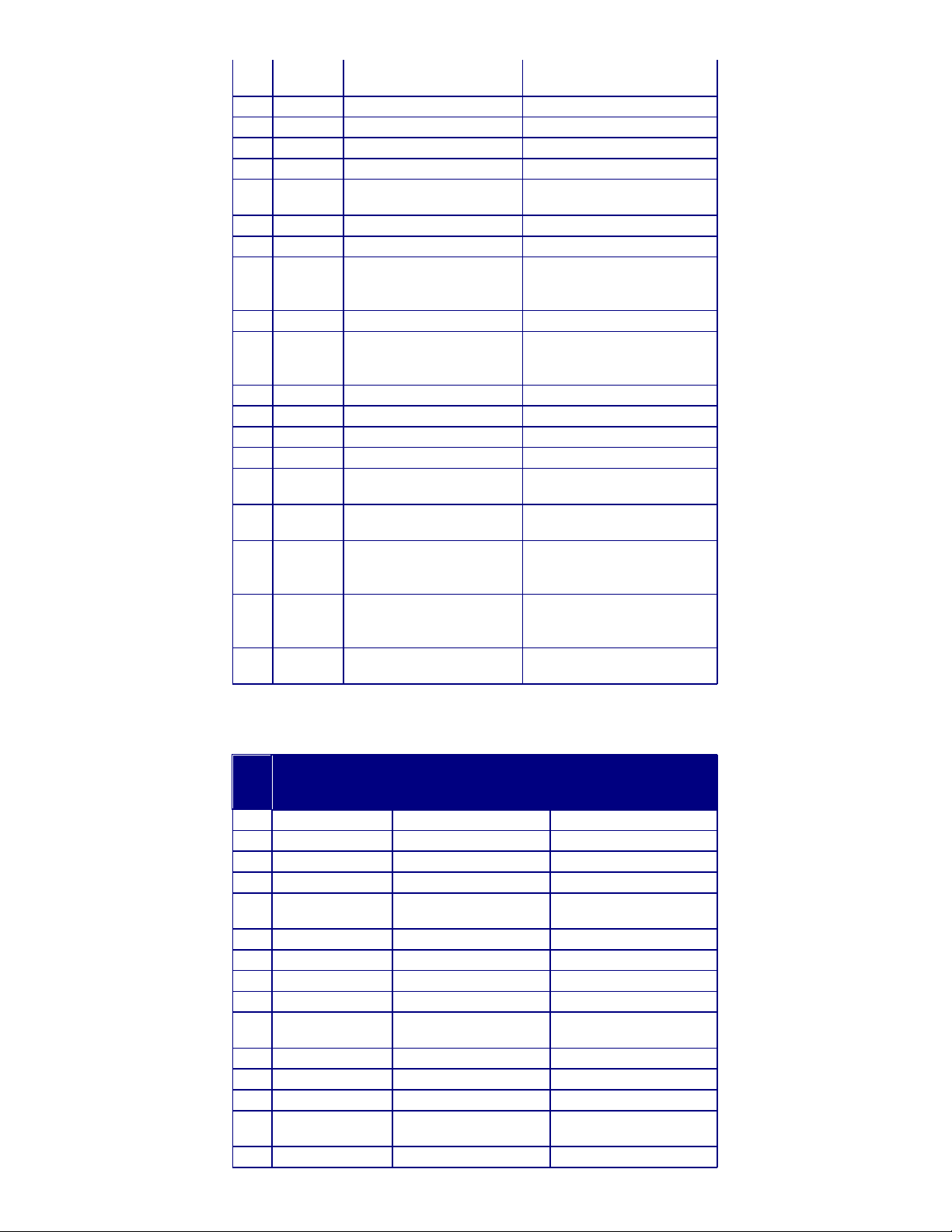

List of Hot Key Commands Activated by ALT

Many of the hot keys work only within related data gathering commands, as opposed to working from the main menus.

Hot Keys vary by command. For example, in the Store Points screen, the hot keys are as follows.

ALT-R

ALT-S

ALT-O

ALT-C

ALT-B

Here is a list of other common hot keys:

ALT-E

Elevation Difference and virtually all stakeout commands except Stakeout Points, ALT-E will allow the user to

enter an alternate design elevation different from the computed current design elevation. The screen prompt

appears below:

ALT-F

all but the setup point number, backsight point number and current foresight shot. This is helpful when points are

densely located. Alt F again returns to the full point plot. Linework remains. In GPS Mode, Alt-F hides (freezes)

all points, but shows a solid square symbol for the last GPS-measured point.

ALT-H:

: Read (Total Station Only)

: Store (or Shot/Store)

: Offset

:Configure Reading

: Backsight (Total Station Only)

: Target Elevation — From the stakeout screen in any Stakeout Line/Arc command, Offset Stakeout,

: Foresight Only Toggle. When in the Store Points graphic screen and taking new shots, ALT-F will freeze

Help. Takes you to the Help menu, where available.

p19

Page 22

ALT-I

Key

GPS

Conventional TS

Robotic TS

A

Take

Average

Reading

Read and Store (All)

Read and Store (All)

B

Total Station Setup

Setup and Robotics

C

Configure

Reading

Configure Reading

Configure Reading, Sets,

Settings and Search

D

Monitor

GPS

Manual Read

Leica: Toggle EDM; Others:

Manual Read

E

F

Freeze

Points

Freeze Points

Freeze Points

G

Start/Stop

Start/Stop Interval Recording

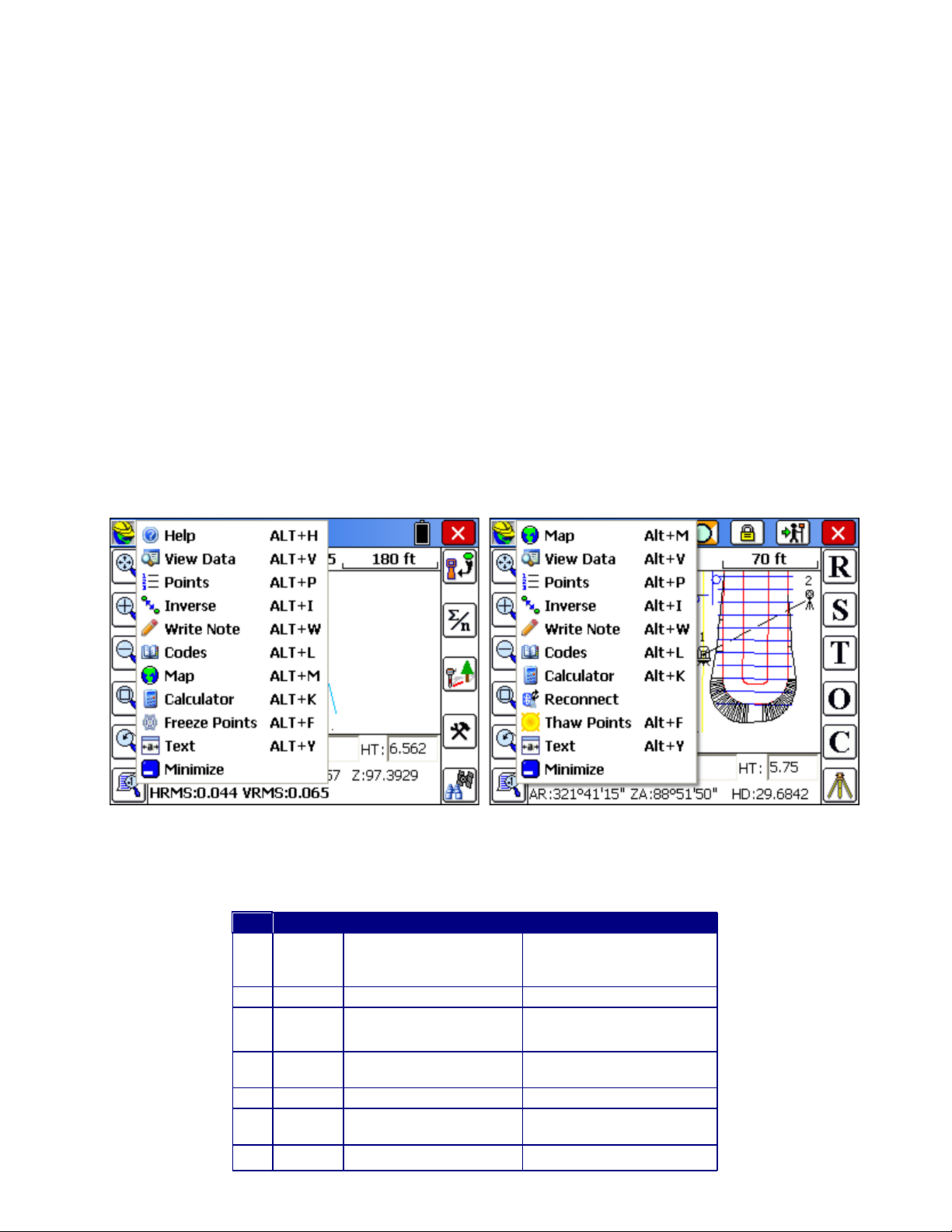

In most measurement screens you can also select the FAST Survey Helmet icon at the top left to access the hot list of

shortcuts to other routines. Depending on what commands you are in, or if a Bluetooth devices is involved (Reconnect

option), the Helmet options appear as shown:

: Inverse. Does a quick inverse, and upon exit, returns you to the command you were in. Inverse is also

accessible from the Helmet in the upper left of the screen, in many commands including Store Points.

ALT-J

: Joystick. Applies only to robotic total station. Takes you to the Settings option. ALT-J typically only

functions if you are configured for a robotic total station. ALT-J will work from within data gathering commands,

most stakeout commands (eg. Stake Points) and from the main menus.

ALT-L

: List, as in Feature Code List. When entered in any Description field, this will recall the Feature Code List,

which displays the characteristics (layer/linework) of the feature code. This serves not only as a way to select the

code and apply it to the description, but it also serves as a handy reminder of the code’s properties. Helmet-Codes

also goes to the Feature Code List.

ALT-M

ALT-N

ALT-T

presented for verification. Applies when in the Store Points routine.

ALT-V

ALT-W

ALT-X

?

SDR8100 is an exception. This device uses the ‘=’ symbol.)

: Map Screen. ALT-M will switch to the map screen.

: Next. Moves you to the Next point or station in the Stakeout commands.

: Traverse. Takes a reading and advances the setup to the measured point. The instrument setup dialog is

: Shortcut to View the Raw Data, Point Data, Feature Codes and Cutsheets.

: Write a Note anytime with this command. Notes store to the Raw File.

: Shortcut to Exit most commands. Similar to Esc (escape key).

: The ‘?’ character can be used in any field that requires a numerical entry to access the Calculator. (The Sokkia

While in any Topo (Store Points) or Stakeout routine, a number of features are accessible by pressing ALT, followed by

the corresponding Hot Key. Below is a list of Hot Keys arranged by routine and equipment type.

Action in Topo Mode Summary

p20

Page 23

Interval

Recording

H

Help

Help

Help

I

Inverse

Inverse

Inverse

J

Sokkia Motorized: Joystick

Joystick

K

Calculator

Calculator

Calculator

L

Feature

Code List

Feature Code List

Feature Code List

M

View Map

View Map

View Map

N

O

Offset

Point

Collection

Offset Point Collection

Offset Point Collection

P

List Points

List Points

List Points

Q

Toggle

Prompt for

Hgt/Desc

Toggle Prompt for Hgt/Desc

On and Off

Toggle Prompt for Hgt/Desc

On and Off

R

Read

Read and Store

S

Store

Store

Store

T

Traverse

Traverse

U

V

View Raw

File

View Raw File

View Raw File

W

Write Job

Notes

Write Job Notes

Write Job Notes

X

Exit to

Main

Menu

Exit to Main Menu

Exit to Main Menu

Y

Toggle

Graphics/T

ext Mode

Toggle Graphics/Text Mode

(Helmet-Graph to return)

Toggle Graphics/Text Mode

(Helmet-Graph to return)

Z

Zoom to

Point

Zoom to Point

Zoom to Point

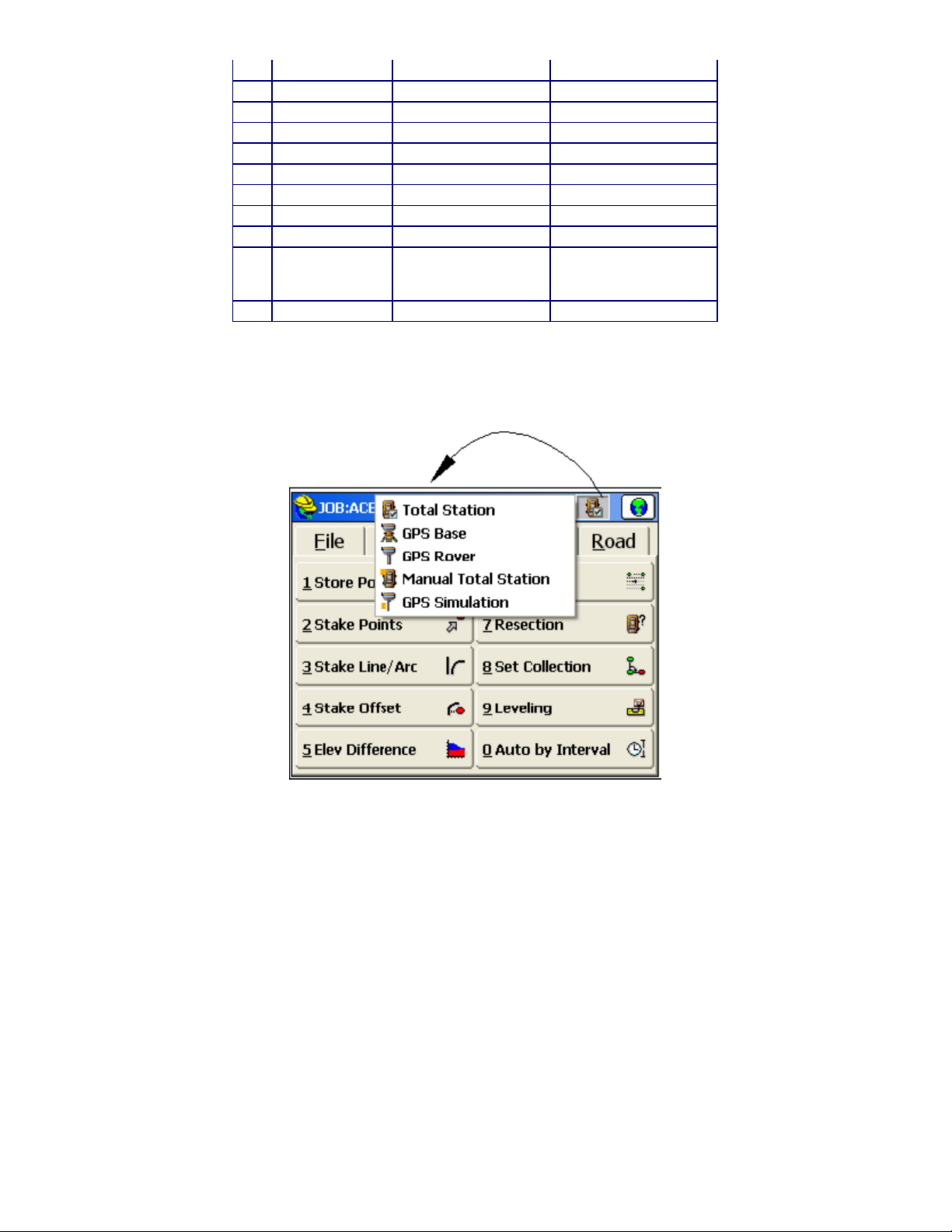

Action in Stakeout Mode Summary

Key

GPS

Conventional TS

Robotic TS

A

B

Total Station Setup

Total Station Setup

C

Configure Reading

Configure Reading

Configure Reading

D

Monitor GPS

Leica: Toggle EDM

E

Set Target

Elevation

Set Target Elevation

Set Target Elevation

F

Freeze Points

Freeze Points

Freeze Points

G

H

Help

Help

Help

I

Inverse

Inverse

Inverse

J

Sokkia Motorized:

Joystick

Joystick

K

Calculator

Calculator

Calculator

L

Feature Code List

Feature Code List

Feature Code List

M

View Map

View Map

View Map

N

Next Point/Station

to Stake

Next Point/Station to

Stake

Next Point/Station to Stake

O

p21

Page 24

P

List Points

List Points

List Points

Q

R

Read

Read and Store

S

Store

Store

Store

T

U

V

View Raw File

View Raw File

View Raw File

W

Write Job Notes

Write Job Notes

Write Job Notes

X

Exit to Main Menu

Exit to Main Menu

Exit to Main Menu

Y

Toggle

Graphics/Text

Mode

Toggle Graphics/Text

Mode (Helmet-Graph to

return)

Toggle Graphics/Text

Mode (Helmet-Graph to

return)

Z

Zoom to Point

Zoom to Point

Zoom to Point

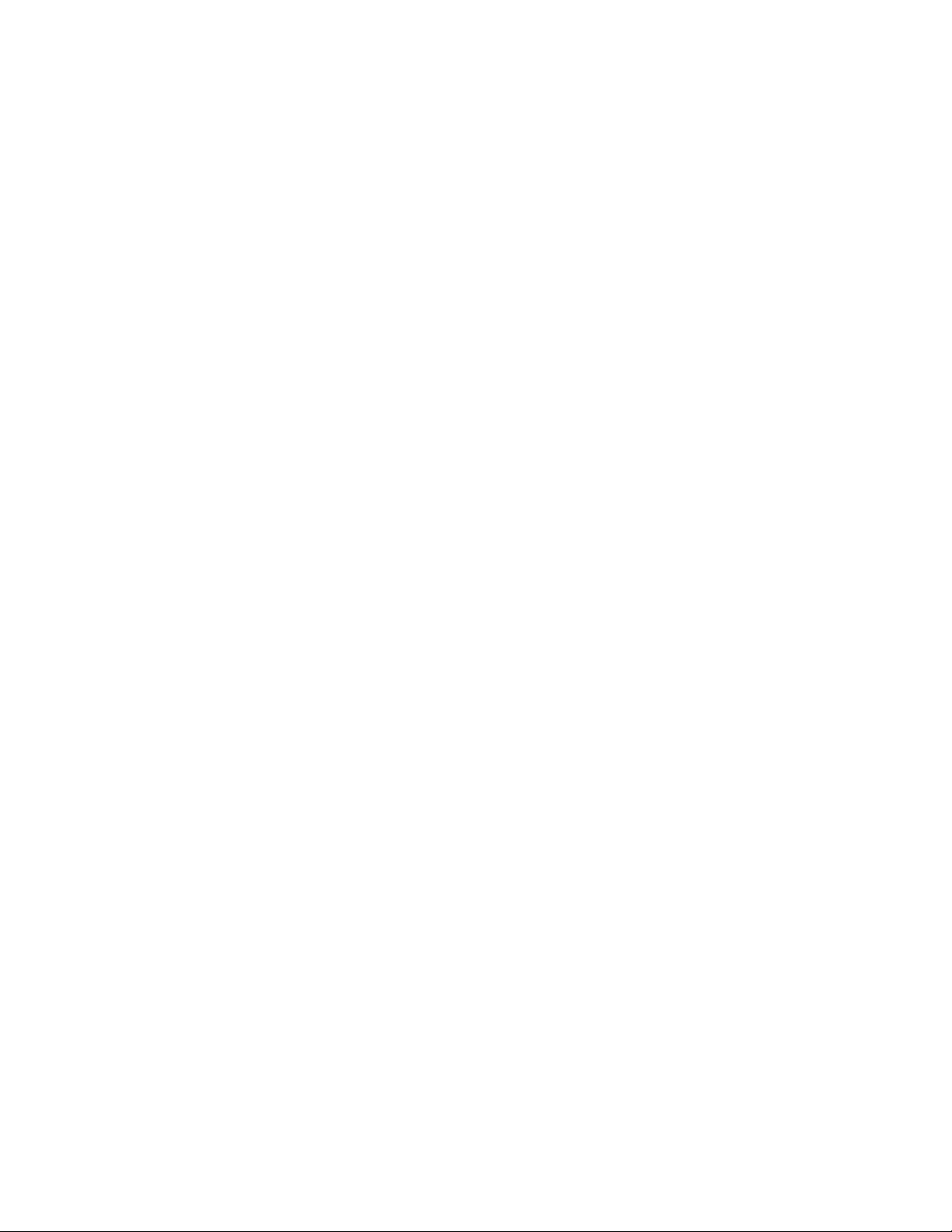

Instrument Selection

The user can switch between current instruments using the Instrument Selection flyout on the top bar of FAST Survey.

Input Box Controls

When point IDs are used to determine a value, the program will search for the point IDs in the current job. If not found

it will then search in the control job, if active.

Formatted Distance/Height Entries

Entries for distances or heights that include certain special or commonly understood measurement extensions are

automatically interpreted as a unit of measurement and converted to the working units as chosen in job setup. For

example, a target height entry of 2m is converted to 6.5617 feet if units are configured for feet. The extension can

appear after the number, separated by a space (2 m), or can be directly appended to the number (2m). For feet and inch

conversion, the second decimal point informs the software that the user is entering fractions (See Below). Recognized

text and their corresponding units are shown below:

f or ft:

US Feet

i or ift:

International Feet

in:

Inches

cm:

Centimeters

m:

Meters

#.##.#:

Feet and Inches (e.g. 1.5.3.8 = 1'5 3/8" either entry format is supported)

p22

Page 25

These extensions are automatically recognized for target heights and instrument heights, and within certain distance

entry dialogs. Entries are not case sensitive.

Formatted Bearing/Azimuth Entries

Most directional commands within FAST Survey allow for the entry of both azimuths and bearings. Azimuth entries are

in the form 350.2531 (DDD.MMSS), representing 350 degrees, 25 minutes and 31 seconds. But that same direction

could be entered as N9.3429W or alternately as NW9.3429. FAST Survey will accept both formats. Additional

directional entry options, which might apply to commands such as Intersection under Cogo, are outlined below:

If options in Job Settings are set to Bearing and Degrees (360 circle), the user can enter the quadrant number before the

angle value.

Example

120.1234

The result is N20°12’34’’E.

Quadrants

1 NE

2 SE

3 SW

4 NW

In the case where Job Settings have been set for Bearing, and the user would like to enter an Azimuth, the letter A can

be placed before the azimuth value and the program will convert it to a Bearing.

Example

A20.1234

The result is N20°12’34’’E.

In the case where Job Settings is set to Azimuth and the user would like to enter a bearing, the quadrant letters can be

used before the bearing value.

Example

NW45.0000

The result is 315°00’00”.

Formatted Angle Entries

Interior Angle:

The user can compute an angle defined by three points by entering the point IDs as <Point ID>,<Point

ID>,Point ID>. The program will return the interior angle created by the three points using the AT-FROM-TO logic.

Such entries might apply to the Angle Right input box in Store Points when configured to Manual Total Station.

Example

1,2,3

Using the coordinates below, the result is 90°00’00”. Point 2 would be the vertex point.

Pt. North East

1 5500 5000

2 5000 5000

3 5000 5500

Mathematical Expressions

Mathematical expressions can be used in nearly all angle and distance edit boxes. For example, within the Intersection

routine, an azimuth can be entered in the form 255.35-90, which means 255 degrees, 35 minutes minus 90 degrees.

Additionally, point-defined distances and directions can be entered with a comma as separator, as in 4,5. If point 4 to

point 5 has an azimuth of 255 degrees, 35 minutes, then the same expression above could be entered as 4,5-90. For

math, the program handles “/”, “*”, “-“ and “+”. To go half the distance from 103 to 10, enter 103,10/2.

Point Ranges

p23

Page 26

When ranges of points are involved, such as in stakeout lists, a dash is used. You can enter ranges in reverse (e.g..

75-50), which would create a list of points from 75 down to 50 in reverse order. For example, in Stake Points, you

could enter 75-50 for the point to stake, click "Add to List", then starting at point 75, stake 74, then 73, etc. by clicking

N for Next.

Survey Data Display Controls

ANGLE

The angle control will display the angle as defined by the current settings in Job Settings.

Options are available for Azimuth (North or South) or Bearing combined with the option of Degrees or Grads.

Format

The display format of degrees uses the degree, minute, and second symbols. For the case of a bearing we display the

quadrant using the characters N, S, W, E.

Example Bearing

N7°09'59"E

Example Azimuth

7°09'59"

All angular values entered by the user should be in the DD.MMSS format.

Example

7.0959

The result is 7°09'59".

Formulas

Formulas can be entered for working with angles. The format must have the operator after the angle value.

Example

90.0000 * 0.5

The result would be 45°00’00”

DISTANCE

The distance control will display the value using the current Job Settings unit. You can enter a formula using the

mathematical operators as described above.

Inverse

You can compute a distance from a point-to-point inverse by entering <Point ID>,<Point ID>.

Example

1,2

Using the coordinates listed below, the result is 500’.

Pt. North East

1 5500 5000

2 5000 5000

STATION

The station control will display the value using the current Job Settings format.

The same options described above for distance input boxes apply.

SLOPE

The slope control will display the value using the current Job Settings format.

Keyboard Operation

FAST Survey allows the user to operate the interface entirely from keyboard navigation, as well as touch screen

navigation. The rules for keyboard navigation are outlined below:

Controls

Button (Radio Buttons, Check Boxes and Standard Buttons)

Enter:

o

Right/Left Arrows:

o

Select the button.

Move to the next tab stop.

p24

Page 27

Right

Left

Up/Down Arrows:

o

Down

Up

Tab:

o

In Menus like Job Settings, Tab Right and Tab Left move through the tab headings (New Job, System, Format, Options,

Stake) along the top of the dialog, while the right and left arrows move up and down through the options within each

tab.

Drop List

o

o

o

o

Edit Box

o

o

o

o

Tab

o

o

o

o

Move to the next tab stop.

Enter:

Right/Left Arrows:

Up/Down Arrows:

Tab:

Enter:

take a reading. For all other edit boxes, ENTER moves through the tab stops.

Right/Left Arrows:

Up/Down Arrows:

Tab:

Enter:

Right/Left Arrows:

Up/Down Arrows:

Tab:

Selects the highlighted option within each drop list.

Right

Left

Move to the next tab stop.

Move to the next tab stop. For any measurement screen, if focus is in the description edit box,

Down

Up

Move to the next tab stop.

Move to the next tab stop.

Right

Left

Down

Up

Move to the next tab stop.

[Tab]

[Shift+Tab]

Move to the next tab stop.

[Tab]

[Shift+Tab]

Move to the next tab stop.

[Tab]

[Shift+Tab]

Move through the list items.

Move through the text like standard windows.

Move to the next tab stop.

[Tab]

[Shift+Tab]

Move through the tabs.

Next Tab

Previous Tab

Move to the next tab stop.

[Tab]

[Shift+Tab]

Abbreviations

Adr: Address

AR: Angle Right

Avg: Average

Az: Azimuth

Bk: Back

Calc: Calculate

Char: Character

Chk: Check

cm: Centimeter

Coord(s): Coordinate(s)

Ctrl: Control

Desc: Description

Dev: Deviation

p25

Page 28

Diff: Difference

Dist: Distance

El: Elevation

Fst: Fast

ft: Foot

Fwd: Forward

HD: Horizontal Distance

HI: Height of Instrument.

Horiz: Horizontal

Ht: Height or Height of Antenna with GPS.

HT: Height of Target.

ID: Identifier

ift: International Foot

in: Inch

Inst: Instrument

Int: Interval

L: Left

m: Meter

No: Number

OS: Offset

Prev: Previous

Pt: Point ID

Pts: Points

R: Right

Rdg: Reading

SD: Slope Distance

Sta: Station

Std: Standard

Vert: Vertical

ZE: Zenith

p26

Page 29

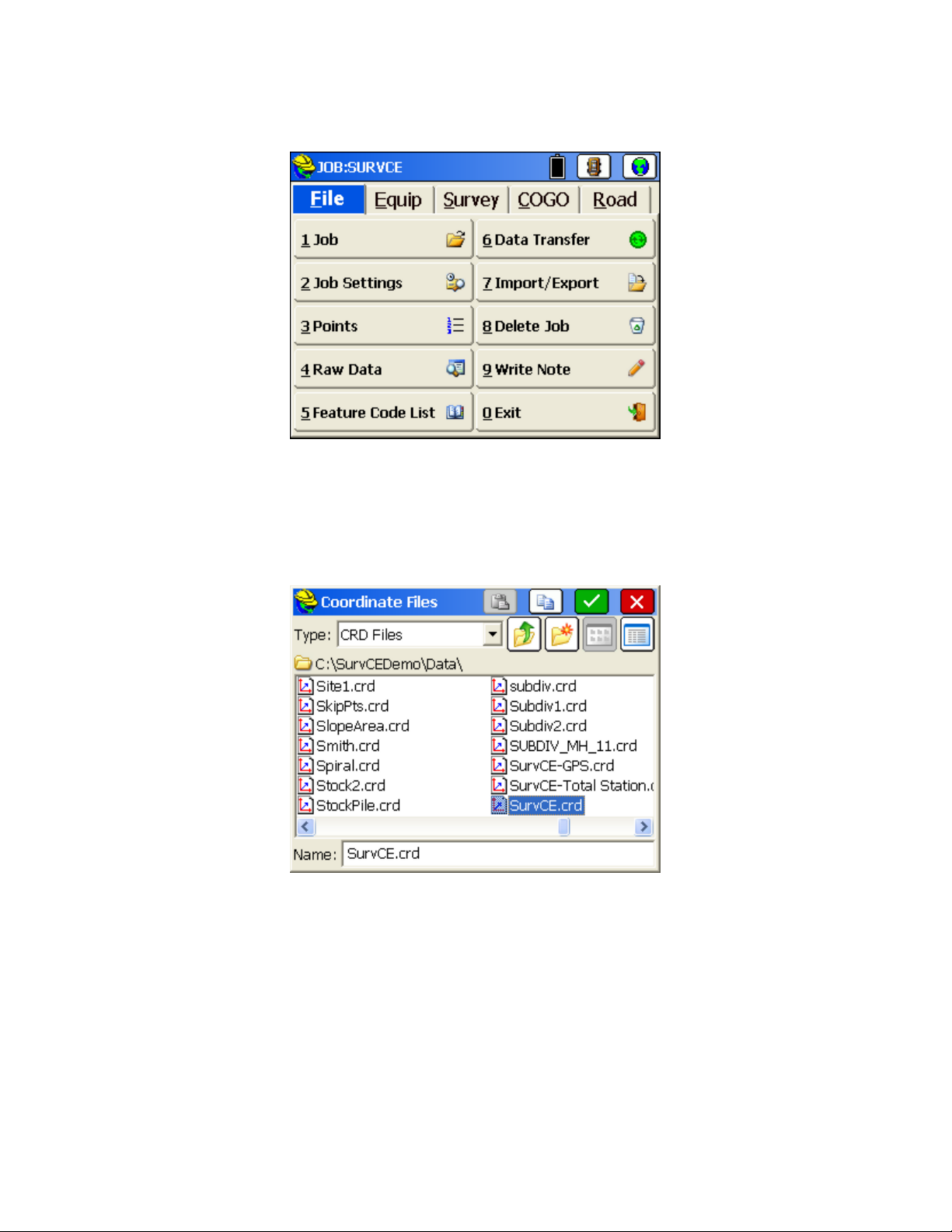

FILE

This chapter provides information on using the commands from the File menu.

Job

This command allows you to select an existing coordinate file for your job or to create a new coordinate file. The

standard file selection dialog box appears for choosing a coordinate file, as shown in the next figure. Buttons for moving

up the directory structure, creating a new folder, listing file names and listing file details appear in the upper right corner

of the dialog box.

All data points you collect are stored in the coordinate (.crd) file you select or create. The .crd file extension will

automatically be appended to the file name.

Select Existing Job

To select an existing job, browse to and select an existing file, then select OK (the green check icon).

Create a New Job

To create a new job, simply enter a new name and select OK. You can control where your job is saved by browsing to

the desired folder where the job is to be created before entering the new name and selecting OK. You can also create a

new folder for this new file name. Following job creation, you will be asked to enter in Job Attribute information. This

feature lets you set up prompting for each new job with job-related attributes like Client, Jurisdiction, Weather

Conditions and the like. The information is stored in the raw file. This is discussed in detail in the Job Setting section.

Copy and Paste Job

The Copy icon at the top of the dialog let's you copy an existing file and then paste it with the Paste icon into a different

p27

Page 30

directory, as selected.

Note:

If you key in a coordinate file that already exists, it will load the file instead of overwriting it with a new file. The

benefit of this feature is that you cannot accidentally overwrite an existing coordinate file from within FAST Survey.

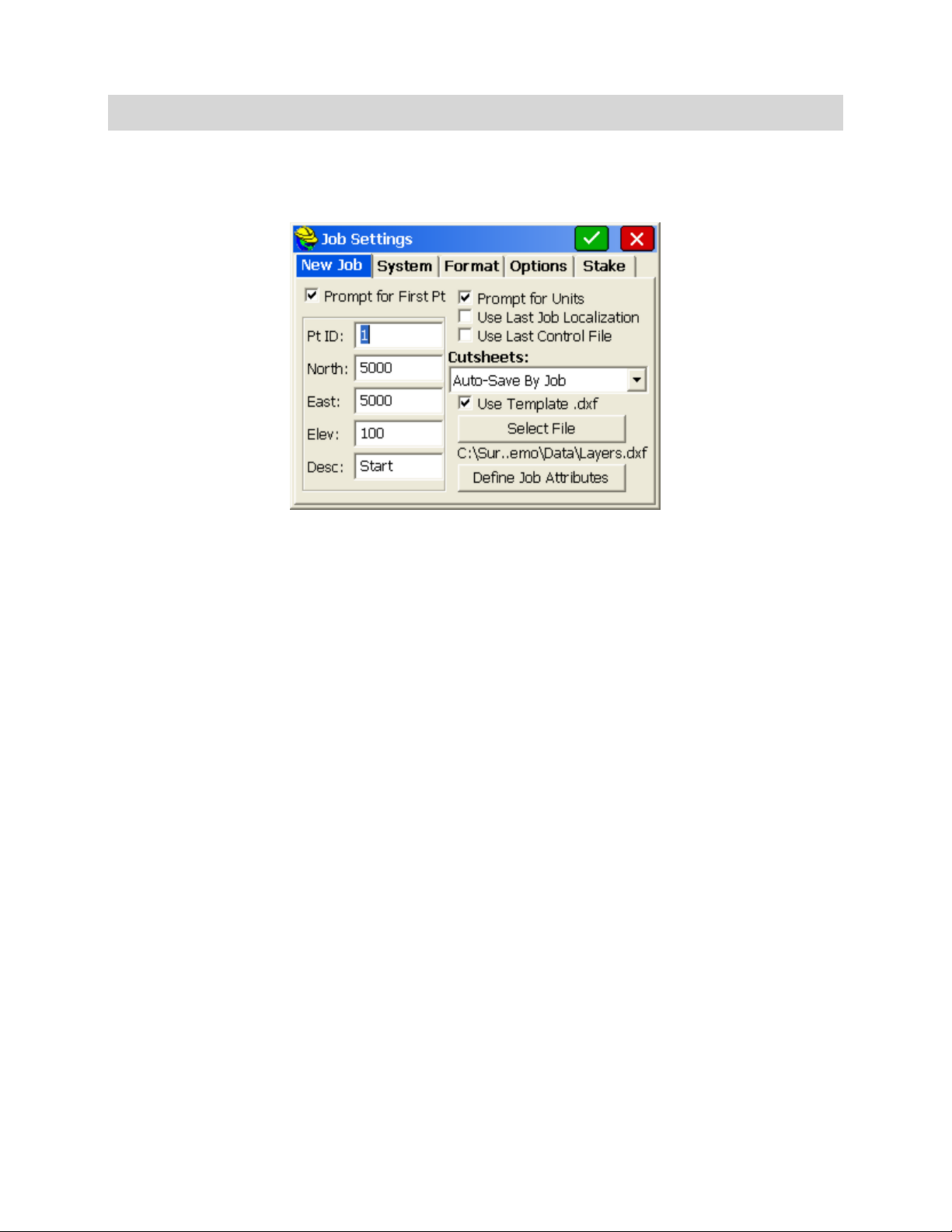

Job Settings (New Job)

This tab allows you to configure how all new jobs will be created.

Prompt for First Pt

when starting a new job. If enabled, you specify the default starting point coordinates in the left column. This

applies for total station use only.

Prompt for Units

start a new job.

Use Last Job Localization:

project scale. If this feature is disabled, each new job will start out with no localization and a project scale of 1.0.

The default value is off.

Attach Last Control Data:

the control file will automatically be deactivated during new job creation.

Cutsheets:

your job was named Macon1.crd, then the 3 cutsheet files created would be Macon1-Pt.txt (for non-alignment,

point-only stakeout), Macon1-CL.txt (for stakeout involving alignments) and Macon1-Sl.txt (for slope staking).

Recall Previous will allow the user to use the same cutsheets on all new jobs. With Manual, the control file will

automatically be deactivated during new job creation and you will need to create cutsheet files within the Stake tab

of Job Settings. Cutsheets normally store in ASCII (*.txt) format but can store in EXCEL (*.csv) format if selected

within Job Settings, Options.

Use Template DXF:

will be used and displayed in the field. The feature works well with use of Feature Codes for linework. If you

designate code 201, for example, as a pavement edge in the layer BitPav, you could make a blank DXF drawing

with BitPav layer created, set to color blue. Then using that "template dxf" file, everytime you code a 201, you will

see the blue linework as an extra confirmation of correct coding. This color-coding could be repeated for other

often used layers.

Define Job Attributes:

Jurisdiction, Weather Conditions, Party Chief and other notes. These will prompt when each new job is started, and

the attributes and entries will appear in the raw file (.rw5) file. Select Add to enter new attributes.

Auto-Save by job will automatically create cutsheet files (in the last format used) for each new job. If

: This option specifies whether or not FAST Survey will prompt you to specify a starting point

: This option specifies whether or not FAST Survey will prompt you to set the units when you

If this feature is enabled, each new job will use the previous job’s localization file and

This allows the user to use the same control file on all new jobs. With this option off,

This allows users to create an empty DXF file that contains all of the layers and colors that

This lets you set up prompting, for each new job, for job-related attributes like Client,

p28

Page 31

Job Settings (System)

This tab allows you to define the units for the current job.

Distance

or International Feet is selected, you have the option to display distances as decimal feet (Dec Ft) or Feet and

Inches (Inches). This is a display property only and will not change the format of the data recorded to the raw file.

Angle

(also refered to as grads- 400 circle and fully decimal). An angle of 397.9809 gons is equivalent to 358 degrees, 10

minutes and 58 seconds. (Note: you can verify this in Cogo, Calculator, Conversion tab). The Angle Unit

configuration impacts commands such as Inverse, Traverse, Sideshot, Input-Edit Centerline and other commands

where a direction is displayed or entered.

Zero Azimuth Setting

Edit Projection List

This is done by selecting projectcions from Predefined choices, per the menu option below. Predefined choices

include NAD 27 and NAD 83 for the United States and UTM for projections around the globe, as well as individual

country projections. You can also Add User Defined projection systems, where you enter the New System name,

choose the Projection type for an extensive list, then enter all the information requested such as False Northing,

False Easting, and the items within "New Datum".

: Select the units that you want to use. Choices include US Feet, International Feet, and Metric. If US Feet

: This offers the option of degrees (360 circle, 60 minutes to a degree and 60 seconds to a minute) or gons

: Allows you to specify the direction for zero azimuth, North or South.

: You can create a short list of commonly used projections that appear in the pulldown list.

p29

Page 32

Note:

The Projection selection applies primarily to GPS work and your localization file. It enables automatic

calculation of grid to ground and ground to grid factors, for example (See Localization). However, the Projection can

also apply to total station work. When you do any processing of your data within the Raw Data option (File Menu),

there is an option "Reduce to Grid Coordinates". If this option is turned on, then the position on the projection is

calculated for each point in the traverse and for each sideshot, and leads to a specific grid factor. The grid factor,

combined with the elevation factor, leads to computation of the combined factor, which is applied to each traverse and

sideshot. The program then calculates the fieldwork at sea level on the projection (ground to grid). This can improve

your closures especially when traversing from one known grid system monument to another. Selecting and applying the

correct projection is also useful when trying to match total station measurements (often located on the ground) to

GPS-based survey work (typically located on the grid, at sea level).

Job Settings (Format)

This tab allows you to select the viewing format of the data displayed and entered in the current job.

Coordinate Display Order:

East then North.

Angle Entry and Display

prompting and displays in Sideshot Traverse (the backsight as azimuth or bearing), Intersections, and Inverse.

Vertical Observation Display

Vertical Angle (90 degrees up, 0 degrees level) or Elevation Difference (up is positive in absolute units, down is

negative). Normally combine Elevation Difference with Horizontal Distance. If combined with Slope Distance, the

non-zero Elevation Difference will be used to compute the equivalent zenith angle and will reduce the Slope

Distance to a lesser Horizontal Distance. (Applies to entries in Manual Total Station mode).

This option allows you to display coordinates with the order of North then East or

: Options are Bearing or Azimuth. This applies to numerous commands, such as

: Allows you to set the default prompting to Zenith (0 degrees up, 90 degrees level),

p30

Page 33

Distance Observation Display

station readings.

Slope Entry and Display

Percent, Degrees or Ratio; however, some commands such as 3D Inverse will automatically report both slope and

ratio and are unaffected.

Station Display

the U.S., for example, roads designed in feet are “stationed” by every 100 feet, so that a road at linear position

14280.5 is given a station of 142+80.50. Metric roads in the U.S. are often stationed by kilometers, where the same

road position has a station of 14+280.500. You can configure the placement of the “+” as desired, independent of

your configuration for metric vs feet units. You can also configure for a purely decimal display of

stationing/chainage, as in 14280.500. This display form shows up in such commands as Input-Edit Centerline,

within the Start Station dialog box. Please note that you should still input the stationing in purely numeric form,

without the “+” convention. Only the display is impacted by this option.

: This option impacts the display of centerline stationing, sometimes referred to as “chainage”. In

: Options are Slope or Horizontal. This applies to the values displayed from total

: Whenever slopes are reported or prompted, you have the option to specify the default in

Job Settings (Options)

This tab allows you to set configuration options for the current job.

Time Stamp Each Point

Raw files in FAST Survey have a .RW5 extension and are nearly identical to the TDS .RW5 format. See the image

below for simple FAST Survey .RW5 file.

Store GPS Accuracy in Raw File

the horizontal and vertical quality as reported by the GPS will be stored to the raw file with each point (RMS or

CEP/SEP typically).

: When enabled, a date and time stamp will be noted in the raw file beside each point.

: This option is available when configured to any GPS equipment. If enabled,

p31

Page 34

Use Code Table for Descriptions

draw symbols and linework within specific layers. Special code icons also appear when "Hgt/Desc Prompt on

Save" is on (within Equip-Configure). If "Use Code Table" is clicked off, use of feature codes is disabled and no

linework or symbol drawing will occur. When clicked off, only the current descriptions used in the current job will

appear. Most users will turn on the "Use Code Table" option and access the power of the feature codes. Only users

who do not want linework and symbols and only wish to see the specific descriptions in their current, active job will

benefit from turning off "Use Code Table". When clicked off, only the current descriptions used in the active job

appear for re-use by picking.

: This feature activates feature code usage. If on, feature codes can be used to

Recall Job Road Files

in the non-roading version of FAST Survey. When enabled, this option will recall the last roading files (centerlines,

profiles, templates, superelevation files, etc.) used in road stakeout. Routines in the Road menu such as Stake Road

and Slope Staking will automatically recall the last-used roading files

Recall Job Localization

for several days. It allows you to set up the base in the same location, change only the base antenna height in

Configure Base (if applicable), then continue to work. You must have at least 1 point in the file (which initiates the

RW5, “raw”, file) for the GPS localization to be auto-recalled. With this option disabled, you would have to go to

Localization within the Equip menu and Load the stored localization (.dat) file. Even with the option turned on,

you can always move to a new job and create or load another localization file. The localization file (*.dat file) is

recalled as long as there is at least one coordinate point in the job.

Auto Load Map and Auto Save Map

These maps can be created by using the command IDXF which imports a DXF drawing file. AutoCad DXF formats

12 through 2000 are fully compatible and will import. Microstation DXF files and DXF files from other CAD

programs will also work. Linework (referred to as polylines) can be produced within the MAP view by using the

PL (polyline) command, or other commands such as Offset (O2 and O3). In addition, use of Feature Codes, where

linework is associated with field codes such as EP for edge-of-pavement, will lead to the drawing of polylines in the

Map view. These maps can then be auto-saved whenever you exit a coordinate file, and auto-loaded whenever you

load a particular coordinate file. The maps are saved in DXF format. It is typical to enable both Auto Load Map

and Auto Save Map if you want to auto-recall your latest map. If Auto Load Map is on and Auto Save Map is

turned off, you will recall the map that was saved previously—when Auto Save Map was on. If you want to start

your map from a clean slate (from the point plot only—which always appears in map view), you can turn off Auto

Load Map and re-enter the program. Then add polylines, use IDXF to import maps (polylines), then click on Auto

Save Map and Auto Load Map and you will store and recall only the new linework.

: This command only applies to Stakeout Centerline, Offset Stakeout, and Point Projection

: Enabling this option is advisable if you are working on the same job with GPS equipment

: Maps can be viewed in the MAP and Graphic views within FAST Survey.

p32

Page 35

Note:

The above graphic display is non-default. In the Map screen, the normal display includes pull down menus.

These can be disabled by selecting Preferences under the File menu. The screen shown below will appear with

display options. The pull down menu format is recommended, since it contains the same graphic space, and also

responds identically to keyed-in commands (such as PL for polyline).

Recall Image Database

database background screen, such as an aerial photo, on each new job or existing job. Whatever image is actively

displayed when the option is selected will be displayed when other jobs are loaded. If no image is active when the

option is selected, then it has no effect. This would be useful for repeated new jobs where a particular aerial photo

graphic is needed for reference. The actual graphic used is set within the Map screen, Tools menu, option Place

World Image, Use Image Database.

Allow Import .dxf/.dwg Options

.dxf and .dwg files. If you wish to avoid importing and exporting of points and want to focus only on linework,

then this option can be turned off.

: Similar to the DXF file used for new jobs, this option would recall and place an image

: This creates additional options within the Map Screen, Import and Export of

p33

Page 36

Default Cutsheets to EXCEL (*.csv) Files

Use Control File

file.

Select File

control file, even when the control file option is disabled (in which case it is grayed out). Control files remain

associated with active coordinate files.

: The control file is used for selecting and using points that don’t exist in your current working

: You need to select a file for the control file. The chosen file appears, and will remain as the default

: Stores Cutsheets in *.csv (EXCEL) format.

General Rule:

the control file. If the point is not found in either file, a warning that the point does not exist will be displayed.

You can force a point to come from the control file or the current file, regardless of settings, by using the List

icon to the right of the point ID input box. While in the point list selection window, select the Control file radio

button prior to selecting the desired point.

Stakeout Option:

Job Settings and set the program to give priority to the control file points when duplicate points exist. If this

option is turned on, and the selected point is found in both files, you will actually be staking out the point from

the control file.

Coordinate File Rule:

file. This allows users to avoid large gaps in coordinate files and eliminates the potential for conflicting points.

Raw Data File Rule:

processing purposes. There will not be an SP record written for control file points, only an OC record. Note

that if the raw file is reprocessed, the point will be written to the current coordinate file.

FAST Survey will always look for the defined point in the current working file first, and then

Control files work similarly in stakeout. However, you can go to the STAKEOUT tab in

At no time will a point be automatically copied from the control file into the current

Any time a point is occupied, the occupation record (OC) is written to the raw file for

Job Settings (Stake)

This tab allows you to set configuration options for the stakeout routines.

p34

Page 37

Precision:

Store Data Note File

Use this to control the decimal precision reported during stakeout routines.

: This option specifies whether or not to store the stakeout data in the note file (.NOT) for

the current job. At the end of staking out a point, there is an option to store the staked coordinates in the current