Page 1

HTSD37XH

HTSD28XH

(37X Optical Zoom)

(28X Optical Zoom)

960H Indoor / Outdoor Speed Dome Cameras

Please read this manual thoroughly before operation and keep it handy for further reference

Page 2

CAUTION

RISK OF ELECTRIC SHOC

K

DO NOT OPEN

CAUTION : TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT OPEN THE COVERS.

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONAL

This lightning flash with arrowhead symbol is intended to alert the

user to the presence of un-insulated "dangerous voltage" within the

product's enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

This exclamation point symbol is intended to alert the user to the

presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

This Device compiles with Part 15 of the FCC Rules. Operation is

subject to the following two conditions:

(1) This device may not cause harmful interface, and

(2) This device must accept any interference received, including

interference that may cause undesired operations.

2/56

Page 3

NOTICE

Important Safety Guide

1. Read, heed and follow all the instructions

Read all the safety and operating instructions before using the product.

2. Keep this manual

Keep this manual for reference in future.

3. Attachments / Accessories

Use only the attachments or accessories specified by the manufacturer.

4. Installation

Do not install near any heat resources such as radiators, heat registers, stoves,

or other appratus including amplifiers that product heat. Improperly installed

product may fall, cause serious injury to a child or adult and damage the

product.

Do not block any ventilation holes or openings. Install in accordance with the

manufacturer’s instructions.

Use only with the cart, stand, tripod, bracket, mounting devices, or table

specified by the manufacturer.

Installation should be done only by qualified personnel and conform to all the

instructions by the manufacturer.

Refer all servicing to qualified service personnel.

Unless the product is specifically marked as IP67, more than IP67 or confirmed

by the manufacturer, it is designed for indoor use only and it must not be

installed where exposed to rain and moisture.

Do not load on the product.

Use stainless steel hardware to fasten the mount.

To prevent damage from water leakage when installing a mount outdoors on a

roof or wall, apply sealant properly around holes.

These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing other that

contained in the operationg instructions unless you are qualified to do so.

Use only replacement parts specified by the manufacturer.

5. Power source

This product should be operated only from the type of the power source indicated

on the marking label.

3/56

Page 4

NOTICE

Caution

Operating

Before using, make sure that the power supply and others are properly

installed.

While operating, if any abnormal condition or malfunction is observed, stop

using the product immediately and then contact your local dealer.

Handling

Do not disassemble or tamper with the parts inside the product.

Do not drop or subject the product to shock and vibration as this can damage

the product.

Care must be taken when you clean the clear dome cover. Especially, scratch

and dust will ruin the quality of the product.

Installation and Storage

Do not install the product in areas of extreme temperature, which exceed the

allowable range.

Avoid installing in humid or dusty places.

Avoid installing in places where radiation is present.

Avoid installing in places where there are strong magnetic fields and electric

signals.

Avoid installing in places where the product would be subject to strong

vibrations.

4/56

Page 5

Feature

s __________________

6

Package Components

9

Main Part Description

10

DIP Switch Setup

11

Installation with

Ceiling Mount Bracket

14

Installation with Wall Mount Bracket

15

Wiring

and Cabling

16

Check Point before Operation

19

Check Points for Preset and Pattern Function before Operation

19

OSD

Menu

20

Reserved Preset (Hot Keys)

20

Preset

21

Swing

21

Pattern

22

Group

23

Other Functions

23

OSD Display

25

Quick P

rogramming Guide

26

Main Menu

26

Display

Setup

27

Privacy Zone Mask Setup

28

Clock Setup

30

Camera Setup

31

Motion Setup

35

Preset Setup

38

Swing Setup

40

Pattern Setup

41

Group Set

up

42

Schedule Setup

45

Password Setup

46

S

ystem Initialize

48

Dimens

ion

s

53

TABLE OF CONTENTS

①①①① Introduction

②②②② Installation

③③③③ Operation

④④④④ OSD Menu

⑤⑤⑤⑤ Specifications

49

5/56

Page 6

I

NTRODUCTION

Features

Powerful Zoom Camera & Setup Options

Image Sensor : 1/4" Interline Transfer CCD

Zoom : HTSD37XH (×37 Optical Zoom, ×32 Digital Zoom)

1

: HTSD28XH (

×28 Optical Zoom, ×32 Digital Zoom)

Day & Night, Privacy Mask and WDR

DNR (Digital Noise Reduction) Function

Various Focus Mode : Auto-Focus, Manual Focus, Semi-Auto Focus

Various Setup Options in OSD Menu.

Powerful Pan/Tilt Functions

MAX. 500°/sec High Speed Pan/Tilt Motion

With the Vector Drive Technology, Pan/Tilt motions are accomplished along

the shortest path. As a result, the time to target view is remarkably short and

the video on the monitor is very natural in monitoring.

With the Micro-Stepping Control Technology, the video looks very natural at

high zoom magnification during a jog operation on a controller since the

camera can be controlled by 0.05°/sec. Hence it is very easy to make the

camera focus on desired target views at high zoom magnification.

Additionally it is easy to make the camera focus on desired positions with

zoom-proportional pan/tilt movement.

RTC(Real Time Clock) Function

Date and Time can be configured for Schedule Function

With Backup Battery Function, Date and Time configuration should be kept up for a

while, even though power is off

6/56

Page 7

Preset N

o. White Balance

Auto Exposure

•••

Label

Remarks

Preset 1

Case

A Case

3 “E

NTRANCE

”

Preset 2

Case

C Case

5 “WAREHOUSE

”

•••

Preset 95

− − − −

Reserved for

OSD

Menu

•••

Preset 255

Case

K Case

9 “TERRACE

”

I

NTRODUCTION

Preset, Pattern, Swing, Group, Schedule, Privacy Mask and More…

MAX. 209 Presets are programmable and each preset can have its own

parameter values independently from the other presets.

For an example, refer to the below table.

1

MAX. 10 sets of Swing are programmable. This function is that a camera

moves repetitively between two preset positions at programmed speeds.

MAX. 8 Patterns are programmable. This function is that a camera memorizes

the path (mostly curve path) by the joystick of the controller and revives the

trajectory operated by the joystick as closely as possible.

MAX. 8 sets of Group are programmable. This function is that a camera

memorizes the combination of Presets, Pattern and/or Swings sequently and

runs Presets, Pattern and/or Swings repetitively. A Group can be combined

upto 40 functions with any of Preset/Pattern/Swing.

MAX. 8 Privacy Masks are programmable, not to intrude on any other’s

privacy.

MAX. 8 sets of Schedule are programmable. This function is that a camera runs a

function such as Preset, Pattern, Swing or Group at an assigned time. Also this

function can be run periodically by pre-defined schedules.

PTZ(Pan/Tilt/Zoom) Control

With the RS-485 communication connection, MAX. 255 units of cameras can

be connected to a single controller.

Pelco-D or Pelco-P protocols can be selected as a control protocol in the

current firmware version.

OSD(On Screen Display) Menu

OSD menu is provided to display the status of camera and to configure the

functions interactively. A P

menu can be protected.

The information such as Camera ID, Pan/Tilt Angle, Time/Date, Direction,

Alarm Input and Preset is displayed on screen.

Multi-Language OSD menu is supported.

assword can be configured in OSD menu and OSD

7/56

Page 8

I

NTRODUCTION

Alarm In/Out Function

3 alarm sensor inputs and 1 alarm sensor outputs are available.

Alarm sensor input is decoupled with photo-couplers to avoid external

electric noise and shock perfectly.

Both of N.O.(Normal Open) sensors and N.C.(Normal Close) sensors can be

used and the signal range of the sensor input is from DC 5.0V to 12.0V for

various applications.

The camera can be set to move to a Preset position or to run functions such

as Pattern, Swing and Group when there are external sensor activations. Also

“Post Alarm” function is possible, which is supposed to activate after userdefined time period and sequentially in succession to the action by external

sensor activations.

Reserved Presets(Hot Keys)

Most camera setup options can be set up easily and directly with the

reserved presets (Hot Keys), without entering into OSD menu. For more

information, refer to “Reserved Presets(Hot Keys)” in this manual.

1

Dual Power Input

The input power source is DC 12 V or AC 24 V.

Perfect Outdoor Environment Compatibility and Easy Installation

The fans and heaters are built-in in the camera for cold and hot temperature

environment. Also idealistic mechanical design protects the camera from

water and dust. (IP67 when installed properly with wall mount bracket only)

It is easy to install and repair the camera.

8/56

Page 9

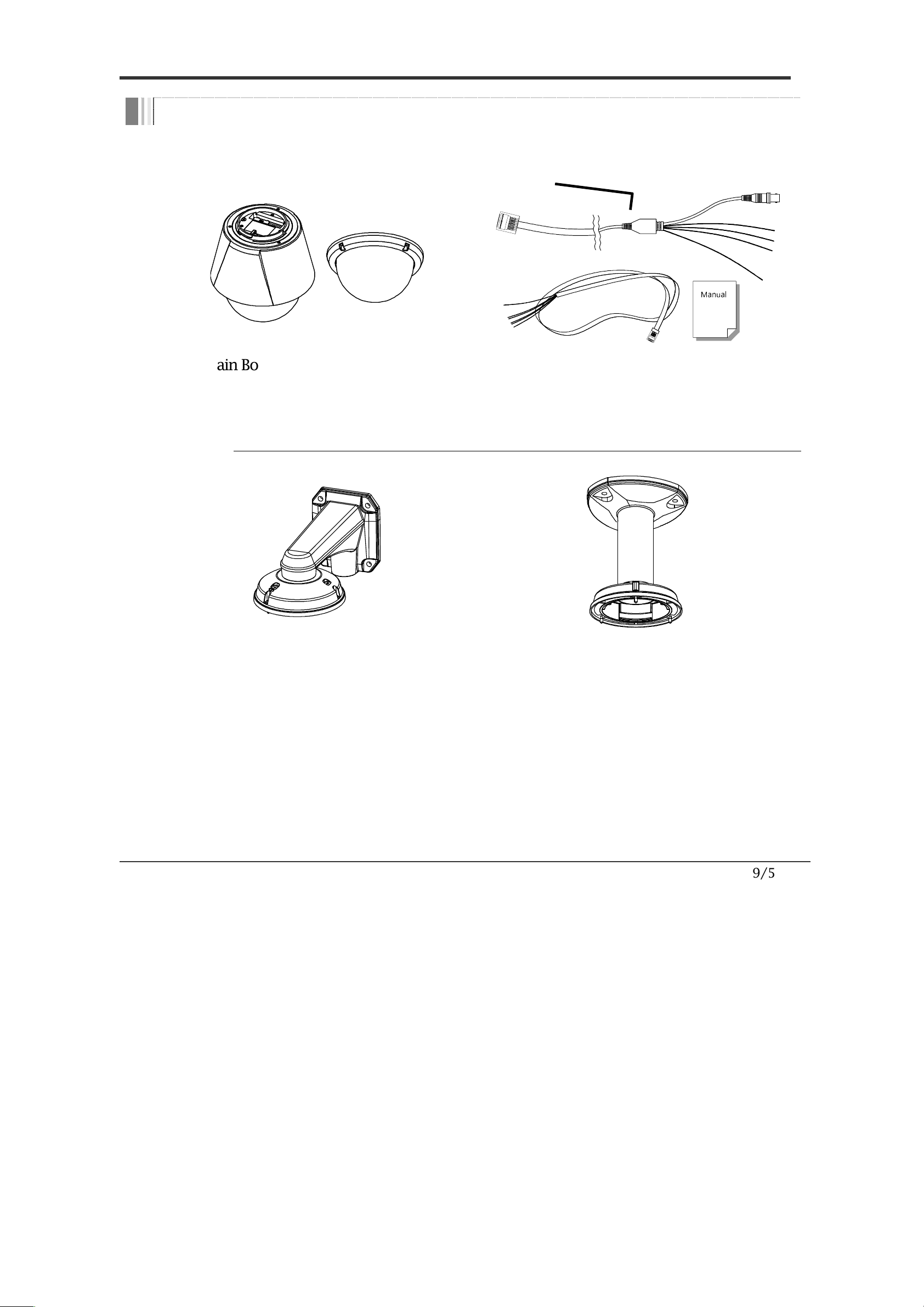

Main Body & Surface Mount Bracket

Default Accessories

Manual

]

Wall Mount Bracket

included in the

Ceiling Mount Bracket

(CLGMT37X) is

I

NTRODUCTION

Package Component

Product & Accessories

1

Manual

[Main Cable, I/O Cable ,Wrench, Owner’s

Brackets (Wall Mount Bracket is included but Ceiling Mount Bracket is optional)

[Screws :

package

TORX Machine M4×L18

#14×50]

, Hex Lag

[Screws :

TORX Machine M4×L18

optional

, Anchor Bolt

3/8"×70]

9/56

Page 10

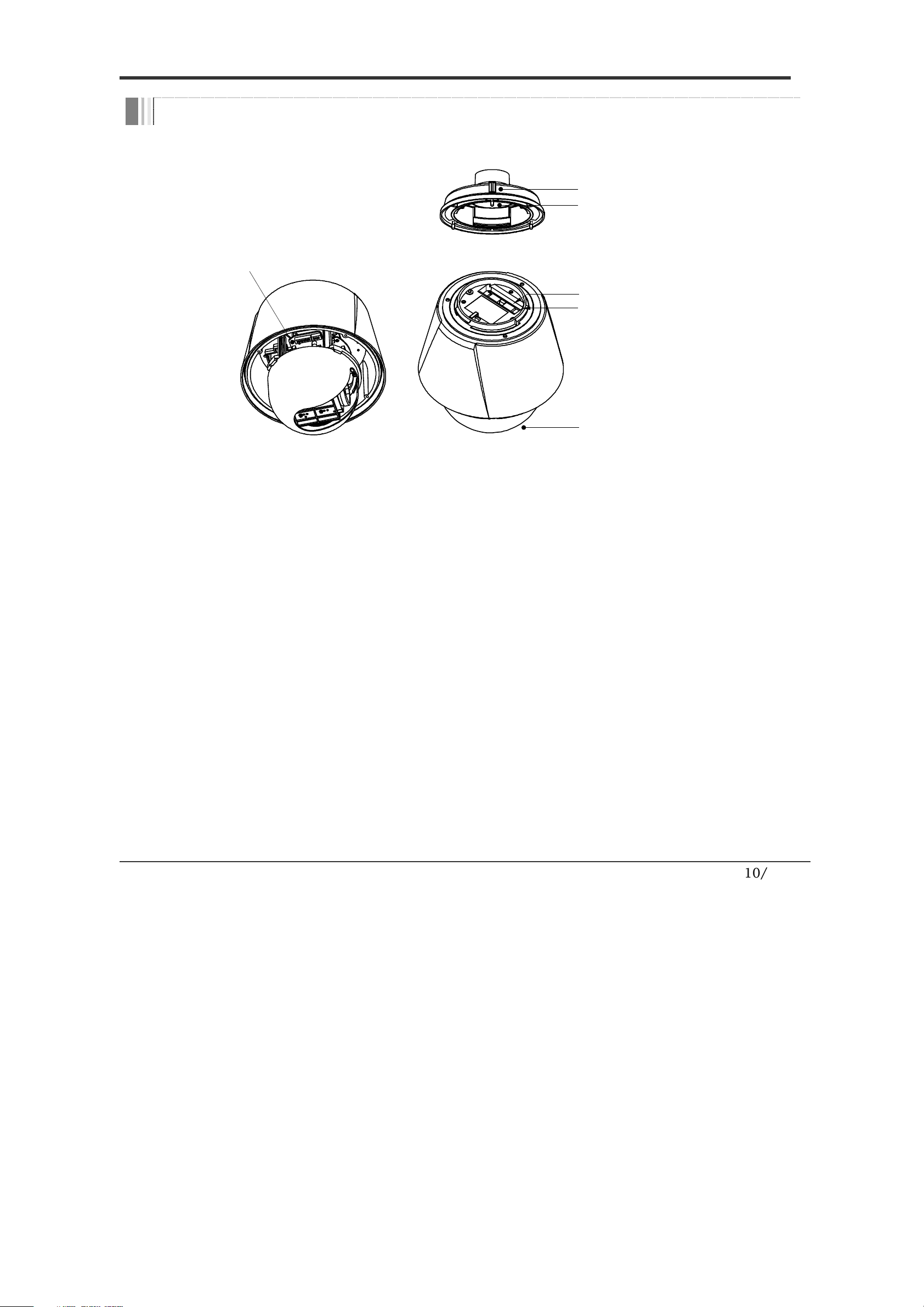

Dome Cove

r Do not detach the protection vinyl from the dome cover

DIP Switch

Used to set up camera IDs and protocols.

Drop Prevention

This part keeps the c

amera from dropping during

Mounting Screw

Used to assemble the main body with a bracket

with screws.

Main Connector

Used for the power wire, the video cable and the RS

-

485

Sensor I/O Port

Used for the sensor in/out connection.

I

NTRODUCTION

1

Main Part Description

Mounting Sc re w Hol e

Drop P re vention Sp rin g

DIP Switch

Main Connector

Sensor I/ O Port

Spring

Hole

Dome C ove r

before finishing all the installation process to protect the

dome cover from scratches or dust.

installation and maintenance. After install the Bracket,

please, hang the spring to the drop prevention hook of main

body as shown in picture for further tasks.

communication cable connection.

10/56

Page 11

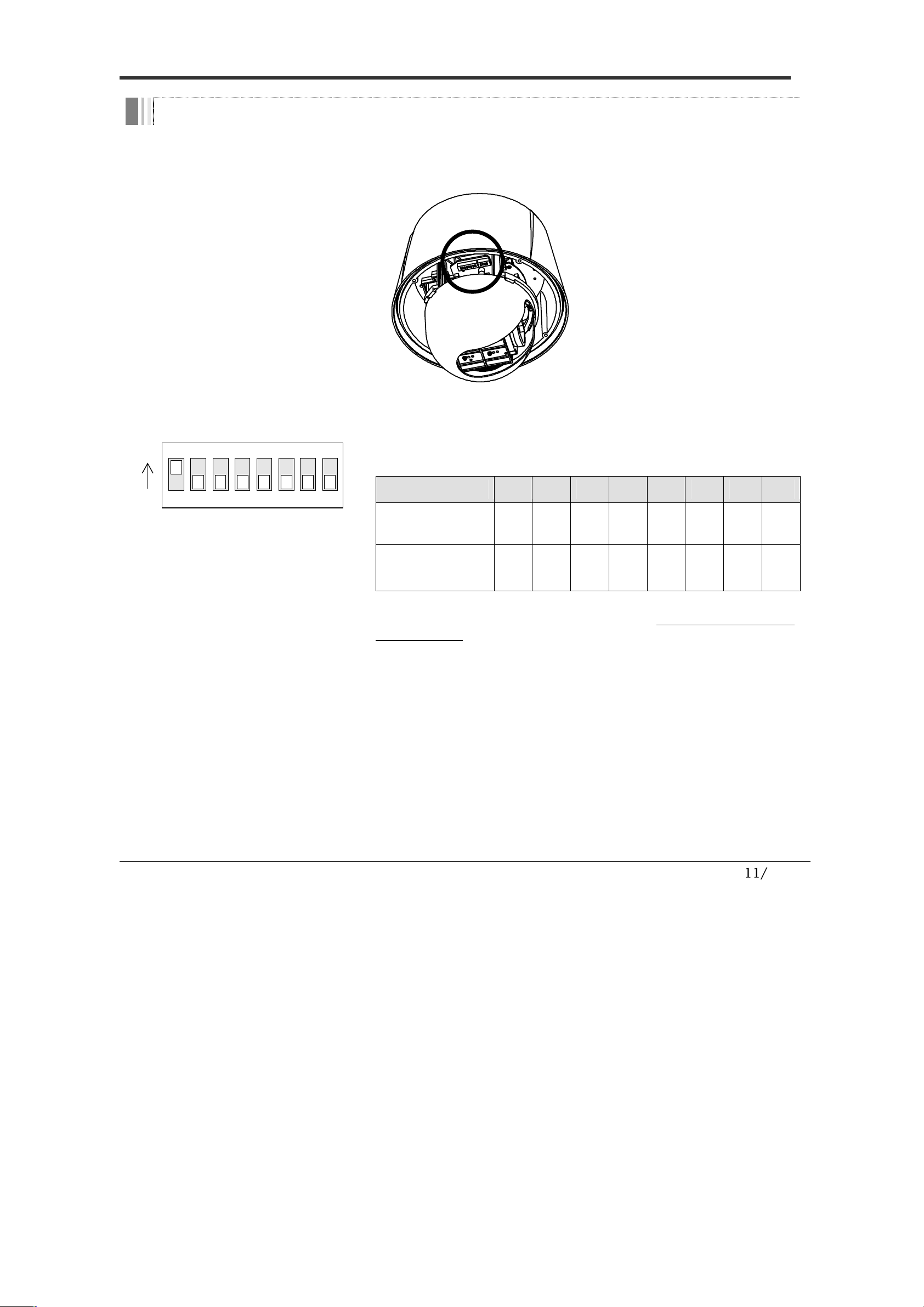

Before installing the camera, set

up the DIP swit

ch to configure

the

camera ID

ID numbers of cameras are set up with binary

Pin

1 2 3 4 5 6 7 8

Binary Value

1 2 4 8 16 32 64

12

ex) ID=5

on

off

on

off

off

off

off

off

ex) ID=10

off

on

off

on

off

off

off

off

INSTALLATION

2

DIP Switch Setup

and the communication protocol.

Camera ID Setup

ON

ON

1 2 3 4 5 6 7 8

numbers. See the examples shown below.

8

The camera ID range is “1~255”. Camera ID must

not be “0”!

The factory default of the camera ID is “1”.

Match the camera ID with the Cam ID setting of your

DVR or Controller to control the camera.

If you are connecting a single camera to a controller,

terminate the camera. When connecting more than

one camera to a single controller, terminate the last

camera on the communication line. The last camera

means the camera farthest in cable length from the

controller.

Note that the total length of the communication

11/56

Page 12

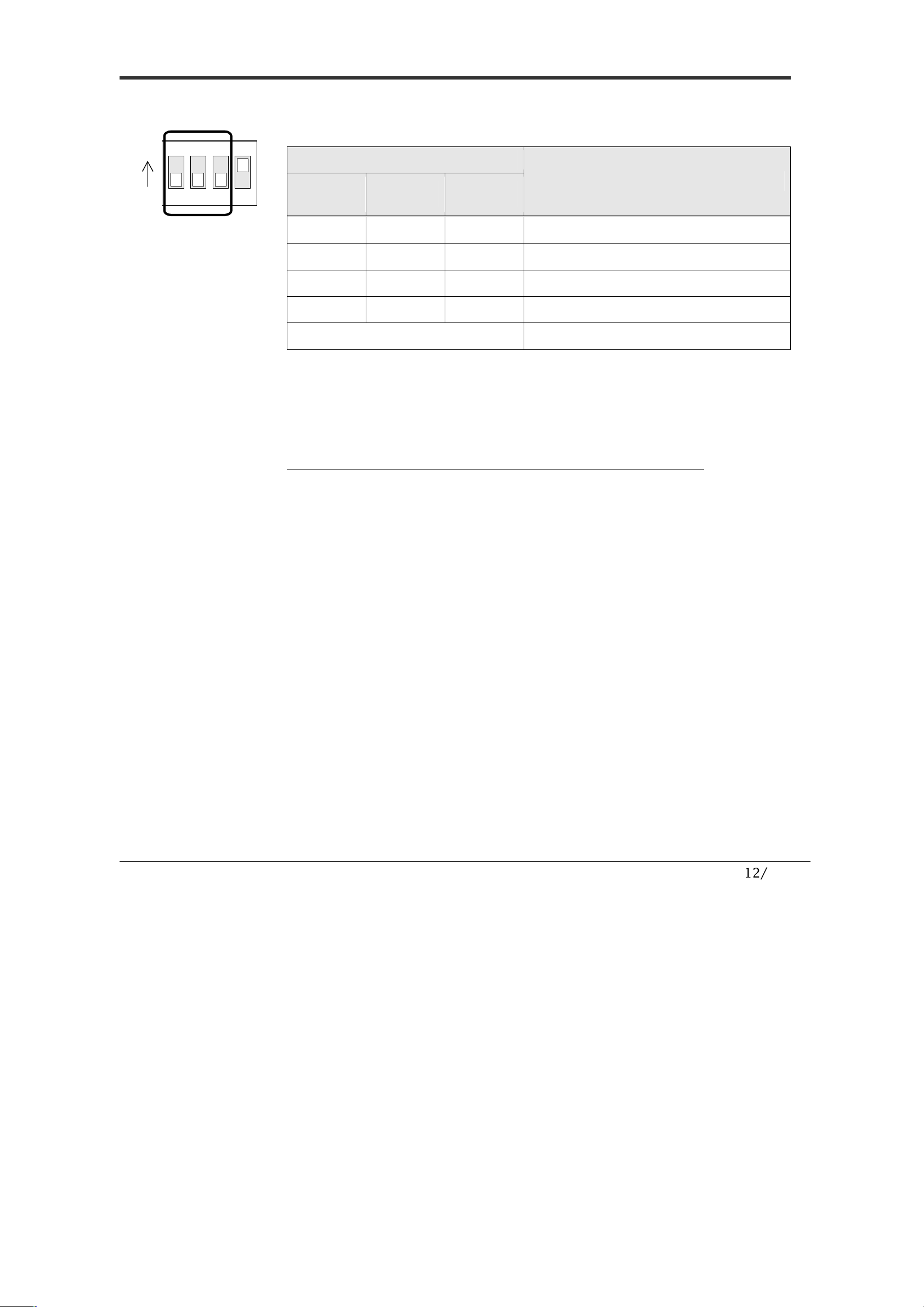

INSTALLATION

Communication Protocol Setup

Select an appropriate Protocol with the DIP switch combination.

ON

ON

2

Switch Mode

Protocol

1 2 3 4

P0

(Pin 1)

P1

(Pin 2)

P2

(Pin 3)

OFF OFF OFF PELCO-D, 2400 bps

ON OFF OFF PELCO-D, 9600 bps

Match the camera protocol with the camera protocol in the

Adjust the DIP switch after turning off the camera. If you

The factory default protocol is “Pelco-D, 2400 bps”.

OFF ON OFF PELCO-P, 4800 bps

ON ON OFF PELCO-P, 9600 bps

Others Reserved

setting of your DVR or controller to control the camera.

changed the camera protocol by changing the DIP S/W, the

change will be effective after you reboot the camera.

12/56

Page 13

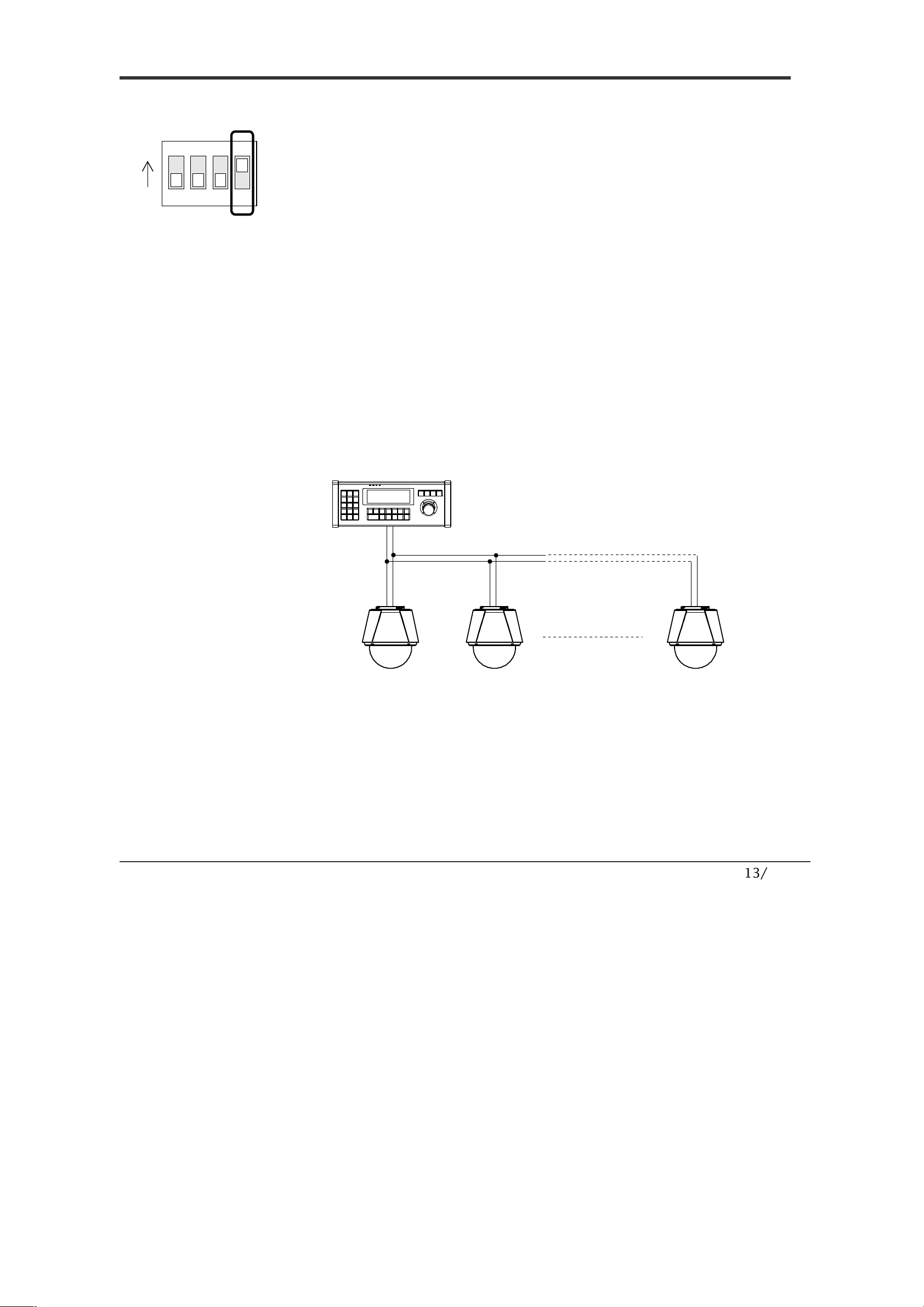

The terminal resistor is used for the following cases.

INSTALLATION

Terminal Resistor Setup

ON

ON

Case 1 : In case that the control cable length between a

1 2 3 4

camera and a controller is relatively very long (1:1

Connection)

If the communication cable length is very long, the electrical

signal will bound in the terminal point. This reflected signal

causes distortion of original signal. Accordingly, the camera can

be out of control. In this case, the terminal resistor of both sides

i.e. the camera and the controller must be set to ‘ON’ state.

Case 2 : In case that multiple cameras are connected to a

controller.

Due to similar reasons with the case 1, the terminal resister of

the controller and the last camera must be set to ‘ON’ state. The

last camera means the camera farthest in cable length from the

controller. Do not turn on the terminal resistor of all the

cameras on the same communication cable.

2

Contr oller

Terminal Resistor ON

RS-485

#1 #2 #n

Terminal Resistor

OFF

Terminal Resistor

OFF

Terminal Resistor

ON

13/56

Page 14

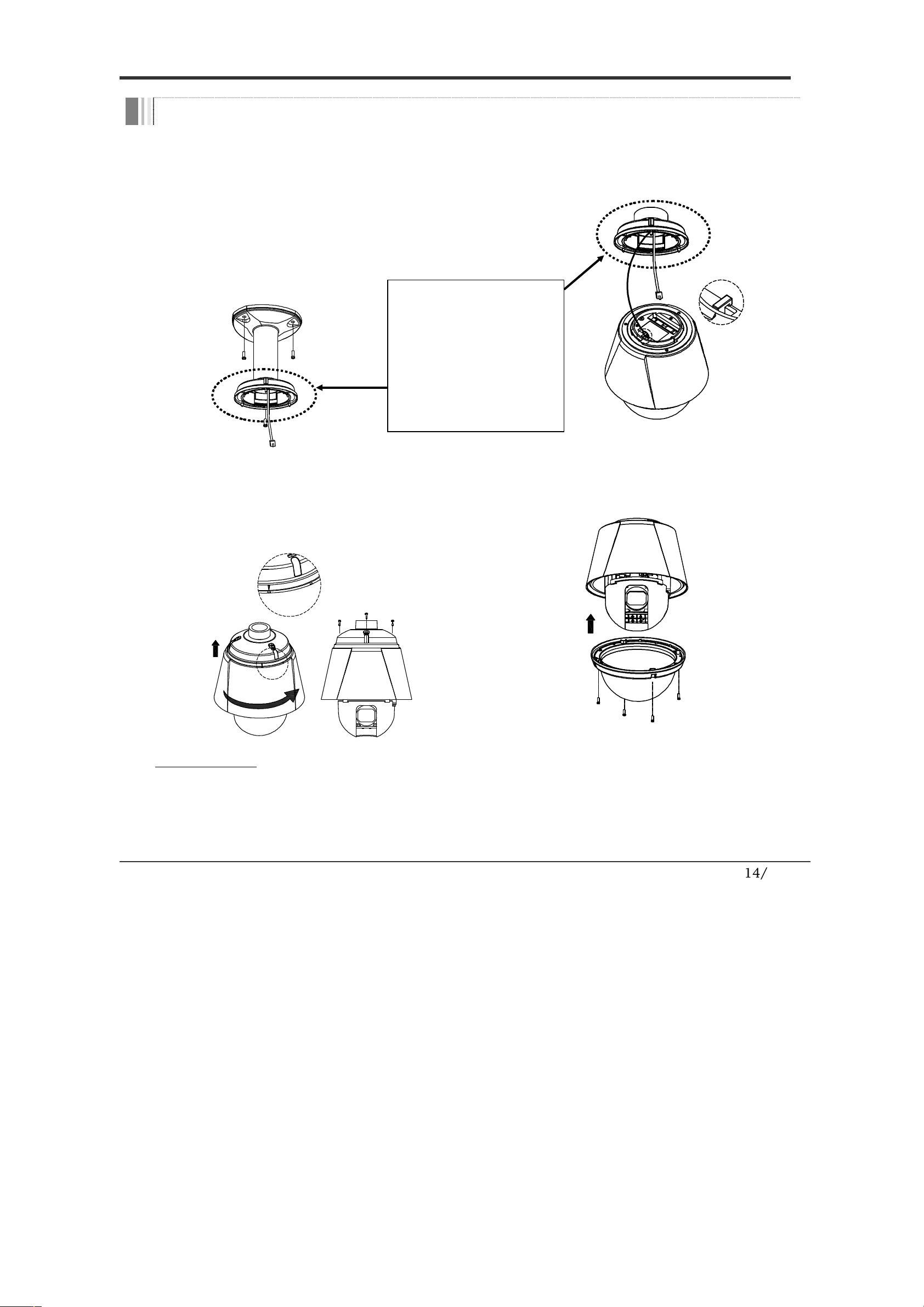

①

Remove the ceiling tile from the

②

Hook up

“

Drop Prevention Spring

”

③

L

ine up the mold lines and assemble

④

Screw the dome cover to the main

I

NSTALLATION

2

Installation with Ceiling Mount Bracket (Ver. 2.0)

ceiling and cut a hole whose diameter

is 30~40mm on the ceiling tile to pass

the wire(s) and cable(s) through to the

upside of the ceiling. (In case of the

wiring and cabling through the

mounting surface only) Then prepare

the ceiling mount bracket. Pull the

wire(s) for the system as below.

(Anchor Bolt 3/8"

×70)

** Attention **

If you use the old

ceiling mount bracket,

please use the new

mounting adaptor

from the camera

package.

on main body to prevent camera from

unexpected drop and pull the wire(s)

and cable(s) for the system as below.

Spr ing Wi re Hoo k

main body to mount adaptor and turn

it. And assemble the main body with

the camera mount adaptor with the 3

screws. (

TORX SCREW M4×18

END

START

).

body and remove the protection vinyl

from the dome cover.

Important Notice

Before starting the installation, make sure that the Camera ID and Protocol are set up properly.

To adjust the installation height from the mounting surface, the pipe and coupler should be needed between

the surface mount part of the ceiling mount bracket and the camera mount part of the ceiling mount bracket.

Note that they are not supplied by the manufacturer.

14/56

Page 15

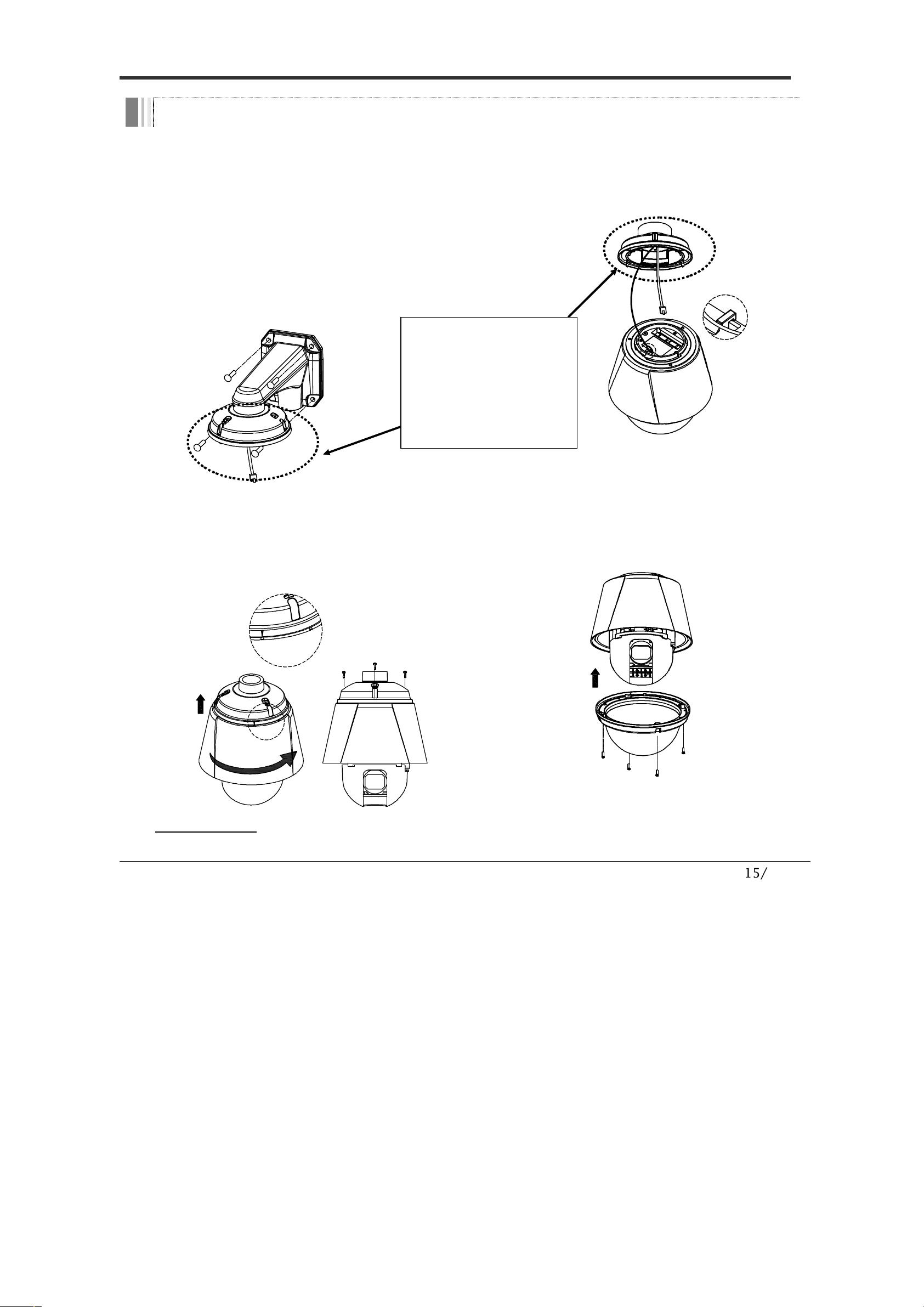

①

Make a hole whose diameter is

②

Hook up

“

Drop Prevention Spring

”

③

Line up the mold lines and assemble

④

Screw the dome cover to the main

INSTALLATION

2

Installation with Wall Mount Bracket

30~40mm on the mounting surface to

pass the wire(s) and cable(s) through

the mounting surface. (In case of the

wiring and cabling through the

mounting surface only) Then prepare

the wall mount bracket. Pull the

wire(s) and cable(s) for the system as

below. Attach the wall mount bracket

to the mounting surface. (Hex Lag

#14

×50)

** Attention **

If you use the old wall

mount bracket, please

use the new mounting

adaptor from the

camera package.

on main body to prevent camera from

unexpected drop and pull the wire(s)

and cable(s) for the system as below.

Spr ing Wi re Hoo k

main body to mount adaptor and turn

it. And assemble the main body with

body and remove the protection vinyl

from the dome cover.

the camera mount adaptor with the 3

screws. (

Important Notice

Before starting the installation, make sure that the Camera ID and Protocol are set up properly.

TORX SCREW M4×18

END

START

).

15/56

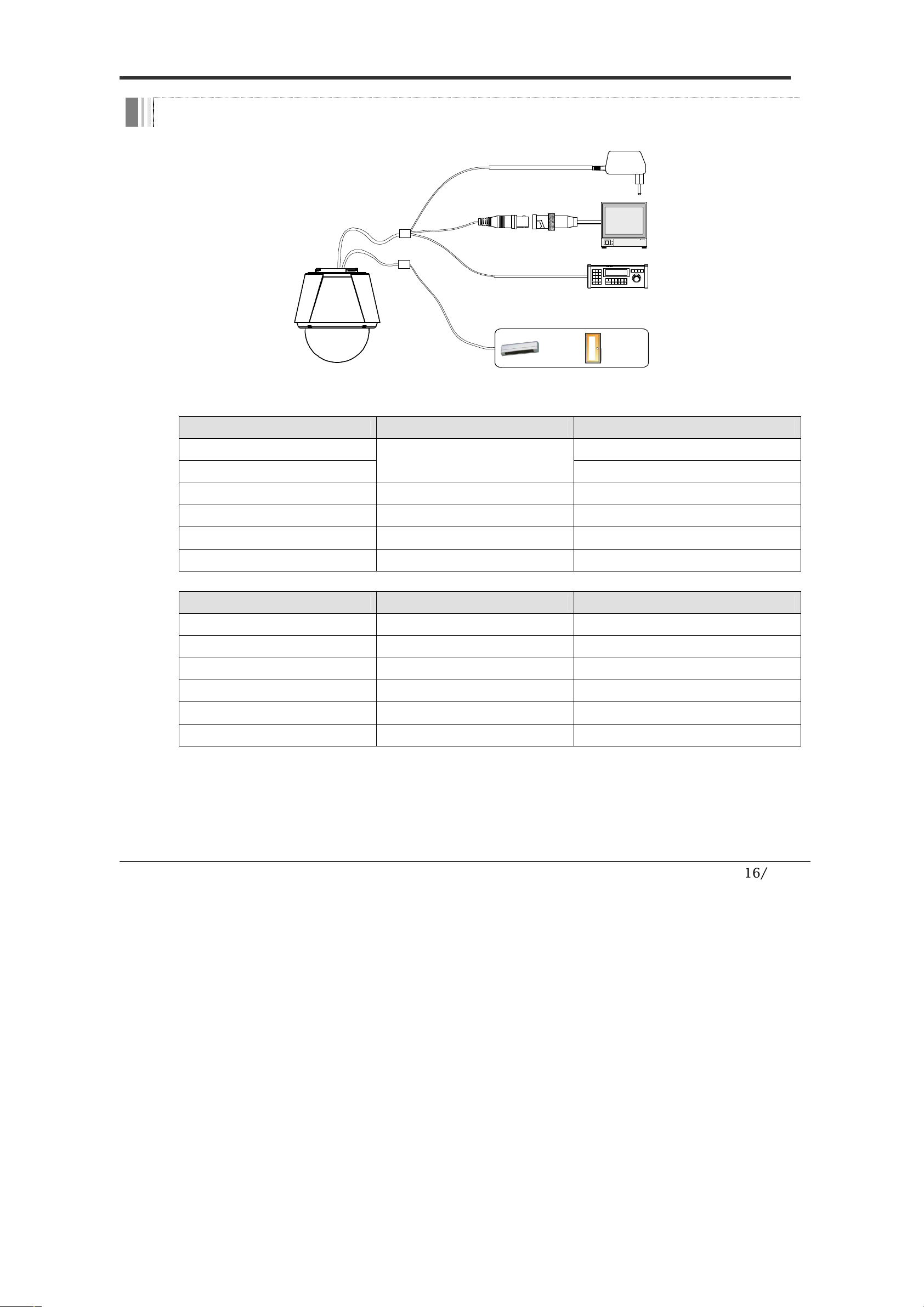

Page 16

Port Pin Number

(RJ45)

Connect

or / Wire

Color

Signal

1

Video +

2,4

Video

−

5 Red

RS-

485 +

3 Yellow

RS-

485

−

7 Orange

Power +

6,8

White

Power

−

Port Pin Number

(RJ25)

Wire Color

Signal

1 Blue

IN COM

+

2 Yellow

IN 1

−

3 Green

IN 2

−

4 Red

IN 3

−

5 Black

OUT A

6 White

OUT B

INSTALLATION

2

Wiring and Cabling

POWER

Port Description

Main Cable

MAIN C ABLE

BNC

RS-485

CONT ROLLER / DVR

I/O CABLE

BNC Connector

SENSOR I/O

IR

SENSOR

MONITOR

DOOR

SWITCH

I/O Cable

16/56

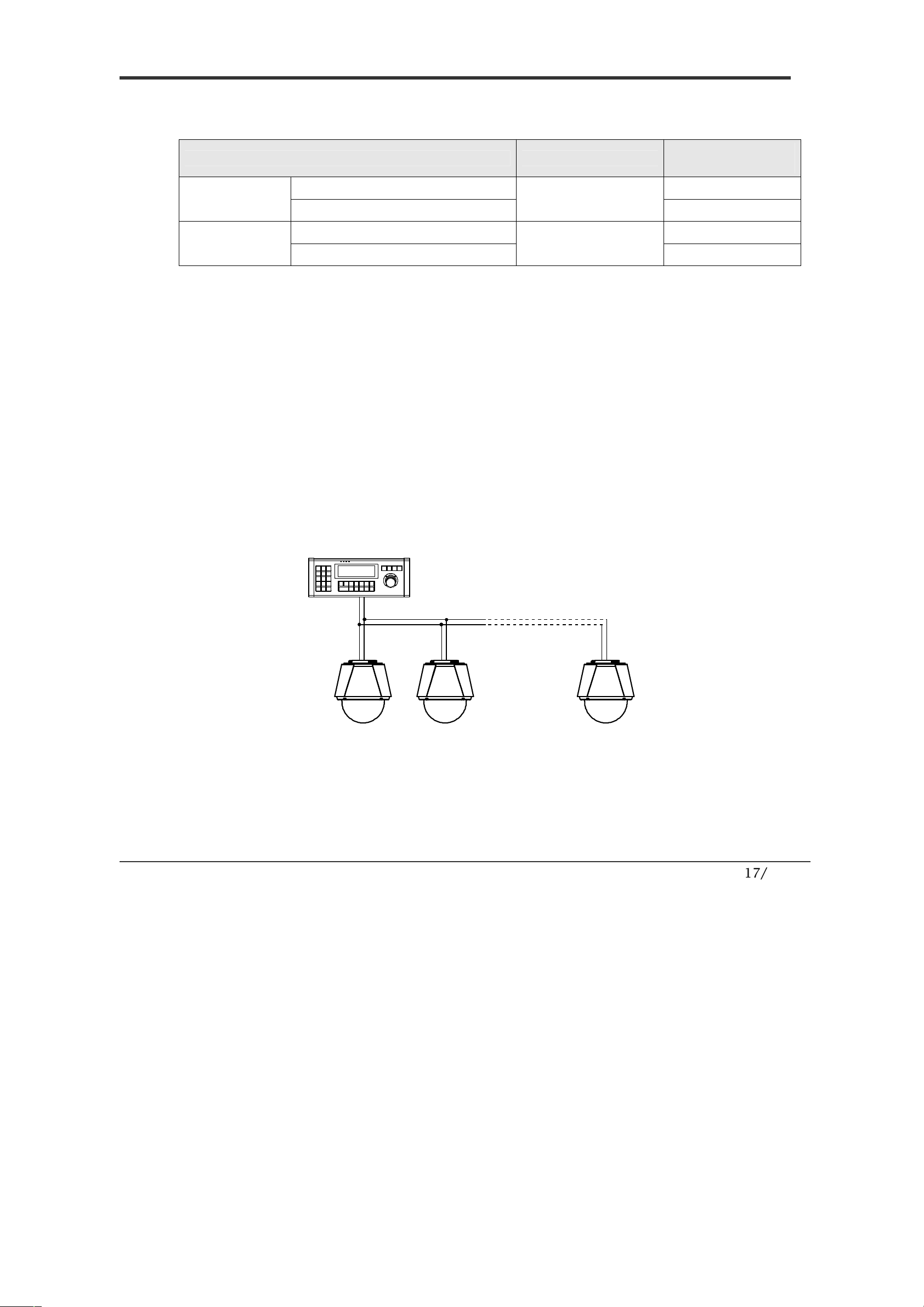

Page 17

Current

Without F

an & Heater

1.0 A

With Fan & Heater

1.8 A

Without F

an & Heater

0.8 A

With Fan & Heater

1.8 A

INSTALLATION

Power Description

Carefully check the voltage and current capacity of the rated power.

2

DC12V Input

AC24V Input

For the DC input, be careful with the polarity of DC power. The system should

be permanentally damaged by wrong DC input.

In case that the length of the power wire is very long, there may be voltage

drop and the syatem may not work properly. Make the length of the power wire

as short as possible.

RS-485 Communication

For PTZ control, connect the cable(s) to your keyboard or DVR. To connect

multiple cameras to a single controller, RS-485 communication should be

connected in parallel as shown below. If you are connecting a single camera to

a controller, terminate the camera. When connecting more than one camera to

a single controller, terminate the last camera on the communication line. The

last camera means the camera farthest in cable length from the controller. Note

that the total length of the communication cable between a controller and the

camera(s) on the same communication line must be less than 1.2Km.

Model Input Voltage Range

DC 11V ~ 18V

AC 17V ~ 29V

Consumption

CONT ROLLER / DVR

-

RS-485

+

-

+

-

+

-

+

#1

#2

#n

17/56

Page 18

Signal

Description

IN COM+

The electric power source to drive input circuit. Connect the (+) wire of

IN1

-

, IN2

-

, IN3

- Connect the outputs of sensors to each port as shown in the

Power Type

DC

Power

AC

Power

Maximum Load

MAX.

DC 24V, 1A

MAX.

AC

125V, 0.5A

INSTALLA

T

ION

Video

2

Use BNC coaxial cable only.

Alarm Input

Before connecting sensors, check driving voltages and output signal types of

the sensors. Since output signal types of the sensors are divided into Open

Collector type and Voltage Output type in general, the wiring must be done

properly after considering those types.

Internal

IN COM+

IN 1-

IN 3-

Sensor 1

Sensor 3

+5V~12V

+

+

+

-

-

-

electric power source to drive the Sensors to this port as shown in the

above circuit.

If you want to use Alarm Input, the types of sensors must be selected in OSD

menu. The sensor types are divided into Normal Open and Normal Close. If

wrong sensor types are selected, alarms should be activated reversely to sensor

inputs.

Normal Open Output Voltage is high state when sensor is activated

Normal Close Output Voltage is high state when sensor is not activated

Relay Output

The maximum loads are as follows.

above circuit.

Internal

AC or DC

OUT 1

LOAD

18/56

Page 19

< Go Preset >

Input [Preset Number] and press [Preset]

button shortly.

< Set Preset >

Input [Preset Number] and keep pressing [Preset] button for more than 2

< Run Pattern

Input [Pattern Number] and press [Pattern] button shortly.

< Set Pattern >

Input [Pattern Number] and keep pressing [Pattern

] button for more than

OPERATION

Check Points before Operation

Before turning on the system, check if the wire(s) and cable(s) are connected

properly.

Check if the camera ID on the controller is properly selected. The camera ID must

be identical to that of the target camera. The camera ID can be checked by reading

the DIP switch of the camera or on OSD.

If your controller supports multi-protocols, the protocol must be changed to

match to that of the camera.

Adjust the DIP switch after turning off the camera. If you changed the camera

protocol by changing the DIP S/W, the change will be effective after you reboot

the camera.

Since the operation method can be different by controllers, refer to your

controller manual if the camera can not be controlled properly. The operation of

this manual is based on the standard Pelco® Controller.

3

Check Points for Preset and Pattern Function before Operation

Check fully how to operate preset function and pattern function with your

controller or DVR in advance to operate the camera functions when using a

controller or a DVR.

Refer to the following table when using standard Pelco® protocol controllers.

seconds.

>

2 seconds.

If your controller or DVR has no pattern button or function, use the Hot Keys with

preset numbers. For more information, refer to “Reserved Presets (Hot Keys)” in

this manual.

19/56

Page 20

Function

With

OSD me

nu,

the system

can be

properly

configured

for

Entering into OSD

Go Preset [95]

Description

Some Preset numbers are reserved to change

some parameters

without

Hot Key

s

OPERATION

3

OSD Menu

each application.

Reserved Presets (Hot Keys)

entering into OSD menu.

Go Preset [95] : Entering into OSD menu

Go Preset [131~138] : Running Pattern Function 1 ~ 8

Go Preset [141~150] : Running Swing Function 1 ~ 10

Go Preset [151~158] : Running Group Function 1 ~ 8

Go Preset [161] : Turning off Relay Output

Set Preset [161] : Turning on Relay Output

Go Preset [167] : Setting Zoom Proportional Function to ON

Set Preset [167] : Setting Zoom Proportional Function to OFF

Go Preset [170] : Setting Camera BLC/WDR Mode to OFF

Go Preset [171] : Setting Camera BLC/WDR Mode to ON

Go Preset [174] : Setting Camera Focus Mode to AUTO

Go Preset [175] : Setting Camera Focus Mode to Manual

Go Preset [176] : Setting Camera Focus Mode to SEMI-AUTO

Go Preset [177] : Setting Day & Night Mode to AUTO

Go Preset [178] : Setting Day & Night Mode to NIGHT

Go Preset [179] : Setting Day & Night Mode to DAY

Go Preset [190] : Setting OSD Display Mode to AUTO (Except Privacy Mask)

Go Preset [191] : Setting OSD Display Mode to OFF (Except Privacy Mask)

Go Preset [192] : Setting OSD Display Mode to ON (Except Privacy Mask)

Go Preset [193] : Setting all Privacy Mask Display to OFF

Go Preset [194] : Setting all Privacy Mask Display to ON

20/56

Page 21

Function

MAX. 209 presets can be configured except the Reserv

ed Presets

Setting Preset

s Set Preset

[

1~255

]

Running Preset

s Go Preset

[

1~255

]

Deleting Preset

s To delete Preset

s

, enter in

to OSD

menu

.

Function

This

function

is that

the camera moves

repetitively

between

Setting Swing

s To set

Swing

,

enter into

OSD menu

.

Running Swing

s

Method 1) <Run Pattern> [Swing NO. + 10]

ex) Run Swing 3 : <Run Pattern> [13]

Deleting Swing

s To delete

Swing

s

, enter into

OSD menu

.

1

C

W

D

i

r

e

c

t

i

o

n

OPERATION

3

Preset

(Hot Keys).

Camera parameters such as White Balance, Auto

Exposure and others can be set up independently and each

preset can have its own parameter values independently from

the other persets. When setting up presets with a controller,

Label should be blank and "Camera Adjust" should be set to

"GLOBAL" as the default. To change the parameters, enter into

OSD menu.

Swing

two preset positions at programmed speeds. When a swing

function runs, the camera moves from the preset assigned as

the 1st point to the preset assigned as the 2nd point in

CW(Clockwise) direction. Then the camera moves from the

preset assigned as the 2nd point to the preset assigned as the

1st point in CCW(Counterclockwise) direction.

2nd Preset

1st Preset

W

C

C

2

n

o

i

t

c

e

r

i

D

In case that the preset assigned as the 1st point and the

preset assigned as the 2nd point are same, the camera turns

on its axis by 360° in CW(Clockwise) direction and then it

turns back on its axis by 360° in CCW(Counterclockwise)

direction. The Swing speed is defined from 1°/sec to

180°/sec.

Method 2) <Go Preset> [Swing NO. + 140]

ex) Run Swing 3 : <Go Preset> [143]

21/56

Page 22

Function

This

function

is that

the camera memorizes the path (mostly

Setting Pattern

s A

Pattern can be created by the following

methods

.

Running Patterns

Deleting Patterns

To delete Patterns,

enter into

OSD menu

.

OPERATION

3

Pattern

curve path) by the joystick of the controller and revives the

trajectory operated by joystick as closely as possible.

MAX. 8 Patterns are programmable and Maximum 880

communication commands can be programmed in a pattern.

Method 1) <Set Pattern> [Pattern NO.]

The Pattern programming window appears on the

monitor as below.

EDIT PATTERN 1

[NEAR:SAVE /FAR:DELETE]

0/0/x1/N

The movement by Joystick and the preset movement can

be memorized in a pattern.

After a pattern is programmed, the remaining storage is

displayed in progress bar on the screen.

To save the recording, press NEAR key and to cancel,

press FAR key.

Method 2) Programming in OSD Menu : See the section “How to use OSD Menu”.

Method 1) <Run Pattern> [Pattern NO.]

Method 2) <Go Preset> [Pattern NO. + 130]

ex) Run Pattern 2 : <Run Pattern> [2]

ex) Run Pattern 2 : <Go Preset> [132]

Note) When the system memorizes Patterns, the commands are stored in the

momories, not the positions of Pan/Tilt/Zoom. Hence there might be small

differences between the original path and the revived path by path type of Patterns.

Note that it is not a problem in position precision.

22/56

Page 23

Function

This

function

is that the camera memorizes the combination

Dwell Tim

e

Setting Groups

To set Groups, enter into

OSD menu

.

Running Groups

Deleting Groups

To

delete Groups, enter into

OSD menu

.

Power Up Action

This setting defines a specific activity (Preset, Pattern, Swing and Group)

Auto Flip

In case tha

t tilt angle

arrives at the top of tilt orbit(

90°),

zoom module

Park

ing Action

This feature allows the camera to begin a spec

ified operation after a

OPERATION

3

Group

of Presets, Pattern and/or Swings sequently and runs Presets,

Pattern and/or Swings repetitively. MAX. 8 sets of Group are

programmable. Each group can have MAX. 40 actions which

are the combination of Preset, Pattern and Swing. Preset

speed can be set up and the repeat number of Pattern & Swing

can be set up in Group setup. Dwell time between actions can

be set up also.

Preset 1 Patte r n 1 Swing 1

Max 40 Entities

Method 1) <Run Pattern> [Group NO. + 20]

Method 2) <Go Preset> [Group NO. + 150]

ex) Run Group 7 : <Run Pattern> [27]

ex) Run Group 7 : <Go Preset> [157]

Other Functions

to be performed in the event that the power to the camera is cycled.

This function enables the user to resume, after turning on power, the

last action being executed before turning off the power. Most of actions

such as Preset, Pattern, Swing and Group are available for this function

but Jog actions are not available to resume.

camera turns on its axis by 180° at the top of tilt orbit and moves to

opposite tilt direction (180°) to keep tracing targets.

programmed time of inactivity. This function makes the camera

automatically run a pre-defined action if there is no command from

controller for a pre-defined time period. “Wait Time” means how long a

camera should wait for from the previous-last (most recent) command

before running the pre-defined action. It can be set to 1 second ~ 3 hrs.

23/56

Page 24

Alarm

Input

3 Alarm Inputs are available. When

external

sensors activate, the

camera

Schedule

8 Schedule are programmable. A

camera

runs function

s such as Preset,

Priv

acy

Zone

Mask

Privacy Zone Mask allows

a user to program

8 rectangulars that can not

Password for OSD

A P

asswor

d can be configured in OSD menu and OSD menu can be

GLOBAL/LOCAL

WB(White Balance) and AE(Auto Exposure) can be set up independently

Semi

-

Auto Focus

This mode automatically ex

changes focus mode

s between Manual Focus

OPERATION

3

runs pre-defined actions such as Preset, Pattern, Swing and Group. After

the pre-defined time period passed, “Post Alarm” activates, which is

pre-defined. Note that only the latest alarm input is effective when

multiple sensors are activated at the same time.

Pattern, Swing and Group at assigned times. After a pre-defined time

passes, “Post Action” runs. Also this function can be run periodically by

pre-defined schedules. A Period can be configured by

Hour/Day/Week/Month.

be viewed by the operator of the system. To protect others’ privacy,

MAX. 8 Privacy Masks can be created on the arbitrary position to hide

objects such as windows, shops or private house. With the Spherical

Coordinates system, powerful Privacy Zone Mask function is possible. A

mask area will move with pan and tilt functions and automatically

adjust in size as the lens zooms telephoto and wide.

Image Setup

protected.

[Important Notice] It is mandatorily recommended that a user must

take a memo for a password before a user applies a password to a

system. When a Password is forgotten, a unit can not be unlocked

and the unit is supposed to be shipped back to the manufacturer.

for each preset. There are 2 modes, "Global" mode & "Local" mode. The

Global mode is that WB and/or AE are/is set up totally and

simultaneously for all presets. The Global parameter setup such as WB

and AE can be done in "ZOOM CAMERA SETUP" menu. The Local mode is

that WB and/or AE are/is set up independently or separately for each

preset. The Local parameter setup for WB and AE can be done in each

preset setup menu. Each Local parameter such as WB and AE activates

correspondingly when the camera arrives at each preset position.

During jog operation, Global WB/AE value should be applied. All Local

WB/AE values do not change although Global WB/AE value changes. The

Local mode has the prior to the Global mode.

mode and Auto Focus mode by operation. Manual Focus mode activates

in preset operation and Auto Focus mode activates during jog operation.

With Manual mode at presets, Focus data is memorized in each preset in

advance and the camera calls focus data in correspondence with presets

as soon as the camera arrives at presets. It should shorten time to get

focuses. The focus mode automatically changes to Auto Focus mode

when jog operation starts.

24/56

Page 25

Displays the amount of pan from zero degree vertical, the amount of

tilt

When Swing x is in action. Displays both of Swing

Displays activated alarms.

This information shows current state of Alarm

OPERATION

3

OSD Display

Preset Label

Date(D a y/Month/ Year)

Time(Hour/Min./Sec.)

Camer a ID

P/T/Z Information

from zero degree horizontal and current compass direction. Also

identifies the amount of the zoom magnification.

Camera ID Displays the selected Camera ID (Address).

LABEL12345 PRESET1

01/JAN/2013

01:15:35 I:-2- O:1

CAM 1 15/4/x1/N

P/T/Z Inf ormation

Action Title

Alarm Inf ormation

Action Title Identfies Actions

"SET PRESET xxx" When Preset xxx is memorized.

"PRESET xxx" When the camera reaches Preset xxx.

"PATTERN x" When Pattern x is in action.

"SWG×/PRESET xxx"

number and Preset number.

"UNDEFINED" When a undefined function is called to run

Preset Label Displays preset labels when the camera arrives at presets.

Alarm Information

Inputs and Relay Outputs. If an Input point is ON state, it will show a

number corresponding to each point. If an Input point is OFF state, ''''----''''

will be displayed.

Example) The point 2 & 3 of inputs are ON and Output is ON, OSD will

show as below.

I:-23 O:1

25/56

Page 26

System

Information

Displays the system information and con

figuration.

The

Display Setup

Configures labels and how to display labels on a monitor.

Clcok

Setup

Configures current time and how to display in OSD

.

Dome

Camera Setup

Configures various functions of a camera.

Password

Setup

Configures a Password for OSD

.

System Initialize

Initializes all system

configurations

and all data to the

OSD MENU

Quick Programming Guide

The menu items with < > always have sub-menus.

To go to submenus or make the cursor move to the right, press NEAR key.

To go to the previous-upper level menus, press FAR key.

To make a selection, press NEAR key

4

To cancel a selection, press FAR

key

To move the cursor in the menu, use the joystick to the Up/Down direction or

Left/Right direction.

To change a value of an item, use Up/Down of the joystick in the controller.

To save changes, press NEAR key.

To cancel changes, press FAR key.

Main Menu

SPEED DOME SETUP

----------------------- <SYSTEM INFORMATION>

<DISPLAY SETUP>

<CLOCK SETUP>

<DOME CAMERA SETUP>

<PASSWORD SETUP>

<SYSTEM INITIALIZE>

EXIT

system setting can not be changed using the OSD menu

and the information is for reference only.

factory default parameters.

26/56

Page 27

Display setup allows you to program how

labels are

Camera ID

[ON/OFF]

PTZ

[ON/OFF/AUTO]

Action Title

[ON/OFF/AUTO]

Preset Label

[ON/OFF/AUTO]

Alarm I/O

[ON/OFF/AUTO]

Language

[ENG/POL/FRN/ITL]

OSD MENU

4

Display Setup

DISPLAY SETUP

----------------------- CAMERA ID ON

PTZ INFORMATION AUTO

ACTION TITLE AUTO

PRESET LABEL AUTO

ALARM I/O AUTO

LANGUAGE ENG

<SET NORTH DIRECTION>

<PRIVACY ZONE>

BACK

EXIT

displayed on the monitor. In case of AUTO, the

labels are displayed on the monitor when there are

any changes in parameters.

Displays the selected Camera ID.

Information

Displays the positions of pan/tilt,

zoom magnification and current

compass direction.

Identifies Actions.

"SET PRESET xxx"

"PRESET xxx"

"PATTERN x"

"SWG/PRESET xxx"

"UNDEFINED"

Displays the preset labels when the

camera arrives at presets.

Displays the activated alarms. This

information shows the current state

of Alarm Inputs and Relay Outputs.

If an Input point is ON state, it will

show a number corresponding to

each point. If an Input point is OFF

state, ''''----'''' will be displayed.

Example) The point 2 & 3 of inputs

are ON and Output is ON.

I:-23 O:1

Selects a language for OSD menu.

27/56

Page 28

Move the camera to a target position and press

Privacy Zone Mask allows the user to program

8

Mask NO

[1~8]

Display

[ON/OFF

]

Clear Mask

[CANCEL/OK]

OSD MENU

Compass Direction Setup

SET NORTH DIRECTION

------------------------

MOVE TO TARGET POSITION

[NEAR:SAVE /FAR:CANCEL

Privacy Zone Mask Setup

4

NEAR button to save the direction as North. The

direction is the reference direction to assign other

compass directions.

PRIVACY ZONE

----------------------- MASK NO 1

UNDEFINED

DISPLAY OFF

CLEAR MASK CANCEL

<EDIT MASK>

rectangular zones that cannot be viewed by the

operator of the system. To protect privacy, MAX. 8

Privacy Masks can be created on the arbitrary

position to hide objects such as windows, shops or

private house. With the Spherical Coordinates

system, powerful Privacy Zone Mask function is

possible. A mask area will move with pan and tilt

functions and automatically adjust in size as the

BACK

EXIT

lens zooms telephoto and wide.

Selects a Mask number to program. If

the selected mask has already data,

the camera moves as it was

programmed. Otherwise,

“UNDEFINED” will be displayed under

the Mask number.

Sets if the mask of the selected mask

number shows or not on the screen.

Deletes the mask data of the selected

mask number.

28/56

Page 29

Move your camera to an area to mask. Then a mask

Adjusts the mask size. Use the joystick or the arrow

(Left/Right)

Adjusts the mask width.

(Up/Down)

Adjusts the mask height.

OSD MENU

Privacy Zone Mask Area Setup

EDIT MASK 1

------------------------

MOVE TO TARGET POSITION

[NEAR:SELECT/FAR:CANCEL]

Privacy Zone Mask Size Setup

4

and the menu to adjust the mask size will be

displayed.

EDIT MASK 1

------------------------

[ :ADJUST MASK WIDTH]

[ :ADJUST MASK HEIGHT]

[NEAR:SAVE /FAR:CANCEL]

buttons of your controller to adjust mask size.

29/56

Page 30

Configures current time and ho

w to display in OSD

.

Display Date

[ON/OFF]

Display

T

ime

[ON/OFF]

Set Clock

[CANCEL/OK]

OSD MENU

4

Clock Setup

CLOCK SETUP

----------------------- DISPLAY DATE ON

DISPLAY TIME ON

SET CLOCK

01/JAN/2013 TUE

00:01:02 [hh:mm:ss]

BACK

EXIT

Configures whether Date will be

displayed in OSD or not

Configures whether Time will be

displayed in OSD or not

Configures current date

(DD/MM/YYYY) and time (hh:mm:ss).

A day should be automatically

changed according to Date change

.

.

.

30/56

Page 31

OSD MENU

Camera Setup

4

ZOOM CAMERA SETUP

----------------------- FOCUS MODE SEMIAUTO

DIGITAL ZOOM ON

FLICKERLESS OFF

COLOR ON

IMAGE FLIP OFF

<WHITE BALANCE SETUP>

<AUTO EXPOSURE SETUP>

<SPECIAL>

BACK

EXIT

Sets the general functions of zoom camera module.

Focus Mode [AUTO/MANUAL/SEMIAUTO]

Sets camera Focus mode.

SEMIAUTO Mode

This mode automatically exchanges focus

modes between Manual Focus mode and

Auto Focus mode by operation. Manual

Focus mode activates in preset operation

and Auto Focus mode activates during jog

Digital Zoom [ON/OFF]

operation. With Manual mode at presets,

Focus data is memorized in each preset in

advance and the camera calls focus data in

correspondence with presets as soon as

camera arrives at presets. It should shorten

time to get focuses. Focus mode

automatically changes to Auto Focus mode

when jog operation starts.

Sets the digital zoom functions to ON/OFF.

If this is set to OFF, the optical zoom

function runs but the zoom function stops

at the end of optical zoom magnification.

Flickerless [ON/OFF]

If NTSC camera is used in 50Hz frequency

circumstance or if PAL camera is used in

60Hz frequency circumstance, there should

be flicker on monitor since power

frequency is different from sync frequency

of camera. In this case, set it to ON to

prevent flicker

Color [ON/OFF]

Image Flip [ON/OFF]

Sets System Image Flip Function to ON/OFF.

When this function is set to ON, flipped

images always come out. When the camera

is installed as Desktop type, set to ON to

get proper images.

31/56

Page 32

WB Mode

[AUTO/MANUAL]

Red Adjust

[0-

255

]

Blue Adjust

[0-

255

]

OSD MENU

White Balance Setup

WB SETUP - GLOBAL

----------------------- WB MODE AUTO

RED ADJUST -- BLUE ADJUST ---

4

Retains color balance over a color

temperature range. In auto mode,

this feature automatically processes

the viewed image. In Manual mode,

Red and Blue level can be set up

manually.

BACK

EXIT

Adjusts the picture output in the red

range.

Adjusts the picture output in the

blue range.

32/56

Page 33

O

SD MENU

Auto Exposure Setup

4

AE SETUP-GLOBAL

----------------------- BACKLIGHT OFF

DAY/NIGHT AUTO

WDR OFF

AE MODE AUTO

IRIS -- AGC -- SHUTTER ---

BACK

EXIT

Backlight [ON/OFF]

Sets Backlight Compensation. If a bright

backlight is present, the subjects in the

picture may appear dark or as a silhouette.

Backlight compensation enhances objects in

the center of the picture. The camera uses the

center of the picture to adjust the iris. If there

is a bright light source outside of this area, it

will wash out to white. The camera will adjust

the iris so that the object in the sensitive area

is properly exposed.

Day/Night

WDR [ON/OFF]

AE Mode [AUTO/SHUTTER/IRIS/MANUAL]

Iris [CLOSE/1~16/OPEN]

AGC [-3dB ~ 28dB]

[AUTO/DAY/NIGHT]

Sets Day&Night mode.

The WDR (Wide Dynamic Range) is a function

for dividing an image into several blocks and

correcting blocked-up shadows and blown-out

highlights in accordance with the intensity

difference. It enables you to obtain images in

which portions ranging from dark to light can

be recognized, even when capturing a subject

with a large intensity difference that is backlit

or includes extremely light portions.

Set Auto Exposure mode.

If AE mode is set to IRIS mode or MANUAL

mode, this can be set up.

If AE mode is set to MANUAL mode, this can

be set up.

Shutter [×512~ 1/100000]

If AE mode is set to SHUTTER mode or

MANUAL mode, this can be set up.

33/56

Page 34

OSD ME

NU

Special Setup

4

SPECIAL

----------------------- AUTO DSS OFF

NIGHT>DAY LEVEL 10

APERTURE 6

NR 3

STABILIZATION OFF

HLC OFF

HR 3

BACK

EXIT

Auto DSS [ON/OFF]

When set to ON, ensure that the slow

shutter is set to automatically when

the brightness drops.

Night > Day Level [0 ~ 28]

Adjust the sensitivity to change

Night mode to Day mode.

Aperture [0 ~ 15]

Adjust the enhancement of the edges

of objects in the picture.

NR [0 ~ 10]

Stabilization [ON/OFF]

NR(Noise Reduction) function

removes noise to provide clearer

images.

Compensates image vibrations by

wind or others. The images with

vibrations are compensated by

Digital Zoom function and the image

resolution with this function should

be lower than normal image

resolution when this function is

turned on.

HLC [ON/OFF]

HLC(High Light Compensation)

function removes the high light in a

limited environment such as parking

garage

HR [OFF/1~7]

The horizontal resolution of 700 TN

Lines at Color mode and 750 TV

Lines at B/W mode can be achieved

by using the HR(High Resolution)

mode.

34/56

Page 35

Sets the general functions of Pan/Tilt motions.

Motion

[ON/OFF]

Power Up

[ON/OFF]

Auto Flip

[ON/OFF]

Jog Max

[1°/sec ~360

°

/sec]

Jog

[INVERSE/NORMAL]

Freeze

[ON/OFF]

OSD MENU

4

Motion Setup

MOTION SETUP

----------------------- MOTION LOCK OFF

PWR UP ACTION ON

AUTO FLIP ON

JOG MAX SPEED 120/SEC

JOG DIRECTION INVERSE

FRZ IN PRESET OFF

<PARKING ACTION SETUP>

<ALARM INPUT SETUP>

BACK

EXIT

Lock

Action

If Motion Lock is set to ON, it is impossible

to set up and delete Preset, Swing, Pattern

and Group. It is possible only to run those

functions. To set up and delete those

functions, enter into OSD menu.

Refer to “Other Functions" section.

Refer to “Other Functions" section.

Speed

Sets the maximum jog speed. Jog speed is

inversely proportional to the zoom

magnifications. As the zoom magnification

goes up, the pan/tilt speed goes down.

Direction

Sets the Jog Direction. If this is set to

‘Inverse’, the view direction in the screen

is same as the direction of joystick. If this

is set to ‘Normal’, the view direction in

the screen is the reverse direction of

joystick.

in Preset

Sets Frame Freeze Function. This feature

freezes the scene on the monitor when

going to a preset. At the start point of a

preset movement, a camera starts freezing

the image of the start point. Camera keeps

displaying the image of the start point

during preset movement and does not

display the images which camera gets

during preset movement. As soon as

camera stops at preset end point, camera

starts displaying live images which it gets

at the end preset point. This feature also

reduces bandwidth when working with

digital systems or digital network systems.

This function availability should be

different by models.

35/56

Page 36

This feature allows the camera to begin a specified

Park Enable

[ON/OFF]

Wait Time

[1~59 sec. / 1~180 min.]

Park Action

[HOME/PRESET/PATTERN/SWING/G

OSD MENU

Parking Action Setup

4

PARKING ACTION SETUP

----------------------- PARK ENABLE OFF

WAIT TIME 00:10:00

PARK ACTION HOME

BACK

EXIT

action after a programmed time of inactivity.

If Park Enable is set to ON, the

camera runs an assigned function

automatically if there is no PTZ

command during the programmed

"Wait Time".

Wait Time can be programmed

from 1 second to 180 minutes.

ROUP/PREV ACTION]

This feature defines the activity

when the camera parks. If Park

Action is set to “HOME”, the

camera moves to the home position

which is memorized when the

system boots. If Park Action is set

to “PREV. ACTION”, the camera

runs the previous action which it

ran most recently.

36/56

Page 37

Defines Alarm Function. When an alarm is receive, an input

[NOT

[HOME/PRESET/PATTERN/SWING/GROUP/PR

OSD MENU

Alarm Input Setup

4

ALARM INPUT SETUP

----------------------- ALARM NO. 1

TYPE N.OPEN

ACTION NOT USED

HOLD TIME ENDLESS

POST ACTION HOME

BACK

EXIT

signal to the camera triggers the user-defined action

programmed for the alarm.

Alarm No [1~3]

Selects a sensor number to set up.

Type [Normal OPEN/Normal CLOSE]

Selects sensor operation type.

Action

USED/PRESET/PATTERN/SWING/GROUP]

Selects an action to run when a sensor

signal is input.

Hold Time [ENDLESS / 1~59 SEC. / 1~180 MIN.]

Sets the time period for the action which is

run by external sensor activation. After the

time period passes, the action pre-defined

in “Post Action” runs sequentially in

succession to the action by external sensor

activation. If this option is set to

“ENDLESS”, “Post Action” does not

activate.

Post Action

EV ACTION]

Selects the action that a camera will run

after the time period in “HOLD TIME”

passes. If Post Action is set to “PREV.

ACTION”, the camera runs the previous

action which it ran most recently.

37/56

Page 38

Preset

[1~255

] MAX.

209 Presets except the

Clear

[CANCEL/OK]

Edit

Re-defi

nes the scene position of the

Edit

Edits the label of the selected Preset to

Relay Out

Defines the relay output.

CAM Adjust

[GLOBAL/LOCAL]

OSD MENU

4

Preset Setup

PRESET SETUP

----------------------- PRESET NO. 1

CLR PRESET CANCEL

<EDIT SCENE>

<EDIT LABEL> LABEL123

RELAY OUT OFF

CAM ADJUST GLOBAL

BACK

EXIT

Number

Preset

Preset Scene

Preset Label

Reserved Presets (Hot Keys)

Selects a preset number to set up. If a

selected preset is already defined, the

camera moves to the pre-defined position

and preset parameters such as Label and

CAM Adjust show on the monitor. If a

selected preset is not defined,

“UNDEFINED” shows on the monitor.

Deletes the data of the selected Preset.

selected Preset.

show on the monitor when the preset

runs. MAX. 10 alphanumeric

characteristics are allowed.

WB(White Balance) and AE(Auto Exposure)

can be set up independently for each

preset. There are 2 modes, "Global" mode

& "Local" mode. The Global mode is that

WB and/or AE are/is set up totally and

simultaneously for all presets. The Global

parameter setup such as WB and AE can

be done in "ZOOM CAMERA SETUP" menu.

The Local mode is that WB and/or AE

are/is set up independently or separately

for each preset. The Local parameter

setup for WB and AE can be done in each

preset setup menu. Each Local parameter

such as WB and AE activates

correspondingly when the camera arrives

at each preset position. During jog

operation, Global WB/AE value should be

applied. All Local WB/AE values do not

change although Global WB/AE value

changes. The Local mode has the prior to

the Global mode.

38/56

Page 39

○

1 Use the Joystick to move the camera to a desired

○

2 Save the preset position by pressing

NEAR

key.

○

3 Press

FAR

key to cancel targeting the preset

Edit the label of the selected preset to show on the

①

With

Left/Right/Up/Down

of the joystick, move

②

If you complete the Label editing, move the

OSD MENU

[ ]

----------

Preset Scene Setup

4

EDIT SCENE - PRESET 1

------------------------

MOVE TO TARGET POSITION

[NEAR:SAVE /FAR:CANCEL]

Preset Label Setup

EDIT LABEL - PRESET 1

----------------------- [ ]

--------- 1234567890 OK

ABCDEFGHIJ CANCEL

KLMNOPQRST

UVWXYZabcd

efghijklmn

opqrstuvwx

yz<>-/:.

----------

position.

position.

monitor when camera arrives at the preset. In the

Edit Label menu, the dark rectangular is the cursor.

As soon as finishing selecting an alphabet or a

number, the cursor moves to the next digit.

Current Cursor Position

to a desired Alphabet or a desired number in the

Alphanumeric set. To select a desired Alphabet or

a desired number, press the NEAR key.

1234567890

ABCDEFGHIJ

KLMNOPQRST

UVWXYZabcd

efghijklmn

opqrstuvwx

yz<>-/:.

----------

Back Space Char.Space Char.

If you want to use a blank, select the double

quotation mark (" "). If you want to delete an

Alphabet or a number, use the back space

character (" ←").

cursor to "OK" and press the NEAR key to save the

completed label. To abort the current change,

move the cursor to "Cancel" and press the NEAR

key.

39/56

Page 40

Swing

[1~10

]

1st Position

[PRESET 1~255

]

Swing

[1°/sec. ~180

°

/sec.]

Clear Swing

[CANCEL/OK]

Run Swing

Runs Swing for the test purposes to

OSD MENU

4

Swing Setup

SWING SETUP

----------------------- SWING NO. 1

1ST POS. NOT USED

2ND POS. NOT USED

SWING SPEED 30/SEC

CLEAR SWING CANCEL

RUN SWING

BACK

EXIT

Number

2nd Position

Selects a Swing number to edit. If the

selected Swing is not defined, "NOT

USED" is displayed in the 1st Position and

the 2nd Position.

Sets the 2 positions for a Swing function.

If the selected preset is not defined,

"UNDEFINED" is displayed as shown

below.

SWING SETUP

----------------------- SWING NO. 1

1ST POS. PRESET5

2ND POS. NOT USED

UNDEFINED

Speed

When a swing function runs, the camera

moves from the preset assigned as the

1st point to the preset assigned as the

2nd point in CW(Clockwise) direction.

Then the camera moves from the preset

assigned as the 2nd point to the preset

assigned as the 1st point in CCW

(Counterclockwise) direction. In case that

the preset assigned as the 1st point and

the preset assigned as the 2nd point are

same or only 1 Preset position is

assigned, the camera turns on its axis by

360° in CW direction and then it turns on

its axis by 360° in CCW direction.

Defines Swing speed between the 2 Preset

positions from 1°/sec to 180°/sec

Deletes the data of the selected Swing.

check if it works properly.

40/56

Page 41

Pattern Number

[1~8

]

Clear Pattern

[CANCEL/OK]

Run Pattern

Runs

the

Pattern for the test purposes

Edit Pattern

Edits the selected pattern.

①

With the Joystick of your controller, move the

FAR

key

.

OSD MENU

4

Pattern Setup

PATTERN SETUP

----------------------- PATTERN NO. 1

UNDEFINED

CLR PATTERN CANCEL

RUN PATTERN

<EDIT PATTERN>

BACK

EXIT

Selects a Pattern number to edit. If the

selected pattern number is not

defined, "UNDEFINED" will be

displayed under the selected pattern

number.

Deletes the data of the selected

pattern.

to check if it works properly.

Pattern Edit

EDIT PATTERN 1

------------------------

MOVE TO START POSITION

[NEAR:START /FAR:CANCEL]

EDIT PATTERN 1

camera to the start position with an appropriate

zoom magnification. To start the pattern

recording, press NEAR key. To exit, press FAR key.

② Move camera with joystick of controller or run

preset function to memorize the path (mostly

curve path) in the selected pattern. The

movement by Joystick and preset movement will

be memorized in a pattern. After a pattern is

programmed, the remaining storage is displayed

in progress bar on the screen.

[NEAR:SAVE /FAR:DELETE]

0/0/x1/N

③ To save the data and exit, press NEAR key. To

cancel saving the data and delete the data, press

41/56

Page 42

Group Number

[1~8]

Clear Group

[CANCEL/OK]

Run Group

Runs

the Group

for the test

①

Press

N

ear

key when the cursor is at

“

NO

” to start

OSD MENU

4

Group Setup

GROUP SETUP

----------------------- GROUP NO. 1

UNDEFINED

CLEAR GROUP CANCEL

RUN GROUP

<EDIT GROUP>

BACK

EXIT

Selects a Group number to edit.

If the selected Group number is not

defined, "UNDEFINED" will be

displayed under the selected Group

number.

Deletes the data of the selected

Group.

purposes to check if it works

properly.

Group Edit

EDIT GROUP 1

----------------------- NO ACTION ### DWELL OPT

----------------------- 1 NONE

2 NONE

3 NONE

4 NONE

5 NONE

----------------------- SAVE

CANCEL [NEAR:EDIT]

EDIT GROUP 1

----------------------- NO ACTION ### DWELL OPT

----------------------- 1 NONE

2 NONE

3 NONE

4 NONE

5 NONE

----------------------- SAVE [NEAR:EDIT ACT]

CANCEL [FAR :EDIT END]

editing the selected Group.

② Note that MAX. 40 actions are allowed in a Group.

Move the cursor up/down to select an Action.

Press Near key to edit.

42/56

Page 43

④

Edit the items such as Action, ###, Dwell and OPT

③

Define Action, Dwell time and Option. N

ote that

Action ###

[NONE/PRESET/SWING/PATTERN]

DWELL

[0 SEC. ~ 4 MIN.]

OPT

Op

tion. It is a preset speed when a

OSD MENU

4

EDIT GROUP 1

----------------------- NO ACTION ### DWELL OPT

----------------------- 1 NONE

2 NONE

3 NONE

4 NONE

5 NONE

----------------------- SAVE [ :MOVE CURSOR]

CANCEL [ :CHANGE VAL.]

EDIT GROUP 1

----------------------- NO ACTION ### DWELL OPT

----------------------- 1 PRESET 1 00:03 360

2 NONE

3 NONE

4 NONE

5 NONE

----------------------- SAVE [ :MOVE CURSOR]

CANCEL [ :CHANGE VAL.]

the dark rectangular is the cursor. Move the cursor

Left/Right to select an item and move cursor

Up/Down to change each parameter.

Sets the Dwell Time between

functions.

preset is selected in the Action. It is

the number of repeat when a

by moving the cursor.

EDIT GROUP 1

----------------------- NO ACTION ### DWELL OPT

----------------------- 1 PRESET 1 00:03 360

2 NONE

3 NONE

4 NONE

5 NONE

----------------------- SAVE [NEAR:EDIT ACT]

CANCEL [FAR :EDIT END]

⑤ After finishing editing a Action, press Near key to

go to the previous-upper level menu (Step ②). Move

the cursor Up/Down to select an Action number

and repeat Step ② ~ Step ④ to keep editing the

selected Group.

43/56

Page 44

⑥

After finishing setting up, press

FAR

key to exit

.

OSD MENU

4

EDIT GROUP 1

----------------------- NO ACTION ### DWELL OPT

----------------------- 1 PRESET 1 00:03 360

2 NONE

3 NONE

4 NONE

5 NONE

----------------------- SAVE

CANCEL

Then the cursor will move to “SAVE”. Press Near

key to save the data.

44/56

Page 45

Schedule No

[1~8]

Action

[NOT USED/PRESET/PATTERN/SWING

Hold Time

[ENDLESS / 1~59 SEC. / 1~180 MIN.]

Post Action

[HOME/PRESET/PATTERN/SWING/GR

Cycle

[ONCE/HOUR/DAY/WEEK/MONTH]

Time

Configures a Date(DD/MM/YYYY) and

OSD MENU

4

Schedule Setup

SCHEDULE SETUP

----------------------- SCHEDULE NO 1

ACTION NOT USED

HOLD TIME ENDLESS

POST ACTION HOME

CYCLE ONCE

TIME

01/JAN/2013 TUE

09:00:00 [hh:mm:ss]

BACK

EXIT

Selects a Schedule to be configured.

/GROUP]

Configures a function to be run for a

configured time period.

Configures a time period to run an

Action. After this time passes, “Post

Action” should run. If Post Action is

configured to ENDLESS, Post Action

should not run.

OUP

/PREV ACTION]

Configures a function to be run after

a Hold Time. When “PREV. ACTION" is

configured, the latest function which

is running just before a Schedule

Function should keep running again.

Configures a time period to

repetitively run a Schedule Function.

If “ONCE” is configured, a Schedule

function should run once and it

should not run again. For an example,

if Time is set to 00:15:00 & CYCLE is

set in HOUR, a camera starts running

at 00:15:00 and keeps repetitively

running at 01:15:00 / 02:15:00 /

03:15:00……..

a Time(hh:mm:ss) to run a Schedule

Function. A day should be

automatically changed according to

Date change.

45/56

Page 46

Password

S

etup

[ON/OFF

]

OSD MENU

4

Password Setup

PASSWORD SETUP

----------------------- CHECK PASSWORD OFF

<EDIT PASSWORD>

BACK

EXIT

Configures

be protected with a password. A

password can be configured in

[EDIT PASSWORD].

whether OSD menu will

[Caution] It is mandatorily recommended that a user must take a memo for a

password before a user applies a password to a system. When a Password is

forgotten, a unit can not be unlocked and the unit is supposed to be shipped

back to the manufacturer.

46/56

Page 47

A password should be made up with a 4 Alphanumeric

①

With

Left/Right/Up/Down

of the joystick, move

②

If you complete the

Password

editing, move the

----------

OSD MENU

[ ]

Edit Password

4

EDIT PASSWORD

----------------------- [ ]

--------- 1234567890 OK

ABCDEFGHIJ CANCEL

KLMNOPQRST

UVWXYZabcd

efghijklmn

opqrstuvwx

yz<>-/:.

----------

combination

to a desired Alphabet or a desired number in the

Alphanumeric set. To select a desired Alphabet

or a desired number, press the NEAR key.

Cu rrent Cursor Positio n

1234567890

ABCDEFGHIJ

KLMNOPQRST

UVWXYZabcd

efghijklmn

opqrstuvwx

yz<>-/:.

----------

If you want to use a blank, select the double

quotation mark (" "). If you want to delete an

Alphabet or a number, use the back space

Back Space Char.Space Char.

character (" ←").

cursor to "OK" and press the NEAR key to save.

To abort the current change, move the cursor to

"Cancel" and press the NEAR key.

47/56

Page 48

System Initialization

Display

Parameters

Motion Parameters

Camera ID

ON

Motion Lock

OFF

PTZ Information

AUTO

Power Up Action

ON

Action Titl

e AUTO

Auto Flip

ON

Preset Label

AUTO

Jog Max Speed

120

°

/sec

Alarm I/O

AUTO

Jog Direction

INVERSE

Language

ENG

Freeze In Preset

OFF

North Direction

Pan 0

°

Park Action

OFF

Privacy Zone

Undefined

Alarm Action

OFF

Display Date

ON

User

-

Defined Data

Di

splay Time

ON

Preset 1~255

Undefined

Swing 1~10

Undefined

Pattern 1~8

Undefined

Group 1~8

Undefined

Schedule 1~8

Not Used

Password

OFF / Blank

Camera Parameters

Focus Mode

SemiAuto

WDR

OFF

Digital Zoom

ON

AE Mode

AUTO

Flickerless

OFF

Auto DSS

OFF

Color

ON

Night > Day Level

10

Image Flip

OFF

Aperture

6

White Balance

AUTO

NR 3

Backlight

OFF

Stabilization

OFF

Day&Night

AUTO

HLC

OFF

HR 3

Clear All Data

Dele

tes all configuration data and the system is

Clear Display Set

Initializes all the configuration data for Display.

Clear Camera Set

Initializes all the configuration data for Camera.

Clear Motion Set

Initializes all the

configuration data for Motion.

Clear Edit Data

Deletes all the

configuration

data for Preset,

Reboot Camera

Reboots the zoom camera module.

Reboot System

Reboots the system.

OSD MENU

SYSTEM INITIALIZE

----------------------- CLEAR ALL DATA NO

CLR DISPLAY SET NO

CLR CAMERA SET NO

CLR MOTION SET NO

CLR EDIT DATA NO

REBOOT CAMERA NO

REBOOT SYSTEM NO

4

set to the factory default.

Swing, Pattern and Group.

BACK

EXIT

48/56

Page 49

CAMERA PART (

HTSD37XH

)

Video Signal Format

NTSC

PAL

Image S

e

nsor

1/4''

Sony Super

HAD II (Double Scan)

CCD

Total

Pixels

1028

(H)

×

508

(V)

520

K 1028

(H)

×

596

(V)

610

K

Horizontal Resolution

700

TV

Lines

(Color), 750 TV Lines (B/W) @ HR 7 mode

Video Signal

-to-

Noise

50 dB

Zoom

×37 Optical Zoom,

×32

Digital Zoom

Fo

cal Length

F1.

6~4.5

, f=3.

5~129

.5

mm

Day & Night

Auto / Day / Night(ICR)

Focus

Auto / Manual / SemiAuto

AE Mode

Auto / Iris / Shutter / Manual

White Balan

ce Auto / M

anual(Red, Blue Gain Adjustable

)

BLC

On

/ Off

HLC

On

/ Off

WDR

On

/ Off

Flickerless

On

/ Off

Aperture

Adjustable

NR Adjustable

HR Adjustable

Privacy Zone

8

Masks

,

Spherical Coordinate

Stabilization

ON / OFF

SPECIFICATIONS

5

Specifications

Minimum Illuminance

0.5 Lux (Color) / 0. 2 Lux (B/W) @ DSS OFF

0.001 Lux (Color) / 0. 0004 Lux (B/W) @ DSS ON

49/56

Page 50

CAMERA PART (

H

TSD28XH

)

Video Signal Format

NTSC

PAL

Image S

e

nsor

1/4''

Sony Super

HAD II (Double Scan)

CCD

Total

Pixels

1028

(H)

×

508

(V)

520

K 1028

(H)

×

596

(V)

610

K

Horizontal Resolution

700

TV

Lines

(Color), 750 TV Lines (B/W) @ HR 7 mode

Video Signal

-to-

Noise

50 dB

Z

oom

×28 Optical Zoom,

×32

Digital Zoom

Fo

cal Length

F1.

6~4.5

, f=3.

5~98

mm

0.001

Lux (Color) / 0.

0004

Lux (B/W

)

@ DSS ON

Day & Night

Auto / Day / Night(ICR)

Focus

Auto / Manual / SemiAuto

AE Mode

Auto / Iris / Shutter / Manual

White Balance

Auto / M

anual(Red, Blue Gain Adjustable

)

BLC

On

/ Off

HLC

On

/ Off

WDR

On

/ Off

Flickerless

On

/ Off

Aperture

Adjustable

NR Adjustable

HR Adjustable

Privacy Zone

8

Masks

,

Spherical Coordinate

S

tabilization

ON / OFF

Minimum Illuminance

0.5 Lux (Color) / 0. 2 Lux (B/W) @ DSS OFF

50/56

Page 51

M

ECHANISM PART

Pan

360

°

(Endless)

Tilt

90°

Preset

500°/sec

.

Jog

0.05 ~ 360

°

/sec

. (

Proportional to Zoom)

Swing

1~ 180

°

/sec

.

209

Presets

(

Label, Independent Camera Parameter

Pattern

8 Patterns

[880 Commands(Approx. 4

Minute) / Pattern]

Swing

10

Swings

8

Groups

(MAX.

40 Actions with The Combination of

Schedule

8 Schedules

Other

Pan/Tilt

Real

Time Clock

Yes

, RTC battery backup time : 2

weeks

Communication

RS-

485

Protocol

Pelco

-

D, Pelco

-P

Selectable

4 Languages (

English

/Polish/French/Italian)

Sensor Input

3

Inputs

, Photo

-

Coupler

Typ

e

, DC 5V~12V

1

Output

, Relay Output,

MAX. Load

DC24V 1A / AC125V

0.5A

Fan

Always

ON

Heater

Operation Start from Internal Temperature

10°C

Operation

SPECIFICATIONS

5

Movement

Range

Speed

Preset

Group

Functions

OSD

Alarm Outputs

Setting)

Preset, Pattern and Swing)

Auto Flip, Auto Parking, Power Up Action and etc.

Menu / Time / PTZ information etc, Password protection

Temperature

-30°C ~ 50°C

Rated Power DC 12V / 1.8A or AC 24V / 1.8A

51/56

Page 52

MECHANICAL

Cei

ling Mount

Wall Mount

Dome

Polycarbonate

Internal

Polycarbonate, ABS

External

Aluminium

Dome

Size

∅150mm

/ ∅ 5.9

”

Dimension

∅200

×

407.8

mm

300

×

309.1

mm

Weight

Approx 3.6

Kg

Approx 3.4

Kg

[Note]

SPECIFICATIONS

5

Material

1) Specification and features are subject to change without prior notice.

2) Check the voltage and current capacity of rated power carefully.

52/56

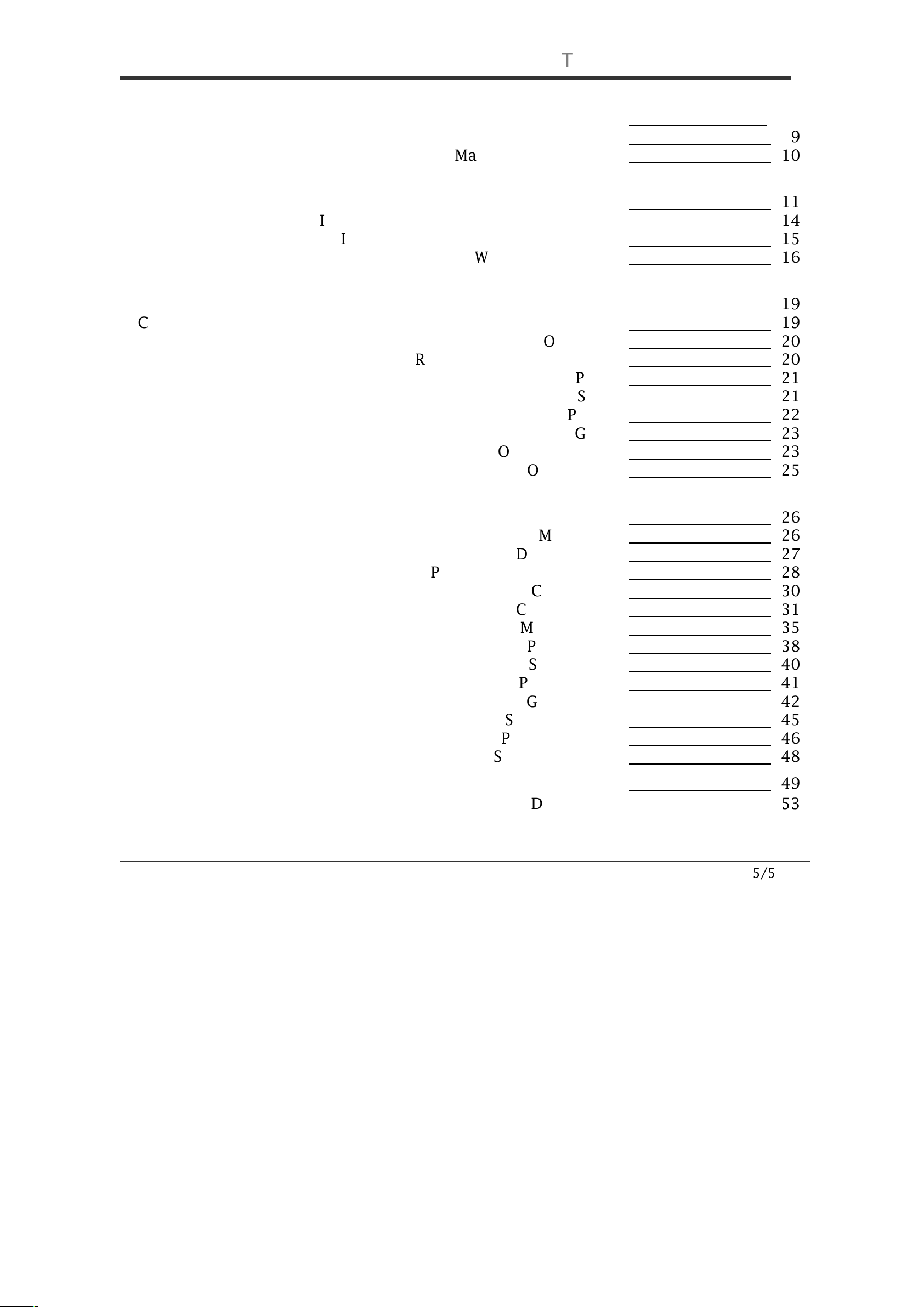

Page 53

220.3

SPECIFICATIONS

Dimensions

Main Body Ceiling Mount Type (Optional)

56.4 56.4

32.3

65

5

74.181.5

207.8

1

5

0

200

Wall Mount Type (Included)

300

1.5" NPT

158.2

50207.8

110

40

118.6

80

4- 8

100

138.6

309.1

[Unit : mm]

53/56

Page 54

54/56

Page 55

55/56

Page 56

Speco Technologies is constantly developing product improvements.

We reserve the right to modify product design and specifications without

notice and without incurring any obligation. (Rev. 05152014)

56/56

Loading...

Loading...