Page 1

1

12/06 ID# M682001

© COPYRIGHT 2006 by SPALDING

Toll-Free Customer Service Number for U.S: 1-800-558-5234,

For Canada: 1-800-284-8339,

For Europe: 00 800 555 85234 (Sweden: 009 555 85234),

For Australia: 1-800-632 792

Internet Address: www.huffysports.com www.spalding.com

REQUIRED TOOLS AND MATERIALS:

• 2 Capable Adults

• Tape Measure

• Wood Board (scrap)

• Sawhorse or Support Table

• Hammer

• Step Ladder 8 ft. (2.4m)

• Safety Glasses

• (2 each) Wrenches

(2) Socket Wrenches and Sockets

• Extension

• Phillips-Head Screwdriver

1/2" 9/16" 3/4"

AND/OR

• Garden Hose or Sand

• Optional: Large & Small

Adjustable Wrenches

SAND

SAND

(475 lb.)

(475 lb.)

(216 kg)

(216 kg)

1/2" 9/16" 3/4"

READ AND UNDERSTAND

OPERATOR'S MANUAL

BEFORE USING THIS UNIT.

FAILURE TO FOLLOW

OPERATING

INSTRUCTIONS COULD

RESULT IN INJURY OR

DAMAGE TO PROPERTY.

WARNING!

Write Model Number

From Box Here:

Portable System

Owners Manual

Customer Service Center

• N53 W24700 South Corporate Circle • Sussex, WI 53089 • U.S.A.

This manual, accompanied by sales receipt, should be saved and kept on hand as a convenient reference, as it

contains important information about your model.

Adult Assembly Required.

Page 2

2

ID# M682001 12/06

BEFORE YOU START

To ensure optimal playability of backboard system, a close tolerance fit between the elevator components and

hardware is required. Test-fit large bolts into large holes of elevator tubes, backboard brackets, and triangle plates.

Carefully rock them in a circular motion to ream out any excess paint from holes if necessary.

NOTE: Not all items pictured are included with every model.

56620012/05

T

ADJUS

G

M

Adj

d

.

W

g

p

otate

basketba

d

unt

s

engage

th

.

M

ll

s

desired

.

C

ll

.

2

5

C

bility

33

NOTICE TO ASSEMBLERS

Adult Assembly Required. Dispose of ALL packaging materials promptly. As with all products, periodically inspect

for loose small parts.

Assembled unit MUST be filled with sand or water at ALL times.

ALL basketball systems, including those used for DISPLAYS, MUST be assembled and installed according to

instructions. Failure to follow instructions could result in SERIOUS INJURY. It is NOT acceptable to devise a

makeshift support system.

EIGH

TO ADJUST BACKBOARD:

1. Grasp handle and press button.

2. Raise or lower to desired height.

3. Release button.

VIN

1

2

3

4

TMENT

YSTE

ustbasketball backboar

heightto

owest position

hileholdin

.

3.

.

ll system forwar

il wheel

ground

ovebasketba

ocation

arefully rotate basketba

system upright

heck system for sta

ole, r

wi

ystem to

.

Page 3

12/06 ID# M682001

3

SAFETY INSTRUCTIONS

FAILURE TO FOLLOW THESE SAFETY INSTRUCTIONS MAY RESULT IN SERIOUS INJURY OR

PROPERTY DAMAGE AND WILL VOID WARRANTY.

Owner must ensure that all players know and follow these rules for safe operation of the system.

To ensure safety, do not attempt to assemble this system without following the instructions carefully. Check

entire box and inside all packing material for parts and/or additional instruction material. Before beginning

assembly, read the instructions and identify parts using the hardware identifier and parts list in this document.

Proper and complete assembly, use, and supervision are essential for proper operation and to reduce the risk

of accident or injury. A high probability of serious injury exists if this system is not installed, maintained, and

operated properly.

• If using a ladder during assembly, use extreme caution.

• Check base regularly for leakage. Slow leaks could cause the system to tip

over unexpectedly

• Seat the pole sections properly (if applicable). Failure to do so could allow the

pole sections to separate during play and/or during transport of the system.

• Climate, corrosion or misuse could result in system failure.

• If technical assistance is required, contact Customer Service.

• Minimum operational height is 6'-6" (1.98m) to the bottom of backboard.

Most injuries are caused by misuse and/or not following instructions.

Use caution when using this unit.

IMPORTANT!

Remove all contents from boxes.

Be sure to check inside pole sections,

hardware and additional parts are packed inside.

PRODUCT REGISTRATION:

Please remember to complete your product registration form online at:

www.huffysports.com/customer_support/product_registration.

WARNING!

IF YOUR SYSTEM IS EQUIPPED WITH AN ACRYLIC BACKBOARD, EXAMINE BACKBOARD FOR ANY DAMAGE

THAT MAY HAVE OCCURRED DURING SHIPMENT. CRACKS IN THE BACKBOARD COULD RESULT IN

SUDDEN BREAKAGE. IF BACKBOARD IS DAMAGED IN ANY WAY PRIOR TO OR AFTER ASSEMBLY, CALL

TOLL-FREE NUMBER:

U.S. 1-800-558-5234; CANADA: 1-800-284-8339; http://www.huffysports.com

Page 4

4

ID# M682001 12/06

Get to know the basic parts of your basketball system...

TOP POLE

MIDDLE POLE

BOTTOM POLE

STRUTS

ELEVATOR ASSEMBLY

BACKBOARD

BASE

WHEEL CARRIAGE ASSEMBLY

FRONT BACK

RIM

Page 5

12/06 ID# M682001

5

Item Qty.

Part No.

Description

1 1 600053 Tank

2 2 908556 Strut, Pole to Base

3 1 904501 Handle Assembly

4 1 FR908356 Top Pole Section

5 1 FR908357 Middle Pole Section

6 1 FR908360 Bottom Pole Section

7 2 800332 Wheel Bracket

8 2 600056 Wheel, 3.5”

9 1 108306 Rod, Axle

10 2 203099 Nut, Ny-lock, 5/16-18

11

12 1 203131 Bolt, Hex Head, 5/16-18 x 5 Long

13 2 206938 Pushnut, 7/16 Shaft Diameter

14 12 203100 Hex Flange Nut 5/16-18

15 1 108163 Bracket, Pole Mount

16 2 204846 Carriage Bolt, 5/16-18 x 4.5 Long

17 1 918162 Tube, Outer

18 6 203153 Bolt, Hex Head, 5/16-18 x .75 Long

19 1 108181 Plate, Pole Mounting

20 1 202739 Bolt, Hex Head, 5/16-18 x 1.75 Long

21 1 600086 Front Cover

22 6 203738 Bolt, Carriage, 5/16-18 x 1.75 Long

23 4 206665 Bolt, Hex Head, 1/2-13 x 2 Long

24 8 203218 Washer, Flat, 5/16

25 2 203679 Bolt, Hex Head, 3/8-16 x 2 Long

26 4 203104 Bolt, Hex Head, 5/16-18 x 2 Long

27 1 908395 Bracket, Spring Mount

Item

Qty.

Part No.

Description

28 1 908355 Cover Plate, Rim

29 4 205809 Bolt, Hex Head, 1/2-13 x 10.25 Long

30 4 201651 Spacer, Plastic, .530 I.D. x .25 Long

31 10 206340 Lock Nut, Hex 1/2-13

32 2 908375 Elevator Tube, Lower - Long

33 1 566200 Label, Height Adjustment and Moving

FR566200 Label, French

34 1 Rim

35 2 908374 Elevator Tube, Upper - Short

36 2 204837 Spring, 2-Hook, Board Support

37 1 203470 Washer, Flat, .625 I.D. x .1.5 O.D.

38 1 600080 Cap, Pole Top

39 2 204558 Screw, 1/4 x .375 Long

40 2 900867 Triangle Plate

41 1 700012 Cap, Base

42 1 206990 Reinforcement Bracket

43 1 Net

44 1 900033 Bracket, Slam Jam

45 1 203796 Bolt, Tee, 3/8-16, 5” Long

46 1 200318 Bracket, Reinforcement, Slam Jam

47 1 203472 Spring, Rim

48 1 203795 Nut, Special, 3/8-16

49 1 206664 Spacer, Plastic, .53 I.D., .75 O.D. x 4” Lg

50 8 202862 Spacer, Plastic, .53 I.D., .75 O.D.

x 1.19” Lg

51 2 202900 Bolt, Hex, 1/2-13 x 5” Long

* YOU MAY HAVE EXTRA PARTS WITH THIS MODEL.

PARTS LIST - See Hardware Identifier

NOTE

Hardware kit is designed for more than one

style of basketball system. Not all hardware

will be used.

Page 6

6

ID# M682001 12/06

#16 (2)

#12 (1)

#45 (1)

#39 (2)

#23 (4)

#26 (4)

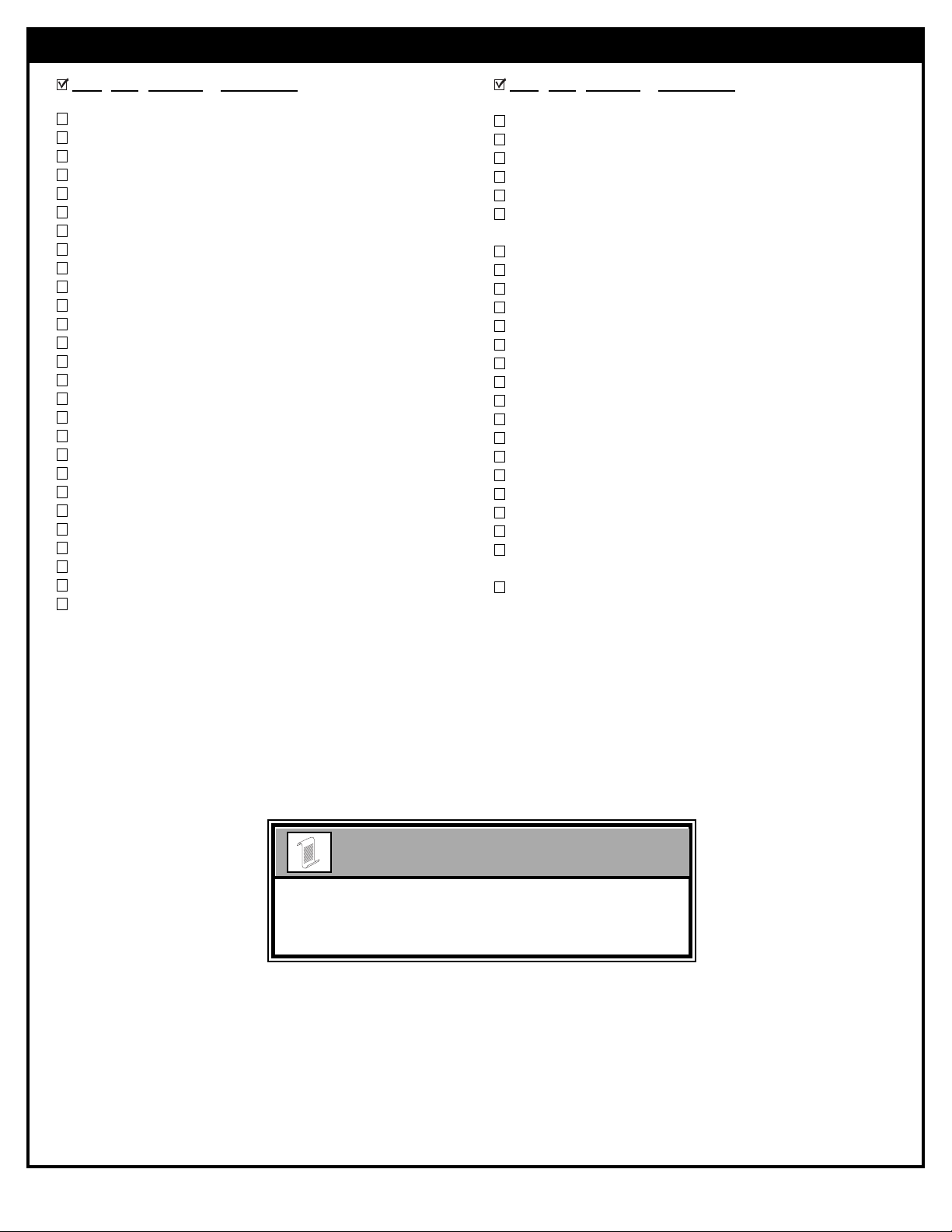

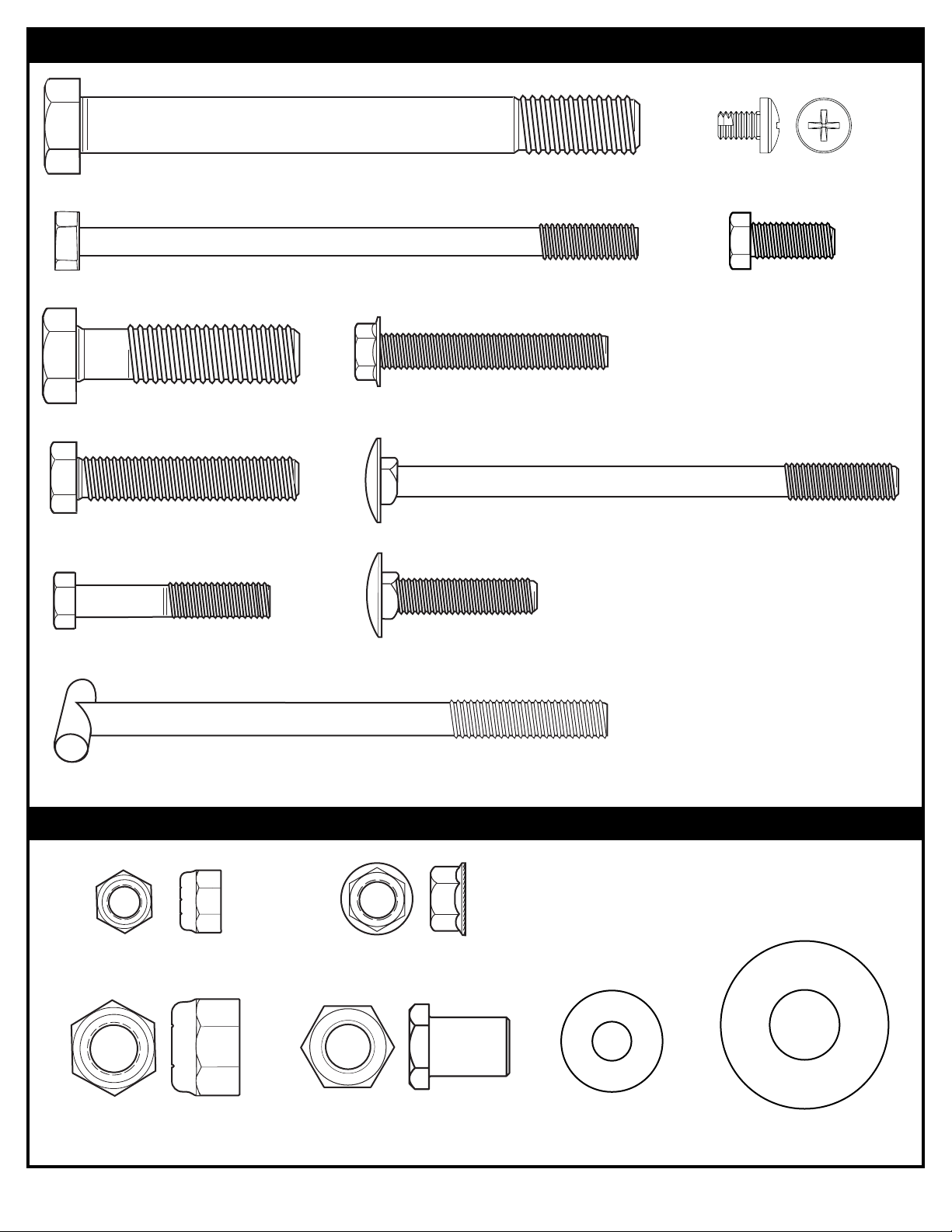

HARDWARE IDENTIFIER (BOLTS & SCREWS)

#20 (1)

#25 (2)

#51 (2)

#18 (6)

HARDWARE IDENTIFIER (NUTS & WASHERS)

#14 (12)

#10 (2)

#31 (10)

#48 (1)

#37 (1)

#24 (8)

#22 (6)

Page 7

12/06 ID# M682001

7

#44 (1)

#46 (1)

#47 (1)

#13 (2)

#30 (4)

#49 (1)

#50 (8)

HARDWARE IDENTIFIER (PLASTIC SPACERS CAPS & CLIPS)

HARDWARE IDENTIFIER (OTHER)

* You may have extra parts with this model.

Page 8

8

ID# M682001 12/06

7

8

8

9

13

13

Complete wheel assembly as shown in Figure A. Secure wheel bracket (7) and wheel assembly (Fig. A.)

to the tank (1) with a bolts (18) and washers (24).

24

TO INSTALL SECOND

PUSHNUT:

• Assemble Pushnut,

Wheels, Axle, And

Wheel Bracket As

Shown.

• Support Pushnut/Axle

From The End With A

Block Of Wood To

Install The Second

Pushnut Onto The

Axle.

NOTE:

Wood Block

TOOLS REQUIRED FOR THIS SECTION

SECTION A: ASSEMBLE THE BASE

This is what your system will look like when

you’ve finished this section.

9/16”, 1/2”

9/16”

1/2”

(2) Wrenches

AND/OR

(2) Socket Wrenches and Sockets

Extension

1.

Sawhorse or

support table

18

Fig. A.

7

1

18

24

Page 9

12/06 ID# M682001

9

Correctly identify each pole section. Poles have an identification sticker that will be used as a

reference point in the next step.

2.

Bounce middle pole section (5) into top section (4) using a wood scrap as shown until the top pole no

longer moves toward the pole identification sticker on the middle pole.

3.

4

5

6

BOTTOM

TOP

MIDDLE

IDENTIFICATION STICKER

5

4

Wood Scrap (not supplied)

Align dimple of top pole section (4) into trough of

middle pole section (5) as shown.

IMPORTANT!

HOLE

DIMPLE

middle pole

5”

(12.7 cm)

middle pole

1.5” (3.81 cm)

ID STICKER

Trough

THE IDENTIFICATION

STICKER IS LOCATED

5" FROM THE END OF

THE POLE. WHEN

PROPERLY POUNDED

TOGETHER, THE

POLE SECTIONS

SHOULD HAVE A 41/2" MINIMUM

OVERLAP, LEAVING

1/2" BETWEEN THE

OVERLAPPING POLE

AND THE

IDENTIFICATION

STICKER.

CAUTION!

Page 10

10

ID# M682001 12/06

4.

Bounce top and middle pole assembly (4 and 5)

onto bottom pole section (6) using a wood scrap as

shown. Bounce until the top and middle pole

assembly no longer moves toward the pole

identification mark on the bottom pole.

4

5

6

RODS SHOWN ARE FOR

VISUAL REPRESENTATION OF

ALIGNMENT AND ARE NOT

SUPPLIED WITH THE

HARDWARE

Align dimple of middle pole section (5) into

trough of bottom pole section (6) as shown.

IMPORTANT!

HOLE

DIMPLE

Bottom pole

1.5” (3.81 cm)

ID STICKER

Bottom pole

5”

(12.7 cm)

Trough

Dimple

Wood Scrap

(not supplied)

Page 11

12/06 ID# M682001

11

6.

Secure tank struts (2) through center hole in

pole as shown.

12

10

2

2

TWO CAPABLE ADULTS

REQUIRED FOR THIS

PROCEDURE. FAILURE TO

FOLLOW THIS WARNING COULD

RESULT IN SERIOUS INJURY

AND/OR PROPERTY DAMAGE.

WARNING!

IMPORTANT!

DO NOT TIGHTEN

COMPLETELY.

5.

Attach pole assembly to tank (1) as shown.

Secure pole assembly to tank using

bolts (25) and pole mounting plate (19) as

shown.

TWO CAPABLE ADULTS

REQUIRED FOR THIS

PROCEDURE. FAILURE TO

FOLLOW THIS WARNING COULD

RESULT IN SERIOUS INJURY

AND/OR PROPERTY DAMAGE.

WARNING!

6

19

1

25

24

24

Page 12

12

ID# M682001 12/06

8.

42

6

14

16

15

IMPORTANT!

DO NOT OVER

TIGHTEN!

7.

2

2

18

24

24

2

2

18

IMPORTANT!

DO NOT TIGHTEN

COMPLETELY.

TWO CAPABLE ADULTS

REQUIRED FOR THIS

PROCEDURE. FAILURE TO

FOLLOW THIS WARNING COULD

RESULT IN SERIOUS INJURY

AND/OR PROPERTY DAMAGE.

WARNING!

Rotate non-secured ends of tank struts (2) to mounting

holes in tank as shown. Secure non-secured ends of tank

struts (2) to tank as shown.

IMPORTANT!

TIGHTEN ALL HARDWARE

FROM STEPS 6-8 AFTER THIS

ASSEMBLY IS COMPLETED.

Install pole mount bracket (15) and

reinforcement bracket (42) with carriage bolts

(16) as shown. Tighten flange nuts (14)

completely.

Page 13

12/06 ID# M682001

13

Securely rest the assembly on sawhorse. Identify elevator

tubes (32 and 35).

35

32

9.

Toward Pole

Toward Board

4

35

51

50

40

49

29

29

40

50

COMPLETED ASSEMBLY

31

32

TWO CAPABLE ADULTS

REQUIRED FOR THIS

PROCEDURE. FAILURE TO

FOLLOW THIS WARNING COULD

RESULT IN SERIOUS INJURY

AND/OR PROPERTY DAMAGE.

WARNING!

TIGHTEN BOLT (29) IN

LOCK NUT (31) UNTIL

FLUSH (EVEN) WITH LOCK

NUT’S OUTER EDGE.

WARNING!

10.

While the system is securely resting on the sawhorse. Install elevator tubes (32 and 35) to top pole

section (4) as shown. Install pole cap (38) at this time.

Lower Elevator tube

32

Upper Elevator tube

35

50

38

32

31

31

50

35

Page 14

14

ID# M682001 12/06

While still supported on sawhorse. Attach elevator tubes (32, 35) to backboard using spacers (30),

bolts (23), and nuts (31) as shown.

30

1.

Sawhorse or Support Table

9/16”, 1/2”, 3/4”

9/16”

1/2”

3/4”

Extension

TOOLS REQUIRED FOR THIS SECTION

SECTION B: ATTACH THE BACKBOARD

This is what your system will look like when you’ve

finished this section.

(2) Wrenches

AND/OR

(2) Socket Wrenches and Sockets

31

Phillips Screwdriver

23

Page 15

12/06 ID# M682001

15

2.

45

Insert T-bolt (45) into Slam Jam bracket (44) then, attach that assembly to board using

bolts (26) and nuts (14).

14

26

27

IMPORTANT!

Carefully cut and

peel protective film

away from board

prior to attaching

rim.

44

44

Page 16

16

ID# M682001 12/06

3.

29

31

36

35

35

WARNING!

USE EYE PROTECTION WHEN

INSTALLING SPRINGS.

35

35

Support pole on sawhorse. Attach counter balance spring (36) to the spring support bracket (27) using bolt (51) and

nut (31) as shown.

Insert bolt (29) through left side upper elevator tube (35), then stretch spring (36) onto bolt (29). Insert

bolt (29) through right side upper elevator tube (35) and secure with nut (31).

51

31

36

27

Page 17

12/06 ID# M682001

17

Install Slam Jam Rim to Backboard

A. Fit rim (34) securely into bracket (44) as shown. Allow T-bolt (45) to slip through center

hole in rim (34).

B. Install reinforcement bracket (46) onto T-bolt (45) as shown.

C. Install spring (47) onto T-bolt (45) as shown.

D. Install special nut (48) and washer (37) onto T-bolt (45).

E. Tighten nut (48) until flush with end of T-bolt (45).

4.

46

48

37

44

45

34

47

45

37

48

A

B

C

D

E

45

45

NOTE:

ORIENTATION

OF BRACKET

46

Page 18

18

ID# M682001 12/06

Slide upper tube (17) onto handle assembly (3). Reinsert screws removed in previous step as shown.

5.

6.

Remove packaging materials from handle assemblies (17 and 3).

Remove screws on both sides of tube.

17

3

17

Screws removed in step 6

3

Rotate upper tube to line up screw holes. Reinsert

screws removed in previous step as shown.

NOTE:

Page 19

12/06 ID# M682001

19

Install handle assembly (17) to lower elevator tubes (32) using bolt (29),

spacers (50), and nut (31) as shown.

Secure the handle assembly (3 & 17) to pole bracket

(15) using bolt (20) and nut (10) as shown.

8.

Secure the front panel (21) to struts (2) as

shown with carriage bolts (22) and nuts (14).

9.

17

29

31

15

42

20

10

3

14

22

21

50

50

7.

Loosening the strutto-pole bolt (12)

can help when

aligning front cover

to struts.

Retighten bolt (12)

when front cover

attachement is

completed.

NOTE:

WARNING!

Page 20

20

ID# M682001 12/06

10.

Roll completed assembly to desired position. Fill tank with water (approx. 40 gallons (128 Liters)) or

sand (approx. 475 lbs. (216 kg)) and rotate the cap (41) into base (1).

TWO CAPABLE ADULTS

REQUIRED FOR THIS

PROCEDURE. FAILURE TO

FOLLOW THIS WARNING

COULD RESULT IN SERIOUS

INJURY AND/OR PROPERTY

DAMAGE.

ADD TWO GALLONS (7.6

LITERS) OF NON-TOXIC

ANTIFREEZE IN SUBFREEZING CLIMATES.

IF USING SAND

: 2 GALLONS

OF ANTI-FREEZE IS NOT

REQUIRED.

CAUTION!

SAND

SAND

(475 lb.)

(475 lb.)

(216 kg)

(216 kg)

WARNING!

DO NOT LEAVE ASSEMBLY

UNATTENDED WHEN EMPTY;

IT MAY TIP OVER.

Cap (41) MUST be tightened COMPLETELY and

SECURELY to prevent leakage.

CHECK WATER LEVEL BEFORE EACH USE!

FAILURE TO FOLLOW THIS WARNING COULD

RESULT IN SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

WARNING!

1

41

Page 21

12/06 ID# M682001

21

Apply Height Adjustment and Moving Label (33) to front of

pole, where it is clearly visible.

11.

12.

B.

D.

C.

A.

Install net (43).

34

39

28

Cover plate (28) will fit

INSIDE back bracket.

NOTE:

43

34

43

34

13.

RIM COVER ATTACHMENT

39

56620012/05

T

ADJUS

G

M

Adj

d

heigh

to

lowest

.

W

g

p

otate

basketba

d

unt

s

engage

th

.

M

ll

s

desired

.

C

ll

.

2

3

5

C

bility

33

EIGH

TO ADJUST BACKBOARD:

1. Grasp handle and press button.

2. Raise or lower to desired height.

3. Release button.

TMENT

VIN

1

2

3

4

YSTE

ustbasketball backboar

t

hileholdin

.

.

.

ll system forwar

il wheel

ground

ovebasketba

location

arefully rotate basketba

system upright

heck system for sta

position

ole, r

wi

ystem to

.

Page 22

22

ID# M682001 12/06

SECTION C: BOARD PAD

Item Qty. Part No. Description

1 1 20157801 Board Pad, Left Section

2 1 20157901 Board Pad, Right Section

3 1 201580 Board Pad, Center Section

4 4 206081 Screw, Self Drilling, Hex Washer Head, 1/4 x .75” Long

5 6 202219 Cap, Screw

6 1 205355 Drill Bit, 11/64

7 2 201596 Screw, Lag, Hex Washer Head, 1/4 x 1.25” Long

HARDWARE IDENTIFIER

PARTS LIST - See Hardware Identifier

#4 (4)

#7 (2)

#6 (8)

#5 (8)

#1 (1) #2 (1) #3 (1)

ITEMS REQUIRED FOR THIS SECTION

Flat-Head Screwdriver

Socket Wrenches and Sockets

OR

3/8”

Portable Drill with Torque Adjustment

Page 23

12/06 ID# M682001

23

Using a portable drill (with adjustable torque) and a

5/16 socket and extension drill through the

backboard frame and secure the pads in place with

self-tapping screws provided. Use screws (7) for

center pad and screws (4) for outer pads

It may be necessary to use an 11/16 drill bit (6) to

pre-drill on some backboards (FIG. A).

A center punch is recommended to mark hole

locations prior to drilling to keep drill bit from

wandering.

If the ends of the screws are exposed after

installation, place the screw protectors (5) over the

ends to prevent injury.

BOARD PAD - INSTALLATION

1.

Check the fit of the edge guards and reposition

slightly if necessary. It may be necessary to trim

away some material to fit it around the goal or

supports. NOTE: CHECK FASTENER LOCATIONS

TO MAKE SURE THEY WILL NOT DAMAGE THE

BACKBOARD GLASS.

1

2

7

4

4

3

5

4

4 or 7

FIG. A.

6

The enclosed Molded Edge Guards interlock together to form bottom and side protection for

one backboard with an overall width of 54".

3.

2.

Collect any metal shavings that may have fallen

onto the floor or driveway to prevent injury.

Loading...

Loading...