Page 1

H

U

F

F

Y

HUFFY

SPOR

TS

REQUIRED TOOLS

SAND

450 LBS

.

(204 KG)

AND MATERIALS:

• 2 People

Por table System

• Tape Measure

• Wood Board (scrap)

• Sawhorse or Support

Table

• Hammer

• Tape

• Safety Glasses

• Phillips Screwdriver

• Scissors

• (2 each) Wrenches and/or

Socket Wrenches and Sockets

(Deep-Well Sockets are

Recommended).

3/8" 1/2" 9/16" 3/4"

AND/OR

Owners Manual

Customer Service Center

• N53 W24700 South Corporate Circle • Sussex, WI 53089 • U.S.A.

3/8" 1/2" 9/16" 3/4"

• Extension is Recommended.

• Garden Hose or Sand

SAND

SAND

(360 lb.)

(360 lb.)

(163 kg)

(163 kg)

• Step Ladder - 8 ft. (2.4 m)

OPTIONAL TOOLS

AND MATERIALS:

• Large & Small Adjustable

Wrenches

WARNING!

READ AND UNDERSTAND

OPERATOR'S MANUAL

BEFORE USING THIS UNIT.

FAILURE TO FOLLOW

OPERATING INSTRUCTIONS

COULD RESULT IN INJURY

OR DAMAGE TO

PROPERTY.

Write Model Number

From Box Here:

Toll-Free Customer Service Number for U.S: 1-800-558-5234,

For Canada: 1-800-284-8339,

For Europe: 00 800 555 85234 (Sweden: 009 555 85234),

For Australia: 1-800-632 7921

Internet Address: http://www.huffysports.com

© COPYRIGHT 2005 by SPALDING

1

08/05 P/N M601111

Page 2

10-3/4" High

4" Wide

PMS 021 for Warning

Owner must ensure that all players know and follow these rules

for safe operation of the system.

WARNING

•

DO NOT HANG on the rim or any part of the system including

backboard, support braces or net.

•

During play, especially when performing dunk type activities,

keep player's face away from the backboard, rim and net.

Serious injury could occur if teeth/face come in contact with

backboard, rim or net.

•

Do not slide, climb, shake or play on base and/or pole.

•

After assembly is complete, fill system completely with water

or sand. Never leave system in an upright position without

filling base with weight, as system may tip over causing

injuries.

•

When adjusting height or moving system, keep hands and

fingers away from moving parts.

•

Do not allow children to move or adjust system.

•

During play, do not wear jewelry (rings, watches, necklaces,

etc.). Objects may entangle in net.

•

Surface beneath the base must be smooth and free of gravel or

other sharp objects. Punctures cause leakage and could cause

system to tip over.

•

Keep organic material away from pole base. Grass, litter, etc.

could cause corrosion and/or deterioration.

•

Check pole system for signs of corrosion (rust, pitting,

chipping) and repaint with exterior enamel paint. If rust has

penetrated through the steel anywhere, replace pole

immediately.

•

Check system before each use for proper ballast, loose

hardware, excessive wear and signs of corrosion and repair

before use.

•

Check system before each use for instability.

•

Do not use system during windy and/or severe weather

conditions; system may tip over. Place system in the storage

position and/or in an area protected from the wind and free

from personal property and/or overhead wires.

•

Never play on damaged equipment.

•

When moving system, use caution to keep mechanism from

shifting.

•

Keep pole top covered with cap at all times.

•

Do not allow water in tank to freeze. During sub-freezing

weather add 2 gallons of non-toxic antifreeze, sand or empty

tank completely and store. (Do not use salt.)

•

While moving system, do not allow anyone to stand or sit on

base or have added ballasting on base.

•

Do not leave system unsupervised or play on system when

wheels are engaged for moving.

•

Use Caution when moving system across uneven surfaces.

System may tip over.

•

Use extreme caution if placing system on sloped surface.

System may tip over more easily.

•

See instruction manual for proper installation and

maintenance.

Read and understand warnings listed

below before using this product.

Failure to follow these warnings may

result in serious injury and/or property

damage.

ID#: 556790 05/05

MUNSELL NOTATION

Hue Value Chroma

5.0 YR 6.0/15

Equiv. CIE Data

(Y%) x y

30.05 0.5510 0.4214

Approx. PMS Color

13 parts yellow

3 parts Warm Red

1/4 part Black

Warning Area = Orange

Size = 4" x 6.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

In the U.S.: 1-888-713-5488

In the U.S.: 1-800-558-5234

Canada: 1-800-284-8339

In the U.S.: 1-800-334-9111

In the U.S.: 1-800-772-5346

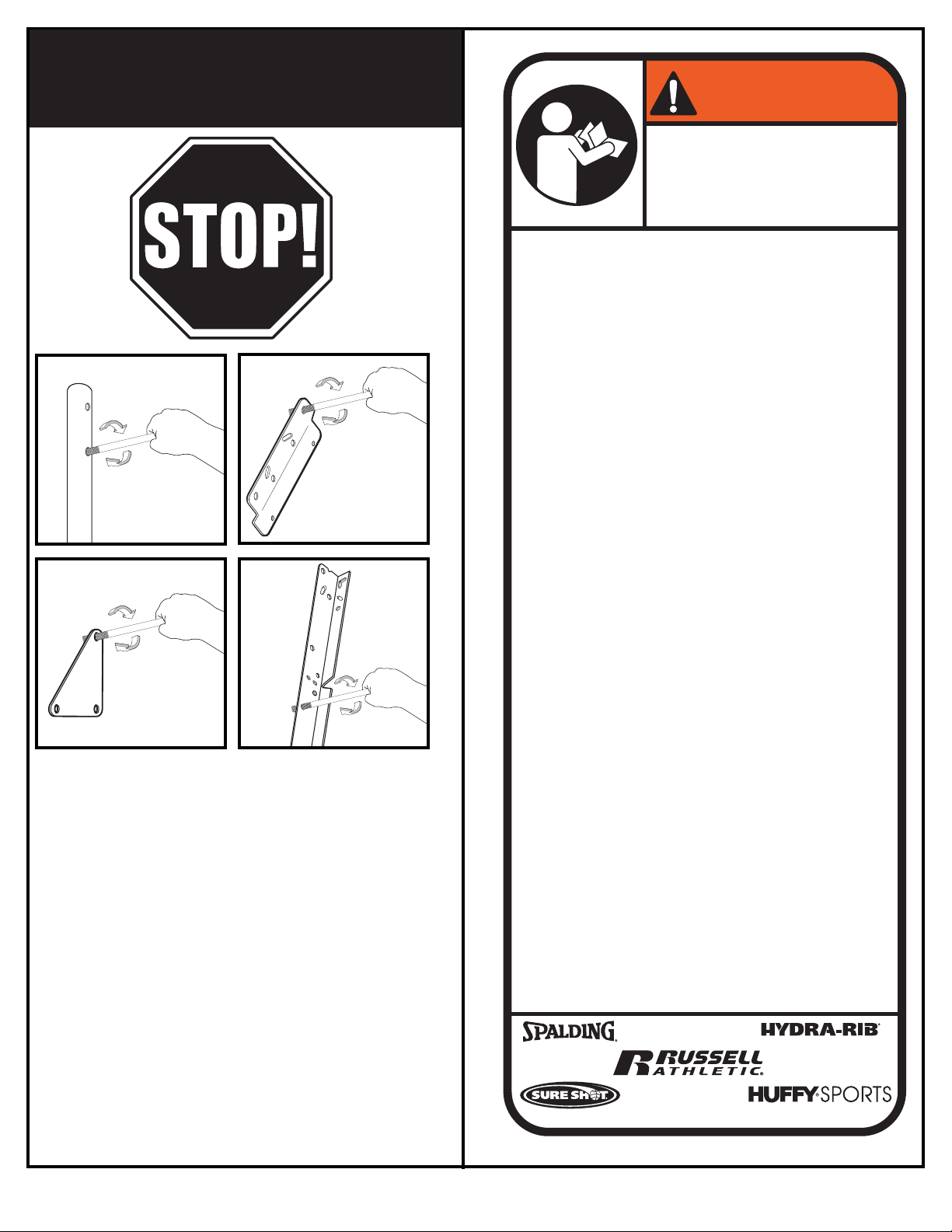

BEFORE YOU START!

o ensure optimal playability of backboard system, a

T

close tolerance fit between the elevator components

and hardware is required. Test-fit large bolts into large

holes of elevator tubes, backboard brackets, and

motion to ream out any excess paint from holes if

Not all items pictured are included with every model.

triangle plates. Carefully rock them in a circular

necessary

.

P/N M601111 08/05

2

Page 3

SAFETY INSTRUCTIONS

Size = 4" x 5.5"

Corner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

2

2

1

3

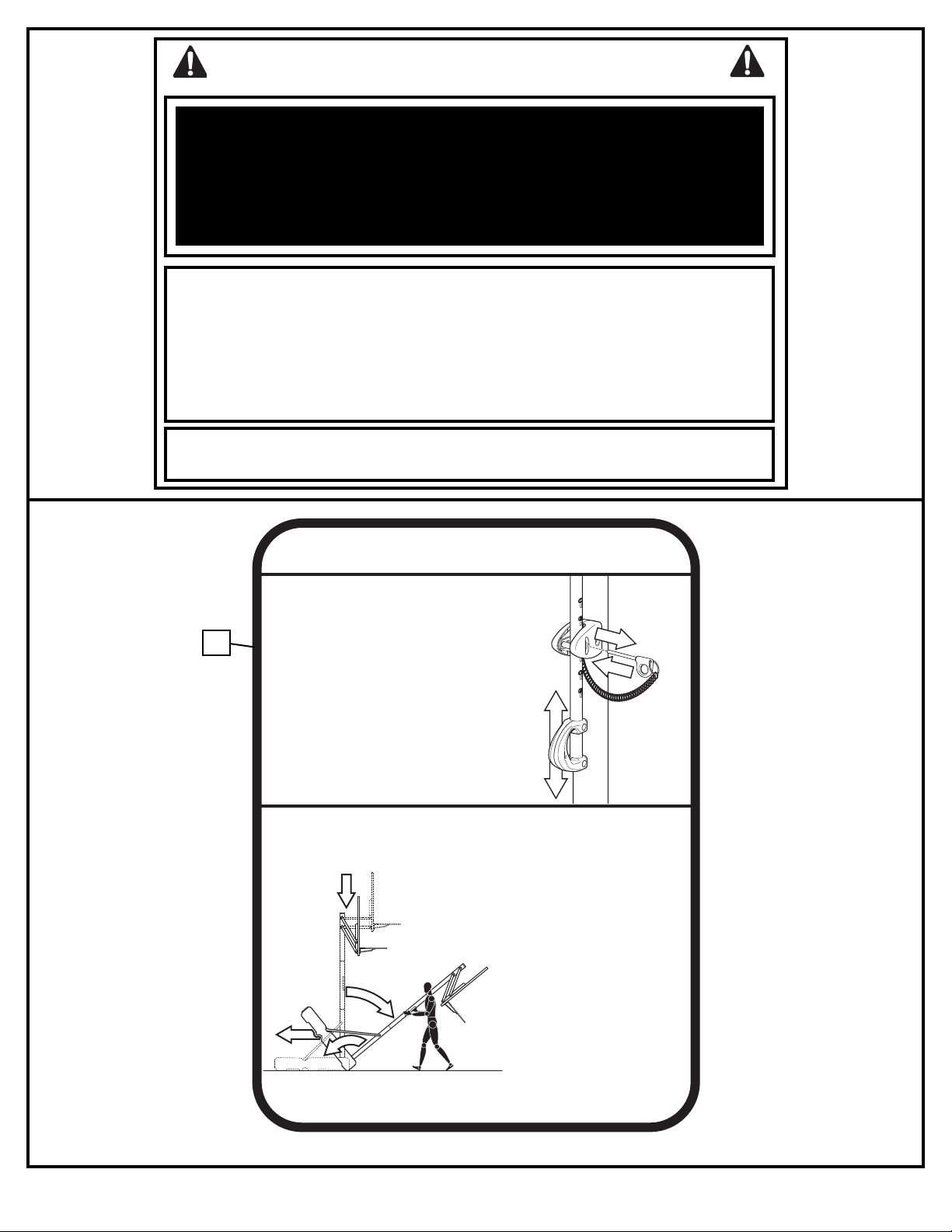

TO ADJUST BACKBOARD:

1. While holding handle, remove pin.

2. Move elevator up or down to

desired height.

3. Replace pin full length to lock

system at desired height.

511679 05/05

1

2

4

3

MOVING SYSTEM

Adjust basketball backboard

height to lowest position.

While holding pole, rotate

basketball system forward

until wheels engage with

ground.

Move basketball system to

desired location.

Carefully rotate basketball

system upright.

1.

2.

3.

4.

5.

Check system for stability.

HEIGHT ADJUSTMENT

FAILURE TO FOLLOW THESE SAFETY INSTRUCTIONS MAY RESULT IN SERIOUS INJURY,

PROPERTY DAMAGE AND WILL VOID WARRANTY.

Owner must ensure that all players know and follow these rules for safe operation of the system.

To ensure safety, do not attempt to assemble this system without following the instructions carefully. Proper

and complete assembly, use and supervision is essential for proper operation and to reduce the risk of

accident or injury. A high probability of serious injury exists if this system is not installed, maintained, and

operated properly.

• If using a ladder during assembly, use extreme caution.

• Check base regularly for leakage. Slow leaks could cause the system to tip over

unexpectedly

• Seat the pole sections properly (if applicable). Failure to do so could allow the pole

sections to separate during play and/or during transport of the system.

• Climate, corrosion or misuse could result in system failure.

• If technical assistance is required, contact Huffy Sports.

• Minimum operational height is 6’6” (1.98m) to the bottom of backboard.

Most injuries are caused by misuse and/or not following instructions.

Use caution when using this unit.

42

3

08/05 P/N M601111

Page 4

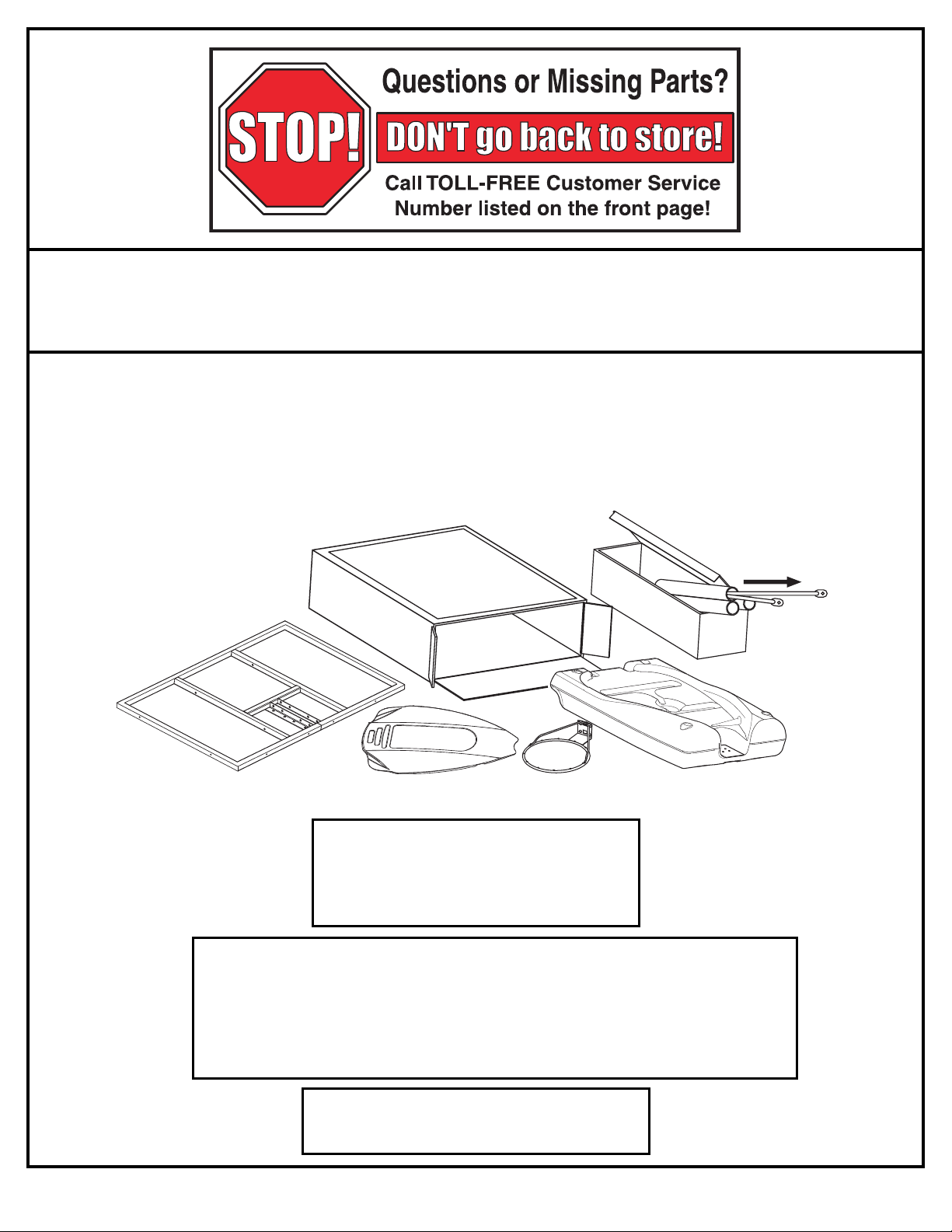

NOTICE TO ASSEMBLERS

ALL Huffy Sports Basketball Systems, including those used for DISPLAYS, MUST be assembled

and ballasted with sand or water according to the instructions. Failure to follow instructions

could result in SERIOUS INJURY. It is NOT acceptable to devise a makeshift weight system.

IMPORTANT!

Remove all contents from boxes.

Be sure to check inside pole sections;

hardware and additional parts are packed inside.

P/N M601111 08/05

WARRANTY CARD:

Please remember to complete your product

registration form either on-line at:

www.huffysports.com or mail-in the

enclosed postcard.

WARNING: IF YOUR SYSTEM IS EQUIPPED WITH AN ACRYLIC BACKBOARD,

EXAMINE BACKBOARD FOR ANY DAMAGE THAT MAY HAVE OCCURRED

DURING SHIPMENT. CRACKS IN THE BACKBOARD COULD RESULT IN

SUDDEN BREAKAGE. IF BACKBOARD IS DAMAGED IN ANY WAY PRIOR TO OR

AFTER ASSEMBLY, CALL TOLL-FREE NUMBER:

U.S. 1-800-558-5234; CANADA: 1-800-284-8339; http://www.huffysports.com

For more information on assembly, placement, proper

use, and maintenance, visit The American Basketball

Council website at http://www.smarthoops.com.

4

Page 5

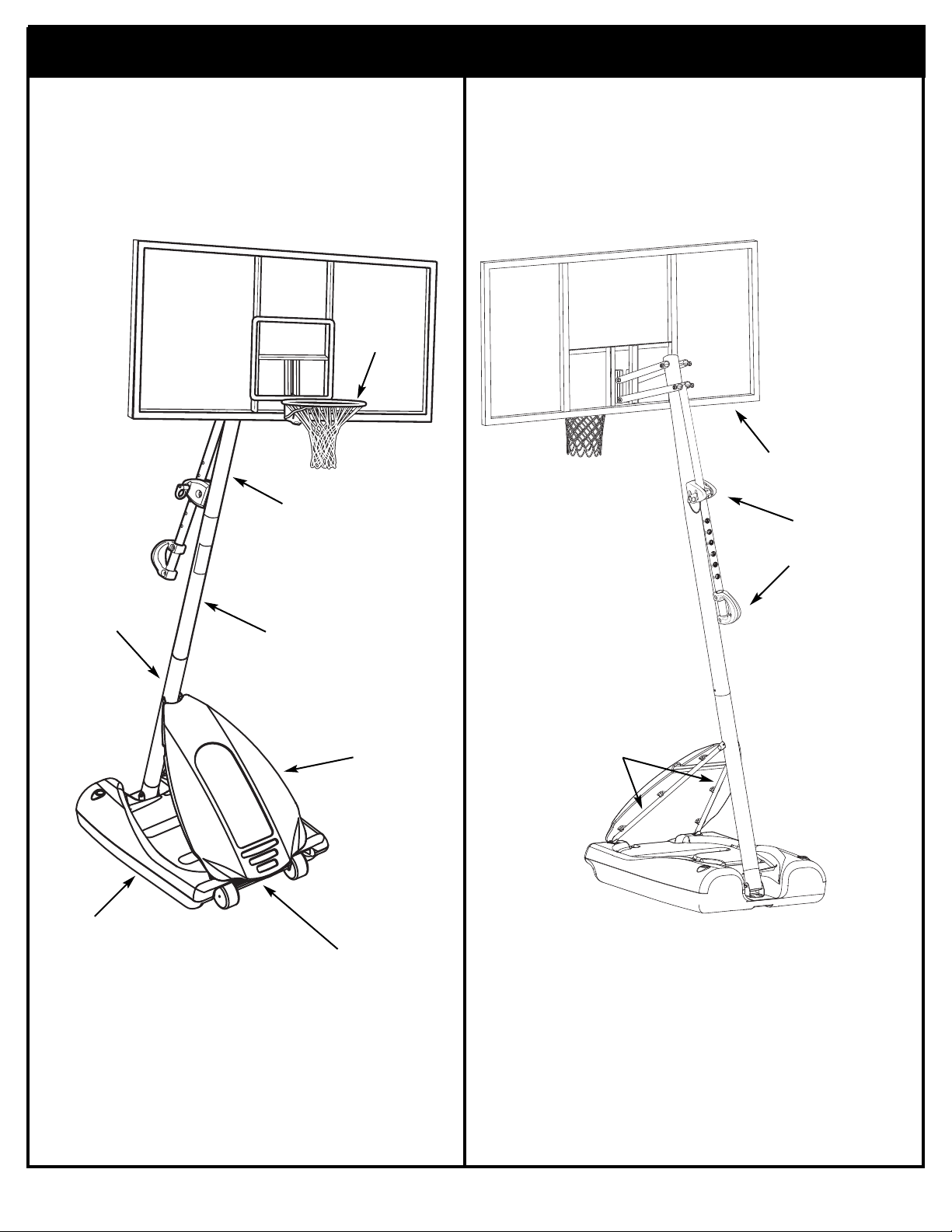

Get to know the basic parts of your basketball system...

FRONT

TOP POLE

BACK

RIM

BACKBOARD

ELEVATOR

ASSEMBLY

BOTTOM

POLE

BASE

MIDDLE

POLE

COVER

WHEEL

CARRIAGE

ASSEMBLY

FRONT

STRUTS

5

08/05 P/N M601111

Page 6

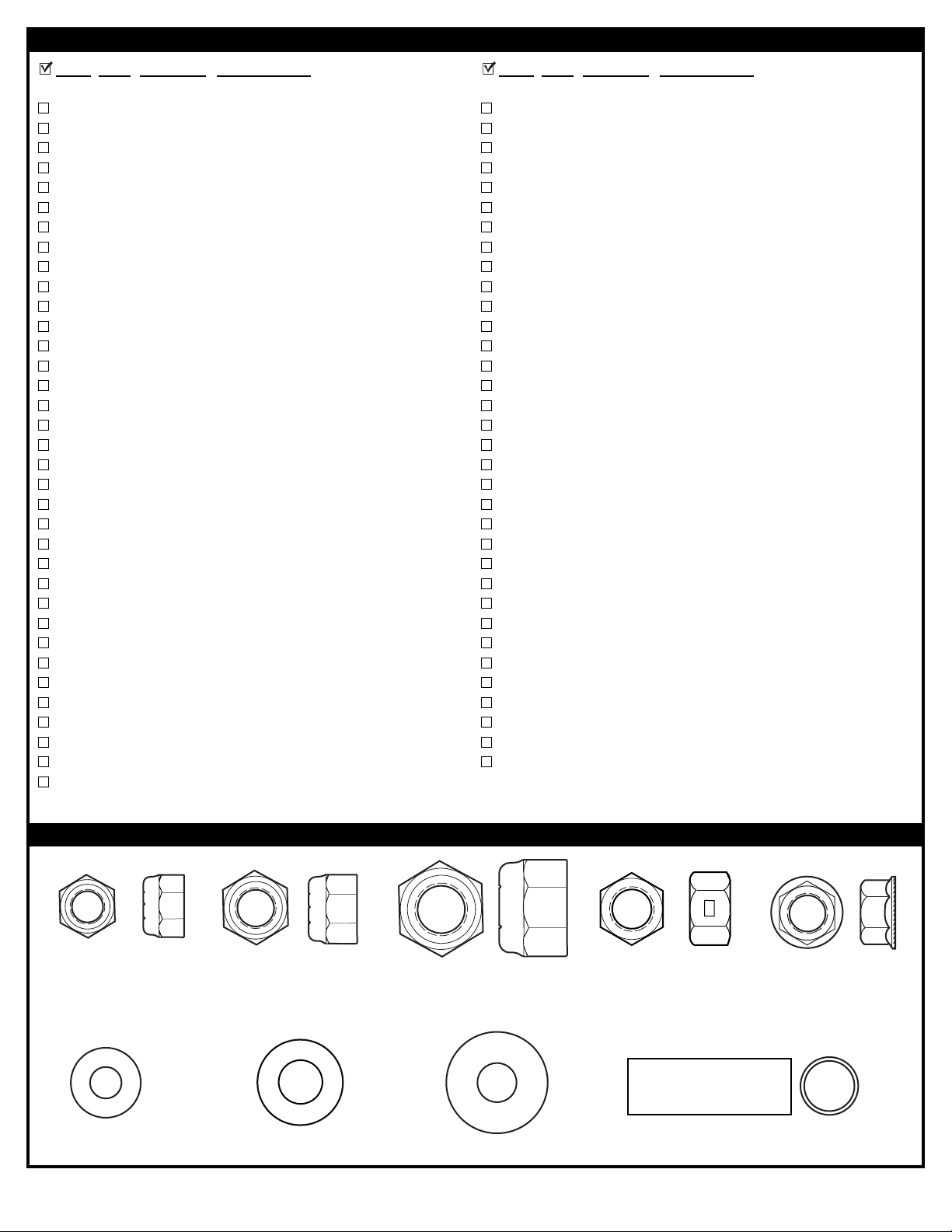

PARTS LIST - See Hardware Identifier

Item Qty. Part No. Description

1 1 908026 Top Pole Section

2 1 90810701 Middle Pole Section (with Label

3 1 908015 Bottom Pole Section

4 1 900223 Wheel Bracket

1 206940 Axle

5

6 2 226403 Wheel

7 2 206938 Pushnut

8 1 206660 Base

9 6 203156 Hex Bolt, 5/16-18 x 1

10 18* 203218 Flat Washer, 5/16

11 15* 203100 Hex-Flange Nut, 5/16-18

12 1 201581 Pole Bracket

13 2 202662 Hex Bolt, 5/16-18 x 4.5

14 2 203099 Lock Nut, 5/16-18

15 4 203223 Carriage Bolt, 5/16-18 x 1

16 2 906410 Tank Strut

17 1 200516 Bolt Cover

18 1 206990 Reinforcement Bracket

19 3 203038 Carriage Bolt, 5/16-18 x 2-3/4 Long

20 8 202862 Spacer, Plastic, 1.19" Long

21 7 206340 Lock Nut, 1/2-13

22 2 203053 Carriage Bolt, 5/16-18 x 4 Long

23 1 204872 Label, Height Indicator

24 2 204858 Spacer, Plastic, Biscuit

25 1 207103 Pole Cap

26 1 204853 Lanyard, Black Coil

27 1 204850 Pin, Locking

28 1 204832 Bracket, Pole Mount

29 4 206360 Hex Bolt, 3/8-16 x 2.625

30 6 203063 Nylon Insert Lock Nut, 3/8-16

31 4 201124 Lock Nut, 3/8-16

32 2 900867 Plate, Triangle

33 2 904807 Elevator Tube, Upper - Short

34 2 900183 Elevator Tube, Lower - Long

35 2 204859 Cover, Pin Slide

Item Qty. Part No. Description

36 2 204838 Spring, Counter Balance

37 2 203617 Base Plug

38 1 201965 Front Cover

39 4* 203257 Tie Straps

0 1 200504 Rim Cover

4

41 2 200520 Screw, #8 x .75

42 1 511679 Label, Height Adj and Moving

43 2 204857 Spacer, Metal 1/2” O.D. x 1.44 Long

44 1 205226 Left Board Pad

45 1 205225 Right Board Pad

46 6* 201596 Sheet Metal Screw, #14 x 1.25

47 6* 206303 Flat Washer, 1/4

48 1 205241 Center Board Pad

49 1 202856 Bolt, Hex, 1/2-13 x 4" Long

50 4 203232 Flat Washer, 3/8

51 1 202795 Label, NBA

52 2 90096401 Bracket, Backboard Support

53 4 201681 Spacer, Plastic, .530 I.D. x .88 Long

54 2 203103 Carriage Bolt, 5/16-18 x 2 Long

55 1 204803 Screw, Phillips Head

56 4 201682 Spacer, .530 I.D. x 1.875

57 6 202532 Bolt, Hex, 1/2-13 x 9.5"

58 1 904866 Height Adjustment Rod

59 1 204855 Handle, Left

60 1 204856 Handle, Right

61 1 900033 Bracket, Slam Jam

62 1 200318 Bracket, Reinforcement, Slam Jam

63 1 203470 Washer Flat, Slam Jam

64 1 203472 Spring, Black, Slam Jam

65 1 203795 Nut, Special, Slam Jam

66 1 203796 T-Bolt, 3/8-16 x 5 Long

67 Rim

68 4 205528 Bolt, Hex Flange, 5/16-18 x 1 Long

68 1 Net

*You may have extra parts with this model.

Item #14 (2)

Item #47 (6)*

P/N M601111 08/05

HARDWARE IDENTIFIER (NUTS, WASHERS & METAL SPACERS)

Item #30 (4)

Item #21 (7)

Item #31 (4)

Item #43 (2)

Item #50 (4)

Item #10 (18)*

6

Item #11 (15)*

Page 7

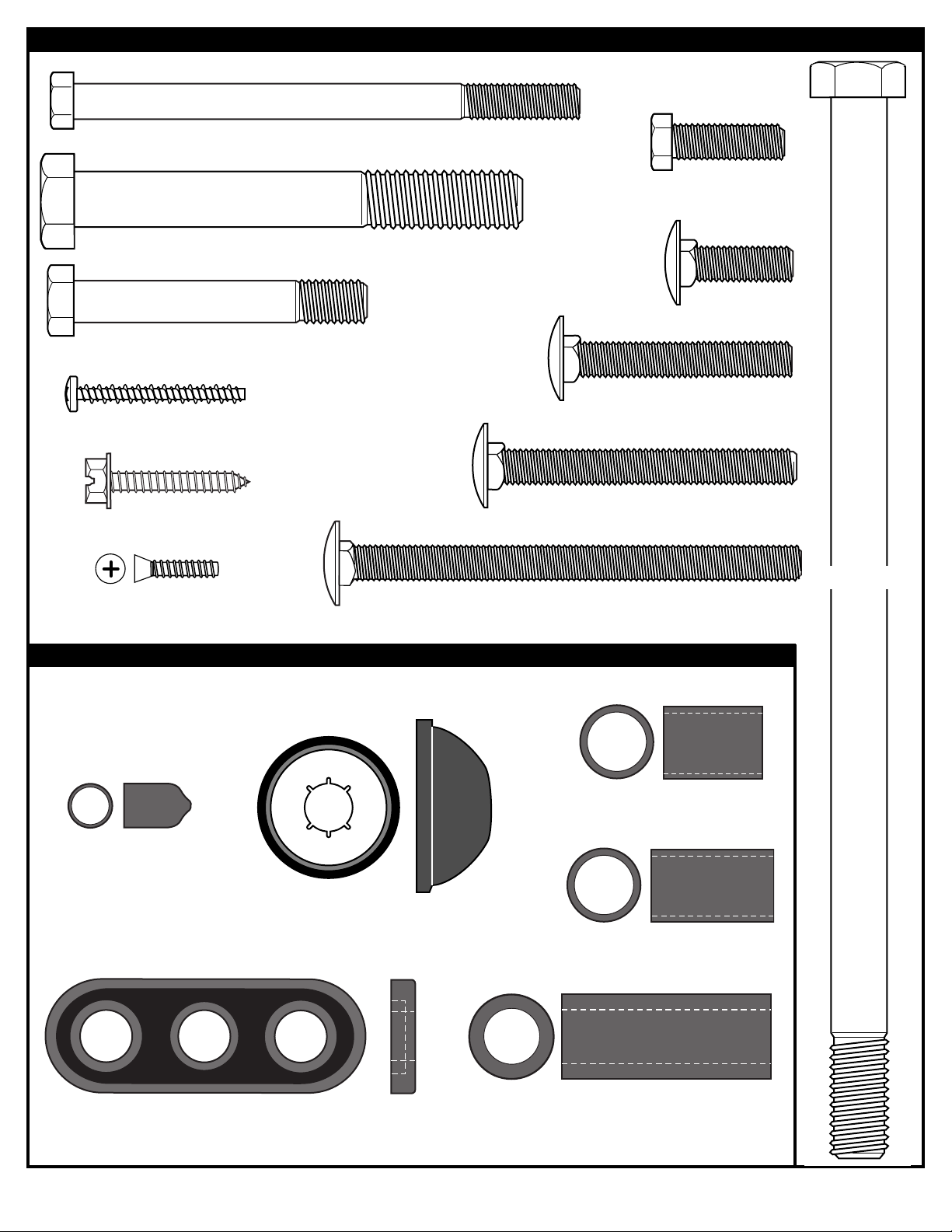

Item #29 (4)

Item #55 (1)

HARDWARE IDENTIFIER (BOLTS & SCREWS)

Item #13 (2)

Item #9 (6)

Item #49 (1)

Item #15 (4)

Item #54 (2)

Item #46 (6)

Item #41 (2)

HARDWARE IDENTIFIER (PLASTIC SPACERS & CAPS)

Item #17 (1)

Item #19 (1)

Item #57 (6)

Item #22 (2)

Item #53 (4)

Item #7 (2)

Item #20 (8)

Item #24 (2)

Item #56 (4)

7

08/05 P/N M601111

Page 8

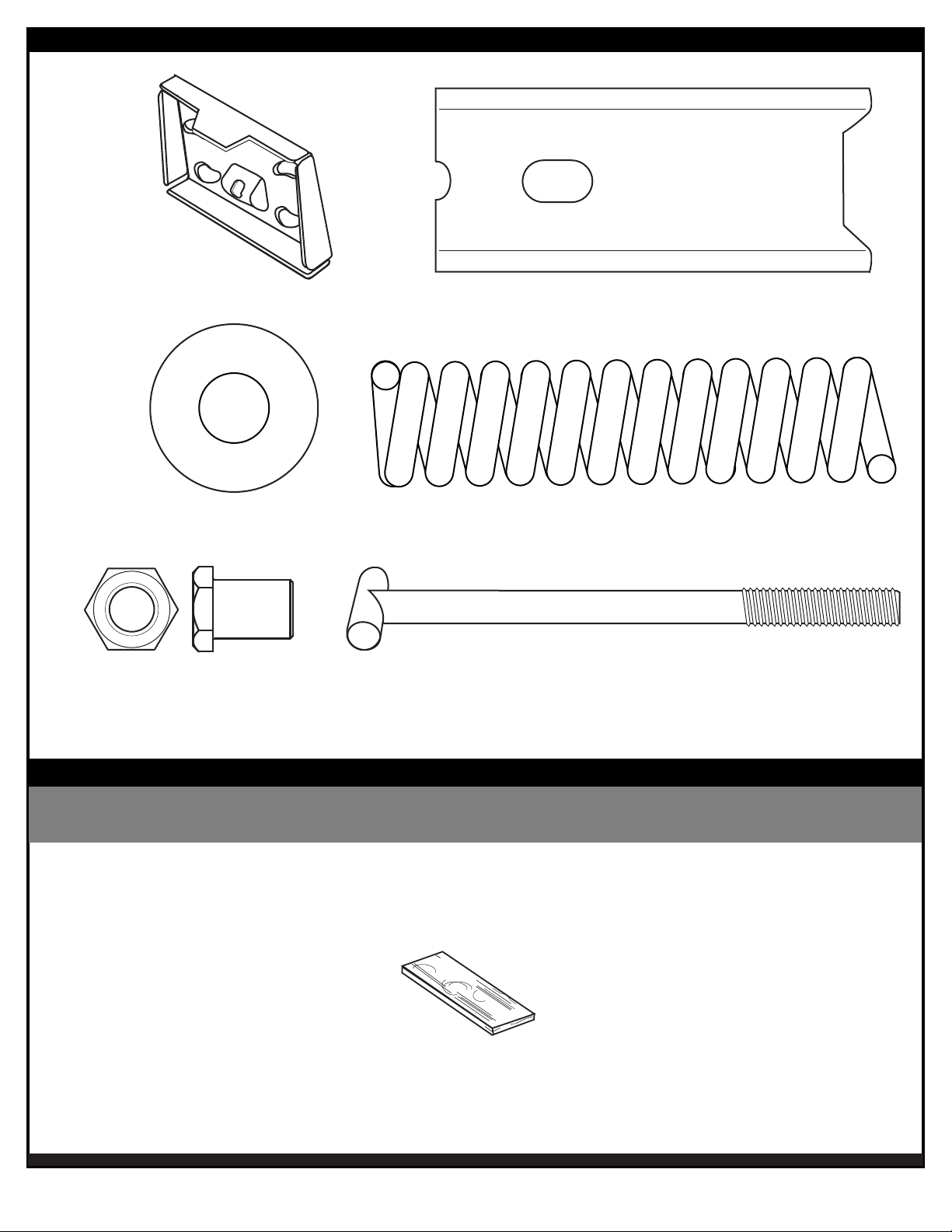

HARDWARE IDENTIFIER (RIM)

Item #61 (1)

Item #63 (1)

Item #65 (1)

Item #62 (1)

Item #64 (1)

Item #66 (1)

P/N M601111 08/05

SECTION A:

TOOLS REQUIRED FOR THIS SECTION

ASSEMBLE THE POLES

Wood Board (scrap)

8

Page 9

1.

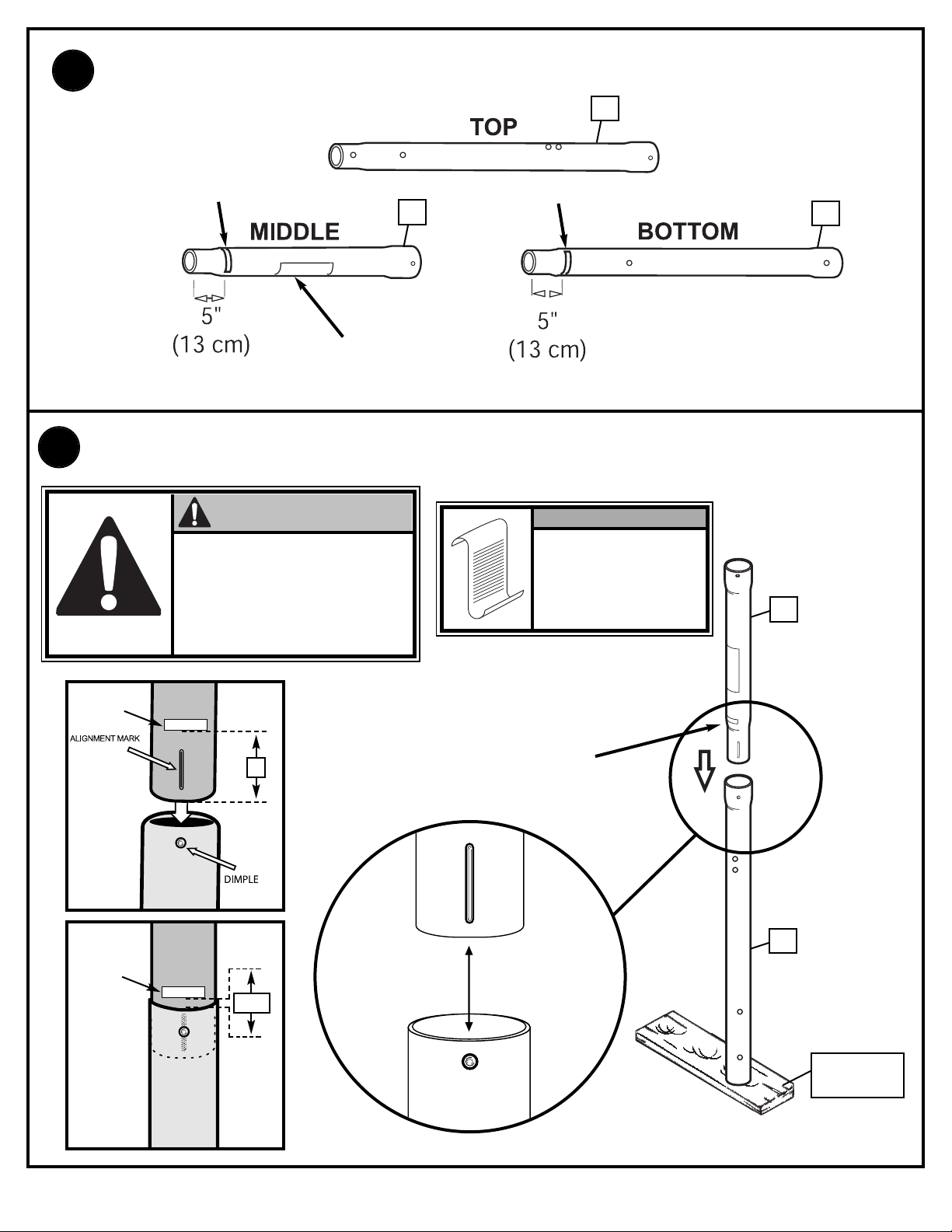

Correctly identify each pole section.

1

I.D. Label

I.D. Label

2

WARNING

LABEL

Bounce middle pole (2) into top pole section (1) using a wood scrap as shown until top

2.

pole no longer moves toward pole identification mark on middle pole.

CAUTION!

THE IDENTIFICATION STICKER IS

LOCATED 5" FROM THE END OF THE

POLE. WHEN PROPERLY POUNDED

TOGETHER, THE POLE SECTIONS

SHOULD HAVE A 3-1/2" MINIMUM

OVERLAP, LEAVING 1-1/2" BETWEEN

THE OVERLAPPING POLE AND THE

IDENTIFICATION STICKER.

NOTE:

POLE SECTIONS

SHOULD HAVE A

3-1/2" (9 CM)

MINIMUM

OVERLAP.

3

2

IDENTIFICATION

STICKER

IDENTIFICATION

STICKER

middle pole

middle pole

5"

1-1/2"

POLE

IDENTIFICATION

MARK

1

WOOD SCRAP

(NOT SUPPLIED)

9

08/05 P/N M601111

Page 10

Align dimple of middle pole with slot of bottom pole.While maintaining alignment, bounce

3.

top and middle pole assembly (1 & 2) onto lower pole section (3) as shown until they no

longer move toward pole identification mark.

CAUTION!

THE IDENTIFICATION STICKER IS

LOCATED 5" FROM THE END OF

THE POLE. WHEN PROPERLY

POUNDED TOGETHER, THE POLE

SECTIONS SHOULD HAVE A 3-1/2"

MINIMUM OVERLAP, LEAVING 1-1/2"

BETWEEN THE OVERLAPPING

POLE AND THE IDENTIFICATION

STICKER.

NOTE:

POLE SECTIONS

SHOULD HAVE A

3-1/2" (9 CM)

MINIMUM

OVERLAP.

IDENTIFICATION

STICKER

1

IDENTIFICATION

STICKER

ottom Pole

B

Bottom Pole

5"

1-1/2"

POLE

IDENTIFICATION

MARK

WOOD SCRAP

(NOT SUPPLIED)

2

RODS SHOWN ARE

FOR VISUAL

REPRESENTATION

OF ALIGNMENT

AND ARE NOT

SUPPLIED WITH

3

THE HARDWARE

IMPORTANT!

Holes in top (1) and bottom (3)

pole sections MUST align to

correctly position elevator

system toward playing

surface.

P/N M601111 08/05

10

Page 11

SECTION B: ASSEMBLE THE BASE

This is what your system will look like

when you’ve finished this section:

(2) 1/2”Wrenches

TOOLS REQUIRED FOR THIS SECTION

(2) Socket Wrenches

and Sockets

AND/OR

AND

Hammer or

Mallet

1/2”

11

08/05 P/N M601111

Page 12

1.

Assemble pole bracket (12) using bolt (13) and

Lock Nut (14) as shown.

2.

Attach pole assembly to base

using carriage bolts (15)

washers(10) and nuts (11) as

shown. Two people are required

for this step.

IMPORTANT!

DO NOT OVER

TIGHTEN

13

WARNING!

TWO PEOPLE REQUIRED

FOR THIS PROCEDURE.

FAILURE TO FOLLOW THIS

WARNING COULD RESULT

IN SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

14

12

15

IMPORTANT!

P/N M601111 08/05

12

11

10

THE CUT CORNERS OF

THE POLE BRACKET

NEED TO FACE TOWARD

THE BACK OF THE BASE

AS SHOWN.

Page 13

Secure tank struts (16) to pole as shown.

3.

Nut should be tightened until flush (even) with lock nuts outer edge. Place cap (17) over

exposed end of bolt as shown.

10

10

17

13

14

TWO PEOPLE REQUIRED

FOR THIS PROCEDURE.

16

Rotate non-secured ends of tank struts (16) outward to mounting holes in tank as

4.

FAILURE TO FOLLOW THIS

WARNING COULD RESULT

IN SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

WARNING!

shown.Secure ends of tank struts (16) to tank as shown. Repeat for opposite side.

16

13

9

16

10

10

11

08/05 P/N M601111

Page 14

Insert axle (5) through wheel bracket (4). Secure wheels (6) to axle using pushnuts (7).

5.

Carefully tap pushnuts onto axle with hammer or mallet

IMPORTANT!

6

7

4

SIDE OF WHEEL WITH

LONGER PLASTIC AXLE

NEEDS TO FACE THE

WHEEL BRACKET.

6

7

5

Install wheel assembly to base (8) using bolts(9),

6.

washers(10) and nuts (11) as shown.

NOTE:

CAREFULLY TIPPING THE

SYSTEM ON IT'S SIDE WILL

ALLOW EASIER ACCESS

TO THE UNDERSIDE OF

BASE.

8

9

10

P/N M601111 08/05

14

10

1

1

Page 15

SECTION C: ASSEMBLE THE ELEVATOR & BACKBOARD

This is what your system will look like

when you’ve finished this section:

TOOLS REQUIRED FOR THIS SECTION

(1) 3/8”, (2) 1/2”, (2) 9/16” and

(2) 3/4” Wrenches

Phillips Screwdriver

AND/OR

(2) Socket Wrenches and Sockets

3/8”

1/2”

9/16”

3/4”

15

08/05 P/N M601111

Page 16

Install pole mount bracket (28) and reinforcement bracket (18) with carriage bolts (22) as

1.

shown. Tighten flange nuts (11) completely.

18

1

28

11

11

Attach spacers (24, 43) to pole mount bracket (28) with bolts (29), washers (50), and lock

2.

22

22

nuts (31) as shown.

P/N M601111 08/05

IMPORTANT!

Tighten just until

washers (50) stop

moving.

43

24

31

43

28

50

50

50

50

29

24

16

Page 17

Assemble lanyard (26) to locking pin (27) as shown (FIG A). Attach covers (35) onto pole

3.

mount bracket (28) with carriage bolt (19) and nut (11) as shown.

FIG. A

11

35

IMPORTANT!

19

26

Apply logo and height indicator labels (23) to

4.

adjustment rod (58) as shown. Attach handle parts

(59, 60) to adjustment rod with screw (55), carriage

bolts (54), and flange nuts (11) as shown.

Loop end of pin

lanyard (26) over

carriage bolt (19) as it

passes through the

pole mount bracket (28)

27

during this assembly.

23

28

26

35

19

27

58

IMPORTANT!

Indicator labels should

be applied as close to

holes as possible to

prevent labels from

being damaged during

height adjustment.

17

11

23

11

60

54

55

59

54

08/05 P/N M601111

Page 18

27

Insert handle assembly through pole mount assembly as

5.

shown. Lock pole assembly in place at the 10’ (3.05 m)

mark with pin (27).

30

30

6.

Assemble backboard brackets (52)

using bolts (29), and nuts (30) as

shown.

29

52

29

52

P/N M601111 08/05

18

Page 19

7.

A

Assemble board pad to board.

Work from the center - out.

Using the holes which line up for your

board size, attach center pad (48), right

pad (45) and left pad (44) sections to

board using screws (46) and washers (47)

as shown.

IMPORTANT!

DO NOT TIGHTEN

HARDWARE

COMPLETELY.

BOARD STYLE MAY

VARY

Secure left (44) and right (45) pad sections to

B

board by pushing pads over the corners of the

board. Secure completely by using screws (46)

and washers (47) as shown.

IMPORTANT!

TIGHTEN ALL

HARDWARE

COMPLETELY.

44

47

46

46

48

47

45

47

46

45

BOARD STYLE MAY

VARY

46

44

47

19

47

46

48

47

46

08/05 P/N M601111

Page 20

Identify elevator tubes (33 & 34).

8.

Toward

Board

Toward

Board

Upper Elevator tube

Lower Elevator tube

33

34

Toward

Pole

Toward

Pole

Attach lower elevator tubes (34) and counter balance spring (36) to backboard support

brackets (52) using spacers (53 & 56), bolt (57), and nut (21) as shown.

53

57

56

34

36

52

56

52

36

21

34

66

52

P/N M601111 08/05

68

20

Page 21

Attach upper elevator tubes (33) to backboard support brackets (52) using spacers

9.

(53), bolt (57), and nut (21) as shown.

IMPORTANT!

Tighten ALL Hardware

from Steps 6-8 After this

Assembly is Completed.

53

56

57

56

21

52

33

53

21

56

33

57

56

33

33

21

08/05 P/N M601111

Page 22

10.

Support pole on sawhorse. Attach backboard assembly to top pole section (4) as

shown. Install pole cap (25).

11.

WARNING!

U

SE CAUTION; ELEVATOR

A

SSEMBLY IS HEAVY.

T

WO PEOPLE REQUIRED FOR

THIS PROCEDURE. FAILURE

TO FOLLOW THIS WARNING

C

OULD RESULT IN SERIOUS

INJURY AND/OR PROPERTY

DAMAGE.

1

20

32

20

57

Install upper elevator tubes (33) to triangle plates (63) as shown. Install handle assembly

to lower elevator tubes (34) using bolt (57), spacers (20), and nut (21) as shown.

21

34

21

25

32

49

34

58

1

NOTE:

Before going on to

next step, set

adjustable system

assembly to the

10’ (3.05 m) setting.

20

57

20

34

57

21

21

33

20

34

32

34

20

33

P/N M601111 08/05

22

Page 23

12.

A. Fit rim (67) securely into bracket (61) as shown. Allow T-bolt (66) to slip through center hole

in rim (67).

B. Install reinforcement bracket (62) onto T-bolt (66) as shown.

C. Install spring (64) onto T-bolt (66) as shown.

D. Install special nut (65) and washer (63) onto T-bolt (66).

E. Tighten special nut (65) until flush with end of T-bolt (66).

Install Rim to Backboard

A.

67

C.

64

66

61

B.

D.

63

62

65

NOTE:

ORIENTATION

OF BRACKET

66

62

66

E.

66

65

63

23

08/05 P/N M601111

Page 24

13.

Install net (43).

A.

14.

B.

C.

D.

Insert bolt (57) through left side upper elevator tube (33), then stretch spring (36) onto

bolt (57). Insert bolt (57) through right side upper elevator tube (33) and secure with

nut (21).

WARNING!

USE EYE PROTECTION

WHEN INSTALLING

SPRINGS.

NOTE:

Peel protective

film from surface

of acrylic

backboard prior

to use.

57

36

36

33

21

33

58

P/N M601111 08/05

24

Page 25

SECTION D: FILL BASE

SAND

450 LBS

.

(204 KG)

SAND

450 LBS

.

(204 KG)

TOOLS REQUIRED FOR THIS SECTION

Garden Hose or Sand

SAND

SAND

(360 lb.)

(360 lb.)

(163 kg)

(163 kg)

Roll assembly to desired playing area. Fill base (8) with water (approx. 40 gallons) and

1.

snap base plugs (37) in place.

WARNING!

DO NOT LEAVE

ASSEMBLY UNATTENDED

WHEN EMPTY; IT MAY TIP

OVER.

WARNING!

TWO PEOPLE REQUIRED

FOR THIS PROCEDURE.

FAILURE TO FOLLOW THIS

WARNING COULD RESULT IN

SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

CAUTION!

37

8

ADD TWO GALLONS (7.6 LITERS)

OF NON-TOXIC ANTIFREEZE IN

SUB-FREEZING CLIMATES.

37

SAND

SAND

(360 lb.)

(360 lb.)

(163 kg)

(163 kg)

NOTE:

IF USING SAND:

2 GALLONS OF

ANTI-FREEZE IS

NOT

REQUIRED

25

08/05 P/N M601111

Page 26

SECTION E: INSTALL FRONT COVER

TOOLS REQUIRED FOR THIS SECTION

Scissors

Install front cover (38) by lining up stand-offs along the tank struts. Insert a tie strap (39)

1.

through the top two and bottom two stand offs. Wrap tie straps around tank struts as

shown and secure tightly. Trim excess of tie strap as shown in FIG.A.

39

38

STANDOFFS

FIG. A

P/N M601111 08/05

26

Page 27

Phillips

Screwdriver

SECTION F: INSTALL RIM COVER

TOOLS REQUIRED FOR THIS SECTION

1.

Install cover (40) over spring return mechanism with screws (41) as shown.

Place NBA label (51) on front of rim cover (40).

41

41

40

27

51

08/05 P/N M601111

Page 28

SECTION G: HEIGHT ADJUSTMENT AND MOVING LABEL

S

ize = 4" x 5.5"

C

orner Radius = 3/8"

Die Cut Label

3.25 Mil Vinyl

All Temp. Permanent Adhesive

1 Mil. Polypropolyne Overlaminate

Illustrator 8.0 = EPS

Backing + 1/16 Circumference

Rolls of 500

2

2

1

3

TO ADJUST BACKBOARD:

1. While holding handle, remove pin.

2. Move elevator up or down to

desired height.

3. Replace pin full length to lock

system at desired height.

511679 05/05

1

2

4

3

MOVING SYSTEM

Adjust basketball backboard

height to lowest position.

While holding pole, rotate

basketball system forward

u

ntil wheels engage with

ground.

Move basketball system to

desired location.

Carefully rotate basketball

s

ystem upright.

1.

2.

3.

4.

5.

Check system for stability.

HEIGHT ADJUSTMENT

Apply Height Adjustment and Moving Label (42) to front of pole, where it is clearly

1.

visible.

A. While holding handle, remove pin (27).

2.

B. Move elevator up or down to desired height.

C. Replace pin (27) full length to lock system at

desired height.

P/N M601111 08/05

WARNING!

DO NOT ALLOW

CHILDREN TO

ADJUST HEIGHT.

28

42

27

A.

58

C.

B.

Loading...

Loading...