Page 1

SOUNDCRAFT

RM100

USER GUIDE

Page 2

Harman International Industries Ltd. 1994, 1997

All rights reserved

Parts of the design of this product may be protected by worldwide patents.

Part No. ZM0079 Issue 3

Soundcraft is a trading division of Harman International Industries Ltd.

Information in this manual is subject to change without notice and does not

represent a commitment on the part of the vendor. Soundcraft shall not be liable

for any loss or damage whatsoever arising from the use of information or any

error contained in this manual, or through any mis-operation or fault in hardware

contained in the product.

No part of this manual may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, electrical, mechanical,

optical, chemical, including photocopying and re co rd ing, fo r a ny purpose

without the express written permission of Soundcraft.

It is recommended that all maintenance and servic e on the pro duc t should be

carried out by Soundcraft or its authorised agents. Soundcraft cannot accept any

liability whatsoever for any loss or damage caused by service , ma inte na nc e or

repair by unauthorised personnel.

Harman International Industries Ltd.

Cranborne House

Cranborne Industrial Estate

Cranborne Road

Potters Bar

Herts.

EN6 3JN

England

Tel: 0707 665000

Fax: 0707 660482

Page 3

&RQWHQWV

Introduction 1.1

Introduction 1.2

Precautions and Safety Instructions 1.4

Installation 2.1

Installation 2.2

Connections 2.3

Module Block Diagrams 3.1

Mic/Line Input Module 4.1

Description & Operation 4.2

Specifications 4.4

Stereo Input Module 4.5

Description & Operation 4.6

Specifications 4.8

Telco Input Module 4.9

Description & Operation 4.10

Specifications 4.12

Master Module 4.13

Description & Operation 4.14

Specification 4.18

Meterbridge 4.19

Stereo Source Select Module 4.20

Page 4

Appendices A.1

Dimensions A.2

Glossary A.3

Warranty A.4

CPS150 Power Supply P.1

Page 5

Introduction

Introduction

Precautions and Safety Instructions

Introduction 1.1

Page 6

,QWURGXFWLRQ

The RM100 is designed as a simple-to-operate on-air Radio console. Front panel

controls are kept to a minimum to give a clear and uncluttered appearance while

providing sufficient flexibility and choice to meet individual requirements.

The design of the console allows for desktop mounting or drop-through mounting

into a table-top.

A choice of input modules and frame sizes is available, with the option of a script

tray on the larger frame sizes.

The console features illuminated switches throughout for clear operation and a

choice of high quality carbon or conductive plastic faders.

Frame Sizes

Module Options

Metering

The RM100 is available in three frames sizes:

• 8 Inputs + Master

• 12 Inputs + Master

• 20 Inputs + Master

Frames may be fitted with a choice of modules as follows:

• Mono Mic/Line Input module

• Stereo Line Input module

• Telco Input module

• Master Broadcast Module

• Master Production Module (with PGM and AUD Master Faders)

Two meterbridge styles are available.

The standard version comprises:

• a single pair of VU meters (PPM meters optional)

• two pairs of VU meters on the 20 input frame

The alternative version comprises:

• a single pair of VU meters (PPM meters optional)

• two pairs of VU meters on the 20 input frame

• 4-digit timer module

• cue loudspeaker

1.2 Introduction

Page 7

Power Supplies

• 8, 12 and 20 input frames CPS150 power supply

Introduction 1.3

Page 8

3UHFDXWLRQVDQG6DIHW\,QVWUXFWLRQV

General Precautions

Caution!

Handling and Transport

Power Supplies & cables

Avoid storing or using the mixing console in conditions of excessive heat or cold,

or in positions where it is likely to be subject to vibration, dust or moisture. Do not

use any liquids to clean the fascia of the unit: a soft dry brush is ideal. Use only

water or ethyl alcohol to clean the trim and scribble strips. Other solve nts may cause

damage to paint or plastic parts.

Avoid using the console close to strong sources of electromagnetic radiation (e.g.

video monitors, highpower electric cabling): this ma y cause degradation of the audio

quality due to induced voltages in connecting leads and chassis. For the same

reason, always site the power supply away from the unit.

In all cases, refer servicing to qualified personnel.

The console is supplied in a strong carton. If it is necessary to move it any distance

after installation it is recommended that this packing is used to protect it. Be sure

to disconnect all cabling before moving. If the console is to be regularly mov ed we

recommend that it is installed in a foamlined flightcase. At all times avoid applying

excessive force to any knobs, switches or connectors.

Always make sure that the power supply unit (PSU) has been set to the same voltage

as the mains supply

Warning!

Always use the power supply and cable supplied with the mixer: the use of

alternative supplies may cause damage and voids the warranty; the extension of

power cables may result in malfunction of the mixing console.

Always switch the power supply off before connecting or

disconnecting the mixer power cable, removing of installing

modules, and servicing. In the event of an electrical storm, or large

mains voltage fluctuations, immediately switch off the PSU and

unplug from the mains.

Always ensure that you use the correct PSU for your mixer. The RM100 uses a

CPS150 power supply for the 8, 12 and 20 input frames.

1.4 Introduction

Page 9

Signal Levels

It is important to supply the correct input levels to the console, otherwise signalto

noise ratio or distortion performance may be degraded; and in extreme cases,

damage to the internal circuitry may result. Likewise, on all balanced inputs avoid

sources with large commonmode DC, AC or RF voltages, as these will reduce the

available signal range on the inputs. Note that 0dBu = 0.775V RMS.

The microphone inputs are designed for use with balanced low impedance (150 or

200 ohms) microphones.

Caution!

DO NOT use unbalanced microphones or battery powered

condenser microphones without isolating the +48V phantom power:

degraded performance or damage to the microphone may result.

The sensitivity of the Mic inputs is variable from -20dBu to -70dBu, with a

maximum input level of +6dBu. The Line Input sensitivity is variable from -48dBu

to +2dBu with a maximum input level of +28dBu.

The Stereo and Telco input sensitivity is variable from -12dBu to +9dBu, with a

maximum input level of +28dBu.

The main outputs of the console (PGM, AUD and MONO) are balanced at a nominal

level of 0dBu, with the option of -10dBV on the AUD output by changing internal

jumpers. Maximum output level is +26dBu into 600 ohms.

The Telco mix-minus output is balanced at a nominal level of 0dBu with a maximum

output level of +20dBu into 600 ohms.

Introduction 1.5

Page 10

1.6 Introduction

Page 11

Installation

Installation 2.1

Page 12

,QVWDOODWLRQ

The RM100 is designed for reliability and high performance, and is built to the

highest standards. Whilst great care has been taken to ensure that installations are

made as troublefree as possible, care take n at this stage, followed b y correct setting

up will be rewarded by a long life and reliable operation.

Wiring Considerations

Power Supply

Warning!

A For optimum performance it is essential for the earthing system to be clean and

noisefree, as all signals are referenced to this earth. A central point should be

decided on for the main earth point, and all earths should be ’star-fed’ from this

point. It is recommended that an individual earth wire be run from each electrical

outlet, back to the system star point to p rovide a safety earth reference for each piece

of equipment.

B Install separate mains outlets for the audio equipment, and feed these

independently from any other equipment.

C Avoid locating mains distribution boxes near audio equipment, especially tap e

recorders, which are very sensitive to electromagnetic fields.

D Where possible ensure that all audio cable screens and signal earths are

connected to ground only at their source.

Always ensure that you use the correct PSU for your mixer. The RM100 uses a

CPS150 power supply for the 8, 12 and 20 input frames.

Before switching on your RM100 console, check that the mains

voltage selectors on the power supply unit is set to the correct

mains voltage for your area, and that the fuse is of the correct rating

and type. This is clearly marked on the case of the power supply.

Do not replace the fuse with any other type, as this could become a

safety hazard and will void the warranty.

2.2 Installation

Page 13

&RQQHFWLRQV

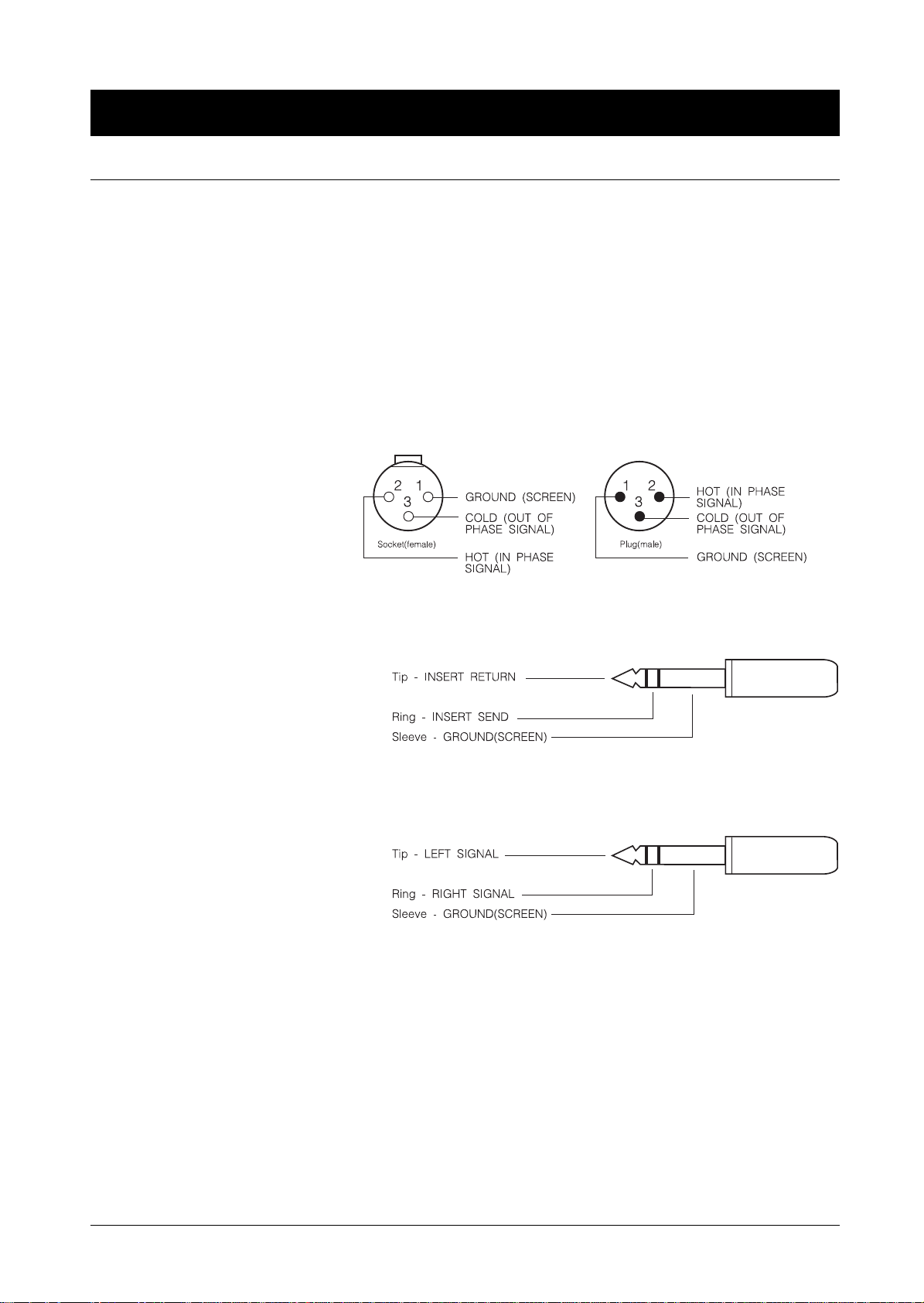

Wiring conventions

1

The RM100 uses various different types of aud io connector: 3-pin XLR ,

⁄

" 3-pole

4

jacks and ‘D’ type connectors. This section describes how to connect external

equipment to the console. Correctly-made cables of the proper type will ensure

peak performance from your console.

MICROPHONE INPUTS

& LINE INPUTS

1

/4" ‘A’ Gauge Stereo Jack Plug used as an insert point:

PGM, AUD, MONO

& C/F OUTPUTS

1

/4" ‘A’ Gauge Stereo Jack Plug used as stereo output:

Headphones and Control Room Monitors

The following pages give details of the connectors which are not covered by the

diagram above.

Installation 2.3

Page 14

Stereo Input Module

Telco Input Module

Input 2 + Remotes (15-pin ‘D’ type connector)

Pin 1 Chassis

Pins 2, 9 Machine 1 Start

Pins 3, 10 Machine 1 Stop

Pins 4, 11 Machine 2 Start

Pins 5, 12 Machine 2 Stop

Pins 6, 13 Input 2 Right -,+

Pin 7 Ground

Pins 8, 15 Input 2 Left -,+

Pin 14 Ground

Remotes (15-pin ‘D’ type connector)

Pin 1 Chassis

Pin 2 Divert n/c

Pin 3 Divert n/o

Pins 9,10 Divert common

Pin 8 Insert Return

Pin 15 Insert Send

Master Module

Pins 7, 14 Ground

Pins 4, 5, 6, 11, 12, 13 no connection

External Inputs (15-pin ‘D’ type male connector)

Pin 1 Chassis

Pin 2 External Input 1 Left +

Pin 3 External Input 1 Right +

Pin 4 External Input 2 Left +

Pin 5 External Input 2 Right +

Pin 6 Ground

Pin 7 External Input 3 Left

Pin 8 External Input 3 Right

Pin 9 External Input 1 Left Pin 10 External Input 1 Right Pin 11 External Input 2 Left Pin 12 External Input 2 Right Pin 13 Ground

Pin 14 External Input 4 Left

Pin 15 External Input 4 Right

2.4 Installation

Page 15

Master Module

Remote (9-pin ‘D’ type connector)

Pin 1 C/Room Mute Contact 1 common

Pin 2 C/Room Mute Contact 1 n/o

Pin 3 C/Room Mute Contact 2 common

Pin 4 C/Room Mute Contact 2 n/o

Pin 5 no connection

Pin 6 no connection

Pin 7 no connection

Pin 8 no connection

Pin 9 no connection

Guest H/P + Rev T/B (9-pin ‘D’ type connector)

Pin 1 Chassis Ground

Pin 2 Guest Headphones Left Ground

Pin 3 Guest Headphones Left Signal

Pin 4 Guest Headphones Right Ground

Pin 5 Guest Headphones Right Signal

Pin 6 Audio Ground

Pin 7 Reverse Talkback Input

Pin 8 Reverse Talkback Control Signal

Pin 9 no connection

Installation 2.5

Page 16

2.6 Installation

Page 17

Module Block Diagrams

Module Block Diagrams 3.1

Page 18

3.2 Module Block Diagrams

Page 19

Mic/Line Input Module

Description & Operation

Specification

Mic/Line Input Module 4.1

Page 20

0LF/LQH,QSXW0RGXOH

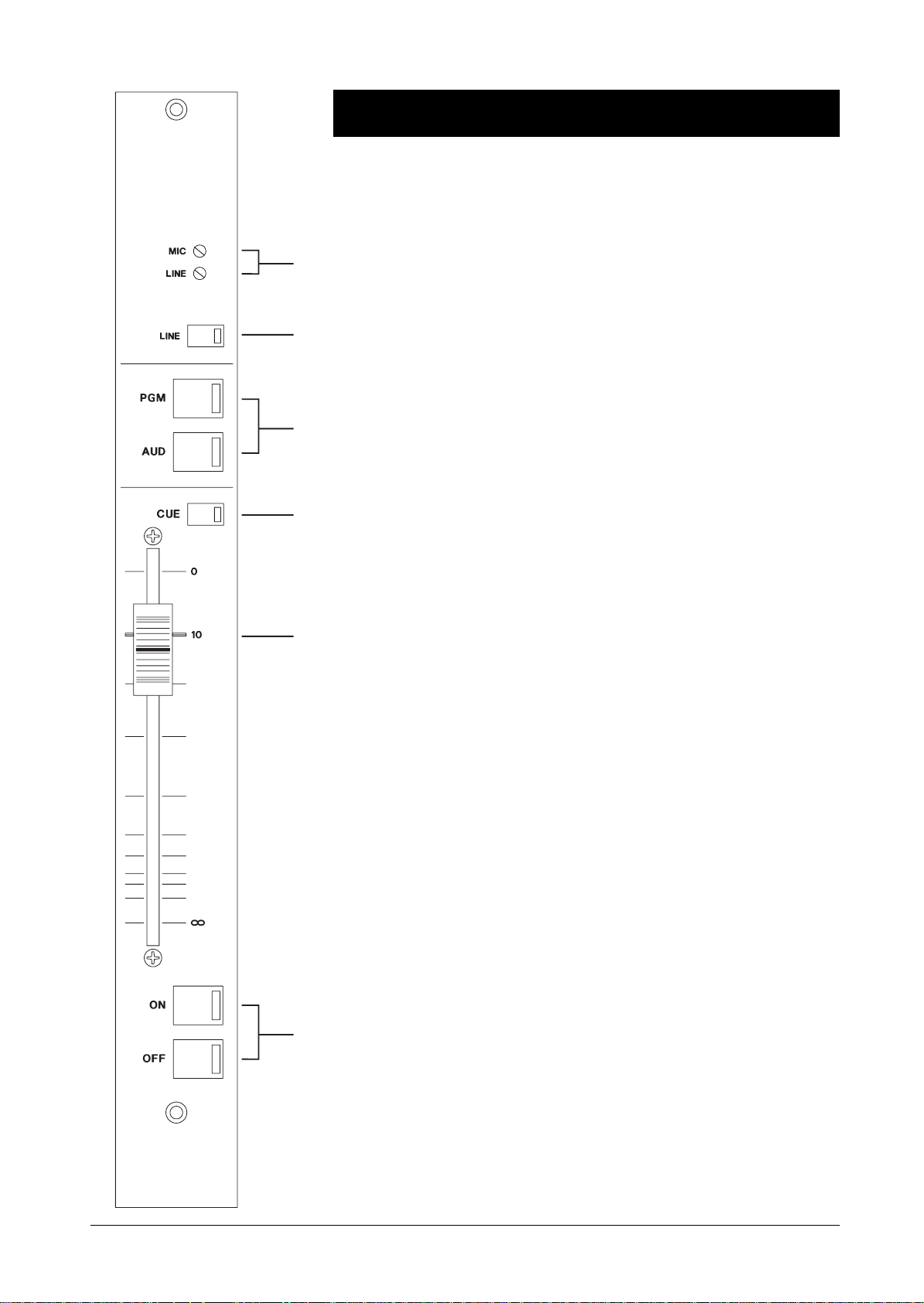

Input Stage

Two inputs, one microphone level and one line level, are provided to the module

1

on separate XLR connectors. The MIC input has +4 8V Phantom Powe r ava ilable ,

which may be activated by an internal jumper.

1

Each input has individual

2

5

3

adjusted using a small screwdriver through the front panel.

The

LINE

switch selects the Line Input socket when depressed and the Mic

2

Input socket when released. An LED in the switch glows red when the Line Input

is selected.

Note that phantom power is not connected to the LINE XLR, even when selected

on the MIC input.

Cueing

The

CUE

switch works in conjunction with a microswitch on the Fader.

3

Pressing the electronically latching CUE switch routes the pre-fa de, pre-mute signal

to the stereo Cue bus. This signal appears on the Headphones or Cue Speaker (if

fitted) and can be selected onto the main monitors by pressing the AUTO CUE

button on the Master module.

GAIN

control via a multiturn preset which may be

4

Cue may be cancelled in three ways:

• Pressing the CUE switch a second time

• Moving the fader away from rest at infinity

• Pressing the ON button (see below)

CUE cannot be selected when the module is ON, and the Fader lifted away from

the end stop. If the Fader is fully down, CUE may be selected in the normal way.

Output Control

4

The smoothaction, 100mm

up position. The 10 scale marking corresponds to a nominal unity gain.

There is a microswitch attached to the Fader which detects when it is in the fully

down position. This microswitch affects the ON and CUE functions which are

described in this section.

5

6

The mono Fader output may be routed to a choice of two stereo mix busses,

PGM and AUD. These switches are mechanically latching and have an integral

LED to show when the bus is selected. The output is only ac tive whe n the module

is switched ON (see below).

FADER

gives a gain of 10dB when it is in the fully

4.2 Mic/Line Input Module

Page 21

6

The output from the module is controlled by the ON and OFF switches, in

conjunction with the fader microswitch.

If the Fader is fully down:

Pressing the ON switch prepares the module to be active, and lights the red LED in

the ON switch at half brightness. The signal becomes active as soon as the Fader

is moved away from the infinity position, and the LED changes to full brightness.

If the Fader is lifted:

Pressing the ON switch immediately activates the module, and the LED lights at

full brightness.

Pressing the OFF switch will always turn the module off.

Send/Return

A pre-fade, pre-talkback Insert Point is provided on a 1/4" 3-pole jack on the rear

panel. This allows for the use of an effects mac hine to be a dded to the mono input

channel, e.g. voice processor, echo. The send and return lines are unbalanced and

care will need to be taken with the length and type of leads which are used.

Rear Connector Panel

The Insert is bypassed when no jack is connected.

Jumper Options

J1 Fit in position ‘B’ to enable +48V Phantom Power to the MIC input XLR.

J2 Fit to enable the pre-fade module output to the Talkback Mix bus which

feeds the Telco module clean feed output.

Mic/Line Input Module 4.3

Page 22

Specifications

Microphone Input

Electronically balanced

Input Impedance >2.2kΩ

Maximum I/P level +6dBu

Sensitivity Range -70dBu to -20dBu

CMRR > 100dB

EIN -128dBu, 150Ω source

Line Input

Electronically balanced

Input Impedance >20kΩ

Input Range -48dBu to +2dBu

General

Patch Send Level -10dBu unbalanc e d

THD < 0.02%

4.4 Mic/Line Input Module

Page 23

Stereo Input Module

Description & Operation

Specification

Stereo Input Module 4.5

Page 24

6WHUHR,QSXW0RGXOH

Input Stage

Two stereo Line Inputs are provided to the module, one on XLR connectors and

1

2

5

one on the multipin connector.

1

The input has individual gain controls for Right and Left via multiturn presets

which may be adjusted using a small screwdriver thro ugh the front panel. The gain

range allows matching to -10dBV or +4dBu sources.

2

The B switch selects Input B on the multipin connector when depresse d and the

Input A XLR connectors when released. An LED in the switch glows red when

Input B is selected. The switch also selects the corresponding pair of start/stop

remote contacts (see below).

Cueing

3

3

Pressing the electronically latching CUE switch routes the pre-fa de, pre-mute signal

to the stereo Cue bus. This signal appears on the Headphones or Cue Speaker (if

fitted) and can be selected onto the main monitors by pressing the AUTO CUE

button on the Master module.

Cue may be cancelled in three ways:

The

CUE

switch works in conjunction with a microswitch on the Fader.

4

• Pressing the CUE switch a second time

• Moving the fader away from rest at infinity

• Pressing the ON button (see below)

CUE cannot be selected when the module is ON, and the Fader lifted away from

the end stop. If the Fader is fully down, CUE may be selected in the normal way.

Output Control

4

The smooth action, 100mm

up position. The ‘10’ scale marking corresponds to a nominal unity gain.

There is a microswitch attached to the Fader which detects when it is in the fully

down position. This microswitch affects the ON and CUE functions which are

described in this section.

FADER

gives a gain of 10dB when it is in the fully

5

The Fader output may be routed to a choice of two stereo mix busses, PGM and

AUD. These switches are mechanica lly latching and have an integral LED to show

6

when the bus is selected. The output is only active when the module is switched

ON (see below).

4.6 Stereo Input Module

Page 25

6

The output from the module is controlled by the ON and OFF switches, in

conjunction with the fader microswitch.

If the Fader is fully down:

Pressing the ON switch prepares the module to be active, and lights the red LED in

the ON switch at half brightness. The signal becomes active as soon as the Fader

is moved away from the infinity position, and the LED changes to full brightness.

If the Fader is lifted:

Pressing the ON switch immediately activates the module, and the LED lights at

full brightness.

Pressing the OFF switch will always turn the module off.

Remotes

The multipin connector on the rear panel provides individua l sta rt/stop c omma nds

for each stereo input, as selected by the B switch. The outputs are isolated relay

contact closures.

Rear Connector Panel

Jumper Options

J1 Fit in position ‘B’ for latching start

Stereo Input Module 4.7

Page 26

Specifications

Line Inputs

Electronically balanced

Input Impedance >40kΩ

Maximum I/P level +28dBu

Sensitivity Range -12dBu to +9dBu

EIN -85dBu, 600Ω source

General

THD < 0.02%

4.8 Stereo Input Module

Page 27

Telco Input Module

Description & Operation

Specification

Telco Input Module 4.9

Page 28

7HOFR,QSXW0RGXOH

Input Stage

The Telco module must be conected to the telephone system via a Telephone

1

2

3

Hybrid.

1

The balanced

which the output from an external Telephone Hybrid may be plugged. A gain

control is provided via a multiturn preset which may be adjusted using a small

screwdriver through the front panel.

LINE

Input is a female XLR connector on the rear panel into

2

The balanced

panel which may be plugged into the input of an external Telephone Hybrid. The

6

4

Clean Feed signal (also known as Mix Minus) is the programme output minus the

telephone signal. A multiturn preset is accessible through the front panel to allow

optimum nulling of the local phone signal to be set.

Output level may be set at a nominal 0dBu or -10dBV by means of an internal

jumper.

The

DIVERT

3

to connect to an external Telephone Hybrid to allow a caller to be diverted to or

from, for example, a standard telephone handset. These switch contacts are

provided on the Remotes connector.

C/F

(Clean Feed) output is a male XLR connector on the rear

switch with integral LED provides an isolated switch changeover

5

Cueing

The

CUE

switch works in conjunction with a microswitch on the Fader.

4

Pressing the electronically latching CUE switch routes the pre-fa de, pre-mute signal

to the stereo Cue bus. This signal appears on the Headphones or Cue Speaker (if

fitted) and can be selected onto the main monitors by pressing the AUTO CUE

button on the Master module.

Cue may be cancelled in three ways:

• Pressing the CUE switch a second time

• Moving the fader away from rest at infinity

• Pressing the ON button (see below)

CUE cannot be selected when the module is ON, and the Fader lifted away from

the end stop. If the Fader is fully down, CUE may be selected in the normal way.

Output Control

7

5

The smooth action, 100mm

up position. The ‘10’ scale marking corresponds to a nominal unity gain.

There is a microswitch attached to the Fader which detects when it is in the fully

down position. This microswitch affects the ON and CUE functions which are

described in this section.

When CUE is active the caller will hear the signal on the talkback bus, enabling

two-way off-air communication.

4.10 Telco Input Module

FADER

gives a gain of 10dB when it is in the fully

Page 29

6

The Fader output may be routed to a choice of two stereo mix busses, PGM and

AUD. These switches are mechanica lly latching and have an integral LED to show

when the bus is selected. The output is only active when the module is switched

ON (see below).

7

The output from the module is controlled by the ON and OFF switches, in

conjunction with the fader microswitch.

If the Fader is fully down:

Pressing the ON switch prepares the module to be active, and lights the red LED in

the ON switch at half brightness. The signal becomes active as soon as the Fader

is moved away from the infinity position, and the LED changes to full brightness.

If the Fader is lifted:

Pressing the ON switch immediately activates the module, and the LED lights at

full brightness.

Pressing the OFF switch will always turn the module off.

Remotes

Rear Connector Panel

The Remotes connector provides the following facilities:

• Insert Point - unbalanced, which may be bypasse d by an internal jumper.

• Divert - isolated single-pole switch changeover.

Jumper Options

J1 Position B enables Insert Point.

J2 Position A selects 0dBu Clean Feed output, Position B selects -10dBV.

Telco Input Module 4.11

Page 30

Specifications

Line Inputs

Electronically balanced

Input Impedance >40kΩ

Maximum I/P level +28dBu

Sensitivity Range -12dBu to +9dBu

Clean Feed Output

Electronically balanced

Output Impedance < 75Ω

Output Level 0dBu or -10dBV, jumper selectable

4.12 Telco Input Module

Page 31

Master Module

Description & Operation

Specification

Master Module 4.13

Page 32

1

12

2

3

4

5

7

6

8

RM100

9

10

11

4.14 Master Module

Page 33

0DVWHU6HFWLRQ

Main Outputs

The Master module incorporates the mix amps outputs for the PGM and AUD

busses, plus a MONO output which can be sourced from the PGM or AUD busses

as selected by the MONO OUTPUT SOURCE switches (see below). These three

outputs are electronically balanced on male XLR conne c tors on the rear pa ne l.

Output levels are nominally 0dBu, but the AUD outputs may be changed via internal

jumpers to give -10dBV.

Master Faders are available as an option for the PGM a nd AUD outputs.

External Inputs

There are four stereo external available on a 15-pin male ‘D’-type connector on the

rear panel. Inputs 1 & 2 are electronically balanced at 0dBu and Inputs 3 & 4 are

unbalanced at -10dBV.

Mono Output

The MONO OUTPUT SOURCE switches select either one or both of PGM

1

or AUD as the source for the MONO output. Integral LED indicators illuminate

when the source is selected.

Monitoring

Separate source selectors feed the Guest Headphones, Co ntrol Room Monitors and

the Presenter’s Headphones

Guest Headphones

The LEVEL control sets the output level to the stereo Guest Headphone s output.

2

The source is normally PGM.

Normally the Cue signal appears on the Presenter’s Hea phones and Cue Speaker

3

in the meterbridge (when fitted). Pressing AUTO CUE routes an active CUE to

the Guest Headphones, replacing the normal PGM source. When the CUE is

released the headphones return to the original source.

Pressing T/B routes the signal from the Talkback Bus directly to the Guest

4

Headphones, replacing the PGM signal. (The Talkback Bus normally carries the

Presenter’s Mic signal via a dedicated Mic/Line input with the Talback jumper

fitted). The PGM signal is restored when T/B is released.

Control Room Monitor

Three SOURCE SELECT switches provide a choice of External Input 1, PGM

5

or AUD as the source for the monitors.

The LEVEL control sets the output level to the stereo C/Room Monitor jack

3

on the rear panel. The outputs are unbalanced.

Master Module 4.15

Page 34

1

12

2

3

4

5

7

6

8

RM100

9

10

11

4.16 Master Module

Page 35

The Control Room Monitors may be muted automatically when local

7

microphones are turned ON and the corresponding Faders opened. The MUTE

LED illuminates to show that a ’Mic Live’ condition has muted the monitors. The

same signal is used to activate a relay which provides two isolated single-pole

contact closures on the 9-pin ‘D’-type REMOTE socket on the rear panel.

Normally the Cue signal appears on the Presenter’s Hea phones and Cue Speaker

8

in the meterbridge (when fitted). Pressing AUTO CUE routes an active CUE to

the Control Room Monitors, replacing the previous source. When the CUE is

switched off the monitor returns to the original source.

Presenter’s Headphones

Six SOURCE SELECT switches provide a choice of External Inputs 1-4, PGM

9

or AUD as the source for the headphones.

The LEVEL control sets the level of the headphone signal.

10

The headphone output is a 3-pole 1/4" jack.

11

The meterbridge is fitted with a pair of VU meters as standard. The METER

12

SELECT switches provide a choice of PGM, AUD or MON (C/Room Monitor) as

the source for the meters. Note that the MON position provides a means of

monitoring the external inputs via the C/Room Monitor source se le ction.

On the larger frame sizes an additional pair of meters may be fitted , and in this case

one pair of meters will always display the PGM output.

Power Input

The 5way locking POWER connector is the power input to the console. The

console requires +17V, 17V and +48V.

Rear Connector Panel

Master Module 4.17

Page 36

Specifications

PGM, AUD & Mono

Max. output +26dBu into 600Ω

Output impedance <75Ω

General

THD < 0.02%

Crosstalk < -80dB @ 20kHz

4.18 Master Module

Page 37

0HWHUEULGJH

Two meterbridge styles are available. The following facilities are provided as

standard:

a single pair of VU meters (PPM meters optional). These display the level of

1

the source selected by the METER SELECT switches, and can be calibrated by

means of two screwdriver presets on the Master Panel (see earlier in this chapter).

The following facilities are only available on the optional meterbridge :

4-digit TIMER MODULE. This can be programmed by internal jumpers on

2

the stereo modules to start automatically when the stereo channel is activated, or

controlled manually by the local switches.

The CUE SPEAKER and associated LEVEL control monitor the output of the

3

CUE bus

213

Master Module 4.19

Page 38

SOURCE A

1

2

3

4

6WHUHR6RXUFH6HOHFW0RGXOH

The Stereo Source Select module provides switching from 8 balanced stereo

sources, which are presented on a 38-way male EDAC connector to two independent

balanced stereo outputs on a 15-way male D-type connec tor. Switching is done via

two independent banks of eight switches.

Select Switches

An LED in each switch indicates which switch in each bank is selected. The

switches in each bank are interlocked, i.e. pressing a switch will deselect any othet

switch in the same bank.

5

6

7

8

SOURCE B

1

2

3

4

5

6

7

8

EDAC Connector Pinouts

Pin Signal Pin Signal

A 1 L+ X Chassis Ground

B 1 L- Y Chassis Ground

C 1 R+ Z 5 L+

D 1 R- AA 5 LE 2 L+ BB 5 R+

F 2 L- CC 5 RH Not used DD 6 L+

J 2 R+ EE 6 LK 2 R- FF 6 R+

L 3 L+ HH 6 RM 3 L- JJ 7 L+

N 3 R+ KK 7 LP 3 R- LL Not used

R 4 L+ MM 7 R+

S 4 L- NN 7 RT 4 R+ PP 8 L+

U 4 R- RR 8 LV Chassis ground SS 8 R+

W Chassis ground TT 8 R-

4.20 Master Module

Page 39

15-Way D-type Pinout

Pin Signal Pin Signal

1 Chassis ground 9 Source A L+

OUTPUT B

OUTPUT A

+

2 Source A L- 10 Not used

3 Not used 11 Source A R+

4 Source A R- 12 Not used

5 Not used 13 Source B L+

6 Source B L- 14 Not used

7 Not used 15 Source B R+

INPUTS

8Source B R-

Master Module 4.21

Page 40

4.22 Master Module

Page 41

Appendices

Dimensions A.2

Glossary A.3

Warranty A.4

Appendices A.1

Page 42

Dimensions

9.68" (246mm)

MODULES AT 10

14.76" (375mm)

17.16" (436mm)

8 IP CHASSIS = 17.01" (432mm)

12 IP CHASSIS = 22.52" (572mm)

20 IP CHASSIS = 33.54" (852mm)

o

3.27" (83mm)

8 IP CHASSIS = 15.35" (390mm)

12 IP CHASSIS = 20.87" (530mm)

20 IP CHASSIS = 31.89" (810mm)

8 IP CHASSIS = 16.54" (420mm)

12 IP CHASSIS = 22.05" (560mm)

20 IP CHASSIS = 33.07" (840mm)

A.2 Appendices

Page 43

Glossary

Attenuation The reduction of a signal level. The attenuation is usually measured in dB.

Clipping The onset of severe distortion in the signal path, usually caused by the peak signal

voltage being limited by the circuit’s power supply voltage.

CMRR Common Mode Rejection Ratio. It is the ratio of the extent to which a differential

amplifier will cancel noise, which is present on both inputs, compared to its ability

to amplify the wanted signal.

dB (decibel) A ratio of two voltages or signal levels, expressed by the equation

V

1

(

⁄

dB=20LOG

Adding the suffix ’u’ denotes that the signal is relative to 0.775V RMS. Adding

the suffix ’v’ denotes that the signal is relative to 1V RMS.

EIN Equivalent Input Noise. It is the ratio of output no ise to th e gain. It describes the

level of noise which would need to be fed into an ideal amplifier to produce the

measured output noise.

Gain The degree of amplification, or attenuation applied to a signal.

10

).

V

2

Hybrid A device which allows a telephone line to be connec ted to a broadcast desk in such

a way that the caller may hear the programme output without the caller’s voice being

re-introduced on to the phone line which would cause unwanted fee dback.

LED Light Emitting Diode.

TELCO TELephone COmmunication.

THD Total Harmonic Distortion.

Appendices A.3

Page 44

Warranty

1 Soundcraft means Soundcraft Electronics Ltd.

End User means the person who first puts the equipment into regular operation.

Dealer means the person other than Soundcraft (if any) from whom the End

User purchased the Equipment, provided such a person is authorised for this

purpose by Soundcraft or its accredited Distributor.

Equipment means the equipment supplied with this manual.

2 If within the period of twelve months from the date of delivery of the Equipment

to the End User it shall prove defective by reason only of faulty materials and/or

workmanship to such an extent that the effectiveness and/or usability thereof is

materially affected the Equipment or the defective component should be returned

to the Dealer or to Soundcraft and subject to the following conditions the Dealer

or Soundcraft will repair or replace the defective components. Any components

replaced will become the property of Soundcraft.

3 Any Equipment or component returned will be at the risk of the End User whilst in

transit (both to and from the Dealer or Soundcraft ) and postage must be prepaid.

4 This warranty shall only be available if:

a) the Equipment has been properly installed in accordance with instructions

contained in Soundcraft’s manual; and

b) the End User has notified Soundcraft or the Dealer within 14 days of the

defect appearing; and

c) no persons other than authorised representatives of Soundcraft or the Dealer

have effected any replace ment of parts mai ntenance adjust ments or repairs to th e

Equipment; and

d) the End User has used the Equipment only for such purposes as Soundcraft

recommends, with only such operating supplies as meet Soundcraft’s

specifications and otherwise in all respects in accordance Soundcraft’s

recommendations.

5 Defects arising as a result of the following are not covered by this Warranty: faulty

or negligent handling, chemical or electro-chemical or electrical influences,

accidental damage, Acts of God, neglect, deficiency in electrical power,

air-conditioning or humidity control.

6. The benefit of thi s Wa rr anty may not be assig ned by the End User.

7. End Users who are consumers should note their rights under this Warranty are in

addition to and do not affect any other rights to which they may be entitled

against the seller of the Equipment.

A.4 Appendices

Page 45

CPS150 Power Supply

CPS150 Power Supply 43

Page 46

CPS150 User & Technical Manual

IMPORTANT: PLEASE READ THIS MANUAL CAREFULLY

BEFORE CONNECTING YOUR SOUNDCRAFT CPS150 POWER

SUPPLY TO THE MAINS FOR THE FIRST TIME.

WARNING SYMBOLS

For your own safety and to avoid invalidation of the warranty

all text marked as this paragraph should be read carefully.

FOR UK USERS ONLY

IMPORTANT WARNING

THIS APPLIANCE MUST BE EARTHED

The wires in the mains lead are coloured in accordance with the following code:

Green and Yellow:

Blue:

Brown:

As the colours of the wires in the mains lead may not correspond with the

coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured Green and Yellow must be connected to the

•

terminal in the plug which is marked with the letter E or by the earth symbol.

The wire which is coloured Blue must be connected to the terminal in the plug

•

which is marked with the letter N or coloured Black.

The wire which is coloured Brown must be connected to the terminal in the

•

plug which is marked with the letter L or coloured Red.

Earth

Neutral

Live

CPS 150 P.1

Page 47

Introducing the CPS150

The CPS150 is a linear power supply which, like other linear supplies, produces

DC voltages by rectifying, smoothing and regulating AC voltages from the

secondary windings of a mains transformer.

In regulating these voltages there is some heat generated, the dissipation of

which is achieved through a ventilated cover.

The CPS150 is designed to be free standing or it can be installed in a 19" rack.

For rack mounting, an optional fron t panel provided with the necessary fixing

holes can be obtained from Soundcraft (Part No. PP2288). Refer to the section

"RECOMMENDATIONS FOR INSTALLATION" for details.

LED indication is provided on the front panel to show indication of operation

of all regulating circuits.

SAFETY APPROVAL: HD 195 S6 TYPE TESTED

This manual covers the CPS 150 unit, that has been type tested and conforms to

the CENELEC Harmonised Document HD195 S6, consisting of IEC 65

(1985)ed 5 and BS 415 1990, with CENELEC deviations.

EMC CONDUCTED EMISSION

Certification of Conformity has been received for both:

USA Statutory Emission Requirements (FCC CFR47 Part 15J, A and B)

German Statutory Emission Requirements (VDE0871, A and B)

P.2 CPS 150

Page 48

Mains Voltage Selection

Special attention should be given to the following information:

This unit is capable of operating over a wide range of mains voltages by means

of a comprehensive set of selectable voltage settings. It is important to ensure

that the correct voltage setting has been selected for the level of local mains

voltage supply, for safe, uninterrupted operation of the unit.

A COVER PLATE is secured to the back panel over the VOLTAGE

SELECTION switches. A cut out in one corner of the cover plate indicates one

of the mains voltages. It is essential that the MAINS VOLTAGE displayed by

the cover pla te correspon ds to both the LOC AL MAINS VOLT AGE and the

VOLTAGE SELECTION switches position.

Do not change the voltage setting without first unplugging the

mains lead.

There are two MAINS VOLTAGE SELECTION switches at the rear of the

unit, Voltage selection is achieved by moving the switches using a screwdriver

blade, into the correct positions, as shown by the symbols above the switches In

this way the unit is set up for operation at one of the following ranges of mains

supply:

NOMINAL VOLTAGE

Vrms AC

240 216-264

OPERATING VOLTAGE RANGE

Vrms AC

220 198-242

120 (115) 108-132

100 NORM. 90-110

NOTE: The cover plate must be replaced after setting of the

VOLTAGE SELECTION

switches.

CPS 150 P.3

Page 49

Replacing Mains Fus e

In the event of incorrect switching of the mains voltage selectors, a mains power

surge or underrated fuse value, the mains fuse in the front panel will blow and

the CPS150 will not function. Switch the ON/OFF switch back to the OFF

position. Check the fuse and replace if necessary; also check that the voltage

selection is correct for the mains supply level before switching the unit ON

again.

In the event of repeated failure of the mains fuse consult the Soundcraft dealer

from where the unit was purchased.

TO AVOID RISK OF FIRE

REPLACE ONLY WITH THE

CORRECT VALUE FUSE, AS

INDICATED ON THE UNIT

THIS UNIT CONTAINS NO USER SERVICE-ABLE PARTS.

REFER ALL SERVICING TO A QUALIFIED SERVICE ENGINEER,

THROUGH THE APPROPRIATE SOUNDCRAFT DEALER.

OUTPUT CPS 150

17V @ 1.25A

48V @ 125mA

PRODUCT COMPLIES WITH

Voltage selector Cover Plates Indication

240V

UK

EUROPEAN

UK

EUROPEAN

220V

SAFETY STANDARD HD195 S6

AMERICAS

120V

P.4 CPS 150

Page 50

Recommendations for Installation

The CPS150 power supply can be prov ided with an optional front panel with

fixing holes for 19" rack-mounting and will occupy 2U of rack space.

Location

Ventilation

As with any power supply that contains a large mains voltage transformer, it is

preferable to provide a degree of physical isolation of the unit from other

electronic equipment, particularly that which carries low level audio signals, to

avoid any possible hum pick-up. For this reason the unit is provided with a long

(3.0 metres) output cable to enable it to be positioned away from the mixing

console.

For the same reason, when rack-mounting it is preferable to avoid locating the

unit near to sign al pr ocessing equip me nt .

It should be noted that if a complete rack contain ing a CPS150 unit is to be

operated from a different mains supply level, then the unit should be withdrawn

from the rack in order to reselect the mains voltage setting, at the same time as

resetting any other equipment.

The other important consideration when rack-mounting the unit is the need for

natural convection of air over the heatsink cooling fins.

Good ventilation below the unit, in the floor or back of the rack, and similarly

above the unit, at the top of the rack, will ensure a path for continuous air flow.

Other equipment in the rack which is known not to produce a significant amount

of heat should be mounted below the unit. Equipment that also relies on good

air flow within the rack (i.e.. most power amplifiers and other power supplies)

should be give n du e con si dera ti on an d some s pace sho uld be pr ov ided be twee n

such units and between these and the CPS150 unit. Forced convection, by means

of a fan-tray, may be desirable in this situation.

Free standing

The CPS150 is designed to operate as a free-standing unit without requiring any

special cooling arrangement, but should not be allowed to be accidentally or

deliberate ly covered in any way.

Earthing

Finally, some consideration should be given to the earthing arrangement of the

system at the centre of whi ch are the console an d the CPS150. Th e console

chassis is earthed, to the mains earth, via the power supply. When rack-mounting

the CPS150 care should be taken to avoid any possible ’ground loop s’ in the

system which would introd uce audible hum to otherwise cle an audio signals.

Ground loops may oc cur where signal processing equipme nt, patched to the

console, has its signal earth commoned to the equipment chassis. The ground

loop is formed if this chassis and the CPS150 chassis are in electrical contact

through the fixing rails they share in the rack.

W A R N I N G

UNDER NO CIRCUMSTANCES SHOULD THE MAINS EARTH

BE DISCONNECTED FROM THE CPS150 POWER SUPPLY UNIT

CPS 150 P.5

Page 51

Optional Rackmount fixing

• Remove the four front cover fixing screws.

• Place the rack mounting panel over the CPS 150.

• Secure the rack mounting panel to the CPS 150, fitting two screws to the top,

and one to each side of the unit.

General Precautions

As with all electrical/electronic equipment some care should be taken when

handling this unit. Avoid general mishandling and do not drop. Avoid storage

and operation in dus t y locations and do not ex po se to co rr os i v e atmospheres.

TO AVOID RISK OF FIRE DO NOT EXPOSE

THIS UNIT TO RAIN OR MOISTURE.

Retain all packaging for transportation in the event of the unit requiring

servicing. Retain this manual, along with all other relevant documents, safely.

P.6 CPS 150

Page 52

CPS150 Technical Specification

Mains input voltage range

240/220/120/100 V AC +/-10% @ 50/60 Hz

Rated input power (max.)

100 VA

Mains fuse rating:

T1.0A 120/240 V AC

T2.0A 110/120 V AC(115V)

Outputs

DC Voltage rails Max output current Max noise

+17V 1.25 AMPS -68 dBu

-17V 1.25 AMPS -68 dBu

+48V 0.125 AMPS -80 dBu

NOTE: All voltage current measurements are to be taken at the console end of

the power supply cable

Operating temperature range (ambient)

-10 TO +50 C.

Humidity

Similar unit tested to 92% Relative Humidity at 40 C for 16 Hours. Load

switched between 20% and 100% at regular 30 minute intervals.

Mechanical

Similar unit Drop tested to Military DEF.STAN 07-55 (part 2) Section 1/1.

Overall Dimensions

CHASSIS

HEIGHT: 85mm

WIDTH: (Chassis ) 287mm

DEPTH: 190mm

OPTIONAL FRONT PANEL

HEIGHT: 87mm (2U)

WIDTH: 482mm

WEIGHT:

Excl. Packaging: 4.0Kg

Packed incl. lead: 5.0Kg

:

CPS 150 P.7

Page 53

Circuit Description

Mains Input

The CPS150 is a Linear power supply, the operation of which avoids the

induction of switchin g noise, associated with switch-mode design s, in audio

signal paths. It has been possible to produce a design which is silent in

operation, and which will function over a greatly improved range of mains input

voltages. Additionally, the design of each supply is very similar and of a modular

format that will assist when servicing.

Refer to circuit diagram ED2770 which accompanies this section.

The mains supply is applied to the unit via the 3-pin IEC inlet on the unit back

plate. The earth feed is led directly to the chassis earth stud: AT NO TIME

SHOULD THIS CONNECTION BE BROKEN. The LIVE (black) and

NEUTRAL (white) feeds are led to the double-pole rocker switch on the front

of the unit, so that live and neutral switching to the following circuitry is made

simultaneously.

From this switch, the neutral feed is led directly to the MAINS PCB. The live

feed passes through the mains fuse (T1.0A 250V: 240V/220V or T2.0A 250V:

120V/100V) situated in the fuseholder on the front, below the ON-OFF switch,

and from there to the MAINS PCB.

Secondary Circuits

Circuit description

The design of the regulator circuitry is essentially the same for each supply rail,

but with different component values for the different voltage levels and power

requirements of the rails.

Each regulator circuit is fused at the input from the transformer secondary

winding, to protect against an over-current condition, in the event of component

failure in the regulator circuit.

Regulation is achieved using positive, adjustable voltage regulators, each housed

in a standard TO3 package, with the exception of the high voltage regulator for

the +48v rail, which is in a TO220 package.

Each regulator circuit is essentially similar, and the following general

description applies in each case. Component references are given for the +17V

rail as a guide.

The Mains Transformer steps-down the mains voltage to produce the required

alternating voltage across each secondary winding. The appropriat e pair of

lead-outs (same colour) are connected to the REGULATOR PCB. One side of

this secondary feed is led directly to the bridge rectifier BR1, while the other is

routed via the secondary protect ive fuse F1 to the bridge rectifier. The level of

the secondary vo ltage may be mea sured by apply ing an AC voltm eter across the

desired pair of secondary lead-outs.

The voltage waveform between points 3 and 4 is full-wave rectified, and

smoothed by a high value electrolytic capacitor C1, so that it appear as a DC

voltage with a small AC ‘ripple’ element. This level may be measured with the

voltmeter set for DC. A 100nF capacitor C2 in parallel with the smoothing

capacitor but closer to the regulator ensures its stability under any condition of

capacitive load.

P.8 CPS 150

Page 54

The regulator REG1 is adjustable, the output voltage being set by a preset

potentiometer in series with a fixed resistance R2 between the adjustment pin

and the "0V" reference. This allows a degree of adjustment equal to:

NOMINAL RATED OUTPUT VOLTAGE (V.dc) -10% +(10% + 0.7 V

(each preset is set and fixed at the factory test stage)

The actual regulated output voltage level is given by:

Vout = Vref x (1 + Radj/R1) + Iadj x R2

~ Vref x (1 + Radj/R1) as Iadj is negligible (~100uA)

The value of R1 is optimised for each regulator type:

For LM338 REGULATORS REG 1, REG 2 R1 = 120R

FOR TL783C REGULATOR R1 = 82R

The electrolytic capacitor C3 in parallel with the adjustment resistor, PR1 + R2

(Radj), improves ripple rejection in the regulator, and also produces a time

constant that causes the DC output of the regulator to rise more slowly when the

unit is switched on. In the case of the +17V and -17 V rails the rise time is about

3 seconds.

The output filter capacitor C4, between the regulator output and the ‘0V’

reference, eliminates ‘ringing’ and a slow regulator shut-down time in the event

of the output becoming short-circuited.

The two diodes D2 and D1 around the regulator, situated between the

adjust-output and output-input terminals, provide protection for low-current

paths within the regulator in the event of a reverse-bias condition. This occurs

when the regulator input voltage is less than the voltage present at the regulator

output, causing the output filter capacitor C4 and the capacitor across the

adjustment resistor C3 to discharge ‘backwards’ through the circuit. In this

situation the reverse current would pass through the diodes instead of the

regulator.

The LED and series resistor R3, across the output of the regulator provide a

visual indication that the regulator circuit is operational, with the LED situated

on the forward edge of the circuit board, projecting through the front panel of

the unit.

The resistor R3 provides a current limit of approximately 10mA through the

LED in normal operation.

The regulated output voltage between the regulator output and the "0V"

reference line is fed to the DC OUTPUT CONNECTOR on the back of the

unit by a pair of 24/0.2 insulated wires that are soldered directly to solder pads

on the circuit board.

CPS 150 P.9

Page 55

Negative Supply Rails

All direct audio signal paths in the console require +17V and -17V supplies. The

negative rail is derived using the same basic regulator circuit described above,

but the regulator output is connected to the ‘0V’ reference of the complementary

positive supply rail through a link on the circuit board. This means that the ‘0V’

reference of the negative supply rail becomes the negative output with respect

to the regulator output terminal (for LM338 regulators the terminal is the ca se).

Shutdown Method for +/- 17V Outputs

Under normal operating conditions TR1 and TR2 are both inoperative, due to

the potential divider R4, R24 and D7.

If the +17V output shuts down due to fault conditions, this will cause a negative

potential on the base of TR1 to increase, and TR1 will conduct. The voltage on

the adjust pin of REG2 will decrease and will close down REG2 and the -17V

output.

The same principle of operation will also apply to the +17V output if the -17V

output should shut down under fault conditions.

CAUTION

UNDER NO CIRCUMSTANCES SHOULD TR1 OR TR2

BE REMOVED AS THIS WILL RESULT IN DAMAGE TO THE

CONSOLE UNDER SOME FAULT CONDITIONS.

P.10 CPS 150

Page 56

Servicing

THIS OPERATION SHOULD ONLY BE CARRIED OUT

BY A COMPETENT SERVICE ENGINEER.

Initial operational tests on the power supply can be carried out by switching the

unit ON and checking the voltages present on the output connector on the back

of the unit. While the unit remains disconnected from the mixing conso le the

DC voltage rails are floating with respect to each other, i.e. they do not all have

a common reference within the unit. When connection is made to the mixing

console variou s ou tpu t p i ns become ear t he d to a common st ar-point, whic h h as

a mains earth return in the power supply cable itself.

An indication of obvious fault condition is the failure of one or more of the

front-panel LED’s to light. Note that due to the automatic shutdown circuit on

the =/-17V rails, if a fault causes one ra il to fail then the other ra il will also shut

down., and neither LED will be illuminated.

Any fault condition, with the exception of simple mains fuse failure due to

underrating or an unusual mains input condition, will require removal of the top

cover to enable correction of the fault. This is achieved using a No. 1 or No. 2

cross-head screwdriver to remove the eight retaining screws and washers.

ENSURE THAT MAINS POWER IS REMOVED FROM THE UNIT

BEFORE REMOVING THE TOP COVER

Carefully lift the cover to avoid the earth connecting lead to the cover from

snagging. Place the cover face down behind the unit.

SERVICING COMPONENTS

REPLACEMENT OF ANY COMPONENTS SHOULD BE

UNDERTAKEN ONLY AFTER DISCONNECTING THE MAINS

SUPPLY LEAD FROM THE POWER SUPPLY UNIT.

Replacement of any of the fuses and regulators in the power supply units is

possible without the removal of the circuit board.

The fuses are held in open fuseholders on the board, close to the other

components associated with that circu it. These can be carefully re moved by

hand.

The regulators that are in metal T03 packages can be removed by unscrewing

the two M3 screws on each end and lifting them by hand.

CPS 150 P.11

Page 57

If the electrically insulating SIL pad between the regulator and the heatsink

bracket looks damaged then it should be replaced before installing the new

regulator. Note that the regulators rely on good thermal contact with the

heatsinks to dissipate heat. The regulator fixing screws are used for an elec trical

connection between the regulator output and the rest of the circuit on the PCB:

the case of the T03 package is at the output potential of the device.

The +48V regulator is a TL783C high voltage device housed in a TO220

package. It can be removed by first withdrawing the PCB, desoldering the three

legs and unscrewing the M3 fixing screw, taking care to retain the small

insulating bush beneath the head of the screw. Again, an insulating SIL pad is

used and this should be replaced if it appears to be damaged. The metal tab at

the top of the package is at the output po tential of the device, as is the centre

lead. When refixing or replacing the device, it is pref erable to scre w the de vice

down before resoldering the leads, to avoid placing a strain on the circuit board

pads.

NOTE that the heatsink bracket is earthed through its mechanical contact with

the rest of the chassis and so a faulty SIL pad may cause the output of its

regulator to be connected to earth. In the case of a positive voltage rail the output

then becomes short circuited when the mixing console is connected. In this case

the regulator will shut down safely, unless faulty, and the associated front-panel

LED will not light. In the case of a negative voltage rail the regulator output is

normally eart hed at the console anyway, and so a fa ul t y S IL pad may not be s o

apparent. It may, however, affect the noise performance of the supply rail by

producing a ground loop. This can be checked against the maximum expected

noise figures listed in the ‘Technical Specification’. Alternatively, if necessary

the negative supply rail can be isolated from its complementary positive rail by

removing the link on the circuit board, and an individual load can b e applied

across the output of the supply rail with the ‘0V’ reference side commoned to

the chassis. The front-panel LED will not light if the output is short-circuited.

General

To replace any other components in a regulation circuit it is also necessary to

withdraw the circuit board.

First disconnect the leads to REG 1 and REG 2 by unplugging CN 1 and CN 2.

Unscrew the three No. 4 self-tapping screws holding down the PCB. Remove

the PCB, taking care not to damage the 3 LED indicators.

After servicing, re-assemble the unit in reverse, ensuring that all screws ar e fixed

tightly and that the PCB supports are latched onto the board. Re-dress cable

forms in their original positions and secure where applicable with cable ties.

Before replacing the top cover on the unit, carefully remove any dust from

surfaces within the unit.

CAREFULLY CHECK ALL WIRING CONNECTIONS

AND ENSURE THAT THERE ARE NO LOOSE PARTS

LYING AROUND INSIDE THE UNIT.

P.12 CPS 150

Page 58

CPS 150 P.13

Page 59

Application Guide

Use only with recommended SOUNDCRAFT consoles

Power Connector Pinouts

23

5

(viewed from cable end)

Pin Function Colour PCB No

1 Protected Earth (Green/Yellow) Chassis

2 0V (White) CON1-2

3 +48v (Grey) CON1-4

4 +17V (Brown) CON1-1

5 -17V (Blue) CON1-3

DC POWER INPUT

1

4

P.14 CPS 150

Page 60

Warranty

1 Soundcraft is a trading division of Harman International Industries Ltd.

End User means the person who first puts the equipment into regular operation.

Dealer means the person other than Soundcraft (if any) from whom the End User

purchased the Equipment, provided such a person is authorised for this purpose

by Soundcraft or its accredited Distributor.

Equipment means the equipment supplied with this manual .

2 If within the period of twelve months from the date of delivery of the Equipment

to the End User it shall prove defective by reason only of faulty materials and/or

workmanship to such an extent that the effectiveness and/or usability thereof is

materially affected the Equipment or the defective component should be returned

to the Dealer or to Soundcraft. Subject to the following conditions the Dealer or

Soundcraft will repair or replace the defective components. Any components

replaced will become the property of Soundcraft.

3 Any Equipment or component returned will be at the risk of the End User whilst

in transit (both to and from the Dealer or Soundcr af t ) an d po stage mu st be

prepaid.

4 This warranty shall only be available if:

a) the Equipment has been properly installed in accordance with instructions

contained in Soundcraf t’s manual; and

b) the End User has notified Soundcraft or the Dealer within 14 days of the defect

appearing; and

c) no persons other than authorised representatives of Soundcraft or the Dealer have

effected any replacement of parts maintenance adjustments or repairs to the

Equipment; and

d) the End User has used the Equipment only for purposes which Soundcraft

recommends, with only such operating supplies as meet specifications and

otherwise in all respects in accordance with Soundcraft’s recommendations.

5 Defects arising as a result of the following are not covered by this Warranty: faulty

or negligent handling, chemical or electro-chemical or electrical influences,

accidental damage, Acts of God, neglect, deficiency in electrical power,

air-conditioning or humidity control.

6 The benefit of this Warranty may not be assigned by the End User.

7 End Users who are consumers should note their rights under this Warranty are in

addition to and do not affect any other rights to which they may be entitled

against the seller of the Equipment.

CPS 150 P.15

Page 61

P.16 CPS 150

Loading...

Loading...