Page 1

Working Instruction, Electrical

Working Instruction, Electrical

Applicable for W595

CONTENTS

1 Read this first .........................................................................................3

2 Lead-free soldering ................................................................................ 4

3 Soldering issues..................................................................................... 6

3.1 Hot air gun temperature requirements .................................................. 6

3.2 Soldering tip temperature requirements ................................................ 6

3.3 Bottom heat requirements ..................................................................... 6

3.4 BGA rework specifications .................................................................... 6

4 Shield fence instruction......................................................................... 7

5 Preparations of Thor’s shield can lid ...................................................8

6 Replacement of components ................................................................9

6.1 Shield Cover........................................................................................ 10

6.2 B2100 Crystal 32,768 kHz................................................................... 11

6.3 B3105 Microphone .............................................................................. 11

6.4 B4200 Vibrator .................................................................................... 11

6.5 C2217 Capacitor 220 μF 4.0 V............................................................12

6.6 L2200 Inductor Wire wound 4.7 μH.....................................................12

6.7 L2401 - L2404 and L2411 Filter 0.0 Hz 0402...................................... 12

6.8 L2421 - L2422 Inductor 120nH 5% 0402 0.11A .................................. 13

6.9 N1002 IC Amplifier .............................................................................. 13

6.10 N1200 Thor2 Radio Module EDGE..................................................... 13

6.11 N1210 RF-Module Squid prebumped.................................................. 14

6.12 N1400 Module Bluetooth + FM STLC2592 ......................................... 14

6.13 N2202 IC Vreg 600mA ........................................................................ 14

6.14 N2203 IC Vreg PLP1010-4.................................................................. 15

6.15 N2205 DC/DC Converter..................................................................... 15

6.16 N2400 1-Bit Level Translator............................................................... 15

6.17 N2402 IC ESD Prot UDFN 6 2x2 mm ................................................. 16

6.18 N2404 IC IF ISP1508 ES3 (3.5*3.5*0.8) ............................................. 16

6.19 N2410 IC ESD Prot CS-5.................................................................... 16

6.20 N2490 ASIC Accelerometer ................................................................ 17

6.21 N3100 IC CS-9.................................................................................... 17

6.22 N3102 IC CS-9.................................................................................... 17

6.23 N3101 ASIC Tjatte3 CSP20................................................................ 18

6.24 N4200 Trans N-ch FET ....................................................................... 18

6.25 N4310 IC Vreg..................................................................................... 18

6.26 N4311 IC Vreg..................................................................................... 19

6.27 R2432 and R2434 Resistor 0 Ohm +/-50m 63mW K0603 .................. 19

6.28 V2200 Zener diode.............................................................................. 19

1215-7375 Rev 1

Company Internal

© Sony Ericsson Mobile Communi cat i ons AB

Page 2

Working Instruction, Electrical

6.29 V2202 Trans P-ch FET........................................................................ 20

6.30 V2405 MOSFET Complementary N P 20 V (DS)................................20

6.31 V2408 Schottky Barrier Diode 2PIN.................................................... 20

6.32 V2420 Zenner Diode 15V.................................................................... 21

6.33 V2421 Zenner Diode 15V.................................................................... 21

6.34 X1200 Conn Receptacle 0p Hirose RF connector .............................. 21

6.35 X1201 Antenna connector................................................................... 22

6.36 X1400 and X1401 Antenna connector ................................................ 22

6.37 X2200 Battery Connector.................................................................... 22

6.38 X2400 System Connector ................................................................... 23

6.39 X2410 MS Connector.......................................................................... 23

6.40 X2420 SIM Connector......................................................................... 23

6.41 X2430 Connector FPC 25p ................................................................. 24

6.42 X4200 Connector FPC 51p ................................................................. 24

6.43 X4300 Connector FPC 26p ................................................................. 24

6.44 Z4200 - Z4203 LC Filter ...................................................................... 25

7 Revision History ................................................................................... 26

1215-7375 Rev 1

Company Internal

2(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 3

Working Instruction, Electrical

1 Read this first

CAUTION

Keep all contact surfaces clean, no dirt or hand grease!

Before you start replacing any components, make sure you have read and fully understood

the contents of section 2 – 5.

Also make sure you have access to the mechanical Working Instruction and the equipment

listed on the first page of section 6.

Attention! All repair action with Hot air station or BGA repair station around and on the

opposite side of these components shall be performed with care, if the soldering joints

temperature on these components will reach 220 degrees than soldering of these

components will be damaged.

Protect the phone from ESD damages whenever it has been opened by using:

• ESD-wristband

• ESD-gloves

1215-7375 Rev 1

Company Internal

3(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 4

Working Instruction, Electrical

2 Lead-free soldering

KEEP ALL CONTACT SURFACES CLEAN OF DIRT AND HAND

GREASE

!

THIS PRODUCT IS MANUFACTURED WITH LEAD-FREE SOLDER

AND LEAD

-FREE COMPONENTS!

During electrical repair, it is critical to make sure that no

lead is introduced.

This symbol indicates that the product is lead- free.

All lead-free PBA’s will be marked with this symbol.

A lead-free work area must be set up completely separated

from work areas that are used to make lead repairs.

The lead-free work area must also be clearly labeled with

the lead free symbol as shown in the adjacent picture.

The items on this desk must remain lead-free.

They must be adequately labeled to make their lead-free

status clearly and easily recognized.

1215-7375 Rev 1

Company Internal

© Sony Ericsson Mobile Communi cat i ons AB

4(26)

Page 5

Working Instruction, Electrical

Lead-free soldering continued

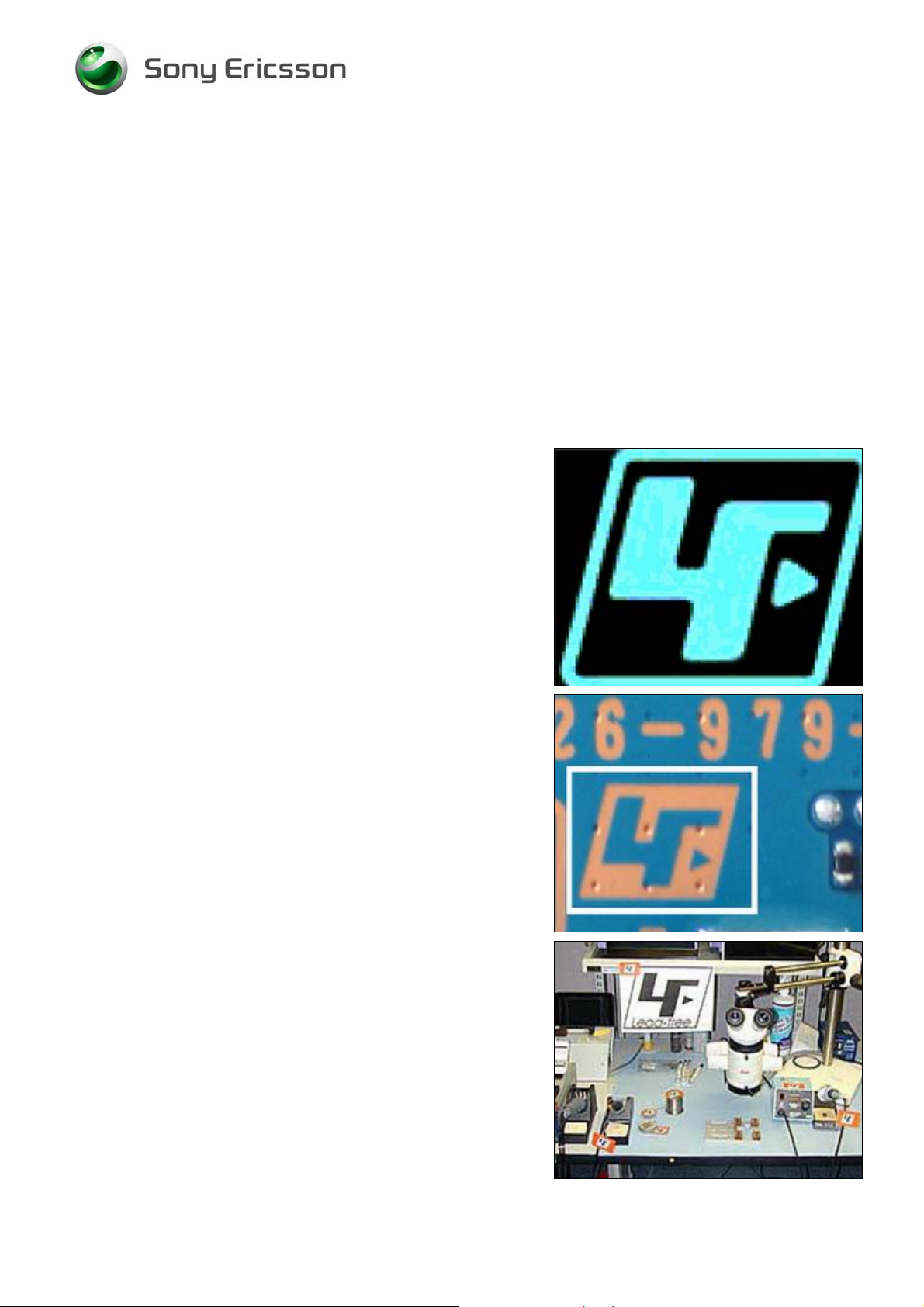

LFS (lead-free solder paste) characteristics:

• High melting point (typically 220°C)

• Low wettability

• High surface tension

• Difficult to spread

• Recommended tip temperature = 360°C

WHEN SERVICING PBA’S THAT HAVE BEEN MANUFACTURED

LFS (LEAD-FREE SOLDER PASTE), LFS MUST BE USED.

WITH

I

F NOT, THERE IS A HIGH RISK FOR UNRELIABLE SOLDERING

JOINTS.

Lead-free solder joints are more difficult to inspect because

they do not have shiny surfaces like leaded solder joints.

Also, lead-free solder does not flow as well as leaded

solder, so some of the solder pad areas may remain

exposed.

1215-7375 Rev 1

Company Internal

5(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 6

Working Instruction, Electrical

3 Soldering issues

3.1 Hot air gun temperature requirements

The air temperature shall not exceed 360°C. The temperature shall be measured 5 mm from the

nozzle outlet.

If it’s not possible to remove and/ or solder with 360°C a BGA Rework Station or another repair

process shall be considered to ensure high process control.

Too high temperature can cause damage and cracks due to thermal stress on sensitive components,

e.g. ceramic components like capacitors.

3.2 Soldering tip temperature requirements

The soldering tip temperature shall be minimum 310°C and maximum 360°C.

Too high temperature can cause damage and cracks due to thermal stress on sensitive components,

e.g. ceramic components like capacitors.

3.3 Bottom heat requirements

In the chapter “Replacement of components” there are components which require to us a bottom

heater during repair to pre-heat the board and to level out the ∆T on the PBA. It will also minimize

thermal stress.

The temperature on the PBA surface shall not exceed 150°C to minimize inter-metallic growth and

thermal stress on PWB.

3.4 BGA rework specifications

Follow the Technical Requirement, 1207-2949, for components that require use of BGA Rework

Station.

1215-7375 Rev 1

Company Internal

6(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 7

Working Instruction, Electrical

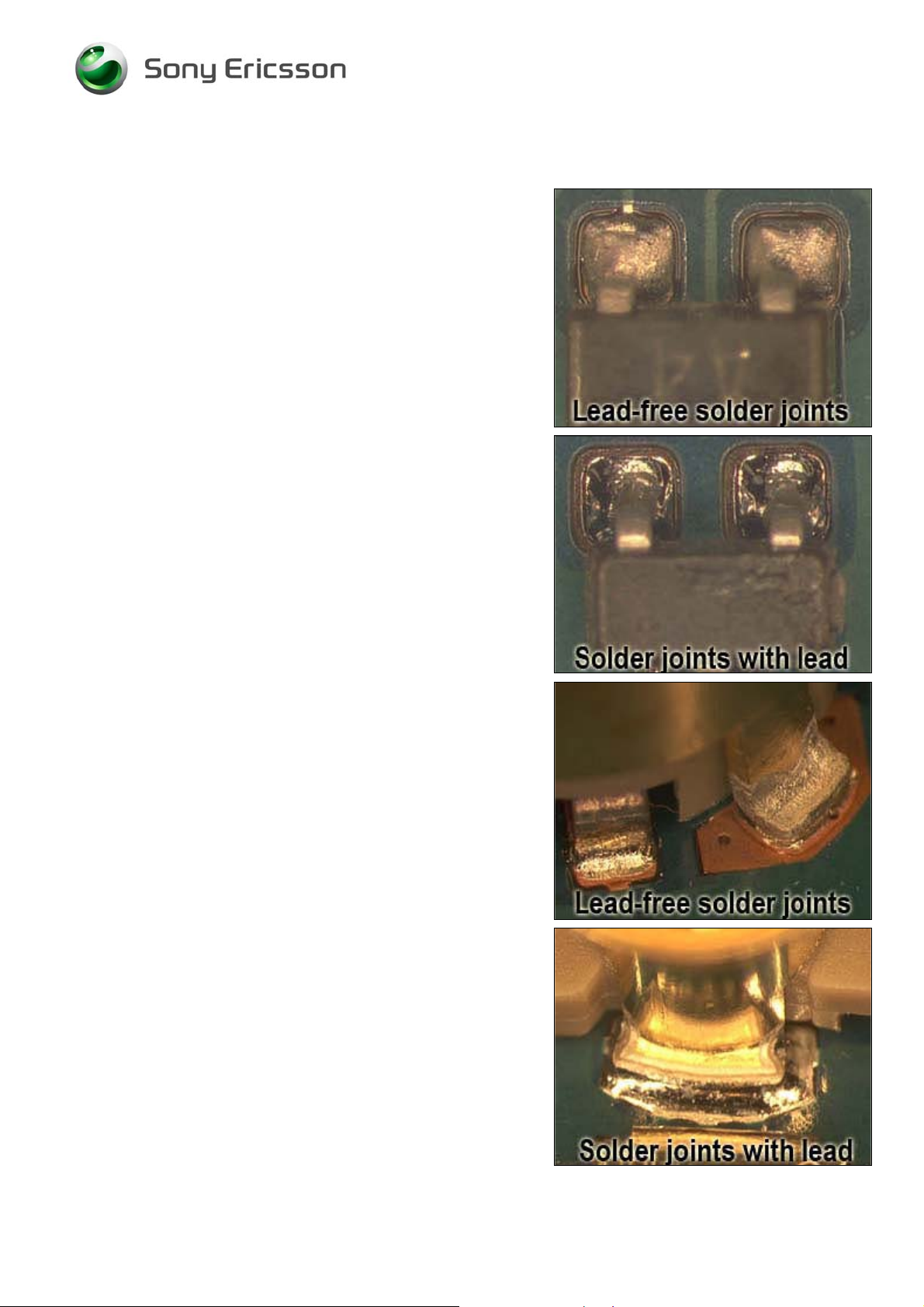

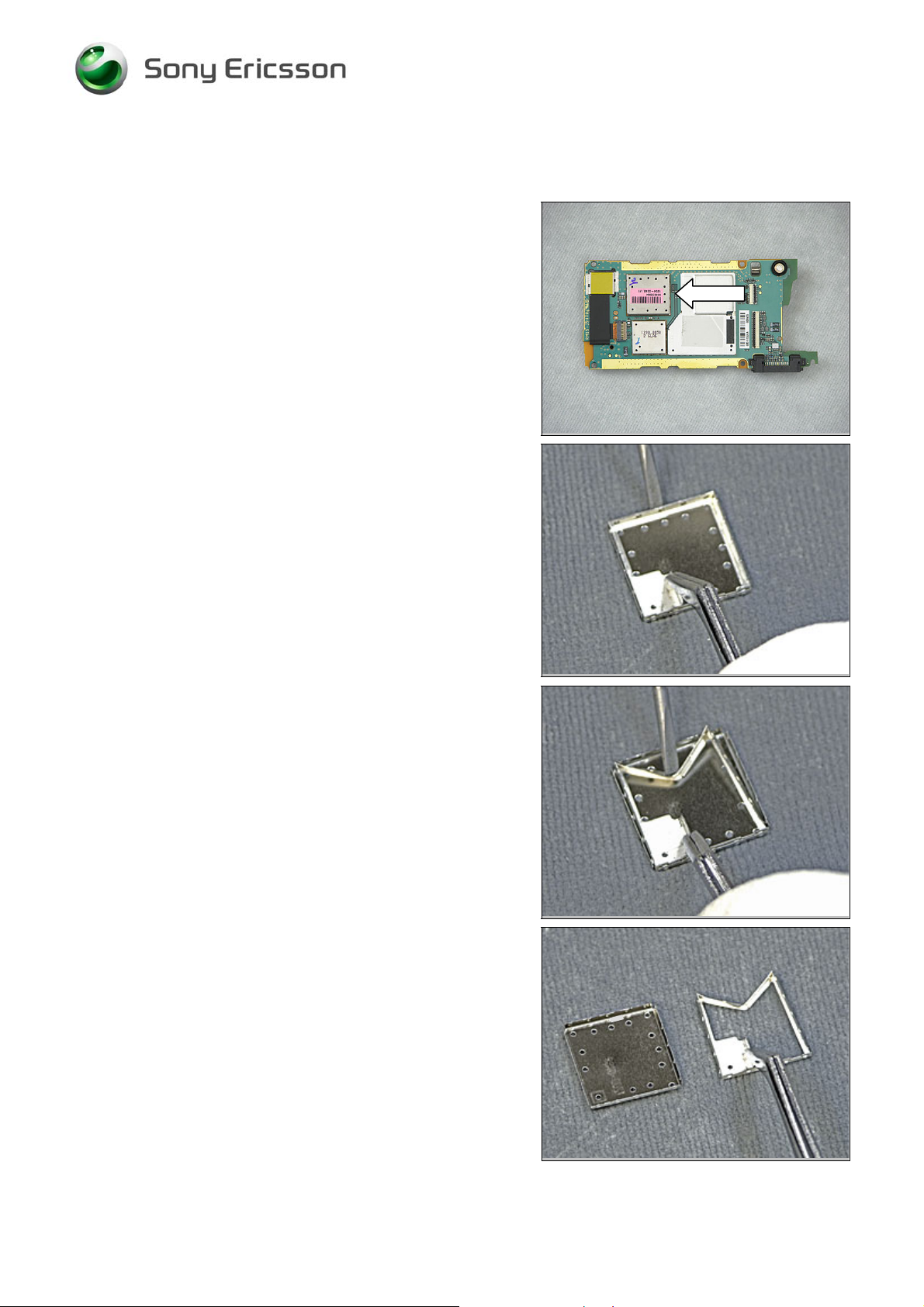

4 Shield fence instruction

This instruction shows how to cut and bend the shield can

fence to be able to replace components under the fence.

Use a sharp-edged pliers to cut the fence.

Use Shield fence pliers NTZ 112 537 to bend the fence.

MAKE SURE THAT CUTTING PLIERS IS SHARP-EDGED TO

PREVENT DAMAGING THE SHIELD CAN FENCE

Remove the shield can lid, use a dentist hook.

Remove the pick up area according to the white lines with

cutting pliers. (1)

This pick up area is only used when machine mounting

and there is no need to put it back again.

Cut the shield can fence according to the white lines with

cutting pliers. (2)

.

1

1

1

2

2

2

Bend carefully the shield fence with a shield fence plier.

Replace the components.

Replace the components.

Bend carefully back the shield fence.

Put back a new shield can lid.

Press on all sides of the lid until you hear a “click” sound.

1215-7375 Rev 1

Company Internal

© Sony Ericsson Mobile Communi cat i ons AB

7(26)

Page 8

Working Instruction, Electrical

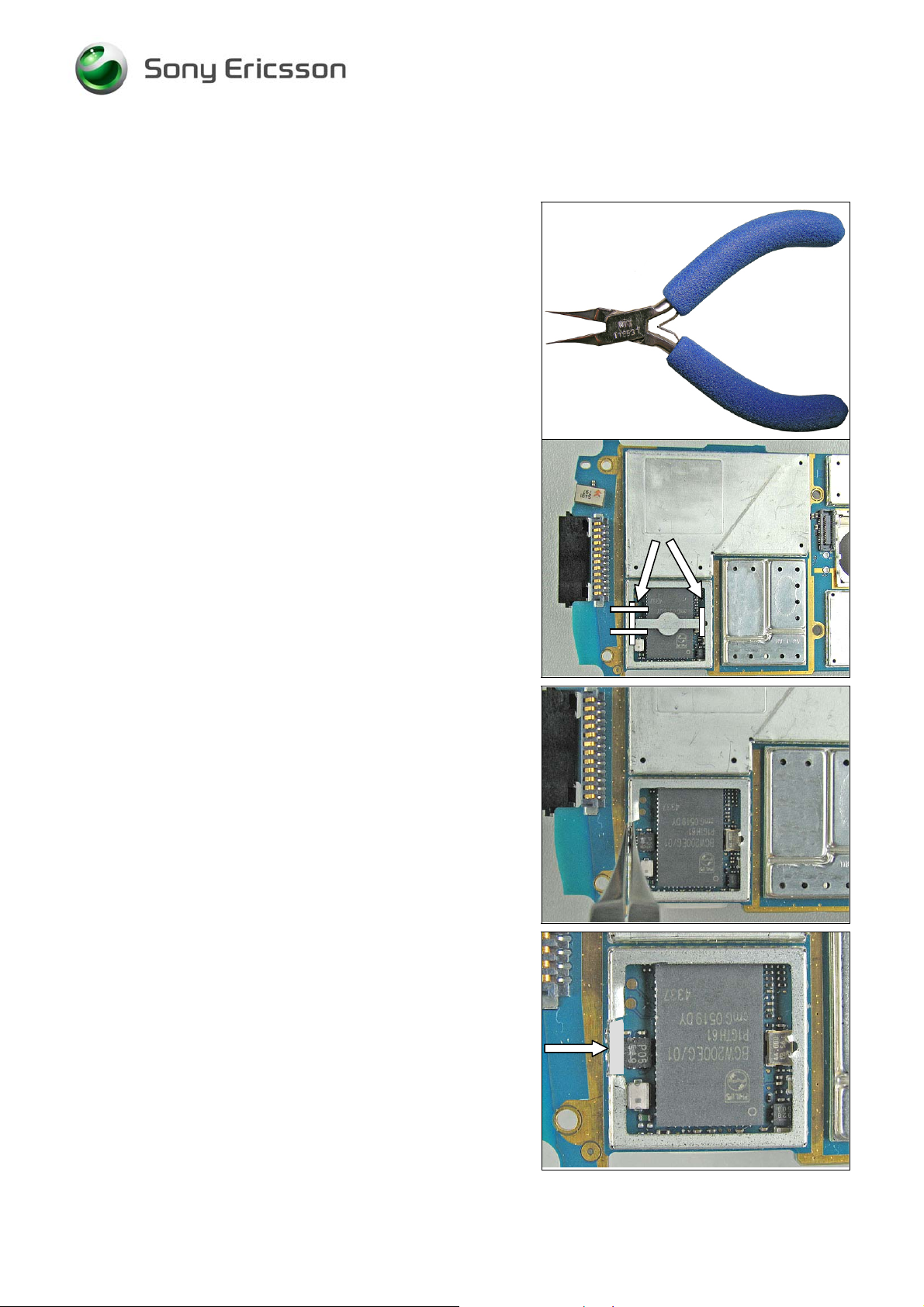

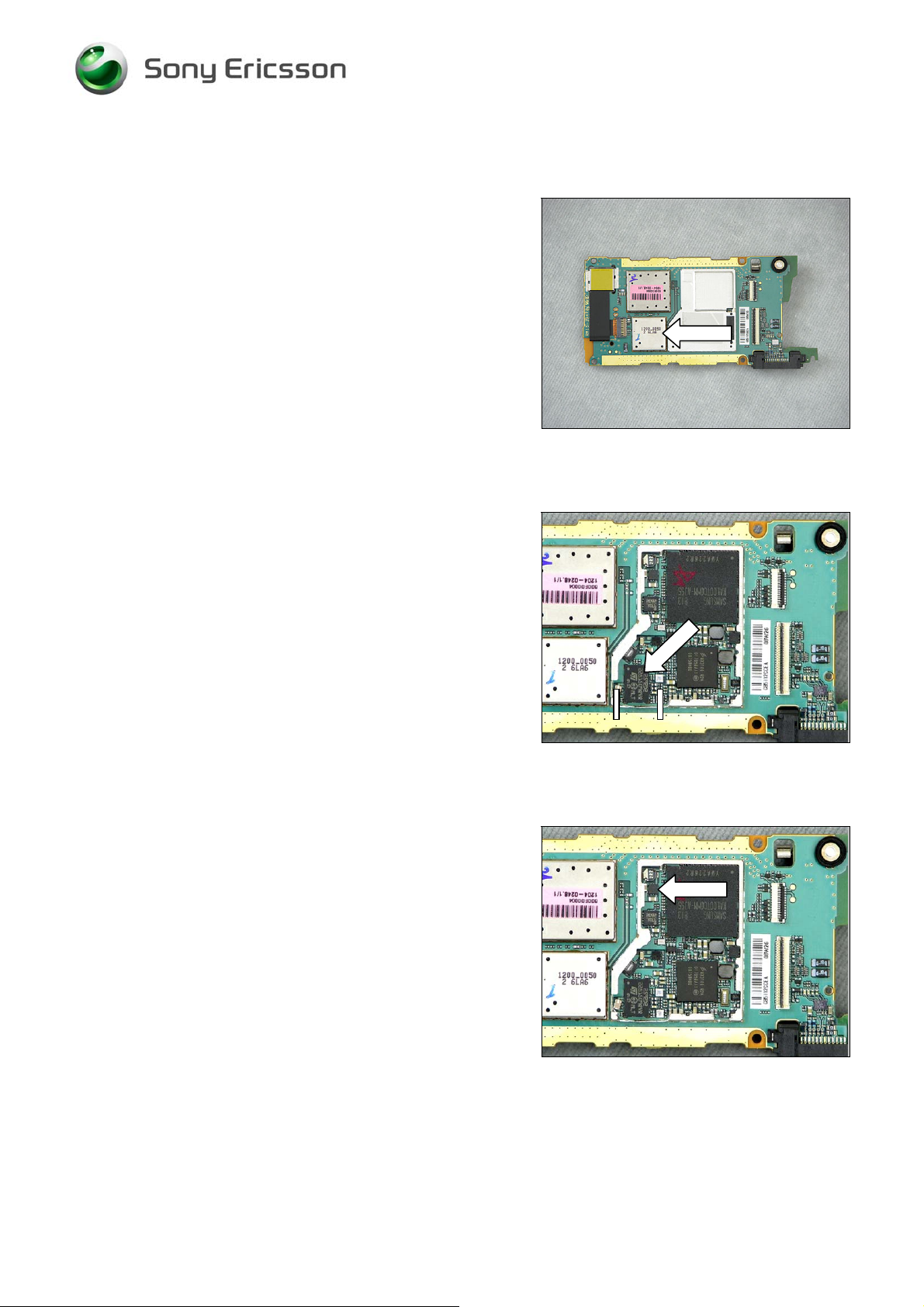

5 Preparations of Thor’s shield can lid

The shield can lid for Thor will be delivered together with

a fence. The fence has to be removed from the lid before

the lid can be used.

Use a screw driver and a par of tweezers.

Place the screw driver between the lid and the fence.

Press the shield can fence to the middle.

Use the tweezers to move the fence from the lid.

The shield can lid is now ready to use.

1215-7375 Rev 1

Company Internal

© Sony Ericsson Mobile Communi cat i ons AB

8(26)

Page 9

Working Instruction, Electrical

6 Replacement of components

EQUIPMENT

• Dentist hook

• ESD-gloves (cotton gloves)

• ESD-wristband

• Shield fence pliers NTZ 112 537

• Soldering iron

• Hot air soldering equipment

• BGA replacement equipment

• Pair of tweezers

• Soldering cleaning wiper (tin wick)

• Solder paste lead-free (SN 96% AG 3.5% Cu 0.5 %)

• Flux, RMA no-clean flux

• Cutting pliers

MECHANICAL INSTRUCTIONS

For all the following part replacements, disassemble and assemble the phone as described in

mechanical Working Instruction.

1215-7375 Rev 1

Company Internal

9(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 10

Working Instruction, Electrical

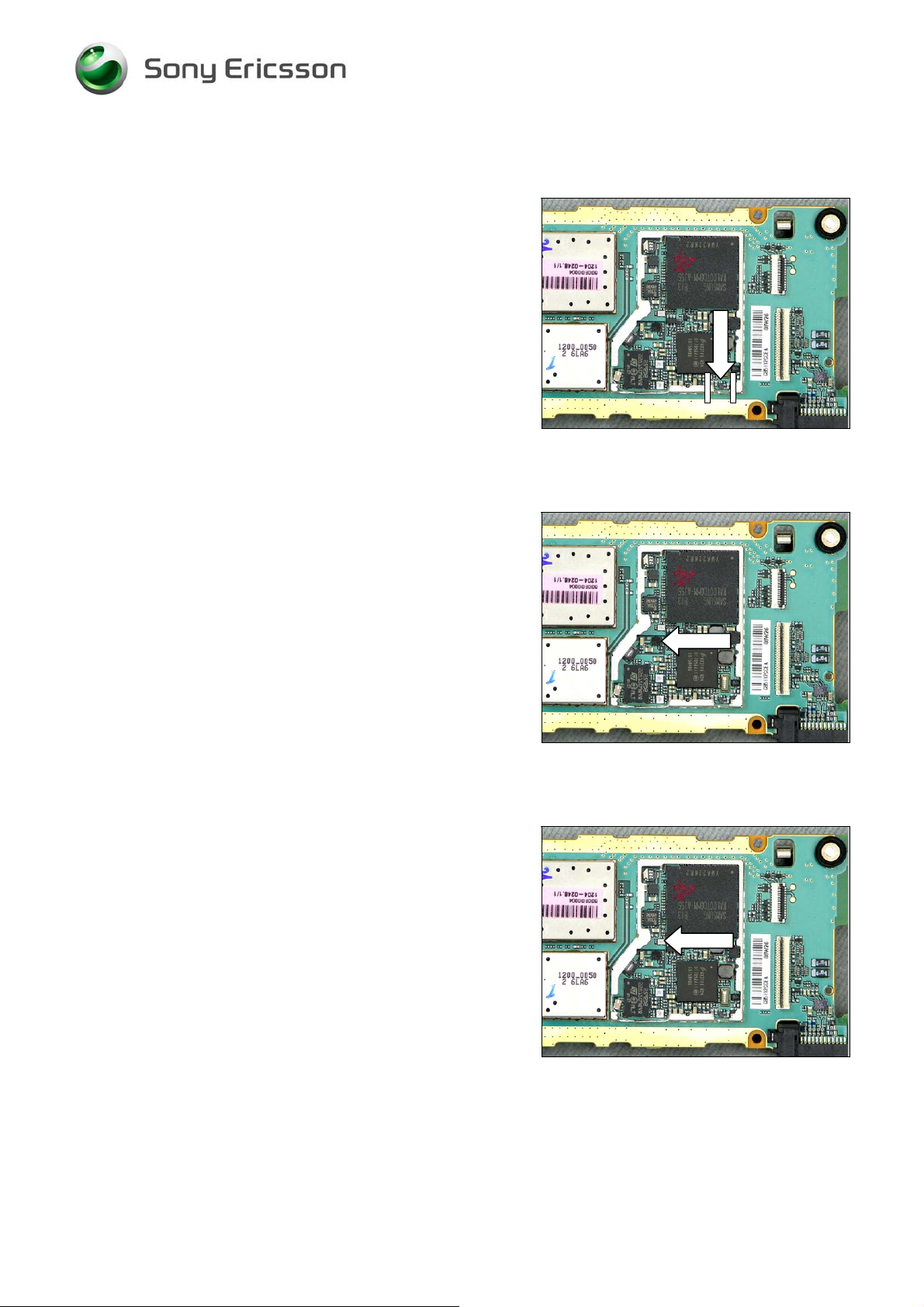

6.1 Shield Cover

REMOVAL

Use a dentist hook or a pair of tweezers to remove the

Shield Cover.

INSTALLATION

Replace a new Shield Cover after repair.

Press down the Shield Cover to snap all hooks onto the

shielding frame.

1215-7375 Rev 1

Company Internal

10(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 11

Working Instruction, Electrical

6.2 B2100 Crystal 32,768 kHz

Replace the Crystal with hot air soldering equipment.

6.3 B3105 Microphone

Remove the Microphone Gasket.

Replace the Microphone with hot air soldering equipment.

Protect the new Microphone with heat resisting tape.

Mount the Microphone

Gasket.

6.4 B4200 Vibrator

Protect the SIM connector with heat resisting tape.

Replace the Vibrator with a soldering iron or hot air

soldering equipment.

1215-7375 Rev 1

Company Internal

11(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 12

Working Instruction, Electrical

6.5 C2217 Capacitor 220 μF 4.0 V

Protect the Camera FPC and the connector with heat

resisting tape.

Replace the Capacitor with a soldering iron or hot air

soldering equipment.

6.6 L2200 Inductor Wire wound 4.7 μH

Protect D2000 and N2000 with heat resisting tape.

Replace the Inductor with hot air soldering equipment.

6.7 L2401 - L2404 and L2411 Filter 0.0 Hz 0402

Protect the System connector with heat resisting tape.

Replace the Filter with a soldering iron or hot air soldering

equipment.

1215-7375 Rev 1

Company Internal

12(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 13

Working Instruction, Electrical

6.8 L2421 - L2422 Inductor 120nH 5% 0402 0.11A

Protect the System connector with heat resisting tape.

Replace the Inductor with a soldering iron or hot air

soldering equipment.

6.9 N1002 IC Amplifier

Remove the shield can lid with a dentist hook.

Replace the IC Amplifier with hot air soldering or BGA

equipment.

Prepare a new shield can lid (see chapter 5 for further

instructions).

Mount the new shield can lid with your fingers and press

the shield can lid to attach it.

A CLICKING SOUND WILL CONFIRM A SECURE FIT!

6.10 N1200 Thor2 Radio Module EDGE

Protect the Camera FPC and the connector with heat

resisting tape.

Replace the Radio Module with BGA equipment.

1215-7375 Rev 1

Company Internal

13(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 14

Working Instruction, Electrical

6.11 N1210 RF-Module Squid prebumped

Protect the Camera FPC and the connector with heat

resisting tape.

Replace the Radio Module with BGA equipment.

6.12 N1400 Module Bluetooth + FM STLC2592

Cut and bend the shield can fence to be able to replace

components under the fence according ‘Shield fence

instruction’.

Replace the Bluetooth Module with hot air soldering

equipment or BGA equipment.

6.13 N2202 IC Vreg 600mA

Replace the IC with hot air soldering equipment.

1215-7375 Rev 1

Company Internal

14(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 15

Working Instruction, Electrical

6.14 N2203 IC Vreg PLP1010-4

Cut and bend the shield can fence to be able to replace

components under the fence according ‘Shield fence

instruction’.

Replace the IC with hot air soldering equipment.

6.15 N2205 DC/DC Converter

Cut and remove the shield can roof to be able to replace

components under the roof according ‘Shield fence

instruction’.

Replace the Converter with hot air soldering equipment.

6.16 N2400 1-Bit Level Translator

Cut and remove the shield can roof to be able to replace

components under the roof according ‘Shield fence

instruction’.

Replace the Translator with hot air soldering equipment.

1215-7375 Rev 1

Company Internal

15(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 16

Working Instruction, Electrical

6.17 N2402 IC ESD Prot UDFN 6 2x2 mm

Cut and bend the shield can fence to be able to replace

components under the fence according ‘Shield fence

instruction’.

Replace the IC with a soldering iron or hot air soldering

equipment.

6.18 N2404 IC IF ISP1508 ES3 (3.5*3.5*0.8)

Replace the IC with hot air soldering equipment.

6.19 N2410 IC ESD Prot CS-5

Cut and bend the shield can fence to be able to replace

components under the fence according ‘Shield fence

instruction’.

Replace the IC with hot air soldering equipment.

1215-7375 Rev 1

Company Internal

16(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 17

Working Instruction, Electrical

6.20 N2490 ASIC Accelerometer

Replace the Accelerometer with hot air soldering

equipment.

6.21 N3100 IC CS-9

Replace the IC with hot air soldering equipment.

6.22 N3102 IC CS-9

Cut and bend the shield can fence to be able to replace

components under the fence according ‘Shield fence

instruction’.

Replace the IC with hot air soldering equipment.

1215-7375 Rev 1

Company Internal

17(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 18

Working Instruction, Electrical

6.23 N3101 ASIC Tjatte3 CSP20

Protect the System connector and the ZIF Connector with

heat resisting tape.

Replace the ASIC with hot air soldering equipment.

6.24 N4200 Trans N-ch FET

Replace the Transistor with hot air soldering equipment.

6.25 N4310 IC Vreg

Replace the IC with hot air soldering equipment.

1215-7375 Rev 1

Company Internal

18(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 19

Working Instruction, Electrical

6.26 N4311 IC Vreg

Protect the Camera FPC and the connector with heat

resisting tape.

Replace the IC with hot air soldering equipment.

6.27 R2432 and R2434 Resistor 0 Ohm +/-50m 63mW K0603

Protect the System connector with heat resisting tape.

Replace the Resistor with a soldering iron or hot air

soldering equipment.

6.28 V2200 Zener diode

Replace the Diode with a soldering iron or hot air

soldering equipment.

1215-7375 Rev 1

Company Internal

19(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 20

Working Instruction, Electrical

6.29 V2202 Trans P-ch FET

Replace the Transistor with hot air soldering equipment.

6.30 V2405 MOSFET Complementary N P 20 V (DS)

Replace the MOSFET transistor with a soldering iron or

hot air soldering equipment.

6.31 V2408 Schottky Barrier Diode 2PIN

Protect the ZIF Connector with heat resisting tape.

Replace the Diode with a soldering iron or hot air

soldering equipment.

1215-7375 Rev 1

Company Internal

20(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 21

Working Instruction, Electrical

6.32 V2420 Zenner Diode 15V

Cut and bend the shield can fence to be able to replace

components under the fence according ‘Shield fence

instruction’.

Replace the Diode with a soldering iron or hot air

soldering equipment.

6.33 V2421 Zenner Diode 15V

Protect the System connector with heat resisting tape.

Replace the Diode with a soldering iron or hot air

soldering equipment.

6.34 X1200 Conn Receptacle 0p Hirose RF connector

Remove the Connector with hot air soldering equipment.

Replace a new Connector with a soldering iron.

NOTE:

Make sure flux does not get on the component body.

Use as little flux as possible to place the new part.

1215-7375 Rev 1

Company Internal

21(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 22

Working Instruction, Electrical

6.35 X1201 Antenna connector

Replace the Connector with a soldering iron.

6.36 X1400 and X1401 Antenna connector

Replace the Connector with a soldering iron.

6.37 X2200 Battery Connector

Remove the Battery Connector with hot air soldering

equipment.

Replace a new Connector with a soldering iron or BGA

equipment.

1215-7375 Rev 1

Company Internal

22(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 23

Working Instruction, Electrical

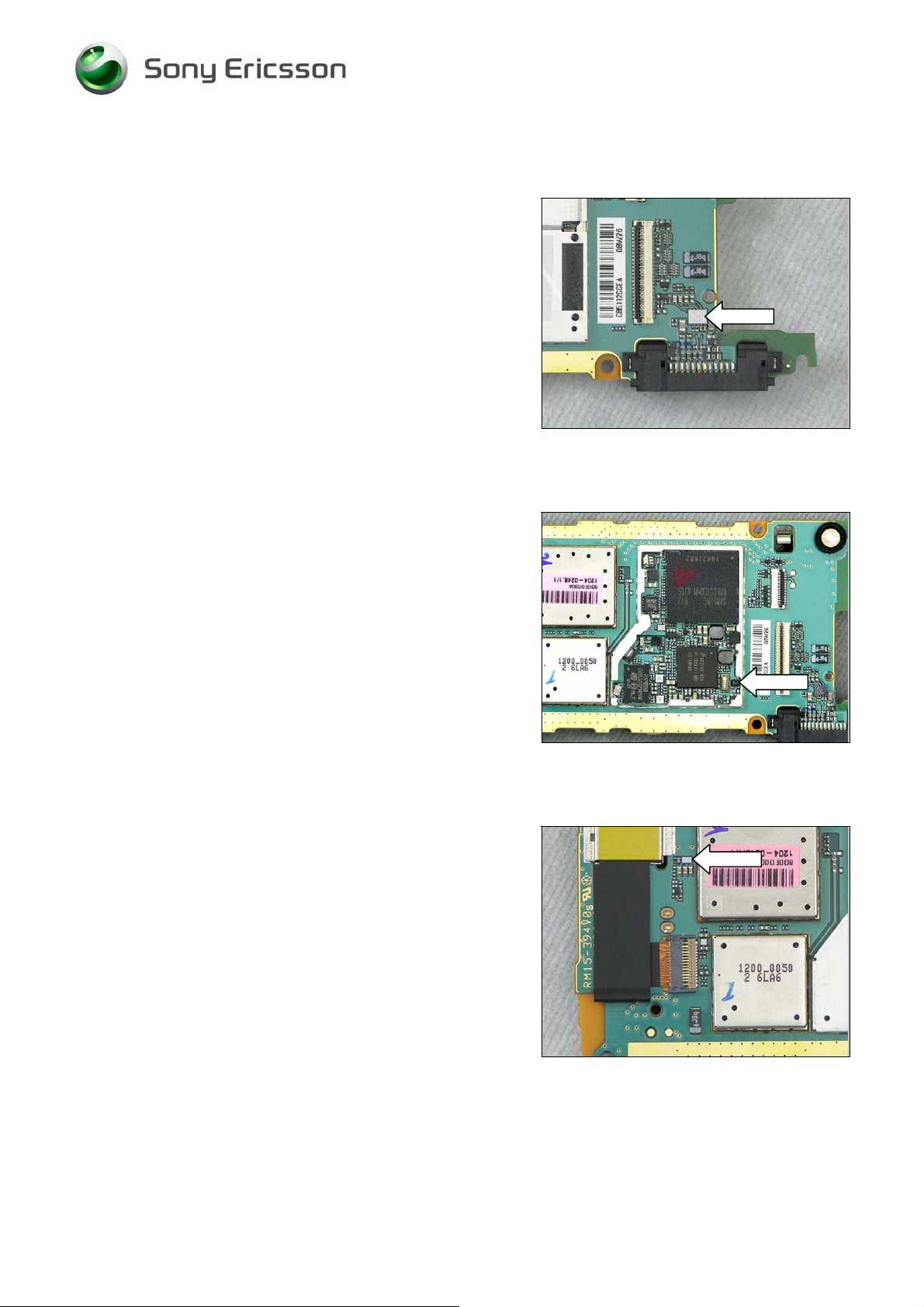

6.38 X2400 System Connector

Remove the Connector with a soldering iron or hot air

soldering equipment.

Mount the new Connector with a soldering iron.

6.39 X2410 MS Connector

Protect the SIM connector with heat resisting tape.

Remove the Connector with hot air soldering equipment.

Use BGA soldering equipment to replace the Connector.

6.40 X2420 SIM Connector

Remove the SIM Connector with hot air soldering

equipment.

Replace a new Connector with a soldering iron or BGA

equipment.

1215-7375 Rev 1

Company Internal

23(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 24

Working Instruction, Electrical

6.41 X2430 Connector FPC 25p

Protect the Connector FPC 51p with heat resisting tape.

Remove the Connector with hot air soldering equipment.

Replace a new Connector with a soldering iron. Bottom

heat is required.

6.42 X4200 Connector FPC 51p

Protect the Connector FPC 25p and the System

connector with heat resisting tape.

Remove the Connector with hot air soldering equipment.

Replace a new Connector with a soldering iron. Bottom

heat is required.

6.43 X4300 Connector FPC 26p

Disassembly the Camera.

Remove the Connector with hot air soldering equipment.

Replace a new Connector with a soldering iron. Bottom

heat is required.

Reassembly the Camera.

1215-7375 Rev 1

Company Internal

24(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 25

Working Instruction, Electrical

6.44 Z4200 - Z4203 LC Filter

Protect the ZIF Connector with heat resisting tape.

Replace the Filter with a soldering iron or hot air soldering

equipment.

1215-7375 Rev 1

Company Internal

25(26)

© Sony Ericsson Mobile Communi cat i ons AB

Page 26

Working Instruction, Electrical

7 Revision History

Rev. Date Changes / Comments

1 2008-09-26 First release

1215-7375 Rev 1

Company Internal

26(26)

© Sony Ericsson Mobile Communi cat i ons AB

Loading...

Loading...