Page 1

Working Instruction, Electrical

Working Instruction, Electrical

Applicable for V800/ 802se

INDEX

1 LEAD FREE SOLDERING..........................................................................................................................................2

1.1 INTRODUCTION.........................................................................................................................................................2

1.1.1 Environment.....................................................................................................................................................2

1.1.2 Soldering temperature .....................................................................................................................................3

2 BGA EQUIPMENT REFLOW PROFILES ...............................................................................................................5

2.1 TEMPERATURE MEASUREMENT ................................................................................................................................5

2.1.1 Reflow Profiles ................................................................................................................................................6

3 REPLACEMENT OF PARTS......................................................................................................................................7

3.1 EQUIPMENT ..............................................................................................................................................................7

3.2 INSTRUCTION HOW REPLACING PARTS ......................................................................................................................7

3.2.1 External Antenna Connector ...........................................................................................................................8

3.2.2 30 PIN BTB Female Connector, behind the System Connector.......................................................................8

3.2.3 30 PIN BTB Female Connector.......................................................................................................................9

3.2.4 50 PIN BTB Female Connector.......................................................................................................................9

3.2.5 Battery Connector..........................................................................................................................................10

3.2.6 USB Connector ..............................................................................................................................................10

3.2.7 MS Duo and SIM Reader...............................................................................................................................11

3.2.8 Hall Element..................................................................................................................................................11

3.2.9 IrDa Module ..................................................................................................................................................12

3.2.10 Coax Connector.............................................................................................................................................12

4 REVISION HISTORY................................................................................................................................................13

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

Approved according to 000 21-LXE 107 42/1

Page 2

Working Instruction, Electrical

1 Lead free soldering

In this chapter there is an introduction that will explain what is important to think about when

working with the product.

1.1 Introduction

This products soldering process is lead-free. It is important that all contact surfaces are kept

clean from dirt and hand-grease. During electrical repair, it is critical to make sure that no

lead is introduced.

1.1.1 Environment

The introduction of the environment is as follow:

Information text

1 This symbol indicates that the product is lead

free.

2 All lead free PCB will be marked with this

symbol, according to the arrow.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

2(13)

Page 3

Working Instruction, Electrical

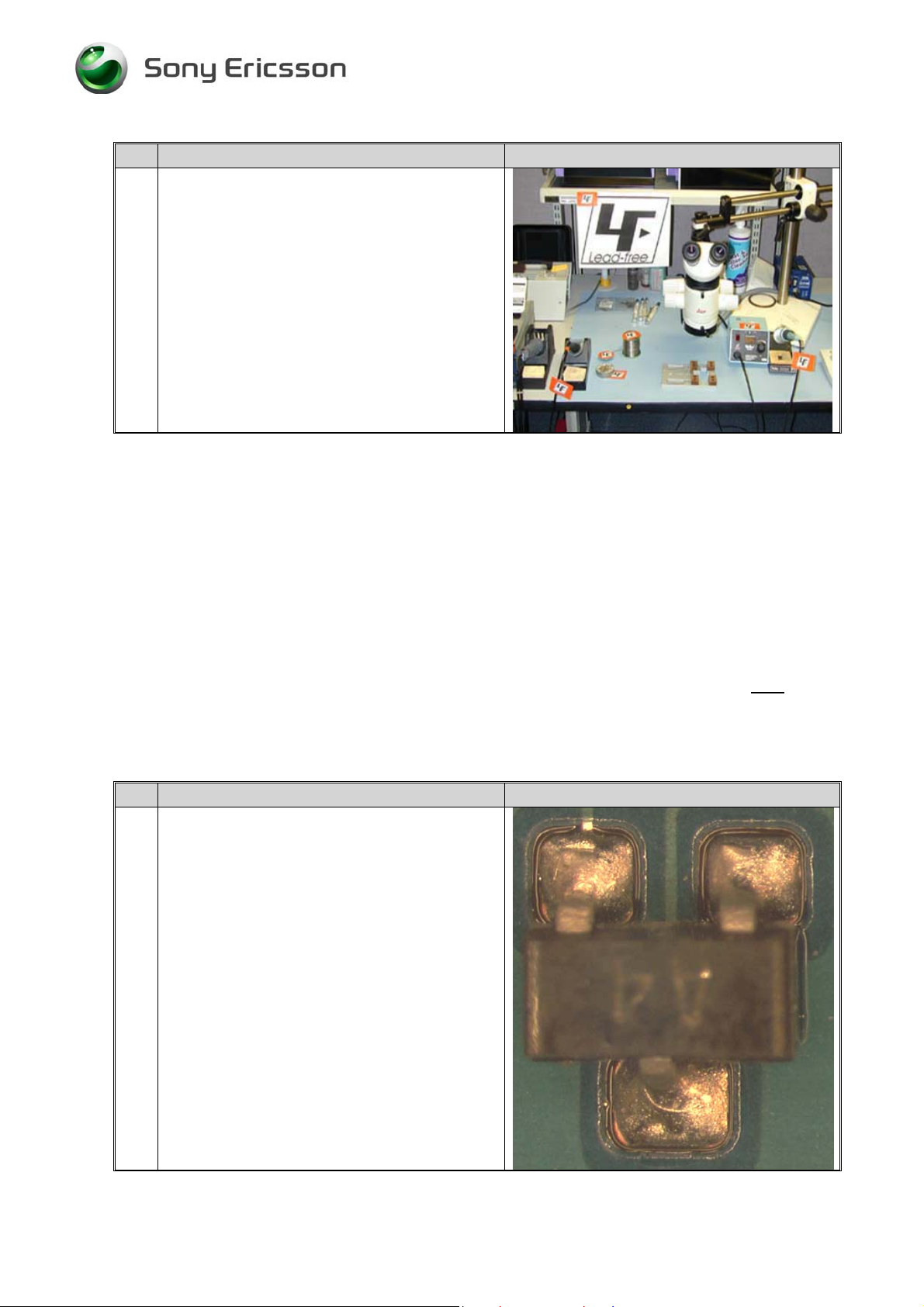

Information text

3 A lead free work area must be set up that is

completely separated from work areas that are

used to make leaded repairs.

The lead-free work area must also be clearly

marked with the lead free symbol as shown in

the figure beside.

The items in this table must remain lead free.

They must be adequately marked to make their

lead free status clearly and easily recognized.

1.1.2 Soldering temperature

The characteristics of Lead Free Solder paste is:

• High melting point (Typically 220°C)

• Low wet ability

• High surface tension

• Difficult to spread

Recommended tip temperature 370°C

When servicing PCB´s that is produced with Lead Free Solder paste this paste must

Otherwise there is a high risk for unreliable soldering joints.

A smaller introduction of the solder temperature, with pictures, is as follow:

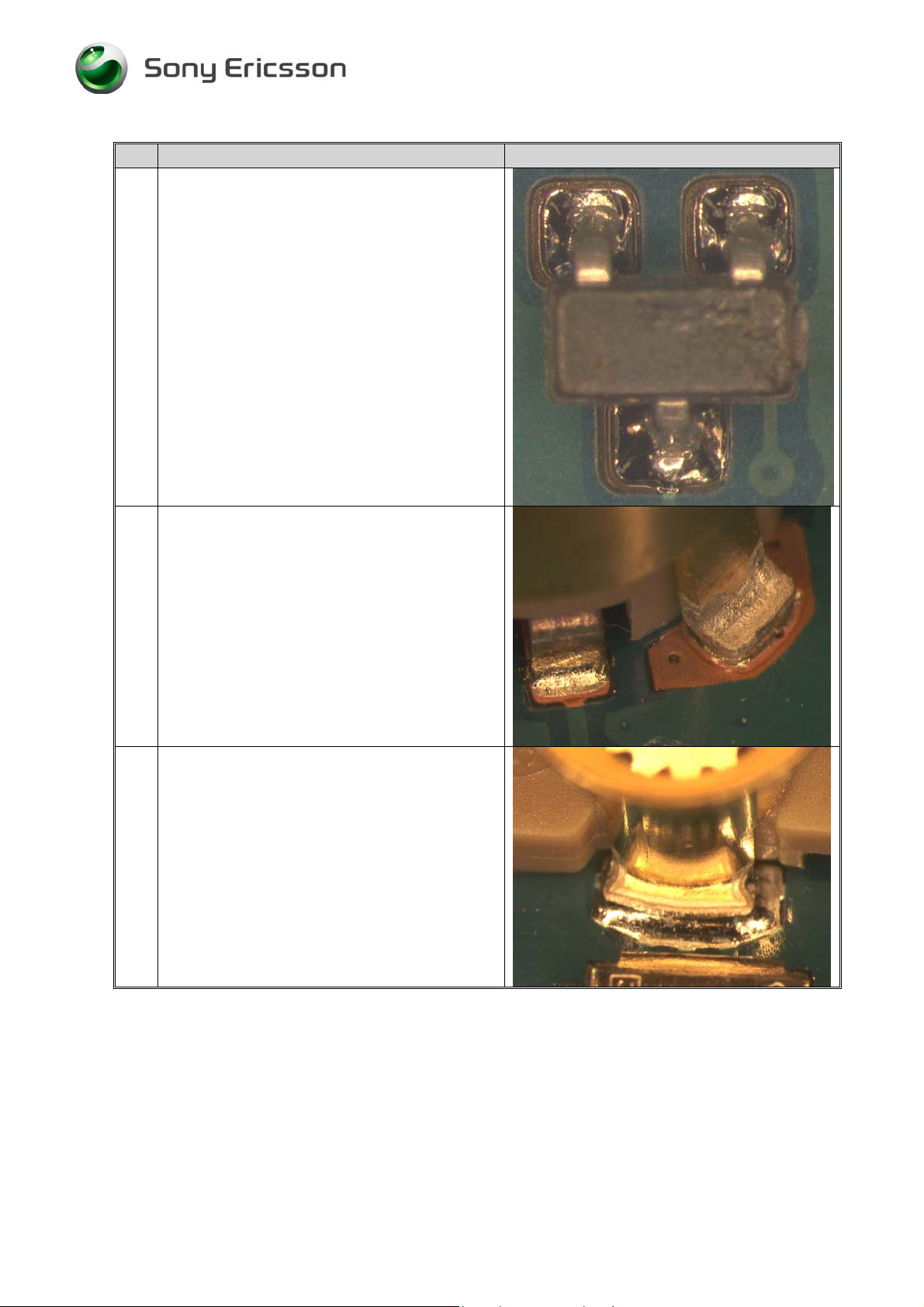

Information text

1 Lead Free Solder joints are more difficult to

inspect because they do not have shiny surfaces

like leaded solders joints.

Lead Free Solder does not flow as well as

leaded solder. Some of the solder pad area may

remain exposed.

The picture shows an example of Lead Free

Solders joints.

be used.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

3(13)

Page 4

Working Instruction, Electrical

Information text

2 The picture shows an example of solder joints

with lead.

3 The picture shows an example of lead free

solder joints.

4 The picture shows an example of solder joints

with lead.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

4(13)

Page 5

Working Instruction, Electrical

2 BGA Equipment reflow profiles

This chapter contains recommendations for reflow profile for mobile phones and similar

products. This is only general recommendation and considerations have to be taken for every

single product. The solder paste is secondary but could also affect the parameters.

In this document one alloy is specified:

SnAgCu (Lead free) melting point 217°C

2.1 Temperature measurement

At least 4 probes should be used:

They should be placed on components with the highest and lowest thermal mass.

They shall be located in the beginning, in the middle and at the end of the board/panel.

They are recommended to be soldered on the board but glue and capton tape could also be

used if necessary.

At least one probe shall be placed in the air or on top of a component.

These values are strongly depending on the BGA replacement equipment.

Nozzle type will be chosen after the outer size of the actual component. Make sure the nozzle

does not affect any near placed components.

NOTE:

These values are recommendations and may have to be changed depending on the type of

equipment.

The maximum temperature for any component must not exceed 250C.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

5(13)

Page 6

Working Instruction, Electrical

2.1.1 Reflow Profiles

Sn/Ag/Cu (Lead free)

290

250

200

150

Temperature [ºC]

100

50

0

Preheat zone

Reflow zone

Cooling zone

40 80 120 160 200 240 280

Time [Seconds]

260°C

245°C

235°C

Ramp rate < 4°C/sec

Ramp rate cooling zone < 6°C/sec

Time above liquids 60-150 sec

Minimum temperature 235°C

Maximum temperature 245°C or 260°C* for 10 sec

Total time Appr. 4-7 min

* The higher temperature in case the board has extremely high ∆T.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

6(13)

Page 7

Working Instruction, Electrical

3 Replacement of parts

In this chapter there is an introduction that explains what equipment to use when replacing

parts in the product and also how to replace these parts. When doing these replacing

procedures it is important it is important that all contact surfaces are kept clean from dirt and

hand-grease.

3.1 Equipment

The list of equipment to use is as follow:

Dentist hook •

•

ESD-gloves (cotton gloves)

•

ESD-wristband

•

Soldering tool

•

Hot air soldering station

•

BGA replacement equipment

•

Pair of tweezers

•

Solder cleaning wiper (Tin wick)

•

Solder paste Lead free (SN 96% Ag 3.5% Cu 0.5%) Use the soldering tip only for lead

free solder paste.

•

Flux, RMA No-clean flux

•

Cutting pliers

•

Shield fence pliers NTZ 112 537

3.2 Instruction how replacing parts

Before it is possible to replace any of these parts the phone has to be dissembled as described

in Working Instruction 3/00021-2/FEA 209 544/88 PA1

After the part is replaced it is important to assemble the phone according to the Working

Instruction 3/00021-2/FEA 209 544/88 PA1.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

7(13)

Page 8

Working Instruction, Electrical

3.2.1 External Antenna Connector

This is the instruction how to replace the External Antenna Connector:

Step-by-Step Instructions

1 Use BGA Repair Equipment to replace the

Antenna Connector, which is located accordig to

the arrow.

3.2.2 30 PIN BTB Female Connector, behind the System Connector

This is the instruction how to replace the 30 PIN BTB Female Connector:

Step-by-Step Instructions

1 NOTE!

The 30 PIN BTB Female Connector is located

behind the System Connector, according to the

arrow (1).

Remove the System Connector.

NOTE!

The Light Gasket is located according to the

arrow (2).

Be careful not to damage other components.

Use a dentist hook to remove the Light Gasket.

Clean the surface with Isopropyl alcohol.

Use BGA Repair Equipment to replace the

Antenna 30 PIN BTB Female Connector to the

right position, according to the arrow (3).

Apply a new Sealing Gasket.

2

3

1

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

8(13)

Page 9

Working Instruction, Electrical

3.2.3 30 PIN BTB Female Connector

This is the instruction how to replace the 30 PIN BTB Female Connector:

Step-by-Step Instructions

1 NOTE!

The Sealing Gasket is located according to the

arrow (1).

Be careful not to damage other components.

Use a dentist hook to remove the Sealing

Gasket.

Clean the surface with Isopropyl alcohol.

Use the BGA Repair Equipment to replace the

antenna 30 PIN BTB Female Connector to the

right position, according to the arrow (2).

Apply a new Sealing Gasket.

1

2

3.2.4 50 PIN BTB Female Connector

This is the instruction how to replace the 50 PIN BTB Female Connector:

Step-by-Step Instructions

1 NOTE!

The Sealing Gasket is located according to the

arrow (1).

Be careful not to damage other components.

Usa a dentist hook to remove the Sealing

Gasket.

Clean the surface with Isopropyl alcohol.

Use the BGA Repair Equipment to replace the

antenna 30 PIN BTB Female Connector to the

right position, according to the arrow (2).

Apply a new Sealing Gasket.

1

2

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

9(13)

Page 10

Working Instruction, Electrical

3.2.5 Battery Connector

This is the instruction how to replace the Battery Connector:

Step-by-Step Instructions

1 NOTE!

The Battery Connector is located according to

the arrow.

Use BGA Repair Equipment to remove and

assemble a new Battery Connector.

3.2.6 USB Connector

This is the instruction how to replace the USB Connector:

Step-by-Step Instructions

1 NOTE!

The USB Connector is located according to the

arrow.

Use a soldering iron to replace USB Connector.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

10(13)

Page 11

Working Instruction, Electrical

3.2.7 MS Duo and SIM Reader

This is the instruction how to replace the MS Duo and SIM reader:

Step-by-Step Instructions

1 NOTE!

The MS Duo and SIM Reader is located

according to the arrow.

Use a soldering iron replace the MS Duo and

SIM Reader.

3.2.8 Hall Element

This is the instruction how to replace the Hall element:

Step-by-Step Instructions

1 NOTE!

The Hall Element is located according to the

arrow.

Use a soldering iron to replace the Hall Element.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

11(13)

Page 12

Working Instruction, Electrical

3.2.9 IrDa Module

This is the instruction how to replace the IrDa Module:

Step-by-Step Instructions

1 NOTE!

The IrDA Module is located according to the

arrow.

Use a soldering iron to replace the IrDa Module.

3.2.10 Coax Connector

This is the instruction how to replace the Coax Connector:

1 NOTE!

The Coax Connector is located according to the

arrow.

Use a soldering iron to replace the Coax

Connector.

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

12(13)

Page 13

Working Instruction, Electrical

4 Revision History

The list over the revision history is as follows:

Rev. Date Changes / Comments

A 2004-11-17 First Release

B 2004-12-13 Due to system problem

C 2004-12-15 Due to system problem

3/000 21-2/FEA 209544/88 C

Company Internal

Sony Ericsson Mobile Communications AB

13(13)

Loading...

Loading...