Sony ZSM-7 Service manual

ZS-M7

SERVICE MANUAL

Ver 1.2 2001.07

With SUPPLEMENT 1

(9-923-346-82)

Dolby noise reduction manufactured under license from

Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of

Dolby Laboratories Licensing Corporation.

MD

Section

CD

Section

US Model

AEP Model

UK Model

Tourist Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-3EG

Optical Pick-up Type KMS-260A

Model Name Using Similar Mechanism NEW

MD Mechanism Type CDM-2411AAA

Optical Pick-up Type DAX-11A

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

With 4-ohm loads, both channels driven from 100 – 10,000 Hz ; rated 7W

per channel-minimum RMS power, with no more

than 10% total harmonic distortion in AC operation (US Model).

CD player Section

System Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wave length: 785 nm

Emission duration : Continuous

Laser output : Less than 44.6 µW

(This output is the value measured at a distance of about 200

mm from the objective lens surface on the optical pick-up

block with 7 mm aperture.)

Spindle speed

200 r/min (rpm) to 500 r/min (rpm) (CLV)

Number of programme positions

2

Frequency response

20 – 20,000 Hz +1 /–2 dB

Wow and flutter

Below measurable limit

Radio section

Frequency range

US Model :

FM : 87.6 – 108 MHz

AM: 530 – 1,710 kHz

EXCEPT US Model :

FM : 87.6 – 107 MHz

MW : 531 – 1,602 kHz

LW : 153 – 279 kHz

IF FM : 10.7 MHz

MW/LW : 450 kHz

Aerials FM : Telescopic areal

Extension areal terminal

AM : Extension areal terminals (US Model)

MW/LW : Extension areal terminals (EXCEPT US Model)

MD player section

System

Minidisc digital audio system

Disc MiniDisc

Laser diode properties

Material: GaAlAs

Wave length: 785 nm

Emission duration : Continuous

Laser output : Less than 44.6 µW

(This output is the value measured at a distance of about 200

mm from the objective lens surface on the optical pick-up

block with 7 mm aperture.)

– Continued on page 2 –

PERSONAL MINIDISC SYSTEM

9-923-346-12

2001G0200-1

© 2001.7

Sony Corporation

Personal Audio Company

Shinagawa Tec Service Manual Production Group

Recording/Playback time

Maximum 74 minutes (with MDW-74)

Revolutions

400 rpm to 900 rpm (CLV)

Error correction

Advanced Cross Interleave Reed Solomon Code (ACIRC)

Sampling frequency

44.1 kHz

Cording Adaptive Transform Acoustic Cording (ATRAC)

Modulation system

EFM (Eight-to-Fourteen Modulation)

Number of programme positions

2 stereo programme positions

Frequency response

20 – 20,000 Hz +1 /–2 dB

Signal-to-noise ratio

Over 80 dB (during playback)

Wow and flutter

Below measurable limit

General

Speaker

Full range : 8 cm (3 in.) dia., 4ohms, cone type (2)

Inputs

LINE IN (stereo minijack) : Sensitivity 436 mV/691 mV

Outputs

Headphones jack (stereo minijack) (2) : For 32 ohms

impedance headphones

Power outputs

7 W + 7 W

Power requirements

For personal minidisc system :

US Model :120V AC, 60Hz

EXCEPT US Model :230V AC, 50Hz

For remote commander :

3V DC, 2 size AA (R6) batteries

Power consumption

30 W

Dimensions (incl. projecting parts)

Approx. 528 x 275 x 139 mm (w/h/d)

(20 7/8 x 10 7/8 x 5 1/2 inches)

Mass approx. 6.4 kg (14 lb. 2 oz)

Supplied accessories

Remote commander (1)

AM loop aerial (1) (US Model)

MW/LW loop aerial (1) (EXCEPT US Model)

Speaker nets (2) (EXCEPT US Model)

Design and specifications are subject to change without notice.

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICE NOTE........................................................... 3

2. GENERAL...................................................................... 5

3. DISASSEMBLY

3-1. Cabinet (Front) ASSY, Cabinet (Rear) ASSY .......... 21

3-2. Left Key Board, Front Key Board, Top Key board,

Right Key Board, Relay Board ................................. 22

3-3. FL Board, Trans Board ............................................. 22

3-4. Tuner Board, FM ANT Board, AM ANT Board....... 23

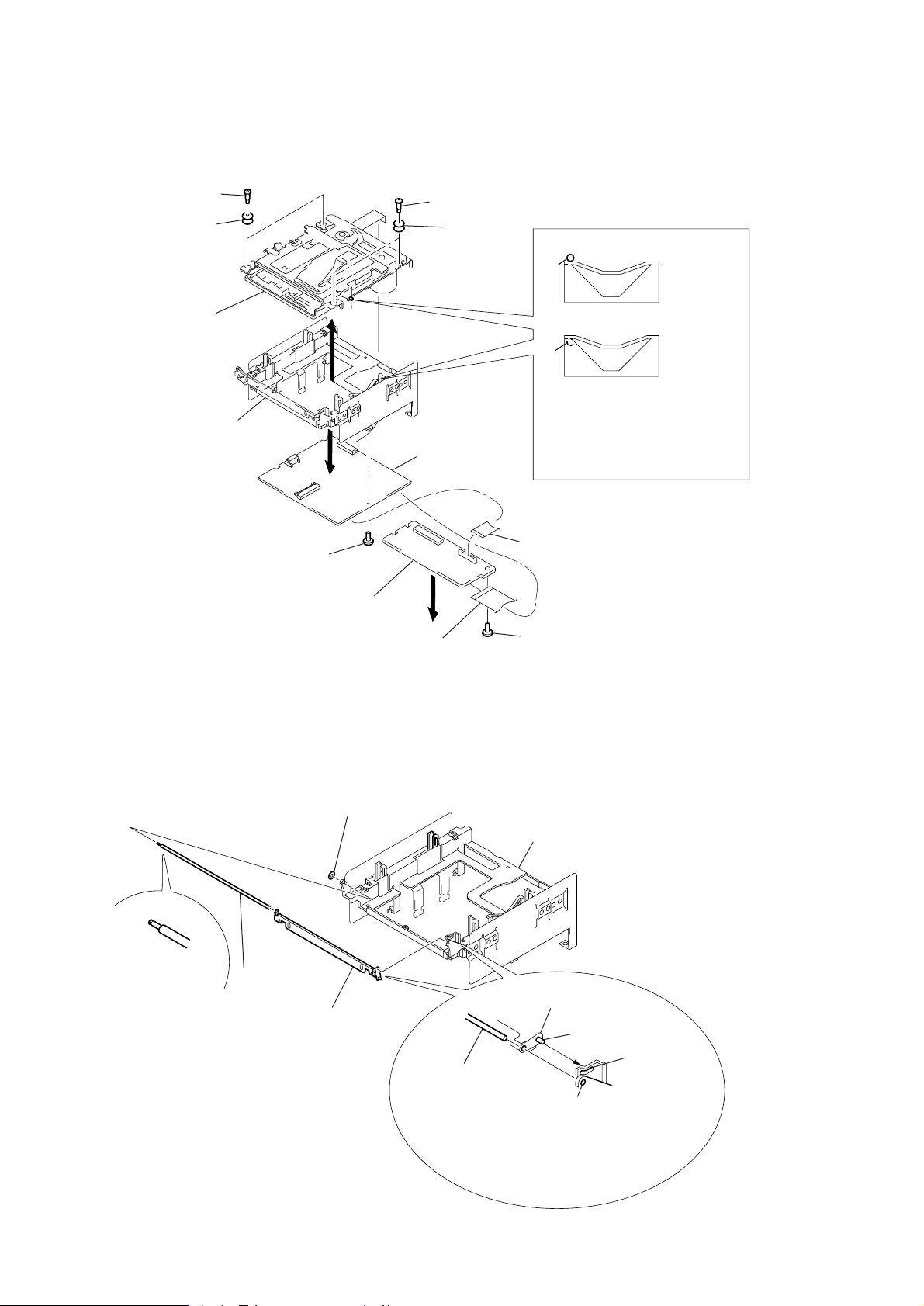

3-5. MD Chassis ASSY ................................................... 23

3-6. MD Block ASSY, Filter Board ................................. 24

3-7. Audio Board, HP Board, Line in Board.................... 24

3-8. Main Board, CD Block ASSY.................................. 25

3-9. Shield Case (Top), Shield Case (Bottom)................. 25

3-10. DG Board, BD Board, MD Mechanism Deck........ 26

3-11. Shutter ASSY.......................................................... 26

3-12. SW Board ............................................................... 27

3-13. Slider ASSY, “Head, Over Write” .......................... 27

3-14. MD Optical Pick-up Block ..................................... 28

3-15. Loading Board, “Tray ASSY, CD” ......................... 29

3-16. CD Optical Pick-up Block, Pick-up Relay Board .. 29

4. TEST MODE

4-1. Caution When Using the Test Mode......................... 30

4-2. Test Mode Settings ................................................... 30

4-3. Releasing the Test Mode........................................... 30

4-4. Basic Operations of the Test Mode........................... 30

4-5. Selecting the Test Mode............................................ 30

4-6. Functions of Other Buttons ...................................... 31

4-7 Test Mode Display ..................................................... 31

5. ADJUSTMENTS

5-1. Cautions When Checking Laser Diode Emission..... 32

5-2. Cautions When Handling

the Optical Pick-up (KSM-260A) ............................ 32

5-3. Cautions During Adjustment .................................... 32

5-4. Creating a Continuous Recording Disk .................... 32

5-5. Temperature Compensation Offset Adjustment........ 33

5-6. Laser Power Adjustment........................................... 33

5-7. Trav erse Adjustment ................................................. 33

5-8. Focus Bias Adjustment ............................................. 34

5-9. Error Rate Check ...................................................... 35

5-10. Focus Bias Check ................................................... 35

5-11. Adjustment and Connection Locations................... 35

6. DIAGRAMS

6-1. Explanation of IC Terminals..................................... 39

6-2. Block Diagram (1) .................................................... 46

6-3. Block Diagram (2) .................................................... 49

6-4. Printed Wiring Boards –Main Section –................... 55

6-5. Schematic Diagram –Main Section (1/2) – .............. 59

6-6. Schematic Diagram –Main Section (2/2) – .............. 63

6-7. Printed Wiring Boards

–Tuner Section (US Model) –.................................. 67

6-8. Schematic Diagram

–Tuner Section (US Model) –................................... 69

6-9. Printed Wiring Boards

–Tuner Section (EXCEPT US Model) –................... 72

6-10. Schematic Diagram

–Tuner Section (EXCEPT US Model) –.................. 74

6-11. Schematic Diagram –BD Section – ........................ 77

6-12. Printed Wiring Boards –BD Section –.................... 79

6-13. Schematic Diagram –Power Section – ................... 82

6-14. Printed Wiring Boards –Power Section – ............... 85

6-15. Schematic Diagram –DG Section –........................ 87

6-16. Printed Wiring Boards –DG Section – ................... 90

6-17. Printed Wiring Boards –Front Key Section – ......... 93

6-18. Schematic Diagram –Front Key Section – ............. 97

7. EXPLODED VIEWS

7-1. Front Cabinet Section ............................................. 106

7-2. Rear Cabinet Section .............................................. 107

7-3. Chassis Section ....................................................... 108

7-4. MD Section (1) ....................................................... 109

7-5. MD Section (2) ........................................................110

7-6. CD Section...............................................................111

7-7. Optical Pick-up Section ...........................................112

8. ELECTRICAL PARTS LIST..................................113

– 2 –

SAFETY CHECK-OUT (US Model)

SECTION 1

SER VICE NOTE

After correcting the original service problem, perform the following safety check before releasing the set to the customer :

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

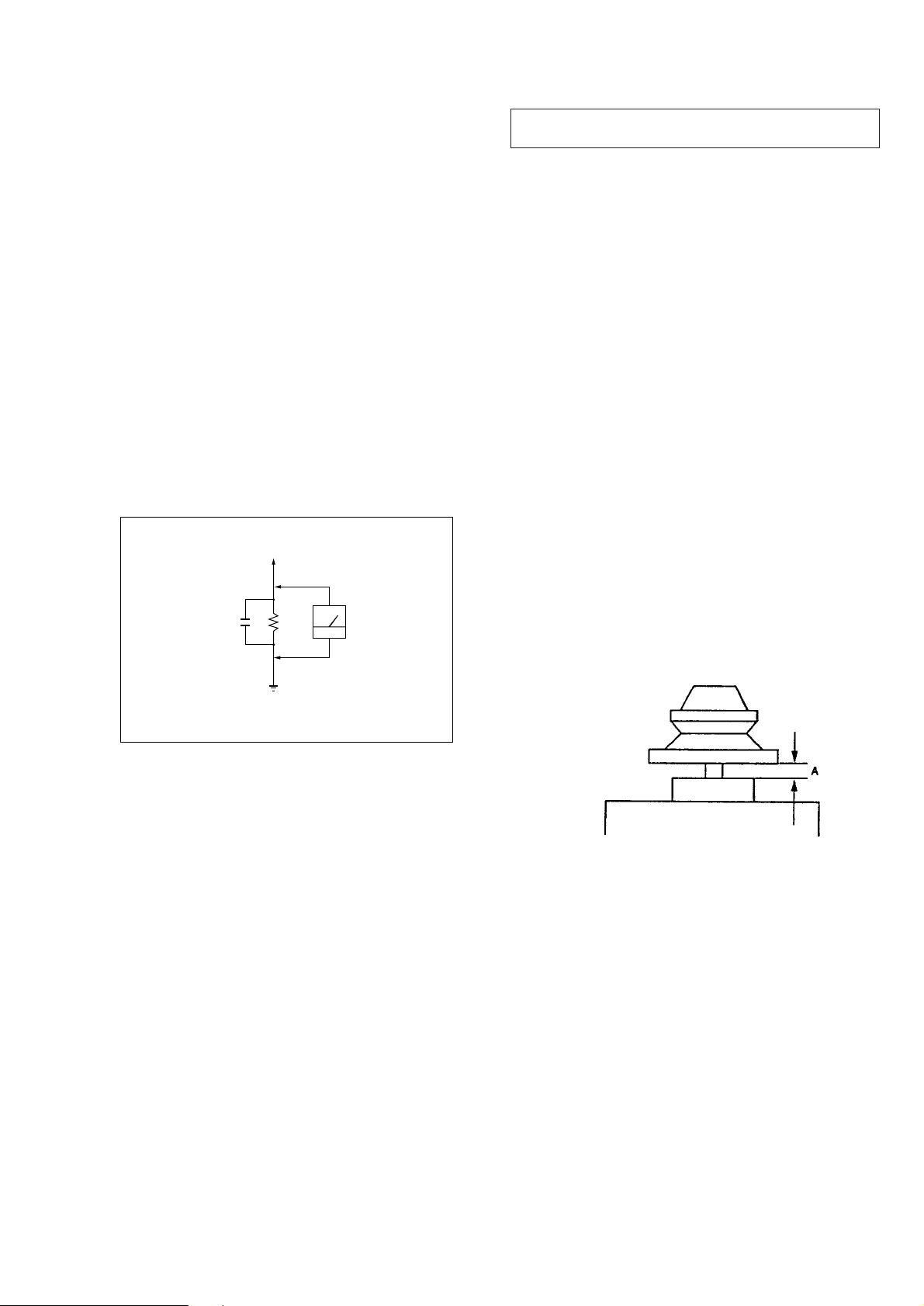

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated A C voltmeter . The “limit” indication is 0.75V,

so analog meters must have an accurate low-voltage scale. The

Simpson 250 and Sanwa SH-63Trd are examples of a passive

VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Close the lid for CD.

2. Press CD ^ button.

3. Confirm the laser diode emission while observing the objecting

lens. When there is no emission, Auto Power Control circuit or

Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

1.5k

0.15

µ

F

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

AC

voltmeter

(0.75V)

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION DURING WHEN MOUNTING THE PULLEY

FOR THE LOADING MOTOR

Make the following adjustment when mounting the loading motor

(part number : 1-698-999-11) and motor pulley (part number : 2627-174-01) of the CD section.

Specification : A = 0.9 to 1.1mm

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 3 –

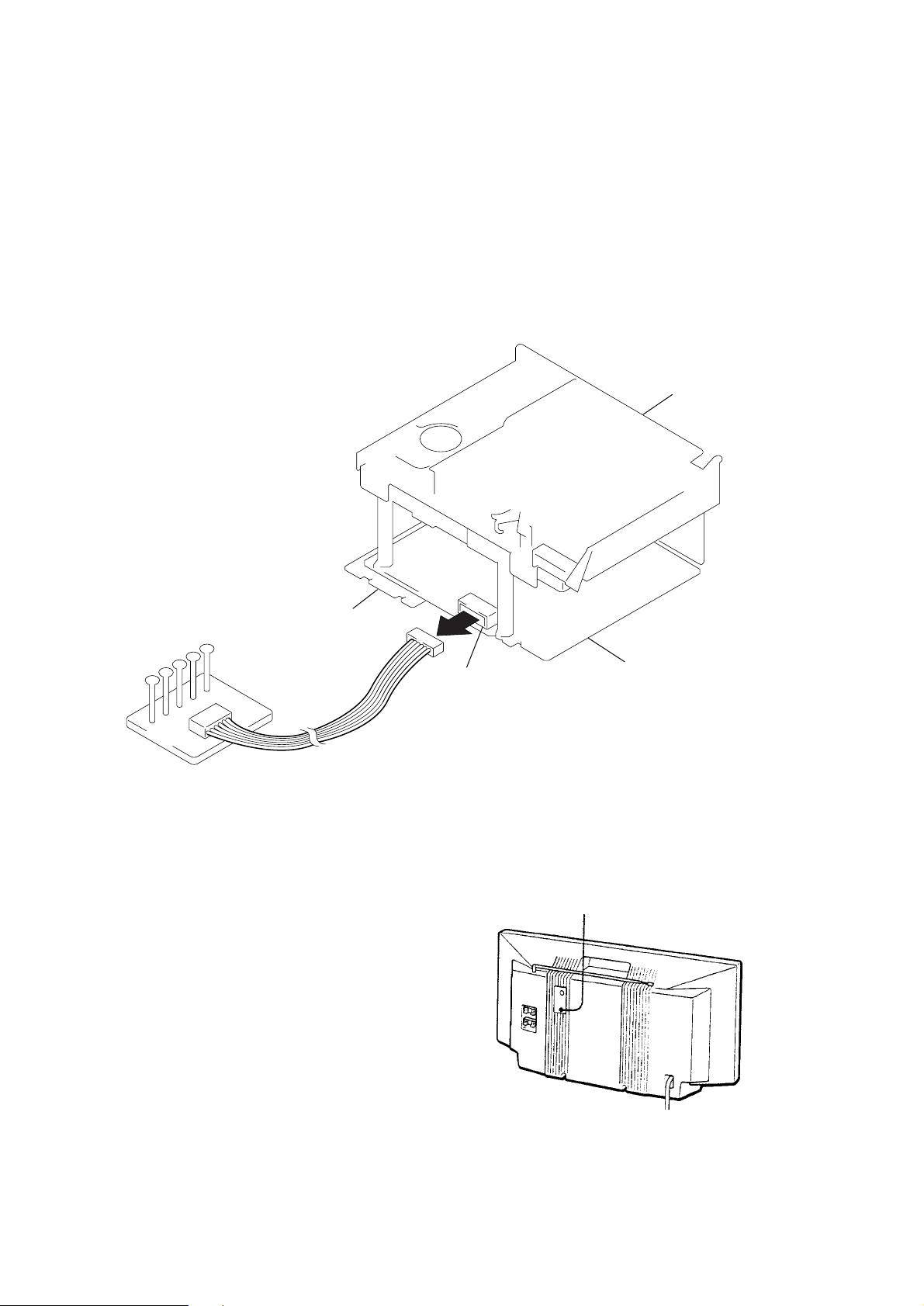

ABOUT THE BD BOARD WAVEFORM CHECKING JIG

The special jig (J-2501-124-A) is highly convenient when checking the waveform of the BD board of the MD section. Pin names

and items to check are as follows:

I+3V : for IOP measurement (check for depleted optical pickup

laser)

IOP : for IOP measurement (check for depleted optical pickup

laser)

TEO : TRK error signal (traverse adjustment)

VC : Standard level for checking signals

RF : RF signal (jitter check)

MD block section

DG board

RF

VC

TEO

IOP

I + 3V

Jig

(J-2501-124-A)

ABOUT THE HARDWARE RESET

It is possible to reset the system microcomputer by pressing the

RESET button located on the rear with a pointed object. Use this

button when the unit cannot be operated properly due to such problems as microcomputer errors, etc.

CN110

BD board

RESET button

– 4 –

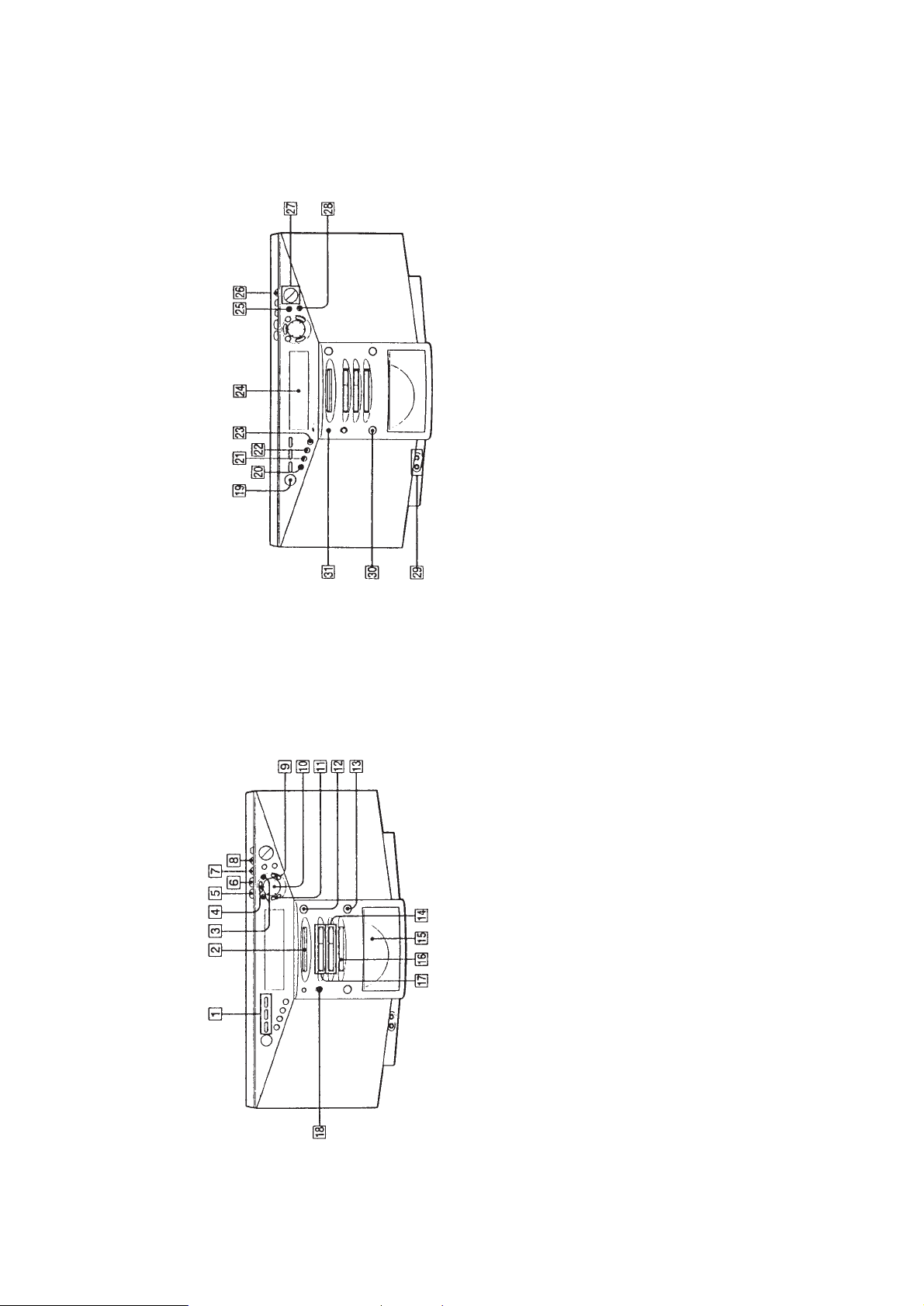

SECTION 2

GENERAL

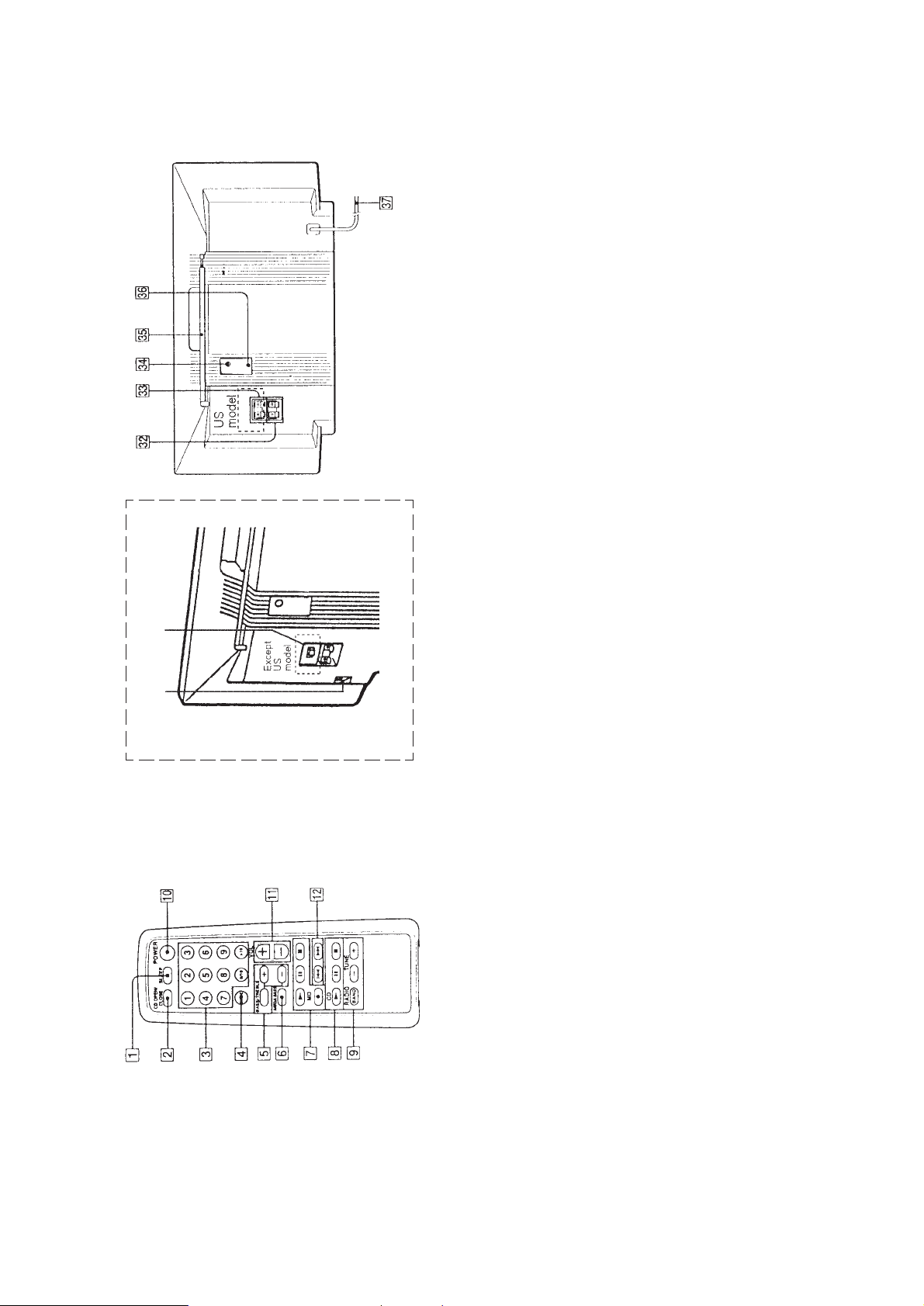

@∞ BASS/TREBLE button

@§ MEGA BASS button

@¶ VOLUM –, + button

@• DISPLAY button

@ª 2 (Headphones) Jack (stereo mini jack)

#º LINE button

#¡ Remote control receiver section

FRONT PANEL : TIMER • COM section

!ª POWER button (US MODEL)

OPERATE button (EXCEPT US MODEL)

@º SLEEP button

@¡ STANDBY button

@™ TIMER button

@£ CLOCK button

@¢ Display window

!¡ CANCEL•NO button

!™ 6 MD EJECT button

!£ 6 CD OPEN/CLOSE button

!¢ CD operation buttons

^ (play/pause)

p (stop)

!∞ CD tray

!§ BAND button

!¶ MD operation button

^ (play/pause)

p (stop)

!• REC button

LOCATION AND FUNCTION OF CONTROLS

FRONT PANEL : RADIO section

– 5 –

1 CD (MD SYNCHRO REC button

DISC ALL

REC IT : TO TOP

TO END

2 MD insert section

3 TUNE–, + • 0, ) •ı, ∫button

4 EDIT button

5 DELETE button

6 INSERT button

7 AUTO PRESET•SHUF/PGM button

8 LINE LEVEL•MONO/ST•REPEAT button

9 ENTER•YES button

!º Jog dial

=/+ AMS

PRESET

#£#•

EXCEPT US Model

#™ AM ANTENNA terminal

MW(LW) ANTENNA terminal

#£ FM EXT ANTENNA terminal (US model)

8 CD operation button

( (play)

P (pause)

ANTENNA SELECTOR switch (Except US model)

#¢ LINE IN (Analog) terminal

#∞ Antenna

#§ RESET button

#¶ Power cord

#• FM EXT ANTENNA terminal (Except US model)

p (stop)

9 Radio operation button

BAND

TUNER –, +

!º POWER button(US MODEL)

OPERATE button (EXCEPT US MODEL)

!¡ VOL +, – button

!™ =, + (AMS/SERCH) button

REMOTE CONTROL REAR PANEL section

– 6 –

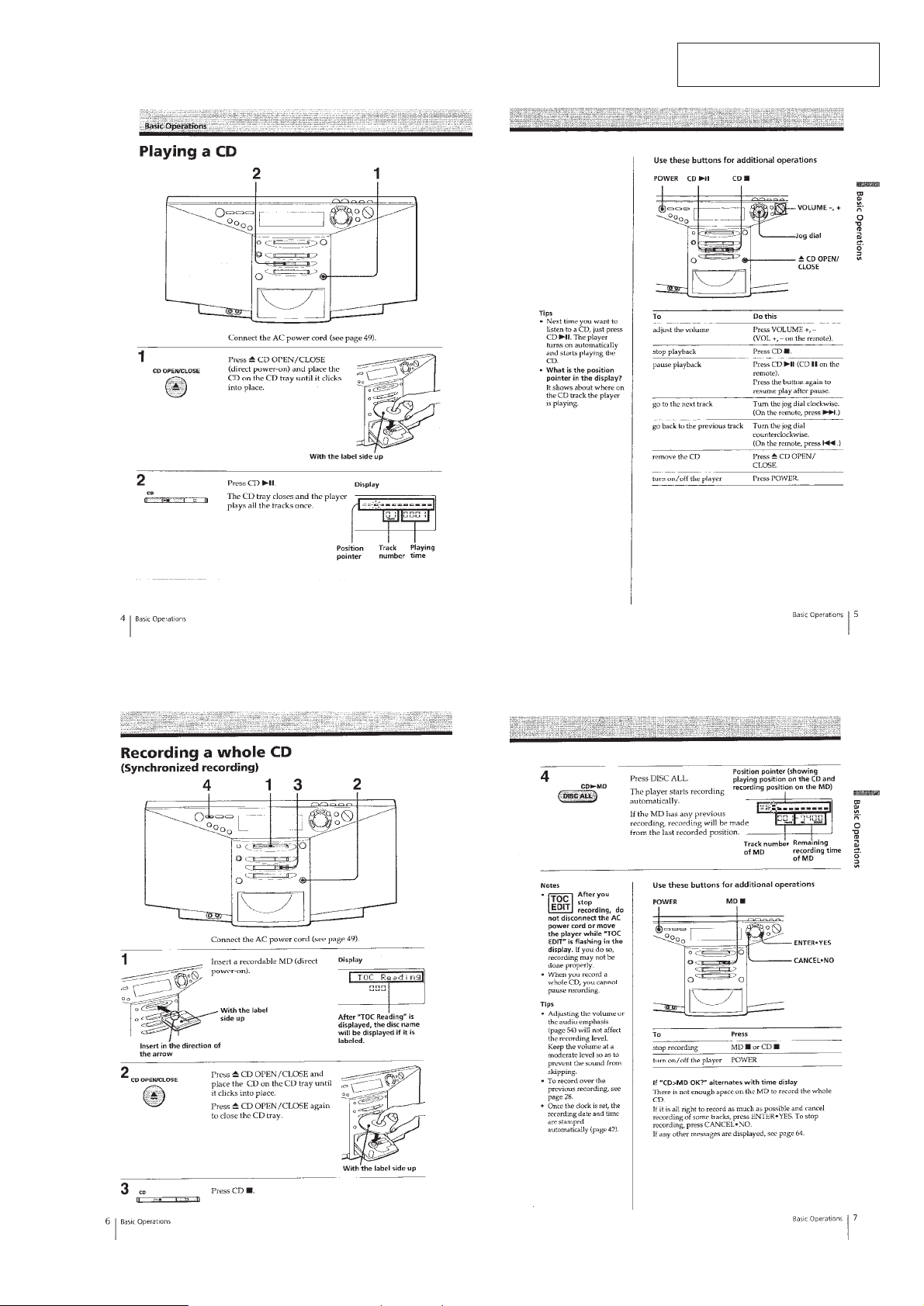

1 SLEEP button

2 CD OPEN/CLOSE button

3 Number button

4 MODE button

5 BASS/TREBLE+, – button

6 MEGA BASS button

7 MD operation button

( (play)

P (pause)

p (stop)

r (REC)

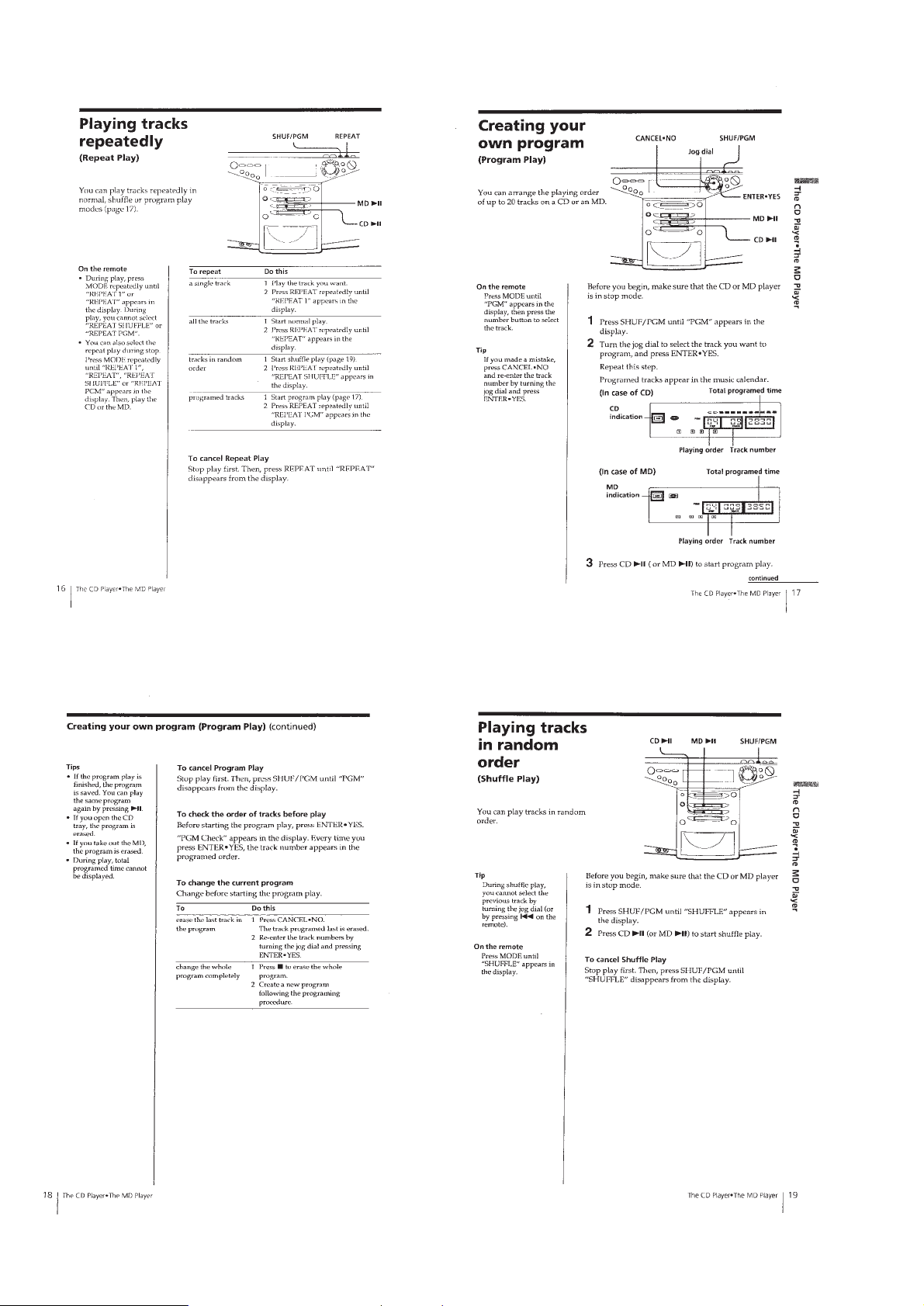

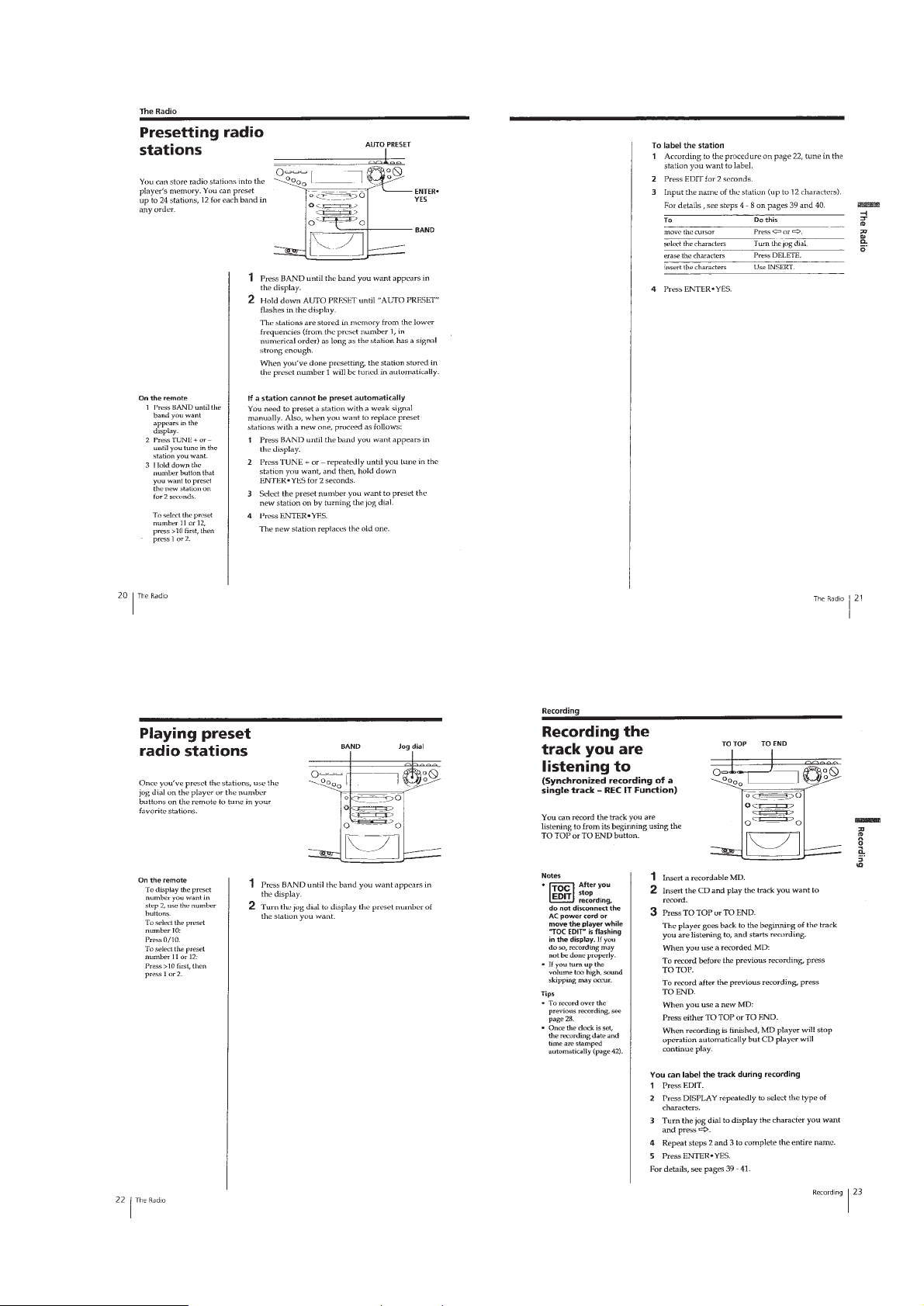

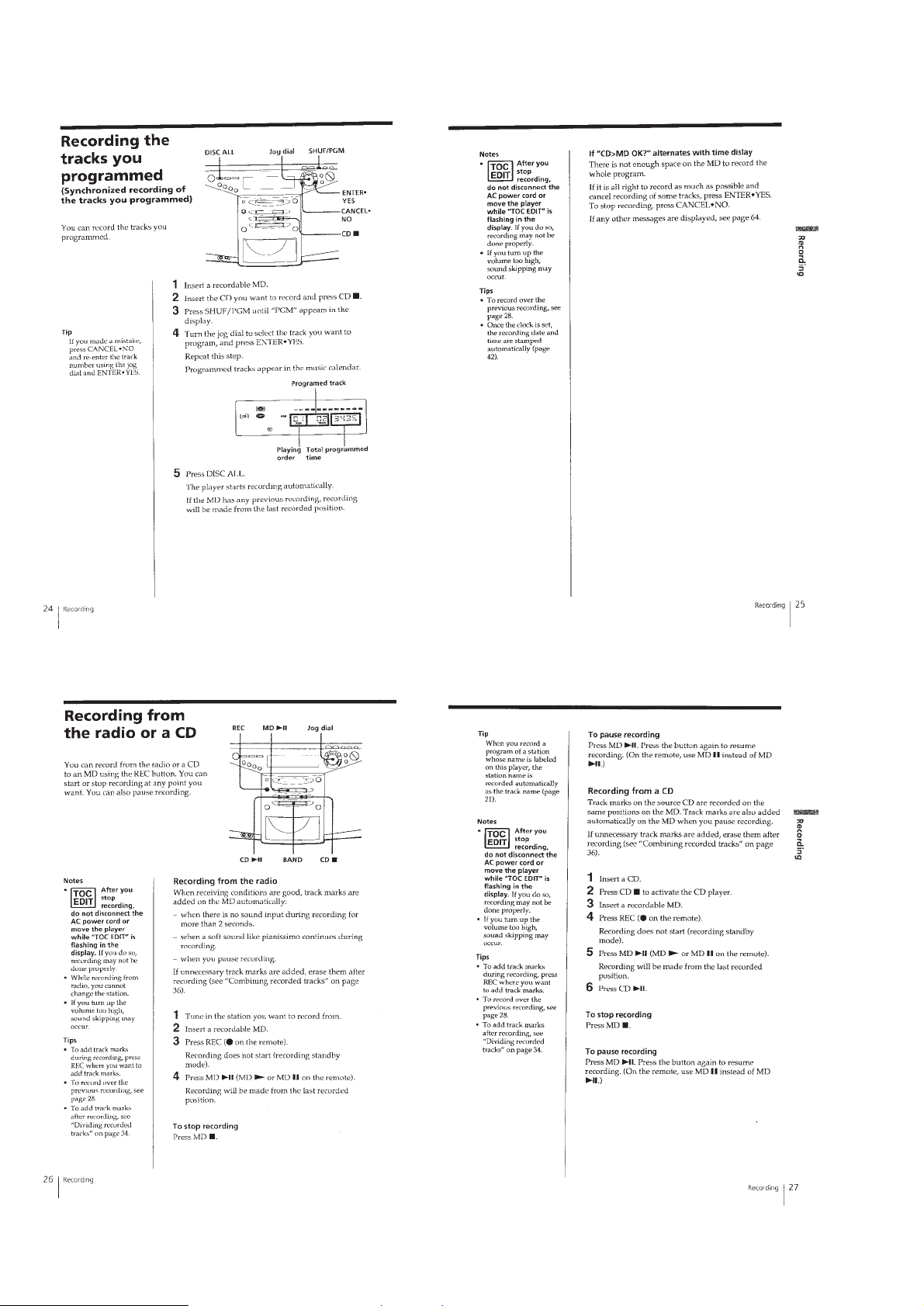

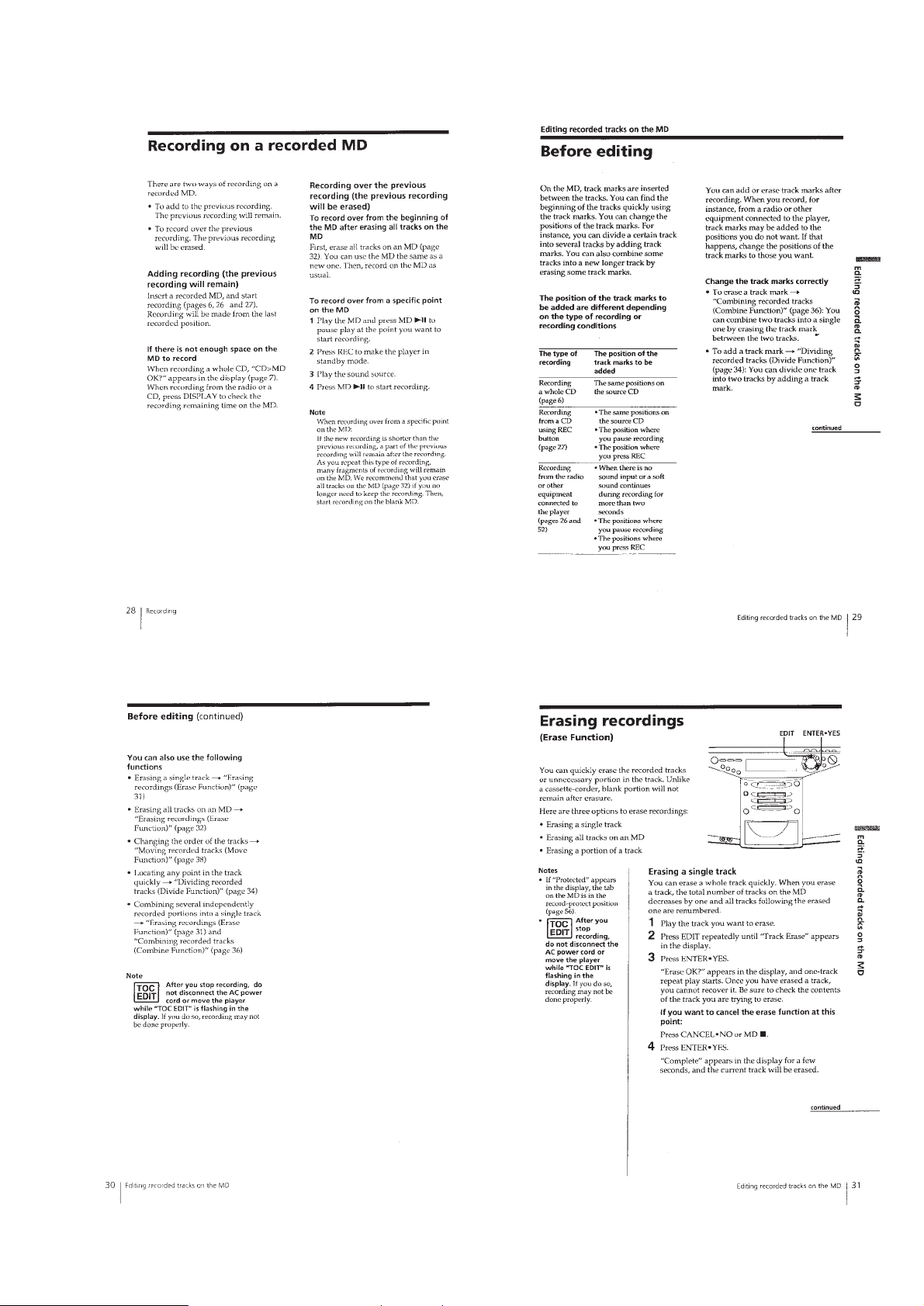

This section is extracted from

instruction manual.

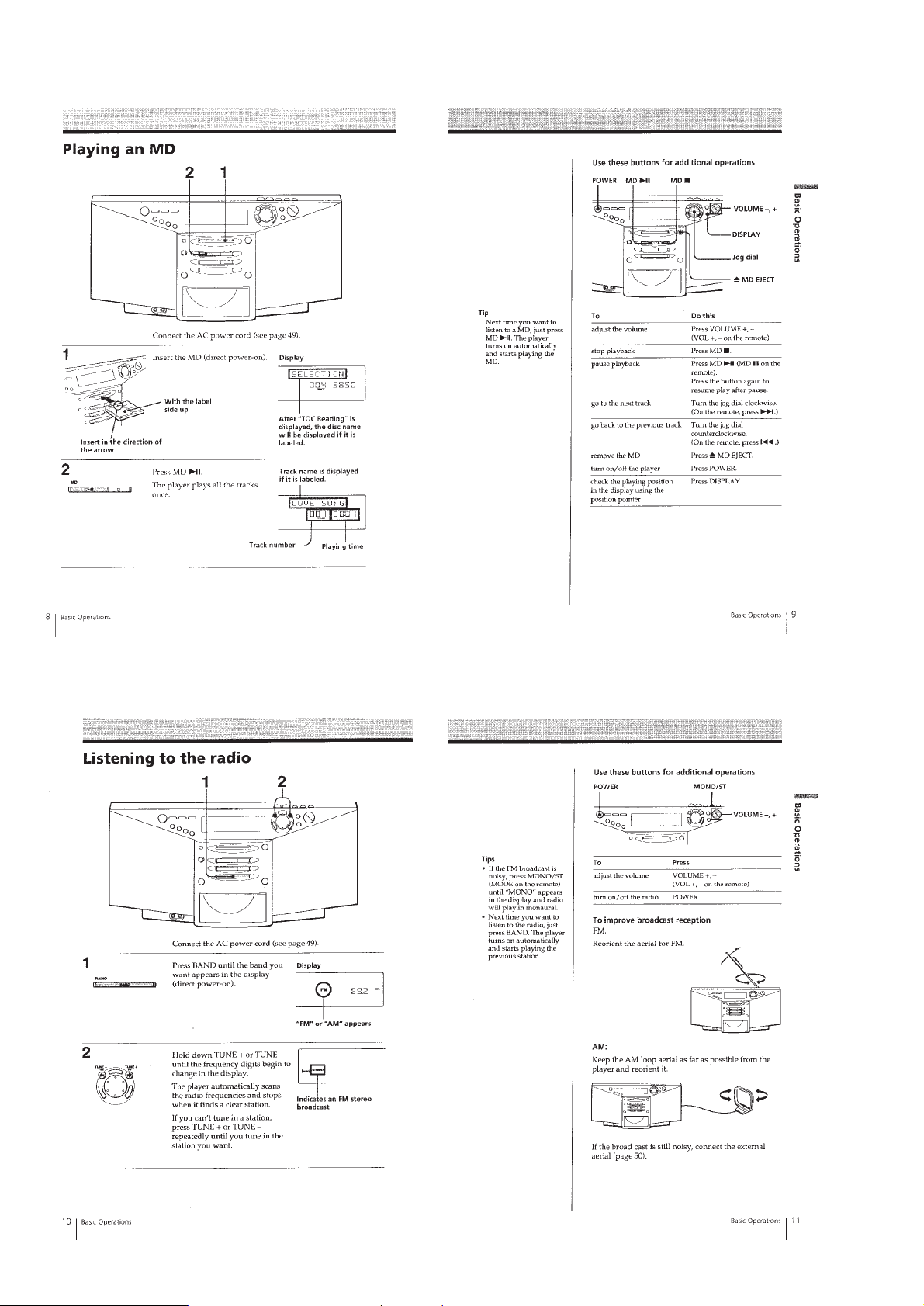

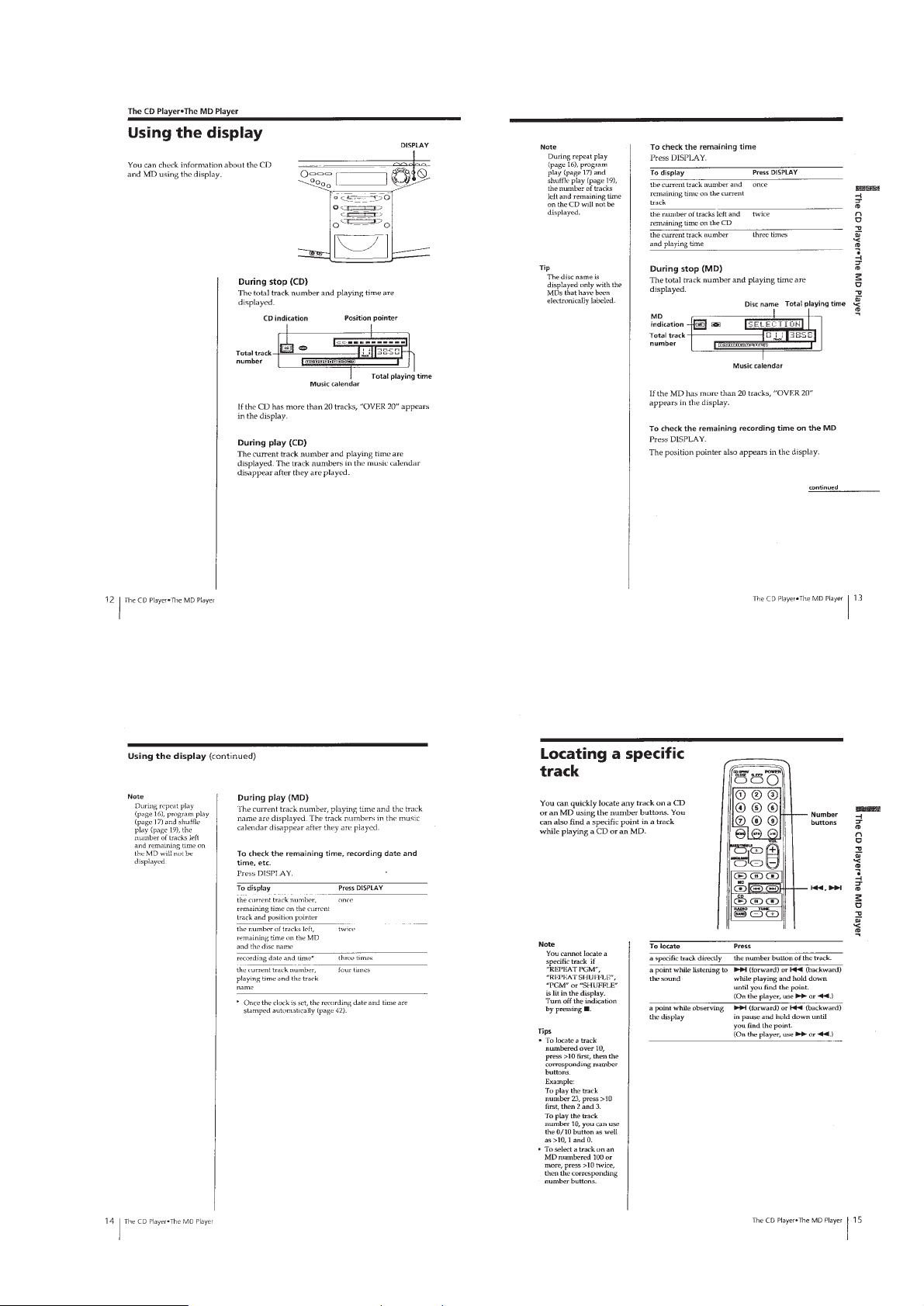

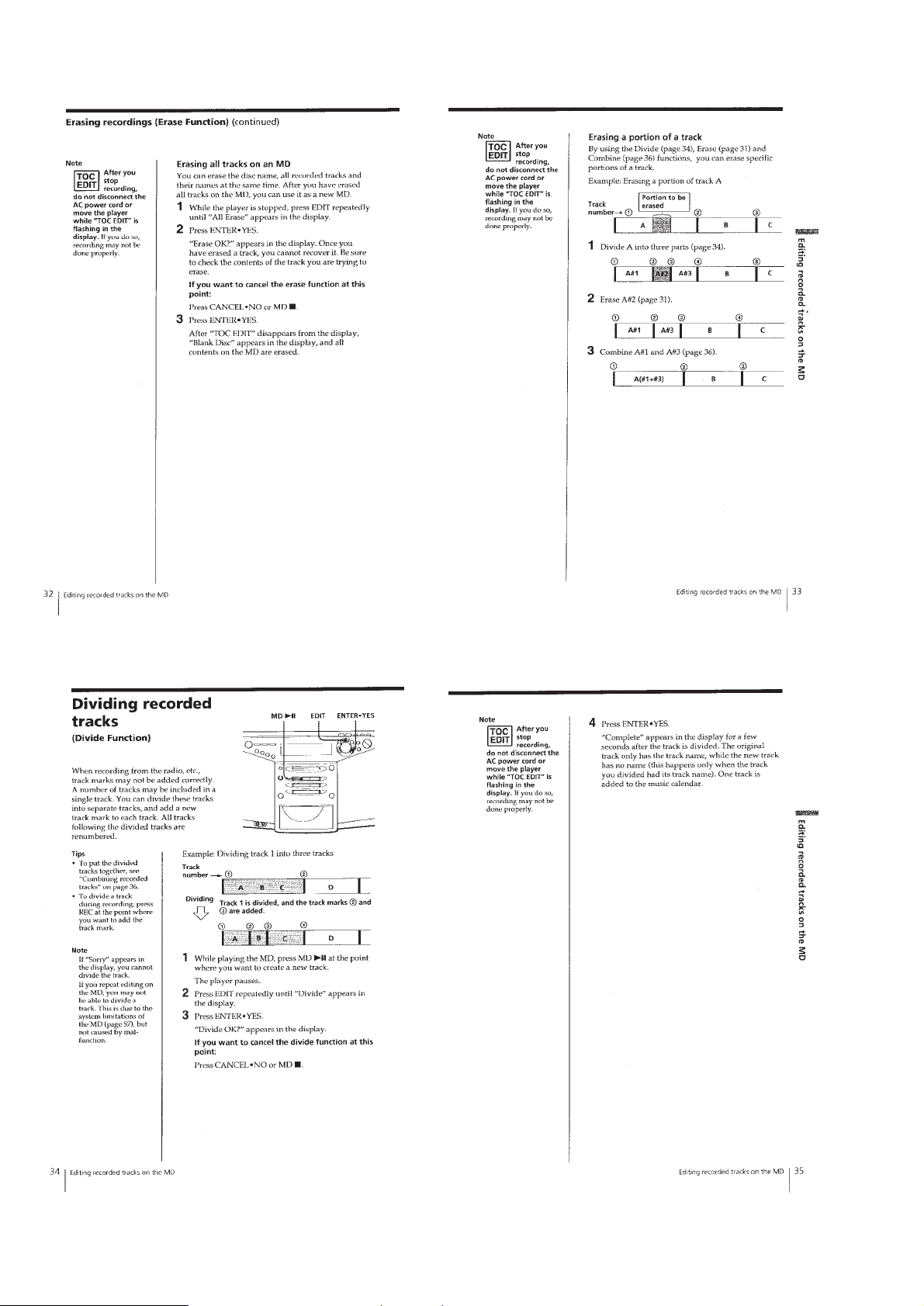

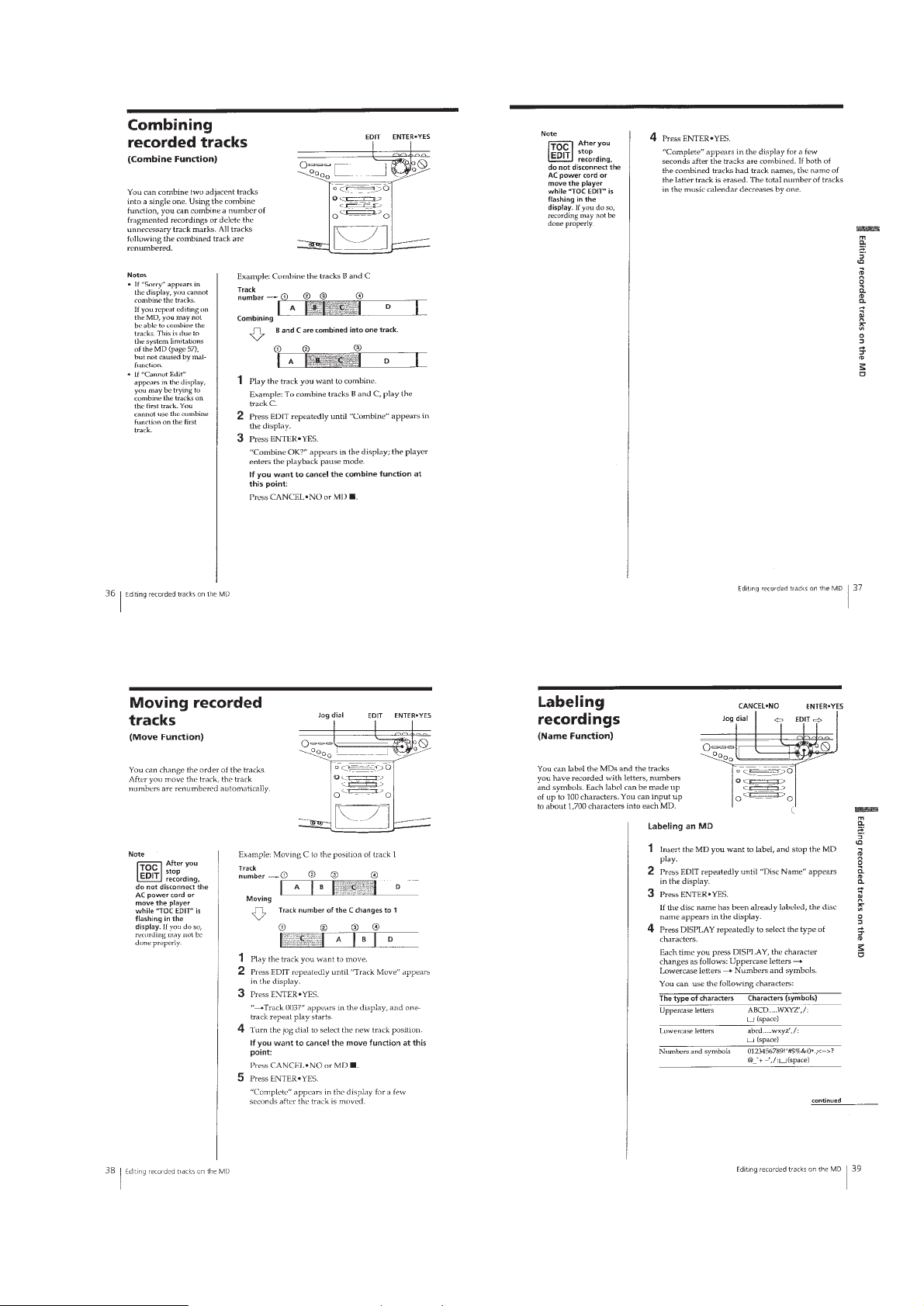

– 7 –

– 8 –

– 9 –

– 10 –

– 11 –

– 12 –

– 13 –

– 14 –

– 15 –

– 16 –

– 17 –

– 18 –

– 19 –

– 20 –

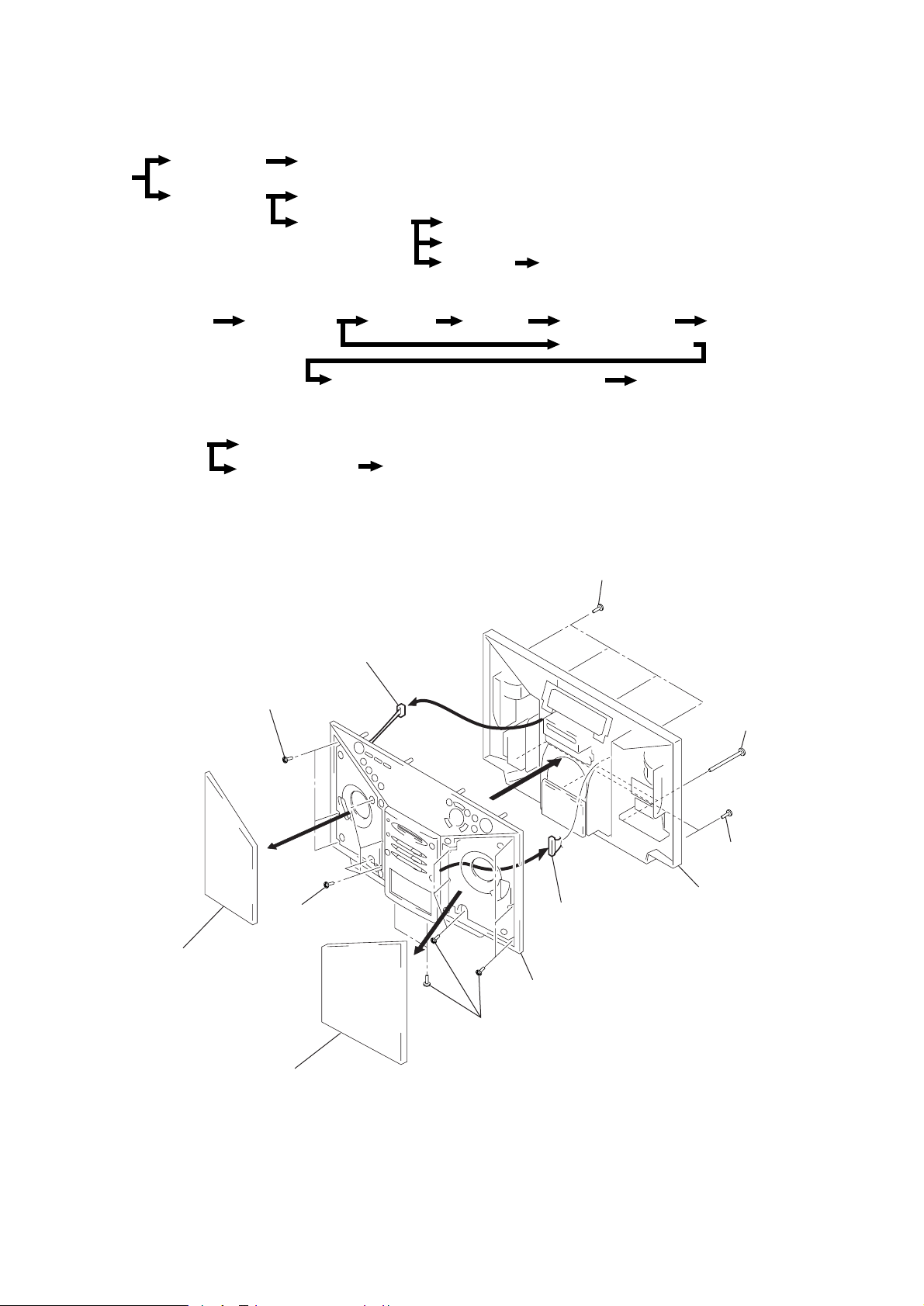

DISASSEMBLY

)

p

r

The equipment can be removed using the following procedure.

< MAIN BLOCK SECTION >

Cabinet (Front)

Set

ASSY

Cabinet (Rear)

ASSY

< MD BLOCK SECTION >

MD Block ASSY

Left key board, Front key board, Top key board, Right board, Relay board

FL board, Trans board, Tuner board, FM ANT board, AM ANT board

MD chassis ASSY MD Block ASSY, Filter board

Shiled case

DG board BD board

(Top, Bottom)

SECTION 3

Audio board, HP board, Line in board

Main board

CD block ASSY

Sub chassis ASSY Shutter ASSY

MD mechanism deck

SW board, Slider ASSY, “Head, Over wright”

< CD BLOCK SECTION >

CD block ASSY

Loading board

“Tray ASSY, CD”

CD Optical pick-up block, Pick-up relay board

Note : Follow the disassembly procedure in the numerical order given.

< MAIN BLOCK SECTION >

3-1. CABINET (FRONT) ASSY, CABINET (REAR) ASSY

6

CN353 (4 pin)

(Audio board)

Screws (+BVTP 3X12)

2

5

tical pick-up block

MD O

3 Screws (2.6X10)

4

Screws (3X45

Net (L) ASSY, SP

1

2

Screws

(+BVTP 3X12)

Net (R) ASSY, SP

1

7

(Relay board)

Cabinet (Front) ASSY

2

Screws (+BVTP 3X12)

– 21 –

CN410 (11 pin)

3

Screws (2.6X10)

Cabinet (Rear) ASSY

3-2. LEFT KEY BOARD, FRONT KEY BOARD, TOP KEY BOARD, RIGHT KEY BOARD, RELAY BOARD

Y

3

Screws (2.6X8)

Front key board

5

1

Screws ( 2.6X8)

Screws (2.6X8)

Left key board

Cabinet (Front) ASSY

3-3. FL BOARD, TRANS BOARD

2

4

!º

!™

6

!¡

Screws (2.6X8)

Relay board

8

7

Screw (M1.7X5)

9

Screws (2.6X8)

Right key board

Button (MEGA BASS)

Top key board

2

Screws (2.6X8)

1

Wire parallel

(FFC)(15 core)

2

Screws (2.6X8)

4

CN954 (4 pin)

4

CN951 (6 pin)

4

CN952 (6 pin)

7

Screws

(+BVTP 4X12)

FL board

5

Screws

(+BVTP 3X16)

8

5

Screws

(+BVTP 3X16)

Trans board

3

Cabinet (Rear) ASS

6

Bracket

(Trans)

– 22 –

3-4. TUNER BOARD, FM ANT BOARD, AM ANT BOARD

7

Screws

(+BVTP 3X12)

5

Screws

(+BVTP 3X12)

FM ANT board

8

Cabinet (Rear) ASSY

EXCEPT US model

3

Screws

(+BTP 3X12)

4!º

1

Wire parallel (FFC)

(13core)

2

Screws

(+BVTP 3X12)

3-5. MD CHASSIS ASSY

Tuner board

6

AM ANT

board

9

Screws

(+BVTP 3X12)

Bracket (Tuner)

2

Screws (2.6X8)

MD chassis ASSY

1

Screws (+BVTP 3X12)

– 23 –

4

3

Screws (+BVTP 3X12)

Cabinet (Rear) ASSY

3-6. MD BLOCK ASSY, FILTER BOARD

3

Screws

(M1.7X5)

2

CN703

(2 pin)

4

3

Screws

(M1.7X5)

3-7. AUDIO BOARD, HP BOARD, LINE IN BOARD

MD chassis

6

Screws

7

MD Block ASSY

5

Wire, Parallel (FFC) (26 core)

Filter board

1

Wire, Parallel (FFC) (26 core)

3

Screws

(+BVTP 3X16)

3

Screws

(+BVTP 3X12)

1

Screw

(+BVTP 3X12)

5

Screw

(+BVTP 3X12)

HP board

Audio board

4

6

2

1

Screw

(+BVTP 3X12)

Chassis (Audio)

8

MD Chassis

Line in board

Screws

7

(+BVTP 3X12)

– 24 –

)

3-8. MAIN BOARD, CD BLOCK ASSY

5

Screws (+BVTP 3X12)

4

Screws (2.6X8)

3

6

1

CN701 Wire, Parallel (FFC)(21 core)

(Main board)

2

CD Block ASSY

CN803 (5pin)

(Main board)

< MD BLOCK SECTION >

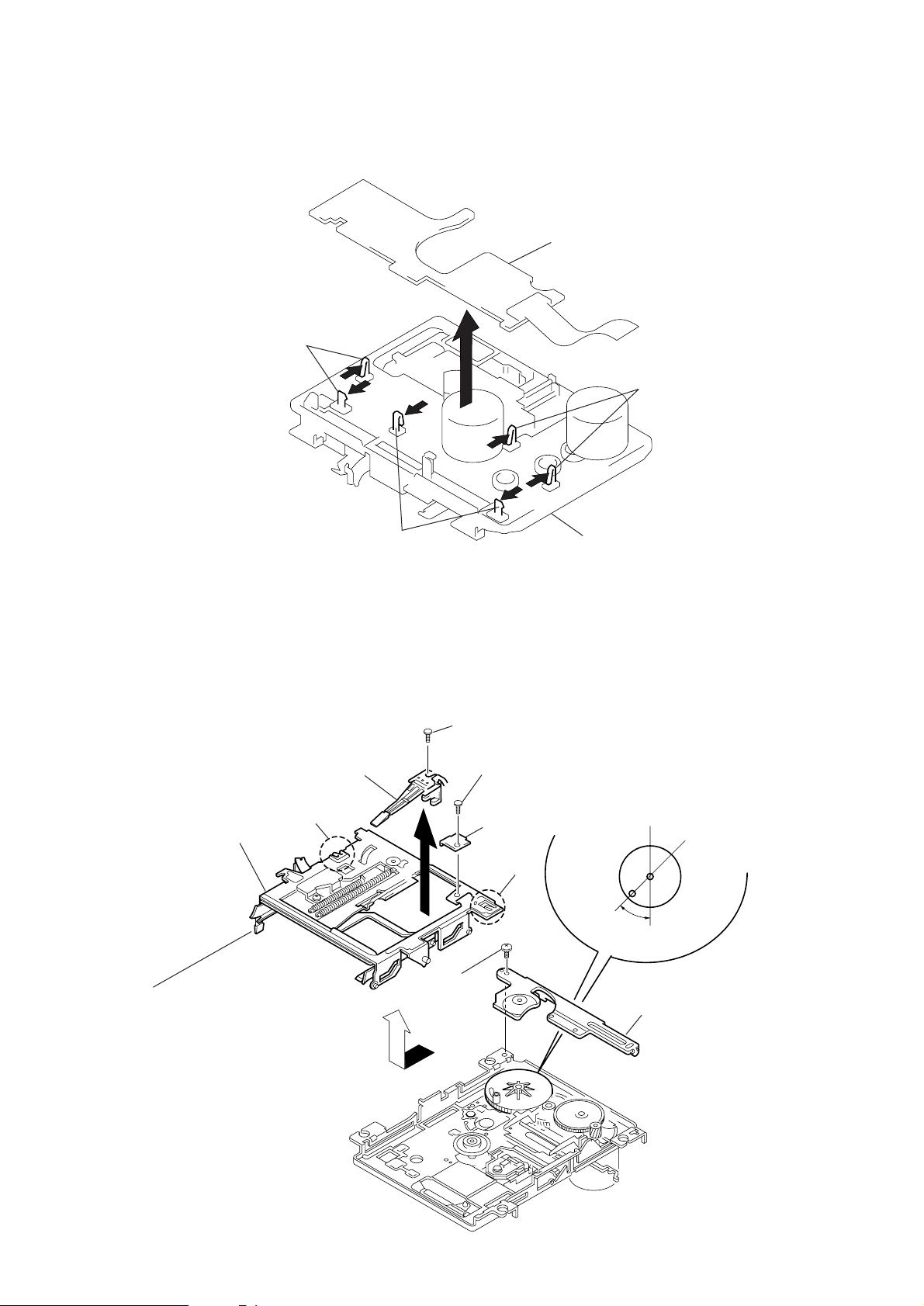

3-9 . SHIELD CASE (TOP), SHIELD CASE (BOTTOM)

1

Shield case (Top)

1

Screws

(M1.7X2)

MD Chassis

Screws (M1.7X2)

1

Screws (M1.7X2)

1

Screws (M1.7X2)

Main board

MD mechanism deck

3

Screws

(+BVTT 2X3)

Shield case (bottom)

2

4

• Note

Insert the projected sections of the MD

mechanism into the grooves on the bottom

of the shield case.

3

Screws (+BVTT 2X3)

– 25 –

MD mechanism deck

Shield case (bottom

3-10 . DG BOARD, BD BOARD, MD MECHANISM DECK

7

Step screw

Insulator

7

Step screw

Insulator

MD mechanism deck

Sub chassis ASSY

A

8

6

5

Screw

(+BVTT 2X4)

DG board

4

Wire, Parallel

1

(FFC)(29core)

BD board

A

A

When mounting, make sure that

sets in the correct position

2

Wire, Parallel (FFC)(19core)

3

Screw

(+BVTT 2X4)

OK

NG

A

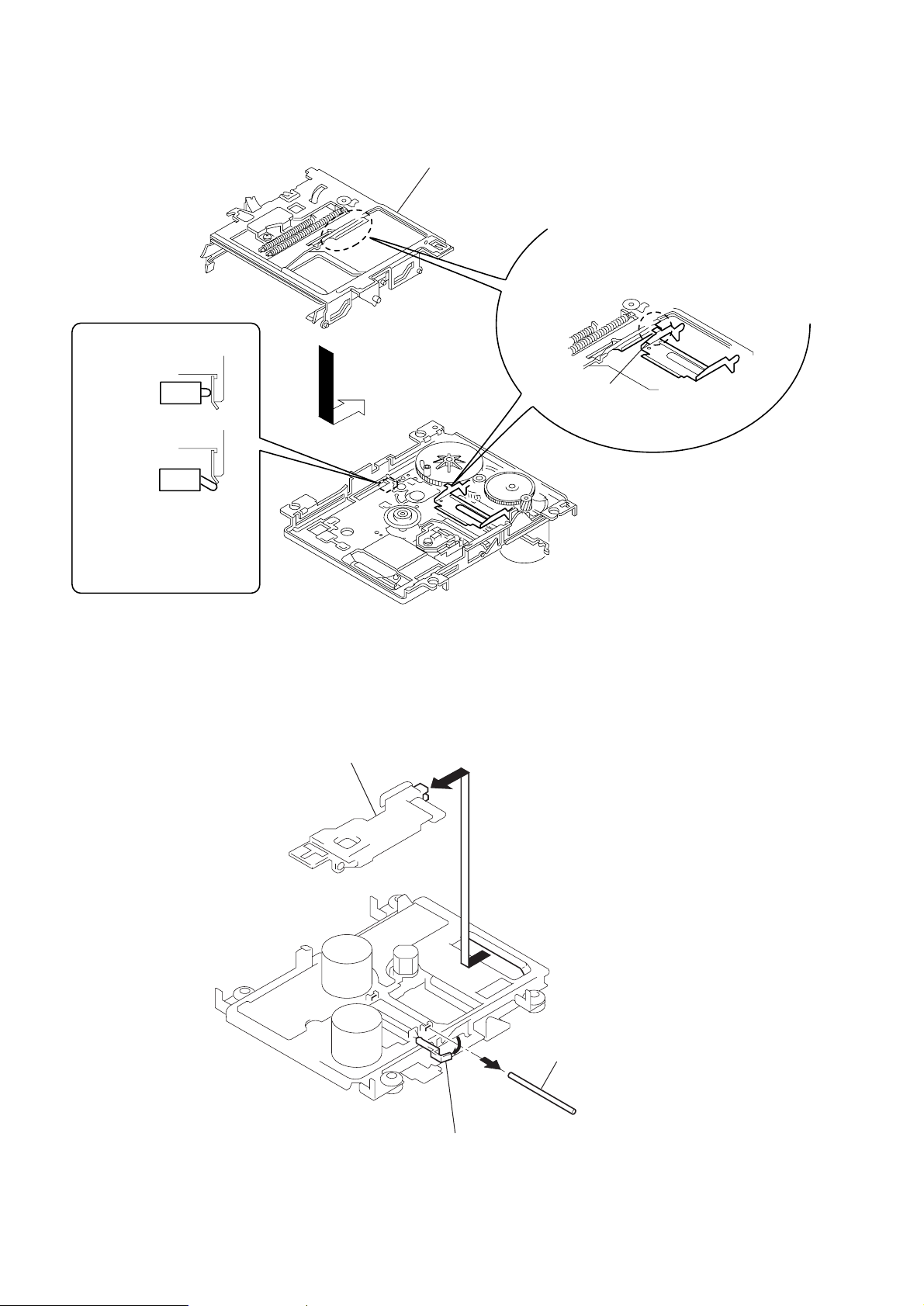

3-11 . SHUTTER ASSY

2

Shaft (shutter)

1

Washer

3

Shutter ASSY

Sub chassis ASSY

Shutter ASSY

Shaft (lid)

Hole B

Shaft (shutter)

Hole A

First mount the shaft (shutter) to hole A sets in the

diagram, then mount the shaft (lid) to hole B

– 26 –

3-12 . SW BOARD

k

1

Claws

1

Claws

2

SW board

MD mechanism dec

1

Claws

3-13. SLIDER ASSY, “ HEAD, OVER WRITE ”

Head, Over write

Claw

Slider ASSY

7

While removing the claw(2 locations),

remove the slider assembly in direction

of the arrow.

3

2

Screw (M1.7X6)

4

Screw

(M1.7X2)

1

Screw (M1.7X2)

Retainer

Claw

6

Position the gear shaft

(L) as ahown in the diagram

5

Retainer (Gear)

– 27 –

r

CAUTION DURING SLIDER ASSY ASSEMBLY

Slider ASSY

Mount the A of the lever (head up) so that it

passes above the slider ASSY.

OK

NG

Take caution as to not damage

the detection switch

3-14. MD OPTICAL PICK-UP BLOCK

MD Optical pick-up block

A

– 28 –

3

2

1

Remove the lever

Shaft (Main shaft)

Loading...

Loading...