Sony ZS-M50 Service Manual

ZS-M50

SERVICE MANUAL

Ver 1.1 1999.07

Dolby noise reduction manufactured under license from

Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of

Dolby Laboratories Licensing Corporation.

MD

Section

CD

Section

AEP Model

UK Model

Tourist Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-3Z

Optical Pick-up Type KMS-260A

Model Name Using Similar Mechanism CFD-S27

CD Mechanism Type KSM-213CDM

Optical Pick-up Type KSS-213C

SPECIFICATIONS

– Continued on page 2 –

MICROFILM

PERSONAL MINIDISC SYSTEM

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICE NOTE........................................................... 3

2. GENERAL...................................................................... 5

3. DISASSEMBLY

3-1. Cabinet (Front) Sub ASSY,

Cabinet (Rear) Sub ASSY......................................... 7

3-2. Control (L) Board...................................................... 8

3-3. Control (R) Board ..................................................... 8

3-4. Control (F) Board, JOG Board.................................. 8

3-5. BATT Board .............................................................. 9

3-6. Power Board.............................................................. 9

3-7. Tuner Board, Antenna SW Board ............................. 9

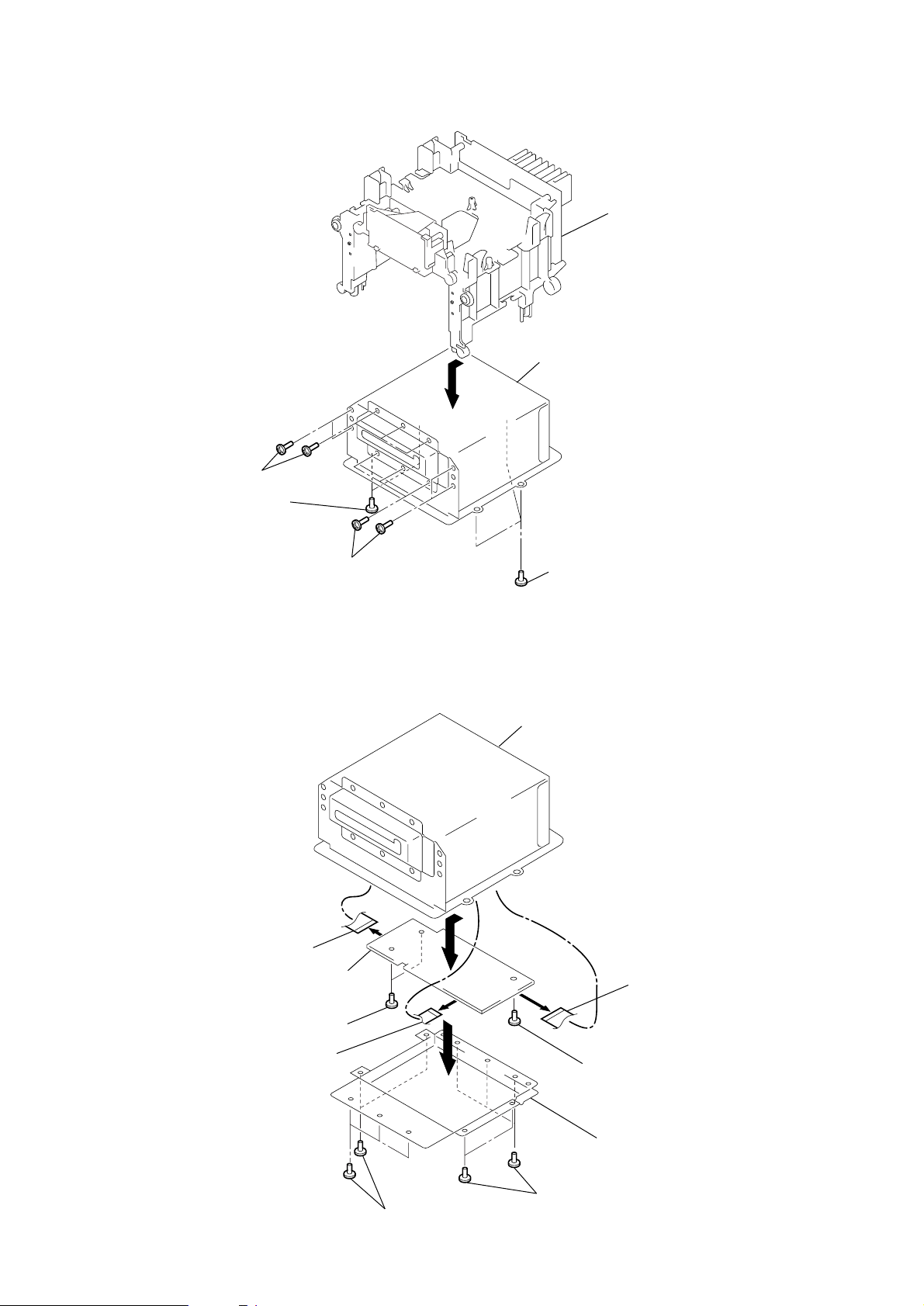

3-8. Center Block Section .............................................. 10

3-9. Cabinet (Upper), Chassis (Main) ............................ 10

3-10.Optical Pick-up ASSY, CD Motor Board.................11

3-11.Control SW Board ....................................................11

3-12.Motor Board, Belt, Motor (M703) ........................... 11

3-13.LCD Board, BL Board ............................................ 12

3-14.Audio Board ............................................................ 12

3-15.Line Board............................................................... 13

3-16.Main Board ............................................................. 13

3-17.MD Block ASSY..................................................... 14

3-18.DG Board ................................................................ 14

3-19.Chassis (MD) .......................................................... 15

3-20.BD Board ................................................................ 15

3-21.Sub Chassis ASSY, MD Mechanism Deck ............. 16

3-22.Shutter ASSY .......................................................... 16

3-23.SW Board ................................................................ 17

3-24.“Head, Over Write”, Slider ASSY .......................... 17

3-25.MD Optical Pick-up Block ..................................... 18

5. ADJUSTMENTS

MD Section ...................................................................... 21

CD Section ....................................................................... 24

Display Section ................................................................ 25

Tuner Section ................................................................... 26

6. DIAGRAMS

6-1. Explanation of IC Terminals ................................... 28

6-2. Block Diagram (Main Section) ............................... 35

6-3. Block Diagram (MD Section) ................................. 39

6-4. Printed Wiring Boards –Main Section – ................. 43

6-5. Schematic Diagram –Main Section (1/3) – ............. 47

6-6. Schematic Diagram –Main Section (2/3) – ............. 51

6-7. Schematic Diagram –Main Section (3/3) – ............. 55

6-8. Printed Wiring Boards –Audio Section –................ 58

6-9. Schematic Diagram –Audio Section – .................... 61

6-10.Schematic Diagram –DG Section – ........................ 66

6-11.Printed Wiring Boards –DG Section – .................... 71

6-12.Printed Wiring Boards –Tuner Section – ................ 73

6-13.Schematic Diagram –Tuner Section –..................... 75

6-14.Schematic Diagram –Control Section – .................. 78

6-15.Printed Wiring Boards –Control Section – ............. 81

6-16.Printed Wiring Boards –BD Section – .................... 83

6-17.Schematic Diagram –BD Section – ........................ 85

7. EXPLODED VIEWS

7-1. Rear Cabinet Section ................................................ 95

7-2. Front Cabinet Section ............................................... 96

7-3. Center Block Section ................................................ 97

7-4. Upper Cabinet Section.............................................. 98

7-5. MD Section (1) ......................................................... 99

7-6. MD Section (2) ....................................................... 100

7-7. CD Optical Pick-up Section ................................... 101

4. TEST MODE

4-1. Caution When Using the Test Mode......................... 19

4-2. Test Mode Settings ................................................... 19

4-3. Releasing the Test Mode........................................... 19

4-4. Basic Operations of the Test Mode........................... 19

4-5. Selecting the Test Mode............................................ 19

4-6. Functions of Other Buttons ...................................... 20

4-7. Test Mode Display .................................................... 20

8. ELECTRICAL PARTS LIST................................. 102

– 2 –

SECTION 1

SER VICE NOTE

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Close the lid for CD.

2. Press CD fl button.

3. Confirm the laser diode emission while observing the objecting

lens. When there is no emission, Auto Power Control circuit or

Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

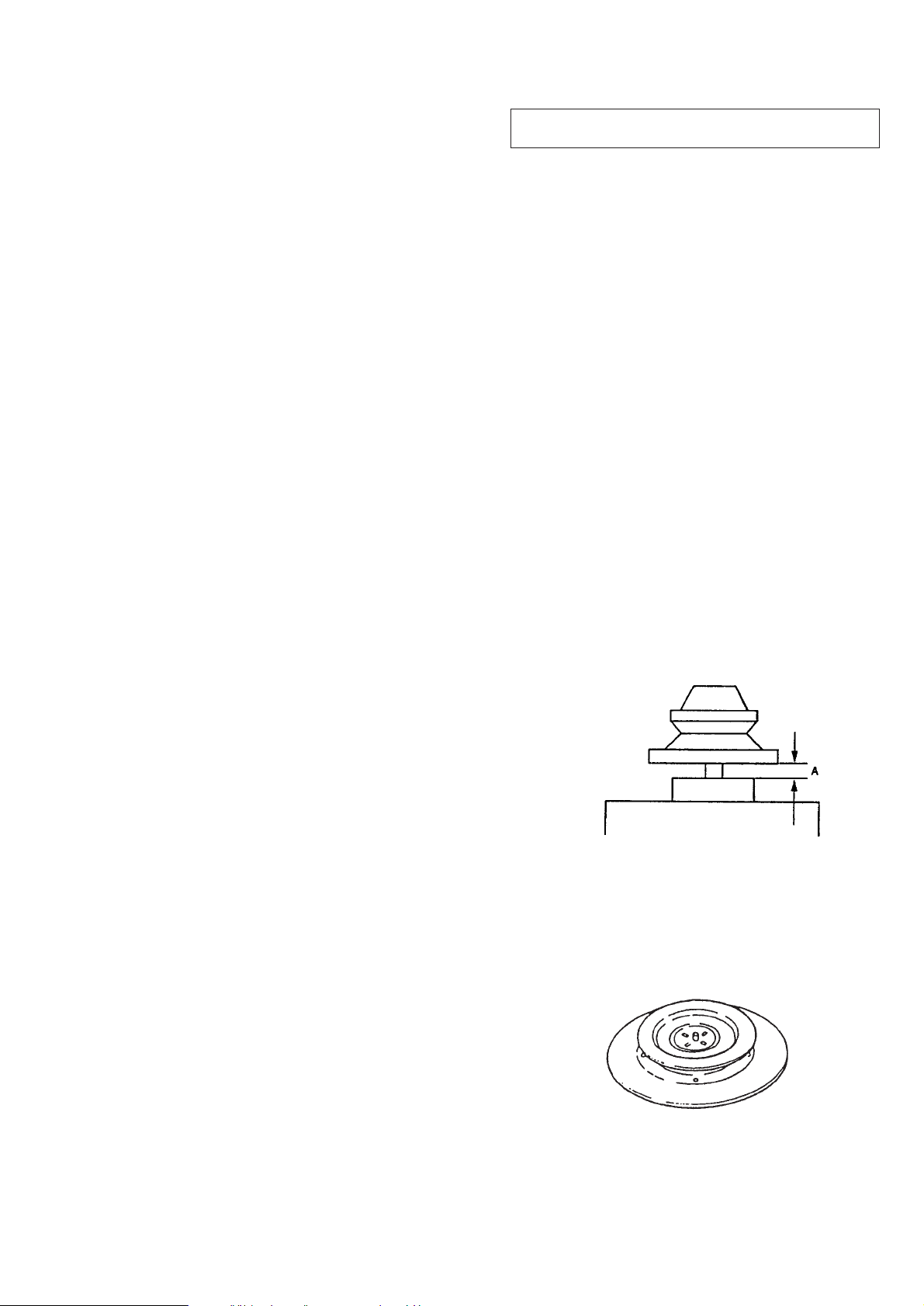

CAUTION DURING WHEN MOUNTING THE PULLEY

FOR THE CD DOOR MOTOR (M703)

Make the following adjustment when mounting the CD door motor

(part number : 1-763-224-11) and motor pulley (part number : 2627-174-01) of the CD section.

Specification : A = 0.9 to 1.1mm

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig : X-4918-255-1

– 3 –

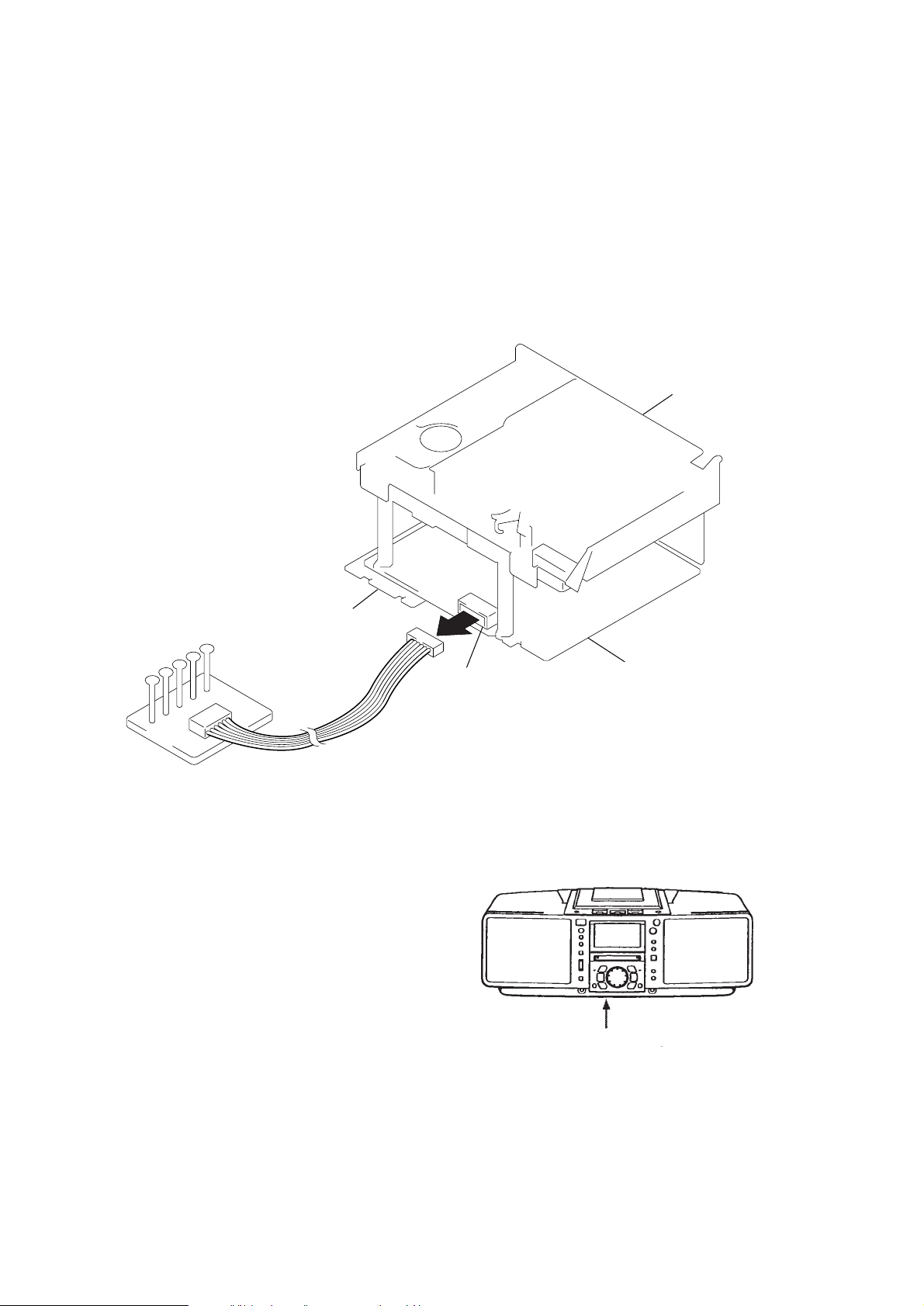

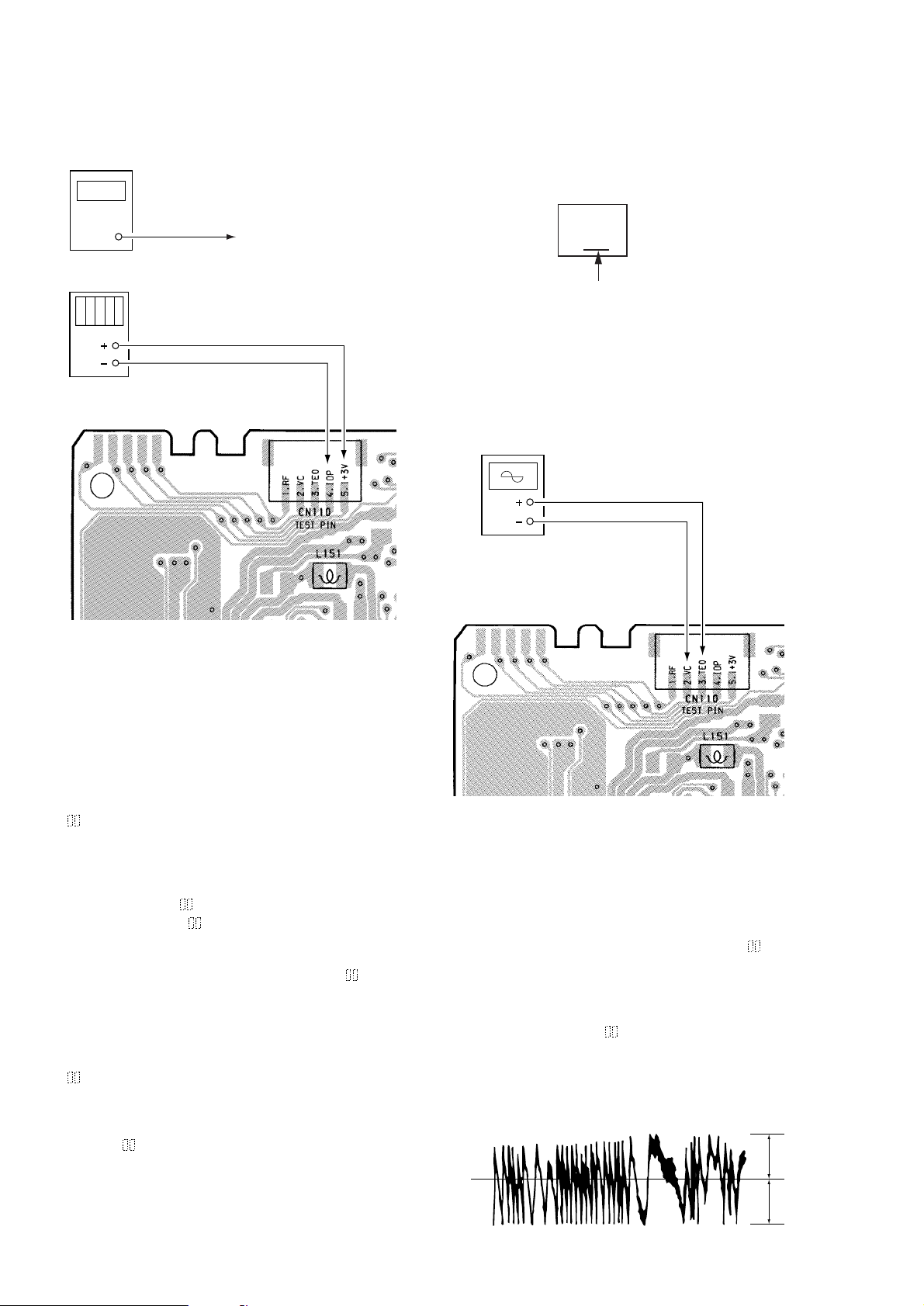

ABOUT THE BD BOARD WAVEFORM CHECKING JIG

The special jig (J-2501-124-A) is highly convenient when checking the waveform of the BD board of the MD section. Pin names

and items to check are as follows:

I+3V : for IOP measurement (check for depleted optical pickup

laser)

IOP : for IOP measurement (check for depleted optical pickup

laser)

TEO : TRK error signal (traverse adjustment)

VC : Standard level for checking signals

RF : RF signal (jitter check)

MD block section

DG board

RF

VC

TEO

IOP

I + 3V

Jig

(J-2501-124-A)

ABOUT THE HARDWARE RESET

It is possible to reset the system microcomputer by pressing the

RESET button located on the bottom with a pointed object. Use

this button when the unit cannot be operated properly due to such

problems as microcomputer errors, etc.

CN110

BD board

RESET button

(Located on the bottom)

– 4 –

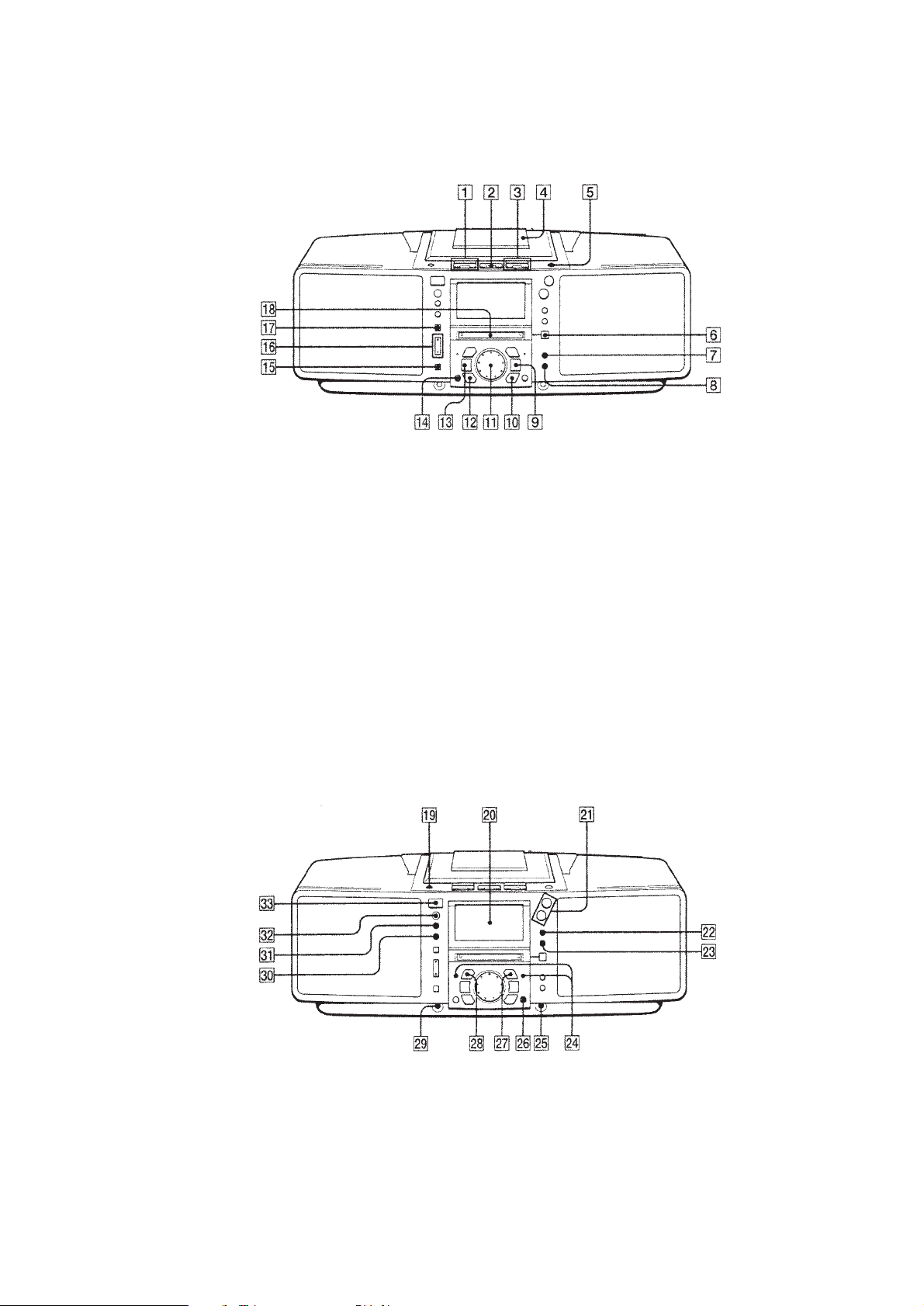

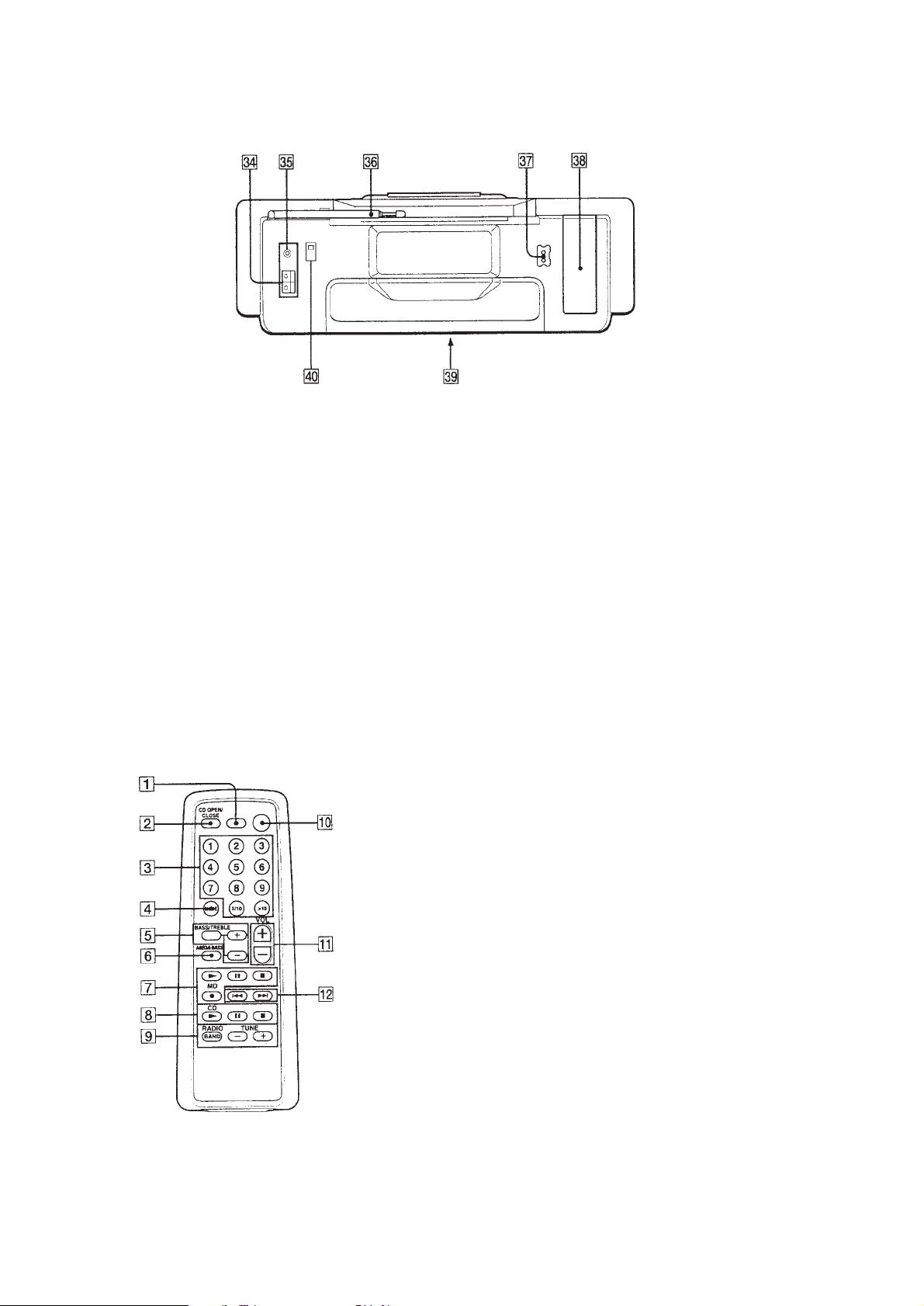

LOCATION AND FUNCTION OF CONTROLS

FRONT PANEL: MD/CD/RADIO Section

SECTION 2

GENERAL

1 MD operation buttons

fl (play/pause)

π (stop)

2 BAND button

3 CD operation buttons

fl (play/pause)

π (stop)

4 CD lid

5 6 CD OPEN/CLOSE button

6 6 MD EJECT button

7 MONO/ST, REPEAT button

8 AUTO PRESET/RDS/SHUF/PGM button

9 TUNE +, ÷, ) button

FRONT PANEL: TIMER, COM Section

!º YES, ENTER button

!¡ Jog dial

=/+ AMS

PRESET

!™ NO, CANCEL button

!£ TUNE –, ¿, 0 button

!¢ EDIT button

!∞ REC button

!§ REC IT button

TO TOP, TO END

!¶ SYNCHRO REC

CD ” MD button

!• MD insert section

!ª LINE/LINE LEVEL button

@º Display window

@¡ VOLUME +, – buttons

@™ BASS/TREBLE button

@£ MEGA BASS button

@¢ Jog dial Function indicator

AMS/PRESET SELECT

@∞ LINE IN terminal

@§ DISPLAY button

@¶ INSERT/TIMER button

@• DELETE/CLOCK button

@ª 2 (Headphones) Jack (stereo mini jack)

#º STANDBY button

#¡ SLEEP button

#™ Remote control receiver section

#£ OPERATE button

– 5 –

REAR PANEL Section

#¢ MW/LW ANTENNA terminal

#∞ FM EXT ANTENNA terminal

#§ FM rod antenna

#¶ ⁄ AC IN jack

#• Battery compartment (for memory back-up)

#ª RESET button (bottom)

$º FM ANTENNA SELECTOR switch

REMOTE CONTROL Section

TA

SEARCH

OPERATE

1 TA SERCH button

2 CD OPEN/CLOSE button

3 Numeric buttons

4 MODE button

5 BASS/TREBLE +, – buttons

6 MEGA BASS button

7 MD operation buttons

” (play)

P (pause)

p (stop)

r (rec)

8 CD operation buttons

” (play)

P (pause)

p (stop)

9 RADIO operation buttons

BAND

TUNE –, +

!º OPERATE button

!¡ VOL +, – buttons

!™ =, + AMS, select, search buttons

– 6 –

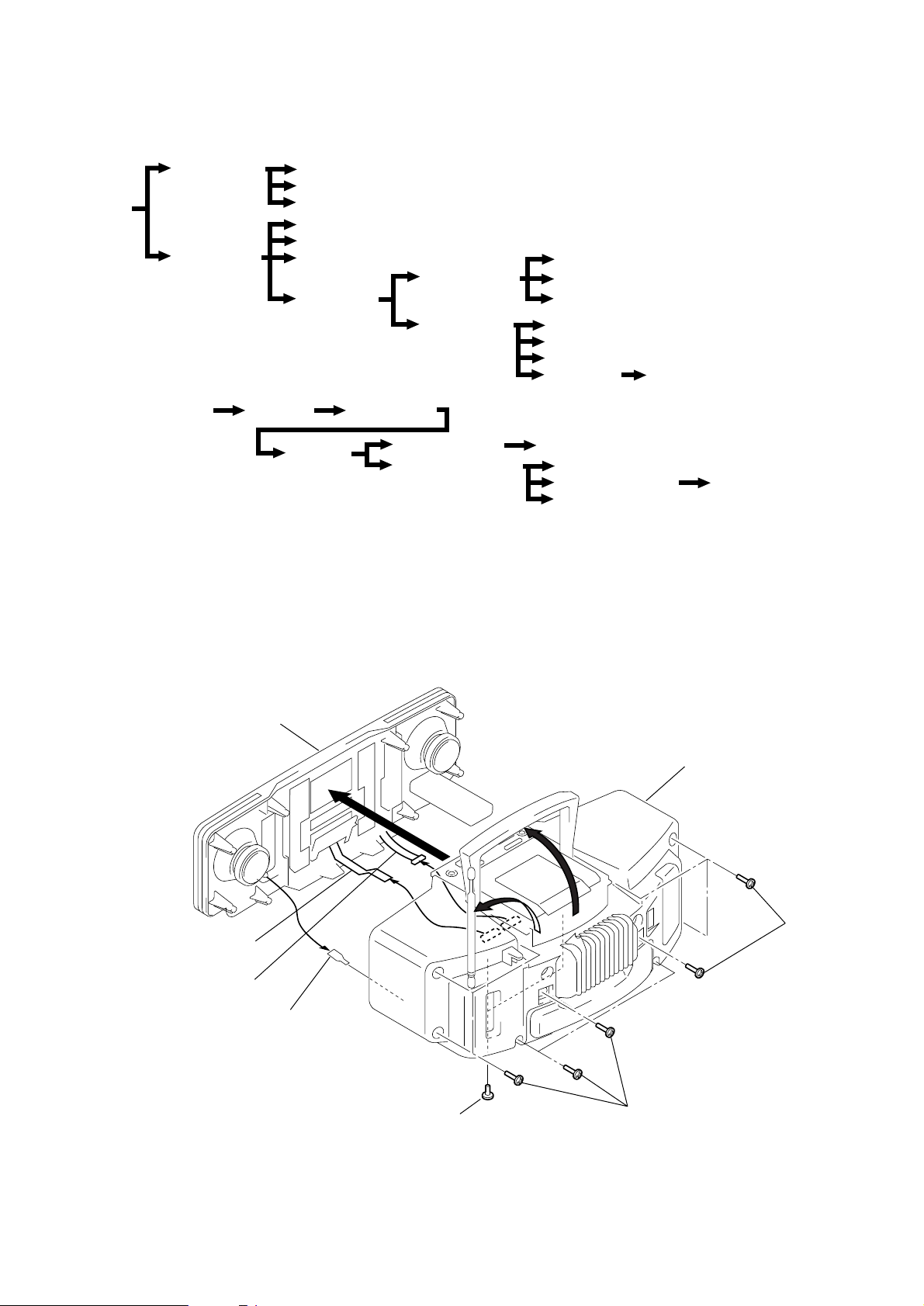

DISASSEMBLY

)

r

The equipment can be removed using the following procedure.

< MAIN BLOCK SECTION >

Cabinet (Front)

sub ASSY

Set

Cabinet (Rear)

sub ASSY

< MD BLOCK ASSY SECTION >

MD Block ASSY

DG board Chassis (MD)

Control (L) board

Control (R) board

Control (F) board, JOG board

BATT board

Power board

Tuner board, Anetenna SW board

Cabinet (Upper)

Center block

section

Chassis (Main)

SECTION 3

Optical pick-up ASSY, CD motor board

Control SW board

Motor board, Belt, Motor (M703)

LCD board, BL board

Audio board

Line board

Main board

MD block ASSY

BD board

Sub chassis ASSY Shutter ASSY

MD mechanism deck

SW board

“Head, Over write”

Slider ASSY

Note : Follow the disassembly procedure in the numerical order given.

<MAIN BLOCK SECTION>

3-1. CABINET (FRONT) SUB ASSY, CABINET (REAR) SUB ASSY

Cabinet (Front) sub ASSY

5

1

2

MD Optical pick-up block

Cabinet (Rear) sub ASSY

7

Wire , parallel (11 core)

(Main board : CN407)

6

CN313 (5 Pin)

(Main board )

8

Lead wire

(Lug, speaker section)

4

Screws (+BVTT 3x6)

– 7 –

3

Screws (+BV 3x14)

3

(+BV 3x14

Screws

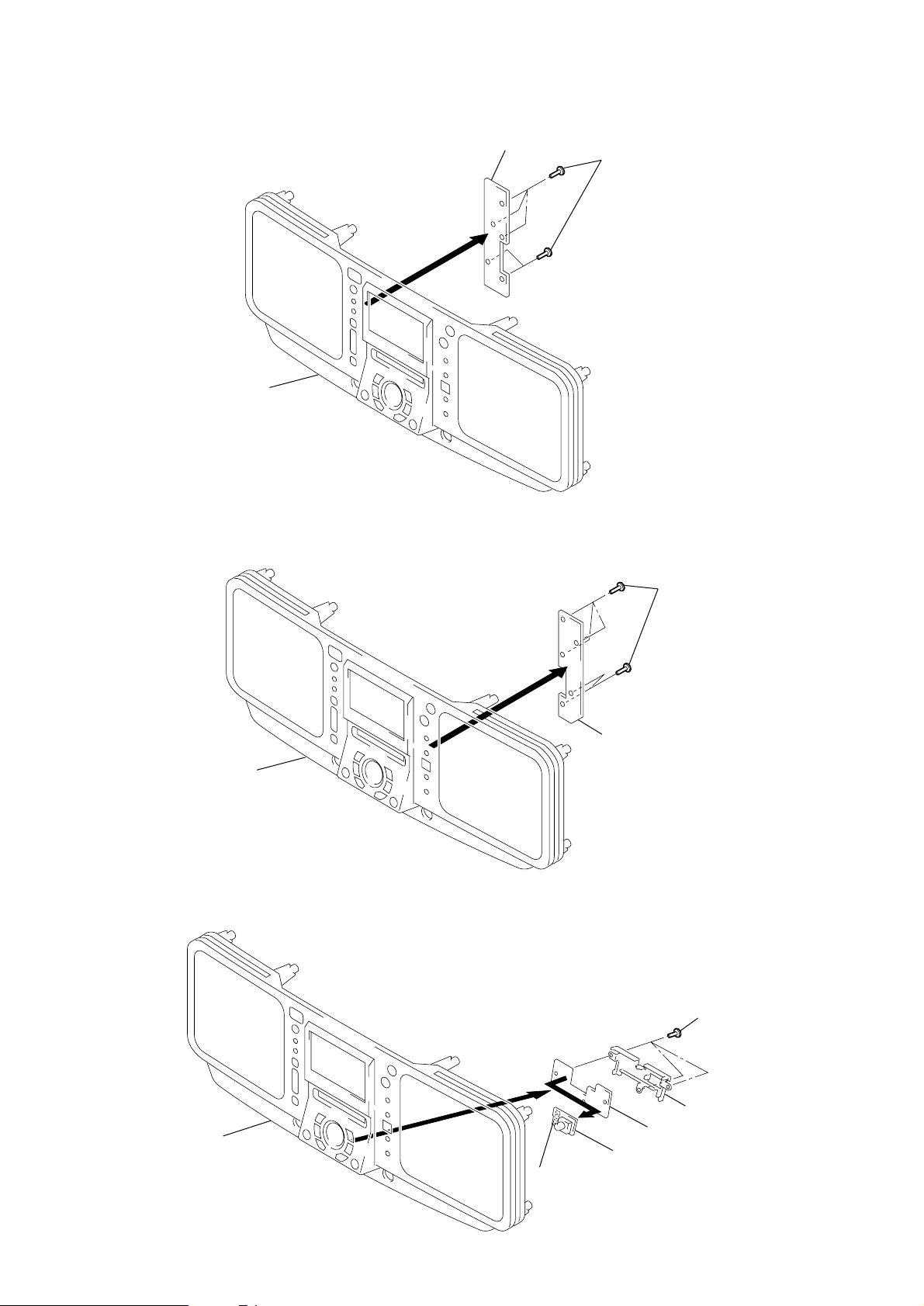

3-2. CONTROL (L) BOARD

)

)

)

Cabinet (Front) sub ASSY

3-3. CONTROL (R) BOARD

Control (L) board

2

1

Screws (+B 2.6x8

1

Screws (+B 2.6x8

Cabinet (Front) sub ASSY

3-4. CONTROL (F) BOARD, JOG BOARD

Cabinet (Front) sub ASSY

2

2

3

Control (R) board

4

JOG board

Remove solder

1

Control (F) board

Screws (+B 2.6x8

Plate (JOG) , retainer

– 8 –

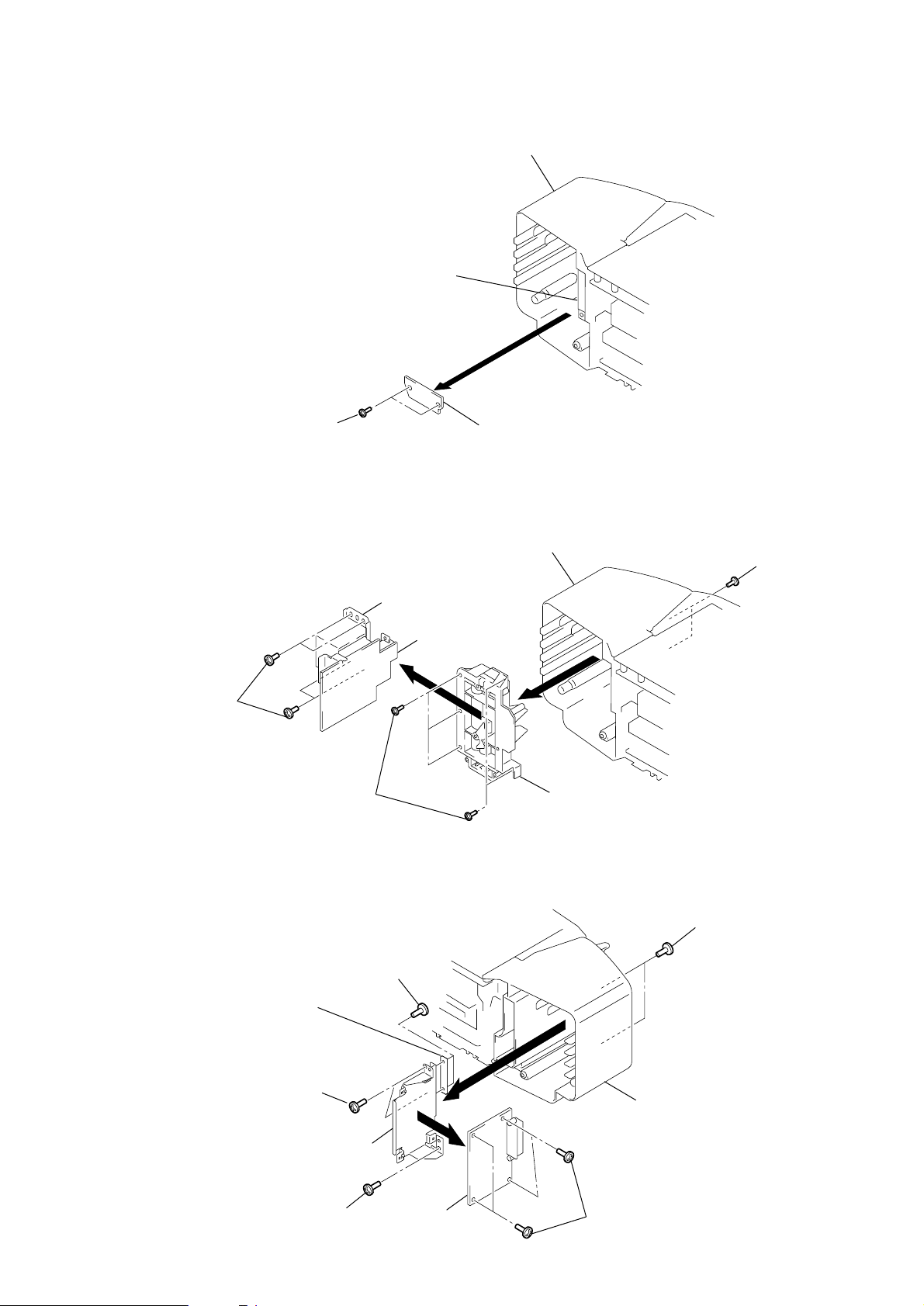

3-5. BATT BOARD

)

)

1

Screws (+BV 3x10)

3-6. POWER BOARD

Chassis, Transformer

2

Cabinet (Rear) sub ASSY

BATT board

Cabinet (Rear) sub ASSY

1

Screws (+BV 3x20

Power transformer

4

Screws (+BV 4x12)

2

Screws (+BV 3x10)

3-7. TUNER BOARD, ANTENNA SW BOARD

6

Screws (+BV 3x10)

Antenna SW board

2

Screws (+BV 3x10)

Chassis (TU)

Power board

5

3

5

3

Chassis, Transformer

1

Screws (+BV 3x14

Cabinet (Rear) sub ASSY

2

Screw (+BV 3x10)

Tuner board

– 9 –

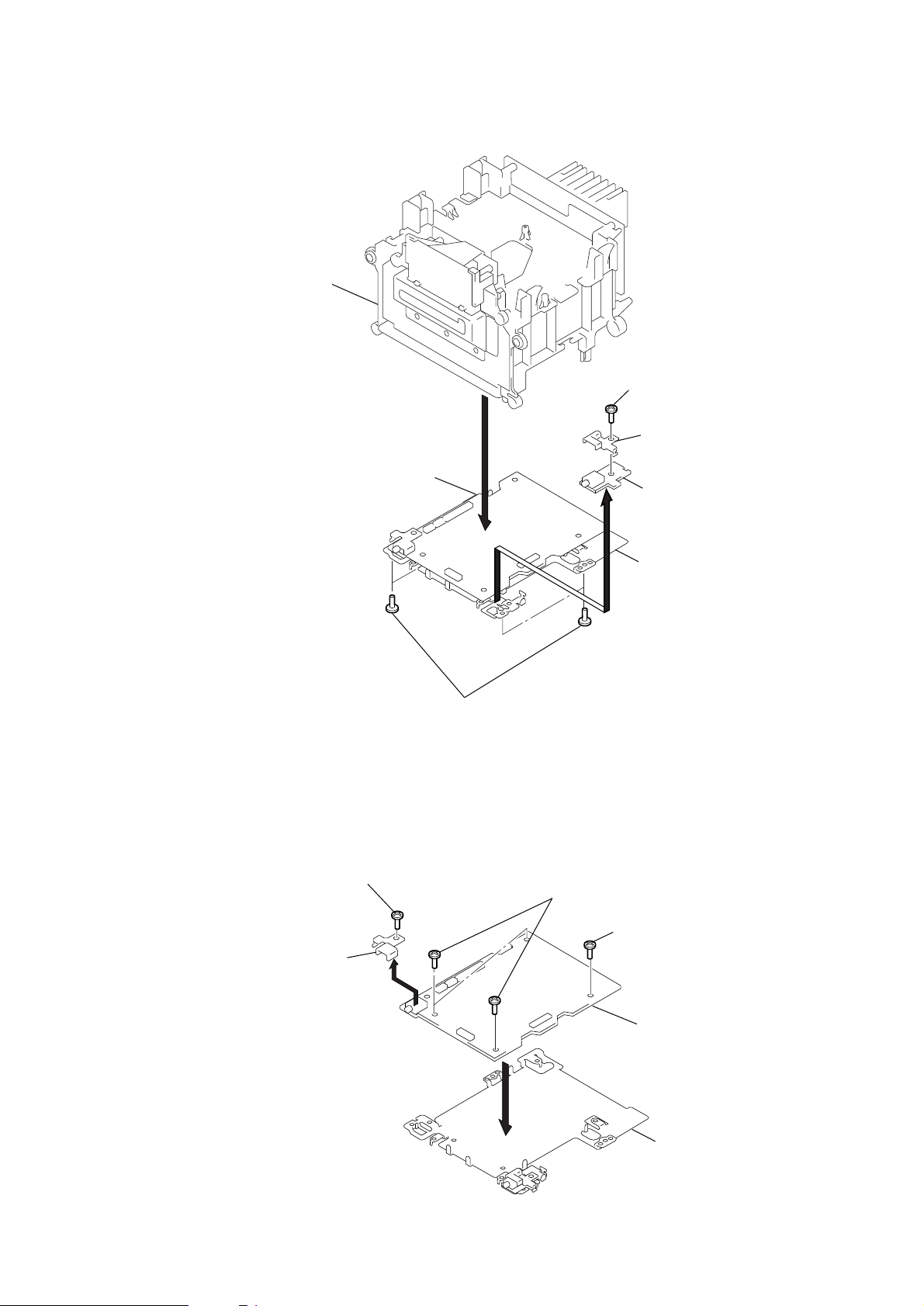

4

Screws (+BV 3x10)

3-8. CENTER BLOCK SECTION

Y

Center Block Section

3

1

Screws (+BV 3x14)

Cabinet (Rear) sub ASS

2

Screws (+BV 3x12)

3-9. CABINET (UPPER), CHASSIS (MAIN)

Cabinet (Upper)

1

Wire , parallel (8 core)

(Control sw board : CN550)

3

Claws

4

2

Wire , parallel (16 core)

(CD optical pick-up)

Chassis (Main)

– 10 –

3

3

Claw

Claw

3-10. OPTICAL PICK-UP ASSY, CD MOTOR BOARD

d

Cabinet (Upper)

1

3-11. CONTROL SW BOARD

Cabinet (Upper)

Screws (+PWH 2.6x8)

CD Motor board

2

4

CD Optical pick-up ASSY

1

Screws (+PWH 2.6x8)

3

Remove solder

3-12. MOTOR BOARD, BELT, MOTOR (M703)

Cabinet (Upper)

2

1

Screws (+B 2.6x8)

Control SW board

5

Chassis, Motor

4

Screws

(+B 3x10)

6

3

Belt

Screws

(+B 2.6x4)

Motor (M703)

(Door open/close)

2

Motor boar

Screws

1

(+B 3x10)

– 11 –

3-13. LCD BOARD, BL BOARD

)

6

Screw (+BV 3x10)

3

LCD Flexible board

1

Screws (+B 2.6x8)

4

Screws (+B 2.6x4)

5

7

Holder LCD

2

BL board

LCD board

Chassis (Main

3-14. AUDIO BOARD

Audio board

2

1

Screws (+BV 3x10)

Chassis (Main)

– 12 –

3-15. LINE BOARD

)

Chassis (Main)

3

Screw (+BVTT 2.6x6)

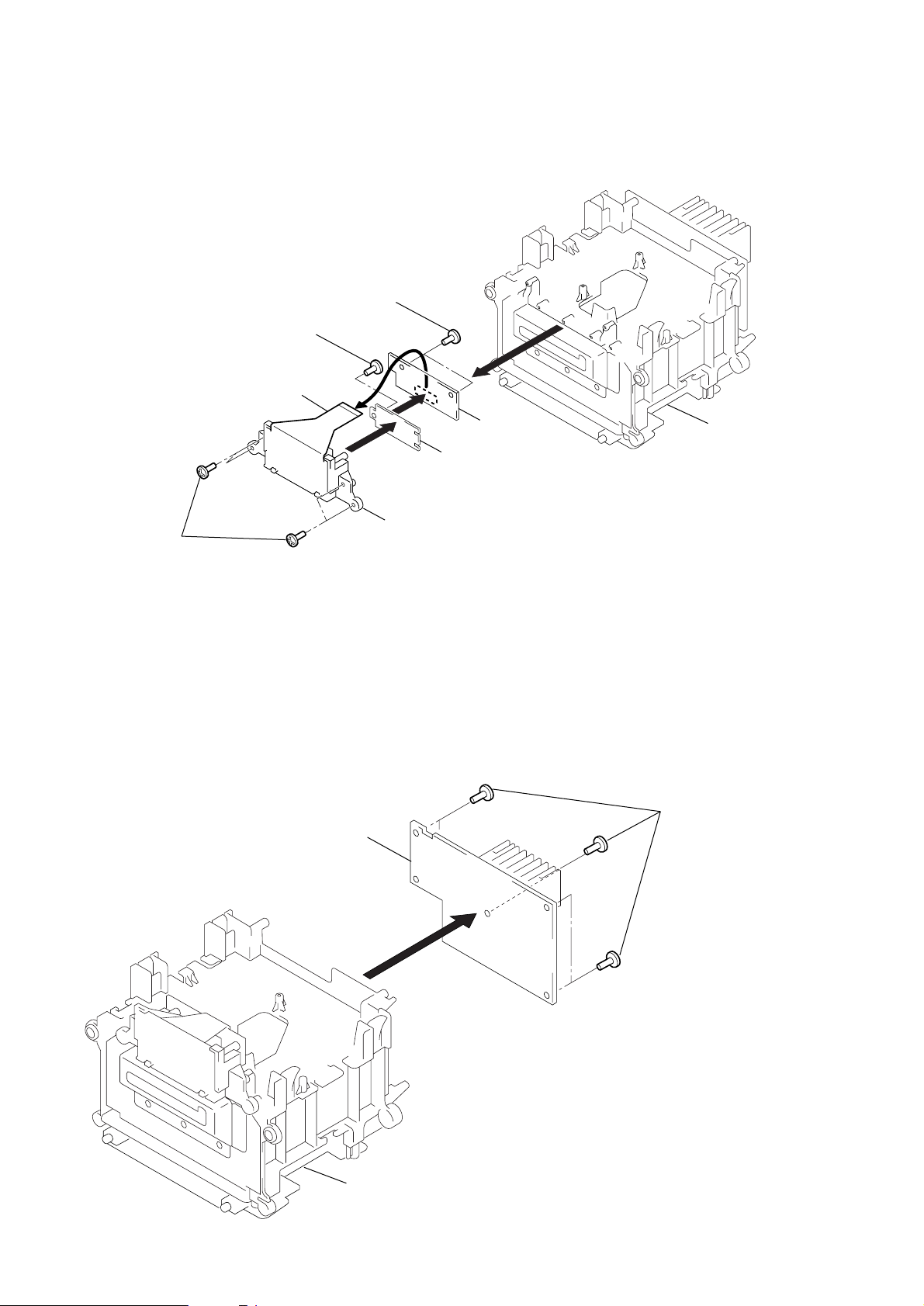

3-16. MAIN BOARD

2

Screw (+BVTT 2.6x6)

Main board

2

Screws (+BV 3x10)

1

Bracket (Line)

Line board

4

Bottom Plate

Screws (+PTPWH 2.6x5)

1

Bracket (HP)

3

– 13 –

4

1

Screw (+BVTT 2.6x6

Main board

Bottom Plate

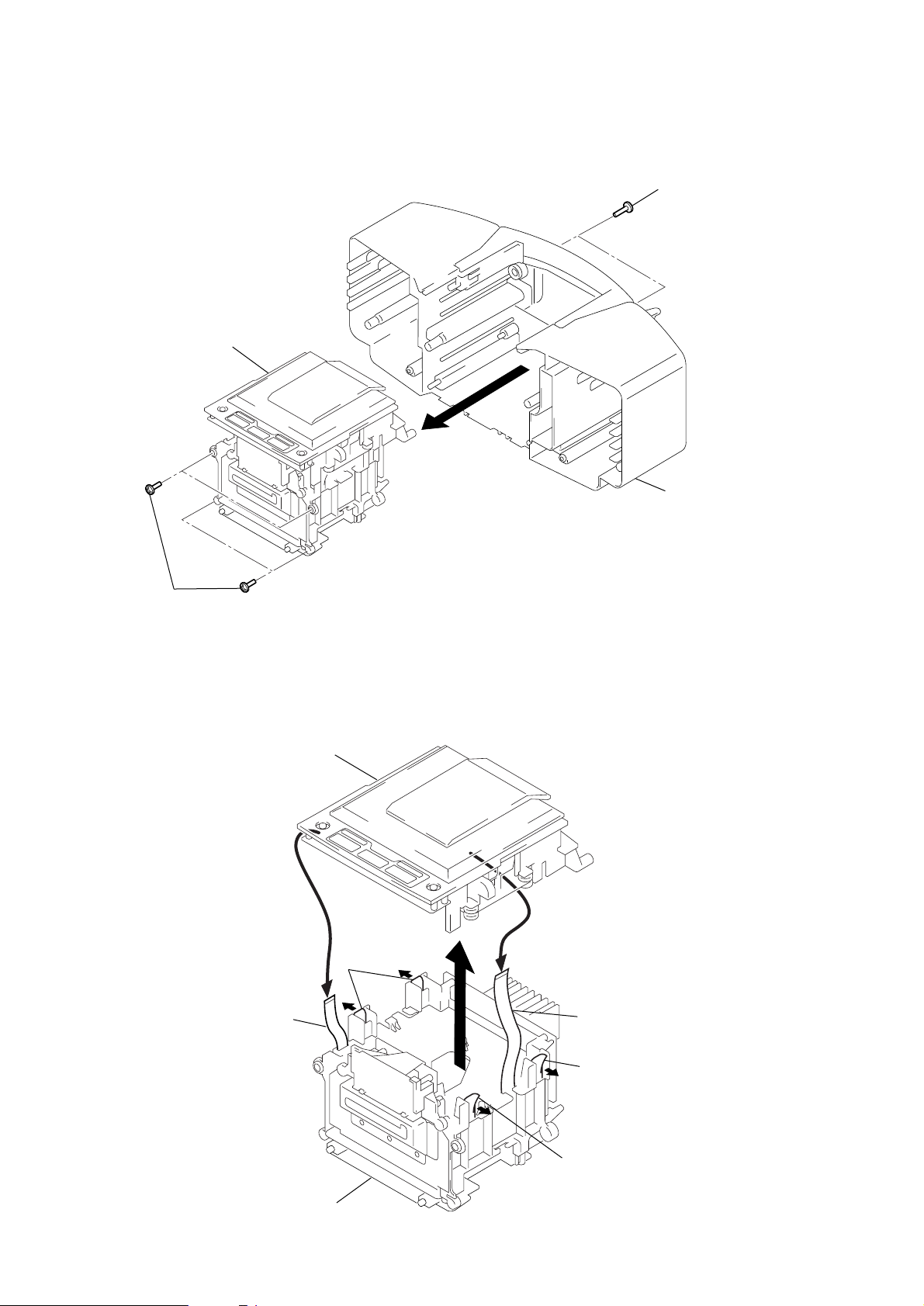

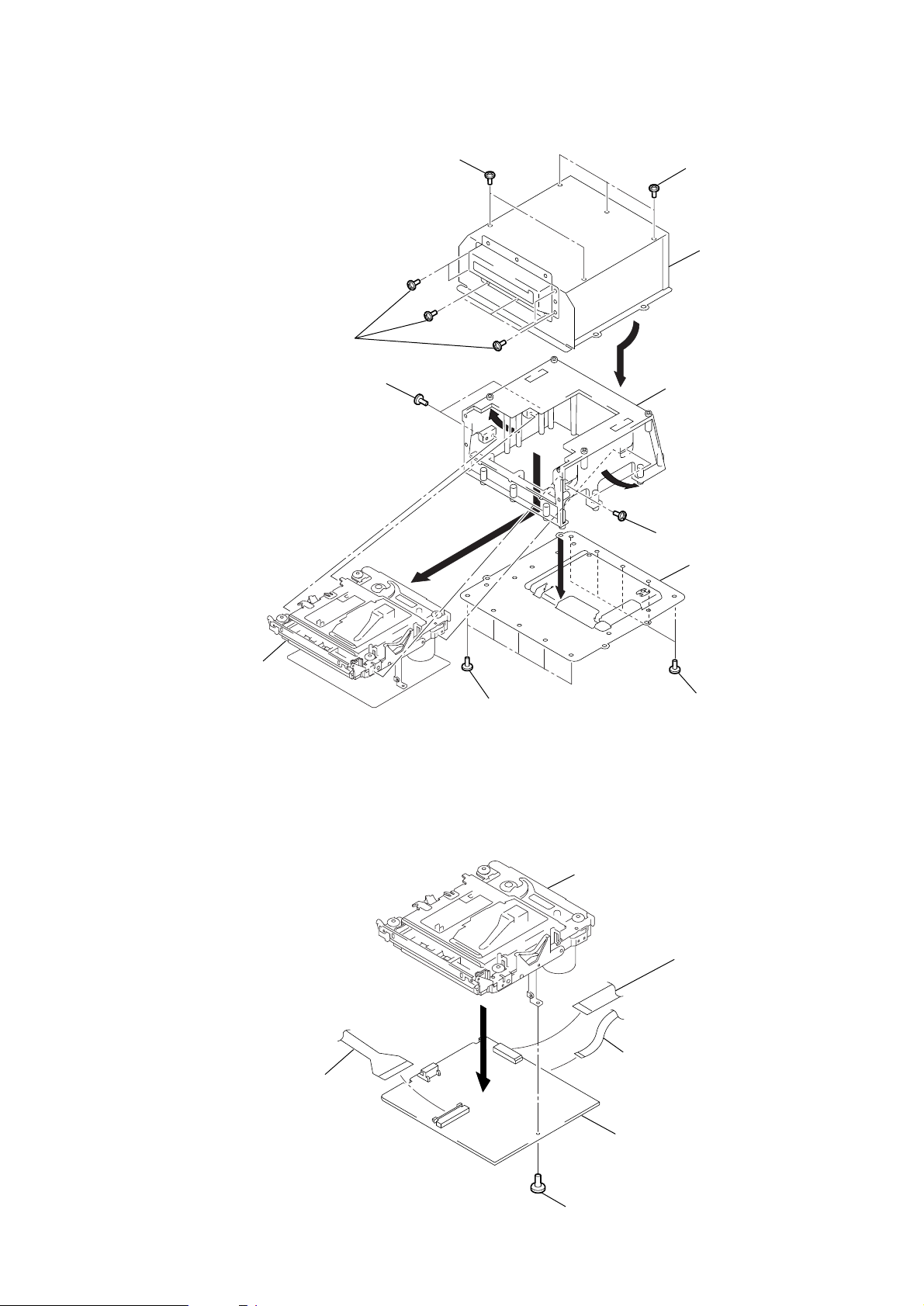

3-17. MD BLOCK ASSY

Screws (+BVTP 2.6x8)

1

2

Screws (+BVTP 2.6x8)

3

1

Screws (+BVTP 2.6x8)

Chassis (Main)

MD Block ASSY

2

Screws (+BVTP 2.6x8)

<MD BLOCK ASSY SECTION>

3-18. DG BOARD

3

Wire , parallel (26 core)

DG board

4

Screws (+BVTP 2.6x8)

3

Wire , parallel (19 core)

5

2

MD Block ASSY

4

Screw (+BVTP 2.6x8)

3

Wire , parallel (29 core)

1

Screws (+BVTP 2.6x8)

– 14 –

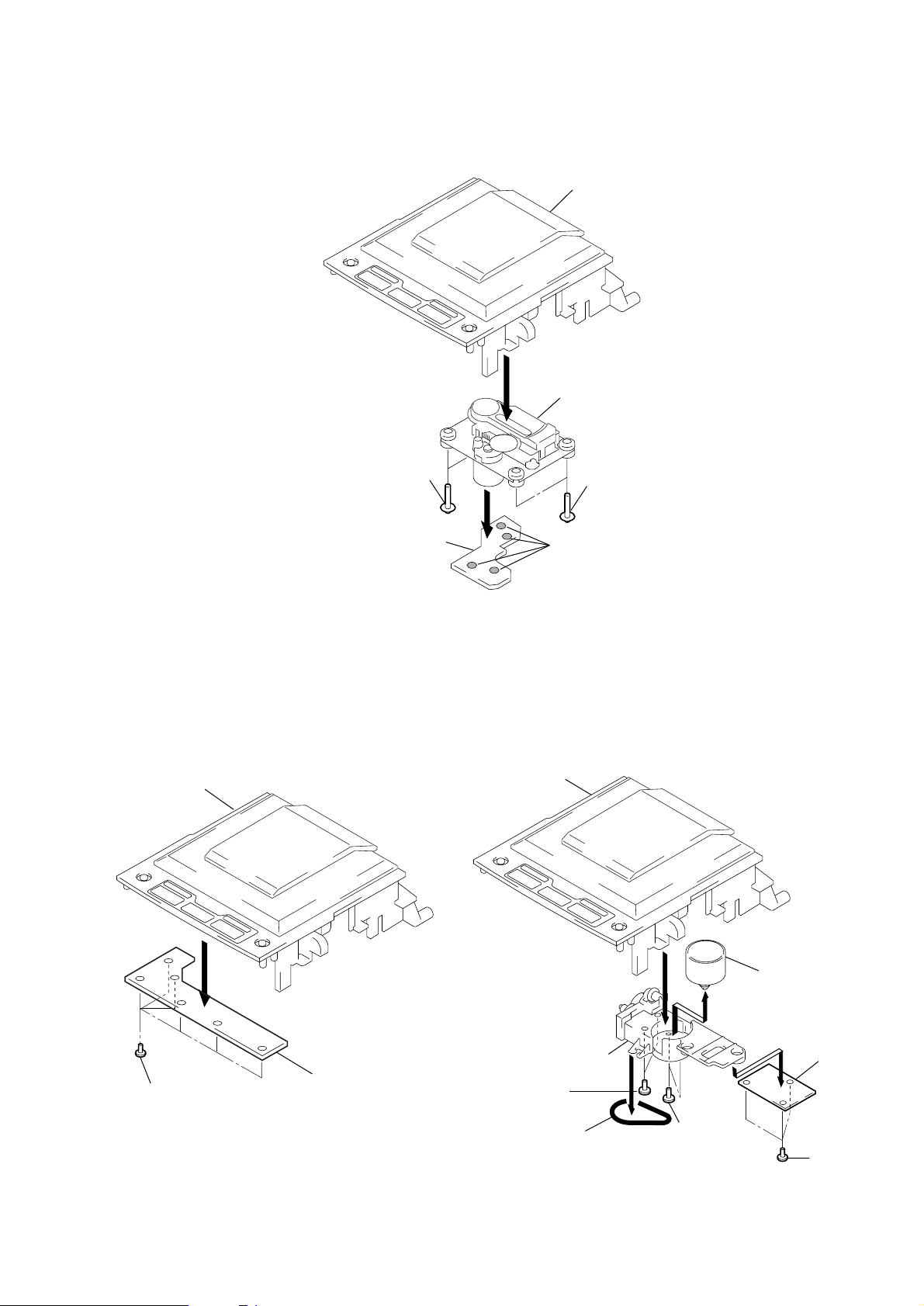

Case (Rear) , MD shield

1

Screws (+BVTP 2.6x8)

3-19. CHASSIS (MD)

d

3

Screws (+BVTP 2.6x8)

3

Screws (+BVTP 2.6x8)

5

Screws (+BVTT 2x3)

6

6

4

3

Screws (+BVTP 2.6x8)

Case (Upper) , MD shiel

Chassis (MD)

MD Mechanism Block

3-20. BD BOARD

7

2

1

Screws (+BVTP 2.6x8)

5

Screw (+BVTT 2x3)

MD Mechanism Block

1

Case (Lower) , MD shield

1

Screws (+BVTP 2.6x8)

Wire , parallel (15 core)

5

OP Relay flexible board

4

– 15 –

2

BD board

3

Screw (+B 2x3)

Head flexible Board

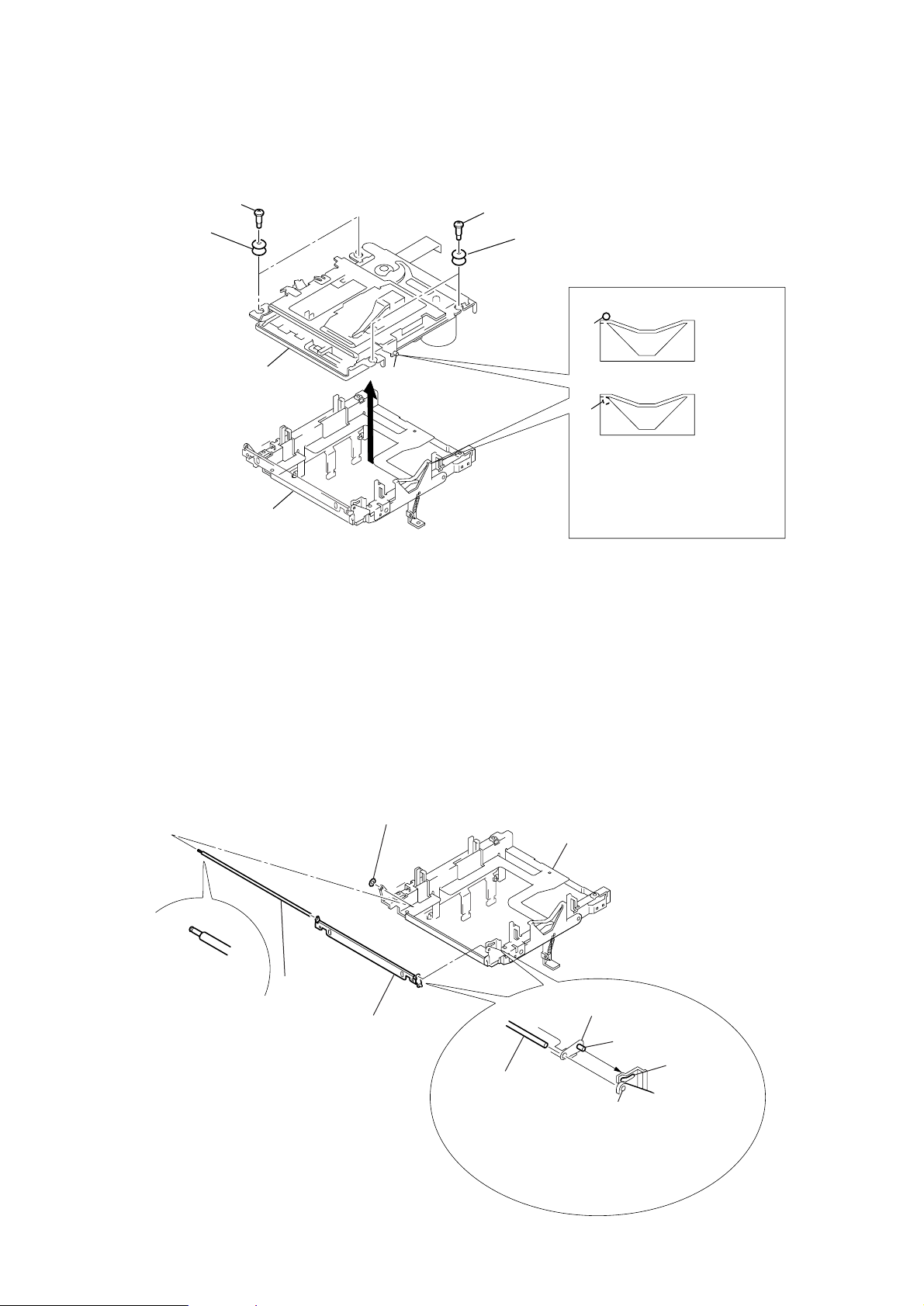

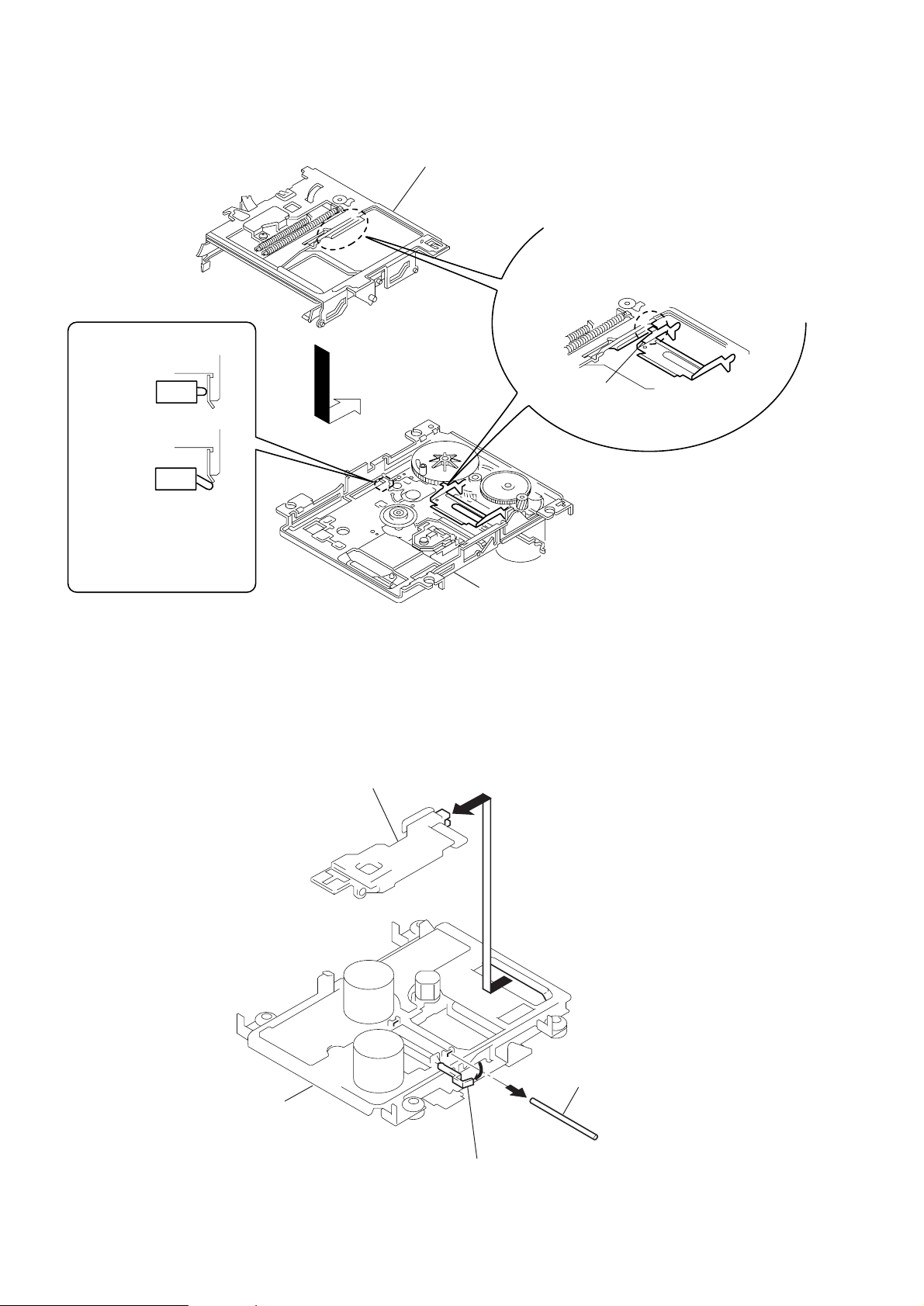

3-21. SUB CHASSIS ASSY, MD MECHANISM DECK

1

Step screws

Insulators

1

Step screws

Insulators

MD mechanism deck

SUB Chassis ASSY

3-22. SHUTTER ASSY

2

A

A

A

When mounting, make sure

that

A

sets in the correct

position.

OK

NG

2

Shaft (shutter)

1

Washer

3

Shutter ASSY

Sub chassis ASSY

Shutter ASSY

Shaft (lid)

Hole B

Shaft (shutter)

Hole A

First mount the shaft (shutter) to hole

A sets in the diagram, then mount the

shaft (lid) to hole B

– 16 –

3-23. SW BOARD

k

1

Claws

1

Claws

2

SW board

MD mechanism dec

1

Claws

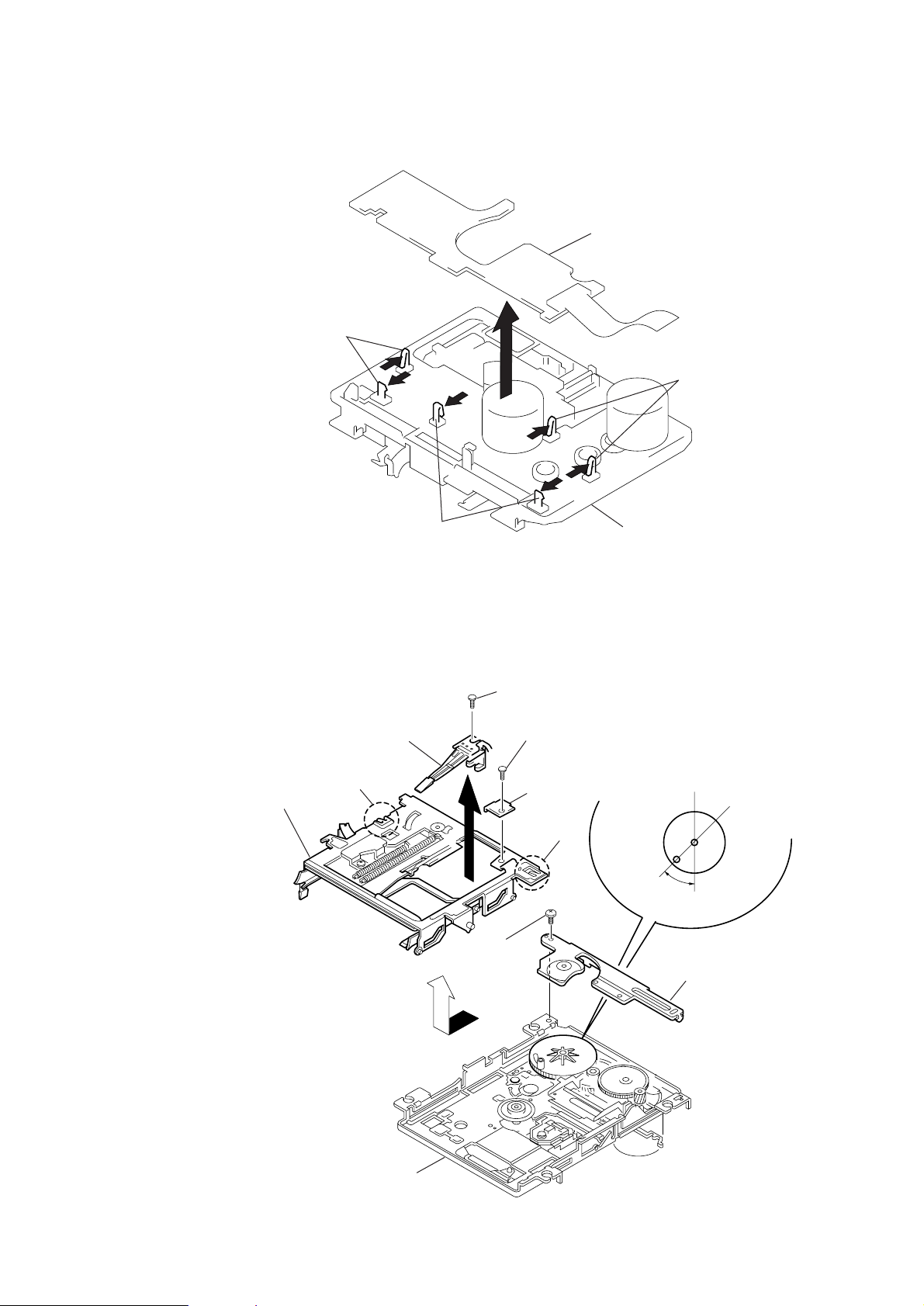

3-24. “ HEAD, OVER WRITE ”, SLIDER ASSY

Head, Over write

7

Claw

Slider ASSY

7

While removing the claw(2 locations),

remove the slider assembly in direction

of the arrow.

3

2

Screw (M1.7x6)

4

Screw

(M1.7x2)

1

Screw (M1.7x2)

Retainer

7

Claw

6

Position the gear shaft

(L) as ahown in the diagram

5

Retainer (Gear)

MD mechanism deck

– 17 –

r

CAUTION DURING SLIDER ASSY ASSEMBLY

Slider ASSY

Mount the A of the lever (head up) so that it

passes above the slider ASSY.

OK

NG

Take caution as to not damage

the detection switch

3-25. MD OPTICAL PICK-UP BLOCK

A

MD mechanism deck

MD Optical pick-up block

MD mechanism deck

– 18 –

3

2

1

Remove the lever

Shaft (Main shaft)

SECTION 4

TEST MODE

4-1. CAUTIONS WHEN USING THE TEST MODE

1 Check to make sure the inserted disk is completed stopped be-

fore removing since loading related operations will operate regardless of the Test mode operation.

The rotation of the inserted disk will not stop even when pressing the MD EJECT button during continuous playback and continuous recording.

In this case, the disk will be ejected while still in motion.

Always press the NO/CANCEL button and check to see that

the disk has stopped turning before pressing the MD EJECT

button.

2 In the Test mode, detection of the write-protect tab is not ex-

ecuted. For this reason, pressing the REC button in modes where

the recording laser is emitted (see 4-1-1) will delete the recorded

contents regardless of the tab position. When using a disk in the

T est mode which its contents must not be deleted, avoid entering the Continuous Recording mode and Traverse Adjustment

mode.

4-1-1. Modes which the record laser is emitted and

button operations

• Continuous Recording mode (CREC MODE)

• Traverse Adjustment mode (EFBAL ADJUST)

• Laser Power Adjustment mode (LDPWR ADJUST)

• Laser Power Check mode (LDPWR CHECK)

• Traverse (MO) check (EF MO CHECK)

• Traverse (MO) adjustment (EF MO ADJUST)

• When pressing the REC button

4-5. SELECTING THE TEST MODE

There are 9 types of test modes (see table below). Turning the AMS

dial clockwise switches modes shown in the table in the order from

top to bottom. Turning the AMS dial counterclockwise switches

modes shown in the table in the reverse order.

Display Description

TEMP ADJUST Temperature compensation offset adjustment

LDPWR ADJUST Laser power adjustment

LDPWR CHECK Laser power check

EF BAL ADJUST Traverse adjustment

FBIAS ADJUST Focus bias adjustment

FBIAS CHECK Focus bias check

CPLAY MODE Continuous playback mode

CREC MODE Continuous recording mode

EEP MODE Non-volatile storage memory control

• For details on each adjustment mode, see respective items of SECTION 5. ADJUSTMENT

• If you have accidently entered another mode, press the NO/CANCEL button to exit.

• The EEP MODE is not used during servicing. Thus, details on

this mode are not given. If this mode is accidently entered, exit

immediately by pressing the NO/CANCEL button as the unit may

not operate correctly if the non-volatile storage memory being

overwritten.

4-2. TEST MODE SETTINGS

MD Test mode :

Press and hold the EDIT button and BASS/TREBLE button,

then press MD ^ n MD p n MD ^ n MD p.

CD Test mode :

Press and hold the EDIT button and BASS/TREBLE button,

then press CD ^ n CD p n CD ^ n CD p.

Display Test mode :

Press and hold the EDIT button and BASS/TREBLE button,

then press BAND n LINE n BAND n LINE (FUNCTION

is LINE).

Note 1 : Each test mode can be entered regardless of whether the

power is on or off. However, it is not possible to enter the

test mode of the particular function being operated. For

example, it its not possible to enter the CD T est mode when

the CD is in function.

4-3. RELEASING THE TEST MODE

Press the RESET button located on the bottom.

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are made using the AMS dial, YES/ENTER button

and NO/CANCEL button.

The functions of each button are as follows:

Function Name Functions

AMS dial Used to change parameters and modes

YES/ENTER button Used to advance and confirm

NO/CANCEL button Used to return and cancel

4-5-1. Operating in the Continuous Playback mode

1. Entering the Continuous Playback mode

1 Insert a disk into the unit (either recordable or playback disk)

2 Turn the AMS dial until “CPLAY MODE” is displayed.

3 Press the YES/ENTER button. The display will change to

“CPLAY IN”.

4 When accessing is completed, the display will change to “C1=

AD = ”.

Note : The numbers of “ ” displayed indicate the error rate and

“ADER”.

2. Changing the playback location

1 Pressing the YES/ENTER button during continuous playback

will change the display in the following manner, enabling

change in the playback location.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

↑

2 When accessing is completed, the display will change to “C1=

AD = ”.

Note :The numbers of “ ” displayed indicate the error rate and

“ADER”.

3. Exiting the Continuous Playback mode

1 Press the NO/CANCEL button. The display will change to

“CPLAY MODE”.

2 To remove the disk, press the MD EJECT button.

Note : The playback initiate addresses of IN, MID and OUT are indi-

cated below. To display the playback position, press the DIS-

PLAY button and “CPLAY( )”.

IN 40h cluster

MID 300h cluster

OUT 700h cluster

– 19 –

4-5-2. Operating in the Continuous Recording mode

1. Entering the Continuous Recording mode

1 Insert a disk that may be recorded into the unit (see Note 3)

2 Turn the AMS dial until “CREC MODE” is displayed.

3 Press the YES/ENTER button. The display will change to

“CREC MID”.

4 When accessing is completed, the display will change to

“CREC (

Note : The numbers of “ ” displayed indicate the record posi-

)”.

tion address.

2. Changing the recording location

1 Pressing the YES button during continuous recording will

change the display in the following manner, enabling change

in the recording location. During location change, the REC

indicator will be off.

“CPLAY MID” n “CPLAY OUT” n “CPLAY IN”

↑

2 When accessing is completed, the display will change to

“CREC (

Note : The numbers of “ ” displayed indicate the record posi-

)” and the REC indicator will light.

tion address.

3. Exiting the Continuous Recording mode

1 Press the NO/CANCEL button. The display will change to

“CREC MODE” and the REC indicator will turn off.

2 To remove the disk, press the MD EJECT button.

Note 1 : The record initiate addresses of IN, MID and OUT are

indicated below. To display the record position, press

the DISPLAY button and “CREC (

)” .

IN 40h cluster

MID 300h cluster

OUT 700h cluster

Note 2 : The NO/CANCEL button can be used at anytime to stop

recording.

Note 3 : Detection for the write-protect tab is not executed when

in the test mode. Do not enter the Continuous Recording

mode with a disk you do not wish to have deleted.

Note 4 : Do not continuously record for more than 5 minutes.

Note 5 : Make sure no vibration is applied to the unit during con-

tinuous recording.

4-5-3. Non-volatile storage memory mode (EEP mode)

This is the mode to read and write the contents of the non-volatile

storage memory.

This mode is not used for servicing.

If you accidently enter this mode, exit immediately by pressing the

NO/CANCEL button.

4-6. FUNCTIONS OF OTHER BUTTONS

Function Name Main Description

Continuous playback when pressed during

EDIT + ^ disk is stopped. Tracking servo ON/OFF

when pressed during continuous playback

EDIT + p Stopping of continuous recording/playback

)

0

EDIT + REC Record ON/OFF during continuous playback

EDIT + Switched between pit and groove every time

SYNCHRO REC the button is pressed

EDIT + SHUF/PGM

DISPLAY

MD EJECT Eject disk

RESET Exit the test mode

The thread moves outward while the button is

pressed

The thread moves inward while the button is

pressed

Spindle servo mode switch

(CLV S N n CLV A)

Display contents are switched every time the

button is pressed

4-7. TEST MODE DISPLAY

The display will switch in the following sequence every time the

DISPLAY button is pressed.

Mode display

Error rate display

Address display

Auto-gain display (not used for servicing)

[00] [69] [3A] display (not used for servicing)

1. Mode display

Displays such information as “TEMP ADJUST” and “CPLAY

MODE”.

2. Error rate display

The error rate is displayed using the following format.

C1=C1ER AD=ADER

3. Address display

The address is displayed using the following format (MO : recordable disk, CD : playback disk)

Switched between pit and groove every time the EDIT and SYN-

CHRO REC button is pressed

h = ππππS = ππππ(MO pit and CD)

h = ππππa = ππππ(MO groove)

h = : header address

S = : SUBQ address

a = : ATIP address

Note : “–” is displayed when servo is off.

4. Auto-gain display (not used for servicing)

The auto-gain is displayed using the following format.

AGF = @@ T = ## [&&]

@@ : focus servo gain coefficient

## : tracking servo gain coefficient

&& : displays [OK], [NG] or [– –].

[– –] indicates that convergence is incomplete

Definitions of other displays

Display

SHUF

P Tracking servo OFF T racking servo ON

REC, SHUF Recording mode ON Recording mode OFF

TOC EDIT

DIGITAL Focus auto-gain OK

TRACK Pit Groove

DISC mark High reflection Low reflection

DATE CLV-S CLV-A

Indicator ON Indicator OFF

Continuous playback in Disk stopped (CLV : OFF)

operation (CLV : ON)

ABCD adjustment

completed

Description

(Flashing) Focus OK

Tracking auto-gain NG

– 20 –

SECTION 5

ADJUSTMENTS

MD SECTION

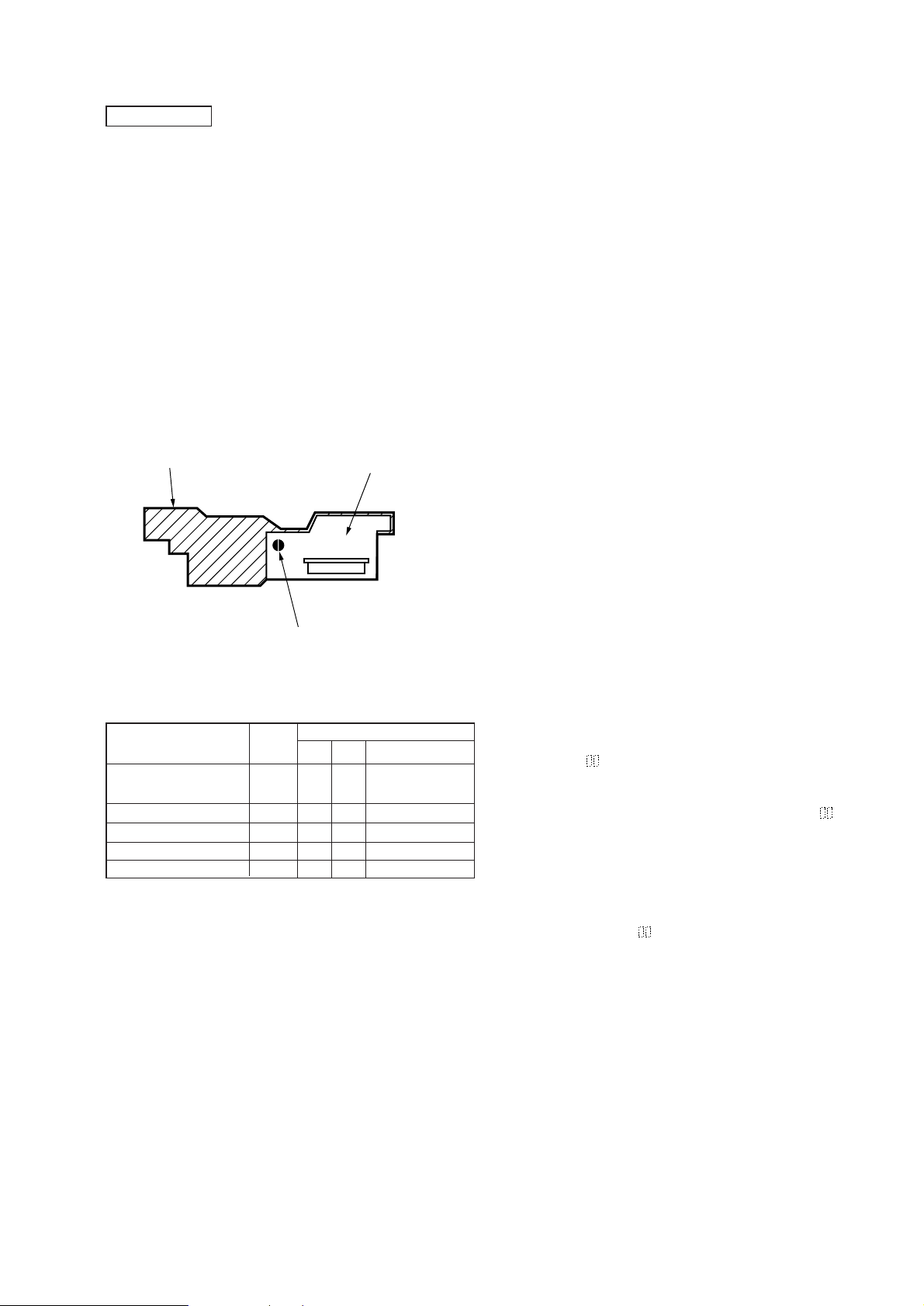

5-1. CAUTION WHEN CHECKING LASER DIODE

EMISSION

Never look from directly above when checking the laser diode emission during adjustment as failure to do so may result in loss of eyesight.

5-2. CAUTIONS WHEN HANDLING THE OPTICAL

PICK-UP (KMS-260A)

The laser diode within the optical pick-up is extremely vulnerable

to static electricity. When handling, bridge the laser tap of the flexible board on the optical pick-up with solder.

When removing the connector, first bridge the laser tap with solder .

Furthermore, do not remove the soldered bridge before reconnecting. In addition, take sufficient measures when working to prevent

electrostatic damage. T ake caution when handling the flexible board

since it is easily torn.

Pick-up

Flexible board

Laser tap

5-3. CAUTIONS DURING ADJUSTMENT

1) After replacing the following parts, make adjustments and checks

for the table items where indicated with a O in the order given.

Optical BD board

pickup

IC171 D101 IC101,IC121,IC192

1. Temperature compensation offset adjustment

2. Laser power adjustment

3. Traverse adjustment

4. Focus bias adjustment

5. Error rate check

X

O

O

O

O

X

O

O

X

O

O

X

O

O

X

2) Perform adjustments in the test mode.

Exit the test mode when completed with adjustment.

2) Perform adjustments in the order given.

3) Use the following jig and measuring equipment:

• Check disk (MD) TDYS-I (Part no : 4-963-646-01)

• Laser power meter LPM-8001 (Part no : J-2501-046-A)

• Oscilloscope (perform measurement after calibrating the

probe)

• Digital voltmeter

• Thermometer

• BD board waveform checking jig (part no : J-2501-124-A)

O

O

O

O

O

5-4. CREATING A CONTINUOUS RECORDING

DISK

• This disk is used during focus bias adjustment and error rate

check. The procedure for creating a continuous recording disk

is as follows.

1. Insert a disk (any commercially available blank disk).

2. Turn the AMS dial until “CREC MODE” is displayed.

3. Press the YES/ENTER button to display “CREC MID”.

“CREC(0300)” will be displayed for an instant and recording

will begin.

4. Complete recording within 5 minutes.

5. Press the NO/CANCEL button to stop recording.

6. Press the MD EJECT button to remove the disk.

A continuously recorded disk can be created by following the procedure above for focus bias adjustment and error rate check.

Note: Take caution as to not apply vibration to the unit during con-

tinuous recording.

5-5. TEMPERATURE COMPENSATION OFFSET

ADJUSTMENT

The temperature data at the time is saved in the non-volatile storage

memory as the standard data of 25°C.

Notes:

1. Do not make this adjustment under normal conditions.

2. Perform this adjustment in an environment with ambient temperature between 22 to 28°C. Furthermore, make the adjustment immediately after turning on the power when the internal

temperature and ambient temperature are between 22 to 28°C.

3. After D101 replacement, perform the adjustment after the part

has ample time to adjust to the ambient temperature.

Procedure:

1. Turn the AMS dial until “ TEMP ADJUST ” is displayed.

2. Press the YES/ENTER button and select the TEMP ADJUST

mode.

3. “ TEMP=

4. To save the data: press the YES/ENTER button

To not save the data: press the NO/CANCEL button

5. After pressing the YES/ENTER button, “ TEMP=

will be displayed momentarily and the display will then return

to “ TEMP ADJUST ”.

The display will immediately return to “ TEMP ADJUST ” when

pressing the NO/CANCEL button.

Specified values:

The value of TEMP=

FF, 00-0F, 10-1F or 20-2F.

” and the current temperature data will be displayed.

SAVE ”

must be within the range of E0-EF, F0-

5) When looking at multiple signals using oscilloscope, etc., make

sure VC and GND are not connected within the oscilloscope.

Failure to do so will short circuit VC and GND.

6) Using the special jig enables checking of the waveform without

soldering (see page 4 of Service Notes).

– 21 –

5-6. LASER POWER ADJUSTMENT

A

Connections:

Laser power meter

Optical pick-up

objective lens

Specified values:

Laser power meter reading : 6.9–7.1mW

Digital voltmeter reading : ±10% the value on the label of the optical pickup.

(Optical pick-up label)

KMS

260A

27X40

B0825

Digital voltmeter

CN110 5 pin (I+3V)

CN110

4

pin (IOP)

[BD BOARD] (SIDE A)

Procedure:

1. Insert the laser power meter into the disk loading port and set

atop the objective lens of the optical pickup (if this cannot be

done successfully, shift the optical pickup using the 0 and

) buttons).

Connect the digital voltmeter to the CN110 5 pin (I+3V) and

CN110 4 pin (IOP).

2. Turn the AMS dial until “ LDPWR ADJUST ” is displayed.

(Laser power: adjustment purposes)

3. Press the YES/ENTER button once to display “ LD 0.9mW $

”.

4. Turn the AMS dial so that the laser power meter reading is between 0.86 – 0.92mW. After setting the range dial of the laser

power meter to 10mW, press the YES/ENTER button to save

the adjustment result to the non-volatile storage memory (at this

time, “ LD SAVE $ ” will be displayed for an instant).

5. Next, “ LD 7.0mW $

” will be displayed.

6. Turn the AMS dial so that the laser power meter reading is between 6.9 – 7.1mW, then press the YES/ENTER button to save

the adjustment result (at this time, “ LD SAVE $

” will be

displayed for an instant).

Note: Do not emit the 7.0mW emission more than 15 seconds con-

tinuously.

7. Next, turn the AMS dial until “ LDPWR CHECK ” is displayed.

8. Press the YES/ENTER button once to display “ LD 0.9mW $

”.

At this time, check to see that the laser power meter reading is

between 0.85 – 0.91mW.

9. Next, press the YES/ENTER button once more to display “ LD

7.0mW $ ”.

At this time check to see that the laser power meter and digital

voltmeter reading comply with the specified values.

In this case, Iop = 82.5mA

Iop(mA) = digital voltmeter reading (mV)/1(Ω)

10.Press the NO/CANCEL button to display “ LDPWR CHECK ”

and stop laser emission. (The NO/CANCEL button can be used

at anytime to stop laser emission)

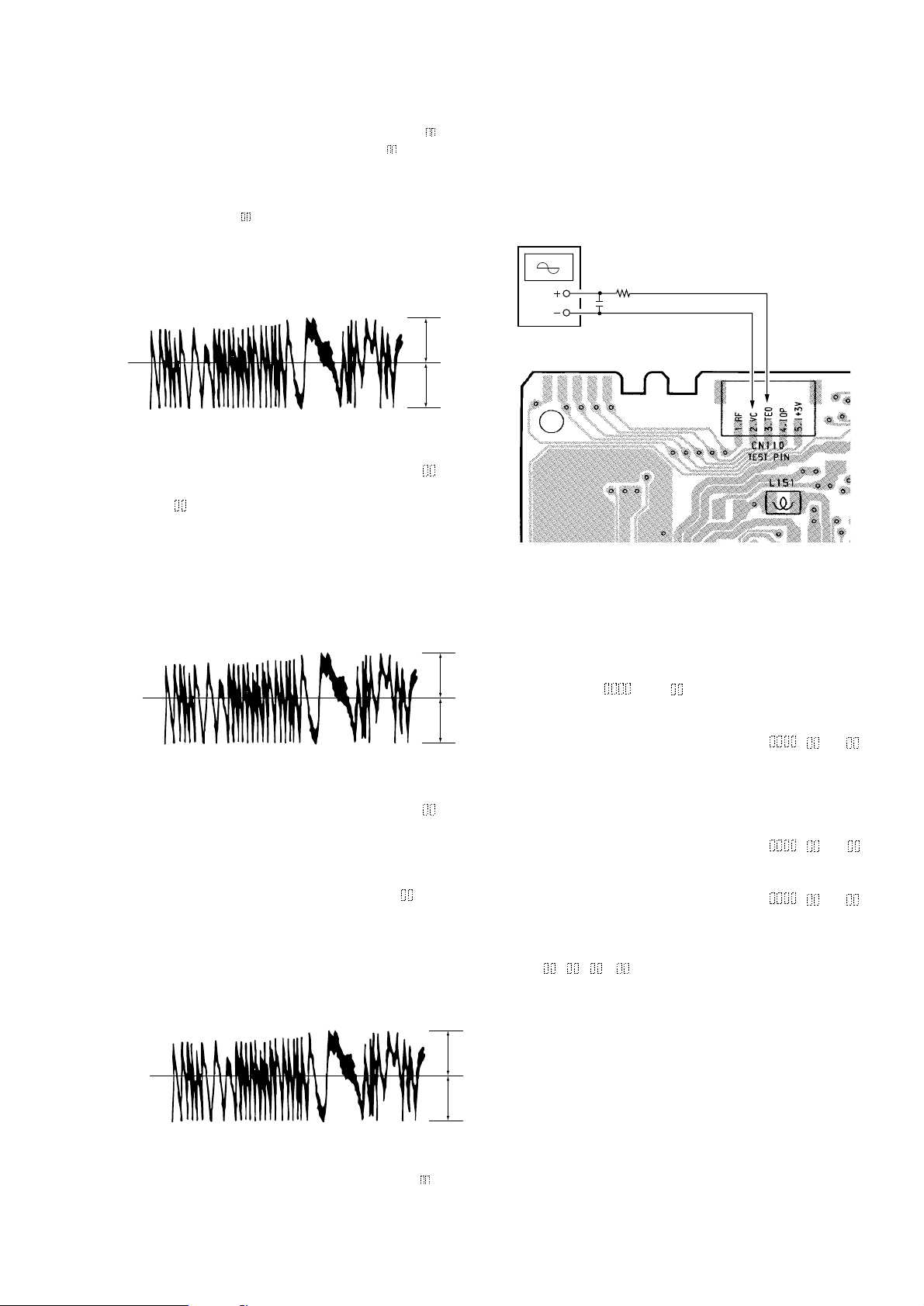

5-7. TRA VERSE ADJUSTMENT

Connection:

Oscilloscope

CN110 3 pin (TEO)

CN110 2 pin (VC)

VOLT/DIV : 0.5V

TIME/DIV : 10msec

Input: DC mode

[BD BOARD] (SIDE A)

Procedure:

1. Connect the oscilloscope to the CN110 3 pin (TEO) and CN110

2 pin (VC) of the BD board.

2. Insert a disk (any commercially available disk) that may be recorded on (see Note 1).

3. Press the 0 or ) button to shift the optical pick-up to the

outer edge of the pit.

4. Turn the AMS dial until “ EFBAL ADJUST ” is displayed.

5. Press the YES/ENTER button to display “ EFB=

(The unit will be in the condition of: laser power READ power,

focus servo ON, tracking servo OFF and spindle (S) servo ON.)

6. Turn the AMS dial so that the waveform on the oscilloscope is

that of the specified value (turning the AMS dial will change

the numbers of “ EFB=

” as well as the waveform). During

this adjustment, the waveform changes for approximately every 2%. Adjust the waveform closest to the specified value.

(read power traverse adjustment)

(Traverse waveform)

VC

MO-R ”.

B

– 22 –

Specification: A=B

7. Press the YES/ENTER button to save the adjustment result to

A

A

A

the non-volatile storage memory (at this time “ EFB=

” will be displayed for an instant, then “ EFB=

SAVE

MO-W ” will

be displayed).

8. Turn the AMS dial so that the waveform on the oscilloscope is

that of the specified value (turning the AMS dial will change the

numbers of “ EFB=

” as well as the waveform). During this

adjustment, the waveform changes for approximately every 2%.

Adjust the waveform closest to the specified value.

(write power traverse adjustment)

(Traverse waveform)

18.Press the MD EJECT button to remove the check disk (MD)

TDYS-1.

Note 1: When using a pre-recorded disk for adjustment, data will

be deleted during MO write.

Note 2: If the traverse waveform is hard to see, reconnect the

oscilloscope as shown below for easier view.

Oscilloscope

Ω

330k

CN110 3 pin (TEO)

VC

B

Specification: A=B

9. Press the YES/ENTER button to save the adjustment result to

the non-volatile storage memory (at this time “ EFB=

SA VE

” will be displayed for an instant).

10 “ EFB=

MO-P ” will then be displayed and the servo will be

activated after the optical pickup is automatically shifted to the

inner edge of the pit.

11. At this time, turn the AMS dial so that the waveform on the

oscilloscope is that of the specified value. During this adjustment, the waveform changes for approximately every 2%. Adjust the waveform closest to the specified value.

(Traverse waveform)

VC

B

Specification: A=B

12.Press the YES/ENTER button to save the adjustment result to

the non-volatile storage memory (at this time “ EFB= SA VE

” will be displayed for an instant). “EFBAL CD” will then be

displayed and the rotation of the disk will automatically stop.

13.Press the MD EJECT button to remove the disk.

14.Insert the check disk (MD) TDYS-1.

15.Press the YES/ENTER button to display “ EFB=

CD ”. The

servo will automatically be activated.

16.Turn the AMS dial so that the waveform on the oscilloscope is

that of the specified value. During this adjustment, the waveform changes for approximately every 2%. Adjust the waveform closest to the specified value.

(Traverse waveform)

10pF

[BD BOARD] (SIDE A)

CN110

2

pin (VC)

5-8. FOCUS BIAS ADJUSTMENT

Procedure:

1. Insert a continuously recorded disk (see 5-4. Creating a continuous recording disk).

2. Turn the AMS dial until “CPLAY MODE” is displayed.

3. Press the YES/ENTER button to display “CPLAY MID”.

4. When “C1=

CEL button.

5. Turn the AMS dial until “FBIAS ADJUST” is displayed.

6. Press the YES/ENTER button to display “

The first 4 digits indicate the C1 error rate, the 2 digits following “/” indicate ADER and the 2 digits following “a=” indicate

the focus bias volume.

7. Turn the AMS dial clockwise and search the focus bias volume

closest to the C1 error rate of 220 (see Note 2).

8. Press the YES/ENTER button to display “

9. Turn the AMS dial counterclockwise and search the focus bias

volume which is the C1 error rate of 220.

10.Press the YES/ENTER button to display “

11.Press the YES/ENTER button after making sure that the C1 er ror rate is below 50 and ADER is 00.

12.Press the YES/ENTER button if the value indicated in the

“

- - ( )” display is more than 20.

Otherwise, press the NO/CANCEL button and repeat procedure

from step 2.

13.Press the MD EJECT button to remove the continuously recorded

disk.

AD= ” is displayed, press the NO/CAN-

/ a= ”.

/ b= ”.

/ c= ”.

VC

B

Specification: A=B

17.Press the YES/ENTER button to save the adjustment result to

the non-volatile storage memory (at this time “EFB=

will be displayed for an instant). “EFBAL ADJUST” will then

SA VE”

be displayed.

Note 1: The relationship of the C1 error and focus bias volume is

shown in the diagram below. Find points a and b shown

in the diagram by following the procedure above. The

met focal point C is found by automatic calculation.

Note 2: The C1 error rate fluctuates. Thus, make the adjustment

using the average value.

– 23 –

Loading...

Loading...