Sony XR-L500, XR-L500V, XR-L500X Service Manual

XR-L500/L500V/L500X

SERVICE MANUAL

Ver 1.1 2001.05

Photo: XR-L500

SPECIFICATIONS

Cassette Player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.08 % (WRMS)

Frequency response 30 – 18,000 Hz

Signal-to-noise ratio

Cassette type

TYPE II, IV 61 dB

TYPE I

Tuner section

FM

Tuning range 87.5 – 108.0 MHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

MW/LW

Tuning range MW: 531 – 1,602 kHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity MW: 30 µV

72 dB (mono)

0.6 % (stereo),

0.3 % (mono)

LW: 153 – 279 kHz

LW: 40 µV

58 dB

AEP Model

UK Model

Model Name Using Similar Mechanism XR-4300R

T ape Transport Mechanism Type MG-25G-136

General

Outputs Audio outputs (Rear)

Inputs Telephone ATT cont ro l lead

Tone controls Bass ±8 dB at 100 Hz

Loudness 100 Hz +8 dB

Power requirements 12 V DC car battery

Dimensions Approx. 178 × 50 × 176

Mounting dimensions Approx. 182 × 53 × 161

Mass Approx. 1.2 kg

Supplied accessories Parts for installation and

Note

This unit cannot be connected to a digital preamplifier

or an equalizer.

Design and specifications are subject to change

without notice.

Power aerial relay control

lead

Power amplifier con trol lead

Remote controller input

connector

Aerial input connector

Treble ±8 dB at 10 kHz

10 kHz +2 dB

(negativ e eart h )

mm (w/h/d)

mm (w/h/d)

connections (1 set)

Front panel case (1)

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power output 50 W × 4 (at 4 ohms)

(sure seal connectors)

FM/MW/LW CASSETTE CAR STEREO

9-870-247-12 Sony Corporation

2001E0500-1 e Vehicle Company

C 2001.5 Shinagawa Tec Service Manual Production Group

SECTION 4

frequency counter

test tape

WS-48A

(3 kHz, 0 dB)

set

AUDIO OUT REAR jack (CNJ151)

–

+

10 kΩ

MECHANICAL ADJUSTMENTS

XR-L500/L500V/L500X

SECTION 5

ELECTRICAL ADJUSTMENTS

1. Clean the following parts with a denatured-alcohol-moistened

swab:

playback head pinch roller

rubber belt capstan

idler

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the power supply

voltage (14.4 V) unless otherwise noted.

• T orque Measurement

Mode Torque Meter Meter Reading

Forward CQ-102C (30 – 65 g•cm)

Forward

Back Tension

Reverse CQ-102RC (30 – 65 g•cm)

Reverse

Back Tension

FF, REW CQ-201B (60 – 200 g•cm)

CQ-102C (0.5 – 4.5g•cm)

CQ-102RC (0.5 – 4.5g•cm)

2.95 – 6.37 mN•m

(0.42 – 0.90 oz•inch)

0.05 – 0.44 mN•m

(0.01 – 0.06 oz•inch)

2.95 – 6.37 mN•m

(0.42 – 0.90 oz•inch)

0.05 – 0.44 mN•m

(0.01 – 0.06 oz•inch)

5.89 – 19.61 mN•m

(0.83 – 2.78 oz•inch)

• T ape Tension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A

Reverse CQ-403R

more than 60 g

(more than 2.12 oz)

more than 60 g

(more than 2.12 oz)

TAPE DECK SECTION

0 dB=0.775 V

Tape Speed Adjustment

Setting:

Procedure:

1. Put the set into the FWD PB mode.

2. Adjust adjustment resistor for inside capstan motor so that the

reading on the frequency counter becomes 3,000 Hz.

Specification: Constant speed

Frequency counter

2,955 to 3,075 Hz

Adjustment Location:

– SET UPPER VIEW –

Tape Speed Adjustment

TUNER SECTION

Tuner section adjustments are done automatically in this set.

13

XR-L500/L500V/L500X

SECTION 6

DIAGRAMS

6-1. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

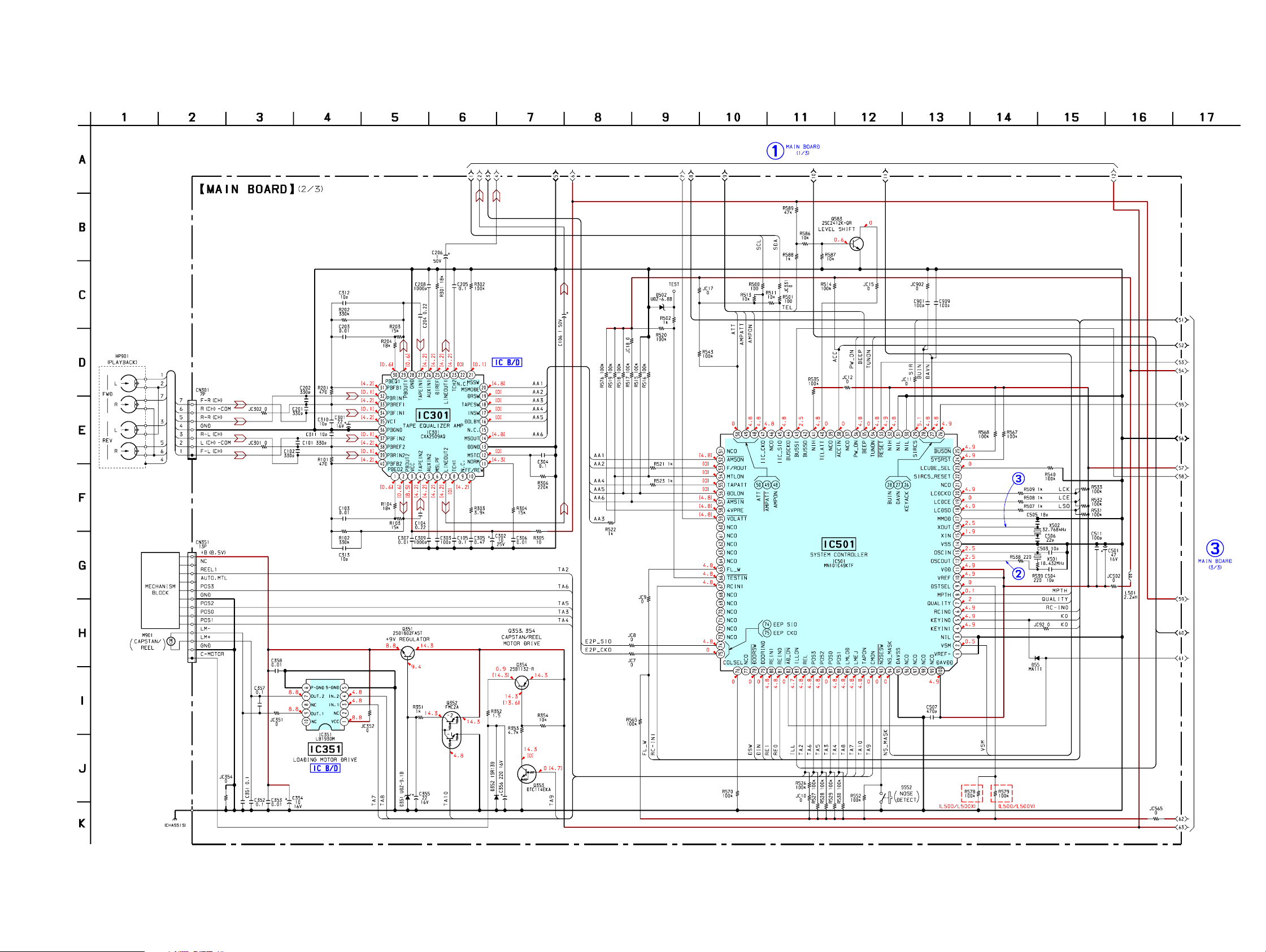

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• C : panel designation.

• A : B+ Line.

• Power v oltage is dc 14.4V and fed with regulated dc power

supply from ACC and BATT cords.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : FM

( ) : MW/LW

〈〈 〉〉 : TAPE PLA YBACK

• Voltages are tak en with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : MW/LW

E : T APE PLA YBA CK

L : BUS AUDIO IN

: Impossible to measure

∗

4

W or less unless otherwise

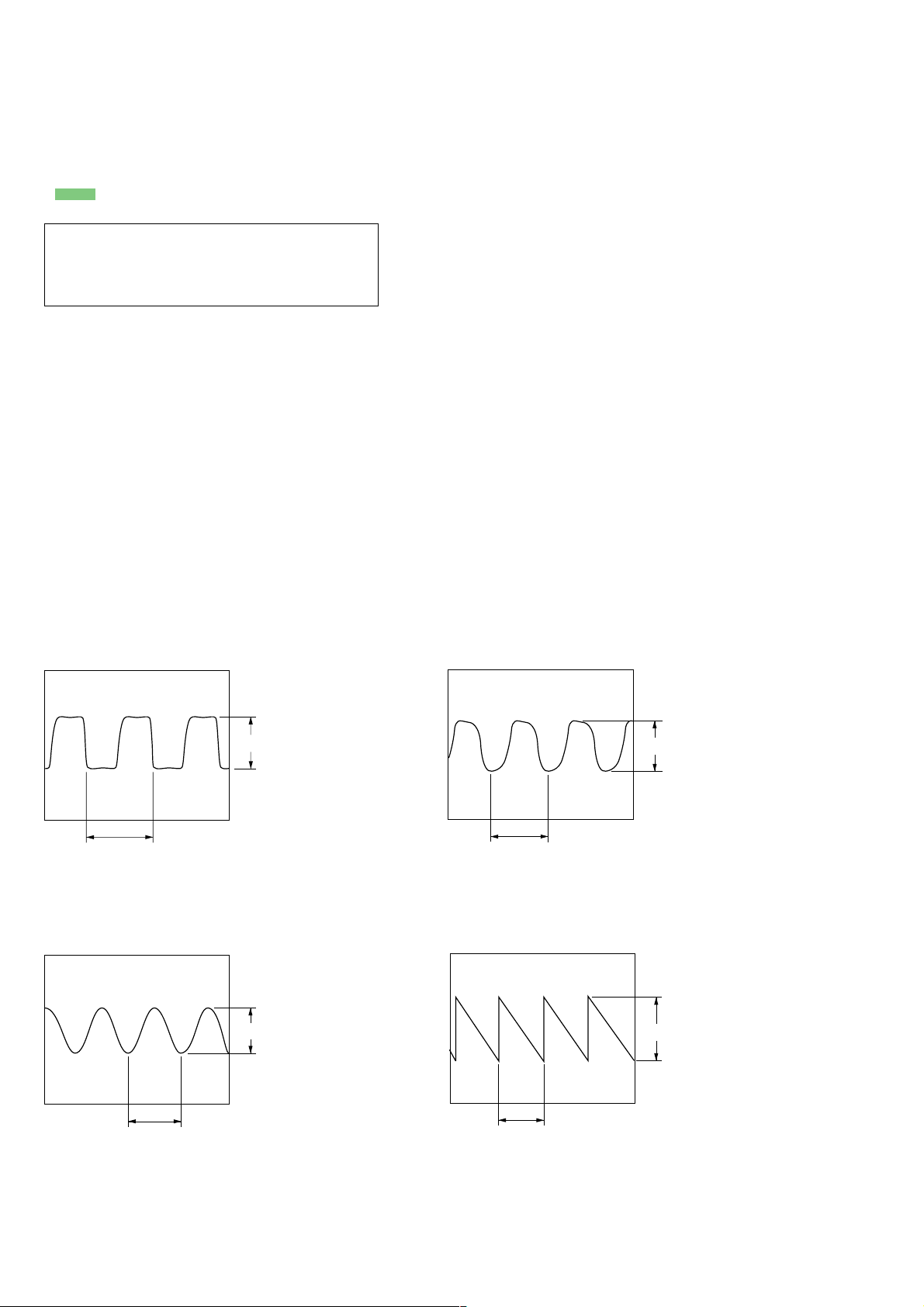

• Waveforms

– MAIN Board –

1 IC51 4 (OSCO)

232 ns

2 IC501 qs (OSCOUT)

5 Vp-p

3.3 Vp-p

3 IC501 qh (XOUT)

5 Vp-p

30.8 µs

– KEY Board –

4 IC900 uf (OSC)

2.5 Vp-p

14

54.4 ns

22.4 µs

XR-L500/L500V/L500X

6-3. SCHEMATIC DIAGRAM – MAIN Board (1/3) – • See page 14 for Waveform. • See page 23 for IC Block Diagrams.

(Page 17) (Page 18)

1616

6-4. SCHEMATIC DIAGRAM – MAIN Board (2/3) – • See page 14 for Waveforms. • See page 23 for IC Block Diagrams.

XR-L500/L500V/L500X

(Page 16)

(Page 18)

1717

Loading...

Loading...