Sony XRH-592-WG Service manual

XR-H592WG/H593WG

SERVICE MANUAL

Photo: XR-H593WG

Dolby noise reduction manufactured under license from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol ; are trademarks of Dolby

Laboratories Licensing Corporation.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Model Name Using Similar Mechanism XR-H572A/H573A

Tape Transport Mechanism Type MG-25H-136

FM/AM CASSETTE CAR STEREO

1

TABLE OF CONTENTS

1. DISASSEMBLY

1-1. Cover ..................................................................................3

1-2. Front Panel Assy ................................................................ 3

1-3. Mechanism Deck Block .....................................................4

1-4. Main Board ........................................................................4

2. ASSEMBLY OF MECHANISM DECK

2-1. Arm (Drive) Assy ...............................................................5

2-2. Gear (LDG-D) .................................................................... 5

2-3. Gear (LDG-B) ....................................................................6

2-4. Gear Position Setting .........................................................6

2-5. Chassis (S) Assy.................................................................7

2-6. Lever (Mode)......................................................................7

2-7. Head Plate Assy ................................................................. 8

2-8. Lever (Pinch) Assy .............................................................8

2-9. Main Motor Assy ...............................................................9

2-10. Flywheel (F) .......................................................................9

2-11. Belt (25) ...........................................................................10

2-12. Hanger ..............................................................................10

2-13. Housing ............................................................................ 11

2-14. Arm (Suction) Assy..........................................................11

2-15. Lever (LDG-A) ................................................................12

2-16. Lever (LDG-B).................................................................12

2-17. Gear (Loading FT) ...........................................................13

3. MECHANICAL ADJUSTMENTS...........................14

4. ELECTRICAL ADJUSTMENTS

Tape Section .........................................................................14

Tuner Section........................................................................15

5. DIAGRAMS

5-1. Block Diagram –Tape Section– ....................................... 19

5-2. Block Diagram –Tuner Section–......................................20

5-3. Block Diagram –Control Section– ...................................21

5-4. Printed Wiring Boards –Main Section– ...........................22

5-5. Schematic Diagram –Main Section (1/3)– ....................... 24

5-6. Schematic Diagram –Main Section (2/3)– ....................... 25

5-7. Schematic Diagram –Main Section (3/3)– ....................... 26

5-8. Schematic Diagram –Display Section–............................27

5-9. Printed Wiring Boards –Display Section– .......................28

5-10. IC Pin Description............................................................32

6. EXPLODED VIEWS

6-1. Chassis Section ................................................................34

6-2. Front Panel Section .......................................................... 35

6-3. Mechanism Deck Section (1) ...........................................36

6-4. Mechanism Deck Section (2) ...........................................37

6-5. Mechanism Deck Section (3) ...........................................38

7. ELECTRICAL PARTS LIST ...................................39

2

SECTION 1

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

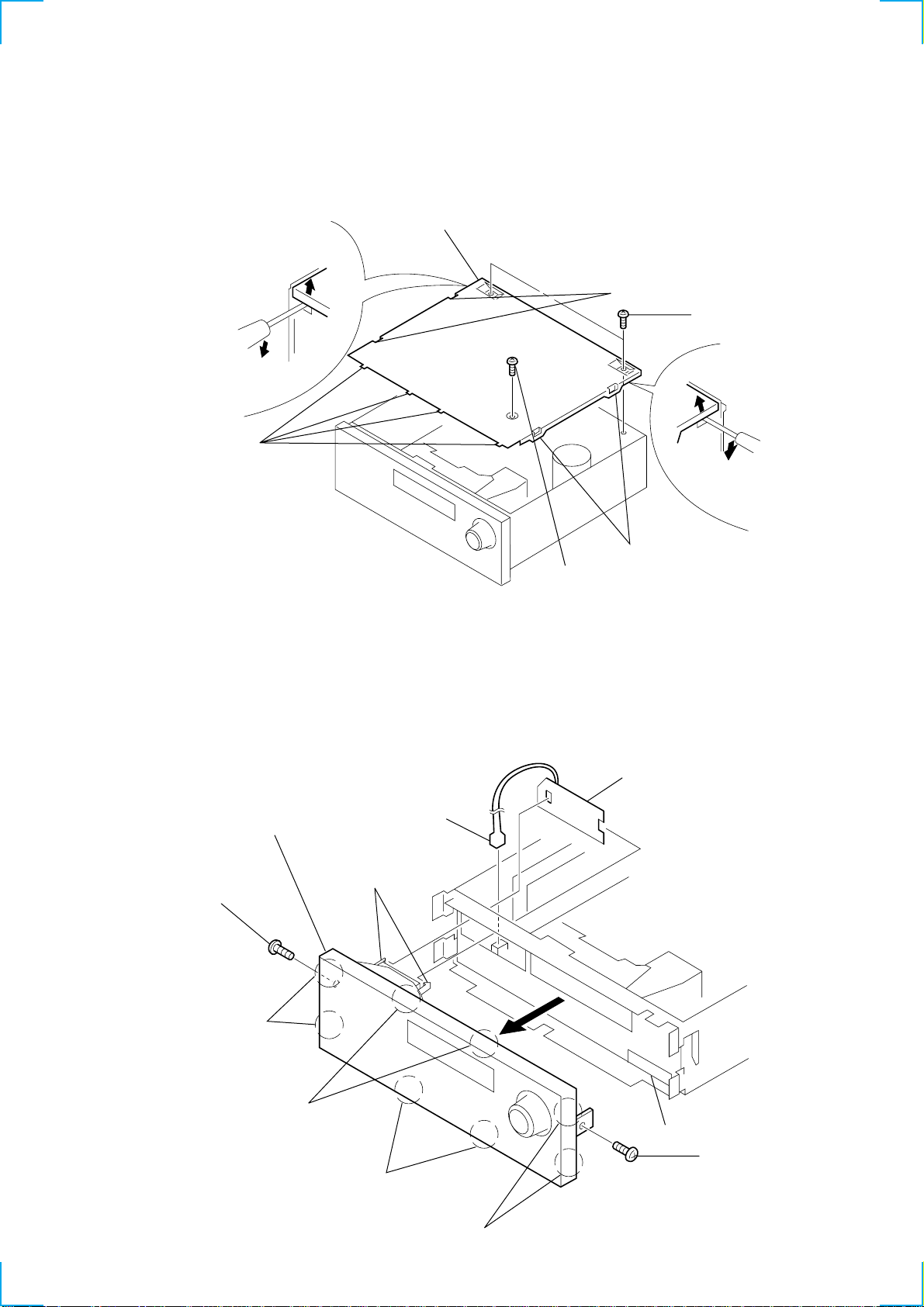

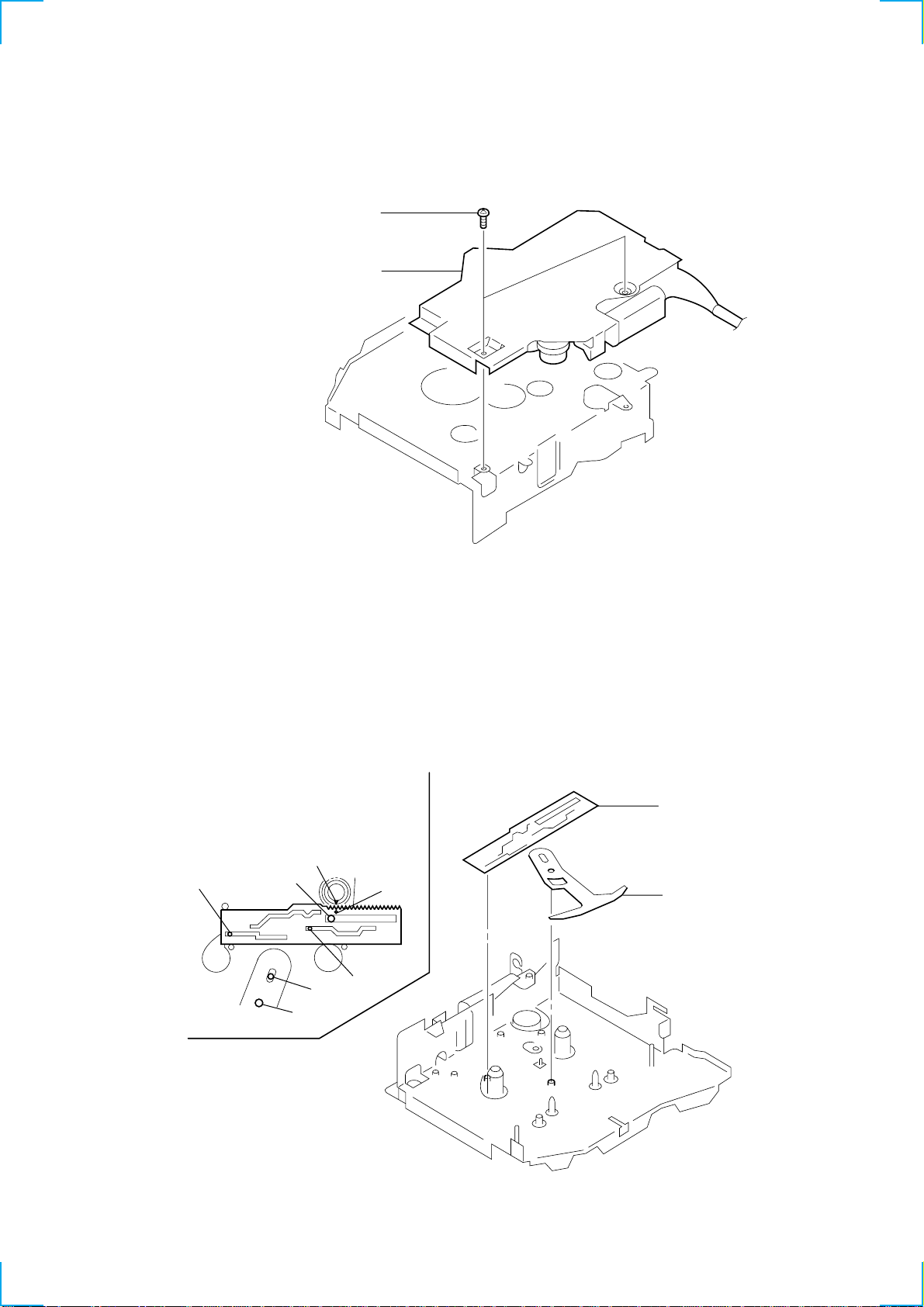

1-1. COVER

6 cover

5 claws

4 claws

1 P 2.6x6

1-2. FRONT PANEL ASSY

Note : When removing the LAMP board from the holder (B), take

care not to bend or break the claw of the holder.

2 CN802

0 front panel assy

claws

(holder (B))

3 screw (TP)

3 claws

2 P 2.6x8

1 LAMP board

5 claws

6 claws

9 CN800

4 screw (TP)

7 claws

8 claws

3

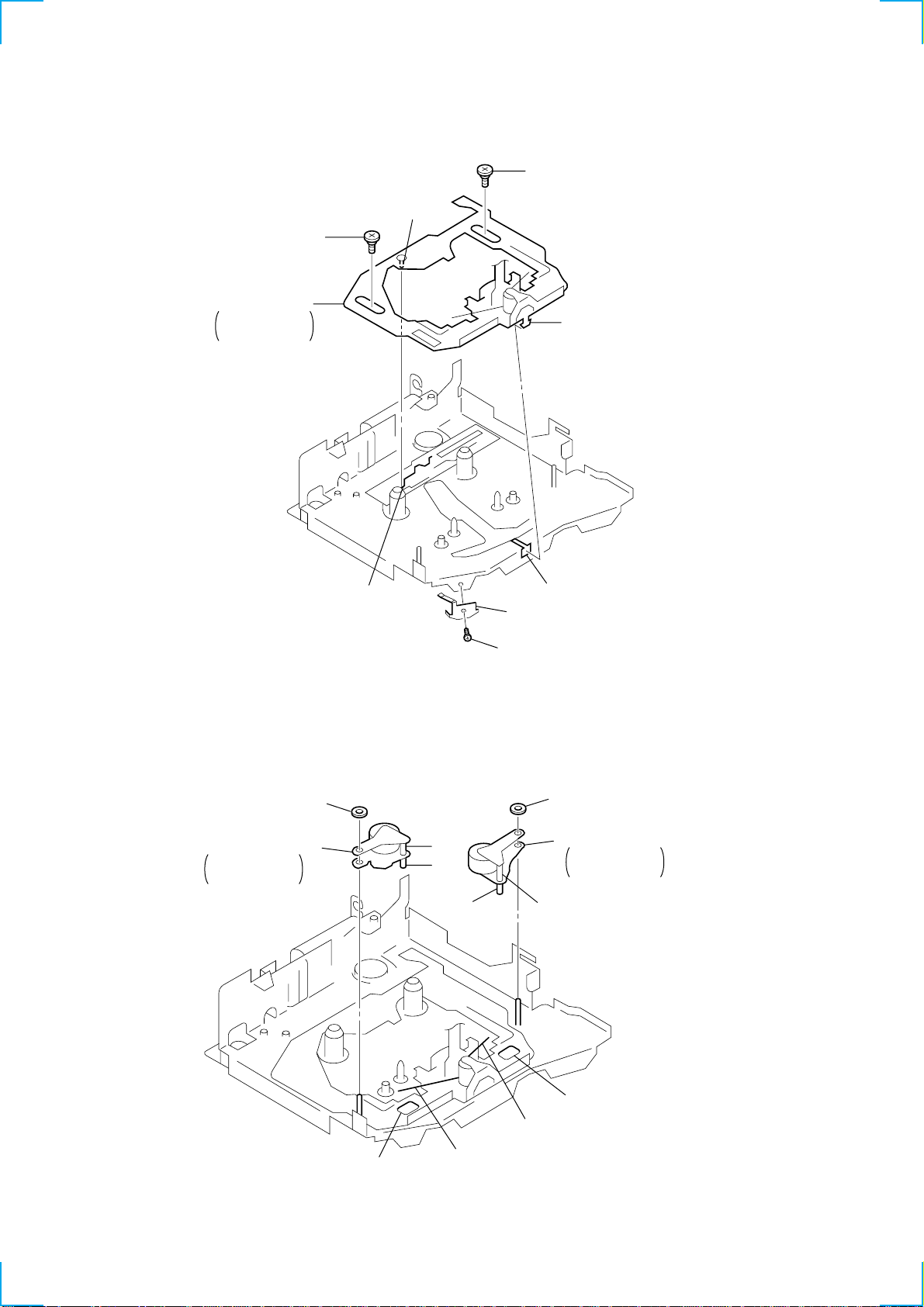

1-3. MECHANISM DECK BLOCK

6

1 P 2.6x6

5 mechanism deck block

1 P 2.6x6

4 CNP501

3 CNP401

1-4. MAIN BOARD

4 MAIN board

3 P 2.6x6

1 P 2.6x

2 P 2.6x6

4

D

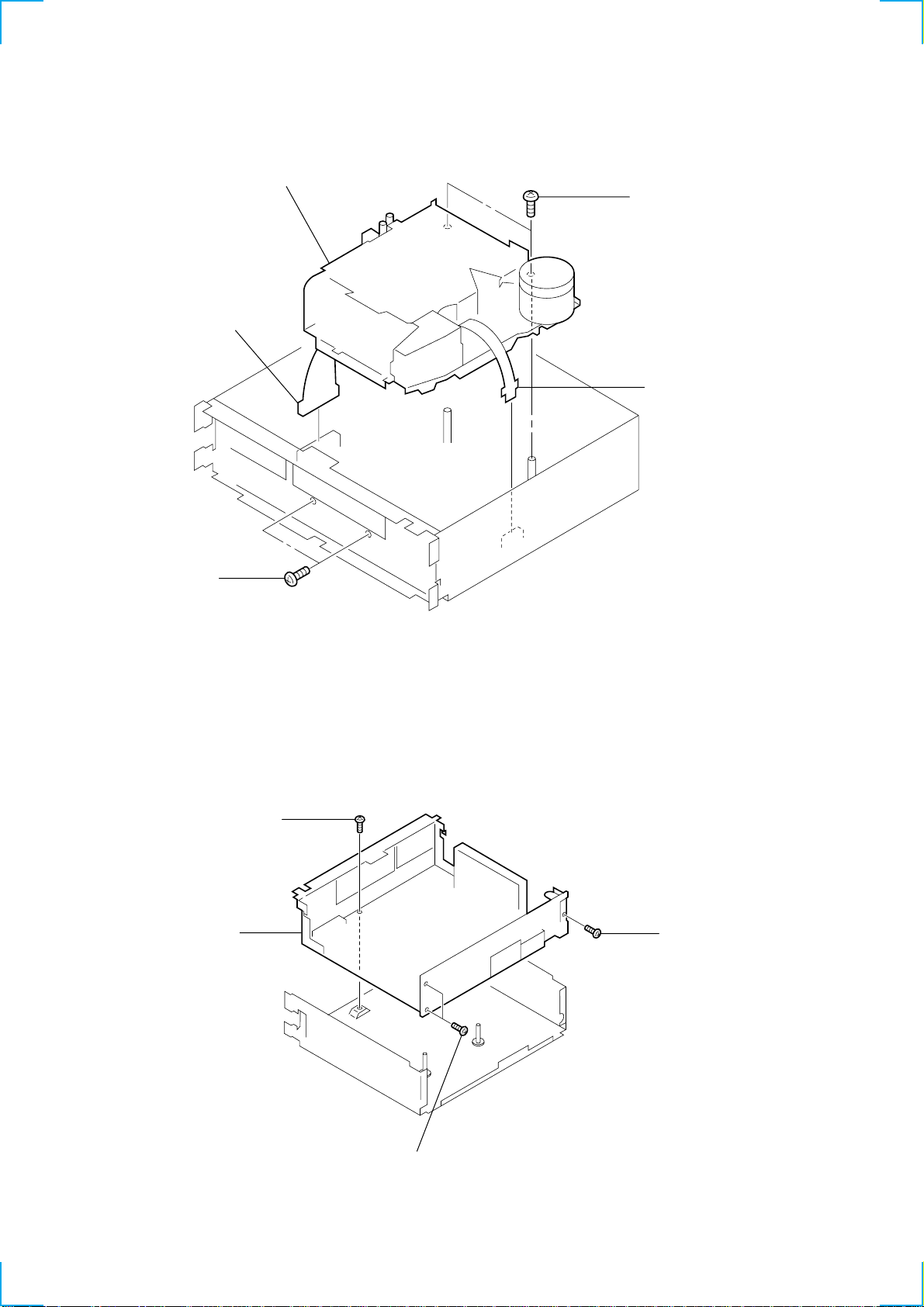

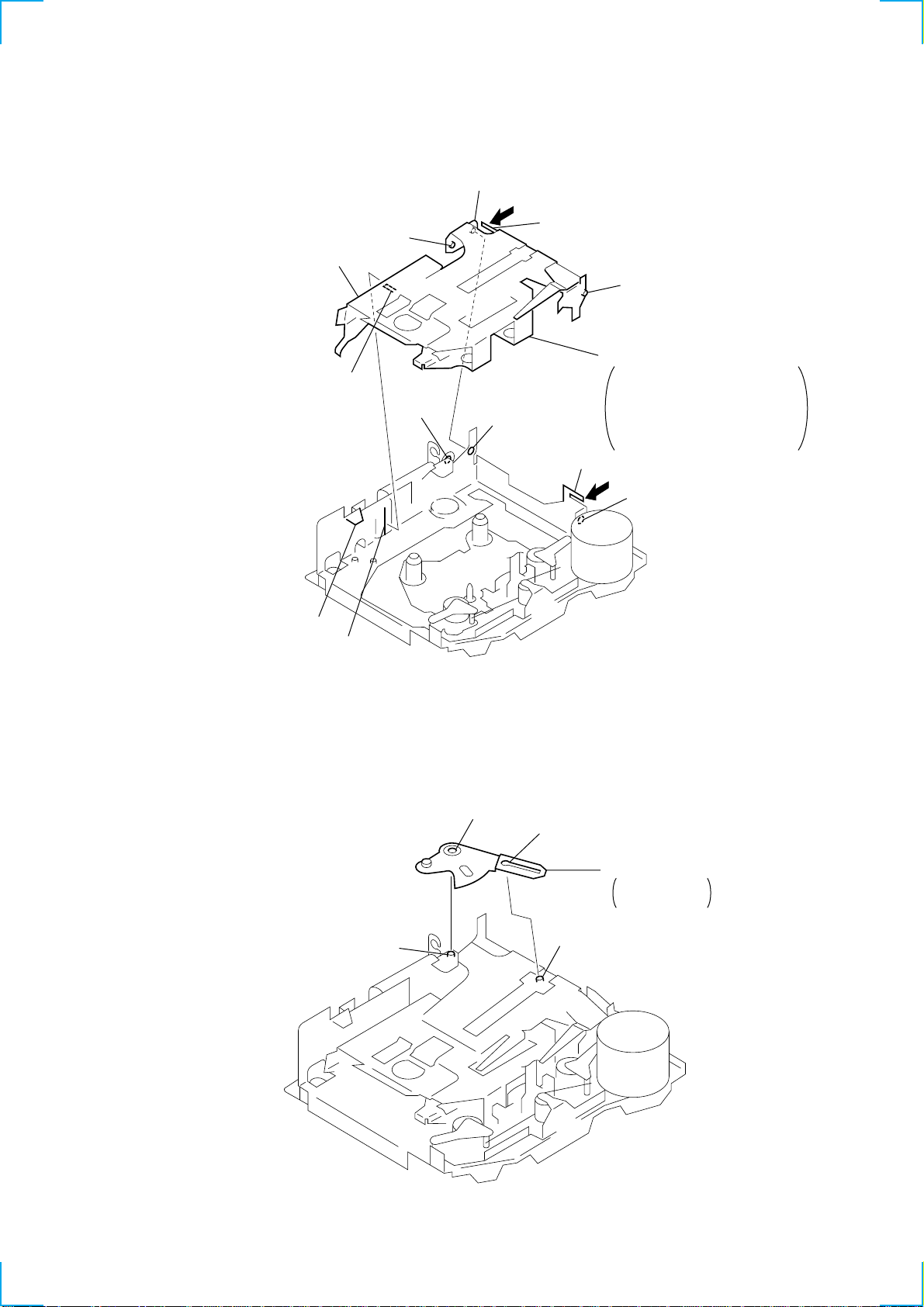

SECTION 2

ASSEMBLY OF MECHANISM DECK

Note : Follow the assembly procedure in the numerical order given.

2-1. ARM (DRIVE) ASSY

Part A

2 gear (LDG-FB)

(Align part A as

shown in the figure.)

1 arm (drive) assy

2-2. GEAR (LDG-D)

B

A

D

1 gear (LDG-D)

(Position A with B and C with

and install them.)

C

5

D

e

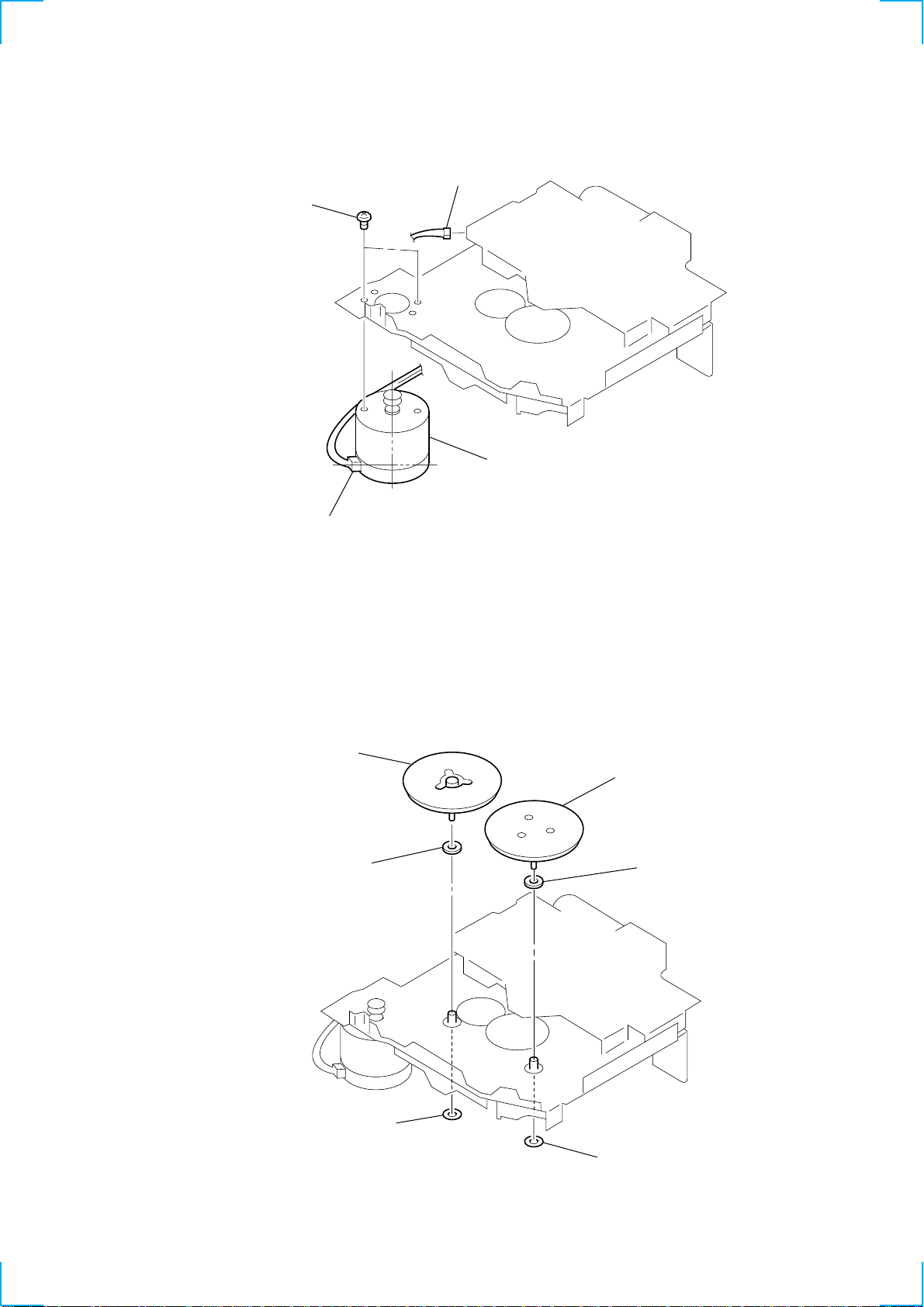

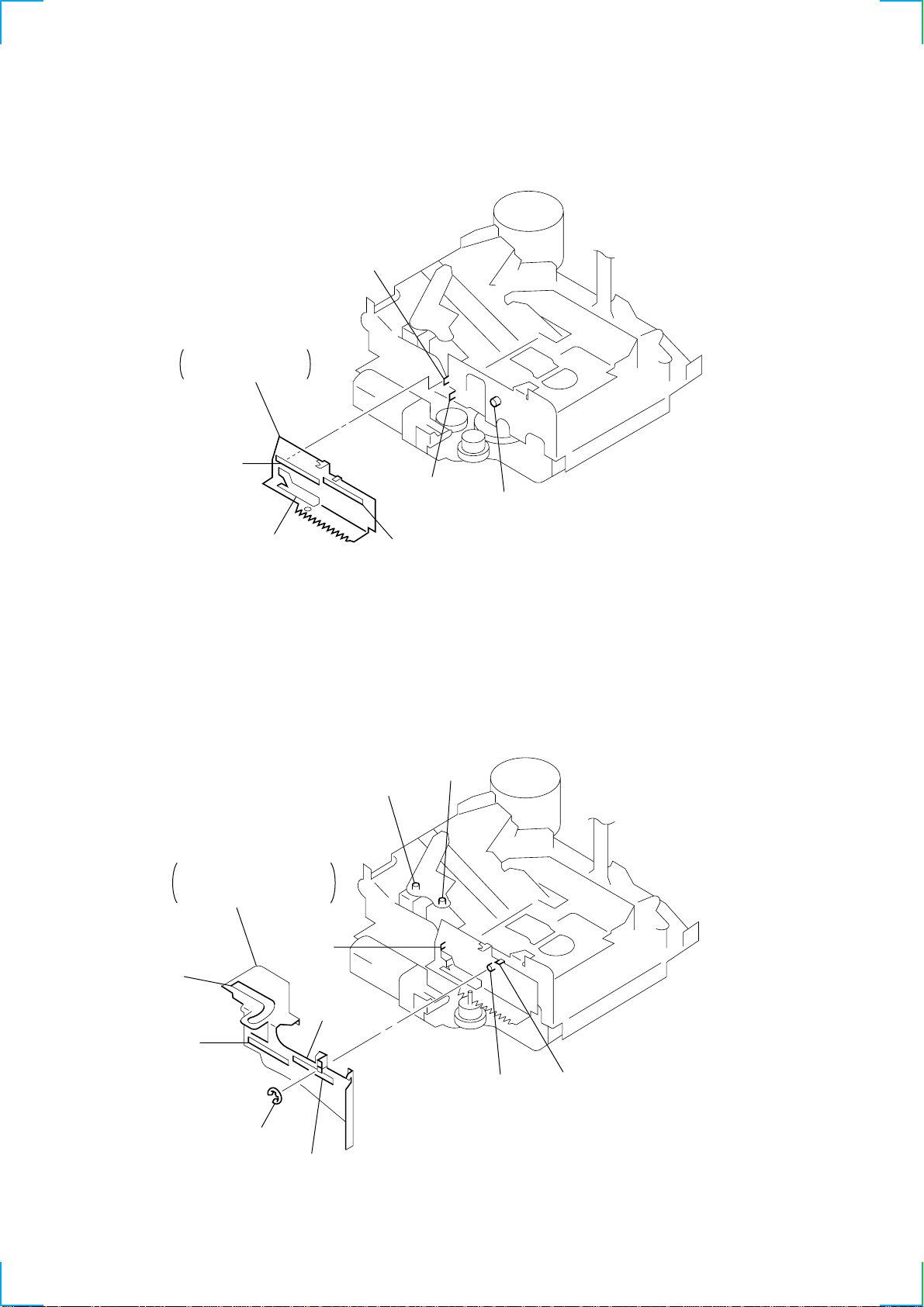

2-3. GEAR (LDG-B)

3 gear (LDG-B)

2 stopper washer

B

D

1 gear (LDG-E)

(Position A with B and C with

and install them.)

A

C

2-4. GEAR POSITION SETTING

• Align A with B.

• Align B with the hole in the chassis (S) assy.

• Align C with the hole in the chassis (S) assy.

• Face D to the rotary slide switch.

• Align E with F.

gear (LDG-FB)

A

B

gear (LDG-D)

gear (LDG-B)

C

gear (LDG-E)

D

switch, rotary slid

E

F

chassis (S) assy

6

)

2-5. CHASSIS (S) ASSY

1 chassis (S) assy

2 PS 2x4

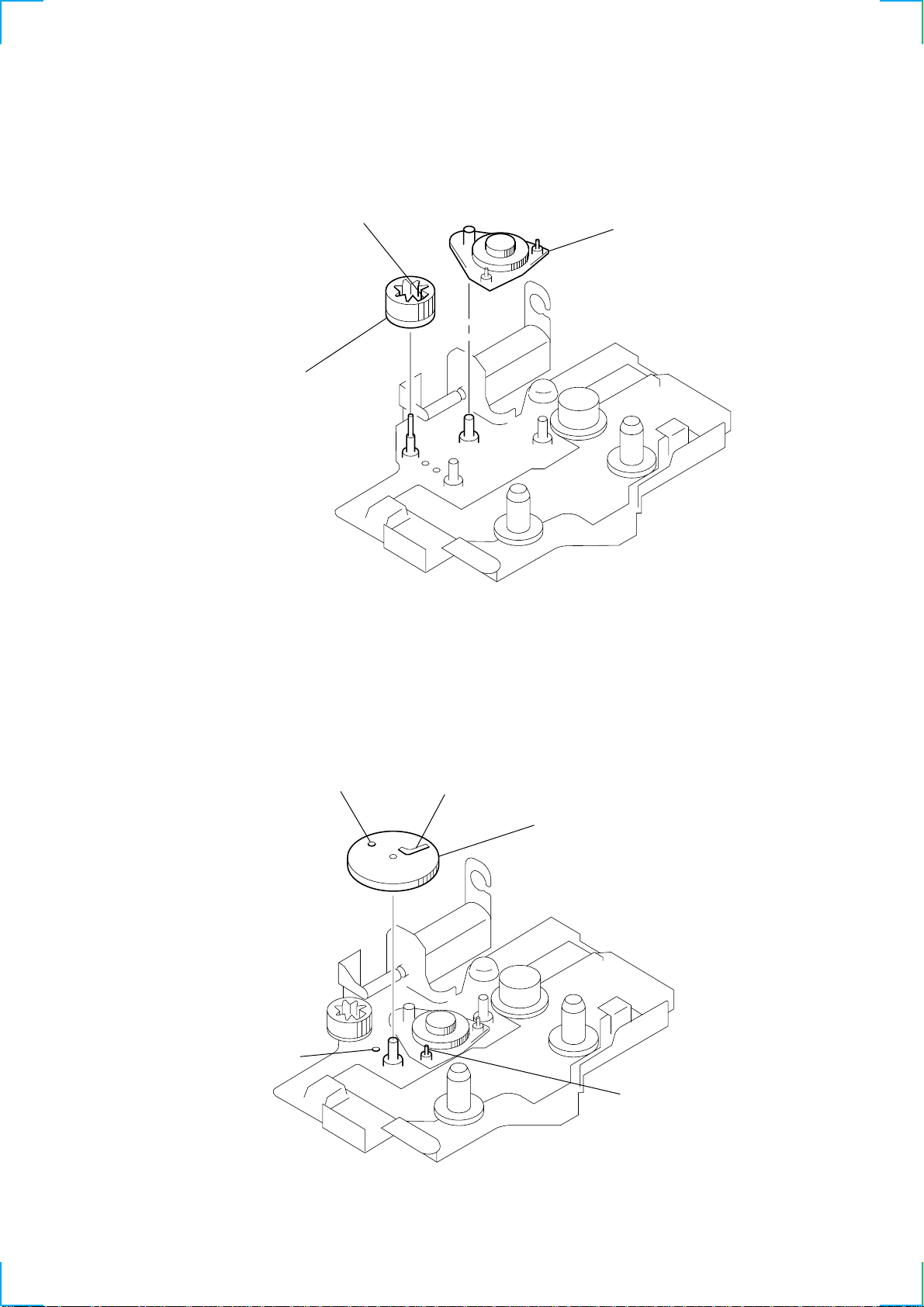

2-6. LEVER (MODE)

• Align A of rotary slide switch with

B of lever (mode).

• Check that each of C through G

is put in the groove.

E

1 lever (mode)

A

C

F

G

B

D

2 lever (pinch selection

7

y

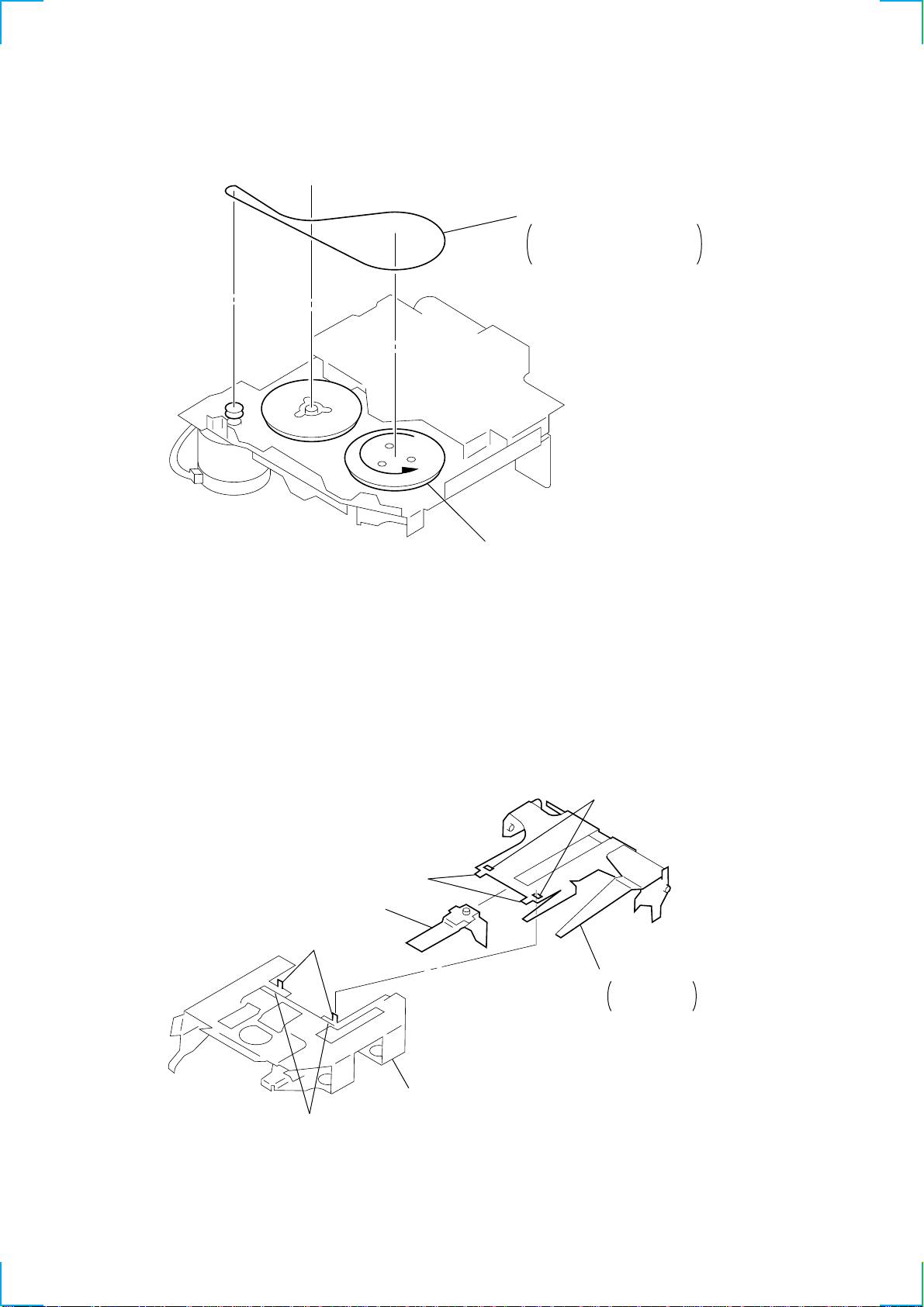

2-7. HEAD PLATE ASSY

1 head plate assy

• Insert A into B.

• Insert C into D.

2 step screw (HP)

C

3 step screw (HP)

A

2-8. LEVER (PINCH) ASSY

1 lever (pinch R) assy

• Insert A into B.

• Hook C to D.

2 washer (pinch)

D

5 P 2x2

D

A

E

B

4 head base retainer spring

4 washer (pinch)

3 lever (pinch F) ass

• Insert E into F.

• Hook G to H.

H

F

G

B

C

8

y

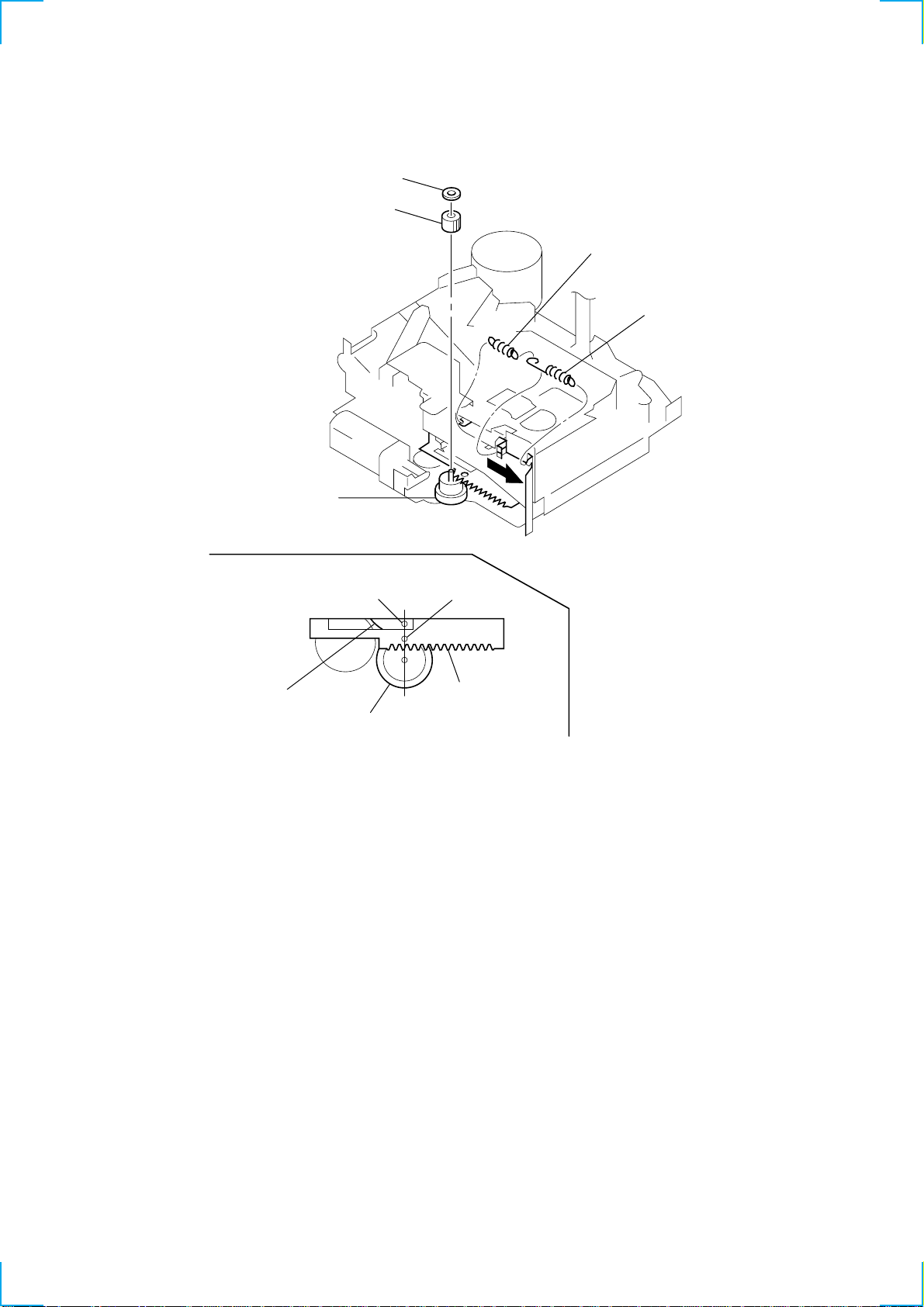

2-9. MAIN MOTOR ASSY

4 P 2x2

1 CN103

3 main motor assy

2 Align the motor terminal with

the position given in the diagrams.

2-10. FLYWHEEL (F)

5 flywheel (F)

4 washer

6 washer

2 clutch (FR) ass

1 washer

3 washer

9

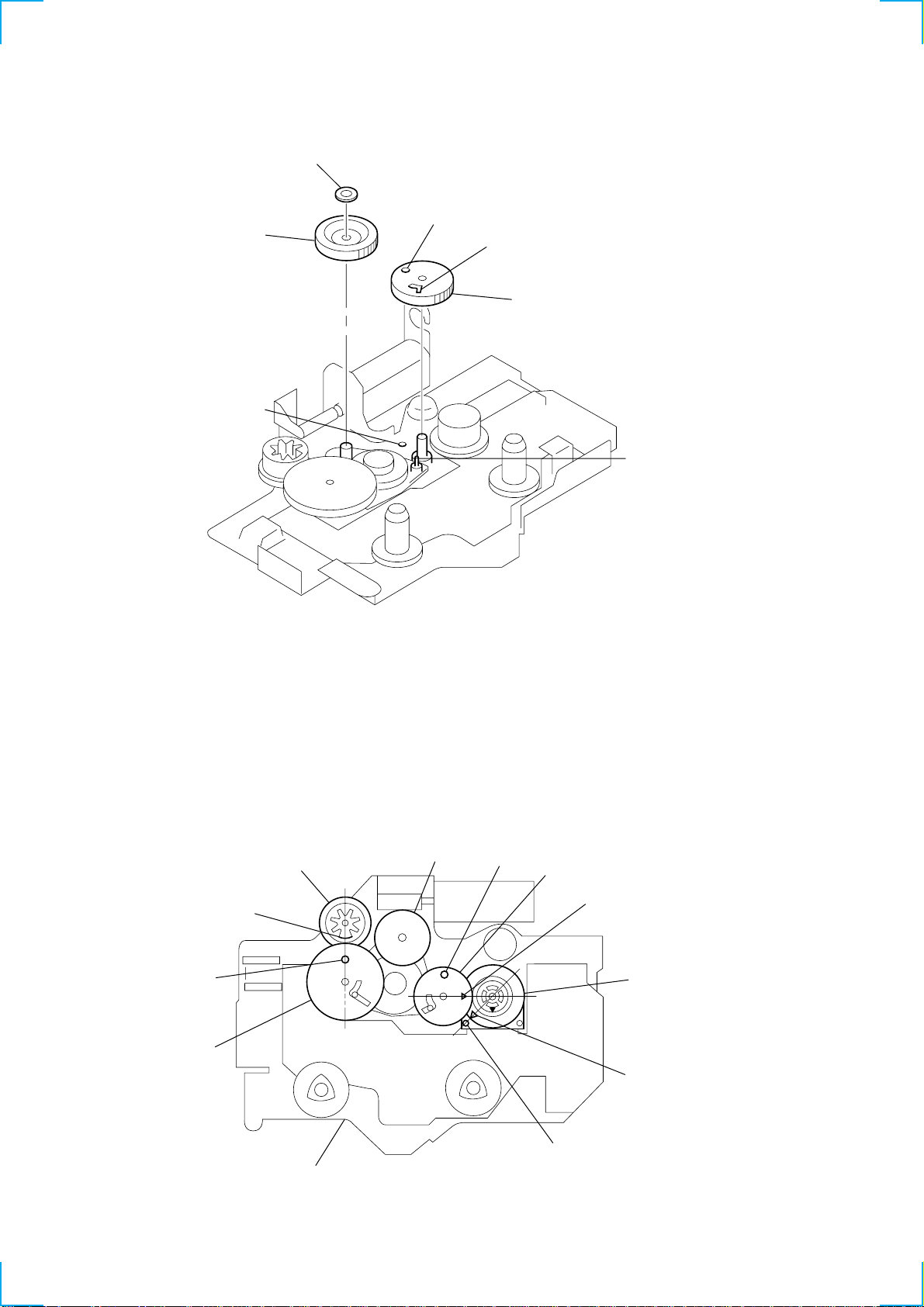

2-11. BELT (25)

1 belt (25)

• Turn the clutch (FR) assy

in the arrowed direction and

correct twist at the belt (25).

clutch (FR) assy

2-12. HANGER

D

A

1 catcher assy

C

2 hanger

• Fit A into B

and C into D.

housing

B

10

2-13. HOUSING

Note : Install the housing with care to avoid

contact with the pinch roller and head.

G

E

A

C

F

B

D

I

L

H

1 housing

• Put A to below B.

• Insert C into D.

• Insert E into F.

• Put G and H into I and J.

• Bend K and L toward the

arrowed directions respectively.

K

J

2-14. ARM (SUCTION) ASSY

C

D

B

1 arm (saction) assy

• Insert A into B.

• Align C with D.

A

11

2-15. LEVER (LDG-A)

1 lever (LDG-A)

• Fit A into B, C into D

and E into F.

B

A

F

D

2-16. LEVER (LDG-B)

1 lever (LDG-B)

• Fit A into B and C into D.

• Fit E into F.

• Put G and H into J.

I

E

B

C

H

G

12

A

2 stop ring 2.0

E

D

C

F

)

2-17. GEAR (LOADING FT)

3 gear (loading FT)

(• Fit A into B.)

gear (LDG-FB)

4 washer

2 tension spring (LD-2)

1 tension spring (LD-1

gear (LDG-D)

B

gear (LDG-FB)

A

gear (LDG-A)

13

r

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Wipe the following components with an absorbent cotton c loth

moistened with alcohol before adjustment :

PB head Pinch roller

Idler Rubber belt

Capstan

2. Demagnetize the PB head using a head demagnetizer.

3. Be careful not to use a magnetized screwdriver.

4. After the adjustment is completed, lock the adjustment parts

using screws.

5. Unless otherwise specified, make adjustments at the specified

voltage (14.4V).

Torque Measurement

Mode Torque Meter Meter Reading

39.3 – 78.4 mN • m

FWD 40 – 80 g • cm

CQ-102C

FWD

Back T ension

REV 40 – 80 g • cm

CQ-102RC

REV

Back T ension

FF, REW CQ-201B 50 – 180 g • cm

(0.56 – 1.11 oz • inch)

0.05 – 0.49 mN • m

0.5 – 5.0 g • cm

(0.01 – 0.07 oz • inch)

39.3 – 78.4 mN • m

(0.56 – 1.11 oz • inch)

0.05 – 0.49 mN • m

0.5 – 5.0 g • cm

(0.01 – 0.07 oz • inch)

4.91 – 17.65 mN • m

(0.7 – 2.5 oz • inch)

See the adjustment location from on page 17 for the adjustment.

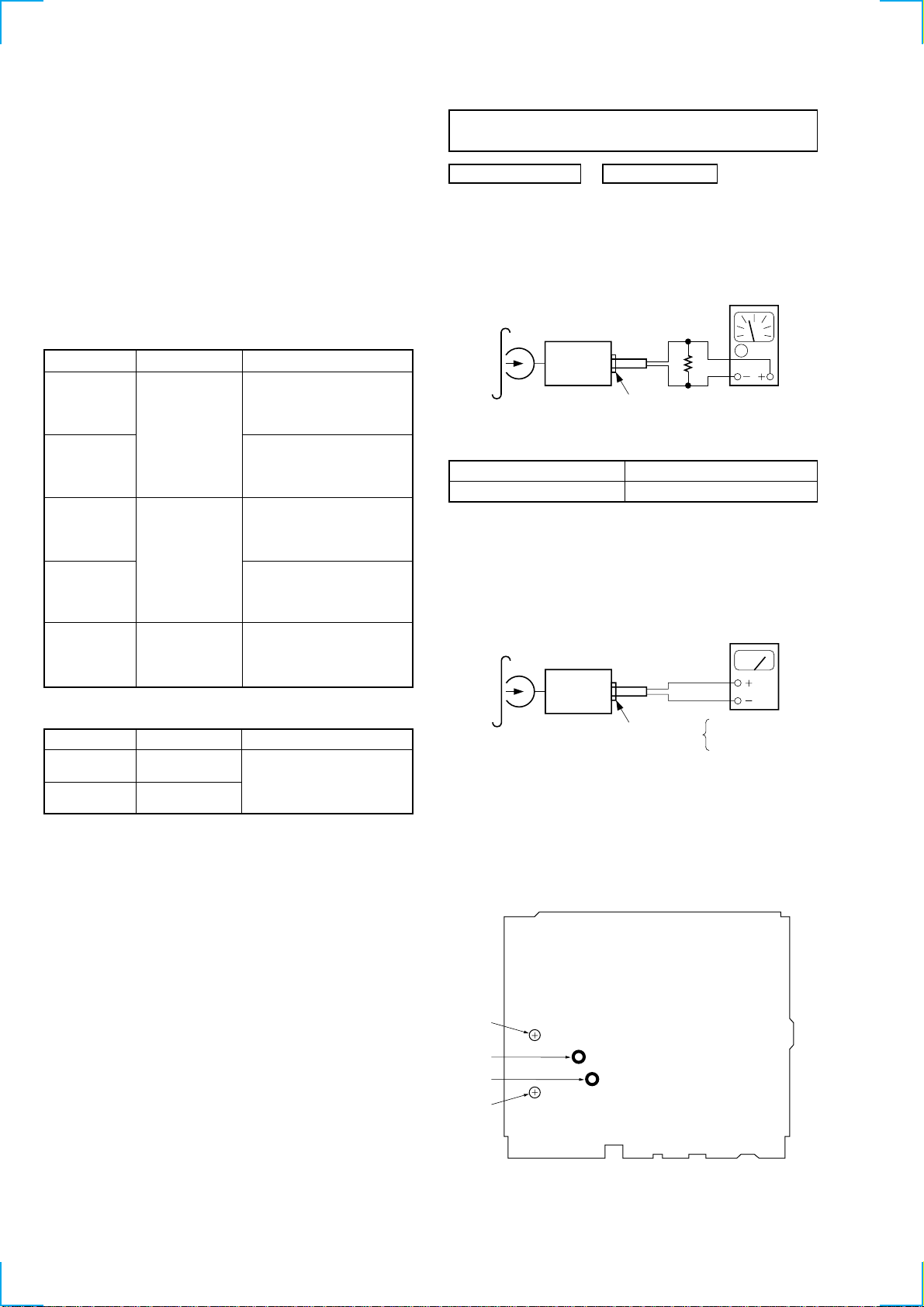

TAPE SECTION

0 dB = 0.775 V

T ape Speed Adjustment

Procedure :

1. Put the set into the FWD PB mode.

speed checker

test tape

WS-48A

(3 kHz, 0 dB)

4 Ω

set

SPEAKER OUT

or

frequency counte

Specification : Constant speed

Speed checker Frequency counter

–1 to + 3 % 2,970 to 3,090 Hz

Adjustment Location : See page 17.

DOLBY Level Adjustment

Setting :

test tape

P-4-D400

(400 Hz, 0 dB)

set

level meter

T ape T ension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A

more than 558.4 mN

more than 60 g

REV CQ-403R

(more than 2.12 oz)

main board

TP (DOLBY)

L-CH

R-CH

Procedure :

1. Put the set into the FWD PB mode.

2. Adjust RV402 (L-CH) and RV401 (R-CH) so that level meter

reading is –6.2 ± 1 dB (0.34 to 4.34 V).

Adjustment Location :

-MAIN BOARD (SIDE B)-

RV401

TP

(RCH)

TP

(LCH)

RV402

14

Loading...

Loading...