Sony XM-1902-SX Service manual

XM-1502SX/1902GX

SERVICE MANUAL

Ver 1.3 2002. 07

Photo: XM-1902GX

SPECIFICATIONS

AUDIO POWER SPECIFICA TIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

150 watts per channel minimum continuous average power into

4 ohms, both channels driven from 20 Hz to 20 kHz with no more

than 0.04% total harmonic distortion per Car Audio Ad Hoc

Committee standards.

US Model

XM-1502SX/1902GX

Canadian Model

AEP Model

UK Model

E Model

XM-1502SX

Other Specifications

Circuit system OTL (output transformerless) circuit

Inputs RCA pin jacks

Outputs Speaker terminals

Speaker impedance 2 – 8 Ω (stereo) (XM-1502SX)

Maximum outputs 300 W × 2 (at 4 Ω)

Rated outputs (supply voltage at 14.4 V)

Frequency response 5 Hz – 100 kHz ( dB)

Harmonic distortion 0.005% or less (at 1 kHz, 4 Ω)

Input level adjustment range

Pulse power supply

High level input connector

Through out pin jacks

1.3 – 8 Ω (stereo) (XM-1902GX)

4 – 8 Ω (when used as a bridging amplifier)

760 W (monaural) at 4 Ω

150 W × 2 (20 Hz – 20 kHz, 0.04% THD,

at 4 Ω)

190 W × 2 (20 Hz – 20 kHz, 0.1% THD,

at 2 Ω)

190 W × 2 (20 Hz – 20 kHz, 0.1% THD,

at 1.3 Ω) (XM-1902GX)

380 W × 1 (20 Hz – 20 kHz, 0.1% THD,

at 4 Ω) (XM-1902GX)

380 W (monaural) (20 Hz – 20 kHz, 0.1% THD,

at 4 Ω) (XM-1502SX)

0.2 – 6.0 V (RCA pin jacks)

0.4 – 12.0 V (High level input)

+0.5

–3

High-pass filter 50 – 300 Hz, –12 dB/oct

Low-pass filter 50 – 300 Hz, –12 dB/oct

Low boost 0 – 10 dB (40 Hz)

Phase shift adjustment range (XM-1902GX)

Power supply voltage 10.5 – 16 V

Current drain at rated output : 40 A (at 4 Ω)

Dimensions Approx. 358 × 50 × 264 mm

Mass Approx. 3.5 kg (7 lb. 11 oz.) not incl. accessories

Supplied accessories Mounting screws (4)

Design and specifications are subject to change without

notice.

0° – 180° (at 40 Hz)

Remote input : 2 mA

1/8 × 2 1/4 × 10 1/2 in.)

(14

(w/h/d) not incl. projecting parts and controls

9-870-239-14

2002G0400-1

© 2002. 07

STEREO POWER AMPLIFIER

Sony Corporation

e Vehicle Company

Published by Sony Engineering Corporation

1

TABLE OF CONTENTS

1. GENERAL

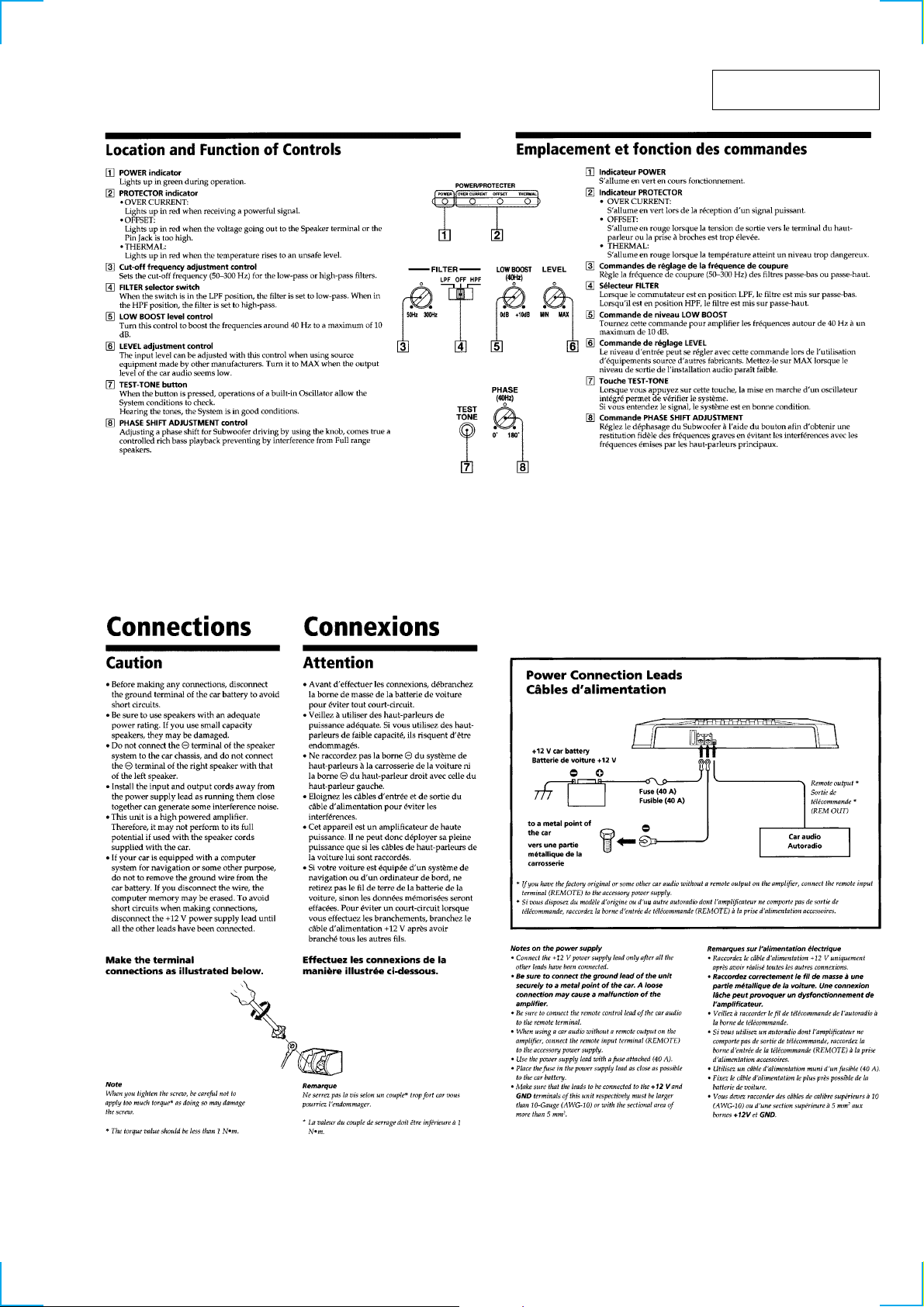

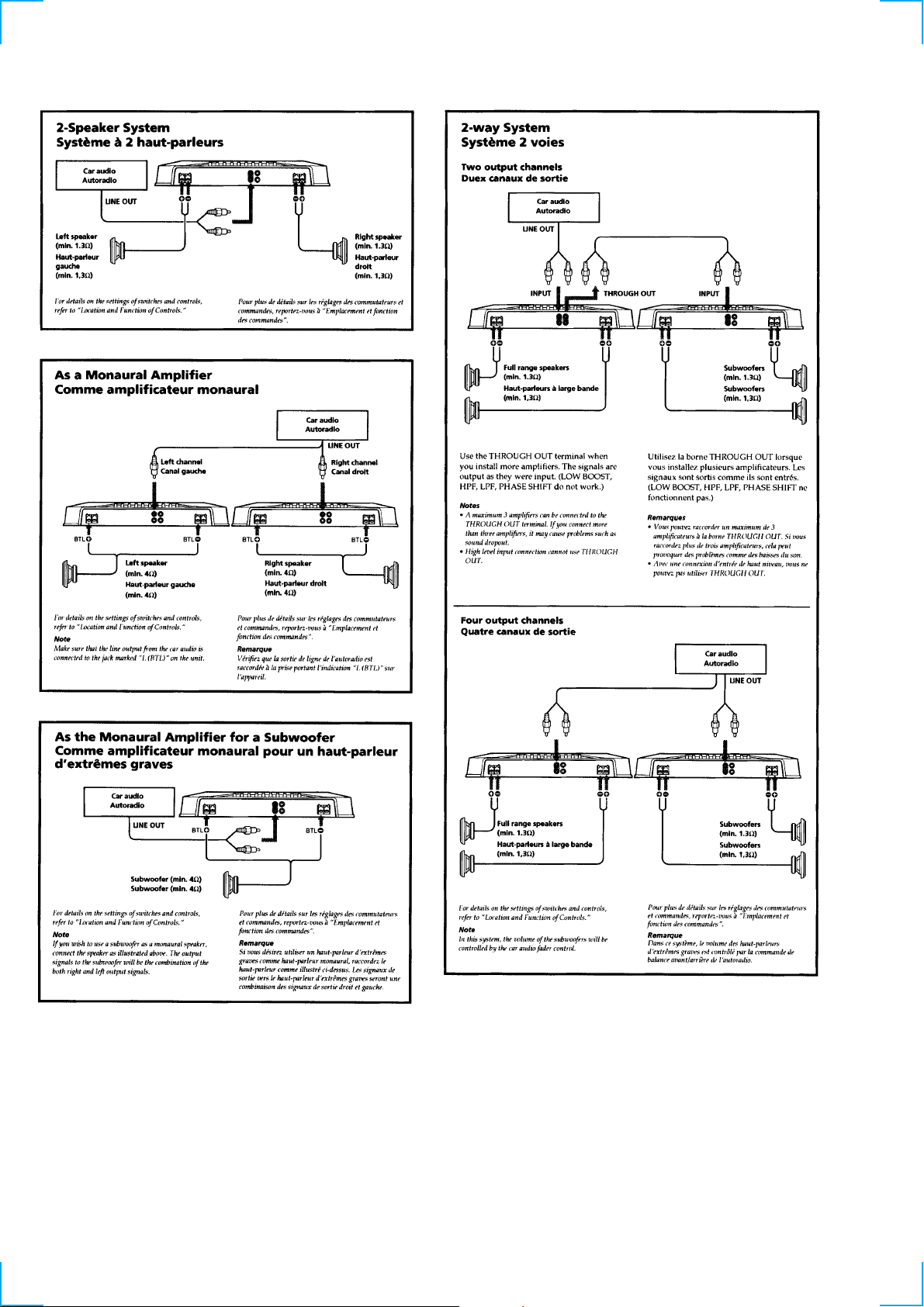

Location and Function of Controls.......................................... 3

Connections ............................................................................. 3

2. DISASSEMBLY

2-1. Plate, Bottom....................................................................... 6

2-2. Main Board ......................................................................... 6

2-3. Front Panel .......................................................................... 7

2-4. Led Board ............................................................................ 7

3. ELECTRICAL ADJUSTMENT...................................... 8

4. DIAGRAMS

4-1. Block Diagram .................................................................... 9

4-2. Printed Wiring Boards –Main Section– ............................ 11

4-3. Schematic Diagram –Main Section (1/2)– ........................ 12

4-4. Schematic Diagram –Main Section (2/2)– ........................ 13

5. EXPLODED VIEWS

5-1. Heat Sink Section .............................................................. 14

5-2. Main Board Section .......................................................... 14

6. ELECTRICAL PARTS LIST......................................... 15

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

2

SECTION 1

GENERAL

This section is extracted

from instruction manual.

3

456

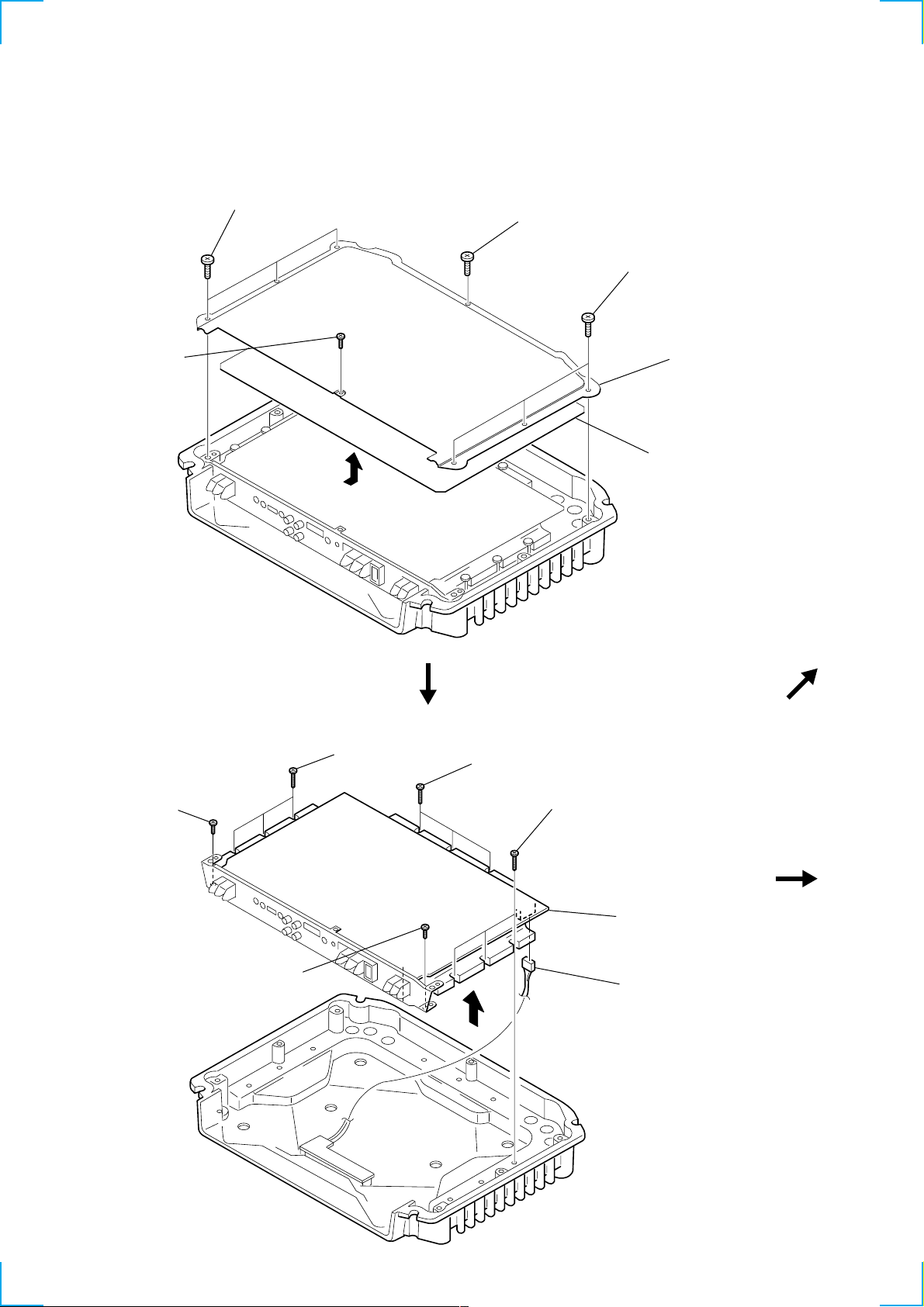

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. PLATE, BOTTOM

4 P 2.6x2.8

3 BTP 3x6

6

2 BTP 3x6

1 BTP 3x6

5 plate, bottom

7 sheet, insulating

2-2. MAIN BOARD

2 BTP 3x6

1 BTP 3x6

3 B.TT. 3x14

4 B.TT. 3x14

5 B.TT. 3x14

7 MAIN board section

8 CN808

6

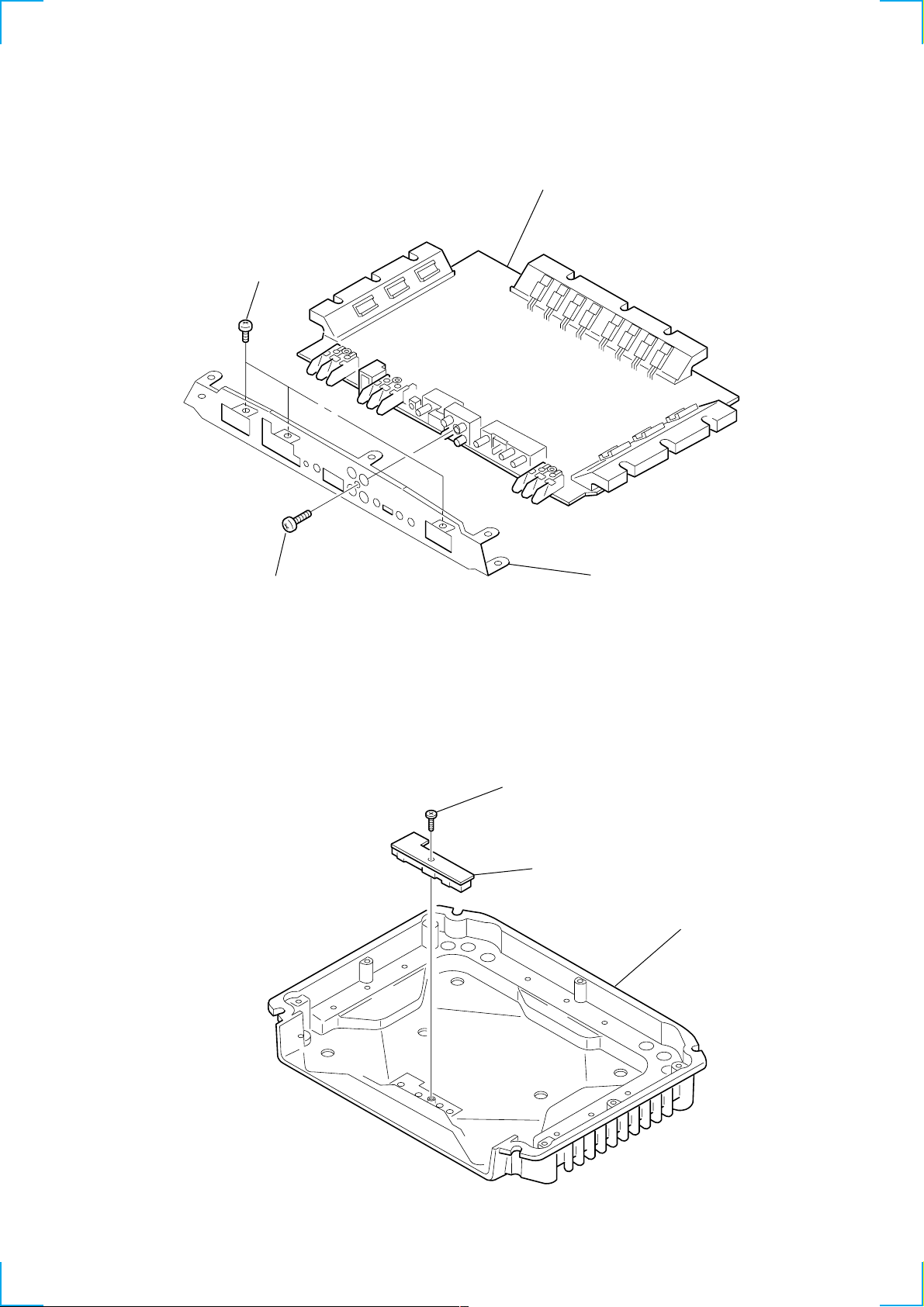

2-3. FRONT PANEL

)

4 MAIN board

2 P 3x8

2-4. LED BOARD

1 P 3x8

3 panel (2ch), front

1 BTP 3x6

2 LED board

heat sink (main

7

l

Ver 1.1

SECTION 3

ELECTRICAL ADJUSTMENT

Bias Adjustment

Note : In Bias Adjustment, adjust RV105 if any of Q108 through

Q113 are replaced. Adjust RV205 if any of Q208 through

Q213 are replaced.

Condition :This adjustment should be performed about one minute

after the remote mode is turned on at a room temperature of about 25°C.

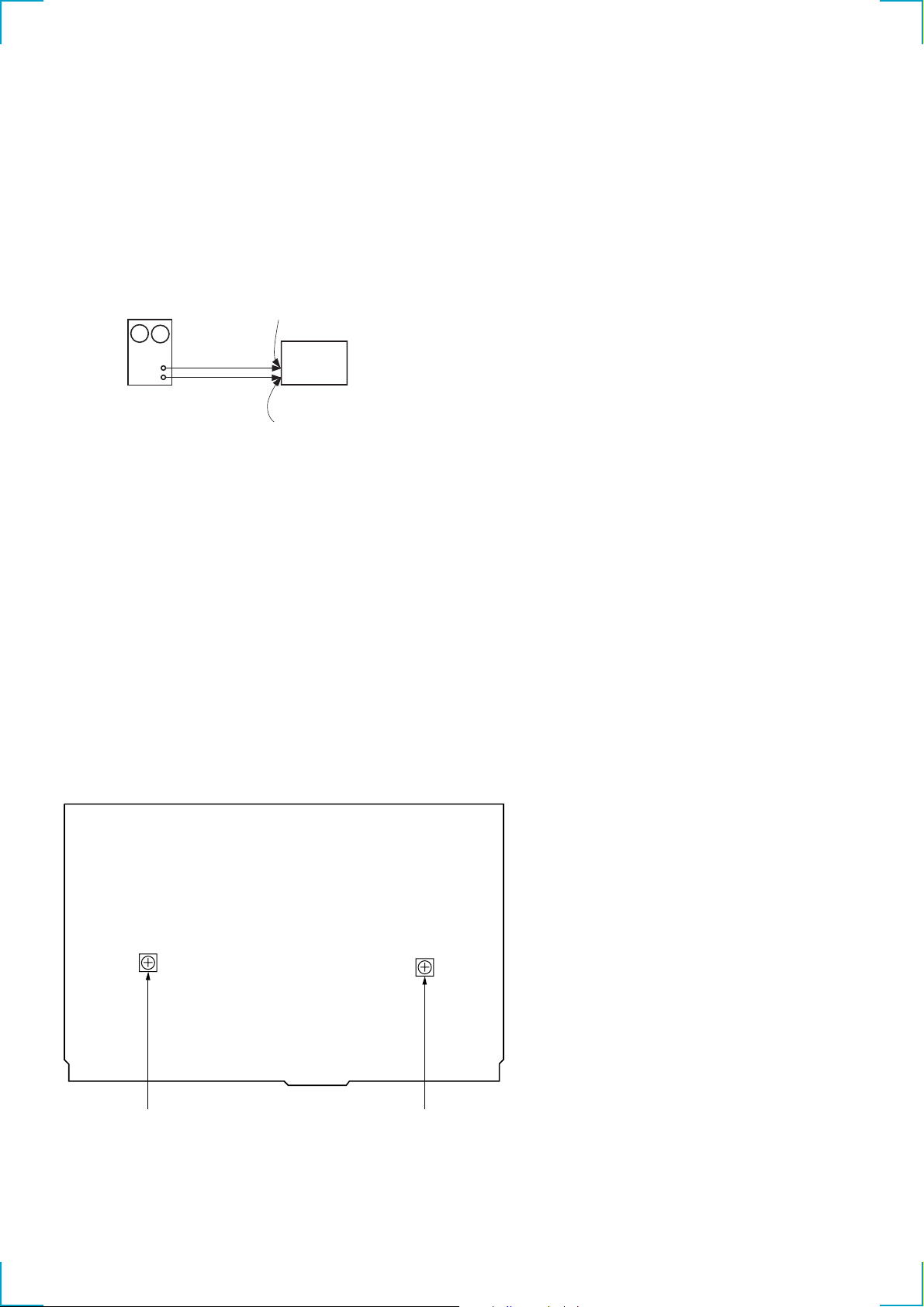

Setting :

B+, REM terminal

set

Stabilized

Power supply

Procedure :

1. Turn the variable resistors RV105 (L-CH) and RV205 (R-CH)

full clockwise as seen from the component side to minimize the

bias current.

2. The input signal is to be no signal.

3. Apply the voltage to the B+ and REM terminals from the stabilized power supply and gradually increase it up to 14.4 V while

checking for any unusual current.

4. For the XM-1502SX, adjust each of R V105 (L-CH) and RV205

(R-CH) so that the power current of the stabilized power supply

is increased in steps of 500 mA (total of 1 A). For the XM1902GX, adjust each of RV105 (L-CH) and RV205 (R-CH) so

that the power current is increased in steps of 600 mA (total of

1.2 A).

5. After adjustment, check that the power current is at 1.3 to 2.0 A.

GND termina

Adjustment Location : Main board (component side)

– MAIN BOARD (COMPONENT SIDE) –

RV105

BIAS ADJUSTMENT

(L-CH)

RV205

BIAS ADJUSTMENT

(R-CH)

8

4-1. BLOCK DIAGRAM

CNJ801-1

INPUT

L

OUTPUT

(THROUGH)

CNJ803

L

HI LEVEL

INPUT

R

CNJ801-2

OUTPUT

(THROUGH)

R

INPUT

S301

TEST TONE

PRE AMP

IC101(1/2)

3

2

PRE AMP

IC201(1/2)

2

3

1

1

TEST TONE

GENERATOR

IC301(2/2)

TEST TONE

GENERATOR

IC301(1/2)

SECTION 4

DIAGRAMS

RV101-1

FILTER

XM-1902GX

RV101-2

FILTER

XM-1902GX

D301

+14.2B

D302

-14.2B

PRE AMP

IC101(2/2)

6

5

PRE AMP

IC201(2/2)

6

5

(B+)

(B–)

H.L.F

IC102(2/2)

7 5 7 2 1 6 7

H.P.F

IC202(2/2)

7 5 7 2 1 2 1

RV801-1

FILTER

RV801-3

FILTER

L.P.F

IC102(1/2)

L.P.F

IC202(1/2)

RV801-2

FILTER

RV801-4

FILTER

L.P.F

IC103(2/2)

L.P.F

IC103(1/2)

S801-2

FILTER

LPF

OFF

HPF

S801-1

FILTER

LPF

OFF

HPF

LOW BOOST

IC104(2/2)

5

6

RV103-1

LOW

BOOST

LOW BOOST

IC204(1/2)

5

6

RV103-2

LOW

BOOST

+14.2V

(B+)

LEVEL

SHIFT

Q101

-14.2V

(B–)

+14.2V

(B+)

LEVEL

SHIFT

Q201

-14.2V

(B–)

XM-1502SX/1902GX

Ver 1.2

LINE AMP

IC104(1/2)

3

7

2

RV104-1

LEVEL

LINE AMP

IC204(2/2)

3

7

2

RV104-2

LEVEL

1

1

LINE SWITCH

CONTROL

Q801,802

LINE

SWITCH

Q102

LINE

SWITCH

Q202

DIFFERENTIAL

AMP

Q103

DIFFERENTIAL

AMP

Q104

DIFFERENTIAL

AMP

Q203

DIFFERENTIAL

AMP

Q204

DRIVE

AMP

Q105

RV105

DRIVE

AMP

Q106

DRIVE

AMP

Q205

RV205

DRIVE

AMP

Q206

BIAS

BIAS

OVER CURRENT

BIAS

Q107

(Q110,111,115:XM-1902GX)

OVER CURRENT

BIAS

Q207

(Q210,211,215:XM-1902GX)

POWER

AMP

Q108,110,112

DET

Q114-116

POWER

AMP

Q109,111,113

POWER

AMP

Q208,210,212

DET

Q214-216

POWER

AMP

Q209,211,213

CN804

CN805

1

2

1

2

SPEAKER

OUT

L

SPEAKER

OUT

R

DC OFFSET

DET

Q803-805

CN802

1

REM

CN801

12V

2

GND

1

+14.2V

(B+)

POWER

04

D808

F901

D809

OVER

CURRENT

D810

OFFSET

Q808

+14.2V

(B+)

D811

THERMAL

D808 D807

LED DRIVE

Q809

POWER

ON/OFF

Q903

B+

SWITCH

Q901,902

LED DRIVE

Q813

PROTECT LATCH

Q812

LED DRIVE

Q811

PROTECT LATCH

Q810

DC DET

IC901

TEMP. DET

TH801-803,

806-809,

812,813

DC-DC CONVERTER

IC901

12

REF.

REG

14

1

2

15

16

3

DC-DC

CONVERTER

TRANSFORMER

T901

11

Q908

Q909

DET

INVERTER

Q904,905

INVERTER

Q906,907

+20.3V

(B+)

-20.3V

(B–)

10

DRIVER

8

9

DRIVER

HI-CURRENT

4

/HI-VOLTAGE

IC903,Q912

DECT

D909

DECT

D905

DECT

D907

DECT

D906

DECT

D908

DECT

D910

• Signal path

: AUDIO

D921

D920

D919

D922

+53V

(B+)

+51V

(B+)

+53V

(B+)

-51V

(B–)

-51V

(B–)

-53V

(B–)

DECT

D911,917

DECT

D912,918

B+

REG

Q910

B+

REG

Q911

+20.3V

(B+)

+14.2V

(B+)

-14.2V

(B–)

-20.3V

(B–)

99

Ver 1.2

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS

AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

for schematic diagram:

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

•%: indicates tolerance.

• 2 : nonflammable resistor.

• U : B+ Line.

• V : B– Line.

• Power voltage is dc 14.4V and fed with regulated dc power

supply from +12V and REM terminals.

•Voltage is dc with respect to ground under no-signal

condition.

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

• Abbreviation

CND : Canadian model

for printed wiring boards:

Note:

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

• Abbreviation

CND : Canadian model

• IC Block Diagram

IC901 µPC494GS-T1

16 15 14 13 12 11 10 9

ERROR

ERROR

REF. REG.

0.1V

OSC

• Semiconductor Location (MAIN SECTION)

Ref. No. Location

D101 E-9

D102 E-9

D103 E-9

D104 E-9

D201 E-4

D202 E-3

D203 E-4

D204 E-4

D301 F-8

D302 G-7

D801 D-7

D802 D-7

D803 B-11

D805 A-11

D807 B-11

D820 C-12

D821 D-12

D824 F-12

D825 G-12

D826 C-1

D827 D-1

D830 F-1

D831 G-1

D901 G-10

D902 G-10

D905 A-4

D906 A-4

D907 A-9

D908 A-8

D909 D-5

D910 D-5

D911 D-6

D912 D-5

D913 B-2

D914 B-2

D915 B-3

D917 D-6

D918 D-5

D919 D-10

D920 D-10

D921 E-3

D922 E-3

Ref. No. Location

Q101 F-4

Q102 E-7

Q103 F-9

Q104 F-9

Q105 E-10

Q106 E-10

Q107 G-11

Q108 C-11

Q109 D-11

(Q110) E-11

(Q111) F-11

Q112 F-11

Q113 G-11

Q114 C-12

(Q115) D-12

Q116 F-12

Q201 G-4

Q202 E-5

Q203 E-3

Q204 E-4

Q205 E-3

Q206 E-3

Q207 G-1

Q208 C-1

Q209 D-1

(Q210) E-1

(Q211) E-1

Q212 F-1

Q213 G-1

Q214 D-1

(Q215) D-1

Q216 F-1

Q801 D-7

Q802 D-7

Q803 B-1

Q804 B-1

Q805 B-1

Q809 A-11

Q810 A-12

Q811 A-11

Q812 B-11

Q813 B-11

Q901 F-10

IC101 F-6

IC102 F-5

IC103 F-5

IC104 F-3

IC201 F-6

IC202 G-5

IC204 G-3

IC301 F-8

IC901 B-10

IC902 F-9

IC903 A-10

Q902 F-10

Q903 G-10

Q904 A-8

Q905 A-7

Q906 A-5

Q907 A-6

Q908 A-7

Q909 A-6

Q910 B-2

Q911 B-2

Q912 B-3

( ) : XM-1902GX only

• Waveform

1

10 10

1 2 3 4 5 6 7 8

1V/DIV, 5µsec/DIV

3.4Vp-p

15µsec

IC901

5

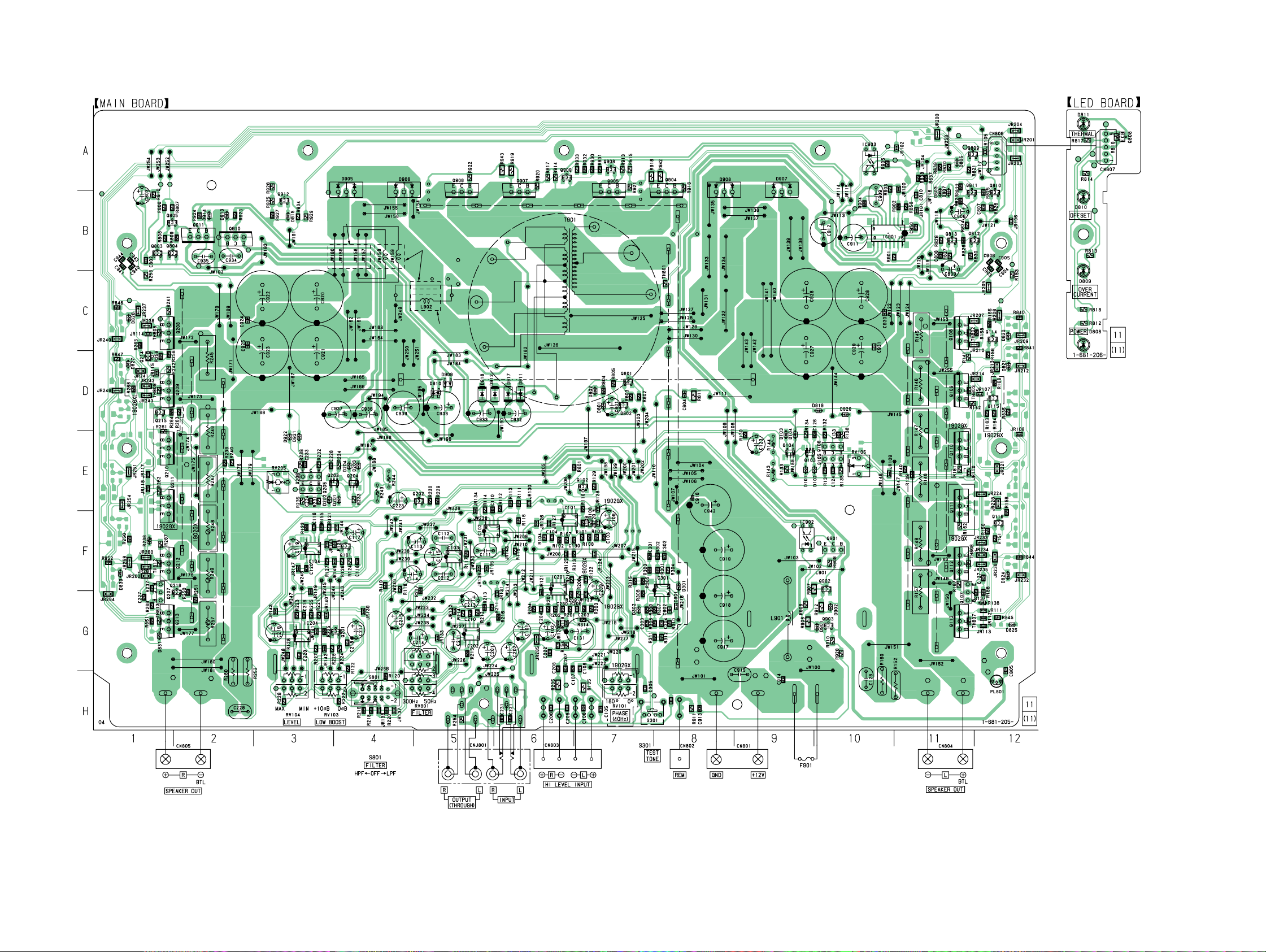

4-2. PRINTED WIRING BOARDS — MAIN SECTION — • Refer to page 10 for Semiconductor Location.

US,CND

MODEL

AEP,UK,E

MODEL

US,CND

MODEL

XM-1502SX/1902GX

Ver 1.2

11 11

Loading...

Loading...