Page 1

XM-1502SX/1902GX

SERVICE MANUAL

Ver 1.1 2001.06

Photo: XM-1902GX

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

150 watts per channel minimum continuous average power into

4 ohms, both channels driven from 20 Hz to 20 kHz with no more

than 0.04% total harmonic distortion per Car Audio Ad Hoc

Committee standards.

US Model

XM-1502SX/1902GX

Canadian Model

AEP Model

UK Model

E Model

XM-1502SX

Other Specifications

Circuit system OTL (output transformerless) circuit

Inputs RCA pin jacks

Outputs Speaker terminals

Speaker impedance 2 – 8 Ω (stereo) (XM-1502SX)

Maximum outputs 300 W × 2 (at 4 Ω)

Rated outputs (supply voltage at 14.4 V)

Frequency response 5 Hz – 100 kHz ( dB)

Harmonic distortion 0.005% or less (at 1 kHz, 4 Ω)

Input level adjustment range

Pulse power supply

High level input connector

Through out pin jacks

1.3 – 8 Ω (stereo) (XM-1902GX)

4 – 8 Ω (when used as a bridging amplifier)

760 W (monaural) at 4 Ω

150 W × 2 (20 Hz – 20 kHz, 0.04% THD,

at 4 Ω)

190 W × 2 (20 Hz – 20 kHz, 0.1% THD,

at 2 Ω)

190 W × 2 (20 Hz – 20 kHz, 0.1% THD,

at 1.3 Ω) (XM-1902GX)

380 W × 1 (20 Hz – 20 kHz, 0.1% THD,

at 4 Ω) (XM-1902GX)

380 W (monaural) (20 Hz – 20 kHz, 0.1% THD,

at 4 Ω) (XM-1502SX)

0.2 – 6.0 V (RCA pin jacks)

0.4 – 12.0 V (High level input)

+0.5

–3

High-pass filter 50 – 300 Hz, –12 dB/oct

Low-pass filter 50 – 300 Hz, –12 dB/oct

Low boost 0 – 10 dB (40 Hz)

Phase shift adjustment range (XM-1902GX)

Power supply voltage 10.5 – 16 V

Current drain at rated output : 40 A (at 4 Ω)

Dimensions Approx. 358 × 50 × 264 mm

Mass Approx. 3.5 kg (7 lb. 11 oz.) not incl. accessories

Supplied accessories Mounting screws (4)

Design and specifications are subject to change without

notice.

0° – 180° (at 40 Hz)

Remote input : 2 mA

1/8 × 2 1/4 × 10 1/2 in.)

(14

(w/h/d) not incl. projecting parts and controls

9-870-239-12

2001F0400-1

© 2001.6

STEREO POWER AMPLIFIER

Sony Corporation

e Vehicle Company

Shinagawa Tec Service Manual Production Group

1

Page 2

TABLE OF CONTENTS

1. GENERAL

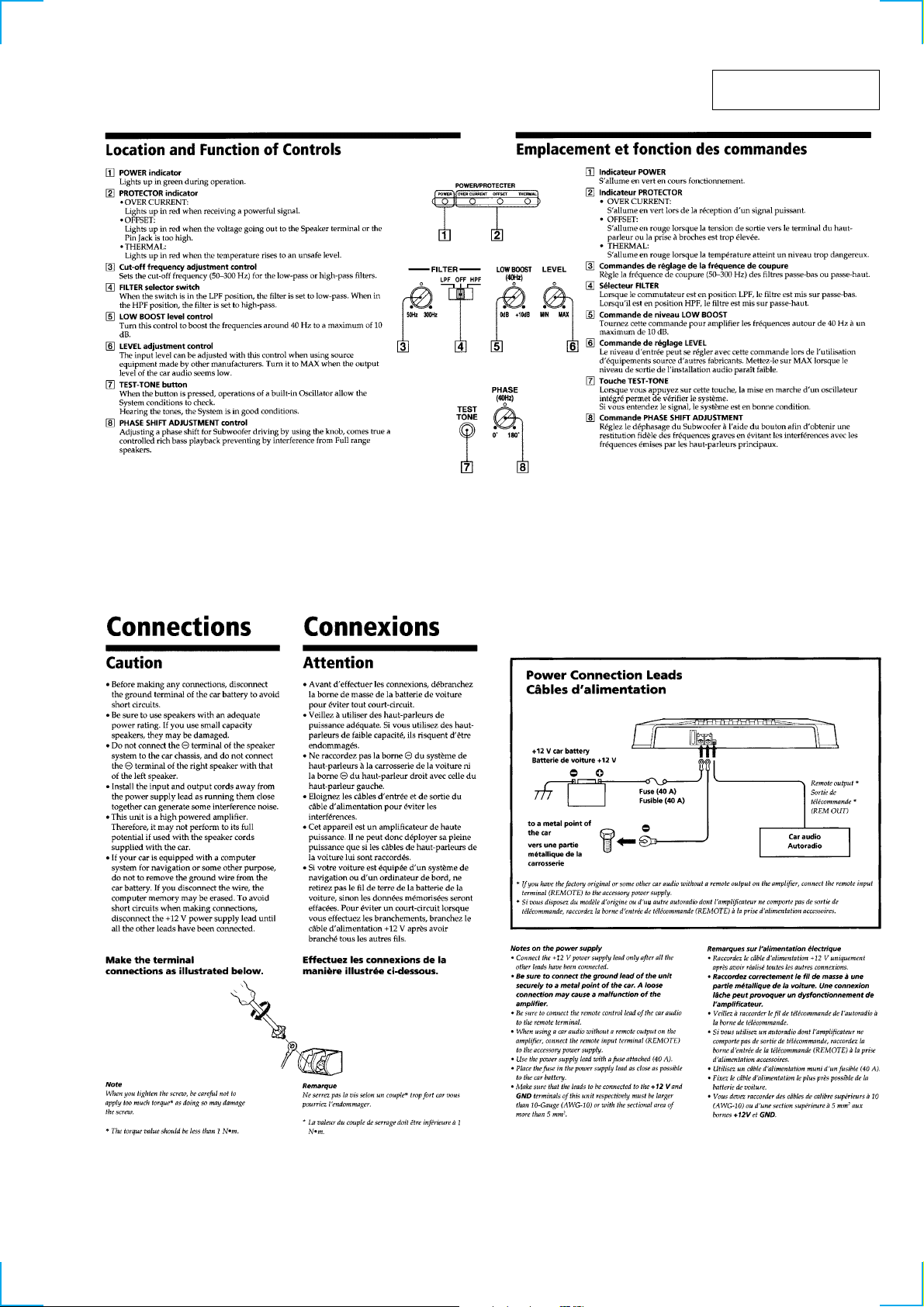

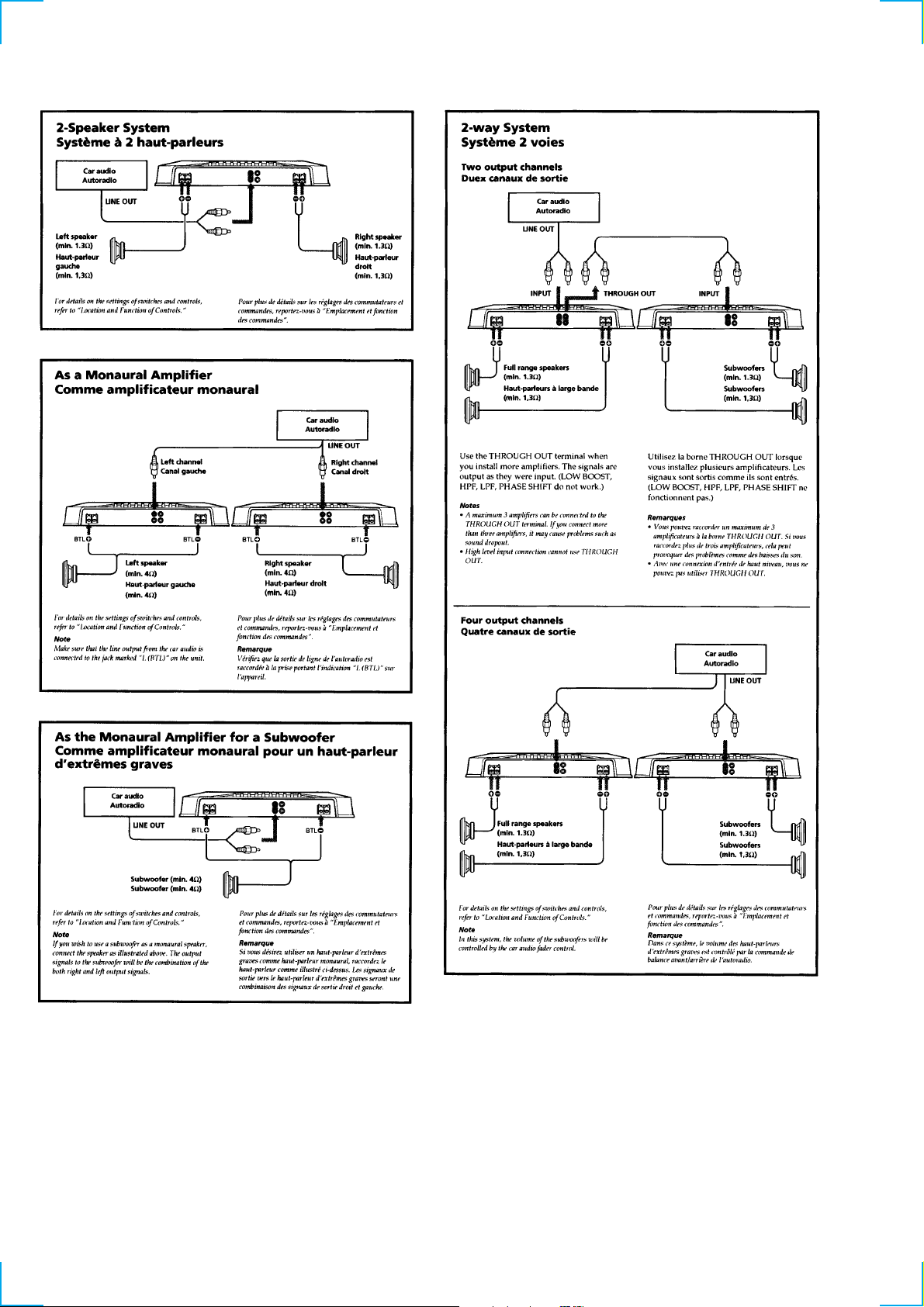

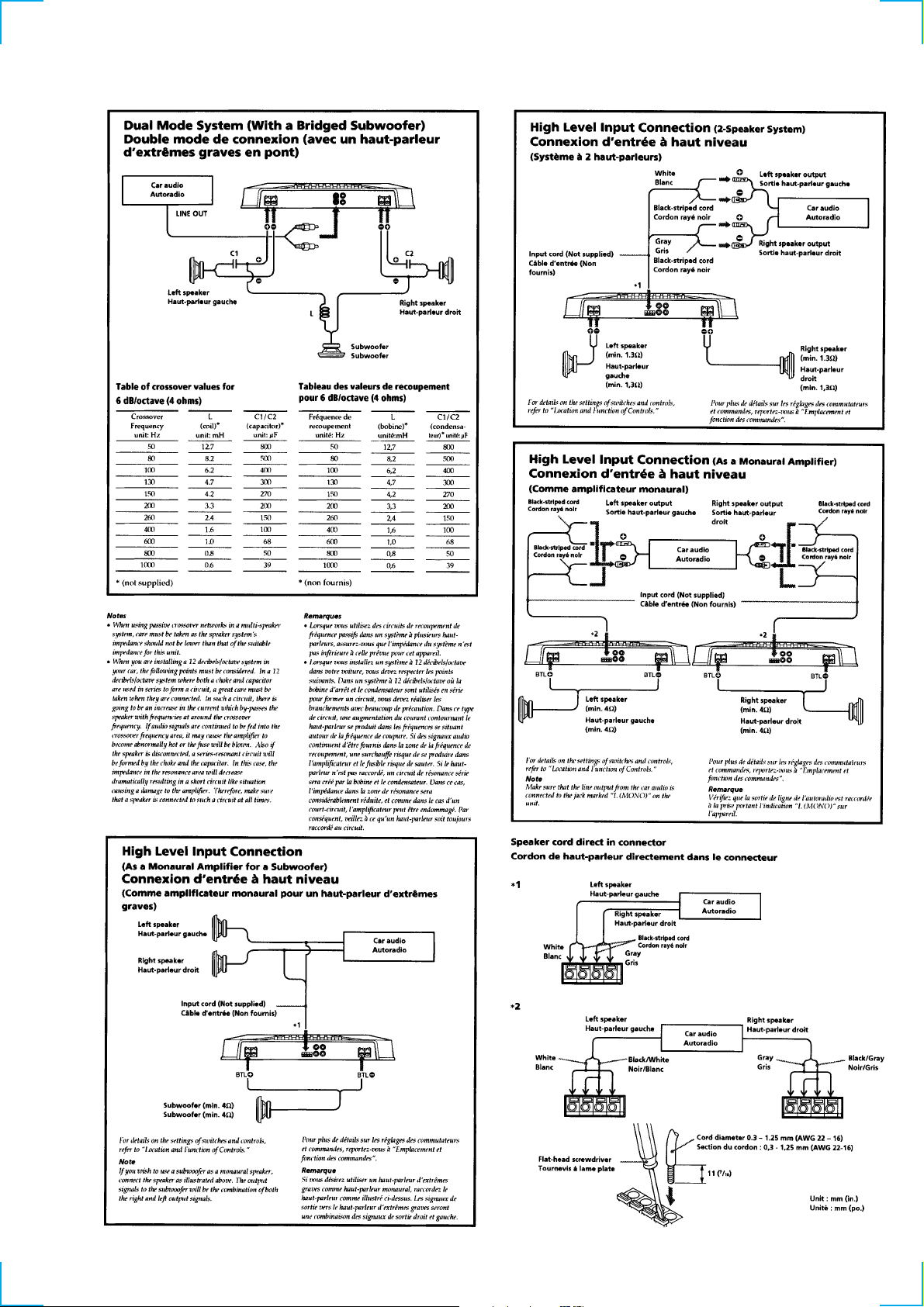

Location and Function of Controls.......................................... 3

Connections ............................................................................. 3

2. DISASSEMBLY

2-1. Plate, Bottom....................................................................... 6

2-2. Main Board ......................................................................... 6

2-3. Front Panel .......................................................................... 7

2-4. Led Board ............................................................................ 7

3. ELECTRICAL ADJUSTMENT...................................... 8

4. DIAGRAMS

4-1. Block Diagram .................................................................... 9

4-2. Printed Wiring Boards –Main Section– ............................ 11

4-3. Schematic Diagram –Main Section (1/2)– ........................ 12

4-4. Schematic Diagram –Main Section (2/2)– ........................ 13

5. EXPLODED VIEWS

5-1. Heat Sink Section .............................................................. 14

5-2. Main Board Section .......................................................... 14

6. ELECTRICAL PARTS LIST......................................... 15

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

2

Page 3

SECTION 1

GENERAL

This section is extracted

from instruction manual.

3

Page 4

456

Page 5

Page 6

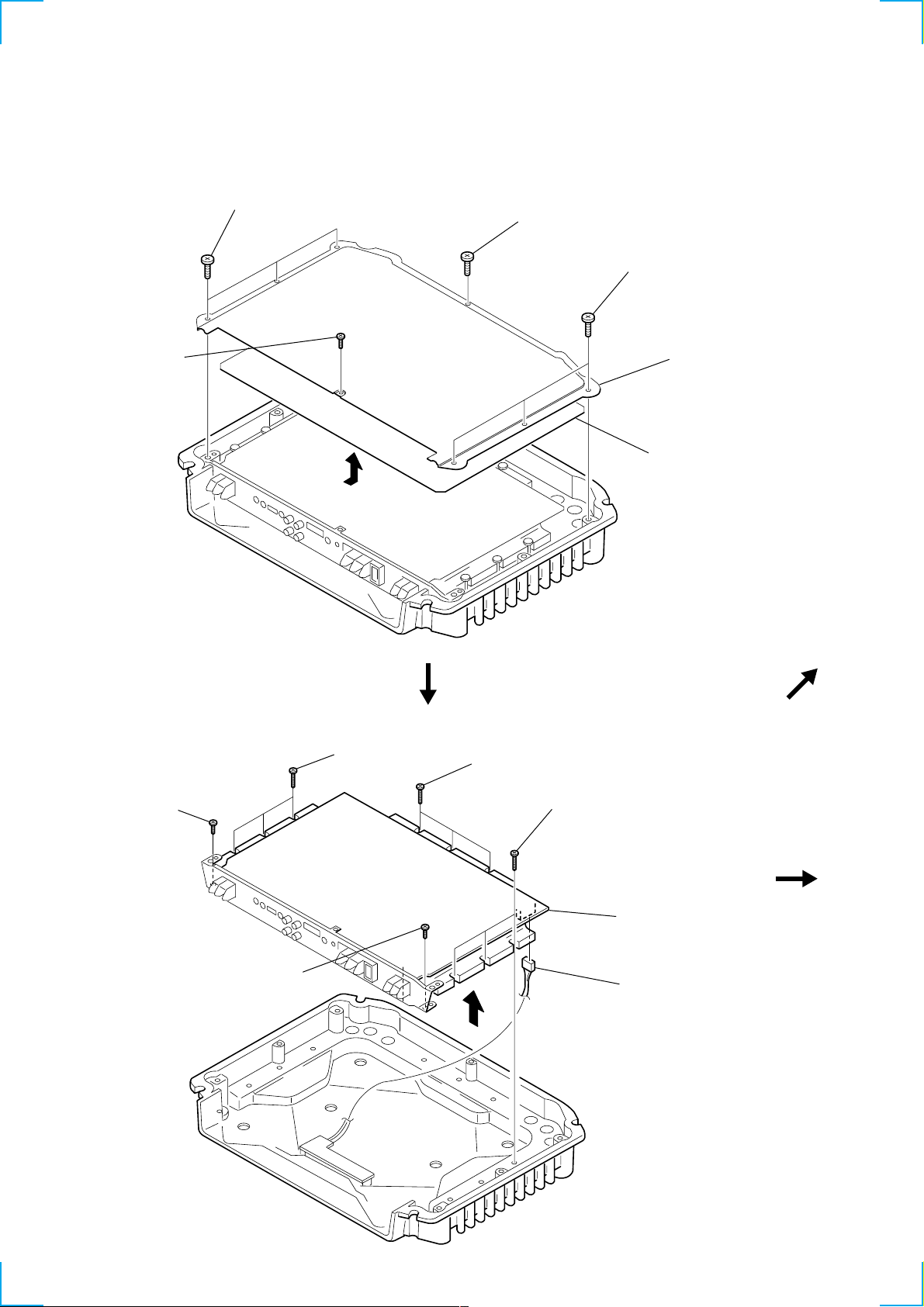

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. PLATE, BOTTOM

4 P 2.6x2.8

3 BTP 3x6

6

2 BTP 3x6

1 BTP 3x6

5 plate, bottom

7 sheet, insulating

2-2. MAIN BOARD

2 BTP 3x6

1 BTP 3x6

3 B.TT. 3x14

4 B.TT. 3x14

5 B.TT. 3x14

7 MAIN board section

8 CN808

6

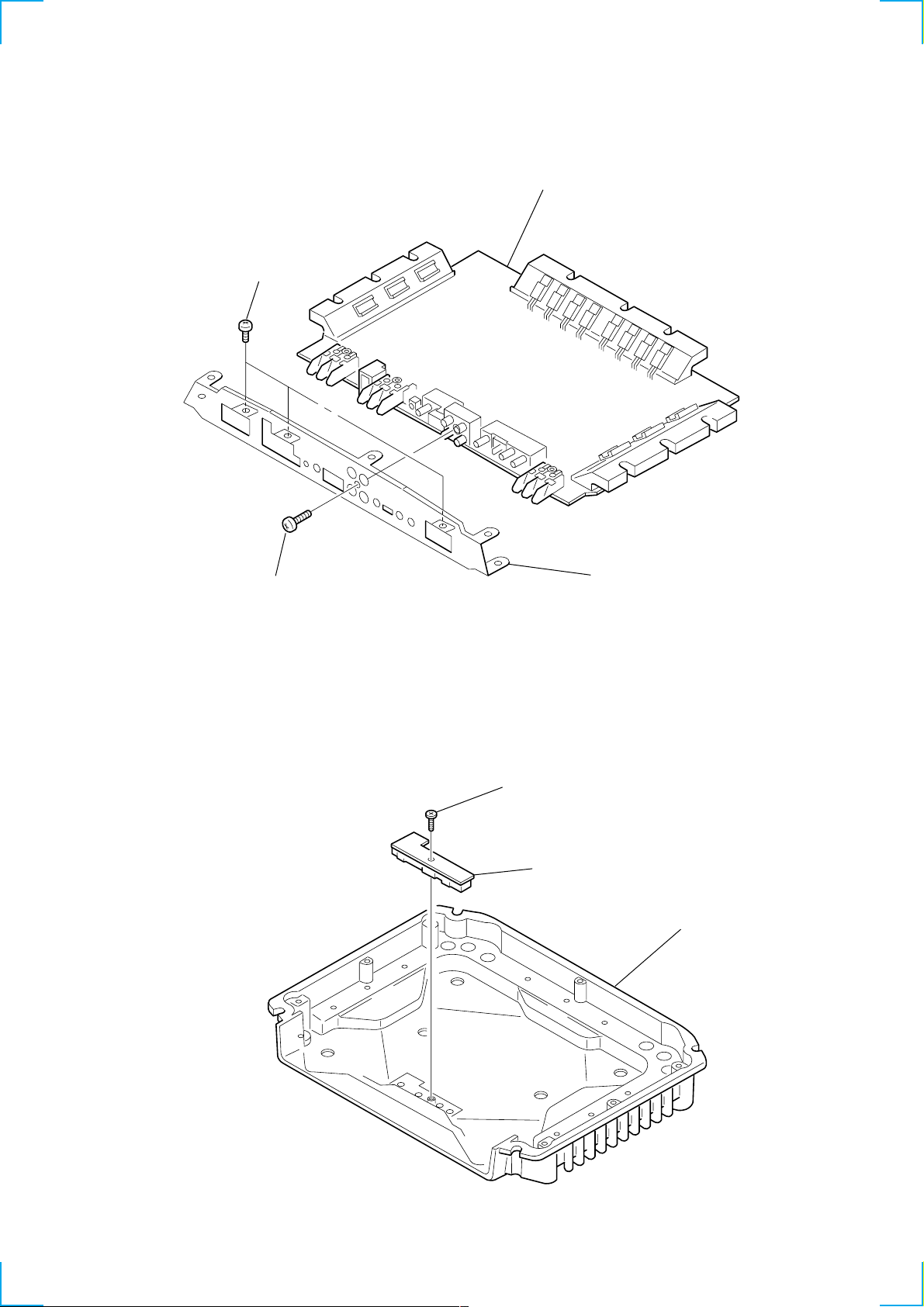

Page 7

2-3. FRONT PANEL

)

4 MAIN board

2 P 3x8

2-4. LED BOARD

1 P 3x8

3 panel (2ch), front

1 BTP 3x6

2 LED board

heat sink (main

7

Page 8

l

Ver 1.1 2001.06

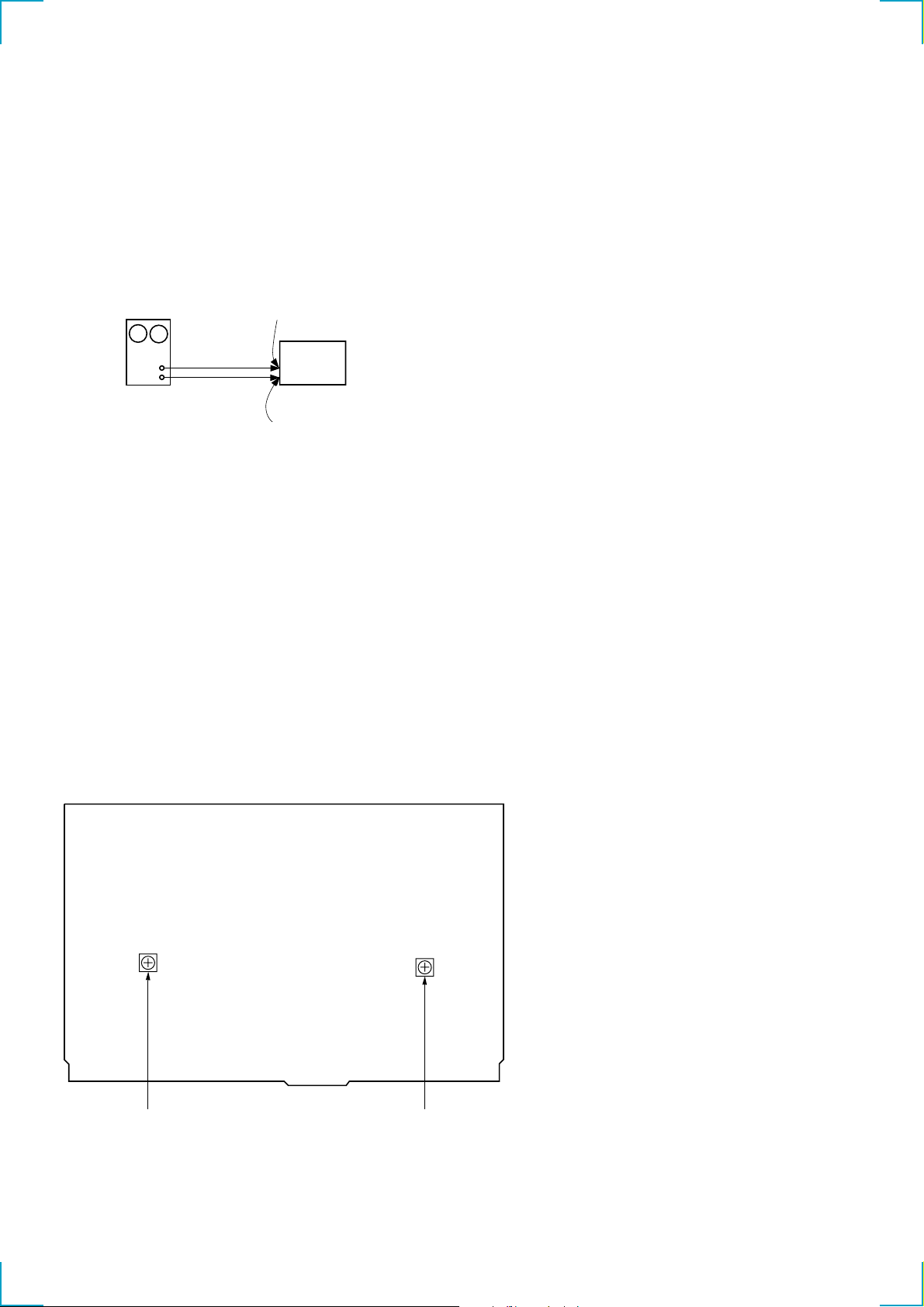

SECTION 3

ELECTRICAL ADJUSTMENT

Bias Adjustment

Note : In Bias Adjustment, adjust RV105 if any of Q108 through

Q113 are replaced. Adjust RV205 if any of Q208 through

Q213 are replaced.

Condition : This adjustment should be performed about one minute

after the remote mode is turned on at a room temperature of about 25°C.

Setting :

B+,REM terminal

set

Stabilized

Power suppy

Procedure :

1. Turn the variable resistors RV105 (L-CH) and RV205 (R-CH)

full clockwise as seen from the component side to minimize the

bias current.

2. The input signal is to be no signal.

3. Apply the voltage to the B+ and REM terminals from the stabilized power supply and gradually increase it up to 14.4 V while

checking for any unusual current.

4. For the XM-1502SX, adjust each of RV105 (L-CH) and RV205

(R-CH) so that the power current of the stabilized power supply

is increased in steps of 500 mA (total of 1 A). For the XM1902GX, adjust each of RV105 (L-CH) and RV205 (R-CH) so

that the power current is increased in steps of 600 mA (total of

1.2 A).

5. After adjustment, check that the power current is at 1.3 to 2.0 A.

GND termina

Adjustment Location : Main board (component side)

– MAIN BOARD (COMPONENT SIDE) –

RV105

BIAS ADJUSTMENT

RV205

BIAS ADJUSTMENT

8

Page 9

3

2

1

6

5

7 5 7 2 1 6 7

PRE AMP

IC101(1/2)

PRE AMP

IC101(2/2)

5

6

7

3

2

1

LOW BOOST

IC104(2/2)

LINE AMP

IC104(1/2)

H.L.F

IC102(2/2)

L.P.F

IC102(1/2)

L.P.F

IC103(2/2)

DIFFERENTIAL

AMP

Q103

POWER

AMP

Q108,110,112

OVER CURRENT

DET

Q114-116

DRIVE

AMP

Q105

DIFFERENTIAL

AMP

Q104

POWER

AMP

Q109,111,113

DRIVE

AMP

Q106

BIAS

Q107

LEVEL

SHIFT

Q101

LEVEL

FILTER

S801-1

LPF

OFF

HPF

LEVEL

RV103-1

LOW

BOOST

+14.2V

(B+)

-14.2V

(B–)

CNJ801-1

INPUT

RV101-1

FILTER

XM-1902GX

RV801-1

FILTER

RV801-2

FILTER

OUTPUT

(THROUGH)

OUTPUT

(THROUGH)

L

SPEAKER

OUT

L

SPEAKER

OUT

R

RV104-1

LINE

SWITCH

Q102

REM

12V

GND

2

3

10

4

1

6

5

7 5 7 2 1 2 1

PRE AMP

IC201(1/2)

PRE AMP

IC201(2/2)

5

6

7

3

2

1

LOW BOOST

IC204(1/2)

LINE AMP

IC204(2/2)

H.P.F

IC202(2/2)

L.P.F

IC202(1/2)

L.P.F

IC103(1/2)

DIFFERENTIAL

AMP

Q203

POWER

AMP

Q208,210,212

OVER CURRENT

DET

Q214-216

DRIVE

AMP

Q205

DIFFERENTIAL

AMP

Q204

POWER

ON/OFF

Q903

LINE SWITCH

CONTROL

Q801,802

POWER

AMP

Q209,211,213

DRIVE

AMP

Q206

BIAS

Q207

LEVEL

SHIFT

Q201

RV103-2

LOW

BOOST

+14.2V

(B+)

-14.2V

(B–)

CNJ801-2

CNJ803

INPUT

RV101-2

FILTER

RV801-3

FILTER

RV801-4

FILTER

R

L

HI LEVEL

INPUT

R

RV104-2

LINE

SWITCH

Q202

RV205

BIAS

RV105

BIAS

DC OFFSET

DET

Q803-805

15

16

1

2

14

12

B+

SWITCH

Q901,902

TEMP.DET

TH801

THP802,803

DC DET

IC901

REF.

REG

LED DRIVE

Q813

LED DRIVE

Q809

PROTECT LATCH

Q812

LED DRIVE

Q811

CN802

CN801

F901

DECT

D909

DECT

D905

DECT

D907

DECT

D906

DECT

D911,917

DECT

D908

DECT

D910

+53V

(B+)

+51V

(B+)

+53V

(B+)

-51V

(B–)

-51V

(B–)

-53V

(B–)

-14.2V

(B–)

-20.3V

(B–)

+14.2V

(B+)

+20.3V

(B+)

INVERTER

Q904,905

INVERTER

Q906,907

HI-CURRENT

/HI-VOLTAGE

DET

IC903,Q912

B+

REG

Q910

B+

REG

Q911

DRIVER

Q908

DRIVER

Q909

11

9

8

3

+14.2V

(B+)

+14.2V

(B+)

D811

THERMAL

D810

OFFSET

D809

OVER

CURRENT

D808

POWER

+20.3V

(B+)

-20.3V

(B–)

D922

D919

D920

D921

DECT

D912,918

DC-DC

CONVERTER

TRANSFORMER

T901

+14.2B

(B+)

-14.2B

(B–)

S301

TEST TONE

TEST TONE

GENERATOR

IC301(2/2)

TEST TONE

GENERATOR

IC301(1/2)

D301

D302

DC-DC CONVERTER

IC901

Q808

D808 D807

• Signal path

: AUDIO

CN804

CN805

1

2

1

2

04

1

2

1

PROTECT LATCH

Q810

XM-1902GX

FILTER

S801-2

LPF

OFF

HPF

(Q110,111,115:XM-1902GX)

(Q210,211,215:XM-1902GX)

XM-1502SX/1902GX

SECTION 4

DIAGRAMS

4-1. BLOCK DIAGRAM

99

Page 10

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS

AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

for schematic diagram:

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

4

W or less unless otherwise

• % : indicates tolerance.

• 2 : nonflammable resistor.

• U : B+ Line.

• V : B– Line.

• Power voltage is dc 14.4V and fed with regulated dc power

supply from +12V and REMOTE terminals.

• Voltage is dc with respect to ground under no-signal

condition.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : AUDIO

for printed wiring boards:

Note:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

(The other layer’s patterns are not indicated.)

• IC Block Diagram

IC901 µPC494GS

16 15 14 13 12 11 10 9

ERROR

ERROR

1 2 3 4 5 6 7 8

REF. REG.

0.1V

OSC

• Wavef orm

1V/DIV, 5µsec/DIV

1

3.4Vp-p

• Semiconductor Location (MAIN SECTION)

Ref. No. Location Ref. No. Location

D101 E-9

D102 E-9

IC902 F-9

IC903 A-10

D103 E-9

D104 E-9

D201 E-4

D202 E-3

D203 E-4

D204 E-4

D301 F-8

D302 G-7

D801 D-7

D802 D-7

D803 B-11

D804 D-12

D805 A-11

D806 D-1

D807 B-11

D820 C-12

D821 D-12

(D822) E-12

(D823) F-12

D824 F-12

D825 G-12

D826 C-1

D827 D-1

(D828) E-1

(D829) F-1

D830 F-1

D831 G-1

D901 G-10

D902 G-10

D905 A-4

D906 A-4

D907 A-9

D908 A-8

D909 D-5

D910 D-5

D911 D-6

D912 D-5

D913 B-2

D914 B-2

D915 B-3

D917 D-6

D918 D-5

D919 D-10

D920 D-10

D921 E-3

D922 E-3

Q101 F-4

Q102 E-7

Q103 F-9

Q104 F-9

Q105 E-10

Q106 E-10

Q107 G-11

Q108 C-11

Q109 D-11

(Q110) E-11

(Q111) F-11

Q112 F-11

Q113 G-11

Q114 C-12

(Q115) D-12

Q116 F-12

Q201 G-4

Q202 E-5

Q203 E-3

Q204 E-4

Q205 E-3

Q206 E-3

Q207 G-1

Q208 C-1

Q209 D-1

(Q210) E-1

(Q211) E-1

Q212 F-1

Q213 G-1

Q214 D-1

(Q215) D-1

Q216 F-1

Q801 D-7

Q802 D-7

Q803 B-1

Q804 B-1

Q805 B-1

Q809 A-11

Q810 A-12

Q811 A-11

Q812 B-11

Q813 B-11

Q901 F-10

Q902 F-10

Q903 G-10

Q904 A-8

IC101 F-6

IC102 F-5

IC103 F-5

IC104 F-3

IC201 F-6

IC202 G-5

IC204 G-3

IC301 F-8

Q905 A-7

Q906 A-5

Q907 A-6

Q908 A-7

Q909 A-6

Q910 B-2

Q911 B-2

Q912 B-3

IC901 B-10

( ) : XM-1902GX only

10 10

15µsec

IC901

5

Page 11

4-2. PRINTED WIRING BOARDS — MAIN SECTION — • Refer to page 10 for Semiconductor Location.

XM-1502SX/1902GX

Ver 1.1 2001.06

11 11

Page 12

XM-1502SX/1902GX

Ver 1.1 2001.06

4-3. SCHEMATIC DIAGRAM — MAIN SECTION (1/2) — • Refer to page 10 for IC Block Diagram. • Refer to page 10 for Waveform.

12 12

Page 13

4-4. SCHEMATIC DIAGRAM — MAIN SECTION (2/2) —

XM-1502SX/1902GX

Ver 1.1 2001.06

13 13

Page 14

NOTE:

51

52

53

54

54

63

63

56

56

55

54

56

55

57

58

59

59

59

61

62

63

61

60

#3

#3

55

54

56

55

63

1902GX

1502SX

1902GX

1502SX

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

5-1. HEAT SINK SECTION

SECTION 5

EXPLODED VIEWS

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

RR

Parts Color Cabinet’s Color

1

8

2

• Accessories and packing materials and

hardware (# mark) list are given in

the last of this parts list.

5-2. MAIN BOARD SECTION

#1

F901

A

#1

7

7

B

7

6

#1

3

4

B

#1

A

5

#1

#2

#1

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 3-225-070-01 PLATE (HEAT SINK), ORNAMENTAL (1902GX)

1 3-225-079-01 PLATE (HEAT SINK), ORNAMENTAL

1 3-225-079-41 PLATE (HEAT SINK), ORNAMENTAL

* 2 3-225-071-01 HEAT SINK (MAIN)

* 3 3-225-065-01 HOLDER, LED

(1502SX:US,CND)

(1502SX:AEP,UK,E)

* 4 1-681-206-11 LED BOARD

* 5 3-225-081-01 SHEET, INSULATING

* 6 3-225-068-01 PLATE, BOTTOM

7 3-225-185-01 SCREW (+B.TT.3X14)

8 3-225-153-01 SHEET (HIAT SINK), ADHESIVE

F901 1-533-743-11 FUSE (BLADE TYPE) (AUTO FUSE) 40A

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 51 A-3326-762-A MAIN BOARD, COMPLETE (1502SX)

* 51 A-3326-764-A MAIN BOARD, COMPLETE (1902GX)

* 52 3-225-067-01 HEAT SINK (SUB 2)

53 3-225-183-01 SCREW (+PSW.TT.3XL)

* 54 3-225-080-01 HEAT SINK (RETAINER PLATE)

55 3-225-183-11 SCREW (+PSW.TT.3XL)

* 56 3-225-066-01 HEAT SINK (SUB 1)

* 57 3-225-063-01 BRACKET (2CH.VR1)

* 58 3-225-064-01 BRACKET (2CH.VR2)

59 3-225-184-01 SCREW (+PS.TT.3X6)

* 60 3-225-069-01 PANEL (2CH), FRONT (1902GX)

* 60 3-225-069-11 PANEL (2CH), FRONT (1502SX)

61 3-369-647-01 SCREW (M4 SPACER)

62 3-912-432-01 SCREW (B)

* 63 3-225-086-01 SHEET (TR), INSULATING

14 14

Page 15

Ver 1.1 2001.06

SECTION 6

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-681-206-11 LED BOARD

**********

* 3-225-065-01 HOLDER, LED

< DIODE >

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

C107 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C108 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C109 1-115-871-11 ELECT 1uF 20% 50V

C110 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C111 1-136-167-00 FILM 0.15uF 5% 50V

When indicating parts by reference

number, please include the board.

MAINLED

(1902GX)

D808 8-719-064-23 LED SEL2411G (POWER)

D809 8-719-302-91 LED SEL2111R (OVER CURRENT)

D810 8-719-302-91 LED SEL2111R (OFFSET)

D811 8-719-302-91 LED SEL2111R (THERMAL)

< TRANSISTOR >

Q808 8-729-230-49 TRANSISTOR 2SC2712-YG

< RESISTOR >

R812 1-216-041-00 METAL CHIP 470 5% 1/10W

R813 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R814 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R817 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R818 1-216-041-00 METAL CHIP 470 5% 1/10W

R819 1-216-073-00 METAL CHIP 10K 5% 1/10W

*************************************************************

* A-3326-762-A MAIN BOARD, COMPLETE (1502SX)

* A-3326-764-A MAIN BOARD, COMPLETE (1902GX)

*********************

* 3-225-063-01 BRACKET (2CH.VR1)

* 3-225-064-01 BRACKET (2CH.VR2)

* 3-225-066-01 HEAT SINK (SUB 1)

* 3-225-067-01 HEAT SINK (SUB 2)

* 3-225-080-01 HEAT SINK (RETAINER PLATE)

* 3-225-086-01 SHEET (TR), INSULATING

3-225-183-01 SCREW (+PSW.TT.3XL)

3-225-183-11 SCREW (+PSW.TT.3XL)

3-225-184-01 SCREW (+PS.TT.3X6)

7-685-646-79 SCREW +P 3X8 TYPE2 NON-SLIT

7-685-544-19 SCREW +BTP 3X5 TYPE2 N-S

< CAPACITOR >

C101 1-126-794-11 ELECT 4.7uF 20% 50V

C102 1-126-794-11 ELECT 4.7uF 20% 50V

C103 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C104 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C105 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C106 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C112 1-136-167-00 FILM 0.15uF 5% 50V

C113 1-126-794-11 ELECT 4.7uF 20% 50V

C114 1-126-794-11 ELECT 4.7uF 20% 50V

C115 1-126-794-11 ELECT 4.7uF 20% 50V

C116 1-162-923-11 CERAMIC CHIP 47PF 5% 50V

C117 1-126-794-11 ELECT 4.7uF 20% 50V

C118 1-127-715-11 CERAMIC CHIP 0.22uF 10% 16V

C119 1-126-796-11 ELECT 22uF 20% 35V

C120 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C123 1-126-786-11 ELECT 47uF 20% 16V

C124 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C126 1-162-925-11 CERAMIC CHIP 68PF 5% 50V

C127 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C128 1-136-161-00 FILM 0.047uF 5% 50V

C130 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C131 1-128-499-11 ELECT 220uF 20% 16V

C201 1-126-794-11 ELECT 4.7uF 20% 50V

C202 1-126-794-11 ELECT 4.7uF 20% 50V

C203 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C204 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C205 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C206 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C207 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C208 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C209 1-115-871-11 ELECT 1uF 20% 50V

(1902GX)

C210 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C211 1-136-167-00 FILM 0.15uF 5% 50V

C212 1-136-167-00 FILM 0.15uF 5% 50V

C213 1-126-794-11 ELECT 4.7uF 20% 50V

C214 1-126-794-11 ELECT 4.7uF 20% 50V

C215 1-126-794-11 ELECT 4.7uF 20% 50V

C216 1-162-923-11 CERAMIC CHIP 47PF 5% 50V

C217 1-126-794-11 ELECT 4.7uF 20% 50V

C218 1-127-715-11 CERAMIC CHIP 0.22uF 10% 16V

C219 1-126-796-11 ELECT 22uF 20% 35V

C220 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C221 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C222 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C223 1-126-786-11 ELECT 47uF 20% 16V

15

Page 16

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C224 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C226 1-162-925-11 CERAMIC CHIP 68PF 5% 50V

C227 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C228 1-136-161-00 FILM 0.047uF 5% 50V

C230 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C937 1-128-126-11 ELECT 100uF 20% 25V

C938 1-128-576-11 ELECT 100uF 20% 63V

C939 1-128-576-11 ELECT 100uF 20% 63V

C940 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C941 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C231 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C301 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C302 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C303 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C304 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C305 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C801 1-126-796-11 ELECT 22uF 20% 35V

C802 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C803 1-126-786-11 ELECT 47uF 20% 16V

C804 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C805 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C806 1-126-796-11 ELECT 22uF 20% 35V

C807 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C808 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C809 1-126-794-11 ELECT 4.7uF 20% 50V

C810 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C901 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C902 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C903 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C904 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C909 1-130-471-00 MYLAR 0.001uF 5% 50V

C910 1-126-786-11 ELECT 47uF 20% 16V

C911 1-128-126-11 ELECT 100uF 20% 25V

C912 1-128-126-11 ELECT 100uF 20% 25V

C913 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C914 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C915 1-137-194-11 FILM 0.47uF 5% 50V

C916 1-136-161-00 FILM 0.047uF 5% 50V

C917 1-131-731-11 ELECT 2200uF 16V

C918 1-131-731-11 ELECT 2200uF 16V

C919 1-131-731-11 ELECT 2200uF 16V

C920 1-126-973-11 ELECT 2200uF 20% 50V

C921 1-126-973-11 ELECT 2200uF 20% 50V

C922 1-126-973-11 ELECT 2200uF 20% 50V

C923 1-126-973-11 ELECT 2200uF 20% 50V

C924 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C925 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C926 1-126-973-11 ELECT 2200uF 20% 50V

C927 1-126-973-11 ELECT 2200uF 20% 50V

C928 1-126-973-11 ELECT 2200uF 20% 50V

C929 1-126-973-11 ELECT 2200uF 20% 50V

C930 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C931 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C932 1-128-126-11 ELECT 100uF 20% 25V

C933 1-128-126-11 ELECT 100uF 20% 25V

C934 1-136-165-00 FILM 0.1uF 5% 50V

C935 1-136-165-00 FILM 0.1uF 5% 50V

C936 1-128-126-11 ELECT 100uF 20% 25V

C942 1-131-731-11 ELECT 2200uF 16V

C950 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

< TERMINAL BOARD >

CN801 1-694-755-11 TERMINAL BOARD (2P+FUSE) (+12V, GND)

CN802 1-815-300-11 TERMINAL (1P) (REM)

CN804 1-694-754-11 TERMINAL BOARD (2P) (SPEAKER OUT L)

CN805 1-694-754-11 TERMINAL BOARD (2P) (SPEAKER OUT R)

< CONNECTOR >

CN803 1-794-219-11 CONNECTOR (4P) (HI LEVEL INPUT L/R)

CN806 1-506-987-11 PIN, CONNECTOR (PC BOARD) 5P

< JACK >

CNJ801 1-779-078-41 JACK, PIN 4P (INPUT L/R,

OUTPUT (THROUGH) L/R)

< DIODE >

D101 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D102 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D103 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D104 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D201 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D202 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D203 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D204 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D301 8-719-016-74 DIODE 1SS352

D302 8-719-016-74 DIODE 1SS352

D801 8-719-065-18 DIODE 02DZ6.8-Y(TPH3)

D802 8-719-016-74 DIODE 1SS352

D803 8-719-016-74 DIODE 1SS352

D804 8-719-016-74 DIODE 1SS352

D805 8-719-016-74 DIODE 1SS352

D806 8-719-016-74 DIODE 1SS352

D807 8-719-016-74 DIODE 1SS352

D820 8-719-016-74 DIODE 1SS352

D821 8-719-016-74 DIODE 1SS352

D822 8-719-016-74 DIODE 1SS352 (1902GX)

D823 8-719-016-74 DIODE 1SS352 (1902GX)

D824 8-719-016-74 DIODE 1SS352

D825 8-719-016-74 DIODE 1SS352

D826 8-719-016-74 DIODE 1SS352

D827 8-719-016-74 DIODE 1SS352

D828 8-719-016-74 DIODE 1SS352 (1902GX)

D829 8-719-016-74 DIODE 1SS352 (1902GX)

D830 8-719-016-74 DIODE 1SS352

D831 8-719-016-74 DIODE 1SS352

D901 8-719-065-18 DIODE 02DZ6.8-Y(TPH3)

16

Page 17

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

D902 8-719-065-46 DIODE 02DZ16-Z(TPH3)

D905 8-719-079-00 DIODE FCH10A15

D906 8-719-079-01 DIODE FRH10A15

D907 8-719-079-00 DIODE FCH10A15

D908 8-719-079-01 DIODE FRH10A15

JR118 1-216-295-11 SHORT 0

JR119 1-216-295-11 SHORT 0

JR120 1-216-295-11 SHORT 0

JR121 1-216-295-11 SHORT 0

JR122 1-216-295-11 SHORT 0

D909 8-719-054-55 DIODE 1SS306(TE85L)

D910 8-719-054-55 DIODE 1SS306(TE85L)

D911 8-719-053-18 DIODE 1SR154-400TE-25

D912 8-719-053-18 DIODE 1SR154-400TE-25

D913 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D914 8-719-065-43 DIODE 02DZ15-Z(TPH3)

D915 8-719-065-18 DIODE 02DZ6.8-Y(TPH3)

D917 8-719-053-18 DIODE 1SR154-400TE-25

D918 8-719-053-18 DIODE 1SR154-400TE-25

D919 8-719-016-74 DIODE 1SS352

D920 8-719-016-74 DIODE 1SS352

D921 8-719-016-74 DIODE 1SS352

D922 8-719-016-74 DIODE 1SS352

< IC >

IC101 8-759-385-17 IC NJM4580E(TE2)

IC102 8-759-385-17 IC NJM4580E(TE2)

IC103 8-759-385-17 IC NJM4580E(TE2)

IC104 8-759-385-17 IC NJM4580E(TE2)

IC201 8-759-385-17 IC NJM4580E(TE2)

IC202 8-759-385-17 IC NJM4580E(TE2)

IC204 8-759-385-17 IC NJM4580E(TE2)

IC301 8-759-385-17 IC NJM4580E(TE2)

IC901 8-759-144-88 IC uPC494GS-T1

< PHOTO TRANSISTOR >

IC902 8-719-800-42 PHOTO TRANSISTOR TP521-1-A

IC903 8-719-800-42 PHOTO TRANSISTOR TP521-1-A

< JUMPER RESISTOR >

JR123 1-216-295-11 SHORT 0

JR124 1-216-295-11 SHORT 0

JR125 1-216-295-11 SHORT 0

JR126 1-216-295-11 SHORT 0

JR127 1-216-295-11 SHORT 0

JR128 1-216-295-11 SHORT 0

JR129 1-216-295-11 SHORT 0

JR130 1-216-295-11 SHORT 0

JR131 1-216-295-11 SHORT 0

JR132 1-216-295-11 SHORT 0

JR133 1-216-295-11 SHORT 0

JR134 1-216-295-11 SHORT 0

JR135 1-216-295-11 SHORT 0

JR136 1-216-295-11 SHORT 0

JR137 1-216-295-11 SHORT 0

JR138 1-216-295-11 SHORT 0

JR139 1-216-295-11 SHORT 0

JR140 1-216-295-11 SHORT 0

JR141 1-216-295-11 SHORT 0

JR142 1-216-295-11 SHORT 0

JR143 1-216-295-11 SHORT 0

JR144 1-216-295-11 SHORT 0

JR145 1-216-295-11 SHORT 0

JR146 1-216-295-11 SHORT 0

JR147 1-216-295-11 SHORT 0

JR148 1-216-295-11 SHORT 0

JR149 1-216-295-11 SHORT 0

JR200 1-216-296-00 SHORT 0

JR201 1-216-296-00 SHORT 0

JR202 1-216-296-00 SHORT 0

JR100 1-216-295-11 SHORT 0

JR101 1-216-295-11 SHORT 0

JR102 1-216-295-11 SHORT 0

JR103 1-216-295-11 SHORT 0

JR104 1-216-295-11 SHORT 0

JR105 1-216-295-11 SHORT 0

JR106 1-216-295-11 SHORT 0

JR107 1-216-295-11 SHORT 0

JR108 1-216-295-11 SHORT 0

JR109 1-216-295-11 SHORT 0

JR110 1-216-295-11 SHORT 0

JR111 1-216-295-11 SHORT 0

JR112 1-216-295-11 SHORT 0

JR113 1-216-295-11 SHORT 0

JR114 1-216-295-11 SHORT 0

JR115 1-216-295-11 SHORT 0

JR116 1-216-295-11 SHORT 0

JR117 1-216-295-11 SHORT 0

JR203 1-216-296-00 SHORT 0

JR204 1-216-296-00 SHORT 0

JR205 1-216-296-00 SHORT 0

JR206 1-216-296-00 SHORT 0

JR207 1-216-296-00 SHORT 0

JR208 1-216-296-00 SHORT 0

JR209 1-216-296-00 SHORT 0

JR210 1-216-296-00 SHORT 0

JR211 1-216-296-00 SHORT 0

JR212 1-216-296-00 SHORT 0

JR213 1-216-296-00 SHORT 0

JR214 1-216-296-00 SHORT 0

JR215 1-216-296-00 SHORT 0

JR216 1-216-296-00 SHORT 0

JR217 1-216-296-00 SHORT 0

JR218 1-216-296-00 SHORT 0

JR219 1-216-296-00 SHORT 0

JR220 1-216-296-00 SHORT 0

17

Page 18

Ver 1.1 2001.06

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

JR221 1-216-296-00 SHORT 0

JR222 1-216-296-00 SHORT 0

JR223 1-216-296-00 SHORT 0

JR224 1-216-296-00 SHORT 0

JR225 1-216-296-00 SHORT 0

JR226 1-216-296-00 SHORT 0

JR227 1-216-296-00 SHORT 0

JR228 1-216-296-00 SHORT 0

JR229 1-216-296-00 SHORT 0

JR230 1-216-296-00 SHORT 0

JR231 1-216-296-00 SHORT 0

JR232 1-216-296-00 SHORT 0

JR233 1-216-296-00 SHORT 0

JR234 1-216-296-00 SHORT 0

JR235 1-216-296-00 SHORT 0

JR236 1-216-296-00 SHORT 0

JR237 1-216-296-00 SHORT 0

JR238 1-216-296-00 SHORT 0

JR239 1-216-296-00 SHORT 0

JR240 1-216-296-00 SHORT 0

JR241 1-216-296-00 SHORT 0

JR242 1-216-296-00 SHORT 0

JR243 1-216-296-00 SHORT 0

JR244 1-216-296-00 SHORT 0

JR245 1-216-296-00 SHORT 0

JR246 1-216-296-00 SHORT 0

JR247 1-216-296-00 SHORT 0

JR248 1-216-296-00 SHORT 0

JR249 1-216-296-00 SHORT 0

JR250 1-216-296-00 SHORT 0

JR251 1-216-296-00 SHORT 0

JR252 1-216-296-00 SHORT 0

JR253 1-216-296-00 SHORT 0

JR254 1-216-296-00 SHORT 0

JR255 1-216-296-00 SHORT 0

JR256 1-216-296-00 SHORT 0

JR257 1-216-296-00 SHORT 0

JR258 1-216-296-00 SHORT 0

JR259 1-216-296-00 SHORT 0

JR260 1-216-296-00 SHORT 0

JR261 1-216-296-00 SHORT 0

JR262 1-216-296-00 SHORT 0

JR263 1-216-296-00 SHORT 0

JR264 1-216-296-00 SHORT 0

JR265 1-216-296-00 SHORT 0

< COIL >

Q101 8-729-230-49 TRANSISTOR 2SC2712-YG

Q102 8-729-202-38 TRANSISTOR 2SC3326N-A

Q103 8-729-014-86 TRANSISTOR 2SC4207-YGRTE85L

Q104 8-729-232-66 TRANSISTOR 2SA1618Y

Q105 8-729-207-89 TRANSISTOR 2SA1358-Y

Q106 8-729-207-82 TRANSISTOR 2SC3421-Y

Q107 8-729-055-13 TRANSISTOR 2SD1861-TV2

Q108 8-729-924-78 FET IRF540

Q109 8-729-053-85 FET IRF9540

Q110 8-729-924-78 FET IRF540 (1902GX)

Q111 8-729-053-85 FET IRF9540 (1902GX)

Q112 8-729-924-78 FET IRF540

Q113 8-729-053-85 FET IRF9540

Q114 8-729-230-49 TRANSISTOR 2SC2712-YG

Q115 8-729-230-49 TRANSISTOR 2SC2712-YG (1902GX)

Q116 8-729-230-49 TRANSISTOR 2SC2712-YG

Q201 8-729-230-49 TRANSISTOR 2SC2712-YG

Q202 8-729-202-38 TRANSISTOR 2SC3326N-A

Q203 8-729-014-86 TRANSISTOR 2SC4207-YGRTE85L

Q204 8-729-232-66 TRANSISTOR 2SA1618Y

Q205 8-729-207-89 TRANSISTOR 2SA1358-Y

Q206 8-729-207-82 TRANSISTOR 2SC3421-Y

Q207 8-729-055-13 TRANSISTOR 2SD1861-TV2

Q208 8-729-924-78 FET IRF540

Q209 8-729-053-85 FET IRF9540

Q210 8-729-924-78 FET IRF540 (1902GX)

Q211 8-729-053-85 FET IRF9540 (1902GX)

Q212 8-729-924-78 FET IRF540

Q213 8-729-053-85 FET IRF9540

Q214 8-729-230-49 TRANSISTOR 2SC2712-YG

Q215 8-729-230-49 TRANSISTOR 2SC2712-YG (1902GX)

Q216 8-729-230-49 TRANSISTOR 2SC2712-YG

Q801 8-729-216-22 TRANSISTOR 2SA1162-G

Q802 8-729-230-49 TRANSISTOR 2SC2712-YG

Q803 8-729-230-49 TRANSISTOR 2SC2712-YG

Q804 8-729-216-22 TRANSISTOR 2SA1162-G

Q805 8-729-230-49 TRANSISTOR 2SC2712-YG

Q809 8-729-230-49 TRANSISTOR 2SC2712-YG

Q810 8-729-230-49 TRANSISTOR 2SC2712-YG

Q811 8-729-216-22 TRANSISTOR 2SA1162-G

Q812 8-729-230-49 TRANSISTOR 2SC2712-YG

Q813 8-729-216-22 TRANSISTOR 2SA1162-G

Q901 8-729-106-60 TRANSISTOR 2SB1115A-YQ

Q902 8-729-216-22 TRANSISTOR 2SA1162-G

Q903 8-729-230-49 TRANSISTOR 2SC2712-YG

< TRANSISTOR >

L901 1-419-851-11 COIL, CHOKE 50uH

L902 1-410-396-41 INDUCTOR, FERRITE BEAD 0.45uH

< PILOT LAMP >

PL801 1-517-156-11 LAMP, PILOT (65mA/14V)

18

Q904 8-729-053-05 FET FKV550T

Q905 8-729-053-05 FET FKV550T

Q906 8-729-053-05 FET FKV550T

Q907 8-729-053-05 FET FKV550T

Q908 8-729-230-49 TRANSISTOR 2SC2712-YG

Q909 8-729-230-49 TRANSISTOR 2SC2712-YG

Page 19

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

Q910 8-729-207-82 TRANSISTOR 2SC3421-Y

Q911 8-729-207-89 TRANSISTOR 2SA1358-Y

Q912 8-729-230-49 TRANSISTOR 2SC2712-YG

< RESISTOR >

R101 1-216-837-11 METAL CHIP 22K 5% 1/16W

R102 1-216-837-11 METAL CHIP 22K 5% 1/16W

R103 1-216-837-11 METAL CHIP 22K 5% 1/16W

R104 1-216-837-11 METAL CHIP 22K 5% 1/16W

R105 1-208-494-61 RES-CHIP 2.2K 2% 1/8W

R106 1-216-845-11 METAL CHIP 100K 5% 1/16W

R107 1-216-845-11 METAL CHIP 100K 5% 1/16W

R108 1-216-025-11 RES-CHIP 100 5% 1/10W

(1902GX)

R109 1-216-833-11 METAL CHIP 10K 5% 1/16W

R110 1-216-833-11 METAL CHIP 10K 5% 1/16W

R111 1-216-833-11 METAL CHIP 10K 5% 1/16W

R112 1-216-837-11 METAL CHIP 22K 5% 1/16W

R113 1-216-833-11 METAL CHIP 10K 5% 1/16W

R114 1-216-833-11 METAL CHIP 10K 5% 1/16W

R115 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R116 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R117 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R118 1-216-845-11 METAL CHIP 100K 5% 1/16W

R119 1-216-845-11 METAL CHIP 100K 5% 1/16W

R120 1-216-845-11 METAL CHIP 100K 5% 1/16W

R147 1-220-894-11 METAL 0.22 10% 5W F

(1902GX)

R148 1-220-894-11 METAL 0.22 10% 5W F

(1902GX)

R149 1-220-894-11 METAL 0.22 10% 5W F

R150 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R151 1-216-821-11 METAL CHIP 1K 5% 1/16W

R152 1-215-859-00 METAL OXIDE 22 5% 1W F

R153 1-216-853-11 METAL CHIP 470K 5% 1/16W

R154 1-216-065-00 RES-CHIP 4.7K 5% 1/10W

R155 1-216-077-00 RES-CHIP 15K 5% 1/10W

R156 1-216-833-11 METAL CHIP 10K 5% 1/16W

R157 1-220-894-11 METAL 0.22 10% 5W F

R158 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R159 1-216-821-11 METAL CHIP 1K 5% 1/16W

R160 1-215-859-00 METAL OXIDE 22 5% 1W F

R161 1-216-017-00 RES-CHIP 47 5% 1/10W

(1902GX)

R162 1-216-017-00 RES-CHIP 47 5% 1/10W

(1902GX)

R163 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

(1902GX)

R164 1-216-821-11 METAL CHIP 1K 5% 1/16W

(1902GX)

R165 1-216-833-11 METAL CHIP 10K 5% 1/16W

R166 1-216-833-11 METAL CHIP 10K 5% 1/16W

(1902GX)

R121 1-216-843-11 METAL CHIP 68K 5% 1/16W

R122 1-216-295-11 SHORT 0

R123 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R124 1-216-045-00 METAL CHIP 680 5% 1/10W

R125 1-216-837-11 METAL CHIP 22K 5% 1/16W

R126 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R127 1-216-833-11 METAL CHIP 10K 5% 1/16W

R128 1-216-811-11 METAL CHIP 150 5% 1/16W

R129 1-216-073-00 METAL CHIP 10K 5% 1/10W

R130 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R131 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R132 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R133 1-216-089-11 RES-CHIP 47K 5% 1/10W

R134 1-216-089-11 RES-CHIP 47K 5% 1/10W

R135 1-216-033-00 METAL CHIP 220 5% 1/10W

R136 1-216-839-11 METAL CHIP 33K 5% 1/16W

R137 1-216-833-11 METAL CHIP 10K 5% 1/16W

R138 1-216-033-00 METAL CHIP 220 5% 1/10W

R139 1-216-845-11 METAL CHIP 100K 5% 1/16W

R140 1-216-845-11 METAL CHIP 100K 5% 1/16W

R141 1-216-017-00 RES-CHIP 47 5% 1/10W

R142 1-216-017-00 RES-CHIP 47 5% 1/10W

R143 1-249-427-11 CARBON 6.8K 5% 1/4W

R144 1-249-421-11 CARBON 2.2K 5% 1/4W

R145 1-220-894-11 METAL 0.22 10% 5W F

R146 1-220-894-11 METAL 0.22 10% 5W F

R167 1-216-017-00 RES-CHIP 47 5% 1/10W

R168 1-216-017-00 RES-CHIP 47 5% 1/10W

R201 1-216-837-11 METAL CHIP 22K 5% 1/16W

R202 1-216-837-11 METAL CHIP 22K 5% 1/16W

R203 1-216-837-11 METAL CHIP 22K 5% 1/16W

R204 1-216-837-11 METAL CHIP 22K 5% 1/16W

R205 1-208-494-61 RES-CHIP 2.2K 2% 1/8W

R206 1-216-845-11 METAL CHIP 100K 5% 1/16W

R207 1-216-845-11 METAL CHIP 100K 5% 1/16W

R208 1-216-025-11 RES-CHIP 100 5% 1/10W

(1902GX)

R209 1-216-833-11 METAL CHIP 10K 5% 1/16W

R210 1-216-833-11 METAL CHIP 10K 5% 1/16W

R211 1-216-833-11 METAL CHIP 10K 5% 1/16W

R212 1-216-837-11 METAL CHIP 22K 5% 1/16W

R213 1-216-833-11 METAL CHIP 10K 5% 1/16W

R214 1-216-833-11 METAL CHIP 10K 5% 1/16W

R215 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R216 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R217 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R218 1-216-845-11 METAL CHIP 100K 5% 1/16W

R219 1-216-845-11 METAL CHIP 100K 5% 1/16W

R220 1-216-845-11 METAL CHIP 100K 5% 1/16W

R221 1-216-843-11 METAL CHIP 68K 5% 1/16W

R222 1-216-295-11 SHORT 0

R223 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R224 1-216-045-00 METAL CHIP 680 5% 1/10W

19

Page 20

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R225 1-216-837-11 METAL CHIP 22K 5% 1/16W

R226 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R227 1-216-833-11 METAL CHIP 10K 5% 1/16W

R228 1-216-811-11 METAL CHIP 150 5% 1/16W

R229 1-216-073-00 METAL CHIP 10K 5% 1/10W

R304 1-216-833-11 METAL CHIP 10K 5% 1/16W

R305 1-216-833-11 METAL CHIP 10K 5% 1/16W

R306 1-216-833-11 METAL CHIP 10K 5% 1/16W

R307 1-216-833-11 METAL CHIP 10K 5% 1/16W

R308 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R230 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R231 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R232 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R233 1-216-089-11 RES-CHIP 47K 5% 1/10W

R234 1-216-089-11 RES-CHIP 47K 5% 1/10W

R235 1-216-033-00 METAL CHIP 220 5% 1/10W

R236 1-216-839-11 METAL CHIP 33K 5% 1/16W

R237 1-216-833-11 METAL CHIP 10K 5% 1/16W

R238 1-216-033-00 METAL CHIP 220 5% 1/10W

R239 1-216-845-11 METAL CHIP 100K 5% 1/16W

R240 1-216-845-11 METAL CHIP 100K 5% 1/16W

R241 1-216-017-00 RES-CHIP 47 5% 1/10W

R242 1-216-017-00 RES-CHIP 47 5% 1/10W

R243 1-249-427-11 CARBON 6.8K 5% 1/4W

R244 1-249-421-11 CARBON 2.2K 5% 1/4W

R245 1-220-894-11 METAL 0.22 10% 5W F

R246 1-220-894-11 METAL 0.22 10% 5W F

R247 1-220-894-11 METAL 0.22 10% 5W F

(1902GX)

R248 1-220-894-11 METAL 0.22 10% 5W F

(1902GX)

R249 1-220-894-11 METAL 0.22 10% 5W F

R250 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R251 1-216-821-11 METAL CHIP 1K 5% 1/16W

R252 1-215-859-00 METAL OXIDE 22 5% 1W F

R253 1-216-853-11 METAL CHIP 470K 5% 1/16W

R254 1-216-049-11 RES-CHIP 1K 5% 1/10W

R255 1-216-077-00 RES-CHIP 15K 5% 1/10W

R256 1-216-833-11 METAL CHIP 10K 5% 1/16W

R257 1-220-894-11 METAL 0.22 10% 5W F

R258 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R259 1-216-821-11 METAL CHIP 1K 5% 1/16W

R260 1-215-859-00 METAL OXIDE 22 5% 1W F

R261 1-216-017-00 RES-CHIP 47 5% 1/10W

(1902GX)

R262 1-216-017-00 RES-CHIP 47 5% 1/10W

(1902GX)

R263 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

(1902GX)

R264 1-216-821-11 METAL CHIP 1K 5% 1/16W

(1902GX)

R265 1-216-833-11 METAL CHIP 10K 5% 1/16W

R266 1-216-833-11 METAL CHIP 10K 5% 1/16W

(1902GX)

R267 1-216-017-00 RES-CHIP 47 5% 1/10W

R268 1-216-017-00 RES-CHIP 47 5% 1/10W

R301 1-216-833-11 METAL CHIP 10K 5% 1/16W

R302 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R303 1-216-833-11 METAL CHIP 10K 5% 1/16W

R309 1-216-847-11 METAL CHIP 150K 5% 1/16W

R310 1-216-847-11 METAL CHIP 150K 5% 1/16W

R311 1-216-833-11 METAL CHIP 10K 5% 1/16W

R312 1-216-833-11 METAL CHIP 10K 5% 1/16W

R313 1-220-397-11 RES-CHIP 4.7M 5% 1/16W

R314 1-220-397-11 RES-CHIP 4.7M 5% 1/16W

R315 1-216-845-11 METAL CHIP 100K 5% 1/16W

R801 1-216-857-11 METAL CHIP 1M 5% 1/16W

R802 1-216-821-11 METAL CHIP 1K 5% 1/16W

R803 1-216-833-11 METAL CHIP 10K 5% 1/16W

R804 1-216-845-11 METAL CHIP 100K 5% 1/16W

R805 1-216-839-11 METAL CHIP 33K 5% 1/16W

R806 1-216-833-11 METAL CHIP 10K 5% 1/16W

R807 1-216-833-11 METAL CHIP 10K 5% 1/16W

R808 1-216-833-11 METAL CHIP 10K 5% 1/16W

R809 1-216-833-11 METAL CHIP 10K 5% 1/16W

R810 1-216-857-11 METAL CHIP 1M 5% 1/16W

R811 1-208-494-61 RES-CHIP 2.2K 2% 1/8W

R820 1-216-833-11 METAL CHIP 10K 5% 1/16W

R821 1-216-833-11 METAL CHIP 10K 5% 1/16W

R822 1-216-833-11 METAL CHIP 10K 5% 1/16W

R823 1-216-833-11 METAL CHIP 10K 5% 1/16W

R824 1-216-841-11 METAL CHIP 47K 5% 1/16W

R825 1-216-833-11 METAL CHIP 10K 5% 1/16W

R826 1-216-833-11 METAL CHIP 10K 5% 1/16W

R827 1-216-833-11 METAL CHIP 10K 5% 1/16W

R828 1-216-833-11 METAL CHIP 10K 5% 1/16W

R829 1-216-833-11 METAL CHIP 10K 5% 1/16W

R830 1-216-833-11 METAL CHIP 10K 5% 1/16W

R833 1-216-839-11 METAL CHIP 33K 5% 1/16W

R834 1-216-839-11 METAL CHIP 33K 5% 1/16W

R835 1-216-841-11 METAL CHIP 47K 5% 1/16W

R836 1-216-841-11 METAL CHIP 47K 5% 1/16W

R837 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R838 1-216-816-11 METAL CHIP 390 5% 1/16W

R839 1-216-857-11 METAL CHIP 1M 5% 1/16W

R840 1-216-816-11 METAL CHIP 390 5% 1/16W

R841 1-216-816-11 METAL CHIP 390 5% 1/16W

R842 1-216-816-11 METAL CHIP 390 5% 1/16W

(1902GX)

R843 1-216-816-11 METAL CHIP 390 5% 1/16W

(1902GX)

R844 1-216-816-11 METAL CHIP 390 5% 1/16W

R845 1-216-816-11 METAL CHIP 390 5% 1/16W

R846 1-216-816-11 METAL CHIP 390 5% 1/16W

R847 1-216-816-11 METAL CHIP 390 5% 1/16W

R848 1-216-816-11 METAL CHIP 390 5% 1/16W

(1902GX)

20

Page 21

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R849 1-216-816-11 METAL CHIP 390 5% 1/16W

(1902GX)

R850 1-216-833-11 METAL CHIP 10K 5% 1/16W

R851 1-216-816-11 METAL CHIP 390 5% 1/16W

R852 1-216-816-11 METAL CHIP 390 5% 1/16W

R853 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R854 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R855 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

(1902GX)

R856 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

(1902GX)

R857 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R858 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R934 1-216-821-11 METAL CHIP 1K 5% 1/16W

R942 1-208-474-61 RES-CHIP 330 2% 1/8W

R943 1-208-474-61 RES-CHIP 330 2% 1/8W

< VARIABLE RESISTOR >

RV101 1-227-320-11 RES, VAR, CARBON 50KX2 (PHASE (40Hz))

(1902GX)

RV103 1-225-648-11 RES, VAR, CARBON 5KX2 (LOW BOOST)

RV104 1-225-648-11 RES, VAR, CARBON 5KX2 (LEVEL)

RV105 1-241-765-11 RES, ADJ, CERMET 22K

RV205 1-241-765-11 RES, ADJ, CERMET 22K

RV801 1-225-647-11 RES, VAR, CARBON 20KX4 (FILTER)

R859 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R860 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R861 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

(1902GX)

R862 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

(1902GX)

R863 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R864 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R901 1-216-833-11 METAL CHIP 10K 5% 1/16W

R902 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R903 1-216-837-11 METAL CHIP 22K 5% 1/16W

R904 1-216-835-11 METAL CHIP 15K 5% 1/16W

R905 1-216-848-11 METAL CHIP 180K 5% 1/16W

R906 1-216-065-00 RES-CHIP 4.7K 5% 1/10W

R907 1-216-190-00 RES-CHIP 470 2% 1/8W

R908 1-216-190-00 RES-CHIP 470 2% 1/8W

R909 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R910 1-216-073-00 METAL CHIP 10K 5% 1/10W

R911 1-216-073-00 METAL CHIP 10K 5% 1/10W

R912 1-208-474-61 RES-CHIP 330 2% 1/8W

R913 1-216-049-11 RES-CHIP 1K 5% 1/10W

R914 1-216-049-11 RES-CHIP 1K 5% 1/10W

R915 1-216-017-00 RES-CHIP 47 5% 1/10W

R916 1-216-001-00 METAL CHIP 10 5% 1/10W

R917 1-216-017-91 RES-CHIP 47 5% 1/10W

R918 1-208-474-61 RES-CHIP 330 2% 1/8W

R919 1-208-474-61 RES-CHIP 330 2% 1/8W

R920 1-216-001-00 METAL CHIP 10 5% 1/10W

R921 1-216-001-00 METAL CHIP 10 5% 1/10W

R922 1-216-001-00 METAL CHIP 10 5% 1/10W

R923 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R924 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

< SWITCH >

S301 1-762-638-11 SWITCH, TACTILE (TEST TONE)

S801 1-572-185-11 SWITCH, SLIDE (FILTER)

< TRANSFORMER >

T901 1-435-857-11 TRANSFORMER, DC-DC CONVERTER

< THERMISTOR (POSITIVE) >

TH801 1-804-301-11 THERMISTOR (SMD)

TH802 1-804-301-11 THERMISTOR (SMD)

TH803 1-804-301-11 THERMISTOR (SMD)

TH804 1-804-301-11 THERMISTOR (SMD) (1902GX)

TH805 1-804-301-11 THERMISTOR (SMD) (1902GX)

TH806 1-804-301-11 THERMISTOR (SMD)

TH807 1-804-301-11 THERMISTOR (SMD)

TH808 1-804-301-11 THERMISTOR (SMD)

TH809 1-804-301-11 THERMISTOR (SMD)

TH810 1-804-301-11 THERMISTOR (SMD) (1902GX)

TH811 1-804-301-11 THERMISTOR (SMD) (1902GX)

TH812 1-804-301-11 THERMISTOR (SMD)

TH813 1-804-301-11 THERMISTOR (SMD)

THP802 1-810-326-11 THERMISTOR (CHIP TYPE)

THP803 1-810-326-11 THERMISTOR (CHIP TYPE)

*************************************************************

MISCELLANEOUS

***************

F901 1-533-743-11 FUSE (BLADE TYPE) (AUTO FUSE) 40A

*************************************************************

R925 1-216-081-00 METAL CHIP 22K 5% 1/10W

R926 1-216-081-00 METAL CHIP 22K 5% 1/10W

R927 1-216-833-11 METAL CHIP 10K 5% 1/16W

R928 1-216-073-00 METAL CHIP 10K 5% 1/10W

R929 1-216-033-00 METAL CHIP 220 5% 1/10W

R930 1-216-821-11 METAL CHIP 1K 5% 1/16W

R931 1-216-821-11 METAL CHIP 1K 5% 1/16W

R932 1-216-821-11 METAL CHIP 1K 5% 1/16W

R933 1-216-821-11 METAL CHIP 1K 5% 1/16W

21

Page 22

XM-1502SX/1902GX

Ref. No. Part No. Description Remark

ACCESSORIES & PACKING MATERIALS

********************************

3-228-684-11 MANUAL, INSTRUCTION (ENGLISH,FRENCH)

3-228-685-11 MANUAL, INSTRUCTION (ENGLISH,FRENCH)

3-228-685-21 MANUAL, INSTRUCTION (GERMAN,ITALIAN)

(1502SX:AEP,UK,E)

3-228-685-31 MANUAL, INSTRUCTION (SPANISH,

PORTUGUESE) (1502SX:AEP,UK,E)

3-228-685-41 MANUAL, INSTRUCTION (DUTCH,SWEDISH)

(1502SX:AEP,UK,E)

(1902GX)

(1502SX)

3-228-685-51 MANUAL, INSTRUCTION (GREEK,RUSSIAN)

3-228-685-61 MANUAL, INSTRUCTION (POLISH,

TRADITIONAL CHINESE) (1502SX:AEP,UK,E)

3-367-410-01 SCREW (DIA.5X15), TAPPING

*************************************************************

**************

HARDWARE LIST

**************

#1 7-685-545-14 SCREW +BTP 3X6 TYPE2 N-S

#2 7-627-556-07 SCREW, PRECISION +P 2.6X2.8

#3 7-685-646-79 SCREW +P 3X8 TYPE2 NON-SLIT

(1502SX:AEP,UK,E)

(MOUNTING SCREW)

22

Page 23

MEMO

XM-1502SX/1902GX

23

Page 24

XM-1502SX/1902GX

REVISION HISTORY

Clicking the version allows you to jump to the revised page.

Also, clicking the version at the upper right on the revised page allows you to jump to the next revised

page.

Ver. Date Description of Revision

1.1 2001. 06 Corrected error for Q108, 110, 112, 208, 210, 212 and R819.

Added for condition of Bias Adjustment. (SPM-01013)

1.0 2000. 12 New

(ENG-01006)

24

Loading...

Loading...