Sony XL MP 40 H Service Manual

XL-MP40H

SERVICE MANUAL

No. S2518XLMP40H/

MICRO COMPONENT SYSTEM

(Except for U.K.)

CONTENTS

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] SAFETY PRECAUTION FOR SERVICE

MANUAL........................................................1-1

[2] IMPORT ANT SERVICE NOTES (FOR U.K.

ONLY)............................................................ 1-1

[3] SPECIFICATIONS .........................................1-2

[4] NAMES OF PARTS........................................ 1-3

CHAPTER 2. ADJUSTMENTS

[1] ADJUSTMENT...............................................2-1

[2] TEST MODE.................................................. 2-2

[3] When the CD does not function..................... 2-3

MODEL

XL-MP40H Micro Component System consisting of XLMP40H (main unit) and CP-MP40H (speaker system).

• In the interests of user-safety the set should be restored to its original condition and only parts identical to those specified be used.

• Note for users in U.K.

Recording and playback of any material may require consent which

SHARP is unable to give. Please refer particularly to the provisions

of Copyright Act 1956, the Dramatic and Musical Performers Protection Act 1956, the Performers Protection Acts 1963 and 1972

and to any subsequent statutory enactments and orders.

CHAPTER 5. CIRCUIT DESCRIPTION

[1] WAVEFORMS OF CD CIRCUIT....................5-1

[2] VOLTAGE......................................................5-2

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] NOTES ON SCHEMATIC DIAGRAM............ 6-1

[2] TYPES OF TRANSISTOR AND LED............6-1

[3] WIRING SIDE OF PWB/SCHEMATIC DIA-

GRAM............................................................6-2

CHAPTER 7. OTHERS

[1] FUNCTION TABLE OF IC.............................7-1

[2] LCD DISPLAY ...............................................7-6

XL-MP40H

CHAPTER 3. MECHANICAL DESCRIPTION

[1] REMOVING AND REINSTALLING THE

MAIN PARTS .................................................3-1

[2] DISASSEMBLY.............................................. 3-3

CHAPTER 4. DIAGRAMS

[1] BLOCK DIAGRAM......................................... 4-1

SHARP CORPORATION

Parts Guide

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

XL-MP40H

AudioXL-MP40HService ManualXLMP40HMarketE

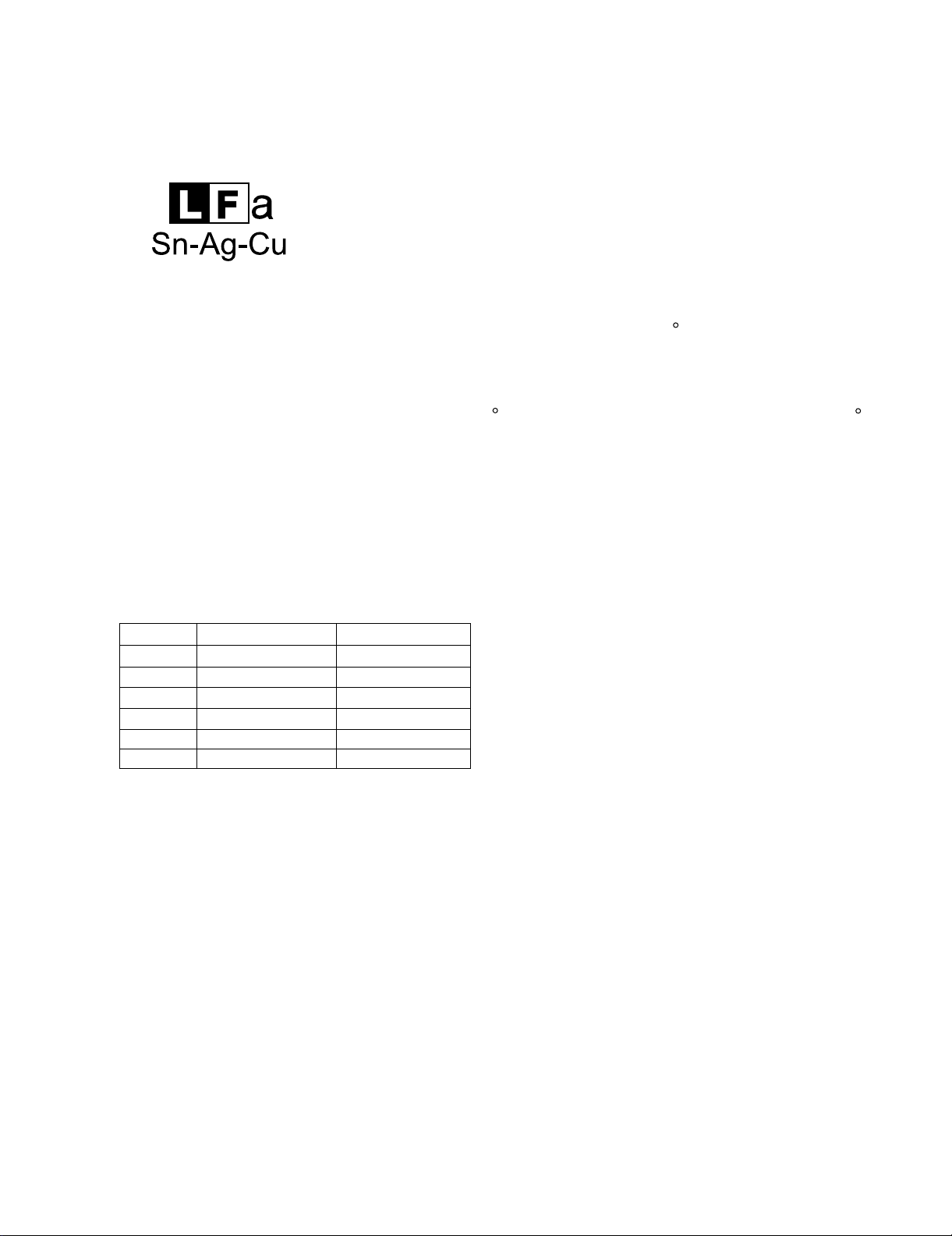

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

"MAIN,DISPLAY,LED,POWER,SWITCH,JACK PWB," of this model employs lead-free solder. The LF symbol indicates

lead-free solder, and is attached on the PWB and service manuals. The alphabetical character following LF shows the

type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free wire solder

When fixingthe PWBsoldered with thelead-free solder,apply lead-free wire solder. Repairingwith conventionallead wire solder

may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, we recommend you to use a

dedicated soldering bit, ifyou are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station

or service branch in your area.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead solder by 40 C,

and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of

time. However, Since the land may be peeled off or the maximum heat-resistance temperature of parts may be exceeded,

remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on and off the

power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after e very use

of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No. DescriptionParts No.

PWB-A1 MAINDCEKKV512SJ03

PWB-A2

PWB-A3

PWB-A4

PWB-A5

PWB-A6 DCEKKV512SJ03 SWITCH

DCEKKV512SJ03

DCEKKV512SJ03

DCEKKV512SJ03 JACK

DISPLAYDCEKKV512SJ03

POWER

LED

i

XL-MP40H

PROBE

AC

OUT

UNIT

SHORT-CIRCUIT

AC POWER

SUPPLY CORD

CONNECT THE PROBE

TO GND OF CHASSIS

SCREW

WITHSTANDING

VOLTAGE TESTER

AudioXL-MP40HService ManualXLMP40HMarketE

CHAPTER 1. GENERAL DESCRIPTION

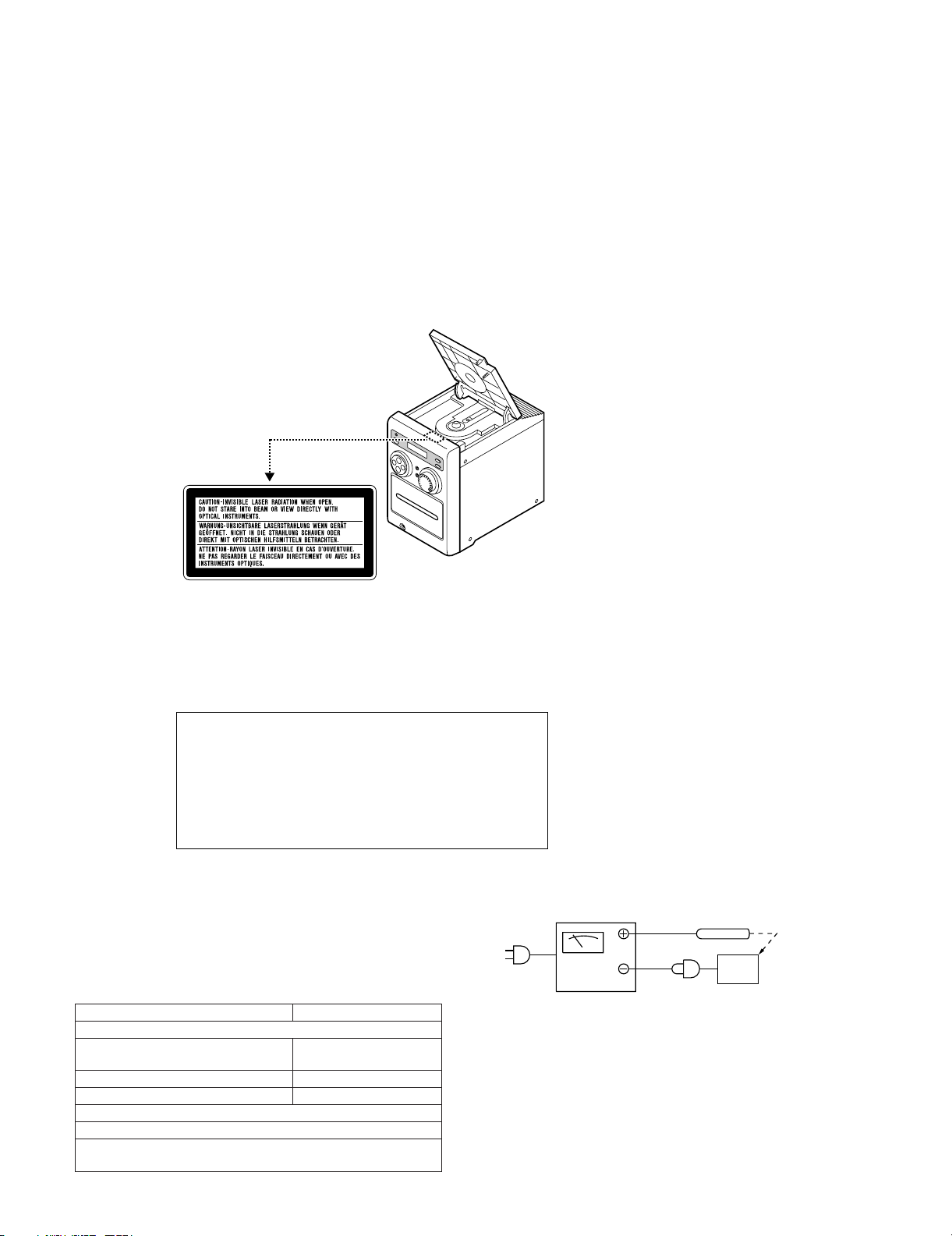

[1] SAFETY PRECAUTION FOR SERVICE MANUAL

Precaution to be taken when replacing and servicing the Laser Pickup.

The AEL (Accessible Emission Level) of Laser Power Output for this model is specified to be lower than Class 1 Requirements. However, the following precautions must be observed during servicing to protect your eyes against exposure to the Laser beam.

1) When the cabinet has been removed, the power is turned on without a compact disc, and th e Pickup is on a position out er than the lead-in position, the Laser will light for several seconds to detect a disc. Do not look into the Pickup Lens.

2) The Laser Power Output of the Pickup inside the unit and replacement service parts have already been adjusted prior to shipping.

3) No adjustment to the Laser Power should be attempted when replacing or servicing the Pickup.

4) Under no circumstances look directly into the Pickup Lens at any time.

5) C AUTION - Use of controls or adjustments, or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

Laser Diode Properties

Material: GaAIAs

Wavelength: 780 nm

Emission Duration: continuous

Laser Output: max. 0.6 mW

[2] IMPORTANT SERVICE NOTES (FOR U.K.

ONLY)

Before returning the unit to the customer after completion of a repair or

adjustment it is necessary for the following withstand voltage test to be

applied to ensure the unit is safe for the customer to use.

Setting of Withstanding Voltage Tester and set.

ADVARSEL-USYNLIG LASERSTRÅLING VED ÅBNING. SE IKKE IND I

STRÅLEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA NÄKYMÄTÖN LASERSÄTEILYLLE.

ÄLÄ TUIJOTA SÄTEESEEN ÄLÄKÄ KATSO SITÄ OPTISEN LAITTEEN

LÄPI.

VARNING-OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD.

STIRRA EJ IN I STRÅLEN OCH BETRAKTA EJ STRÅLEN GENOM

OPTISKT INSTRUMENT.

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT ÄN

I DENNA BRUKSANVISNING SPECIFICERAS. KAN

ANVÄNDAREN UTSÄTTAS FÖR OSYNLIG LASERSTRÅLNING, SOM ÖVERSKRIDER GRÄNSEN FÖR

LASERKLASS 1.

Set name set value

Withstanding Voltage Tester

Test voltage 4,240 VPEAK

Set time 6 secs

Set current (Cutoff current) 4 mA

Unit

Judgment

OK: The “GOOD” lamp lights.

NG: The “NG” lamp lights and the buzzer sounds.

3,000 VRMS

1 – 1

XL-MP40H

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

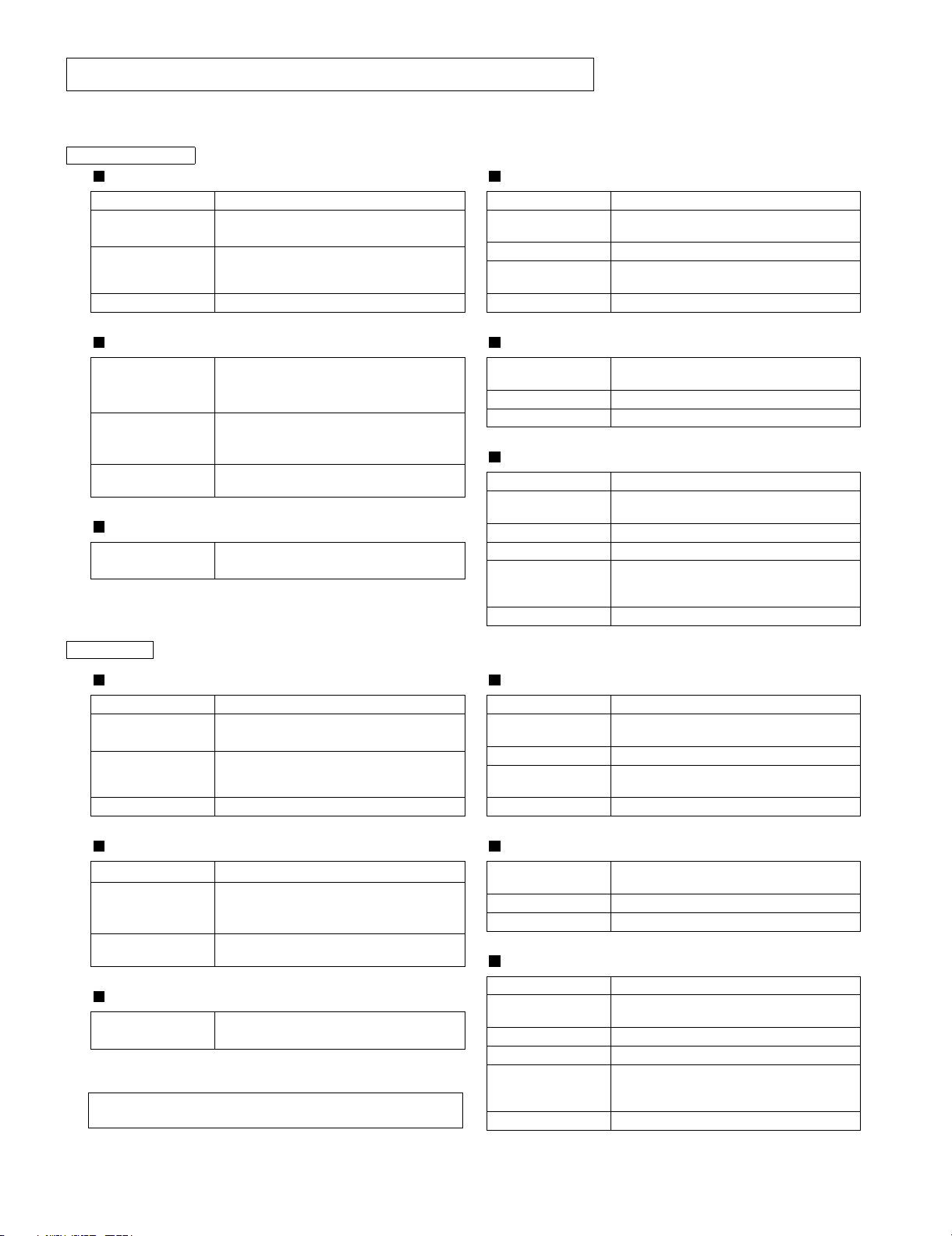

[3] SPECIFICATIONS

Except for U.K.

General

Power source AC 230 V, 50 Hz

Power

consumption

Dimensions Width: 160 mm (6-5/16")

Weight 2.5 kg (5.5 lbs.)

Power on: 25 W

Power stand-by: 0.9 W

Height: 240 mm (9-1/2")

Depth: 245 mm (10")

CD player

Type Compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter 1-bit D/A converter

Frequency

response

Dynamic range 90 dB (1 kHz)

pickup

20 - 20,000 Hz

Amplifier

Output power PMPO: 30 W (total)

MPO: 15 W (7.5 W + 7.5 W) (DIN 45 324)

RMS: 10 W (5 W + 5 W) (DIN 45 324)

Output terminals Speakers: 4 ohms

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Input terminals Video/Auxiliary (audio signal):

500 mV/47 k ohms

Tuner

Frequency range FM: 87.5 - 108.0 MHz

AM: 522 - 1,620 kHz

For U.K.

General

Power source AC 230 V - 240V, 50 Hz

Power

consumption

Dimensions Width: 160 mm (6-5/16")

Weight 2.5 kg (5.5 lbs.)

Power on: 25 W

Power stand-by: 0.9 W

Height: 240 mm (9-1/2")

Depth: 245 mm (10")

Cassette deck

Frequency

response

Signal/noise ratio 50 dB (recording/playback)

Wow and flutter 0.35 % (DIN 45 511)

50 - 14,000 Hz (normal tape)

Speaker

Type 10 cm (4") full-range speaker

Maximum input

power

Rated input power 5W

Impedance 4 ohms

Dimensions Width: 145 mm (5-3/4")

Weight 1.4 kg (3.1 lbs.)/each

10 W

Height: 240 mm (9-1/2")

Depth: 180 mm (7-1/16")

CD player

Type Compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter 1-bit D/A converter

Frequency

response

Dynamic range 90 dB (1 kHz)

pickup

20 - 20,000 Hz

Amplifier

Output power

Output terminals Speakers: 4 ohms

Input terminals Video/Auxiliary (audio signal):

RMS: 10 W (5 W + 5 W) (10 % T.H.D.)

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

500 mV/47 k ohms

Tuner

Frequency range FM: 87.5 - 108.0 MHz

AM: 522 - 1,620 kHz

Specifications for this model are subject to change without prior

notice.

Cassette deck

Frequency

response

Signal/noise ratio 50 dB (recording/playback)

Wow and flutter 0.3 % (WRMS)

50 - 14,000 Hz (normal tape)

Speaker

Type 10 cm (4") full-range speaker

Maximum input

power

Rated input power 5W

Impedance 4 ohms

Dimensions Width: 145 mm (5-3/4")

Weight 1.4 kg (3.1 lbs.)/each

10 W

Height: 240 mm (9-1/2")

Depth: 180 mm (7-1/16")

1 – 2

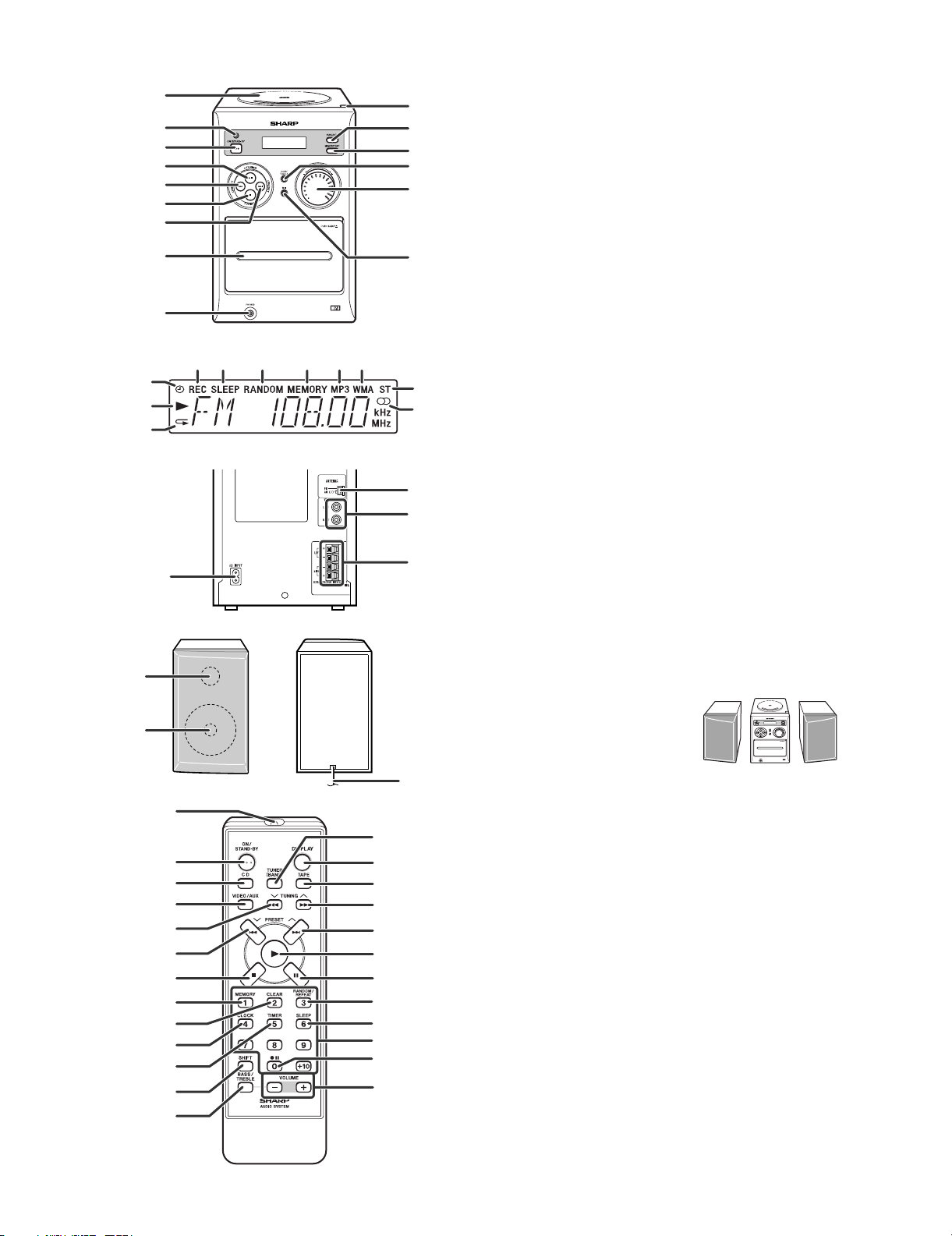

[4] NAMES OF PARTS

XL-MP40H

22

23

24

27

1

2

3

4

5

10

11

12

13

14

6

7

8

15

9

18 19 20 21

17

16

25

26

28

1.Disc Compartment

2.Remote Sensor

3.On/Stand-by Button

4.Disc Play or Pause, Tape Play,

Tuning Up Button

5.Disc Track Down or Fast Reverse, Tape Rewind,

Tuner Preset Down Button

6.Disc or Tape Stop, Tuning Down Button

7.Disc Track Up or Fast Forward, Tape Fast Forward,

Tuner Preset Up Button

8.Cassette Compartment

9.Headphone Socket

10.Disc Eject Button

11.Function Selector Button

12.Memory/Set Button

13.Bass/Treble Selector Button

14.Volume Control

15.Tape Record Pause Button

16.Tape Record Indicator

17.Sleep Indicator

18.Disc Random Play Indicator

19.Memory Indicator

20.MP3 Track Indicator

21.WMA Track Indicator

22.Timer Play Indicator

23.Disc Play Indicator

24.Disc Repeat Indicator

25.FM Stereo Mode Indicator

26.FM Stereo Receiving Indicator

29

27.AC Power Input Socket

28.FM/AM Loop Aerial Socket

30

29.Video/Auxiliary (Audio Signal) Input Sockets

30.Speaker Terminals

1.Bass Reflex Duct

2.Full-Range Speaker

3.Speaker Wire

1

2

3

4

17

5

6

7

8

9

10

11

12

13

14

15

18

19

20

21

22

23

24

25

26

27

28

16

Placing the speaker system:

The left and right speakers have

individual shapes. For best performance, place the speakers according to the illustration on the

right.

Note:

The speaker grilles are not removable.

4.Remote Control Transmitter

5.On/Stand-by Button

6.Disc Button

7.Video/Auxiliary Button

8.Disc Fast Reverse, Tuning Down Button

9.Disc Track Down, Tape Rewind, Tuner Preset Down,

Time Down Button

10.Disc or Tape Stop Button

11.Memory Button

12.Clear Button

13.Clock Button

14.Timer Button

15.Shift Button

16.Bass/Treble Selector Button

17.Tuner and Band Selector Button

18.MP3/WMA Display Button

19.Tape Button

20.Disc Fast Forward, Tuning Up Button

21.Disc Track Up, Tape Fast Forward, Tuner Preset Up,

Time Up Button

22.Disc or Tape Play Button

23.Disc Pause Button

24.Random/Repeat Button

25.Sleep Button

26.Direct Search Buttons

27.Tape Record Pause Button

28.Volume Up and Down Buttons

Right speakerLeft speaker

1 – 3

XL-MP40H

AM ANT.

FM OSC.

TP-VT=28Pin

28 2336

AM BAND

COVERAGE fL

FM RF

AM

Tracking

FM BAND

COVERAGE fL

MAIN PWB-A1

AM IF

AudioXL-MP40HService ManualXLMP40HMarketE

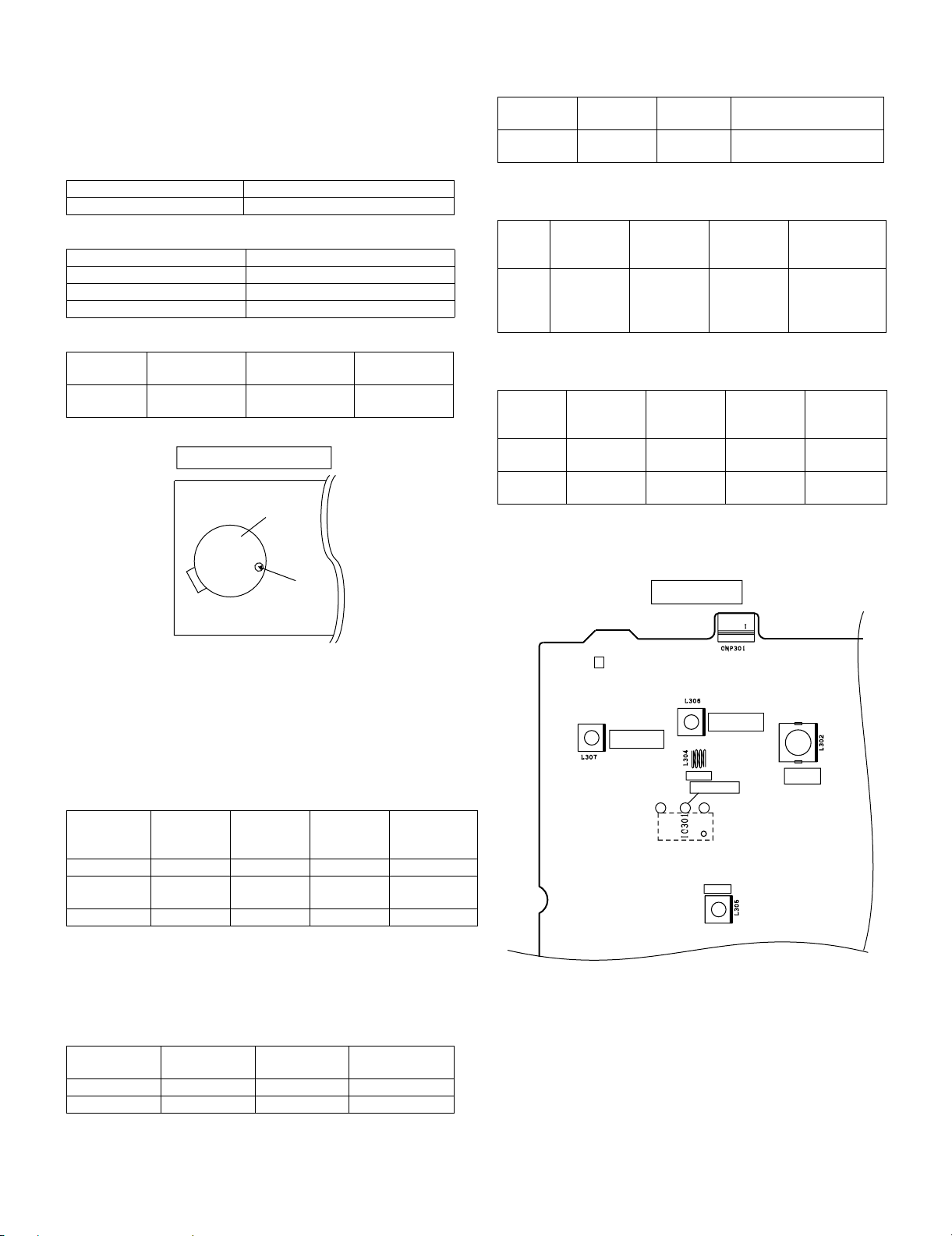

CHAPTER 2. ADJUSTMENTS

• FM Mute Level

Signal generator: 1 kHz, 40 kHz dev., FM modulated

[1] ADJUSTMENT

1. MECHANISM SECTION

• Driving Force Check

Torque Meter Specified Value

Play: TW-2412 Over 80 g

• Torque Check

Torque Meter Specified Value

Play: TW-2111 30 to 60 g.cm

Fast forward: TW-2231 55 to 140 g.cm

Rewind: TW-2231 55 to 140 g.cm

• Tape Speed

Test Tape Adjusting

Point

MTT-111 Variable Resis-

tor in motor.

TAPE MECHANISM

Specified Value Instrument

3,000 ± 30 Hz Headphone

M901

Tape

Motor

Connection

Terminal

Frequency Display Adjusting

Parts

98.00 MHz

98.00 MHz - Input: CNP301

(30 dBµV)

Instrument

Connection

Output: Speaker Terminal

• FM Detection

Signal generator: 10.7 MHz FM sweep generator

Test

Stage

Frequency Frequency

Display

Setting/

Adjusting

Instrument

Connection

Parts

FM IF 10.7 MHz 98.00 MHz - Input: Pin 36 of

IC301

Output: Pin 23

of IC301

• FM RF

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Test

Stage

Frequency Frequency

Display

Setting/

Adjusting

Instrument

Connection

Parts

FM Band

Coverage

FM RF 98.00 MHz

— 87.50 MHz (fL): L307

1.5 ± 0.1 V

98.00 MHz L304 *1

*1

(10 ~ 30dB)

*1. Input: Antenna Output: 23 Pin of IC301

Variable

resistor

in motor

Figure 1

2. TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage Frequency Frequency

Display

IF 450 kHz 1,602 kHz L305 *1

AM Band

— 522 kHz (fL): L306

Coverage

Setting/

Adjusting

Parts

1.1 ± 0.1 V

AM Tracking 990 kHz 990 kHz L302 *3

*1. Input: IC301 1Pin Output: IC301 23Pin

*2. Input: Input is not connected Output: TP-VT (IC301 28Pin)

*3. Input: Antenna Output:IC301 23Pin

• Check FM VT

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency Display Check Point Instrument

87.5 MHz 87.5 MHz 1.5V ± 1.0V TP-VT

108 MHz 108 MHz 5.0V ± 1.0V TP-VT

Instrument

Connection

*2

Connection

Figure 2 ADJUSTMENT POINTS

2 – 1

XL-MP40H

• Setting the Test Mode

Keeping the REW/REV button and BASS/TREBLE button pressed, turn on POWER. Then, the frequency is initially set in the memory as shown in

Table. Call it with the PRESET button to use it for adjustment and check of tuner circuit.

Preset No. BAND FM STEREO

1 FM STEREO FM 87.50 MHz

2 FM 108.00 MHz

3 FM 98.00 MHz

4 FM 90.00 MHz

5 FM 106.00 MHz

6 AM AM 522 kHz

7 AM 1620 kHz

8 AM 990 kHz

Preset No. BAND FM STEREO

9 AM AM 603 kHz

11~25 ——————

26 FM MONO FM 106.00 MHz

27 FM 90.00 MHz

28 FM 98.00 MHz

29 FM 108.00 MHz

30 FM 87.50 MHz

[2] TEST MODE

1. Turning on the test mode

Turning on the test mode

To tu rn on the specific test mode, press the ON/STAND-BY button, holding down the following two buttons in the or dinary stand-by mode (powe r off

state). In this case only the main unit button is valid. Even when the ON/STAND-BY of remote control button is set to on, the test mode is not turned

on.

[Ordinary test mode]

1. CD Test Mode(TEST 1) ........................FUNCTION + Tuning Down

2. Tuner Test Mode(TEST 2)......................FUNCTION + Preset Down

3. Volume Test Mode(TEST 3)....................FUNCTION + Tuning Up

4. Timer Test Mode(TEST 4) ......................FUNCT ION + Preset Up

5. Display Test Mode (TEST 5)...................FUNCTION + Bass/Treble

6. ALL KEY Test (TEST 6)....................MEMORY/SET + Tuning Up

7. Tuner clear test (TEST 7)................FUNCTION + Tape Rec

8. Soft reset test(TEST 8).....................MEMORY/SET + Preset Down

All test modes can be terminated by turning off the power with ON/STAND-BY key.

• CD test(TEST 1)

[cd step 1] Enter test mode.

↓ Hold down the “memory” button

[cd step 2] After some steps, the laser turns on.

↓ Hold down the “memory” button

[cd step 3] After some steps, focus search is performed.

↓ Hold down the “memory” button

[cd step 4] After some steps, CLV rotation is performed.

↓ Hold down the “memory” button

[cd step 5] CD playback starts.

↓ Hold down the “stop” button to return to [cd step 1] ––––––––––

←———————

A

A

In step 5, hold down the AUX key on the remote control. The tracking servo is switched on/off.

From step 3, the pick up can be moved with the FF/REW key.

• Tuner test (TEST 2)

CH BAND FREQUENCY

1 FM STEREO FM 87.50 MHz

2 FM 108.00 MHz

3 FM 98.00 MHz

4 FM 90.00 MHz

5 FM 106.00 MHz

6 AM AM 522 kHz

7 AM 1620 kHz

8 AM 990 kHz

9 AM 603 kHz

10 AM AM 1404 kHz

CH BAND FREQUENCY

11 ——————

·

·

35

36 FM MONO FM 106.00 MHz

37 FM 90.00 MHz

38 FM 98.00 MHz

39 FM 108.00 MHz

40 FM 87.50 MHz

2 – 2

XL-MP40H

• VOLUME test (TEST 3)

Starting from level 23 (default), check all the levels (0 - 23 - MAX).

• TIMER test(TEST4)

At 1:05, the power turns on to activate the tape function, and turns off after 90 seconds (equivalent to 90 minutes on the unit).

• Display test(TEST 5)

When test mode is activated, the entire display lights up. As the “PLAY” key is pressed, half of the display lights up alternately.

• ALL KEY test(TEST6)

In the test mode, hold down all the buttons on the main unit and then press the “ON/STAND-BY”button. “OK” appears.

If only the “ON/STAND-BY” button is pressed, “ERROR” appears.

• Tuner clear test (TEST 7)

All tuner preset stations are cleared.

• Soft reset test (TEST 8)

All data in RAM is cleared.

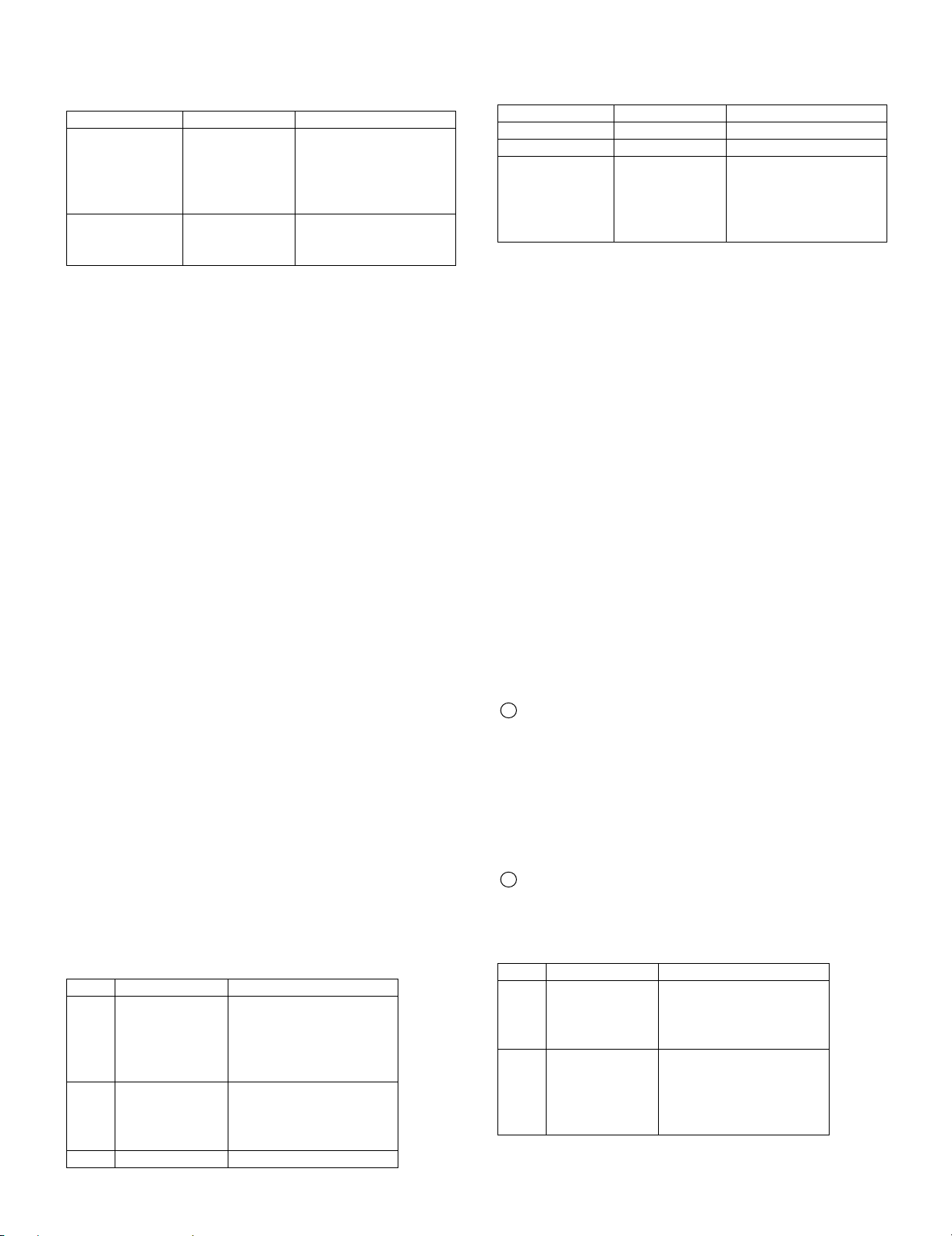

[3] When the CD does not function

The CD section may not operate when the objective lens of the optical pickup is dirty. Clean the objective lens, and check the playback operation.

When this section does not operate even after the above step is taken, check the following items.

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Parts code

1. CD optical pickup Lens cleaner disc UDSKA0004AFZZ

HOW TO USE

1. Using the brush in the cleaner cap, apply 1 or 2 drops of the cleaning fluid to the brush on the CD cleaner disc which has

mark next to it.

the

2. Place the CD cleaner disc onto the CD disc tray with the brush side down, then press the play button.

3. You will hear music for about 20 seconds and the CD player will automatically stop. If it continues to turn, press the stop

button.

CAUTION

The CD lens cleaner should be effective for 30~50 operations, however if the brushes become worn out earller then please

replace the cleaner disc.

If the CD cleaner brushes become very wet then wipe off any excess fluid with a soft cloth.

Do not drink the cleaner fluid or allow it to come in contact with the eyes. In the event of this happening then drink and /

or rinse with clean water and seek medical advice.

The CD cleaner disc must not be used on car CD players or on computer CD ROM drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting this product is prohibited by law.

Cleaner Liquid

Cleaning Disc

PARTS CODE: UDSKA0004AFZZ

2 – 3

AudioXL-MP40HService ManualXLMP40HMarketE

CHAPTER 3. MECHANICAL DESCRIPTION

[1] REMOVING AND REINSTALLING THE MAIN PARTS

1. TAPE MECHANISM SECTION

Perform steps 1 to 5 and 8 of the disassembly method to remove the

tape mechanism. (See page 3-3.)

(A2)x1

ø2x7mm

XL-MP40H

(A2)x1

ø2x3mm

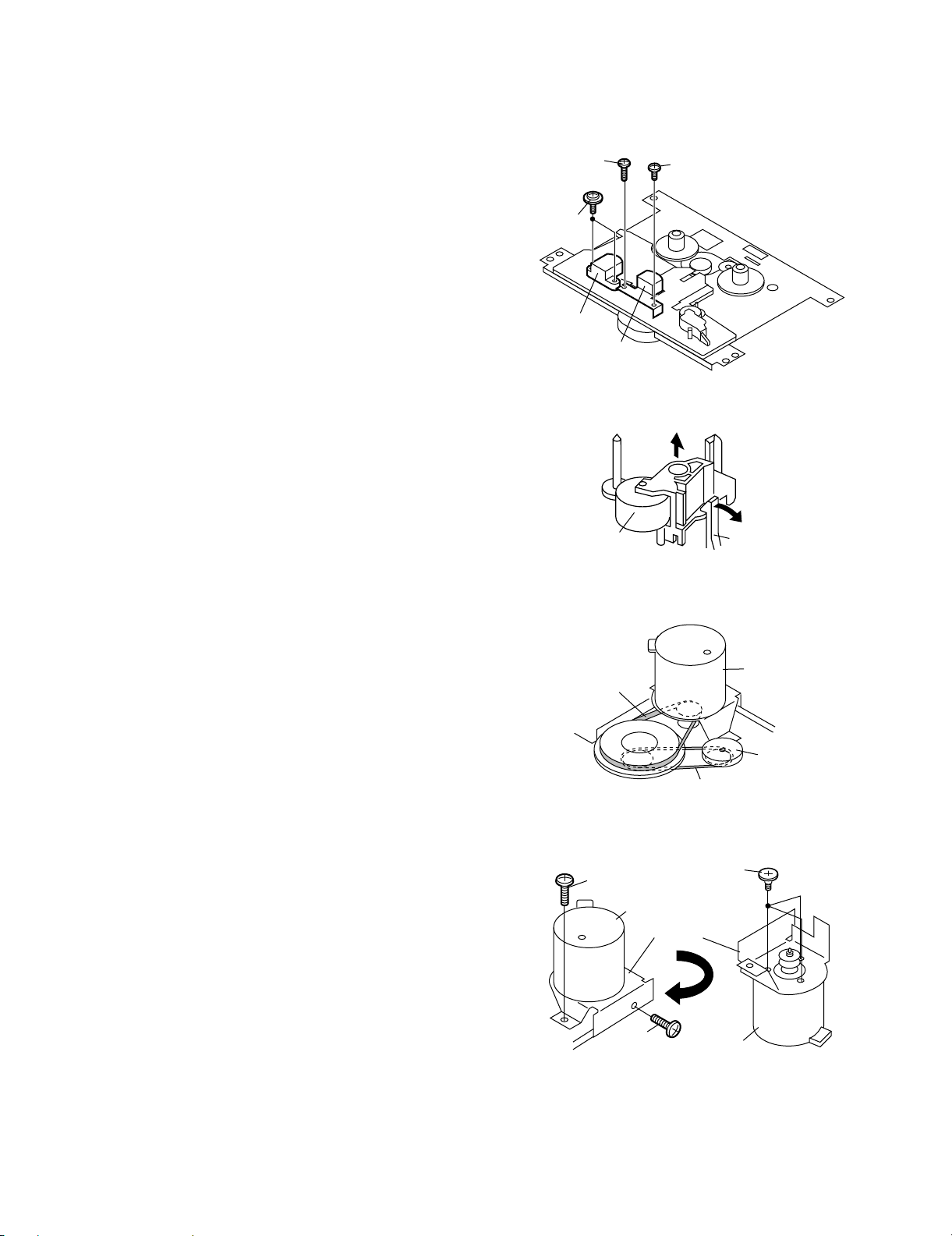

1.1. How to remove the record / playback and erase hea ds

(See Fig. 1)

1. Remove the screws (A1) x 2 pcs., to remove the erase head.

2. Remove the screws (A2) x 2 pcs., to remove the record/playback

head.

NOTE: After replacing the heads and performing the azimuth adjust-

ment, be sure to apply screwlock.

1.2. How to remove the pinch roller (See Fig. 2)

1. Carefully bend the pinch roller pawl in the direction of the arrow

<A>, and remove the pinch roller (B1) x 1 pc., upwards.

1.3. How to remove the belts (See Fig. 3)

1. Remove the main belt (C1) x 1 pc., from the motor pulley.

2. Remove the FF/REW belt (C2) x 1 pc., from the REW/FF roller.

3. Put on the belts in the reverse order of removal.

NOTE: When putting on the belt, ascertain that the belt is not twisted,

and clean it.

(A1)x2

ø2x8mm

Erase Head

Record/

Playback Head

Pinch Roller

(B1)x1

Main Belt

(C1)x1

Figure 1

<A>

Pinch Roller

Pawl

Figure 2

Motor

1.4. How to remove the motor (See Fig. 4)

1. Remove the main belt.

2. Remove the screws (D1) x 2 pcs., to remove the motor bracket.

3. Remove the screws (D2) x 3 pcs., to remove the motor.

NOTE: When mounting the motor, pay attention to the motor mounting

angle.

3 – 1

(D1)x1

ø2x4mm

Motor

(D1)x1

ø2x4mm

REW/FF

Clutch

FF/REW Belt

(C2)x1

Figure 3

(D2)x3

Special

Screw

Motor

Bracket

Motor

Figure 4

XL-MP40H

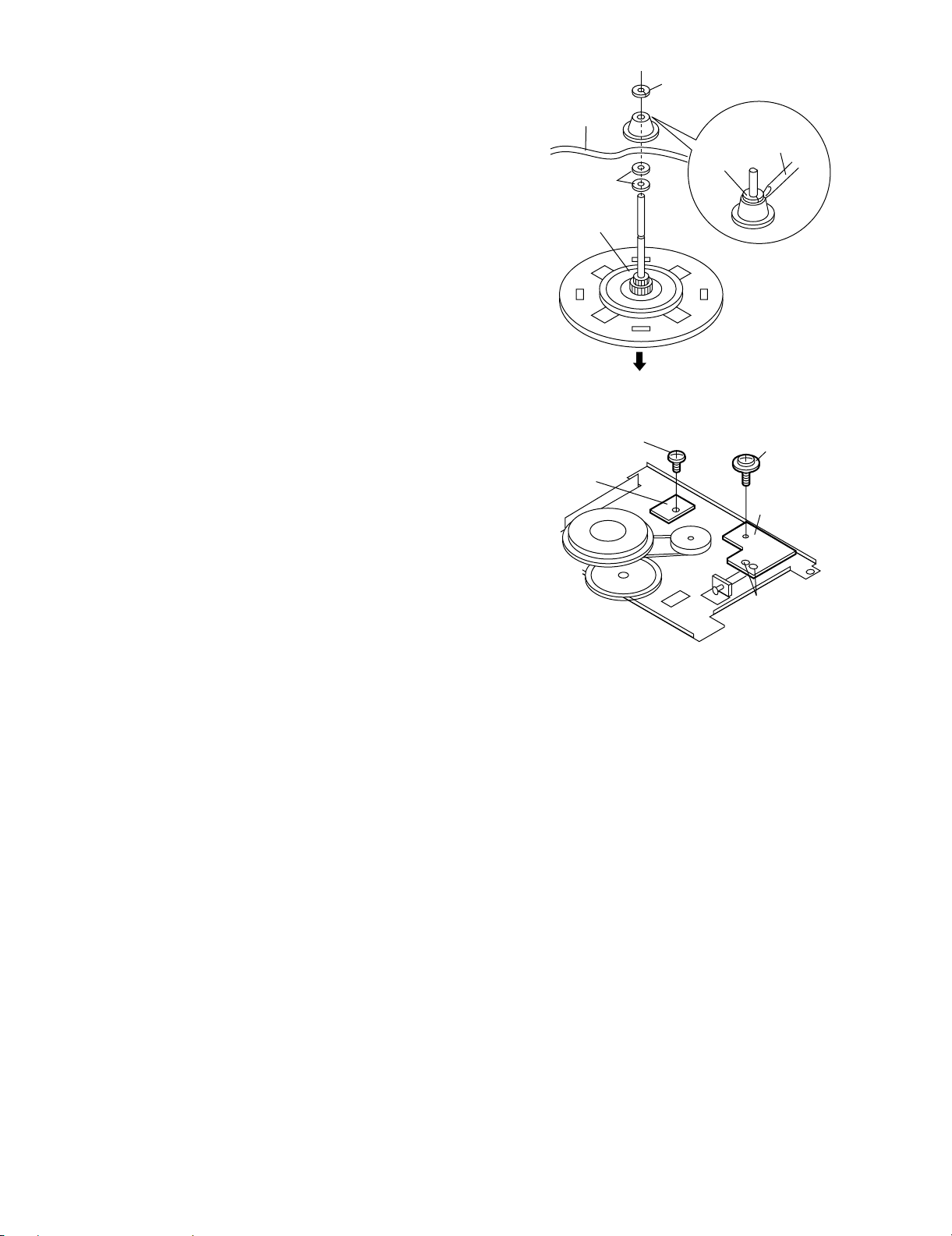

1.5. How to remove the flywheel (See Fig. 5)

1. Remove the belt.

2. Remove the stop washer (E1) x 1 pc., with a small precision screwdriver to extract the flywheel from the capstan metal.

NOTE: When the stop washer is deformed or damaged, replace it with

a new one.

1.6. How to reinstall the parts

Install each part in the reverse order of the removal with care.

Mechanism

Chassis

Washerx2

Flywheel

(E1)x1

Stop Washer

Stop

Washer

Figure 5

Driver

1.7. How to remove the tape mechanism PWB(See Fig. 6)

1. Remove the screw (F1) x 1 pc., to remove the tape mechanism

PWB.

2. Remove the screws (F2) x 1 pc.

3. Remove the solder joints (F3) x 2 pcs., to remove the tape mechanism PWB.

(F1)x1

ø2x3mm

Tape

Mechanism

PWB

(F2)x1

ø2x8mm

Tape

Mechanism

PWB

(F3)x2

Solder

Joint

Figure 6

3 – 2

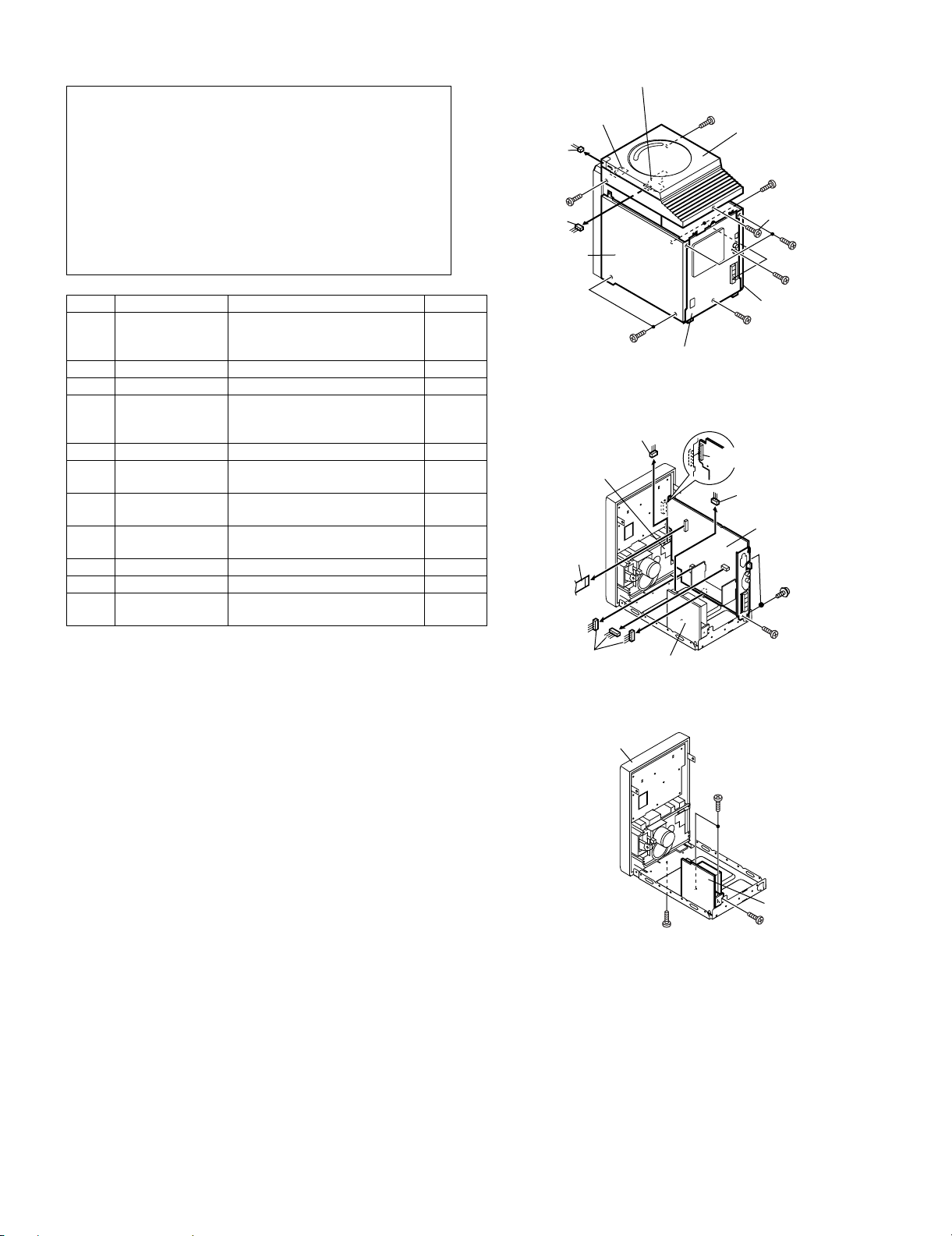

[2] DISASSEMBLY

Side Panel

(Right)

Rear Panel

(C1)x1

ø3x6mm

(C1)x1

ø3x10mm

Side Panel

(Lift)

(A1)x1

ø3x12mm

(A1)x2

ø3x12mm

(A1)x1

ø3x12mm

(A1)x1

ø3x10mm

(A2)x1

(B1)x2

ø3x12mm

(B1)x2

ø3x6mm

Top Cabinet

CD Mechanism PWB

(A2)x1

Open/Close

Switch PWB

Caution on Disassembly

Follow the below-mentioned notes when disassembling the unit and

reassembling it, to keep it safe and ensure excellent performance:

1) Take cassette tape and compact disc out of the unit.

2) Be sure to remove the power supply plug from the wall outlet

before starting to disassemble the unit.

3) Take off nylon bands or wire holders where they need to be

removed when disassembling the unit. After servicing the unit,

be sure to rearrange the leads where they were before disassembling.

4) Take sufficient care on static electricity of integrated circuits and

other circuits when servicing.

STEP REMOVAL PROCEDURE FIGURE

1 Top Cabinet 1. Screw...........................(A1) x 5

2. Socket

3. Flat cable.....................(A3) x 1

2 Side Panel 1. Screw...........................(B1) x 4 1

3 Rear Panel 1. Screw..........................(C1) x 2 1

4 Main PWB 1. Screw..........................(D1) x 3

2. Socket.........................(D2) x 5

3. Socket.........................(D3) x 1

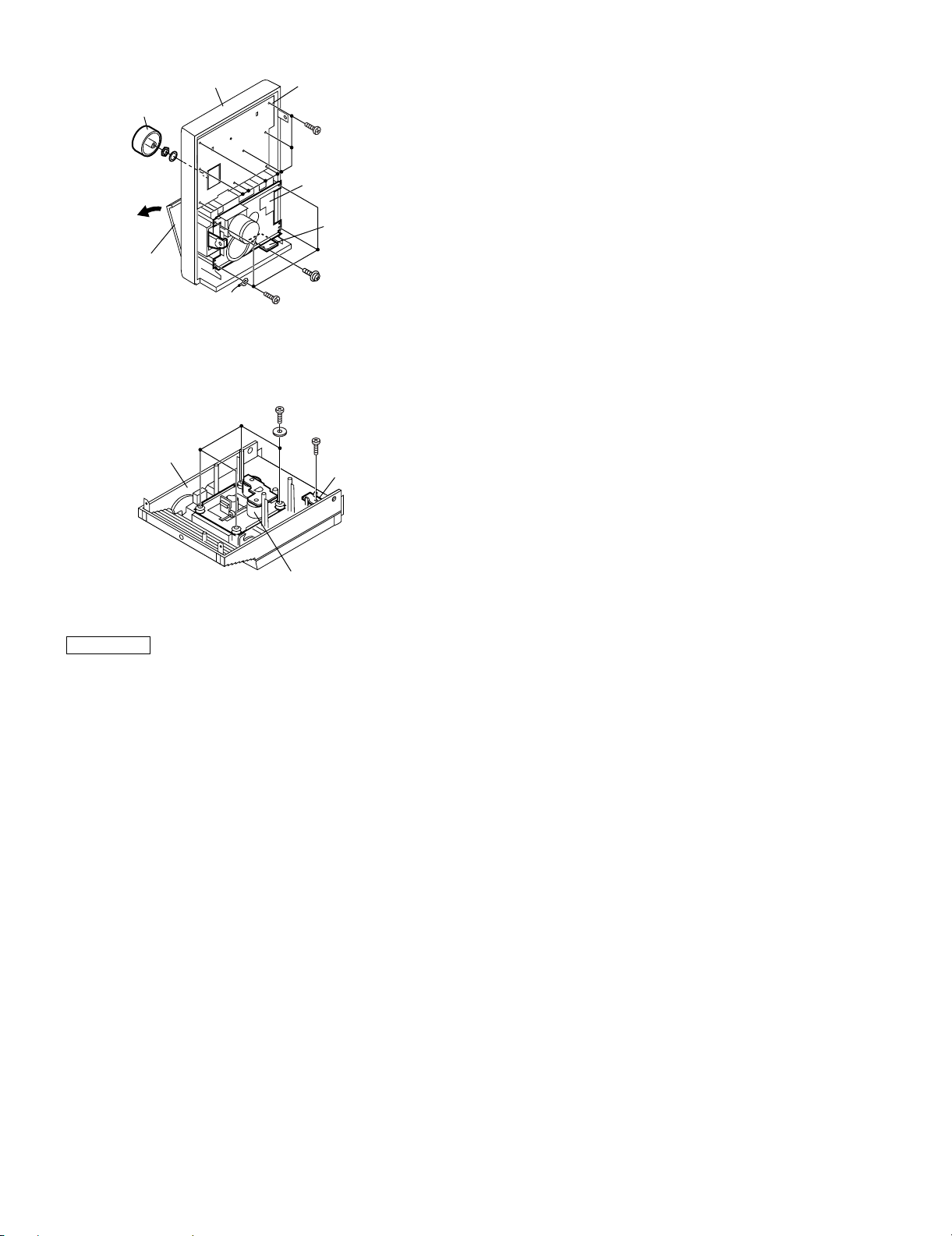

5 Front Panel 1. Screw...........................(E1) x 1 3

6 Power PWB 1. Screw...........................(F1) x 1

2. Screw...........................(F2) x 2

7 Display PWB 1. Knob............................(G1) x 1

2. Screw..........................(G2) x 8

8 Tape Mechanism 1. Open the cassette holder

2. Screw..........................(H1) x 4

9 Jack PWB 1. Screw...........................(J1) x 1 4

10 Switch PWB 1. Screw...........................(K1) x 1 5

11 CD Mechanism

(Note)

Note :

After removing the connector for the optical pickup from the connector,

wrap the conductive aluminium foil around the front end of the connector so as to protect the optical pickup from electrostatic damage.

1. Screw...........................(L1) x 4 5

..........................

(A2) x 2

XL-MP40H

1

2

(D2)x1

Power PWB

Figure 1

(D3)x1

(D2)x1

Main PWB

(D1)x2

ø3x12mm

(D1)x1

ø3x6mm

Figure 2

2

Tape

3

4

4

Mechanism

PWB

(A3)x1

(D2)x3

3 – 3

Front Panel

(E1)x1

ø3x6mm

Figure 3

(F2)x2

ø3x8mm

Power

PWB

(F1)x1

ø3x6mm

XL-MP40H

Front Panel

(G1)x1

Open

Cassette

Holder

Top Cabinet

Display PWB

(G2)x8

ø2.5x10mm

Tape

Mechanism

Jack PWB

(J1)x1

ø2.5x10mm

(H1)x4

ø2.5x10mm

Figure 4

(L1)x4

ø2.5x10mm

(K1)x1

ø2.5x10mm

Switch PWB

CD Mechanism

Figure 5

CP-MP40H

These speaker CP-MP40H are available in assembles only and may

not be disassembled.

3 – 4

-MEMO-

XL-MP40H

3 – 5

XL-MP40H

1

2

3

4

5

6

O

Y

6

AudioXL-MP40HService ManualXLMP40HMarketE

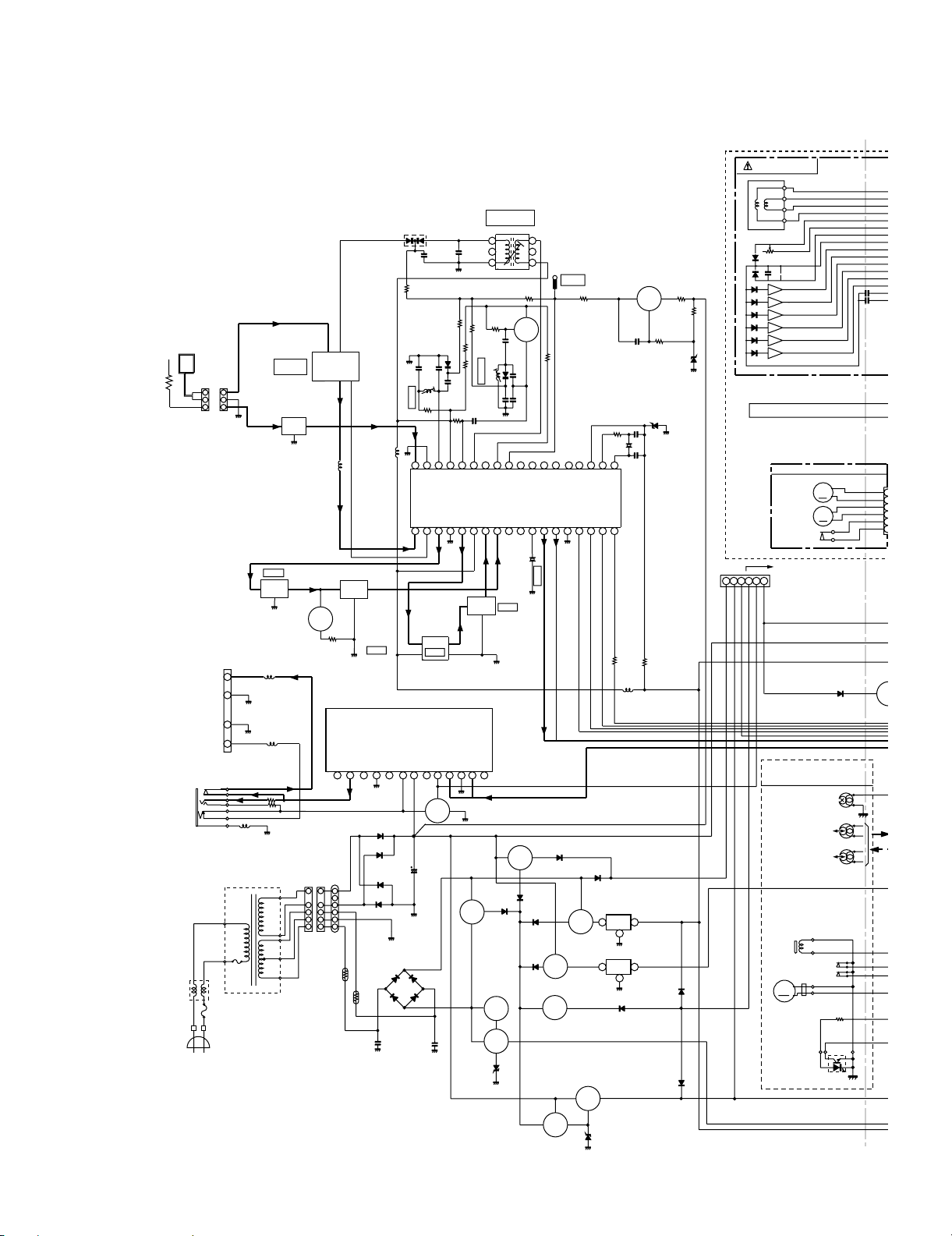

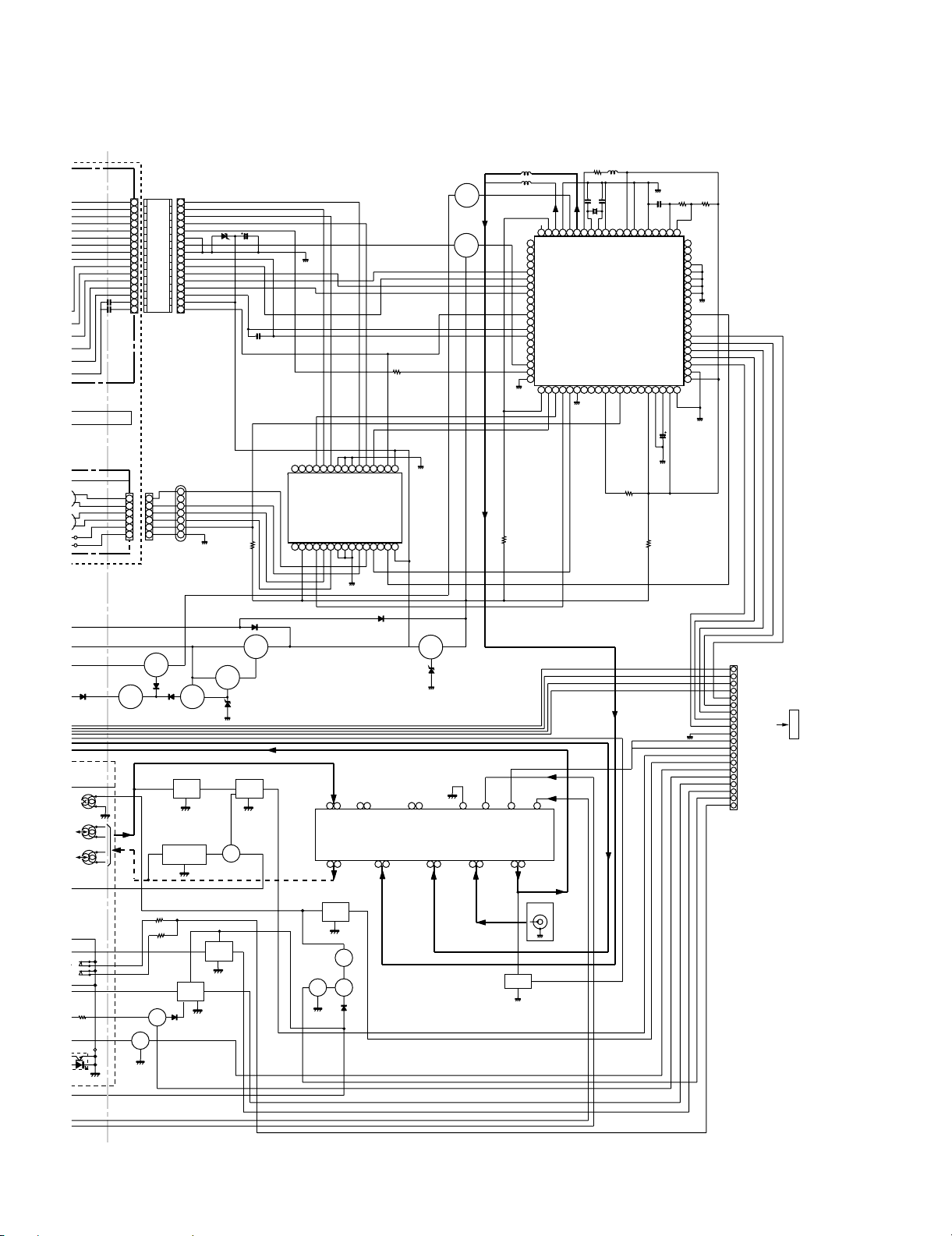

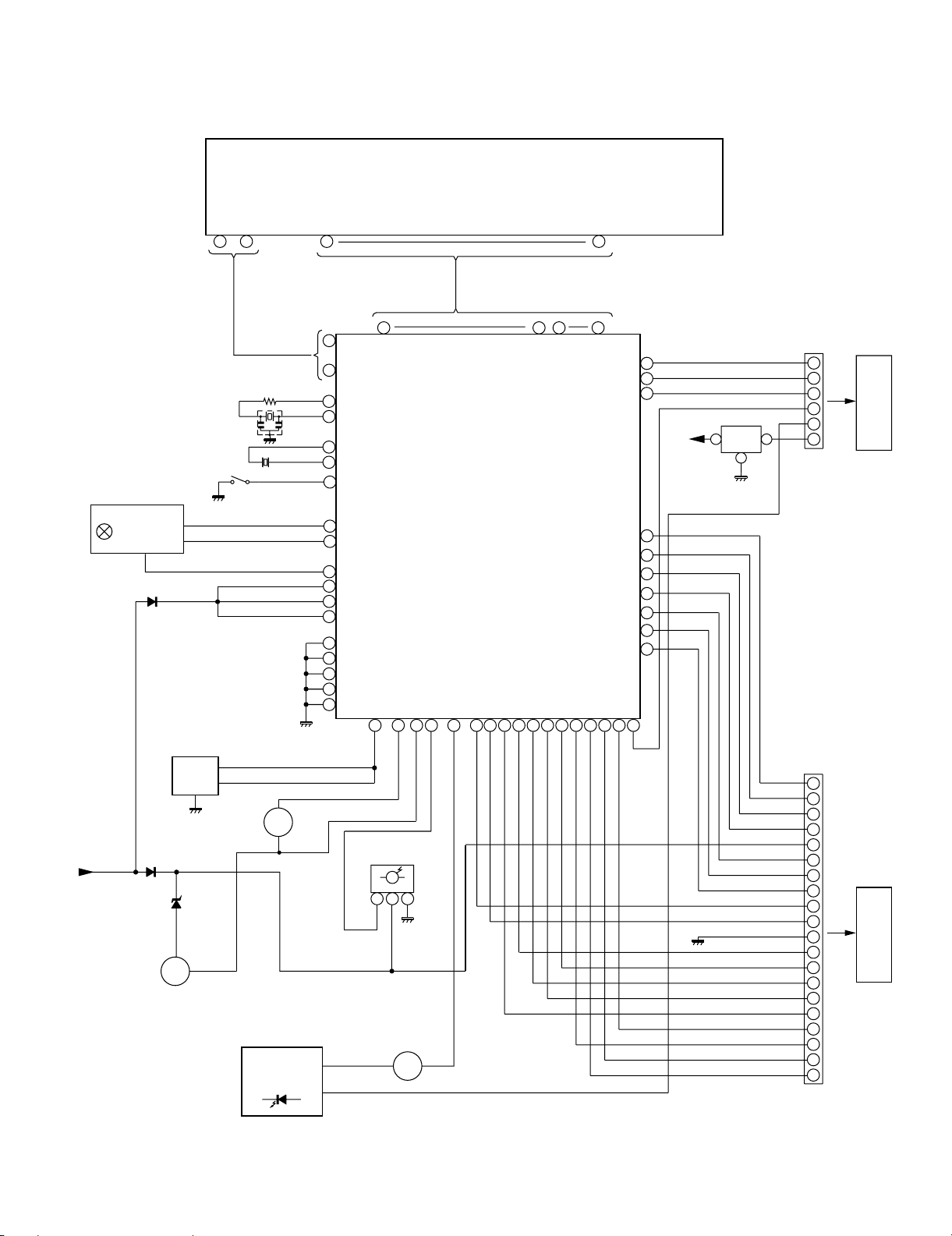

CHAPTER 4. DIAGRAMS

[1] BLOCK DIAGRAM

AM LOOP

ANTENNA

FM ANTENNA

HEADPHONES

LF651

LINE

FILTER

1

1

2

2

3

3

+

L-CH

-

SO601

SPEAKER

TERMINAL

-

R-CH

+

JK101

F101

T200mA L 250V

AC POWER

SUPPLY CORD

Except for U.K.: AC 230 V, 50 Hz

U.K.: AC 230-240 V, 50 Hz

CNP301

POWER

TRANSFORMER

FM IF

CF301

T601

AM

Tracking

BAND PASS

FILTER

BF301

CNP602

1

2

3

4

5

Q303

AM ANT.

CNS602

1

2

3

4

5

L302

(L)

(R)

1

2

3

4

5

6

CNW602

CF303

RP601

RP602

D305

+B

FM IF

IC101

LA4631++

POWER AMP.

D102

D101

D103

D104

D659

D658

AM OSC

D306

L304

FM RF

33 32 31

VCC2

GND2

FMRF-OUT

FM-OSC

REG

Q104

+B

FM-MIX

GND1

-B

AM-MIX

CF304

Q664

AM-OSC

VCC1

FMRF-IN

AMRF-IN

123 1817164 5 6 7 8 9 10 11 12 13 14 15

L305

AM IF

D656

D657

AM BAND

COVERAGE fL

L306

3

2

1

D307

L307

FM OSC

B02

B01

AMIFIN

FMIFIN

AM IF

123457612 10 9 81113

Q665

Q661

Q302

LP-IN

LP-OUT

P-CCMP

P-DET

POW_STB

Q613

4

5

6

PD

FM-DET

CF302

AGC

L-OUT

FM IF

Q662

AMLOWOUT

R-OUT

Q612

Q611

TP-VT

222324252627282930

DET-OUT

VSS

Q660

VTCC

X301

75KHz

19202136 35 34

VDD

XOUT

MPX-IN

CL

DI

CE

31

31

P_CON

Q658

CONSTANT

VOLTAGE

Q301

XIN

IC301

D0

LV23002M

FM FRONT END

IC680

AN78L05

CONSTANT

VOLTAGE

REGULATOR

+5V

2

2

IC681

AN78L05

CONSTANT

VOLTAGE

REGULATOR

PLL(TUNER)

FM IF DET./FMMPX./AM IF

CNP704

VP

-B

CD PICKUP UNIT

FOTR-

TR+

FO+

ACTUATOR

VR

MD

LD

F

C

B

A

D

E

CD MECHANISM UNIT (222)

MECHANISM PWB

SPINDLE

MOTOR

SLED

MOTOR

PICKUP IN

TO DISPLAY PWB

654321

VP

+5V

CD+B

P_CON

P_MUTE

POW_STB

TAPE MECHANISM ASS'Y

(221)

ERASE HEAD

RECORD/PLAYBACK

HEAD

SOL901

SOLENOID

-

M

+

M901

TAPE

MOTOR

+

M

-

+

M

-

L-CH

R-CH

SW902

PLAY

SW901

FOOL

470

PHOTO

INTERRUPTER

PLSN

TR+

FO+

GND

VCC

FOTR-

MD

VR

LD

F

C

B

A

D

E

VC

Q

PLA

FO

Figure 4-1 BLOCK DIAGRAM (1/3)

4 – 1

UNIT (222)

B

+

-

+

-

B

ISM ASS'Y

D

CK

02

Y

01

L

470

PLSN

O

RUPTER

FO-

TRTR+

FO+

MD

VR

LD

GND

F

C

B

A

D

E

VCC

VC

PLAY SW

FOOL SW

XL-MP40H

+B

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

+R

Q237

1

2

3

4

5

6

CNS802

Q663

Q238

+5V

FC801

MOT

CNP801

CNW802

Q208

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

Q211

Q212

Q659Q657

Q216

Q215

TRTR+

FO+

MD

VR

LD

GND

F

C

B

A

D

E

VCC

VC

SP+

SP-

SL+

SLPU-IN

GND

+B

Q207Q210

Q209

SOL

Q218

Q217

+B

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

CD

VG3

VIN3

VO3+

RESET

REG-IN

VIN2

REG-OUT

VO2+

VG2

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

+B

7.7V15V

Q806

Q655

Q213

Q214

Q206

+9V

TP_PLY

SOL

_SW

PLSIN

TAMOTOR

Q230

TP_BIAS

R_CH

2

Q225

Q228

VG4

GND

GND

GND

VO3-

VO2-

3

PB1P

REC1O

VIN4

VO4-

VO4+

VREF

VO1-

VG1

VO1+

GND

GND

GND

GND

PB2P

REC2O

Q226

Q227

MUTE

AUDIO PROCESSOR/

RECORD/PLAYBACK AMP.

L_CH

6

5

SEL-OUT1

SEL-OUT2

C1

C2

CD/MD L

CD/MD R

CD/MP3 L/R

BEAT CANCEL

VCC

VCC

IC401

7

FO-

16

Q805

Q801

IC802

LA6548ND

FOCUS/TRACKING/

SPIN/SLED DRIVER

+B

Q802

BD3881FV

8

9

GND

VOL2

VOL1

B1

B2

TUNER L

TUNER R

+B

+B

12 13 14

+VCC

A1

A2

AUX L

AUX R

AUX R

AUX L

SD

L_CH

Q410

Q411

OUT1

16181920212223242528

+B

AVDD

SLCO

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61

1

EFMIN

2

RF

RCHO

LPF

3

4

PHLPF

5

AIN

6

CIN

7

BIN

8

DIN

FEC

9

RFMON

10

VREF

11

JITTC

12

EIN

13

FIN

14

TEC

15

TE

16

TEIN

17

LDD

18

LDS

19

VSS

20

TDO

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38

FDO

AVDD

-VCC

OUT2

R_CH

SO401

AUX IN

P_MUTE

X801

16.93MHz

+B

XIN

XVSS

LCHO

XVDD

XOUT

LRVSS

LRVDD

MP3 DECODER

DIGITAL SIGNAL

SLDO

SPDO

DOUT

AMUTEB

IC801

LC78690

PROCESSOR

VVSS1

PDOUT1

PDOUT0

PCKIST

VVDD1

DMUTEB

PUIN

CD/MP3 L/R

-B

TUNER L/R

DVSS

DVDD

DEFECT

FSEQ

+B

+B

VVSS2

DVDD1.8

STDATA

C2F

DVDD

VCOC2

VPREF2

TEST1

VPDOUT2

STCK

STREQ

TEST0

CONT0

CONT1

CONT2

INTB1

INTB0

RESB

DO

DI

CL

CE

DVSS

DVDD

DVSS

39 40

VVDD3

DVDD1.8

VVDD2

VVSS3

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

LRSY

DATACK

DATA

+B

0-CD-CE

0-CD-CLK

O-CD-CMD

1-CD-DATA

0-CD-/RESET

1

1-TU-SDI

2

0-TU-SCK

3

0-TU-SDO

4

0-TU-CE

5

0-CD-/RESET

6

1-CD-DATA

7

O-CD-CMD

8

0-CD-CLK

9

0-CD-CE

10

11

12

13

14

15

16

17

18

19

20

CNP701

D-GND

EVR-SDO

EVR-CLK

PLYREC

TABCAN

PLSIN

+5V

TAMOTOR

TASOL

BIAS

SW

CNS701

TO DISPLAY PWB

Figure 4-2 BLOCK DIAGRAM (2/3)

4 – 2

XL-MP40H

SW702-SW704

KEY

SW707-SW709

SW705,SW706

SW701

C0

~

8MHz

X702

32.768kHz

DISC EJECT

X701

SW710

LCD701

FL DISPLAY

C3

S0

514 36

79 465356

COM3

86

~

83

16

15

12

13

96

~

COM0

CF2

CF1

XT1

XT2

SW-CLID

S0

S23

IC701

IXA044SJ

KEY1

18

19

KEY2

I-POWER_KEY

28

VDD1

17

VDD2

54

VDD3

90

14

VSS1

43

55

VSS2

V3

80

VSS3

89

VOL_ENC (JOG)

RESET

1124

SYSTEM

MICROCOMPUTER

LED_CON

HOLD

IRQ

2926 31 99 12345678910

EVR_CLK

EVR_SDO

100

CD_RESET

CD_CE

0-CD-DATA

1-CD_DATA

S31

S31

S24

P_STB

P_CON

SW-TAPE

0-BIAS_TP

0-SOL_TP2

0-MOTOR_TP

1-TP_RUN_PULSE

(B-CAN)

0-REC/PB

O_TU_CLK

0-CD_CLK

I_TU_DATA

O_TU_DATA

CD+B

O_TU_CE

34

33

32

21

39

36

37

42

40

38

0-P-MUTE

+5V

1

IC705

AN78L05

CONSTANT

VOLTAGE

REGULATOR

CNS704

CD+B

6

P_STB

5

P_CON

4

P_MUTE

3

+5V

2

VP

3

1

2

+5V

VOLUME

Q703

Q704

SW700

U_CON5V

Q701

LED

D701~704

RX701

GP1U281X

REMOTE

SENSOR

123

Q705

Figure 4-3 BLOCK DIAGRAM (3/3)

4 – 3

0-BIAS_TP

0-SOL_TP

0-MOTOR_TP

U_CON5V

PLUSE_IN

(B-CNA)

0-REC/PB

EVR_CLK

EVR_SDO

D_GND

O_CD_CE

O_CD_CLK

O_CD_CMD

I_CD_DATA

CD/RESET

O_TU_CE

O_TU_DO

O_TU_SCK

I_TU_SDI

SW

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CNS701

CNP701 CNP704

TO MAIN SECTION TO MAIN SECTION

AudioXL-MP40HService ManualXLMP40HMarketE

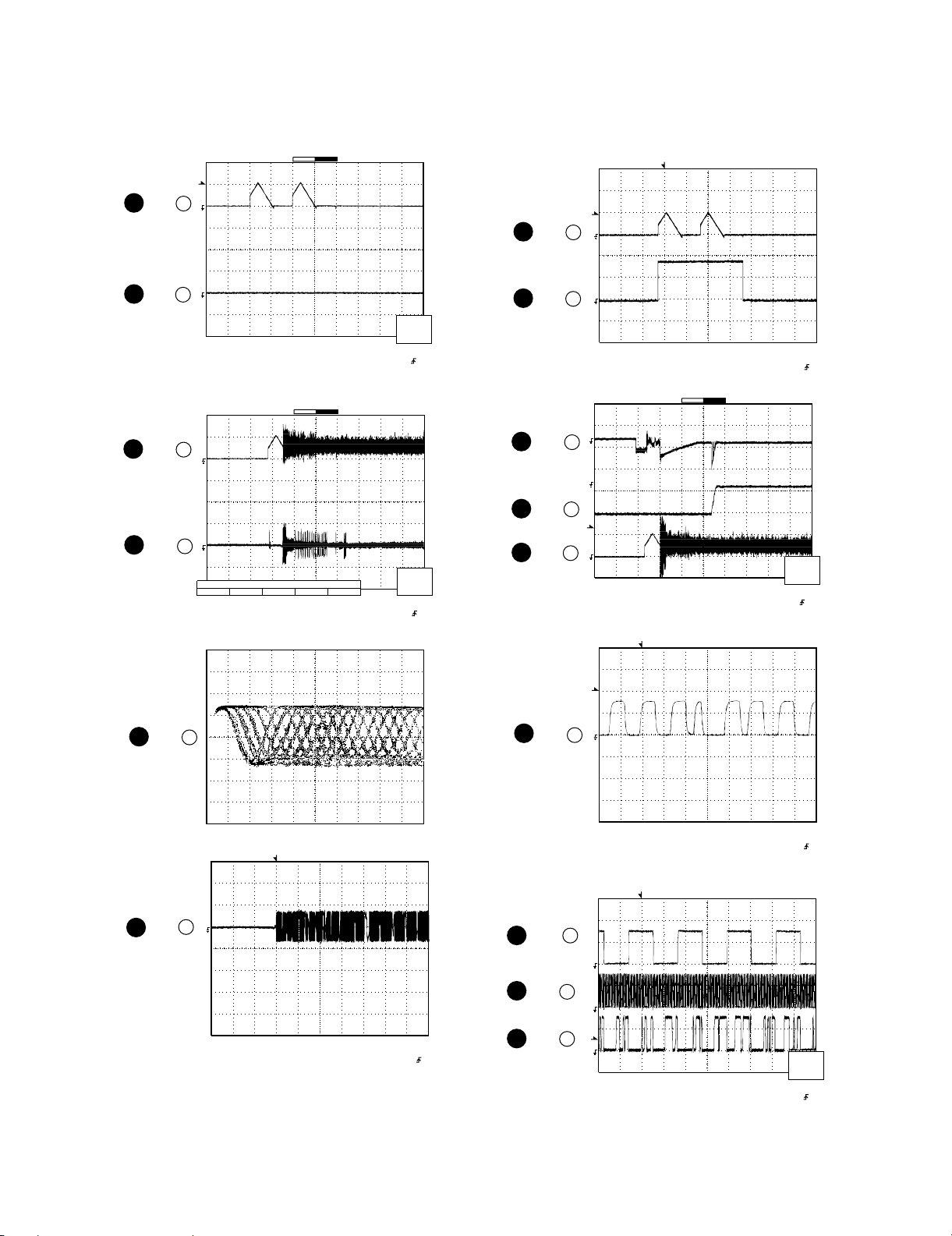

CHAPTER 5. CIRCUIT DESCRIPTION

[1] WAVEFORMS OF CD CIRCUIT

XL-MP40H

1

2

1

3

IC801 22

IC801 23

IC801 22

IC801 16

Stopped

CH1=500 mV

DC 10:1

T

FDO

1

TDO

3

Smoothing : ON CH1 : 0.000 V

BW : FULL

1

3

Smoothing : ON CH1 : 0.000 V

BW : FULL

CH2 : 0.0 V

CH3 : 0.000 V

CH4 : 0.00 V

Stopped

CH1=500 mV

DC 10:1

FDO

TE

-3 div -1 div 0 div +1 div +3div

CH2 : 0.0 V

CH3 : 0.00 V

CH4 : 0.00 V

CH2=10 V

DC 10:1

CH Position To

CH3=500 mV

DC 10:1

=Record Length=

Main : 100 K

Zoom : 2 K

CH3=1 V

DC 10:1

=Record Length=

Main : 100 K

Zoom : 2 K

500 ms/div

(500 ms/div)

NORM:20 kS/s

CH1

v/DIV

500 mV

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH1

Delay : 0.0ns

Hold off : 0.2 µs

500 ms/div

(500 ms/div)

NORM:20 kS/s

CH2

Position

0.20 div

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH1

Delay : 0.0ns

Hold off : 0.2 µs

1

5

6

7

1

IC801 22

IC801 25

IC801 28

IC801 27

IC801 22

Stopped

CH1=200 mV

DC 10:1

T

FDO

2

SPDO

1

Smoothing : ON CH1 : 0.000 V

BW : FULL

Stopped

CH1=500 mV

DC 10:1

PDOUT0

3

4

PDOUT1

T

FDO

1

Smoothing : ON CH1 : 0.000 V

BW : FULL

Stopped

CH1=2 V

DC 10:1

T

T

CH2=500 mV

DC 10:1

CH2 : 0.000 V

CH3 : 0.00 V

CH4 : 0.00 V

CH2 : 0.0 V

CH3 : 0.00 V

CH4 : 0.00 V

T

=Record Length=

Main : 100 K

Zoom : 2 K

CH3=1 V

DC 10:1

=Record Length=

Main : 100 K

Zoom : 2 K

1999/04/07 09:51:15

NORM:20 kS/s

=Trigger==Filter= =Offset=

Mode : NORMAL

Type : EDGE CH2

Delay : 2.924 ms

Hold off : 0.2 µs

1999/04/05 17:33:17

CH4=1 V

500 ms/div

(500 ms/div)

DC 10:1

NORM:20 kS/s

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH2

Delay : 0.0 ns

Hold off : 0.2 µs

1999/04/07 09:25:28

NORM:200 MS/s

500 ms/div

(500 ms/div)

CH1

v/DIV

500 mV

500 ns/div

(500 ns/div)

4

IC801 16

3

IC801 2

Stopped

CH1=10 V

DC 10:1

TE

2

=Filter= =Offset=

Smoothing : ON CH1 : 0.0V

BW : FULL

T

CH2=1 V

DC 10:1

CH2 : 0.00 V

CH3 : 0.00 V

CH4 : 0.00 V

=Record Length=

Main : 100 K

Zoom : 2 K

Vp-p=1.0 V~1.3 V

0.5 mV/div,0.5 µsec/div

100 ms/div

(100 ms/div)

NORM:100 kS/s

=Trigger=

Mode : NORMAL

Type : EDGE CH1

Delay : 2.924 ms

Hold off : 0.2 µs

8

9

10

11

IC801 69

IC801 60

IC801 59

IC801 58

1

DOUT

=Filter= =Offset=

Smoothing : ON CH1 : 0.00 V

BW : FULL

1

2

T

3

Smoothing : ON CH1 : 0.00 V

BW : FULL

Stopped

LRSY

DATACK

DATA

CH1=2 V

DC 10:1

CH2 : 0.00 V

CH3 : 0.00 V

CH4 : 0.00 V

T

CH2=2 V

DC 10:1

CH2 : 0.00 V

CH3 : 0.00 V

CH4 : 0.00 V

=Record Length=

Main : 1 K

Zoom : 100

CH3=2 V

DC 10:1

=Record Length=

Main : 5 K

Zoom : 100

=Trigger=

Mode : NORMAL

Type : EDGE CH1

Delay : 2.887 ms

Hold off : 0.2 µs

1999/04/05 20:50:17

5 µs/div

(5 µs/div)

NORM:100 kS/s

CH3

v/DIV

=Trigger==Filter= =Offset=

Mode : AUTO

Type : EDGE CH3

Delay : 0.0 ns

Hold off : 0.2 µs

2V

5 – 1

XL-MP40H

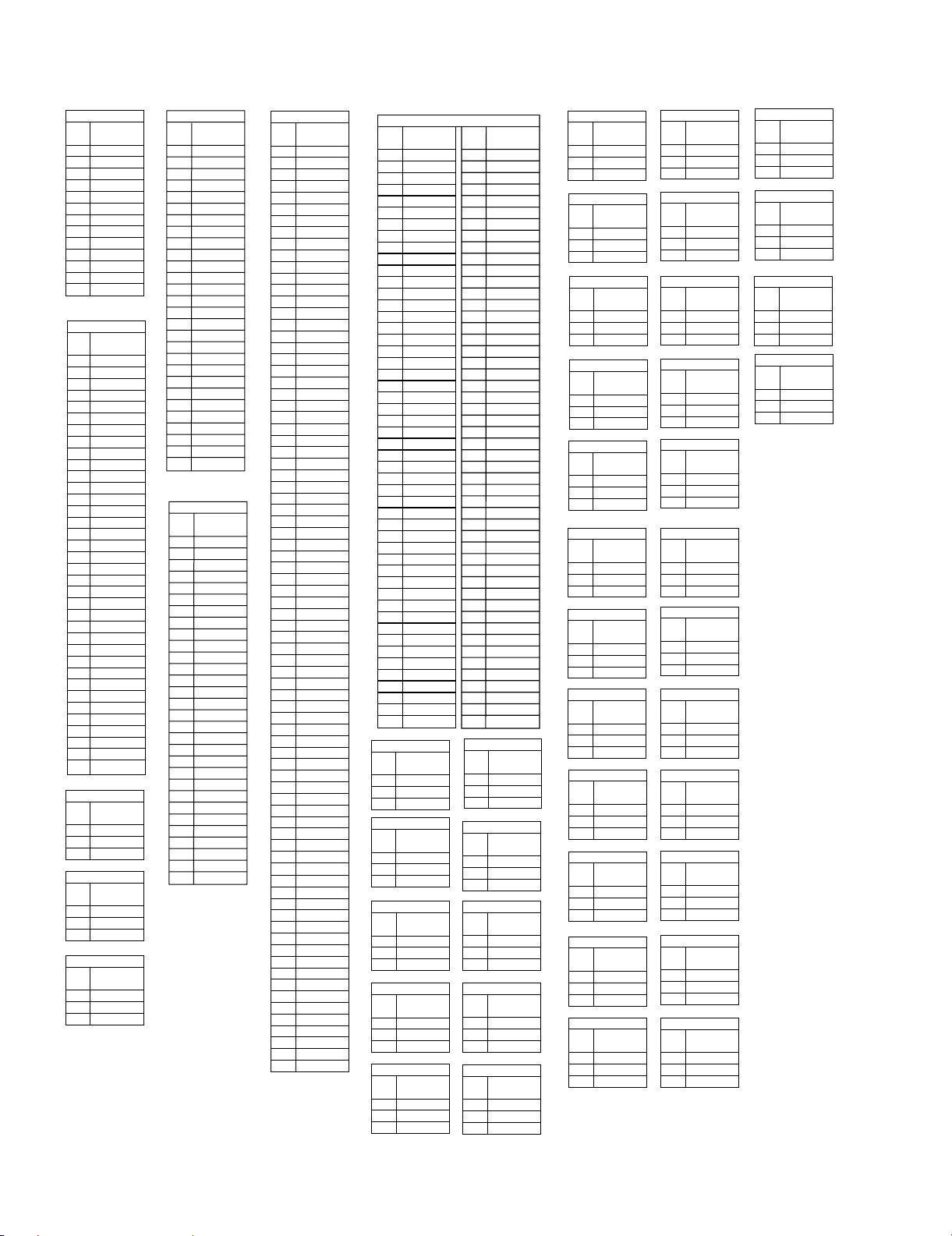

[2] VOLTAGE

PIN

NO.

10

11

12

13

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

1

2

3

1

2

3

IC101

VOLTAGE

4.13V

1.63V

0V

1.63V

1.55V

12V

18.2V

9.2V

0V

0V

0V

9.3V

0V

IC301

VOLTAGE

2.2V

2.2V

2.45V

0V

5V

5V

2.2V

2.2V

4V

3.86V

2.85V

2.28V

2.28V

0V

0V

0V

0V

3.4V

1.26V

1.7V

3.43V

2.2V

2.3V

0V

2.6V

2.14V

2.14V

1.3V

2.7V

1V

4.9V

4.9V

4.9V

4.9V

0V

1V

IC680

VOLTAGE

5.1V

0V

10.6VV

IC681

VOLTAGE

5.1V

0V

20V

IC705

VOLTAGE

5.7V

0.6V

10V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

PIN

NO.

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

IC401

VOLTAGE

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

4.5V

0.7V

-4.5V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

IC802

VOLTAGE

7.75V

2.77V

1.45V

1.47V

3.9V

3.3V

0V

0V

0V

3.5V

3.7V

1.46V

1.45V

2.9V

1V

2.9V

3.4V

1.45V

1.45V

3.7V

3.6V

0V

0V

0V

3.6V

3.6V

1.46V

1.46V

1.46V

7.8V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

1

2

3

4

5

6

7

8

9

IC801

VOLTAGE

1.38V

1.47V

1.45V

1.2V

1.6V

1.7V

1.67V

1.63V

1.42V

1.4V

1.46V

1.74V

1.75V

1.74V

1.43V

1.43V

1.43V

2V

0.18V

0V

2.9V

1.47V

1.5V

1.5V

1.6V

0V

0V

1V

0.93V

2.74V

0V

2.8V

0V

2.8V

0V

2.8V

0V

1.8V

2.8V

0V

2.8V

0V

0.45V

3V

3V

0V

3.23V

2.8V

2.8V

2.8V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

2.57V

1.44V

2.1V

2.1V

0V

1.8V

0V

2.8V

0V

0V

0V

1V

1.14V

2.7V

1.64V

3.3V

0V

1.64V

2.9V

1.4V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

VOLTAGE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Q104

VOLTAGE

0V

3.3V

0.54V

Q206

VOLTAGE

5V

-9V

5V

Q207

VOLTAGE

-3V

0V

-9V

Q208

VOLTAGE

-3V

0V

-9V

Q209

VOLTAGE

-3V

0V

9V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

5V

1.7V

2.4V

0V

0V

0V

5V

0V

5V

0.5V

0V

0V

0V

5V

0V

5V

0V

5V

0V

0V

4.5V

0V

5V

0V

0V

5V

0V

0V

0V

0V

0V

0V

0V

0V

0V

2.4V

2.4V

0V

2.4V

2.4V

IC701

PIN

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

VOLTAGE

2.4V

2.4V

2.4V

4.8V

0V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

2.4V

0V

1.7V

3.3V

2.4V

2.4V

2.4V

2.4V

0V

0V

0V

5V

0V

0V

0V

0V

0V

5V

0V

0V

0V

0V

Q214

VOLTAGE

0V

5V

0V

Q215

VOLTAGE

9.3V

9.2V

8.5V

Q216

VOLTAGE

0V

0V

4V

Q217

VOLTAGE

9.3V

0V

9.3V

Q218

VOLTAGE

0V

9.3V

0V

PIN

NO.

C

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

B

E

C

B

E

C

B

E

C

B

E

C

B

E

B

E

B

E

B

E

C

B

E

C

B

E

C

B

E

C

B

Q237

VOLTAGE

0V

4.8V

0V

Q238

VOLTAGE

4.9V

4.9V

1.2V

Q303

VOLTAGE

0V

3.6V

0.8V

Q410

VOLTAGE

0V

0V

0V

Q411

VOLTAGE

0V

0V

0V

Q611

VOLTAGE

-5V

-12.7V

-5.6V

Q612

VOLTAGE

20V

20V

0.7V

Q613

VOLTAGE

20V

20V

5.1V

Q655

VOLTAGE

3.5V

18V

9.1V

Q657

VOLTAGE

0V

0V

0.7V

Q658

VOLTAGE

9.3V

17.2V

9.9V

Q659

VOLTAGE

18V

18V

0.6V

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

PIN

NO.

C

E

B

E

B

E

B

E

B

E

B

E

B

E

B

E

B

E

B

E

B

E

B

E

B

Q660

VOLTAGE

11V

11V

0.7V

Q661

VOLTAGE

18V

18V

0.7V

Q662

VOLTAGE

0V

0V

4V

Q663

VOLTAGE

5V

5V

0.6V

Q664

VOLTAGE

1.3V

1.3V

0.7V

Q665

VOLTAGE

-12V

-12V

-8V

Q701

VOLTAGE

0V

4.8V

0V

Q703

VOLTAGE

0V

0V

0.7V

Q704

VOLTAGE

0V

5V

0V

Q705

VOLTAGE

0V

0V

0.8V

Q801

VOLTAGE

2.76V

1.8V

2V

Q802

VOLTAGE

2.9V

6.3V

3.6V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

C

B

E

C

B

E

C

B

E

C

B

Q805

VOLTAGE

3.27V

5V

3.93V

Q806

VOLTAGE

7.9V

18.1V

8.55V

Q301

VOLTAGE

10.5V

18V

11V

Q302

VOLTAGE

1V

2.7V

1.7V

5 – 2

AudioXL-MP40HService ManualXLMP40HMarketE

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] NOTES ON SCHEMATIC DIAGRAM

XL-MP40H

•Resistor:

To differentiate the units of resistors, such symbol as K and M are

used: the symbol K means 1000 ohm and the symbol M means

1000 kohm and the resistor without any symbol is ohm-type resistor. Besides, the one with “Fusible” is a fuse type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this symbol P

means micro-micro-farad and the unit of the capacitor without such

a symbol is microfarad. As to electrolytic capacitor, the expression

“capacitance/withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this model

are subject to change for improvement without prior notice.

REF. NO DESCRIPTION POSITION

SW700 VOLUME ON—OFF

SW701 ON/STAND-BY ON—OFF

SW702 STOP/TUNING DOWN ON—OFF

SW703 REW/PRESET DOWN ON—OFF

SW704 PLAY/CD PAUSE/TUNING UP ON—OFF

SW705 MEMORY/SET ON—OFF

• The indicated voltage in each section is th e one measured by Digital Multimeter between such a section and the chassis with no signal given.

1. In the tuner section,

( ) indicates AM

< > indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these parts

with specified ones for maintaining the safety and performance of

the set.

REF. NO DESCRIPTION POSITION

SW706 FUNCTION ON—OFF

SW707 REC/PAUSE ON—OFF

SW708 BASS/TREBLE ON—OFF

SW709 FF/PRESET UP ON—OFF

SW710 DISC EJECT ON—OFF

SW901 FOOL PROOF ON—OFF

SW902 PLAY ON—OFF

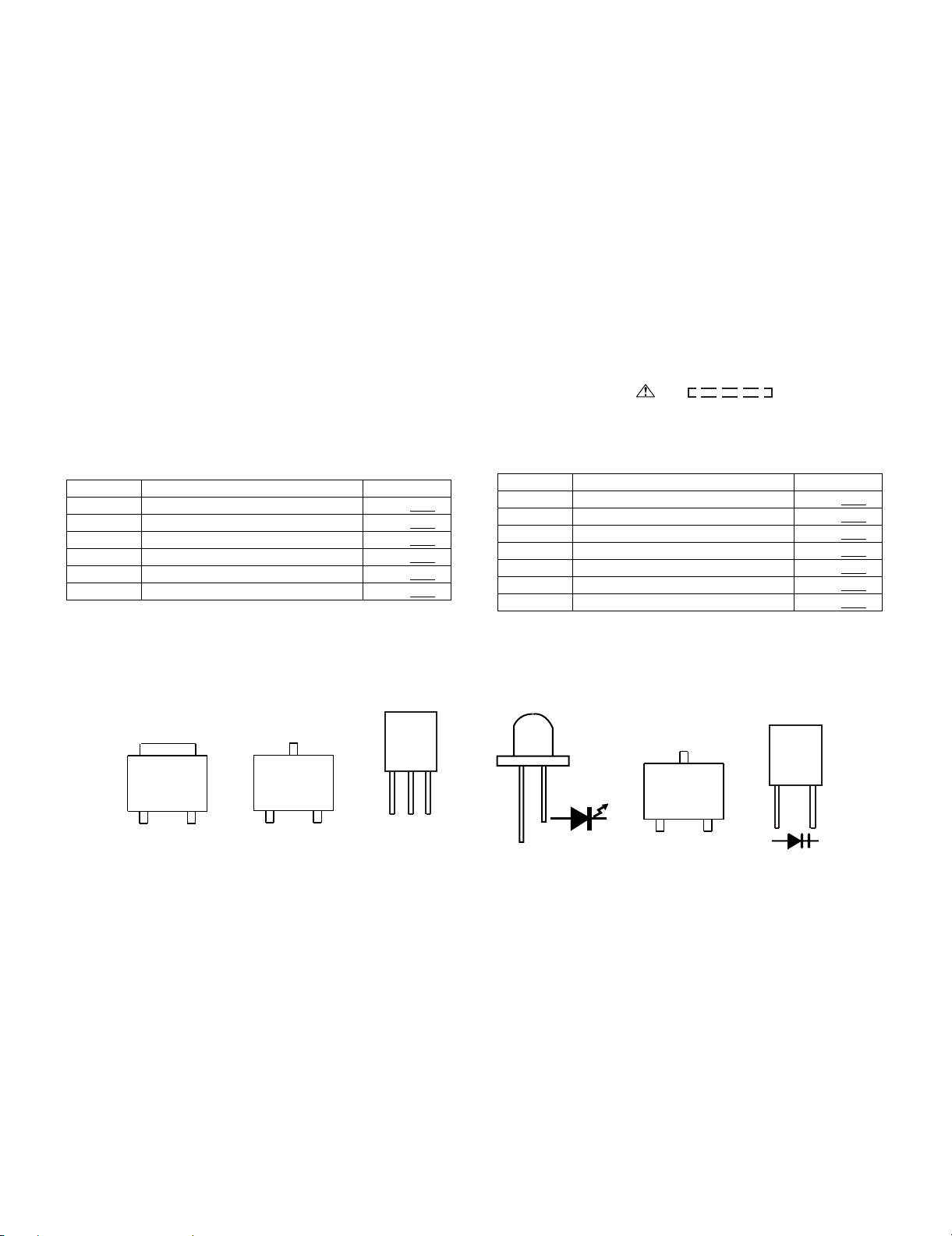

[2] TYPES OF TRANSISTOR AND LED

C

B

2SK2541

E

C

B

2SC3052 F+

2SC5477++

2SA1235 F+

E

FRONT

EC B

(S) (G) (D)

(1) (2) (3)

2HA1015 GR

2HC1815 GR

KTC3200 GR

2SB562 C

KRC101 M

2SB561 C

KRC106 M

KRC107 M

KRA107 M

KTC2026 Y

VIEW

FRONT

VIEW

FRONT

VIEW

SVC347SMPG3372X

SVC201

6 – 1

XL-MP40H

POWER AMP.

0

2

1/50

1/50

0.1

22/50

100K

12P

(CH)

0.018

1µH

1SS133

0

0.1

3.3K

4.7/50

0.001

22/50

0.033

10K

10K

33

2.2K

680

47µH

47/50

1SS133

1/50

0.01

0.01

0.1

22/50

100K

4.7K

0.01

1K

100K

27P

(UJ)

4.7K

0.33/50

100P

(CH)

5P

33P

(CH)

(UJ)

0.015

1K

33P

(CH)

330

5P

0.001

SVC201

2.2K

0.047

100

10µH

10

560P

0.0047

0.001

0.022

SVC201

100K

220

0.01

100K

0

0.001

0.01

10P

(UJ)

10

0

330

22/50

M

1/50

0.0047

10

0.1

10

0.1

0.0047

0.0047

LA4631++

2

1

3

2

1

4

5

6

7

8

9

10

11

1213

123

1362 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

20212223242526272829303132333435

SVC347S

NC

GND2

AMRF-IN

REG

FM-MIX

GND1

AM-MIX

VCC1

AMIFIN

FMIFIN

VSS

CE

P-DET

P-CCMP

FMDET

L-OUT

R-OUT

DI

CL

XOUT

VDD

MPX-IN

DET-OUT

AMLOWOUT

AGC

PD

LP-IN

LP-OUT

B01

B02

AM-OSC

FM-OSC

VCC2

FMRF-OUT

FMRF-IN

OUT1

P_GND

OUT2

VCC

P.P

STBY

IN2

6

5

4

3

1

2

6

4

3

2

1

L-CH

AM

GND

FM

FROM FM/AM ANTENNA

2SC5477++

SPEAKER BOX Ass'y

FM RF

FM BAND COVERAGE fL

AM

Tracking

BAND PASS

FILTER

AM IF

AM IF

FM IF

FM IF

TP-VT

AM BAND

COVERAGE fL

FM IF

CHASSIS

GND

2SC5477++

D305

R303

C305

C308

R310

R315

C318

R311

R304

C310

L306

C311

C348

JR304

C326

C330

C

C333

C332

C329

R316

C335

Z

C325

R313

R314

C321

C320

C346

C345

C344

C312

R308

C316

R329

C343

C317 L307

D307

R328

Q302

JP302

L304

R307

C314

R305

C309

C307

R306

L302

C349

C306

BF301

D306

L301

D303

D302

C301

C302

CNP301

C347

L303

R336

R334

R332

C319

C313

C315

CF302

C327

JR303

C323

R309

R312

CF303

R331

Q303

R333

CF301

C322

C331

L30

C32

C32

CF304

L305

IC101

R107

L103

R103

C105

C109

C103

C131

C130

C107

R327

R302

C303

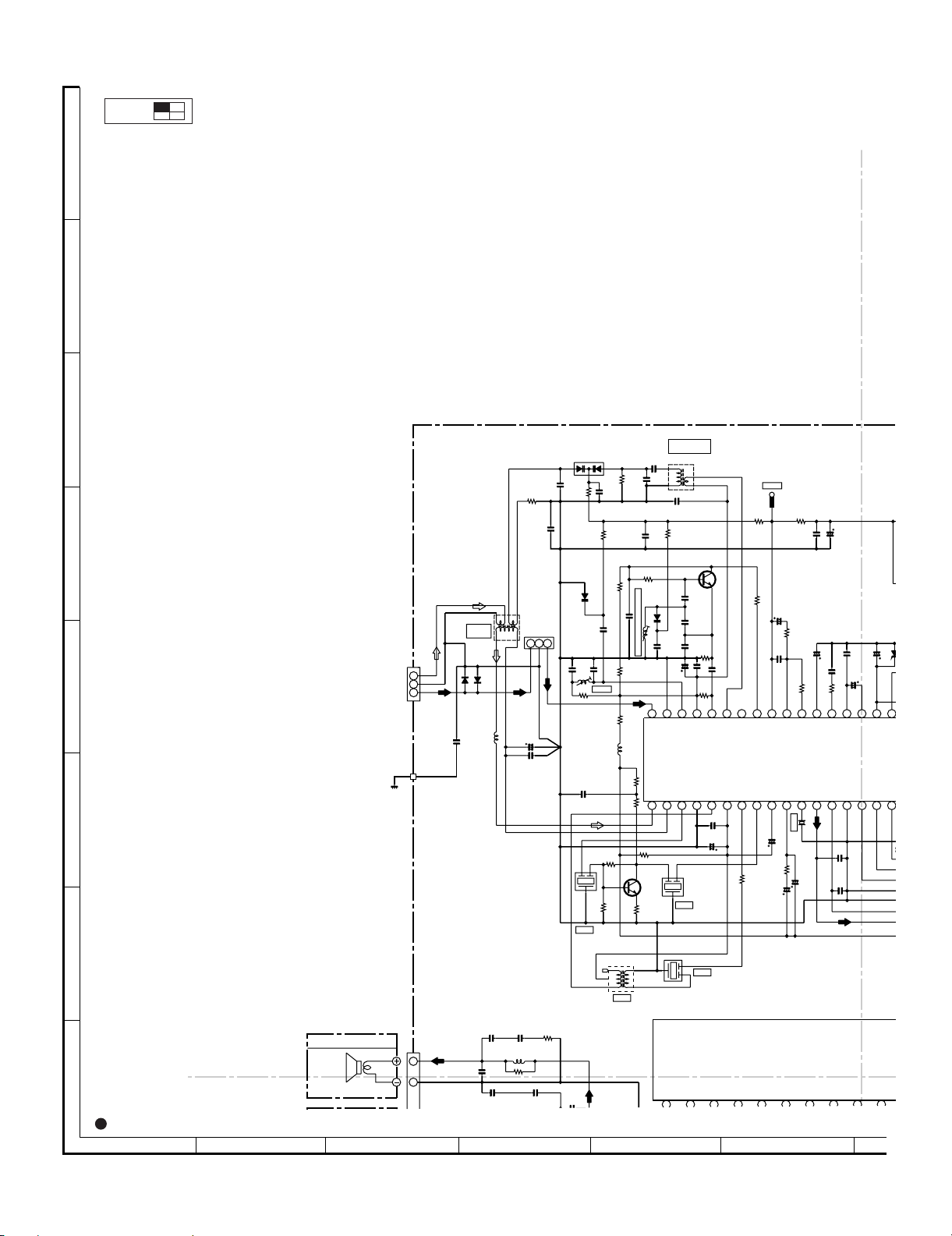

[3] WIRING SIDE OF PWB/SCHEMATIC DIAGRAM

MAIN

A

B

C

D

E

F

G

H

NOTES ON SCHEMATIC DIAGRAM can be found on page 6-1

1

23456

Figure 6-2 SCHEMATIC DIAGRAM (1/10)

6 – 2

Loading...

Loading...