Sony XL70U Service Manual

XL-70/70C

SERVICE MANUAL

No. S5037XL-70///

MICRO COMPONENT SYSTEM

MODEL

XL-70 Micro Component System consisting of XL-70 (main unit) and

CP-XL70U (speaker system).

MODEL

XL-70C Micro Component System consisting of XL-70C (main unit)

and CP-XL70U (speaker system).

• In the interests of user-safety the set should be restored to its original

condition and only parts identical to those specified should be used.

XL-70

XL-70C

CONTENTS

Page

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)...................................................................................................... 2

SPECIFICATIONS ............................................................................................................................................................ 2

NAMES OF PARTS .......................................................................................................................................................... 3

OPERATION MANUAL..................................................................................................................................................... 5

DISASSEMBLY................................................................................................................................................................. 8

REMOVING AND REINSTALLING THE MAIN PARTS.................................................................................................. 10

ADJUSTMENT................................................................................................................................................................ 12

TEST MODE ................................................................................................................................................................... 13

ERROR LIST .................................................................................................................................................................. 17

NOTES ON SCHEMATIC DIAGRAM ............................................................................................................................. 18

TYPES OF TRANSISTOR AND LED.............................................................................................................................. 18

WAVEFORMS OF CD CIRCUIT..................................................................................................................................... 19

BLOCK DIAGRAM .......................................................................................................................................................... 20

SCHEMATIC DIAGRAM ................................................................................................................................................. 24

WIRING SIDE OF P.W.BOARD...................................................................................................................................... 30

TROUBLESHOOTING .................................................................................................................................................... 34

FUNCTION TABLE OF IC .............................................................................................................................................. 40

LCD SEGMENT .............................................................................................................................................................. 48

PARTS GUIDE/EXPLODED VIEW

PACKING OF THE SET (FOR U.S.A. ONLY)

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

XL-70/70C

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

IMPORT ANT SER VICE NOTES (FOR U.S.A. ONLY)

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the

following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinched or that hardware is not lodged between the chassis

and other metal parts in the audio product.

2. Inspect all protective devices such as insulating materials,

cabinet, terminal board, adjustment and compartment covers

or shields, mechanical insulators etc.

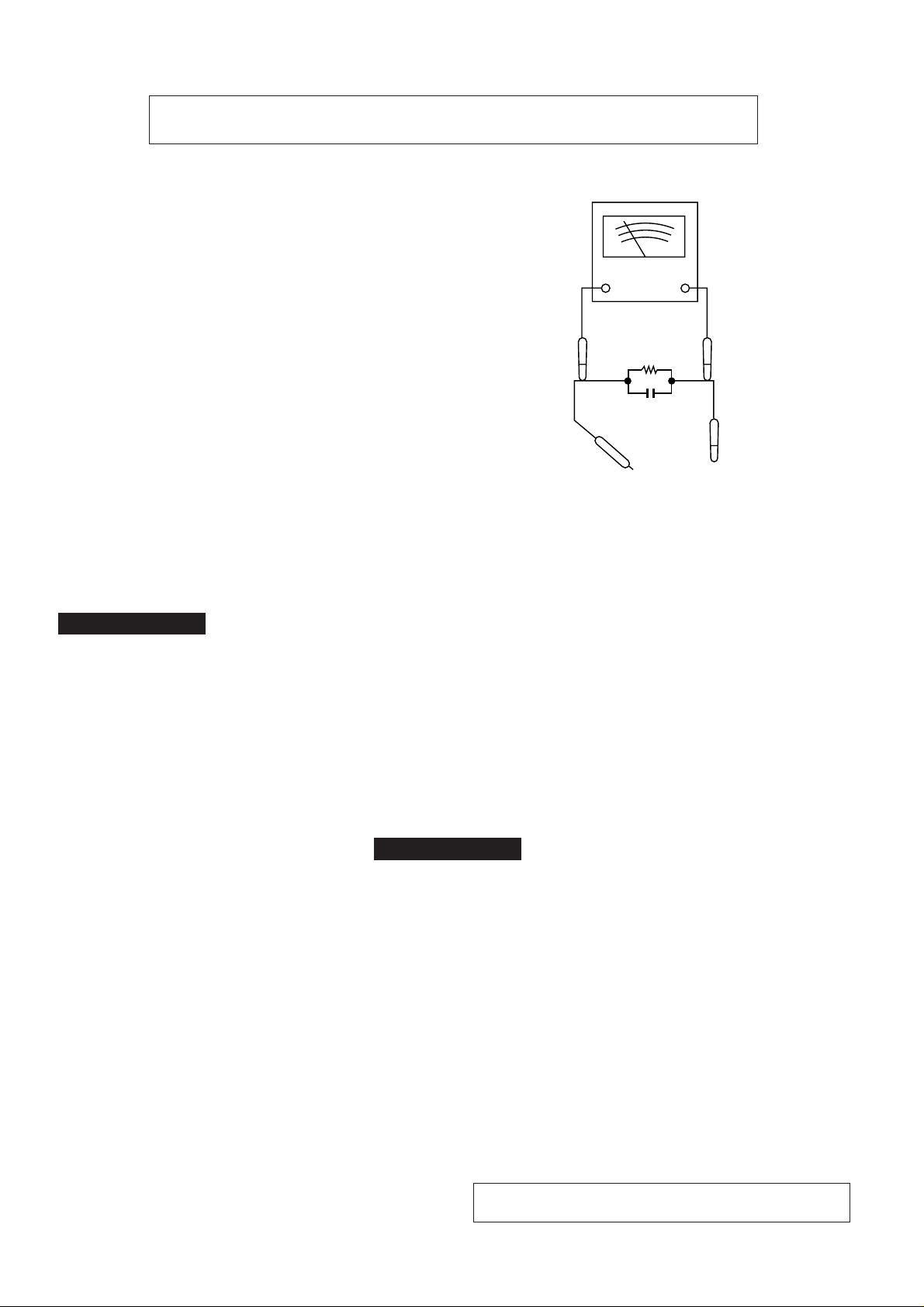

3. To be sure that no shock hazard exists, check for leakage

current in the following manner.

* Plug the AC line cord directly into a 120 volt AC outlet.

* Using two clip leads, connect a 1.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all exposed

metal cabinet parts and a known earth ground, such as

conduit or electrical ground connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or higher,

sensitivity to measure the AC voltage drop across the

resistor (See diagram).

* Connect the resistor connection to all exposed metal parts

having a return path to the chassis (antenna, metal cabinet,

screw heads, knobs and control shafts, escutcheon, etc.)

and measure the AC voltage drop across the resistor.

VTVM

AC SCALE

1.5k ohms

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

All check must be repeated with the AC line cord plug connection

reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp.

AC.) or more is excessive and indicates a potential shock

hazard which must be corrected before returning the audio

product to the owner.

XL-70/70C

● General

Power source: AC 120 V, 60 Hz

Power

consumption: 48 W

Dimensions: Width; 6-5/16" (160 mm)

Height; 9-1/2" (241 mm)

Depth; 11-3/4" (298 mm)

Weight: 7.9 lbs.(3.6 kg)

● Amplifier section

Output power: 16 watts minimum RMS per

channel into 4 ohms from

100 Hz to 20 kHz, 10% total

harmonic distortion

Output terminals: Speakers; 4 ohms

Headphones; 16-50 ohms

(recommended; 32 ohms)

CD digital output (optical)

Sub woofer (audio signal);

500 mV/47 k ohms

Input terminals: Video/Auxiliary (audio signal);

500 mV/47 k ohms

● Compact disc player section

Type: Compact disc player

Signal readout: Non-contact, 3-beam semi-

conductor laser pickup

D/A converter: 1-bit D/A converter

Filter: 8-times oversampling digital

filter

Frequency

response: 20 - 20,000 Hz

Wow and flutter: Unmeasurable

(less than 0.001% W. peak)

SPECIFICATIONS

● Tuner section

Frequency range: FM; 87.5-108 MHz

AM; 530-1,720 kHz

● Cassette deck section

Frequency

response: 50 - 14,000 Hz (Normal tape)

Signal/noise ratio: 50 dB

Wow and flutter: 0.25 % (WRMS)

CP-XL70U

Type: 2-way [4" (10 cm) woofer and

1" (2.5 cm) tweeter]

Rated input

power: 20 W

Maximum input

power: 40 W

Impedance: 4 ohms

Dimensions: Width; 6-5/16" (160 mm)

Height; 9-1/2" (240 mm)

Depth; 7-7/16" (189 mm)

Weight: 5.1 lbs.(2.3 kg)/each

Specifications for this model are subject to change without

prior notice.

– 2 –

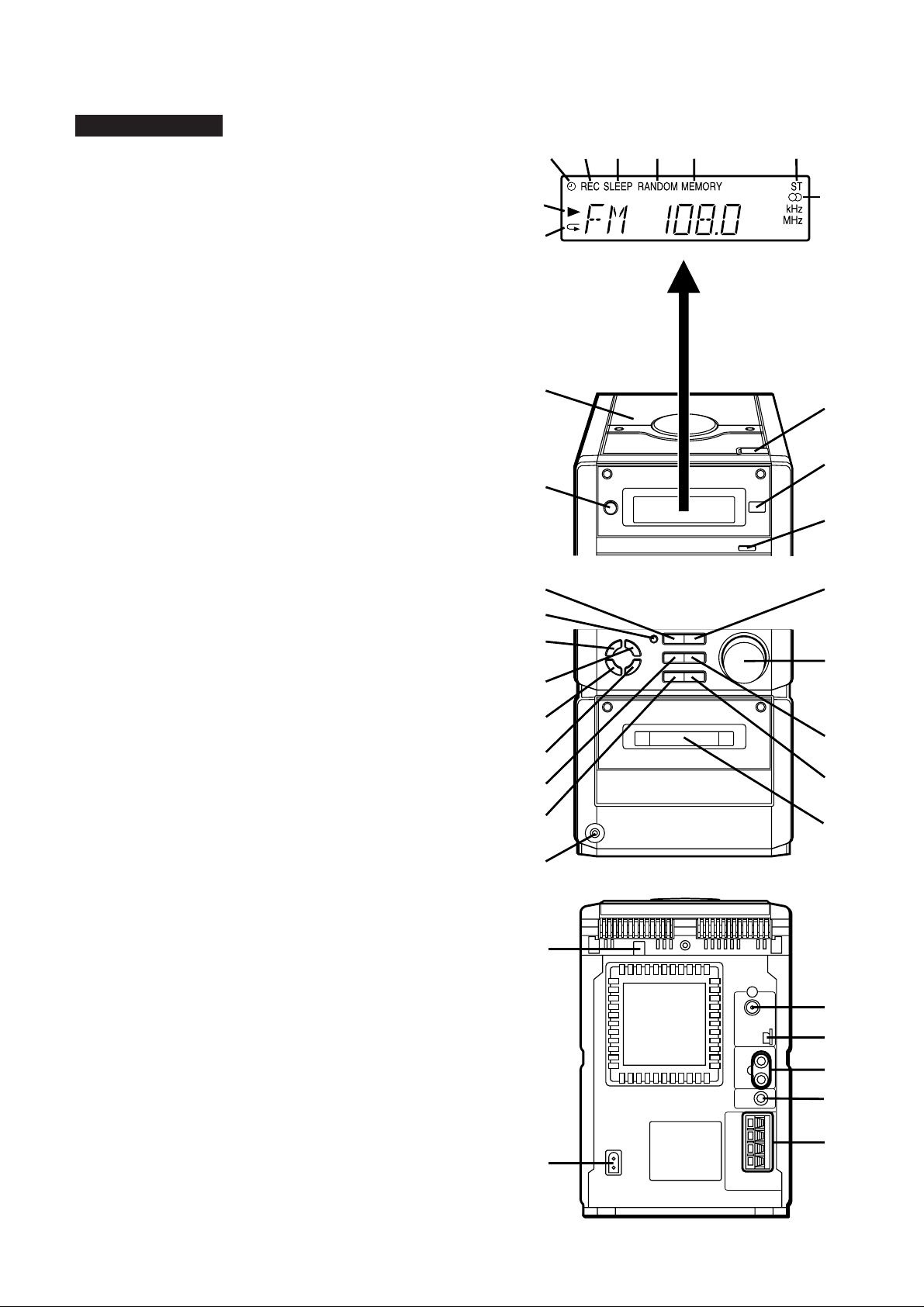

■ Front panel

10

11

12

13

14

15

16

17

18

24

25

26

27

28

19

20

21

22

23

1

2

3

4

5

6

9

8

7

1

2

3

4

5

7

6

1. Timer Indicator

2. Record Indicator

3. Sleep Indicator

4. (CD) Random Indicator

5. (CD/TUNER) Memory Indicator

6. FM Stereo Mode Indicator

7. FM Stereo Indicator

8. (CD) Play Indicator

9. (CD) Repeat Indicator

10. CD Compartment

11. Power Button

12. CD Open/Close Button

13. Remote Control Sensor

14. Volume Select Button

XL-70/70C

XL-70/70C

NAMES OF PARTS

15. (CD/TAPE) Stop Button

(TUNER) Memory Clear Button

16. Record Pause Button

17. Bass/Treble Selector Button

18. Memory/Set Button

19. Clock/Timer/Sleep Button

20. Band Selector Button

21. (CD) Review Button

(TAPE) Rewind Button

(TUNER) Tuning Down Button

22. Function Selector Button

23. Headphone Socket

24. (CD) Play/Pause Button

(TAPE) Play Button

25. Jog Dial

26. (CD) Cue Button

(TAPE) Fast Forward Button

(TUNER) Tuning Up Button

27. Volume/Jog Dial Selector Button

28. Cassette Compartment

■ Rear panel

1. CD Digital Output Jack

2. AC Power Input Jack

3. FM 75 Ohms Antenna Jack

4. AM Loop Antenna Input Jack

5. Video/Auxiliary (Audio Signal) Input Jacks

6. Sub Woofer Output Jack

7. Speaker Terminals

– 3 –

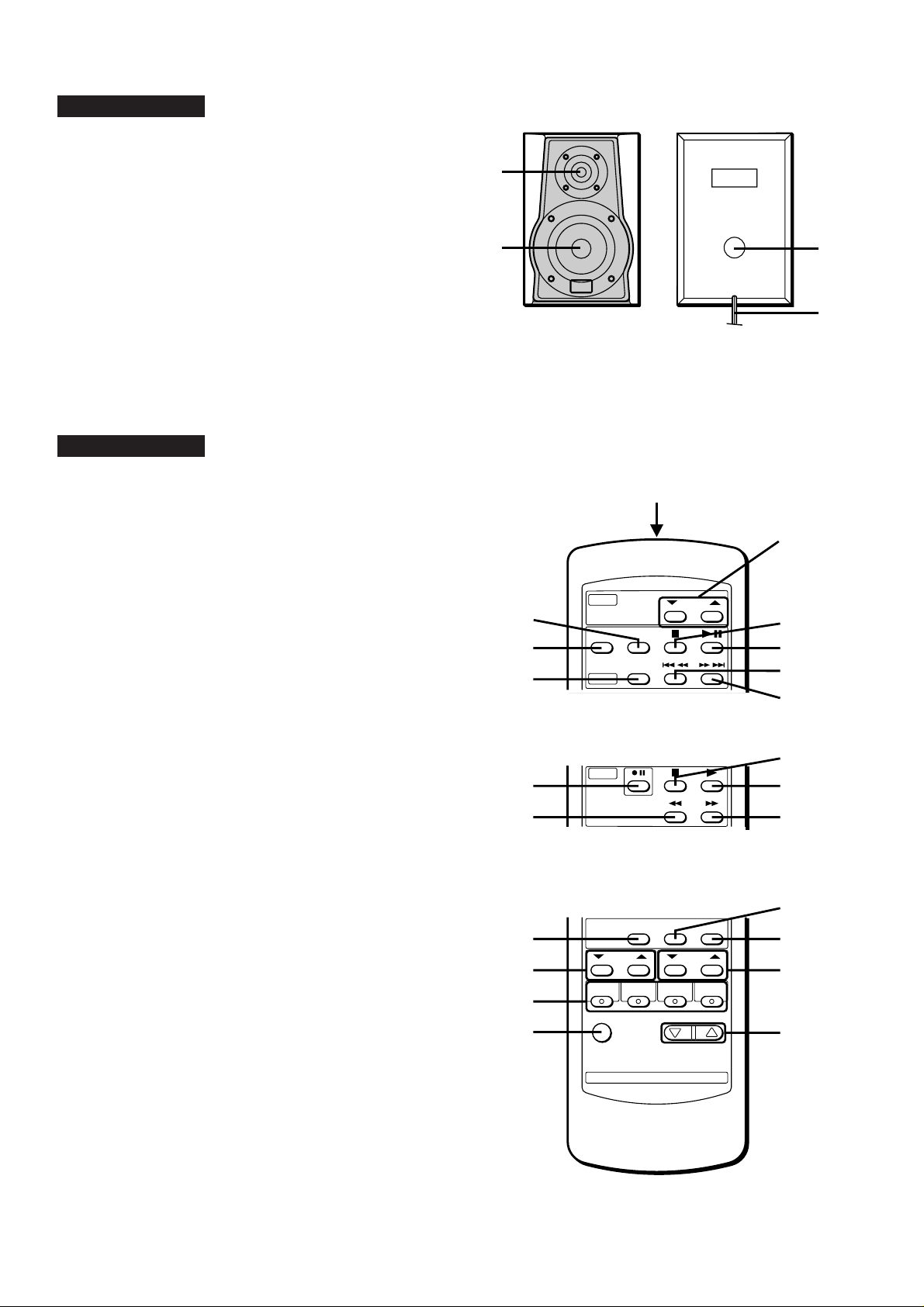

XL-70/70C

CP-XL70U

1. Tweeter

2. Woofer

3. Bass Reflex Duct

4. Speaker Wire

1

XL-70/70C

■ Remote control

1. Remote Control Transmitter LED

● Tuner control section

2. Preset Up/Down Buttons

● CD control section

3. Clear Button

4. Random/Repeat Button

5. Memory Button

6. Stop Button

7. Play/Pause Button

8. Track Down/Review Button

9. Track Up/Cue Button

2

3

4

5

10

3

4

1

2

6

7

8

9

12

13

● Tape control section

10. Record Pause Button

11. Rewind Button

12. Stop Button

13. Play Button

14. Fast Forward Button

● Common section

15. Sleep Button

16. Bass Up/Down Buttons

17. Function Selector Buttons

18. Power Button

19. Timer Button

20. Clock Button

21. Treble Up/Down Buttons

22. Volume Up/Down Buttons

– 4 –

11

15

16

17

18

14

19

20

21

22

OPERATION MANUAL

RESETTING THE MICROCOMPUTER

1

3

2,3

AC INPUT

3

Reset the microcomputer under the following

conditions:

● T o erase all of the stored memory contents (clock

and timer settings, and tuner and CD presets).

● If the display is not correct.

● If the operation is not correct.

1

Press the POWER button to enter the stand-by

mode.2Unplug the AC power cord from the AC INPUT

jack on this unit.

3

Whilst pressing down the MEMORY/SET but-

ton and the button, plug the AC power cord

into the AC INPUT jack on this unit.

Caution:

● The operation explained above will erase all data

stored in memory, such as clock and timer set-

tings, and tuner and CD presets.

15

15

Notes concerning use:

● Replace the batteries if the operating distance is

reduced or if the operation becomes erratic.

● Periodically clean the transmitter LED on the re-

mote control and the sensor on the main unit

with a soft cloth.

● Exposing the sensor on the main unit to strong

light may interfere with operation. Change the

lighting or the direction of the unit.

● Keep the remote control away from moisture,

excessive heat, shock, and vibrations.

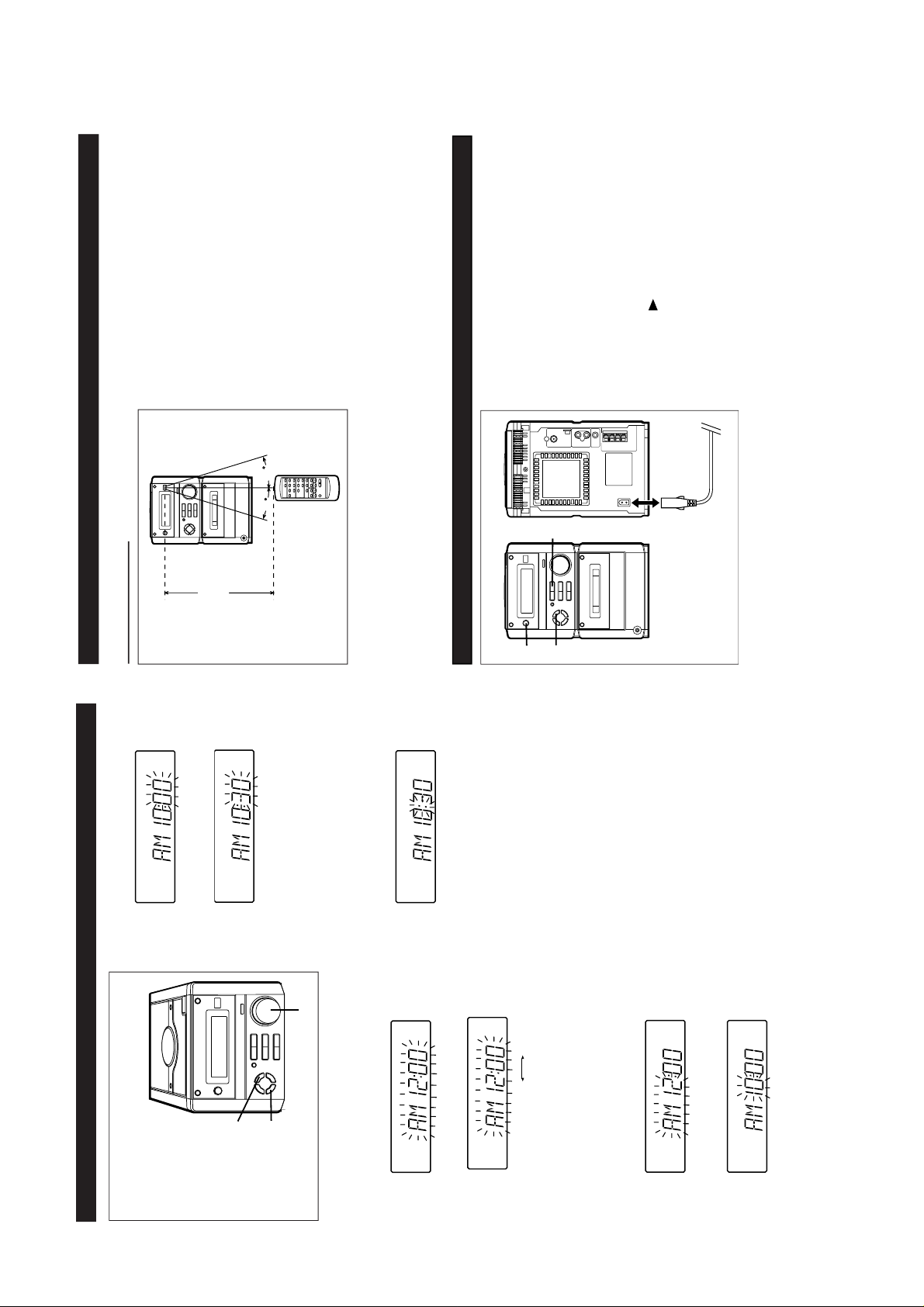

■ Remote control

PREPARATION FOR USE

8” - 20”

(0.2 m - 6 m)

SETTING THE CLOCK

1

Press the CLOCK/TIMER/SLEEP button to en-

ter the time check mode.

2

Within 3 seconds, press the MEMORY/SET

button.3Turn the jog dial to select the time display mode.

AM 12:00 0:00

“AM 12:00” → The 12-hour display will appear.

(AM 12:00 - PM 11:59)

“0:00” → The 24-hour display will appear.

(0:00 - 23:59)

● Note that this can only be set when the unit is

first installed or it has been reset.

4

Press the MEMORY/SET button.

5

Adjust the hour by turning the jog dial.

● When the jog dial is turned one click clockwise,

the time will increase by 1 hour. When it is turned

one click counterclockwise, the time will de-

crease by 1 hour.

Keep turning the jog dial to change the time con-

tinuously.

● When the 12-hour display is selected, “AM” will

change automatically to “PM”.

● In this example, the clock is set for the

12-hour (AM 12:00) system.

CLOCK/TIMER/

SLEEP

MEMORY/SET

Jog dial

6

Press the MEMORY/SET button.

7

Adjust the minutes by turning the jog dial.

● When the jog dial is turned one click clockwise,

the time will increase by 1 minute. When it is

turned one click counterclockwise, the time will

decrease by 1 minute.

Keep turning the jog dial to change the time con-

tinuously.

● The hour setting will not advance even if min-

utes advance from “59” to “00”.

8

Press the MEMORY/SET button.

● The clock starts operating from “0” second. (Sec-

onds are not displayed.)

Note:

● In the event of a power failure or when the AC

power cord is disconnected, the clock display will

go out.

When the AC power supply is restored, the clock

display will flash on and off to indicate the time

when the power failure occurred or when the AC

power cord was disconnected.

If this happens, follow the procedure below to

change the clock time.

To change the clock time:

Perform steps 1, 2 and 4 - 8 above.

To change the time display mode:

1

Perform steps 1 - 3 in the section “RESETTING

THE MICROCOMPUTER”.

2

Perform steps 1 - 8 above.

XL-70/70C

– 5 –

XL-70/70C

Placing the system

Instalación del sistema

4"(10 cm)

4"(10 cm)

8"(20 cm)

4"(10 cm)

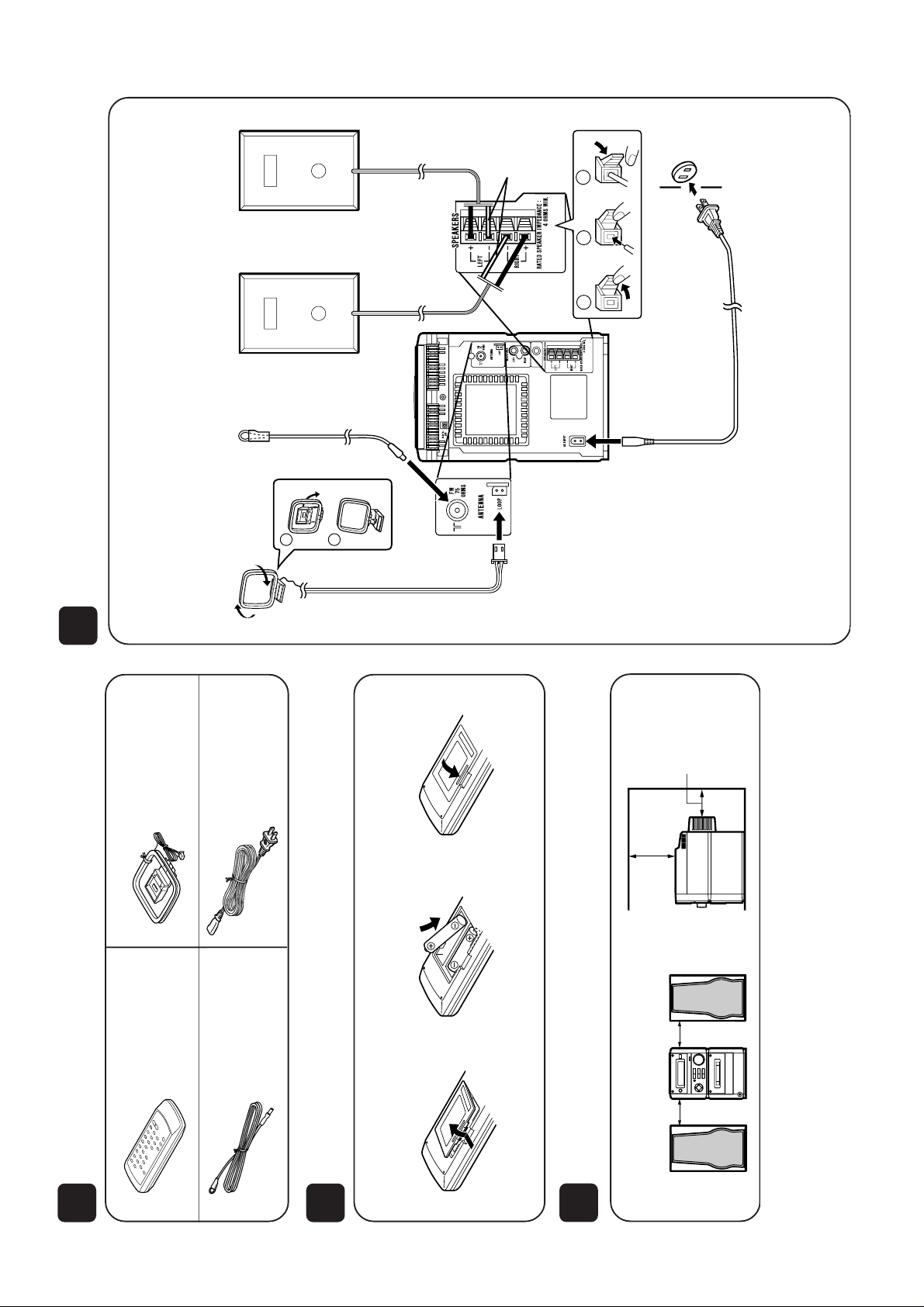

3

2

Putting batteries into the remote control

Inserción de las pilas en el controlador remoto

1

Remove the battery cover.

Extraiga la cubierta de las

pilas.

1

Check the supplied accessories

Compruebe los accesorios suministrados

FM antenna × 1

Antena de FM

×

1

Remote control × 1

Controlador remoto

×

1

AC power cord × 1

Cable de alimentación

de CA

×

1

AM loop antenna ×1

Antena de cuadro de

AM

×

1

2

Insert the batteries.

Inserte las pilas.

3

Replace the battery cover.

Vuelva a colocar la cubierta.

2 “AA” size batteries (UM/SUM-3, R6, HP-7 or similar)

2 pilas del tamaño “AA” (UM/SUM-3, R6, HP-7 or similares)

Batteries are not included.

Las pilas no están incluidas.

4

Connections

Conexiones

1

2

2

1

3

SUB

WOOFER

OUT

1

Connect the AM and FM antennas.

Conecte las antenas de AM y FM.

2

Connect the speaker system.

Conecte el sistema de altavoces.

FM antenna

Antena de FM

AM loop antenna

Antena de cuadro de AM

AC 120 V, 60 Hz

120 V de CA, 60 Hz

3

Connect the AC power cord.

Conecte el cable de alimentación de CA.

White line

Línea blanca

Right speaker

Altavoz derecho

Left speaker

Altavoz izquierdo

– 6 –

XL-70/70C

6

Listening to a tape

Audición de una cinta

1

2

5

3

4

1

2

6

4

3

OPEN/CLOSE

Label side up

7

5

Con el lado de la etiqueta

hacia arriba

1

Press the POWER button to turn the power on.

Pulse el botón POWER para conectar la alimentación.

2

Press the FUNCTION button until “CD” or “NO DISC” ap-

pears.

Pulse el botón FUNCTION hasta que aparezca “CD” o

“NO DISC”.

3

Press the OPEN/CLOSE button to open the CD com-

partment.

Pulse el botón OPEN/CLOSE para abrir el comparti-

miento del CD.

4

Place a CD on the spindle.

Ponga un disco compacto en el eje.

5

Close the CD compartment by pushing the OPEN/

CLOSE button.

Cierre el compartimiento del CD pulsando el botón

OPEN/CLOSE.

6

Press the /CD button.

Pulse el botón /CD .

7

Adjust the VOLUME control.

Ajuste el control VOLUME.

5

Listening to a CD

Audición de un disco CD

1

Press the POWER button to turn the power on.

Pulse el botón POWER para conectar la alimentación.

2

Press the FUNCTION button until “TAPE” appears.

Pulse el botón FUNCTION hasta que aparezca “TAPE”.

3

Load a cassette.

Inserte un cassette.

4

Press the button.

Pulse el botón .

5

Adjust the VOLUME control.

Ajuste el control VOLUME.

8

Recording from a CD

Grabación de un disco CD

1

Press the POWER button to turn the power on.

Pulse el botón POWER para conectar la alimentación.

2 Press the FUNCTION button until “CD” or “NO DISC” ap-

pears.

Pulse el botón FUNCTION hasta que aparezca “CD” o

“NO DISC”.

3

Load a CD and a recordable cassette.

Inserte un disco compacto y un cassette grabable.

4 Press the REC PAUSE button.

Pulse el botón REC PAUSE.

5 Press the button.

Pulse el botón .

1

2

5

4

3

1

2

3

4

5

1 Press the POWER button to turn the power on.

Pulse el botón POWER para conectar la alimentación.

2 Press the FUNCTION button until “FM” or “AM” appears.

Pulse el botón FUNCTION hasta que “FM” o “AM” aparezca.

3 Press the BAND button to select FM ST, FM or AM.

Pulse el botón BAND para seleccionar FM ST, FM o AM.

4 Press the TUNING ( or ) button to tune into a station.

Pulse el botón TUNing ( o ) para sintonizar una

emisora.

5

Adjust the VOLUME control.

Ajuste el control VOLUME.

Listening to the radio

Audición de la radio

7

– 7 –

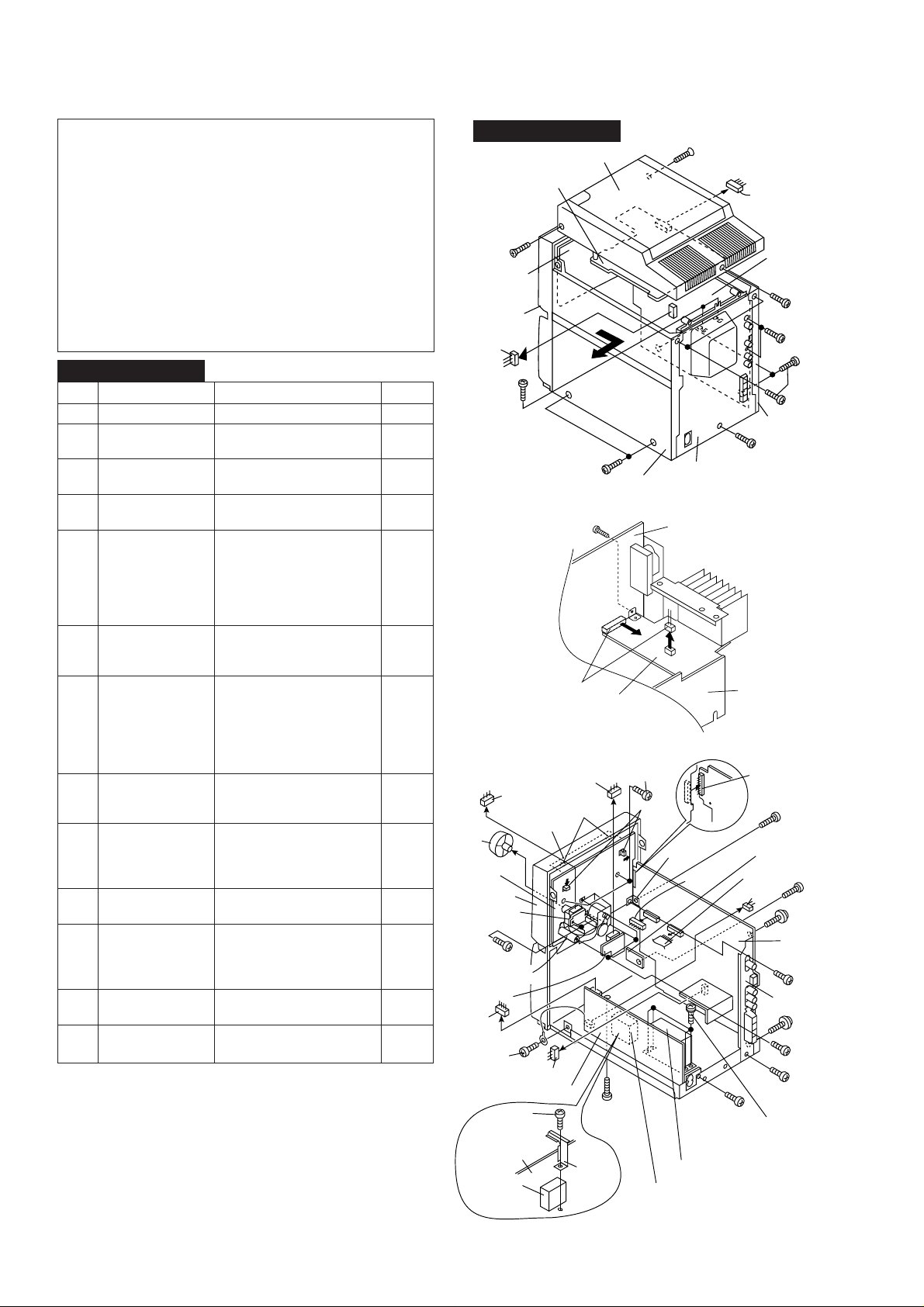

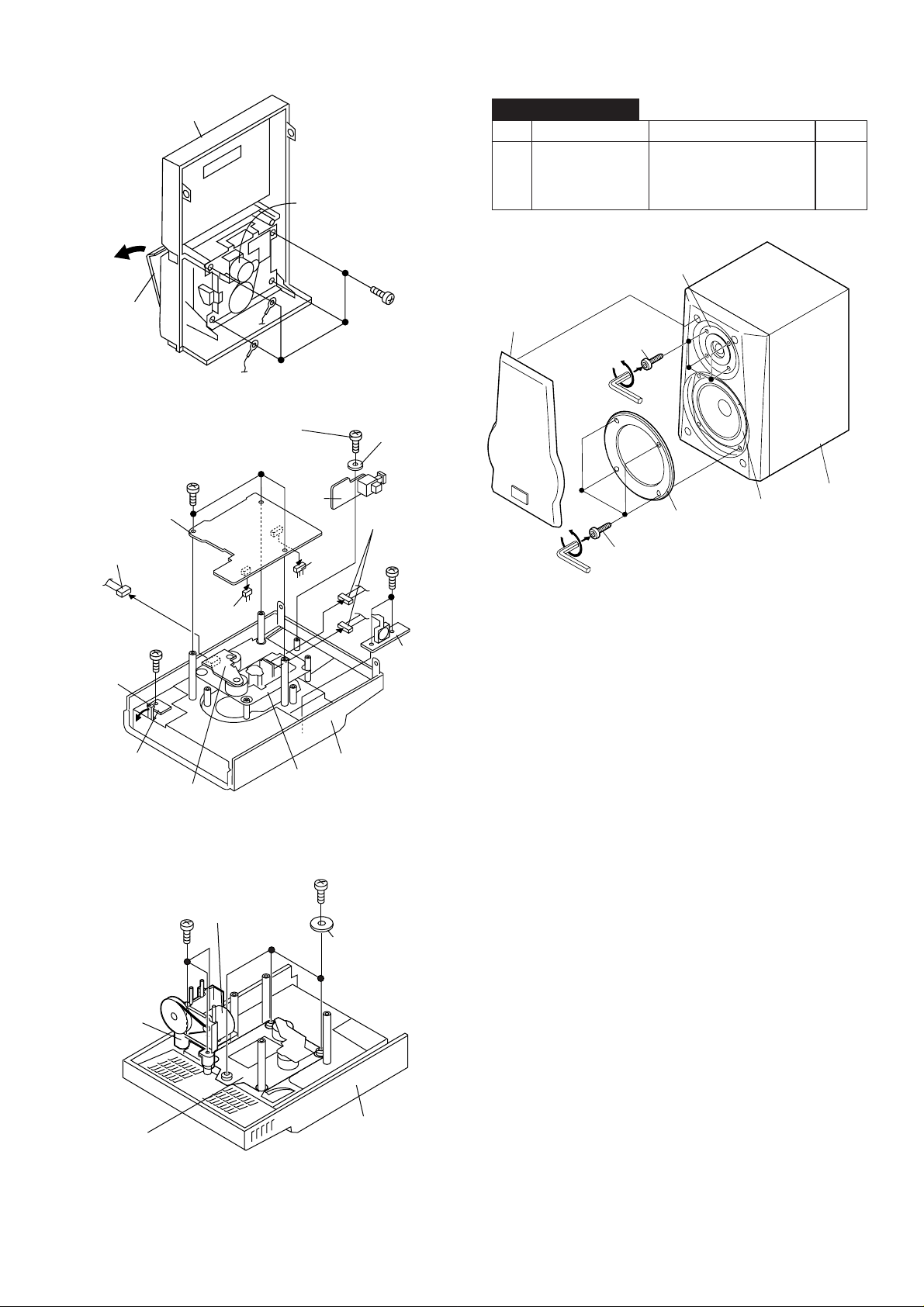

(A1)x2

ø3x10mm

(B2)x1

(C1)x2

ø3x10mm

Side Panel (Right)

Front

Panel

RearPanel

(C1)x1

ø3x10mm

Side Panel

(Lift)

(B2)x1

(A1)x4

ø3x10mm

(A1)x1

ø3x10mm

(A1)x1

ø3x10mm

(B1)x1

ø3x10mm

Top Cabinet

CD PWB

Display

PWB

Main PWB

(C2)x2

ø3x8mm

XL-70/70C

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to

be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

XL-70/70C

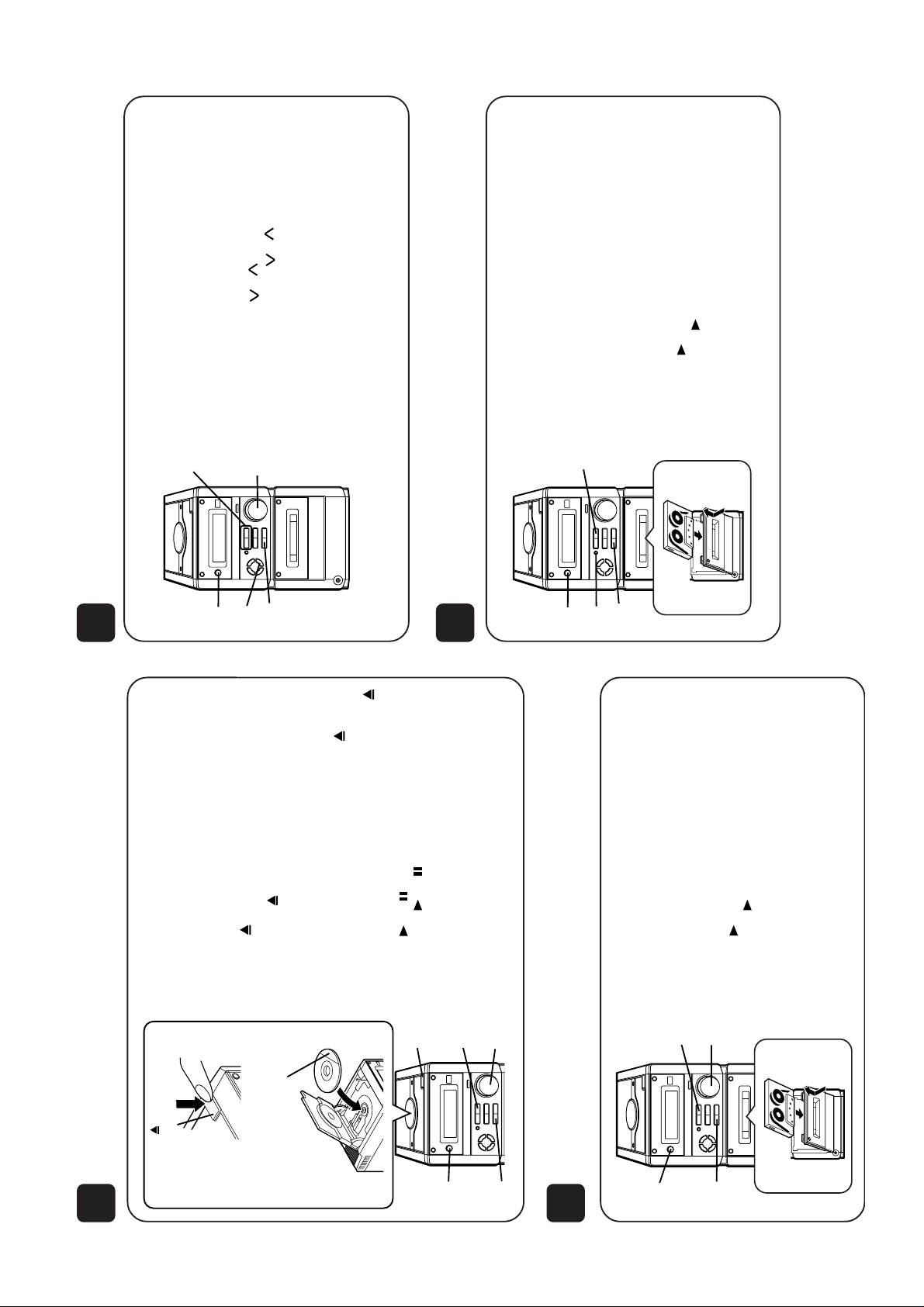

STEP REMOVAL

1 Side Panel

(Left/Right)

2 Top Cabinet 1. Screw .................. (B1) x1 8-1

3 Rear Panel 1. Screw .................. (C1) x3 8-1

4 Power Amp. PWB 1. Screw .................. (D1) x1 8-2

5 Main PWB/ 1. Screw .................. (E1) x3 8-3

Headphones PWB 2. Screw .................. (E2) x2

6 Jog Switch PWB 1. Socket ................. (F1) x1 8-3

7 Display PWB/ 1. Screw .................. (G1) x3 8-3

LED PWB 2. Screw .................. (G2) x3

(With Jog Motor 3. Bracket................ (G3) x1

Holder) 4. Socket ................. (G4) x1

8 Front Panel 1. Screw .................. (H1) x1 8-3

9 Power PWB 1. Screw .................. (J1) x4 8-3

10 Tape Mechanism 1. Open the cassette holder 9-1

11 CD PWB/ 1. Screw .................. (L1) x6 9-2

Open Close Switch 2. Socket ................. (L2) x4

PWB/CD Lid PWB 3. Hook .................... (L3) x1

(Note)

12 Digital Out PWB 1. Socket ................. (M1) x1 9-2

13 CD Mechanism 1. Screw .................. (N1) x3 9-3

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

PROCEDURE

FIGURE

1. Screw .................. (A1) x8 8-1

2. Socket ................. (B2) x2

2. Screw .................. (C2) x2

2. Socket ................. (D2) x2

3. Bracket ................ (E3) x1

4. Socket ................. (E4) x3

5. Flat wire............... (E5) x1

6. Socket ................. (E6) x1

2. Screw .................. (F2) x2

3. Knob .................... (F3) x1

5. Hook .................... (G5) x2

6. Hook .................... (G6) x2

2. Socket ................. (H2) x1

3. Screw .................. (H3) x1

2. Screw .................. (J2) x1

3. Screw .................. (J3) x1

4. Bracket ................ (J4) x1

2. Screw .................. (K1) x4

2. Screw .................. (M2) x1

2. Screw .................. (N2) x3

(F3)x1

Display PWB

Front Panel

Jog Switch

(F2)x2

ø2.5x12mm

Tape

Mechanism

PWB

(G4)x1

Sub Power

Transformer

– 8 –

XL-70/70C

(F1)x1

PWB

Jog Motor

Holder

(H3)x1

ø3x6mm

Power PWB

(J3)x1

ø3x6mm

Power PWB

(D1)x1

ø3x8mm

LED PWB

(E4)x1

(D2)x2

(E4)x1

(G6)x2

(J4)x1

Figure 8-1

Power Amp.

PWB

Figure 8-2

(G2)x2

ø2.5x10mm

(G5)x2

(H1)x1

ø3x8mm

Sub Power Transformer

Figure 8-3

Main PWB

Power

PWB

(E6)x1

(G3)x1

(E4)x1

(J2)x1

ø3x10mm

Main Power Transformer

Headphones

PWB

(E5)x1

(H2)x1

(E3)x1

(E2)x1

ø3x8mm

(J1)x4

ø4x6mm

(E2)x1

ø3x8mm

(E1)x1

ø3x8mm

(E1)x1

ø3x10mm

Main PWB

(G2)x1

ø2.5x10mm

(E1)x1

ø3x10mm

(G1)x3

ø2.5x10mm

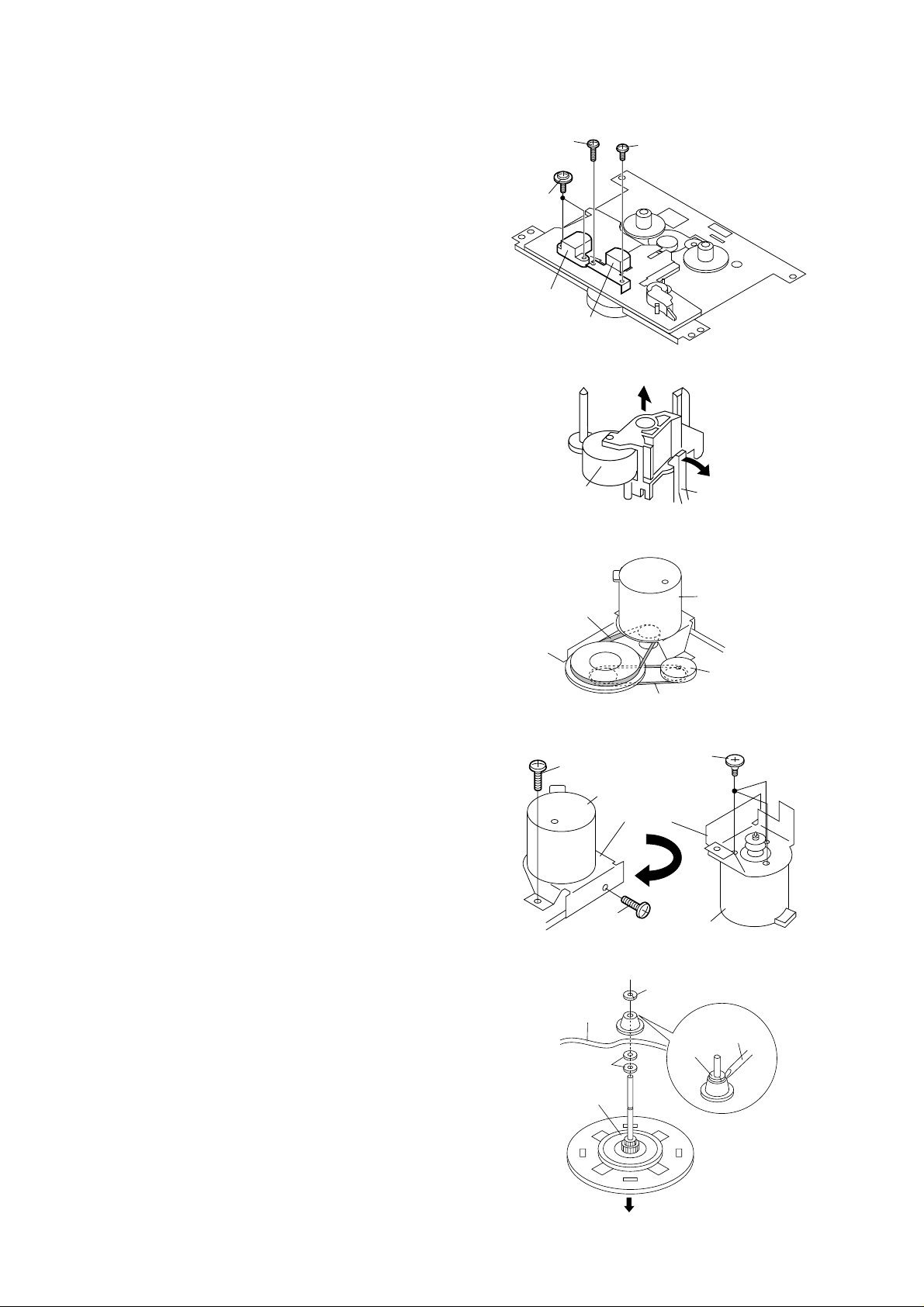

XL-70/70C

(A1)x1

(A3)x1

(A4)x4

ø3x12mm

Woofer

Tweeter

(A2)x4

ø4x20mm

Speaker Box

Front Panel

Open

Cassette

Holder

CD PWB

(L2)x1

(L1)x3

ø2.5x14mm

Figure 9-1

(M2)x1

ø2.5x10mm

Tape

Mechanism

Digital

Out

PWB

(M1)x1

(K1)x4

ø2.5x10mm

PWB

Washer

(L2)x2

(L1)x2

ø2.5x8mm

CP-XL70U

STEP REMOVAL

1 Speaker 1. Net Frame ........... (A1) x1 9-4

PROCEDURE

2. Screw .................. (A2) x4

2. Woofer Ring ........ (A3) x1

4. Screw .................. (A4) x4

FIGURE

(L1)x1

ø2.5x10mm

(L3)x1

Open/Close

Switch PWB

CD Motor PWB

(N1)x3

ø2.5x14mm

CD Lid

Motor

Holder

(L2)x1

CD Lid

Motor

Figure 9-4

CD Lid

PWB

Top Cabinet

CD Mechanism

Figure 9-2

(N2)x3

ø2.5x10mm

PWB

Washer x3

CD Mechanism

Figure 9-3

Top Cabinet

– 9 –

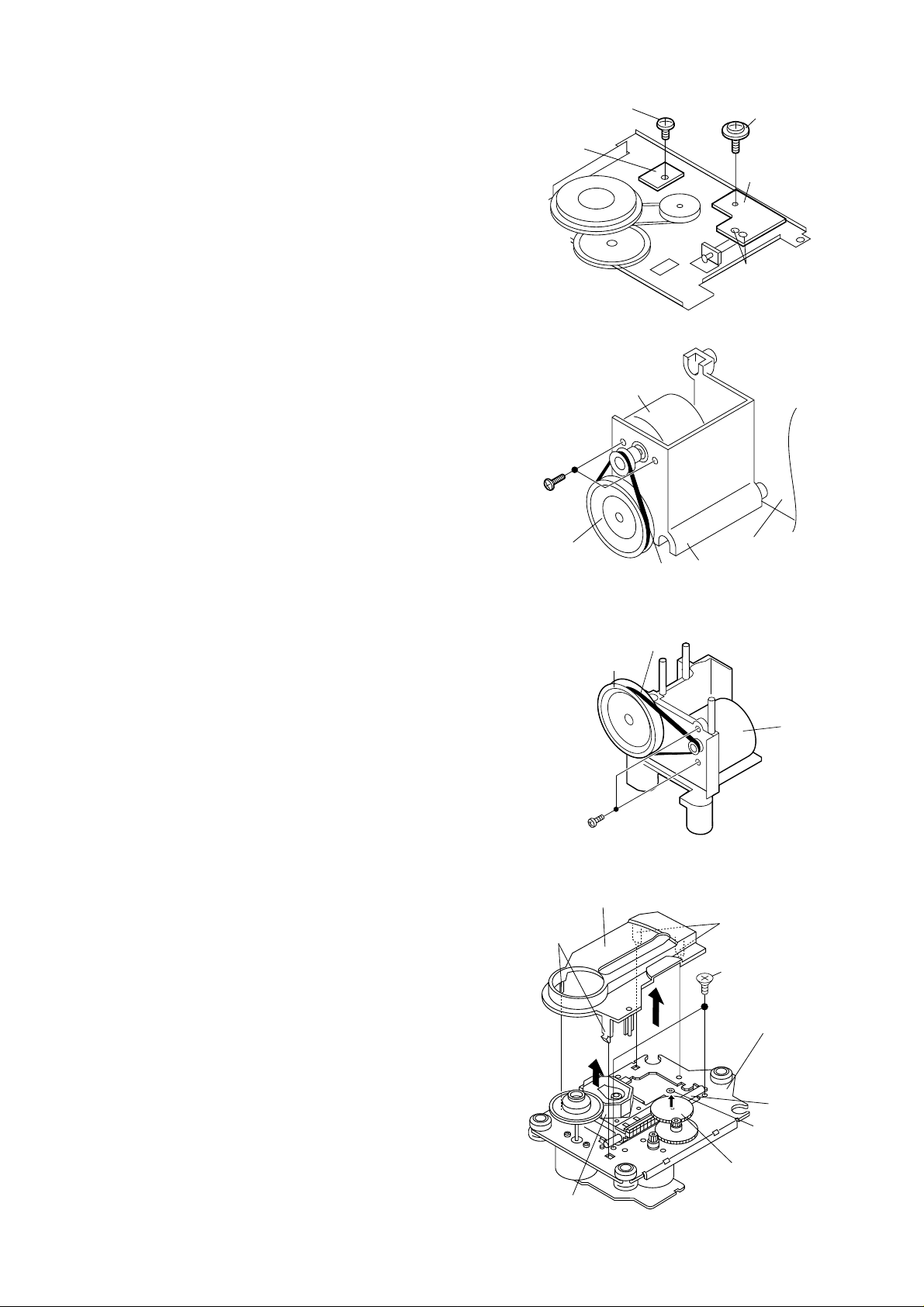

XL-70/70C

REMOVING AND REINSTALLING THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps 1 to 8 and 10 of the disassembly method to

remove the tape mechanism. (See page 8.)

How to remove the record / playback and erase

heads (See Fig. 10-1.)

1. Remove the screws (A1) x 2 pcs., to remove the erase

head.

2. Remove the screws (A2) x 2 pcs., to remove the record/

playback head.

Note:

After replacing the heads and performing the azimuth

adjustment, be sure to apply screwlock.

How to remove the pinch roller (See Fig. 10-2.)

1. Carefully bend the pinch roller pawl in the direction of the

arrow <A>, and remove the pinch roller (B1) x 1 pc.,

upwards.

How to remove the belts (See Fig. 10-3.)

1. Remove the main belt (C1) x 1 pc., from the motor pulley.

2. Remove the FF/REW belt (C2) x 1 pc., from the REW/FF

roller.

3. Put on the belts in the reverse order of removal.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

(A2)x1

ø2x7mm

(A1)x2

ø2x8mm

Erase Head

Record/

Playback Head

Pinch Roller

(B1)x1

Main Belt

(C1)x1

(A2)x1

ø2x3mm

Figure 10-1

Figure 10-2

FF/REW Belt

(C2)x1

Figure 10-3

<A>

Pinch Roller

Pawl

Motor

REW/FF

Clutch

How to remove the motor

(See Figs. 10-4.)

1. Remove the main belt.

2. Remove the screws (D1) x 2 pcs., to remove the motor

bracket.

3. Remove the screws (D2) x 3 pcs., to remove the motor.

Note:

When mounting the motor, pay attention to the motor mounting

angle.

How to remove the flywheel (See Fig. 10-5.)

1. Remove the belt.

2. Remove the stop washer (E1) x 1 pc., with a small precision

screwdriver to extract the flywheel from the capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

How to reinstall the parts

Install each part in the reverse order of the removal with care.

(D1)x1

ø2x4mm

Motor

(D1)x1

ø2x4mm

Mechanism

Chassis

Washerx2

Flywheel

(D2)x3

Special

Screw

Motor

Bracket

Motor

Figure 10-4

(E1)x1

Stop Washer

Stop

Washer

Driver

– 10 –

Figure 10-5

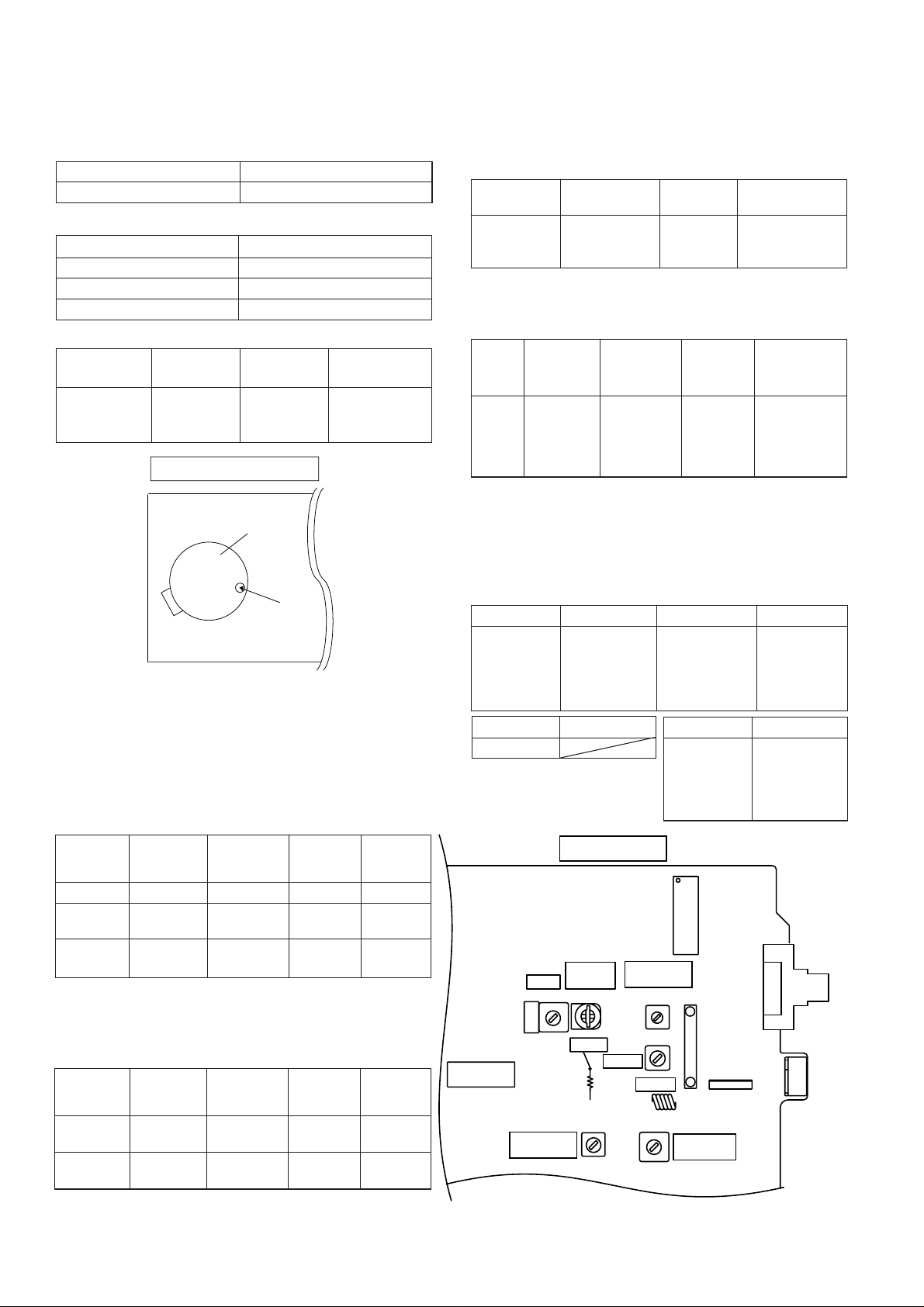

XL-70/70C

How to remove the tape mechanism PWB

(See Fig. 11-1.)

1. Remove the screws (F1) x 1 pc., to remove the tape

mechanism PWB.

2. Remove the screws (F2) x 1 pc.

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

mechanism PWB.

How to remove the jog motor

(See Figs. 11-2.)

1. Remove the side panel and top cabinet.

2. Remove the jog belt (G1) x 1 pc., from the motor pulley.

3. Remove the screws (G2) x 2 pcs., to remove the jog motor.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

How to remove the CD lid motor

(See Figs. 11-3.)

1. Remove the CD PWB.

2. Remove the belt (H1) x 1 pc., from the motor pulley.

3. Remove the screws (H2) x 2 pcs., to remove the CD Lid

motor.

Note:

When putting on the belt, ascertain that the belt is not twisted,

and clean it.

Tape

Mechanism

PWB

(G2)x2

ø2x5mm

Worm

Gear

(F1)x1

ø2x3mm

Jog Motor

Worm

Gear

Figure 11-1

Jog Belt

(G1)x1

Jog Motor

Holder

Figure 11-2

(H1)x1

Belt

(F2)x1

ø2x8mm

Tape

Mechanism

PWB

(F3)x2

Solder

Joint

Display PWB

CD Lid

Motor

CD MECHANISM SECTION

Perform steps 1, 2 and 10 to 12 of the disassembly method to

remove the CD mechanism.

How to remove the pickup (See Fig. 11-4)

1. Remove the mechanism cover, paying attention to the

pawls (A1) x 4 pcs.

2. Remove the screws (A2) x 2 pcs., to remove the shaft (A3)

x 1 pc.

3. Remove the stop washer (A4) x 1 pc., to remove the gear

(A5) x 1 pc.

4. Remove the pickup.

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

(H2)x2

ø2.5x10mm

Figure 11-3

Mechanism Cover

(A1) x2

(A1) x2

(A2) x2

ø2.6 x6mm

CD Mechanism

Shaft

(A3) x1

StopWasher

(A4) x1

Gear

(A5) x1

Pickup Unit

Figure 11-4

– 11 –

XL-70/70C

MECHANISM SECTION

• Driving Force Check

Torque Meter

Play: TW-2412 Over 80 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 60 g. cm

Fast forward: TW-2231 55 to 140 g.cm

Rewind: TW-2231 55 to 140 g.cm

• Tape Speed

Test Tape

MTT-111 Variable 3,000 ± Headphone

Adjusting

Point

resistor in 90 Hz terminal

motor.(M901)

TAPE MECHANISM

Specified Value

Specified Value

Specified

Value

Instrument

Connection

ADJUSTMENT

• FM Mute Level

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency

98.00 MHz 98.00 MHz VR351*1 Input: SO301

(30 dBµV) Output: Speaker

*1. Adjust so that an output signal appears.

• FM Detection

Signal generator: 10.7 MHz, FM sweep generator

Test

Stage

FM IF 10.7 MHz 98.0 MHz T304(Turn Input: Pin 1 of

Display

Frequency Frequency

Display

Adjusting

Parts

Terminal

Setting/

Adjusting

Parts

the core of IC301

T304 fully

counterclockwise.)

Instrument

Connection

Instrument

Connection

M901

Tape

Motor

Variable

resistor

in motor

Figure 12-1 ADJUSTMENT POINT

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Frequency

AM IF 450 kHz 1,620 kHz T351 *1

AM Band — 522 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

AM 990 kHz 990 kHz (fL): T302 *1

Tracking

*1. Input: Antenna, Output: Speaker Terminal

*2. Input: Input is not connected, Output: TP301

Frequency Display

Setting/

Adjusting

Parts

Instrument

Connection

• Setting the Test Mode

Keeping the FF/FWD button and MEMORY/SET button

pressed, turn on POWER. Then, the frequency is initially set

in the memory as shown in Table. Call it with the JOG DIAL

knob to use it for adjustment and check of tuner circuit.

Preset No.

1 87.5 MHz 6 530 kHz

2 108.0 MHz 7 1,720 kHz

3 98.0 MHz 8 990 kHz

4 90.0 MHz 9 600 kHz

5 106.0 MHz 10 1,400 kHz

Preset No.

11~25

FM STEREO Preset No.

BAND

Preset No.

26 106.0 MHz

27 90.0 MHz

28 98.0 MHz

29 108.0 MHz

30 87.5 MHz

AM

FM MONO

MAIN PWB

AM IF

T351

FM Mute

Level

VR351

FM Band

Coverage fL

L303

IC302

9

SO301

FM

ANTENNA

SOCKET

• FM RF

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Test Stage

FM Band — 87.5 MHz (fL): L303 *1

Coverage 3.4 ± 0.1 V

FM RF 98.00 MHz 98.0 MHz L302 *2

Frequency

(10~30 dB)

Frequency

Display

Setting/

Adjusting

Parts

Instrument

Connection

*1. Input: Antenna, Output: TP301

*2. Input: Antenna, Output: Speaker Terminal

– 12 –

IC303

FM IF

L302

T304

FM RF

T302

1

AM

Tracking fL

CF352

R336

AM Band

Coverage fL

TP301

T306

Figure 12-2 ADJUSTMENT POINTS

IC301

BF301

CNP301

AM

ANTENNA

SOCKET

XL-70/70C

TEST MODE

The test mode applied to this microcomputer has three modes, namely ordinary test mode to be used for adjustment or

measurement, aging test mode to be used for aging test, and self-diagnosis test mode for self-inspection in case of final product

inspection.

1. Turning on the test mode

To turn on the specific test mode, press the POWER button, holding down the following two buttons in the ordinary stand-by

mode (power off state). In this case only the main unit button is valid. Even when the POWER of remote control button is set

to on, the test mode is not turned on.

[Ordinary test mode]

1. CD Test Mode (TEST 1)…………………… Volume/JOG Dial Selector + FF/FWD

2. Tuner Test Mode (TEST 2)………………… Volume/JOG Dial Selector + Volume Select

3. Electronic volume Test Mode (TEST 3)……REW/REV + FF/FWD

4. Timer Test Mode (TEST 4)………………… FUNCTION + Volume Select

5. LCD Test Mode (TEST 5)……………………FUNCTION + FF/FWD

[Self-diagnosis Test Mode]

1. Button input diagnosis test mode (TEST6).…

REW/REV + Volume Select

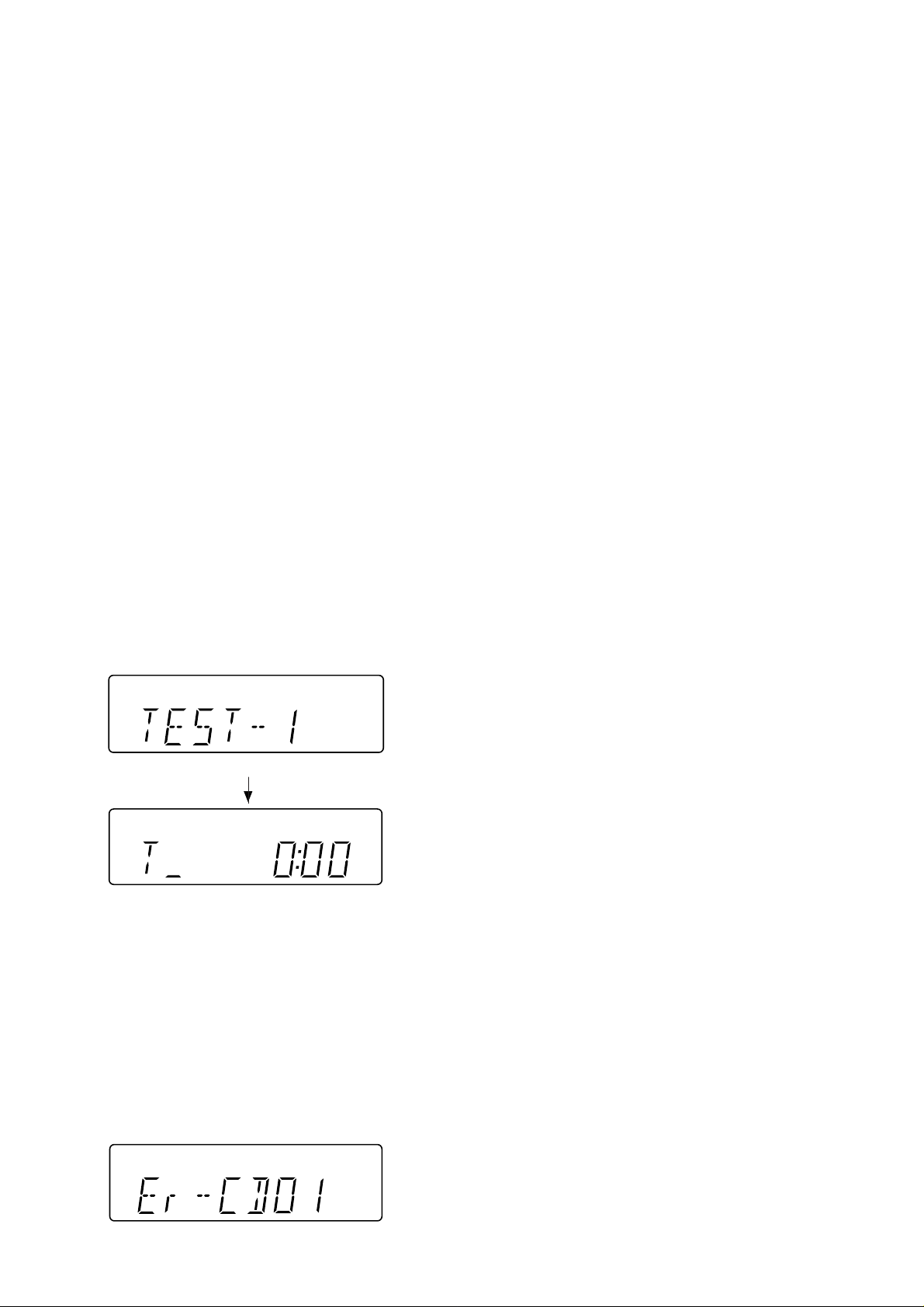

2. CD Test Mode (TEST 1)

In the CD test mode the operation of each step is enabled even when the LID-SW is off. However, if focus cannot be set in step

3 or any error processing is started, it is impossible to proceed to the next step. When the error processing is started, operations

other than termination of test mode by pressing the POWER button or return to the step 1 by pressing the STOP button are inhibited.

1. Step 1 Mode

When the CD test mode is turned on, the following indication lights, the processing (until turning-off of CD STB terminal of CD

initialization operation flow) is executed, and the next button input is waited.

After lighting for one second

If the following operation buttons are pressed in this state, the operation is performed as follows.

"POWER".................The test mode is turned off, the power is turned off, and the ordinary standby mode is set.

"FF/FWD".................After the pickup returns once to the innermost periphery, it slides toward the outer periphery while this

button is held down.

"REW/REV"..............After the pickup returns once to the innermost periphery, it slides toward the inner periphery while this

button is pressed. However, if PU-IN is on, input is invalid.

"PLAY" .....................Shift to step 2

"STOP".....................Invalid

"REC PAUSE"..........Shift to step 5

* In case of initialization the pickup is moved toward the inner periphery. Any buttons other than "POWER" button are not

accepted until the shift of pickup to the inner periphery is completed at this time. If PU-IN SW ON cannot be detected within

10 seconds, the slide motor is stopped, and the following error indication appears. Press the POWER button to end the test

mode, or press the STOP button to return to step 1. Any other operations are inhibited.

– 13 –

XL-70/70C

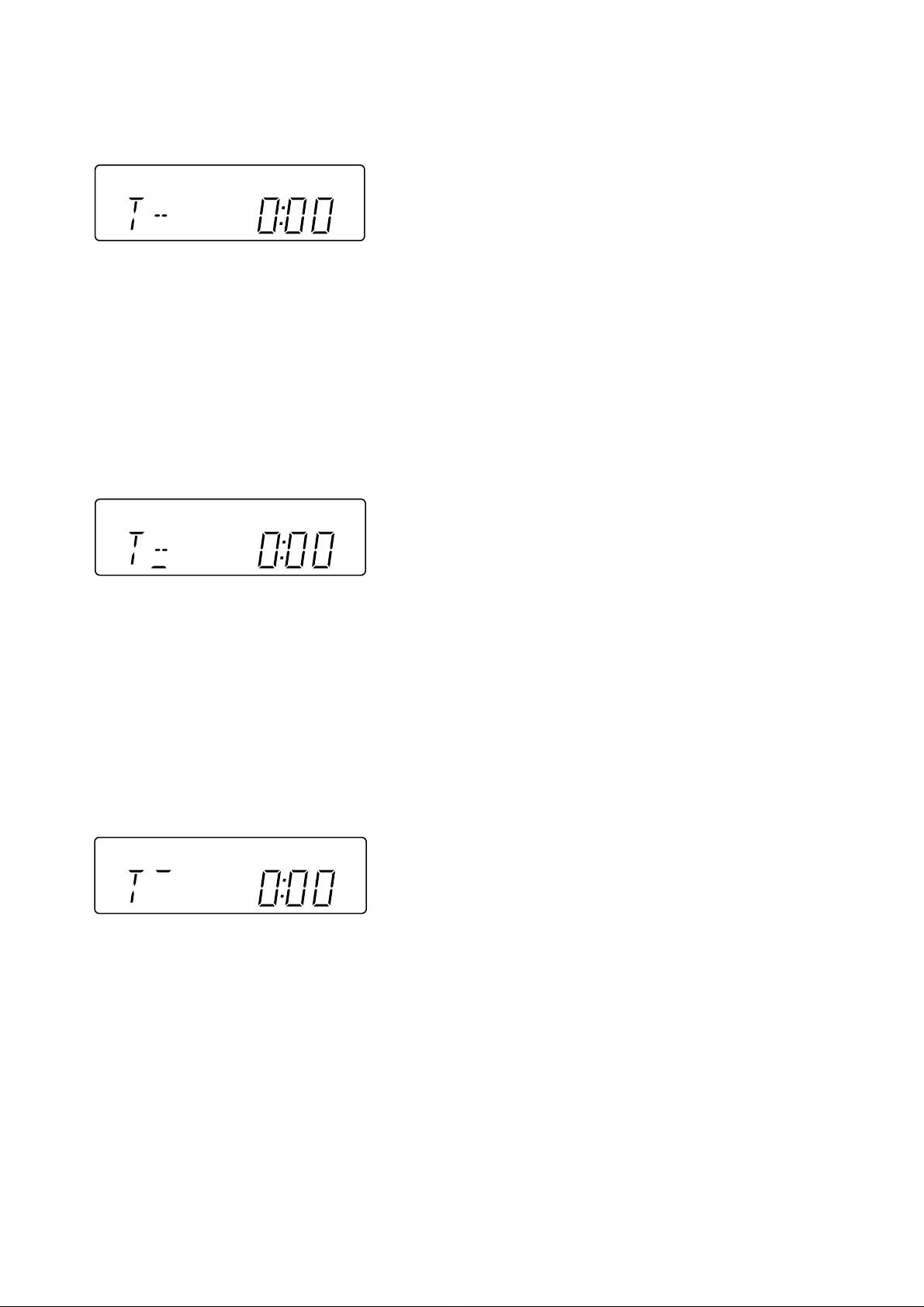

2. Step 2 Mode

When the "PLAY" button is pressed in this mode, the laser lighting command LDON (8400) is sent, and the laser is turned on.

Other operations are not performed.

If the following buttons are pressed in this state, the operation is performed as follows.

"POWER" ................ The test mode is turned off, the power is turned off, and the ordinary standby mode is set.

"FF/FWD" ................The pickup slides toward the outer periphery while this button is held down.

"REW/REV" .............The pickup slides toward the inner periphery while this button is held down. However, if PU-IN is on, input

is invalid.

"PLAY".....................Shift to step 3

"STOP" ....................Return to step 1

"REC PAUSE" .........Shift to step 5

3. Step 3 Mode

The laser is kept lighting. The processing (until turning-on of CLV servo of CD initialization operation flow) is executed, and

the next button input is waited. (The focus servo is turned on, and focus search is performed.)

The focus search is repeated until the focus is set.

When the following operation buttons are pressed in this state, the operation is executed as follows.

"POWER" ................The test mode is turned off, the power is turned off, and the ordinary standby mode is set.

"FF/FWD" ................The pickup slides toward the outer periphery while this button is held down.

"REW/REV" .............The pickup slides toward the inner periphery while this button is held down. However, if PU-IN is on, input

is invalid.

"PLAY".....................If the focus has been set, shift to step 4 is executed. If the focus has not been set, acceptance is inhibited.

"STOP" ....................Return to step 1

"REC PAUSE" .........Shift to step 5

*If the focus is disturbed after it has been set, the process returns to step 1.

4. Step 4 Mode

The CLV servo ON command (8600) sending operation is performed, and the next button input is waited. (The disc is rotated

to perform CLV locking.)

The time display indicates always "0:00".

When the following buttons are pressed in this state, the operation is executed as follows.

"POWER" ................The test mode is turned off, the power is turned off, and the ordinary standby mode is set.

"FF/FWD" ................The pickup slides toward the outer periphery while this button is held down.

"REW/REV" .............The pickup slides toward the inner periphery while this button is held down. However, if PU-IN is on, input

is invalid.

"PLAY".....................Shift to step 5

"STOP" ....................Return to step 1

"REC PAUSE" .........Shift to step 5

*If the focus is disturbed, the process returns to step 1.

– 14 –

XL-70/70C

5. Step 5 Mode

The CD initialization operation flow is executed to the end, the mute is set to off, and playback is started. Even when the

playback reaches the outermost periphery of disc, the operation does not stop. The LCD display indicates the playback past

time as in case of ordinary CD playback.

When the following operation buttons are pressed in this sate, the operation is executed as follows.

"POWER".................The test mode is turned off, the power is turned off, and the ordinary standby mode is set.

"FF/FWD"................. The pickup slides toward the outer periphery while this button is held down.

"REW/REV"..............The pickup slides toward the inner periphery while this button is held down. However, if PU-IN is on, input

is invalid.

"PLAY" ..................... Invalid

"STOP".....................Return to step 1

*If the focus is disturbed, the process returns to step 1.

Other cautions

• TOC IL is not executed in the test mode.

• As for button operations other than those shown above, only the sound volume operation (with JOG) is accepted.

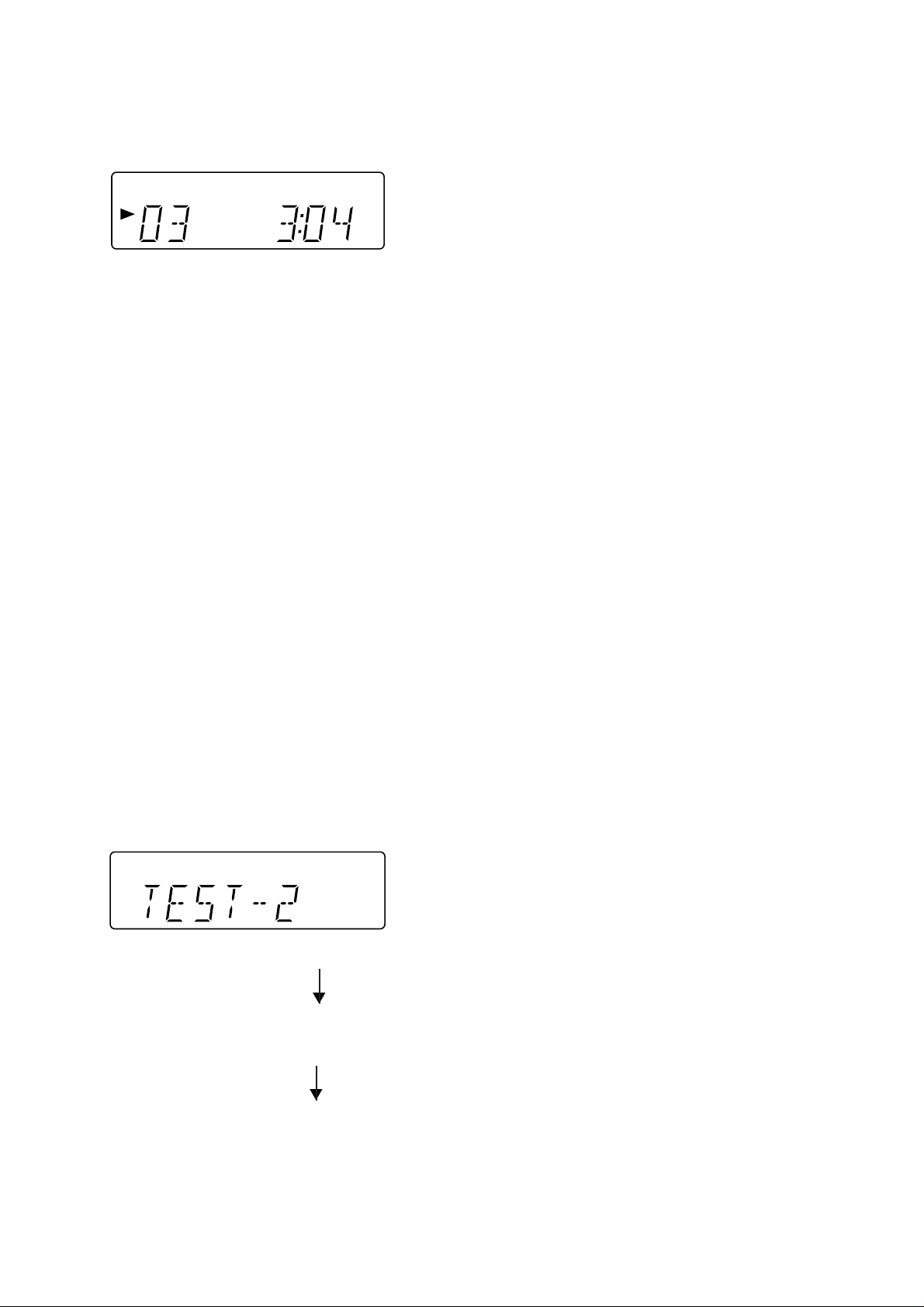

3. Tuner Test Mode (TEST 2)

1. Outline of tuner (radio) test mode

The tuner test mode is intended to store the adjustment and measurement frequencies in the preset memory CH without

frequency setting by adjusting personnel when the tuner section is adjusted in the production line.

2. Details of tuner test mode

When the power is turned on by using the "POWER" button while the "Volume/JOG Dial Selector" and "Volume Select"

buttons are held down in POWER OFF state, the frequency for adjustment and measurement of destination specified by the

AREA terminal is preset and stored in the preset memory CH. However, Ordinary 1 and Ordinary 2 are set to the designation

(destination selected by SPAN switching operation) set when the test mode is set. (As for frequencies to be preset and stored

for each destination, refer to item 3.)

The tuner test mode is started from preset No.1.

The operations of test mode are identical with the ordinary operations of TUNER function. However, FUNCTION switching

is invalid.

Since it is necessary to discard the content of preset memory when the tuner test mode is ended, "0000" or "1111" bits are

written in the memory to be checked in case of memory check (in case of initial setting) so that memory abnormality is detected

in case of initial setting so as to ensure memory initialization.

When the tuner test mode is turned on, the following indication lights for one second.

• The TUNER TEST2 mode is set as a result of Volume Select + POWER. -> IF AC is set to OFF in the TEST2 mode, the initial

state is restored.

When POWER is set to OFF, the memory of TEST2 mode is protected.

When the power is turned on again, the ordinary operation is enabled while the data is stored in the

memory (besides TUNER).

If AC OFF state is maintained in this state for about 1/2 day, start is executed in the initial state.

• To clear the whole memory, insert the AC cord, holding down MEMORY + PLAY.

– 15 –

XL-70/70C

3. Preset frequencies for various destinations (random preset memory)

U.S.A. ,BrazilCH

1 FM 87.5 MHz

2 FM108.0 MHz

3 FM STEREO FM 98.0 MHz

4 FM 90.0 MHz

5 FM106.0 MHz

6 AM 530 kHz

7 AM1720 kHz

8 AM AM 990 kHz

9 AM 600 kHz

10 AM1400 kHz

11

12

13 LW

14

15

• The hatched sections of the table are not stored in memory.

4. Electronic volume Test Mode (TEST 3)

When the test mode is set, the following indication lights for one second.

16

17

18

19

20

21

22

23

24

25

26 FM106.0 MHz

27 FM 90.0 MHz

28 FM MONO FM 98.0 MHz

29 FM108.0 MHz

30 FM 87.5 MHz

BAND

U.S.A. ,BrazilCHBAND

When this mode is set, BASS/TREBLE is set to 0 (0 dB) and SURROUND mode is set to off, and start-up function is set to CD

when volume is -14 dB (STEP 17). The button operations in the test mode are the same as those of ordinary operation excepting

sound volume UP/DOWN.

(1) The indication is the same as that of ordinary operation excepting test mode setting.

(2) The sound volume control with the sound volume UP/DOWN button is only the following 3 steps unlike the ordinary state.

Volume- ∞ (STEP 0) <-> Volume-14 dB (STEP 23) <-> Volume-0 (STEP 30)

(3) BASS/TREBLE and SURROUND are switched when button operation is performed.

5. Timer test Mode (TEST 4)

When the test mode is set, the following indication lights for one second.

The current time and timer time are set in the following procedure to perform the timer playback.

1.Set the current time to 1:00, set the timer to ON time 1:02, set the function to Tape, and set volume STEP 8. One minute is counted

as one second, and the timer playback operation is performed. The fade-in (when playback is started) is executed at a rate of

one step for 0.5 sec. After completion of fade-in the fade-out is executed at a rate of one step for 0.5 sec (WAIT 1 sec inserted).

After completion of fade-out the power is turned off (after WAIT 1 sec), and the mode is changed to the standby mode.

The indication during operation is the same as that of ordinary timer operation.

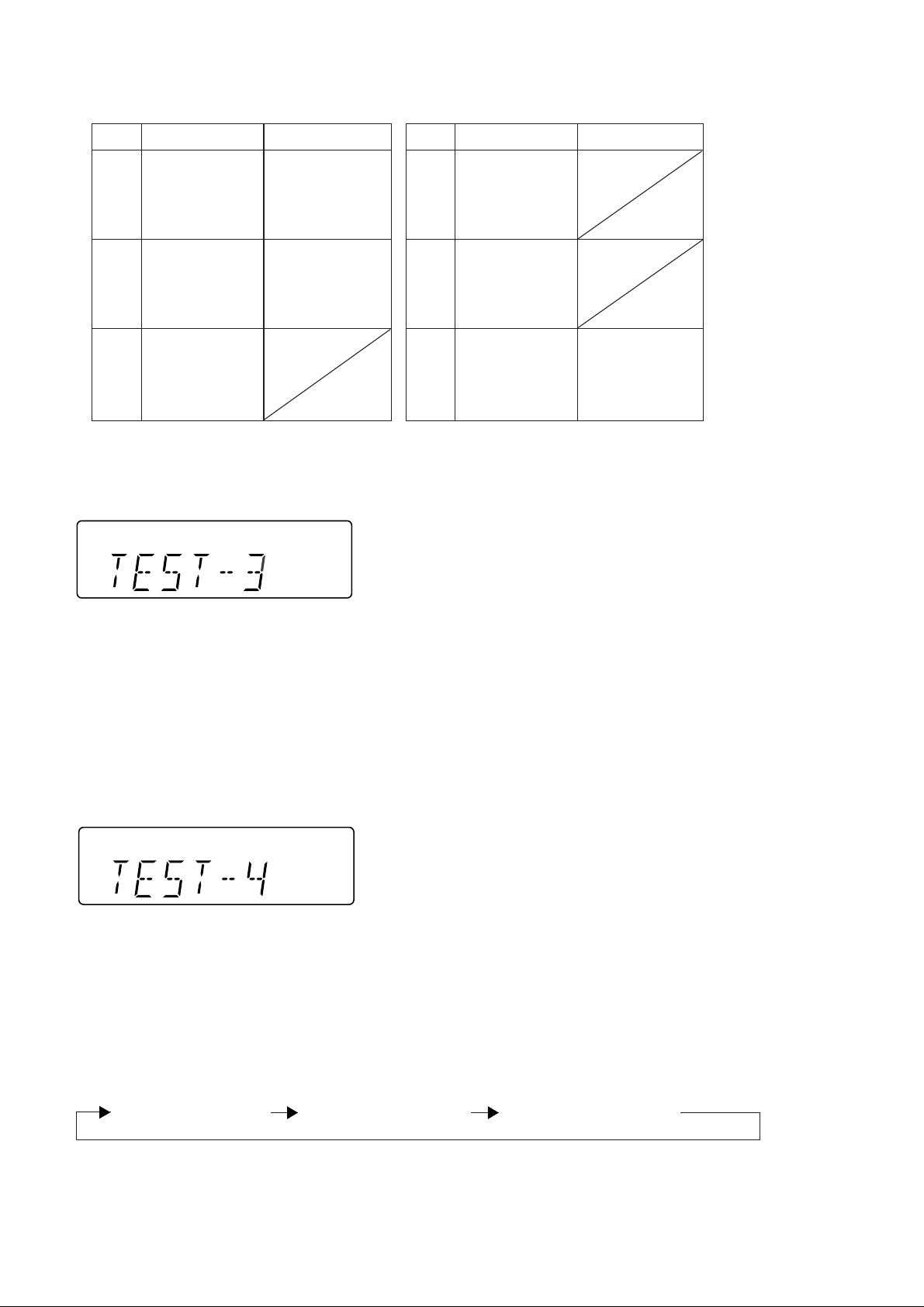

6. LCD Test Mode (TEST 5)

When the LCD test mode is set, all the LCD segments are lighted. After that the indication is changed as follows according to

the "PLAY" button input.

Lighting of all segments Lighting of odd segments Lighting of even segments

– 16 –

XL-70/70C

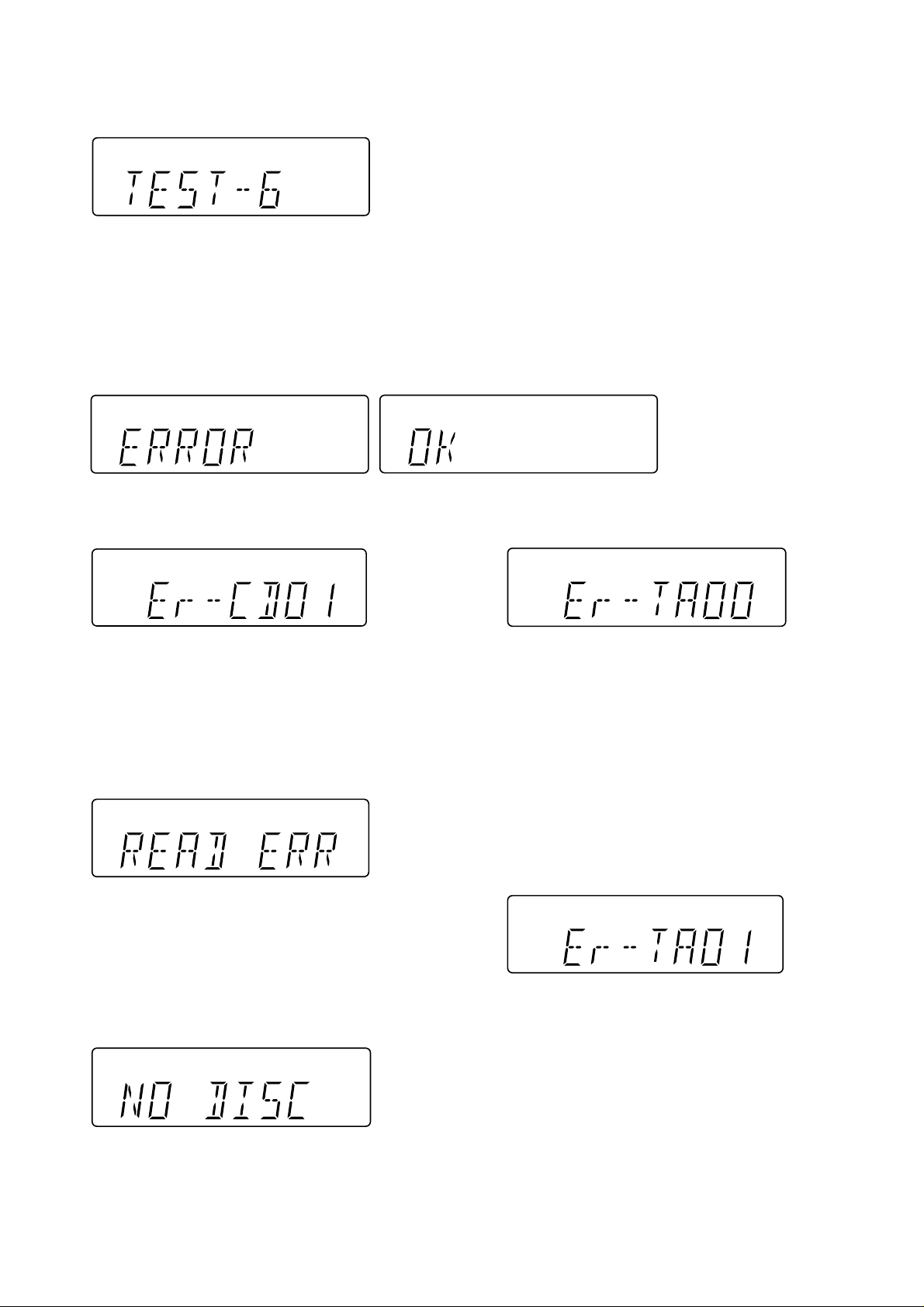

7. Key input diagnosis Test Mode (TEST 6)

When the test mode is set, the following indication appears.

This test mode is intended to check whether all the main unit buttons can be detected. Accordingly, in this test mode checking

as to whether the "POWER" button was pressed after all the buttons shown below were pressed is performed. If the result is

OK, OK is indicated. Even any one of keys was not pressed, an error is indicated. In case of OK termination or error termination

exit from this mode occurs when the "POWER" button is pressed next time, and the standby mode is set.

1. In case of "Review" + "Volume/Jog Dial Select Button"

The following 13 buttons are detected as all buttons.

The OK/NG indication of test result is as follows.

ERROR LIST

PU-IN SW detection error

Tape mechanism error 1

Error content............ The detection SW cannot detect ON

after a fixed period of time even if the

microcomputer controls the CD pickup

to return to the innermost position.

Probable cause........Defective or poorly connected PU-IN

SW or slide motor.

Action .......................Solve the problem and turn on the power

again.

CD read error

Error content ........... Disc data cannot be read properly or

even if it can be read, the disc is not a

playable one.

Probable cause....... The disc is loaded upside down, not CD-

DA, scratches, stains, etc.

Action ...................... Open the CD lid, then reload the disc

correctly. Remove the scratches or stains

on the disc.

NO DISC

Error content ........... Focusing is impossible.

Probable cause....... The disc is loaded upside down, not CD-

DA, scratches, stains, etc.

Action ...................... Open the CD lid, then reload the disc

correctly. Remove the scratches or stains

on the disc.

Error content........... The detection SW "CAM-SW" cannot

detect ON (mechanism in operation) even

if the motor and solenoid are controlled

to play back, fast forward, rewind, or

record the tape.

Probable cause....... Mechanism is in operation when this

message appears: Defective or poorly

connected CAM-SW. Mechanism stops:

Defective or poorly connected motor or

solenoid.

Action ...................... Solve the problem and turn on the power

again.

Tape mechanism error 2

Error content ........... Initialization cannot be completed when

the microcomputer controls the motor

and solenoid to initialize the tape

mechanism (to set the mechanism to the

stop mode). The detection SW "CAMSW" cannot detect OFF While the

mechanism is in operation.

Probable cause....... Mechanism is in operation when this

message appears: Defective or poorly

connected CAM-SW. Mechanism stops:

Defective or poorly connected motor or

solenoid.

Action ...................... Solve the problem and turn on the power

again.

– 17 –

XL-70/70C

NOTES ON SCHEMA TIC DIAGRAM

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means micro-micro-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/withstand

voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

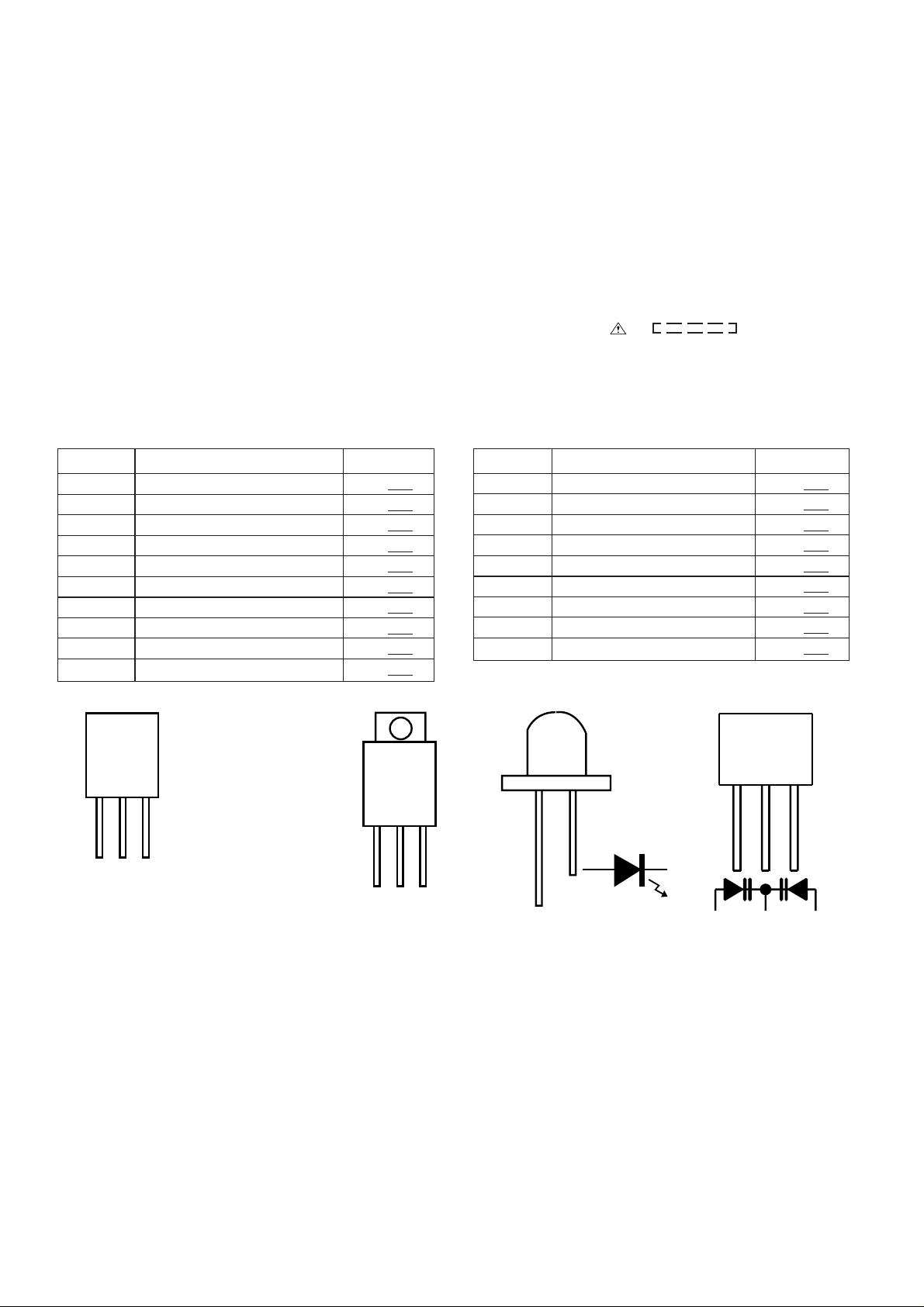

REF. NO DESCRIPTION POSITION POSITIONREF. NO DESCRIPTION

NSW801 PICKUP IN ON—OFF

SW700 JOG ON—OFF

SW709 ON/STAND-BY ON—OFF

SW710 CLOCK/TIMER/SLEEP ON—OFF

SW711 TUNING UP ON—OFF

SW712 PLAY/CD PAUSE ON—OFF

SW713 VOLUME SELECT ON—OFF

SW721 MEMORY/SET ON—OFF

SW722 BASS/TREBLE ON—OFF

SW723 BAND ON—OFF

• The indicated voltage in each section is the one measured

by Digital Multimeter between such a section and the chassis with no signal given.

1. In the tuner section,

( ) indicates AM

< > indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

SW724 REC. PAUSE ON—OFF

SW725 STOP/CLEAR ON—OFF

SW726 TUNING DOWN ON—OFF

SW727 FUNCTION ON—OFF

SW728 VOLUME JOG ON—OFF

SW730 CD LID OPEN/CLOSE ON—OFF

SW802 CD LID ON—OFF

SW901 FOOL PROOF ON—OFF

SW902 CAM ON—OFF

FRONT

VIEW

ECB

(S)(G)(D)

(1) (2) (3)

2SB562 C

2SC2001 K

2SC535 C

2SD468 C

KRA102 M

KRC102 M

KRC104 M

KRC107 M

KTA1266 GR

KTC3199 GR

FRONT

VIEW

BCE

2SD2012 Y

Figure 18 TYPES OF TRANSISTOR AND LED

MPG3372X

HY2043

FRONT

VIEW

1 2 3

SVC348S

KDV147B

– 18 –

Loading...

Loading...