Sony XAV-7W Service Manual

XAV-7W

SERVICE MANUAL

Ver 1.0 2002.04

The XAV-7W is composed of the following models.

Media Center XAV-7W

Connection Box XA-114

Wireless Remote Commander RM-X118

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

22 watts per channel minimum continuous average power into 4 ohms, 4 channels driven from

20 Hz to 20 kHz with no more than 5 % total harmonic distortion.

US Model

E Model

Media center/FM/AM receiver

Monitor section

Display type Wide LCD color monitor

Size 7 in.

System TFT active matrix

Number of pixel

336,960 pixels

Tuner section

FM

Tuning range

87.5 - 107.9 MHz

Intermediate frequency

10.7 MHz

Usable sensitivity

8 dBf

Frequency response

30 - 15,000 Hz

Selectivity 75 dB (400 kHz)

S/N ratio 66 dB (stereo)

72 dB (mono)

Harmonic distortion at 1 kHz

0.6% (stereo)

0.3% (mono)

Separation 35 dB at 1 kHz

AM

Tuning range

530 - 1,710 kHz

Intermediate frequency

10.7 MHz/450 kHz

Usable sensitivity

30 µV

Amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance

4 - 8 ohms

Maximum power output

45 W × 4 (into 4 ohms, at 1 kHz)

General

Power requirements

12 V DC, from car battery (negative

ground)

Inputs FM/AM antenna (1)

Power supply (1)

Telephone ATT control lead (1)

Illumination control lead (1)

Remote control input connector (1)

MEDIA CENTER FM/AM RECEIVER

Outputs Front audio (1)

I/O connector

Tone controls

Loudness +8 dB at 100 Hz

Dimensions With monitor closed

Mass Approx. 1.7 kg (3 lb 12 oz)

Supplied accessories

Rear audio (1)

Subwoofer (mono)

Power antenna relay control lead (1)

Power amplifier control lead (1)

Dedicated 22-pin connector

Bass ±7.5 dB at 100 Hz

Treble ±7.5 dB at 10 kHz

+2 dB at 10 kHz

Approx. 178 × 50 × 185 mm (7

3

2 × 7

/

8

in.) (W × H × D)

Card remote commander RM-X118

(1) (incl. 1 lithium battery)

Connection box (1)

Parts for installation and

connections (1 set)

Operating Instructions (1 set)

– Continued on next page –

1

/

8

×

9-873-928-01 Sony Corporation

2002D0500-1 e Vehicle Company

C 2002.04 Published by Sony Engineering Corporation

XAV-7W

Connection box

Inputs Vid eo/audio

Outputs Vid eo/audio (1)

Connection to main unit

Dimensions Approx. 136 × 77 × 30 mm (5

Mass Approx. 260 g (9 oz)

Design and specifications are subject to

change without notice.

(Sony bus compatible, 1)

BUS control input connector (1)

Vid eo/audio (2)

Dedicated 22-pin connector

1

3

3

/

8

× 1

/

16

in.) (W × H × D)

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 5

3. DISASSEMBLY

3

/

8

×

3-1. Disassembly Flow ........................................................... 9

3-2. Front Panel Assy ............................................................. 9

3-3. Case (Upper) Assy .......................................................... 10

3-4. MAIN Board ................................................................... 11

3-5. Motor Assy (M701)......................................................... 12

3-6. Setting of Lead from Motor Assy (M701) ..................... 12

3-7. Monitor............................................................................ 13

3-8. Monitor (F)/(R) Cabinet Assy......................................... 13

3-9. LCD ................................................................................. 14

3-10. MONITOR Board ........................................................... 14

4. ASSEMBLY

4-1. Assembly of Flat Cable................................................... 15

5. ELECTRICAL ADJUSTMENTS......................... 16

6. DIAGRAMS

6-1. Block Diagram – MAIN Section – ................................ 21

6-2. Block Diagram

– DISPLAY/BUS CONTROL Section – ........................ 22

6-3. Block Diagram – MONITOR Section – ........................ 23

6-4. Block Diagram – POWER SUPPLY Section – ............. 24

6-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 25

6-6. Schematic Diagram – FM/MAIN (1/5) Boards – ......... 27

6-7. Schematic Diagram – MAIN Board (2/5) – .................. 28

6-8. Schematic Diagram – MAIN Board (3/5) – .................. 29

6-9. Schematic Diagram – MAIN Board (4/5) – .................. 30

6-10. Schematic Diagram – MAIN (5/5)/SYNC Boards – .... 31

6-11. Printed Wiring Boards

– MAIN (Component Side)/SYNC Boards –................. 32

6-12. Printed Wiring Boards

– FM/MAIN (Conductor Side) Boards – ....................... 33

6-13. Printed Wiring Board – FRONT Board –...................... 34

6-14. Schematic Diagram – FRONT Board –......................... 35

6-15. Printed Wiring Board

– MONITOR Board (Component Side) – ...................... 36

6-16. Printed Wiring Board

– MONITOR Board (Conductor Side) – ........................ 37

6-17. Schematic Diagram – MONITOR Board (1/3) – .......... 38

6-18. Schematic Diagram – MONITOR Board (2/3) – .......... 39

6-19. Schematic Diagram – MONITOR Board (3/3) – .......... 40

6-20. Printed Wiring Boards – ANGLE/KEY Boards – ......... 42

6-21. Schematic Diagram – ANGLE/KEY Boards – ............. 43

6-22. Printed Wiring Board – MOTOR Board –..................... 44

6-23. Schematic Diagram – MOTOR Board – ....................... 45

6-24. Printed Wiring Boards – PULSE/SWITCH Boards –... 46

6-25. Schematic Diagram – PULSE/SWITCH Boards – ........ 46

6-26. IC Pin Function Description ........................................... 52

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

2

7. EXPLODED VIEWS

7-1. Front Panel Section ......................................................... 61

7-2. Case (Upper) Assy Section ............................................. 62

7-3. Open Close Motor Section.............................................. 63

7-4. Case (Lower) Assy Section ............................................. 64

7-5. Monitor Section............................................................... 65

8. ELECTRICAL PARTS LIST ............................... 66

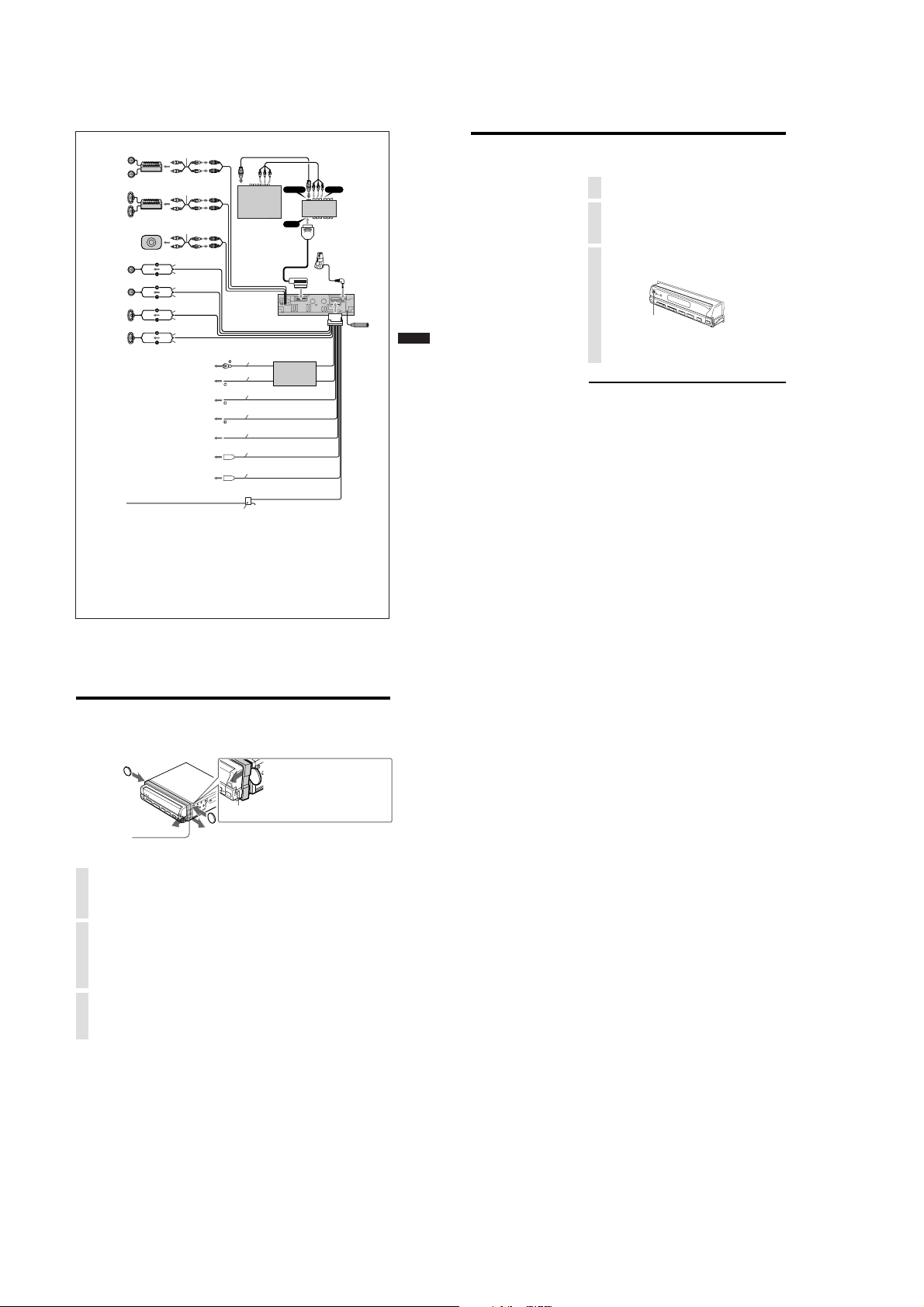

SECTION 1

SERVICING NOTES

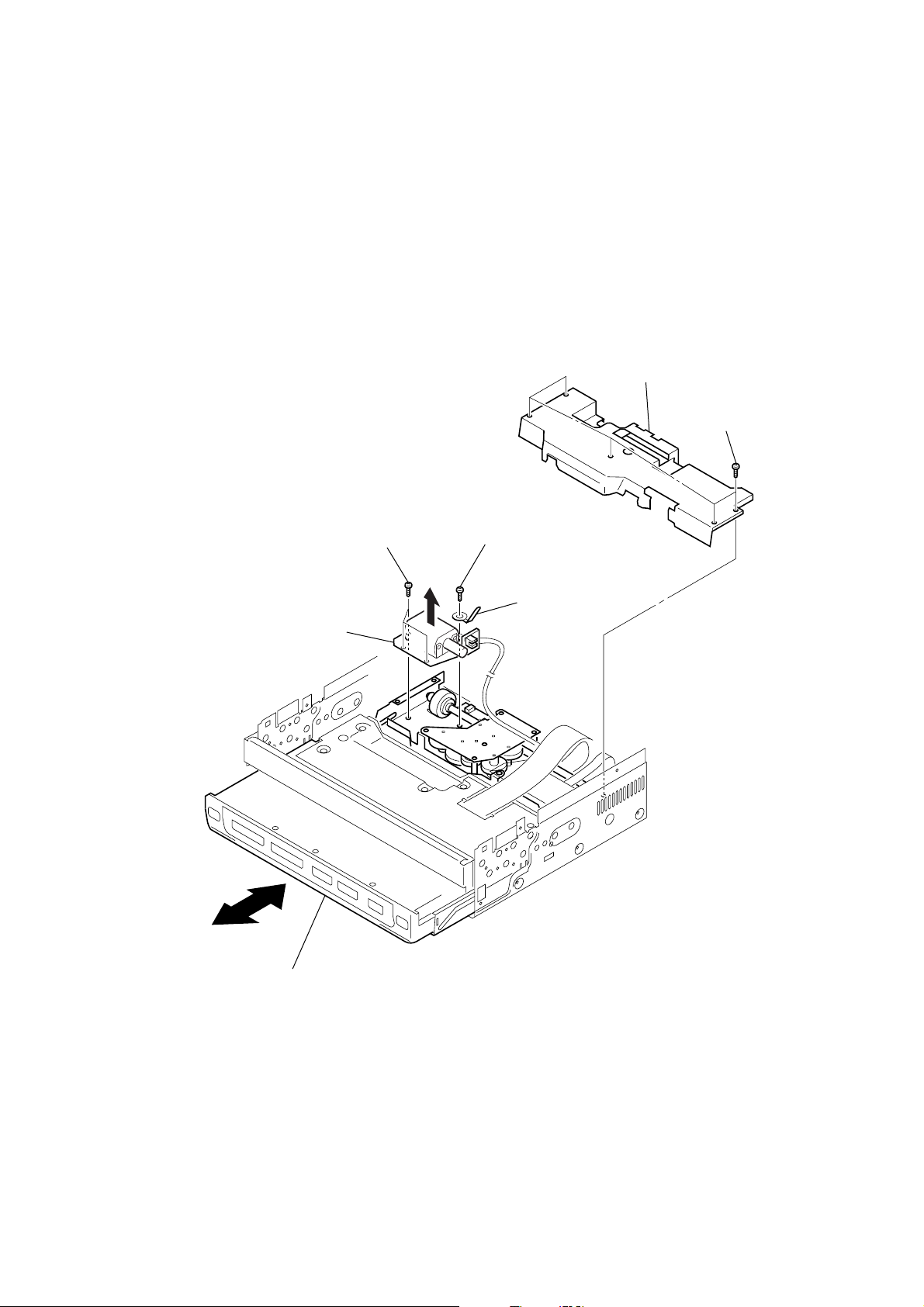

OPENING AND CLOSING OF THE MONITOR IN

AN ELECTRIC INTERRUPTION STATE

In the state of electric interruption, if a monitor is opened and

closed by force, it will became the cause of failure.

Please open and close a monitor at the time of repair after the

following procedure decomposes and removing a motor.

1) Front Panel Assy (Disassembly page 9)

2) Case (Upper) Assy (Disassembly page 10)

3) Motor Assy (Monitor Open/Close) (M701)

Note: Follow the disassembly procedure in the numerical order given.

2

cover

XAV-7W

1

five screws (M2 × 2.3)

3

three screws (M2 × 2.3)

motor assy (monitor open/close) (M701)

6

Open and close a monitor after lifting

a motor assy (monitor open/close) (M701).

5

3

screw (M2 × 2.3)

4

lug

3

XAV-7W

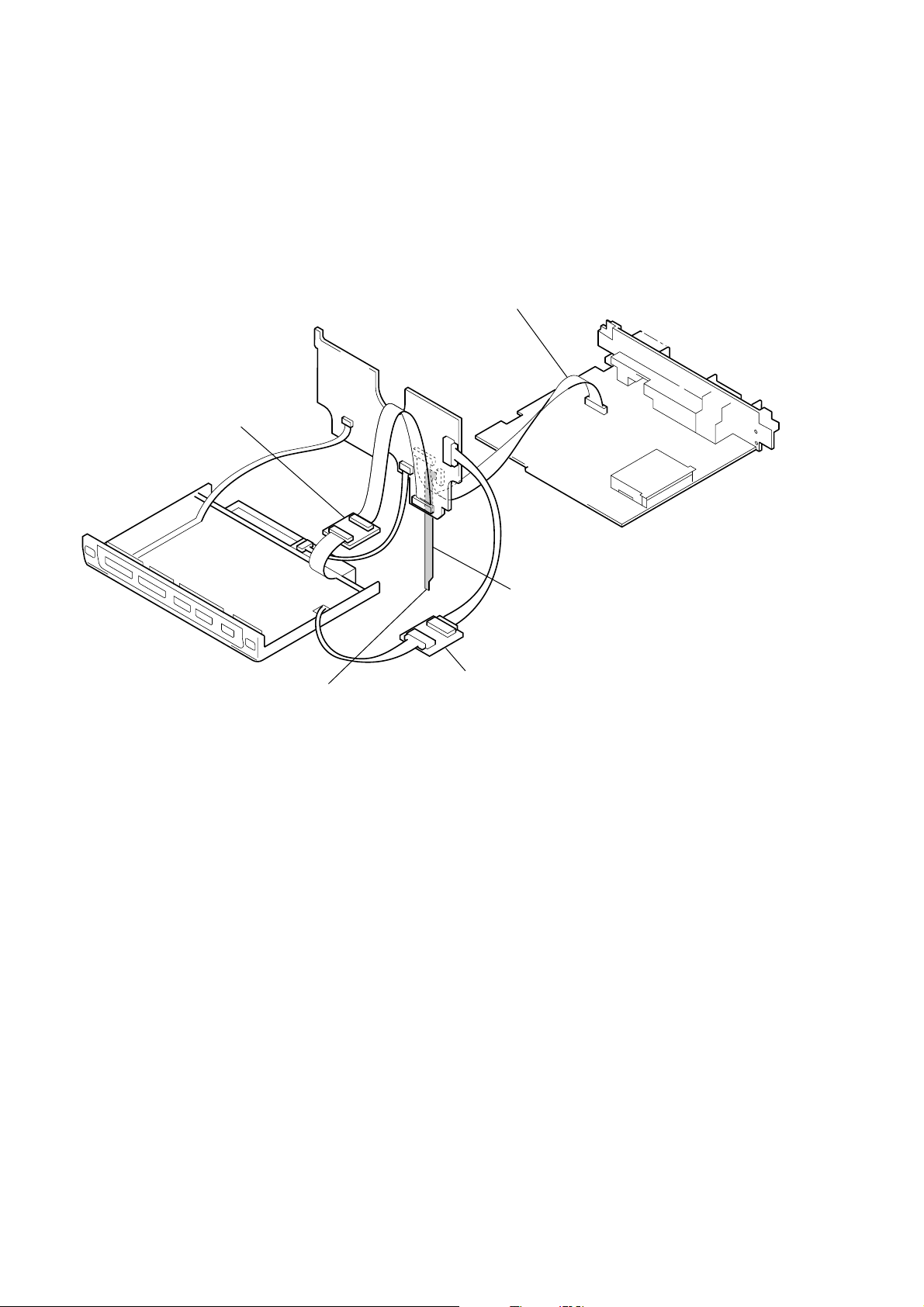

JIG ON REPAIRING

When repairing this set, etc., connect the extension cable as the figure shown below.

extension cable

(main board – monitor board)

(Part No. J-2502-056-3)

extension cable

(LCD unit – monitor board)

(Part No. J-2502-051-1)

connect the earth

extension cable

(monitor board – monitor ground plate)

(Part No. J-2502-056-4)

extension cable

(7 inch monitor back light – monitor board)

(Part No. J-2502-051-3)

4

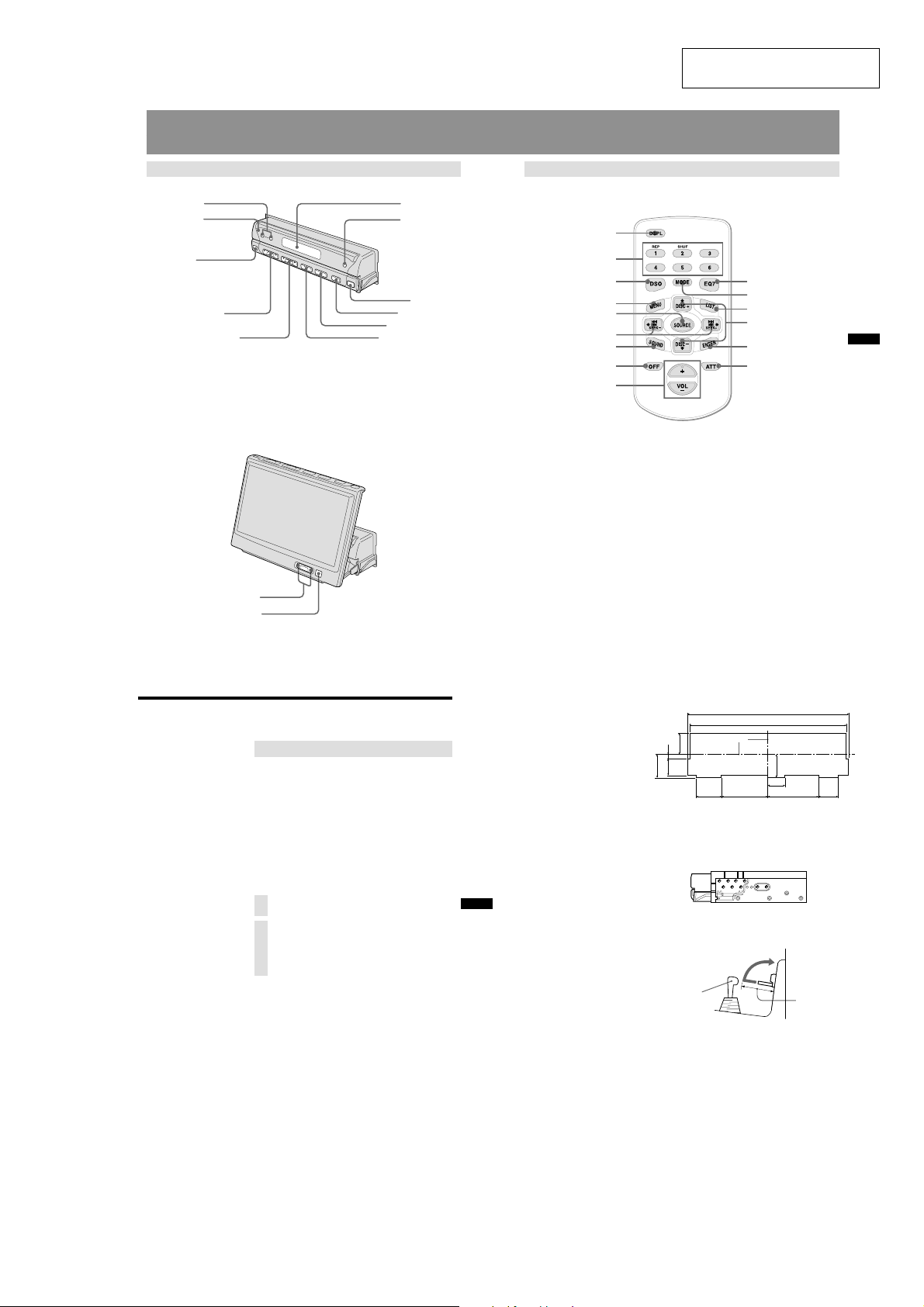

Location of Controls

Main unit

Monitor closed

1 DISC –/+ buttons

2 Reset button

3 Sensor for card remote commander

4 VOL (volume adjust) –/+ buttons

5 SEEK/AMS –/+ buttons

* Warning when installing in a car without an ACC (accessory) position on the ignition switch

Monitor opened up

1

2

6

7

3

4

5

6 Display window

7 OFF (Standby/Power off) button*

8 OPEN/CLOSE button

9 ATT button

0 MODE button

qa SOURCE (Power on/Radio/CD/MD/VIDEO or TV)

button

After turning off the ignition, be sure to press OFF on the unit for 2 seconds to turn off the clock display.

Otherwise, the clock display does not turn off and this causes battery drain.

9

0

qa

SECTION 2

GENERAL

8

XAV-7W

This section is extracted from

instruction manual.

Card remote commander

The unit can be operated with the card remote commander. For safety, stop the car before

using the card remote commander, or have a passenger operate it.

1

2

3

4

5

6

7

8

9

1 DSPL (display mode change) button

2 Number buttons

3 DSO button

4 MENU button

5 SOURCE (Power on/Radio/CD/MD/AUX) button

6 B/b SEEK/AMS –/+ buttons

7 SOUND button

8 OFF (Standby/Power off) button

9 VOL (volume adjust) +/– buttons

Note

If the unit is turned off by pressing OFF for 2 seconds, it cannot be operated with the card remote commander unless

SOURCE on the unit is pressed to activate the unit first.

Tip

See “Replacing the lithium battery” for details on how to replace the batteries (page 44).

0 EQ7 button

qa MODE button

qs LIST button

qd V/v DISC +/– buttons

qf ENTER button

qg ATT button

0

qa

qs

qd

qf

qg

1

2

1 ANGLE (monitor angle adjust) –/+ buttons

2 Sensor for card remote commander

8

1 Installing the Main Unit

Installation angle

The unit should be installed within an

angle of 25 degrees from horizontal. If

this angle is exceeded, the monitor may

not open up or retract properly.

Note

Keep the units and connection cables

apart.

The Media Center main unit and the

connection box 1 should not be in close

proximity.

Before installation

This unit is designed to be completely safe, but if not installed

correctly, it can cause accidents. Be sure to verify the following

points before installation.

Install the main unit to the in-dash location, and the connection

box under the navigator’s seat, etc.

• If the monitor in the opened position is close to a airconditioning outlet, the outlet should be closed.

• Install the unit so that the monitor when opened up will not

block access to the hazard switch or other important controls.

•Do not install the unit (monitor) in locations which may be

subject to excessively low or high temperatures. (Otherwise the

unit may be deformed and the LCD may be damaged.)

Exposure to direct sunlight can also lead to high temperatures

and should be avoided.

Selecting the installation location

Set the ignition key to OFF or remove it.

1

Place the units in their intended mounting

2

locations to check the cable length and monitor

installation conditions.

Note

If the installation dimensions shown at

right are not observed, the monitor may

not open up smoothly. If this happens,

check the installation once more and

modify the cluster panel where the

dimension requirements are not met. For

some car models, a separately available

mounting kit may be required.

(For details, please consult your dealer.)

Cluster panel dimensions

)

32

/

29

)

(

4

/

1

(

)

16

6.2

/

1

(1

25.5

17.3

Installation procedure precautions

• Perform the installation carefully. Dropping the unit or

otherwise subjecting it to strong impact or force may deform

the chassis, resulting in failure of the monitor loading

mechanism or other defects.

•To allow for proper opening and closing of the monitor, there

must be a clearance of at least 147 mm between the closest

position of the gear shift lever and the mounting surface for the

unit.

Gear shift lever

• In some cases, the gear shift lever may touch the monitor when

moved to a certain position. Make sure that there is no

obstruction to driving operations.

•When installing this unit together with other car audio

equipment (single DIN slot size) in a stacked configuration,

install the Media Center main unit on top.

Center line

22.5

)

16

/

11

(

33.6 44.7 55.7 20.6

3

(1

/8)

TT

N

(7)

175.4

3

(6

/4)

171

(1)

25

18

22

/32)

(

13

/16)

(1

T/N T/N

N

N

T

T/N

(2 1/4)

Unit: mm (inch)

At least 147 mm

7

(5

/8 in.) from

mounting surface

9

13

/16)

(

5

6

5

XAV-7W

Installation procedure

Mounting example

When installing this unit, be sure to close the monitor of the unit.

If the monitor is opened while installing and given too much

force, it may cause a malfunction.

182 mm (7

1

/

4

1

q;

inch)

53 mm (2 1/8 inch)

2

Bend these claws outward

for a tight fit, if necessary.

3

4

qa

7

6

9

6

9

9

6

Dashboard

q;

When removing front panel plate

Front panel

Do not throw away the front panel plate,

since it will be needed when you change

the car you install the unit.

For details, see “Removing the Front

Panel Plate”. (page 17).

Note

• Do not press the front panel buttons of

the unit during installation and do not

apply strong force.

• Do not place any objects on top of the

unit.

plate 4

Toyota cars (illustration shows an example for a Toyota car)

Align the brackets of the factory-installed car stereo with the

mounting holes marked “T” on the side of the Media Center main

unit, and use the supplied screws to fasten the brackets. For

Toyota cars, the supplied screws 6 should be used.

Nissan cars

Align the brackets of the factory-installed car stereo with the

mounting holes marked “N” on the side of the Media Center

main unit, and use the supplied pan-head screws 6 to fasten the

brackets.

* Be sure to use only the supplied pan-head screws 6 for

installation. If any other screws are used, make sure they

conform to the requirements shown below.

Using longer screws can cause internal damage to the unit.

Damage can also occur if the screws are used directly on the

unit without the brackets of the factory-installed car stereo.

6 mm

6

Screws of factoryinstalled car stereo

bracket

6

Screws of factoryinstalled car stereo

bracket

5 mm

Bracket of

factory-installed

car stereo

Bracket of

factory-installed

car stereo

Note

• Ensure that the mounting surface is

clean.

•Do not install the connection box

- in locations subject to high

temperatures

-in locations subject to direct sunlight,

warm air from heater outlets, or

other locations that can get hot.

•When attaching the hook-and-loop

fastener to the bottom of the connection

box, do not cover the model name plate

in the center.

Use of connectors

Insert until the connector clicks into

place. To remove, press here and pull out.

Installing the connection box XA-114

Cut off the required length of hook-and-loop fastener 8 and fix

the connection box 1 on the carpet or similar.

Hook-and-loop

fastener 8

On installation surface

Hook-and-loop

fastener 8

Hooking up the connection box

Refer also to the section “3 Car Systems Connections” (page 14 -

15).

Main unit/connection

box interconnect 3

To Media Center main unit

Insert 3 until a click is heard.

7

8

2 Main Unit Connections

Refer also to the section “3 Car Systems Connections”

Use of connectors

Insert until the connector clicks into

place. To remove, press here and pull

out.

Insert until the connector clicks into

place. To remove, press here and pull

out.

(page 14 - 15).

To connection

box

Main unit/

connection box

interconnect 3

Power supply leads 2

(for main unit)

Insert 3 until a click is heard.

9

10

6

Connection Example

For details, see the section “3 Car Systems Connections” (page 14 - 15). Be sure to refer also to the

documentation for all other components in the system.

Speaker connections

Front speakers

Media Center

main unit

SUB WOOFER

OUT(MONO)

Active subwoofer

(optional)

FRONT AUDIO

Media Center

main unit

SUB WOOFER

OUT(MONO)

Notes

•Be sure to connect the ground cord before connecting the amplifier.

• If you connect an optional power amplifier and do not use the built-in amplifier, the beep sound will be deactivated.

OUT

REAR AUDIO

OUT

Active subwoofer

(optional)

(optional)

Rear speakers

(optional)

Front speakers

(optional)

Rear speakers

(optional)

Connection of separately available accessories

Items except the main unit and the connection box are optionally available.

With Sony bus system TV tuner unit

CONTROL(IN)

INPUT

Monitor

REAR MONITOR OUTPUT

Media Center

main unit

CONTROL(OUT)

CONTROL

XAV

TV tuner unit

OUTPUT VIDEO IN

INPUT

Connection box

(supplied)

INPUT1/2

DVD changer (not

Sony bus compatible)

Without TV tuner unit

Media Center

main unit

CONTROL(OUT)

CONTROL

XAV

CD/MD changer, or

Source selector XAC30

OUTPUT VIDEO IN

INPUT

Connection box

(supplied)

INPUT1/2

CONTROL(IN)

INPUT

Monitor

REAR MONITOR OUTPUT

XAV-7W

CD/MD changer, or

Source selector XAC30

CD/MD changer

CD/MD Changer

Connecting Information

For details, see the section “3 Car Systems Connections” (next page).

Using the tap

Notes

•Be sure to connect the power input

cord after all other cords have been

connected.

• If the parking brake switch cord is too

thin, connect the parking cord to the

parking brake switch cord directly

without using the tap.

Attach and fix the tap securely as illustrated.

Tap 5

Connecting the parking cord

Be sure to connect the parking cord (Light green) to the parking

brake switch cord. The mounting position of the parking brake

switch cord depends on your car. Refer to the system connection

diagram below and consult your car dealer or your nearest Sony

dealer for further details.

Parking brake

warning light

Parking brake

switch cord

Body earth

Hand brake type

Parking brake switch

cord

Parking cord

(Light green)

Battery power

Tap 5

Parking cord

(Light green)

Media Center

main unit

Parking brake switch

Parking brake switch cord

Foot brake type

Parking brake switch cord

DVD changer (not

Tip

For connecting two or more CD/MD changers, the source selector XA-C30 (optional) is necessary.

11

12

Sony bus compatible)

3 Car Systems Connections

Refer also to the documentation for all other components in the system.

Also see “Connecting Information” on page 13.

•Components listed here except for supplied accessories are available separately. When connecting such

components, be sure to also refer to their documentation.

For specifications and other information on separately available components, contact your dealer.

Prevention of accidents caused by short-circuits

To prevent the risk of accidents caused by short-circuits, connect the power supply leads (red and yellow)

only after all other wiring has been completed, and only with the ignition key in the OFF position.

Otherwise, accidental short-circuiting can lead to electric shock and to serious damage.

When a fuse has blown, check the wiring and locate the cause of the problem before replacing the fuse.

When replacing the fuse, be sure to use only a fuse of the same rating (ampere rating). Using a different

fuse or bridging the contacts with wire is highly dangerous and can lead to serious damage.

Make sure to connect all of the following leads.

Otherwise there is a risk of electric shock, damage to the equipment, or malfunction.

•Connect light green lead to parking brake switch lead of car.

•Connect yellow lead to battery power supply of car.

•Connect red lead to accessory power supply of car.

•Connect black lead to metal point on car chassis.

* Do not to mix up the yellow and red leads, as this will cause the memory contents to be lost.

Observe the following precautions.

Otherwise there is a risk of electric shock, damage to the equipment, or malfunction.

•Cover unused connectors with electrician’s tape to prevent accidental contact.

• Route FM/AM antenna cable, bus cable, RCA interconnects, and power supply leads as far apart from

each other as possible, to prevent noise interference.

•Always grasp the connector and do not pull the cable when disconnecting the bus cable or other cables.

Otherwise the cable may become detached.

Note

Install the TV antennas away from the FM/AM antenna.

Notes on the control and power supply leads

• The power antenna control lead (blue) supplies +12 V DC when turn on the tuner.

•When your car has built-in FM/AM antenna in the rear/side glass, connect the power antenna control

lead (blue) or the accessory power input lead (red) to the power terminal of the existing antenna

booster. For details, consult your dealer.

•A power antenna without relay box cannot be used with this unit.

Memory hold connection

When the yellow power input lead is connected, power will always be supplied to the memory circuit

even when the ignition key is turned off.

Notes on speaker connection

• Before connecting the speakers, turn the unit off.

•Use speakers with an impedance of 4 to 8 ohms, and with adequate power handling capacities to avoid

its damage.

•Do not connect the speaker terminals to the car chassis, or connect the terminals of the right speakers

with those of the left speaker.

•Do not connect the ground lead of this unit to the negative (–) terminal of the speaker.

•Do not attempt to connect the speakers in parallel.

•Connect only passive speakers. Connecting active speakers (with built-in amplifiers) to the speaker

terminals may damage the unit.

•To avoid a malfunction, do not use the built-in speaker wires installed in your car if the unit shares a

common negative (–) lead for the right and left speakers.

•Do not connect the unit’s speaker cords to each other.

13

14

7

XAV-7W

RCA interconnects

Front speakers

(optional)

Rear speakers

(optional)

Active subwoofer

(optional)

Left

Front speakers

(optional)

Right

Left

Rear speakers

(optional)

Right

To a metal surface of the car

To the +12 V power terminal which is

energized at all times

To the +12 V power terminal which is

energized in the accessory position of

the ignition key switch

To a car’s illumination signal

To ATT (the interface cable of a car

telephone)

To AMP REMOTE IN of an optional

power amplifier

To the power antenna control lead or

power supply lead of antenna booster

amplifier

Parking brake switch lead of car

*1 Be sure to connect the black ground lead to it first.

*2 First connect the black ground lead, then connect the yellow and red power input leads.

*3 When your car has built-in FM/AM antenna in the rear/side glass, see “Notes on the control and power

supply leads” (previous page).

*4 This connection is only for amplifiers. Connecting any other system may damage the unit.

*5 It is not necessary to connect this lead if there is no power antenna or antenna booster, or with a manually-

operated telescopic antenna.

Note on the accessory power input lead (red)

If there is no accessory position, connect to the +12 V power (battery) terminal which is energized at all times.

(optional)

RCA interconnects

(optional)

RCA interconnects

(optional)

White

White/black

Gray

Gray/black

Green

Green/black

Purple

Purple/black

*2

*1

*1*3

*1

*4

*3*5

Bus cable (5.3 m) (supplied with XT-63V)

CONTROL

Blue (0.25 m)

XAV

Media Center

main unit

Fuse (10 A)

Light green (2 m)

TV tuner unit

XT-63V

(optional)

Black (0.45 m)

Yellow (0.25 m)

Red (0.25 m)

Orange/white (0.25 m)

Light blue (0.25 m)

Blue/white (0.25 m)

Max. supply current 0.3 A

Max. supply current 0.1 A

Tap 5

RCA interconnects

(5.3 m) (supplied

with XT-63V)

INPUT

Connection

box 1

Main unit/

connection box

interconnect 3

Rotary

Commander

RM-X4S

(optional)

From car

antenna

Power

supply leads

2 (for main

unit)

4 After Installation and Connections

Start the car’s engine.

1

Verify that the brake lights, other lights, horn, turn

2

indicators, and all other electrical parts operate

Note

To avoid the possibility of damage, you

should not use a needle or push the

button too strongly.

normally.

Use a ball-point pen or similar to push the Reset

3

button on the unit.

Reset button

When you press the Reset button, the system becomes

operative.

Warning when installing in a car without ACC

(accessory) position on the ignition key switch

Be sure to press and hold OFF on the unit for more than two

seconds to turn off the clock display after turning off the

engine.

When you press OFF only momentarily, the clock display does

not turn off and this causes battery wear.

Removing the Front Panel Plate

To remove the front panel plate from the unit,

use the following procedure.

Be careful not to pull off the plastic parts.

Front panel plate

Plaque de panneau

avant

Pull the lower side of the front

1

panel plate forward (arrow A), to

open a gap between the front panel

plate and the body of the unit.

Insert a coin or similar thin item in

2

this gap, and twist to remove the

front panel plate.

Be careful not to damage the unit.

Remove in the order left-to-right.

Spreading the lower side of the

3

front panel plate outward (arrow

B), detach the plate from the body.

Note

Be careful not to pull off the plastic parts attached to the

lower side of the unit together with the front panel plate.

BA

Insert a coin and twist to remove

the front panel plate.

15

16

17

8

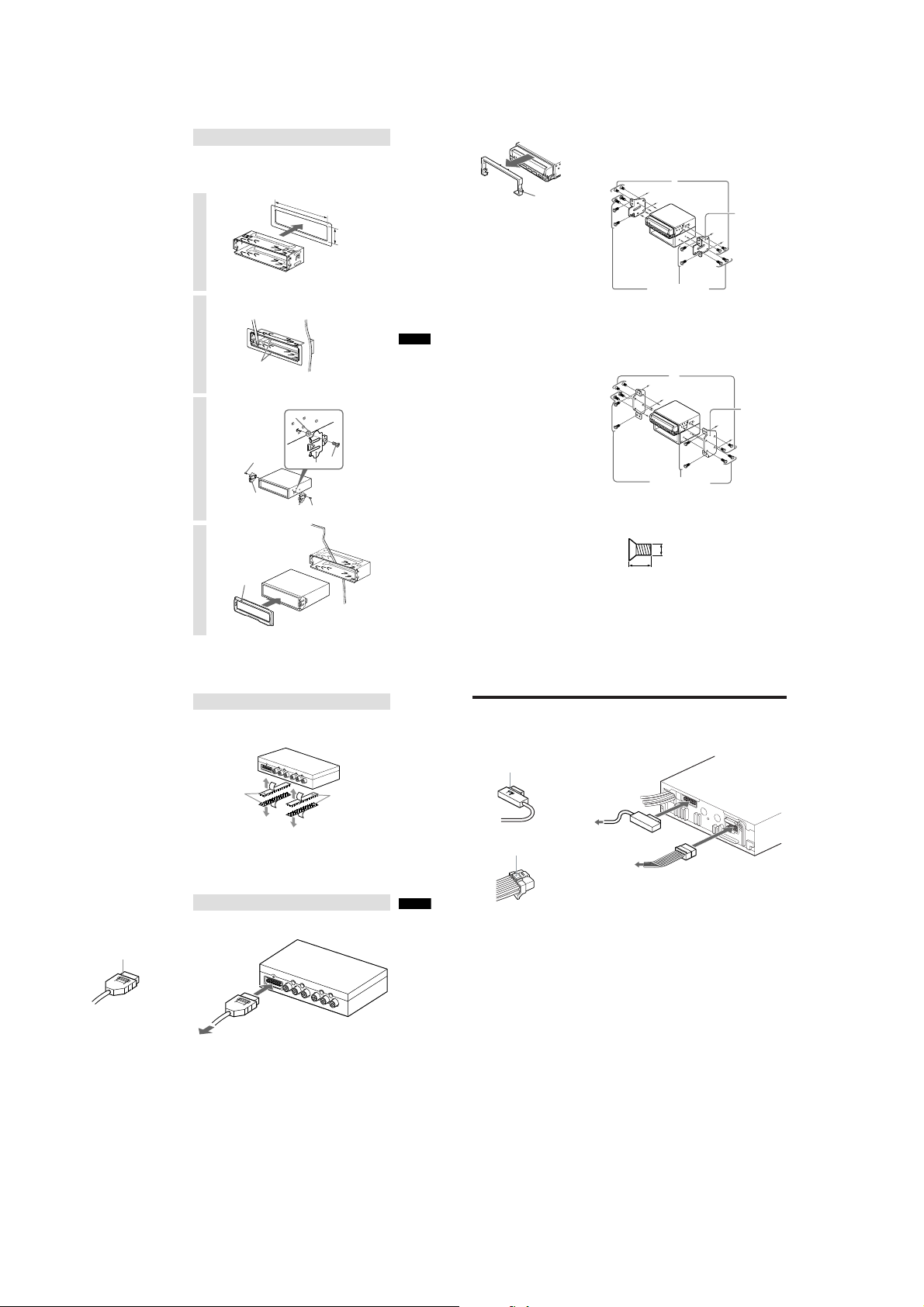

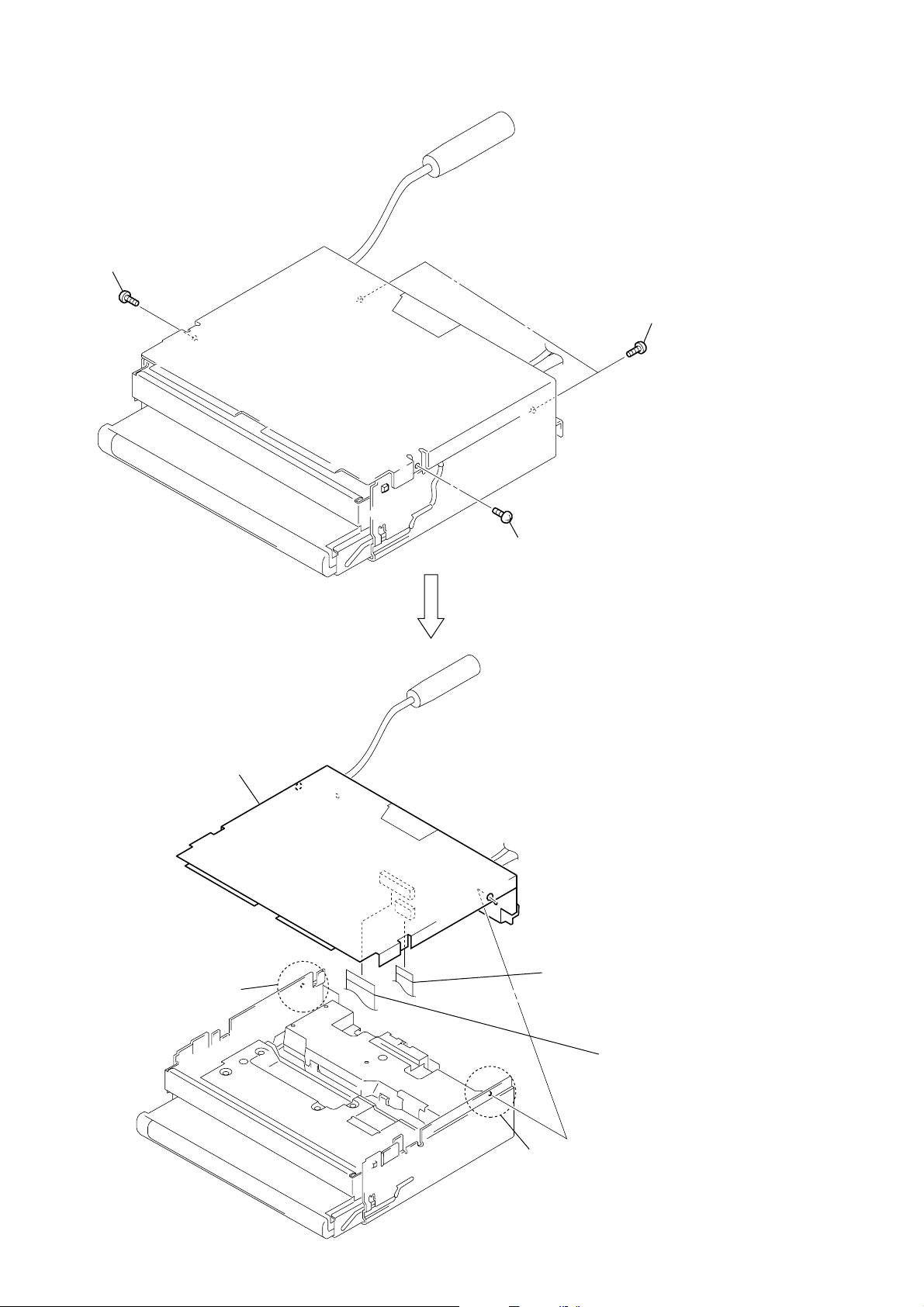

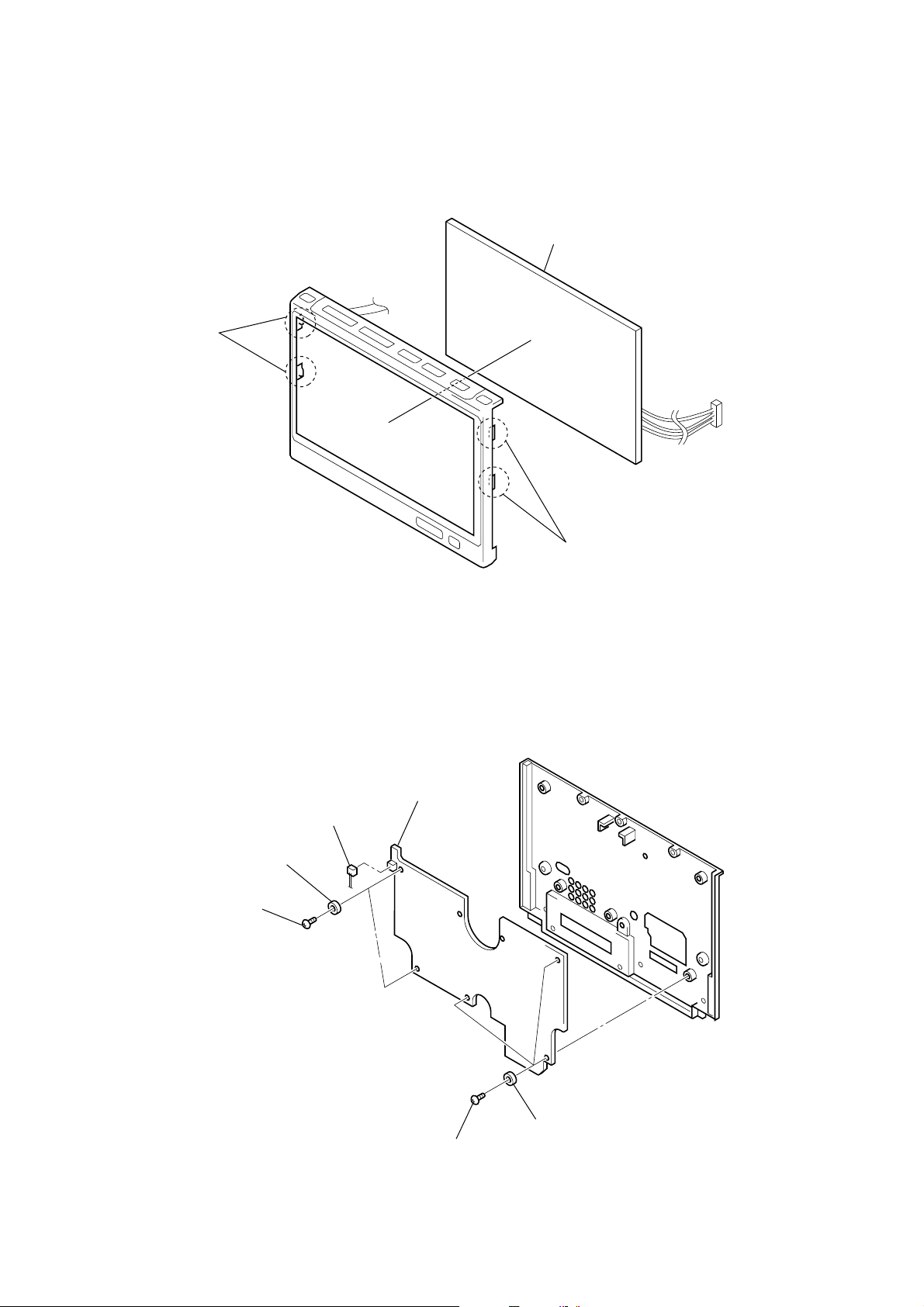

3-2. FRONT PANEL ASSY

(Page 9)

3-3. CASE (UPPER) ASSY

(Page 10)

3-4. MAIN BOARD

(Page 11)

3-5. MOTOR ASSY (M701)

(Page 12)

3-6. SETTING OF LEAD FROM MOTOR ASSY (M701)

(Page 12)

3-7. MONITOR

(Page 13)

3-8. MONITOR (F)/(R) CABINET ASSY

(Page 13)

3-9. LCD

(Page 14)

3-10. MONITOR BOARD

(Page 14)

SET

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

XAV-7W

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

3-2. FRONT PANEL ASSY

4

connector (CN770)

3

claw

5

front panel assy

1

2

9

XAV-7W

)

)

3-3. CASE (UPPER) ASSY

1

screw (PTT2.6 × 10)

2

two screws (PTT2.6 × 10

8

case (upper) assy

3

boss

1

screw (PTT2.6 × 10)

4

flat cable 16P (CN15)

10

3

boss

4

flat cable 40P (CN14

3-4. MAIN BOARD

)

2

four screws (PTT2.6 × 5)

XAV-7W

3

1

two screws (PTT2.6 × 5)

6

five screws (PTT2.6 × 10

8

main board

3

connector (CN3)

4

connector (CN20)

7

heatsink

11

XAV-7W

P

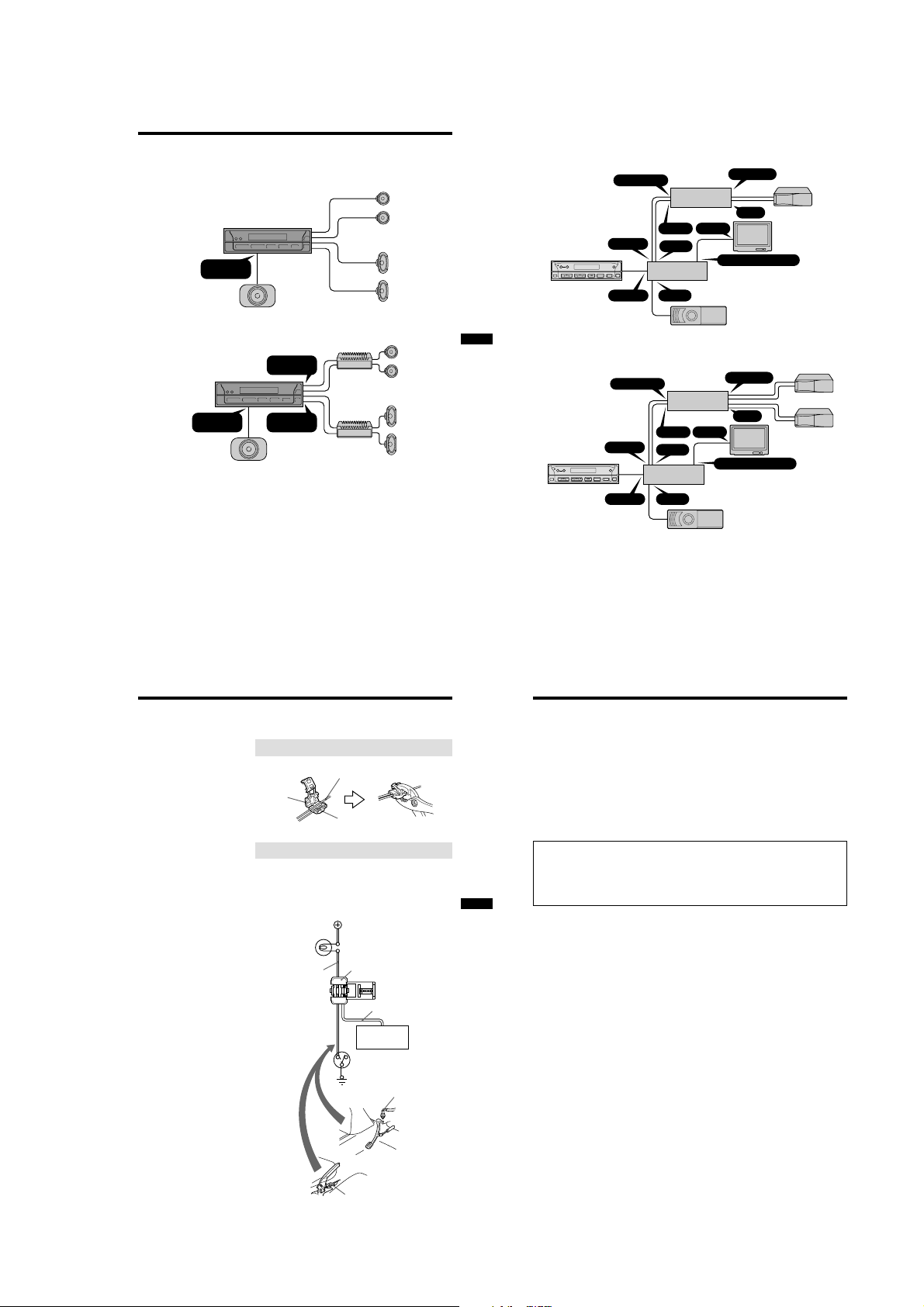

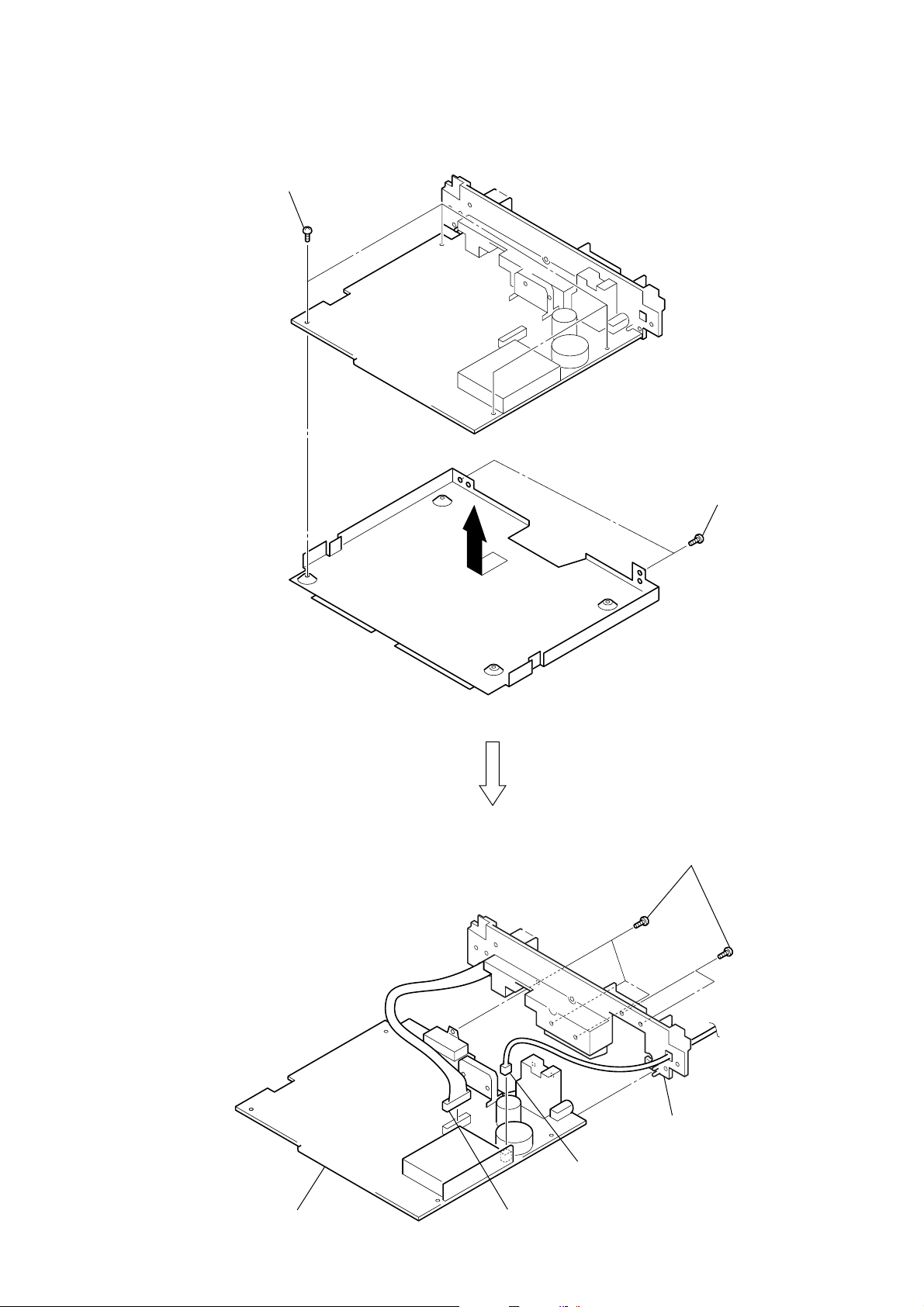

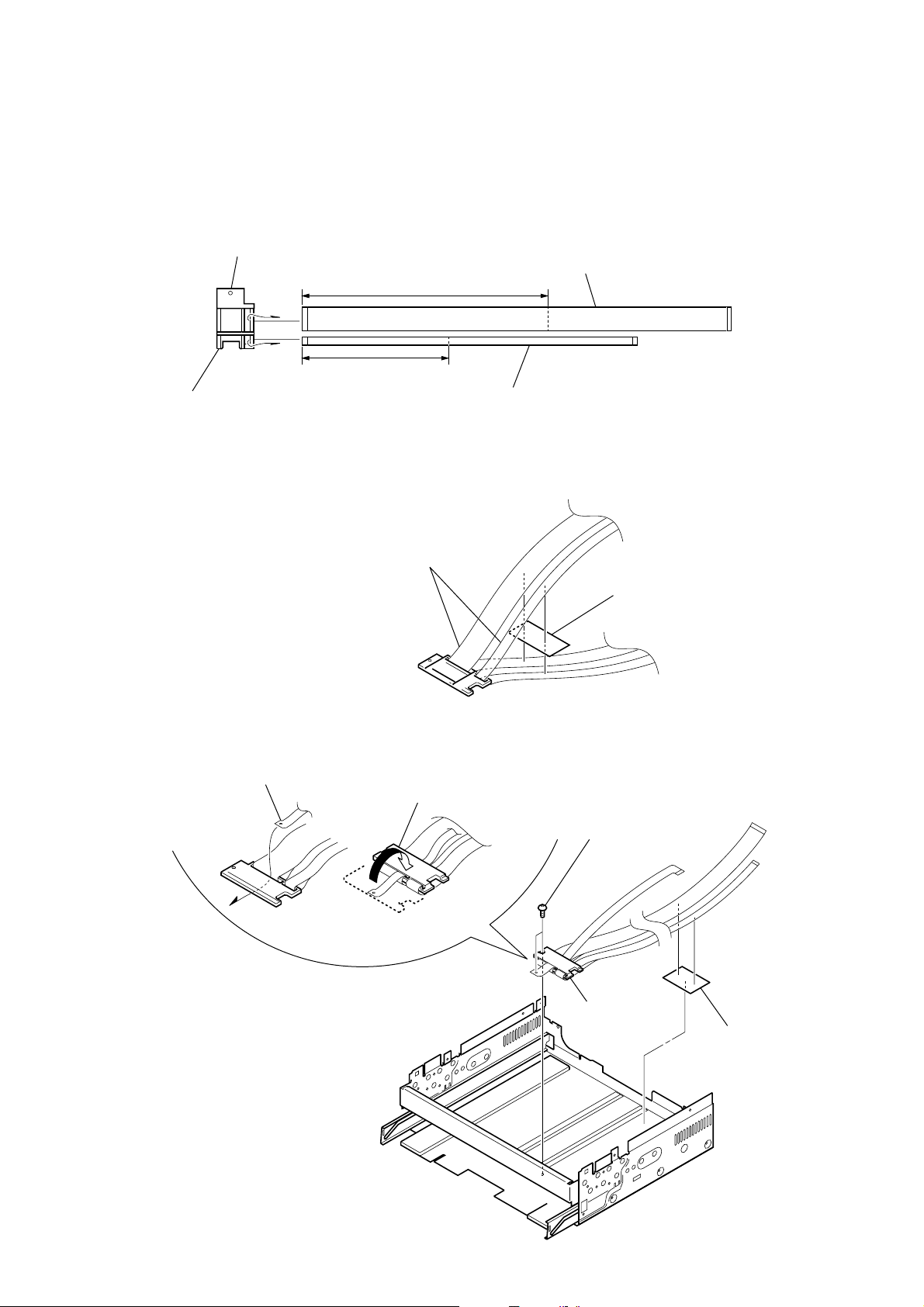

3-5. MOTOR ASSY (M701)

qh

motor assy (M701)

9

three screws

(M2

×

2.3)

qa

motor bracket

qg

two screws

(M2

×

2.3)

qd

connector

(CN780)

9

screw (M2 × 2.3)

0

lug

qf

pulse board

qs

3

two screws (M2 × 4)

7

screw

(M2

×

4)

screw

(M2

×

2.3)

5

connector

(CN790)

4

insulating

sheet (2)

8

2

cover

motor board

1

five screws

(M2

6

flat cable 16

(CN700)

×

2.3)

3-6. SETTING OF LEAD FROM MOTOR ASSY (M701)

lead

lug

plate (gear)

line

switch board

Note: Crawl on a lead from CN790 along

with a switch board, and rises perpendicularly

and sticks according to the line of a plate (gear).

CN790

Note: Fixed a lead from motor assy (M701)

by the lug.

lead from motor assy (M701)

motor assy (M701)

12

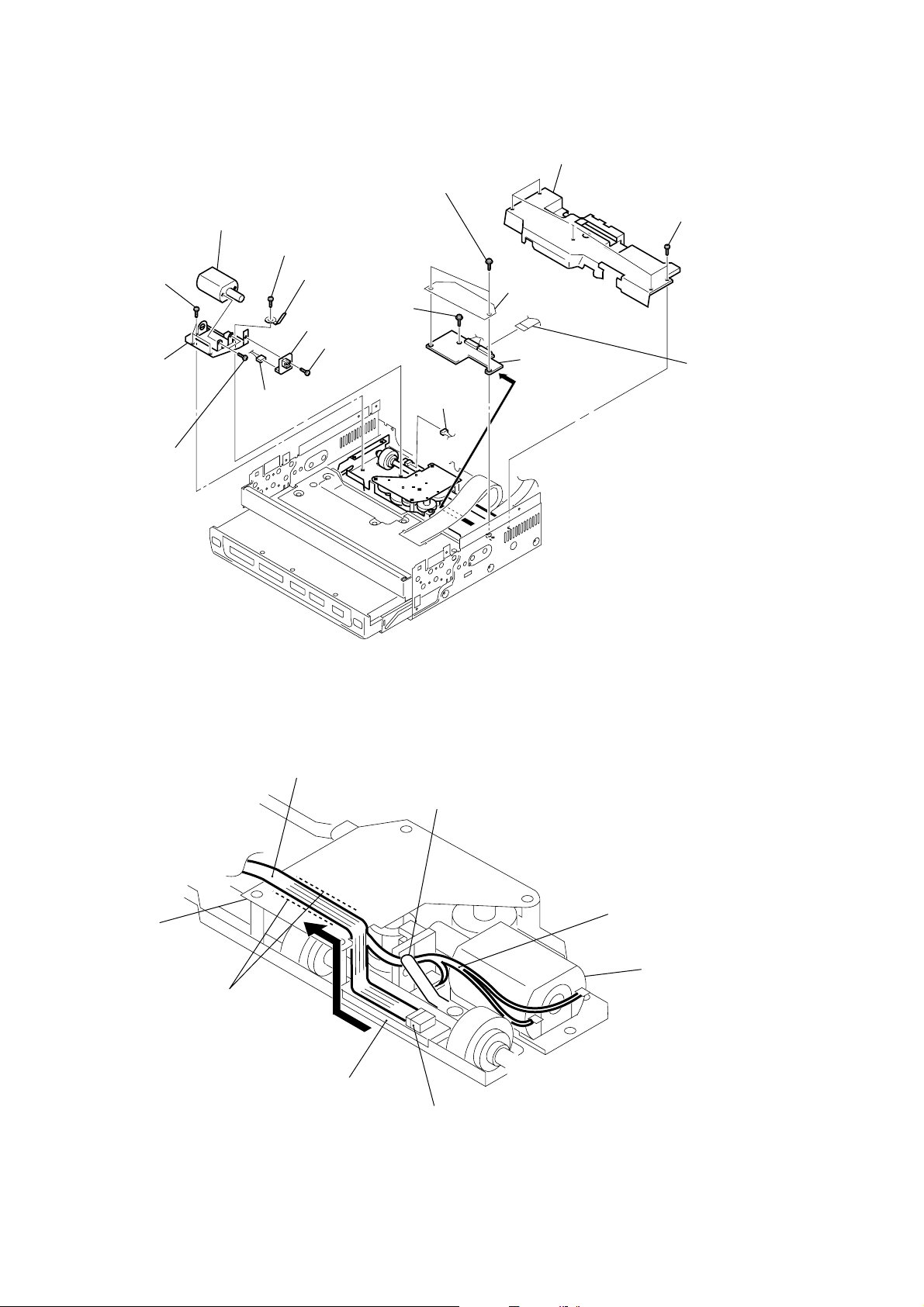

3-7. MONITOR

5

monitor

3

flat 40P cable (CN201)

2

six screws (BTP2.6 × 6)

4

ground sheet (A) (CN202)

XAV-7W

1

Pull the monitor.

3-8. MONITOR (F)/(R) CABINET ASSY

5

flat cable 10P (CN202)

4

two claws

0

monitor (R) cabinet assy

1

three screws (2 × 6)

8

connector (CN601)

2

three screws (2 × 6)

9

monitor (F) cabinet assy

3

two claws

6

flexible board (CN401)

7

connector (CN205)

13

XAV-7W

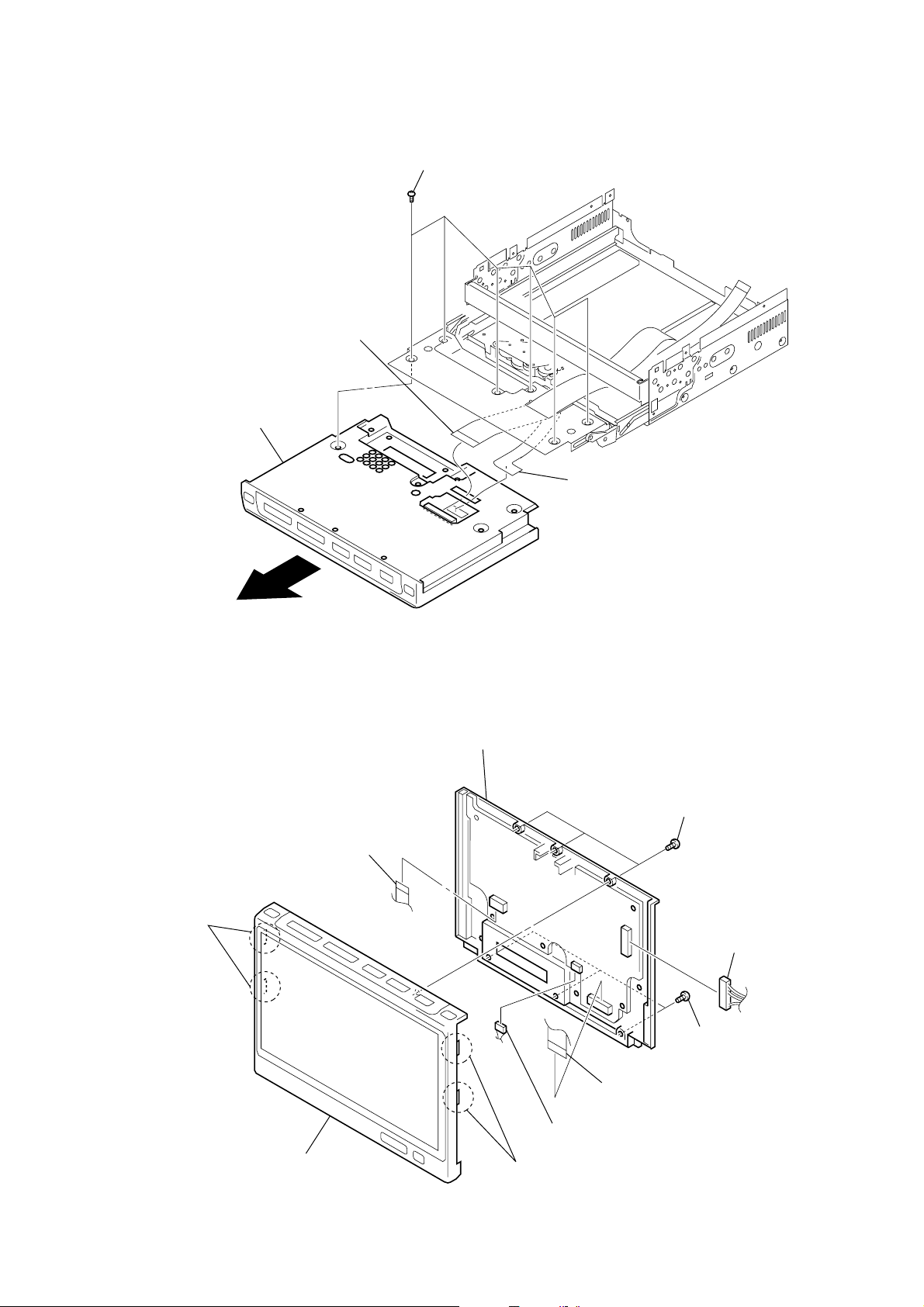

3-9. LCD

1

two claws

2

LCD

3-10. MONITOR BOARD

3

two PCB retainers

2

two screws (2 × 6)

1

connector (CN301)

4

monitor board

1

two claws

14

2

three screws (2 × 6)

3

three PCB retainers

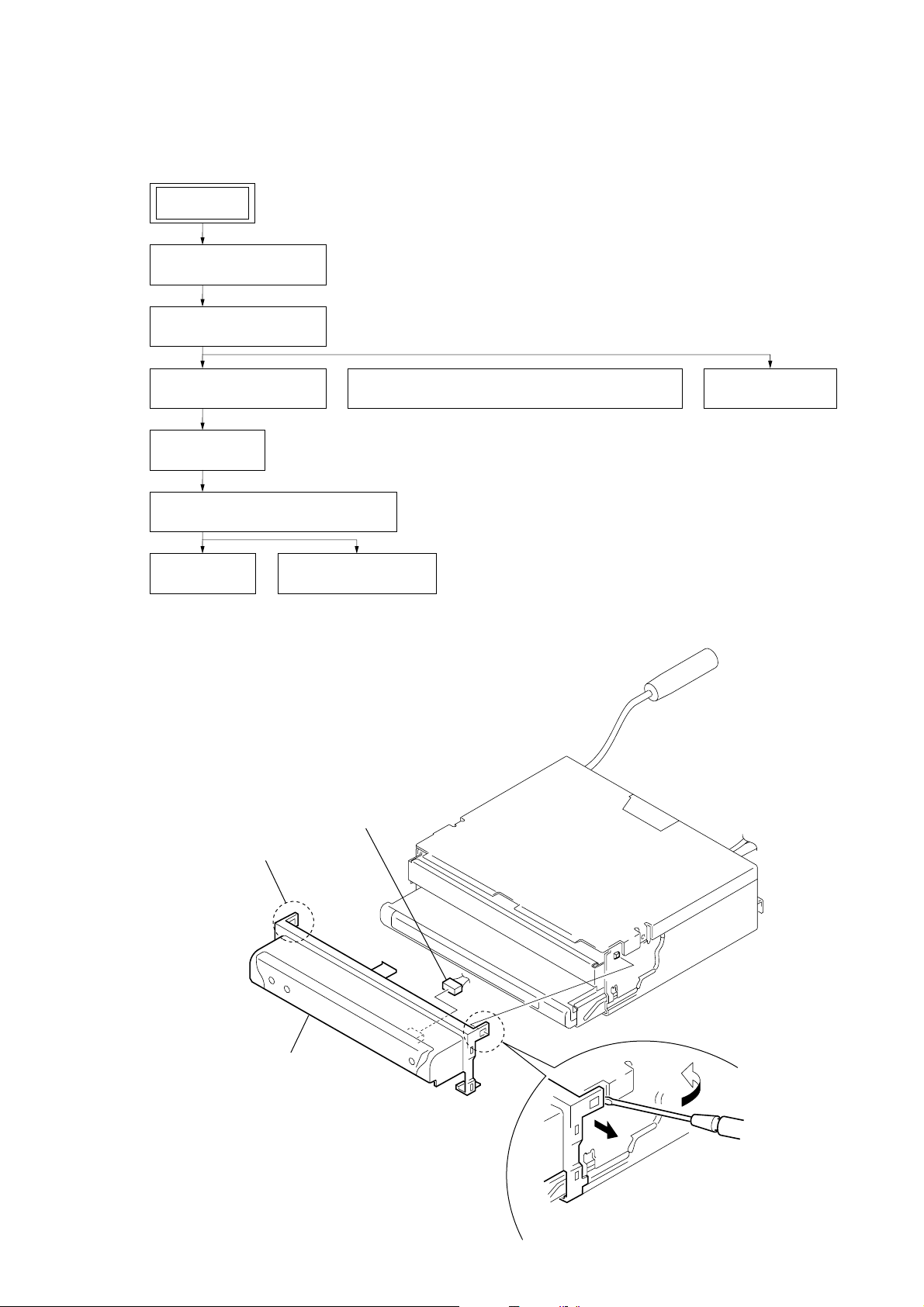

SECTION 4

)

Note: Follow the assembly procedure in the numerical order given.

4-1. ASSEMBLY OF FLAT CABLE

flexible retainer

250

150

3

It lets flat cables pass

in two holes of flexible retainer.

ASSEMBLY

1

2

flat cable 16P

Note: Turn the point-of-contact side up, bend to

XAV-7W

flat cable 40P

Note: Turn the point-of-contact side up, bend to

a valley type in a 250 mm portion,

and make a crease.

a valley type in a 150 mm portion,

and make a crease.

4

5

Pass the ground sheet (A) as

shown in a figure.

Two cables are turned up

in a fold portion and

stuck with a sheet (tape).

6

Bent a flexible retainer

as shown in a figure.

sheet (tape

8

two screws

(M2

×

2.3)

7

flexible retainer

9

sheet (tape)

15

XAV-7W

)

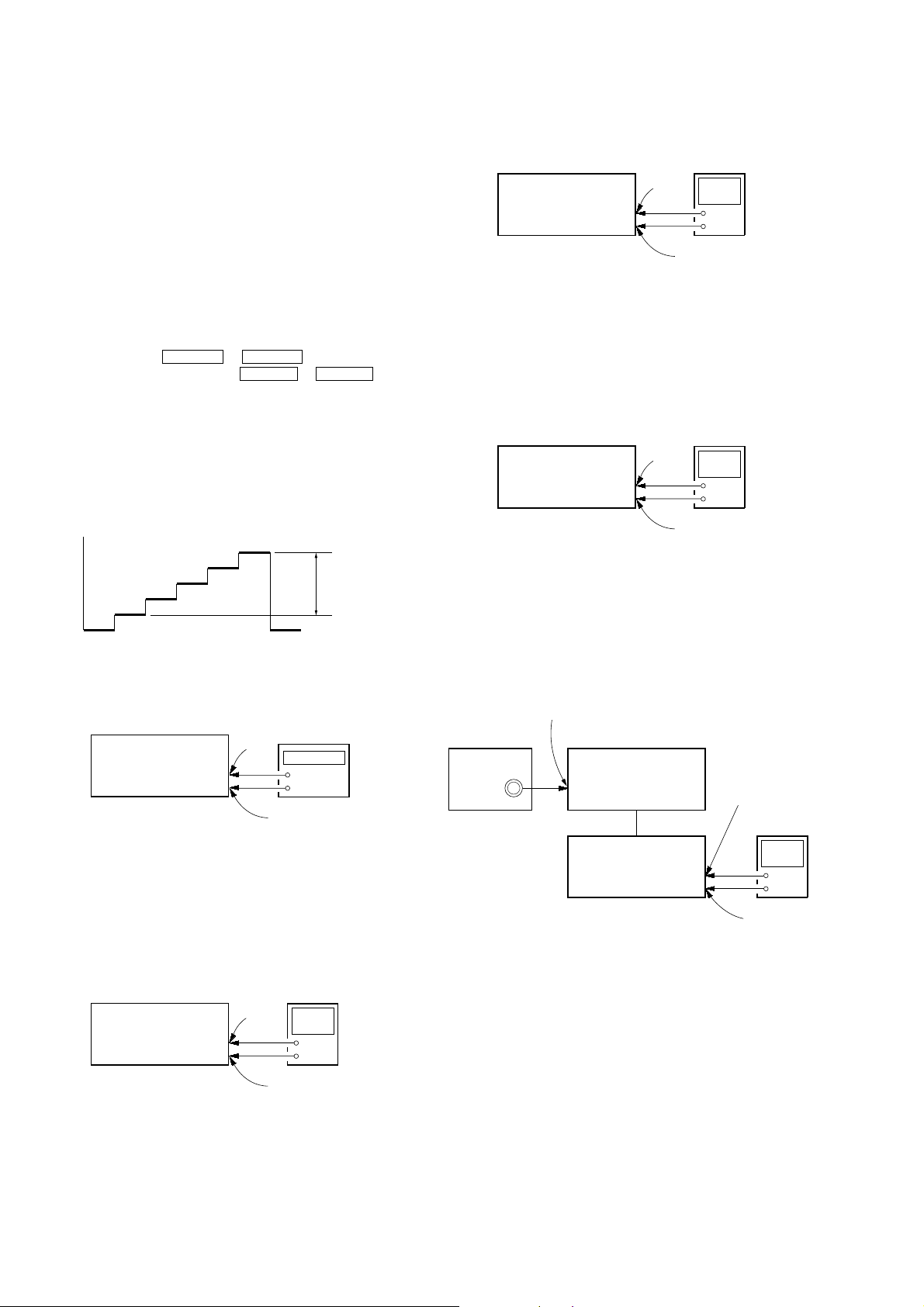

SECTION 5

ELECTRICAL ADJUSTMENTS

EQUIPMENT USED

Use the following measuring equipment for the electrical

adjustment.

• Set (XAV-7W)

• Connection box (XA-114)

• NTSC/PAL pattern generator

• Oscilloscope

• Frequency counter

• Digital voltmeter

• Regulated power supply

SETUP FOR ADJUSTMENT

1. Open the monitor , and press the [MENU] b utton on the wireless

remote commander (RM-X118), and select the “MONITOR

TUNE” with the M DISC + or

the “COLOR”, “HUE” with the M DISC + or

and set the COLOR and HUE to the standard setting by pressing

the [ENTER] button for more than 2 seconds respectively.

2. For the monitor adjustment, use the 5-step gray scale signal

(chroma off) obtained from the pattern generator. Enter the

gray scale signal to the connection box (XA-114) and connect

an oscilloscope to the TP154 on the MONITOR board. Check

that the voltage between black and white of the gray scale signal

is 0.74Vp-p.

m

DISC – button. Then, select

m

DISC – button,

white

0.74Vp-p

black

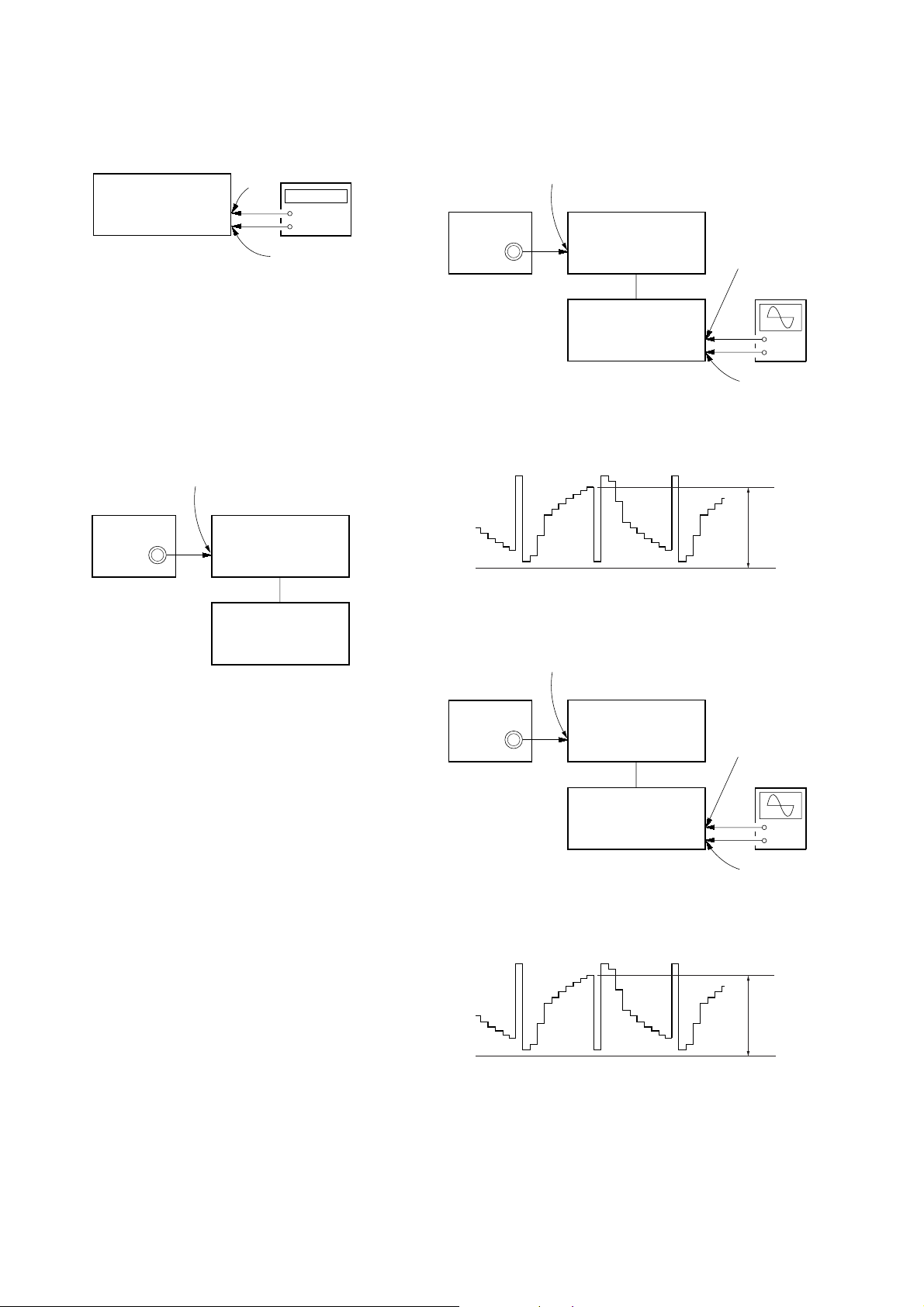

7.5V ADJUSTMENT

Connection:

TP58

set

(XAV-7W)

Adjusting Procedure:

1. Connect a digital voltmeter to the TP58 on the MONITOR

board.

2. Adjust the RV501 so that the reading of digital voltmeter is

7.50 ± 0.04 V .

degital

voltmeter

+

–

TP152 (GND)

INVERTER V OLTAGE ADJUSTMENT

Connection:

degital

voltmeter

set

(XAV-7W)

Adjusting Procedure:

1. Connect a digital voltmeter to the TP64 on the MONITOR

board.

2. Adjust the RV602 so that the reading of digital voltmeter is

6.80 ± 0.04 V .

TP64

+

–

TP152 (GND)

DC/DC FREQUENCY ADJUSTMENT

Connection:

frequency

set

TP88

(XAV-7W)

counter

+

–

TP152 (GND)

Adjusting Procedure:

1. Connect a frequency counter to the TP88 on the MONITOR

board.

2. Adjust the RV900 so that the reading of frequency counter is

165 ± 0.5 kHz.

5V ADJUSTMENT

Connection:

TP57

set

(XAV-7W)

digital

voltmeter

+

–

TP152 (GND)

γ2 ADJUSTMENT

Connection:

INPUT1

VIDEO jack

NTSC pattern

generator

connection box

(XA-114)

set

(XAV-7W)

Adjusting Procedure:

1. Connect a digital voltmeter to the TP67 on the MONITOR

board.

2. Adjust the RV213 so that the reading of digital voltmeter is

2.50 ± 0.04 V .

TP67

degital

voltmeter

+

–

TP152 (GND

Adjusting Procedure:

1. Connect a digital voltmeter to the TP57 on the MONITOR

board.

2. Adjust the RV503 so that the reading of digital voltmeter is

5.00 ± 0.04 V .

16

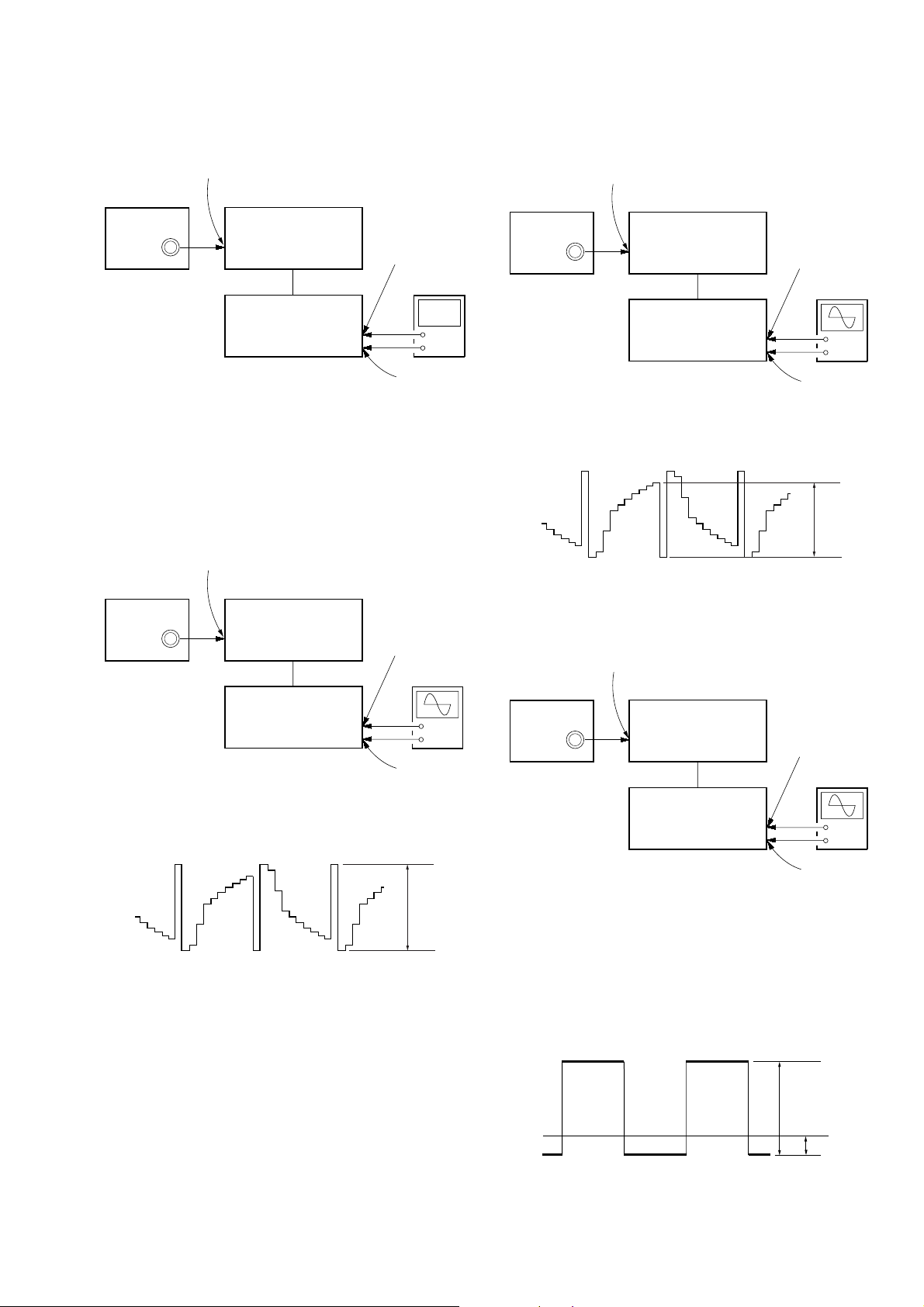

XAV-7W

)

)

)

)

C

0V

D

γ0 ADJUSTMENT

Connection:

INPUT1

VIDEO jack

NTSC pattern

generator

connection box

(XA-114)

set

(XAV-7W)

TP65

degital

voltmeter

+

–

TP152 (GND

Adjusting Procedure:

1. Connect a digital voltmeter to the TP65 on the MONITOR

board.

2. Adjust the RV212 so that the reading of digital voltmeter is

2.51 ± 0.04 V .

RGB AMP ADJUSTMENT

Connection:

INPUT1

VIDEO jack

NTSC pattern

generator

connection box

(XA-114)

set

(XAV-7W)

Adjusting Procedure:

1. Connect an oscilloscope to the TP77 on the MONITOR board.

2. Adjust the RV208 so that the A level of the waveform on the

oscilloscope is 4.80 ± 0.04 V.

TP77

osclloscope

+

–

TP152 (GND

BRIGHT ADJUSTMENT

Connection:

INPUT1

NTSC pattern

generator

VIDEO jack

connection box

(XA-114)

set

(XAV-7W)

TP77

osclloscope

+

–

TP152 (GND

Adjusting Procedure:

1. Connect an oscilloscope to the TP77 on the MONITOR board.

2. Adjust the RV201 so that the B level of the waveform on the

oscilloscope is 4.20 ± 0.04 V.

B

V COM, V COM CENTER ADJUSTMENT

Connection:

INPUT1

NTSC pattern

generator

VIDEO jack

connection box

(XA-114)

set

(XAV-7W)

TP108

osclloscope

+

–

TP152 (GND

Adjusting Procedure:

A

1. Connect an oscilloscope to the TP108 on the MONITOR board.

– V COM ADJUSTMENT –

2. Adjust the RV210 so that the C level of the waveform on the

oscilloscope is 8.40 ± 0.05 V.

– V COM CENTER ADJUSTMENT –

3. Adjust the RV211 so that the D level of the waveform on the

oscilloscope is –2.40 ± 0.05 V.

17

XAV-7W

)

V

)

V

FREE-RUN FREQUENCY ADJUSTMENT

Connection:

frequency

set

TP70

(XAV-7W)

counter

+

–

TP152 (GND)

Adjusting Procedure:

1. Place the monitor in the no signal input status.

2. Connect a frequency counter to the TP70 on the MONITOR

board.

3. Press the [SOURCE] button to activate the video mode.

4. Adjust the RV402 so that the reading of frequency counter is

15.37 ± 0.02 kHz.

H CENTER ADJUSTMENT

Connection:

INPUT1

VIDEO jack

NTSC pattern

generator

connection box

(XA-114)

B SUB BRIGHT ADJUSTMENT

Connection:

INPUT1

NTSC pattern

generator

Adjusting Procedure:

1. Connect an oscilloscope to the TP78 on the MONITOR board.

2. Adjust the RV209 so that the E level of the waveform on the

oscilloscope is 4.00 ± 0.05 V.

VIDEO jack

connection box

(XA-114)

set

(XAV-7W)

TP78

osclloscope

+

–

TP152 (GND

E

0

set

(XAV-7W)

Adjusting Procedure:

1. Enter the monoscope (NTSC) signal from the pattern generator .

2. Press the

[SOURCE] button to activate the video mode so as

to display the monoscope on the monitor screen.

3. Adjust the R V401 so tha t the monoscope on the monitor screen

is horizontally symmetric.

R SUB BRIGHT ADJUSTMENT

Connection:

INPUT1

NTSC pattern

generator

Adjusting Procedure:

1. Connect an oscilloscope to the TP76 on the MONITOR board.

2. Adjust the RV207 so that the F level of the waveform on the

oscilloscope is 4.40 ± 0.05 V.

VIDEO jack

connection box

(XA-114)

set

(XAV-7W)

TP76

osclloscope

+

–

TP152 (GND

F

0

18

CHECKINIG AFTER ADJUSTMENT

Enter color bars from the pattern generators for both NTSC and

PAL signal systems to check that there is no problem in the liquid

crystal display of the monitor in both signal systems.

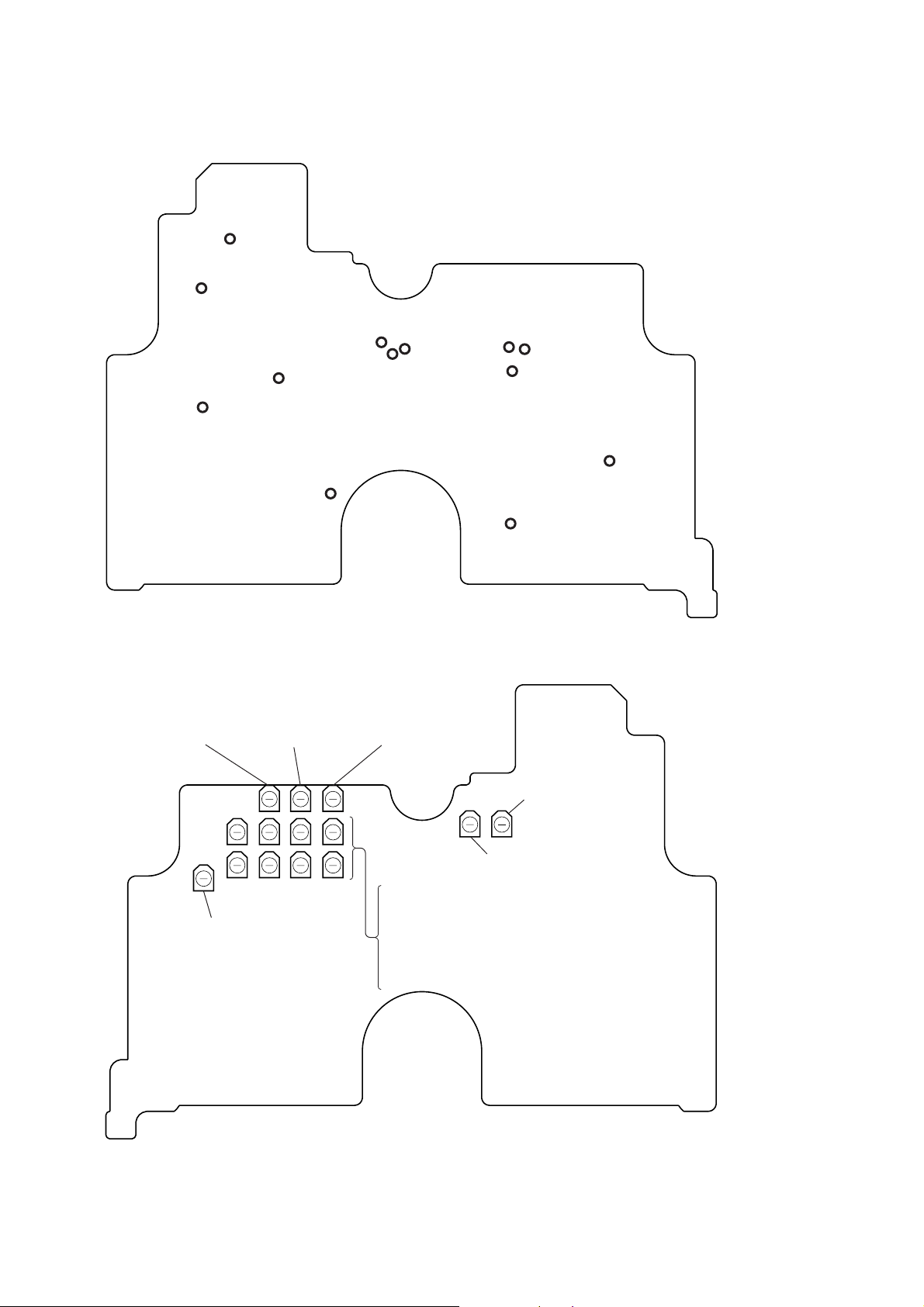

Connecting and Adjustment Location:

– MONITOR BOARD (Component Side) –

TP108

TP70

TP154

TP152

(GND)

TP64

TP76

TP78

TP77

TP67

XAV-7W

TP65

TP57

TP58

– MONITOR BOARD (Conductor Side) –

RV503

5V Adjustment

DC/DC Frequency Adjustment

B Sub Bright Adjustment

RV900

RV209

RV210

V COM Adjustment

Free-run Frequency Adjustment

RV212

γ

0

Adjustment

RV501

7.5V

Adjustment

RGB AMP

Adjustment

Inverter V oltage

Adjustment

TP88

H Center Adjustment

RV402

RV208

RV602

RV401

RV210

Bright

Adjustment

RV211

V COM Center

Adjustment

RV207

R Sub Bright

Adjustment

RV213

γ

2

Adjustment

19

XAV-7W

MEMO

20

SECTION 6

DIAGRAMS

XAV-7W

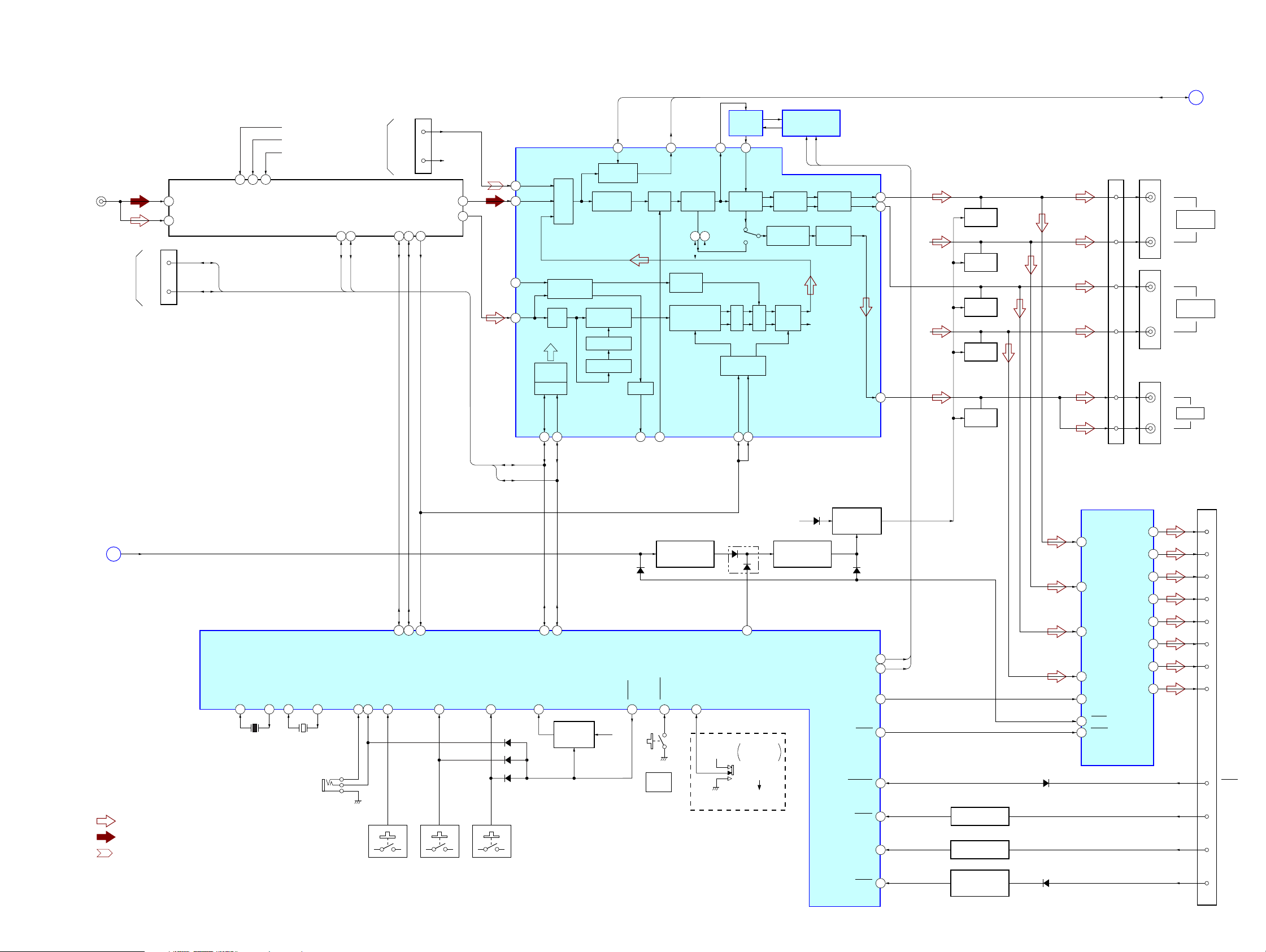

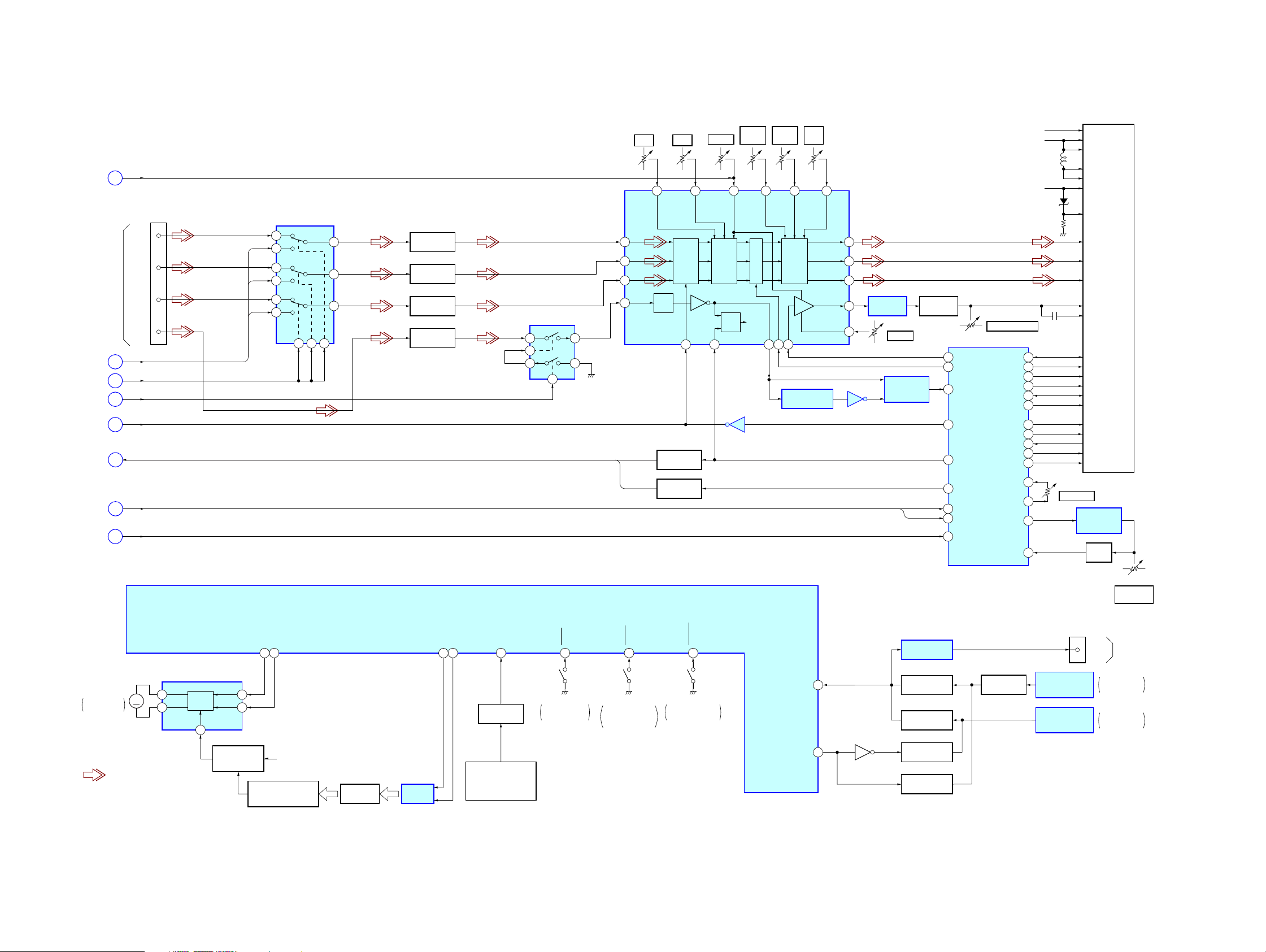

6-1. BLOCK DIAGRAM – MAIN Section –

BU +5V

TU +8.5V

TU +5V

TUNER UNIT

(ANTENNA IN)

TO

CONNECTION

BOX

SDA

SCL

1

2

CN2 (1/7)

17

18

TU2

ANT-AM

ANT-FM

SDA

SCL

11

5

VCC (8.5V)

VDD E2P (5V)

16

VDD (5V)

FROM

CONNECTION

BOX

SDA (I2CBUS)

SCL (I2CBUS)

12 13

SCL

SDA

CN2 (2/7)

AU-L

13

AU-R

SDA (E2PROM)

SCL (E2PROM)

17

18

14

2

AM-DET

S-METER

MPX

R-CH

SA DATA,

SA CLK

ADSO

CONTROL SWITCH

IC9

ADSO1

SOFT STEP

FADER

FILTER

HIGH-

CUT

ADSO2

MIXER

SOFT STEP

FADER

R-CH

OUTLF

OUTLR

OUTSW

CN3

28

27

R-CH

R-CH

24

MUTING

Q311-1

MUTING

Q312-1

MUTING

Q311-2

MUTING

Q312-2

MUTING

Q310

9

7

4

6

1

3

(L)

(R)

(L)

(R)

(L)

(R)

SDA

38 33

ACOUT L

SCL

LOW-PASS

FILTER

IC101

ACIN L

OUTPUT

SELECTOR

LPF

D/A

CONVERTER

MP IN

LEVEL

1413

SUB WOOFER

S & H

INPUT SELECT, FM MPX

ELECTRICAL VOLUME

IC302

AU-L

44

AM

8

10

9

AM IF

10

12

MPX1

AM/FM NOISE

LPF

DIGITAL

CONTROL

IIC BUS

SCL

SDA

19 20

INPUT

MULTIPLEXER

BLANKER

SA CLK

21

SPECTRUM

ANALYZER

LOUDNESS

VOLUME

PILOT

CANCELATION

PILOT DET

PLL

SA CLK

QUAL

QUALITY

16

SOFT

MUTE

S MUTE

17

23

SA DATASA OUT

TONE

CONTROL

12 13

PULSE

FORMER

DEMODULATOR

STEREO ADJUST

STEREO BLEND

B

FRONT

AUDIO OUT

REAR

AUDIO OUT

SUB OUT

(Page 22)

(Page 24)

RESET

A

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: FM

: AM

: AUDIO

X0

92X193

X452

3.58MHz

X0A74X1A

73

X701

32.768kHz

(REMOTE IN)

J901

10

TROM-SDA

RC-IN172RC-IN048KEYIN2

49

SW101 – 105, 107,

SW750, 751

53

11

S-METER

TROM-SCL

KEYIN1

47

SW106, 108

SDA

SCL

KEYIN0

46

D909-2

D909-1

D316

LSW965 – 967

70

71

I2C-SCL

I2C-SDA

MASTER CONTROLLER

KEY ACK

79

KEY ACTIVE

SWITCH

Q912

IC703 (1/4)

BU

+5V

D314

AD-ON

80

MUTING

CONTROL SWITCH

Q301

OPNCLS

61

SW108

OPEN/

CLOSE

DESTSEL2

105

(E)

BU

+5V

D15

5

ATT

S1

FREQUENCY

SELECT

FM 50 kHz

AM 9 kHz

FM 200 kHz

AM 10 kHz

BACK-UP B+

CONTROL SWITCH

MUTING

Q307

D310

BATTERY OFF

MUTE DRIVER

Q306

D311

ADSO1

ADSO2

BEEP

ST-BY

SIDEBRK

ACCIN

TEL ATT

ILL-IN

POWER AMP

IC171

9

11

IN1

12

IN2

IN3

15

ADSO1

35

ADSO2

36

15

55

58

81

117

95

ACCESSORY CHECK

Q910

LEVEL SHIFT

Q906

ILLUMINATION

CHECK

Q904

D11

D908

14

IN4

10

AUX

MUTE

22

4

ST-BY

OUT1+

OUT1–

OIT2+

OUT2–

OUT3+

OUT3–

OUT4+

OUT4–

7

5

3

17

19

21

23

CN901 (1/2)

2

1

3

4

10

9

11

12

13

7

14

15

FL+

FL–

FR+

FR–

RL+

RL–

RR+

RR–

SBRK

ACC

ATT

ILL

2121

XAV-7W

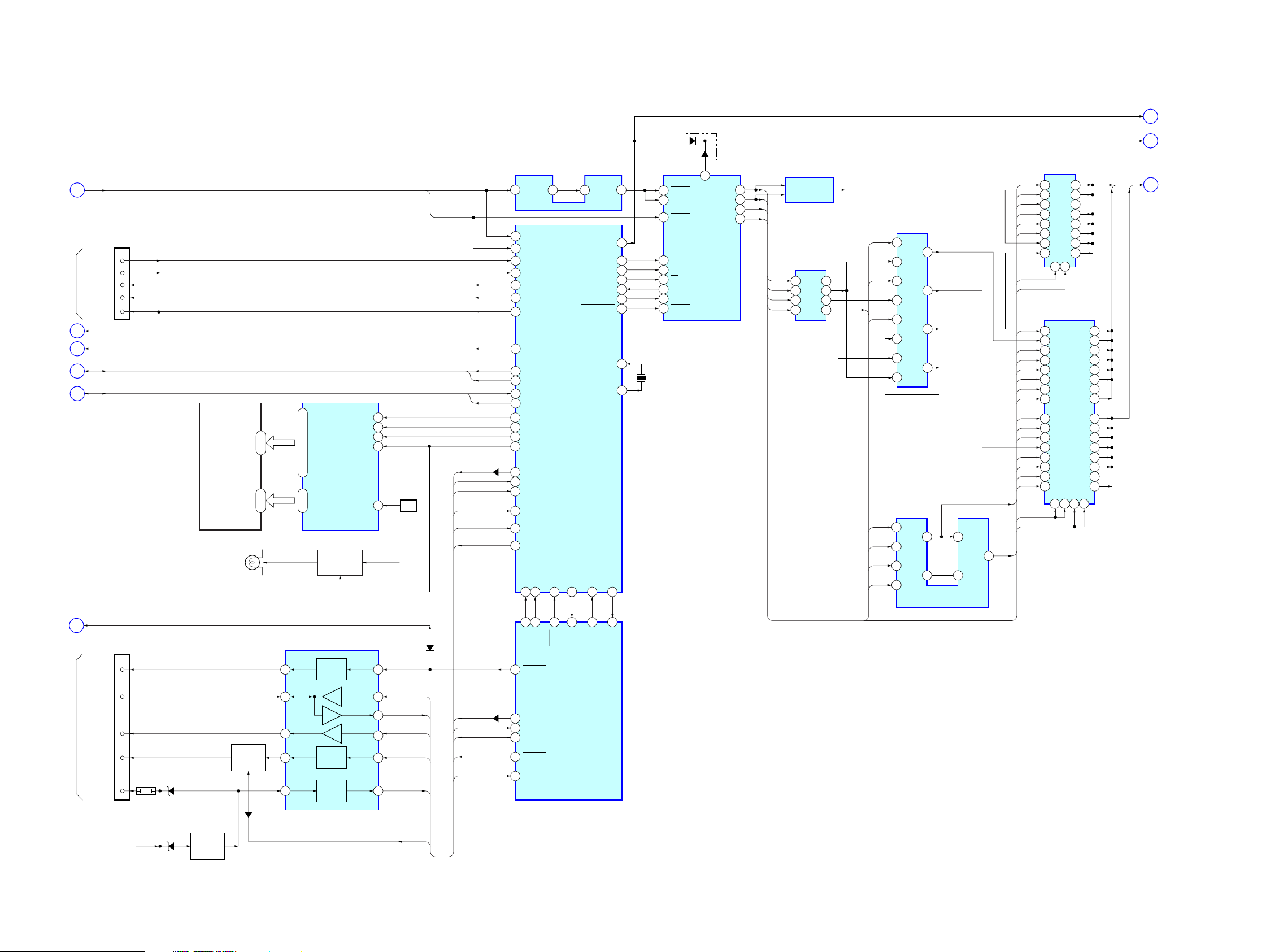

6-2. BLOCK DIAGRAM – DISPLAY/BUS CONTROL Section –

(Page 23)

TO

CONNECTION

BOX

(Page 23)

(Page 23)

(Page 23)

(Page 21)

C

D

E

F

B

HSYNC,

VSYNC

H SYNC

V SYNC

COL

HUE

NP SEL

NP SEL

BRIGHT

WIDE1,

WIDE2

SA DATA,

SA CLK

CN2 (3/7)

16

3

7

9

14

LIQUID

CRYSTAL

DISPLAY

LCD901

P1, 2

(LCD BACK LIGHT)

1 – 45

S1 – S45

46 – 49

COM1 – COM4

S1 – S45

LIQUID

CRYSTAL

DISPLAY

2 – 25, 27 – 38, 40 – 48

DRIVER

IC14

DRIVE

Q901

OSC

52 – 55

COM1 – COM4

PILOT RAMP

INH

AV SEL1

D13

R

G

B

I

001

003

I

002

R

G

G

B

B

I

001

R

R

G

B

B

I

001

I

002

BUS BUFFER

IC7

15

17

13

11

8

6

4

2

1

19

BUS BUFFER

IC1

35

29

33

27

36

30

32

26

46

40

44

38

47

41

43

37

12524

5

3

7

9

12

14

16

18

48

MULTIVIBRATOR

IC11

HSYNC

VSYNC

WIDE1

WIDE2

SA DATA

SA CLK

64

DI

63

CL

62

CE

61

UNISO

UNISI

UNICKO

60

OSC

C122, R139

ILL B+

BUS ON

BU CHK

LINK-OFF

D755

(2/2)

5

120 HSYNC MON

119 VSYNC MON

117 HSYNC SEEP

116 VSYNC SEEP

73 RGB COL

75 RGB HUE

77 NP SEL

CONTROLLER

111 BRIGHT

42 WIDE1

43 WIDE2

105

SA DATA

95 SA CLK

59

LCD DI

63

LCDCKO

70

LCD CE

69

LCD INH

97

UNISO

98

UNISI

101

UNISCK

38

BUSON

34

BU IN

LINKOFF

50

LED SW1

LED SW2

46

47

7

DISPLAY

IC900 (1/2)

BOOT

12

OSDCSO/TX

COBOXCOBOX ST

1

EXTAL

RGBVSELRGB SEL

40

XTAL

SA ENINSA ENIN

96

9

128AV SEL

60

64OSDCCKO

66OSDCCE

48OSDC TRE

122OSDC DISP

54OSDCRESET

86

85

12 HSYNC

8

13 VSYNC

25

24 SCLK

26

23 TRE

14 DISP

5 RESET

X901

18.432MHz

16

ROUT

VOB1

CONTROLLER

IC2

GOUT

BOUT

DOCKI

ON SCREEN DISPLAY

SIN

CS

IOUT

R

19

G

18

B

20

I

17

R

G

B

I

GATE SWITCH

IC10

LEVEL SHIFT

IC6

5

1

3

13

SWITCHING

IC5

R

9

8

10

G

B

R

G

B

I

12

13

5

4

2

1

SWITCHING

IC3

1

2

10

9

11

6

3

003

3

4

001

6

8

5

6

2

4

002

12

AV SEL2

B

G

R

14

20

16

22

13

19

17

23

3

9

5

11

2

8

6

12

H

J

K

(Page 23)

(Page 23)

(Page 23)

(Page 24)

TO

CONNECTION

BOX

SYSRST

G

D701

(1/2)

UNISO

UNISI

UNICKO

BUS ON

BU CHK

LINK-OFF

UNISO

UNISI

UNICKO

BUS ON

BU CHK

RESET

DATA

CLK

BUS ON

BACK-UP B+

CN2 (4/7)

+B

12

5

6

4

D759

TH752

11

D765

BATTERY

DETECT

Q754

BUS ON

SWITCH

Q753

D764

RST

RESET

SWITCH

DATA

6 9

CLK

4

BUS

ON

1 12

3 10

BUS ON

SWITCH

BATT

BATTERY

SWITCH

SONY BUS INTERFACE

IC751

RST

DATA IN

DATA OUT

CLK-IN

BUS ON

B/U-C

8

11

D755

(1/2)

115

11657106

LED SW2

LED SW1

62 13

SYSRST

MASTER CONTROLLER

UNISO

18

UNISI

17

UNICLK

19

14

BUS-ON

77

BU IN

1

BOOT

IC703 (2/4)

59

107

2222

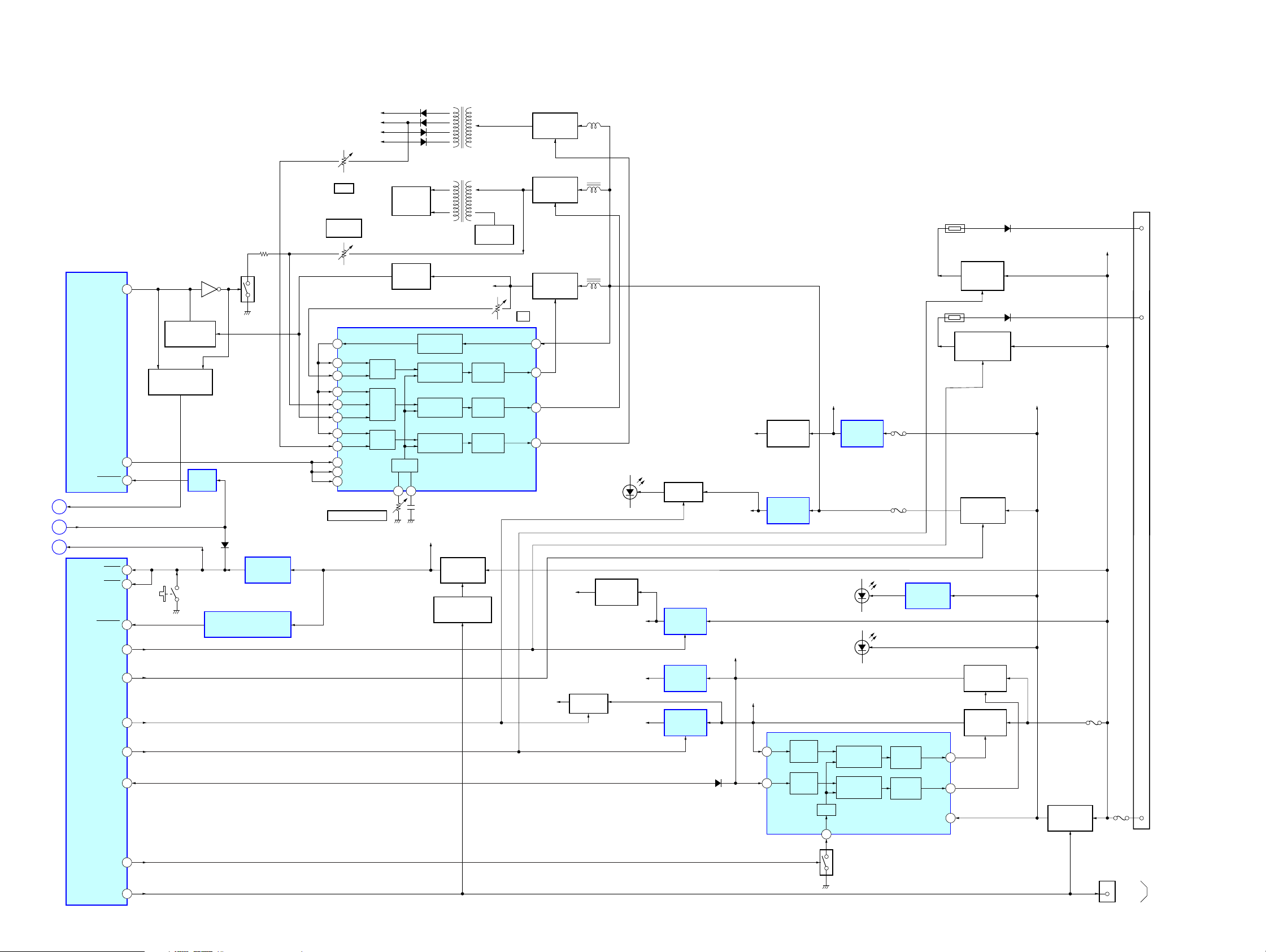

6-3. BLOCK DIAGRAM – MONITOR Section –

RV213 RV212

γ 2

γ 0

RV201

BRIGHT

RV207

R SUB

BRIGHT

RV209

B SUB

BRIGHT

RV208

RGB

AMP

MONITOR +13V

MONITOR +5V

LIQUID CRYSTAL

DISPLAY MODULE

VCS

VSHL1

VSHL2

XAV-7W

(Page 22)

E

FROM

CONNECTIOM

BOX

(Page 22)

K

(Page 22)

J

(Page 22)

H

(Page 24)

L

(Page 22)

C

(Page 22)

F

(Page 22)

D

M701

MONITOR

OPEN/CLOSE

• SIGNAL PATH

: VIDEO

BRIGHT

VIDEO

R, G, B

AV SEL2

AV SEL1

SW

HSYNC,

VSYNC

WIDE1,

WIDE2

NP SEL

M

CN2 (5/7)

21

R

20

G

8

B

10

MONITOR OPEN/CLOSE

OUT1

8

OUT2

5

MOTOR DRIVE

IC702

MOTOR

DRIVE

VREF

20

FW

17

RW

19

REGULATOR

D703, 706 – 708,

Q702

REGULATOR CONTROL

RGB/OSD SELECT SWITCH

IC15

8

R

9

11

G

14

16

B

1

2 12 7

MOPEN

MCLOSE

97 98 96

SYS+B

SWITCH

Q710 – 713

6

5

3

INVERTER

Q714 – 717

RGB R BUFFER

Q198

RGB G BUFFER

Q199

RGB B BUFFER

Q200

VIDEO BUFFER

DECODER

IC710

Q1

MCNT1

MCNT2

103

102

MONITOR OPEN/CLOSE

MOTOR ROTATION

LODPLS

LEVEL SHIFT

Q782

DETECT

PH780

SWITCH

2

7

6

IC1

CLOSE DETECT

1

5

3

MASTER CONTROLLER

IC703 (3/4)

CLSW

101

S790

MONITOR

RIN

42

GIN

41

BIN

40

SYNC

SEP

36

HSYNC

VSYNC

MDSW

100

S792

MONITOR

START STANDING

DETECT

26 27 29 31 30 28

GAMMA

AMP

BGP

GEN

SYNCIN

BRIGHT

IC204

INV

BGP

SUBBRTR

FRP

SYNCOUT

SUBBRTB

AMP

COMOUT

COMAMP

COMFRP

3233353439

MULTIVIBRATOR

IC250

24

SICRS

113

MNTOPN

GAMMA2

INT/

EXT

SWITCH

SYNC

SEP

LEVEL SHIFT

Q420

LEVEL SHIFT

Q421

MONITOR ANGLE

GAMMA0

SW

ANGSW

99

S791

DETECT

RGBAMP

ROUT

GOUT

BOUT

VIDEO INTERFACE

IC201

19

21

24

V COM AMP

38

37

IC280

SIRCS SELECT

Q350

IC203

RV210

V COM

SYNC

COMPARATOR

IC281

V COM BIAS

Q207-210

HSYNC

VSYNC

SIRCS BUFFER

IC4

SIRCS BUFFER

Q353

SIRCS BUFFER

Q351

SIRCS MUTING

Q352

SIRCS MUTING

Q354

FRPT

6

FRPV

8

SYNI

7

VCS

10

HSY

4

VSY

12

MDN

21

MDW

20

NTPC

11

MONITOR –16V

RV211

V COM CENTER

MOD1

MOD2

LIQUID CRYSTAL

DISPLAY DRIVER

(FOR MONITOR)

IC401

LEVEL SHIFT

Q756

SPOI

HR

PS

CTR

SPIO

CLD

CLS

SPS

VR

BLKI

BLKO

PDP

OSCI

D402

28

33

35

36

37

47

57

58

59

60

32

70

71

38

44

REMOTE CONTROL

RECEIVER

REMOTE CONTROL

RECEIVER

RV401

H CENTER

CN2 (6/7)

IC750

IC450

VSHA1

VSHA2

VSS

VCC

R

G

B

COM

VCL

SPOI

HR

PS

CTR

SPIO

CLD

CLS

SPS

VR

MODE1

MODE2

PHASE

COMPARATOR

IC205

VCO

Q450

15

SIRCS

RV402

FREE-RUN

FREQUENCY

TO

CONNECTION

BOX

When monitor

is opened

When monitor

is closed

2323

XAV-7W

6-4. BLOCK DIAGRAM – POWER SUPPLY Section –

Q611, 612

DIMMER CONTROL

Q612

DIMMER

MUTING SWITCH

Q260, 264

CONTROL

Q262, 263

BUFFER

IC901

SW960

(RESET)

Q611

D701

(2/2)

RESET SIGNAL

GENERATOR

IC704

RESET SIGNAL GENERATOR

(FOR INTERNAL RAM)

IC705

(Page 23)

(Page 22)

(Page 21)

DISPLAY CONTROLLER

IC900 (2/2)

DIMMER

LCDPW

SYSRST

SW

L

SYSRST

G

RESET

A

RAM-BU

ILL ON

MASTER

CONTROLLER

IC703 (4/4)

KEY ILL

RSTX

HSTX

PWM

51

ON SCREEN DISPLAY

52

81

90

86

85

114TUNER-ON

112

60

83P-ON

65

+13V (MONITOR +13V)

+7.5V (MONITOR +7.5V)

–5V (MONITOR –5V)

–16V (MONITOR –16V)

RV501

7.5V

RV602

INVERTER

VOLTAGE

VREF

19

–IN1

6

+IN1

7

+IN4

30

–IN4

31

DTC4

33

+IN3

25

–IN3

26

CTL1

20

CTL2

21

CTL3

22

RV900

DC/DC FREQUENCY

ERROR

AMP

ERROR

AMP

ERROR

AMP

D502

D506

BACK LIGHT

UNIT

POWER ON

RESET

Q963, 964

OSC

CTRT

16 17

CONVERTER

D503

D505

INVERTER

TRANSFORMER

(MONITOR +5V)

REFERENCE

VOLTAGE

PWM

COMPARATOR

PWM

COMPARATOR

PWM

COMPARATOR

BU +5V

REGULATOR

Q809, 810

REGULATOR

CONTROL SWITCH

T501

DC/DC

T601

OSC

Q609, 610

+5.1V

OUTPUT

CIRCUIT

OUTPUT

CIRCUIT

OUTPUT

CIRCUIT

POWER CONTROL

(FOR MOINTOR SYSTEM)

IC900

+5V

Q811

RV503

VCC1

OUT1

OUT4

OUT3

5V

SWITCHING

REGULATOR

Q501

SWITCHING

REGULATOR

Q608

SWITCHING

REGULATOR

Q900

18

46

39

40

TU +5V

ILL B+

L510

L602

L901

D106, 107,

SW101 – 105, 107

REGULATOR

B+ SWITCH

Q908

+5V

Q13

TU +8.5V

+3.3V B+

AUDIO +8V

LED DRIVE

Q101, 102

+8.5V

REGULATOR

IC13

+3.3V

REGULATOR

IC12

+8V

REGULATOR

IC304

+9V

(LED/SW9V)

D +5V

D800

+5V

(M5V)

AUDIO

+10V

REGULATOR

Q720

REGULATOR

IC355

NINV

IN1

3

NINV

IN2

14

+5V

+9V

ERROR

AMP

ERROR

AMP

+9V

(M9V)

D110 – 112,

SW106, 108

LSW965 – 967

COMPARATOR

COMPARATOR

OSC

RT

2

+9V

REGULATOR

IC701

PWM

PWM

POWER CONTROL

IC860

F2

F1, 101

OUTPUT

CIRCUIT

OUTPUT

CIRCUIT

+9V

REGULATOR

IC356

OUT1

OUT2

VCC

TH901

AMP REMOTE

B+ SWITCH

Q900-2, 902-2

TH900

ANTENNA REMOTE

B+ SWITCH

Q900-1, 901-1

SYSTEM B+

SWITCH

Q1, 2

SWITCHING

REGULATOR

Q861, 862-2

SWITCHING

REGULATOR

Q860, 862-1

7

10

9

D912

D910

SYSB+

SYSTEM B+

SWITCH

Q3, 4

BACK-UP B+

F201

CN901 (2/2)

F901

6

5

16

AMP REM

ANT REM

BATT

SHIFT

DDC-ON

37

57

OSC

SWITCH

Q802

CN2 (7/7)

22

SYSPW

CONNECTION

BOX

2424

Loading...

Loading...