Sony UP-D898MD, UP-X898MD Service Manual

DIGITAL GRAPHIC PRINTER

UP-D898MD

HYBRID GRAPHIC PRINTER

UP-X898MD

SERVICE MANUAL

1st Edition

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

UP-D898MD/X898MD

注意

[For UP-X898MD]

注意

指定以外の電池に交換すると,破裂する危険があります。

必ず指定の電池に交換してください。

使用済みの電池は,国または地域の法令に従って

処理してください。

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

When you dispose of the battery, you must obey the

law in the relative area or country.

ATTENTION

Il y a danger d’explosion s’il y a remplacement incor-

rect de la batterie. Remplacer uniquement avec

une batterie du même type ou d’un type équivalent

recommandé par le constructeur.

Lorsque vous mettez la batterie au rebut, vous devez

respecter la législation en vigueur dans le pays ou la

région où vous vous trouvez.

FÖRSIKTIGHET!

Fara för explosion vid felaktigt placerat batteri.

Byt endast mot samma eller likvärdig typ av batteri,

enligt tillverkarens rekommendationer.

När du kasserar batteriet ska du följa rådande lagar

för regionen eller landet.

PAS PÅ

Fare for eksplosion, hvis batteriet ikke udskiftes

korrekt.

Udskift kun med et batteri af samme eller tilsvarende

type, som er anbefalet af fabrikanten.

Når du bortskaffer batteriet, skal du følge

lovgivningen i det pågældende område eller land.

HUOMIO

Räjähdysvaara, jos akku vaihdetaan virheellisesti.

Vaihda vain samanlaiseen tai vastaavantyyppiseen,

valmistajan suosittelemaan akkuun.

Noudata akun hävittämisessä oman maasi tai

alueesi lakeja.

VORSICHT

Explosionsgefahr bei Verwendung falscher Batterien.

Batterien nur durch den vom Hersteller empfohlenen

oder einen gleichwertigen Typ ersetzen.

Wenn Sie die Batterie entsorgen, müssen Sie die

Gesetze der jeweiligen Region und des jeweiligen

Landes befolgen.

FORSIKTIG

Eksplosjonsfare hvis feil type batteri settes i.

Bytt ut kun med samme type eller tilsvarende

anbefalt av produsenten.

Kasser batteriet i henhold til gjeldende avfallsregler.

注意

如果更换的电池不正确,就会有爆炸的危险。

只更换同一类型或制造商推荐的电池型号。

处理电池时,必须遵守相关地区或国家的法律。

UP-D898MD/X898MD

1 (P)

Table of Contents

Manual Structure

Purpose of this manual ............................................................ 3 (E)

Related manuals ...................................................................... 3 (E)

Trademarks .............................................................................. 3 (E)

1. Service Overview

1-1. Service Flow Chart .................................................... 1-1 (E)

1-1-1. Flow Chart before Service ............................... 1-1 (E)

1-1-2. Flow Chart after Service .................................. 1-3 (E)

1-2. Precaution for Transporting .......................................1-4 (E)

1-3. Board Location and Main Parts Location .................1-5 (E)

1-3-1. Board Location ................................................1-5 (E)

1-3-2. Main Parts Location ......................................... 1-5 (E)

1-3-3. Sensor Location ...............................................1-6 (E)

1-4. Tightening torque ...................................................... 1-6 (E)

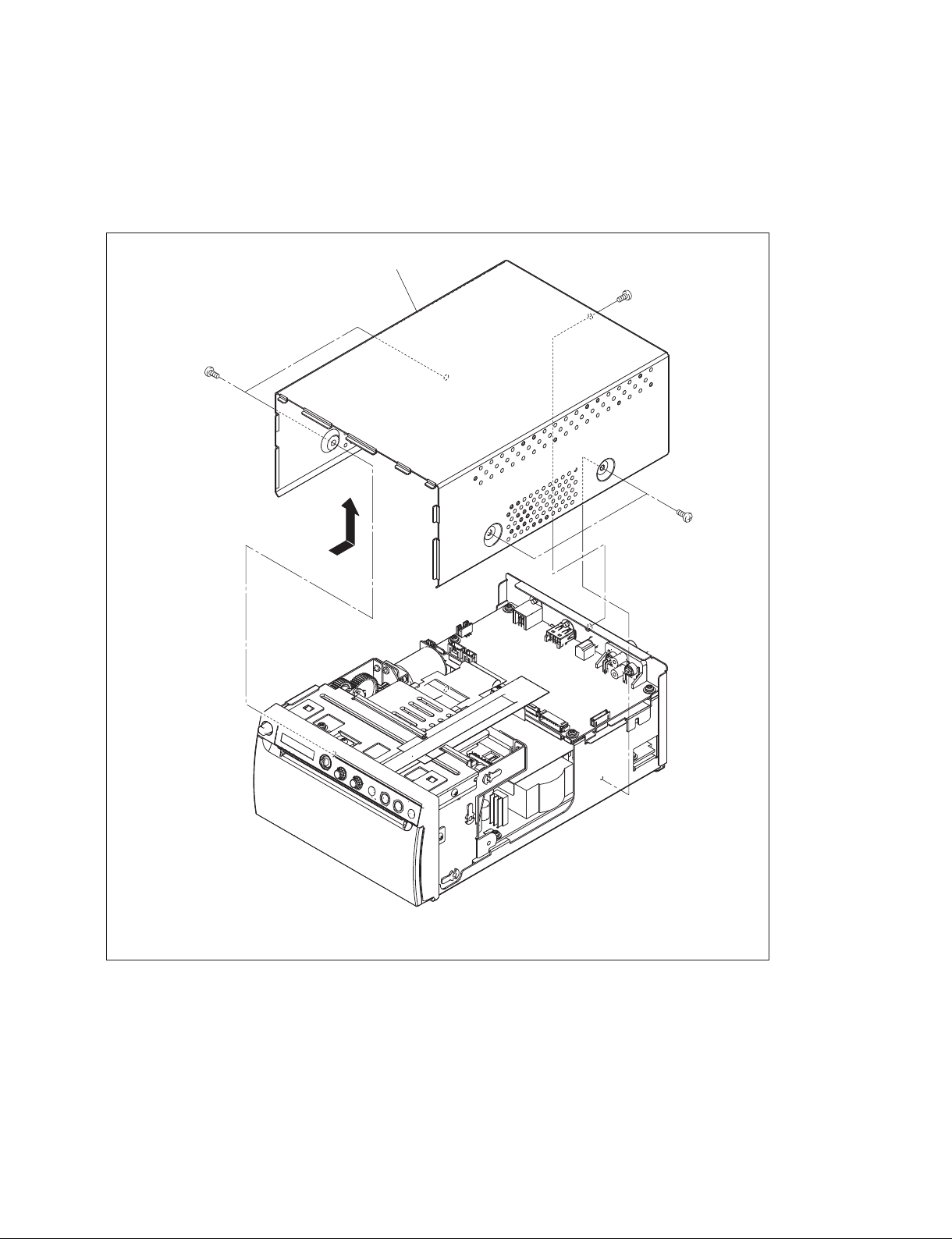

1-5. Removing/Installing the Cabinet ............................... 1-7 (E)

1-5-1. Top Cover ........................................................ 1-7 (E)

1-5-2. Front Panel Block Assembly ...........................1-8 (E)

1-5-3. Rear Panel ......................................................1-10 (E)

1-6. General Information of Utility Software ................. 1-11 (E)

1-6-1. Required Equipment/Tools ............................ 1-11 (E)

1-6-2. Preparation ..................................................... 1-11 (E)

1-6-3. Function Description......................................1-12 (E)

1-7. Firmware Version Upgrade .....................................1-21 (E)

1-8. Service Mode...........................................................1-22 (E)

1-8-1. Startup Procedure ........................................... 1-22 (E)

1-8-2. Service Mode Menu ....................................... 1-22 (E)

1-9. Menu Lock Function ............................................... 1-26 (E)

1-10. Lithium Battery (UP-X898MD) .............................. 1-27 (E)

1-11. Cleaning ..................................................................1-28 (E)

1-11-1. Cleaning the Cabinet ...................................... 1-28 (E)

1-11-2. Cleaning the thermal head .............................1-28 (E)

1-11-3. Cleaning the Platen Roller ............................. 1-29 (E)

1-12. Periodic Inspection and Periodic

Replacement Parts ................................................... 1-30 (E)

1-13. Print Size ................................................................. 1-30 (E)

1-13-1. Rough Standard of Print Size.........................1-30 (E)

1-13-2. Interval Between Print Screens ...................... 1-31 (E)

1-13-3. Blank in Horizontal Direction........................1-31 (E)

1-14. Lead-free Solder ......................................................1-31 (E)

2. Troubleshooting

2-1. Error Log Acquisition Procedure .............................. 2-1 (E)

2-1-1. Error Code Table .............................................. 2-1 (E)

2-2. Trouble Flow Chart ................................................... 2-3 (E)

2-2-1. Power does not turn on even though the

power switch is turned on ................................ 2-3 (E)

2-2-2. Keys and LEDs on the front panel cannot be

controlled normally .......................................... 2-4 (E)

2-2-3. Printing cannot be performed normally from

PC or no image is output .................................. 2-5 (E)

2-2-4. Printing cannot be performed normally from

video signal

(NTSC/PAL) (UP-X898MD Only) .................. 2-7 (E)

2-2-5. Print image is distorted in the paper feed

direction (irregular feeding) .............................2-8 (E)

2-2-6. Print density is too high or too low .................. 2-9 (E)

2-2-7. Feed operation failure .................................... 2-10 (E)

2-2-8. Thermal head UP/DOWN operation

failure ............................................................. 2-11 (E)

2-2-9. Door open/close operation failure..................2-12 (E)

2-2-10. Printing paper presence/absence sensor

failure .............................................................2-13 (E)

2-2-11. Real time clock does not operate normally

(UP-X898MD only) .......................................2-14 (E)

2-2-12. Remote terminal does not operate normally

(UP-X898MD only) .......................................2-14 (E)

2-2-13. Image is not written in the USB flash memory

after printing (UP-X898MD only) .................2-15 (E)

3. Replacement of Board and Main Parts

3-1. MA-195 Board ..........................................................3-2 (E)

3-1-1. Flow Chart .......................................................3-2 (E)

3-1-2. Saving of Setting Value .................................... 3-3 (E)

3-1-3. Sample (Step) Printing ..................................... 3-4 (E)

3-1-4. Replacement Procedures of MA-195 Board ....3-5 (E)

3-1-5. Setting and Check of Setting Value .................3-7 (E)

3-1-6. Density Adjustment (Thermal Head Voltage

Adjustment) and Set Serial Number Setting .... 3-8 (E)

3-2. KY-711 Board.......................................................... 3-10 (E)

3-3. SE-1142 Board ........................................................ 3-12 (E)

3-4. SE-1143 Board ........................................................ 3-13 (E)

UP-D898MD/X898MD

1 (E)

3-5. Switching Regulator ................................................3-14 (E)

3-5-1. Replacement of Switching Regulator ............ 3-14 (E)

3-5-2. Total Power on Time Reset ............................ 3-15 (E)

3-6. MD General Assembly ............................................ 3-16 (E)

3-7. Thermal Head ..........................................................3-17 (E)

3-7-1. Replacement Flow Chart ...............................3-18 (E)

3-7-2. Sample (Gray) Printing ..................................3-19 (E)

3-7-3. Replacement of Thermal Head ......................3-20 (E)

3-7-4. Density Adjustment (Thermal Head Voltage

Adjustment) ...................................................3-23 (E)

3-7-5. Input of Thermal Head Information and

Reset of Total Print Count..............................3-24 (E)

3-8. Stepping Motor/DC Motor Assembly .....................3-25 (E)

3-9. Cam Assembly.........................................................3-29 (E)

3-10. Platen Roller ............................................................3-31 (E)

3-11. Timing Belt..............................................................3-33 (E)

3-12. Pinch Arm Block Assembly ....................................3-35 (E)

3-13. Check (Self-diagnosis) ............................................ 3-36 (E)

4. Circuit Description

4-1. Outline .......................................................................4-1 (E)

4-2. MA-195 Board ..........................................................4-1 (E)

4-3. KY-711 Board............................................................ 4-2 (E)

4-4. SE-1142 Board .......................................................... 4-2 (E)

4-5. SE-1143 Board .......................................................... 4-2 (E)

4-6. SU-167 Board ............................................................ 4-2 (E)

5. Spare Parts

5-1. Notes on Repair Parts ......................................................5-1

5-2. Exploded Views ...............................................................5-2

5-3. Packing Materials & Supplied Accessories ................... 5-14

6. Diagrams

Overall ............................................................................. 6-1

Frame Wiring...................................................................6-2

2 (E)

UP-D898MD/X898MD

Purpose of this manual

Related manuals

Trademarks

Manual Structure

This manual is the Service Manual of the Hybrid Graphic Printer UP-X898MD and

Digital Graphic Printer UP-D898MD.

This manual describes the information items that premise the service based on the

board replacement assuming use of service engineers.

Therefore, the schematic diagram, board layout and electrical parts list are not

contained.

In addition to this Service Manual the following manual is provided.

. Instructions for Use CD-ROM (Supplied with this unit)

This manual contains information required to operate and use the unit.

Trademarks and registered trademarks used in this manual are as follows.

. Windows and Windows Vista are the registered trademarks of Microsoft Corpora-

tion in the United States and Other countries.

Other system names, product names, and company names appearing in this manual

are trademarks or registered trademarks of their respective holders.

UP-D898MD/X898MD

3 (E)

Section 1

Service Overview

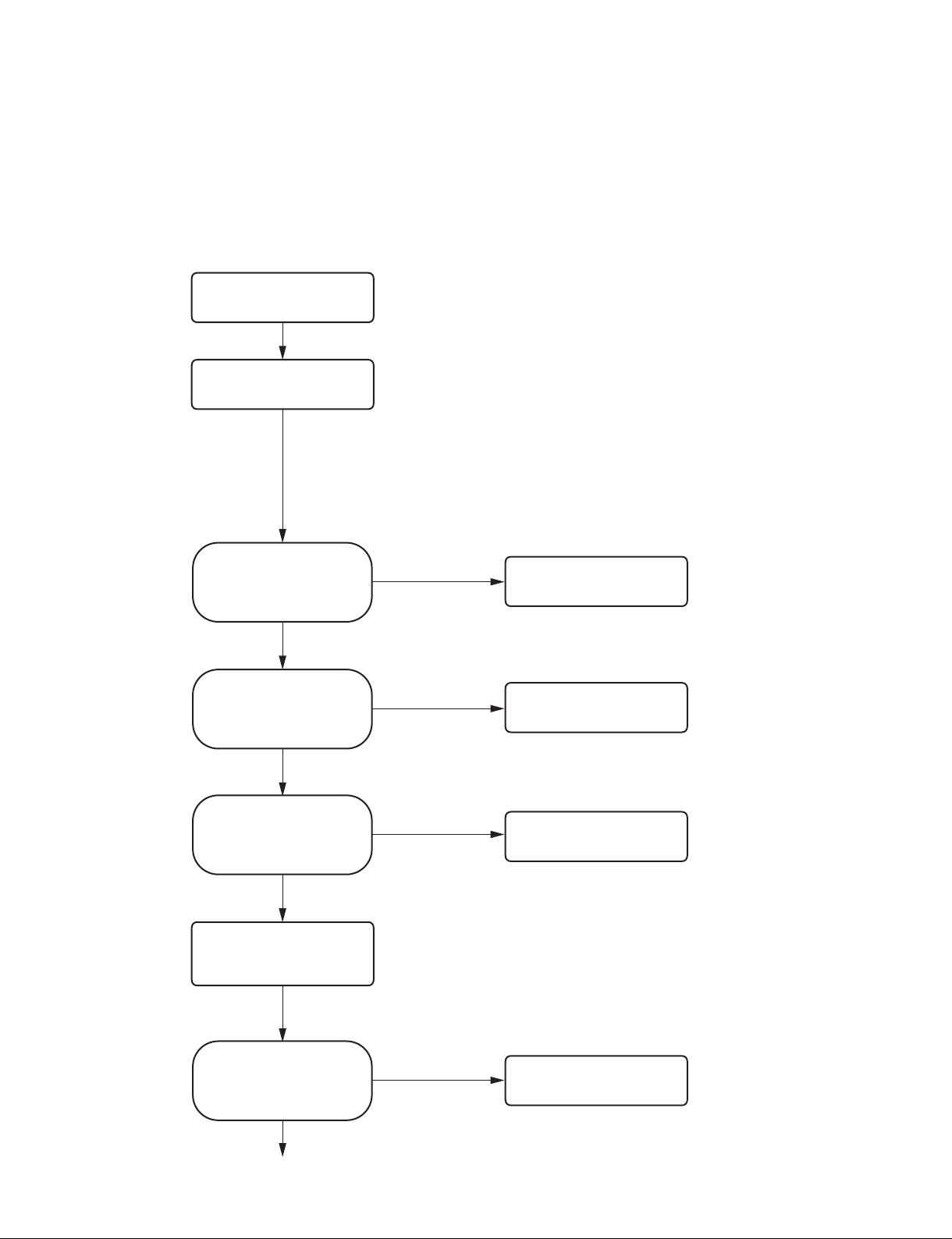

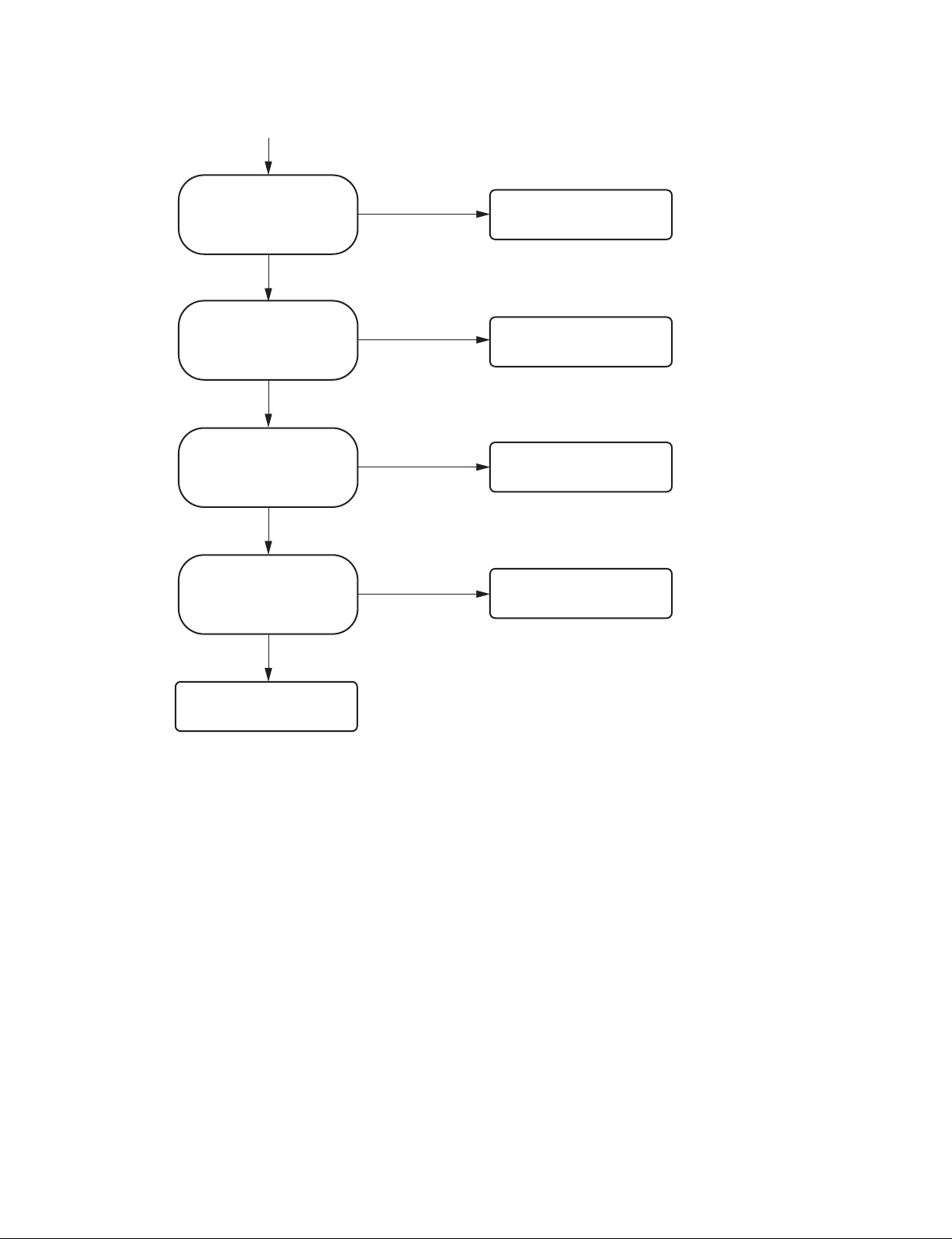

1-1. Service Flow Chart

1-1-1. Flow Chart before Service

Before providing services, check symptoms according to the flow chart below.

Start

Serial number of this unit

Information of connection equipment (Modality name, application, etc.)

Check the information from a user.

Occurrence date and its status

Frequency of occurrence (Did defects occur for the first time, irregularly

several times, or in a specific case?)

Which operation did you perform after occurrence of defects?

$

The items above are used as an information source for analyzing defects.

Therefore, collect detailed information as far as possible.

Is the cause of defects streaks

(white or black) or scratches in

a print direction or a failure or

trouble?

Failure or trouble

Does this unit normally start with

the power turned on?

Yes

Is USB connection recognized?

Yes

Acquire the information of this unit

using utility software. (Refer to step

of “1. Information tab” in

3

Section 1-6-3.)

Stripes or flaws

No

No

$

Communication with this unit cannot be performed using utility software

when menu “DIGITAL” - “DRIVER” is set to “DRV: 897” .

In this case, start this unit in a service mode (refer to Section 1-8) and

use utility software.

Check the symptoms, clean the

thermal head or replace it.

&

Cleaning: Refer to Section 1-11-2.

Replacement: Refer to Section 3-7.

Refer to “2-2-1. Power does not

turn on even though the power

switch is turned on” .

Refer to “2-2-3. Printing cannot be

performed normally from PC or no

image is output” .

UP-D898MD/X898MD

Could the defects be determined

from user information and error

history? (Refer to steps 1 and

of “1. Information tab” in

2

Section 1-6-3.)

No

Go to next page

Yes

Check the determined point or

replace the relevant parts.

1-1 (E)

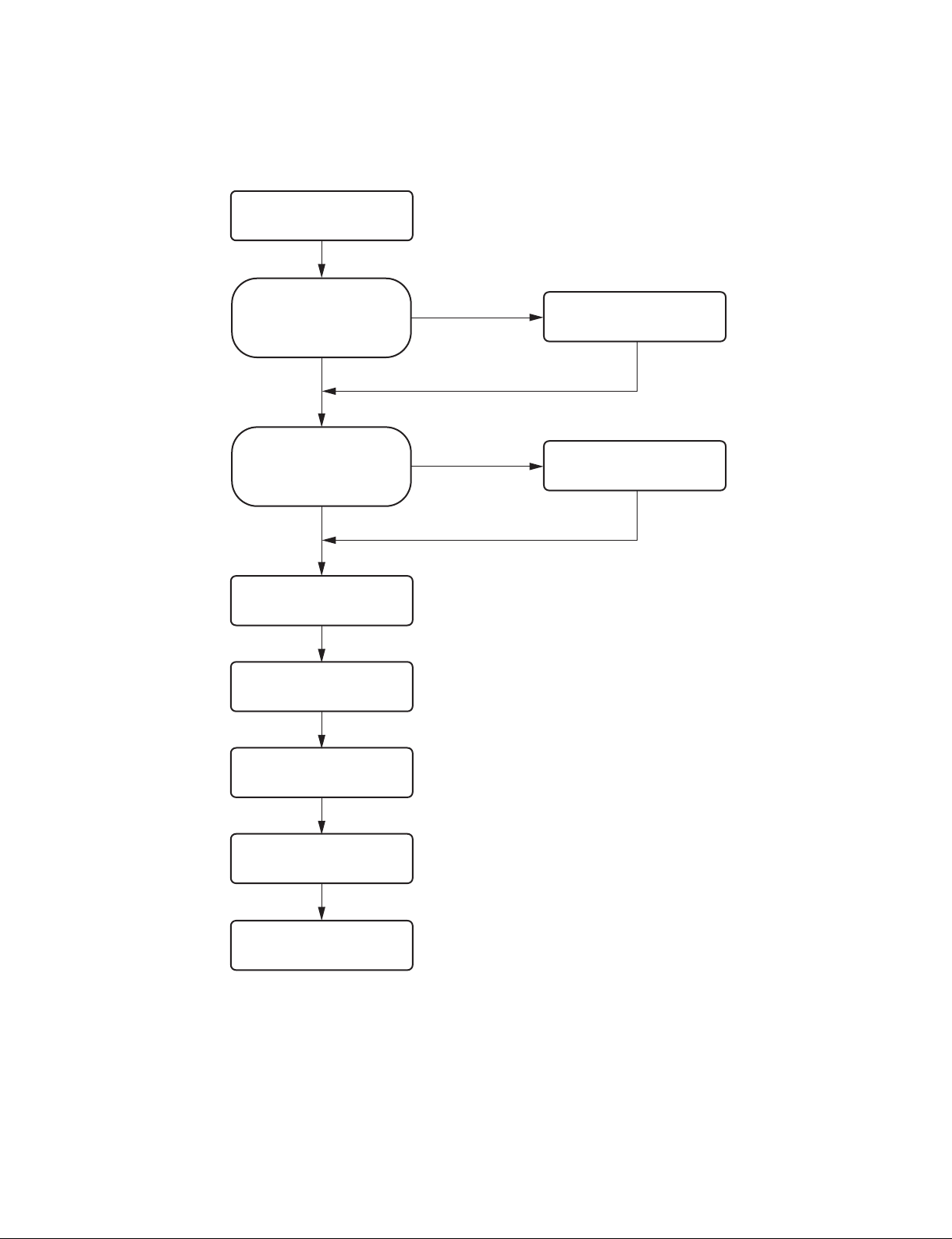

From the previous page

Can a defective point be

determined by self-diagnosis?

(Refer to Section 3-13.)

No

Can a 17-step test pattern be

normally printed?

(Refer to Section 3-1-3.)

No

Cannot paper be printed at all or

is paper printed in white?

No

Is the image in a test pattern

disturbed?

No

Yes

Yes

Yes

Yes

Check the determined point or

replace the relevant parts.

(Refer to Section 2-1.)

Normal

Refer to “2-2-3. Printing cannot be

performed normally from PC or no

image is output” .

Refer to “2-2-5. Print image is

distorted in the paper feed direction

(irregular feeding)” .

Check the contents of a trouble.

1-2 (E)

UP-D898MD/X898MD

1-1-2. Flow Chart after Service

After terminating services, check symptoms according to the flow chart below.

Start

Was this unit disassembled?

No

Is upgrading of firmware required?

No

Install a UPP-110HG.

Print a 17-step test pattern.

(Refer to Section 3-1-3.)

Clean the thermal head and platen

roller. (Refer to Section 1-11.)

Yes

Yes

&

Thermal head: Refer to Section 1-11-2.

Platen roller: Refer to Section 1-11-3.

Perform self-diagnosis and check

that no problem exists in

assembling. (Refer to Section 3-13.)

Upgrade the firmware.

(Refer to Section 1-7.)

UP-D898MD/X898MD

Check the external view and

clean it. (Refer to Section 1-11-1.)

Return this unit to a user.

$

Check that paper and USB flash memory are removed.

1-3 (E)

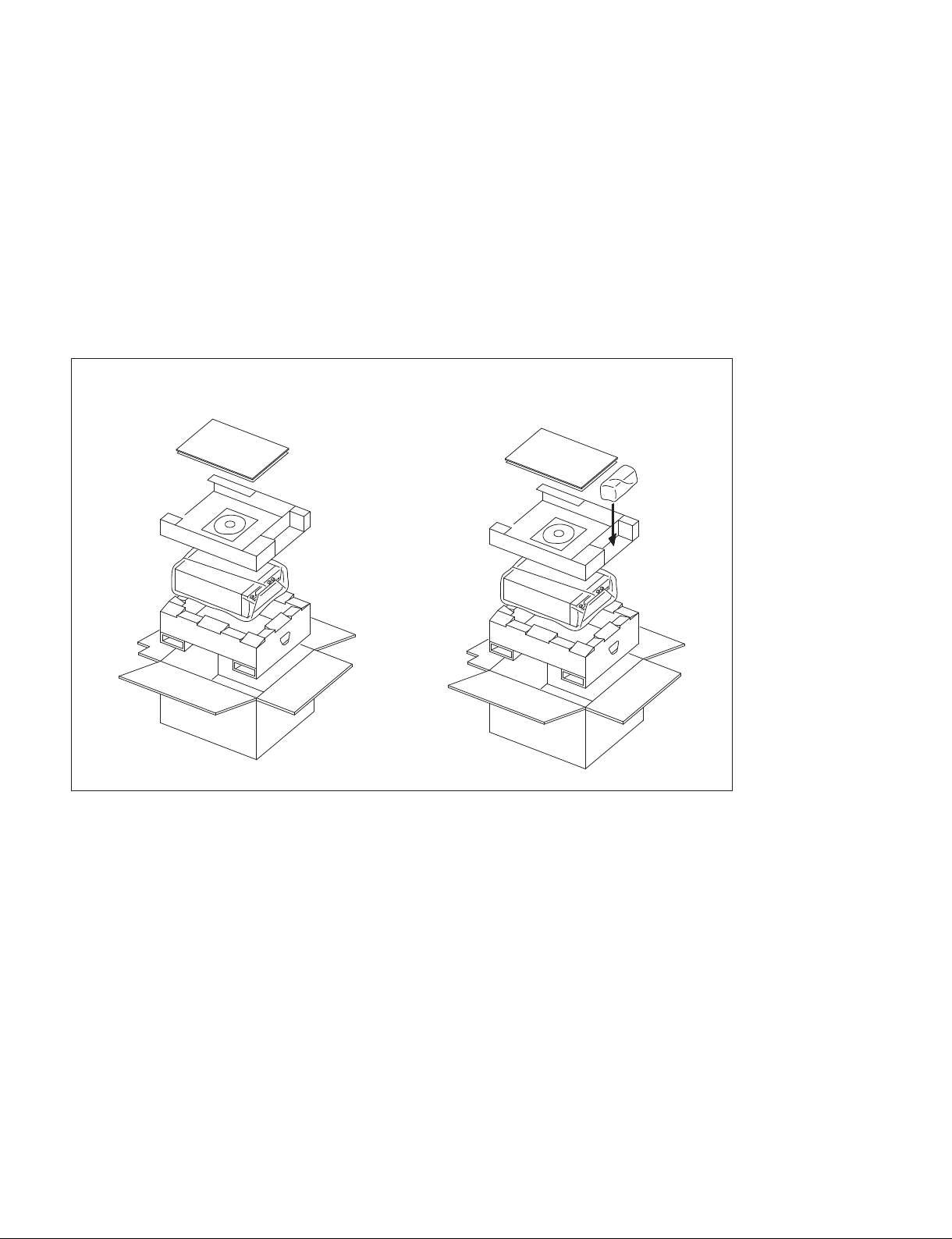

1-2. Precaution for Transporting

Perform the operation below so as to prevent the damage due to vibration and shock when transporting

this unit.

. Remove the printer paper and transport with closing the door.

. When you lift up the printer, do not hold the opened door. Otherwise, it may cause a failure due to an

excessive force applied to the door mechanism. Also, your hand might accidentally get caught between

the door and main unit resulting in injury.

. Use the packaging materials supplied for this unit.

n

Keep the packing materials removed during the delivery and installation. Do not discard them.

UP-D898MD UP-X898MD

1-4 (E)

UP-D898MD/X898MD

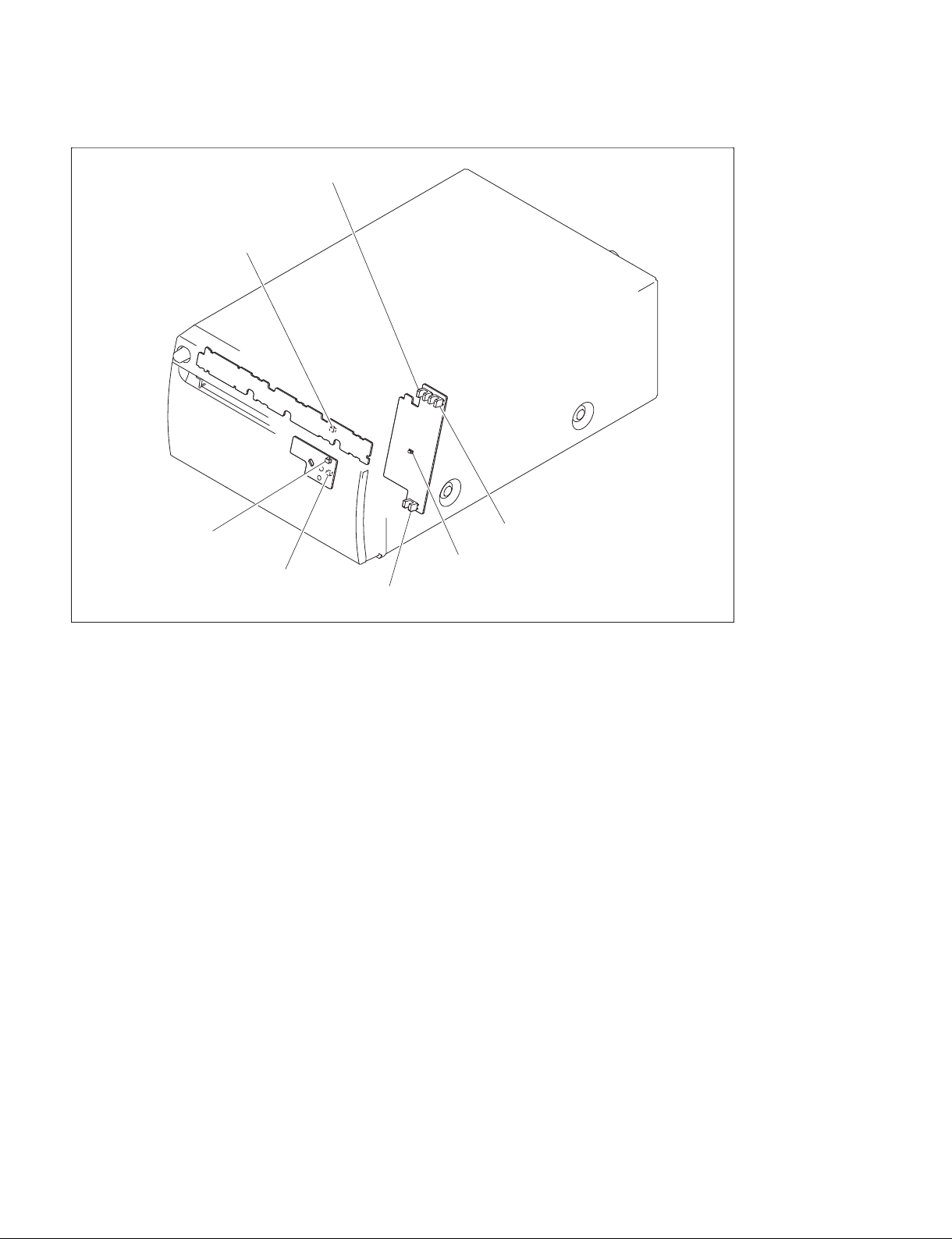

1-3. Board Location and Main Parts Location

1-3-1. Board Location

KY-711 board

SE-1143 board

SU-167 board

MA-195 board

SE-1142 board

1-3-2. Main Parts Location

DC motor

Stepping motor

Thermal head

Switching regulator

UP-D898MD/X898MD

1-5 (E)

1-3-3. Sensor Location

Head position sensor (Print)

Edge sensor

(Light receiving side)

Edge sensor

(Light emitting side)

Tray sensor

(Light receiving side)

Door sensor

Head position sensor

(Home)

Tray sensor

(Light emitting side)

1-4. Tightening torque

Tighten the following screws to the tightening torques as described below.

n

The screw (BVTT2.6 x 5) of this unit has two types of the tighten torque. Be careful not to confuse.

. B3 x 6: 0.80 ?0.05 N.m

. BVTT2.6 x 4: 0.80 ?0.05 N.m

. BVTT2.6 x 5 (for excluding paper holder): 0.80 ?0.05 N.m

. BVTT2.6 x 5 (for paper holder): 0.50 ?0.05 N.m

. P3 x 4: 0.50 ?0.05 N.m

. PS3 x 4: 0.80 ?0.05 N.m

. PS3 x 6: 0.80 ?0.05 N.m

. PS4 x 8: 1.40 ?0.15 N.m

. PSW3 x 8: 0.80 ?0.05 N.m

. LOCK ACE screw (M2): 0.20 ?0.05 N.m

. Tapping screw M1.7: 0.13 ?0.02 N.m

. N6, TYPE2: 1.20 ?0.10 N.m

When using the torque driver with the unit representation of cN.m, calculate the value as follows.

Example: 0.8 N.m = 80 cN.m

1-6 (E)

UP-D898MD/X898MD

1-5. Removing/Installing the Cabinet

1-5-1. Top Cover

1. Remove the five screws, then remove the top cover in the direction of the arrow.

Top cover

B3 ) 6

) 6

B3

B3

) 6

The illustration indicates UP-X898MD.

2. To install, reverse the removal procedure.

UP-D898MD/X898MD

1-7 (E)

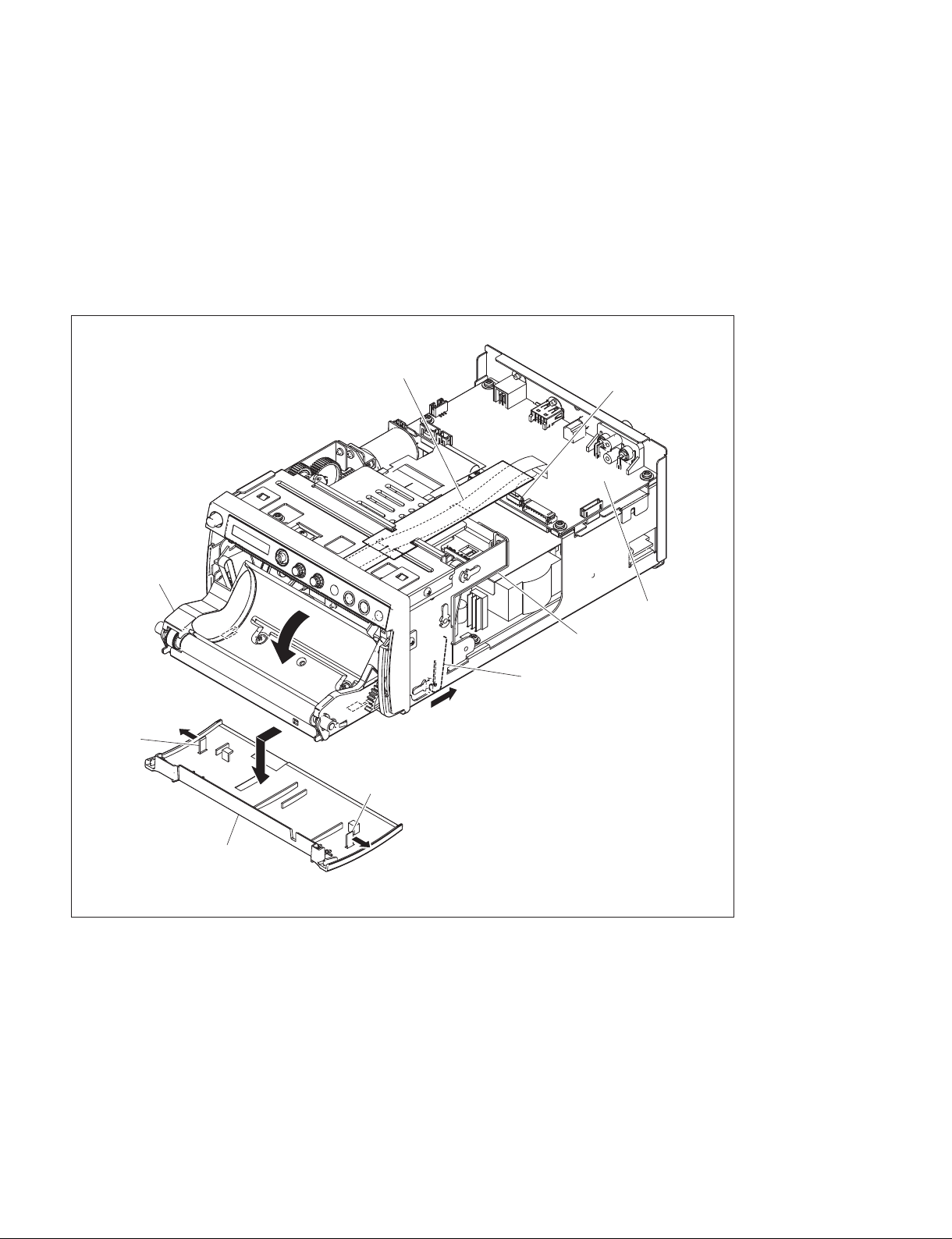

1-5-2. Front Panel Block Assembly

1. Remove the top cover. (Refer to Section 1-5-1.)

2. Release the lock arm on the mechanical deck portion (bottom) in the direction of the arrow A, then

open the door block assembly in the direction of the arrow B.

3. Remove the two hooks in the right and left directions of the arrows C, then remove the door panel in

the direction of the arrow D.

4. Disconnect the flexible flat cable from the connector (CN1103) on the MA-195 board.

Door block assembly

C

Hook

B

D

Flexible flat cable

CN1103

MA-195 board

Mechanical deck portion

Lock arm

A

Hook

1-8 (E)

Door panel

C

The illustration indicates UP-X898MD.

UP-D898MD/X898MD

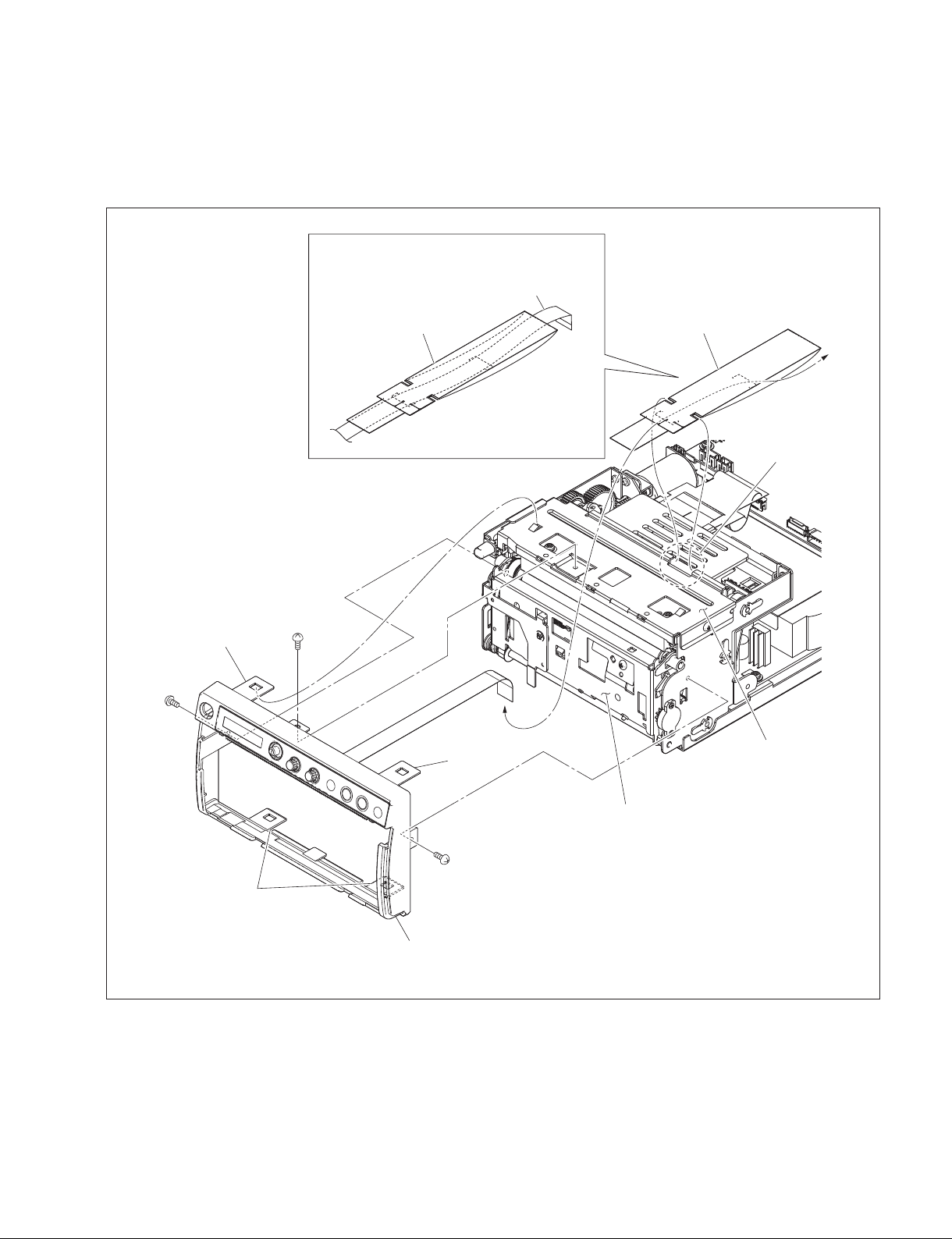

5. Close the door block assembly.

6. Remove the FFC guard (KY) from the portion A of the MD top chassis.

7. Remove the three screws and four hooks, then remove the front panel block assembly.

8. Remove the FFC guard (KY) from the flexible flat cable.

When attaching the flexible flat cable, route it

through the FFC guard (KY).

Flexible flat cable

BVTT

2.6 ) 4

Hook

BVTT

2.6

FFC guard (KY)

)

4

Hook

FFC guard (KY)

Portion A

MD top chassis

Hooks

9. To install, reverse the removal procedure.

UP-D898MD/X898MD

BVTT

2.6

)

4

Front panel block assembly

Door block assembly

The illustration indicates UP-X898MD.

1-9 (E)

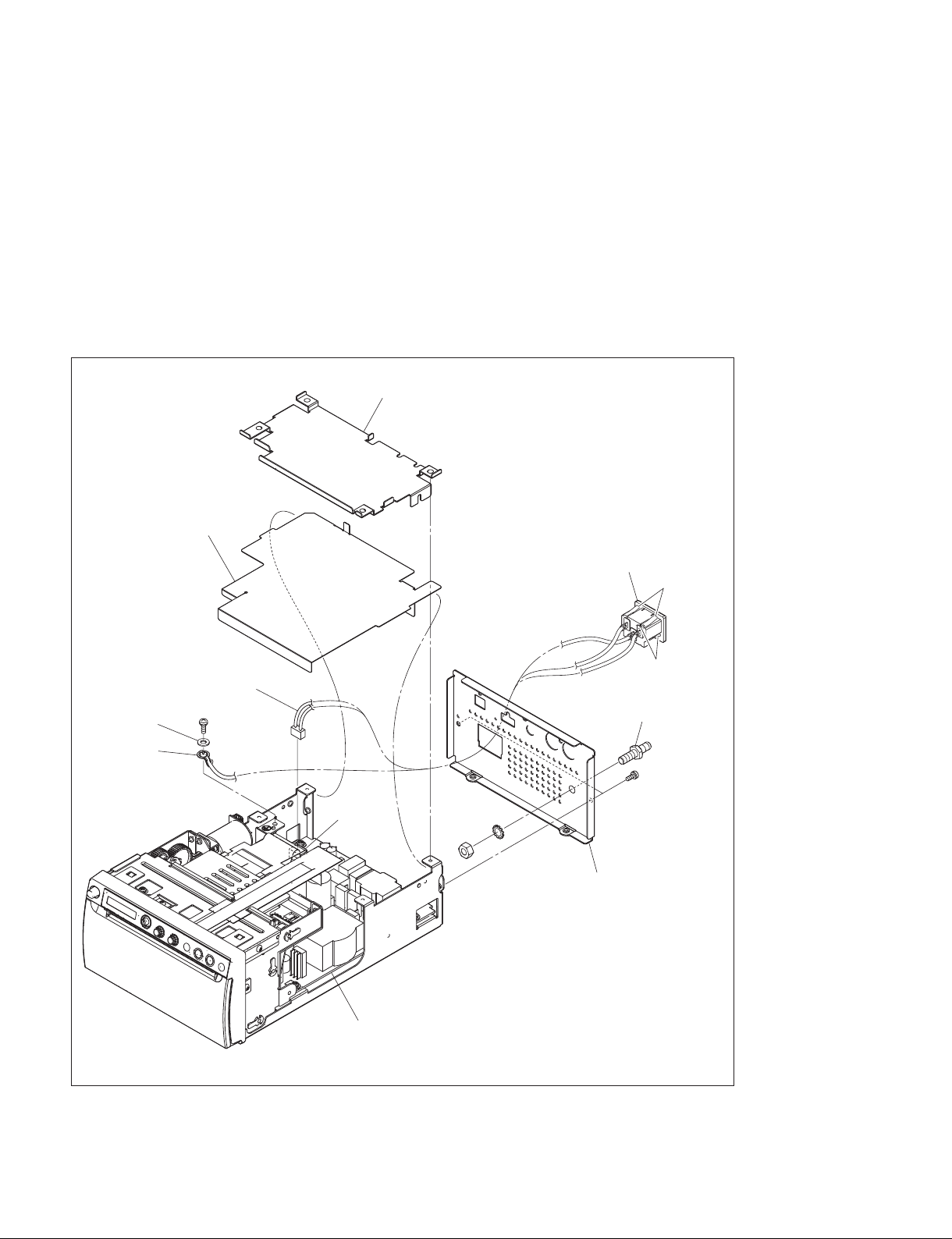

1-5-3. Rear Panel

1. Remove the top cover. (Refer to Section 1-5-1.)

2. Remove the MA-195 board. (Refer to Section 3-1.)

3. Remove the shield plate (MA) and insulating sheet (MA).

4. Remove the screw (PS4 x 8), then remove the washer (W4) and earth terminal.

5. Disconnect the harness from the connector (CN101) on the switching regulator.

6. Remove the two screws (P3 x 4), then remove the rear panel.

7. Remove the four hooks, then remove the AC inlet.

8. Remove the nut (N6) and washer (LW6), then remove the equipotential terminal.

Shield plate (MA)

Insulating sheet (MA)

AC inlet

Hooks

Harness

PS4 ) 8

W4

Earth terminal

CN101

Switching regulator

9. To install, reverse the removal procedure.

N6

Equipotential terminal

P3

LW6

Rear panel

The illustration indicates UP-X898MD.

Hooks

) 4

1-10 (E)

UP-D898MD/X898MD

1-6. General Information of Utility Software

1-6-1. Required Equipment/Tools

. Personal computer (PC) having the USB interface

. OS: Windows Vista/7/8

. Utility software: Utility Tool for UP-DX898MD.exe

t

For obtaining the utility software, contact your local Sony Sales Office/Service Center.

. USB cable

n

Use the USB 2.0 certified USB cable having a length of 2 m or less. Use of cables other than specified

may cause unstable operation of this unit.

. Thermal Print Media: UPP-110HG (Part number: 1-772-473-13)

1-6-2. Preparation

1. Connect this unit and PC using the USB cable.

t

The installation of printer driver may be requested when this unit and PC are connected. However, it

is not required to install the printer driver when using this utility software.

2. Turn on the power of PC.

3. Press the power switch of this unit to turn on the power.

4. Start the utility software (Utility Tool for UP-DX898MD.exe).

UP-D898MD/X898MD

1-11 (E)

1-6-3. Function Description

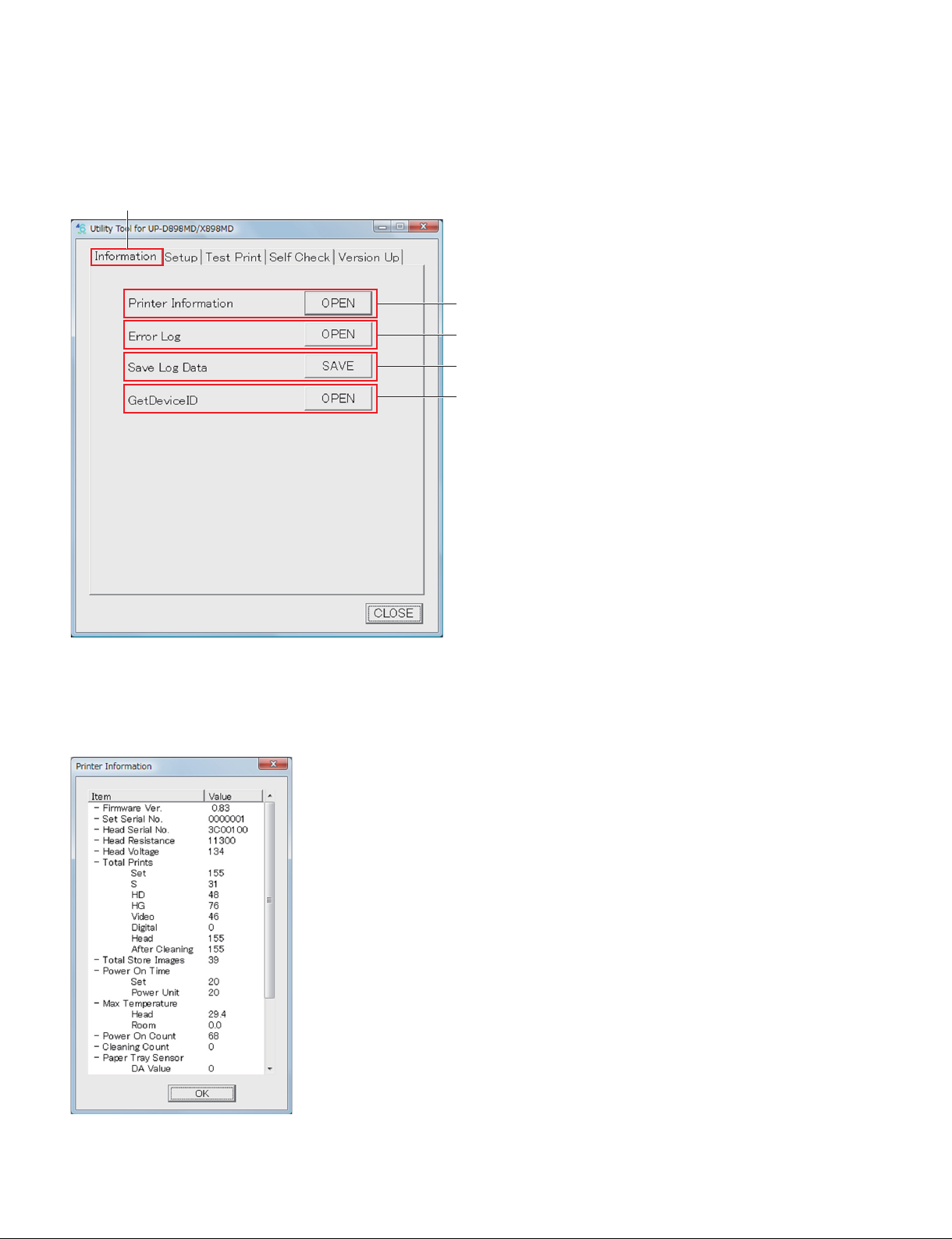

1. Information tab

Information tab

1

2

3

4

1 Printer Information

When you click the [OPEN] button, the information of this unit is obtained from EEPROM (IC507/

MA-195 board) of this unit and displayed.

1-12 (E)

UP-D898MD/X898MD

. Firmware Ver.: Version of firmware

. Set Serial No.: Serial number of this unit

. Head Serial No.: Serial number of thermal head

. Head Resistance: Resistance value (Z) of thermal head

. Head Voltage: Voltage setting value (D/A value) of thermal head

. Total Prints:

Set: Total print count of this unit

S: Total print count of paper (UPP-110SE)

HD: Total print count of paper (UPP-110HD)

HG: Total print count of paper (UPT-110HG)

Video: Total print count of image captured from video signal

Digital: Total print count of digital image transmitted from PC

Head: Total print count of thermal head

After Cleaning: Total print count after cleaning of thermal head

. Total Store Images: Number of image stored in USB flash memory

. Power On Time

Set: Total power on time of this unit (h)

Power Unit: Total power of time of power unit (h)

. Max Temperature

Head: Maximum temperature of thermal head (dC)

Room: Maximum room temperature (dC)

. Power ON Count: Number of power ON times

. Cleaning Count: Number of thermal head cleaning times

. Paper Tray Sensor: Information of paper tray sensor (Luminance side: D201/SE-1143 board, light

receiving side: Q301/SE-1142 board)

DA Value: Amount of luminescence (D/A value)

High Level: Light receiving portion High level

Low Level: Light receiving portion Low level

Threshold: Light receiving portion threshold level

. Paper Front Sensor: Information of paper tray sensor (Luminance side: D301/SE-1142 board, light

receiving side: Q201/KY-711 board)

DA Value: Amount of luminescence (D/A value)

High Level: Light receiving portion High level

Low Level: Light receiving portion Low level

Threshold: Light receiving portion threshold level

. [OK] button: Closes the Printer Information screen.

UP-D898MD/X898MD

1-13 (E)

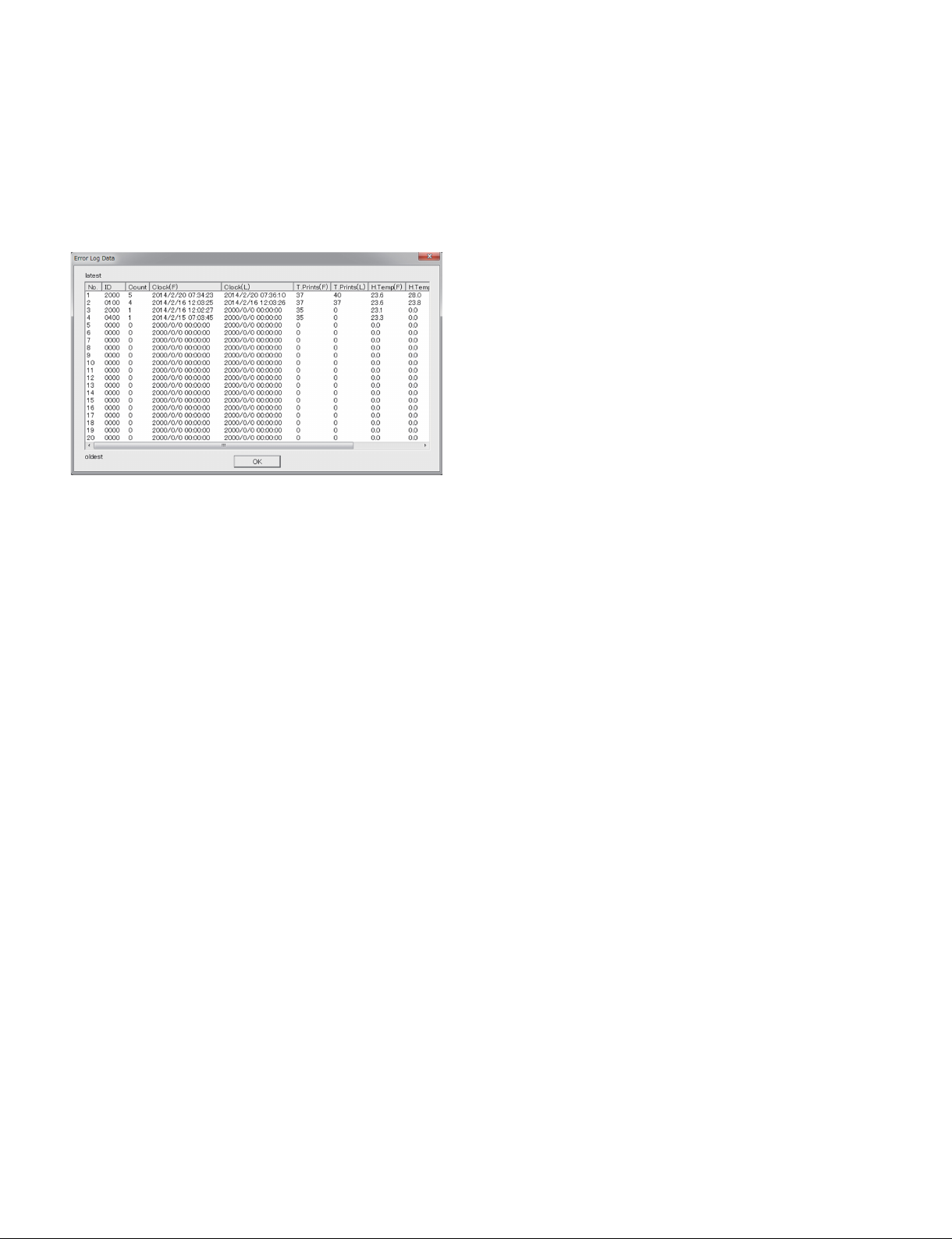

2 Error Log

When you click the [OPEN] button, the 20 errors that have occurred in the past are displayed. When the

number of error exceeds 20, the error is overwritten by the latest error beginning with the chronologically

oldest error (No. 20). However, when the same errors are overlapped (the errors of the same error code

occurred continuously), only the Count number of the latest error (No. 1) is overwritten (increased) and

the error No. 20 is not deleted.

t

For the error code ID, refer to Section 2-1.

. ID: Error code ID information

. Count: Number of overlapping errors

. Clock (F): Date and time when the first error is detected

. Clock (L): Date and time when the last error is detected (This is displayed only when the errors are

overlapped.)

. T.Prints (F): Total print count of this unit when the first error is detected

. T.Prints (L): Total print count of this unit when the last error is detected (This is displayed only when

the errors are overlapped.)

. H.Temp (F): Thermal head temperature (dC) when the first error is detected

. H.Temp (L): Thermal head temperature (dC) when the last error is detected (This is displayed only

when the errors are overlapped.)

. R.Temp (F): Room temperature (dC) when the first error is detected

. R.Temp (L): Room temperature (dC) when the last error is detected (This is displayed only when the

errors are overlapped.)

. [OK] button: Closes the Error Log screen.

3 Save Log Data

When you click the [Save] button, the menu setting and operation log information of this unit as well as

the information displayed in Printer Information and Error Log are saved as CSV format file on PC.

The saved file can be displayed by using the spreadsheet software such as Excel.

The information in this file is important when the person in charge of design performs a failure analysis.

4 GetDeviceID

Not used

1-14 (E)

UP-D898MD/X898MD

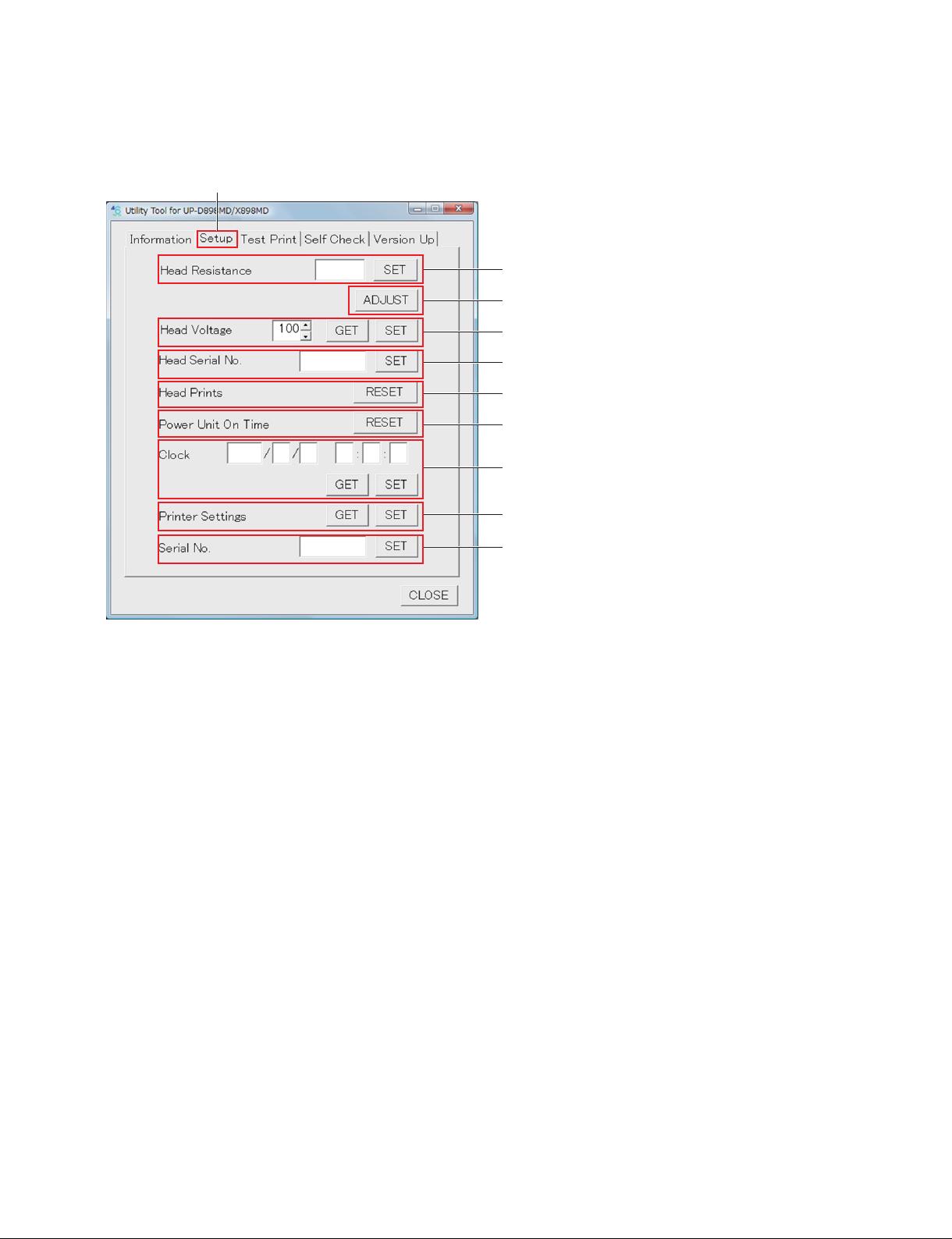

2. Setup tab

Setup tab

1

2

3

4

5

6

7

8

9

1 Head Resistance

Sets the thermal head resistance value.

When you click the [SET] button, the value in the edit box is written in EEPROM (IC507/MA-195

board) of this unit.

2 [ADJUST] button

Calculates the head voltage setting value based on the thermal head resistance value, and write the value

(D/A value) in EEPROM (IC507/MA-195 board) of this unit.

3 Head Voltage

Obtains and sets the thermal head voltage setting value (D/A value).

. [GET] button: When you click this button, the information stored in EEPROM (IC507/MA-195 board)

of this unit is displayed in the edit box.

. [SET] button: When you click this button, the value in the edit box is written in EEPROM (IC507/

MA-195 board) of this unit.

4 Head Serial No.

Sets the thermal head serial number.

When you click the [SET] button, the number in the edit box is written in EEPROM (IC507/MA-195

board) of this unit.

5 Head Prints

When you click the [RESET] button, the total print count of thermal head is reset.

UP-D898MD/X898MD

1-15 (E)

6 Power Unit On Time

When you click the [RESET] button, the total on time of power unit is reset.

7 Clock

Obtains and sets the date/time information.

. [GET] button: When you click this button, the date/time information obtained from this unit is dis-

played in the edit box.

. [SET] button: When you click this button, the date/time information in the edit box is set in this unit.

8 Printer Settings

Obtains and sets the menu setting information of this unit.

. [GET] button: When you click this button, the menu setting information stored in EEPROM (IC507/

MA-195 board) of this unit is saved as binary file (.CNS) on PC.

. [SET] button: When you click this button, the menu setting information of the specified binary file

(.CNS) is written in EEPROM (IC507/MA-195 board) of this unit.

9 Serial No.

Sets the serial number of this unit.

When you click the [SET] button, the number in the edit box is written in EEPROM (IC507/MA-195

board) of this unit.

1-16 (E)

UP-D898MD/X898MD

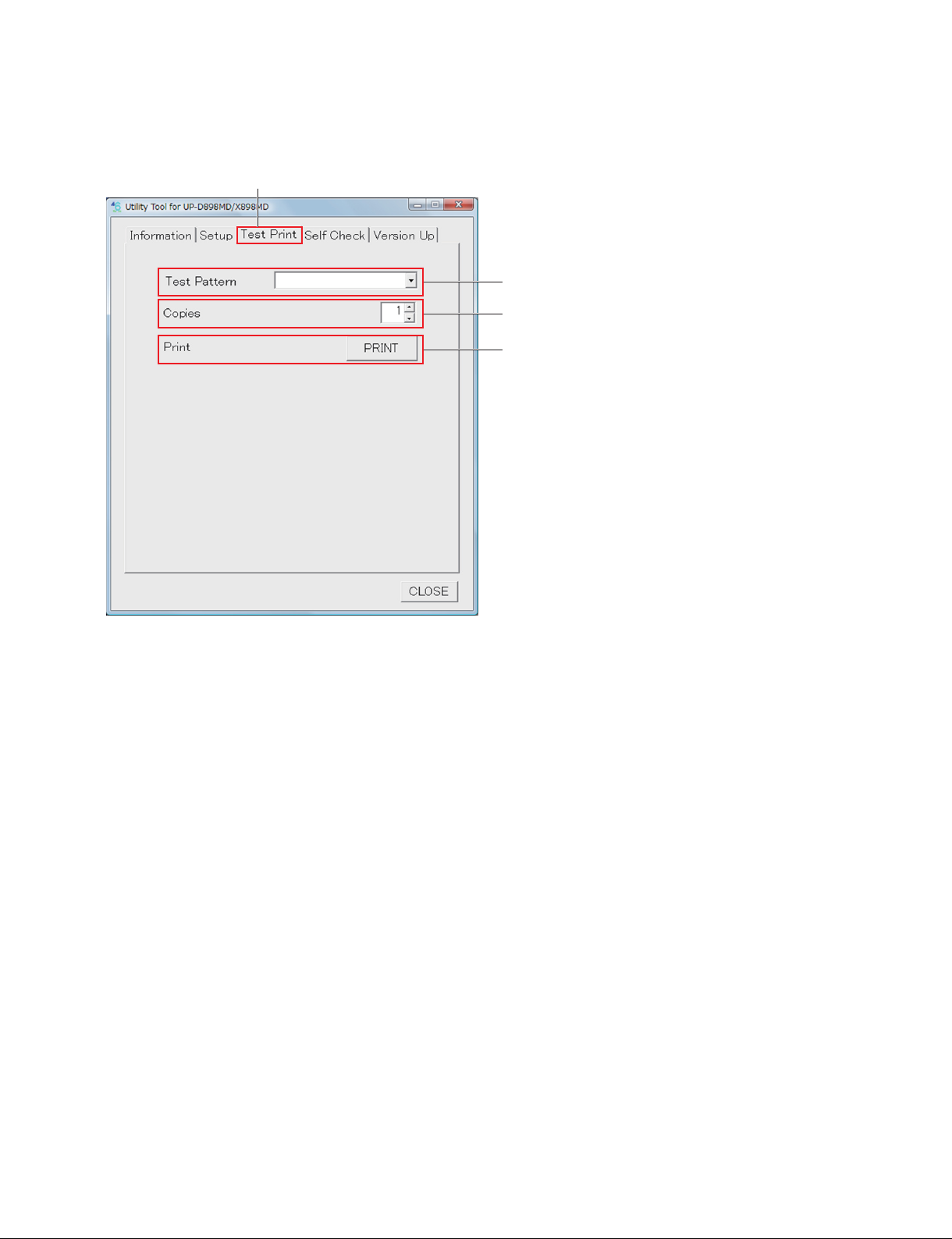

3. Test Print tab

Test Print tab

1

2

3

1 Test Pattern

Selects the image pattern to be printed.

. STEP: Built-in stair-step pattern

. CROSS STEP: Built-in cross step pattern

. LAMP: Built-in lamp image

. CROSS LAMP: Built-in cross lamp image

. SKEW LAMP: Built-in skew lamp image

. HEAD CONFIRM PAT1: Built-in thermal head confirmation pattern 1

. HEAD CONFIRM PAT2: Built-in thermal head confirmation pattern 2

. LOG: Log information in this unit

. BLACK (S/L)

. DARK GRAY (S/L)

. GRAY (S/L)

. LIGHT GRAY (S/L)

. WHITE (S/L)

*

: Built-in 100% black pattern

*

*

: Built-in gray pattern

: Built-in gray pattern (darker)

*

*

: Built-in gray pattern (lighter)

: Built-in 100% white pattern

*: Print size: Horizontal x Vertical [mm]

S: 100 x 75

L: 100 x 117

UP-D898MD/X898MD

1-17 (E)

2 Copies

Sets the number of copies.

You can set the number of copies from 1 to 255 sheets.

3 Print

When you click the [PRINT] button, the test print is performed.

The pattern selected in 1 is printed by the number of copies set in 2.

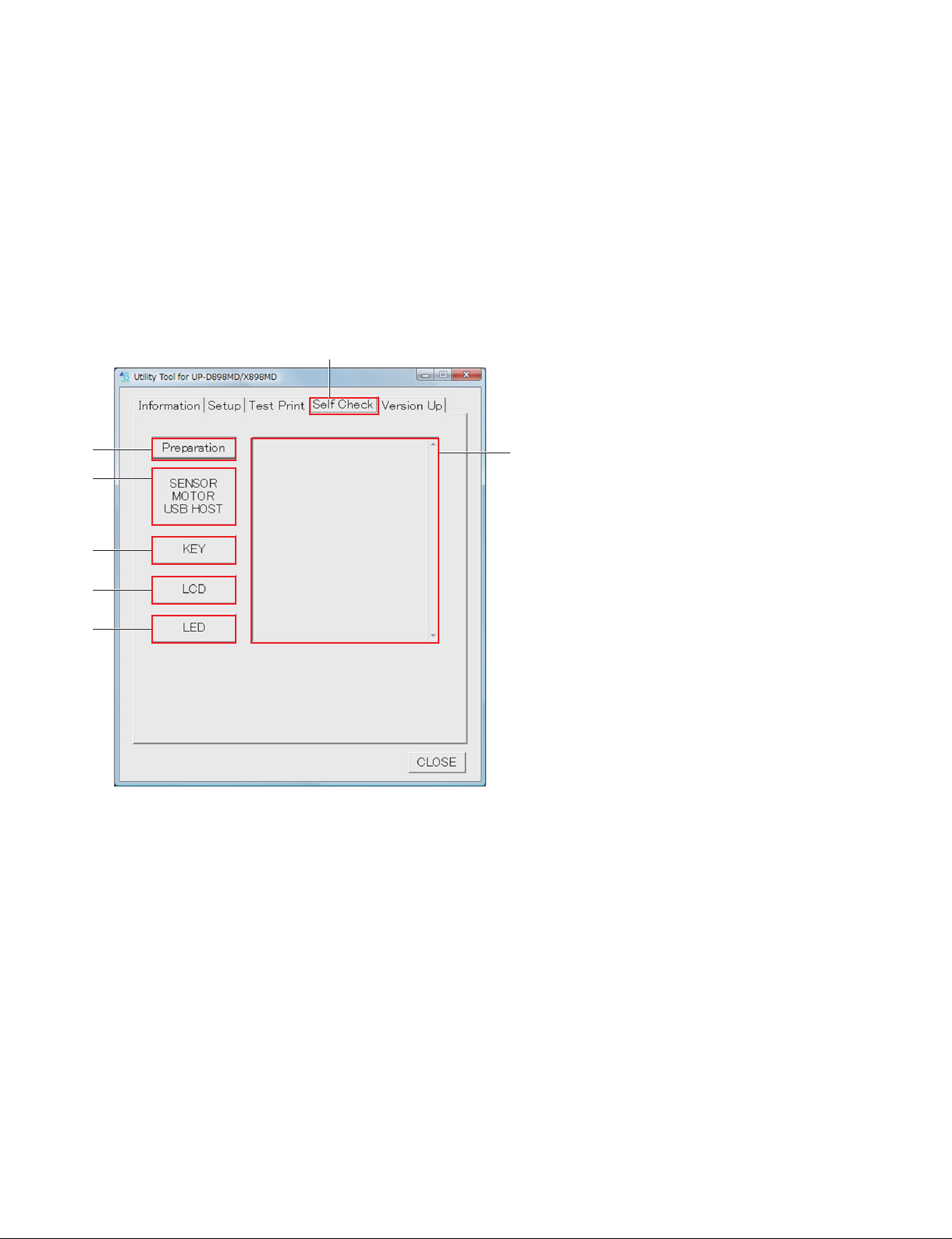

4. Self Check tab

Self Check tab

1

2

3

4

5

6

1 [Preparation] button

Performs the preparation of self check.

When this button is clicked, “Before checking… Eject the paper. Close the door. Insert USB Flash Drive.

(UP-X898MD)” is displayed in the edit box 7.

According to the display, eject the paper, close the door and connect the USB flash memory (UP-X898MD

only).

2 [SENSOR|MOTOR|USB|HOST] button

Performs the self check of SDRAM, EEPROM, sensors, and DC motor and thermistor of thermal head in

this unit.

After the check is completed, if there is no defective portion, “Check Result No Error, Check OK!” is

displayed in the edit box 7.

If any defective portion is detected, it is displayed.

t

For the cause and remedy of the defective portion, refer to Section 2-1.

1-18 (E)

UP-D898MD/X898MD

3 [KEY] button

When this button is clicked, the Check Key screen is opened. The conduction check of button, knob and

menu lever of this unit is performed.

Operate the front operation device displayed on LCD of this unit, then click the [OK] button of the Check

Key screen.

After the check is completed, the check result is displayed in the edit box 6.

4 [LCD] button

When this button is clicked, the Check LCD screen is opened, and all LCDs of this unit light up. Visually

check that all LCDs of this unit are lit.

After the check is completed, click the [OK] button of the Check LCD screen.

5 [LED] button

When this button is clicked, the Check LED screen is opened, and all LEDs of this unit light up.

. Button LED: Blinks in white.

. LCD backlight LED: Blinks in green and amber alternately.

. USB access LED (UP-X898MD only): Blinks in green and amber alternately.

Visually check that all LEDs of this unit blink.

After the check is completed, click the [OK] button of the Check LED screen.

6 Edit box

Displays the check result and message.

UP-D898MD/X898MD

1-19 (E)

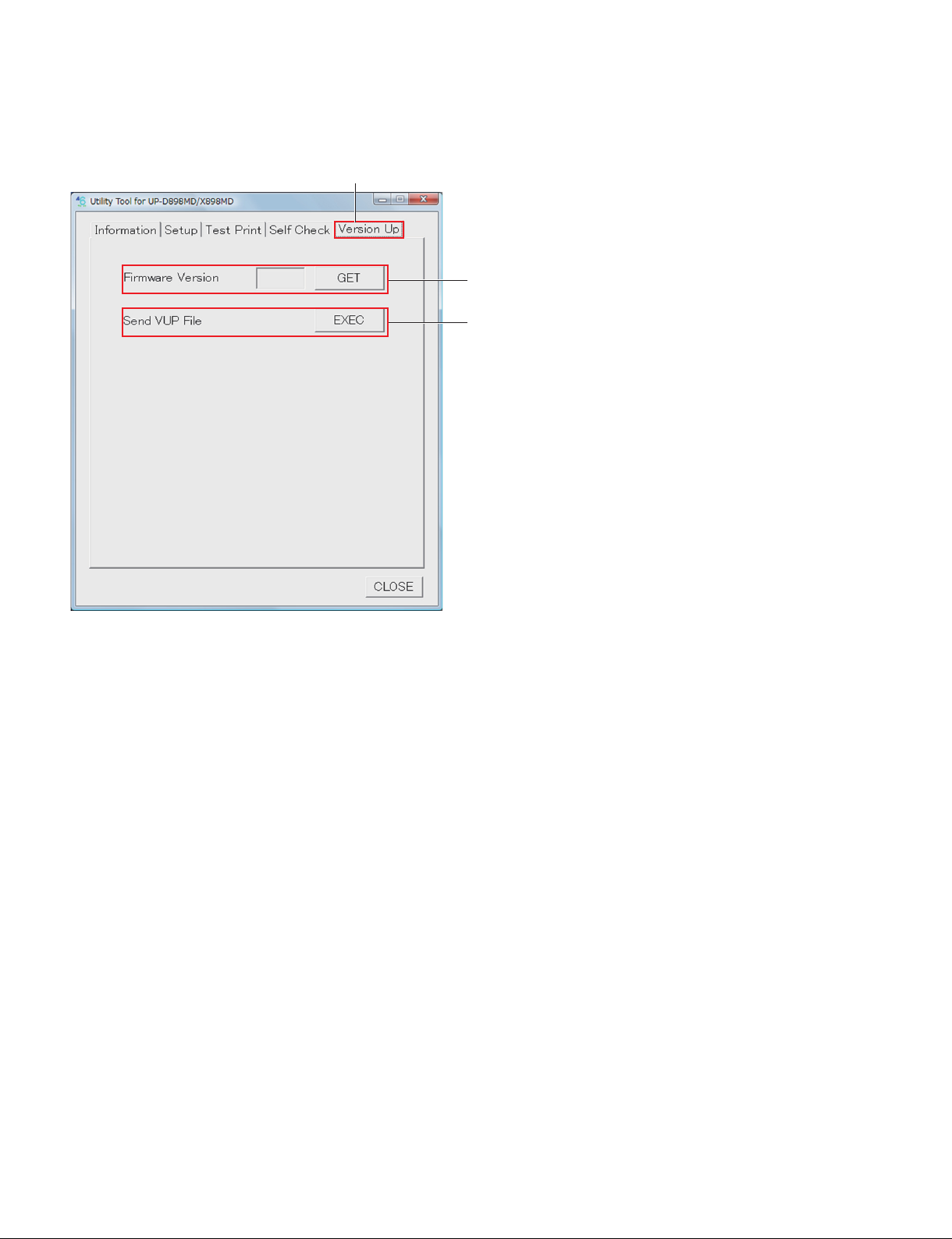

5. Version Up tab

Version Up tab

1

2

1 Firmware Version

Displays the firmware version of this unit.

When the [GET] button is clicked, the firmware version is displayed in the edit box.

2 Send VUP File

Performs the firmware version upgrade.

When the [EXEC] button is clicked, the specified version upgrade file is sent to this unit.

n

If the power is turned off in the course of the firmware writing, this unit will not start. Never turn off the

power of this unit before completing the writing. If the power is accidentally turned off and this unit will

not start, replace the MA-195 board. (Refer to Section 3-1.)

t

For the firmware version upgrade procedure, refer to Section 1-7.

1-20 (E)

UP-D898MD/X898MD

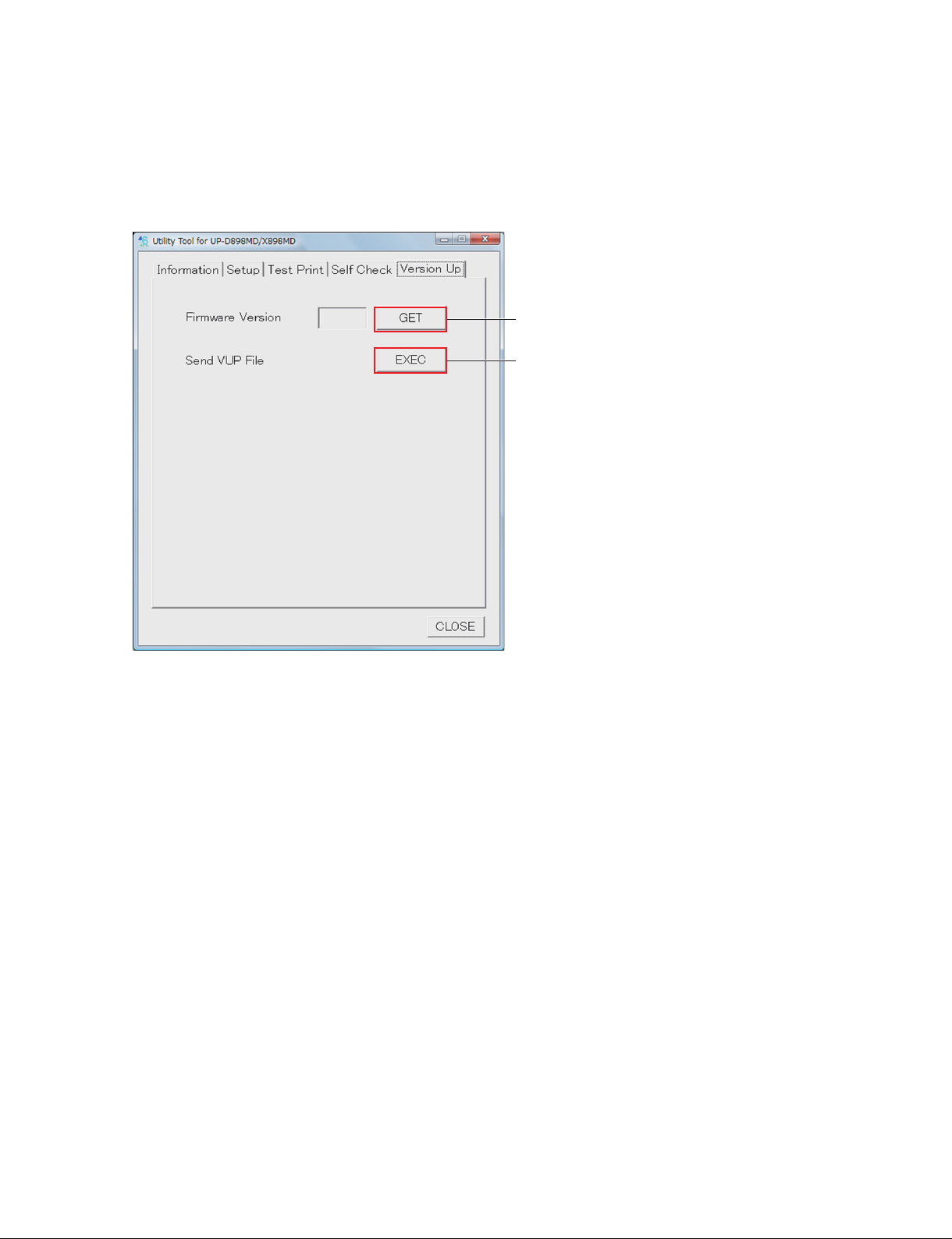

1-7. Firmware Version Upgrade

1. Start the utility software. (Refer to Section 1-6.)

2. Click the [GET] button of “Firmware Version” of the Version Up tab.

The version of the firmware currently installed in this unit is displayed.

[GET] button

[EXEC] button

3. Write down the current firmware version.

4. Click the [EXEC] button of “Send VUP File”.

5. Select the firmware (vup) file, and then click the [OPEN] button.

After the file is transferred, the firmware writing is started.

The display of LCD during the firmware writing is as follows.

. UPGRADE (blinks): Information is being written in FLASH.

. REBOOT (lights up): Writing is completed.

When the firmware writing is completed, 3 beep sounds are made.

n

If the power is turned off in the course of the firmware writing, this unit will not start. Never turn off

the power of this unit before completing the writing. If this unit will not start, replace the MA-195

board. (Refer to Section 3-1.)

6. Check that the writing is completed, and then restart this unit.

7. Click the [GET] button of “Firmware Version” of Version Up tab.

8. Check that the firmware is upgraded to the latest version.

UP-D898MD/X898MD

1-21 (E)

1-8. Service Mode

It is possible to perform the printing of built-in pattern and the various settings with this unit alone. This

mode is used when you cannot use the utility software due to the USB device failure and so forth.

1-8-1. Startup Procedure

1. Turn on the power while pressing and holding the [FEED] button and [COPY] button simultaneously.

2. After approx. 4 seconds, check that the LCD backlight of this unit blinks in green and amber alternately, and then release each button.

The service mode is started.

1-8-2. Service Mode Menu

When this unit is started in the service mode, the first item of menu is changed from “HISTORY” (normal

mode) to “SERVICE”.

The menu structure of service mode is as follows.

When this unit is started in the service mode, even if you do not operate the button for approx. 20 seconds,

the unit does not exit from the menu mode because the time out function does not work.

READY

SERVICE

PATERN Test pattern print

SV.QTY Number of test pattern print

STR.MEM USB flash memory saving function ON/OFF

HEAD.V Thermal head voltage setting

LPF Low pass filter

PRT.LOG Log print

INIT Initialization of setting

MECHA Mechanical operation of individual motors

TEMP Temperature display

TMODE Switching of Toshiba mode

RMCAP Remote capture timing

PRT.HELP

ADJUST

VIDEO

DIGITAL

PRT.MENU

PREF.

CLEAN.TH

CONFIG.

SERIAL.N

1-22 (E)

UP-D898MD/X898MD

Loading...

Loading...