Page 1

3-207-372-11 (1)

Digital Film Imager

Instructions for Use Page 2

Setup Manual Page 31

This manual is comprised of the Instructions for Use and the Setup Manual.

The Instructions for Use gives the information on how to use the printer for the

routine work.

The Setup Manual gives the system administrator the information needed to setup

the printer and connect it to the network.

UP-DF500

© 2003 Sony Corporation

Page 2

Owner's Record

The model and serial numbers are located at the rear.

Record these numbers in the space provided below.

Refer to these numbers whenever you call upon your

Sony dealer regarding this product.

Model No. ____________________

Serial No. ____________________

WARNING

For the customers in Canada

This unit has been certified according to Standard CSA

C22.2 NO.601.1.

For the customers in the U.S.A and

Canada

Model UP-DF500 is Non-Patient Equipment.

This unit can not be used in the vicinity of patients.

* Patient Vicinity

To prevent fire or shock hazard, do not expose the unit to

rain or moisture.

To avoid electrical shock, do not open the cabinet. Refer

servicing to qualified personnel only.

THIS APPARATUS MUST BE EARTHED.

This symbol indicates the equipotential

terminal which brings the various parts

of a system to the same potential.

This symbol is intended to alert the user

to the presence of important operating

and maintenance (servicing) instructions

in the literature accompanying the

appliance.

For the customers in the U.S.A.

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection again harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference in

which case the user will be required to correct the

interference at his own expense.

R1.83m

(6 feet)

Important safeguards/notices for use in

the medical environments

1. All the equipments connected to this unit shall be

certified according to Standard IEC60601-1,

IEC60950, IEC60065 or other IEC/ISO Standards

applicable to the equipments.

2. When this unit is used together with other equipment

in the patient area*, the equipment shall be either

powered by an isolation transformer or connected via

an additional protective earth terminal to system

ground unless it is certified according to Standard

IEC60601-1.

* Patient Area

R1.5m

You are cautioned that any changes or modifications not

expressly approved in this manual could void your

authority to operate this equipment.

This device requires shielded interface cables to comply

with FCC emission limits.

2

3. The leakage current could increase when connected

to other equipment.

4. This equipment generates, uses, and can radiate

frequency energy. If it is not installed and used in

accordance with the instruction manual, it may cause

interference to other equipment. If this unit causes

interference (which can be determined by

unplugging the power cord from the unit), try these

measures: Relocate the unit with respect to the

Page 3

susceptible equipment. Plug this unit and the

susceptible equipment into different branch circuit.

Consult your dealer. (According to standard

EN60601-1-2 and CISPR11, Class B, Group 1)

Caution

When you dispose of the unit or accessories, you must

obey the law in the relative area or country and the

regulation in the relative hospital.

Warning on power connection

Use a proper power cord for your local power supply.

Warning on power connection for medical use

Please use the following power supply cord.

With connectors (plug or female) and cord types other

than those indicated in this table, use the power supply

cord that is approved for use in your area.

United States Canada

Plug Type HOSPITAL GRADE* HOSPITAL GRADE*

Female end E62405, E35708 LR53182, LL022442,

Cord type E159216, E35496

Minimum cord set

rating

Safety approval UL Listed CSA

*Note: Grounding reliability can only be achieved when the equip-

ment is connected to an equivalent receptacle marked ‘Hospital Only’

or ‘Hospital Grade’.

Min.Type SJT

Min.18 AWG

10A/125V 10A/125V

LL088408

LL112007-1,

LL20262, LL32121,

LL84494

Min.Type SJT

Min.18AWG

Voor de Klanten in Nederland

Dit apparaat bevat een vast ingebouwde batterij die niet

vorvangen hoeft te worden tijdens de levensduur van het

apparaat.

Raadpleeg uw leverancier indien de batterij toch

vervangen moet worden.

De batterij mag alleen vervangen worden door

vakbekwaam servicepersoneel.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Lever het apparaat aan het einde van de levensduur in

voor recycling, de batterij zal dan op correcte wijze

verwerkt worden.

3

Page 4

Instructions for Use

Table of Contents

Introduction

About this Manual .................................................5

System Overview ....................................................5

System Configuration Example ............................6

Location and Function of Parts and Controls .....6

Preparation

Supplied Accessories ..............................................8

Assembly ............................................................8

Placing the Unit ..................................................8

Connections ............................................................9

Operation

Loading Film ........................................................11

Loading Film .....................................................11

Printing .................................................................14

Adjustment

Menu Operation ...................................................15

Confirming Information ....................................15

Adjusting the Print Quality ...............................15

Calibrating the Printing Density .......................16

Adjusting the Tone ............................................17

Selecting a Gamma Curve ................................19

Miscellaneous

Precautions ...........................................................20

Safety ................................................................20

Installation ........................................................20

Transporting the Unit ........................................20

Cleaning the Cabinet .........................................20

Maintenance ......................................................20

Specifications ........................................................24

Messages ................................................................25

Error Messages .................................................25

Other Messages .................................................26

Troubleshooting ....................................................27

If Damage is Suspected .....................................27

If the Film Jams ................................................27

Index ......................................................................30

Page 5

Introduction

About this Manual

Introduction

Describes the features and system configuration of the

digital film imager. Also provided is information on the

location and function of parts.

Preparation

Explains the steps involved in placing and connecting

the unit prior to getting started - checking the supplied

accessories and assembly. Once all assembly and all

connections have been made, there should be no need to

perform these operations again during normal printing

operations.

Operation

Describes loading of the film tray and blue thermal film,

and actual printing operations.

Adjustment

Describes how to make adjustment such as sharpness,

calibration and density adjustment, and to how to select

gamma curve, using the menus displayed on the LCD.

System Overview

The UP-DF500 digital film imager is a thermal printer

designed to reproduces image data in DICOM format

sent via the network.

The UP-DF500 has the following functions’

• Equipped with DICOM (Digital Imaging and

Communications in Medicine) features

The DICOM portion of the unit receives image data in

DICOM format sent from the modality via the

network, processes them at 14 inches × 17 inches

either by enlarging or reducing them.

• High quality and high print resolution

The unit allows you to print out in high-resolution

black and white (4096 shades) and in high-resolution

print mode (320 dpi).

• Suitable for diagnosing using image data captured by

diagnosis equipment

The unit prints image data on the 14 × 17 inches blue

thermal film, and these prints are used for diagnosing.

Also, the unit provides sufficient high picture quality

for image diagnosis.

• Space saving

You can place the unit either horizontally or vertically.

This allows you to design system configuration freely

in accordance with the location.

Introduction

Miscellaneous

Provides technical information in the unit, regular

maintenance, how to handle error messages displayed in

the LCD, and how to deal with paper jams. Also, an

index will assist you in locating the desired section

quickly.

Conventions used

Cross reference

Throughout this manual you will find references to other

sections of the manual that contain related information.

Important note

Be sure to read the sections marked . They

explain points that you should be aware of to operate the

unit correctly and prevent malfunctions.

Note

About this Manual / System Overview

5

Page 6

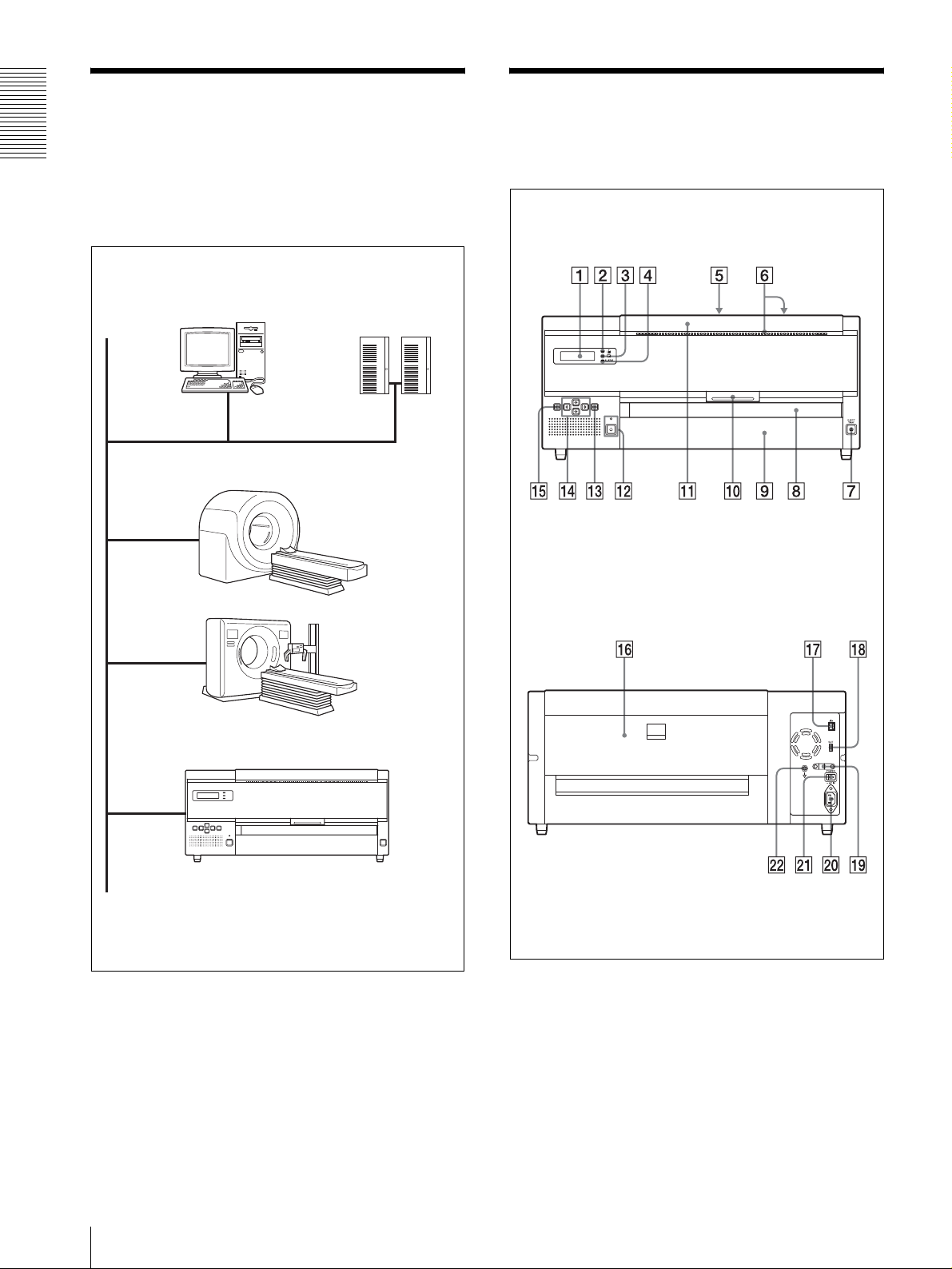

System Configuration

Location and Function

Introduction

Example

The system allows you to make printouts of the data in

DICOM format, sent from image diagnosis equipment

such as CTs, MRIs.

The following shows a system configuration example.

Personal computer for

managing the system

DICOM LAN network

DICOM server

Modality

Image diagnosis

equipment and so on

of Parts and Controls

For details, refer to the pages given in parentheses.

Front panel

UP-DF500

Modality

Image diagnosis

equipment and so on

Rear panel

A Liquid Crystal Display (LCD) (14, 15, 25, 26)

Displays messages showing the status of the unit.

Operational information is displayed when the unit

is in use. Error messages are displayed when an

error condition occurs.

6

System Configuration Example / Location and Function of Parts and Controls

B Film remaining confirmation indicator (11)

Allows you to check the remaining amount of film

in the film tray.

When films are loaded enough: Lights in green.

Page 7

When film is running short: Lights in yellow.

When film has been exhausted: Goes off. The

ALARM indicator lights in orange and the message

is displayed in the LCD.

C PRINT indicator (14, 26)

Lights in green while the printer is printing.

D ALARM indicator (25)

Lights in orange when the film has been used up,

film jams occur, or other problems occur.

E TOP cover (28)

Open when removing jammed film.

F Ventilation holes (23)

There is a built-in fan to prevent the thermal head

from overheating.

G EJECT TRAY button (11)

Push this button to pull the film tray out. This

button activates when the power is on and all covers

are closed.

N G, g, F, f (Cursor control) buttons (15, 16, 17,

19)

Press these buttons to increase or decrease the

setting values. Also press these buttons to select

menu items.

Introduction

O MENU button (15, 16, 17, 19)

Press these buttons to display menus on the printer

window display. Also press these buttons to return

to the normal window.

P Rear cover (28)

Open this cover when removing jammed film.

Q Network connector (RJ-45 modular jack) (9)

Conforms to the 100BASE-TX standard. Used to

connect to the LAN.

When using a LAN cable: For safety, do not

connect to the connector for peripheral device

wiring that might have excessive voltage.

R Special output connector

Not used. For future use.

H Film output slot (14)

Printed film sheets (printouts) are ejected here.

I Film tray (8, 11)

Load film sheet into this tray. Also, ejected film

sheets accumulate on this tray.

J Front cover lock lever (21, 22)

Used to open the front cover.

K Front cover (21, 28)

Open when the thermal head and rollers are being

cleaned. Also open when jammed film is being

removed.

L ON/STANDBY switch/indicator (14, 26)

Press this switch to set the unit to on or to the

standby status. When the power is on, the indicator

lights in green. When the this switch is set to

STANDBY, the indicator blinks, and then goes off.

Pressing this switch while the indicator is blinking

turns the power back on.

Note

S Cable stopper

Fixes the network cable to prevent it from being

disconnected.

T -AC IN connector (9)

Used to connect the unit to a wall outlet with the

supplied power cable.

U Main POWER switch

Main power switch of the unit. Turns the unit on or

off. When this switch is set to on, the unit power is

on when the ON/STANDBY switch on the front

panel is set to on.

V Equipotential ground terminal connector

Used to connect to a ground (equipotential) plug to

bring the various parts of the system to the same

potential.

Refer to “Important safeguards/notices for use in

the medical environments” (on page 2)

If the main POWER switch on the rear panel is not

set to on, the power is not on even though the ON/

STANDBY switch on the front panel is set to on.

M EXEC button (16, 17)

Use this button in menu operations.

Location and Function of Parts and Controls

7

Page 8

Preparation

Preparation

Supplied Accessories

The unit is packed together with the following

accessories. Check that nothing is missing from your

package.

Film tray (1)

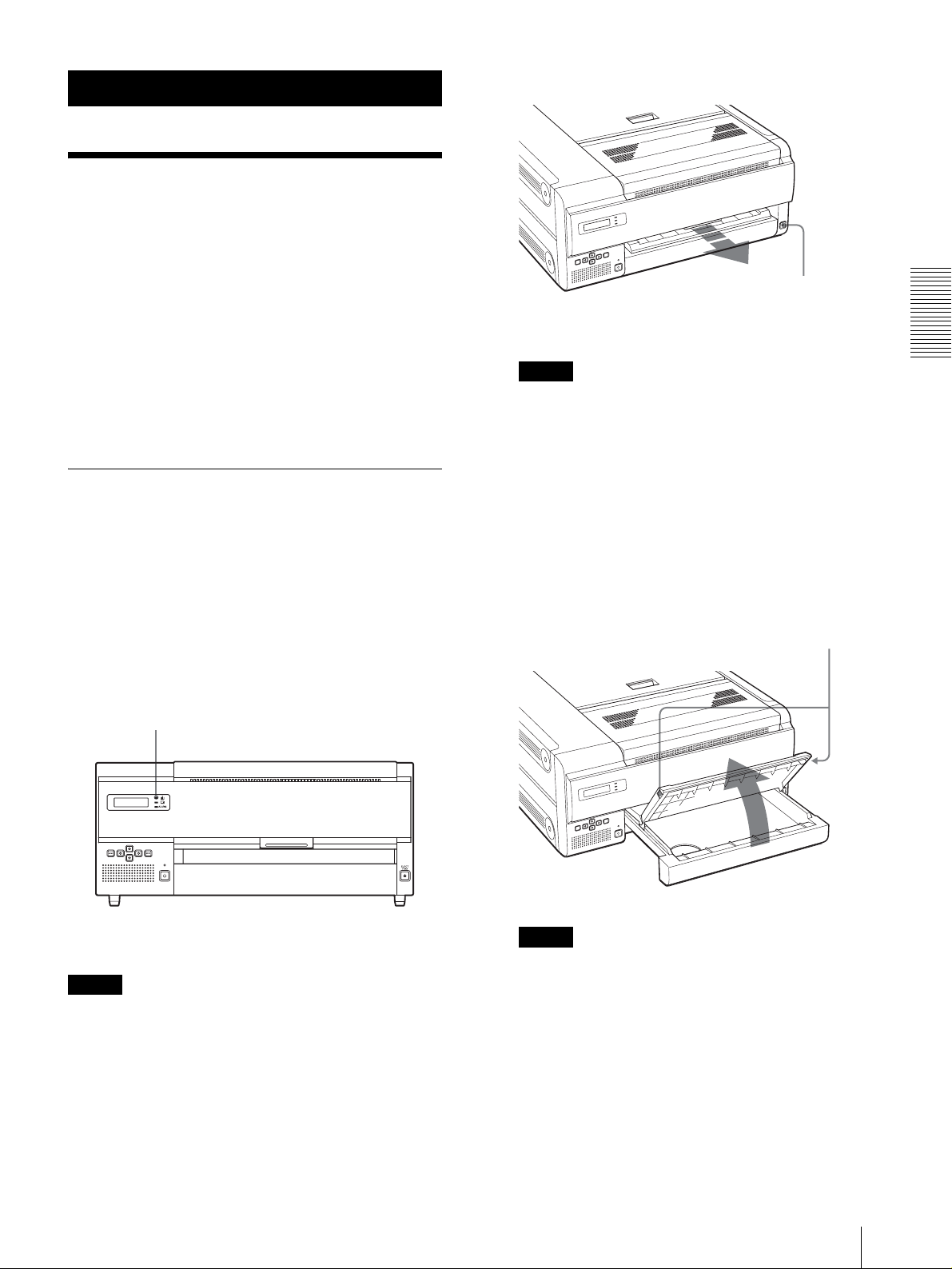

Assembly

Insert the film tray into the unit.

Holding both sides of the film tray and tray cover with

both hands, insert the film tray all the way into the unit.

Casters for vertical placement of the unit (2

AC power cord (1)

Cleaning kit (1)

Stopper sheet (1)

Ferrite cores (2)

Warranty card (1) (for the customers in the U.S.A. and

Canada only)

CD-ROM (Instructions for Use disk) (1)

Floppy disk (1)

Operation Guide (1)

a) Footnote for the customers in the U.S.A and Canada

When you use the printer in the U.S.A. or Canada, use the

AC power cord supplied. When you use the printer in a

country other than the U.S.A. or Canada, use the proper

AC power cord for your local power system.

a)

)

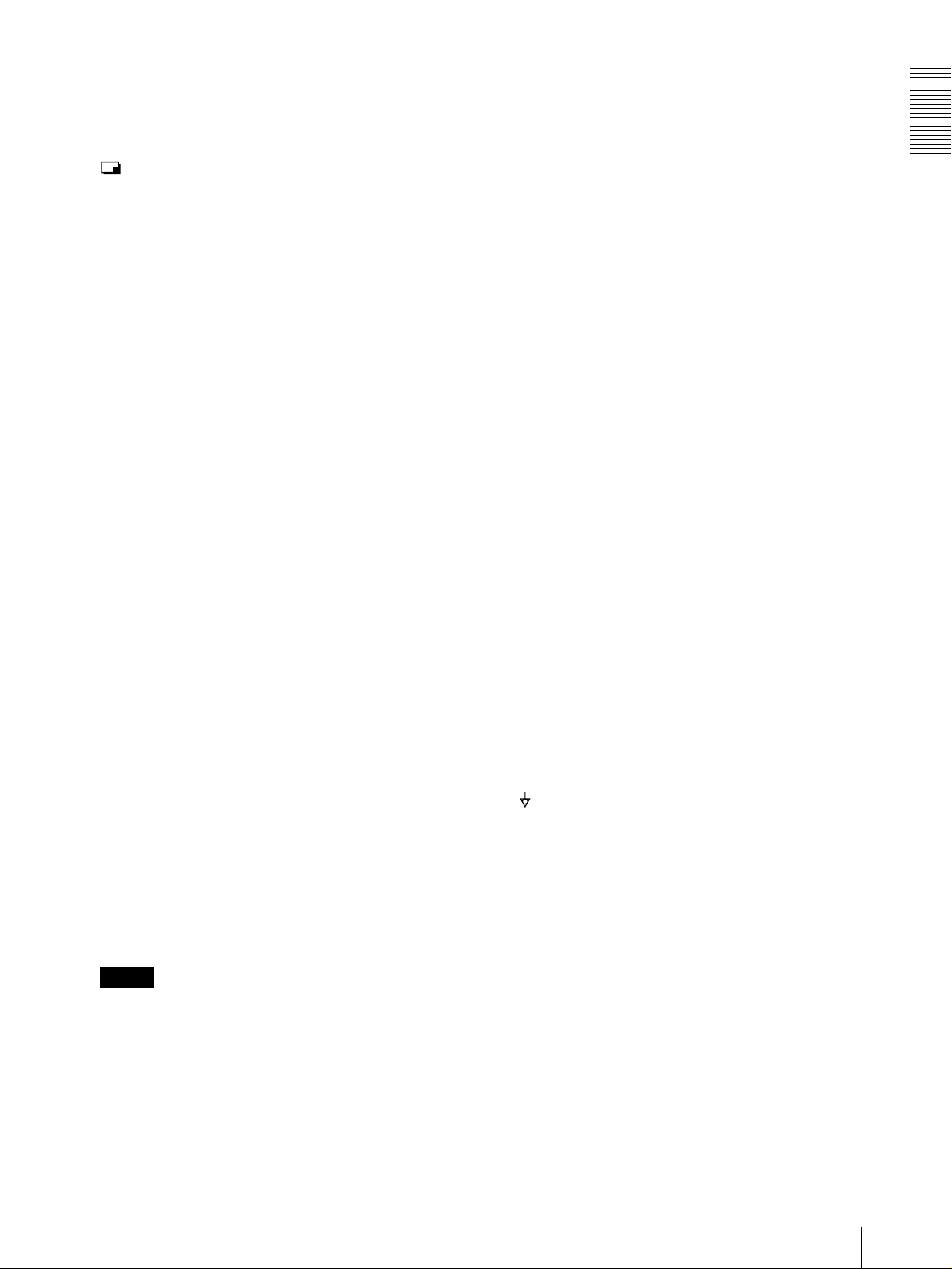

Placing the Unit

You can place the unit horizontally or vertically.

When placing the unit horizontally

To maintain performance, adequate space is needed for

ventilation. Also, to remove jammed film, space of

about 11 cm (4 3/8 inches) towards the back and about

26 cm (10 1/4 inches) over the top of the unit are

required.

26 cm

21 cm

(8 5/8 inches)

(10 1/4 inches)

11 cm

(4 3/8 inches)

Notes

• Retain the original carton and packing materials in

case you have to transport the unit in the future.

• Keep the supplied floppy disk, since it is required

when repairing.

8

Supplied Accessories

Page 9

When placing the unit vertically

You can place the unit vertically if you attach the casters

provided. This is convenient for placing the unit under a

desk and to pull it out easily.

Fix the unit using the front caster.

Connections

Connect the unit to the 100BASE-TX LAN.

Notes

• Connect the AC power cord last.

• Before connecting to the LAN, be sure to set up the

required IP address and sub-net mask.

For detailed information, consult the system

administrator.

• Before connecting the unit using a 100BASE-TX

cable, attach the ferrite cores provided to both ends of

the cable for noise prevention.

For detailed information on how to attach the ferrite

cores, see “How to attach the ferrite cores” (on

page 10)

Preparation

Stopper sheet

Fix the front caster using the stopper sheet

(supplied).

Be sure to place the roller of the caster in the groove

of the stopper sheet.

Notes

• Ask your nearest Sony dealer to attach the casters to

the unit.

• Use the casters to allow the unit to be pulled out from

under the desk and so on. Be sure not to use the casters

for moving the unit on an uneven surface.

• Place the stopper sheet (supplied) under a unit with

casters attached.

• When pulling the unit in and out while the unit is

equipped with the casters provided, be careful not to

damage the power cord, LAN cable, and so on.

• When placing the unit vertically, make sure the LCD

is near the floor, and leave a space of more than 8 cm

(3 1/4 inches) between the top of the unit and the

subject to prevent blocking the ventilation holes.

to the network connector

100BASE-TX cable

to the LAN

a) Be sure to use a network cable of less

than 30 m in length, and rated more than

category 5.

a)

Power cord (supplied)

to- AC IN

Connections

9

Page 10

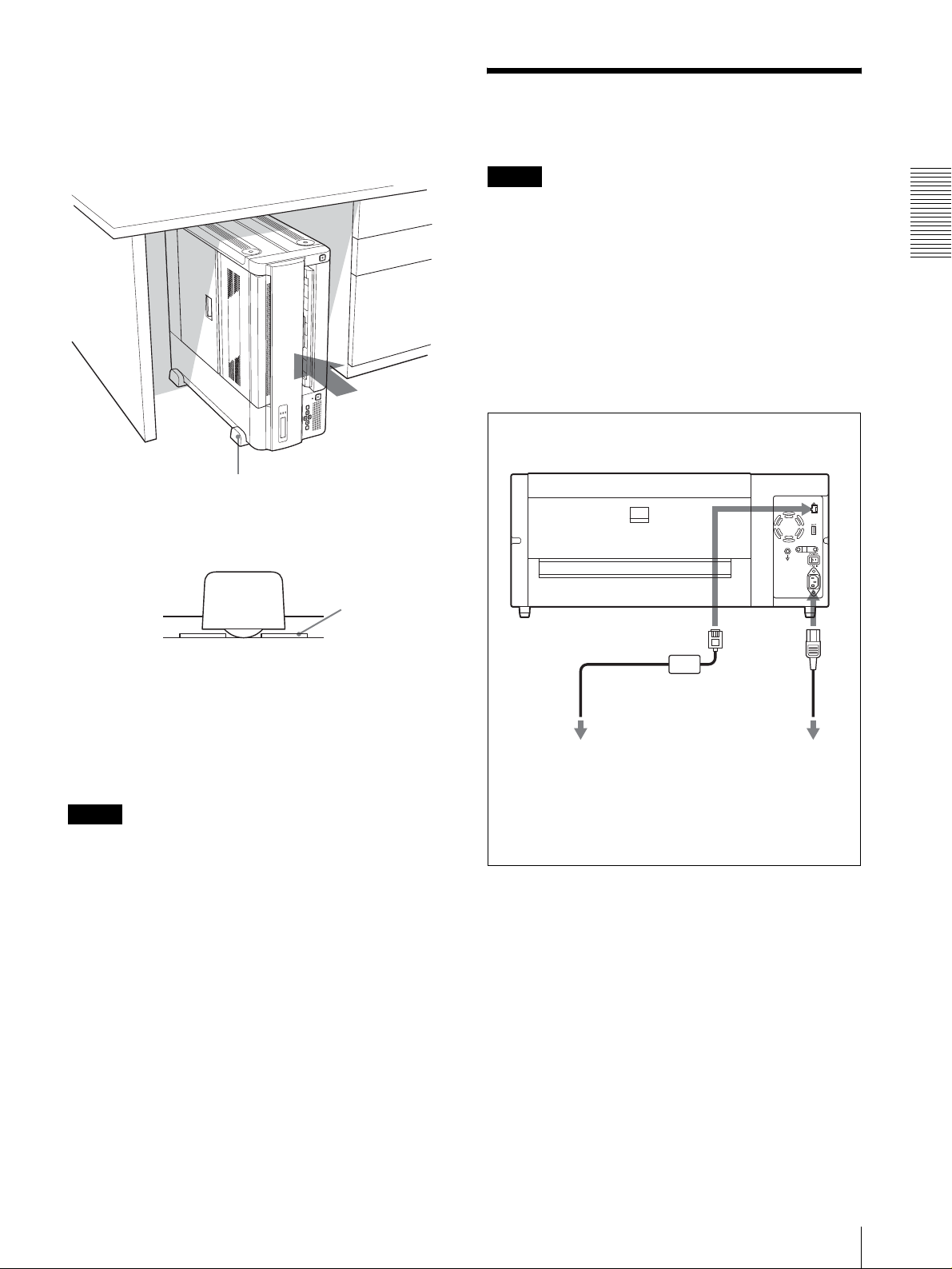

Preparation

How to attach the ferrite cores

Before using the unit, attach the supplied ferrite cores

for noise prevention.

To confirm to radiation standards, attach the supplied

ferrite cores to both ends of the cable.

Ferrite core

Stoppers

12.5 mm

(1/2 inch)

12.5 mm

(1/2 inch)

1

Release the two stoppers to open the ferrite core.

2

Attach the ferrite cores to the end of the cable about

12.5 mm (1/2 inch) away from the connector.

3

Close the ferrite core until it clicks.

10

Connections

Page 11

Operation

Loading Film

Recommended Film

The following blue thermal film is made especially for

the UP-DF500.

UPT-517BL Blue Thermal Film printing pack

Contains blue thermal transparent film.

125 sheets of 14 × 17 inch film

Be sure to use film made expressly for the UP-DF500. If

you use other film, the quality of the printout cannot be

guaranteed. Use of another type of film may also cause

malfunction of the unit.

Loading Film

Proceed as follows to load film sheets.

If you use the unit immediately after purchase, start

operations from step 2.

To confirm the remaining amount of film

The remaining film confirmation indicator allows you to

confirm the amount of film remaining.

When this indicator is not lit, film has run out. Load new

film.

The film tray is partially ejected.

Push the EJECT TRAY button

Notes

• You can replace film without pulling out the film

tray completely out. However, if you want to pull

out it completely, hold both sides of the film tray

and film tray cover firmly.

• The film tray can not be ejected while printing or

when the covers are open.

2

Open the film tray cover by putting your fingers in

the grooves on both sides of the film tray, and

pulling it upward in the direction of the arrow.

Pull it upward in the direction of the arrow,

putting your fingers in the grooves.

Operation

Remaining film confirmation window

Notes

• Hold the film using the aluminum damp-proof bag. Do

not touch the film directly. Dust, finger prints, or sweat

are likely to cause unsatisfactory printing.

• Hold both sides of the film tray and tray cover tightly

when handling the film tray.

1

Push the EJECT TRAY button on the front panel.

Note

If the old printing surface protection sheet remains

in the film tray, remove it.

3

Remove the aluminum damp-proof bag from the

film carton.

Loading Film

11

Page 12

Operation

4

Cut the blank part of the bag from the wedges on

the bag.

Note

Remove the seal after loading the film in the film

tray. If you remove it before loading, the film may

slip and drop.

5

Hold the aluminum damp-proof bag with both

hands so that the opened side faces toward the inner

side of the tray and place the film in the film tray so

that the printing surface faces down, with the

printing surface protection sheet on the bottom.

Film tray

Face the cut part toward the inner side of the film tray.

Place the film with the printing surface facing down and

the printing surface protection sheet on the bottom.

Seal used to grasp the film sheets

An IC tag is attached to the printing surface protection

sheet. Be careful not to damage the IC tag or give it a

shock.

Notes

• When handling the film, do not touch the printing

surface of the film. Dust, finger prints, or sweat

are likely to cause unsatisfactory printing.

• Load the film so that it lays flat in the film tray. If

the film is curled, it will overflow the film tray

and the printing position may shift. Also, it may

cause film jamming.

• If you place the film in the film tray with its

printing surface facing up, it is recommended that

you clean the thermal head with the cleaning kit

(supplied). See “To clean the thermal head, platen

12

Loading Film

Page 13

roller, pinch roller, and separation rubbers” (on

page 21).

• Do not add film halfway through one bag of film.

The reason for this is because the unit counts the

remaining film using the IC tag on the printing

protection sheet on the bottom.

6

Remove the seal from the film placed in the film

tray.

1 Remove the sticky part of the seal, pulling the

blank part of the seal toward you.

Note

Be sure to check that the hooks of the film tray

cover and its magnets are attached firmly on the

film tray. If the film tray cover is not closed

correctly, film placed in the film tray may slide

around.

3 Remove the seal from the film completely, by

pulling the blank portion out of the film tray.

7

Insert the film tray.

Operation

2 Close the film tray cover after you pull the

blank portion of the seal out of the film tray.

After a few seconds, the film tray is locked and the

following message appears on the LCD.

Notes on storing film

• If you remove the film and plan to keep them for a long

time, store unused film in the damp-proof bag.

• Store the unopened package in a cool, dark place.

Check that the hooks of the film tray cover are

locked and its magnets are attached firmly on

the film tray.

Loading Film

13

Page 14

Operation

Printing

Before printing

• Ensure that the unit is properly connected to the LAN.

(page 9)

• Ensure that the film sheets are properly loaded in the

film tray. (page 11)

LCD

PRINT indicator

2 The stored image data is printed.

During printing, the PRINT indicator is lit.

It takes about 70 seconds for a printout to

emerge from the film outlet. Once printing has

been completed, the PRINT indicator goes off,

and the unit returns to READY status.

1

1

Turn on the power of the unit.

After turning on the power, the LCD should appear

as shown here.

After a few minutes, the LCD should appear as

shown here.

When READY is displayed, the printer is ready to

print.

2

Send the image data from the modality.

1 While the unit is receiving image data, the

following message appears:

Notes

• During printing, do not open the covers.

• To prevent film jamming, do not allow more than

30 printouts to remain on the film output slot. The

message “REMOVE PRINTS” may appear even

if the number of printouts less than 30 has

accumulated, depending on the usage

environmental condition.

• Do not put the printout, which has been removed

from the film output slot, back inside the film

output slot. This may cause film jamming.

If the unit does not print

When an error message is displayed in the LCD, the unit

does not print. Take remedies according to “Messages”

(on page 25).

Notes on storing your printouts

• Do not leave the printouts in direct sunlight or bright

room light. Store in a cool and low humid place (under

77 °F (25 °C)). We recommend storing the printouts in

a polypropylene pouch in a cabinet.

• Do not allow any volatile organic solvent such as

water or alcohol to come in contact with the printouts.

This can cause fading of the printout. If the printouts

come in contact with such liquid, wipe them off

quickly.

• Adhesives from cellophane tape or PVC will cause

fading of the printout. Be careful when storing

printouts.

• Do not stack the printouts on or under a freshly

developed diazo copy sheet as this could cause the

film sheets to fade or stick to each other.

14

The image data is stored in the unit memory.

Printing

Page 15

Adjustment

Menu Operation

You can set the following items using the relevant menu:

• Confirming information (INFORMATION) (page 15)

• Adjusting the print quality (PRINT QUALITY)

(page 15)

• Calibration (CALIBRATION) (page 16)

• Adjusting the density (DENSITY ADJ) (page 17)

• Selecting a gamma curve (GAMMA SEL) (page 19)

Notes

• The next printout will be printed with the values most

recently set. You cannot adjust the setting during

printing. Once you have adjusted and stored the

settings, the printer operates according to those

settings until their values are modified.

• If you do not press any button for approximately 15

seconds after pressing the MENU button, the printer is

automatically reset to standby status.

3

Select the item you want to confirm by pressing the

F or f button.

To display the IP address

Select IP ADDRESS.

IP address

Note

You can change the IP address using the browser on

the computer used to manage the unit.

For details, see the Setup Manual.

To confirm the total number of prints made

since you started the unit

Select TOTAL PRINTS.

Adjustment

Confirming Information

You can confirm the IP address and the total number of

prints made since you started the unit.

1

3

2

1

Press the MENU button.

2

Display the INFORMATION menu by pressing the

F or f button, then press the g button.

Total number of prints

This item is useful to estimate when regular

maintenance such as replacing the cleaning roller,

cleaning the thermal head, etc., is necessary.

For details, see “Maintenance” (on page 20).

Adjusting the Print Quality

You can adjust the sharpness of the printout.

1, 4

2

3

1

Press the MENU button.

2

Display the PRINT QUALITY menu by pressing

the F or f button, then press the g button.

Menu Operation

15

Page 16

Adjustment

The unit enters the sharpness adjustment mode.

3

Select the desired level by pressing the G or g

button.

Current sharpness

The sharpness can be adjusted among 15 levels

between 1 and 14 including OFF.

As the * mark is moved towards the right, the

outline is emphasized.

OFF: The * mark is placed at most left position.

(Default level)

Pressing the g button: Increases the sharpness

level, and the outline is emphasized.

Pressing the G button: Decreases the sharpness

level, and the outline is blurred.

4

Press the MENU button.

The adjusted level is executed.

The unit returns to standby status and READY is

displayed on the LCD.

The unit operates according to the adjusted level

until these values are modified.

2

Display the CALIBRATION menu by pressing the

F or f button, then press the g button.

The calibration menu is displayed.

The unit enters the automatic calibration mode.

3

Select the desired calibration type by pressing the F

or f button.

To calibrate the unit

1 Display FULL RANGE CAL by pressing the F

or f button.

2 Press the EXEC button.

The unit starts printing and during printing, the

density is automatically calibrated.

The calibration performed at this printing

becomes effective for the next printing.

Printout of results of density calibration

Calibrating the Printing Density

The unit automatically calibrates the printing density

according to the density curve set.

1, 4

3

2

1

Press the MENU button.

16

Menu Operation

To make a simple calibration

The unit can perform a simple calibration each time

it makes a printout. When this simple calibration is

selected, the test pattern is printed on the printout.

The calibration performed at this printing becomes

effective for the next printing.

Page 17

1 Display LIMITED CAL, by pressing the F or f

button.

2 Select ON by pressing the G or g button.

Adjusting the Tone

You can adjust the high tone (dark areas of the images)

and the low one (light areas of images).

1

3

5

Display ON in capital letters by pressing the G or g

button.

To reset to the default status

If you reset to the default status, the calibration is

not performed by selecting FULL RANGE CAL.

1 Display CAL RESET by pressing the F or f

button.

2 Press the EXEC button.

4

Press the MENU button.

The unit returns to standby status and READY is

displayed on the LCD.

24

1

Press the MENU button.

2

Display the DENSITY ADJ menu by pressing the

F or f button, then press the g button.

The unit enters the automatic tone adjustment

mode.

3

Display PATTERN PRINT by pressing the F or f

button.

Adjustment

4

Press the EXEC button to make a printout of the

pattern print.

Menu Operation

17

Page 18

Adjustment

The unit starts the printing of the tone pattern.

5

Adjust the tone while checking the pattern print.

To adjust the low tone

Select the way the light areas of images will be

printed.

1 Display SELECT POINT 95% by pressing the

F or f button.

3 Display the selected number by pressing the G

or g button.

Display the selected number.

To reset to the default setting of the low

tone range

Display 25.

To adjust the high tone

Select the way the dark areas of images will be

printed.

1 Display SELECT POINT 5% by pressing the F

or f button.

2 Select the number of the desired high tone area

(dark area data 5%).

The high tone range is between 51 and 99 (60,

70, 80 and 90 are skipped).

2 Select the number of the desired low tone area

(light area data 95%) by pressing the G or g

button.

The low tone range is between 01 and 49 (10,

20, 30 and 40 are skipped).

Chart of the low tone range

The inside tone of each box on the chart is changed

in the right and left direction on the chart.

The outside

tone of each

box on the

cart is

changed in

the upper and

lower

direction on

the chart.

The next lightest part

Chart of the high tone range

The inside tone of each box on the chart is changed in

the right and left direction on the chart.

The outside

tone of each

box on the

cart is

changed in

the upper

and lower

direction on

the chart.

The next darkest part

The darkest part

18

The lightest part

Menu Operation

Page 19

3 Display the selected number by pressing the G

or g button.

Display the selected number.

To reset to the default setting of the high

tone range

Display 75.

Selecting a Gamma Curve

When the gamma curve is not specified at the modality

side, select the gamma curve to be used at the unit.

1

3

4

Gamma curve Meaning

SONY 1 Default setting

SONY 2 The half tone is darker compared to

SONY 1

SONY 3 The half tone is lighter compared to

SONY 1

SONY 4 The half tone is smoother compared to

SONY 1

SONY 5 The half tone is sharper compared to

SONY 1

USER 6 to 10 Not preset. For advice on settings,

contact your nearest Sony dealer. If

you select these gamma curves,

USER 6 to 10 before setting, same

setting as the one of SONY 1 is

applied.

Gamma curve

The gamma curves of SONY 1 to SONY 5 are

shown below.

Dark

Adjustment

2

1

Press the MENU button.

2

Display the GAMMA SEL menu by pressing the F

or f button, then press the g button.

The unit enters the gamma selecting mode.

3

Select the desired gamma curve by pressing the G

or g button.

The gamma curves for SONY 1 to SONY 5 have

been pre-set, you cannot change these settings.

The gamma curves for USER 6 to USER 10 can be

set to the desired value. For advice on the settings,

contact your nearest Sony dealer.

Printout

Light

Light

Input data

Dark

Menu Operation

19

Page 20

Miscellaneous

Precautions

Safety

film tray. This will cause the printer to malfunction.

Also, if the film is used in this state, spots are likely to

appear on the printout.

• To store a half-used package of film, replace the film

in its original packing and reseal the package. If

possible, before using sealed film, place it, in its

sealed package, in a warm room for several hours.

Doing so prevents condensation from forming when

the film is removed from its package.

Miscellaneous

• Operate the unit using the power source specified in

“Specifications” (on page 24).

• Be careful not to damage the AC power cord by

placing or dropping heavy objects on it; it is dangerous

to use the unit with a damaged AC power cord.

• If you do not intend to use the unit for a long time,

disconnect the AC power cord.

• Unplug the AC power cord by grasping the plug, not

the cable itself.

• Do not disassemble the unit.

• Do not remove the cabinet. There is a danger of

electric shock from the internal parts.

• Be careful not to spill water or other liquids on the

unit, or to allow combustible or metallic material to

enter the cabinet. If used with foreign matter in the

cabinet, the unit is liable to fail, or present a risk of fire

or electric shock.

• If the unit malfunctions or if a foreign body falls into

the cabinet, disconnect the power immediately and

consult your Sony dealer.

Installation

Avoid placing the unit in a location subject to:

mechanical vibration

– high humidity

– excessive dust

– direct or excessive sunlight

– extremely high or low temperatures

– Ventilation holes are provided to prevent the unit

from overheating. Be careful not to obstruct them

with other units or by covering the unit with a cloth

etc.

Condensation

• If the unit is subjected to wide and sudden changes in

temperature, such as when it is moved from a cold

room to a warm room or when it is left in a room with

a heater that tends to produce large amounts of

moisture, condensation may form inside the printer. In

such cases the printer will probably not work properly,

and may even develop a fault if you persist in using it.

If moisture condensation forms, turn off the power and

allow the printer to stand for at least one hour.

• If the film is subjected to wide and sudden changes in

temperature, condensation may form on the film in the

Transporting the Unit

Before transporting the unit, remove the supplied

accessories and then put them back into their original

packing. Transporting the unit with the supplied

accessories still installed may cause malfunctions.

Note

It is dangerous to move the unit with the casters used to

stand it vertically. Do not use the caster to move the unit.

Cleaning the Cabinet

Clean the cabinet, panel and controls with a soft dry

cloth, or a soft cloth lightly moistened with a mild

detergent solution. Do not use any type of solvent, such

as alcohol or benzine, which may damage the finish.

Note

Be sure to set the ON/STANDBY switch on the front

panel to STANDBY before cleaning the cabinet.

Maintenance

Perform the following maintenance regularly after every

500 printings.

• Replacing the cleaning roller

• Cleaning the thermal head, platen roller, pinch roller

and separation rubbers

• Cleaning the fan filter

In addition to the above maintenance, regular

maintenance is required after every 5,000 printings.

However, you should ask your nearest Sony dealer to

perform this maintenance.

You can check the total number of prints using the

TOTAL PRINTS item of the INFORMATION menu.

For details, see “To confirm the total number of prints

made since you started the unit” (on page 15).

Note

Before starting the following maintenance, be sure to set

the ON/STANDBY switch on the front panel to

STANDBY, and then the main POWER switch on the

rear panel to OFF.

20

Precautions

Page 21

To replace the cleaning roller

The supplied cleaning kit contains the cleaning rollers

(for replacement) and wet pads.

Proceed as follows to replace the cleaning roller with a

new one.

1

Pull the lever toward you to open the front cover.

2

Hold the left side of the cleaning roller and remove

it by sliding it toward the right.

3

Remove the packing film on the new cleaning roller

and attach a new cleaning roller.

Insert the right side of the cleaning roller and push it

toward the right. Then push the left side of the cleaning

roller until it is locked.

Notes

• Be careful not to scratch the surface of the

cleaning roller and not to drop it.

• Do not wipe the surface of the cleaning roller

with the supplied wet pad.

Miscellaneous

Cleaning roller

4

Close the front cover completely.

If you continue the cleaning of the thermal head,

platen roller, pinch roller and separation rubber, it is

not necessary to close the front cover. Go to step 2

of the “To clean the thermal head, platen roller,

pinch roller, and separation rubbers” (on page 21)

Note

When you close the cover, be careful not to catch

your fingers or hand with the front cover.

To clean the thermal head, platen roller, pinch

roller, and separation rubbers

Proceed as follows to perform the following cleaning

tasks with the supplied wet pad.

Precautions

21

Page 22

1

Pull the lever toward you to open the front cover.

3

Wipe the platen roller (black rubber roller) gently.

Platen roller (black rubber roll)

Miscellaneous

2

Wipe the thermal head with the wet pad.

Note

Before wiping the thermal head, touch the metallic

part of the unit to remove static electricity from

your body.

Thermal head

Wipe the surface of the thermal head gently

with the wet pad.

Wipe the platen roller gently with the wet pad

while turning it.

4

Wipe the pinch roller (dark blue rubber roller).

Pinch roller (dark blue rubber roller)

Wipe the pinch roller gently with the wet pad

while turning it.

22

Notes

• Be careful not to touch the surface of the thermal

head with your hand.

• Do not discard the wet pad. This wet pad is used

for the cleaning tasks to be performed on other

parts of the unit.

• Since the thermal head is still very hot just after

printing is finished, be careful not touch the

thermal head. Touching the hot thermal head may

cause a burn.

Precautions

5

Close the front cover.

6

Remove the film tray.

You can remove the film tray without pushing the

EJECT TRAY button when the power is off.

Page 23

Note

When removing the film tray, hold both sides of the

film tray and the tray cover with both hands and

remove it.

7

Open the tray cover and wipe the separation rubbers

with the wet pad.

To clean the filters

Ventilation holes are provided on the unit to prevent it

from overheating.

Three filters are provided on the front cover for covering

the ventilation holes.

To clean the filters, proceed as follows.

1

Pull the lock lever to open the front cover.

2

Lift the filters upward a little and pull it toward you

to remove it.

Miscellaneous

Separation

rubbers

8

Reset the film tray.

The cleaning has been completed.

Notes

• Be sure to perform the cleaning tasks in the order

described above.

• Close the cover after the wiped parts have dried

completely.

• Do not use the wet pad used for wiping rollers to clean

the thermal head.

Filters

3

Clean the filters using a vacuum cleaner or the like.

Notes

• Be careful that the filter does not get caught in the

vacuum cleaner.

• Do not rub the net of the filter roughly.

Precautions

23

Page 24

Miscellaneous

4

Reset the filters and close the cover.

After you have finished all cleaning tasks

Set the main POWER switch on the rear panel to ON,

and then set the ON/STANDBY switch on the front

panel to ON.

The following message appears for about several

minutes.

After the following message is displayed after about

several minutes, you can start printing again.

Specifications

Power requirements

100 to 240 V AC, 50/60 Hz

Input current 4.4 to 1.8 A

Operating temperature

10°C to 30°C (50°F to 86°F)

Operating humidity

20% to 80% (no condensation allowed)

Storage and transport temperature

–20°C to +60°C (–4°F to +140°F)

Storage and transport humidity

20% to 90% (no condensation allowed)

Dimensions About 600 × 250 × 686 mm (w/h/d)

(23 5/8 × 9 7/8 × 27 1/8 inches)

Mass Approx. 55 kg (121 lb 4 oz)

Printing system Thermal printing

Resolution 12.59 dot/mm (320dpi)

Gradations 4,096 levels

Maximum print size

401.8 × 335.4 mm

Picture elements

4,224 × 5,060 dots (w/h)

Printing time Approx. 70 sheets/hour (excluding the

time for cooling the head)

Digital interface

Network port × 1

(RJ-45 Modular jack), Conforming

to 100BASE-TX standard

Special output connector × 1

Input connector AC IN (for power)

Accessories supplied

Film tray (1)

Cleaning Kit (1)

Caster for setting the printer vertically

(2)

Stopper sheet (1)

Ferrite cores (2)

AC power cord (1)

Operation Guide (1)

CD-ROM (1)

Floppy disk (1)

Warranty card (1) (for the customers in

the U.S.A and Canada)

a) Footnote for the customers in the U.S.A

and Canada

When you use the printer in the U.S.A. or

Canada, use the AC power cord supplied.

When you use the printer in a country

other than the U.S.A. or Canada, use the

proper AC power cord for your local

power system.

Accessories supplied separately

Blue Thermal Film Printing Pack

UPT-517BL

Cleaning kit UPA-500

a)

24

Specifications

Page 25

Medical Specifications

Protection against electric shock:

Class I

Protection against harmful ingress of

water: Ordinary

Degree of safety in the presence of

flammable anesthetics or oxygen:

Not suitable for use in the presence

of flammable anesthetics or oxygen

Mode of operation:

Continuous

Messages

There are two kinds of messages: error messages and

warning messages. This section lists these messages

together with their possible causes and remedies. Note

the messages and act accordingly.

Besides error and warning messages, other messages

stating the operating status of the unit are also displayed.

Those messages are not described here.

Design and specifications are subject to change without

notice.

SOP and Meta SOP Classes

SOP Class Name SOP Class UID

Verification SOP 1.2.840.10008.1.1

Basic Grayscale Print Management

Meta SOP Class

Basic Film Session SOP Class 1.2.840.10008.5.1.1.1

Basic Film Box SOP Class 1.2.840.10008.5.1.1.2

Basic Grayscale Image Box SOP

Class

Print SOP Class 1.2.840.10008.5.1.1.16

Basic Annotation Box SOP Class 1.2.840.10008.5.1.1.15

1.2.840.10008.5.1.1.9

1.2.840.10008.5.1.1.4

Error Messages

If a problem occurs, the ALARM indicator lights and an

error message stating the problem appears on the LCD

window. Note the message and perform whatever action

is necessary to solve the problem.

In the error messages introduced in the following table,

“nn” indicates the number of the symbol displayed in the

actual message.

Error messages Possible causes and remedies

SET FILM The film sheets have run out.

SET TRAY The film tray is not installed.

REMOVE PRINTS The maximum number of printouts has

CLOSE COVER One of the front, top, or rear cover is

REMOVE FILM

TRAY:J0

REMOVE FILM

REAR:J1

REMOVE FILM

REAR & TOP:J2

REMOVE FILM

TOP:J3

REMOVE FILM TOP

& FRONT:J4

REMOVE FILM

FRONT:J5

tLoad the film into the film

tray.(page 11)

tInstall the film tray (page 8).

accumulated on the film tray.

tRemove the printouts. Printing

starts again.(page 14)

open.

tClose the opened cover.

The film has jammed near the film

tray.

tPull out the film tray and remove

the jammed film.(page 27)

The film has jammed around the rear

of the unit.

tOpen the rear cover and remove the

jammed film.(page 28)

The film has jammed between the rear

and top of the unit.

tOpen the rear and top covers and

remove the jammed film.(page 28)

The film has jammed around the top of

the unit.

tOpen the top cover and remove the

jammed film.(page 28)

The film has jammed between the top

and front of the unit.

tOpen the top and front covers and

remove the jammed film.(page 28)

The film has jammed around the front

of the unit.

tOpen the front cover and remove

the jammed film.(page 28)

Miscellaneous

Messages

25

Page 26

Miscellaneous

Error messages Possible causes and remedies

REMOVE FILM TOP

& INNER:J6

REMOVE FILM

TRAY:J7

REMOVE FILM

SOME PLACES:J8

CALIBRATION

INVALID

MECHA TROUBLE

S nn

MECHA TROUBLE

M nn

MECHA TROUBLE

U nn

DICOM TROUBLE Trouble has occurred in the DICOM

TAG INVALID Trouble has occurred in the IC tag part.

The film has jammed around the front

or inside the unit.

tOpen the top cover, then the inner

cover and remove the jammed

film.(page 28)

The film has jammed near the film

tray.

tPull out the film tray and remove

the jammed film.(page 29)

The film has jammed at several points.

tOpen all of the covers and remove

the jammed film.(page 29)

The unit takes certain measurements to

estimate a value for automatic

calibration. However, the correct value

could not actually be measured. The

unit can print, but the automatic

calibration value is not updated.

tTry calibration again. If white strips

or scratches appear on the printout,

clean the thermal head and

rollers.(page 16)

Mechanical trouble has occurred in the

sensor system of the unit.

tTurn off the power once and then

turn it on. The unit may operate

correctly. However, if the message

still remains on the LCD, turn off

the power immediately and contact

your Sony dealer.

Mechanical trouble has occurred in the

motor system of the unit.

tTurn off the power once and then

turn it on. The unit may operate

correctly. However, if the message

still remains on the LCD, turn off

the power immediately and contact

your Sony dealer.

Mechanical trouble has occurred in the

unit system of the unit.

tTurn off the power once and then

turn it on. The unit may operate

correctly. However, if the message

still remains on the LCD, turn off

the power immediately and contact

your Sony dealer.

part of the unit.

tTurn off the power immediately and

contact your Sony dealer.

tTurn off the power immediately and

contact your Sony dealer.

Other Messages

When the following message appears, the ALARM

indicator does not light. The PRINT indicator blinks.

Messages Possible causes and remedies

HEAD IN COOLING

PLEASE WAIT

HEAD IN HEATING

PLEASE WAIT

PLEASE WAIT The unit is retruning to the intial

The thermal head has overheated.

tLeave the unit until the head has

cools down and this message

disappears.

The thermal head is warming up.

tLeave the unit until the head has

warms up and this message

disappears.

settings to restart printing after closing

the covers which opened for removing

jammed film or cleaning.

tLeave the unit until this message

disapperas. When this message

appears, the PRINT indicator does

not blink.

26

Messages

Page 27

When REMOVE FILM TRAY: J0 appears

Troubleshooting

If Damage is Suspected

If a problem appears, check the following trouble

shooting guide first and perform whatever action is

necessary to solve the problem. If the problem persists,

turn off the printer and consult your Sony dealer.

Symptom Possible causes and remedies

Nothing appears in the

LCD.

The unit has not

turned on even though

ON/STANDBY

the

switch on the front

panel is set to ON.

The unit does not

print.

ON/STANDBY switch on

•The

the front panel of the unit is not set

to ON.

tSet the

• The connections may not be

correct.

tMake the connections correctly.

The main POWER switch on the rear

panel is not set to ON.

tSet the main POWER switch on the

rear panel to ON. (page 7)

An error message appears on the

window display.

tTake the measures recommended in

“Messages”. (page 25)

ON/STANDBY

switch of the printer to ON.

(page 14)

(page 9)

1

Remove the film tray.

When the unit is not turned on, you can pull the film

tray out without pushing the EJECT TRAY button.

Note

When you pull out the film tray, hold both sides of

the film tray and the tray cover with both hands.

Note

If any printouts have been ejected onto the film tray,

remove them first before removing the film tray.

Miscellaneous

If the Film Jams

If the film jams before printing starts or during printing,

printing stops and the following messages appear on the

LCD.

An error message indicates the position where the film

has jammed. Check the position and follow the steps

below to remove the jammed film.

After the jammed film has been removed, the unit starts

printing if there is image data still to be printed.

• REMOVE FILM TRAY: J0

• REMOVE FILM REAR: J1

• REMOVE FILM REAR & TOP: J2

• REMOVE FILM TOP: J3

• REMOVE FILM TOP & FRONT: J4

• REMOVE FILM FRONT: J5

• REMOVE FILM TOP & INNER: J6

• REMOVE FILM TRAY: J7

• REMOVE FILM SOME PLACES: J8

Notes

• When you put your hands inside of the unit, be careful

not to hurt yourself by touching parts.

• If you turn off the power, image data that has not been

printed yet is cleared.

2

Remove the film jammed around the sepration

rubbers.

3

Re-insert the film tray as it was.

When messages from J1 to J6 appear

1

Open the cover corresponding to the message and

remove the jammed film slowly while holding the

film with both hands.

Message Cover to be opened

REMOVE FILM

REAR: J1

REMOVE FILM

REAR & TOP: J2

REMOVE FILM

TOP: J3

REMOVE FILM

TOP & FRONT: J4

REMOVE FILM

FRONT: J5

REMOVE FILM

TOP & INNER: J6

Rear cover

Rear and top cover

Top cover

Top and front cover

Front cover

Top and inner cover

Troubleshooting

27

Page 28

When the rear cover is opened

When the front cover is opened

Miscellaneous

When the top cover is opened

When the top and the front covers are

opened

When the top and inner covers are opened

2

Close the opened cover firmly.

The following message appears on the LCD.

28

Wait until the message disappears.

When the unit enters standby status, the following

message appears.

Troubleshooting

Page 29

When REMOVE FILM TRAY: J7 appears

1

Remove the film tray completely.

2

Remove the jammed film near the inside of the unit.

3

Re-insert the film tray as it was.

When REMOVE FILM SOME PLACES: J8

Several film sheets have jammed. Open all of the covers,

rear, front, top and inner covers and check the location

of the jammed film.

Since there may be a film sheet jammed around the film

tray, pull the film tray out and check for the jammed

films.

Miscellaneous

Troubleshooting

29

Page 30

Index

front panel 6

rear panel 6

configuration example 6

feature 5

A

About this Manual 5

C

Calibrating the density

each time the unit makes a printout

16

unit 16

CALIBRATION

FULL RANGE CAL 16

LIMITED CAL 17

Cleaning

cabinet 20

cleaning roller 20

filters 23

pinch roller 22

platen roller 22

separation rubbers 23

thermal head 22

Connections 9

D

DENSITY ADJ

adjusting the high tone 18

adjusting the low tone 18

F

Film

confirming the remaining amount

Index

of film 11

loading 11

note on storing 13

recommended film 11

removing the jammed film 27

Films

total number of prints 15

Maintenance

cleaning the filters 23

cleaning the pinch roller 22

cleaning the platen roller 22

cleaning the separation rubbers

23

cleaning the thermal head 22

replacing the cleaning roller 21

Menu items

CALIBRATION 16

DENSITY ADJ 17

GAMMA SEL 19

INFORMATION 15

PRINT QUALITY 15

Messages

error messages 25

other messages 26

P

Placing the unit

horizontally 8

vertically 9

Precautions

condensation 20

installation 20

safety 20

transporting the unit 20

Printing

before printing 14

if the unit does not print 14

Printouts

adjusting the sharpness of

printouts 15

adjusting the tone 17

note on storing 14

pattern printout 17

M

T

Troubleshooting

if damage is suspected 27

if the film jams 27

R

G

Gamma curve 19

Removing jammed film 27

S

I

IC tag 12

INFORMATION

IP address 15

total number of prints made 15

L

Location and function of parts and

controls

SOP and Meta SOP classes 25

Specifications 24

Supplied accessories

assembly 8

checking 8

cleaning kit 21

ferrite cores 10

how to use casters 9

stopper sheet 9

System

30

Index

Page 31

Setup Manual

Table of Contents

Preparation

Overview ...............................................................32

Requirements ........................................................32

IP Address .............................................................33

Setup

Setting up the Personal Computer to be Used for

Setup ......................................................................34

About the Setup Window ....................................34

Opening the Setup Window ..............................34

Components of Pages ........................................35

Setup of the Unit ...................................................37

Setup of E-Mail ....................................................37

Confirmation After Setup ...................................38

Page 32

Preparation

Preparation

Overview

This setup manual gives the system administrator

information needed to setup the unit on the network or

to reset the IP address and so on.

This setup manual describes the preparation for the

setup, gives an overview of the setup window, explains

how to perform setup related to IP address and so on,

and explains how to setup an E-mail warning to tell

automatically when any trouble occurs.

Requirements

The following hardware and Web browser software are

necessary to perform the setup.

• Computer: A computer which can be connected to the

network connector of the UP-DF500

• Operating system

Windows 98, Windows NT 4.0, Windows 2000, or

Windows XP

• LAN cable: 100BASE-TX cross cable

• Web browser software: Internet Explorer

later, or Netscape

Set the Web browser software as follows:

No proxy

A blank page is opened when the Web browser

software is started.

a) Microsoft, Windows, Windows NT, and Internet

Explorer are registered trademarks of Microsoft

Corporation in the United States and/or in other

countries.

Netscape and Netscape Navigator are registered

trademarks of Netscape Communications Corporation

in the United States and/or in other countries.

Other system names and product names mentioned in

this manual are also trademarks and registered

trademarks.

a)

: Microsoft Windows 95,

a)

4 or later

a)

5.5 or

32

Overview / Requirements

Page 33

IP Address

When you use the unit for the first time immediately

after you purchase the unit, it is necessary to set up the

DICOM part placed inside the unit, adding an IP address

and so on.

Before starting the setup, confirm the following with the

network administrator.

• The IP address the UP-DF500 will use on the network

• Sub-net mask of the network

• Gateway address, if a gateway is included in the

network

To confirm the IP address

The IP address assigned to the UP-DF500 can be

confirmed.

1

Turn the UP-DF500 on.

2

Press the MENU button.

3

Display INFORMATION on the LCD by pressing

the F or f button, and then push the g button.

4

Display IP ADDRESS on the LCD by pressing the

F or f button.

The IP address assigned to the UP-DF500 appears

on the LCD.

Preparation

IP Address

33

Page 34

Setup

Setting up the Personal

Computer to be Used for

Setup

Setup

1

Start the personal computer to be used for setup.

2

Open the TCP/IP setting page.

3

Enter the IP address of the computer and the subnet mask.

IP address of the computer: NNN.NNN.NNN.nnn

NNN.NNN.NNN.NNN: IP address assigned to

the UP-DF500 on the network

nnn: Arbitrary numbers (from 1 to 254, should

not be the same as those of the fourth NNN of

the UP-DF500 IP address.)

Sub-net Mask:255.255.255.0

4

Restart the personal computer.

5

Connect the UP-DF500 and the personal computer

to be used for setup using the network cross cable.

About the Setup Window

The UP-DF500 can be set up on the setup window

displayed on the Web browser of the personal computer

to be used for setup.

The setup window has the following pages:

• Summary/Print Job page

Displays the summary and print job status of the UPDF500.

• DICOM Settings page

Sets up the IP address, DICOM AE title, and so on.

• Printer Status page

Displays the status of the UP-DF500.

• E-Mail Settings page

Sets up the items related to E-Mail.

Opening the Setup Window

1

Start the personal computer to be used for setup,

and then start the Web browser software.

2

Enter the following address.

http://NNN.NNN.NNN.NNN

This is the IP address assigned to the UP-DF500 on

the network.

Page selection area

34

Setting up the Personal Computer to be Used for Setup / About the Setup Window

3

Click the desired page in the page selection area.

The desired page opens.

Page 35

Components of Pages

Summary/Print Job Page

This page displays information on the UP-DF500.

DICOM Settings Page

This page allows you to set up the IP address and

DICOM AE title.

Setup

A Printer (printer status) display section

Printer Status: Displays the printer status.

Thermosensitive Film: Displays the type of film in

use.

14 × 17: Displays the size of the film in use (14 ×

17 inches)

B Printer Job List display section

Displays when a job is waiting to be printed.

C Add test pattern film to print job

Push this button to print the test pattern.

D Refresh button

Click this button to update the window.

A TCP/IP section

Setup Software Version: Displays the version of the

setup window.

IP Address: Sets the IP address and displays it.

Sub-net Mask: Sets the Sub-net mask and displays

it.

Default Gateway: Sets the default gateway and

displays it.

B Printer section

DICOM Software Version: Displays the version of

the DICOM software.

DICOM Software Serial #: Displays the serial

number of the DICOM software.

AE Title: Sets the AE title and displays it.

Port ID: Displays the port number.

Status: Displays the status of the DICOM software.

Communication Log: Keeps a communication log

if a checkmark is placed here.

C Save settings button

Click this button to save the settings performed on

this page. If you move to another page without

pushing this button, the settings will be lost.

Note

The “Secondary Printer (optional)” section is not used

currently.

About the Setup Window

35

Page 36

Printer Status Page

This page displays the status of the UP-DF500.

D Refresh button

Click this button to update the window.

E-Mail Settings Page

This page allows you to perform settings related to Email.

Setup

A Printer Status display area

Motor/Sensor: Displays the error status of the

motor/sensor system.

Film Path: Displays the status of the printing path.

Cover: Displays the status of covers (opened or

closed).

Film Tray: Displays whether or not the film tray is

inserted.

Films: Displays whether or not film is loaded on the

film tray.

Tag: Displays the confirmability status of the IC

tag.

Film Output: Displays the status of the film output

slot.

Printer Engine Status: Displays the printer

operating status (idling, printing and so on)

B Printer Statistics display area

Displays the total printings performed by the unit.

Print count with the current thermal head: Displays

the total prints after the thermal head has been

replaced.

Lifetime print count: Displays the total prints since

the unit has been shipped.

A Errors/events to monitor setting area

Sets the criteria for sending the E-mail.

B Mail Server and Address setting area

Performs the setup of E-mail service.

C Send a test E-Mail button

Press this button to send an E-mail message for

testing purposes.

D Save settings button

Click this button to save the settings performed on

this page. If you move to another page without

pushing this button, the settings will be lost.

C Printer/Media Information display area

Vendor ID, Model Name, Version Number, Media

Type, Media Size, Pixel Matrix, Resolution,

Maximum Density, Minimum Density: Displays

various information on the unit status.

Film Remaining: Displays approximate number of

film sheets remaining in the film tray.

36

About the Setup Window

Page 37

Setup of the Unit

Setup of E-Mail

Perform the following settings when the unit is used for

the first time after being purchased, or when the IP

address assigned to the UP-DF500 is changed.

1

Open the DICOM Settings page.

For detailed information on how to open the page,

see “Opening the Setup Window” (on page 34).

2

Perform the required settings related to TCP/IP.

IP Address text box

Sub-net Mask text box

Default Gateway text box

1 Enter the IP address of the UP-DF500 on the

network in the IP Address text box.

2 Enter the sub-net mask in the Sub-net Mask text

box.

3 Enter the IP address of the default gateway if a

gateway is used on the network.

The E-Mail settings page allows you to set up E-mail

service so that an e-mail message will be sent

automatically when an error occurs in the UP-DF500.

1

Open the E-Mail settings page.

For detailed information on how to open the page,

see “Opening the Setup Window” (on page 34).

2

Set criteria determining when an e-mail message

should be sent.

Motor/sensor error check box

Film jamming check box

More than 50,000 printed with the

current thermal head check box

Place the check marks on the check box

corresponding to an error that requires notification

via an e-mail message.

Setup

3

Enter the DICOM AE title in the AE Title text box.

Up to 16 characters can be entered.

DICOM AE text box

4

Click the [Save settings] button.

The settings are saved.

Error item Content

Motor/Sensor error When an error occurs in the motor/

Film Jamming When a film sheet has jammed.

More than 50,000

printed with the

current thermal

head

sensor system.

When the total number of prints

with the current thermal head

exceeds 50,000.

Setup of the Unit / Setup of E-Mail

37

Page 38

3

Perform the settings related to e-mail.

Confirmation After

Mail Server IP Address text box

User ID text box

Setup

From text box

Send to text box

Enter addresses in the corresponding text boxes.

Enter item Content

Mail Server IP

Address

User ID User ID

From Return address of the E-mail

Send to Destination address of the E-mail.

IP address of the mail server

notification when an error occurs and

an e-mail message is sent.

a)

Setup

After all of settings have been completed

Turn off the power of the UP-DF500 and disconnect the

UP-DF500 and the personal computer for setup.

Proceed as follows to confirm the operation of the UPDF500.

1

Connect the UP-DF500 to the network.

2

Turn on the power of the UP-DF500.

3

Insert a film tray in which film sheets have been

loaded.

4

Send the image data from a modality.

The unit starts printing.

When the image data is not sent

Check whether or not the IP address of the modality side

is correct.

When setting up an E-mail

Confirm the settings for an E-mail as follows.

a) Use only numerical characters for the IP

address.

4

Click the [Save settings] button.

The settings are saved.

1

Click E-mail settings in the page selection area to

open the E-mail settings page.

When this page is opened after E-mail settings have

been completed, the Send a test E-Mail button

appears.

2

Click the [Send a test E-Mail] button.

A test e-mail message is sent if settings have been

correctly performed.

38

Confirmation After Setup

Send a test E-Mail button

Page 39

Sony Corporation

Loading...

Loading...