SONY TRV118, TRV318, TRV418 Diagram

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

RMT-708

Ver 1.0 2002. 11

Revision History

Revision History

Link

Link

Before starting adjustments

Before starting adjustments

Adjusting items when replacing main parts and boards

Adjusting items when replacing main parts and boards

CAMERA SECTION ADJUSTMENTS

CAMERA SECTION ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

INITIALIZATION OF D, E, F, 7 PAGE DATA

INITIALIZATION OF D, E, F, 7 PAGE DATA

CAMERA SYSTEM ADJUSTMENTS

CAMERA SYSTEM ADJUSTMENTS

LCD SYSTEM ADJUSTMENTS

LCD SYSTEM ADJUSTMENTS

MECHANISM SECTION ADJUSTMENTS

MECHANISM SECTION ADJUSTMENTS

ADJUSTMENT REMOTE COMMANDER

ADJUSTMENT REMOTE COMMANDER

OPERATING WITHOUT CASSETTE

OPERATING WITHOUT CASSETTE

SECTION 6

ADJUSTMENTS

VIDEO SECTION ADJUSTMENTS

VIDEO SECTION ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

PREPARATIONS BEFORE ADJUSTMENTS

SYSTEM CONTROL SYSTEM ADJUSTMENTS

SYSTEM CONTROL SYSTEM ADJUSTMENTS

SERVO SYSTEM ADJUSTMENTS

SERVO SYSTEM ADJUSTMENTS

VIDEO SYSTEM ADJUSTMENTS

VIDEO SYSTEM ADJUSTMENTS

AUDIO SYSTEM ADJUSTMENTS

AUDIO SYSTEM ADJUSTMENTS

SERVICE MODE

SERVICE MODE

ADJUSTMENT REMOTE COMMANDER

ADJUSTMENT REMOTE COMMANDER

DATA PROCESS

DATA PROCESS

SERVICE MODE

SERVICE MODE

ADJ

TAPE PATH ADJUSTMENT

TAPE PATH ADJUSTMENT

9-876-257-51

Sony EMCS Co.

2002K0500-1

©2002.11

Published by DI Customer Center

CCD-TRV118/TRV218/TRV318/TRV418/TRV418E

TABLE OF CONTENTS

Section Title Page Section Title Page

6. ADJUSTMENTS

Before Starting Adjustments ·····················································6-1

1-1. Adjusting Items when Replacing

Main Parts and Boards ····················································6-2

6-1. Camera Section Adjustments··········································· 6-4

1-1. Preparations before Adjustments (CAMERA Section)···6-4

1-1-1.List of Service Tools························································6-4

1-1-2.Preparations ·····································································6-5

1-1-3.Precaution········································································6-7

1. Setting the Switch····························································6-7

2. Order of Adjustments ······················································6-7

3. Subjects ···········································································6-7

1-2. Initialization of D, E, F, 7 Page Data·······························6-8

1. Initializing the D, E, F, 7 Page Data ································6-8

2. Modification of D, E, F, 7 Page Data ······························6-8

3. D Page Table····································································6-9

4. E Page Table ····································································6-9

5. F Page Table ··································································6-10

6. 7 Page Table···································································6-11

1-3. Camera System Adjustments·········································6-12

1. Hall Adjustment·····························································6-12

2. Flange Back Adjustment

(Using the Minipattern Box) ·········································6-13

3. Flange Back Adjustment

(Using the Flange Back Adjustment Chart

and Subject More than 500 m Away) ····························6-14

4. Flange Back Check························································6-15

5. Optical Axis Adjustment ···············································6-16

6. Picture Frame Setting ····················································6-17

7. Color Reproduction Adjustment····································6-18

8. AWB & LV Standard Data Input ···································6-19

9. Auto White Balance Adjustment ···································6-20

10. Auto White Balance Check ···········································6-21

11. Angular Velocity Sensor Output Check and Steadyshot

Check (CCD-TRV318/TRV418/TRV418E)··················6-22

1-4. LCD System Adjustments ·············································6-23

1. VCO Adjustment (PD-180 Board) ································6-23

2. RGB AMP Adjustment (PD-180 Board) ·······················6-24

3. Contrast Adjustment (PD-180 Board) ···························6-24

4. COM AMP Adjustment (PD-180 Board) ······················6-25

5. V-COM Adjustment (PD-180 Board)····························6-25

6. White Balance Adjustment (PD-180 Board)·················6-26

6-2. Mechanism Section Adjustments ··································6-27

2-1. Adjustment Remote Commander ··································6-27

2-2. Operating Without Cassette ···········································6-27

2-3. Tape Path Adjustment····················································6-27

6-3. Video Section Adjustments ···········································6-28

3-1. Preparations before Adjustments···································6-28

3-1-1.Equipment Required······················································6-28

3-1-2.Precautions on Adjusting ···············································6-29

3-1-3.Adjusting Connectors ····················································6-30

3-1-4.Connecting the Equipment ············································6-30

3-1-5.Alignment Tapes····························································6-31

3-1-6.Output Level and Impedance········································· 6-32

3-1-7.Recording Mode (Standard 8/Hi8) Switching···············6-32

3-2. System Control System Adjustments ····························6-33

1. Initialization of D, E, F, 7 Page Data·····························6-33

3-3. Servo System Adjustments ············································6-33

1. CAP FG Offset Adjustment (VC-303 Board) ···············6-33

2. Switching Position Adjustment (VC-303 Board)··········6-33

3-4. Video System Adjustments············································6-34

1. 28 MHz Origin Oscillation Adjustment

(VC-303 Board)·····························································6-34

2. AFC f0 Adjustment (VC-303 Board)·····························6-34

3. S VIDEO OUT Y Level Adjustment

(VC-303 Board)·····························································6-35

4. S VIDEO OUT C Level Adjustment

(VC-303 Board)·····························································6-35

5. VIDEO OUT Level Check (VC-303 Board)·················6-36

6. REC Y Current Adjustment (VC-303 Board)················6-37

7. REC C/AFM Current Adjustment ·································6-38

7-1. Preparations ···································································6-38

7-2. REC C Current Check (VC-303 Board)························6-38

7-3. REC AFM Current Adjustment (VC-303 Board)··········6-39

7-4. Processing after Completed Adjustment ·······················6-39

3-5. Audio System Adjustments ···········································6-40

1. BPF f0 Adjustment (VC-303 Board)······························6-40

2. 1.5 MHz Deviation Adjustment (VC-303 Board) ·········6-40

6-4. Service Mode·································································6-41

4-1. Adjustment Remote Commander ··································6-41

1. Using the Adjustment Remote Commander··················6-41

2. Precautions Upon Using the Adjustment

Remote Commander······················································6-41

4-2. Data Process ··································································6-42

4-3. Service Mode·································································6-43

1. Setting the Test Mode ····················································6-43

2. Emergency Memory Address ········································6-44

2-1. EMG Code (Emergency Code) ·····································6-44

2-2. MSW Codes ··································································6-45

3. Bit Value Discrimination ···············································6-46

4. Switch Check (1) ···························································6-46

5. Switch Check (2) ···························································6-46

6. Switch Check (3) ···························································6-47

7. LED, Video Light, IR Light Check ·······························6-47

8. Record of Use Check·····················································6-48

9. Record of Self-diagnosis Check ····································6-49

* The optical axis frame is shown on page 6-50

The color reproduction frame is shown on page 6-51

— 2 —

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

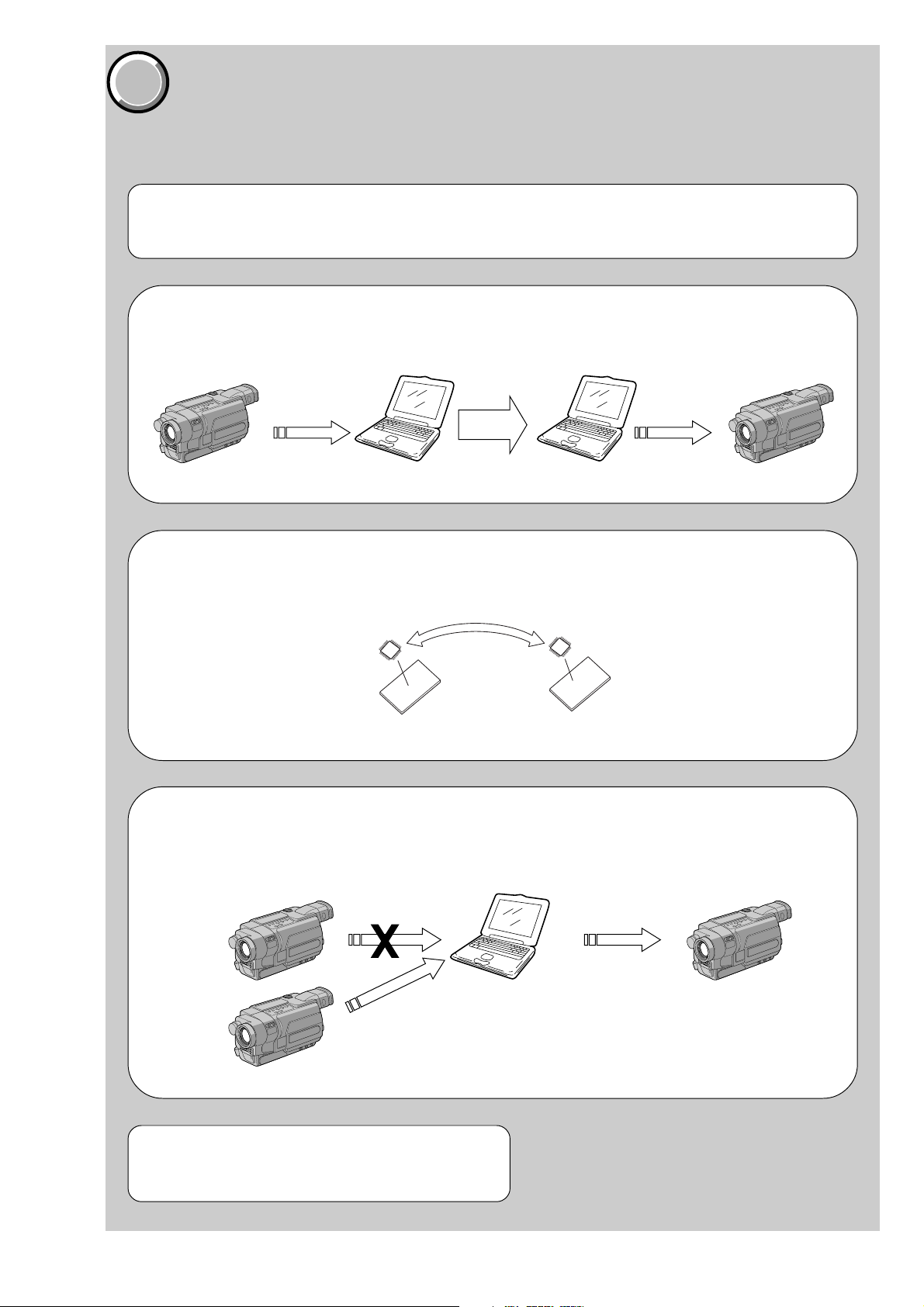

(Machine before starting repair)

(Machine after a board is replaced)

PC PC

Save the EVR data

to a personal computer.

Download the saved

data to a machine.

COVER

COVER

1. Before starting adjustments

EVR Data Re-writing Procedure When Replacing Board

The data that is stored in the repair board, is not necessarily correct.

Perform either procedure 1 or procedure 2 or procedure 3 when replacing board.

Procedure 1

Save the EVR data of the machine in which a board is going to be replaced. Download the saved data after a

board is replaced.

SECTION 6

ADJUSTMENTS

Procedure 2

Remove the EEPROM from the board of the machine that is going to be repaired. Install the removed

EEPROM to the replaced board.

Remove the EEPROM and install it.

(Former board)

(New board)

Procedure 3

When the data cannot be saved due to defective EEPROM, or when the EEPROM cannot be removed or

installed, save the data from the same model of the same destination, and download it.

(Machine to be repaired) (Machine to be repaired)

PC

Download the data.

After the EVR data is saved and downloaded, chec k the

respective items of the EVR data.

(Refer to page 6-3 for the items to be checked)

Save the data.

(The same model of the same destination)

6-1

CCD-TRV118/TRV218E/TRV318/TR V418/TRV418E

COVER

COVER

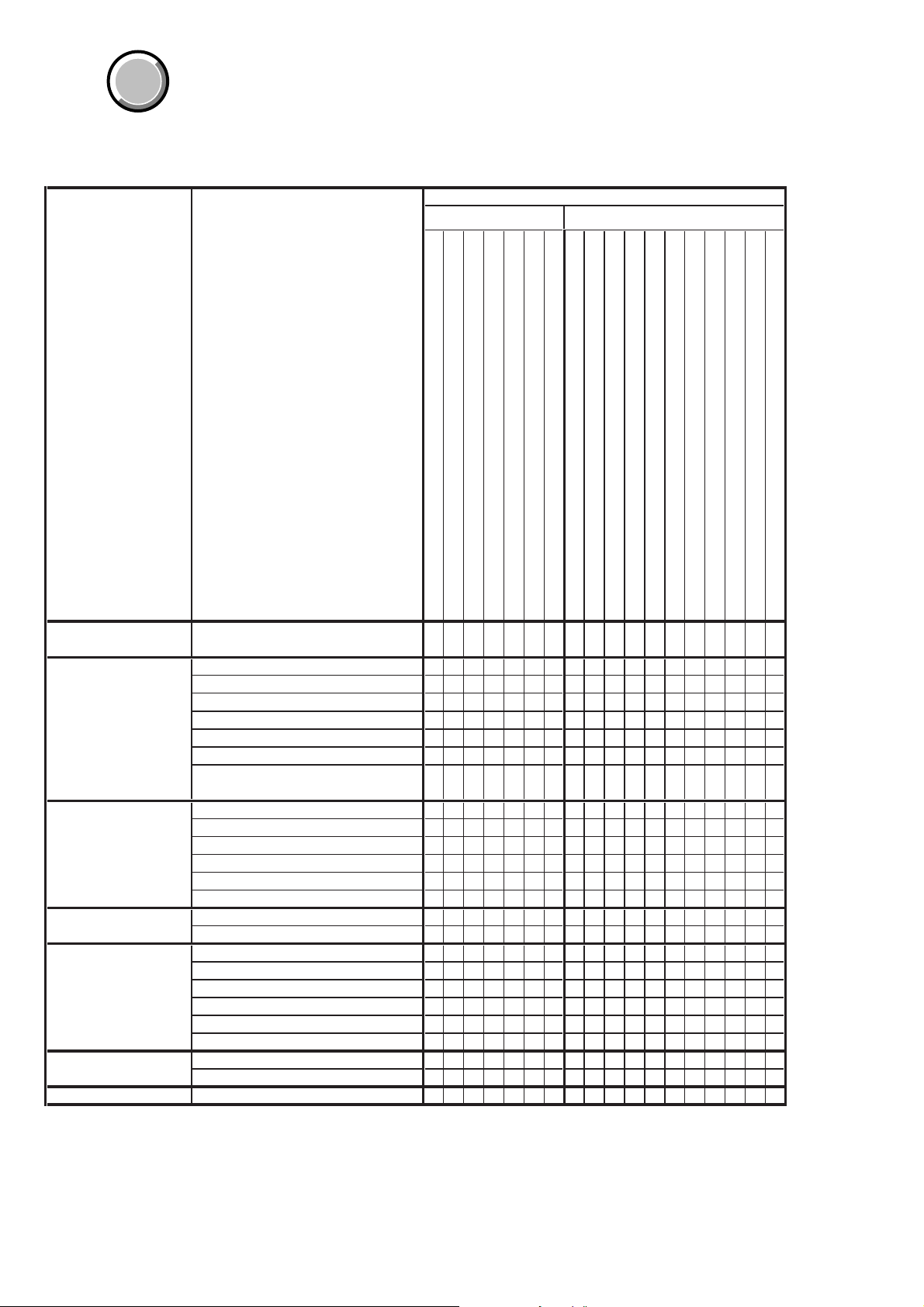

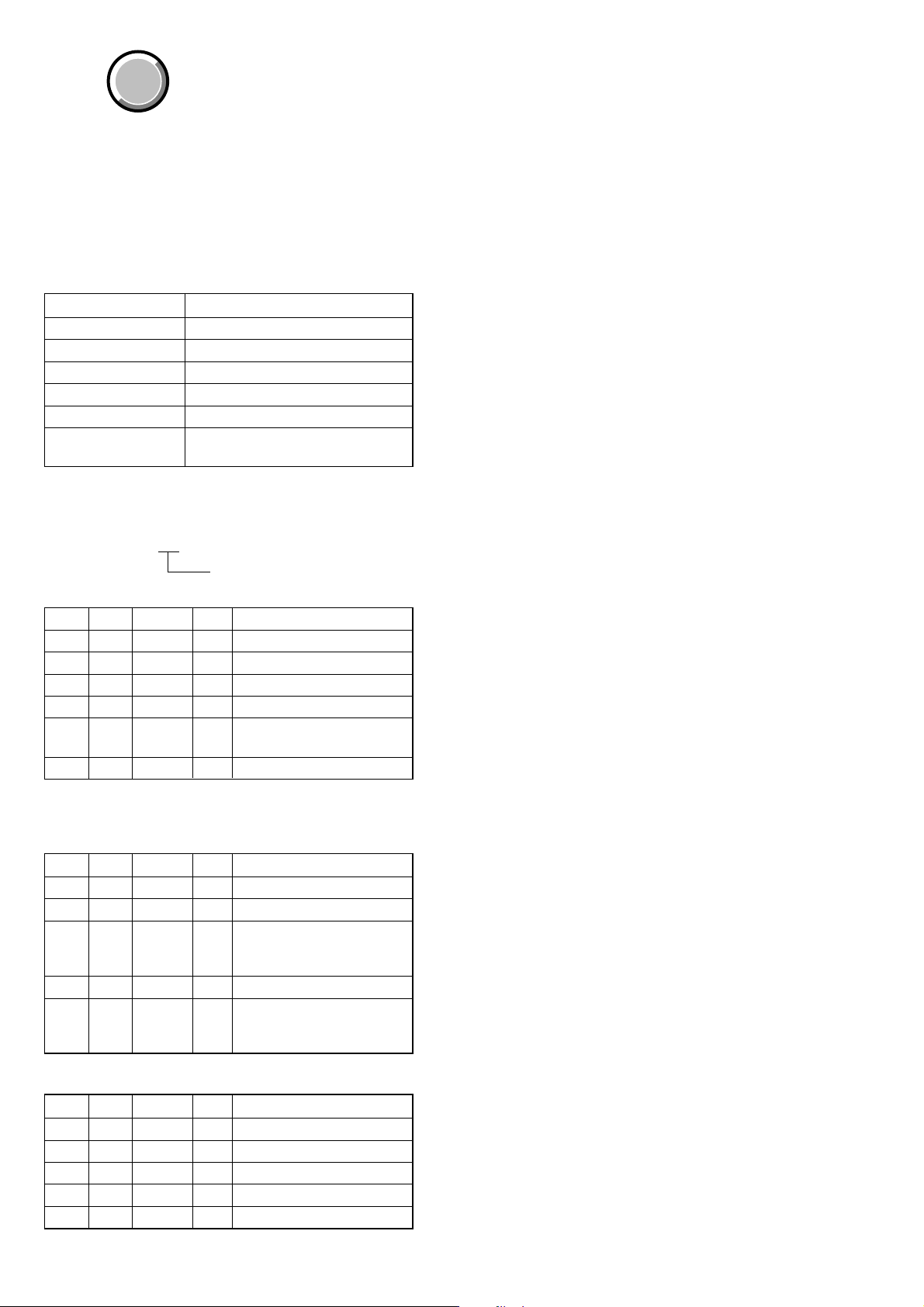

1-1. Adjusting items when replacing main parts and boards

• Adjusting items when replacing main parts

When replacing main parts, adjust the items indicated by z in the following table.

Block replacement Mounted part replacement

Replaced part

Adjustment Section Adjustment

Initialization of D, E,

F, 7 page data

Camera HALL adj. z

LCD VCO adj. zz

Servo CAP FG offset adj. zz

Video 28 MHz origin osillation adj. zz

Audio BPF f

Mechanism Tape path adj.

Initializing of D, E, F, 7 page data

Flange back adj. zz

Optical axis adj. zz

Color reproduction adj. zz

AWB & LV standard data input zz

Auto white balance adj. zz

Angular velocity sensor output check

and steadyshot check (Note 3)

RGB AMP adj. z

Contrast adj. z

COM AMP adj. z

V-COM adj. zz

White balance adj.

Switching position adj.

0

adj. z

AFC f

S VIDEO OUT Y level adj. zz

S VIDEO OUT C level adj. zz

REC Y current adj. zz

REC C/AFM current adj.

0

adj. z

1.5 MHz deviation adj.

Table 6-1-1 (1)

(LCD panel)

(Fluorescent tube)

(Drum assembly) (Note 1)

(Capstan motor)

(CCD imager)

(YAW, PITCH sensor) (Note 3)

(Timing generator)

(S/H, AGC, A/D CONV.)

(Camera/VTR process)

(REC/PB AMP)

Lens device

Video light (Note 2)

LCD block LCD901

LCD block ND901

Mechanism deck (Note 1)

Mechanism deck M901

Mechanism deck M902

CD-409 board IC951

SI-035 board SE751/752

VC-303 board IC271, X271

VC-303 board IC272

VC-303 board IC151

VC-303 board IC101

z

zz z

zz

zz

zzz

(Y/C MIX, Buffer)

(EVR)

(Audio process)

(LCD drive)

(Timing generator)

VC-303 board IC651

VC-303 board IC601

VC-303 board IC351

PD-180 board IC5501

PD-180 board IC5502

z

Note 1: When replacing the drum assy or mechanism deck, reset the data of page: 2, address: A2 to A4.

(Refer to “Record of Use Check” of “6-4. SERVICE MODE”)

Note 2: When replacing the video light, reset the data of page: 2, address: E0 to E2.

(Refer to “Record of Use Check” of “6-4. SERVICE MODE”)

Note 3: CCD-TRV318/TRV418/TRV418E only

6-2

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

• Adjusting items when replacing a board or EEPROM

When replacing a board or EEPROM, adjust the items indicated by z in the following table.

Replaced part

Adjustment Section Adjustment

(COMPLETE)

(COMPLETE)

(EEP ROM)

RadarWRadarWRadarW

PD-180 board

VC-303 board

VC-303 board IC401

Supporting

Initialization of D, E,

F, 7 page data

Camera HALL adj. zzz

LCD VCO adj. zzz

Servo CAP FG offset adj. zzz

Video 28 MHz origin osillation adj. zz

Audio BPF f

Mechanism Tape path adj.

Initializing of D, E, F, 7 page data

zz

Flange back adj. zzz

Optical axis adj. zz

Color reproduction adj. zz

AWB & LV standard data input zzz

Auto white balance adj. zzz

Angular velocity sensor output check

and steadyshot check (Note 3)

zzz

RGB AMP adj. zzz

Contrast adj. zzz

COM AMP adj. zzz

V-COM adj. zzz

White balance adj.

Switching position adj.

0 adj. zzz

AFC f

zzz

zz

S VIDEO OUT Y level adj. zz

S VIDEO OUT C level adj. zz

REC Y current adj. zz

REC C/AFM current adj.

0 adj. zz

1.5 MHz deviation adj.

zz

zz

Table 6-1-1 (2)

6-3

CCD-TRV118/TRV218E/TRV318/TR V418/TRV418E

COVER

COVER

6-1. CAMERA SECTION ADJUSTMENTS

1-1. PREPARATIONS BEFORE ADJUSTMENTS (CAMERA SECTION)

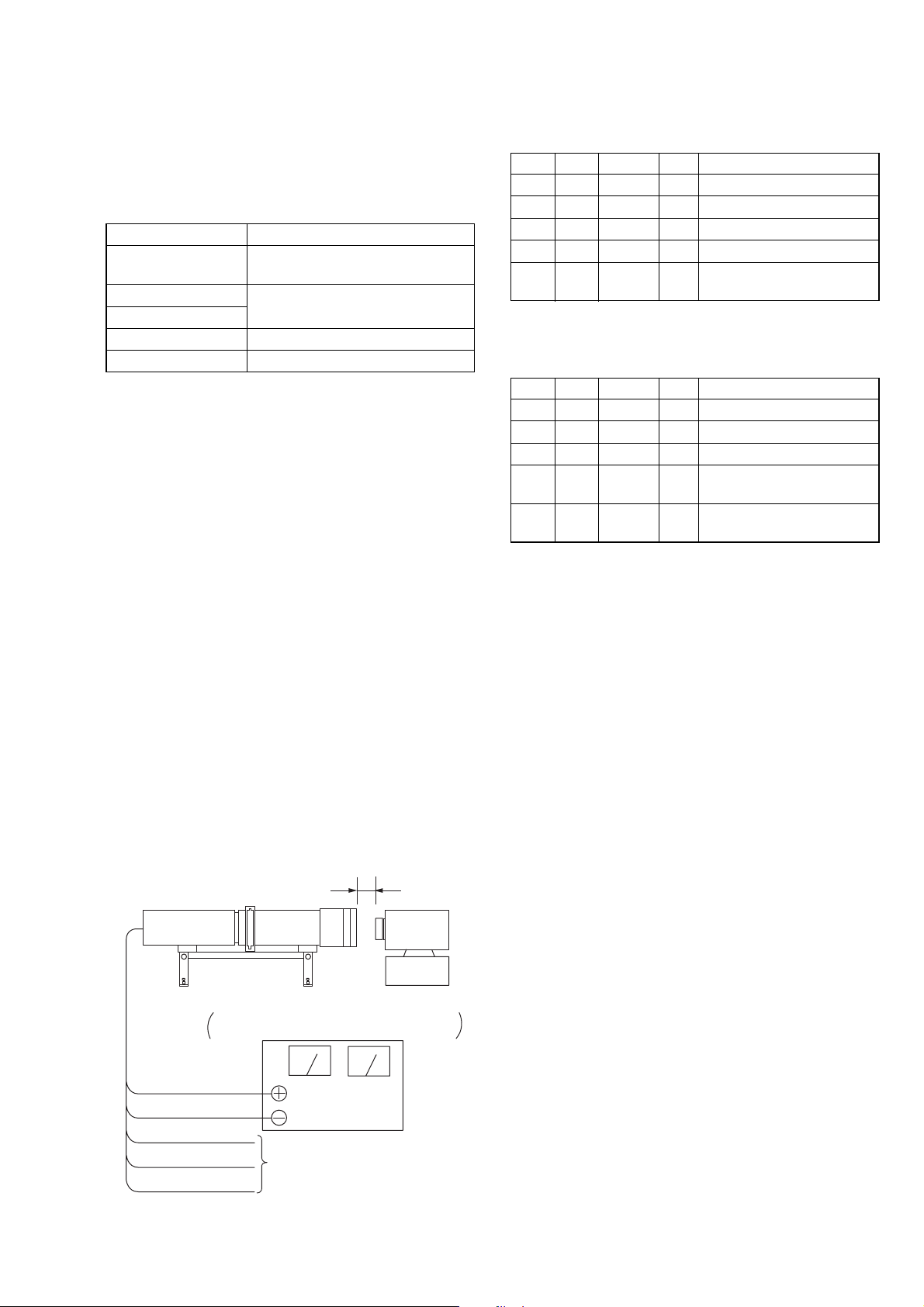

1-1-1. List of Ser vice Tools

• Oscilloscope • Color monitor • Vectorscope

• Regulated power supply • Digital voltmeter • Frequency counter

Ref. No.

J-1

J-2

J-3

J-4

J-5

J-6

J-7

J-8

J-9

J-10

J-11

J-12

Filter for color temperature correction (C14)

ND filter 1.0

ND filter 0.4

ND filter 0.1

Pattern box PTB-450

Color chart for pattern box

Adjustment remote commander (RM-95 upgraded).

(Note)

Siemens star chart

Clear chart for pattern box

CPC jig connector

I/F unit for LANC control

Mini pattern box

Camera table

Multi CPC jig

Name

Parts Code

J-6080-058-A

J-6080-808-A

J-6080-806-A

J-6080-807-A

J-6082-200-A

J-6020-250-A

J-6082-053-B

J-6080-875-A

J-6080-621-A

J-6082-539-A

J-6082-521-A

J-6082-353-B

J-6082-384-A

J-6082-311-A

Auto white balance adjustment/check

White balance adjustment/check

White balance check

White balance check

White balance check

For checking the flange back

For connecting the adjustment remote commander

For connecting the adjustment remote commander

For adjusting the flange back

For adjusting the flange back

For adjusting the LCD system

Usage

Note: If the micro processor IC in the adjustment remote com-

mander is not the new micro processor (UPD7503G-C56-

12), the pages cannot be switched. In this case, replace with

the new micro processor (8-759-148-35).

J-1 J-2

J-6

J-11

J-7 J-8

J-12

J-3

J-4 J-5

J-9 J-10

Fig. 6-1-1

6-4

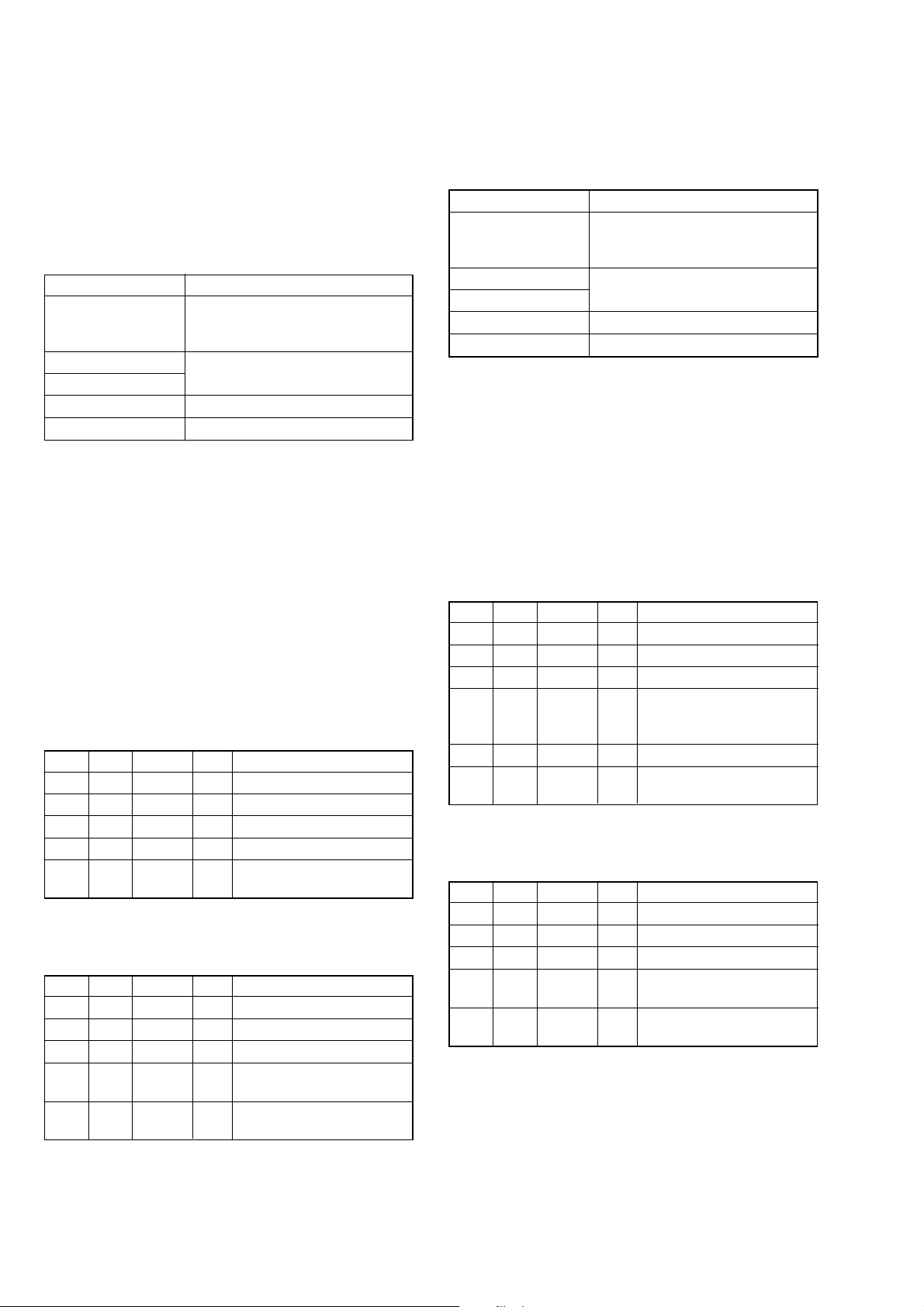

1-1-2. Preparations

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

Note 1: For details of how remove the cabinet and boards, refer

to “2. DISASSEMBLY”.

Note 2: When performing only the adjustments, the lens block

and boards need not be disassembled.

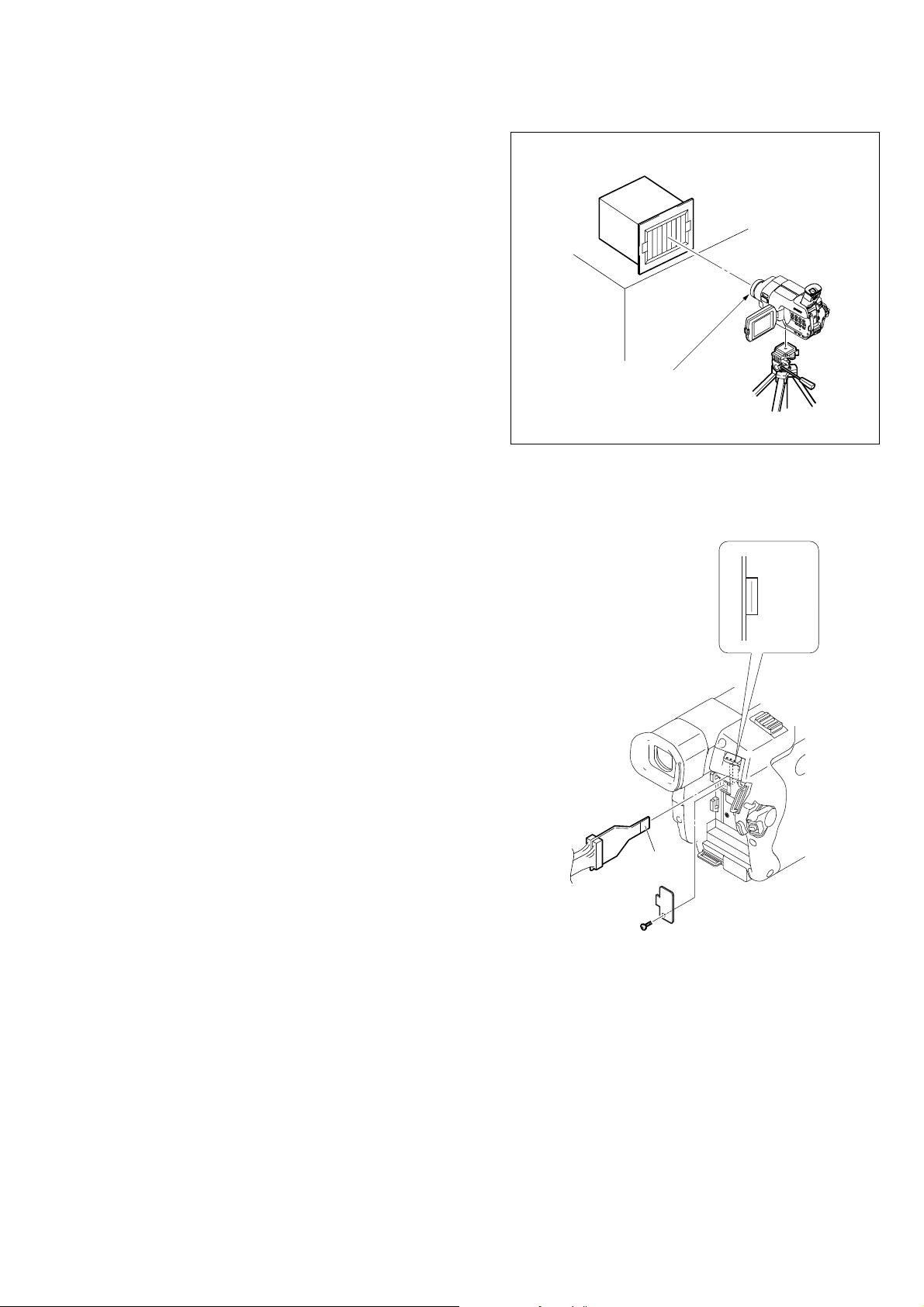

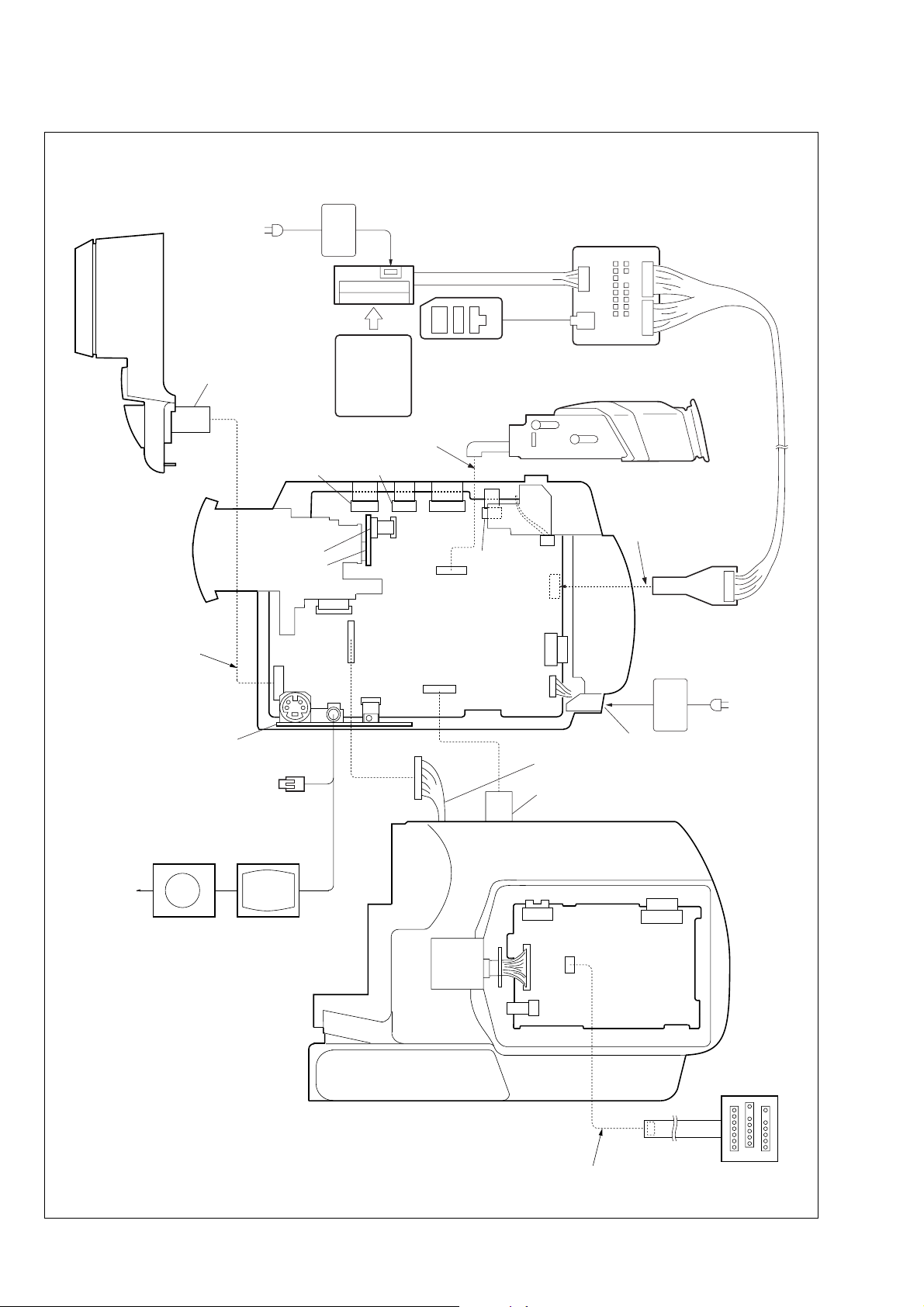

1) Connect the equipment for adjustments according to Fig. 6-1-

4.

2) Connect the adjustment remote commander to VC-303 board

CN712 via I/F unit for LANC control (J-6082-521-A) and CPC

jig connector (J-6082-539-A). (Fig. 6-1-3)

To operate the adjustment remote commander, connect the A C

power adaptor to the DC IN jack of I/F unit for LANC control,

or connect the L series Info-LITHIUM battery to the battery

terminal of I/F unit for LANC control.

3) The front panel block (SI-035 board, video light, microphone

unit) need not be assembled except during the steadyshot operation check.

Note 3: As removing the cabinet (R) (removing the VC-303 board

CN713) means removing the lithium 3V power supply

(CF-3000 block BT001), data such as date, time, userset menus will be lost. After completing adjustments,

reset these data. If the cabinet (R) has been removed, the

self-diagnosis data, data on history of use (total drum

rotation time, etc. ) will be lost. Before removing, note

down the self-diagnosis data (data of page: 2, address:

B0 to C6) and data on history use (data of page: 2, address: A2 to AA and E0 to E2). (Refer to “SELF-DIAGNOSIS FUNCTION” for the self-diagnosis data, and to

“6-4. Service Mode” for the data on the history use)

Pattern box

1.5 m

Front of the lens

Fig. 6-1-2

CN712

1

16

Note 4: Setting the “Forced Camera Power ON” Mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 01, and press

the PAUSE button of the adjustment remote commander.

The above procedure will enable the camera power

to be turned on with the power switch (SS-3000 block)

removed. After completing adjustments, be sure to

exit the “Forced Camera Power ON Mode”.

Note 5: Exiting the “Forced Camera Power ON” Mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 00, and press

the PAUSE button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

Conductor

side

Fig. 6-1-3

6-5

CCD-TRV118/TRV218E/TRV318/TR V418/TRV418E

Note: Use either the AC power adaptor or the InfoLITHIUM battery as the power supply of I/F unit for LANC control.

AC power adaptor

FRONT PANEL BLOCK

Must be connected

when performing

the steadyshot check.

To SI-035 board

CN753

LENS BLOCK

CD-409 board

CN708

CN951

CN301

CN703

L series

Info LITHIUM

Adjustment

remote commander

battery

(7.2 Vdc)

Need not connected

CN101

CN707

CN271

VC-303 board

CN701

CN702

CN713

CN705

EVF BLOCK

CN704

CN706

I/F unit for LANC control

(J-6082-521-A)

LANC

jack

CN712

CN711

CN001

Must be connected

CPC jig connector

(J-6082-539-A)

AC power adaptor

Terminated

75 Ω

FP-576 flexible

Audio (black)

Color monitorVector scope

Video

(yellow)

CABINET (R)

DC IN jack

To PD-180 board CN5701

To CONTROL SWITCH BLOCK (CF-3000)

CN5601

CN5502

CN5701

CN5501

PD-180 board

CN5702

Multi CPC jig

(J-6082-311-A)

Must be connected when performing

the LCD sytem adjustment.

Fig. 6-1-4

6-6

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

1-1-3. Precaution

1. Setting the Switch

Unless otherwise specified, set the switches as follows and perform adjustments without loading cassette.

1. POWER switch (SS-3000 block) ..........................CAMERA

2. FOCUS (CF-3000 block) ..................................... MANUAL

3. BACK LIGHT (CF-3000 block) .................................... OFF

4. PROGRAM AE (MENU setting) ................................... OFF

5. NIGHT SHOT switch (Lens block) ............................... OFF

2. Order of Adjustments

Basically carry out adjustments in the order given.

Color bar chart (Color reproduction adjustment frame)

H

Yellow

Cyan

Green

AB B

Fig. a

(VIDEO terminal of A/V jack

output waveform)

A=B

White

Magenta

Red

CD

Blue

A

Enlargement

C=D

Difference in level

6. EXPOSURE (CF-3000 block) .................................... AUTO

7. P EFFECT (MENU setting) ........................................... OFF

8. D ZOOM (MENU setting) ............................................. OFF

9. DEMO MODE (MENU setting) .................................... OFF

10. 16 : 9 WIDE (MENU setting) ........................................ OFF

Electronic beam scanning frame

Red

Cyan

White

Green

Yellow

V

Fig. b (monitor TV picture)

Blue

Magenta

CRT picture frame

B

A

Fig. 6-1-5

3. Subjects

1) Color bar chart (Color reproduction adjustment frame)

When performing adjustments using the color bar chart, adjust

the picture frame as shown in Fig. 6-1-5. (Color reproduction

adjustment frame)

2) Clear chart (Color reproduction adjustment frame)

Remove the color bar chart from the pattern box and insert a

clear chart in its place. (Do not perform zoom operations during

this time)

3) Chart for flange back adjustment

Join together a piece of white A0 size paper (1189mm × 841

mm) and a piece of black paper to make the chart shown in

Fig. 6-1-6.

Note: Use a non-reflecting and non-glazing vellum paper. The

size must be A0 or larger and the joint between the white

and black paper must not have any undulations.

Adjust the camera zoom and direction to

obtain the output wavef orm shown in Fig. a and

the monitor TV display shown in Fig. b.

White

841 mm

Black

1189 mm

Fig. 6-1-6

6-7

CCD-TRV118/TRV218E/TRV318/TR V418/TRV418E

COVER

COVER

1-2. INITIALIZATION OF D , E, F, 7 PAGE DATA

1. Initializing the D, E, F, 7 Page Data

Note 1: If “Initialization of Pages D, E, F , 7” is executed, all data

on pages D, E, F, 7 are initialized. (Only an individual

page cannot be initialized)

Note 2: If the D, E, F, 7 page data has been initialized, “Modifi-

cation of D, E, F , 7 P age Data” and all adjustments need

to be performed again.

Note 3: NTSC model: CCD-TRV118/TRV318/TRV418

PAL model: CCD-TRV218E/TRV418E

Adjusting Page D

Adjusting Address 10 to 87

Adjusting Page E

Adjusting Address 00 to FF

Adjusting Page F

Adjusting Address 10 to FF

Adjusting Page 7

Adjusting Address 00 to 63

Initializing method:

Order Page Address Data Procedure

10 0101

Set the following data.

26 00

36 01

46 02

52 0029

62 01 29 Press PAUSE button.

7

55: NTSC model

51: PAL model

Set the following data, and

press PAUSE button.

55: NTSC model

51: PAL model

Check the data changes to

“01”.

Perform “Modification of D,

E, F, 7 Page Data”

2. Modification of D, E, F, 7 Page Data

If the D, E, F, 7 page data has been initialized, change the data of

the “Fixed data-2” address shown in the following table by manual

input.

Modifying method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) New data for changing are not shown in the tables because

they are different in destination. When changing the data, cop y

the data built in the same model.

Note: If copy the data built in the different model, the

camcorder may not operate.

3) When changing the data, press the PAUSE button of the adjustment remote commander each time when setting new data

to write the data in the non-volatile memory.

4) Check that the data of adjustment addresses is the initial value.

If not, change the data to the initial value.

Processing after Completing Modification of D, E, F, 7 Page

data

Order Page Address Data Procedure

12 0029

22 01 29 Press PAUSE button.

30 0100

Note: If the following symptoms occur after completing of the

“Modification of D, E, F , 7 page data”, check that the data

of the “Fixed data-2” addresses of D, E, F , 7 page are same

as those of the same model of the same destination.

1) The power is shut off so that unit cannot operate.

6-8

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

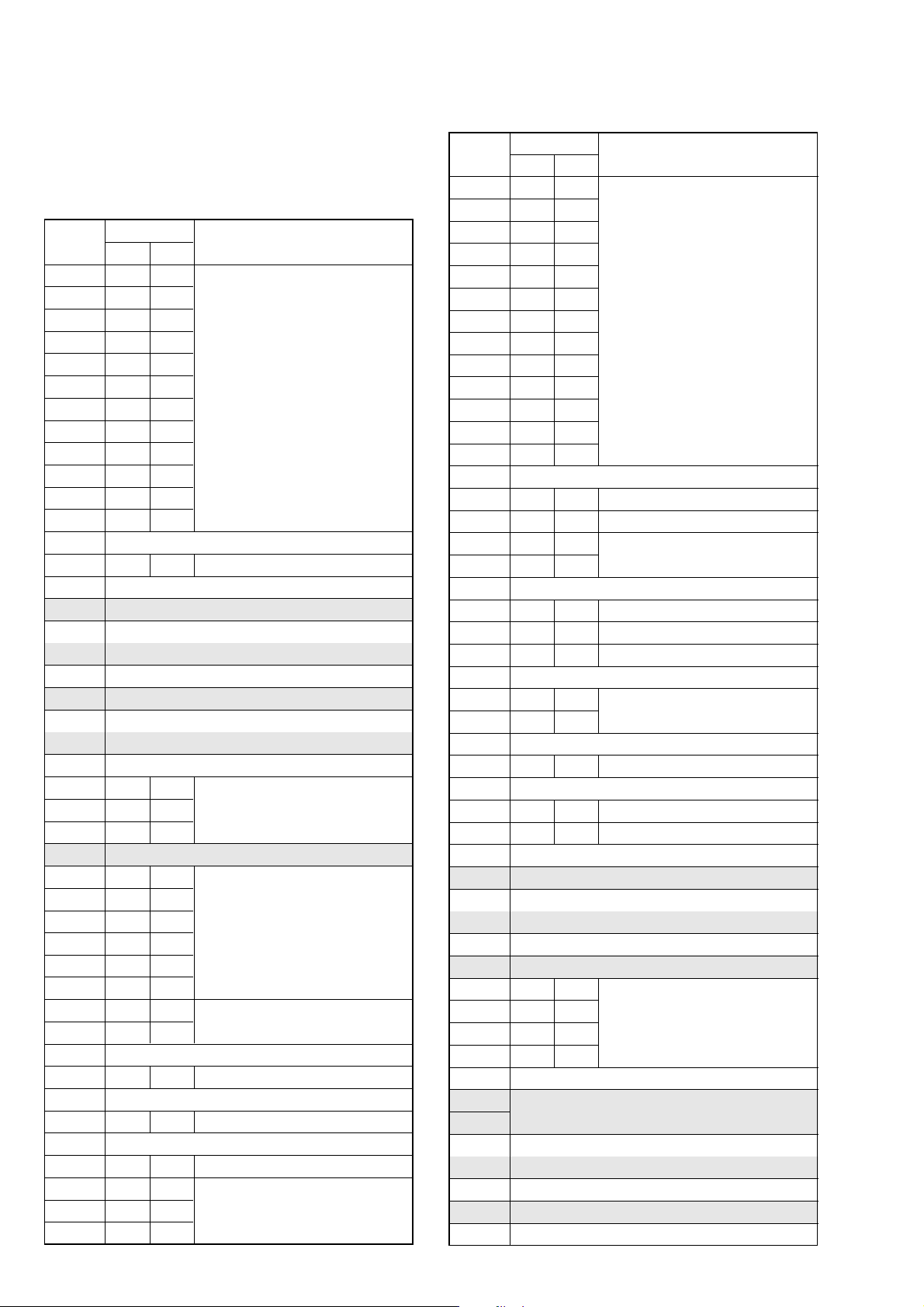

3. D Page Table

Note 1: Fixed data-1: Initialized data. (Refer to “1. Initializing

the D, E, F, 7 Page Data”)

Note 2: Fixed data-2: Modified data. (Refer to “2. Modification

of D, E, F, 7 Page Data”)

Address

11, 12 Fixed data-1 (Initialized data)

14 to 19 Fixed data-1 (Initialized data)

1A Fixed data-2

1B to 21 F ixed data-1 (Initialized data)

24 to 26 Fixed data-1 (Initialized data)

28 to 33 Fixed data-1 (Initialized data)

36, 37 Fixed data-1 (Initialized data)

3A to 40 Fixed data-1 (Initialized data)

42 to 44 Fixed data-1 (Initialized data)

49 to 4C F ixed data-1 (Initialized data)

4D Fixed data-2

4E, 4F Fixed data-1 (Initialized data)

51 to 5A Fixed data-1 (Initialized data)

5B Fixed data-2

5C to 72 F ixed data-1 (Initialized data)

74 to 7B F ixed data-1 (Initialized data)

7C Fixed data-2

7D to 84 Fixed data-1 (Initialized data)

86, 87 Fixed data-1 (Initialized data)

Initial value

NTSC PAL

10 00 00 Test mode

13 Fixed data-2

22

23

27 Fixed data-2

34

35

38

39

41 Fixed data-2

45

46

47

48

50 Fixed data-2

73 Fixed data-2

85 Fixed data-2

Fixed data-2

Fixed data-2

Fixed data-2

Fixed data-2

Remark

4. E Page Table

Note 1: Fixed data-1: Initialized data. (Refer to “1. Initializing

the D, E, F, 7 Page Data”)

Note 2: Fixed data-2: Modified data. (Refer to “2. Modification

of D, E, F, 7 Page Data”)

Address

00 to 09 Fixed data-1 (Initialized data)

0A Fixed data-2

0B Fixed data-1 (Initialized data)

0C

0D

0E Fixed data-1 (Initialized data)

0F Fixed data-2

10 to 15 Fixed data-1 (Initialized data)

16 Fixed data-2

17 Fixed data-1 (Initialized data)

18 Fixed data-2

19 to 28 Fixed data-1 (Initialized data)

29

2A

2B Fixed data-1 (Initialized data)

2C Fixed data-2

2D Fixed data-1 (Initialized data)

2E

2F

30

31 Fixed data-2

32

33

34

35 to 51 Fixed data-1 (Initialized data)

52 Fixed data-2

53 to 58 Fixed data-1 (Initialized data)

59 FF FF Optical axis adj.

5A to FF Fixed data-1 (Initialized data)

Initial value

NTSC PAL

Remark

Fixed data-2

Fixed data-2

6-9

CCD-TRV118/TRV218E/TRV318/TR V418/TRV418E

5. F Page Table

Note 1: Fixed data-1: Initialized data. (Refer to “1. Initializing

the D, E, F, 7 Page Data”)

Note 2: Fixed data-2: Modified data. (Refer to “2. Modification

of D, E, F, 7 Page Data”)

Address

1A 00 00

1B 00 00

1C to 1F Fixed data-1 (Initialized data)

21 to 23 Fixed data-1 (Initialized data)

25 to 27 Fixed data-1 (Initialized data)

2A Fixed data-2

2B, 2C Fixed data-1 (Initialized data)

2D Fixed data-2

2E, 2F Fixed data-1 (Initialized data)

3A 8D 8D

3B 87 87

3C to 3E Fixed data-1 (Initialized data)

42 to 44 Fixed data-1 (Initialized data)

Initial value

NTSC PAL

10 00 00

11 00 00

12 00 00

13 00 00

14 00 00

15 00 00

16 00 00

17 00 00

18 00 00

19 00 00

20 00 00 Test mode

24 Fixed data-2

28 Fixed data-2

29 Fixed data-1 (Initialized data)

30 52 68

31 89 80

32 88 8D

33 Fixed data-2

34 80 80

35 7A 7A

36 2B 2B

37 80 80

38 65 65

39 80 80

3F 33 33 Color reproduction adj.

40 Fixed data-1 (Initialized data)

41 34 34 Color reproduction adj.

45 8C 8C 28 MHz origin osillation adj.

46 28 28

47 EC EC

48 35 35

Emergency memory

HALL adj.

AWB & LV standard data input

Auto white balance adj.

Flange back adj.

Remark

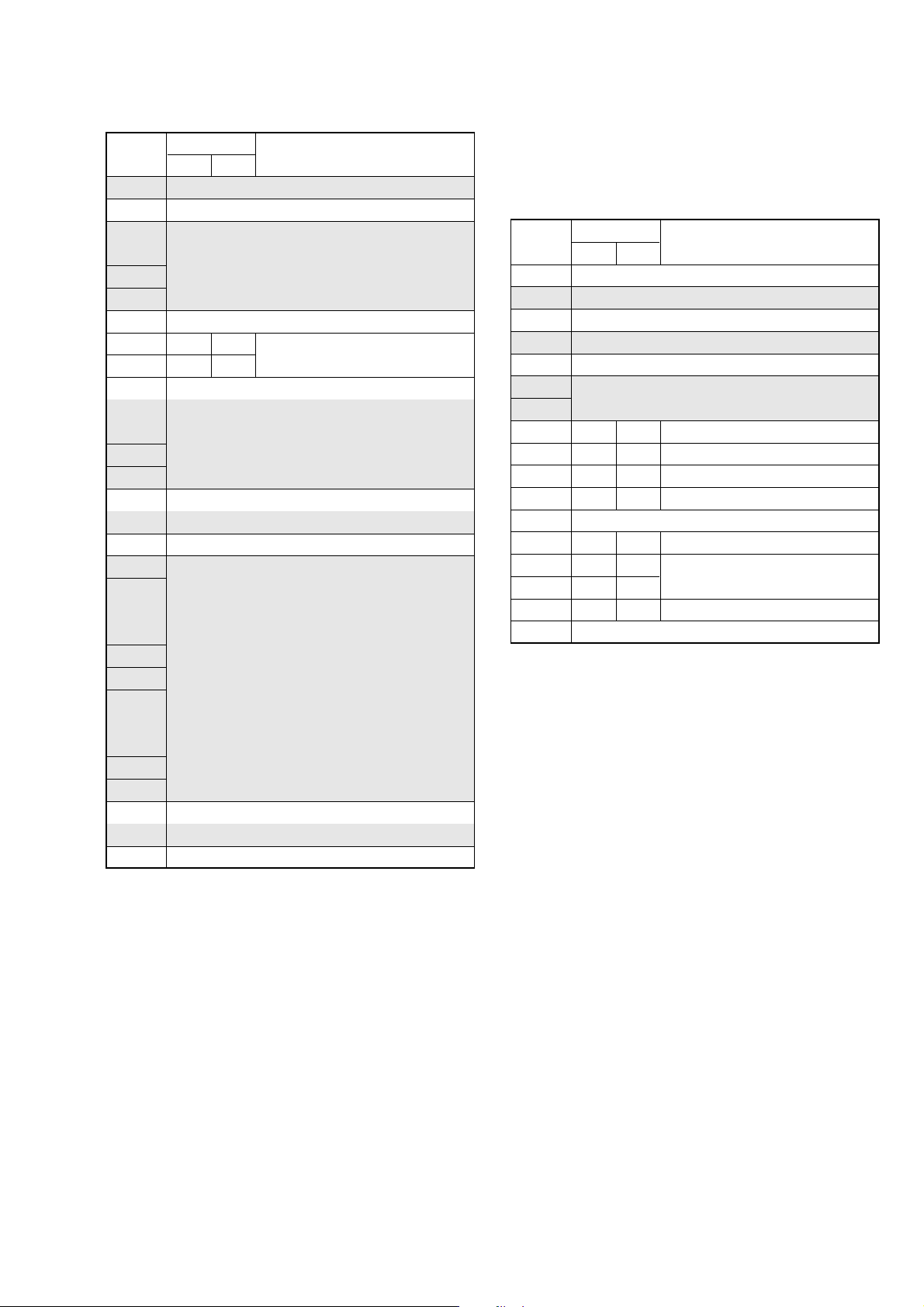

Address

4A 13 13

4B B8 B8

4C 2B 2B

4D 00 00

4E 19 19

56, 57 Fixed data-1 (Initialized data)

5A 0B 0A

5B 00 00

5C Fixed data-1 (Initialized data)

5D 50 50 AFC f0 adj.

5E 68 62 S VIDEO OUT Y level adj.

60, 61 Fixed data-1 (Initialized data)

64 to 68 Fixed data-1 (Initialized data)

6A to 72 Fixed data-1 (Initialized data)

75, 76 Fixed data-1 (Initialized data)

78 to 81 Fixed data-1 (Initialized data)

83 to 8E Fixed data-1 (Initialized data)

97, 98 Fixed data-1 (Initialized data)

9A to 9F Fixed data-1 (Initialized data)

A0 Fixed data-2

A1 Fixed data-1 (Initialized data)

Initial value

NTSC PAL

49 8F 8F

4F 00 00

50 32 32

51 00 00

52 00 00

53 04 04

54 00 00

55 00 00

58 00 00 Flange back adj.

59 83 83 CAP FG offset adj.

5F 62 62 S VIDEO OUT C level adj.

62 B4 D7

63 B4 D7

69 A0 A0 REC C/AFM current adj.

73 A6 A6 1.5 MHz deviation adj.

74 80 80 BPF f0 adj.

77 Fixed data-2

82 Fixed data-2

8F Fixed data-2

90 2B 2B

91 D0 E0

92 57 58

93 80 70

94 Fixed data-1 (Initialized data)

95

96

99 Fixed data-2

Flange back adj.

Switching position adj.

REC Y current adj.

Auto white balance adj.

Fixed data-2

Remark

6-10

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

Address

A2 Fixed data-2

A3 toA7 Fixed data-1 (Initialized data)

A8

A9

AA

AB

AC to AE Fixed data-1 (Initialized data)

AF FD FC

B0 F4 F2

B1 to B4 Fixed data-1 (Initialized data)

B5

B6

B7

B8

B9 to D0 Fixed data-1 (Initialized data)

D1 Fixed data-2

D2 to E8 Fixed data-1 (Initialized data)

E9

EA

EB

EC

ED

EE Fixed data-2

EF

F4 to F6 Fixed data-1 (Initialized data)

F8 to FF F ixed data-1 (Initialized data)

Initial value

NTSC PAL

Fixed data-2

Color reproduction adj.

Fixed data-2

F0

F1

F2

F3

F7 Fixed data-2

Remark

6. 7 Page Table

Note 1: Fixed data-1: Initialized data. (Refer to “1. Initializing

the D, E, F, 7 Page Data”)

Note 2: Fixed data-2: Modified data. (Refer to “2. Modification

of D, E, F, 7 Page Data”)

Address

00 to 0B Fixed data-1 (Initialized data)

0C Fixed data-2

0D to 2C Fixed data-1 (Initialized data)

2D Fixed data-2

2E to 40 Fixed data-1 (Initialized data)

41

42

43 78 5B VCO adj.

44 68 63 VCO adj. (PAL)

45 89 89 V-COM adj.

46 2C 2B RGB AMP adj.

47 Fixed data-1 (Initialized data)

48 86 B2 COM AMP adj.

49 74 5D

4A 67 57

4B 53 53 Contrast adj.

4C to 63 Fixed data-1 (Initialized data)

Initial value

NTSC PAL

Remark

Fixed data-2

White balance adj.

6-11

CCD-TRV118/TRV218E/TRV318/TR V418/TRV418E

COVER

COVER

1-3. CAMERA SYSTEM ADJUSTMENTS

Before perform the camera system adjustments, check that the

specified values of “28 MHz Origin Oscillation Adjustment”, “S

VIDEO OUT Y level Adjustment” and “S VIDEO OUT C level

Adjustment” of “VIDEO SYSTEM ADJUSTMENT” are satisf ied.

1. HALL Adjustment

For detecting the position of lens iris, adjust the hall AMP gain

and offset.

Mode CAMERA

Subject Not required

Measurement Point Displayed data of page: 1 (Note 2)

Measuring Instrument Adjusting remote commander

Adjustment Page F

Adjustment Address 30 to 32

Specified value 85 to 89 during IRIS OPEN

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Note 2: The right two digits of the page: 1 displayed data of the

adjusting remote commander.

1:00:XX

Adjusting method:

Order Page Address Data Procedure

10 0101

26 9487

36 9517

46 01 6D Press PAUSE button. (Note 3)

56 02

66 01 00 Press PAUSE button.

Note 3: The adjustment data will be automatically input to page:

F, address: 30 to 32.

RadarWRadarWRadarW

15 to 19 during IRIS CLOSE

Displayed data

Check the data changes to

“01”.

Checking method:

Order Page Address Data Procedure

10 0303

26 01 01 Press PAUSE button.

Check that the displayed data

31

46 01 03 Press PAUSE button.

51

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

26 9400

36 9500

40 0300

50 0100

(Note 2) during IRIS OPEN

satisfied the specified value.

Check that the displayed data

(Note 2) during IRIS CLOSE

satisfied the specified value.

6-12

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

RadarW

RadarW

RadarW

RadarW

2. Flange Back Adjustment

(Using the minipattern box)

The inner focus lens flange back adjustment is carried out

automatically. In whichever case, the focus will be deviated during auto focusing/manual focusing.

Mode CAMERA

Subject Siemens star chart with ND filter for

minipattern box (Note 1)

Measurement Point Check operation on monitor TV

Measuring Instrument

Adjustment Page F

Adjustment Address 46 to 55, 58

Note 1: Dark Siemens star chart.

Note 2: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Note 3: Perform the adjustment with the camcorder in horizon-

tal state.

Note 4: Perform “HALL Adjustment” before this adjustment.

Switch setting:

1) NIGHT SHOT.................................................................. OFF

Preparations before adjustments:

1) The minipattern box is installed as shown in the following figure.

Note 5: The attachment lenses are not used.

2) Install the minipattern box so that the distance between it and

the front of lens of camcorder is less than 3 cm.

3) Make the height of minipattern box and the camera equal.

4) Check the output voltage of the regulated power supply is the

specified voltage ± 0.01 Vdc.

5) Check that the center of Siemens star chart meets the center of

shot image screen with the zoom lens at TELE end and WIDE

end respectively.

RadarW

Adjusting method:

Order Page Address Data Procedure

10 0101

26 8201

36 01 13 Press PAUSE button.

46 01 27 Press PAUSE button. (Note 6)

56 02

Check the data changes to

“01”.

Note 6: The adjustment data will be automatically input to page:

F, address: 46 to 55 and 58.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

26 8200

30 0100

4

5

Turn OFF the main power

supply.

Perform “Flange Back

Check”.

Specified voltage: The specified voltage varies according to the

minipattern box, so adjust the power supply

output voltage to the specified voltage written

on the sheet which is supplied with the

minipattern box.

Below 3 cm

Minipattern box

Camcorder

Camera

table

Output voltage : Specified voltage ±0.01 Vdc

Red (+)

Black (–)

Yellow (SENS +)

White (SENS –)

Black (GND)

Regulated power supply

Output current : more than 3.5 A

Need not connected

Fig. 6-1-7

6-13

CCD-TRV118/TRV218E/TRV318/TR V418/TRV418E

RadarW

RadarW

3. Flange Back Adjustment

(Using the flange back adjustment chart and

subject more than 500 m away)

The inner focus lens flange back adjustment is carried out automatically. In whichever case, the focus will be deviated during

auto focusing/manual focusing.

3-1. Flange Back Adjustment (1)

Mode CAMERA

Subject Flange back adjustment chart

(2.0 m from the front of lens)

(Luminance: 300 to 400 lux)

Measurement Point Check operation on monitor TV

Measuring Instrument

Adjustment Page F

Adjustment Address 46 to 55, 58

Note 1: Check that the data of page: 6, address: 02 is “00”.

If not, turn the power of unit OFF/ON.

Note 2: Perform the adjustment with the camcorder in horizon-

tal state.

Note 3: Perform “HALL Adjustment” before this adjustment.

Switch setting:

1) NIGHT SHOT.................................................................. OFF

Preparations before adjustments:

1) Place the Flange back adjustment chart 2.0 m from the front

of the lens.

2) Check that the center of Flange back adjustment chart meets

the center of shot image screen with the zoom lens at TELE

end and WIDE end respectively.

Adjusting method:

Order Page Address Data Procedure

10 0101

26 8201

36 01 13 Press PAUSE button.

46 01 15 Press PAUSE button. (Note 4)

56 02

Note 4: The adjustment data will be automatically input to page:

F, address: 46 to 55 and 58.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

26 8200

30 0100

4

5

RadarWRadarWRadarW

Check the data changes to

“01”.

Turn OFF the main power

supply.

Perform “Flange Back

Adjustment (2)”.

3-2. Flange Back Adjustment (2)

Perform this adjustment after performing “Flange Back Adjustment (1)”.

Mode CAMERA

Subject Subject more than 500 m away

Measurement Point Check operation on monitor TV

Measuring Instrument

Adjustment Page F

Adjustment Address 46 to 55, 58

Note 1: Check that the data of page: 6, address: 02 is “00”.

Switch setting:

1) NIGHT SHOT.................................................................. OFF

Preparations before adjustments:

1) Set the zoom lens to the TELE end and expose a subject that is

more than 500 m away.

(subjects with clear contrast such as building, etc.)

(Nearby subjects less than 500 m away should not be in the

screen)

Adjusting method:

Order Page Address Data Procedure

10 0101

26 8201

36 01 13 Press PAUSE button.

4

56 01 29 Press PAUSE button. (Note 2)

66 02

Note 2: The adjustment data will be automatically input to page:

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 01 00 Press PAUSE button.

26 8200

30 0100

4

5

RadarW

RadarW

RadarW

(Subject with clear contrast such as

buildings, etc.)

If not, turn the power of unit OFF/ON.

Place ND filter on the lens so

that the optimum image is

obtain.

Check the data changes to

“01”.

F, address: 46 to 55 and 58.

Turn OFF the main power

supply.

Perform “Flange Back

Check”.

6-14

CCD-TRV118/TRV218E/TRV318/TRV418/TRV418E

4. Flange Back Check

Mode CAMERA

Subject Siemens star

(2.0 m from the front of the lens)

(Luminance: approx. 200 lux)

Measurement Point Check operation on monitor TV

Measuring Instrument

Specified value Focused at the TELE end and WIDE

end

Switch setting:

1) NIGHT SHOT.................................................................. OFF

Note: When the auto focus is ON, the lens can be checked if

it is focused or not by observing the data on the page: 1

of the adjusting remote commander.

1 : 00 :

XX

Odd: Focused

Even: Unfocused

Checking method:

Order Page Address Data Procedure

1

2

36 4002

46 4101

5

6Turn on the auto focus.

70 030F

81

96 2110

10

11

Place the Siemens star 2.0 m

from the front of the lens.

To open the IRIS, decrease

the luminous intensity to the

Siemens star up to a point

before noise appear on the

image.

Shoot the Siemens star with

the zoom TELE end.

Check that the lens is

focused. (Note)

Shoot the Siemens star with

the zoom WIDE end.

Observe the TV monitor and

check that the lens is

focused.

Processing after Completing Adjustment:

Order Page Address Data Procedure

16 2100

26 4000

36 4100

40 0300

6-15

Loading...

Loading...