Sony TCTX-313 Service manual

TC-TX313/TX515

SERVICE MANUAL

• TC-TX313 is the optional stereo cassette

deck that can be used only with section

DHC-MD313.

• TC-TX515 is the optional stereo cassette

deck that can be used only with section

DHC-MD515.

SPECIFICATIONS

Recording system 4-track 2-channel stereo

Frequency response (DOLBY NR OFF)

50 - 14,000 Hz (± 3 dB),

using Sony TYPE I

cassettes

50 - 15,000 Hz (± 3 dB),

using Sony TYPE II

cassettes

Input TAPE IN (phono jacks):

impedance 47 kilohms

Output TAPE OUT (phono jacks):

voltage 550 mV

impedance 47 kilohms

Photo: TC-TX515

US Model

Tourist Model

TC-TX515

AEP Model

UK Model

E Model

TC-TX313/TX515

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type

General

Power requirements

US model: 120 V AC, 60 Hz

AEP, UK model: 220 - 230 V AC, 50 / 60 Hz

E, Tourist model: 110 - 120 V or 220 - 240 V

AC, 50 / 60 Hz

Adjustable with the

voltage selector

Power consumption 12 W

Dimensions Approx. 215 × 60 × 195

mm (w / h / d)

incl. projecting parts and

controls

Mass Approx. 2.5 kg

Supplied accessories: Audio connecting cords

(2)

Design and specifications are subject to change

without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

Dolby noise reduction manufactured under license from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby

Laboratories Licensing Corporation.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

STEREO CASSETTE DECK

MICROFILM

– 1 –

TABLE OF CONTENTS

1. GENERAL

Parts and Controls...................................................................... 3

2. TEST MODE

2-1. Checking the Items of Test Mode ......................................... 4

3. DISASSEMBLY

3-1. Top Cover.............................................................................. 5

3-2. Front Panel Assy ................................................................... 5

3-3. Front Board (TC-TX313) ...................................................... 6

3-4. Panel Board (TC-TX515)...................................................... 6

3-5. Back Plate ............................................................................. 7

3-6. Bracket (Power Trans) .......................................................... 7

3-7. Main Board ........................................................................... 8

3-8. TCM Assy ............................................................................. 8

3-9. Lever ..................................................................................... 9

3-10. T ension Spring....................................................................... 9

3-11. Housing ............................................................................... 10

3-12. Chassis ................................................................................ 10

3-13. Motor (A)/(B) Assy..............................................................11

3-14. Head Plate ............................................................................11

3-15. Pinch Roller Assy................................................................ 12

3-16. Bracket (Head Unit) ............................................................ 12

4. MECHANICAL ADJUSTMENTS................................. 13

5. ELECTRICAL ADJUSTMENTS................................... 13

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................... 16

6-2. Printed Wiring Board –Deck Section– ................................ 17

6-3. Schematic Diagram –Deck Section–................................... 18

6-4. Printed Wiring Boards –Main Section– .............................. 20

6-5. Schematic Diagram –Main Section–................................... 23

6-6. Printed Wiring Boards –Front Panel Section– .................... 27

6-7. Schematic Diagram –Front Panel Section–......................... 29

6-8. IC Pin Description............................................................... 31

7. EXPLODED VIEWS

7-1. Top Cover Section............................................................... 33

7-2. Front Panel Section (TC-TX313)........................................ 34

7-3. Front Panel Section (TC-TX515)........................................ 35

7-4. Chassis Section ................................................................... 36

7-5. TCM Assy Section .............................................................. 37

8. ELECTRICAL PARTS LIST........................................... 38

– 2 –

SECTION 1

GENERAL

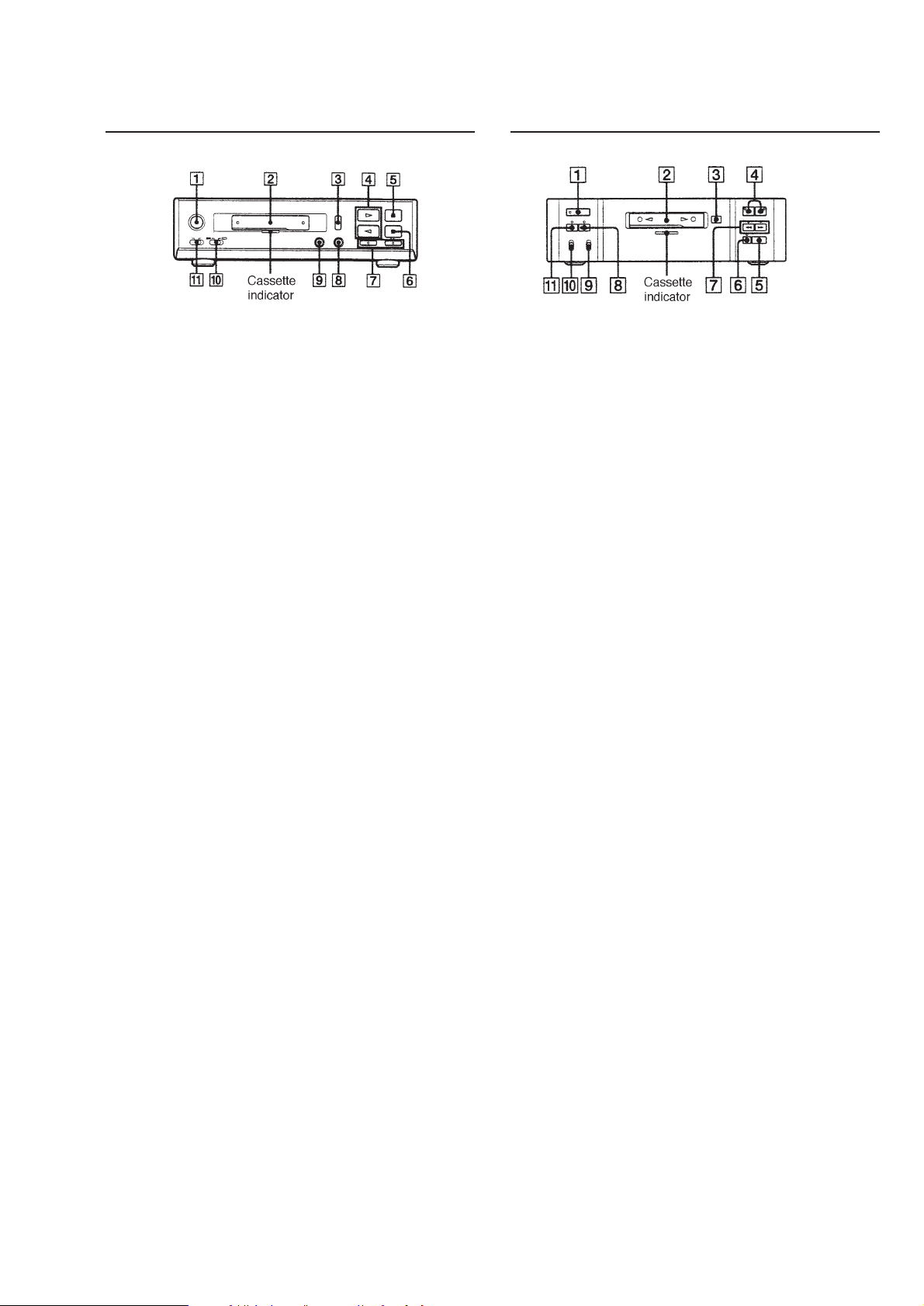

• TC-TX313

Parts and Controls

1 POWER switch

Only the power to this set is turn on.

2 Cassette slot

With a cassette inserted, the cassette

indicator is illuminated red when the

power is turned on.

3 § (eject) button

4 ª (lower side play)/

· (upper side play) button

Even without cassette, the power to

this set and the DHC-MD313 will be turned

on when one of these buttons is pressed.

5 ∏ (pause) button

6 π (stop) button

7 º/‚ (fast forward, fast backward/AMS)

button

8 ® REC (recording) button

9 CD SYNC (CD synchro) button

This button allows CD synchro recording

to be executed as this set is interlocked

with the DHC-MD313.

!º DIRECTION switch

!¡ DOLBY NR (Dolby Noise Reduction) switch

• TC-TX515

Parts and Controls

1 POWER switch

Only the power to this set is turn on.

2 Cassette slot

With a cassette inserted, the cassette

indicator is illuminated red when the

power is turned on.

3 6 (eject) button

4 9 (lower side play)/

( (upper side play) button

5 p (stop) button

6 P (pause) button

7 0/) (fast forward, fast backward/AMS)

button

8 r REC (recording) button

9 DIRECTION switch

!º DOLBY NR (Dolby Noise Reduction) switch

!¡ CD SYNC (CD synchro) button

This button allows CD synchro recording

to be executed as this set is interlocked

with the DHC-MD515.

– 3 –

SECTION 2

TEST MODE

2-1. CHECKING THE ITEMS OF TEST MODE

The set allows you to check the items of the test mode although this

may not be directly related with the adjustment.

3) All LED Flickering

When no tape is inserted, all LED indicators are flickering.

1 Setting/Releasing the Test Mode:

1) Setting

With power OFF, short between test pin 1 and pin 2 of

CN09 on the LOW-VOLTAGE board. (See page 15.)

Then, turn power ON to enter the test mode.

2) Releasing

Open between pin 1 and pin 2 of CN09.

2 Items of Test Mode

1) Memory Stop

1-1) In side A record mode, press the REW ( 0 ) button.

The tape is rewind to the start point of recording and stopped.

1-2) In side B record mode, press the FF ( ) ) button.

The tape is rewind to the start point of recording and stopped.

2) Memory Play

2-1) In side A record mode, press the FWD Auto Play

( ” + 0 ) buttons simultaneously. The tape is rewind to

the start point of recording and FWD played.

2-2) In side B record mode, press the REV Auto Play

( “ + ) ) buttons simultaneously. The tape is rewind to

the start point of recording and REV played.

4) Aging Operation

When tape with record erase preventing claw is inserted for

both sides A and B, enter the aging operation start command

by pressing p and CD SYNC simultaneously. The system

will change the direction to one side and perform the

following operations:

1 Rewind in REW mode until side A of tape is stopped.

2 Playback tape in FWD mode for 1 minute.

3 Pause mode.

4 Record tape for 3 minutes.

5 Forward tape in FF mode to the end of side A of tape.

6 Shut off and switch to side B.

7 Playback tape in REV mode for 1 minute.

8 Pause mode.

9 Record tape for 3 minutes.

!º Forward tape in FF mode to the end of side B of tape.

!¡ Shut off and switch to side A.

!™ Repeat the procedure from 2 to !¡.

!£ Pressing the STOP ( p ) button will release the set from

these operations.

– 4 –

SECTION 3

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

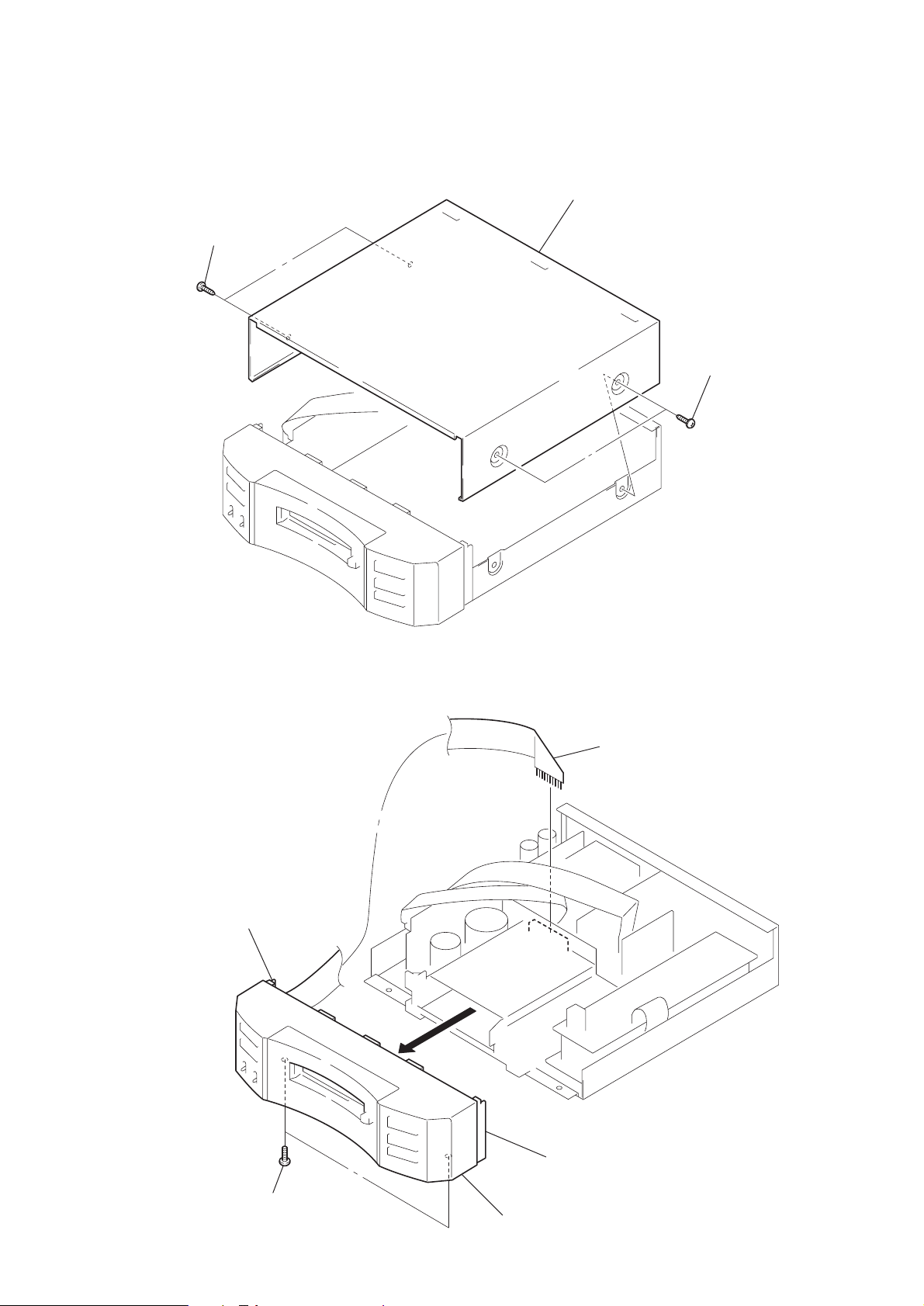

3-1. T OP COVER

1

screws (case 3 TP2)

3

top cover

2

screws (case 3 TP2)

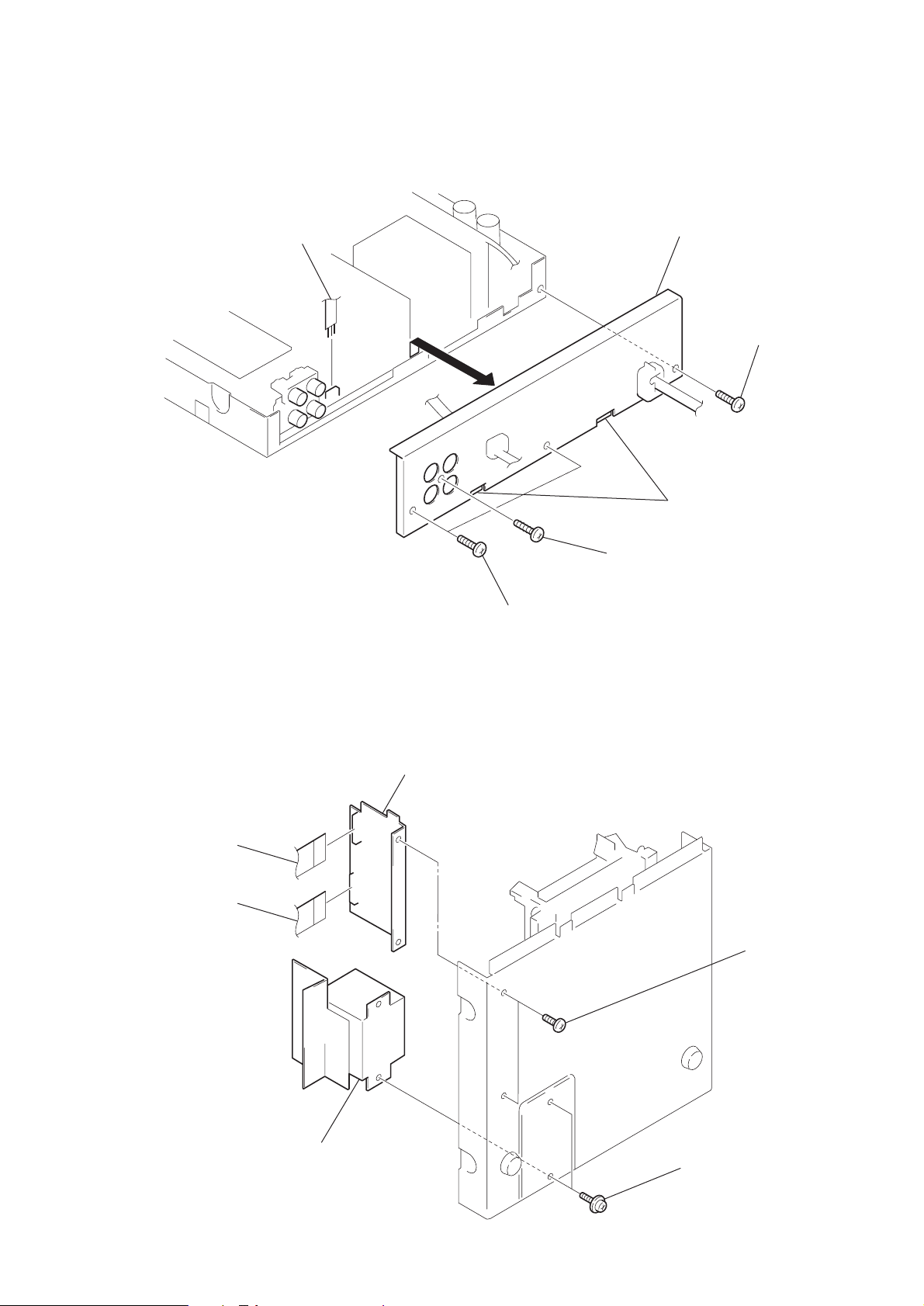

3-2. FRONT PANEL ASSY

3

claw

1

CN6

2

BVTT 3x8

5

front panel assy

– 5 –

4

claw

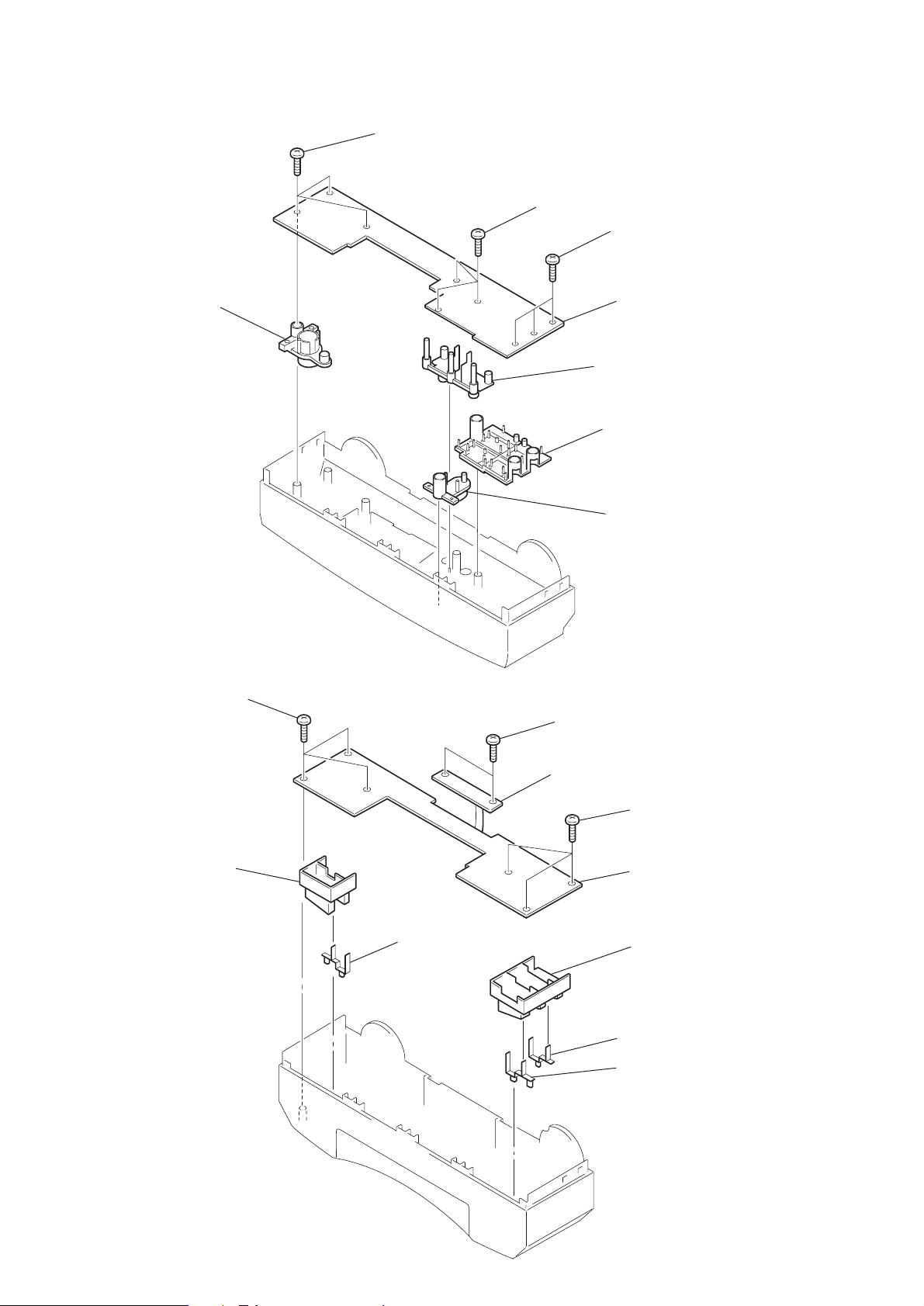

3-3. FRONT BOARD (TC-TX313)

d

d

8

POWER button

1

BVTP 2.6x8

2

BVTP 2.6x8

3

BVTP 2.6x8

4

FRONT boar

6

REC button

5

PLAY button

7

EJECT button

3-4. PANEL BOARD (TC-TX515)

4

BVTP 2.6x8

6

POWER button

7

lens (C)

1

2

BVTP 2.6x8

LED board

9

!º

3

BVTP 2.6x8

5

PANEL boar

8

PLAY button

lens (D)

lens (C)

– 6 –

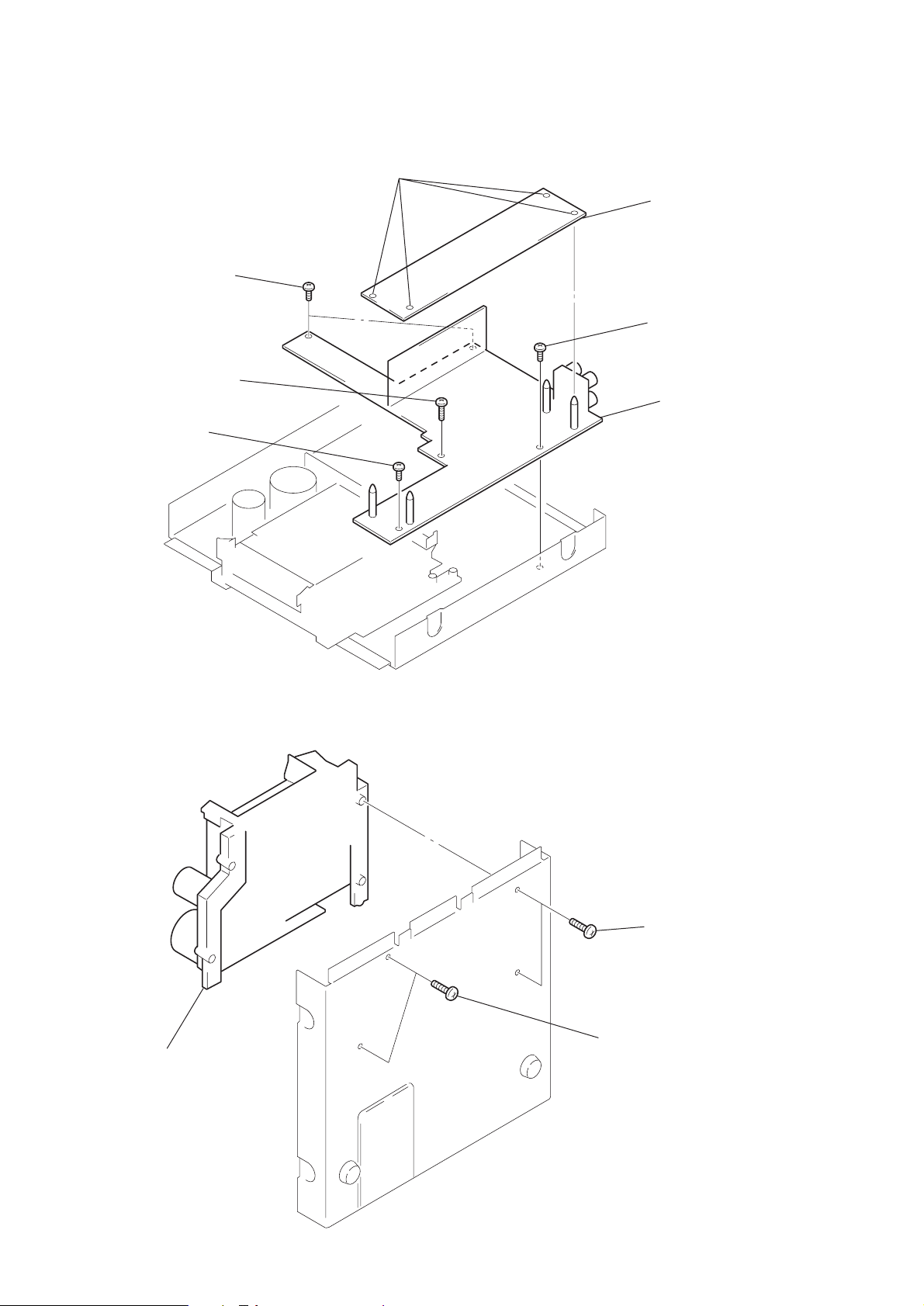

3-5. BACK PLATE

8

1

CN04

2

BVTP 3x10

6

back plate

5

claws

4

BVTP 3x

3-6. BRACKET (POWER TRANS)

2

CN14

1

CN7

4

DECK board

3

BVTP 3x8

3

BVTP 3x8

6

bracket (power trans)

– 7 –

5

bind type (A)

3-7. MAIN BOARD

d

0

5

3

4

BVTP 3x8

BVTP 3x8

BVTP 3x10

1

PC board holders

2

REC board

6

BVTP 3x8

7

MAIN boar

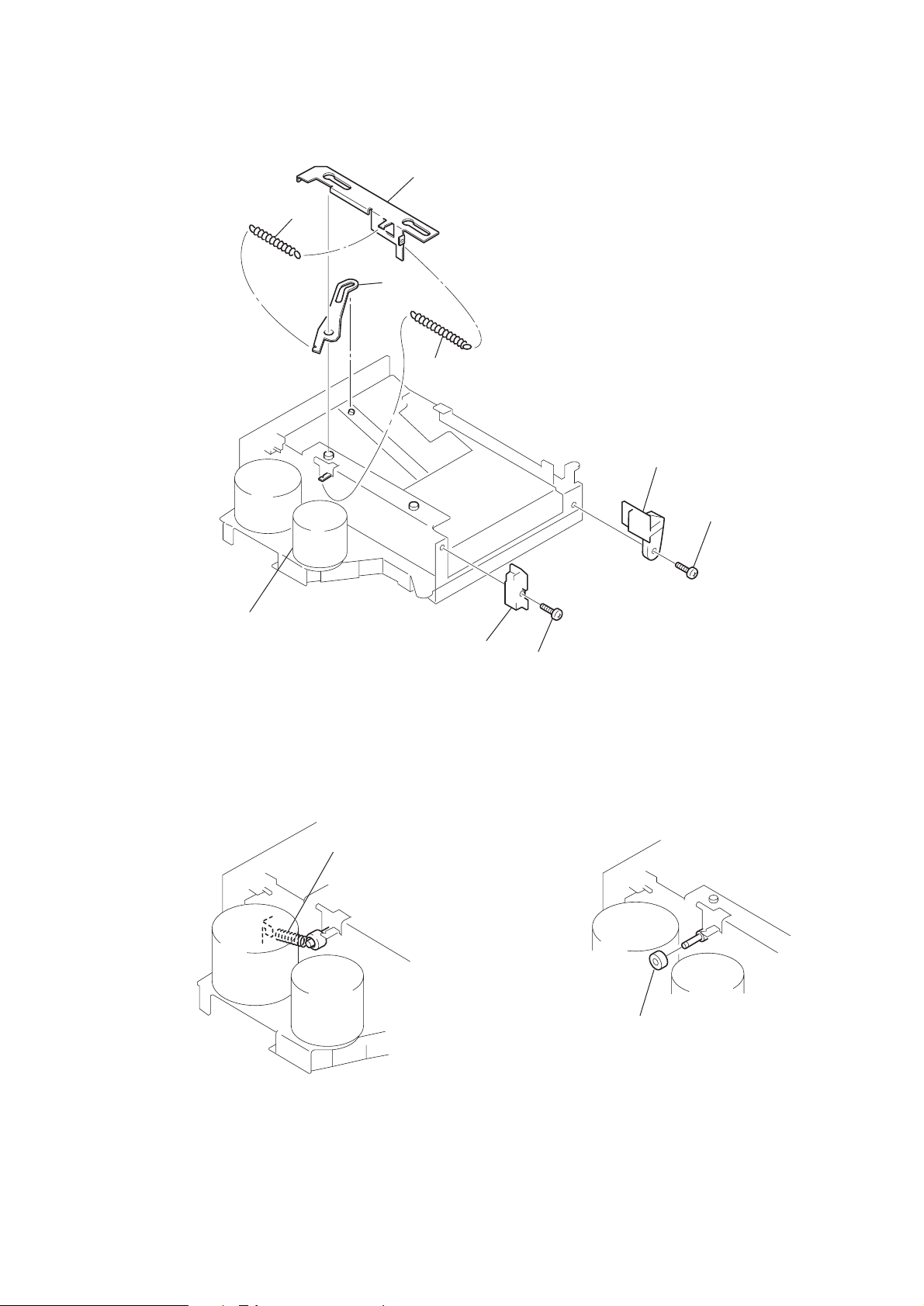

3-8. TCM ASSY

3

TCM assy

2

BVTP 3x1

1

BVTP 3x10

– 8 –

3-9. LEVER

8

7

9

8

5

4

tape guide (R)

3

BVTP 3x

6

Turn the loading motor

and down the cassette

holder.

3-10. TENSION SPRING

1

2

tape guide (L)

1

BVTP 3x8

2

– 9 –

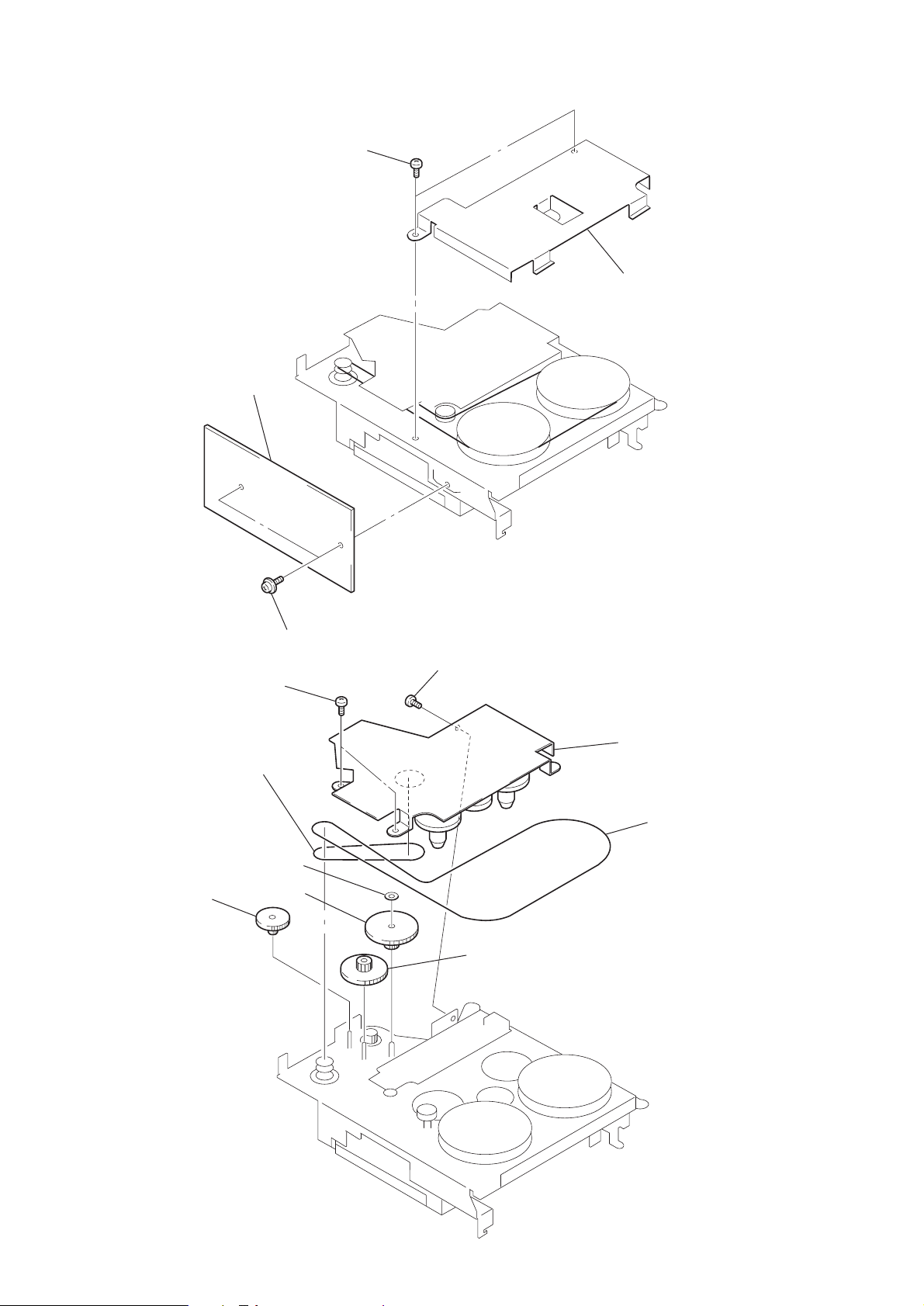

3-11. HOUSING

3

4

2

3-12. CHASSIS

8

5

belt (A)

2

1

6

7

1

9

3

4

belt (B)

– 10 –

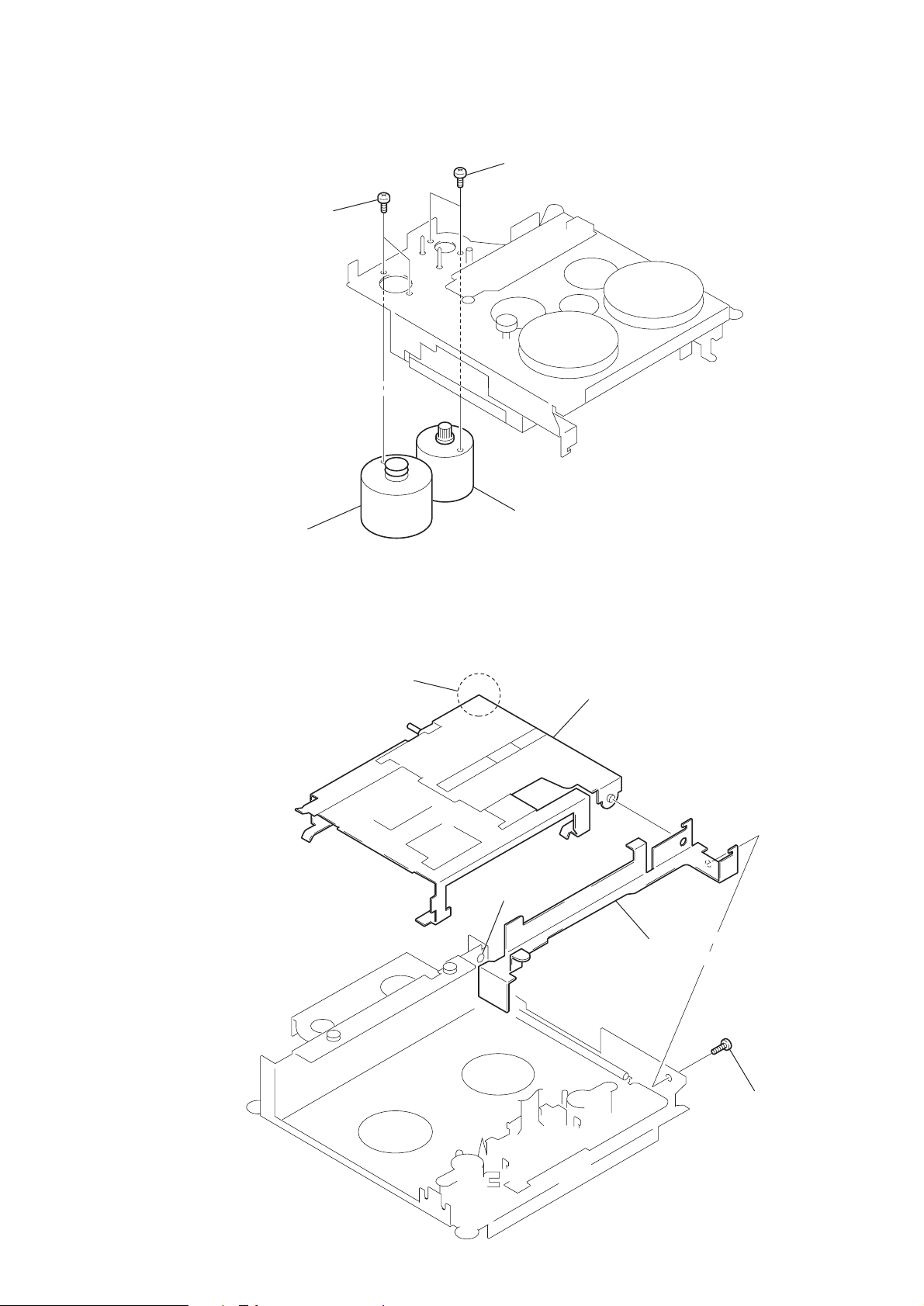

3-13. MOTOR (A)/(B) ASSY

2

motor (A) assy

1

3

4

motor (B) assy

3-14. HEAD PLATE

Note : On install, set the portions A and B.

B

3

A

2

– 11 –

1

Loading...

Loading...