Page 1

TC-SD1

SERVICE MANUAL

Manufactured under license from Dolby Laboratories

Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks

of Dolby Laboratories Licensing Corporation.

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism TC-PX100

Tape Transport Mechanism Type TCM-ACLM572

SPECIFICATIONS

MICROFILM

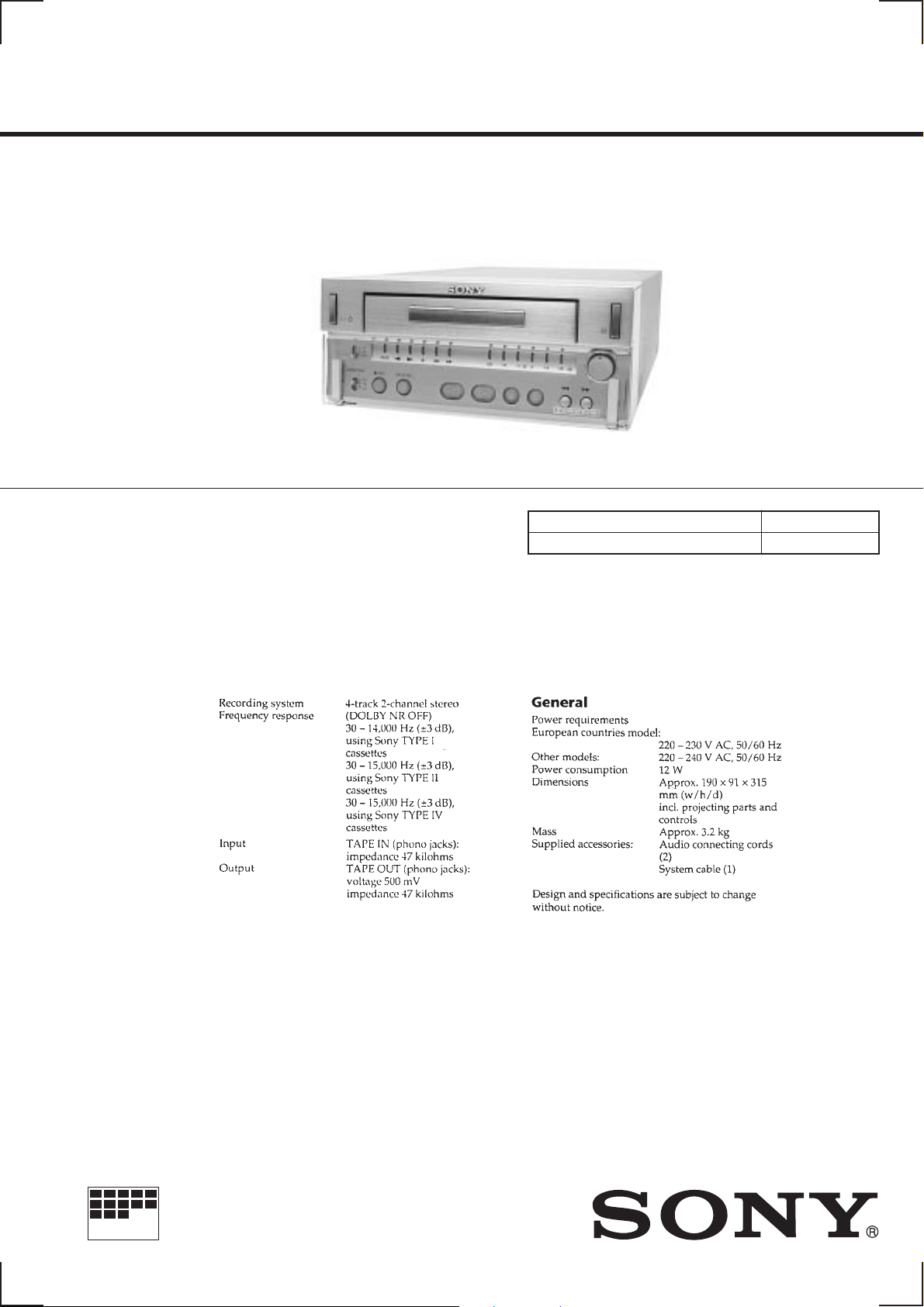

STEREO CASSETTE DECK

Page 2

TABLE OF CONTENTS

1. GENERAL ·········································································· 3

2. DISASSEMBLY

2-1. Case, Front Panel································································ 4

2-2. Mechanism Deck (TCM-ACLM572)································· 5

2-3. Control Board, Dolby Board ·············································· 5

2-4. Power Trans Board, AC Select SW Board, Power Board··· 6

2-5. Tray Assembly···································································· 6

2-6. Mechanism Chassis Block·················································· 7

2-7. Capstan Reel Motor (M902)··············································· 7

3. DIAGRAMS

3-1. Circuit Boards Location ····················································· 8

3-2. Schematic diagram — Display Section —·························9

3-3. Printed Wiring Board — Display Section — ··················· 11

3-4. Printed Wiring Board — Main Section — ······················· 16

3-5. Schematic Diagram — Main Section — ·························· 21

3-6. IC Block Diagrams ··························································· 25

3-7. IC Pin Function Description·············································27

4. MECHANICAL ADJUSTMENT ································ 29

5. ELECTRICAL ADJUSTMENT ·································· 29

6. EXPLODED VIEWS

6-1. Case, Front Panel Section················································· 33

6-2. Chassis Section·································································34

6-3. Mechanism Deck Section-1 (TCM-ACLM572) ·············· 35

6-4. Mechanism Deck Section-2 (TCM-ACLM572) ·············· 36

6-5. Mechanism Deck Section-3 (TCM-ACLM572) ·············· 37

7. ELECTRICAL PARTS LIST······································· 38

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

— 2 —

Page 3

SECTION 1

GENERAL

This section is extracted

from instruction manual.

— 3 —

Page 4

SECTION 2

e

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

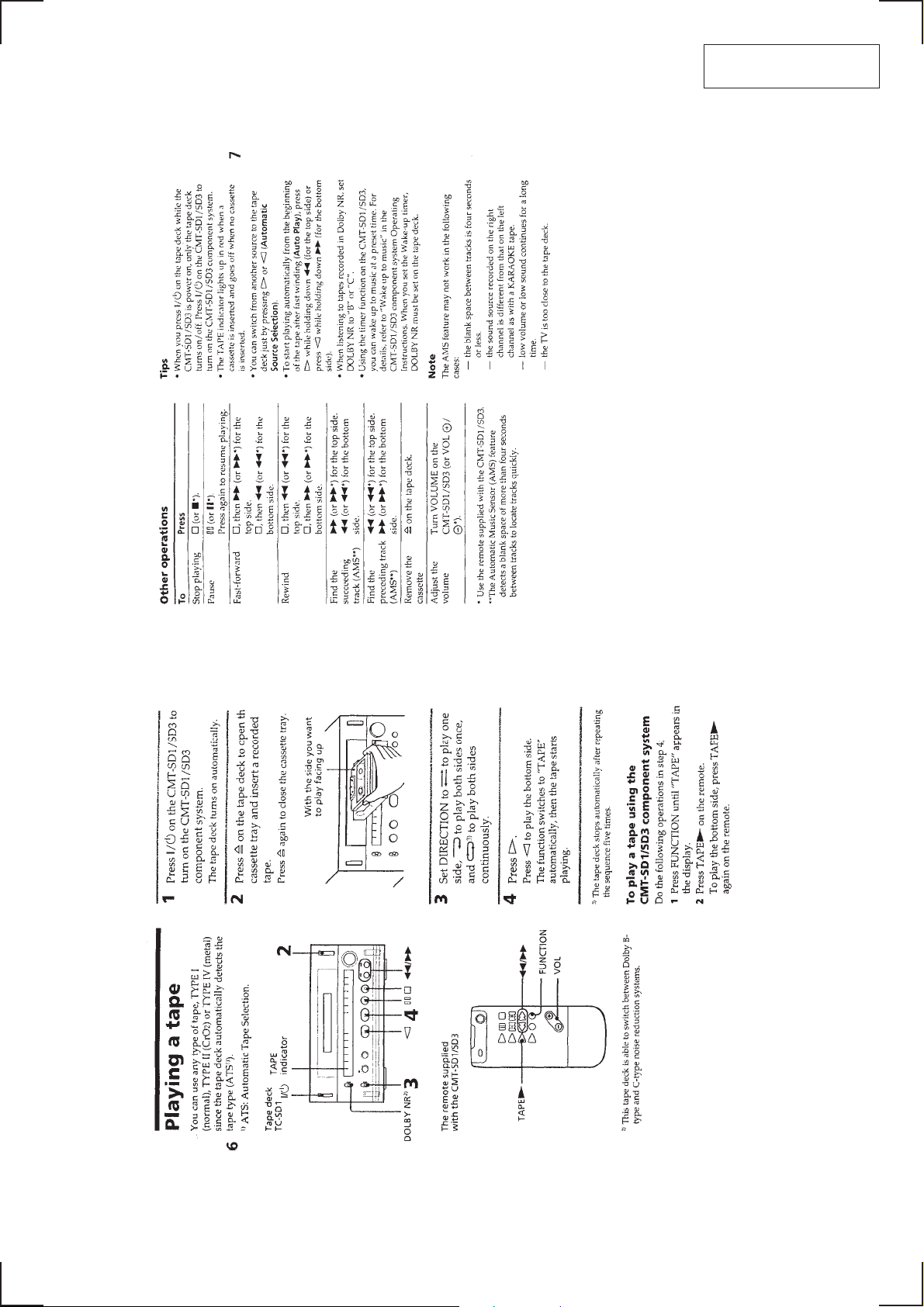

2-1. CASE, FRONT PANEL

4

Case

2

Two screws,

case stopper

3

Screw (+B 2.6 × 8)

1

Two screws,

case stopper

8

Front panel

7

Two screws

(+B 2.6

6

Loading panel

Connector

M901

×

8)

Rear sid

Pin-1

Pin-6

CN05

Connector

— 4 —

5

Slide the tray.

(Remove the connector from M901, supply the 6 V

power from an external regulated power supply to

pin-5 and pin-6 of CN05.)

Regulated DC

power supply

+

–

Pin-5

Pin-6

CN05

‘

’

1

6

Page 5

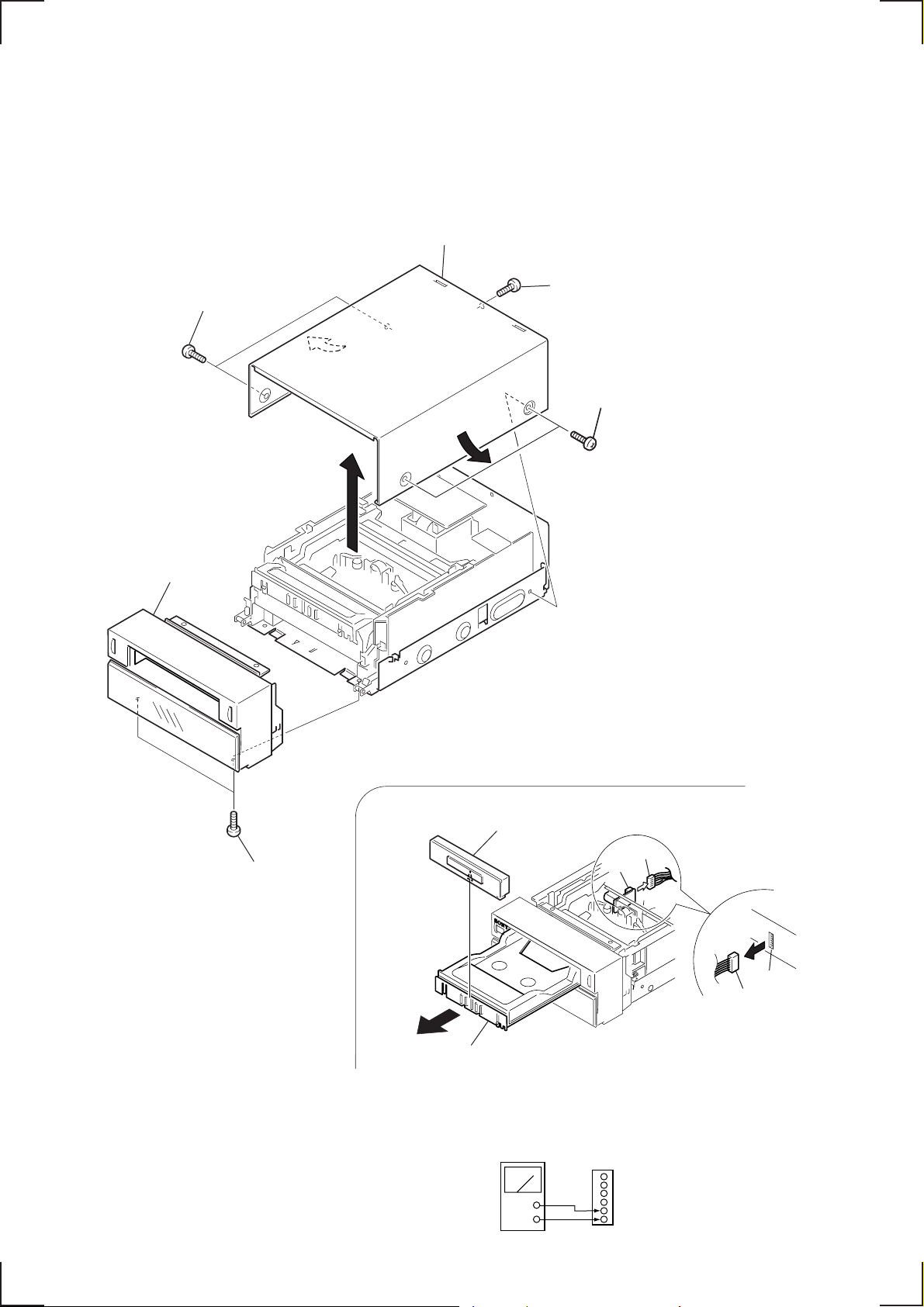

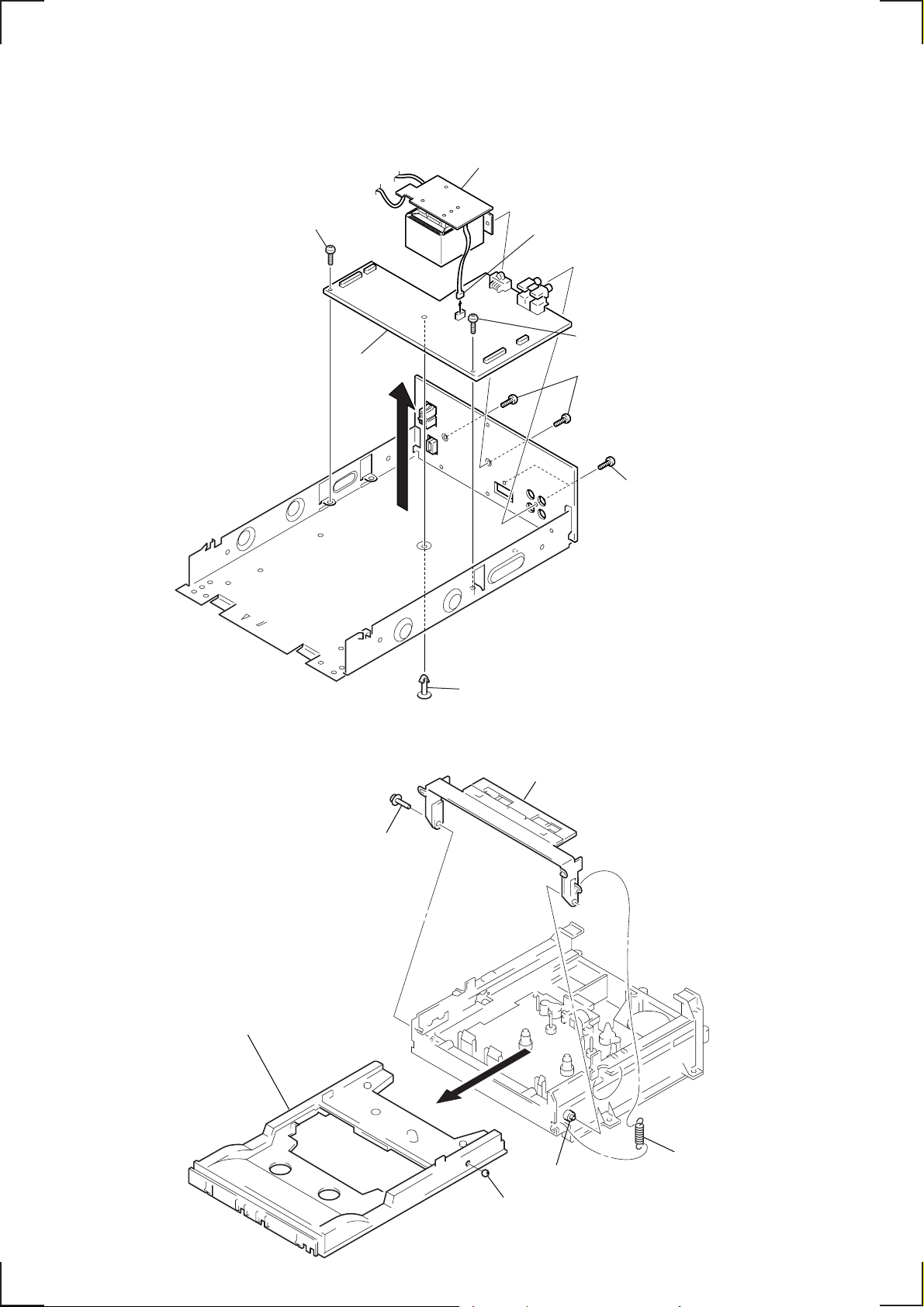

2-2. MECHANISM DECK (TCM-ACLM572)

r

4

Connector

5

Mechanism deck (TCM-ACLM572)

2

Connecto

3

Connector

2-3. CONTROL BOARD, DOLBY BOARD

3

Two screws

2

Two screws

(+B 2.6

1

Two connectors

×

8)

(+B 2.6

×

8)

1

Four screws

(+B 3

4

CONTROL board

×

10)

Clamper

Harness

Harness

Precaution for assembling :

Fix the harness with the clamper.

7

DOLBY board

— 5 —

5

Connector

6

Four screws

(+B 2.6

×

8)

Page 6

2-4. POWER TRANS BOARD, AC SELECT SW BOARD, POWER BOARD

)

3

POWER TRANS board

5

Screw (+B2.6 × 8)

8

POWER

board

1

Connector

6

Screw (+B2.6 × 8)

2

Two screws

(+PWH3

×

6)

4

Two screws

(+B3

×

10)

2-5. TRAY ASSEMBLY

5

Tray assembly

Note : Be careful not to drop

the stainless ball (5 DIA)

when removing the tray assembly.

1

Screw (1.7 × 8.2)

7

Suport

4

Arm (576)

— 6 —

3

Boss

Stainless ball (5 DIA)

2

Spring (B

Page 7

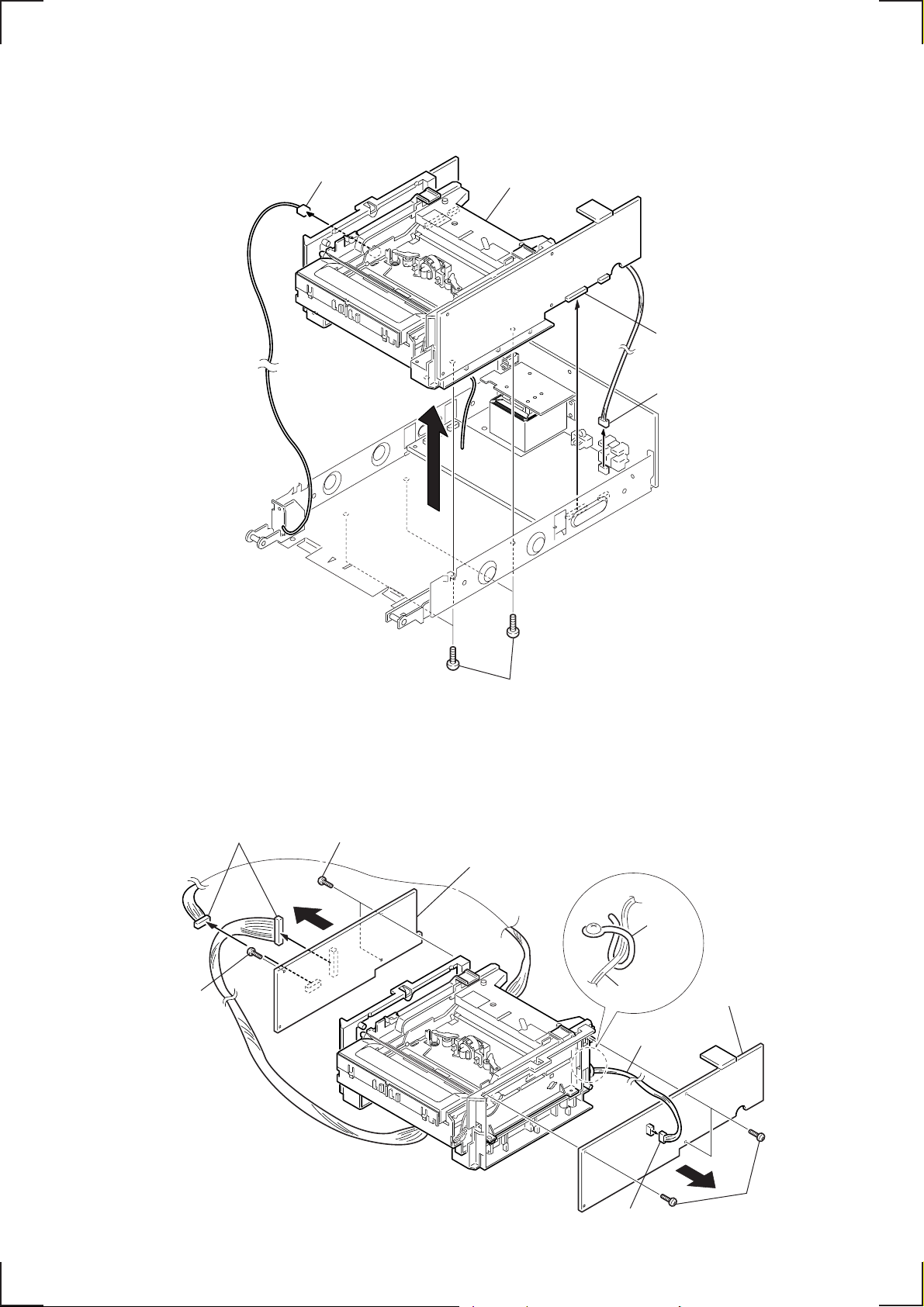

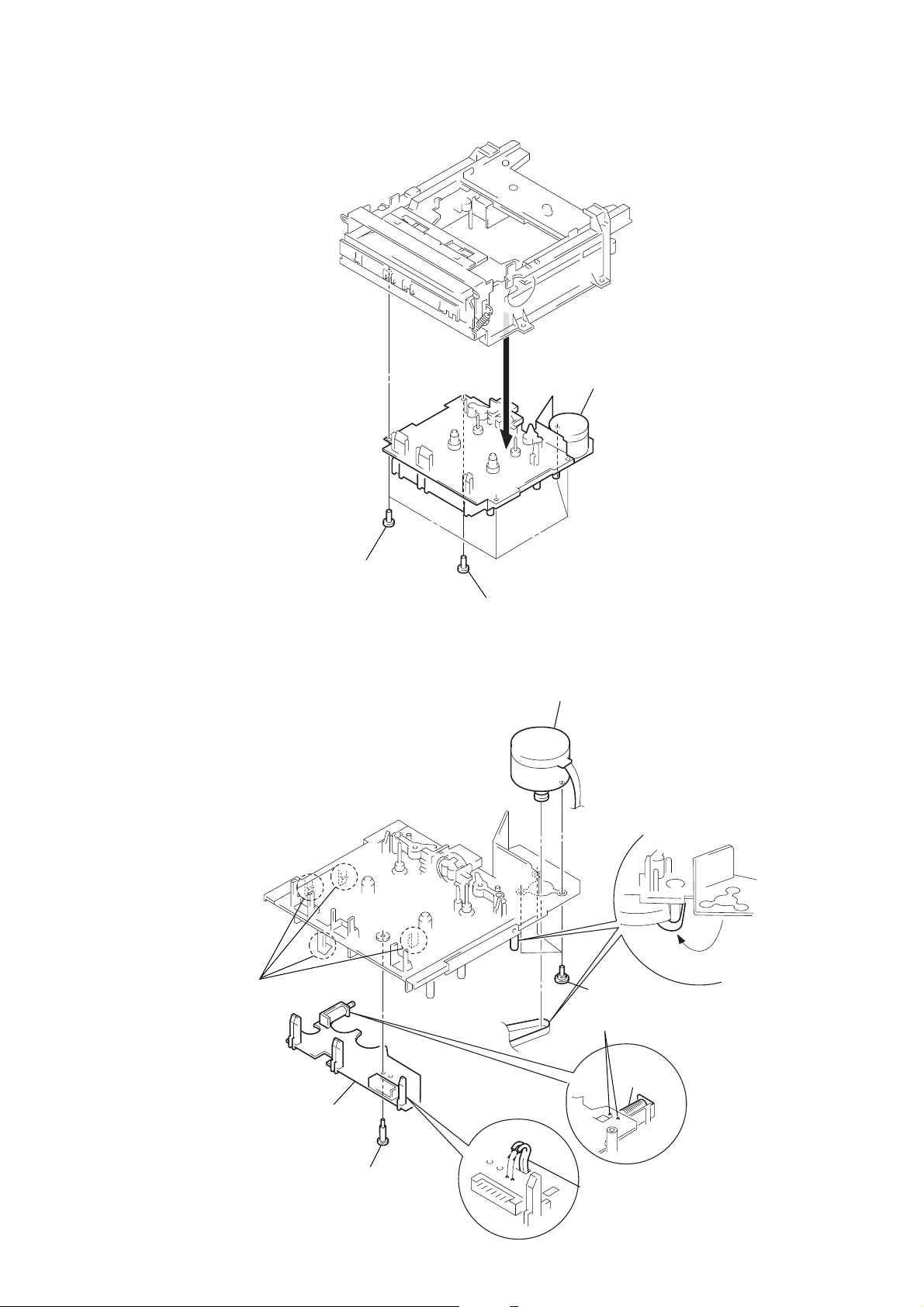

2-6. MECHANISM CHASSIS BLOCK

s

3

Mechanism chassi

1

Four screws (+P 3 × 6)

2-7. CAPSTAN REEL MOTOR (M902)

3

Claws (4 claws)

2

Screw (+P 3 × 8)

8

Capstan reel motor (M902)

7

Hook the belt.

6

Three screws for motor

1

Remove soldering of

the plunger solenoid

Plunger

solenoid

4

CONTROL board

2

Screw (stepped)

5

Remove soldering of

the motor lead wire.

— 7 — — 8

Page 8

SECTION 3

d

DIAGRAMS

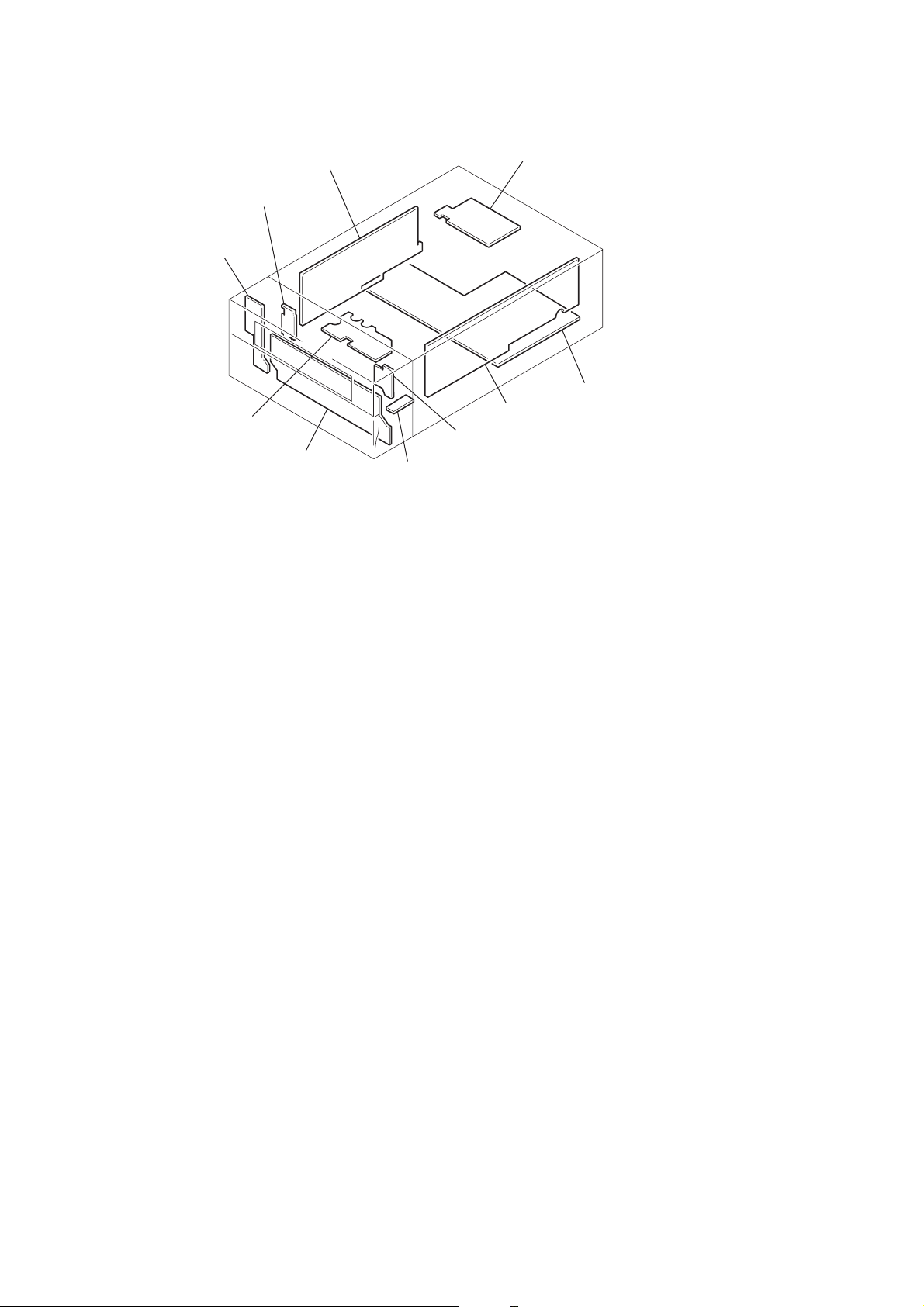

3-1. CIRCUIT BOARDS LOCA TION

REAR PANEL board

CONNECTION board

MODE CONTROL board

CONTROL board

FRONT board

POWER TRANS board

POWER boar

DOLBY board

O/C SW board

VR board

— 8 —

Page 9

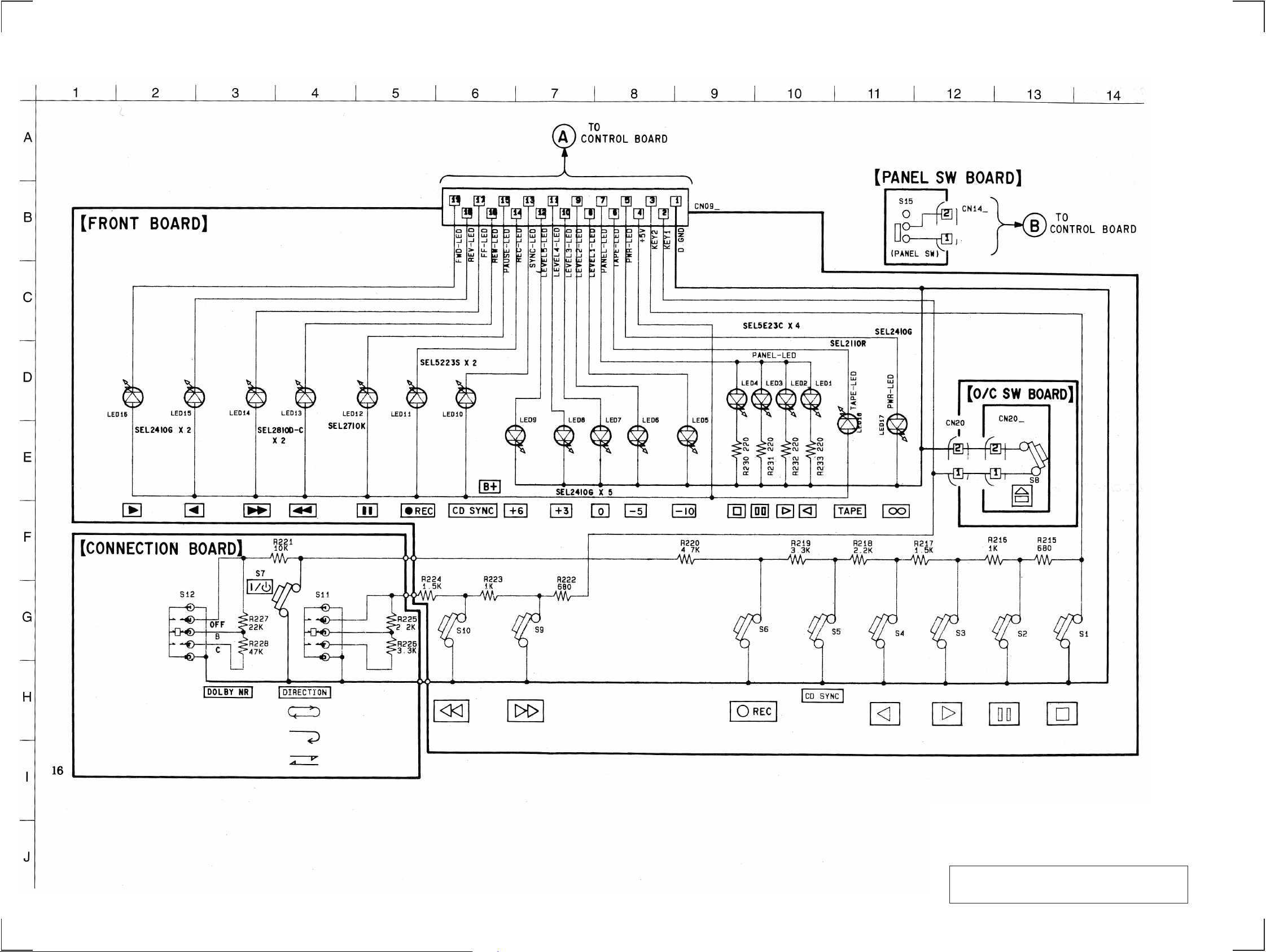

TC-SD1

3-2. SCHEMATIC DIAGRAM — DISPLAY SECTION —

— 9 — — 10 —

Note on Schematic Diagram:

• All resistors are in Ω and 1/

specified.

• C : panel designation.

Note: The components identified by mark ! or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

• U : B+ Line.

4

W or less unless otherwise

Page 10

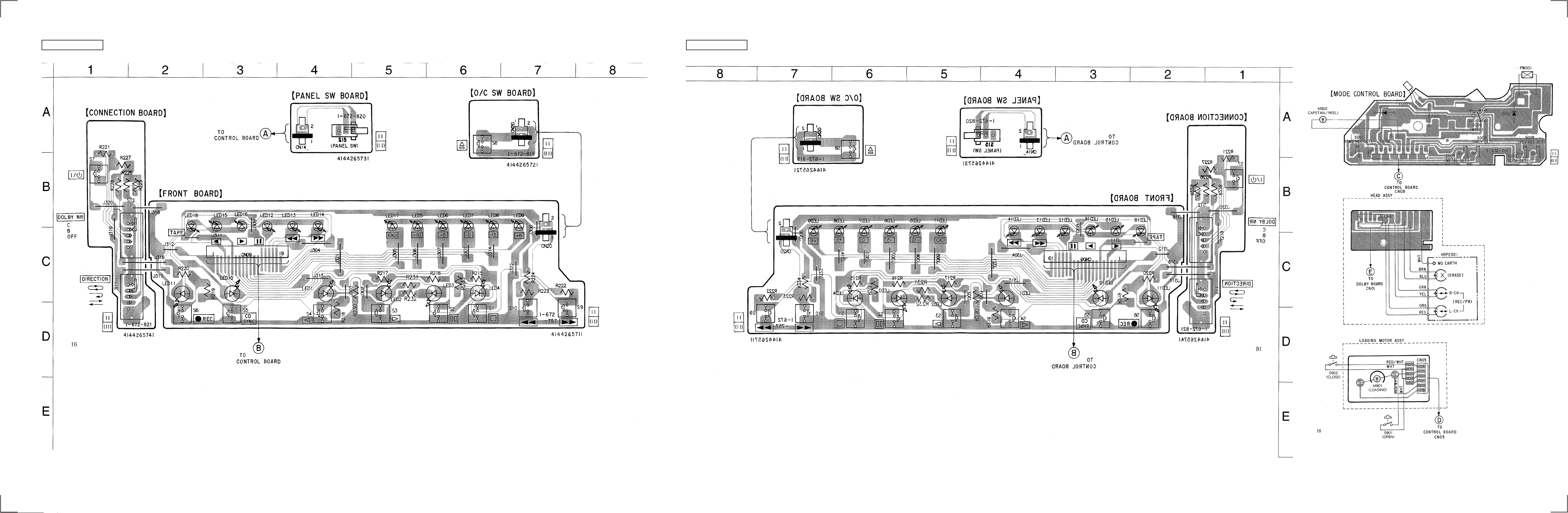

3-3. PRINTED WIRING BOARD — DISPLAY SECTION —

TC-SD1

COMPONENT SIDE CONDUCTOR SIDE

• Refer to page 8 for Circuit Boards Location.

• Refer to page 24 for MODE CONTROL board Schematic Diagram.

Note on Printed Wiring Board:

• Y : parts extracted from the conductor side.

• b : Pattern of the rear side.

— 15 —— 14 —— 13 —— 12 —— 11 —

Page 11

TC-SD1

3-4. PRINTED WIRING BOARD — MAIN SECTION —

COMPONENT SIDE CONDUCTOR SIDE

• Refer to page 8 for Circuit Boards Location.

Note on Printed Wiring Board:

• Y : parts extracted from the conductor side.

• b : Pattern of the rear side.

— 16 — — 17 — — 18 — — 19 — — 20 —

Page 12

TC-SD1

3-5. SCHEMATIC DIAGRAM — MAIN SECTION —

• Refer to page 25 for IC Block Diagrams. • Refer to page 27 for IC Pin Function Description. • Refer to page 15 for MODE CONTROL board Printed Wiring Board.

• Semiconductor Location

Ref. No. Location

D01 F-5

D02 B-1

D03 B-7

D04 B-7

D05 E-9

D06 E-10

D07 D-12

D12 F-14

D13 C-1

D14 A-1

D15 C-3

D16 B-3

D17 E-12

D19 B-3

D20 C-3

D22 E-14

D23 E-14

D24 E-12

D25 E-12

D28 D-2

D36 F-14

D37 F-15

IC01 F-5

IC02 F-9

IC03 F-1

IC04 G-13

IC05 C-6

IC06 C-1

IC07 D-5

IC08 C-2

IC10 G-14

IC11 E-15

Q01 F-7

Q02 G-7

Q03 E-9

Q04 E-8

Q05 G-10

Q05A H-15

Q06 G-9

Ref. No. Location

Q06A G-14

Q07 G-5

Q08 G-4

Q09 F-3

Q10 G-4

Q11 G-4

Q12 G-3

Q12A G-3

Q13 F-3

Q13A G-3

Q14 E-1

Q15 F-1

Q16 G-2

Q17 G-2

Q18 G-2

Q19 B-2

Q20 D-11

Q21 B-3

Q22 C-2

Q23 C-2

Q24 C-2

Q25 D-2

Q26 C-3

Q27 D-3

Q29 C-7

Q30 C-7

Q31 C-7

Q32 C-7

Q33 C-7

Q34 D-7

Q35 C-6

Q36 C-6

Q37 B-12

Q38 C-7

Q39 G-12

Q40 G-12

Q41 H-13

Q42 B-12

Q43 C-13

Q44 E-14

Q45 G-10

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• C : panel designation.

Note: The components identified by mark ! or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : REC/PB

( ) : REC

< > : PB

[ ] : STOP

• Voltages are tak en with a V OM (Input impedance 10 M Ω).

Voltage v ariations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage v ariations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

E : PB

a : REC

4

W or less unless otherwise

— 21 — — 22 — — 23 — — 24 —

Page 13

3-6. IC BLOCK DIAGRAMS

GHCAL

GPCAL

GL

GH

GP

RECCALNCREC IN

REF

BOOST

VCC

REC OUT

VEE

REC OUT

2021222324 19 18 17 16 15 14 13

12

11

F/Q

FQ

FM

FPCAL

DGND

MUTE

NC

REC IN

GND

BOOST

1 2 3 4 5 6 7 8 9 10

PARA

METER

CTRL

IC02 CXA1561S

VCT

22 21 20 19

PBIN1

LINEIN1

MPXIN1

MPXOUT1

18 17 16

LINEOUT1

SSK

TCH1

CC

TCL1

15

RECOUT1

14 13 12

REC AMP

MODE

V

V

CC

IREF

1 2 3 4

IREF

PBIN2

LINEIN2

IC01 µPC4570HA

1

2

VCC

OUT1

5

3

4

6

8

7

VEE

–IN1

+IN1

–IN2

OUT2

+IN2

MOA

MOA

MPXIN2

HLS HDET LDET LLS

HLS

SSK

5 6 7

MPXOUT2

HDET LDET LLS

TCH2

LINEOUT2

8

REC AMP

9 10 11

TCL2

RECOUT2

Mode

Control

NRSW

EE

V

EE

V

IC03 CXA1598S

9

VCC

— 25 —

Page 14

IC04 LA5617

ON/OFF

ERROR

AMP

2 3

1

VO1

VCC

IC06 LB1641

VREF

CN1

4

EN

CURRENT

LIMITER

VMUTE VCC

VCC

CURRENT

LIMITER

~_

~_

5 6 7 8 9

GND

EN DISPLAY

ON/OFF

140uA

COMPARATER

VREF

1.8V

NC

CN2

ERROR

AMP

START

CIRCUIT

VREF

OVER HEAT

PROTECT

VEE

10

VO2

T.S.D O.C.P

NOISE

MOTOR

DRIVE

FILTER

MOTOR

DRIVE

FWD/REV/STOP

CONTROL LOGIC

2 3

1

GND

DRIVE

MOTOR

NOISE

FILTER

5 6 7 8 9 10

4

VCC 1

FWD.IN

REV.IN

CLAMP

VCC 2

DRIVE

MOTOR

— 26 —

Page 15

3-7. IC PIN FUNCTION DESCRIPTION

• CONTROL BOARD IC05 TMP87CH48DF (SYSTEM CONTROL)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Pin Name

VSS

OSC-OUT

OSC-IN

RESET

NC

NC

TEST

POWER-IN

POWER-OUT

TYPE4

TYPE2

TYPE1

CHROM-SW

METAL-SW

REC.FWD-SW

REC.REW-SW

MODE-SW

I2C-CLOCK

I2C-DATA

OPEN-SW

CLOSE-SW

TEST

SOLENOIDE

CAPSTAN

OPEN-M

CLOSE-M

PANEL-SW

OP-VERSION

NC

AD-GND

AD-REF

VCC

KEY1

KEY2

HALF-SW

AMS-IN

PULSE

METER-L/R

I2C-BUSY

SYS

REC/PB

RELAY

BIAS

LINE MUTE

REC MUTE

I/O

—

System ground terminal

O

System clock output (8 MHz)

I

System clock input (8 MHz)

I

Reset input

—

No used

—

No used

I

Test terminal

I

Primary power supply ON/OFF input

O

Mechanism. AU power supply ON/OFF output

O

Type 4 recording bias selector output

O

Type 2 recording bias selector output

O

Type 1 recording bias selector output

I

Tape type 2 input

I

Tape type 4 input

I

Record safety tab input of side A

I

Record safety tab input of side A

I

Head sensor input

I/O

12C clock input/output

I/O

12C data input/output

I

Loader open switch input

I

Loader close switch input

I

TEST input

O

Solenoid output

O

Capstan motor output

O

Loader open (motor) output

O

Loader close (motor) output

I

Panel switch input

I

Option TC version input

—

No used

—

AD ground terminal

—

AD reference voltage

—

System power input

I

Key 1 input

I

Key 2 input

I

Half switch input

I

AMS input

I

Pulse input

I

Meter L-CH input

I/O

I2C BUSY input/output

—

No used

O

REC/PB selector output

O

RELAY selector output

O

Bias selector output

O

LINE mute selector output

O

Record mute selector output

Description

— 27 —

Page 16

Pin No.

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Pin Name

PB MUTE

DOLBY ON/OFF

DOLBY B/C

STB-R-LED

STB-G-LED

P ANEL-LED

LEBEL1-LED

LEVEL2-LED

LEVEL3-LED

LEVEL4-LED

LEVEL5-LED

T APE-LED

CDSYNC-LED

REC-LED

P AUSE-LED

REW-LED

FF-LED

REV -LED

FWD-LED

I/O

O

Playback mute selector output

O

Dolby ON/OFF output

O

Dolby B/C output

O

No used

O

Power ON LED (green) output

O

Panel LED (blue) output

O

Level meter 1 (minimum dB) LED (green) output

O

Level meter 2 LED (green) output

O

Level meter 3 LED (green) output

O

Level meter 4 LED (red) output

O

Level meter 5 (maximum dB) LED (red) output

O

Tape indicator LED (amber) output

O

CD synchro LED (red) output

O

REC LED (red) output

O

PAUSE LED (orange) output

O

REW LED (amber) output

O

FF LED (amber) output

O

REV LED (green) output

O

FWD LED (green) output

Description

— 28 —

Page 17

SECTION 4

MECHANICAL ADJUSTMENT

SECTION 5

ELECTRICAL ADJUSTMENT

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

• Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

• Tape Tension

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

31 to 61 g • cm

2 to 6 g • cm

36 to 61 g • cm

2 to 6 g • cm

61 to 143 g • cm

100 g or more

100 g or more

Precaution

1. Perform adjusting on the test mode.

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjust.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

6. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

7. The adjustments should be performed for both L-CH and RCH.

8. Switches should be set as follows.

DOLBY NR..................................................................... OFF

DIRECTION ....................................................................A

• Standard Recording Position

Adjust the REC LEVEL (VR02) control so that the standard input/

output signal level is obtained in the following connection.

— Record Mode —

audio oscillator

level meter

10k

600

Ω

Ω

LINE IN

attenuator

Standard Input Level

Input terminal LINE IN

source impedance 10kΩ

input signal level 0.5V (–3.8dB)

Standard Output Level

Output terminal LINE OUT

load impedance 47kW

output signal level 0.5V (–3.8dB)

0dB = 0.775 V

Test Mode

Turn OFF the main power and insert the shorting plug to the test

point CN13 (2P) on the CONTROL board (setting IC05 pin 22 to

“L”). Then turn ON the main power which activ ate the TEST mode.

All displays flash once.

If a recording is performed in the TEST mode, the REC MEMOR Y

mode becomes active at the moment of recording so that the tape is

rewound by the amount of recording when a tape is rewound after

recording.

After adjustment, be sure to remove the shorting plug from the test

point CN13 (2P).

set

47k

Ω

LINE OUT

Test Tape

— 29 —

Type Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB PB Level Adjustment

Page 18

B

t

r

Record/Playback Head Azimuth Adjustment

)

r

Note: • Perform this adjustment after the head is turned around.

(If the head is positioned in the FWD direction, turn around

the head and start adjustment from the REV mode as

described below.)

* When the azimuth adjustment is performed, the azimuth

adjustment screw must end up with rotation of tightening

direction (i.e. clockwise direction).

Adjustment procedure :

1. Mode: REV playback

test tape

P-4-A100

(10kHz, –10dB)

47k

set

LINE OUT

level mete

Ω

4. Enter the FWD mode and perform steps 1 to 3.

5. Check that the phase difference between L-CH and R-CH is in

the range of in-phase to 90°.

6. After adjustment, lock the screw with locking compound.

Oscilloscope Lissajous waveform

in phase 45

°

90

°

135

°

Good Wrong

180

°

Adjustment Location:

2. Turn the azimuth adjustment screw for the maximum output

level of L-CH and R-CH.

If the peak levels do not match for L-CH and R-CH, turn the

adjustment screw until both of output levels match together

within 1 dB of peak.

L-CH peak

screw position

output

level

R-CH peak

within

1dB

L-CH peak

R-CH peak

within 1d

angle of

adjustmen

screw

3. Phase Check

Mode: REV playback

Adjustment screw (FWD side) Adjustment screw (REV side

Tape Speed Adjustment

Procedure :

Mode : FWD playback

test tape

WS-48B (3kHz, 0dB)

47k

set

L- or R-CH of LINE OUT

frequency counte

Ω

1. Enter the FWD playback mode, and play back test tape.

2. Adjust the adjustment control (variable resistor) of the motor

(M902) until the frequency counter reading becomes 3,000 Hz

± 90 Hz.

3. Confirm that the tape speed deviation between tape top and tape

end is within 3%.

Adjustment location :

test tape

P-4-A100

(10kHz, –10dB)

R-CH

set

L-CH

47k

Ω

47k

Ω

LINE OUT

oscilloscope

V H

— 30 —

M902

adjustment control

(variable resistor)

Sample Value of Wow and flutter

W. RMS (JIS) within 0.3%

(test tape: WS-48B)

Page 19

Playback Level Adjustment

e

r

Procedure :

1. Mode : FWD playback

test tape

P-4-L300

(315Hz, 0dB)

set

LINE OUT

level meter

Record Level Adjustment

Setting :

• The REC LEVEL control must be positioned at the standard record

level position. (Refer to page 29.)

Procedure :

1. Record

AF OSC

attenuator

600

set

Ω

blank tape

CS-123

Adjust SFR01 (L-CH) and SFR02 (R-CH) so that the reading on

level meter meets the adjustment limits below.

Adjustment Limits :

LINE OUT level : -7.7 ± 0.5 dB (301.5 to 338.5 mV)

Level difference between channels : within 0.5 dB

Check that the LINE OUT level does not change even if Playback

and Stop operations are repeated several times.

Adjustment Location : DOLBY board (Refer to page 32.)

Record BIAS Adjustment

Setting :

• The REC LEVEL control must be positioned at the standard record

level position. (Refer to page 29.)

Procedure :

1. Mode: Record

AF OSC

attenuator

Ω

600

LINE IN

1) 315Hz

2) 10kHz

set

50mV (– 23.8dB)

blank tap

CS-123

LINE IN

315Hz, 50mV (–23.8dB)

2. Playback

recorded portion

set

LINE OUT

level meter

3. Reproduce the portion of tape which is recorded in step 1.

Confirm that the playback level stays within the specified range

of the Adjustment Level.

4. If the playback level is outside the specified range, adjust the

SFR11 (L-CH) and SFR12 (R-CH), and repeat steps 1 to 3 until

the specified range is satisfied.

Adjustment Level : -23.8 dB ± 0.5 dB (47.3 to 53.1 mV)

Adjustment Location : DOLBY board (Refer to page 32.)

2. Playback

recorded portion

set

LINE OUT

level mete

3. Reproduce the portion of tape which is recorded in step 1.

Confirm that the playback level stays within the specified range

of the Adjustment Level.

4. If the playback level is outside the specified range, adjust the

SFR03 (L-CH) and SFR04 (R-CH), and repeat steps 1 to 3 until

the specified range is satisfied.

Adjustment Level : Difference of the playback level between

10 kHz and 315 Hz : 0 dB ± 0.5 dB when 315 Hz is the reference.

Adjustment Location : DOLBY board (Refer to page 32.)

— 31 —

Page 20

Adjustment Location:

DOLBY board (Component Side)

SFR12

SFR11

SFR03

SFR04

SFR01

IC02

SFR02

IC03

CONTROL board (Component Side)

IC01

CN13

IC05

— 32 —

Page 21

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

SECTION 6

EXPLODED VIEWS

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

• Abbreviations

HK : Hong Kong

SP : Singapore

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

6-1. CASE, FRONT PANEL SECTION

10

9

3

8

7

31

#1

18

5

2

4

#3

1

4

2

19

#1

#3

17

20

16

11

#1

21

15

12

#1

11

13

#5

13

22

23

24

#4

#1

6

26

27

28

13

14

#4

14

25

#1

14

#4

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 3-033-056-01 WINDOW, GLASS

2 4-212-579-11 BRACKET (GLASS)

3 4-942-636-21 EMBLEM (NO.3.5), SONY

4 4-214-458-01 TAPE

5 3-033-074-01 CHASSIS, FRONT

6 3-033-079-01 REC LEVEL KNOB

7 3-028-756-01 PANEL (AL-TC), LOADING

8 3-033-054-01 PLATE, LOADING ORNAMENT

9 3-033-055-01 LID, LOADING

10 3-028-755-01 PANEL (AL-TC), FRONT

11 3-033-057-01 SCREW, CASE STOPPER

* 12 3-033-052-01 TOP COVER

* 13 3-033-053-01 FOOT

14 3-033-061-01 FOOT CUSHION

15 1-773-128-11 WIRE (FLAT TYPE) (19 CORE)

* 16 A-2007-825-A CONNECTION BOARD, COMPLETE

17 3-033-080-01 DOLBY KNOB

18 3-033-078-01 DIRECTION KNOB

19 4-212-557-01 BUTTON (REC)

20 3-033-075-01 LENS

* 21 A-2007-817-A FRONT BOARD, COMPLETE

22 3-033-076-01 BUTTON, PLAY

23 3-033-077-01 BUTTON, FF

* 24 A-2007-823-A O/C SW BOARD, COMPLETE

* 25 1-672-765-11 VR BOARD

26 3-033-081-01 REC LEBEL BRACKET

27 3-033-082-01 VR WASHER 9Q

28 3-033-083-01 NUT, VR

31 4-212-539-02 BUTTON (POWER)

— 33 —

Page 22

6-2. CHASSIS SECTION

#1

58

#1

59

57

TCM-ACLM572

#3

#6

66

54

56

#6

53

not supplied

#6

55

#1

#6

#6

#1

T01

A

63

64

60

65

#7

#7

62

#6

#1

A

61

not supplied

#6

52

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 3-033-060-01 SPRING, PLATE

52 4-213-692-02 TAPE (SPRING)

53 X-4950-381-1 BRACKET (R) ASSY

54 3-033-050-01 HINGE (L/C), DOOR

* 55 A-2007-818-A DOLBY BOARD, COMPLETE

* 56 3-033-063-01 CHASSIS (R), DECK

* 57 3-033-062-01 CHASSIS (L), DECK

* 58 A-2007-819-A CONTROL BOARD, COMPLETE

51

* 59 A-2007-820-A POWER BOARD, COMPLETE

* 60 1-672-764-11 POWER TRANS BOARD

* 61 3-035-607-01 REAR PANEL (AEP, UK)

* 61 3-035-608-01 REAR PANEL (E, HK, SP)

* 62 3-033-068-01 CUSHION

! 63 1-555-750-00 CORD, POWER

64 3-033-071-01 STOPPER, AC CORD

! 65 1-526-794-11 OUTLET, AC

* 66 A-2007-824-A PANEL SW BOARD, COMPLETE

! T01 1-433-657-11 TRANSFORMER, POWER

— 34 —

#1

not supplied

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Page 23

6-3. MECHANISM DECK SECTION-1 (TCM-ACLM572)

#10

102

#10

106

105

103

#11

104

107

118

117

108

118

#13

S902

119

116

109

120

122

115

114

#14

121

S901

#12

#13

110

111

M901

112

116

113

#8

#9

101

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 3-017-214-01 HOLDER

102 3-017-215-01 ARM (A)

103 3-017-233-01 RACK, GEAR

104 3-017-216-01 ARM (C)

105 3-017-213-01 CHASSIS

106 3-017-212-01 TRAY

107 3-017-235-01 SPRING (A)

108 3-017-244-01 SCREW (1.7 × 8.2), SPECIAL

109 3-017-217-01 ARM (576)

110 3-017-218-01 RETAINER

114 3-017-234-01 GROUND, PLATE

115 3-017-243-01 NUT

116 3-017-242-01 BUFFER

117 3-017-232-01 GEAR (B)

118 3-017-241-01 SCREW (1.6 × 4), SPECIAL

119 3-017-237-01 BELT (49.2)

120 3-017-231-01 PULLEY (C)

121 3-017-220-01 ARM

122 3-017-240-01 SCREW (2.1 × 4), SPECIAL

M901 3-017-239-01 PULLEY (MOTOR) (LOADING)

111 3-017-219-01 PLATE

112 3-017-211-01 FRAME

113 3-017-236-01 SPRING (B)

S901 3-017-238-01 LIMITTER (SW MSS-8B) (OPEN)

S902 3-017-238-01 LIMITTER (SW MSS-8B) (CLOSE)

— 35 —

Page 24

6-4. MECHANISM DECK SECTION-2 (TCM-ACLM572)

158

157

155

156

159

154

not supplied

153

not

supplied

161

155

160

155

HRPE901

M902

155

A

162

163

164

A

not

supplied

165

155

166

not supplied

167

151

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

151 3-017-294-01 SCREW (S), SPECIAL

153 3-017-273-01 LEVER (AC), SPRING

154 3-017-270-01 AC, LEVER

155 3-017-279-01 SCREW (M2), SPECIAL

156 3-017-274-01 HEAD, SPRING BASE

161 3-017-300-01 WASHER, FLAT

162 3-017-255-01 PINCH ROLLER (R)

163 3-017-296-01 CUSHION (MOTOR)

164 3-017-297-01 SCREW (MOTOR)

165 3-017-280-01 SCREW (M2 TAPPING), SPECIAL

157 3-017-254-01 PINCH ROLLER (F)

158 3-017-253-01 CHASSIS (HEAD)

159 3-017-277-01 PINCH (F), SPRING

160 3-017-278-01 PINCH (R), SPRING

166 3-017-285-01 BELT (MAIN)

* 167 1-672-011-11 MODE CONTROL BOARD

HRPE9013-017-303-01 HEAD (REC/PLAY/ERASE)

M902 3-017-259-01 PULLEY (MOTOR) (CAPSTAN REEL)

— 36 —

Page 25

6-5. MECHANISM DECK SECTION-3 (TCM-ACLM572)

216

214

217

213

212

214

213

215

211

211

218

219

221

220

222

223

210

224

209

208

225

224

209

203

208

207

206

205

204

226

227

202

201

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

201 3-017-258-01 FLYWHEEL (R)

202 3-017-257-01 FLYWHEEL (F)

203 3-017-284-01 BELT (SUB)

204 3-017-265-01 IDLER, GEAR

205 3-017-305-01 GEAR (P)

214 3-017-262-01 REEL, BUSHING

215 3-017-272-01 SPRING (BT)

216 3-017-281-01 WASHER, FLAT

217 3-017-256-01 ARM (PLAY)

218 3-017-275-01 LOCK, SPRING CAM

206 3-017-283-01 WASHER, FLAT

207 3-017-304-01 CLUTCH

208 3-017-263-01 REEL, BASE

209 3-017-295-01 WASHER, FLAT

210 3-017-252-01 CHASSIS (OS)

211 3-017-298-01 WASHER (B/T)

212 3-017-299-01 SPRING (B/T) (F)

213 3-017-288-01 REEL, CAP

219 3-017-267-01 LOCK, ARM CAM

220 3-017-282-01 WASHER, FLAT

221 3-017-264-01 CAM, GEAR

222 3-017-266-01 BASE, LEVER

223 3-017-268-01 ARM (RF)

224 3-017-269-01 GEAR (RF)

225 3-017-276-01 ARM (RF), SPRING

226 3-017-293-01 MAGNET, PLATE

227 3-017-271-01 CAP (MG)

— 37 —

Page 26

CONNECTION

CONTROL

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-2007-825-A CONNECTION BOARD, COMPLETE

***************************

< RESISTOR >

R221 1-247-855-11 CARBON 10K 5% 1/4W

R225 1-247-839-11 CARBON 2.2K 5% 1/4W

R226 1-247-843-11 CARBON 3.3K 5% 1/4W

R227 1-247-863-11 CARBON 22K 5% 1/4W

R228 1-247-871-11 CARBON 47K 5% 1/4W

ELECTRICAL PARTS LIST

• CAPACITORS:

uF: µF

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

• Abbreviations

HK : Hong Kong

SP : Singapore

SECTION 7

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

When indicating parts by reference number,

please include the board name.

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

< CONNECTOR >

* CN05 1-564-708-11 PIN, CONNECTOR (SMALL TYPE) 6P

CN07 1-785-785-11 SOCKET, CONNECTOR 10P

* CN08 1-564-715-11 PIN, CONNECTOR (SMALL TYPE)13P

CN09 1-568-802-11 SOCKET, CONNECTOR 19P

CN12 1-785-779-11 SOCKET, CONNECTOR 13P

CN12A 1-785-780-11 HEADER, PIN 13P

* CN14 1-564-704-11 PIN, CONNECTOR (SMALL TYPE) 2P

< SWITCH >

S7 1-572-647-11 SWITCH, KEY BOARD (POWER)

S11 1-692-505-11 SWITCH, SLIDE (DIRECTION)

S12 1-692-505-11 SWITCH, SLIDE (DOLBY NR)

************************************************************

* A-2007-819-A CONTROL BOARD, COMPLETE

************************

< CAPACITOR >

C68 1-162-282-31 CERAMIC 100PF 10% 50V

C69 1-137-372-11 FILM 0.022uF 5% 50V

C70 1-162-217-31 CERAMIC 56PF 5% 50V

C71 1-126-961-11 ELECT 2.2uF 20% 50V

C73 1-126-960-11 ELECT 1uF 20% 50V

C74 1-126-916-11 ELECT 1000uF 20% 6.3V

C75 1-161-494-00 CERAMIC 0.022uF 25V

C76 1-126-964-11 ELECT 10uF 20% 50V

C77 1-164-159-11 CERAMIC 0.1uF 50V

C78 1-162-306-11 CERAMIC 0.01uF 20% 16V

C79 1-162-306-11 CERAMIC 0.01uF 20% 16V

C81 1-126-935-11 ELECT 470uF 20% 16V

C82 1-126-934-11 ELECT 220uF 20% 16V

C83 1-162-282-31 CERAMIC 100PF 10% 50V

C70A 1-126-964-11 ELECT 10uF 20% 50V

C74A 1-164-159-11 CERAMIC 0.1uF 50V

C76A 1-126-963-11 ELECT 4.7uF 20% 50V

C76B 1-104-664-11 ELECT 47uF 20% 16V

C77A 1-164-159-11 CERAMIC 0.1uF 50V

< DIODE >

D02 8-719-911-19 DIODE 1SS119

D03 8-719-911-19 DIODE 1SS119

D04 8-719-911-19 DIODE 1SS119

D13 8-719-109-97 DIODE RD6.8ES-B2

D14 8-719-109-85 DIODE RD5.1ES-B2

D15 8-719-911-19 DIODE 1SS119

D16 8-719-109-85 DIODE RD5.1ES-B2

D19 8-719-055-76 DIODE 1N4148

D20 8-719-911-19 DIODE 1SS119

D28 8-719-200-02 DIODE 10E2

< IC >

IC05 8-759-575-34 IC TMP87CH48DF-4B67

IC06 8-759-822-09 IC LB1641

IC07 8-759-165-85 IC PST600H-T

IC08 8-759-710-59 IC NJM4580D-D

< TRANSISTOR >

Q19 8-729-119-76 TRANSISTOR 2SA1175-HFE

Q21 8-729-900-63 TRANSISTOR DTA124ES

Q22 8-729-900-63 TRANSISTOR DTA124ES

Q23 8-729-900-63 TRANSISTOR DTA124ES

Q24 8-729-993-43 TRANSISTOR 2SA934R

Q25 8-729-993-43 TRANSISTOR 2SA934R

Q26 8-729-029-86 TRANSISTOR DTC124ESA

Q27 8-729-029-86 TRANSISTOR DTC124ESA

Q29 8-729-900-63 TRANSISTOR DTA124ES

Q30 8-729-900-63 TRANSISTOR DTA124ES

< FILTER >

CF01 1-579-125-11 VIBRA TOR, CERAMIC 8MHz

Q31 8-729-900-63 TRANSISTOR DTA124ES

Q32 8-729-900-63 TRANSISTOR DTA124ES

Q33 8-729-900-63 TRANSISTOR DTA124ES

Q34 8-729-900-63 TRANSISTOR DTA124ES

Q35 8-729-900-63 TRANSISTOR DTA124ES

Q36 8-729-900-63 TRANSISTOR DTA124ES

Q38 8-729-900-63 TRANSISTOR DTA124ES

— 38 —

Page 27

CONTROL DOLBY

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< RESISTOR >

R76 1-249-437-11 CARBON 47K 5% 1/4W

R77 1-249-427-11 CARBON 6.8K 5% 1/4W F

R78 1-247-843-11 CARBON 3.3K 5% 1/4W

R79 1-247-879-11 CARBON 100K 5% 1/4W

R80 1-247-879-11 CARBON 100K 5% 1/4W

R81 1-247-855-11 CARBON 10K 5% 1/4W

R82 1-249-417-11 CARBON 1K 5% 1/4W F

R83 1-249-432-11 CARBON 18K 5% 1/4W

R84 1-249-436-11 CARBON 39K 5% 1/4W

R85 1-247-879-11 CARBON 100K 5% 1/4W

R86 1-249-417-11 CARBON 1K 5% 1/4W F

R87 1-249-413-11 CARBON 470 5% 1/4W F

R88 1-247-855-11 CARBON 10K 5% 1/4W

R89 1-247-855-11 CARBON 10K 5% 1/4W

R90 1-249-417-11 CARBON 1K 5% 1/4W F

R91 1-249-417-11 CARBON 1K 5% 1/4W F

R96 1-247-855-11 CARBON 10K 5% 1/4W

R97 1-249-417-11 CARBON 1K 5% 1/4W F

R98 1-247-855-11 CARBON 10K 5% 1/4W

R99 1-249-417-11 CARBON 1K 5% 1/4W F

R100 1-247-807-11 CARBON 100 5% 1/4W

R101 1-247-855-11 CARBON 10K 5% 1/4W

R102 1-247-847-11 CARBON 4.7K 5% 1/4W

R103 1-247-807-11 CARBON 100 5% 1/4W

R104 1-249-427-11 CARBON 6.8K 5% 1/4W F

R105 1-249-427-11 CARBON 6.8K 5% 1/4W F

R107 1-249-398-11 CARBON 27 5% 1/4W F

R109 1-247-867-11 CARBON 33K 5% 1/4W

R110 1-247-807-11 CARBON 100 5% 1/4W

R111 1-247-879-11 CARBON 100K 5% 1/4W

R112 1-249-430-11 CARBON 12K 5% 1/4W

R113 1-249-440-11 CARBON 82K 5% 1/4W

R114 1-249-417-11 CARBON 1K 5% 1/4W F

R116 1-249-427-11 CARBON 6.8K 5% 1/4W F

R117 1-249-412-11 CARBON 390 5% 1/4W F

R20A 1-247-855-11 CARBON 10K 5% 1/4W

R200 1-249-412-11 CARBON 390 5% 1/4W F

R201 1-249-412-11 CARBON 390 5% 1/4W F

R202 1-249-412-11 CARBON 390 5% 1/4W F

R203 1-249-412-11 CARBON 390 5% 1/4W F

R204 1-249-409-11 CARBON 220 5% 1/4W F

R205 1-249-409-11 CARBON 220 5% 1/4W F

R206 1-249-412-11 CARBON 390 5% 1/4W F

R207 1-249-412-11 CARBON 390 5% 1/4W F

R208 1-249-412-11 CARBON 390 5% 1/4W F

R209 1-249-412-11 CARBON 390 5% 1/4W F

R210 1-249-412-11 CARBON 390 5% 1/4W F

R211 1-249-412-11 CARBON 390 5% 1/4W F

R212 1-249-412-11 CARBON 390 5% 1/4W F

R214 1-249-412-11 CARBON 390 5% 1/4W F

R404 1-249-437-11 CARBON 47K 5% 1/4W

R102A 1-247-855-11 CARBON 10K 5% 1/4W

* A-2007-818-A DOLBY BOARD, COMPLETE

**********************

< CAPACITOR >

C01 1-162-292-31 CERAMIC 680PF 10% 50V

C02 1-162-292-31 CERAMIC 680PF 10% 50V

C03 1-162-282-31 CERAMIC 100PF 10% 50V

C04 1-162-282-31 CERAMIC 100PF 10% 50V

C05 1-137-372-11 FILM 0.022uF 5% 50V

C06 1-137-372-11 FILM 0.022uF 5% 50V

C07 1-104-664-11 ELECT 47uF 20% 25V

C08 1-104-664-11 ELECT 47uF 20% 25V

C09 1-107-714-11 ELECT 10uF 20% 16V

C10 1-107-714-11 ELECT 10uF 20% 16V

C11 1-126-925-11 ELECT 470uF 20% 10V

C12 1-126-925-11 ELECT 470uF 20% 10V

C13 1-137-372-11 FILM 0.022uF 5% 50V

C14 1-137-372-11 FILM 0.022uF 5% 50V

C15 1-126-964-11 ELECT 10uF 20% 50V

C16 1-107-714-11 ELECT 10uF 20% 16V

C17 1-162-288-31 CERAMIC 330PF 10% 50V

C18 1-162-288-31 CERAMIC 330PF 10% 50V

C19 1-107-609-11 CERAMIC 75PF 5% 500V

C20 1-107-609-11 CERAMIC 75PF 5% 500V

C21 1-107-610-11 CERAMIC 82PF 5% 500V

C22 1-107-610-11 CERAMIC 82PF 5% 500V

C23 1-136-562-11 FILM 0.0082uF 5% 630V

C24 1-126-961-11 ELECT 2.2uF 20% 50V

C25 1-137-436-11 FILM 0.0039uF 5% 50V

C26 1-137-436-11 FILM 0.0039uF 5% 50V

C27 1-137-370-11 FILM 0.01uF 5% 50V

C28 1-126-960-11 ELECT 1uF 20% 50V

C29 1-104-665-11 ELECT 100uF 20% 25V

C30 1-126-961-11 ELECT 2.2uF 20% 50V

C33 1-126-963-11 ELECT 4.7uF 20% 50V

C34 1-126-963-11 ELECT 4.7uF 20% 50V

C35 1-162-282-31 CERAMIC 100PF 10% 50V

C36 1-162-282-31 CERAMIC 100PF 10% 50V

C37 1-126-964-11 ELECT 10uF 20% 50V

C38 1-126-964-11 ELECT 10uF 20% 50V

C39 1-136-165-00 FILM 0.1uF 5% 50V

C40 1-136-165-00 FILM 0.1uF 5% 50V

C41 1-136-163-00 FILM 0.068uF 5% 50V

C42 1-136-163-00 FILM 0.068uF 5% 50V

C43 1-126-964-11 ELECT 10uF 20% 50V

C44 1-126-964-11 ELECT 10uF 20% 50V

C45 1-104-665-11 ELECT 100uF 20% 10V

C46 1-104-665-11 ELECT 100uF 20% 10V

C47 1-126-960-11 ELECT 1uF 20% 50V

C60 1-126-960-11 ELECT 1uF 20% 50V

C61 1-126-960-11 ELECT 1uF 20% 50V

C62 1-126-961-11 ELECT 2.2uF 20% 50V

C63 1-126-961-11 ELECT 2.2uF 20% 50V

C64 1-162-282-31 CERAMIC 100PF 10% 50V

< CIRCUIT BLOCK >

RA01 1-234-267-11 CIRCUIT BLOCK, COMPOSITION (10K × 11)

************************************************************

— 39 —

C65 1-162-282-31 CERAMIC 100PF 10% 50V

C66 1-162-306-11 CERAMIC 0.01uF 20% 16V

C67 1-162-306-11 CERAMIC 0.01uF 20% 16V

C400 1-126-960-11 ELECT 1uF 20% 50V

C401 1-126-960-11 ELECT 1uF 20% 50V

Page 28

DOLBY

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< CONNECTOR >

* CN01 1-564-707-11 PIN, CONNECTOR (SMALL TYPE) 5P

CN04 1-785-778-11 SOCKET, CONNECTOR 8P

< DIODE >

D01 8-719-911-19 DIODE 1SS119

D05 8-719-911-19 DIODE 1SS119

D06 8-719-911-19 DIODE 1SS119

< IC >

IC01 8-759-112-93 IC UPC4570HA-1

IC02 8-752-060-46 IC CXA1561S

IC03 8-752-070-69 IC CXA1598S

< COIL >

L01 1-414-223-11 INDUCTOR 470uH

L02 1-414-223-11 INDUCTOR 470uH

L03 1-410-780-11 INDUCTOR 27mH

L04 1-410-780-11 INDUCTOR 27mH

L07 1-429-316-11 TRANSFORMER, BIAS OSCILLATION (BIAS)

< FILTER >

LPF05 1-236-087-11 FILTER, LOW PASS

LPF06 1-236-087-11 FILTER, LOW PASS

R11 1-247-855-11 CARBON 10K 5% 1/4W

R12 1-247-855-11 CARBON 10K 5% 1/4W

R13 1-247-843-11 CARBON 3.3K 5% 1/4W

R14 1-247-843-11 CARBON 3.3K 5% 1/4W

R15 1-249-431-11 CARBON 15K 5% 1/4W

R16 1-249-431-11 CARBON 15] 5% 1/4W

R17 1-249-387-11 CARBON 3.3 5% 1/4W F

R18 1-247-847-11 CARBON 4.7K 5% 1/4W

R19 1-249-390-11 CARBON 5.6 5% 1/4W F

R20 1-249-432-11 CARBON 18K 5% 1/4W

R21 1-249-432-11 CARBON 18K 5% 1/4W

R22 1-249-424-11 CARBON 3.9K 5% 1/4W F

R23 1-249-432-11 CARBON 18K 5% 1/4W

R24 1-249-420-11 CARBON 1.8K 5% 1/4W F

R25 1-247-838-11 CARBON 2K 5% 1/4W

R28 1-247-855-11 CARBON 10K 5% 1/4W

R29 1-247-855-11 CARBON 10K 5% 1/4W

R30 1-247-855-11 CARBON 10K 5% 1/4W

R31 1-247-855-11 CARBON 10K 5% 1/4W

R32 1-247-843-11 CARBON 3.3K 5% 1/4W

R33 1-247-843-11 CARBON 3.3K 5% 1/4W

R34 1-249-428-11 CARBON 8.2K 5% 1/4W F

R36 1-247-863-11 CARBON 22K 5% 1/4W

R37 1-247-863-11 CARBON 22K 5% 1/4W

R38 1-249-418-11 CARBON 1.2K 5% 1/4W F

< TRANSISTOR >

Q01 8-729-029-86 TRANSISTOR DTC124ESA

Q02 8-729-029-86 TRANSISTOR DTC124ESA

Q03 8-729-029-68 TRANSISTOR DTC114TSA

Q04 8-729-029-68 TRANSISTOR DTC114TSA

Q05 8-729-231-55 TRANSISTOR 2SC2878-AB

Q06 8-729-231-55 TRANSISTOR 2SC2878-AB

Q07 8-729-029-86 TRANSISTOR DTC124ESA

Q08 8-729-142-46 TRANSISTOR 2SC2001-LK

Q09 8-729-142-46 TRANSISTOR 2SC2001-LK

Q10 8-729-140-96 TRANSISTOR 2SD774-34

Q11 8-729-900-63 TRANSISTOR DTA124ES

Q12 8-729-029-86 TRANSISTOR DTC124ESA

Q13 8-729-029-86 TRANSISTOR DTC124ESA

Q14 8-729-029-68 TRANSISTOR DTC114TSA

Q15 8-729-029-68 TRANSISTOR DTC114TSA

Q16 8-729-029-86 TRANSISTOR DTC124ESA

Q17 8-729-029-86 TRANSISTOR DTC124ESA

Q18 8-729-029-86 TRANSISTOR DTC124ESA

Q45 8-729-194-57 TRANSISTOR 2SC945-P

Q12A 8-729-900-63 TRANSISTOR DTA124ES

Q13A 8-729-900-63 TRANSISTOR DTA124ES

< RESISTOR >

R39 1-249-418-11 CARBON 1.2K 5% 1/4W F

R40 1-247-863-11 CARBON 22K 5% 1/4W

R41 1-247-863-11 CARBON 22K 5% 1/4W

R44 1-247-883-00 CARBON 150K 5% 1/4W

R45 1-249-428-11 CARBON 8.2K 5% 1/4W F

R46 1-249-428-11 CARBON 8.2K 5% 1/4W F

R49 1-247-839-11 CARBON 2.2K 5% 1/4W

R50 1-247-839-11 CARBON 2.2K 5% 1/4W

R51 1-247-839-11 CARBON 2.2K 5% 1/4W

R52 1-247-839-11 CARBON 2.2K 5% 1/4W

R53 1-247-843-11 CARBON 3.3K 5% 1/4W

R54 1-247-843-11 CARBON 3.3K 5% 1/4W

R55 1-249-417-11 CARBON 1K 5% 1/4W F

R56 1-249-417-11 CARBON 1K 5% 1/4W F

R57 1-249-436-11 CARBON 39K 5% 1/4W

R58 1-249-431-11 CARBON 15K 5% 1/4W

R59 1-247-879-11 CARBON 100K 5% 1/4W

R60 1-249-439-11 CARBON 68K 5% 1/4W

R61 1-247-867-11 CARBON 33K 5% 1/4W

R62 1-247-883-00 CARBON 150K 5% 1/4W

R63 1-249-438-11 CARBON 56K 5% 1/4W

R64 1-249-432-11 CARBON 18K 5% 1/4W

R65 1-247-883-00 CARBON 150K 5% 1/4W

R66 1-249-430-11 CARBON 12K 5% 1/4W

R67 1-247-849-11 CARBON 5.6K 5% 1/4W

R01 1-247-881-00 CARBON 120K 5% 1/4W

R02 1-247-881-00 CARBON 120K 5% 1/4W

R03 1-247-881-00 CARBON 120K 5% 1/4W

R04 1-247-881-00 CARBON 120K 5% 1/4W

R05 1-247-850-11 CARBON 6.2K 5% 1/4W

R06 1-247-850-11 CARBON 6.2K 5% 1/4W

R07 1-249-404-00 CARBON 82 5% 1/4W F

R08 1-249-404-00 CARBON 82 5% 1/4W F

R09 1-247-839-11 CARBON 2.2K 5% 1/4W

R10 1-247-839-11 CARBON 2.2K 5% 1/4W

— 40 —

R68 1-249-431-11 CARBON 15K 5% 1/4W

R69 1-249-436-11 CARBON 39K 5% 1/4W

R70 1-247-863-11 CARBON 22K 5% 1/4W

R71 1-247-876-11 CARBON 75K 5% 1/4W

R72 1-247-876-11 CARBON 75K 5% 1/4W

R73 1-249-431-11 CARBON 15K 5% 1/4W

R74 1-249-431-11 CARBON 15K 5% 1/4W

R75 1-249-434-11 CARBON 27K 5% 1/4W

R01A 1-249-393-11 CARBON 10 5% 1/4W F

R015 1-249-409-11 CARBON 220 5% 1/4W F

Page 29

DOLBY FRONT MODE CONTROL

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R016 1-249-409-11 CARBON 220 5% 1/4W F

R19A 1-249-390-11 CARBON 5.6 5% 1/4W F

R40A 1-247-847-11 CARBON 4.7K 5% 1/4W

R400 1-247-903-00 CARBON 1M 5% 1/4W

R401 1-249-417-11 CARBON 1K 5% 1/4W F

R402 1-249-424-11 CARBON 3.9K 5% 1/4W F

R403 1-247-855-11 CARBON 10K 5% 1/4W

R41A 1-247-847-11 CARBON 4.7K 5% 1/4W

R44A 1-247-862-11 CARBON 20K 5% 1/4W

R45A 1-249-389-11 CARBON 4.7 5% 1/4W F

R46A 1-249-389-11 CARBON 4.7 5% 1/4W F

R57A 1-247-871-11 CARBON 47K 5% 1/4W

< RELAY >

RY01 1-755-294-11 RELAY

< VARIABLE RESISTOR >

SRF01 1-238-598-11 RES, ADJ, CARBON 2.2K (PB LEVEL L)

SRF02 1-238-598-11 RES, ADJ, CARBON 2.2K (PB LEVEL R)

SRF03 1-241-768-11 RES, ADJ, CARBON 220K (BIAS CURRENT L)

SRF04 1-241-768-11 RES, ADJ, CARBON 220K (BIAS CURRENT R)

SRF11 1-238-600-11 RES, ADJ, CARBON 10K (REC LEVEL L)

SRF12 1-238-600-11 RES, ADJ, CARBON 10K (REC LEVEL R)

************************************************************

* A-2007-817-A FRONT BOARD, COMPLETE

**********************

< CONNECTOR >

CN09 1-785-783-11 CONNECTOR, FFC/FPC 19P

< LED >

LED1 8-719-072-76 LED SEL5E23C-TP15 (REV)

LED2 8-719-072-76 LED SEL5E23C-TP15 (PLA Y)

LED3 8-719-072-76 LED SEL5E23C-TP15 (PAUSE)

LED4 8-719-072-76 LED SEL5E23C-TP15 (STOP)

LED5 8-719-304-83 LED SEL2410G (-10)

R215 1-247-827-11 CARBON 680 5% 1/4W

R216 1-249-417-11 CARBON 1K 5% 1/4W F

R217 1-247-835-11 CARBON 1.5K 5% 1/4W

R218 1-247-839-11 CARBON 2.2K 5% 1/4W

R219 1-247-843-11 CARBON 3.3K 5% 1/4W

R220 1-247-847-11 CARBON 4.7K 5% 1/4W

R222 1-247-827-11 CARBON 680 5% 1/4W

R223 1-249-417-11 CARBON 1K 5% 1/4W F

R224 1-247-835-11 CARBON 1.5K 5% 1/4W

R230 1-249-409-11 CARBON 220 5% 1/4W F

R231 1-249-409-11 CARBON 220 5% 1/4W F

R232 1-249-409-11 CARBON 220 5% 1/4W F

R233 1-249-409-11 CARBON 220 5% 1/4W F

S1 1-572-647-11 SWITCH, KEY BOARD (STOP)

S2 1-572-647-11 SWITCH, KEY BOARD (PAUSE)

S3 1-572-647-11 SWITCH, KEY BOARD (PLAY)

S4 1-572-647-11 SWITCH, KEY BOARD (REV)

S5 1-572-647-11 SWITCH, KEY BOARD (CD SYNC)

S6 1-572-647-11 SWITCH, KEY BOARD (REC)

S9 1-572-647-11 SWITCH, KEY BOARD (FF)

S10 1-572-647-11 SWITCH, KEY BOARD (REW)

************************************************************

* 1-672-011-11 MODE CONTROL BOARD

3-017-287-01 TERMINAL (RP)

D001 8-719-911-19 DIODE 1N4148M

D002 8-719-911-19 DIODE 1N4148M

IC001 3-017-289-01 PLATE, ROTARY DETECTION

< RESISTOR >

< SWITCH >

********************

< DIODE >

< IC >

LED6 8-719-304-83 LED SEL2410G (-5)

LED7 8-719-304-83 LED SEL2410G (0)

LED8 8-719-812-41 LED TLR124 (+3)

LED9 8-719-812-41 LED TLR124 (+6)

LED10 8-719-058-04 LED SEL5223S-TP15 (CD SYNC)

LED11 8-719-058-04 LED SEL5223S-TP15 (REC)

LED12 8-719-300-97 LED SEL2710K (PAUSE)

LED13 8-719-311-60 LED SEL2810D-C (REW)

LED14 8-719-311-60 LED SEL2810D-C (FF)

LED15 8-719-304-83 LED SEL2410G (REV)

LED16 8-719-304-83 LED SEL2410G (PLAY)

LED17 8-719-304-83 LED SEL2410G (∞)

LED18 8-719-812-41 LED TLR124 (TAPE)

< PLUNGER SOLENOID >

PM001 3-017-292-01 SOLENOID

< SWITCH >

S001 3-017-290-01 DETECT, SWITCH (FWD REC)

S002 3-017-290-01 DETECT, SWITCH (HALF)

S003 3-017-290-01 DETECT, SWITCH (CrO2)

S004 3-017-290-01 DETECT, SWITCH (METAL)

S005 3-017-290-01 DETECT, SWITCH (REV REC)

S006 3-017-291-01 MODE, SWITCH (MODE)

< RESISTOR >

R001 1-247-862-11 CARBON 20K 5% 1/4W

************************************************************

— 41 —

Page 30

O/C SW PANEL SW

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-2007-823-A O/C SW BOARD, COMPLETE

***********************

< SWITCH >

S8 1-572-647-11 SWITCH, KEY BOARD (EJECT)

************************************************************

POWER POWER TRANS

< IC >

IC04 8-759-288-53 IC LA5617

IC10 8-759-604-35 IC M5F78M05L

IC11 8-759-549-81 IC P82B715TD.112

< JACK >

* A-2007-824-A PANEL SW BOARD, COMPLETE

*************************

< SWITCH >

S15 1-771-612-11 SWITCH, DETECTION (PANEL SW)

************************************************************

* A-2007-820-A POWER BOARD, COMPLETE

***********************

< CAPACITOR >

C31 1-162-290-31 CERAMIC 470PF 10% 50V

C32 1-162-290-31 CERAMIC 470PF 10% 50V

C48 1-126-925-11 ELECT 470uF 20% 10V

C49 1-126-925-11 ELECT 470uF 20% 10V

C50 1-164-159-11 CERAMIC 0.1uF 50V

C51 1-162-294-31 CERAMIC 0.001uF 10% 50V

C52 1-162-294-31 CERAMIC 0.001uF 10% 50V

C53 1-164-159-11 CERAMIC 0.1uF 50V

C54 1-126-943-11 ELECT 2200uF 20% 25V

C55 1-126-943-11 ELECT 2200uF 20% 25V

C56 1-126-943-11 ELECT 2200uF 20% 25V

C57 1-162-306-11 CERAMIC 0.01uF 20% 16V

C58 1-126-926-11 ELECT 1000uF 20% 10V

C59 1-126-960-11 ELECT 1uF 20% 50V

C84 1-102-129-00 CERAMIC 10000PF 10% 50V

C85 1-102-129-00 CERAMIC 10000PF 10% 50V

C86 1-102-129-00 CERAMIC 10000PF 10% 50V

C87 1-102-129-00 CERAMIC 10000PF 10% 50V

C90 1-164-159-11 CERAMIC 0.1uF 50V

C91 1-164-159-11 CERAMIC 0.1uF 50V

C90A 1-124-261-00 ELECT 10uF 20% 50V

< CONNECTOR >

JK01 1-785-822-11 JACK, PIN (TAPE)

< TRANSISTOR >

Q20 8-729-119-78 TRANSISTOR 2SC403SP-51

Q37 8-729-029-68 TRANSISTOR DTC114TSA

Q39 8-729-029-68 TRANSISTOR DTC114TSA

Q40 8-729-900-63 TRANSISTOR DTA124ES

Q41 8-729-900-63 TRANSISTOR DTA124ES

Q42 8-729-012-83 TRANSISTOR 2SK679A

Q43 8-729-012-83 TRANSISTOR 2SK679A

Q05A 8-729-231-55 TRANSISTOR 2SC2878-AB

Q06A 8-729-231-55 TRANSISTOR 2SC2878-AB

< RESISTOR >

R26 1-247-879-11 CARBON 100K 5% 1/4W

R27 1-247-879-11 CARBON 100K 5% 1/4W

R35 1-247-855-11 CARBON 10K 5% 1/4W

R42 1-247-839-11 CARBON 2.2K 5% 1/4W

R43 1-247-839-11 CARBON 2.2K 5% 1/4W

R115 1-247-855-11 CARBON 10K 5% 1/4W

R119 1-247-713-11 CARBON 1K 5% 1/4W F

R120 1-247-855-11 CARBON 10K 5% 1/4W

R121 1-247-855-11 CARBON 10K 5% 1/4W

R122 1-247-855-11 CARBON 10K 5% 1/4W

R123 1-249-417-11 CARBON 1K 5% 1/4W F

R124 1-247-879-11 CARBON 100K 5% 1/4W

R125 1-247-855-11 CARBON 10K 5% 1/4W

R126 1-247-855-11 CARBON 10K 5% 1/4W

R213 1-247-863-11 CARBON 22K 5% 1/4W

R302 1-247-879-11 CARBON 100K 5% 1/4W

R303 1-249-417-11 CARBON 1K 5% 1/4W F

R304 1-249-417-11 CARBON 1K 5% 1/4W F

R305 1-247-879-11 CARBON 100K 5% 1/4W

R306 1-247-807-11 CARBON 100 5% 1/4W

* CN03 1-566-856-11 SOCKET, CONNECTOR 5P (SYSTEM CONTROL)

CN04 1-785-781-11 HEADER, PIN 8P

CN06 1-564-707-11 PIN, CONNECTOR (SMALL TYPE) 5P

CN07 1-785-782-11 HEADER, PIN 10P

* CN15 1-564-706-11 PIN, CONNECTOR (SMALL TYPE) 4P

CN12A 1-785-780-11 HEADER, PIN 13P

< DIODE >

D07 8-719-991-33 DIODE 1SS133T-77

D12 8-719-031-85 DIODE 1N4002L

D17 8-719-073-77 DIODE W005M

D22 8-719-031-85 DIODE 1N4002L

D23 8-719-031-85 DIODE 1N4002L

D24 8-719-031-85 DIODE 1N4002L

D25 8-719-031-85 DIODE 1N4002L

D36 8-719-991-33 DIODE 1SS133T-77

D37 8-719-991-33 DIODE 1SS133T-77

— 42 —

R307 1-247-807-11 CARBON 100 5% 1/4W

R35A 1-249-417-11 CARBON 1K 5% 1/4W F

R38A 1-247-847-11 CARBON 4.7K 5% 1/4W

R39A 1-247-847-11 CARBON 4.7K 5% 1/4W

************************************************************

* 1-672-764-11 POWER TRANS BOARD

*******************

< TRANSFORMER >

! T01 1-433-657-11 TRANSFORMER, POWER

************************************************************

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Page 31

VR

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* 1-672-765-11 VR BOARD

*********

< VARIABLE RESISTOR >

VR02 1-225-749-11 RES, VAR, CARBON 50K/50K (REC LEVEL)

************************************************************

MISCELLANEOUS

**************

15 1-773-128-11 WIRE (FLAT TYPE) (19 CORE)

! 63 1-555-750-00 CORD, POWER

! 65 1-526-794-11 OUTLET, AC

HRPE9013-017-303-01 HEAD (REC/PLAY/ERASE)

M901 3-017-239-01 PULLEY (MOTOR) (LOADING)

M902 3-017-259-01 PULLEY (MOTOR)(CAPSTAN REEL)

S901 3-017-238-01 LIMITTER (SW MSS-8B)(OPEN)

S902 3-017-238-01 LIMITTER (SW MSS-8B)(CLOSE)

************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

#1 7-685-534-19 SCREW +B 2.6 × 8 (TYPE2)

#3 7-685-533-19 SCREW +B 2.6 × 6 (TYPE2)

#4 7-685-535-19 SCREW +B 2.6 × 10 (TYPE2)

#6 7-685-547-19 SCREW +B 3 × 10 (TYPE2)

#7 7-682-903-11 SCREW +PWH 3 × 6

#8 7-685-645-79 SCREW +P 3 × 6 TYPE2 NON-SLIT

#9 7-685-146-11 SCREW +P 3 × 8 TYPE2 NON-SLIT

#10 7-685-132-19 SCREW +P 2.6 × 5 TYPE2 NON-SLIT

#11 7-671-157-01 BALL, STAINLESS (5 DIA)

#12 7-627-551-18 SCREW,PRECISION +P 1.4 × 2

#13 7-685-105-19 SCREW +P 2 × 8 TYPE2 NON-SLIT

#14 7-621-772-10 SCREW +P 2 × 4

**************

HARDWARE LIST

**************

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

1-790-441-11 CABLE, IC CONNECTOR 5P (SYSTEM CABLE)

3-020-441-01 BRACKET (PATCH CORD)(AUDIO CABLE)

3-864-773-11 MANUAL, INSTRUCTION (ENGLISH)

3-864-773-21 MANUAL, INSTRUCTION

3-864-773-31 MANUAL, INSTRUCTION (GERMAN/DUTCH/

3-864-773-41 MANUAL, INSTRUCTION (CHINESE) (E, HK, SP)

************************************************************

(FRENCH/SPANISH) (AEP, UK, E, SP)

SWEDISH/ITALIAN/PORTUGUESE) (AEP, UK)

— 43 —

Page 32

TC-SD1

9-922-983-11

Sony Corporation

Home A&V Products Company

— 44 —

Printed in Japan ©1999.1

99A1653-1

Published by Quality Assurance Dept.

(Shinagawa)

Loading...

Loading...