Page 1

TCON Troubleshooting and Replacement

Introduction

Sony will be announcing the availability of limited TCON replacement boards to service LCD panels beginning

with certain models going back to 2006. For many years technicians have been asking about the availability

of these components. In the relatively small percentage of units that experienced a failure of the TCON board,

replacement of the entire LCD panel was mandatory. This is not only costly from a warranty standpoint but it also

makes it near impossible to justify an out-of-warranty repair since the replacement LCD panel can easily cost 2/3

or more of the price of the entire television.

The reason why TCON assemblies have not been available in the past was due to the large amount of correction

data stored within NVM data points located on the board. Tolerance issues during the manufacture of the LCD

panels required white balance, gamma, and uniformity corrections to compensate for these inherent production

issues. There are other items for correct panel operation but the above mentioned items are the most critical.

Over the years, panel tolerances have improved dramatically and variances in uniformity have been reduced to the

point where a TCON loaded with average data results in a satisfactory picture when installed as a replacement on

a panel. Most Sony television models also have white balance data located on the video process board. Although

the TCON is loaded with data to properly white balance the panel, the ability to adjust white balance from the B

boards is present to compensate for shifts in white balancing due to panel aging and this mainly involves color

balance shifting of the fluorescent backlight lamps which tend to shift towards the magenta spectrum as they

age.

The main issue with previous LCD panel designs was the uniformity adjustment data. Due to variances across

the LCD panel it was impossible to achieve even white balance across the screen. For this reason, small zones

across and down the LCD panel required individual white balance compensation. Without this correction the

picture would have “blotches” of different color in sections of the screen. Better tolerances during manufacturing

have reduced the reliance on this uniformity data and allows for the replacement of TCON boards with satisfactory

results.

As mentioned in the beginning, not all LCD panels will have a TCON board available. This will mainly be

determined by availability of components from the LCD panel vendor along with decisions by Sony based on

sales quantity and failure history of the TCON assemblies. Most technicians have experienced the use of the LCD

panel replacement manual. This manual was created to proper identify the type of LCD panel installed in a unit

based on its serial number since some units changed to a different type of LCD panel during the manufacturing

production. The plan is to use this document to also provide TCON information and whether one is available and,

if available, which TCON is the proper replacement part for that particular panel.

LCD Panel Basics

LCD panels have steadily evolved over the last several years. New designs of the physical structure of the LCD

crystals have greatly improved the contrast ratio and viewing angle. Quicker response times and increased

refresh rates have helped to reduce the motion “smear” associated with LCD displays. Backlighting design

has also aided in producing a picture with color temperatures to make the images as true as possible. With all

these design improvements, one aspect of the LCD panel remains relatively the same: Processing of the video

signal.

Figure 1 illustrates a typical LCD panel and the associated video processing circuits as found in the WAX3

chassis. The various formats and resolutions of video signals are processed on the BU1 board. All video signals

exit the video processor in the native resolution of the LCD panel. In this design, the resolution is for a 1280 by

768 at 60HZ refresh rate panel. 48 horizontal lines are discarded to match up to the 720p resolution of the ATSC

specifications so the video will exit as 720p.

The LCD panel used in this model processes 8-bit RGB video data. Before the video information can be sent

Page 2

to the TCON board it must be converted to a format that allows for practical and noise-free transmission. The

LCD PANEL

GATE

DRIVERS

SOURCE

DRIVERS

LVDS

TRAN SMITTER

BU

LVDS

REC EIVER

TCON

VIDEO

PROCESS

TIMIN G

CONTR OL

large number of parallel lines to transmit the 8-bit RGB data would need to be sent on differential lines for noise

reduction. This would require 48 lines just for the video. The TCON circuit also requires B+, ground connections,

a communications bus, sync, and a clocking line transmitted differentially so we can see that up to 100 lines

would be required. The practical way to transmit this information is to convert the parallel video data to a serial

stream and this is accomplished by the Low-Voltage Differential Signaling (LVDS) transmitter.

The LVDS transmitter contains a circuit to serialize the parallel data. The parallel video information along with

sync and clocking data are transmitted via twisted line pairs. Depending on the logic level, current is sent along

one or the other of the twisted pair of wires. The receiving end of the wires is loaded with a resistor (usually

around 100 to 120 ohms). The receiver detects the polarity of the voltage drop across the resistor to determine

the logic level. The current level swings in the wire are about 3ma with a voltage differential of around 350mv.

This allows for transmission of the video signal with minimal EMI.

The LVDS receiver on the TCON board converts the serialized data back to parallel. This data is processed by

the timing control IC to allocate the RGB data into serial streams for processing by the LCD panel. The LCD

panel contains shift registers and drivers for all of the rows and columns of pixels on the panel. The drivers are

mounted on flexible circuit boards and bonded to the top and side of the panel. Without this arrangement the

TCON would require an IC and connectors to transmit on 4,560 lines!

All of this is accomplished by the TCON board. The term “TCON” is short for Timing Control. Other LCD panel

manufacturers may have a different name for this particular circuit but the term used by Sony will always be

TCON.

FIGURE 1

LCD PANEL VIDEO TIMING

Page 3

Diagnosing a Failed TCON

DEFEC TIVE

DRI VE IC

DEFEC TIVE

TAB BON D

OR DRIVE IC

DEFEC TIVE

TAB BON D

OR DRIVE IC

In order for this concept to move forward successfully, it is important that the service industry be able to properly

identify the symptoms of TCON issues to avoid unnecessary service calls and repair costs. Accurate analysis of

TCON failures will reduce costs significantly (both in parts costs and time) when warranty repairs are involved

and will reduce the number of COD repairs that are lost.

A good approach when determining a TCON failure is a good understanding of which symptoms ARE NOT

caused by the TCON. Examples are as follows:

Video Process Failures: All video inputs received by the video process circuits are handled on a frame-byframe basis. The video frames are converted and scaled to 8 or 10-bit RGB information. It is virtually impossible

for the video process circuits to cause a problem on a specific area of the screen. Failures on this board usually

appear as distortions, color level shifts, video level shifts or noise that involves the entire picture. The TCON can

generate symptoms that appear to be video process related but the video process circuits cannot produce the

symptoms of a failed TCON circuit.

LVDS Cable Failures: Although problems with the LVDS cable or connectors can generate symptoms of TCON

failures this usually tends to be intermittent and wiggling of the connectors will usually provoke a change in the

symptom on the screen. LVDS cables and connectors have become rather robust over the past few years and

most problems are caused by technicians who damage them and this is generally quite obvious upon close

examination.

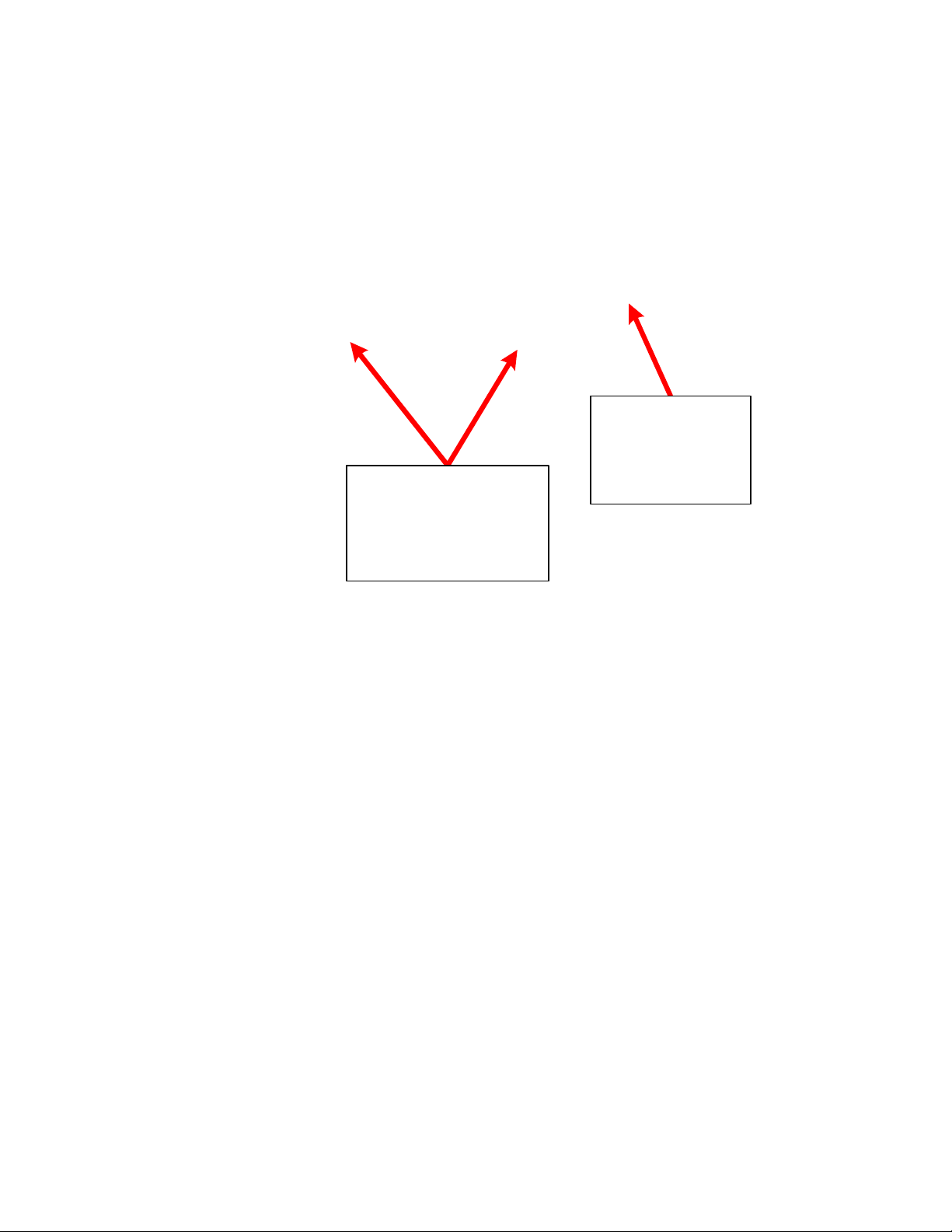

LCD Panel Failures: Some LCD panel failures could possibly be mistaken for TCON issues. Other than damage

to the LCD glass, most panel failures are isolated to a particular area of the screen. Since the TCON disperses

the pixel data to groups of line and column drive IC’s situated on the outer edges of the panel, it is unlikely that

more than one of these IC’s would fail at the same time. Multiple columns of stuck on or stuck off pixels are,

therefore, more likely to be the fault of the TCON circuits. The same applies to a single row of lit or unlit pixels.

The TCON simply cannot cut out a single line of information. Figure 2 illustrates some typical symptoms of

failures that are caused by the LCD panel.

FIGURE 2

LCD PANEL FAILURES

Page 4

TCON Failures

RELEASE TABS

Failures in the timing control circuits of the TCON can produce symptoms of absolutely no video or generate lines

and patterns that usually cover all or a substantial part of the screen. Determining if the TCON is the cause of a

“no video” condition is a bit more difficult since there are no indications on the screen to analyze.

Troubleshooting a “DEAD” TCON

Many of the Sony television models over the last few years will detect a TCON that has completely failed. The

communications data between the video process circuits and the TCON will cease to communicate if the TCON

fails completely. This will cause the television to shut down and display a diagnostics code indicating a failure of

the TCON. Not all chassis designs have this feature and it is not found on older models.

The typical scenario when this failure arises is for the technician to bring a video process board to the repair

location. It is usually safe to assume that the problem lies on the TCON board if the replacement video board

does not remedy the problem since it is highly unlikely that a replacement board with the same failure was

received.

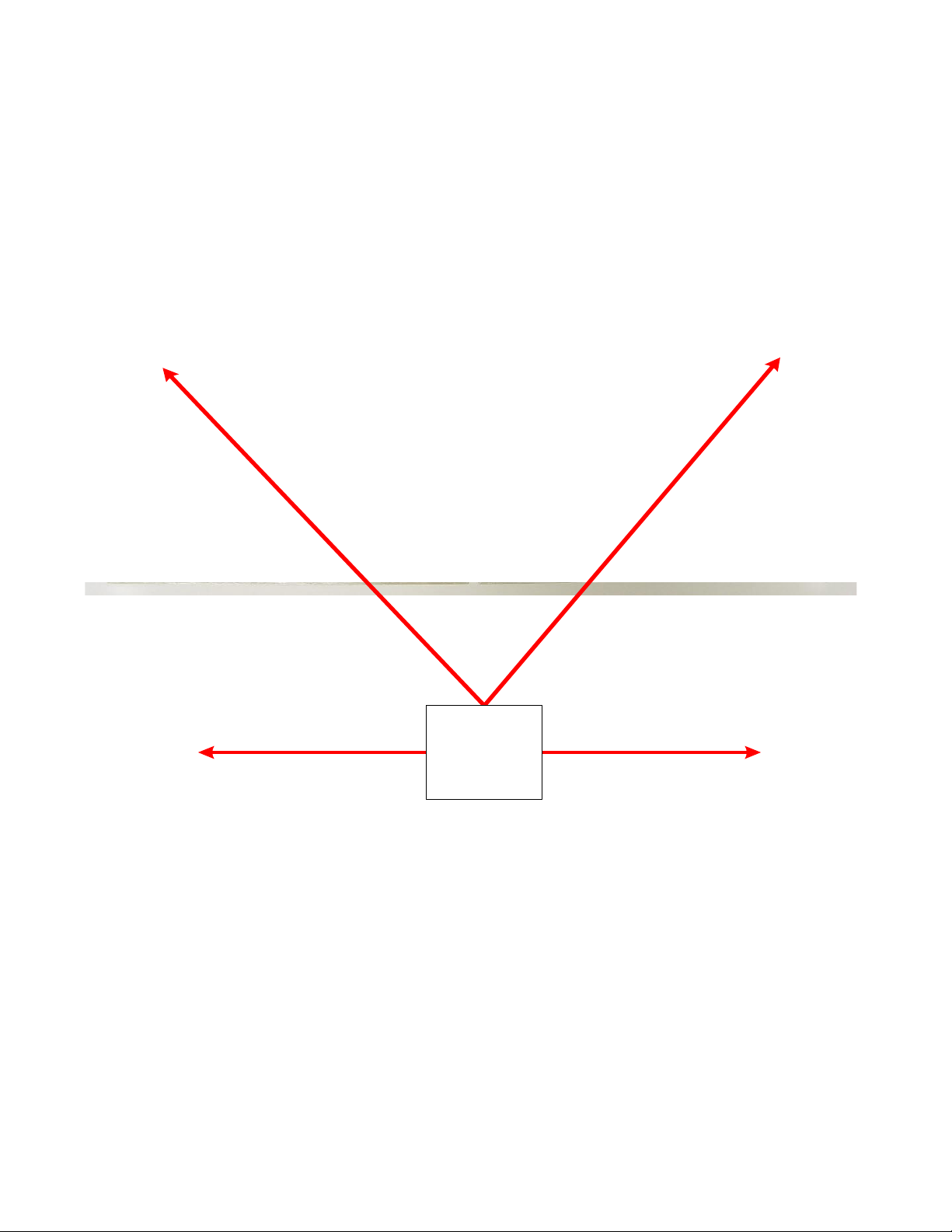

One trick to check most TCONS for functionality is to loosen the LVDS connector at the TCON (as shown In

Figure 3) while the unit is turned on. Handle the LVDS connector with care and be certain to fully release the lock

tabs. Gently rock the cable in and out of the connector while observing the screen for any response. Depending

on the chassis, the symptoms of the screen may be gentle white flashes, intermittent colored lines, or a screen

full of random patterns. The idea at this point is to provoke some kind of response on the screen. TCON boards

that have failed will not usually generate any type of response on the screen.

Another helpful procedure is to rapidly heat and/or cool the TCON with hot air devices or circuit coolant and

watch for patterns to appear on the screen.

EXAMPLES OF REACTIONS WHEN LVDS

CABLE IS PARTIALLY REMOVED

FIGURE 3

LVDS CONNECTOR

Page 5

Figure 4 illustrates 2 examples of a loss of control data to the drive IC’s. In the first example, an entire group of

DEFECTIVE

TCON DATA

OUTPUT

DEFECTIVE

TCON OR LOOSE

TCON TO PANEL

CONNECTING

CABLE

column drivers has lost the data stream for red. The second example involves the complete loss of drive data

for all RGB information to the right side of the screen. This is sometimes caused by the flat cable connecting the

TCON to the LCD panel coming loose. The area of missing video can be dark or completely white depending on

the panel design.

FIGURE 4

EXAMPLES OF TCON FAILURE SYMPTOMS

Page 6

The remaining illustrations show other TCON failures that have been encountered in the field. The idea is to get

a grasp of the concept of TCON induced failures to avoid unnecessary parts replacement.

SYMETRICAL PATTERN

OUTPUT FAILURE OF MULTIPLE DRIVERS

CORRUPTED UNIFORMITY ADJUSTMENT DATA

Page 7

TCON Replacement

REMOVE WIRE

HARNESS FROM

THIS RETAINER

REMOVE 6 MACHINE

SCREWS SECURING

POWER SUPPLY SUB-

C

H

ASSIS AND SWING

DOWNWARD

UNPLUG

CN6600

REMOVE

GROUND CLAMP

SCREW AND

UNPLUG LVDS

CONNECTOR

In many instances, replacement of the TCON board will be relatively straightforward. In some cases, other

boards may have to be loosened or removed to allow access to the mounting screws and clearance to remove

the TCON. The issue of most concern is keeping track of the heat transfer pads, standoffs and insulators. The

TCON is heavily shielded and it is easy to have one or more of these components accidentally fall out of the

assembly when removing.

TCON assemblies that use multiple heat transfer pads must be removed slowly and every attempt must be made

to keep the shield and circuit board together as they are removed from the unit. Check for any service bulletins

pertaining to the model and panel design that contain the subject line of “TCON heat transfer pad locations” for

pictures to show the proper location of these components.

In this example, the removal of the TCON board from a KDL40XBR6 is demonstrated. It serves as an excellent

example since it requires the partial removal of the power supply board along with containing 6 heat transfer

pads, 3 insulating pads, and 5 insulated standoff pads.

Referring to Figure 5, unplug the LVDS connector from the TCON. Remove the screw from the LVDS cable

ground strap so the cable can be moved away. Unplug CN6600 from the inverter board and remove the harness

from the retainer as shown. Remove the 6 black machine screws securing the g board sub-chassis to the panel.

Pull the top of the G board towards you and downward to allow access to the bottom screws securing the

TCON.

FIGURE 5

TCON REMOVAL PREPARATION

Page 8

Referring to Figure 6, carefully un-peel the conductive tape from the top bracket taking care not to tear them.

CAREFULLY PEEL THE

ADHESIVE FOIL SHIELDS

FROM THE TOP

BRACKET. REMOVE TOP

BRACKET.

TOP BRACKET

SECURED WITH 12

SILVER MACHINE

SCREWS

Leave the tape attached to the TCON shield. Remove the top bracket covering the gate and source driver

components. This will allow access to the upper flat cable connectors.

FIGURE 6

TCON REMOVAL PREPARATION (STEP 2)

Page 9

As illustrated in Figure 7, carefully lift the locking tabs securing the flat cables. Leave the flat cables attached to

CAREFULLY LIFT THE

LOCK CONNECTORS

AND REMOVE THE FLAT

CABLES. REMOVE THE

EIGHT SILVER MACHINE

SCREWS SECURING THE

TCON ASSEMBLY

the TCON. Remove the 8 silver machine screws securing the TCON and shield assembly. The TCON board has

an insulating pad between it and the LCD panel that will cause the board to stick. Not much effort is required to

release it. The goal at this point is to remove the board and shield together so as to avoid dropping heat transfer

pads and insulators located between the front of the board and the shield.

FIGURE 7

RELEASING THE FLAT CABLES

Page 10

If successful, both components should stay together as illustrated in Figure 8. Note the spacers mounted on the

TRY TO KEEP TCON

BOARD AND SHIELD

ASSEMBLY TOGETHER

WHEN REMOVING

OBSERVE FOR AN Y

INSULATING PADS

STUC K TO THE CHASSIS

AND NOTE THE

LOCATION

back side of the board. These will need to be transferred to the replacement board. In Figure 9, the insulating

pad can be observed sticking to the chassis.

FIGURE 8

TCON REMOVAL

FIGURE 9

INSULATING PAD STUCK TO CHASSIS

Page 11

Referring to Figure 10, the assembly is laid with the shield down on the work surface. Lift the circuit board upward

HEAT

TRANSFER

PADS

INSULATING

PADS

slowly while observing the location of the heat transfer and insulating pads. In most cases the heat transfer pads

will remain attached to their appropriate IC’s and the insulating pads will be stuck to the shield. If anything falls

off, use the illustration to return them to their proper position. Transfer all heat and insulating pads along with the

flat cables to the replacement board.

FIGURE 10

SEPARATE TCON FROM SHIELD

Page 12

Once the components have been transferred to the front of the circuit board, attach the shield and flip the

SPACER

PADS

CONDUCTIVE

SPACER

assembly over as shown in Figure 11.

Transfer any spacers or insulation pads to the replacement board.

FIGURE 11

TRANSFER SPACERS AND PADS

Page 13

TEMPORARILY

SECURE TCON

TO SHIELD

WITH

ELECTR ICAL

TAPE

Temporarily secure the TCON board to the shield with electrical tape as shown in Figure 12. This helps in

preventing movement of the circuit board while installing the assembly back onto the LCD panel.

Once the TCON assembly is secured to the panel, insert and lock the flat cables. Plug in all connectors and

secure the G board sub-chassis. Don’t forget about the wire harness that was removed from its retainer.

FIGURE 12

USING ELECTRICAL TAPE TO SECURE TCON TO SHIELD

TCON Part numbers

The following pages contain part numbers for the TCON boards currently available. Please note that some

models use more than one panel type and this is distinguished by the serial number of the unit. If the model is

not listed here, the TCON is not available.

Page 14

R

R

A

R

R

A

R

R

A

R

R

A

2008 US MODELS

KDL-26M4000

Serial Range

US: 4,000,001 - 4,200,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

US: 4,200,001 - 4,400,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

KDL-26M4000 (RED)

Serial Range

US: 4,420,001 - 4,425,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

US: 4,425,001 - 4,500,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

DESCRIPTION

DESCRIPTION

NA

KDL-26M4000 (TAN)

Serial Range

US: 4,410,001 - 4,415,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

US: 4,415,001 - 4,420,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

KDL-26M4000 (WHITE)

Serial Range

US: 4,400,001 - 4,405,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

US: 4,405,001 - 4,410,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

Page 15

2008 US MODELS

R

R

A

R

R

A

R

R

R

D

KDL-26N4000

Serial Range

US: 4,000,001 - 4,200,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

US: 4,200,001 - 4,500,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

KDL-26NL140

Serial Range

US: 4,000,001 - 4,200,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

US: 4,200,001 - 4,500,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

DESCRIPTION

DESCRIPTION

NA

KDL-32L4000 (US & Canada Models)

Serial Range

US: 6,000,001 - 6,280,000

PART NUMBE

1-802-699-12 LCD PANEL (32INCH WXGA TFT)

NA NA

Serial Range

US: 6,280,001 - 6,500,000

PART NUMBE

1-802-802-11 LCD PANEL (32INCH WXGA TFT)

NA NA

Serial Range

US & CND: 6,600,001 & UP

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 16

2008 US MODELS

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

KDL-32M4000

Serial Range

US: 4,000,001 - 4,100,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,100,001 - 4,200,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,200,001 - 4,400,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32M4000 (WHITE)

Serial Range

US: 4,400,001 - 4,403,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,403,001 - 4,406,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,406,001 - 4,410,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-32M4000 (TAN)

Serial Range

US: 4,410,001 - 4,415,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,415,001 - 4,418,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,418,001 - 4,420,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 17

2008 US MODELS

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

KDL-32M4000 (RED)

Serial Range

US: 4,420,001 - 4,425,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,425,001 - 4,440,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,440,001 - 4,500,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32N4000

Serial Range

US: 4,000,001 - 4,100,000

PART NUMBE

1-802-614-11 LCD PANEL(32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,100,001 - 4,200,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,200,001 - 4,500,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-32NL140

Serial Range

US: 4,000,001 - 4,100,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,100,001 - 4,200,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

US: 4,200,001 - 4,500,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 18

2008 US MODELS

R

D

R

D

R

R

D

R

R

D

R

D

R

KDL-37L4000 (US & CANADA MODELS)

Serial Range

US: 6,000,001 - 6,054,786

US: 6,059,937 - 6,100,000

PART NUMBE

1-802-622-11 LCD PANEL (37INCH WXGA TFT)

1-857-106-11 (TCON) CONTROL MT BOAR

Serial Range

US: 6,054,787 - 6,059,936

US: 6,100,001 - 6,500,000

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

KDL-37M4000

Serial Range

US: 8,000,001 - 8,200,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

US: 8,200,001 - 8,500,000

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-37N4000

Serial Range

US: 4,000,001 - 4,200,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

US: 4,200,001 - 4,500,000

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

KDL-37NL140

Serial Range

US: 4,000,001 - 4,200,000

US: 4,200,001 - 4,500,000

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

KDL-40M4000

Serial Range

ALL SERIAL RANGES

PART NUMBE

1-802-659-11 LCD PANEL (40INCH WXGA TFT)

1-857-107-11 (TCON) CONTROL MT BOARD

DESCRIPTION

Page 19

2008 US MODELS

R

R

R

R

R

R

R

R

KDL-40W4100

Serial Range

US: 8,000,001 - 8,200,000

PART NUMBE

1-802-674-11 LCD PANEL (40 FHD TFT)

1-857-130-11 (TCON) CONTROL MT BOARD

Serial Range

US: 8,200,001 - 8,400,000

PART NUMBE

1-802-793-11 LCD PANEL (40 FHD TFT)

1-857-317-11 (TCON) CONTROL MT BOARD

KDL-40WL140

Serial Range

US: 8,000,001 - 8,100,000

PART NUMBE

1-802-674-11 LCD PANEL (40 FHD TFT)

1-857-130-11 (TCON) CONTROL MT BOARD

Serial Range

US: 8,100,001 - 8,500,000

PART NUMBE

1-802-793-11 LCD PANEL (40 FHD TFT)

1-857-317-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-46W4100

Serial Range

US: 8,000,001 - 8,100,000

US: 9,000,001 - 9,100,000

PART NUMBE

1-802-673-11 LCD PANEL (46 FHD TFT)

1-857-131-11 (TCON) CONTROL MT BOARD

Serial Range

US: 8,100,001 - 8,300,000

US: 9,100,001 - 9,500,000

PART NUMBE

1-802-792-11 LCD PANEL (46 FHD TFT)

1-857-273-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

KDL-46W4150

Serial Range

US: 8,000,001 - 8,100,000

US: 9,000,001 - 9,100,000

PART NUMBE

1-802-673-11 LCD PANEL (46 FHD TFT)

1-857-131-11 (TCON) CONTROL MT BOARD

Serial Range

US: 8,100,001 - 8,500,000

US: 9,100,001 - 9,500,000

PART NUMBE

1-802-792-11 LCD PANEL (46 FHD TFT)

1-857-273-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

Page 20

2008 US MODELS

R

R

R

R

R

R

KDL-46WL140

Serial Range

US: 8,000,001 - 8,100,000

PART NUMBE

1-802-673-11 LCD PANEL (46 FHD TFT)

1-857-131-11 (TCON) CONTROL MT BOARD

Serial Range

US: 8,100,001 - 8,500,000

PART NUMBE

1-802-792-11 LCD PANEL (46 FHD TFT)

1-857-273-11 (TCON) CONTROL MT BOARD

KDL-52W4100

Serial Range

US: 8,000,001 - 8,100,000

US: 9,000,001 - 9,100,000

PART NUMBE

1-802-672-11 LCD PANEL (52 FHD TFT)

1-857-132-11 (TCON) CONTROL MT BOARD

Serial Range

US: 8,100,001 - 8,300,000

US: 9,100,001 - 9,500,000

PART NUMBE

1-802-791-11 LCD PANEL (52 FHD TFT)

1-857-240-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-52WL140

Serial Range

US: 8,000,001 - 8,100,000

PART NUMBE

1-802-672-11 LCD PANEL (52 FHD TFT)

1-857-132-11 (TCON) CONTROL MT BOARD

Serial Range

US: 8,100,001 - 8,500,000

PART NUMBE

1-802-791-11 LCD PANEL (52 FHD TFT)

1-857-240-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

Page 21

R

R

A

R

R

A

R

R

A

R

R

A

2008 CANADA MODELS

KDL-26M4000

Serial Range

CND: 4,500,001 - 4,505,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 4,505,001 - 4,540,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

KDL-26M4000 (RED)

Serial Range

CND: 4,560,001 - 4,565,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 4,565,001 - 4,570,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

DESCRIPTION

DESCRIPTION

NA

KDL-26M4000 (SILVER)

Serial Range

CND: 4,570,001 - 4,575,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 4,575,001 - 4,600,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

KDL-26M4000 (TAN)

Serial Range

CND: 4,550,001 - 4,555,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 4,555,001 - 4,650,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

Page 22

2008 CANADA MODELS

R

R

A

R

R

A

R

R

A

R

R

R

D

KDL-26M4000 (WHITE)

Serial Range

CND: 4,540,001 - 4,545,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 4,545,001 - 4,550,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

KDL-26N4000

Serial Range

CND: 4,500,001 - 4,600,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 4,600,001 & UP

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

DESCRIPTION

DESCRIPTION

NA

KDL-26NL140

Serial Range

CND: 4,500,001 - 4,600,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 4,600,001 & UP

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

KDL-32L4000 (US & Canada Models)

Serial Range

CND: 6,500,001 - 6,530,000

PART NUMBE

1-802-699-12 LCD PANEL (32INCH WXGA TFT)

NA NA

Serial Range

CND: 6,530,001 - 6,600,000

PART NUMBE

1-802-802-11 LCD PANEL (32INCH WXGA TFT)

NA NA

Serial Range

US & CND: 6,600,001 & UP

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 23

2008 CANADA MODELS

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

KDL-32M4000

Serial Range

CND: 4,500,001 - 4,530,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,530,001 - 4,560,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,560,001 - 4,570,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32M4000 (WHITE)

Serial Range

CND: 4,570,001 - 4,571,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,571,001 - 4,574,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,574,001 - 4,575,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-32M4000 (TAN)

Serial Range

CND: 4,575,001 - 4,576,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,576,001 - 4,578,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,578,001 - 4,580,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 24

2008 CANADA MODELS

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

KDL-32M4000 (RED)

Serial Range

CND: 4,580,001 - 4,581,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,581,001 - 4,584,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,584,001 - 4,585,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32M4000 (SILVER)

Serial Range

CND: 4,585,001 - 4,586,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,586,001 - 4,588,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,588,001 - 4,600,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-32N4000

Serial Range

CND: 4,500,001 - 4,600,000

PART NUMBE

1-802-614-11 LCD PANEL(32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,600,001 - 4,700,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,700,001 & UP

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 25

2008 CANADA MODELS

R

D

R

D

R

D

R

D

R

D

R

R

D

R

R

D

KDL-32NL140

Serial Range

CND: 4,500,001 - 4,600,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,600,001 - 4,700,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 4,700,001 - 4,800,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-37L4000 (US & CANADA MODELS)

Serial Range

CND: 6,500,001 - 6,600,000

PART NUMBE

1-802-622-11 LCD PANEL (37INCH WXGA TFT)

1-857-106-11 (TCON) CONTROL MT BOAR

Serial Range

CND: 6,600,001 & UP

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-37M4000

Serial Range

CND: 8,500,001 - 8,550,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

CND: 8,550,001 - 8,600,000

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

KDL-37N4000

Serial Range

CND: 4,500,001 - 4,600,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

CND: 4,600,001 & UP

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

Page 26

2008 CANADA MODELS

R

R

D

R

R

R

R

R

KDL-37NL140

Serial Range

CND: 4,500,001 - 4,600,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

CND: 4,600,001 & UP

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

KDL-40M4000

Serial Range

ALL SERIAL RANGES

PART NUMBE

1-802-659-11 LCD PANEL (40INCH WXGA TFT)

1-857-107-11 (TCON) CONTROL MT BOARD

KDL-40W4100

Serial Range

CND: 8,400,001 - 8,440,000

PART NUMBE

1-802-674-11 LCD PANEL (40 FHD TFT)

1-857-130-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 8,440,001 - 8,500,000

PART NUMBE

1-802-793-11 LCD PANEL (40 FHD TFT)

1-857-317-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-40WL140

Serial Range

CND: 8,500,001 - 8,550,000

PART NUMBE

1-802-674-11 LCD PANEL (40 FHD TFT)

1-857-130-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 8,550,001 & UP

PART NUMBE

1-802-793-11 LCD PANEL (40 FHD TFT)

1-857-317-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

Page 27

2008 CANADA MODELS

R

R

R

R

R

R

KDL-46W4100

Serial Range

CND: 8,300,001 - 8,330,000

CND: 9,500,001 - 9,600,000

PART NUMBE

1-802-673-11 LCD PANEL (46 FHD TFT)

1-857-131-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 8,330,001 - 8,400,000

CND: 9,600,001 & UP

PART NUMBE

1-802-792-11 LCD PANEL (46 FHD TFT)

1-857-273-11 (TCON) CONTROL MT BOARD

KDL-46W4150

Serial Range

CND: 8,500,001 - 8,600,000

CND: 9,500,001 - 9,600,000

PART NUMBE

1-802-673-11 LCD PANEL (46 FHD TFT)

1-857-131-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 8,600,001 - 9,000,000

CND: 9,600,001 & UP

PART NUMBE

1-802-792-11 LCD PANEL (46 FHD TFT)

1-857-273-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-46WL140

Serial Range

CND: 8,500,001 - 8,600,000

PART NUMBE

1-802-673-11 LCD PANEL (46 FHD TFT)

1-857-131-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 8,600,001 - 8,700,000

PART NUMBE

1-802-792-11 LCD PANEL (46 FHD TFT)

1-857-273-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

Page 28

2008 CANADA MODELS

R

R

R

R

KDL-52W4100

Serial Range

CND: 9,500,001 - ,9,600,000

PART NUMBE

1-802-672-11 LCD PANEL (52 FHD TFT)

1-857-132-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 9,600,001 - ,9,800,000

PART NUMBE

1-802-791-11 LCD PANEL (52 FHD TFT)

1-857-240-11 (TCON) CONTROL MT BOARD

KDL-52WL140

Serial Range

CND: 8,500,001 - 8,600,000

PART NUMBE

1-802-672-11 LCD PANEL (52 FHD TFT)

1-857-132-11 (TCON) CONTROL MT BOARD

Serial Range

CND: 8,600,001 & UP

PART NUMBE

1-802-791-11 LCD PANEL (52 FHD TFT)

1-857-240-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 29

R

R

A

R

R

A

R

R

A

R

R

A

2008 MEXICO MODELS

KDL-26FA400

Serial Range

MX: 4,000,001 - 4,100,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

MX: 4,100,001 - 4,500,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

KDL-26M4000

Serial Range

MX: 4,800,001 - 4,810,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

MX: 4,810,001 - 4,840,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

DESCRIPTION

DESCRIPTION

NA

KDL-26M4000 (RED)

Serial Range

MX: 4,860,001 - 4,865,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

MX: 4,865,001 - 4,870,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

KDL-26M4000 (SILVER)

Serial Range

MX: 4,870,001 - 4,875,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

MX: 4,875,001 - 4,900,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

Page 30

2008 MEXICO MODELS

R

R

A

R

R

A

R

D

R

D

R

D

R

D

R

D

KDL-26M4000 (TAN)

Serial Range

MX: 4,850,001 - 4,855,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

MX: 4,855,001 - 4,860,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

KDL-26M4000 (WHITE)

Serial Range

MX: 4,840,001 - 4,845,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

MX: 4,845,001 - 4,850,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

DESCRIPTION

DESCRIPTION

NA

KDL-32FA400

Serial Range

MX: 4,000,001 - 4,100,000

PART NUMBE

1-802-614-11 LCD PANEL(32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,100,001 - 4,200,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,200,001 - 4,500,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-32L4000 (South America Models)

Serial Range

MX: 4,000,001 - 4,100,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,100,001 - 4,500,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

Page 31

2008 MEXICO MODELS

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

KDL-32M4000

Serial Range

MX: 4,800,001 - 4,830,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,830,001 - 4,860,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,860,001 - 4,890,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32M4000 (WHITE)

Serial Range

MX: 4,890,001 - 4,891,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,891,001 - 4,894,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,894,001 - 4,895,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-32M4000 (TAN)

Serial Range

MX: 4,895,001 - 4,896,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,896,001 - 4,898,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,898,001 - 4,900,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 32

2008 MEXICO MODELS

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

R

D

KDL-32M4000 (RED)

Serial Range

MX: 4,700,001 - 4,703,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,703,001 - 4,705,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,707,001 - 4,708,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32M4000 (SILVER)

Serial Range

MX: 4,705,001 - 4,706,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,706,001 - 4,707,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,708,001 - 4,800,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-32NL140

Serial Range

MX: 4,800,001 - 4,850,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,850,001 - 4,900,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

MX: 4,900,001 & UP

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 33

2008 MEXICO MODELS

R

R

D

R

D

R

R

D

R

R

D

KDL-37FA400

Serial Range

MX: 4,000,001 - 4,200,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

MX: 4,200,001 - 4,500,000

Chile/Peru: 4,900,001 & UP

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

KDL-37L4000 (SOUTH AMERICA MODELS)

Serial Range

MX: 4,000,001 - 4,500,000

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

KDL-37M4000

Serial Range

MX: 8,800,001 - 8,850,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

MX: 8,850,001 - 8,900,000

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-37NL140

Serial Range

US: 4,000,001 - 4,200,000

CND: 4,500,001 - 4,600,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

US: 4,200,001 - 4,500,000

CND: 4,600,001 & UP

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

Page 34

2008 MEXICO MODELS

R

R

R

R

R

R

R

KDL-40M4000

Serial Range

ALL SERIAL RANGES

PART NUMBE

1-802-659-11 LCD PANEL (40INCH WXGA TFT)

1-857-107-11 (TCON) CONTROL MT BOARD

KDL-40W4100

Serial Range

MX/LA: 8,500,001 - 8,600,000

PART NUMBE

1-802-674-11 LCD PANEL (40 FHD TFT)

1-857-130-11 (TCON) CONTROL MT BOARD

Serial Range

MX/LA: 8,600,001 & UP

PART NUMBE

1-802-793-11 LCD PANEL (40 FHD TFT)

1-857-317-11 (TCON) CONTROL MT BOARD

KDL-46W4100

Serial Range

MX/LA: 8,400,001 - 8,500,000

PART NUMBE

1-802-673-11 LCD PANEL (46 FHD TFT)

1-857-131-11 (TCON) CONTROL MT BOARD

Serial Range

MX: 8,500,001 - 9,000,000

PART NUMBE

1-802-792-11 LCD PANEL (46 FHD TFT)

1-857-273-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-52W4100

Serial Range

MX/LA: 8,400,001 - 8,500,000

MX/LA: 9,800,001 - 9,900,000

PART NUMBE

1-802-672-11 LCD PANEL (52 FHD TFT)

1-857-132-11 (TCON) CONTROL MT BOARD

Serial Range

MX/LA: 8,500,001 - 9,000,000

MX/LA: 9,900,001 & UP

PART NUMBE

1-802-791-11 LCD PANEL (52 FHD TFT)

1-857-240-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

Page 35

R

R

A

R

R

A

R

R

A

2008 LATIN AMERICA MODELS

KDL-26FA400

Serial Range

LA: 4,500,001 - 4,600,000

Chile/Peru: 4,800,001 - 4,900,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

LA: 4,600,001 - 4,800,000

Chile/Peru: 4,900,001 & UP

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

KDL-26M4000

Serial Range

LA: 4,600,001 - 4,610,000

Chile/Peru: 4,900,001 - 4,905,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

LA: 4,610,001 - 4,640,000

Chile/Peru: 4,905,001 - 4,950,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

DESCRIPTION

DESCRIPTION

NA

KDL-26M4000 (RED)

Serial Range

LA: 4,660,001 - 4,665,000

Chile/Peru: 4,960,001 - 4,965,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

LA: 4,665,001 - 4,670,000

Chile/Peru: 4,965,001 - 4,970,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

Page 36

2008 LATIN AMERICA MODELS

R

R

A

R

R

A

R

R

A

KDL-26M4000 (SILVER)

Serial Range

LA: 4,670,001 - 4,675,000

Chile/Peru: 4,980,001 - 4,985,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

LA: 4,675,001 - 4,800,000

Chile/Peru: 4,985,001 & UP

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

KDL-26M4000 (TAN)

Serial Range

LA: 4,650,001 - 4,655,000

Chile/Peru: 4,970,001 - 4,975,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

LA: 4,655,001 - 4,660,000

Chile/Peru: 4,975,001 - 4,980,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

DESCRIPTION

DESCRIPTION

NA

KDL-26M4000 (WHITE)

Serial Range

LA: 4,640,001 - 4,645,000

Chile/Peru: 4,950,001 - 4,955,000

PART NUMBE

1-802-613-11 LCD PANEL (26INCH WXGA TFT)

1-857-072-11 (TCON) CONTROL MT BOARD

Serial Range

LA: 4,645,001 - 4,650,000

Chile/Peru: 4,955,001 - 4,960,000

PART NUMBE

1-802-754-11 LCD PANEL (26INCH WXGA TFT)

N

DESCRIPTION

DESCRIPTION

NA

Page 37

2008 LATIN AMERICA MODELS

R

D

R

D

R

D

R

D

R

D

KDL-32FA400

Serial Range

LN: 4,500,001 - 4,600,000

Chile/Peru: 4,800,001 - 4,850,000

PART NUMBE

1-802-614-11 LCD PANEL(32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

LN: 4,600,001 - 4,700,000

Chile/Peru: 4,850,001 - 4,900,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

LN: 4,700,001 - 4,800,000

Chile/Peru: 4,900,001 & UP

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32L4000 (South America Models)

Serial Range

LA: 4,500,001 - 4,600,000

Chile/Peru: 4,800,001 - 4,850,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,600,001 - 4,800,000

Chile/Peru: 4,850,001 & UP

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 38

2008 LATIN AMERICA MODELS

R

D

R

D

R

D

R

D

R

D

R

D

KDL-32M4000

Serial Range

LA: 4,600,001 - 4,630,000

Chile/Peru: 4,900,001 - 4,920,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,630,001 - 4,660,000

Chile/Peru: 4,920,001 - 4,940,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,660,001 - 4,680,000

Chile/Peru: 4,940,001 - 4,950,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32M4000 (WHITE)

Serial Range

LA: 4,680,001 - 4,681,000

Chile/Peru: 4,950,001 - 4,953,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,681,001 - 4,684,000

Chile/Peru: 4,953,001 - 4,958,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,684,001 - 4,685,000

Chile/Peru: 4,958,001 - 4,960,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 39

2008 LATIN AMERICA MODELS

R

D

R

D

R

D

R

D

R

D

R

D

KDL-32M4000 (TAN)

Serial Range

LA: 4,685,001 - 4,686,000

Chile/Peru: 4,970,001 - 4,971,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,686,001 - 4,688,000

Chile/Peru: 4,971,001 - 4,974,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,688,001 - 4,690,000

Chile/Peru: 4,974,001 - 4,985,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-32M4000 (RED)

Serial Range

LA: 4,690,001 - 4,691,000

Chile/Peru: 4,960,001 - 4,963,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,691,001 - 4,694,000

Chile/Peru: 4,963,001 - 4,966,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,694,001 - 4,695,000

Chile/Peru: 4,966,001 - 4,970,000

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

Page 40

2008 LATIN AMERICA MODELS

R

D

R

D

R

D

R

R

D

R

D

KDL-32M4000 (SILVER)

Serial Range

LA: 4,695,001 - 4,696,000

Chile/Peru: 4,980,001 - 4,985,000

PART NUMBE

1-802-614-11 LCD PANEL (32INCH WXGA TFT)

1-857-137-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,696,001 - 4,698,000

Chile/Peru: 4,985,001 - 4,990,000

PART NUMBE

1-802-805-11 LCD PANEL (32INCH WXGA TFT)

1-857-214-11 (TCON) CONTROL MT BOAR

Serial Range

LA: 4,698,001 - 4,700,000

Chile/Peru: 4,990,001 & UP

PART NUMBE

1-802-755-11 LCD PANEL (32INCH WXGA TFT)

1-857-213-11 (TCON) CONTROL MT BOAR

KDL-37FA400

Serial Range

LN: 4,500,001 - 4,600,000

Chile/Peru: 4,800,001 - 4,900,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

LN: 4,600,001 - 4,800,000

Chile/Peru: 4,900,001 & UP

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-37L4000 (SOUTH AMERICA MODELS)

Serial Range

LA: 4,500,001 - 4,800,000

Chile/Peru: 4,800,001 & UP

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

DESCRIPTION

Page 41

2008 LATIN AMERICA MODELS

R

R

D

R

R

R

R

R

KDL-37M4000

Serial Range

LA: 8,600,001 - 8,650,000

Chile/Peru: 8,900,001 - 8,950,000

PART NUMBE

NLA LCD PANEL (37INCH WXGA TFT)

NA NA

Serial Range

LA: 8,650,001 - 8,800,000

Chile/Peru: 8,950,001 & UP

PART NUMBE

1-802-753-11 LCD PANEL (37INCH WXGA TFT)

1-857-216-11 (TCON) CONTROL MT BOAR

KDL-40M4000

Serial Range

ALL SERIAL RANGES

PART NUMBE

1-802-659-11 LCD PANEL (40INCH WXGA TFT)

1-857-107-11 (TCON) CONTROL MT BOARD

KDL-40W4100

Serial Range

MX/LA: 8,500,001 - 8,600,000

PART NUMBE

1-802-674-11 LCD PANEL (40 FHD TFT)

1-857-130-11 (TCON) CONTROL MT BOARD

Serial Range

MX/LA: 8,600,001 & UP

PART NUMBE

1-802-793-11 LCD PANEL (40 FHD TFT)

1-857-317-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-46W4100

Serial Range

MX/LA: 8,400,001 - 8,500,000

PART NUMBE

1-802-673-11 LCD PANEL (46 FHD TFT)

1-857-131-11 (TCON) CONTROL MT BOARD

Serial Range

MX: 8,500,001 - 9,000,000

PART NUMBE

1-802-792-11 LCD PANEL (46 FHD TFT)

1-857-273-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

Page 42

2008 LATIN AMERICA MODELS

R

R

KDL-52W4100

Serial Range

MX/LA: 8,400,001 - 8,500,000

MX/LA: 9,800,001 - 9,900,000

PART NUMBE

1-802-672-11 LCD PANEL (52 FHD TFT)

1-857-132-11 (TCON) CONTROL MT BOARD

Serial Range

MX/LA: 8,500,001 - 9,000,000

MX/LA: 9,900,001 & UP

PART NUMBE

1-802-791-11 LCD PANEL (52 FHD TFT)

1-857-240-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

Page 43

R

R

R

R

R

R

R

R

R

R

2007 MODELS

KDL-32XBR4

PART NUMBE

1-802-411-11/12 LCD Panel (32INCH WXGA TFT)

1-789-796-12 (TCON) CONTROL MT BOARD

DESCRIPTION

KDL-40D3000

PART NUMBE

1-802-414-11 LCD Panel (40INCH WXGA TFT)

1-789-797-11 (TCON) CONTROL MT BOARD

DESCRIPTION

2006 MODELS

KDL-26S2000

PART NUMBE

1-802-061-13 LCD Panel (26WXGA+TFT)

1-789-506-12 (TCON) CONTROL MT BOARD

KDL-26S2010

PART NUMBE

1-802-061-13 LCD Panel (26WXGA+TFT)

1-789-506-12 (TCON) CONTROL MT BOARD

KDL-32S2000

PART NUMBE

1-802-060-12 LCD Panel (32WXGA+TFT)

1-789-503-13 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-32S2010

PART NUMBE

1-802-060-13/14 LCD Panel (32WXGA+TFT)

1-789-503-13 (TCON) CONTROL MT BOARD

DESCRIPTION

KDL-32S20L1

PART NUMBE

1-802-060-12 LCD Panel (32WXGA+TFT)

1-789-503-13 (TCON) CONTROL MT BOARD

DESCRIPTION

KDL-32S2400

PART NUMBE

1-802-060-14 LCD Panel (32WXGA+TFT)

1-789-503-13 (TCON) CONTROL MT BOARD

DESCRIPTION

KDL-V32XBR2

PART NUMBE

1-802-135-22 LCD Panel (32INCH FHD TFT)

1-789-503-13 (TCON) CONTROL MT BOARD

DESCRIPTION

KDL-40S2000

PART NUMBE

1-802-059-11 LCD Panel (40WXGA+TFT)

1-789-499-11 (TCON) CONTROL MT BOARD

DESCRIPTION

Page 44

2006 MODELS

R

R

R

R

R

R

R

R

KDL-40S2010

PART NUMBE

1-802-059-11 LCD Panel (40WXGA+TFT)

1-789-499-11 (TCON) CONTROL MT BOARD

KDL-40S20L1

PART NUMBE

1-802-059-11 LCD Panel (40WXGA+TFT)

1-789-499-11 (TCON) CONTROL MT BOARD

KDL-40S2400

PART NUMBE

1-802-059-11 LCD Panel (40WXGA+TFT)

1-789-499-11 (TCON) CONTROL MT BOARD

KDL-40V2500

PART NUMBE

1-802-184-11/13 LCD Panel (40INCH FHD TFT)

1-789-705-11 (TCON) CONTROL MT BOARD

KDL-46S2000

PART NUMBE

1-802-100-31 LCD Panel (40WXGA+TFT)

1-789-619-11 (TCON) CONTROL MT BOARD

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

DESCRIPTION

KDL-46S2010

PART NUMBE

1-802-100-31 LCD Panel (40WXGA+TFT)

1-789-619-11 (TCON) CONTROL MT BOARD

DESCRIPTION

KDL-46V2500

PART NUMBE

Serial range not available

1-802-552-12 LCD Panel (46INCH FHD TFT) LTZ460HA04-101

1-789-924-12 (TCON) CONTROL MT BOARD

Serial range not available

1-802-183-12 LCD Panel (46INCH FHD TFT) LTY460HS-LH3-001

1-789-703-11 (TCON) CONTROL MT BOARD

DESCRIPTION

KDL-46V25L1

PART NUMBE

Serial range not available

1-802-552-12 LCD Panel (46INCH FHD TFT)

1-789-924-12 (TCON) CONTROL MT BOARD

Serial range not available

1-802-183-12 LCD Panel (46INCH FHD TFT) LTY460HS-LH3-001

1-789-703-11 (TCON) CONTROL MT BOARD

DESCRIPTION

Loading...

Loading...