Sony TCM-900-DV Service manual

TCM-900DV

SERVICE MANUAL

Ver 1.0 2001.02

SPECIFICATIONS

US Model

Canadian Model

AEP Model

Tourist Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MT-900-175

Recording system

2-track 1 channel monaural

Tape speed

4.8 cm/s or 2.4 cm/s

Frequency range

150 - 6 300 Hz using nomal (TYPEI) cassette

(with REC TIME switc hat “NORMAL”)

Speaker

Approx. 3.6 cm (1 7/16 in.) dia.

Power output

250 mW (at 10 % harmonicdistortion)

Input

Microphone input jack (minijack)

sensitivity 0.12 mV for 3 kilohms or lower impedance

microphone

Output

Earphone jack (minijack) for 8 -300 ohms earphone

Variable range of the tape speed

From approx. +100% to –50% (with

REC TIME switch at “NORMAL”)

From approx. +100% to –30% (with

REC TIME switch at “DOUBLE”)

Variable range of pitch control variation

Approx. +1 octave to –1 octave

Power requirements

3 V DC batteries R6 (AA) x 2

External DC 3 V power sources

Dimensions (w/h/d) (incl. projecting

parts and controls)

Approx. 86.7 x 112.8 x 35.7 mm

(3 1/2 X 4 1/2 X 1 7/16 in.)

Mass

Approx. 200g (7.1 oz.)

Supplied accessories

Headphones with remote control (1)

R6 (size AA) batteries (2)

(“Sony World Model” only)

Carrying pouch (1)

Design and specifications are subject

to change without notice.

9-873-082-11

2001B0200-1

© 2001.2

CASSETTE-CORDER

Sony Corporation

Audio Entertainment Group

General Engineering Dept.

TCM-900DV

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. GENERAL

Location of Parts and Controls .......................................... 2

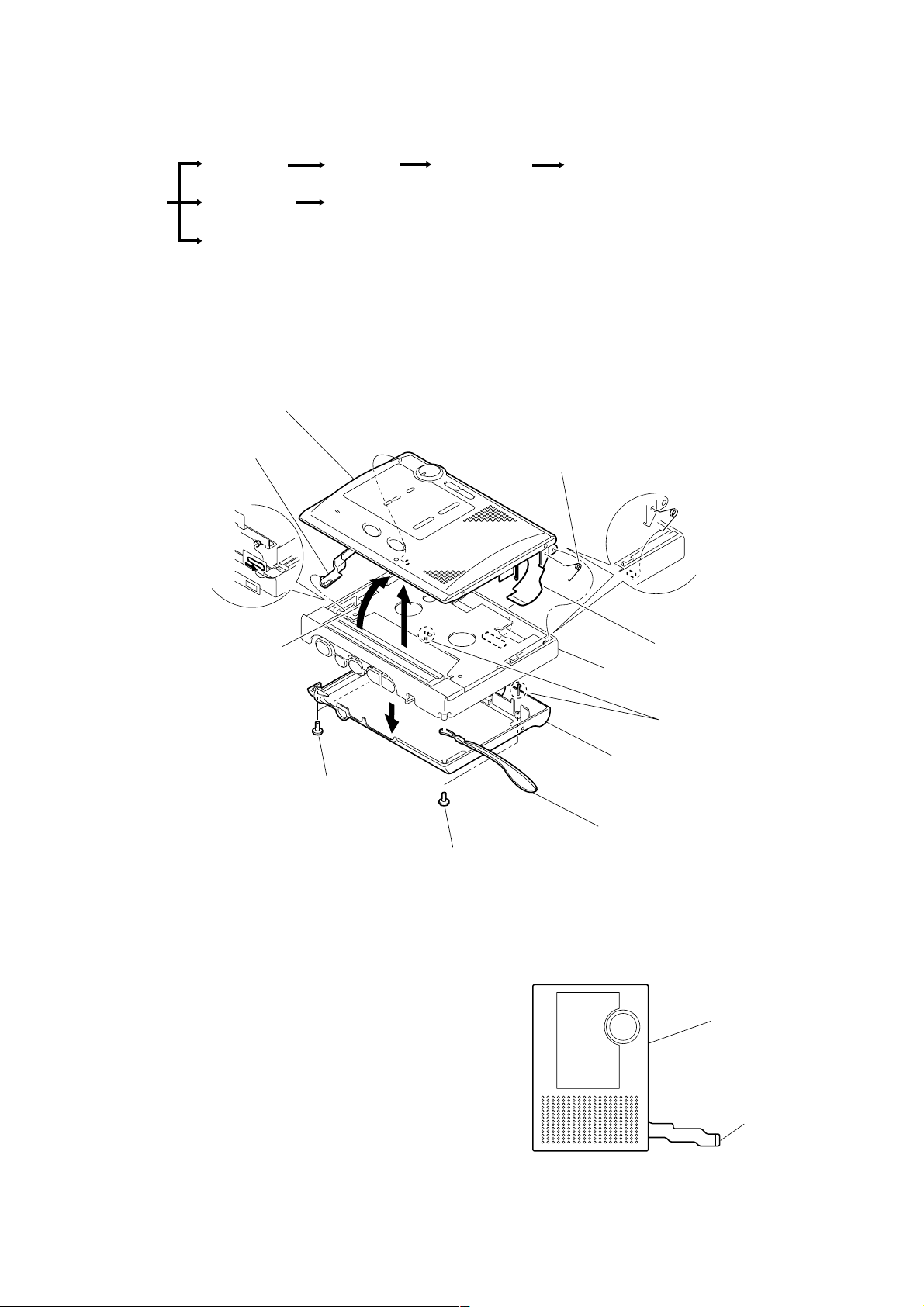

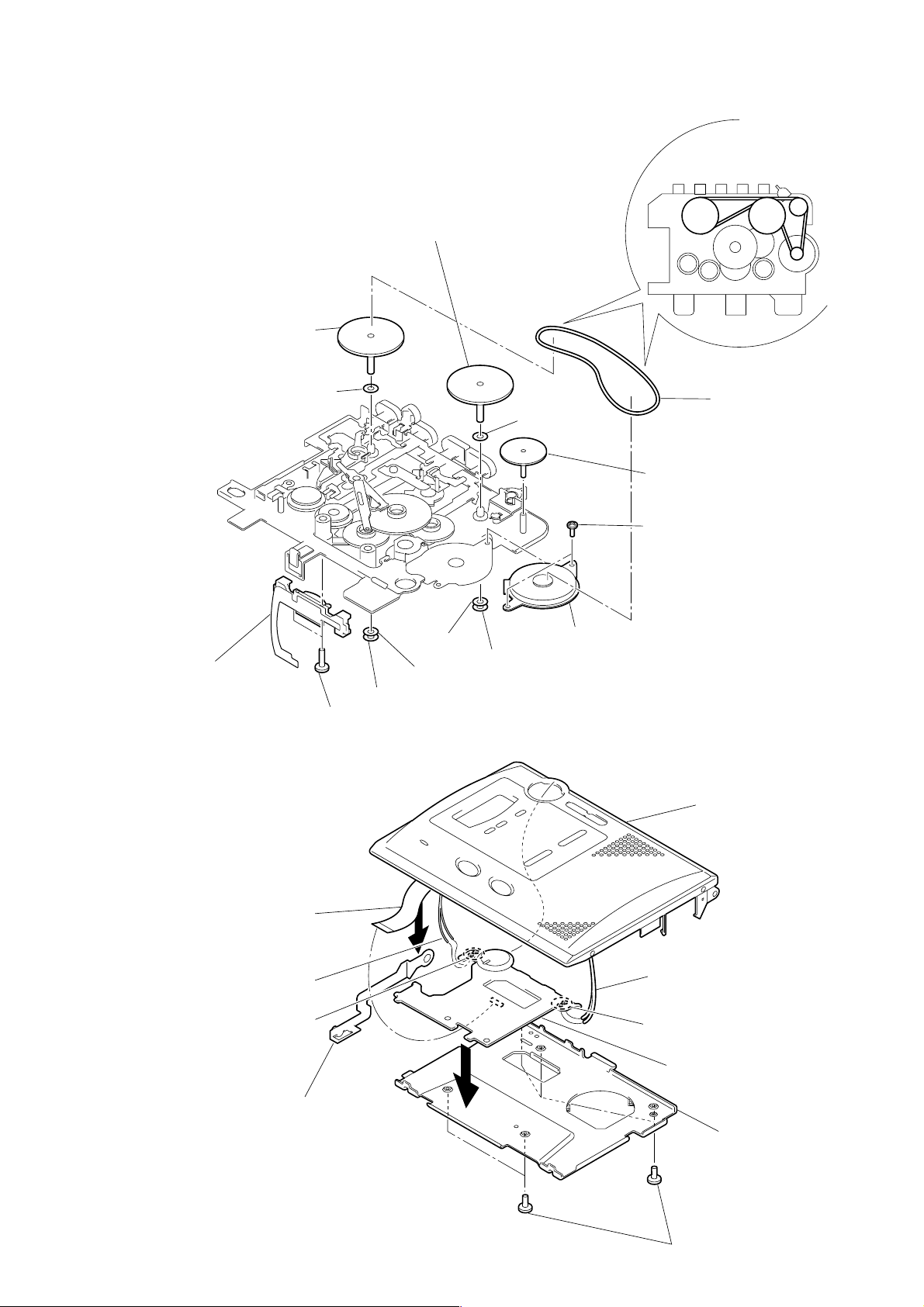

2. DISASSEMBLY

2-1. Cabinet (Rear), Cassette Lid ASSY............................ 3

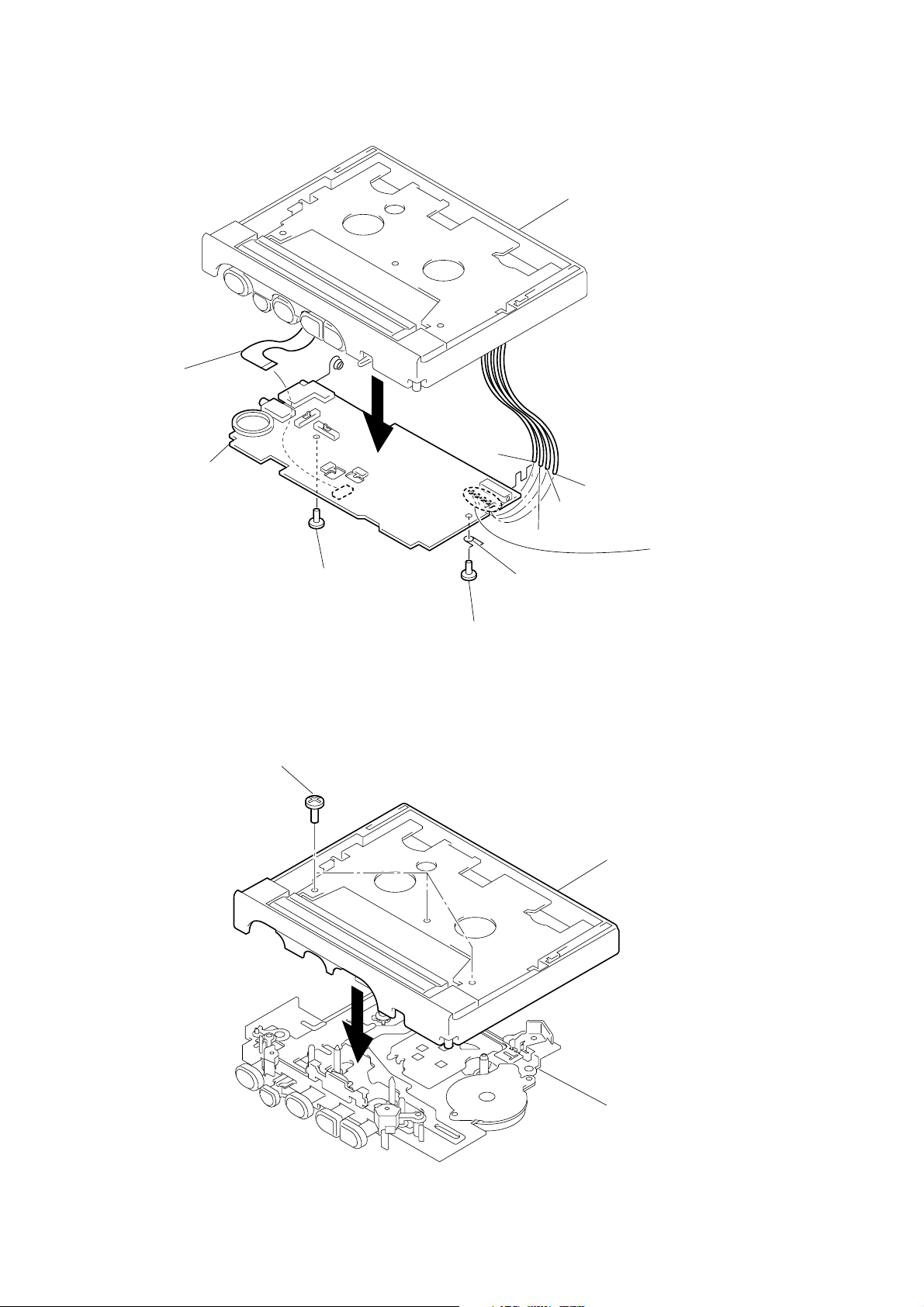

2-2. Main Board ................................................................. 4

2-3. Mechanism Deck ........................................................ 4

2-4. Belt (AR), M601 (Capstan/reel motor),

HRPE901 (REC/PB/ERASE head) ........................... 5

2-5. SW Board ................................................................... 5

3. ADJUSTMENTS

3-1. Mechanical Adjustments............................................. 6

3-2. Electrical Adjustments ................................................ 6

4. DIAGRAMS

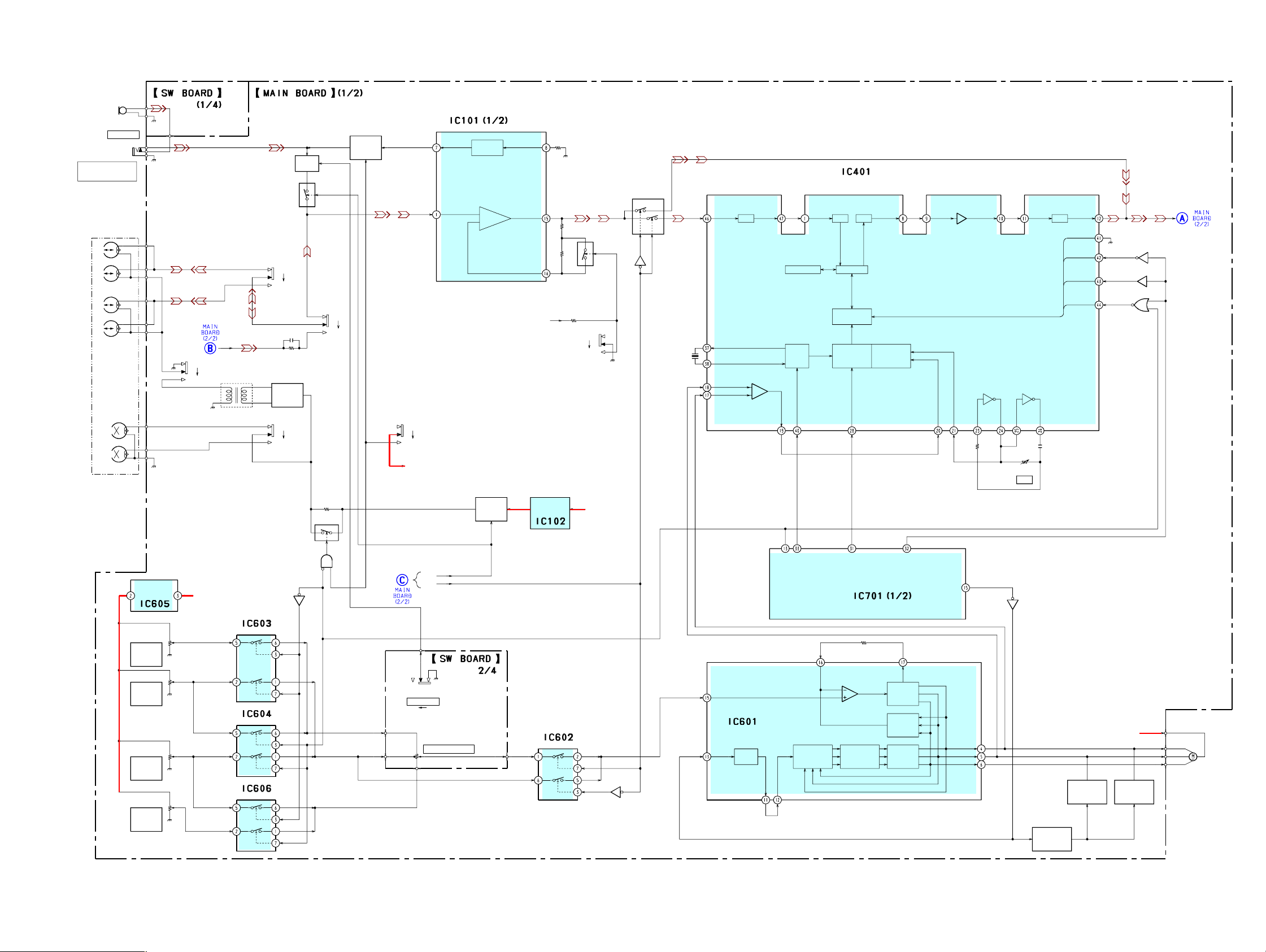

4-1. Block Diagrams -Main Section (1/2) - ....................... 9

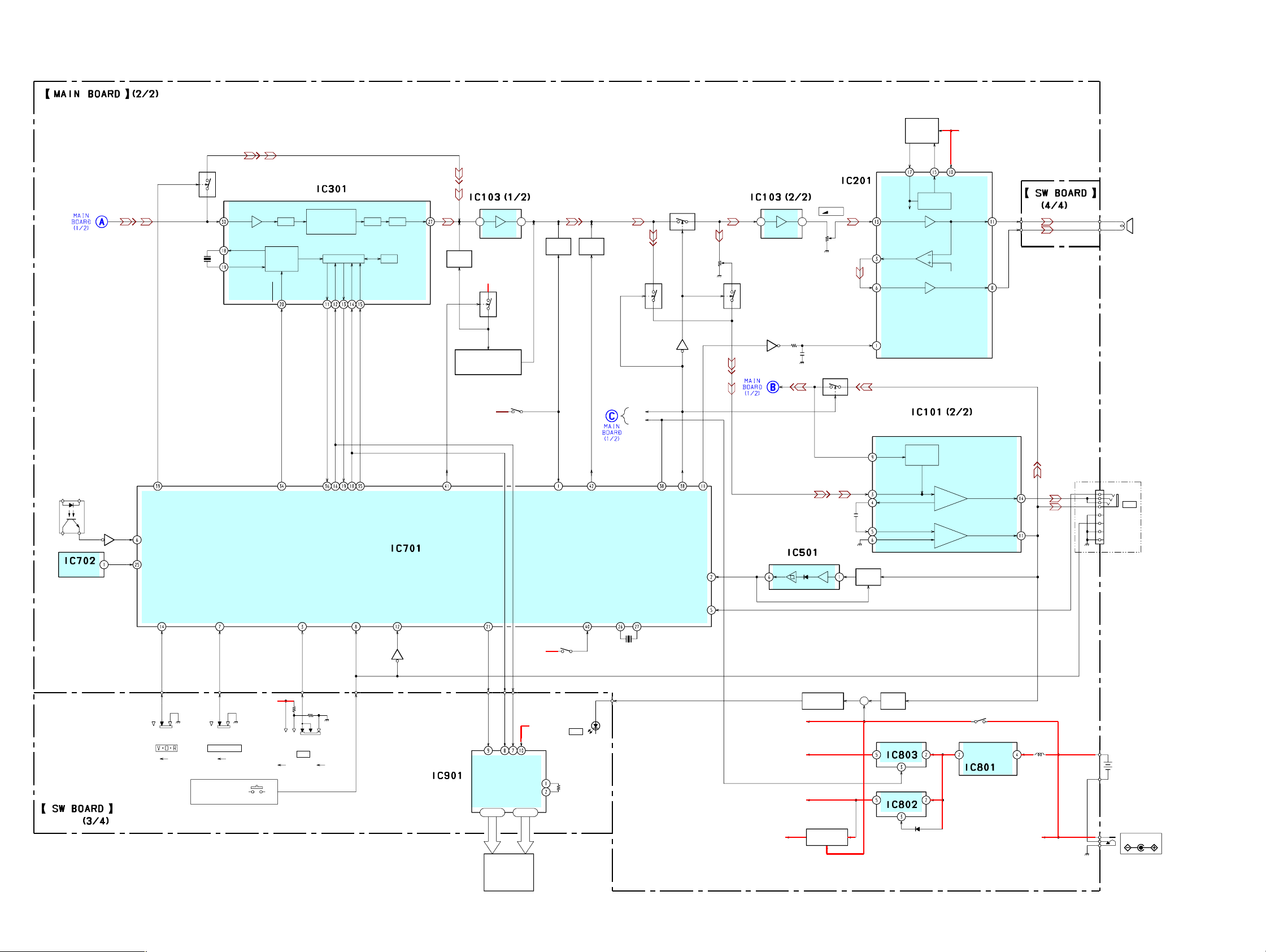

4-2. Block Diagrams -Main Section (2/2) - ..................... 10

4-3. Schematic Diagram - Main Section (1/3) - ................ 11

4-4. Schematic Diagram - Main Section (2/3) - ............... 12

4-5. Schematic Diagram - Main Section (3/3) - ............... 13

4-6.Printed Wiring Boards -Main Section (side A)- ........ 14

4-7.Printed Wiring Boards -Main Section (side B)- ........ 15

4-8.Printed Wiring Boards -SW Section (side A)- ........... 16

4-9.Printed Wiring Boards -SW Section (side B)- .......... 17

4-10.Schematic Diagram - SW Section - ......................... 18

4-11.Explanation of IC Terminals .................................... 19

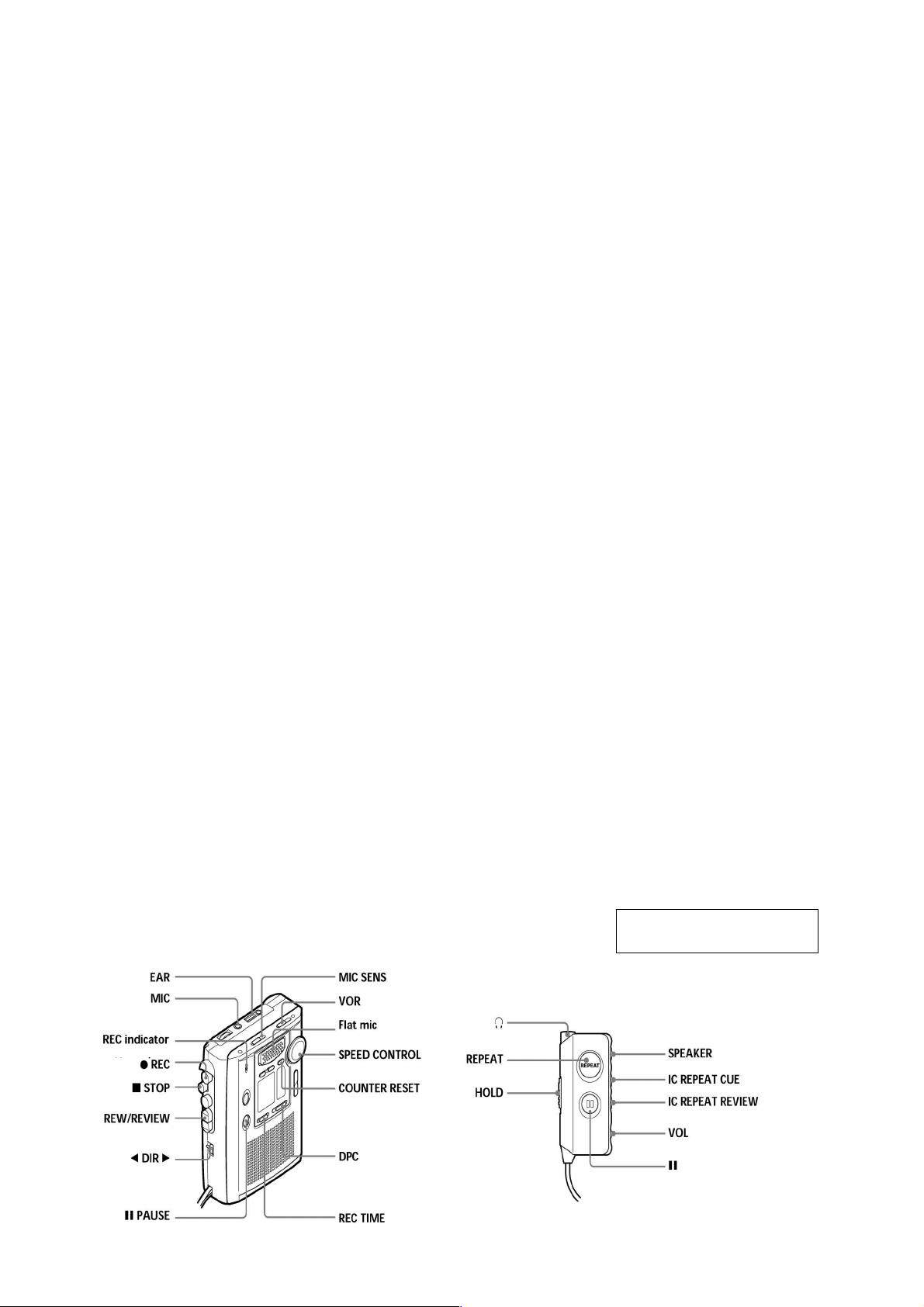

Location of parts and controls

5. EXPLODED VIEWS

5-1. Main Board, Cabinet (Rear) section ......................... 22

5-2. Cassette Lid Section ................................................. 23

5-3. Mechanism deck Section -1(MT-900-175) ............... 24

5-4. Mechanism deck Section -2 (MT-900-175) .............. 25

6. ELECTRICAL PARTS LIST ................................ 26

SECTION 1

GENERAL

This section is extracted from

instruction manual.

2

SECTION 2

)

d

DISASSEMBLY

• The equipment can be removed using the following procedure.

TCM-900DV

Set

Cabinet (front)

Cassette lid assy

Main board

SW board

Mechanism deck

Cabinet (Rear)

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (REAR), CASSETTE LID ASSY

Cassette lid assy

Lever ASSY, FWD return

7Slide the projection

of "lever ASSY, FWD

return" fully in the

arrow direction and

remove it.

Belt (AR), M601 (Capstan/reel motor),

HRPE901 (REC/PB/ERASE head)

8Spring (toggle)

Note on installing the

cassette lid assy

Install the cassette lid assy with

the spring(toggle) as shown in

the figure so that it fits into the

holes on the cassette lid assy.

5Open

2Screws (+B1.7X 9)

9

4

1Screws (+B1.7X 9)

6SW flexible board (Main board:CN901

Cabinet (front)

3Claws

Cabinet (Rear)

Hand strap

Note on installing the SW flexible board

Insert the SW flexible board as shown

in the figure.

Cassette lid ASSY

SW flexible boar

3

TCM-900DV

)

k

2-2. MAIN BOARD

2Flexible board

( from HPR901/HE901)

Cabinet (front)

6

Main board

2-3. MECHANISM DECK

1Screws ( IB LOCK )

5Screws (M1.4)

Red

Black

Orange

White

1Remove soldering

four lead wires (from M601

4Spring, ground

3Screw

Cabinet (front)

2

Mechanism dec

( MT-900-175)

4

2-4. BELT (AR), M601 (CAPSTAN/REEL MOTOR),

d

HRPE901 (REC/PB/ERASE head)

7Fly ASSY,Capstan

7Fly ASSY,Capstan

z

Attaching belt (AR)

TCM-900DV

0HRPE901

(REC/PB/ERASE head)

2-5. SW BOARD

8Washer

9Screws (M1.4)

6Washer

5Washer (stopper N)

6Washer

5Washer (stopper N)

1Belt (AR)

8Washer

4Pulley (reverse)

2Screws (M1.4)

3M601 (Capstan/reel motor)

Cassette lid assy

5Flexible board

( from LCD901)

Lead wires ( from MIC901)

4Remove solder ( two places)

Lever assy, FWD return

6

2

Lead Wires (from SP901)

3Remove solder ( two places)

SW board

Cover, cassette li

1Screws (+B1.7X 3)

5

TCM-900DV

r

SECTION 3

ADJUSTMENTS

3-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured alcohol-moistened

swab :

record/playback/erase head pinch roller

rubber belts

capstan

2. Demagnetize the record/playback head with a head demagne-

tizer. (Do not bring the head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

6. Power supply voltage : 3V DC.

Torque Measurement

Mode Torque Meter Meter Reading

1.97 to 3.92 mN • m

/Reverse

Forward CQ-102C

Forward CQ-102C

Fast Forward

and Rewind

CQ-201B (50 g • cm)

Tape Tension Measurement

Mode Tension Meter Meter Reading

Forward CQ-403A

(20 to 40 g • cm)

(0.28 to 0.55 oz• inch)

0.05 to 0.49 mN • m

(0.5 to 5.0 g • cm)

(0.007 to 0.07 oz• inch)

more than 4.90 mN • m

(0.7 oz• inch)

more than 50g

( 1.77oz)

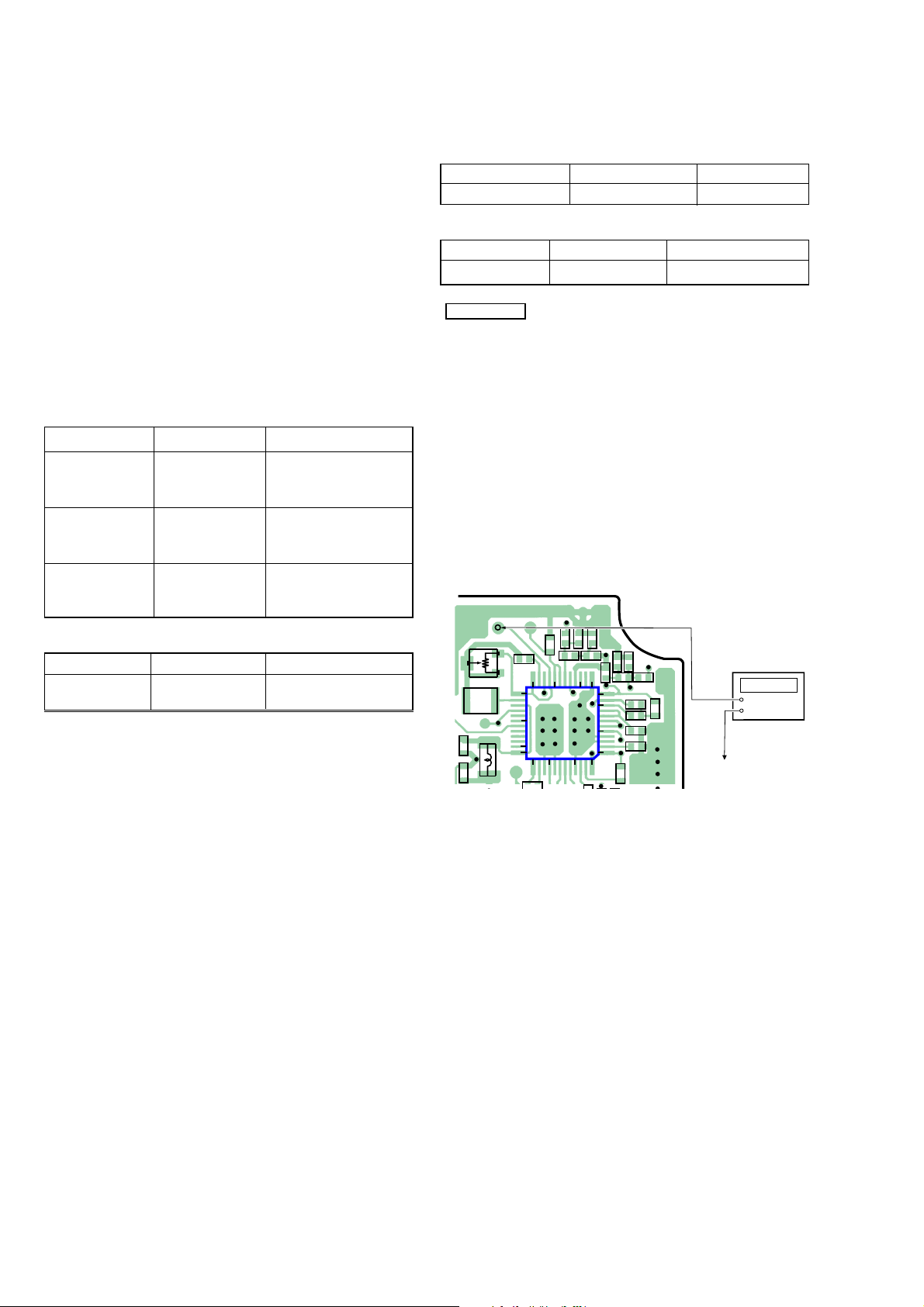

3-2. ELECTRICAL ADJUSTMENTS

• Standard Level

Input signal level MIC – 60dBs

Output signal level EAR (EARPHONE) 1.6kΩ, –22,4dBs

• Test Tape

Type Signal Used for

WS-48A 3kHz, 0dB tape speed adjustment

0dB=0.775V

Setting :

VOL Control (RV301) : mechanical mid

REC TIME (S903) : normal(4.8cm/s)

SPEED CONTROL (RV901): normal (center click)

DPC(MANUAL) Adjustment

Note: Adjust before the tape speed adjustment

Setting :

DPC(S904) switch : MANUAL

Tape speed : 4.8cm/s

Mode : PLAY

Procedure :

[MAIN BOARD](SIDE B)

C407

R406

24

20

IC401

35

40

37 45

TP82

C413

15

C412

R402

13

48

R401

12

10

5

1

R405

R404

R403

R416

R417

C422

C420

C410

C415

C416

frequency counte

TP47

C414

TP8(GND)

TP47

TP51

RV401

R407

25

C401

30

TP63

04

C403

36

L401

TP46

C402

+

–

1. Connect the freguency counter to TP47 and TP8(GND).

2. Adjust RV401 so that the freguency at TP47 becomes 220 Hz.

Standard value : 117 to 223 Hz

Adjustment Location : Main board (See page 7)

6

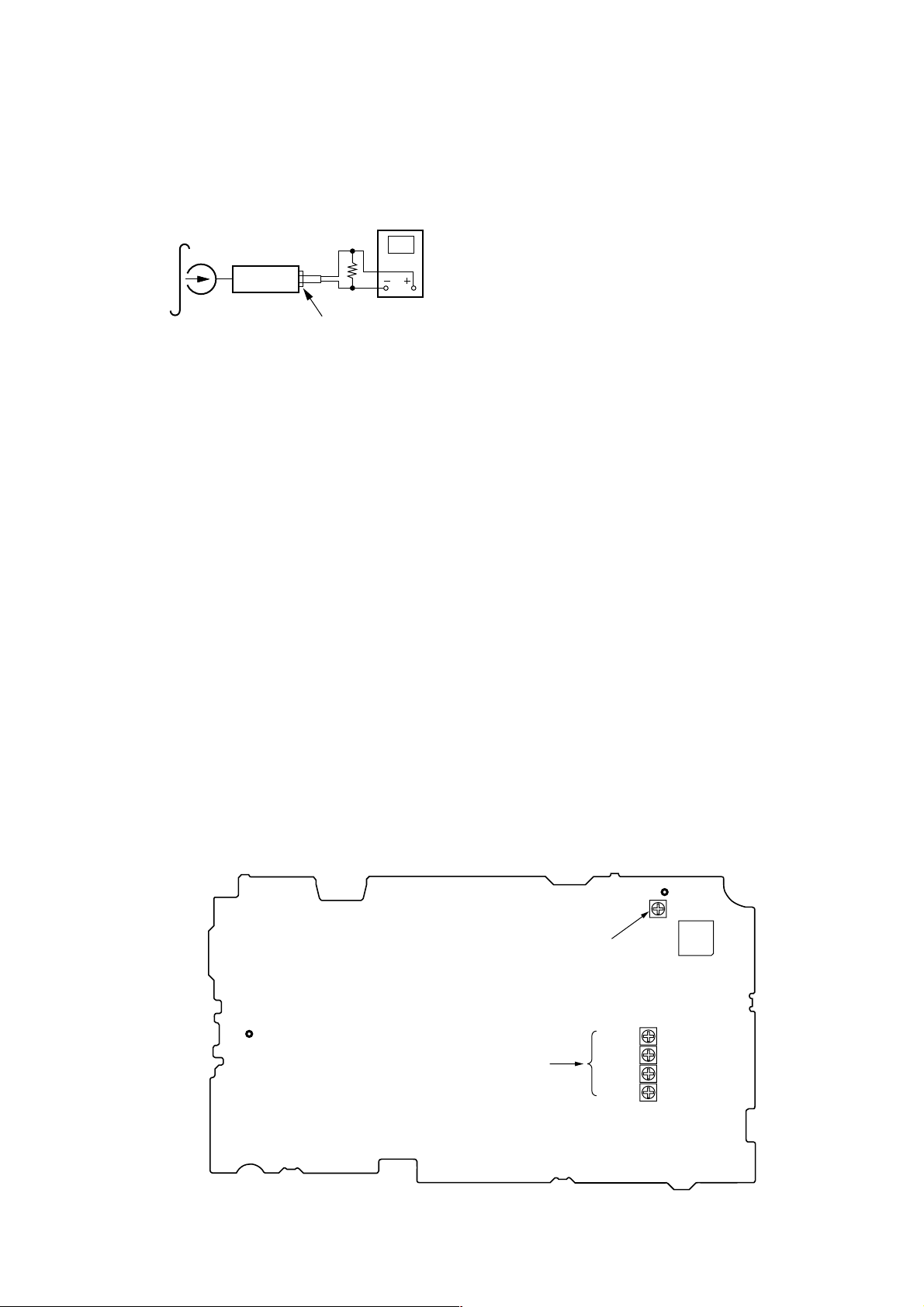

Tape Speed Adjustment

Procedure :

Note: Adjust on both sides DIR switch (S701) “ b “ and “ B “.

TCM-900DV

test tape

WS-48A

(3kHz, 0dB)

set

EAR (earphone) jack (J102)

digital frequency

counter

10kΩ

1. Set DPC switch (S904) to OFF, PITCH CONTROL switches

(S910, 911) to the center and play the test tape WS-48A.

2. Set REC TIME switch (S903) to NORMAL (4.8cm/s) and turn

SPEED CONTROL knob (RV901) fully to FAST.

3. Adjust RV601 so that the reading on the frequency counter

becomes 6000Hz.

4. Turn SPEED CONTROL knob (RV901) to the center and adjust

RV602 so that the reading on the frequency counter becomes

3010Hz.

5. Set REC TIME switch (S903) to DOUBLE (2.4cm/s) and turn

SPEED CONTROL knob (RV901) fully to the center.

6. Adjust RV603 so that the reading on the frequency counter

becomes 1505Hz.

7. Turn SPEED CONTROL knob (RV901) fully to SLOW.

8. Adjust RV604 so that the reading on the frequency counter

becomes 1050Hz.

9. Turn SPEED CONTROL knob (RV901) fully to FAST and

confirm the reading on the frequency counter becomes approx.

3010Hz.

10. Set REC TIME switch (S903) to NORMAL (4.8cm/s) and turn

SPEED CONTROL knob (RV901) fully to SLOW.

11. Confirm the reading on the frequency counter becomes approx.

1505Hz.

Adjustment Location : Main board (B side)

[MAIN BOARD] (B side)

TP8(GND)

DPC (MANUAL) Adjustment

RV401

Tape Speed

Adjustment

TP47

IC401

1

48

RV601

RV602

RV603

RV604

7

TCM-900DV

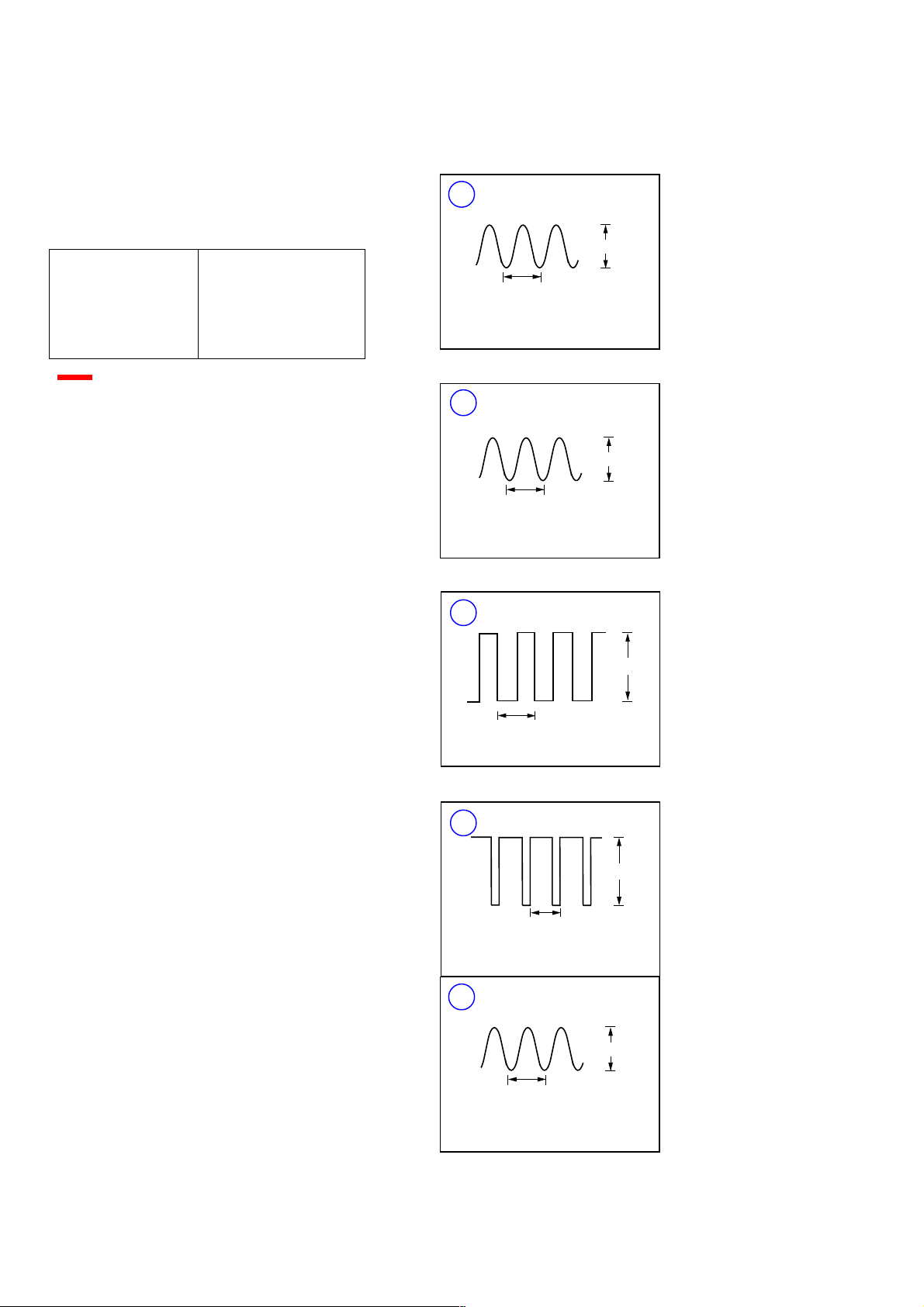

Note on Schematic Diagram: MAIN SECTION

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

Note: Note:

• : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 3V and fed with regulated dc power

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Signal path.

: internal component.

The components identi- Les composants identifiés

fied by mark 0 or dotted par une marque 0 sont cri line with mark 0 are cri- tiques pour la sécurité.

tical for safety. Ne les remplacer que par

Replace only with part une piéce portant le

number specified. numéro spécifié.

supply from battery terminal.

under no-signal conditions.

no mark : PLAY (DPC OFF)

( ) : REC

< > : PLAY (DPC AUTO)

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

E : PB

a : REC

4

W or less unless otherwise

SECTION 4

DIAGRAMS

z

Waveforms

– MAIN SECTION (2/3) –

1

IC701 wh

– MAIN SECTION (1/3) –

2

IC301 ql

– MAIN SECTION (3/3) –

3

REC/PB mode

3.8 Vp-p

0.25 µsec

VOLT/DIV : 1 V AC

TIME/DIV : 0.2 µsec

PB mode

3.6 Vp-p

0.25 µsec

VOLT/DIV : 1 V AC

TIME/DIV : 0.2 µsec

PB (DPC AUTO) mode

µ

sec

1.30

IC401 ej

– SW SECTION –

REC/PB mode

4

25 µsec

IC901 2

REC mode

5

20.0 µsec

3.8 Vp-p

VOLT/DIV : 1 V AC

TIME/DIV : 1 µsec

3.6 Vp-p

VOLT/DIV : 1 V AC

TIME/DIV : 10 µsec

30 Vp-p

T101 wh

VOLT/DIV : 1 V AC

TIME/DIV : 0.2 µsec

8

4-1. BLOCK DIAGRAMS – MAIN SECTION (1/2) –

TCM-900DV

MIC901

FLAT MIC

J101

MIC

(PLUG IN POWER)

HRPE901

RECORD/

PLAYBACK/

ERASE

HEAD

L

FWD

R

R

REV

L

FWD

REV

S101-4

REC

PRE AMP

MIC

POWER

ATT

Q104

Q111

S102-1

FWD

REV

S101-3

PB

T101

S102-2

BIAS

Q105

FWD

REV

OSC

Q107

PB

REC

S101-2

PB

REC

RF OUT

PRE +IN

RIPPLE

FILTER

+

PRE

AMP

-

RF IN

PRE OUT

PRE IN

+B

(PWR)

Q112

GAIN

SWITCH

S101-1

PB

REC

Q402

Q401

PB/REC

SWITCH

X401

768kHz

LPF1I

XTLO

XTLI

CP IN

CP REF

LPF

COMP

LPF1O

DATA RAM

TIMING

CP OUT

OSC

RESETN

A IN

DIGITAL

PITCH CONTROL

D/A

A/D

DSP

KEY SHIFT

CONTROL

MICOM IF

MODE

REGISTOR

MIN

A OUT

AUT

MODE

REGISTOR

BUF IN

FIN

FXIN

BUF OUT

OSC1I

OSC1O

OSC2I

LPF21

OSC2O

LPF

LPF20

MOD0

MOD1

MOD2

MOD3

Q404

Q403

Q405

+1.8V REG

RV601

TAPE

SPEED

9.6cm/s

RV602

TAPE

SPEED

4.8cm/s

RV603

TAPE

SPEED

2.4cm/s

RV604

TAPE

SPEED

1.6cm/s

POWER

(+3.6V)

SPEED CONTROL

SPEED CONTROL

SPEED CONTROL

Q607

Q109

Q101

POWER

(+3.6V)

S901

MIC SENS

L

REC

PIC

H

RV901

SPEED CONTROL

BIAS

SWITCH

Q106

+1.8V

REG

SPEED CONTROL

+B

(PWR)

Q606

IN+

S/S

SERVO

CONTROL

BIAS/

OSC

OSC

COM

PIC RST

SPEED CTL

WAVEFORM

DETECT

VSP

PIC CTL

SOFT

SWITCH

SYSTEM

CONTROL

C1

PIC M

OUT

CURRENT

DETECT

SPEED

DETECT

PRE

DRIVE

OUTPUT

MOTOR CTL

UOUT

VOUT

WOUT

RV401

DPC

Q604

INITIAL

SWITCH

Q603,608

MOTOR

BRAKE

Q601

+B

(BATT)

MOTOR

BRAKE

Q602

COM

U

V

W

M601

MOTOR

• Signal path.

E : PB

a : REC

99

TCM-900DV

4-2. BLOCK DIAGRAMS – MAIN SECTION (2/2) –

RIPPLE

FILTER

Q201

+B(BATT)

PH701

REEL ROTATE

DET

RESET

Q701

REP ON

PHOTO IN

RESET

X301

4MHz

Q301

LIN

XT

XT

A/D

TIMING

OSC

RESET

REP RST

IC REPEAT

ADPCM

ANALIZER

SYNTHESIZER

MUC I/F

SK

BUSY

REP BUSY

LCD REP SCLK

EVR

SO

SI

CS

REP CS

REP SI

LCD/REP DATA OUT

RAM

AOUT

D/A

SYSTEM

CONTROL

5

MUTE

Q307

POWER

(+3.6V)

REPEAT,

QUE/REV BEEP OSC

Q302-305

POWER

(3.6V)

REP QUE/REV

AMP

Q306

(FF/REW)

S702

VCC

POWER AMP

VOR

RV301-2

VOL

1

Q103

AMP

ATT

Q501

IN1

INV

OUT

IN2

STBY

ALC IN

POWER +INA

POWER -INA

POWER -INB

POWER +INB

Q113

7

ATT

MUTE

Q110

SW

Q102

MUTE CTL

REC

PIC

Q115

Q108

REC CTL

PIC ON/OFF

VOR IN

RV301-1

Q114

SP SW

AMP

3

Q202

REF

RIPPLE

FILTER

+

+

PRE AMP,

POWER AMP

ALC

+

-

-

+

REF.

POWER

AMPA

POWER

AMPB

PWR

OUT1

PWR

OUT2

POWER OUTA

POWER OUTB

J102

EAR

SP901

(SPEAKER)

ON

S902

VOR SW

OFF

S903

REC TIME

DOUBLE

KEY MATRIX

S905-911

TAPE SPEED SW

(+3.6V)

NORMAL

+B

AUTO

S904

DPC

MANUAL

DPC SW

OFF

KEY IN

AKE UP

W

Q702

LCD

DRIVER

LCD CS

CS

COM1-4

11

-

SO

SEG1-18

14

LCD901

LIQUID

CRYSTAL

DISPLAY

POWER

SCK

15

(3.6V)

CD

OSC1

OSC2

-

(3.6V)

32

B+

S701

(F/R GEAR)

D901

REC

10 10

F/R GEAR

X2

X701

4MHz

X1

JACK DET

POWER

+3.6V

+B

(PWR)

+B

(PIC)

+B

(+3.6V)

LED DRIVE

Q503

+B SWITCH

Q801-802

AMP

+

Q502

+3.6V REG

+3.6V REG

D803

S801

POWER

DC-DC

CONVERTOR

D801

+B

(BATT)

L801

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION R6)

2PCS, 3V

J801

DC IN 3V

• Signal path.

E : PB

a : REC

Loading...

Loading...