Page 1

TCM-50DV

SERVICE MANUAL

Ver 1.0 1999. 02

SPECIFICATIONS

US Model

Canadian Model

AEP Model

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MT-50-30

Recording system

2-track 1 channel monaural

Tape speed

4.8 cm/s or 2.4 cm/s

Frequency range

250 - 6,300 Hz using normal (TYPE I) cassette (with REC TIME switch

at “NORMAL”)

Speaker

Approx. 3.6 cm (1 7/16 in.) dia.

Power output

250 mW (at 10% harmonic distortion)

Input

Microphone input jack (minijack) sensitivity 0.2 mV for 3 kilohms or

lower impedance microphone

Output

Earphone jack (minijack) for 8 - 300 ohms earphone

Variable range of the tape speed

From approx. +25% to –15% (with REC TIME switch at “NORMAL”)

Power requirements

3 V DC batteries AA (R6) × 2/External DC 3 V power sources

Battery life (Approx. hours) (EIAJ*)

Sony alkaline LR6 (SG) Sony R6P (SR)

Playback 9.5 1.5

Recording 10.5 2

* Measured value by the standard of EIAJ (Electronic Industries

Association of Japan). (Using a Sony HF series cassette tape)

Dimensions (w/h/d) (inci. projecting parts and controls)

Approx. 88.7 × 115.3 × 37.2 mm (3 1/2 × 4 5/8 × 1 1/2 in.)

Mass

Approx. 250 g (8.9 oz.)

Supplied accessories

Size AA (R6) batteries (2) (Tourist model only)

Earphone (1) (Tourist model only)

Design and specifications are subject to change without notice.

MICROFILM

CASSETTE-CORDER

– 1 –

Page 2

TABLE OF CONTENTS

1. SERVICING NOTE ..................................................... 3

2. GENERAL

Operating the Unit ................................................................... 4

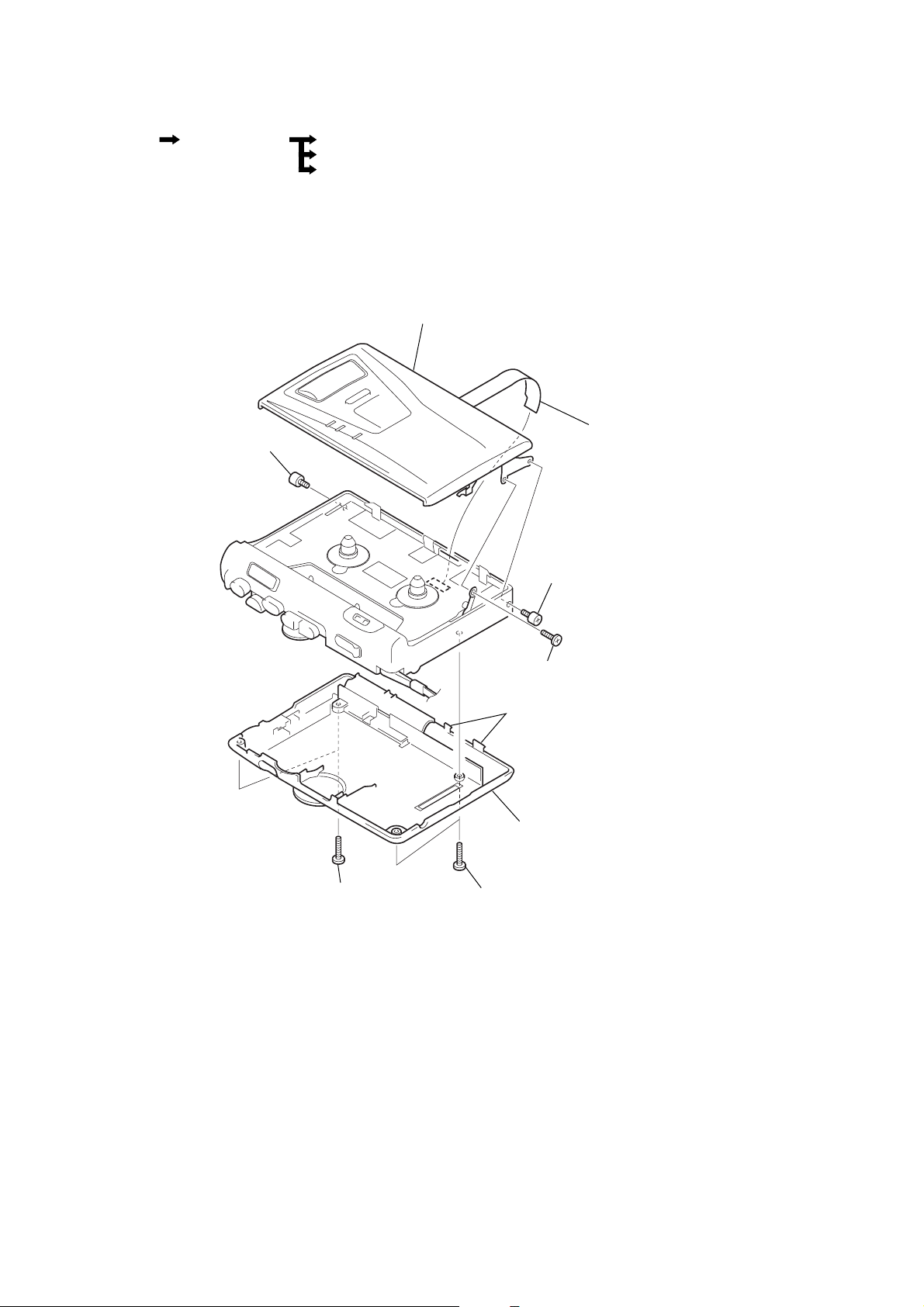

3. DISASSEMBLY

3-1. Cabinet, Cassette Lid Assy ................................................. 6

3-2. MAIN Board, Cassette Machanism .................................... 7

3-3. Belt ...................................................................................... 8

3-4. Head .................................................................................... 8

3-5. Motor, DC ........................................................................... 9

3-6. Note for Installation of Main Board.................................... 9

4. MECHANICAL ADJUSTMENTS............................ 10

5. ELECTRICAL ADJUSTMENTS .............................10

6. DIAGRAMS

6-1. Block Diagram .................................................................. 11

6-2. Printed Wiring Board –Main Section– .............................. 13

6-3. Schematic Diagram –Main Section–.................................15

6-4. Printed Wiring Board –Panel Section– ............................. 17

6-5. Schematic Diagram –Panel Section– ................................ 18

6-6. IC Pin Description............................................................. 20

7. EXPLODED VIEWS

7-1. Case Section ...................................................................... 21

7-2. Panel Section..................................................................... 22

7-3. Mechanism Deck Section-1 .............................................. 23

7-4. Mechanism Deck Section-2 .............................................. 24

8. ELECTRICAL PARTS LIST ....................................25

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

– 2 –

Page 3

SECTION 1

SERVICING NOTE

1-1. SERVICE MODE

Mode to allow the mechanical parts to operate with the main board

open.

This set uses the photo reflector PH701 to detect the rotation of the

idler gear. PH701 is on the main board and so remo val of the main

board does not allow the set to detect the rotation of the idler gear.

This makes motor control impossible which prevents normal

operation.

When repairing the set as energized with the main board removed,

proceed as follows:

1. Setting

1) Remove the cabinet (rear) (refer to the Disassembly) and open

the main board.

2) Apply a trapezoidal of 10 to 100 Hz (at 1.3 V) from oscillator to

TP20. (Connect the ground to TP30.)

3) Supply DC 3.0 V to the positive and negative terminals of the

battery with a stabilized power supply.

2. FF mode

1) Apply a trapezoidal to hall sensor TP20.

2) Press the FF key.

3) Turn on the S103 (POWER) switch.

3. REW mode

1) Apply a trapezoidal to hall sensor TP20.

2) Press the REW key.

3) Turn on the S103 (POWER) switch.

– main board (conductor side) –

TP20

– main board (component side) –

TP30

TP20

TP30

4. PLAY mode

1) Apply a trapezoidal to hall sensor TP20.

2) Press the PLAY key.

3) Change over the S101 (REC/PB) switch to PB side.

4) Turn on the S103 (POWER) switch.

5. REC mode

1) Apply a trapezoidal to hall sensor TP20.

2) Press the REC key.

3) Change over the S101 (REC/PB) switch to REC side.

4) Turn on the S103 (POWER) switch.

S103

(POWER)

S101

PB REC

– 3 –

Page 4

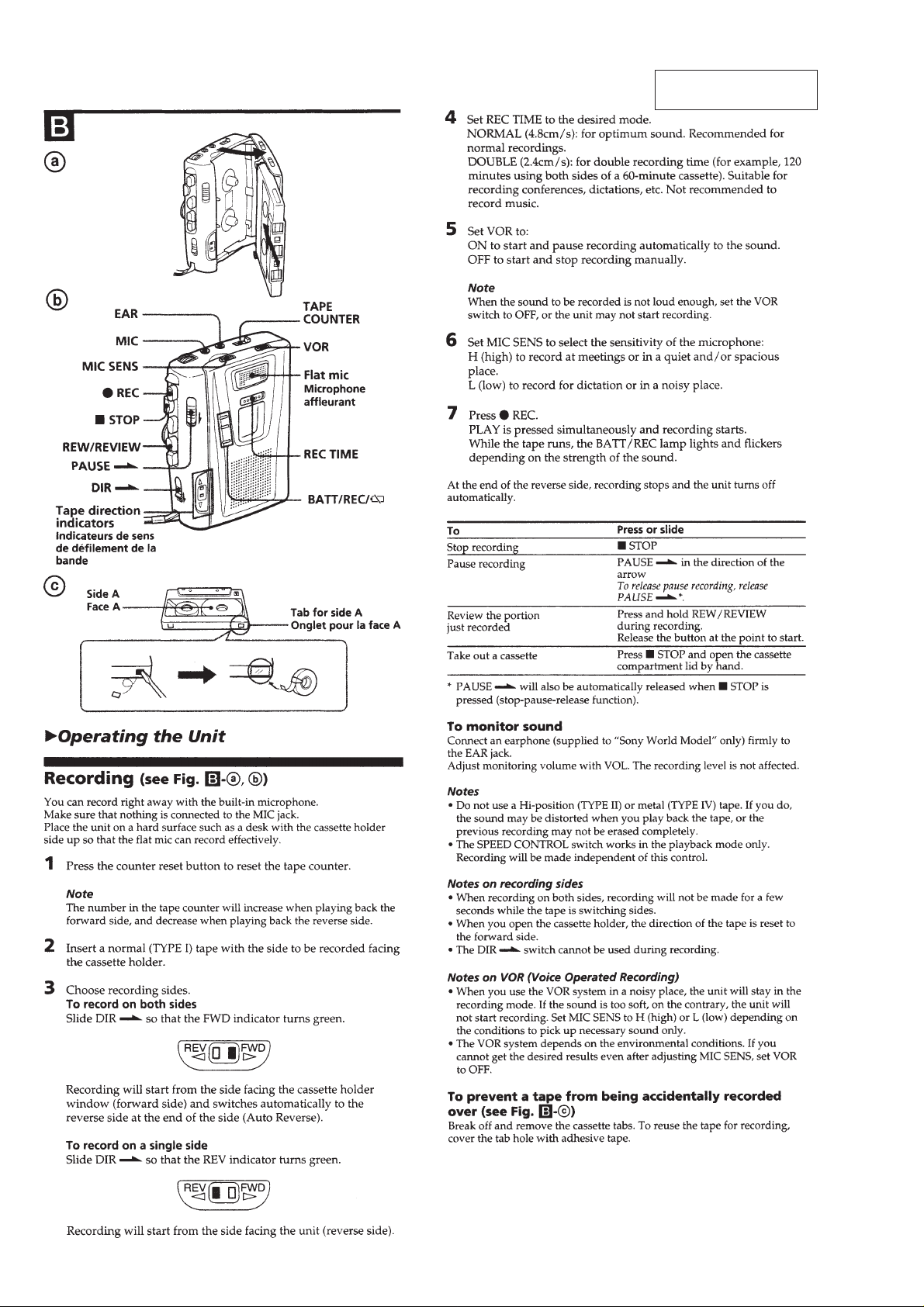

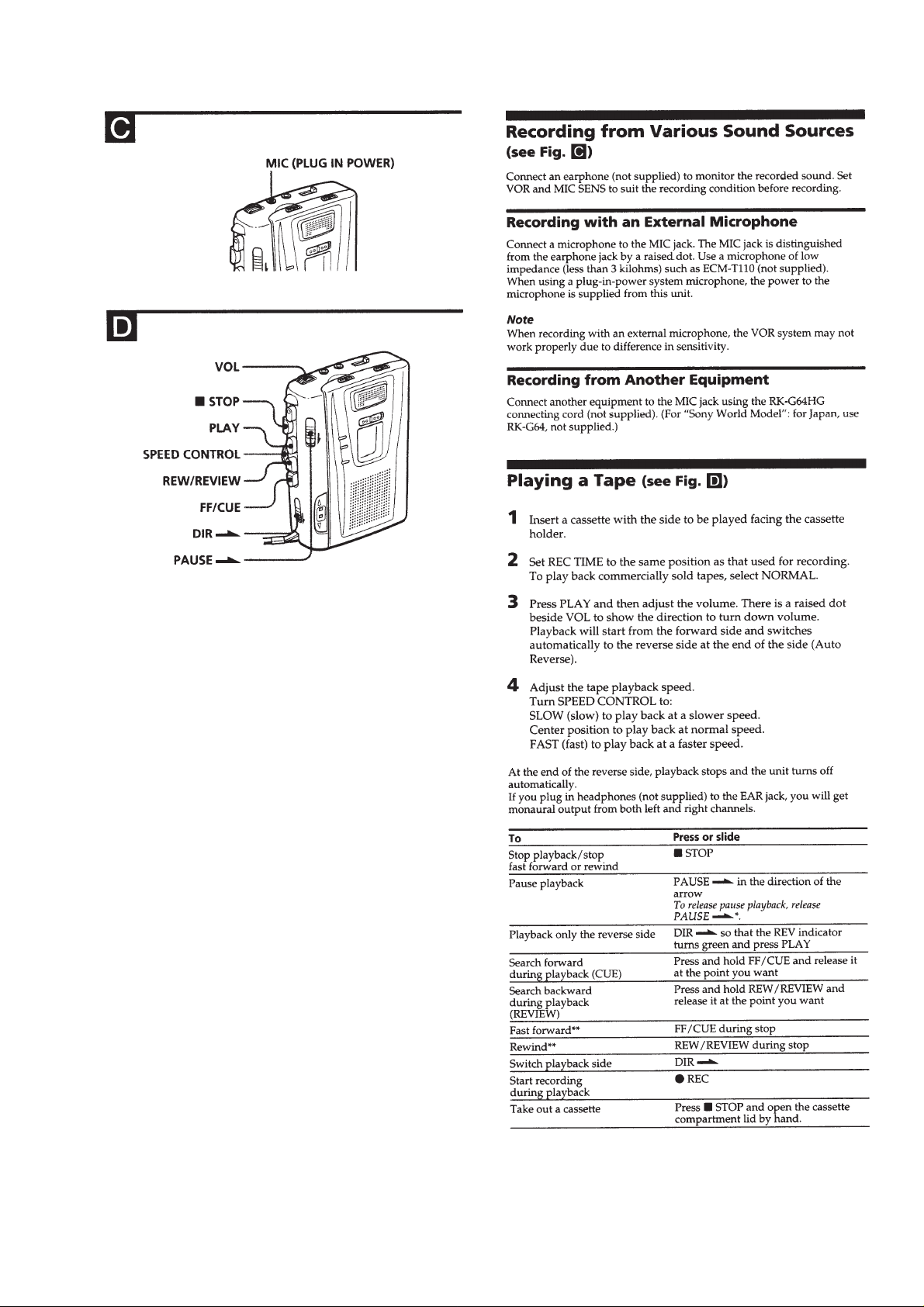

SECTION 2

GENERAL

This section is extracted

from instruction manual.

– 4 –

Page 5

– 5 –

Page 6

SECTION 3

d

DISASSEMBLY

• The equipment can be removed using the following procedure.

Cabinet (rear),

Cassette Lid Assy

Note : Follow the disassembly procedure in the numerical order given.

3-1. CABINET (REAR), CASSETTE LID ASSY

Mechanism Deck,

Main board

8

screw, ornamental

Belts

Head

Motor, DC

9

cassette lid assy

5

LED flexible boar

2

two screws

(screw (B1.7x9), tapping)

7

screw, ornamental

6

shaft (A), stopper

3

two claws

4

cabinet (rear)

1

two screws

(screw (B1.7x9), tapping)

– 6 –

Page 7

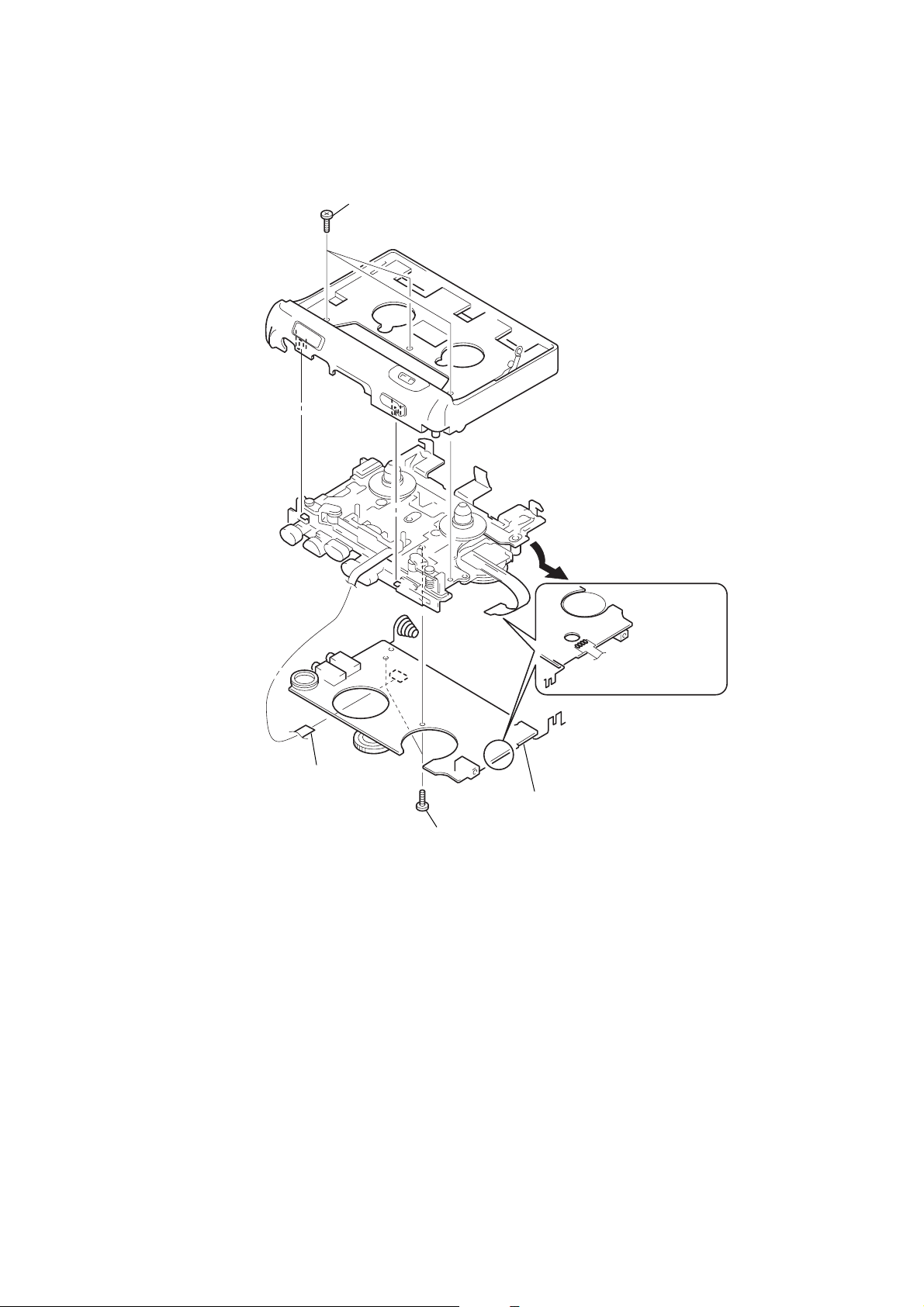

3-2. MACHANISM DECK, MAIN BOARD

1

three screws

(screw (IB lock))

2

mechanism deck,

MAIN board

4

head flexible board

6

MAIN board

5

two screws

(screw (M1.4), toothed lock)

3

Remove the four solders.

– 7 –

Page 8

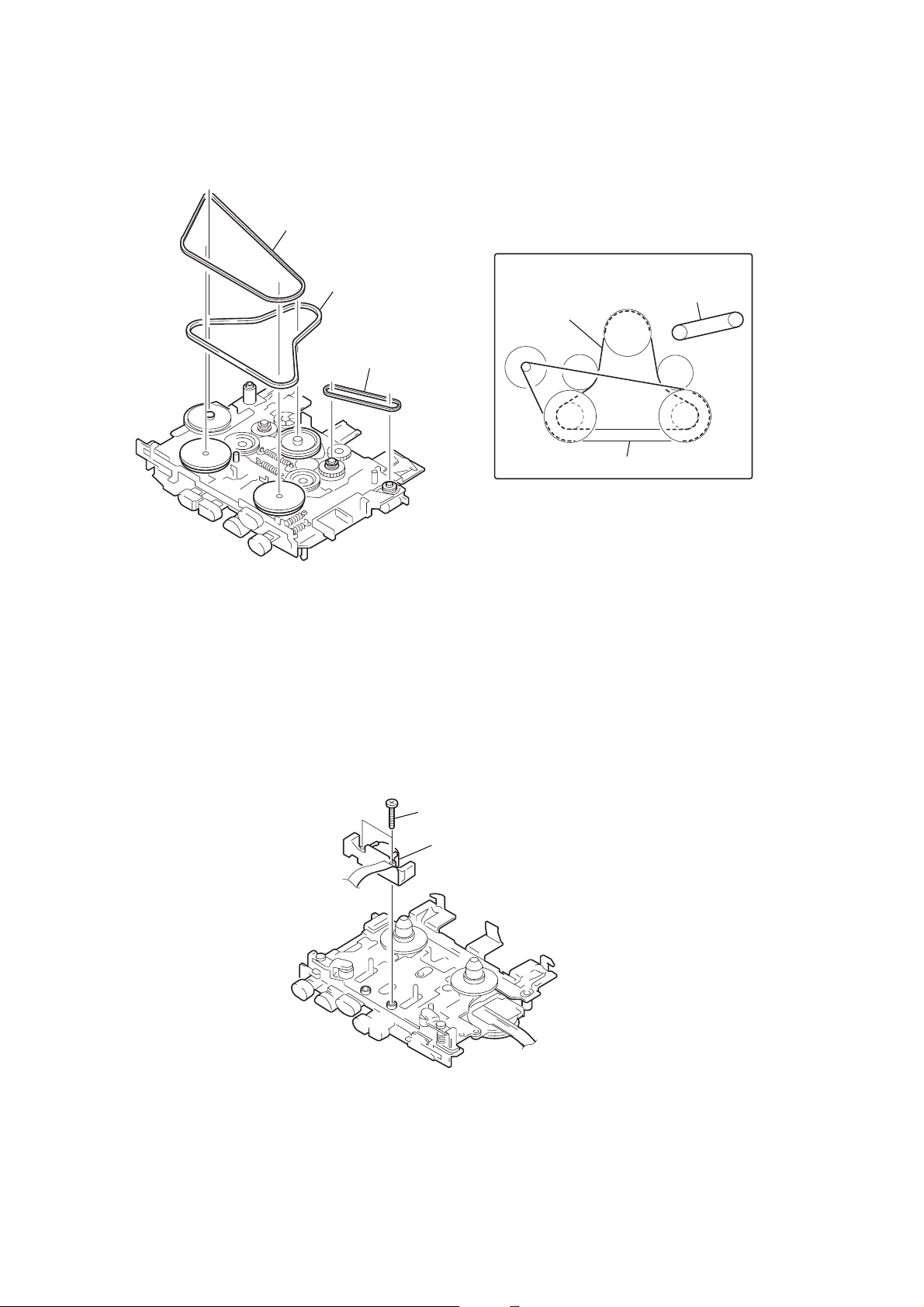

3-3. BELTS

1

belt (motor)

2

belt (flywheel)

3

belt (counter)

• How to apply the belts

belt (counter)

belt (flywheel)

belt (motor)

3-4. HEAD

1

two screws

2

head, magnetic

(REC/PB/ERASE)

– 8 –

Page 9

3-5. MOTOR, DC

2

screw (1.4)

3

Remove the four solders.

1

screw (1.4)

4

Motor, DC

3-6. NOTE FOR INSTALLATION OF MAIN BOARD

Align the knobs of S101, S103 and S701 on the main board with the

claws of the lever (REC) le ver (erase proof 2) and lever (REC) of the

mechanism deck respectively, and install the main board.

screws (M1.4), toothed lock

MAIN board

S701

S103

S101

lever (erase proof 2)

mechanism deck

lever (REC)

lever (PAUSE)

– 9 –

Page 10

r

SECTION 4

MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback/erase head pinch roller

capstan rubber belt

2. Demagnetize the record/playback/erase head with a head

demagnetizer. (Do not bring the head demagnetizer close to the

erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage (1.3 V) unless otherwise noted.

Torque Measurement

Mode Torque Meter Meter Reading

FWD

FWD less than 2 g • cm

back tension (less than 0.03 oz • inch)

REV

REV less than 2 g • cm

back tension (less than 0.03 oz • inch)

FF, REW CQ-201B

CQ-102C

CQ-102RC

15 – 25 g • cm

(0.21 – 0.35 oz • inch)

15 – 25 g • cm

(0.21 – 0.35 oz • inch)

more than 50 g • cm

(more than 0.69 oz • inch)

Tape Speed Adjustment

Procedure :

test tape

WS-48A

(3 kHz, 0 dB)

set

EAR jack

1. REC TIME : NORMAL/FWD ·

Playback WS-48A (tape center part) and adjust RV601 so that

reading on the digital frequency counter becomes 3,000 Hz.

2. REC TIME : DOUBLE/FWD ·

Playback WS-48A (tape center part) and adjust RV602 so that

reading on the digital frequency counter becomes 1,500 Hz.

Specification Value :

Digital Frequency Counter Reading

REC TIME : NORMAL REC TIME : DOUBLE

2,985 to 3,015 Hz 1,485 to 1,515 Hz

3. REC TIME : NORMAL/REV ª

Playback WS-48A (tape center part) and confirm that the

reading on digital frequency counter are between 2,985 to 3,015

Hz.

digital

frequency counte

Ω

8

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

• Supplied voltage : DC 3.0 V

• Switch and control position

VOL control : max (10)

MIC SENS switch : free (L or H)

V•O•R switch : free (OFF or ON)

SPEED CONTROL control : mechanical center

Test T ape

Type Signal Used for

WS-48A 3 kHz, 0 dB tape speed adjustment

4. REC TIME : DOUBLE/REV ª

Playback WS-48A (tape center part) and confirm that the

reading on digital frequency counter are between 1,435 to 1,515

Hz.

Adjustment Location :

–main board (conductor side)–

RV602

RV601

– 10 –

Page 11

6-1. BLOCK DIAGRAM

TCM-50DV

SECTION 6

DIAGRAMS

HRPE901

REC/PB/ERASE HEAD

REC/PB

(FWD)

REC/PB

(REV)

ERASE

(FWD)

ERASE

(REV)

MIC901

Flat Mic

J102

MIC

S102-4

(FWD/REV)

S102-3

(FWD/REV)

FWD

REV

FWD

REV

T101

BIAS OSC

NORMAL

DOUBLE

Q112

S903-1

REC TIME

V O R

ON

OFF

S901

Q106

Q111

+3V

PB

REC

S101-1

(REC/PB)

S902

MIC SENS

L

7

5

6

NF LEVEL

SWITCH

H

OUT1

RECOVERY

TIME CAP

OUT2

Q105

VOR

IC501

NF LEVEL

SWITCH

Q103

PRE / POWER AMP

IC101

EQ IN

29

VREF OUT

27

4

REC OUT

1

IN

SWITCH

Q501

PRE NF

1

NF LEVEL

SWITCH

Q101

Q104

LED CONTROL

Q302,303

28

5

MIC IN

ALC CONT

+

-

+

-

+

PRE

OUT

REC

IN

RV101

2

3

VOL

D903

LED

CONTROL

Q301

MUTE

Q109

MUTE

DRIVE

Q110

AMP

Q102

SWITCH

Q107,108

4

BATTERY

VOLTAGE

DETECTOR

IC301

OUT

S101-2

(REC/PB)

PB

REC

POW

21

23

26

25

IN

R/P MUTE

R/P SW

MIC VCC

R.F OUT

POW

OUT1

1

12

POW

OUT2

2

14

R.F

(REC/PB)

PB

REC

S101-3

+3V

+3V

SP101

SPEAKER

J101

EAR

S103

(POWER)

CN101

DC IN 3V

+

-

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION R6)

2PCS,3V

• Signal path

: TAPE (PB)

: TAPE (REC)

S702

(REW / REVIEW)

S703

(DIR)

S704

(FF / CUE)

04

+3V

IN2

5

IN3

6

8

IN5

TAPE ROTATION DETECTOR

S701

PAUSE

OFF ON

IN7

10

PULSE

AMP

Q708

PH701

Q701

+3V

D901

BATT

D902

D702

4

IN1

CL

3

VCC

24

SWITCH

Q706, 707

DP CON

OSC

Q702

T701

23

CONT

22

D701

REC

SYSTEM CONTROL

IC702

VDD

V OUT V IN

3

IC701

LED CONTROL

REG

Q704

+3V

18

OUT5

IN6

(FWD /REV)

REV FWD

OUT4

S102-2

19

OUT3

IN8

OUT2

OUT1

20

21

MOTOR

CONTROL

Q705

17

IN4

7119 11

SWITCH

Q703

+3V

2

19

11

S903-2

REC TIME

DIR

S/S

DOUBLE

NORMAL

DIRECTION

BIAS

REF VOLTAGE

FOR SPEED CONTROL

REF

VOLTAGE

VREF

12

PULSE

DET

OSC

CURRENT

RV601

TAPE SPEED

REC TIME NORMAL

RV602

TAPE SPEED

REC TIME DOUBLE

OPERATION

DET

LOGIC

MOTOR SERVO

IC601

DRIVER

FREQ.

CHARC.

S101-4

(REC/PB)

PB

REC

PRE

ERROR

AMP

IN +

13

U OUT

V OUT

W OUT

RV603

SPEED CONTROL

20

1

2

MOTOR

BRAKE SW

Q601 - 604

M901

CAPSTAN/REEL

MOTOR

– 11 – – 12 –

Page 12

TCM-50DV

6-2. PRINTED WIRING BOARD — MAIN SECTION —

A

B

C

D

1

S702

(REW/REVIEW)

234567891011121314

S703

(DIR)

TP20

TP30

E

F

G

H

J

I

04

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

®

•

• b : Pattern from the side which enables seeing.

: Through hole.

(FF/CUE)

SPEED CONTROL

1-672-148- (11)

11

S701

ON

OFF

S101

(REC/PB)

PB REC

REV FWD

S102 (FWD/REV)

11

1-672-148- (11)

DRY BATTERY

SIZE " AA "

(IEC DESIGNATION R6)

2PCS,3V

• Semiconductor Location

Ref. No. Location

D701 C-1

D702 D-2

IC101 F-9

IC301 F-10

IC501 E-2

IC601 C-8

IC701 C-1

IC702 C-2

PH701 D-1

Q101 H-10

Q102 D-9

(Page 17)

HRPE901

REC/PB/ERASE

HEAD

REC/PB

( )

ERASE

( )

REC/PB

( )

ERASE

( )

Ref. No. Location Ref. No. Location

Q103 D-9

Q104 D-9

Q105 E-10

Q106 H-2

Q107 F-8

Q108 F-8

Q109 F-9

Q110 F-8

Q111 F-1

Q112 G-3

Q301 F-10

Q302 F-10

Q303 F-10

Q501 E-2

Q601 B-10

Q602 B-10

Q603 B-9

Q604 B-9

Q701 D-2

Q702 D-1

Q703 D-2

Q704 D-9

Q705 C-2

Q706 B-2

Q707 B-2

Q708 D-1

– 13 – – 14 –

Page 13

6-3. SCHEMATIC DIAGRAM — MAIN SECTION — • Refer to page 19 for IC Block Diagrams.

TCM-50DV

(Page 18)

Note on Schematic Diagram:

• All resistors are in Ω and 1/

specified.

• C : panel designation.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 3 V and fed with regulated dc power

supply from external power voltage jack.

• Voltage is dc with respect to ground under no-signal

(detuned) condition.

4

W or less unless otherwise

– 15 – – 16 –

no mark : PB

( ) : REC

[ ] : FF/REW

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

E : PB

a : REC

Page 14

TCM-50DV

6-5. SCHEMATIC DIAGRAM — PANEL SECTION —6-4. PRINTED WIRING BOARD — PANEL SECTION —

A

B

C

D

1

23456

11

1-672-149-

(11)

(Page 15)

E

F

G

H

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

®

•

• b : Pattern from the side which enables seeing.

S902

H L

S903

DOUBLE NORMAL

I

S901

ON OFF

04

18

: Through hole.

1-672-149-

Note on Schematic Diagram:

• All resistors are in Ω and 1/

specified.

• C : panel designation.

• Signal path.

E : PB

11

(11)

1

4

W or less unless otherwise

J

1

LED

FLEXIBLE

BOARD

(Page 14)

– 17 – – 18 –

Page 15

• IC Block Diagrams

IC101 LA4168ML

PRE GND

EQ IN

MIC IN

Vref OUT

MIC VCC

R, F OUT

LED DRIVE

R/P SW

PAUSE

P/R MUTE

21222324252627282930

GVN CONT

GVN Vref

Vs

GVN GND

GVN OUT

181920

17

16

1

PRE NF

300k

SPEED

8

GNV SPEED UP

PAUSE

MIC

VCC

+

–

Vref

9

AUT STOP CONT

10

AUT STOP IN

11

PWR IN

1

12

PWR OUT1

R/P

R, F

POWER

13

PWR GND

2

14

PWR OUT2

GVN

15

Vcc

2.2k

30k

2k

+

–

EQ

2

PRE OUT

+

3

REG IN

+

4

–

20k

REC

REG OUT

5

ALC CONT

ALC

6

VOX CONT

VOX

VOX

7

VOX DELAY

–

MIC

IC601 LB1877V

1

VOUT

2

WOUT

PGND

3

4

WB

VB

5

UB

6

OSC

7

OSC

COM

GND

START

8

DET

9

FEED

10

RI

BACK

PRE DRIVER

OPERATION LOGIC

PULSE DET

DIRECTION

ANTI

LOCKING

CURRENT

DET

TSD

FREQ.

CHARC.

ERROR

–

AMP

SLEEP

DET

REF VOLTAGE

FOR SPEED CONTROL

REF

VOLTAGE

BIAS

IC501 NJM2072M

20

UOUT

19

DR

18

VCC

LB

17

16

FC

OUT

15

VSP

14

+

IN+

13

VREF

12

S/S

11

INPUT

GAIN CONT

AMP OUT

GND

1

2

3

4

IC301 MM1251M

NC

VCC

VS

7

8

6

–

+

+

VREF

1

2

CT

NC

VOLTAGE UP

–

CIRCUIT

3

GND

5

HYS

VCC

8

OUTPUT2

7

OUTPUT1

6

RECOVERY

5

TIME CAP

4

OUT

– 19 –

Page 16

6-6. IC PIN DESCRIPTION

• IC702 TB2004FN-020 (SYSTEM CONTROL)

Pin No. Pin Name I/O Pin Description

1 GND — GND

2 OSC — For system clock generation (fosc=3.2 kHz)

3 CL I RESET input

4 IN1 I Pause ON/OFF by PAUSE SW and VOR. “L” : ON, “H” : OFF

5 IN2 I FWD reset by cassette cover open-close. “L” : ON, “H” : OFF

6 IN3 I Direction “L” : ON, “H” : OFF

7 IN4 I REC/PB switch “L” : REC, “H” : PB

8 IN5 I FF/REW “L” : ON, “H” : OFF

9 IN6 I POWER ON/OFF “L” : ON, “H” : OFF

10 IN7 I Photo reflector pulse input for tape end detection.

11 IN8 I FWD/REV switch “L” : FWD, “H” : REV

12 I/O1 — Not used.

13 I/O2 — Not used.

14 OUT8 — Not used.

15 OUT7 — Not used.

16 OUT6 — Not used.

17 OUT5 O LED ON/OFF “L” : ON, “H” : OFF

18 OUT4 O Audio mute “L” : ON, “H” : OFF

19 OUT3 O Motor brake “L” : ON, “H” : OFF

20 OUT2 O Motor direction “L” : FWD, “H” : REV

21 OUT1 O Motor ON/OFF “L” : ON, “H” : OFF

22 VDD — Power supply for CMOS.

23 CONT O Boosting circuit control output

24 VCC — Power supply for bipolar.

– 20 –

Page 17

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

7-1. CASE SECTION

SECTION 7

EXPLODED VIEWS

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

N

Parts Color Cabinet’s Color

• Accessories and packing materials are

given in the last of this parts list.

N

28

1

MT-50-30

10

2

11

24

12

4

8

3

6

5

9

7

3

26

13

14

25

23

16

15

27

22

1 X-3376-765-1 CABINET (FRONT) ASSY

2 4-969-980-21 SCREW (IB LOCK)

3 3-315-989-11 SCREW, ORNAMENTAL

4 3-925-231-01 REFLECTOR

5 3-035-304-11 CUSHION

6 3-676-387-00 POLY-SLIDER (DIA.1.6)

7 3-315-384-31 WASHER, STOPPER

* 8 X-3370-480-1 TOGGLE ASSY

9 3-311-772-11 SHAFT (A), STOPPER

10 3-032-431-01 KNOB (PAUSE)

11 3-032-432-01 KNOB (DIR)

12 X-3376-766-1 LEVER ASSY, COVERING INDICATION

13 3-328-319-01 STRAP, HAND

14 9-911-815-01 CUSHION

21

20

17

18

18

19

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

15 3-032-434-01 LID, BATTERY CASE

16 3-032-441-01 SHEET (PICK)

17 3-032-437-11 CABINET (REAR)

18 3-318-203-92 SCREW (B1.7X9), TAPPING

19 3-032-436-01 FOOT (B), RUBBER

20 3-032-435-01 FOOT (A), RUBBER

21 3-925-229-01 TERMINAL, PLUS

22 3-345-648-01 SCREW (M1.4), TOOTHED LOCK

23 A-3021-163-A MAIN BOARD, COMPLETE

24 3-925-230-01 SPRING, BATTERY COIL

25 3-035-304-01 CUSHION

26 3-704-245-42 SCREW (1.4)

27 4-017-441-01 CUSHION (B)

28 3-545-710-01 CUSHION

– 21 –

Page 18

7-2. PANAL SECTION

52

60

64

68

73

MIC901

72

78

63

51

70

62

66

69

76

61

71

57

67

54

65

56

58

57

59

53

55

54

56

SP901

74

77

75

75

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 3-032-423-01 SHEET (WINDOW), ADHESIVE

52 3-032-421-11 WINDOW (CASSETTE)

53 3-032-417-11 PANEL (CASSETTE LID)

54 3-389-523-22 SCREW (IB LOCK)

55 3-032-422-01 SHEET (FRAME), ADHESIVE

56 3-035-251-01 SHEET (FRAME B), ADHESIVE

57 3-035-729-01 CUSHION

58 3-032-427-01 GUIDE, LIGHT

59 3-032-946-01 SHEET (LIGHT GUIDE)

60 3-035-730-01 SHEET

61 3-032-422-01 SHEET (FRAME), ADHESIVE

62 3-032-428-01 KNOB (REC TIME)

63 3-032-420-01 KNOB (V•O•R)

64 3-032-419-01 KNOB (MIC SENS)

65 3-032-418-01 FRAME (CASSETTE LID)

67 4-017-491-01 CUSHION (B)

68 3-032-424-01 PANEL (MICROPHONE)

* 69 1-672-149-11 LED BOARD

70 3-035-305-01 CUSHION

71 1-672-139-11 LED FLEXIBLE BOARD

72 3-032-414-01 CUSHION (MICROPHONE)

73 3-032-425-01 HOLDER (MICROPHONE)

74 3-032-415-01 RETAINER (MICROPHONE)

75 3-318-382-01 SCREW (1.7X3), TAPPING

* 76 3-032-430-01 HOLDER (CASSETTE)

77 4-017-441-01 CUSHION (B)

78 3-032-416-01 GROUND, COMPRESSION SPRING (M)

MIC901 1-542-298-11 MICROPHONE, ELECTRET CONDENSER

(Flat Mic)

SP901 1-529-188-11 SPEAKER (3.6cm)

66 3-032-439-01 CUSHION (FRAME)

– 22 –

Page 19

7-3. MECHANISM DECK SECTION-1

(MT-50-30)

109

108

114

116

HRPE901

112

111

113

119

110

117

119

120

118

112

122

121

125

not supplied

123

112

not supplied

(see page 24.)

A

126

124

105

M901

115

104

107

106

103

102

101

122

127

128

129

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 3-925-247-11 BUTTON, FF/CUE

102 3-925-246-11 BUTTON, REW/REVIEW

103 3-925-245-11 BUTTON, PLAY

104 3-032-787-01 BUTTON, REC

105 3-925-248-11 BUTTON, STOP

106 3-924-596-01 SPRING (PINCH-R), TORSION

107 X-3370-380-1 ARM (PINCH-R) ASSY

108 3-924-595-01 SPRING (PINCH-N), TORSION

109 X-3370-379-1 ARM (PINCH-N) ASSY

* 110 3-924-572-01 LEVER (DIR)

117 3-365-630-02 SCREW (M1.4)

* 118 3-924-535-01 LEVER (FR)

119 X-3370-375-1 TABLE ASSY, REEL

120 3-018-121-01 SPRING (B.T), COMPRESSION

* 121 3-924-536-01 LEVER (OFF)

122 3-321-483-11 RING, RETAINING

123 3-924-569-14 PAD (S-OFF)

124 3-924-602-01 SPRING, TENSION

* 125 3-924-538-12 LEVER (S-OFF)

126 1-657-172-11 MOTOR FLEXIBLE BOARD

* 111 3-924-575-01 LEVER (DIR-M)

112 3-924-601-01 SPRING, TENSION

* 113 3-924-534-01 LEVER (C/R)

114 X-3370-378-1 LEVER (HEAD) ASSY

115 4-017-441-01 CUSHION (B)

116 3-938-133-01 SCREW

127 3-704-245-42 SCREW (1.4)

128 3-035-367-01 BELT (MOTOR)

129 3-924-577-01 PULLEY (COUNTER)

HRPE9011-500-590-11 HEAD, MAGNETIC (REC/PB/ERASE)

M901 1-698-804-21 MOTOR, DC (including PULLEY) (CAPSTAN/REEL)

– 23 –

Page 20

7-4. MECHANISM DECK SECTION-2

(MT-50-30)

159

156

158

159

160

161

191

155

163

154

164

153

(including A)

(see page 23.)

152

151

167

158

161

162

165

166

168

171

169

170

176

175

172

177

174

173

185

159

159

183

184

178

179

183

184

181

180

not

supplied

159

182

186

187

188

not supplied

157

190

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 X-3370-373-1 CHASSIS ASSY

* 152 3-924-537-01 LEVER (F/R)

153 3-924-605-01 SPRING (FF), TENSION

154 3-924-593-01 BELT (FLYWHEEL)

155 3-701-437-51 WASHER

156 X-3377-138-1 FLYWHEEL ASSY

157 3-924-602-01 SPRING, TENSION

158 3-924-558-01 PULLEY (T)

159 3-321-483-11 RING, RETAINING

160 3-924-548-01 ARM (T-N)

161 3-924-557-01 GEAR (T)

162 3-924-549-01 ARM (T-R)

* 163 3-924-539-01 LEVER (REW-F)

* 164 3-924-540-01 LEVER (REW-R)

165 3-924-603-01 SPRING (F/R), TENSION

193

192

173 3-924-604-01 SPRING (PLAY), TENSION

* 174 3-924-547-01 ARM (PLAY-SUB)

* 175 3-924-545-01 LEVER (LOCK)

* 176 3-924-546-01 LEVER (SW)

177 3-924-606-01 SPRING (LOCK), TENSION

178 3-924-725-01 REFLECTOR

179 3-924-579-01 GEAR (REF)

180 3-348-993-01 WASHER

181 X-3370-376-1 LEVER (CENTER) ASSY

182 3-924-556-01 GEAR (REW)

183 3-924-562-01 GEAR (FF)

184 3-924-560-01 GEAR (REEL)

185 3-924-600-01 SPRING (REC), TENSION

186 3-032-620-01 BELT (COUNTER)

187 3-704-245-42 SCREW (1.4)

189

166 3-924-597-01 SPRING (F/R), TORSION

* 167 3-924-568-01 LEVER (FF)

* 168 3-924-567-01 LEVER (REW)

* 169 3-924-566-01 LEVER (STOP)

* 170 X-3370-377-1 LEVER (REC) ASSY

* 171 3-924-565-01 LEVER (PLAY)

172 3-924-598-01 SPRING (P/S), TORSION

188 3-032-438-01 BRACKET (COUNTER)

189 1-548-582-11 COUNTER, TAPE (SMALL TYPE)

* 190 3-924-574-01 LEVER (PAUSE)

191 3-924-607-01 SPRING (ARM-T), TENSION

192 3-321-483-01 RING, RETAINING

193 3-305-925-00 WASHER

– 24 –

Page 21

LED

LED FLEXIBLE

SECTION 8

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-672-149-11 LED BOARD

**********

< DIODE >

D901 8-719-059-96 LED SML-210LT-T86 (BATT • •)

D902 8-719-059-96 LED SML-210LT-T86 (BATT • /REC)

D903 8-719-057-99 LED SML-211YT-T86 (i)

< RESISTOR >

R901 1-216-049-11 RES,CHIP 1K 5% 1/10W

R902 1-216-049-11 RES,CHIP 1K 5% 1/10W

< SWITCH >

S901 1-572-922-11 SWITCH, SLIDE (V•O•R)

S902 1-572-922-11 SWITCH, SLIDE (MIC SENS)

S903 1-571-277-51 SWITCH, SLIDE (REC TIME)

*************************************************************

1-672-139-11 LED FLEXIBLE BOARD

******************

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

C123 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C124 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C125 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C126 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

C127 1-164-346-11 CERAMIC CHIP 1uF 16V

C128 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C129 1-164-346-11 CERAMIC CHIP 1uF 16V

C130 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C131 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C132 1-164-346-11 CERAMIC CHIP 1uF 16V

C133 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C134 1-110-501-11 CERAMIC CHIP 0.33uF 10% 16V

C135 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

C136 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C137 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C138 1-163-014-00 CERAMIC CHIP 0.0027uF 10% 50V

C139 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C140 1-126-607-11 ELECT CHIP 47uF 20% 4V

C142 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C143 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

When indicating parts by reference

number, please include the board.

• Abbreviation

CND : Canadian model

JE : Tourist model

MAIN

*************************************************************

A-3021-163-A MAIN BOARD, COMPLETE

*********************

< CAPACITOR >

C101 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C103 1-135-208-11 TANTAL. CHIP 1uF 20% 10V

C104 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

C105 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

C106 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C107 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C108 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C109 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C110 1-127-569-11 TANTAL. CHIP 100uF 20% 4V

C111 1-127-569-11 TANTAL. CHIP 100uF 20% 4V

C112 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C113 1-104-847-11 TANTAL. CHIP 22uF 20% 4V

C115 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C116 1-126-246-11 ELECT CHIP 220uF 20% 4V

C117 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C118 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C119 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C120 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C121 1-124-778-00 ELECT CHIP 22uF 20% 6.3V

C144 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C145 1-164-492-11 CERAMIC CHIP 0.15uF 10% 16V

C146 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C147 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C148 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C149 1-127-569-11 TANTAL. CHIP 100uF 20% 4V

C150 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C152 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C153 1-164-346-11 CERAMIC CHIP 1uF 16V

C301 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C302 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C303 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C304 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C305 1-104-847-11 TANTAL. CHIP 22uF 20% 4V

C501 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C502 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C503 1-104-847-11 TANTAL. CHIP 22uF 20% 4V

C504 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C505 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C601 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C602 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C603 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C604 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C605 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C606 1-164-344-11 CERAMIC CHIP 0.068uF 10% 25V

– 25 –

Page 22

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C607 1-164-344-11 CERAMIC CHIP 0.068uF 10% 25V

C608 1-164-344-11 CERAMIC CHIP 0.068uF 10% 25V

C609 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C701 1-124-779-00 ELECT CHIP 10uF 20% 16V

C702 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

Q105 8-729-230-72 TRANSISTOR 2SA1362YG

Q106 8-729-230-63 TRANSISTOR 2SC4116-YG

Q107 8-729-402-96 TRANSISTOR UN5114

Q108 8-729-402-93 TRANSISTOR UN5214-TX

Q109 8-729-402-96 TRANSISTOR UN5114

C703 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C704 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C705 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C706 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

C707 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C708 1-163-038-00 CERAMIC CHIP 0.1uF 25V

< JACK >

CN101 1-750-061-11 JACK, DC (POLARITY UNIFIED TYPE)

(DC IN 3V)

< CONNECTOR >

CN102 1-750-341-11 CONNECTOR, FFC/EPC (ZIF) 18P

CN103 1-750-336-21 CONNECTOR, FFC/FPC (ZIF) 9P

< DIODE >

D701 8-719-988-61 DIODE 1SS355TE-17

D702 8-719-049-09 DIODE 1SS367-T3SONY

< FERRITE BEAD >

FB101 1-414-235-22 FERRITE BEAD INDUCTOR

FB102 1-414-235-22 FERRITE BEAD INDUCTOR

< IC >

IC101 8-759-492-49 IC LA4168ML-TE-L

IC301 8-759-399-49 IC MM1251BFBE

IC501 8-759-701-51 IC NJM2072M

IC601 8-759-566-10 IC LB1877V-TLM

IC701 8-759-280-84 IC S-81211SG-QA-T1

IC702 8-759-494-76 IC TB2004FN-020-ER

< JACK >

J101 1-785-791-11 JACK (EAR)

J102 1-785-790-11 JACK (MIC (PLUG IN POWER))

Q110 8-729-420-50 TRANSISTOR UN5215

Q111 8-729-429-71 TRANSISTOR XN4314

Q112 8-729-230-63 TRANSISTOR 2SC4116-YG

Q301 8-729-402-93 TRANSISTOR UN5214-TX

Q302 8-729-230-63 TRANSISTOR 2SC4116-YG

Q303 8-729-230-63 TRANSISTOR 2SC4116-YG

Q501 8-729-230-63 TRANSISTOR 2SC4116-YG

Q601 8-729-402-96 TRANSISTOR UN5114

Q602 8-729-402-93 TRANSISTOR UN5214-TX

Q603 8-729-823-86 TRANSISTOR 2SA1745

Q604 8-729-823-86 TRANSISTOR 2SA1745

Q701 8-729-402-93 TRANSISTOR UN5214-TX

Q702 8-729-230-63 TRANSISTOR 2SC4116-YG

Q703 8-729-420-16 TRANSISTOR XN1214

Q704 8-729-402-96 TRANSISTOR UN5114

Q705 8-729-422-41 TRANSISTOR XN1114

Q706 8-729-402-93 TRANSISTOR UN5214-TX

Q707 8-729-230-63 TRANSISTOR 2SC4116-YG

Q708 8-729-420-24 TRANSISTOR 2SB1218A-QRS

< RESISTOR >

R101 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R102 1-216-049-11 RES,CHIP 1K 5% 1/10W

R103 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R104 1-216-073-00 METAL CHIP 10K 5% 1/10W

R105 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R106 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R107 1-216-049-11 RES,CHIP 1K 5% 1/10W

R109 1-216-073-00 METAL CHIP 10K 5% 1/10W

R110 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R111 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R112 1-216-009-00 RES,CHIP 22 5% 1/10W

R113 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R114 1-216-089-00 RES,CHIP 47K 5% 1/10W

R115 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R116 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

< COIL >

L301 1-412-032-11 INDUCTOR CHIP 100uH

< PHOTO REFLECTOR >

PH701 8-749-925-05 PHOTO REFLECTOR NJL5183KA-F20-TE1

< TRANSISTOR >

Q101 8-729-800-37 TRANSISTOR 2SD1048-X7

Q102 8-729-402-84 TRANSISTOR XN4601

Q103 8-729-420-50 TRANSISTOR UN5215

Q104 8-729-420-50 TRANSISTOR UN5215

R117 1-216-059-00 METAL CHIP 2.7K 5% 1/10W

R118 1-216-049-11 RES,CHIP 1K 5% 1/10W

R119 1-216-121-00 RES,CHIP 1M 5% 1/10W

R120 1-216-105-00 RES,CHIP 220K 5% 1/10W

R121 1-216-073-00 METAL CHIP 10K 5% 1/10W

R122 1-216-085-00 METAL CHIP 33K 5% 1/10W

R123 1-216-033-00 METAL CHIP 220 5% 1/10W

R124 1-216-041-00 METAL CHIP 470 5% 1/10W

R125 1-216-073-00 METAL CHIP 10K 5% 1/10W

R126 1-216-025-00 RES,CHIP 100 5% 1/10W

R127 1-216-073-00 METAL CHIP 10K 5% 1/10W

R128 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

– 26 –

Page 23

MAIN

Ref. No. Part No. Description Remark

R129 1-216-009-00 RES,CHIP 22 5% 1/10W

R130 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R131 1-216-065-00 RES,CHIP 4.7K 5% 1/10W

R132 1-216-009-00 RES,CHIP 22 5% 1/10W

R133 1-216-021-00 METAL CHIP 68 5% 1/10W

R134 1-216-009-00 RES,CHIP 22 5% 1/10W

R301 1-216-105-00 RES,CHIP 220K 5% 1/10W

R302 1-216-101-00 METAL CHIP 150K 5% 1/10W

R303 1-216-077-00 METAL CHIP 15K 5% 1/10W

R304 1-216-081-00 METAL CHIP 22K 5% 1/10W

R305 1-216-033-00 METAL CHIP 220 5% 1/10W

R306 1-216-037-00 METAL CHIP 330 5% 1/10W

R307 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R308 1-216-037-00 METAL CHIP 330 5% 1/10W

R309 1-216-045-00 METAL CHIP 680 5% 1/10W

R310 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R311 1-216-075-00 METAL CHIP 12K 5% 1/10W

R312 1-216-081-00 METAL CHIP 22K 5% 1/10W

R313 1-216-009-00 RES,CHIP 22 5% 1/10W

R314 1-216-021-00 METAL CHIP 68 5% 1/10W

R315 1-216-073-00 METAL CHIP 10K 5% 1/10W

R501 1-216-021-00 METAL CHIP 68 5% 1/10W

R502 1-216-097-00 RES,CHIP 100K 5% 1/10W

R503 1-216-073-00 METAL CHIP 10K 5% 1/10W

R504 1-216-063-00 RES,CHIP 3.9K 5% 1/10W

R505 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R601 1-216-085-00 METAL CHIP 33K 5% 1/10W

R602 1-216-085-00 METAL CHIP 33K 5% 1/10W

R603 1-216-067-00 METAL CHIP 5.6K 5% 1/10W

R604 1-216-121-00 RES,CHIP 1M 5% 1/10W

R605 1-216-121-00 RES,CHIP 1M 5% 1/10W

R606 1-216-121-00 RES,CHIP 1M 5% 1/10W

R607 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R608 1-216-067-00 METAL CHIP 5.6K 5% 1/10W

R609 1-216-025-00 RES,CHIP 100 5% 1/10W

R610 1-216-025-00 RES,CHIP 100 5% 1/10W

R611 1-216-049-11 RES,CHIP 1K 5% 1/10W

R701 1-216-088-00 METAL CHIP 43K 5% 1/10W

R702 1-216-073-00 METAL CHIP 10K 5% 1/10W

R703 1-216-073-00 METAL CHIP 10K 5% 1/10W

R704 1-216-073-00 METAL CHIP 10K 5% 1/10W

R705 1-216-073-00 METAL CHIP 10K 5% 1/10W

R706 1-216-073-00 METAL CHIP 10K 5% 1/10W

R707 1-216-089-00 RES,CHIP 47K 5% 1/10W

R708 1-216-035-00 METAL CHIP 270 5% 1/10W

Ref. No. Part No. Description Remark

< SWITCH >

S101 1-771-678-11 SWITCH, SLIDE (REC/PB)

S102 1-572-964-11 SWITCH, SLIDE (FWD/REV)

S103 1-572-288-21 SWITCH, PUSH (POWER)

S701 1-572-922-11 SWITCH, SLIDE (PAUSE)

S702 1-572-688-11 SWITCH, PUSH (1 KEY) (REW/REVIEW)

S703 1-572-288-21 SWITCH, PUSH (DIR)

S704 1-762-594-41 SWITCH, PUSH (1 KEY) (FF/CUE)

< TRANSFORMER >

T101 1-433-286-11 TRANSFORMER, BIAS OSCILLATION

T701 1-450-667-11 TRANSFORMER, DC-DC CONVERTER

< THERMISTOR (POSITIVE) >

THP601 1-810-794-11 THERMISTOR, POSITIVE

*************************************************************

MISCELLANEOUS

***************

126 1-657-172-11 MOTOR FLEXIBLE BOARD

189 1-548-582-11 COUNTER, TAPE (SMALL TYPE)

HRPE9011-500-590-11 HEAD, MAGNETIC (REC/PB/ERASE)

M901 1-698-804-21 MOTOR, DC (including PULLEY) (CAPSTAN/REEL)

MIC901 1-542-298-11 MICROPHONE, ELECTRET CONDENSER

(Flat Mic)

SP901 1-529-188-11 SPEAKER (3.6cm)

*************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

3-865-282-11 MANUAL, INSTRUCTION (JAPANESE) (JE)

3-865-282-21 MANUAL, INSTRUCTION (ENGLISH,FRENCH)

(US,CND)

3-865-282-31 MANUAL, INSTRUCTION (ENGLISH,SPANISH,

PORTUGUESE) (AEP,E)

3-865-282-41 MANUAL, INSTRUCTION (FRENCH,GERMAN,

DUTCH) (AEP)

3-865-282-51 MANUAL, INSTRUCTION (SWEDISH,ITALIAN,

FINNISH) (AEP)

3-865-282-61 MANUAL, INSTRUCTION (ENGLISH,CHINESE,

KOREAN) (JE)

3-865-282-71 MANUAL, INSTRUCTION (CHINESE,RUSSIAN)

(JE)

8-952-251-90 HEADPHONE MDR-E122 SET (JE)

< VARIABLE RESISTOR >

RV101 1-223-931-11 RES, VAR, CARBON 10K (VOL)

RV601 1-238-663-11 RES, ADJ, CARBON 4.7K

RV602 1-223-584-11 RES, ADJ, CARBON 2.2K

RV603 1-223-931-11 RES, VAR, CARBON 10K (SPEED CONTROL)

– 27 –

Page 24

TCM-50DV

9-926-919-11

Sony Corporation

Personal A&V Products Company

– 28 –

Printed in Japan C1999. 2

99B0486-1

Published by Quality Engineering Dept.

(Shinagawa)

Loading...

Loading...